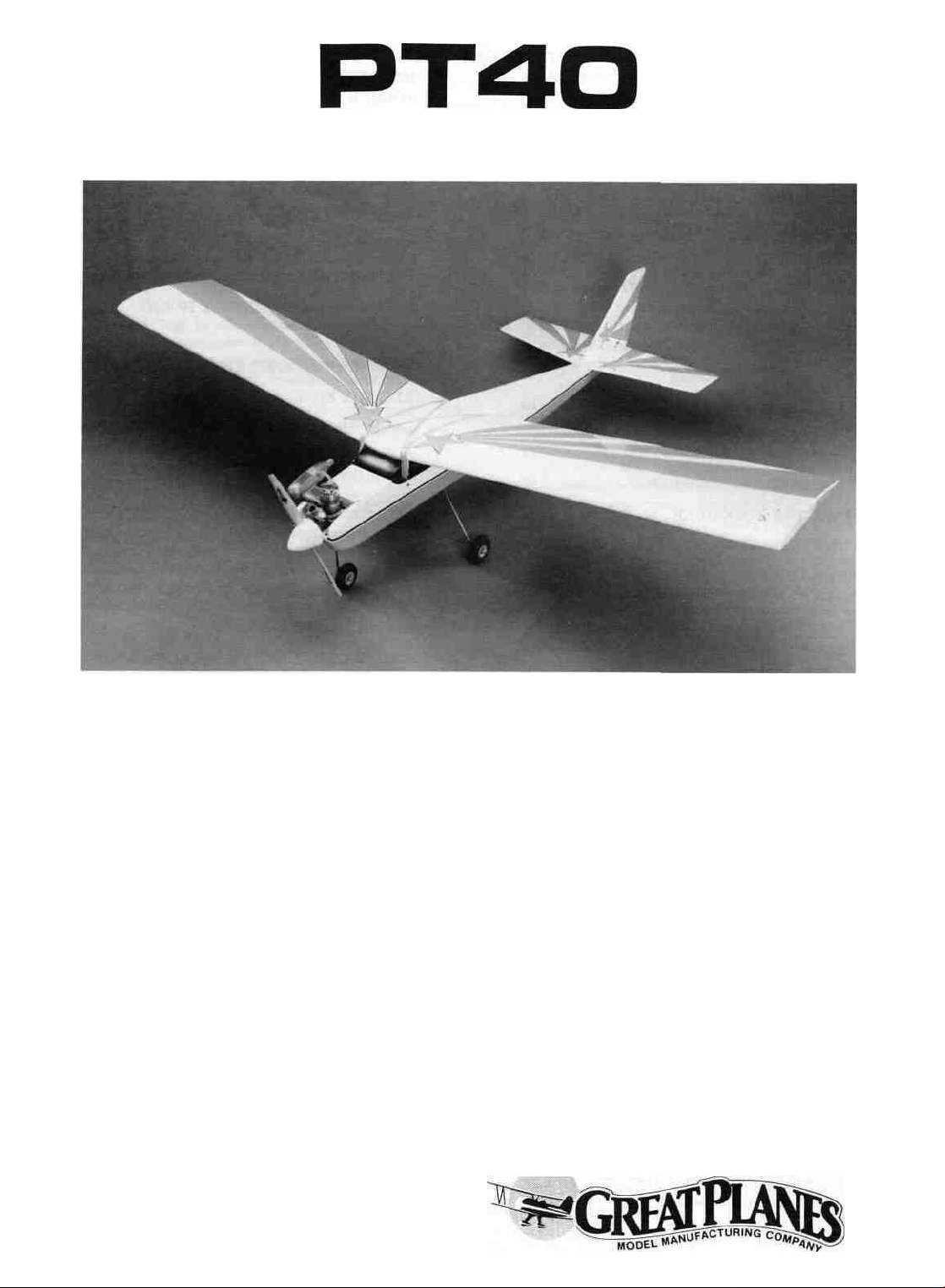

Page 1

Instruction Book

Welcome to the World of Radio Control Model Airplanes!

