Page 1

INSTRUCTION MANUAL

SPECIFICATIONS

Wingspan:

Length: 40.5 in [ 1030mm]

Wing Area: 503 in

WARRANTY

Great Planes® Model Manufacturing Co. guarantees this

kit to be free from defects in both material and workmanship at

the date of purchase. This warranty does not cover any

component parts damaged by use or modication. In no case

shall Great Planes’ liability exceed the original cost of

the purchased kit. Further, Great Planes reserves the right to

change or modify this warranty without notice.

In that Great Planes has no control over the nal assembly or

material used for nal assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of

the nal user-assembled product. By the act of using the

user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability

associated with the use of this product, the buyer is

52 in [ 1320 mm]

2

[32.4 dm2]

Weight:

Wing

Loading:

3.6 – 3.75 lbs

[1630–1700 g]

16.5 – 17.2 oz /f t

[50– 52.5 g/dm2]

Radio: 4 −Channel with V-Tail Mixing

2

Engine: .40 − .55 cu in [6.5– 9.0 cc]

2-stroke glow

advised to return this kit immediately in new and

unused condition to the place of purchase.

To make a warranty claim send the defective part or item to

Hobby Services at the address below:

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone

number, fax number, e-mail address), a detailed description of

the problem and a photocopy of the purchase receipt. Upon

receipt of the package the problem will be evaluated as quickly

as possible.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

© 2016 Great Planes Model Mfg. A subsidiary of Hobbico,® Inc.

Champaign, Illinois

(217) 398-8970, Ext 5

airsupport@greatplanes.com

GPMA1250

Page 2

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 2

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . . 3

Engine and Engine Accessories . . . . . . . . . . . . . . . . 3

Radio and Servos . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Adhesives, Hardware, and Accessories . . . . . . . . . . 3

Glow Plug Ignitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

KIT INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ORDERING REPLACEMENT PARTS . . . . . . . . . . . . . . . 4

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ASSEMBLE THE MODEL . . . . . . . . . . . . . . . . . . . . . . . . . 5

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Install the Ruddervator Servos . . . . . . . . . . . . . . . . . 8

Test Fit the V-Tail. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Make the Carbon Fiber Pushrods . . . . . . . . . . . . . . 10

Make the Wire Pushrods . . . . . . . . . . . . . . . . . . . . . 13

Attach the V-Tail . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hinge the Ruddervators . . . . . . . . . . . . . . . . . . . . . . 16

Mount the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Hook Up the Throttle . . . . . . . . . . . . . . . . . . . . . . . . 17

Install the Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . 18

Hook Up the Fuel Cut Wire . . . . . . . . . . . . . . . . . . . 20

Mount the Landing Gear . . . . . . . . . . . . . . . . . . . . . 22

Install the Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . 23

Hook Up the Ailerons . . . . . . . . . . . . . . . . . . . . . . . . 25

FINAL ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Check the C.G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Attach the Tail Covers . . . . . . . . . . . . . . . . . . . . . . . 27

PREPARE THE MODEL FOR FLIGHT . . . . . . . . . . . . . . 30

Install the Battery and Receiver . . . . . . . . . . . . . . . 30

Final C.G. Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Balance the Model Laterally . . . . . . . . . . . . . . . . . . 31

Set the Control Throws . . . . . . . . . . . . . . . . . . . . . . 32

Basic Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

ENGINE SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . 33

AMA SAFETY CODE (excerpts) . . . . . . . . . . . . . . . . . . 34

QUIK-V6 TRIMMING NOTES . . . . . . . . . . . . . . . . . . . . . 34

QUIK-V SERIES HISTORY . . . . . . . . . . . . . . . . . . . . . . . 36

INTRODUCTION

Congratulations and thank you for purchasing the Great

Planes Quik-V6 Quickie 500 pylon racer. If you’re on a quest

for speed the Quik-V6 is the answer, but the Quik-V6s primary

objective is to be a competitive weapon in AMA 424 or 426

(Sport Quickie or Super Sport Quickie) pylon racing. If you

spend any time reviewing race results on the internet or if

you attend any of the major pylon races you’ll know that

Jim Allen is one of the premier pilots. Jim is the designer

of the Quik-V6 (as well as the Great Planes Proud Bird EF1

pylon racer). You can read all about Jim’s interesting and

insightful development history of the Quik-V6 (and the origin

of the name) on the back cover. Also make it a point to read

Jim’s regimen on i ght tr imming fo r pyl on rac ing o n pag e 34.

For the latest technical updates or manual corrections to

the Quik-V6 ARF visit the Great Planes web site at www.

greatplanes.com. Open the “Airplanes” link, then select the

Quik-V6. If there is new technical information or changes

to this model a “tech notice” box will appear in the upper

left corner of the page.

If you are not already a member of the AMA, please join! The

AMA is the governing body of model aviation and membership

provides liability insurance coverage, protects modelers’

rights and interests and is required to y at most R/C sites.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

IMPORTANT!!! Two of the most important things you can

do to preserve the radio controlled aircraft hobby are to

avoid ying near full-scale aircraft and avoid ying near

or over groups of people.

SAFETY PRECAUTIONS

Protect Your Model, Yourself & Others…

Follow These Important Safety Precautions

1. Your Quik-V6 should not be considered a toy, but rather a

sophisticated, working model that functions very much like

a full-size airplane. Because of its performance capabilities,

the Quik-V6, if not assembled and operated correctly,

could possibl y cause injur y to yourself or spectators and

damage to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or un yable model.

In a few cases the instructions may differ slightly from

the photos. In those instances the written instructions

should be considered as correct.

3. You must take time to build straight, true and strong.

4.

You must use an R/C radio system that is in good condition,

a correctly sized engine, and other components as

speci ed in this instruction manual. All components must

be correctly installed so that the model operates correctly

on the ground and in the air. You must check the operation

of the model and all components before every ight.

5.

If you are not an experienced pilot or have not own this

type of model before, we recommend that you get the

assistance of an experienced pilot in your R/C club for

2

Page 3

your rst ights. If you’re not a member of a club, your

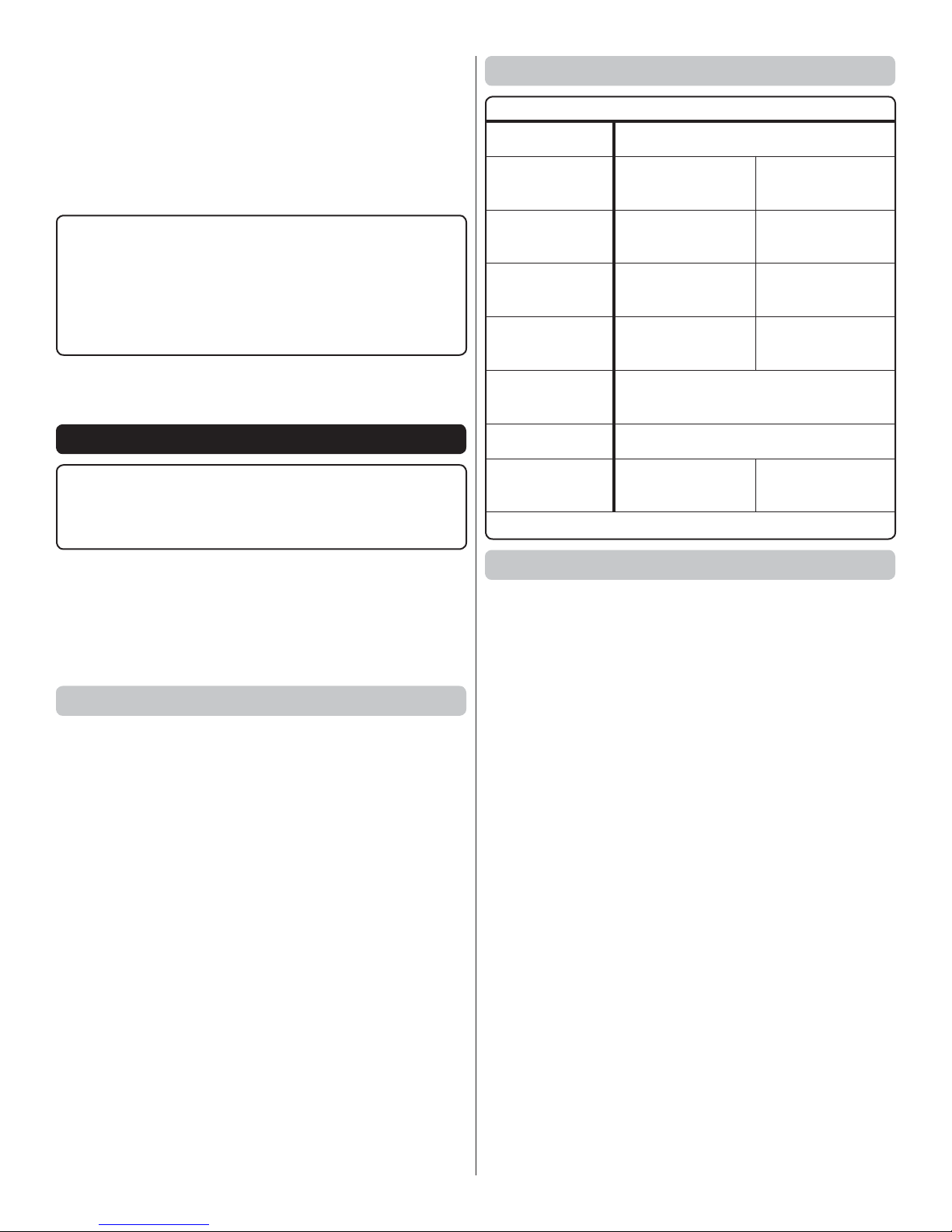

TRANSMITTER

Futaba 4-channel on 2.4 GHz w/V-tail mixing

2S 1300mAh LiFe receiver battery

(HCAM6411)

FUTM4350

FUTM4190

(3) Futaba 9670SV

(FUTM0725)

(3) Futaba 9650

(FUTM0260)

(1) Futaba 3172SV

(FUTM0125)

(1) Futaba 3102

(FUTM0034)

R6303SB Micro

3-18ch (FUTL7661)

Futaba R617FS

FASST (FUTL7627)

(1) 6" dual servo

extension (FUTM4135)

(3) 6" (TACM2090)

RUDDERVATOR,

AILERON SERVOS

THROTTLE/

FUEL-CUT SERVO

RECEIVER

SERVO

EXTENSIONS

RECEIVER

BATTERY

ON-OFF SWITCH

SBC-1 CHANNEL

SETTING TOOL*

*Not required if using a Futaba transmitter with Serial Interface

S.Bus

Non-S.Bus

local hobby shop has information about clubs in your

area whose membership includes experienced pilots.

6. While this ARF has been ight-tested to exceed normal

use, if an engine larger than one in the recommended

range is used, the modeler is responsible for taking steps

to reinforce the high stress points and/or substituting

hardware more suitable for the increased stress.

We, as the ARF manufacturer, provide you with a top

quality, thoroughly tested ARF and instructions, but ultimately the quality and yability of your nished model

depends on how you assemble it; therefore, we cannot

in any way guarantee the performance of your completed

model, and no representations are expressed or implied

as to the performance or safety of your completed model.

REMEMBER: Take your tim e and fo llow t he inst r u c t ions

to end up w ith a w ell-bu i lt mod e l that i s straigh t and t r u e.

ADDITIONAL ITEMS REQUIRED

NOTE: Some of the items speci ed are in accordance

with current AMA/NMPRA rules. If you plan on racing your

Quik-V6, be certain to consult the rules for the latest speci ed

equipment to make sure your plane is in compliance.

Radio and Servos

Most of the specialty pylon racing items for AMA 426

(Super Sport Quickie), including the Jett brand engine and

muf er, J ett ba ck plate e ngine moun t, Jet t remote un iver s a l

needle valve, Tettra fuel tanks, Super Tanker fueler, etc.,

are available on the internet from Jett Engineering Inc.

and/or Darrol Cady Racing.

