GREAT PLANES Sportster Bipe 40 Instruction Manual

Sportster

Instruction Manual

Bipe

40

Engine size

Wingspan 45 1/2"

Wing Area

Length 41 1/2"

Weight

Materials Needed to Complete

4

Channel radio Propeller Fuel tank

Engine Wheel collars Spinner

Fiberglass cloth/resin Wheels Covering

Engine mounting bolts Hinges Instant glue

Pushrods/clevises Wing bolts EPOXY

The Sportster Bipe

vides full aerobatic maneuverability, yet has enough wing area for docile low speed capability.

The parts are machine cut and sanded for accurate fit. Should you notice a difference in size between

plans and parts, it is usually because paper changes size with moisture.

Different types of glue may be used such

glue). Build on a flat surface for straight wings and fuselage.

Please read through this step

overall idea of the construction steps and t o avoid mistakes. Use the plan and parts list to identify the var

ious parts.

40

.35-.45

716 sq

5-61/2

was designed for sport flying. This biplane design with symmetrical wings pro

.

in.

Ibs.

the

Sportster:

as

epoxy, cyanoacrylate(instant glue) and aliphatic resin (white

-by-

step instruction manual before you start building soyou will have an

-

-

This R/C kit and the model you will build is not a toy! It is capable of serious

bodily harm and property damage.

-

ALONE

gear (engine, tank, pushrods, etc.) and to test the model and fly

enced, competent help in accordance with all safety standards and common

sense as set down in the Academy of Model Aeronautics Safety Code.

gested that you join the AMA and become properly insured before you attempt to

fly this model. I F YOU ARE JUST STARTING R/C MODELING, CONSULT YOUR

LOCAL HOBBY SHOP

TO

FIND AN EXPERIENCED INSTRUCTOR IN YOUR AREA.

to build this kit correctly, properly install all R/C components and flying

OR

Academy of Model Aeronautics

1810 Samuel Morse Dr.

Reston, VA

22090

WAR

WRITE TO THE ACADEMY OF MODEL AERONAUTICS

N

IT

I

N

G

IS

YOUR RESPONSIBILITY AND YOURS

PO

BOX

!

788

URBANA

it

only

lLLlNOlS61801

with experi

It

is sug

2171367

2069

-

-

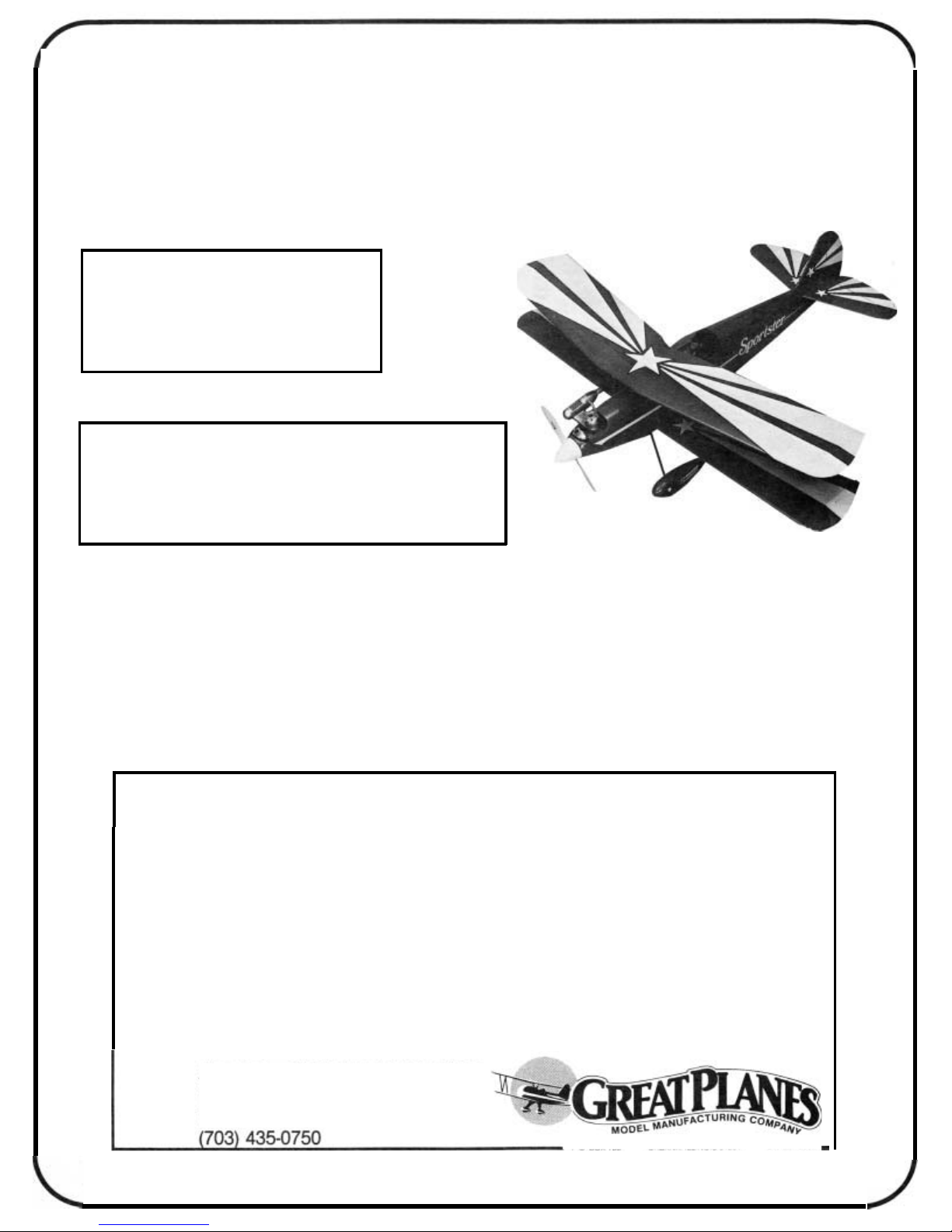

BUILDING THE TAIL

PREPARE THE FIN AND RUDDER

SECTION

Sandthe forwardand rear sectionsof the fin

sary for a good fit. Working over the plans, glue the fin section

pieces together. Sand both sides of the rudder.