READ THROUGH THIS INSTRUCTION

BOOKLET FIRST. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE BUILDING AND USE OF THIS

MODEL.

WARNING!

This R/C kit and the model you will build is not a toy! It is capable of serious

bodily harm and property damage. IT IS YOUR RESPONSIBILITY AND YOURS

ALONE — to build this kit correctly, properly install all R/C components and flying

gear (engine, tank, pushrods, etc.) and to test the model and fly it only with experienced, competent help in accordance with all safety standards and common

sense as set down in the Academy of Model Aeronautics Safety Code. It is suggested that you join the AMA and become properly insured before you attempt to

fly this model. IF YOU ARE JUST STARTING R/C MODELING, CONSULT YOUR

LOCAL HOBBY SHOP OR WRITE TO THE ACADEMY OF MODEL AERONAUTICS

TO FIND AN EXPERIENCED INSTRUCTOR IN YOUR AREA.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

(800) 435-9262

PO BOX 788 URBANA ILLINOIS 61801

Page 2

TABLE OF CONTENTS

GENERAL COMMENTS .................... 2

BUILDING PRECAUTIONS ................. 3

GLUES .................................. 3

BUILDING HINTS ......................... 4

ITEMS NEEDED .......................... 4

TOOLS OR SUPPLIES NEEDED ............. 4

SPECIAL NOTE ON ENGINES .............. 4

PARTS IDENTIFICATION DRAWINGS 5

GET READY TO BUILD .................... 6

BUILD THE FUSELAGE SIDES ............. 7

ASSEMBLE THE FUSELAGE ............... 8

INSTALL THE WINDSHIELD AND HATCH .. 10

MOUNT THE ENGINE BEAMS AND

BREAKAWAY

PLATES

....................

11

INSTALL THE LANDING GEAR ............ 12

PREPARE THE NOSE GEAR ............... 12

CUT THE NOSE GEAR PUSHROD OPENING . 12

CUT THE PUSHROD EXIT SLOTS FOR THE

RUDDER AND ELEVATOR

................

13

BUILD AND INSTALL THE

"TAIL FEATHERS" ....................... 13

MAKE THE HINGES ...................... 14

MARK THE HINGE LOCATIONS ........... 14

CUT THE HINGE SLOTS .................. 14

MOUNT THE STAB ON THE FUSE ......... 14

MOUNT THE FIN TO THE STAB ........... 15

BUILD THE WING PANELS ............... 16

INSTALL TRAILING EDGE, AILERONS AND

TORQUE RODS (WING B ONLY) ........... 20

INSTALL THE WING TIPS ................. 21

SAND THE WING SMOOTH ............... 22

INSTALL THE WING PLATES .............. 22

TRIAL FIT THE WING IN THE SADDLE .... 22

MOUNT THE ENGINE .................... 23

INSTALL THE SERVOS ................... 24

INSTALL NYLON CONTROL HORNS ....... 25

PUSHRODS .............................. 26

BALANCE THE AIRPLANE LATERALLY .... 29

ADD THE FUSELAGE TOP ................ 29

SAND THE FUSELAGE ................... 30

FUELPROOF THE ENGINE AND FUEL

TANK COMPARTMENTS .............

30

PREPARE THE MODEL FOR COVERING .... 30

COVER THE STABILIZER ................. 30

COVER THE FIN, RUDDER AND ELEVATOR . 30

COVER THE FUSELAGE .................. 30

COVER THE WING ....................... 31

ADD "WASHOUT" AT THE WING TIPS ...... 31

FINAL ASSEMBLY ....................... 32

BALANCE YOUR MODEL ................. 34

FLYING ................................. 34

AMA SAFETY CODE ..................... 36

CHANGING FROM 3 TO 4

CHANNEL VERSION .................... 37

JOIN THE WING PANELS ................. 18

INSTALL THE CENTER RIBS AND

BOTTOM SHEETING ..................... 19

INSTALL TAPERED TRAILING EDGE

(WING A ONLY)

..........................