Engine and Engine Accessories

For sport flying:

❍ O.S. 46AXII ABL w/Muffler (OSMG0548) OR O.S.

.55AX ABL 2 w/muffler (OSMG0557)

For AMA 424 (Sport Quickie):

❍ ThunderTiger Pro .40 w/muffler

❍ APC 9 x 6 Sport propeller (APCQ9725)

For AMA 426 (Super Sport Quickie):

❍ Jett Engineering Inc. QJ-1 .40 engine and muffler

❍ Jett back plate mount

❍ Jett remote universal needle valve

❍ Darrol Cady or Sullivan thin-wall fuel tubing

(SULQ1205)

❍ Spare glow plugs (Merlin 1125A Red most

common)

❍ Jett Super Tanker syringe-type fueler

❍ Suitable propellers (APC 8.8 x 8.75 most popular –

APCQ8975)

❍ Bubbless, bladder-type fuel tank (Tettra 6 oz. or

Tettr a 5 . 25 oz.)

❍ Pylon racing-type glow igniter system

❍ Silver solder (STAR2000)

Adhesives, Hardware & Accessories

Other than common hobby tools here is a list of the rest

of the items required:

❍ Z-bend pliers (HCAR2000)

❍ 30-minute epoxy (GPMR6043)

❍ Dave Brown carbon ber tape (DAVR2000)

❍ Thin CA (GPMR6001)

❍ Medium CA (GPMR6007)

❍ CA applicator tips (HCAR3780)

❍ CA activator (GPMR6035)

❍ Threadlocker (GPMR6060)

❍ 1/4" RC foam rubber (HCAQ1000)

❍ 10-24 drill and tap set (or #25 or 5/32" drill and 10-

24 tap)

❍ Spare 10-24 x 1/2" nylon at-head screws (for main

landing gear)

❍ Covering iron (COVR2700)

❍ Cover Sock (COVR2702)

❍ Trim Sealing Iron (COVR2750)

❍ After-run engine oil (GPMP3001)

For optional carbon fiber ruddervator pushrods:

❍ (2) 4mm [5/32"] Midwest carbon ber pushrod

tubes (MIDR5721)

❍ (1) K&S 3/16" aluminum tube (K+SR8104)

On page 7 you’ll see the common practice of reinforcing all

the critical, high-stress joints with llets made from 30-minute

epoxy and chopped carbon ber or berglass. Dave Brown

carbon ber tape is recommended for this (DAVR2000).

3

Page 4

A covering iron is also required for applying the included

GPMA2550.....Backplate Engine Mount

GPMA2552.....Fuel Tank

GPMA4575.....Fuselage Set

GPMA4576.....Wing

GPMA4577.....Tail Surface Set

GPMA4578.....Landing Gear

GPMA4579.....Servo Hatch

GPMA4580.....Wheel Set

Mo noKote c ove ring over the wood tail c ove r s afte r they have

be e n glu e d into place, a s we ll as t ightening the covering ove r

the entire model in general. The 21st Century Sealing Iron

(COVR2700) and Cover Sock (COVR2702) are recommended.

A Trim Sealing Iron is also helpful (COVR2750).

Glow Plug Igniter

KIT INSPECTION

Before starting to build, inspect the parts to make sure

they are of acceptable quality. If any parts are missing or

are not of acceptable quality, or if you need assistance

with assembly, contact Product Support. When reporting

defective or missing parts, use the part names exactly as

they are written in the Kit Contents list.

If you’re a little serious about racing, a racing-type glow plug

igniter system is preferred over the one-piece, integrated

glow-driver/battery unit commonly used for sport ying.

Racing-type glow igniters developed for the ight line

feature a high-capacity battery and a lighted display

that can alert you of the condition of your glow plug and

automatically discontinue power after a prescribed time.

For security and safety, and to relieve stress from the

glow plug, the lightweight clip is connected to the battery/

controller unit via an electrical cord. Pylon racing glow

igniter systems are available from the aforementioned

pylon racing specialty sources.

NOTE: The stabilizer and wing incidences and engine thrust

angles have been factory-built into this model. However,

so me te chnic ally- minde d mod elers m ay wish to chec k the se

me a surem ents a nyway. To vi ew this informa tion visit the web

site at www.greatplanes.com and click on “Technical Data.”

Due to manufacturing tolerances which will have little or no

effect on the way your model will y, please expect slight

deviations between your model and the published values.

Great Planes Product Support

3002 N Apollo Drive, Suite 1

Champaign, IL 61822

Ph: (217) 398-8970, ext. 5

Fax: (217) 398-7721

E-mail: airsupport@greatplanes.com

ORDERING REPLACEMENT PARTS

Replacement parts for the Great Planes Quik-V6 ARF are

available using the order numbers in the Replacement

Parts List that follows. The fastest, most economical

service can be provided by your hobby dealer or mailorder company.

To locate a hobby dealer, visit the Great Planes web site at

www.greatplanes.com. Choose “Where to Buy”. Follow

the instructions provided on the page to locate a U.S.,

Canadian or International dealer.

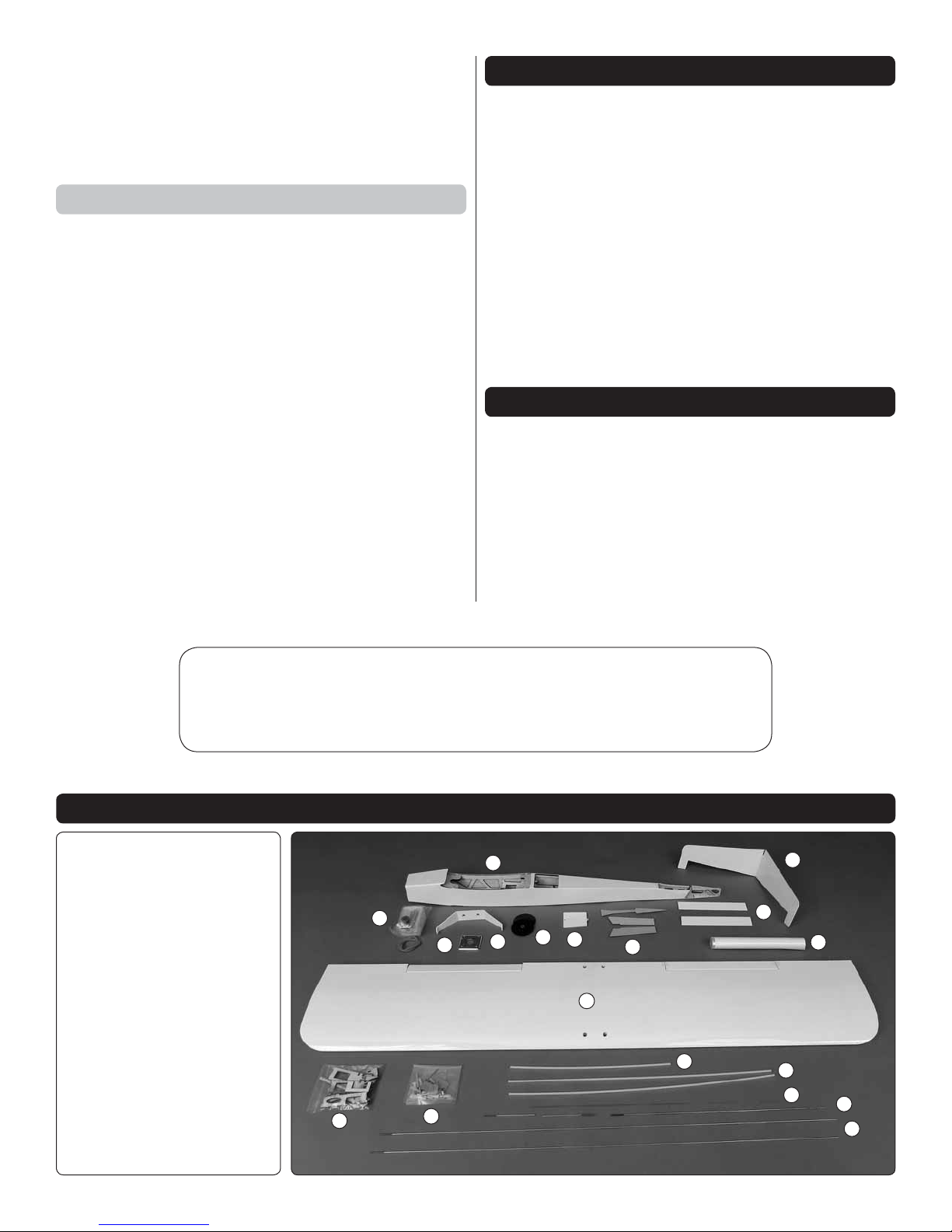

1. Fuse lage

2. V-Tail

3. Fuel Tank & Hardware

4. Engine Mount

5. Main Landing Gear

6. Main Wheels

7. Hatch Cover

8. Tail Covers

9. Ruddervators

10. MonoKote

11. Wing/Ailerons

12. Wood Parts

13. Hardware

14. Throttle Guide Tube

15. Ruddervator Guide Tubes

16. Fuel Cut Wire

17. Aileron/Throttle Pushrods

18. Ruddervator Pushrods

KIT CONTENTS

1

3

4

12

13

5

4

2

9

6

7

11

8

14

10

15

16

17

18

Page 5

ASSEMBLE THE MODEL

Preparation

1. Examine the covering over all the parts of the model

❏

to nd wrinkles or areas that are not bonded to the wood

underneath. Where necessary, use a covering iron with

a cover sock to tighten the covering, pushing down on

the iron to bond the covering to the wood. Be thorough—

this procedure can take anywhere from a few minutes to

an hour or so. The optimum temperature for shrinking/

bonding MonoKote is around 320°F – 360°F (which requires

a dial setting of about 350°F – 375°F on the 21st Century

Sealing Iron with a Cover Sock). If the covering bubbles or

blisters, this may indicate too much heat. Allow the area to

cool and don’t hold the iron in one spot for too long. Press

down harder and/or use less heat. A sharp hobby blade

may be used to puncture the bubble in a few areas, but be

careful; if using solution to apply vinyl graphics or trim cut

from MonoKote later, it will wick through the perforations

and cause the wood to swell, causing a minor blemish in

that area. You could always puncture these trouble spots

later after you have applied your graphics.

3. Then, laying the piece into position, gently squeegee

❏

out the solution with a piece of soft balsa. This procedure

removes air bubbles that would otherwise form between

the layers.

4. Allow to dry at least over night before permanently

❏

ironing the trim down—the longer you wait before ironing

the better.

2. When ready to apply graphics, trim colors may be

❏

cut from MonoKote. Applying MonoKote over MonoKote

is best done by spraying the back of the trim piece with

window cleaner. NOTE: If any of your trim graphics cross

the aileron hinge gaps it may be better to apply the graphics

after the hinges have been joined and the hinge gaps have

been sealed as illustrated on page 25.