CUT THE HINGE SLOTS IN THE FIN AND RUD

DER; CUT OUT RUDDER FOR JOINER CLEAR

ANCE

Draw centerlines down the trailing edge of the fin

and the leading edge of the rudder. Mark and cut the hinge

slots. Two hinges are used above the stabilizer. The third hinge

should be just below the stab and above the tail wheel strut

tab. Cut out part of the rudder leading edge for elevator joiner

wire clearance. Wait to shape the leading edge until the hole

is drilled for the tail wheel tiller arm later.

if

neces

-

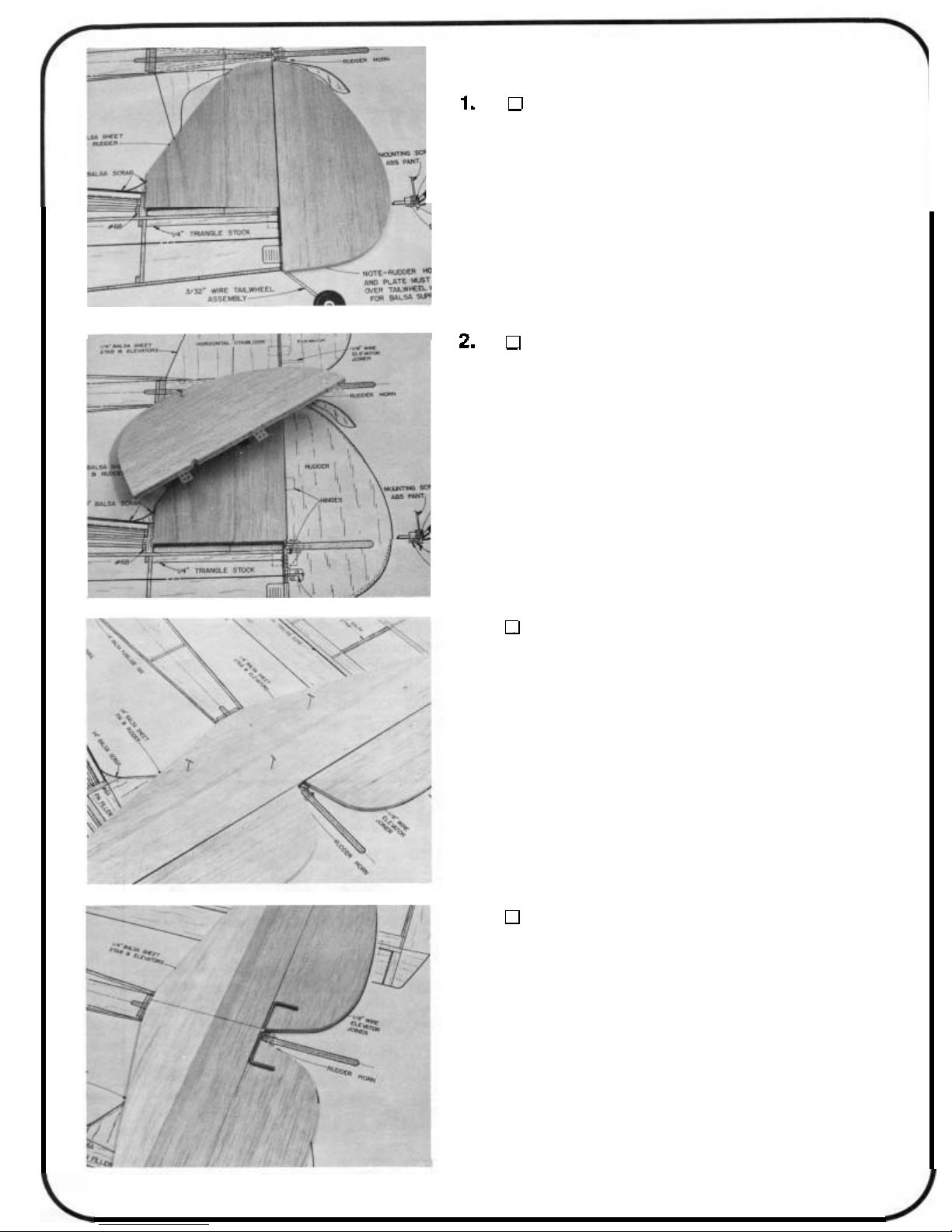

-

-

3.

the stab

sides of the stab and elevator halves.

4.

the stab and a centerlinedown the leadingedges of the elevator

halves. Mark the center of the elevator joiner wire. Align the

stab, elevator and joiner wire and mark the hole locations for

the joiner wire arms on the centerline of the elevator leading

edge. Drill the holes.

GLUE STAB PARTSTOGETHER; SAND THE STAB

AND ELEVATORS

Check the fit and sand the forward and rer parts of

so

they fit together well. Glue them together. Sand both

DRILL HOLES IN THE ELEVATOR HALVES FOR

ELEVATOR JOINER WIRE

Draw a front to back centerline down the top side of

2

5.

the hole

the leading edge of the elevator.

GROOVE OUT THE ELEVATORS

WIRE CLEARANCE

Cut a groove in the elevator leading edge inside of

so

when the joiner wire is installed it will be flush with

FOR

Do

both elevator halves.