19

GENERAL COMMENTS

Congratulations on your purchase of Great

Planes' PT40, the Perfect Trainer! You now own the

easiest building, easiest flying trainer on the market.

By following these instructions and by referring to

the plans, you will have a model you can be proud of

and one that will fly, almost by itself!

FLIGHT PROBLEMS CHART ............... 38

GLOSSARY .............................. 39

PARTS LIST ............................. 40

Our line of R/C kits is the fastest growing and

we believe the finest in the nation. As a result of

intensive testing, combined with our years of experience, we know that a well built Great Planes' kit

will fly right. But that means:

Page 3

1. You must build the plane according to the plans

and instructions

2. You must take time to build straight, true and

strong.

3. You must use a proper R/C radio that is in first

class condition, the correct sized engine and correct

components (fuel tank, wheels, etc) throughout

your building process

4. You must properly install all R/C and other

components so that the model operates properly on

the ground.

5. You must test the operation of the model before

the first and each successive flight to insure that all

equipment is operating and you must make certain

that the model has remained structurally sound.

6 You must fly the model only with competent

help from a well experienced R/C pilot if you are not

already an experienced and knowledgeable R/C pilot

at this time.

Note- We, as the kit manufacturer, can provide

you with a top quality kit and great instructions, but

ultimately the quality and flyability of your finished

model depends on how you build it, therefore, we

cannot in any way guarantee the performance of your

completed model, and no representations are expressed or implied as to the performance or safety of your

completed model.

BUILDING PRECAUTIONS

Keep in mind that it is impossible for us to

guide you specifically as to every possible matter that

might come up as you build The fun and challenge

is to tackle the problem, using the plans and instructions for resources as well as the assistance and advice of fellow builders and your local hobby dealer.

The plans are the basic guide to building Do

not alter or modify the model as represented by

these plans Follow the step by step procedures given

in the building instructions.

Invest in the proper tools for building Knives,

drills and bits, saws, rulers, pliers and screw drivers

are but a few of the tools you will need Check the

list of tools needed in this book and seek the advice

of your dealer.

For best results, you should have such components as the engine, tank and radio on hand as you

build for fitting and installation purposes, it is much

more difficult, sometimes impossible, to do a proper

building job when components are purchased and

fitting attempted after most of the model is completed Always have an eye on installation of the

components you intend to use as you build, take time

to think through and prepare for the installation of

those components Don't hurry! Take your time to

create a well built model that conforms to the plans

Build on a large, flat surface. Use waxed paper over

the part of the plans you are working on to prevent

glues from sticking to the plans Remember a careful

builder will build a warp-free, straight model that

will fly as it was designed to

Read and obey cautions, warnings and directions on such items as glues, paints and other materials These are often TOXIC to the human body in

terms of breathing and/or touch Be especially cautious of cyanoacrylate glues that dry almost instantly

and bond with great power (also known as CA glues)

They require special care since they can be extremely

dangerous if they get into the eyes or on human skin

Watch for ventilation warnings and observe them

Keep small children and pets away from all building

and finishing materials. Keep your building area safe

and clean

We urge you to read through these instructions,

identify all the parts, mark them with their names,

letters or numbers and look over the plans so you

become familiar with what the model will look like

and what the names of the different parts are

Throughout the instructions we will be referring to

the various parts of the model as they are called out

on the plan There is a glossary in the back of these

instructions if you are unfamiliar with any words or

part names. Refer to it for help.

If when you are identifying the parts you find

that a part is missing or broken, please let us know

about it before you start building and we will correct

the problem

CONSTRUCTION PROCEDURE

GLUES (ADHESIVES)

If you look at the "ITEMS NEEDED" list you

will see that we recommend only two basic types of

glue for building the PT-40...CA glue and epoxy.