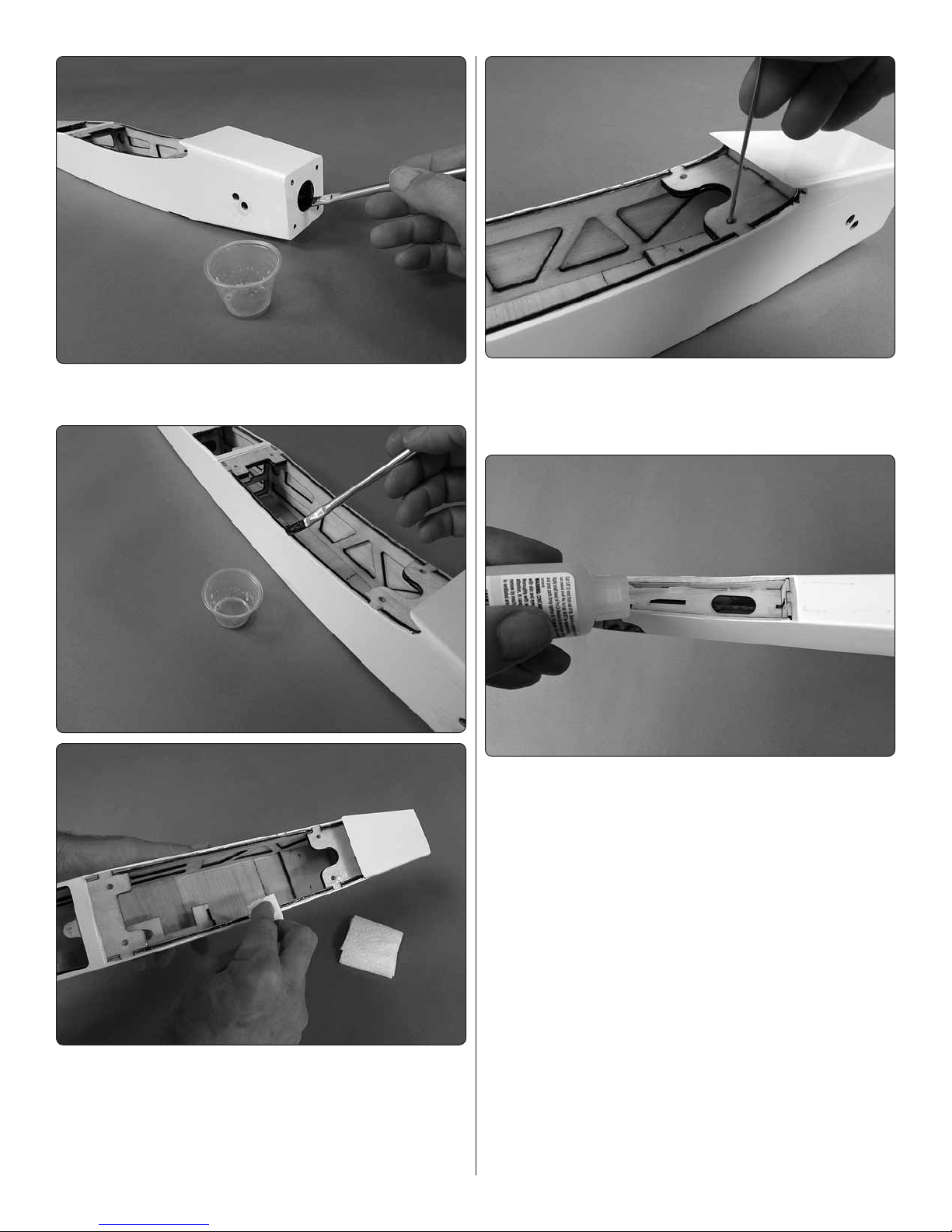

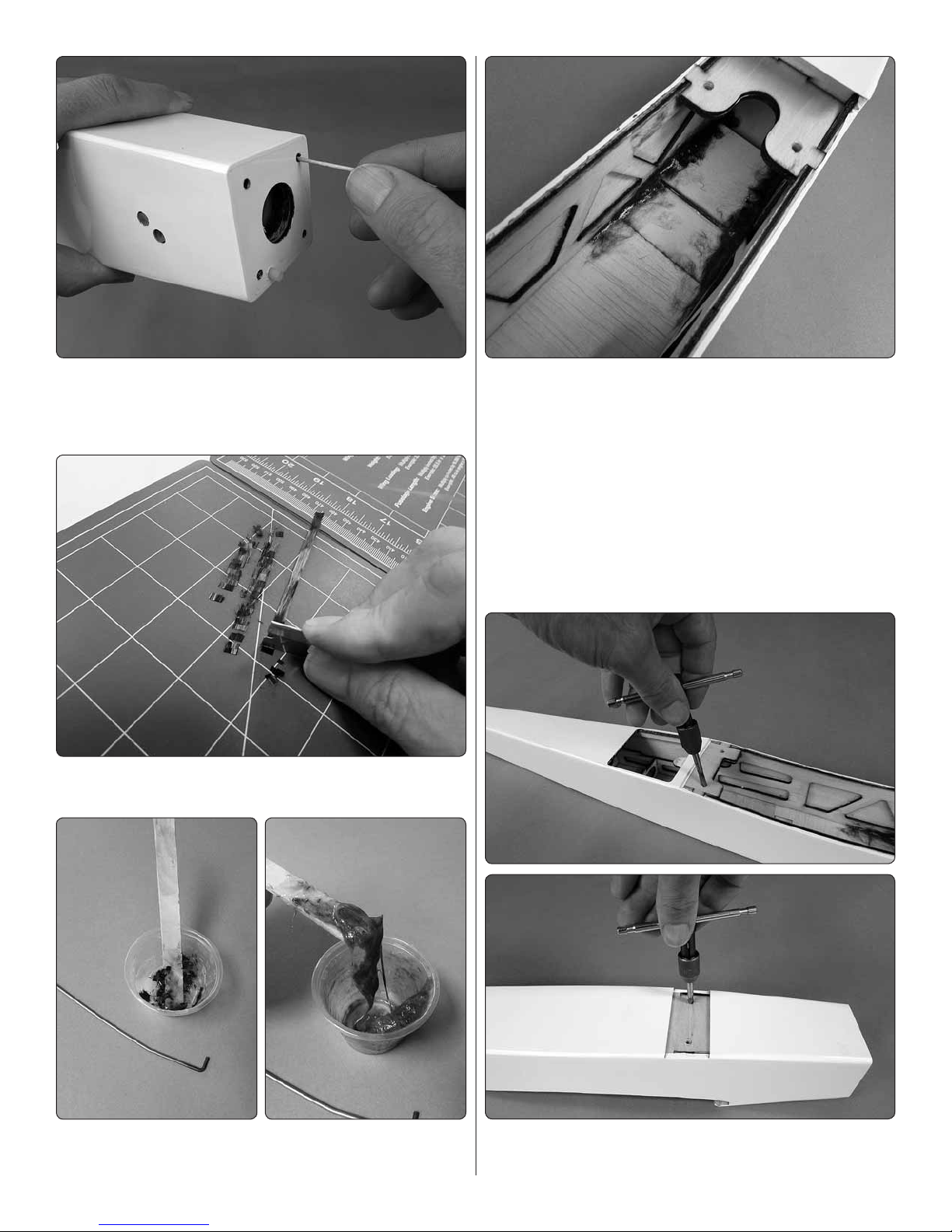

5. There are several instances during assembly where

❏

epoxy cleanup with denatured alcohol will be necessary.

To conserve whole paper towels and to make cleanup

easier, stack a few paper towels on top of each other and

cut them into small squares as shown. This may seem

ridiculous now, but you’ll thank us later and continue to

keep a supply of paper towel squares on your workbench

from now on!

5

Page 6

6. Use 30-minute epoxy to fuelproof areas that may be

❏

exposed to exhaust, fuel or cleaning solution (see next page).

8. Also lightly coat the holes in the wing bolt plates and

❏

the holes in the landing gear plate with 30-minute epoxy.

Allow to fully harden before re cutting the holes with a 1024 tap later.

9. Inspect all visible glue joints looking for areas in

❏

the cabin or tail that could use reinforcement. Where

necessary, use a CA applicator to apply thin or medium

CA to any glue joints that don’t look strong.

7. Don’t forget to coat the outside of the landing gear

❏

plate on the bottom of the fuselage. Apply liberally, allow

to soak in, and then remove excess epoxy before it

hardens.

Next, epoxy/carbon ber epoxy llets will be added to

key structural areas in the fuselage. First, we’ll mix up a

batch and apply to the landing gear plate and wing bolt

plates. Then, we’ll repeat the process for the rewall

with a new batch of resin. Separating the job into two

procedures insures plenty of working time before the

epoxy begins to harden.

6

Page 7

10. Use a toothpick to apply a little petroleum jelly to

❏

the threads in the blind nuts inside the rewall to prevent

excess epoxy from clogging up the threads. (Any material

that remains can also be removed with a 6-32 tap later.)

11. Chop 3" – 4" [80 – 100mm] of Dave Brown carbon

❏

ber tape into 1/8" [3mm] segments.

13. Apply the epoxy/carbon ber llets to the joints

❏

between the fuselage sides and the bottom of the wing

bolt plates and to the landing gear area as shown. You

can dip your nger in denatured alcohol to smooth and

form the llets as you go.

14. Mix up another batch of epoxy/carbon ber. Using

❏

the hole in the rewall for access, apply llets all the way

around the joint of the back of the rewall and the fuselage

sides and top and bottom—don’t worry too much about

getting excess epoxy into the blind nuts in the back of

the rewall—if necessary, a drill and 6-32 tap can be run

through the blind nuts to clean them out later.

12. Mix approximately 1 oz. [30cc] of 30-minute epoxy,

❏

then mix in the chopped carbon ber.

15. After all the epoxy has hardened, clean out the wing

❏

bolt holes and the landing gear bolt holes with 10-24 tap.

7

Page 8

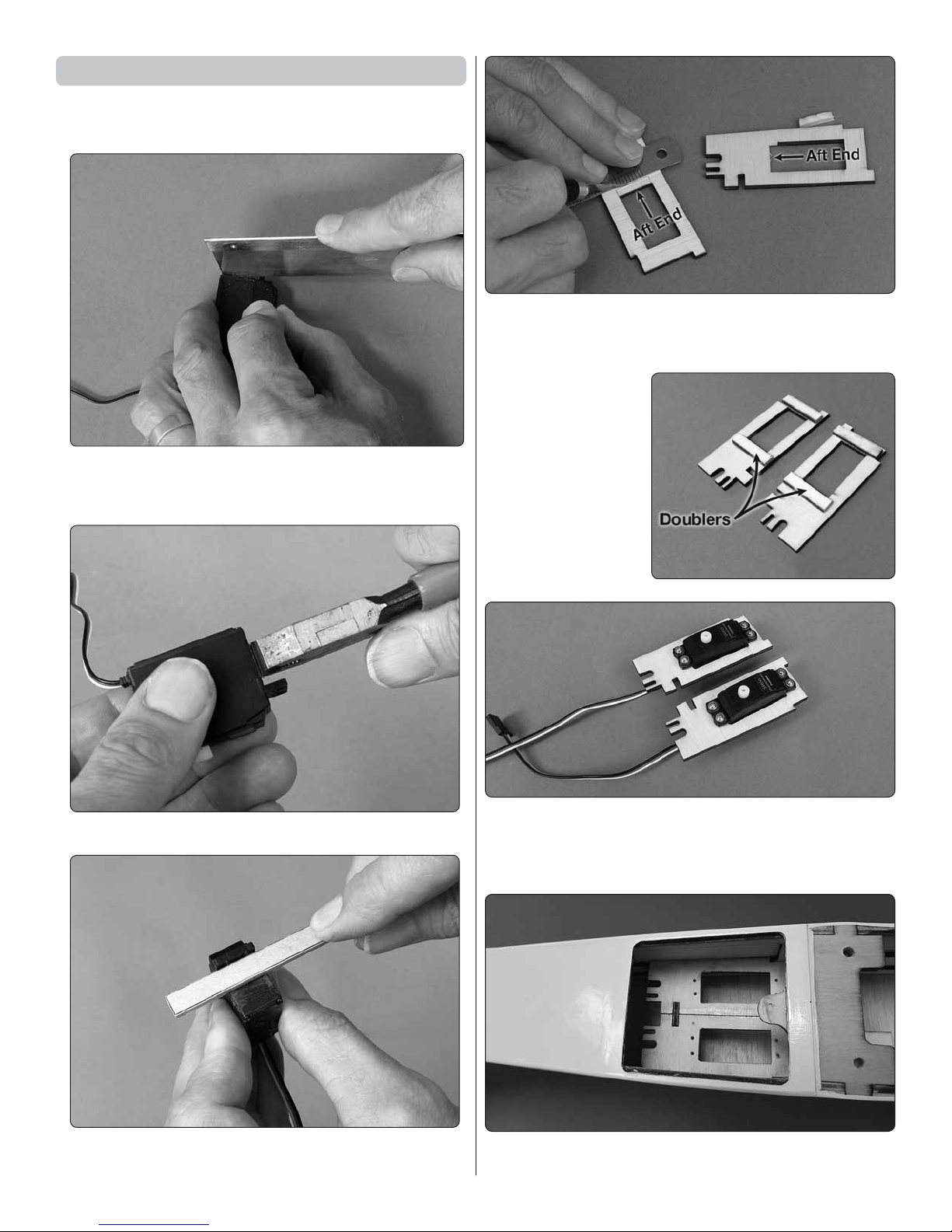

Install the Ruddervator Servos

1. If using the recommended servos that come with

❏

side tabs, carefully remove the tabs as follows:

A. First, use a razor saw to score or cut most of the

❏

way through the tabs—of course, use extreme care not

to cut into the servo wires where they exit the case!