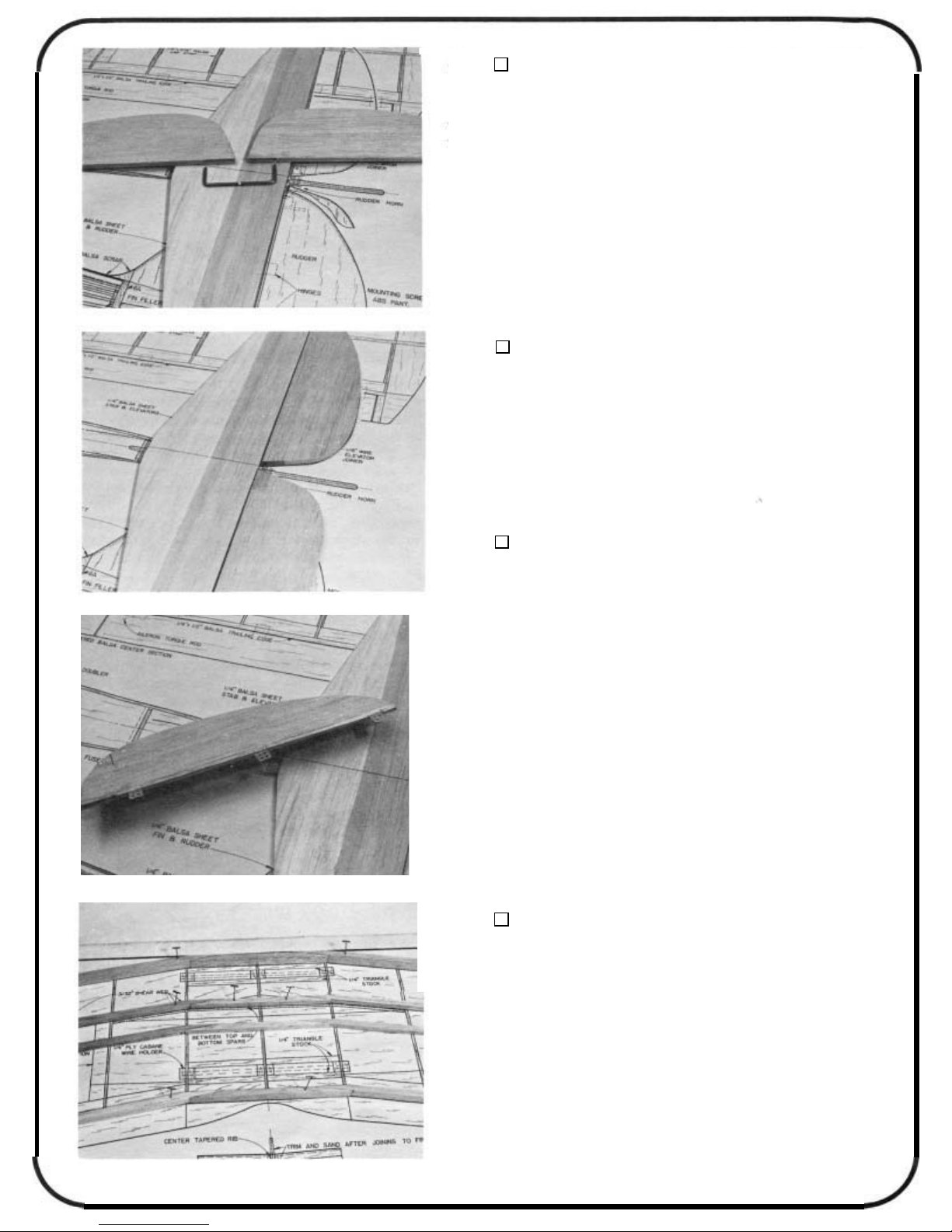

JOINER

6.

elevator halves. Check to make sure that this assembly is

aligned properly. Bend the joiner arms

fit.

DO NOT GLUE THE JOINER WIRE TOTHE ELEVATOR

HALVESUNTILAFTERTHE PIECESARE COVERED LATER.

7.

halves as you did with the fin and rudder. See the plans for

locations. Shape the leading edges of the elevator halves to a

V’.