CA (cyanoacrylate) glues are great for model

building because they set fast Rather than pinning

glued joints together and waiting for hours while the

glue dries, CA glues will harden in a few seconds

while you hold the parts together Thin CA runs

right into a good fitting Joint, so you can assemble

the parts first, then apply thin CA Thick CA is more

like syrup and it will not harden until you press the

two parts together, squeezing the glue out to a thin

layer A related and very handy product is CA Ac-

celerator spray (Zip Kicker or Hot Shot), and is

used to instantly harden CA glue When using CA

glues make sure the parts fit well before gluing

because they don't give you a second chance

If you need time to position glued pieces cor-

rectly or need extra strength, use epoxy glues Epoxy

is normally used in the firewall and engine mount

area and when gluing the two wing panels together

Five minute epoxy (it starts to harden in 5 minutes)

is great for most applications If you need longer time

use 15 or 30 minute epoxy You need not use large

amounts of epoxy. Squeeze out the amounts of epoxy

Page 4

and hardener that your particular brand requires.

For example, some epoxies use equal amounts and

some use a 1 to 2 mixture . Mix these together. Coat

one piece with epoxy; squeegee the excess glue off

with scrap wood. The epoxy glue will work better if

there isn't too much oozing out at the edges of the

glued piece. Wipe off any of this excess glue.

In any case, glue is never a substitute for a

good-fitting joint; once the joint is formed, use a

minimum amount of glue and wipe off the excess.

Clamp, pin or hold the joint while the glue is drying.

Remember: Take your time and follow directions to end up with a well-built model that

is straight and true.

BUILDING HINTS

Your work area ideally should be large and comfortable enough for you to work without having to

put everything away every night. (The kitchen table

is not recommended!) The key to a straight fuselage

and warp-free wings is a straight, flat building board

or work bench. Remember, your model is only as

straight as the board you build on. Have all your

tools handy and your building will go much easier.

Build over the plans when instructed. Cover

the part of the plan you are using with waxed paper

so you don't glue the model to the plans! If the parts

do not match the plans exactly, it is because the plans

have changed size with moisture in the air. Do not

be concerned about this. The parts were all cut to fit

each other. Use the plans as a guide.

Remember this: In order for your PT40 to perform as it should it is your responsibility to take your

time when building and to follow all the instructions

given. A careful builder will produce a model that is

straight, true and warp-free. A well built model performs best and will fly like it was designed to. So

take your time and enjoy!

If at all possible, get an experienced model builder to look at your model during the construction

process. It is much easier to make corrections at these

times.

The building instructions follow. If you have

any questions about building or flying the PT40,

please call us at (217) 398-8970 and we'll be glad to

help.

6- 5/32" Wheel Collars

1- 6 or 8 oz. Fuel Tank

1/4 pound- #64 Rubber Bands

Thin Cyanoacrylate Glue, 2 oz.

Thick Cyanoacrylate Glue, 1 oz.

5 Minute Epoxy, 2.5 oz.

15 or 30 minute epoxy, 2.5 oz.

Wing Seating Tape

Balancing Weights

Iron-On Covering Material (Top Flite Super

MonoKote Recommended)

Foam Rubber (For Cushioning Radio Receiver

and Battery)

Radio System (3 or 4 Channel)

Engine (.25-.40 2-Cycle or .30 to .45 4-Cycle)

Fuel Line, medium size

Chicken Stick or Electric Starter

Glow Plug Clip

Glow Plug Battery

TOOLS OR SUPPLIES NEEDED:

Hand or Electric Drill

Drill Bits 3/16", 5/64", 3/32", 1/8", 3/16", 7/32", 5/16")

Sanding Block or T- Bar

Sealing Iron

Heat Gun

Hobby Saw (X-Acto Razor Saw)

X-Acto Knife, #11 Blades

Pliers

Screw Driver

10 ft.-Kite String or Strong Thread

T-Pins

Straightedge

Masking Tape

Sandpaper, Coarse (100 grit) and fine (220 grit)

Waxed Paper

Balsa Filler

Note: As with any other hobby, you may go "all

out" if you choose by purchasing all sorts of special

hobby tools and accessories (there are hundreds available). However, most of the PT40 parts are accurately

pre-cut so you can build it without a lot of special

tools. Some of the more advanced R/C kits require

the builder to do a lot more cutting and sanding, so

you may eventually want to equip your workshop

with tools like a Dremel Moto Tool, jig saw, small

table saw, disk/belt sander, small drill press, small

band saw, etc., but these are not necessary now.