2. If necessary, enlarge the openings in the servo trays

❏

to t your servos, then test- t the servos—if the cutouts

do require cutting, remove material from the aft end of the

openings.

3. Cut the included

❏

3mm lite-ply strip into

segments and glue

them to the bottom

of the servo trays for

screw doublers.

B. Then, break off the tabs with pliers.

❏

C. Use a stick with sandpaper to remove any

❏

remaining tab material and smooth the edges.

4. Drill 1/16" [1.6mm] holes for the servo mounting

❏

screws, temporarily mount the servos, remove the screws,

and add a few drops of thin CA to the screw holes. We’ll

remount the servos into the tray later.

5. Test- t, then securely glue the servo trays into the

❏

fuselage.

8

Page 9

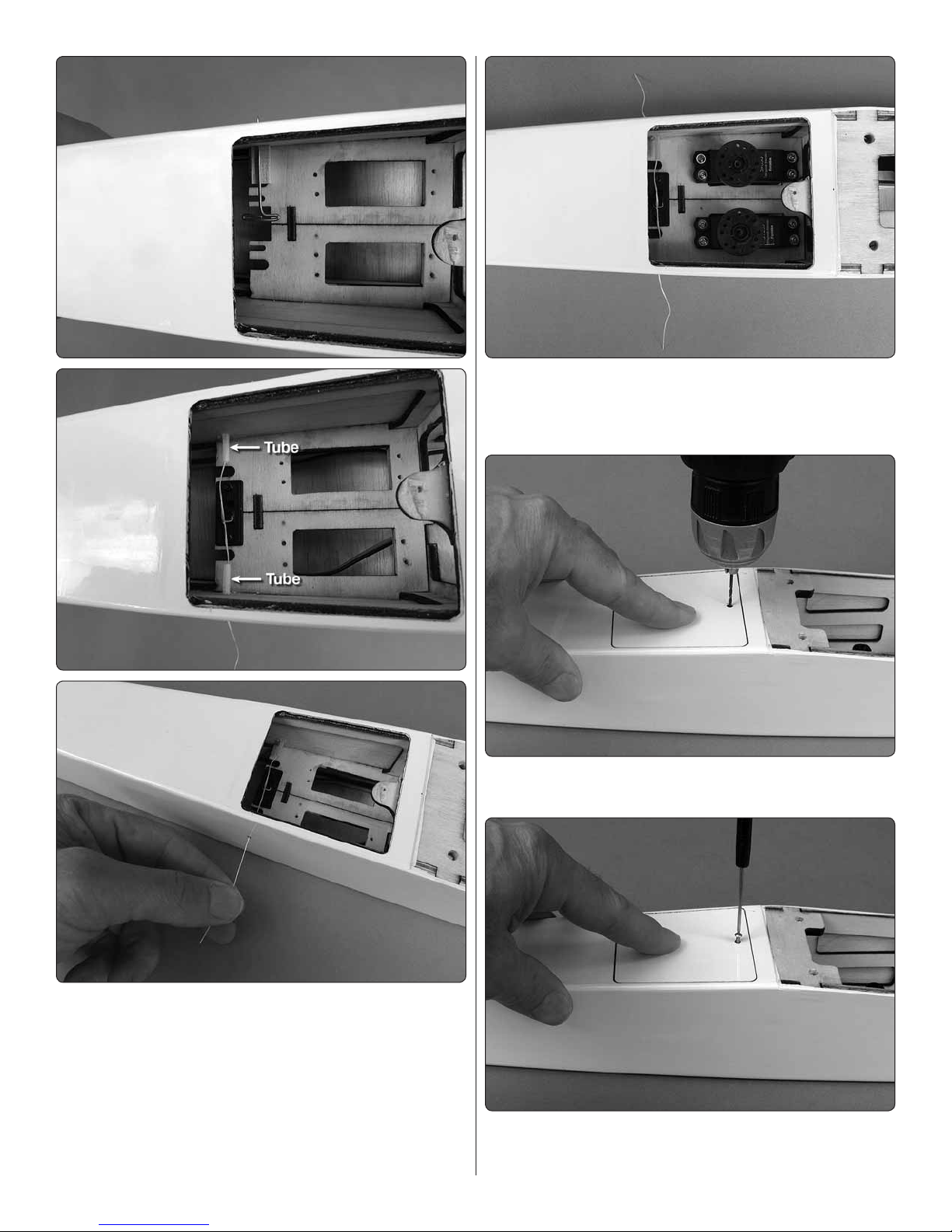

7. Mount the servos. If using the included pushrod wires

❏

(whether as supplied, or with the carbon ber pushrod

tube option), enlarge the holes in the servo wheels with

a .074" drill.

8. Drill the hole for the servo hatch cover screw with a

❏

1/16" [1.6mm] drill.

6. Determine how you are going to actuate the switch

❏

from outside the fuselage. One popular way is the “string

technique” to pull the switch on from one side and off

from the other. Test- t the switch and use a pin to locate

the holes for the string. Use a sharpened brass tube or a

drill to make holes in the fuselage for small plastic tubes

(cut from any kind of spray applicator) glued into position

as a bearing for the holes. Drill a hole in the switch for

the string, then mount the switch with threadlocker on the

threads and connect the string.

9. Fit the hatch cover with a #2 x 3/8" button-head

❏

screw. Remove the screw and hatch, add a few drops of

thin CA to harden the hole and allow to harden.

9

Page 10

Test Fit the V-Tail

Do not use any glue until instructed to do so—we’re going

to go as far as possible tting up the V-tail and hooking

up the pushrods before permanently gluing anything in.

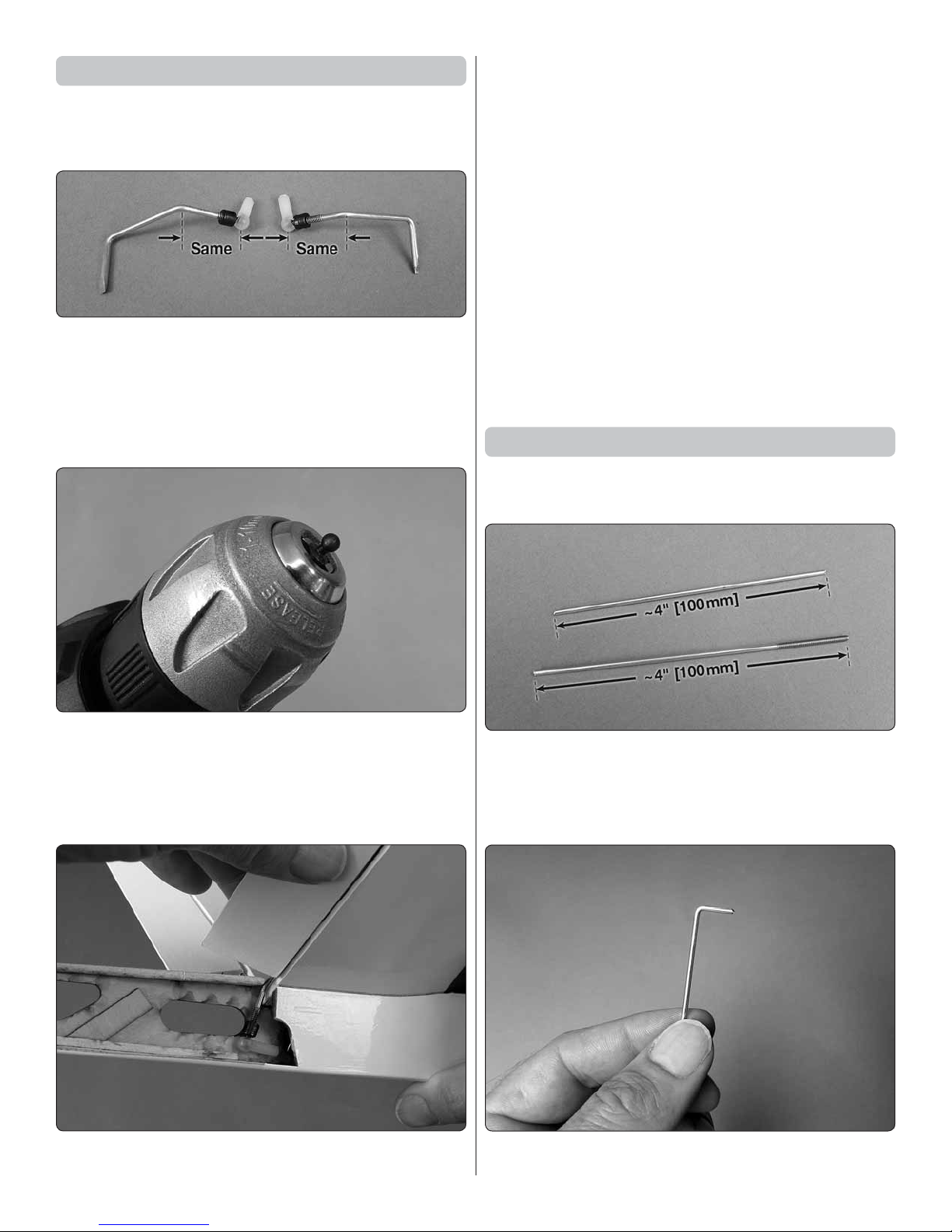

1. Temporarily thread the ball link balls onto the

❏

ruddervator torque rods. Examine the ball link balls to

make sure there is no burr or a sharp point on the tip. If

necessary, use a metal le to grind off the protrusion, then

snap the ball links onto the balls. Also make sure the ball

link balls are the same length. If necessary, shorten the

longer torque rod to match the short one.

notch in the former and the tab on the bottom into the

slot in the base). Without glue, test- t the ruddervators

with the hinges, torque rods and ball links. Make sure

the ruddervators move smoothly and the ball links don’t

interfere with anything. Make any adjustments necessary.

4. If you haven’t yet done so, program your radio for

❏

V-tail mixing.

Now it’s time to decide what kind of pushrods you are

going to use—either the included rod-and-tube setup,

or an optional 5/32" [4mm] carbon ber pushrods (not

included). Most pilots use the standard wire pushrods,

but some pylon racers prefer carbon ber pushrods for

ultimate precision.

If using the pushrods included, skip to Make the Wire

Pushrods on page 13. If using carbon ber pushrods,

follow these instructions, or use your preferred method to

make the pushrods:

Make the Carbon Fiber Pushrods

The instructions illustrate making one pushrod at a time,

but you could make them simultaneously.