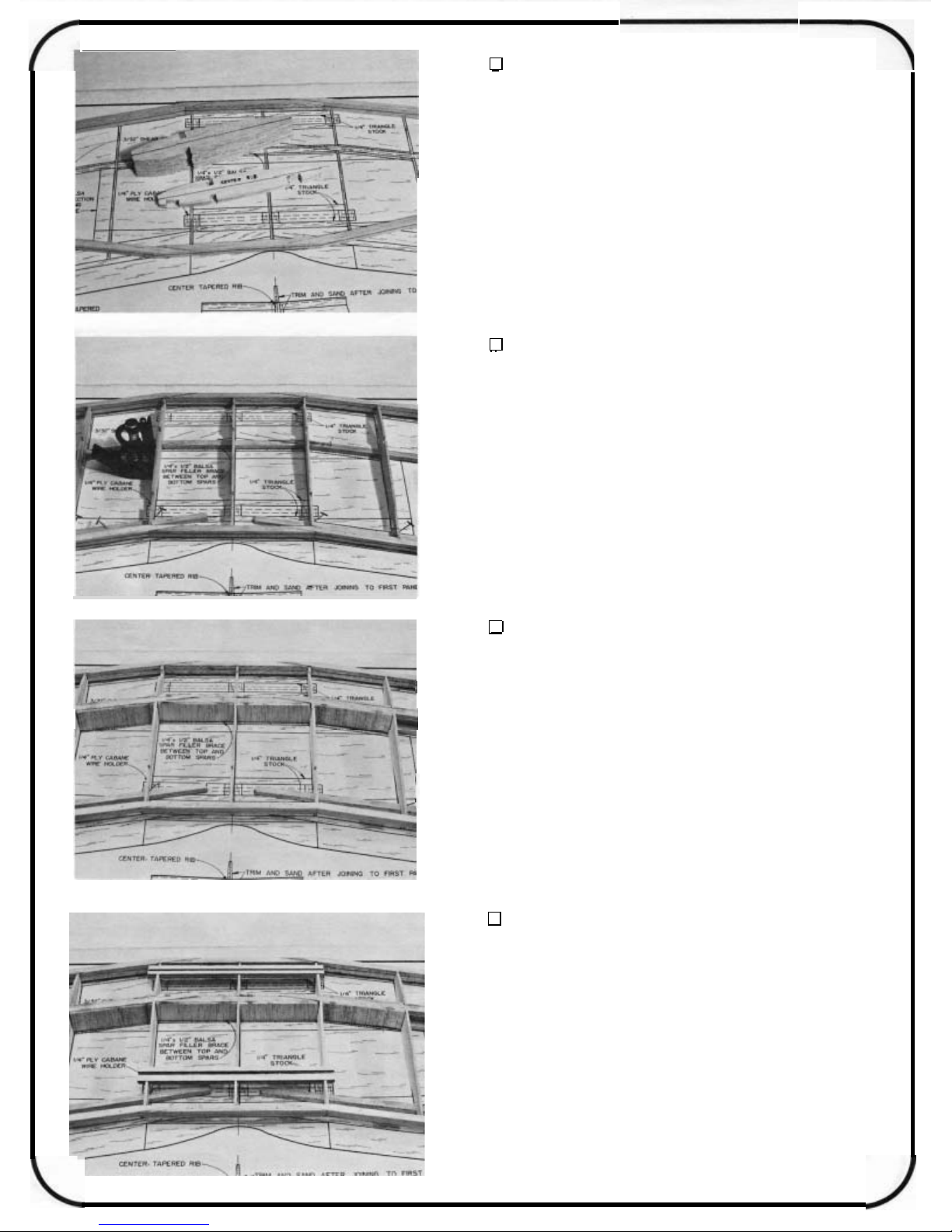

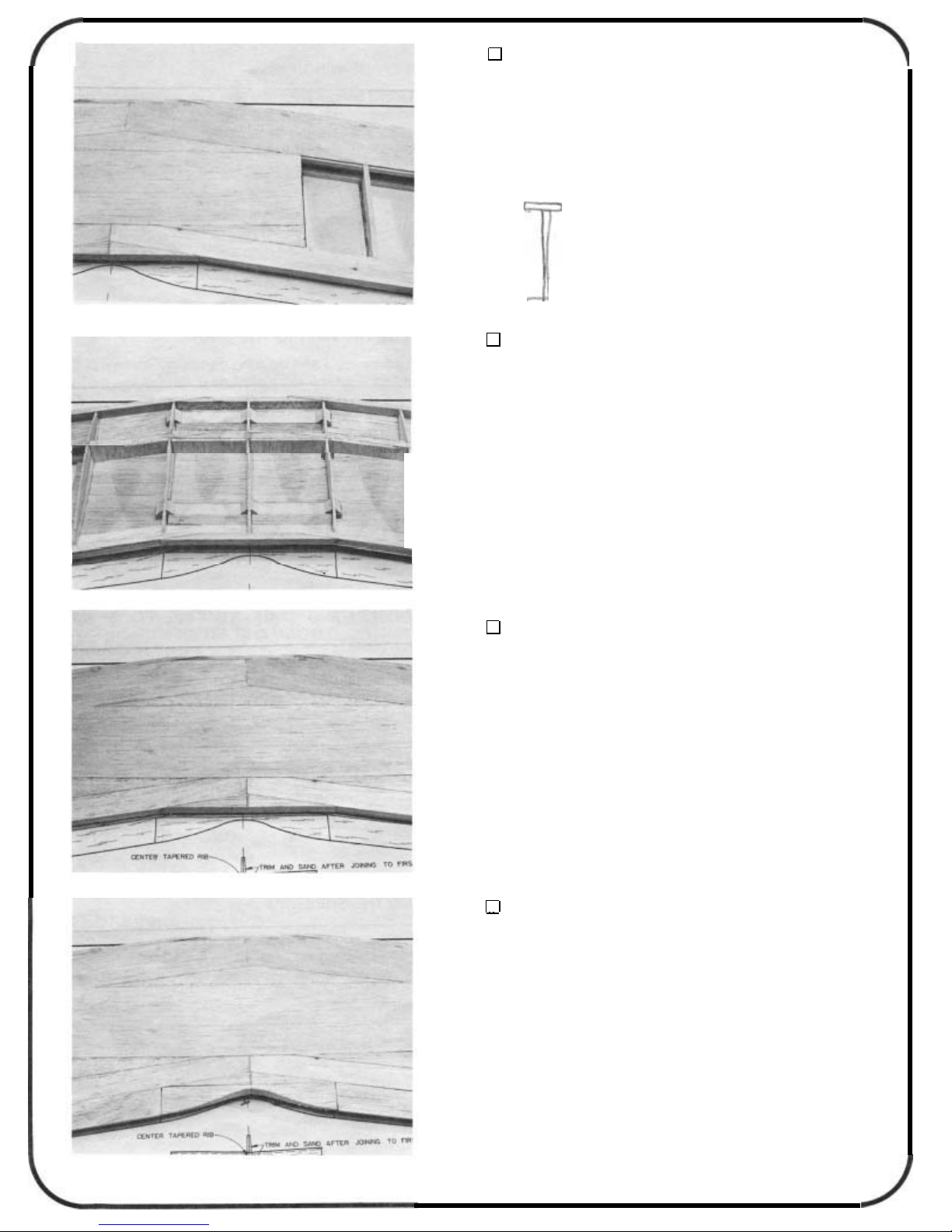

READ THIS FIRST BEFORE YOU START BUILDING THE

WING PANELS: It is very important that you build straight wings

with nowarps or twists or you will get some flying characteristics

you didn’t expect! Bevery careful when you align the ribs, spars,

leading edges, trailing edges and sheeting at the various steps

below. All these parts should be in their correct positions before

you glue them in place. Hold or pin the parts in place, then

glue. Use the following instructions to help you build the wing

straight and warp free.

TRIAL FIT THE JOINER WIRE

Temporarily install the elevator joiner wire into the

if

necessary for a perfect

CUT HINGE SLOTS FOR THE STAB AND

ELEVATOR

Mark and cut the hinge slots for the stab and elevator

Remember: Anyone can build a wing. Only

can build a straight wing.