It is a good idea to obtain the following items

before you start building as you will need to install

or test fit some of them before assembly is complete.

Most of these items can be purchased from your local

hobby dealer.

ITEMS NEEDED:

1- 10 x 6 Propeller or Proper Size for Your Engine

1- 2-1/4" Spinner or Acorn Type Prop Nut

2- 2 1/2" or 2-3/4" Main Wheels

1- 2-1/4" or 2-1/2" Nose Wheel

SPECIAL NOTE ON ENGINES

Choose the right sized engine for the PT40 as

indicated here. We recommend a .25 to .40 two cycle

engine or a .30 to .45 four cycle engine. Too large or

too small an engine can result in an unsafe or poor

flying model. Remember that a model engine is not

a "toy" but a device that can cause serious bodily

harm to you or others on the ground or cause harm

in the air if abused or misused.

Page 5

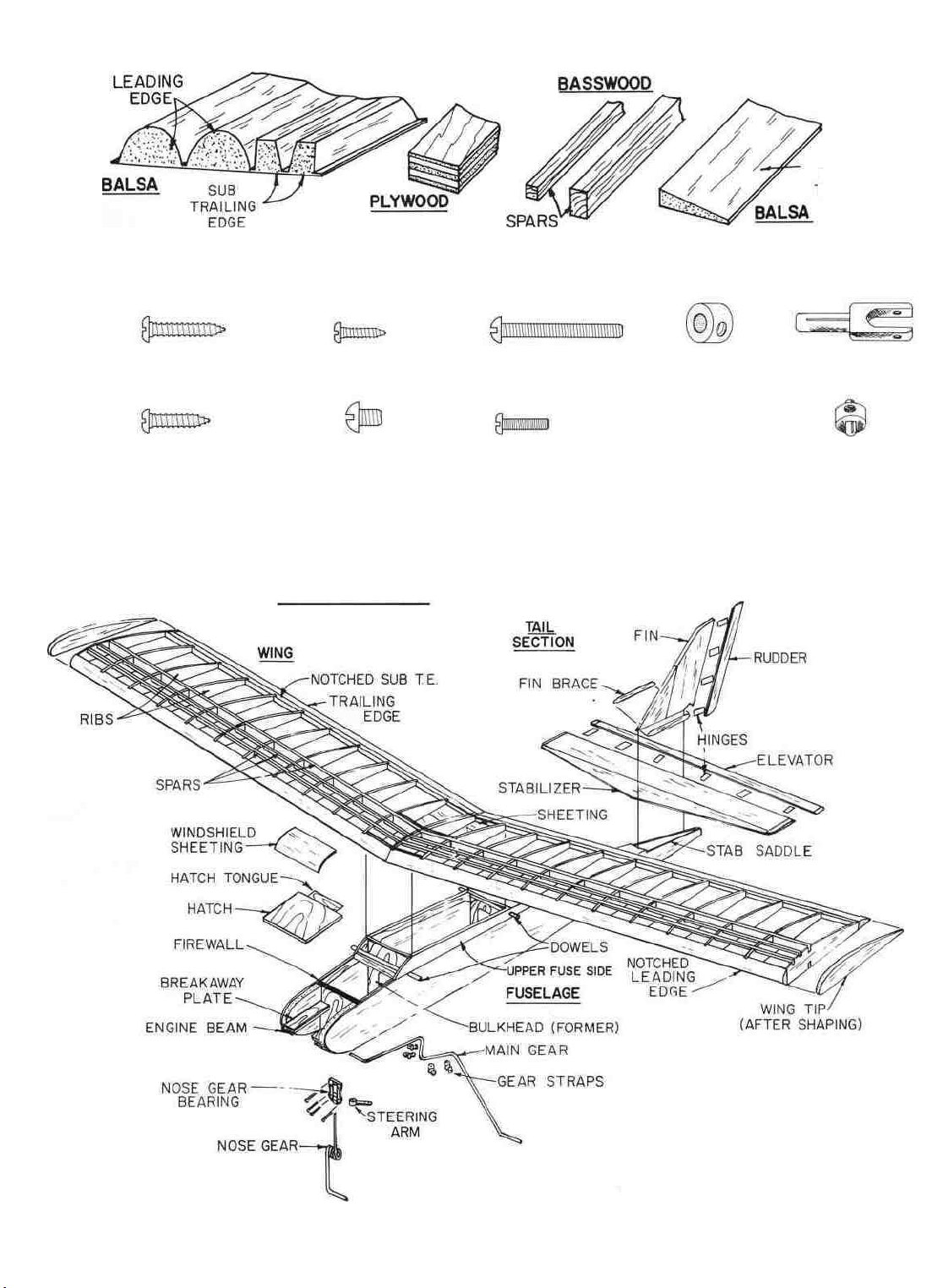

TYPES OF WOOD

HARDWARE

TAPERED

AILERON AND

TRAILING EDGE

STOCK

#4x5/8

#4x1/2"

SCREW

SCREW

#2x3/8"SCREW

6-32x3/16"

SCREW

PT40 PARTS

4-40x1"

2-56 x 3/8"

BOLT

SCREW

5/32"