2. Make sure the ball links can move freely and are not

❏

too tight. If they are too tight, chuck the base of the ball in

a hand drill (or, try another ball link if you have a supply of

your own). Polish the ball with metal polish and a cloth or

other mildly abrasive product until the ball links swivel on

the balls smoothly. Temporarily reassemble and set aside.

3. Temporarily t the V-tail to the fuselage (being certain

❏

to key the tab at the front of the V-tail center rib into the

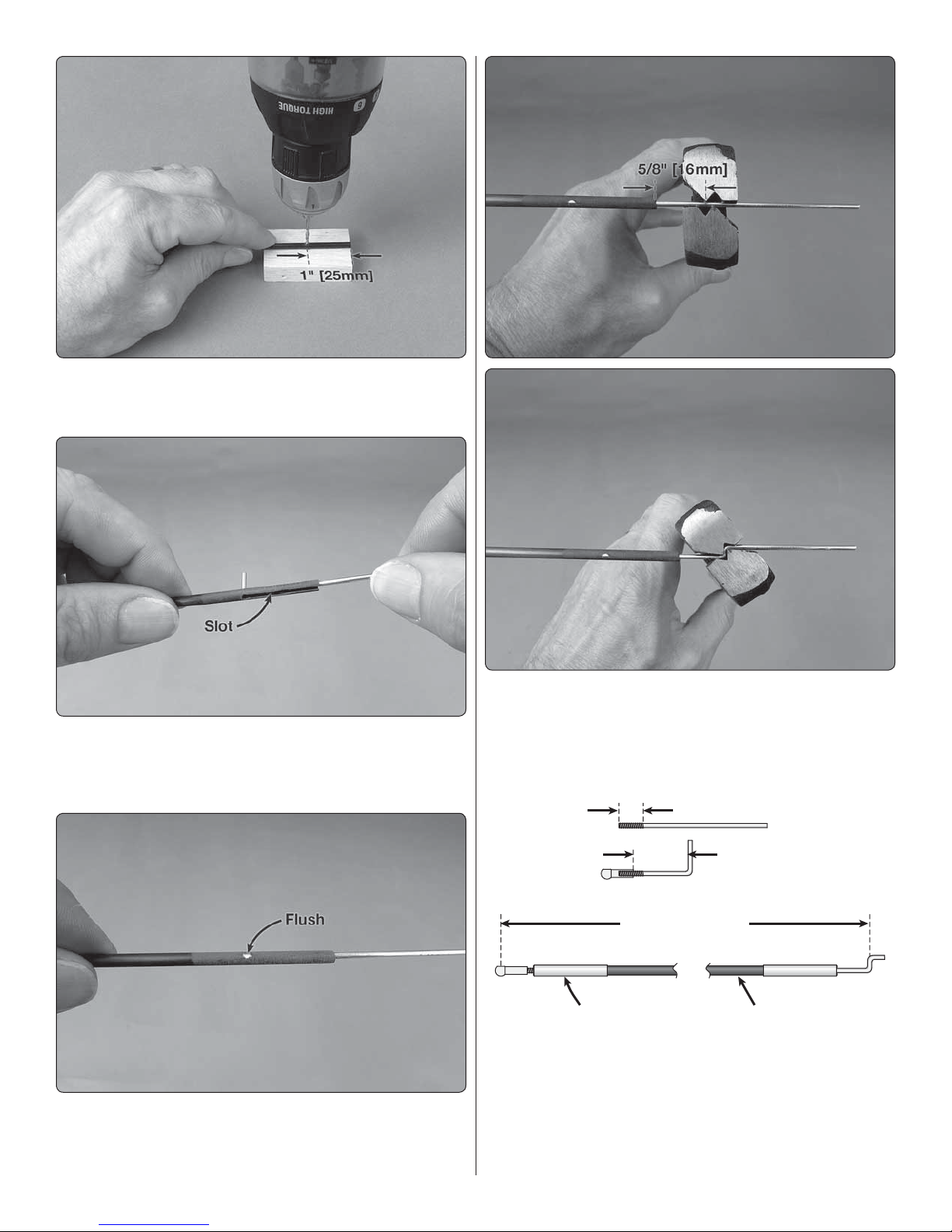

1. Cut two, approximately 4" [100mm] segments from

❏

the threaded end of one of the long pushrod wires so you

have a threaded piece and a non-threaded piece. Clean

the wires with denatured alcohol, then roughen with

medium-grit sandpaper so glue will adhere.

2. Make a 90° “L-bend” as sharp as you can on one of

❏

the non-threaded wires.

10

Page 11

3. Drill a .074" or 5/64" [2.0mm] hole all the way through

16-5/8" [422mm]

Carbon Fiber TubeAluminum Tube/Sleeve

1/2" [13mm]

1-1/8" [29mm]

❏

a 5/32" [4mm] carbon ber pushrod tube 1" [25mm] from

the end.

4. Wearing respiratory and eye protection, use a razor

❏

saw or a reinforced cutoff wheel to cut a slot from one

of the holes up to the end of the tube, then install the

pushrod wire.

6. Make a Z-bend in the wire 5/8" [16mm] from the end

❏

of the tube. Cut the excess wire off the end of the Z-bend

and use a le or a reinforced cutoff wheel to deburr the

end of the wire.

5. Tack-glue the pushrod into place with a few drops of

❏

thin CA. Cut the “L” of the pushrod even with the tube, then

use a le to make the wire completely ush with the tube so

an aluminum sleeve can be t over the assembly later.

7. If installing the Futaba servos recommended, you

❏

can skip steps 8 through 12 and simply nish making the

pushrod to the dimensions shown above. If using other

servos, it would be better to custom- t the pushrods in

case the output shaft of your servos is different requiring

different pushrod lengths.

11

Page 12

8. Guide the pushrod up through the back of the

Aluminum Tube

Epoxy or CA

❏

fuselage and temporarily connect it to the servo.

11. Lay the pushrod wire alongside the pushrod tube

❏

with the socket in the ball link aligned with the mark you

made on the pushrod. (The pushrod was wrapped with

masking tape for clarity in the photo.) Mark the pushrod

1/8" [3mm] from the ball link and a third mark 1" [25mm]

from the second.

12. Cut the pushrod at the second mark made in the

❏

previous step. Then, drill the holes through the pushrod at

the second mark. Cut another slot same as was done on

the front of the pushrod.

13.

Unthread the ball link from the pushrod wire and use

❏

thin CA to tack-glue the pushrod into the tube and trim the

excess wire so it is ush with the outside of the tube.

14. Cut two 1-1/2" [40mm] pieces from a 3/16" K&S

❏

aluminum tube. Clean the inside of the tubes with a small

paper towel square and denatured alcohol.

9. With the V-tail and torque rods temporarily held

❏

in place and the ruddervator and elevator servo wheel

centered, mark the pushrod tube at the ball. This is where

the socket on the ball link must end up after the back of

the pushrod is done. Remove the pushrod.

10. Cut the threaded end of the 4" [100mm] pushrod

❏

wire so approximately 1/2" [13mm] of thread remains.

Thread a ball link most of the way onto the threads so

approximately 1/8" [3mm] of the thread is exposed, but

the ball link could be threaded on an additional 1/8" [3mm]

as well—this will leave room for adjustment later. Bend an

“L” bend in the wire 1-1/8" [29mm] from the ball link and

cut off the excess wire.

15. Thoroughly pack the slots in both ends of the

❏

pushrods with 30-minute epoxy mixed with microballoons

or milled glass ber and coat the ends of the pushrod tubes.

16. Apply epoxy inside the aluminum tubes, then slip

❏

the tubes over the ends of the pushrods (the aluminum

tube that goes over the pushrod with the Z-bend will have

to go on from the other end because it won’t t over the

12

Page 13

Z-bend). Be certain to remove any epoxy from the threads

on the pushrod wire. Allow the epoxy to harden.

17. If you haven’t yet done so, make and test- t

❏

the other pushrod the same way. After the epoxy has

hardened, thread the ball links onto the threaded end

of the pushrods. Set the pushrods aside until it’s time

to hinge the ruddervators. Skip to “Attach the V-tail” on

page 14.

Make the Wire Pushrods

5. With the V-tail held in position and the ruddervators

❏

and servo wheels centered, mark the pushrods where

they cross the holes in the servo wheels.

1. Cut the included pushrod guide tubes to a length

❏

of 14-1/2" [370mm] and the included pushrod wires to a

length of 17-1/2" [445mm]. Use medium-grit sandpaper to

roughen the outside of the guide tubes so glue will adhere,

then install the tubes up through the formers in the fuselage.

2. Thread a ball link ball about 3/8" [10mm] onto each

❏

of the pushrod wires.

3. Thoroughly clean the pushrod wires with a paper

❏

towel square and denatured alcohol. Lightly coat the

wires with any light oil.

6. Disconnect the ball links from the metal balls. Cut

❏

the pushrods 5/16" [8mm] past the marks, chamfer ends

of the wires to remove any burrs, and then make a Z-bend

in each pushrod wire at the marks.

4. Install the pushrods up through the guide tubes.

❏

Place the V-tail with the torque rods and ball link balls into

position and snap the ball links onto the balls.

7. Connect the pushrods to the servos.

❏

13

Page 14

8. Glue the guide tubes into the two formers in the

MarkMark

11"

[280mm]

11"

[280mm]

❏

fuselage with medium CA and a CA applicator tip.

Attach the V-Tail

1. If you haven’t yet done so, permanently attach the

❏

thread-on ball link balls to the ruddervator torque rods

with threadlocker, epoxy, JB Weld or even silver solder if

you prefer.

2. Use medium-grit sandpaper to roughen the torque

❏

arm portion of the torque rods that go into the ruddervators

so glue will adhere.

5. If any covering does require trimming, use the tip of

❏

a soldering iron set to about 400°F to melt through the

covering where necessary.

6. Also trim off any MonoKote that may have been

❏

wrapped around the stab saddle.

3. Securely glue the torque rods into the ruddervators

❏

with 30-minute epoxy. Set aside and allow the epoxy to

harden.

4. Hold the V-tail into position on the fuselage and view

❏

the joint from the bottom. Make sure the covering has

been trimmed so there will be a full, wood-to-wood glue

joint between the bottom of the V-tail and the fuselage. If

necessary, use a ne-point felt-tip pen to mark where the

fuselage sides meet the bottom of the V-tail halves.

7. Without using any glue, t the ailerons to the wing

❏

with the hinges and tape the ailerons to the wing so they

will be centered. Use a ne-point felt-tip pen to mark

centerline of wing between aft wing bolts. Also mark lines

on each aileron 11" [280mm] out from centerline.

14

Page 15

8. Mount the wing to the fuselage with the included

❏

10-24 wing bolts.

NOTE: In following images you will see the

ruddervators connected to the V-tail, but yours should

not yet be installed (or at least not yet permanently

attached with the hinges).

edge of the ailerons. If the tips do not align, carefully sand

the high-side of the stab saddle until you can get the V-tail

to align—use care—sanding a small amount of material

can have a drastic effect. (The stab in the image needs to

be rotated clockwise to bring the left tip up and the right

tip down, requiring material to be trimmed from the right

fuselage side at the stab saddle.)

9. Fit the V-tail to the fuselage. Place a weight on the

❏

V-tail to hold it down. View the assembly from 4' – 6' [1 – 2m]

behind the plane.

10. When viewing the model from behind, the tips of the

❏

V-tail should align with the marks precisely at the trailing

11. Once alignment has been achieved, prepare to

❏

permanently glue on the V-tail. Mix about 1/4 oz. [10cc] of

30-minute epoxy. First apply a lm of epoxy to all joining

surfaces, then add microballoons to what remains in the

cup and repeat the process coating all joining surfaces

with the epoxy/microballoons mixture.

12. Fit the V-tail into position, place weight over the

❏

V-tail to hold it down and double-check the alignment.

Wipe away excess epoxy and do not disturb the assembly

until the epoxy has hardened.