BUILDING

Start the top wing by building twospars from 1/4 x

1/4 x 24 balsa, aleadingedge from 1/4 x1/2 x 24 balsa and

a trailing edge from1/4x

on the plan. Cut the parts, fit them together and then glue

overtheplan. The top wing is builtin one piece. You will

build the top wing upside down at first. Use epoxy when

you gluethese pieces together in this step.

3

THE

TOP

1/4 x 24

WING

balsa. U se waxedpaper

a

careful builder

2.

top wing rib. Note that the three center ribs have2 extra notches

for the cabane mounting plate. Draw rib alignment centerlines

down the back of the leading edge and the front of the trailing

edge.

PREPARE THE RIBS

Draw a rib alignment line down the center of each

3.

down) over the waxed paper covered plan. Place the ribs on

the spar. Align the ribs at the positions shown on the plans.

Make sure that the three center ribs have the cabane notches

"up"

extra 1/4 x 1/4

drew on the ribs are parallel to the building board. When the

ribs are aligned correctly, and at 90 degrees to the building

board, glue the ribs

with the line on the leading edge. Glue the ribs

edge. Line up the trailing edge line

ribs

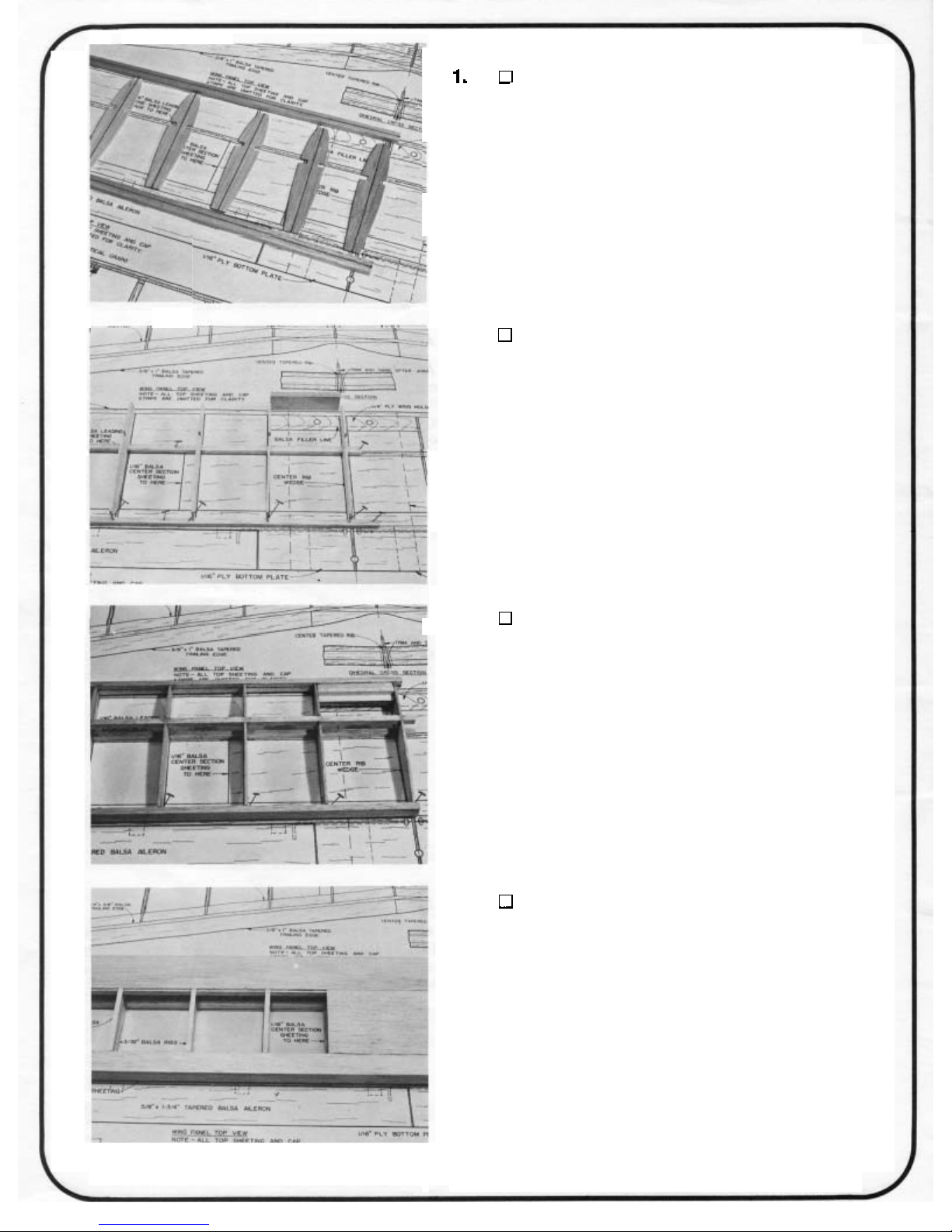

4.

two end center ribs for the 1/4 x 9/16 balsa spar filler brace.

Glue in the 1/4 x 9/16 filler brace pieces from the center rib out

past the spar scarf joint on both sides of the center rib. Glue

in the bottom spar. Now cut shear web pieces from 3/32 x 3

24 balsa to fit between the spars at the rib bays shown on the

plan. The wing should still be shimmed up with the extra spars

throughout the building process. Use epoxy in this step.

ALIGN AND GLUE RIBS, LEADING EDGE AND

TRAILING EDGE TO TOP SPAR

Pin the top spar (the wing will be built (upside

as shown. Shim up the trailing edges of the ribs with the

x

24 spars, making sure the centerlines you

to

the spar. Line up the lines on the ribs

to

the leading

to

the rib lines and glue the

to

the trailing edge.

GLUE IN SPAR FILLER BRACE, BOTTOM SPAR

AND SHEAR WEB

Cut out the area between the spar notches on the

x

I

5.

wire holders with epoxy into the slots in the htree center ribs.

Make sure the cabane holders are flush with the top edges of

the ribs.