COLLAR

AILERON

AILERON CLEVIS

CONNECTOR

CLEVIS

Page 6

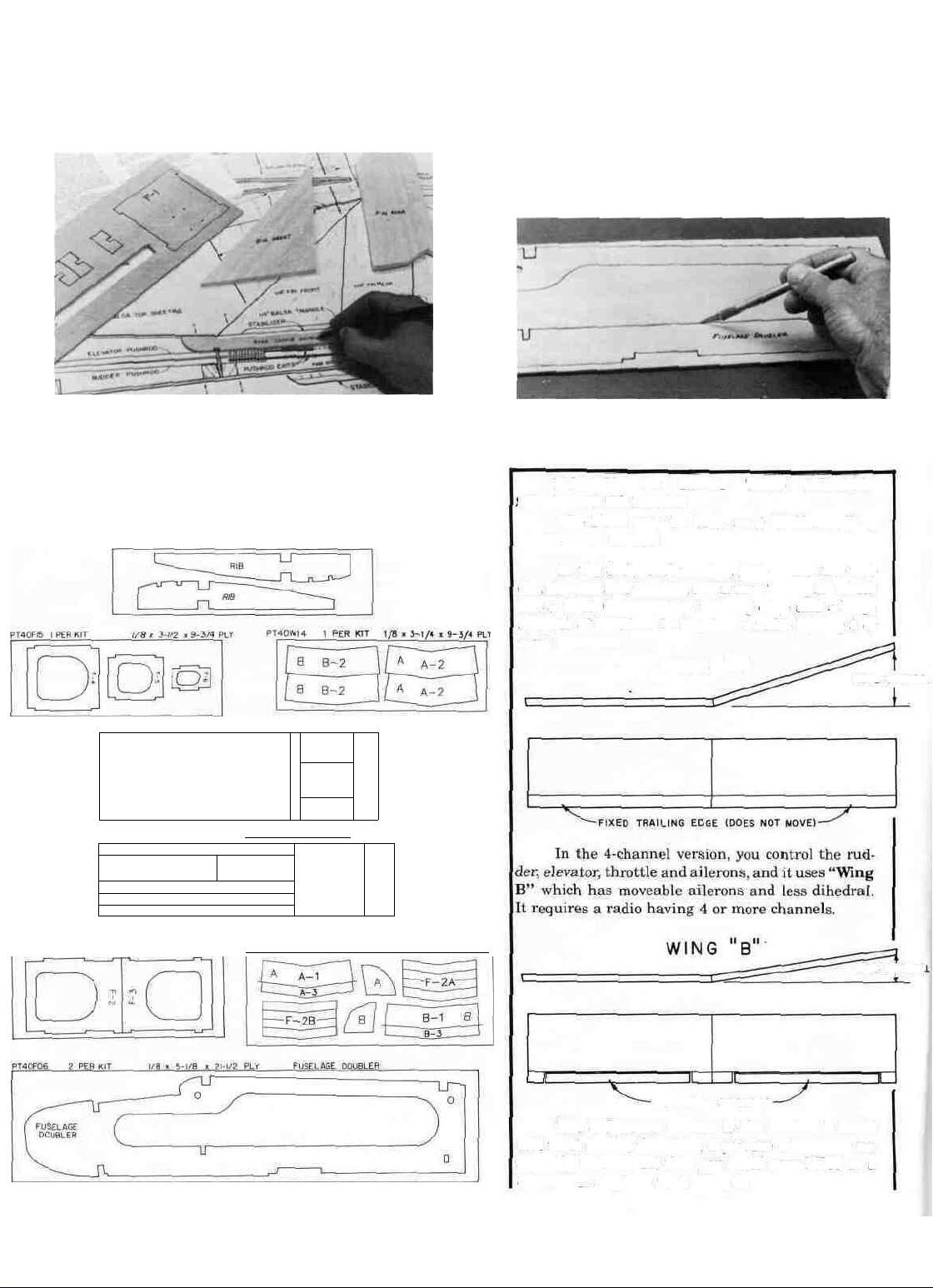

GET READY TO BUILD

D 1. Unroll the plan sheet. Re- roll it inside out to

make it lie flat. Note: The fuselage plan is printed

on Side 1 and the wing plan is printed on Side 2.

D 3. Punch out all the die cut parts excepting the

sheets stamped "A" and "B". If a part does not come

out easily, cut around it with an X-Acto knife. Mark

the die cut parts before punching them out. Also

save any scrap wood until you are completely finished

building. You will use some scrap to build the model.

You will find that scrap wood is quite handy to use

for lots of things, like spreading epoxy for instance.

D 2. As you remove all parts from the box, use a felt

tip pen to write the name or number on each part.

To identify the parts, compare them with the plans

and with the die-cut parts patterns shown here:

DIE CUT PARTS PATTERNS

«

PT40W07 13 PER KIT WING RIBS 3/32x 3x12 BALSA

PT40F07 I PER KIT 1/8 x 3-7/8 x 12 3/4 PLY

C3

SERVO TRAY

FUSELAGE BOTTOM

PT40FIO 2 PER KIT 1/8 x 3-7/8 x 13-1/2 PLY

LOCKPLATES |

F-l

J