15

Page 16

Hinge the Ruddervators

1. Install the ruddervator pushrods if they aren’t already

❏

installed. Connect the balls on the ruddervator torque rods

to the ball links on the pushrods, then t the ruddervators

to the V-tail with the hinges—be certain the hinges remain

centered as they go in.

Mount the Engine

Installation of both a sport setup with an O.S. Max .55AX

with the included back plate mount and the Jett QJ-1

engine for AMA 426 with the Jett back plate mount are

illustrated. Follow the instructions for the setup you will

be using.

SPORT ENGINE WITH INCLUDED BACKPLATE MOUNT:

2. Connect the ruddervator servos to your receiver and a

❏

battery so you can operate the servos and ruddervators with

your transmitter. Make sure everything moves smoothly and

operates correctly and that the pushrods are the correct

length so the ruddervators will be centered when the servos

are centered. Make any adjustments necessary.

3. Permanently join the ruddervators with the torque

❏

rods to the V-tail by securely gluing in the hinges with 6

– 8 drops of thin CA on both sides of each hinge. Allow

time between drops so the CA soaks into the hinge slots

instead of running down the hinge gap.

1. If using the O.S. .46 or .55AX (or most other engines

❏

that will have the carburetor arm on the bottom with the

engine mounted on its side), cut the back plate template

labeled “Back” from the back of the manual. Tape the

template to the back of the back plate mount, then mark

the throttle pushrod hole using a small drill. (This hole also

aligns with the hole for the throttle cut wire in the Jett

Engineering back plate mount.)

4. Any excess CA or CA “fog” can be removed with a

❏

small paper towel square and debonder.

5. Pull hard on each ruddervator to make sure the

❏

hinges are secure.

The wood tail covers will be added after it has been

determined whether or not any ballast is required in

the tail to achieve the correct C.G.

2. Drill a 1/16" [1.6mm] hole at the mark, then enlarge

❏

the hole with a 3/16" [4.8mm] drill.

3. Run a 6-32 tap down through the blind nuts in the

❏

rewall to clean up any epoxy leftover from the llet inside.

If the tap won’t go through, drill out the obstruction with a

#36 (or 7/64" [2.8mm]) drill, then run the tap.

16

Page 17

4. Temporarily fasten the back plate mount to the

❏

rewall as shown with four 6-32 x 5/8" [16mm] SCHS

(socket-head cap screws). Use the hole in the mount as

a guide to drill an 11/64" [4.4mm] (or 3/16" [4.8mm]) hole

through the rewall. Remove the mount.

Hook Up the Throttle

1. Glue the laser-cut 1/8" [3.2mm] plywood doubler

❏

to the bottom of the laser-cut 1/8" [3.2mm] plywood

throttle servo mount. Test- t your servos and make any

adjustments if necessary.

5. M3 x 10 SHCS and M2.5 x 10 SHCS are included for

❏

mounting your engine to the included back plate mount.

These screws should be slightly longer than the screws that

are in your engine. Remove the back plate from your engine

and fasten the back plate mount with whichever screws are

suitable and a drop of threadlocker on the screws.

2. Glue the throttle servo mount and the laser-cut 1/8"

❏

[3.2mm] plywood support for the front of the mount into

the fuselage.

6. Mount the back plate mount to the rewall with four

❏

6-32 x 5/8" [16mm] SCHS and threadlocker.

Mount the landing gear as illustrated on pages 22 & 23.

Refer to these images to hook up the throttle as described

in the following steps.

17

Page 18

3. Cut the 3/16" [4.8mm] throttle guide tube

Screw-Lock Connector

4-40 Set Screw

One-Way Star Retainer

❏

approximately one inch longer than required (for trimming

later). Roughen the tube with medium-grit sandpaper so

glue will adhere, then install the tube through the back

plate mount and the rewall. Glue the front of the guide

tube into the back of the rewall.

4. Mount the throttle servo to the servo tray. Cut the

❏

guide tube to the correct length, then install the throttle

pushrod using a clevis and a silicone retainer on the

carburetor arm and a screw-lock connector with a metal

one-way star retainer on the servo arm. Glue the guide

tube to the side of the fuselage and glue the laser-cut 1/8"

[3.2mm] guide tube holder into position.

3. Use tape to wrap the sides and bottom of the tank in

❏

a sheet of 2-1/2" x 5" [60 x 130mm] 1/4" [6.5mm] RC foam.

5. Use the radio to set up your throttle linkage and lock

❏

the pushrod to the screw-lock connector with the 4-40 set

screw and threadlocker.

6. Mount the muf er to the engine.

❏

Install the Fuel Tank

4. Install the fuel tank and hold it into position with the

❏

1/8" [3.2mm] lite-ply fuel tank plate and another piece of

1/4" [6.5mm] RC foam.

1. Prepare the fuel tank as shown—it would be a good

❏

idea to mark the location of the fueling line (“F”) and the

vent/pressure line (“V”) on the outside of the tank so you

don’t forget when connecting the fuel tubing later.

2. Insert the stopper into the tank and tighten the screw

❏

to expand the stopper sealing the tank.

5. Guide the pressure/vent line and the pickup fuel

❏

lines through the holes in the side of the fuselage and

connect them to the fuel tank. Connect the pickup tube

to the carburetor and the pressure/vent line to the muf er.

Skip to Hook up the Ailerons on page 25.

18

Page 19

JETT QJ-1 ENGINE

The fuel line included with this kit is suitable for the fuel

lines from the fuel tank to the needle valve and from the

fuel tank to the muf er, but thin-wall fuel tubing from

Darrol Cady or Sullivan is preferred for the line from the

needle valve to the engine because it will be easier for the

fuel cut wire to pinch for stopping the engine.

1. Form the fuel cut wire before mounting the engine:

❏

NOTE: Forming the loop on the fuel cut wire is somewhat

of an art that takes a little practice—if your rst attempt

at making the loop is unsuccessful using the wire that

comes with this kit, make a new wire from K&S .031"

music wire. The method illustrated below uses a 3/16"

[4.8mm] brass tube for making the loop, but round-nose

pliers could also be used to make the loop.

A.

Use 400-grit sandpaper to scuff 2" – 3" [50 – 75mm] of

❏

one end of the wire and clean off any residue or oxidation.

E. Use silver solder to permanently close the

❏

loop. Use steel wool to thoroughly clean any residual

soldering ux from the wire, then apply a ne coat of oil

so the wire won’t rust. Set the fuel cut wire aside.

2. Run a 6-32 tap down through the blind nuts in the

❏

rewall to clean up any epoxy leftover from the llet inside.

If the tap won’t go through, drill out the obstruction with a

#36 (or 7/64" [2.8mm]) drill, then run the tap.

B. Wrap the cleaned end of the wire four or ve times

❏

around a 3/16" [4.8mm] tube or rod—the coils will get

tighter with each wrap until the I.D. of the last coil is

about the same as the tube.

C. Cut off the extra coils so only the last, tightest coil

❏

remains.

3. Temporarily fasten the back plate mount to the

❏

rewall as shown with four 6-32 x 5/8" [16mm] SHCS.

Hook Up the Fuel Cut Wire

D. Use pliers to bend and manipulate the coil until it

❏

will slip through the hole in the back plate mount and

your fuel tubing will pass through.

1. Mark the center of the hole in the back plate mount

❏

onto the rewall for the guide tube for the fuel cut wire.

Drill a 1/16" [1.6mm] pilot hole through the rewall at the

mark, then enlarge the hole with a 1/8" [3.2mm] drill.

19

Page 20

3. Remove the engine mount from the rewall. Use a

❏

hobby knife and/or a small, at-blade screwdriver to pick

the material out of the counter bore. Use your covering

iron to make sure the covering is thoroughly sealed to the

rewall around the hole.

4. Cut the 1/8" [3.2mm] guide tube for the fuel cut wire

❏

to a length of 11" [280mm]. Roughen the tube so glue will

adhere, then insert the tube into the rewall so the end of

the tube aligns with the bottom of the counter bore hole.

Use thin CA to glue the tube into the hole from the backside of the rewall.

5. Using care not to get any glue inside the tube,

❏

fuelproof the bare wood inside the hole with CA or epoxy.

2. The hole in the rewall for fuel cut wire must be

❏

counter-bored so the loop can travel far enough to pinch

the fuel line without overdriving the servo. The easiest

way to cut a precise counter-bore is with a 1/4" K&S brass

tube sharpened on the end. Mark a line on the tube 3/8"

[10mm] from the end and use a drill to turn the tube into

the rewall up to the line. This will provide a counter bore

that’s approximately 3/16" [5mm] deep.

6. Install one of the 6-32 x 5/8" [16mm] SHCS into the

❏

hole in the back plate mount near the engine exhaust,

then mount the back plate mount to your engine.

7. Mount the engine to the rewall with four 6-32 x 5/8"

❏

[16mm] SHCS and threadlocker.

Refer to this photo for the following three steps.

20

Page 21

8. Position the remote needle valve mount where

❏

desired so that the mounting screws will thread into the

side of the rewall (also making sure they will not interfere

with the engine mount screws already in place). Drill 3/32"

[2.4mm] holes for one of the screws and temporarily

mount the needle valve with two #4 x 1/2" [13mm] screws.

9. Remove the screws, harden the holes with thin CA,

❏

allow to harden, then mount the needle valve.

11. Glue the fuel-cut servo mount and the laser-cut 1/8"

❏

[3.2mm] plywood support for the front of the mount into

the fuselage.

10. Glue the laser-cut 1/8" [3.2mm] plywood doubler to

❏

the bottom of the laser-cut 1/8" [3.2mm] plywood fuel-cut

servo mount. Test- t your throttle servo and make any

necessary adjustments.

Refer to these images to hook up the fuel-cut wire as

described in the following steps.

21

Page 22

Screw-Lock Connector

4-40 Set Screw

One-Way Star Retainer

12. Mount the fuel-cut servo to the servo tray with a

6-32 Flat Head Screw

6-32 Set Screw

Bushing

❏

servo arm cut down to the correct length. Cut the guide

tube so it won’t interfere with the throttle servo arm when

the arm rotates all the way forward, then install the fuel

cut wire with a screw-lock connector with a metal oneway star retainer on the servo arm.

13. Glue the guide tube to the side of the fuselage and

❏

glue the laser-cut 1/8" [3.2mm] guide tube holder into

position. Balsa scraps (not included) can be used to help

secure the guide tube to the side of the fuselage so it

won’t become dislodged or interfere with the fuel tank.

rst. This takes a lot of elbow grease, but that’s the way it’s

done! Use whatever means available to grind the edges

such as a belt sander, a grinding wheel or a metal le.

Finish with increasingly ner grades of wet-dry sandpaper

until the gear is polished to suit your taste. Steel wool and

dish soap (or a Brillo pad) really make it shine!

14.

Route the fuel line from the engine to the needle valve

❏

through the loop in the fuel cut wire and use the radio to set

the servo travel and nalize your fuel cut linkage—Darrol

Cady or Sullivan 3/32" fuel line is preferred for this segment

of the fuel system. Lock the fuel-cut wire to the screw-lock

connector with a 4-40 set screw and threadlocker.

Mount the Landing Gear

The main landing gear is fastened to the fuselage with

the supplied 10-24 x 1/2" [13mm] nylon at-head screws.

This is a “break-away” system where the bolts will break

allowing the gear to separate from the plane to prevent

structural damage in the event of an unusually hard

landing. It is a good idea to purchase spare screws from

your local hardware or home improvement store and store

them in your eld box when you go to the races.

1. The landing gear may be used as-is, but most pilots

❏

prefer to chamfer the front and back edges of the gear

2. Mount the wheels to the landing gear as shown—

❏

be certain to lightly wet the threads of the screws with

threadlocker.