4

ADD THE CABANE HOLDERS

Glue in the two plywood 1/4 x 1/2

x

6 1/2 cabane

6.

on the 1/16

x

24 trailing edge sheeting and the 1/16x3x15 center section

sheeting. Do not glue the sheeting

you will cut away this sheeting later. Cut cap strips from 1/16

3/16x36 balsa and glue them in place over the rib edges.

ADD THE SHEETING AND CAP STRIPS

Cut the sheeting to fit first then glue in place. Glue

x

2-1/8x24 leading edge sheeting, the 1/16x7/8

to

the cabane holders as

x

7.

down

pieces

on the plan. Glue this 1/4 tri

holder. Also cut tri stock

.

ribs on top ofthe cabane holders. Glue these braces in place.

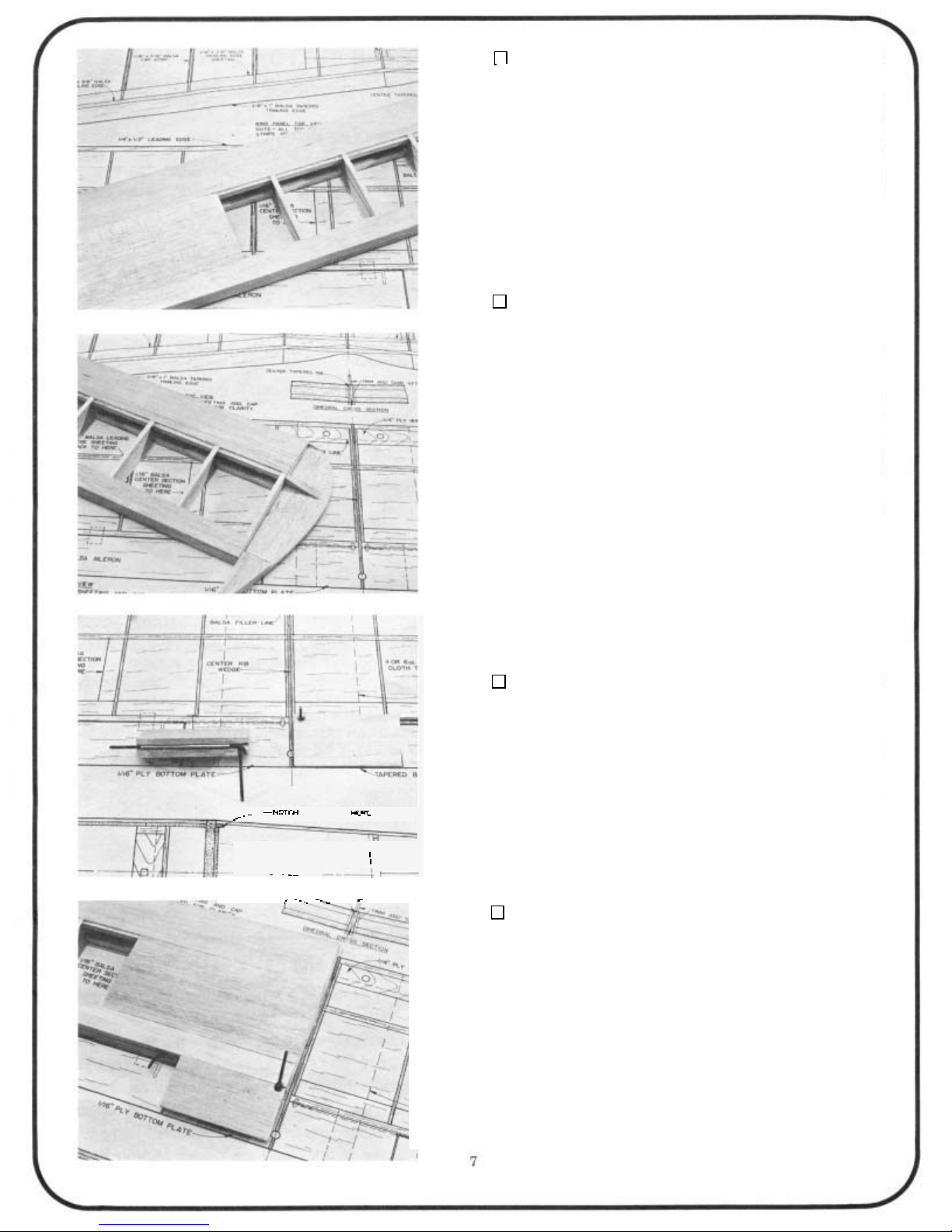

ADD 1/4 TRI STOCK BRACES

After the glue is dry, turn the wing over and pin it

to

the building board. Use 1/4x36 triangle stock and cut

to

fit along the length of the cabane holders as shown

to

the sheeting andtothe cabane

to

fitoneither side of the three center

\

8.

the1/16

center section sheeting. Glue onthe1/16

ADDTHE REST OFTHE SHEETING

x

Glue on the1/16

x

7/8

x

24trailingedge sheeting and the 1/16x3

2-1/8x24leading edge sheeting,

x

x

3/16cap strips.

15

9.

andthe3/8

to

fit first and then glue them in place. Now cut the curve in the

center trailing edge as shown on the plan and in the photo.

5

ADDTHETRAILINGEDGE

x

Addthetapered3/8

x1x

6taperedcentertrailingedgepiece.Cutparts

1x24balsa trailing edgestock

BUILDING

line. Also draw centerlines down the 1/4

and the 1/4

bottom to the bottom wing at this point.

THE

PREPARE WING RIBS

Mark all bottom wing ribs with a rib alignmentcenter-

x

1/2x24 trailing edge pieces. There is no top or

BOTTOM

WING

x

1/2x24 leadingedge

2.

the left panel first. Use the extra spar as a shim at the trailing

edge as you did with the tio wing. Pin the bottom spar over the

plans. Align the ribs to the spar, shim up the trailing edges of

the ribs and glue the ribs

hold down block as a spacer for location of ribs #1 and #2.

(Note: These hold downs are the same size as the ones that

glue into the fuselage later.) Do not glue the hold down block

in place yet.

3.

(leading edge, trailing edge and top spar). Use epoxy to glue

the hold down in place. Glue the balsa 1/4

the hold down and sand the it

GLUE THE RIBS TO THE SPAR

Build the right and left wing panels separately. Build

to

the spar. Use the 1/4x7/8

ADD LEADING EDGE, TRAILING EDGE, TOP

SPAR, HOLD DOWN AND FILLER

Align the above parts first and then glue in place

x 5/8 x

to

the shapeofthe rib contour.

x

3

3

filler above

wing

4.

ADD THE SHEETING

x

Glue on the 1/16

leading edge sheeting, the 1/16

edge sheeting and the 1/16 x 3

sheeting. Cut cap strips from 1/16

and glue them in place.

6

x 7/8 x

x

15 center section

x

2-118x24

24 trailing

3/16x36 balsa

5.

it to the board and glue in the balsa filler on the other side of

the holddown. Sand it to shape. Add the leadingedge sheeting,

the trailing edge sheeting and the center section sheeting. Add

the cap strips. This completes the left wing panel for now. Re

move the panel from the building board when it is dry. Now

build the right wing panel by following steps 1 through

ADDTHE SHEETINGAND FILLER ONTHEOTHER

OF

SIDE

When the glue is dry, turn the wing panelover, realign

THE WING PANEL

5.

INSTALLING THE WING TIPS

-

1.

Do not cut

top and bottom wingslpanels. The tips should be centered on

the tip rib and the leading edge centerline. The wing tips for

the top wing will have to sanded to an angle at the top to fit

against the leading edge. Cut the tip brace pieces from the 114

scrap provided (1/4

lower end of the wing tips, top and bottom. Sand this filler to

shape later after hinging and installing the ailerons. Sand the

leading edge to the rounded shape shown on the plans. Cut

off

the spars and sheeting even with the root rib on the panels.

Cut

the inside

GLUE THE WING TIPS TO TOP AND BOTTOM

WING PANELS

Cut

off

the sheeting and spars even with the tip rib.

off

the leading edge! Glue the wing tips on both the

x

3x11-7/8). Add the filler piece at the

the inner tip filler from some scrap balsa and add to

of

the tip. Shape

it

to

match the ailerons and

tip filler blocks.

INSTALLING THE CENTER

TRAILING EDGE (BOTTOM WING)

I.

panels and down the leading edges of the center sections. Cut

a groove along the centerline in the tapered

balsa center section pieces for the aileron torque rods. Notch

the center sections for backward torque rod arm movement.

Glue the brass sleeves of the torque rods into the blocks with

epoxy. Make right and left assemblies. Also notch the trailing

edge of the wing panelfor forward movementof the torque arms.

MAKE CENTER SECTlON/TORQUE ROD AS

SEMBLIES

Draw a centerline down the trailing edges of the wing

5/8

x

1-3/4x3-1/2

-

2.

rod

so

to move. Glue the rod/center sections to the wing panels up

the centerlines.