22

Page 23

5/16"

[8mm]

10-24 x 5/8" Nylon

Landing Gear Screw

3. Cut the included 10-24 x 5/8" [16mm] nylon landing

V-Cut

3/32" [2.4mm]

“cross hole”

2-1/2"

[60mm]

❏

gear screws to a length of 5/16" [8mm].

4. Mount the landing gear to the fuselage with the

❏

screws—note that the gear may be swept forward for

landing and taking off from grass or swept back for hard

surfaces.

5. Check the screws inside the fuselage—make sure

❏

you’ve cut them so they are not protruding from the

landing gear plate too far to interfere with the fuel tank.

Trim farther if needed.

1. Prepare and t the aluminum fuel tube and silicone

❏

pickup line as illustrated.After making the "V" cut, also

use a 3/32" sharpened brass tube to cut a "cross hole"

throught both sides of the tubing.

2. Secure the stopper in the tank with the hardware

❏

included with the tank – don’t forget the thin, metal plate

shown in the instructions that came with the Tettra tank.

Install the Fuel Tank

A Tettra 6 oz. bubbles fuel tank is illustrated. There is

more than one way to prepare the tank, but the method

illustrated is popular. Because the tank features a

collapsing bladder (pressurized between itself and the

plastic container) only a single pickup line is used inside

the tank. A Bubble Jett Fuel Tanker syringe-type fueler

(or similar) is required for lling the tank properly without

introducing air into the tank.

3. If the fuel tank ever requires removal in the future, it

❏

will be helpful to have a strap made from tape as shown

to facilitate pulling the tank out.

23

Page 24

4. The fuel tank must be stabilized so it cannot shift

❏

forward or aft, but because the tank is bubble-less,

completely isolating the tank in RC foam is not necessary.

But some foam will be helpful for holding the tank into

place and preventing vibration from eventually wearing

the tank. A popular method for keeping the tank from

moving forward is a popsicle stick or similar wood plate

fastened to the tank with Zap Goo and/or tape. Sheets of

1/4" [6.5mm] RC foam were also held to the sides of the

tank with tape.

6. Use additional pieces of foam padding on top of

❏

the tank and under the tank as needed. As shown, the

tank was secure and will not shift forward or aft, but if a

little more security is desired a balsa stick could be glued

across the fuselage sides at the back of the tank.

7. Mount the muf er and connect the fuel lines. Might

❏

as well install the propeller too—be certain to lock the

propeller down so that it will be horizontal when the

piston is at the top of the compression stroke to prevent

damaging the tips when landing.

5. Guide the fuel lines through the holes in the side of

❏

the fuselage and connect them to the fuel tank. Install

the tank as you guide the lines through – be certain the

fuel lines are not kinked or pinched inside the fuselage. If

you have any concerns about the fuel lines being kinked

inside the fuselage, you could always pull the engine and

view the lines through the hole in the rewall.

NOTE: If you ever replace the wing bolts with different

bolts, be certain they do not contact the top of the

fuel tank.

Hook Up the Ailerons

Note: The aileron servo is shown with the output shaft

toward the back of the wing. This orientation may be

necessary to clear the included fuel tank for the sport

setup, but if using a Tettra fuel tank the servo may be

positioned with the output shaft closer to the front of

the wing. In any case, test- t the wing with your servo to

make sure it clears your fuel tank before deciding which

way to mount the servo.

24

Page 25

1. The ailerons should already be test- tted to the

❏

wings from the V-tail alignment procedure. If you haven’t

yet done so, make sure the ailerons t properly to the

wing and torque rods and make sure the ailerons move

up and down freely. Make any adjustments necessary.

2. Remove the ailerons. Apply 30-minute epoxy to the

❏

joiner wires where they go into the ailerons and in the

joiner pockets in the ailerons. Join the ailerons to the wing

with the hinges and remove excess epoxy that comes out

of the ailerons. Apply 6 – 8 drops of thin CA to both sides

of all the hinges.

5. Examine the hinge gaps on the top and bottom of

❏

both ailerons. Larger blobs of CA can be picked away with

a hobby knife while smaller smears can be removed with

a small paper towel square dampened with CA debonder.

3. After the CA on the hinges has hardened, pull hard

❏

on each aileron to make sure the hinges are secure.

In the following steps the aileron hinge gaps will be

sealed from the ends of the torque rods out to the tips.

This is an important procedure to prevent utter and

increase the effectiveness of the ailerons.

4. Cut four 1/2" x 8-3/4" [10mm x 220mm] strips from

❏

the included white MonoKote sheet.

6. Use a couple strips of tape to hold one of the ailerons

❏

as up as far as it will go.

25

Page 26

7. Lay one of the strips of MonoKote on the bottom

13/16"

[20mm]

Swivel

❏

of the wing with the edge extending forward of the hinge

gap by approximately 1/8" [3mm]. Use a regular covering

iron to iron the piece of covering to the wing only.

10. Trim any excess covering as necessary, or simply

❏

iron it down to the bottom of the aileron.

11. Remove the tape that was holding the aileron

❏

down, then move the aileron up and down a few times

to make sure it moves reasonably smoothly. Make any

adjustments necessary.

12. Seal the top of the aileron and the top and bottom

❏

of the other aileron the same way.

13. Any glue or residual MonoKote adhesive that may

❏

have been deposited on the strips may be cleaned with a

small paper towel square and CA debonder.

8. Use a trim iron to seal the covering tightly all the way

❏

down the trailing edge of the wing only.

9. Now seal the strip down the leading edge of the aileron.

❏

14. Use a 3/8" [9.5mm] brass tube sharpened on the

❏

end or a hobby knife to cut a hole in the wing sheeting and

through the foam to pass the aileron servo wire. Install

the aileron servo. Drill 1/16" [1.6mm] holes for the servo

mounting screws and mount the servo with the screws.

Remove the screws, add a few drops of thin CA to the

screw holes and allow the CA to harden.

26

Page 27

the ends of the wires. Enlarge the holes in the servo wheels

3"

[76mm]

with a .074" [1.9mm] drill, then connect the pushrods.

18. Use your radio to center the servo and the ailerons

❏

adjusting the length of the pushrods as necessary. Install

silicone retainers on the clevises and the servo screw in

the servo wheel.

FINAL ASSEMBLY

Check the C.G.

15. Thread a nylon swivel onto each torque rod until it

❏

is 13/16" [20mm] from the bottom of the wing—grasping

the swivels with a paper towel square or a tissue makes

them easier to turn.

16. Mount the aileron servo in the wing. Make the aileron

❏

pushrods as shown and attach them to the swivels. With

the servos and the ailerons centered, mark the pushrods

where they cross the servo wheels. Note: High-wing

Quickie 500 planes do not require aileron differential, but

the pushrod hardware and torque rod con guration on

some quickies require offsetting the pushrods forward of

the pivot point in the servo wheel to remove the “backward”

differential (more down than up) that results. But since the

swivel clevises used on the Quik-V6 align the pivot point

of the clevis with the torque rod, the pushrods should be

installed in the servo wheel in-line with the pivot point as

shown so there should be no differential.

This is an initial C.G. check. The beginning C.G. for initial

ights will be set after the model has been completed,

but now is a good time to do a simulated check while

you have the opportunity to conceal weight inside the tail

(should tail weight be needed) and determine the location

of the receiver and battery. Refer to Final C.G. Check on

page 31 for full C.G. information.

1. Set your Great Planes C.G. Machine to the starting,

❏

recommended C.G. which is 3" [76mm], or mark a line on

the bottom of the wing noting the starting C.G. 3" [76mm]

back from the leading edge.

2. Mount the wing to the fuselage and make sure

❏

everything else is in place including the propeller and prop

nut, fuel tank, landing gear, servos and servo hatch cover.

Also have your receiver battery and receiver nearby and

the thin, plywood tail covers, the tail skid wire and some

MonoKote approximately equal to the amount of MonoKote

that will be used to cover the tail. Alternately, you could

substitute a quarter, which approximately simulates the

weight of the tail covers, skid wire and covering (about 5.5g).

17. Use Z-bend pliers to make the Z-bends in the

❏

pushrods, cut off the excess wire, and le any burrs from

3. Place the receiver and battery on top of the wing in

❏

the approximate location they will be inside the fuselage.

27

Page 28

Attach the Tail Covers

1. Perform a nal check to make sure the servos operate

❏

the elevators smoothly and the linkages and ruddervator

torque rods are secure.

2. Use a ne-point felt-tip pen or ballpoint pen to mark

❏

the outlines of the top tail cover and both side covers onto

the clear backing on the bottom of the included white

MonoKote sheet. NOTE: The grain direction on the side

covers was changed after the images were taken.

4. Lay the tail covers and MonoKote (or a quarter) on

❏

the tail. Place the model on your C.G. machine or lift it

at the balance point to see where it balances. Quik-V6s

with the 426 Jett setup will tend to not require any ballast

(depending upon the location of the battery and receiver)

and sport setups with different engines (that are probably

slightly heavier than the Jett engine) may require tail ballast.

5. If the Quik-V6 doesn’t balance, rst try to arrange the

❏

receiver battery and receiver to get the model to balance,

then place lead ballast over the nose or on the tail. With

the sport setup the Quik-V6 may require 1 – 1.5 oz. [30 –

40g] of ballast on the tail.

3. Sand a bevel to the bottom of the top tail cover to

❏

match the angle of the V-tail.

5. Arrange the battery and receiver to get the model

❏

to balance, or add ballast where necessary. Tail ballast

can be added as shown, but be certain it is securely

glued into place—30-minute epoxy is recommended and

doesn't interfere with the V-tail linkages.

4. Test- t the top cover and side covers (the bottom

❏

of the side covers will likely require trimming). Note that

the front edge of each side cover ts over the fuselage

28

Page 29

sides, but the bottom edge of each side cover transitions

to rest on top of the fuselage bottom. If the resulting

forward-facing edge of the side covers is objectionable

(though this area will be out of view because it will be

concealed by the V-tail), you could cut the fuselage sides

to accommodate the front of the side covers, or sand the

front of the side covers to a ne point that will smoothly

blend down to the fuselage sides.

5. Glue the top cover into position.

❏

6. Cut and remove the covering from the fuselage sides

❏

where the side covers will t. If your technique is to pinch

the plane by the tail for launching for a pylon race, you

may lightly reinforce the side covers by adding small “ribs”

made from scrap balsa (not included).

7. Glue one, then the other side cover into position.

❏

9. Continue sanding the side covers for a nished

❏

appearance—you can move the servos to hold the

ruddervators in the extreme up and down positions for

access with your sander. You can also have an assistant

hold the fuselage while you use a strip of sandpaper to

sand the corners of the covers at the root ends of the

elevators where a sander won’t t.

8. Sand the side covers even with the top cover.

❏

29

Page 30

Here are a couple more images of the nished side covers

1/4"

[7mm]

1/4"

[7mm]

1/4"

[7mm]

1/8"

[3mm]

1/8"

[3mm]

1/8"

[3mm]

1/2"

[13mm]

ready for covering with MonoKote.

10. Using the approximate dimensions in the sketch,

❏

use a hobby knife and a straightedge to cut the pieces of

MonoKote around the outlines you drew.

11. Use a covering iron to iron the MonoKote top, then

❏

the side pieces into place—a trim iron is also useful here.

12. Glue the tail skid wire into place—non-permanent

❏

glue such as Zap Goo is recommended in case the skid

ever wears down and requires replacement.

30

Page 31

PREPARE THE MODEL FOR FLIGHT

Install the Battery and Receiver

1. Now that the tail covers have been completed, you

❏

could do another C.G. check before determining where

the receiver battery and receiver will be mounted.

sided adhesive foam tape was used to mount the receiver

as shown, but rst the fuselage bottom was coated with

medium CA for better adhesion of the foam tape.