GLUE THE CENTER SECTIONS TO THE WING

PANELS

Use vaseline at the ends of the tube of the torque

you don't glue the wire to the wing. The rod must be free

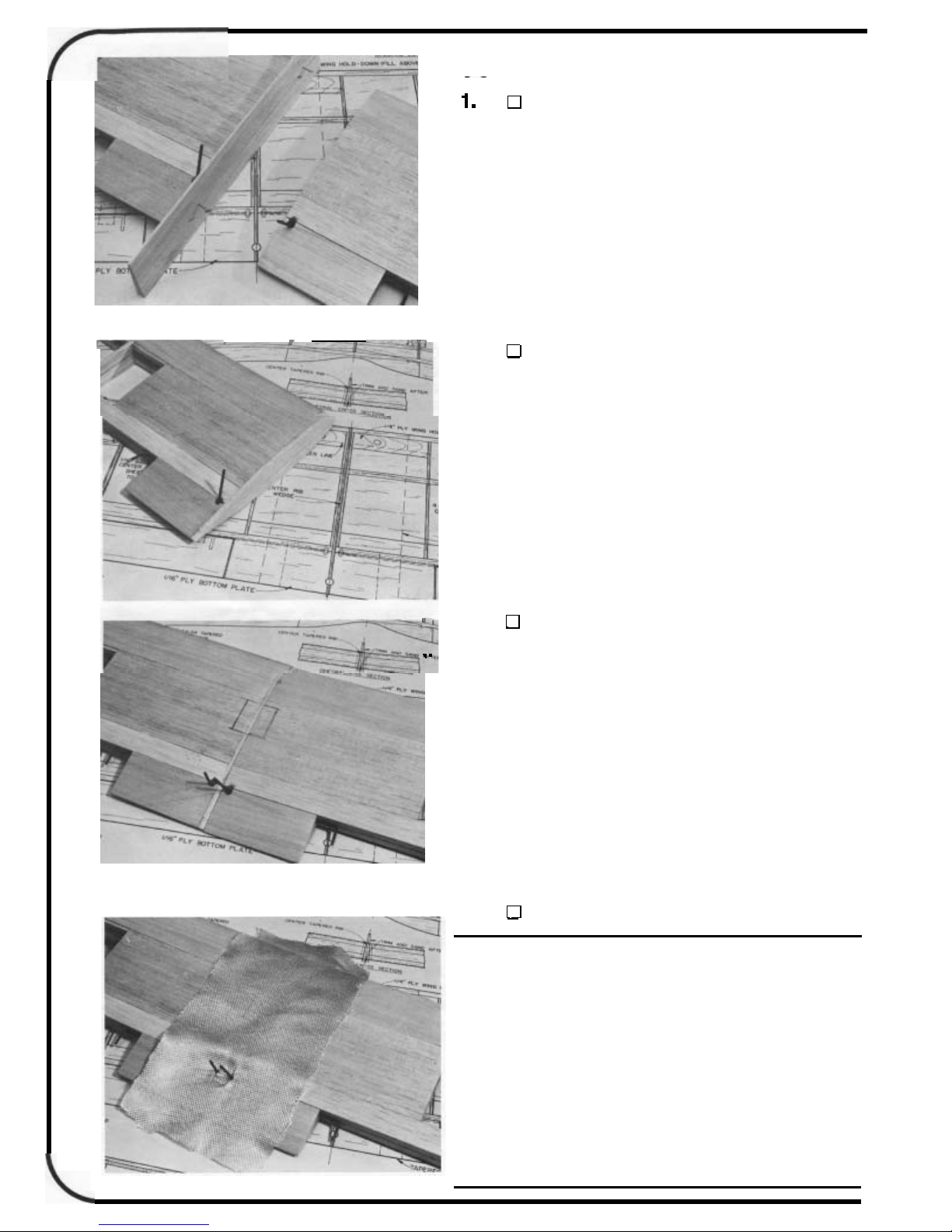

JOINING

GLUE THE CENTER RIB TO THE LEFT WING

PANEL

THE

BOTTOM

WING PANELS

With the wing panels

balsa center rib

sure the wider edge of the center rib is down and that the

leading edge and trailing edge are centered on the tapered rib.

5

Use

_

minute epoxy.

2.

it about

block

surfaces.

1/8"

so

that the center rib edges are flush with the wing sheeting

to

the root end of the left wing panel. Make

SAND THE CENTER RIB TO THE WING PANEL

CONTOUR

Rough cut the center rib to the wing airfoil, leaving

oversize. Sand the remainder away with a sanding

"up"

, glue the wedge-shaped

3.

ing and trailing edges of the panels.

make sure the leading edge of the wing is straight. Block up

the wing

slow set epoxy. See the drawing on the plan.

wing is upside down

the wing over and mark the aileron servo well location. Add the

1/16x2

I

4.

JOINTHEWING PANELS; ADDTHEWING PLATES

Join the wing panels upside down. Line up the lead-

Use a straight edge to

7/8"

at the center and glue the panels together using

Remember the

at

this point! When the glue is dry, turn

x

3-1/4

DO

plywoodwing plateto the bottomof the wing.

GLASS THE CENTER SECTION OF THE WING

NOT OMIT

THIS

STEP!

Doingsomay result in a wing failure during flight!

Coat the

minuteepoxy and use

area

where the wings werejoined with

a

4

"

wide strip

of

6

oz.

5

glass or nylon

cloth to reinforce the center joint. Saturate the cloth with

off

epoxy and then wipe

should cover both the top and the bottom

When the epoxy is

any extra epoxy. The cloth strip

of

the wing joint.

dry,

sand the center section lightly

without sanding into the glass cloth.

PREPARE THE AILERONS

Cut the aileron stock

length and draw a centerline down the leading edge of the

ailerons. Mark and drill the torque rod holes. Groove the aileron

for torque rod clearance. Make right and left ailerons.

2.

the wing trailing edge. Shape the leading edge

to a

the fit. Final sand the wing tips to match the aileron contour at

neutral. Do not permanently hinge the ailerons until after they

are covered.

CUTTHE HINGE SLOTS; FINAL SAND THE AILE-

RONS

Mark and cut the hinge slots into the ailerons and

“V’.

Temporarily install the ailerons with hinges to check

(5/8 x

17-1/2 tapered stock) to

of

the ailerons

LEFT

BUILDING

,

,

1.

“left”. Cut out part of the wing saddle area at the rear as shown

on the plan.

STOP!

the instructions on installationof 4

this instruction book.

2.

Firewall. Mark the “top” of the firewall (the bottom has a slight

angle). Mark the position of the motor mount. Mark and drillthe

holes for the motor mount

in positions in these holes you drilled. Temporarily place the

mount on the firewall with the screws. Cut the screws

,

back of the firewall

Notch a hole in Bulkhead # 2 for the throttle linkage. Prepare

Bulkhead #3 by drilling holes for the outer pushrod housings.

PREPARE THE FUSELAGE SIDES

Mark the inside of the fuselage sides “right” and

If

you plan to install a 4-cycle engine, read and follow

PREPARE THE BULKHEADS

Locate the 1/4

THE

so

FUSELAGE

-

cycle engines at the end of

x 3

x 2-3/4

4-40

they won’t get in the wayofthe fuel tank.

plywood Bulkhead

screws. Put the 4-40 blind nuts

#1,

off

the

in

9

3. D GLUE THE DOUBLERS TO

THE

FUSELAGE SIDES

Using Bulkhead #1 as a spacer, install the 1/8" balsa

doublers crossgrain on the inside of the fuselage sides. Cut the

doubler pieces from 1/8 x 3 x 36 balsa first, position and then

glue in place. Use slow set epoxy or thick cyanoacrylate. The

doubler should extend 1/4"beyond the position of bulkhead #3.

Trim the doublers to the fuselage contour.

Note:

Be careful

when

you

cut the

doubler

stock

as you

need

to use what is left in the next step.

4. D BUILD THE THREE REAR FORMERS

Make Formers #4,5 and 6 from 1/8 x 1/4 x 36 balsa.

Use the plans as a guide and cut the balsa to size. Glue the

parts together to make the three formers. Make push rod braces

from scrap 1/8 x 3 x 36 left over from the doubler stock in the

step you just did. The widths of the braces are the same as

that of each of the formers. The braces will be installed when

the pushrods are installed

later. STOP!

Did you read the 4-cycle

engine instructions if you plan to install a 4-cycle?

D MARK BULKHEAD POSITIONS

Mark the positions of bulkheads #2 and #3 on the

fuselage sides. Also

mark

the

position

of

the balsa dash between

#2 and #3. Mark the positions of the cabane blocks now if you

wish.

6. D DRILL PUSHROD EXIT HOLES

Mark and drill the holes in the fuselage sides for the

pushrod exits for the elevator and rudder. See the plans for

suggested positions of the pushrods to estimate the hole positions. A piece of brass tubing sharpened on the inside with an

X-Acto knife blade makes a neat, clean angled hole for tubestyle pushrods.

10

Loading...

Loading...