4. Depending on the length of the ruddervator servo

❏

wires and the location of your receiver, servo extensions

may be required. If using servo extensions, secure the

connection with pieces of 1/2" [13mm] shrink tubing.

2. If you wish to use the included battery mount,

❏

assemble the mount and t your battery. Or, use your own

method to secure the battery.

5. If you prefer not to connect and disconnect the

❏

aileron servo wire directly into the receiver every time

you install and remove the wing, you may also connect

a servo extension to the aileron channel in your receiver.

Final C.G. Check

NOTE: Additional information regarding C.G., lateral

balance and control throws is in the Trimming Notes

section on page 34, but start by balancing your Quik-V6

as described below:

As stated earlier, a safe, beginning C.G. location is with

the Quik-V6 balanced 3" [76mm] aft of the wing leading

edge. The full C.G range is from 2-5/8" [67mm] to 3-1/4"

[83mm]. The Quik-V6 will y balanced beyond these

measurements, but for pylon racing you’ll probably nd

that you’ll settle right on 3" [76mm] or possibly 1/8" [3mm]

ahead of that (2-7/8" [73mm]) depending on your personal

taste and preferences.

With the Quik-V6 in a completely ready-to- y state (fuel

tank empty) with all components installed including the

propeller and propeller nut, use your C.G. Machine or

balance lines marked on the bottom of the wing to do

your nal C.G. check. Make any adjustments needed to

set the C.G. where desired.

3. Securely glue the battery mount into the fuselage,

❏

then mount your receiver and battery. 1/8" [3mm] double-

31

Page 32

Balance the Model Laterally

These are the recommended control surface throws:

ELEVATOR

HIGH RATE LOW RATE

Up and

Down

7/32"

[6 mm]

10.2°

Up and

Down

5/32"

[4 mm]

7.3°

Up and

Down

7/32"

[6 mm]

10.1°

Up and

Down

5/32"

[4 mm]

7.2°

Right

& Left

7/32"

[6 mm]

10.2°

Right

& Left

1/8"

[3 mm]

5.8°

RUDDER

AILERONS

1. With the crankshaft at the bottom of its stroke (so

❏

the piston is not under compression and the crank shaft

can move freely), lift the model by the spinner nut with

the tail on the workbench so the model can rotate about

the crankshaft. The weight and position of the engine

will undoubtedly cause the Quik-V6 to rotate to the right

requiring ballast in the left tip.

Set the Control Throws

Like many aspects of model setup for pylon racing, the

control throws are a matter of personal taste. But the

throws speci ed below will be a great starting point and

should allow you to be comfortable enough to get the

plane low and on the course immediately after the initial

trim passes:

NOTE: The throw values provided in 1/32" increments

may be rounded up to the nearest 1/16" if it’s easier for

you to measure.

2. There are several ways to add tip weight, but one

❏

way is to cut a pocket into the tip, glue in the lead required,

and then seal with MonoKote.

1. Support the fuselage so the model will be level,

❏

then measure and set the throws. The ruddervators are

measured with the ruler perpendicular to them.

2. While programming the radio, don’t forget to set your

❏

Failsafe so when you turn off the transmitter (simulating

loss of signal) the throttle/fuel cut servo causes the engine

to stop.

32

Page 33

3. Finally, make one last check to be sure all the controls are

❏

responding in the correct direction—same as a conventional

tail, the ruddervators should move up with up elevator stick

input and move right with right rudder stick input.

Basic Checklist

ENGINE SAFETY PRECAUTIONS

Failure to follow these safety precautions may result

in severe injury to yourself and others.

●

Keep all engine fuel in a safe place, away from high heat,

sparks or ames, as fuel is very ammable. Do not smoke

near the engine or fuel; and remember that engine exhaust

gives off a great deal of deadly carbon monoxide. Therefore

do not run the engine in a closed room or garage.

● Get help from an experienced pilot when learning to

operate engines.

● Use safety glasses when starting or running engines.

●

Do not run the engine in an area of loose gravel or sand;

the propeller may throw such material in your face or eyes.

● Keep your face and body as well as all spectators away

from the plane of rotation of the propeller as you start

and run the engine.

● Keep these items away from the prop: loose clothing,

shirt sleeves, ties, scarfs, long hair or loose objects

such as pencils or screwdrivers that may fall out of shirt

or jacket pockets into the prop.

●

Use a “chicken stick” or electric starter to start the engine.

Do not use your ngers to ip the propeller. Make certain

the glow plug clip or connector is secure so that it will

not pop off or otherwise get into the running propeller.

● Make all engine adjustments from behind the rotating

propeller.

● The engine gets hot! Do not touch it during or right after

operation. Make sure fuel lines are in good condition so

fuel will not leak onto a hot engine, causing a re.

● To stop a glow engine, cut off the fuel supply by closing

off the fuel line or following the engine manufacturer’s

recommendations. Do not use hands, ngers or any

other body part to try to stop the engine. To stop a

gasoline powered engine an on/off switch should be

connected to the engine coil. Do not throw anything

into the propeller of a running engine.

Perform these basic checks before heading out to the eld:

Receiver battery charged

❏

Servo mounting screws present and tight

❏

Servo wheel/arm retainer screws present and tight

❏

Fuel tank secure

❏

Engine and muf er bolts tight

❏

C.G. check

❏

Throws check

❏

Control response direction

❏

Failsafe set

❏

Spare parts:

❏

Glow plugs

❏

10-24 nylon landing gear screws

❏

Propellers

❏

CAUTION: Monitor the threads in the wing bolt plates

each time you mount the wing to the fuselage to make

sure they are strong. If there are ever signs of the

threads breaking down, reinforce them with epoxy or

CA and re-tap the threads.

Range Check

Don’t forget to perform a ground range check as written in

the instruction manual that came with your radio system

to be certain it is operating correctly.

AMA SAFETY CODE (EXCERPTS)

Read and abide by the following excerpts from the Academy

of Model Aeronautics Safety Code. For the complete Safety

Code refer to Model Aviation magazine, the AMA web site

or the Code that came with your AMA license.

General

1) I will not y my model aircraft in sanctioned events,

air shows, or model ying demonstrations until it has

been proven to be airworthy by having been previously,

successfully ight tested.

33

Page 34

2) I will not y my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

airport operator. I will give right-of-way and avoid ying

in the proximity of full-scale aircraft. Where necessary,

an observer shall be utilized to supervise ying to avoid

having models y in the proximity of full-scale aircraft.

3)

Where established, I will abide by the safety rules for the

ying site I use, and I will not willfully and deliberately y my

models in a careless, reckless and/or dangerous manner.

5)

I will not y my model unless it is identi ed with my name

and address or AMA number, on or in the model. NOTE:

This does not apply to models while being own indoors.

7) I will not operate models with pyrotechnics (any device

that explodes, burns, or propels a projectile of any kind).

Radio Control

1)

I will have completed a successful radio equipment ground

check before the rst ight of a new or repaired model.

2) I will not y my model aircraft in the presence of

spectators until I become a quali ed ier, unless assisted

by an experienced helper.

3) At all ying sites a straight or curved line(s) must be

established in front of which all ying takes place with the

other side for spectators. Only personnel involved with

ying the aircraft are allowed at or in the front of the ight

line. Intentional ying behind the ight line is prohibited.

4)

I will operate my model using only radio control frequencies

currently allowed by the Federal Communications Commission.

5) I will not knowingly operate my model within three

miles of any pre-existing ying site except in accordance

with the frequency sharing agreement listed [in the

complete AMA Safety Code].

9) Under no circumstances may a pilot or other person

touch a powered model in ight; nor should any part

of the model other than the landing gear, intentionally

touch the ground, except while landing.

QUIK-V6 TRIMMING NOTES

By Jim Allen

Quickie 500 racing has seen its share of development

since its inception in the early 70’s, but the premise has

remained the same; to develop the skills necessary for

AMA 3-pole racing with simple, .40-size planes that y

well. The Quik-V6 is an example of the latest design in the

series with a shoulder-wing and V-tail that originated with

the original Quik-V in 1987.

Racing your Quik-V6 is fun, but it can be even better with

a plane that is properly setup and trimmed making it as

easy as possible to get around the course quickly and

consistently—it all comes down to doing the little things

that improve your lap times. The easier it is to y those

fast lap times consistently, the better your heat times

will be. This guide will walk you through the process of

trimming your Quik-V6 to allow you to make the most of

its great ying qualities.

34

If you haven’t yet done so, accurately set the initial C.G.

C.G.:

according to the speci cations in this manual. Eventually,

you may end up ne tuning the C.G. to adjust the way the

plane ies on the course, but you need a good starting point

and we’ll cover adjusting the C.G. with ight trimming later.

LATERAL BALANCE:

as described in this manual. Taping coins to the bottom of

the wing works well, or you can use lead tape available at

golf stores or on e-bay. Same as the C.G., lateral balance

may also end up changing based on the way the plane ies.

THROWS:

results in lower lap times and consequently lower heat

times. Every time you move a control surface you increase

drag slowing the plane. The more you move the surfaces

the more the plane slows. Minimizing control movement

while maintaining a tight course will always result in faster

lap times. Learning to y those faster laps consistently will

result in faster heat times and more heat wins. Set your

throws as recommended in this manual. This will be a

good place to start.Low rates are intended for racing and

high rates are ne for sport ying or for landing in windy

or bumpy conditions. When measuring throws, use a ruler

with ne increments such as a machinist’s 6-inch rule.

AILERON DIFFERENTIAL: Note that the rotation pin on

the included swivel clevises on the aileron torque rods

should provide close to equal up and down throw for the

ailerons. This is important – you do not want more than

a 1/32" [.8mm] difference in up vs. down. If there is a

difference, more up throw than down throw is preferred. If

necessary, the degree of up or down aileron throw can be

altered by changing where the aileron pushrods connect

to the aileron servo wheel—moving the pushrod holes

in the servo wheel forward (toward the leading edge of

the wing) will provide more up throw; the opposite will

increase down throw. If you have to resort to this, a blank

servo wheel will be required so you can drill your own

offset holes. Try to work to make sure both ailerons are

the same—the Quik-V6 does not require differential.

ELEVATOR SYNCHRONIZATION: For the Ruddervators,

make sure the elevator movement is the same on both

sides. Remember, the elevator is relying on separate

servos and separate linkages potentially contributing to

small differences in throw. If necessary, use the End Point

adjustment in your radio to equalize elevator throw. Later,

after ying, we may come back to this while trimming for

the course, but begin by getting the throws as close as

you can on the bench. Again, measure carefully with a

ne-increment ruler.

FLIGHT TRIMMING: The plane is now ready to y. The

rst order of business is always to get the plane trimmed

for straight-and-level ight. Make extended passes at

that are not too close and not too high so you can really

get a good read on how it’s trimmed. As the trimming

process continues, always re-trim for level ight before

you do anything else. And don’t even think about putting

your Quik-V6 down on the course until you’ve trimmed it!

This is important.

TURN RADIUS: Whether racing around a 2-pole course

(standing outside the course) or around the 3-pole course

(standing within the course near pylons 2 and 3), your turns

Over-controlling or over- ying a pylon racer

Now check the lateral balance also

Page 35

always must be as ef cient as possible. Pulling too hard

on the elevator causes too much drag resulting in the loss

of too much speed by the time you complete the turn.You

may cover less distance, but you’ll dramatically reduce

your airspeed entering the following straight. Conversely,

making too soft and wide a turn will take too much time

by covering too much distance. Exit speed will be higher,

but not enough to offset the distance own. The optimum

turn is somewhere between the two.Many of the fastest

racers set their elevator throws so that they pull full

elevator de ection around P1 (pylon 1) and around P2-P3.

If you have your rate set correctly for the 3-pole course,

you should be able to bank into pylon 2 and smoothly pull

elevator to full de ection and end up just clearing pylon 3.

ROLL STABILITY IN TURNS: The next step is to dial