D 4. Separate the parts into four groups: 1-

FUSELAGE, 2- WING, 3- FIN & STABILIZER, 4HARDWARE

IMPORTANT: READ THIS BEFORE

STARTING TO BUILD

The PT40 may be built as a "3-Channel" or

"4-Channel" trainer.

In the 3-channel version, you control the rud-

der, elevator and throttle, and it uses "Wing A" which

has a fixed (non-moving) trailing edge and a large

amount of dihedral. It requires a radio having 3 or

more channels.

WING "A"

MORE DIHEDRAL

PT40F05 I PER

\^ STAB SADDLE DOUBLER /

KIT

1/8 x 3-7/8 x 9-3/4

PLY

PT40W15 1 PER

1

KIT____1/8 x 4-1/4 x 11-1/2

PLY

MOVEABLE AILERONS

The 3-Channel version is the easiest to build

and most stable; therefore, if you are a beginner we

strongly recommend that you build your PT40 as a

3-Channel airplane with Wing A.

LESS

DIHEDRAL

i

Page 7

The 4-Channel version has more ability to perform acrobatic maneuvers, but is more difficult to

build and its self-recovery characteristics are not

quite as good. If you already have some R/C flying

experience and are ready to move up to an airplane

that is more maneuverable, you may choose to build

your PT40 as a 4-Channel airplane with Wing B.

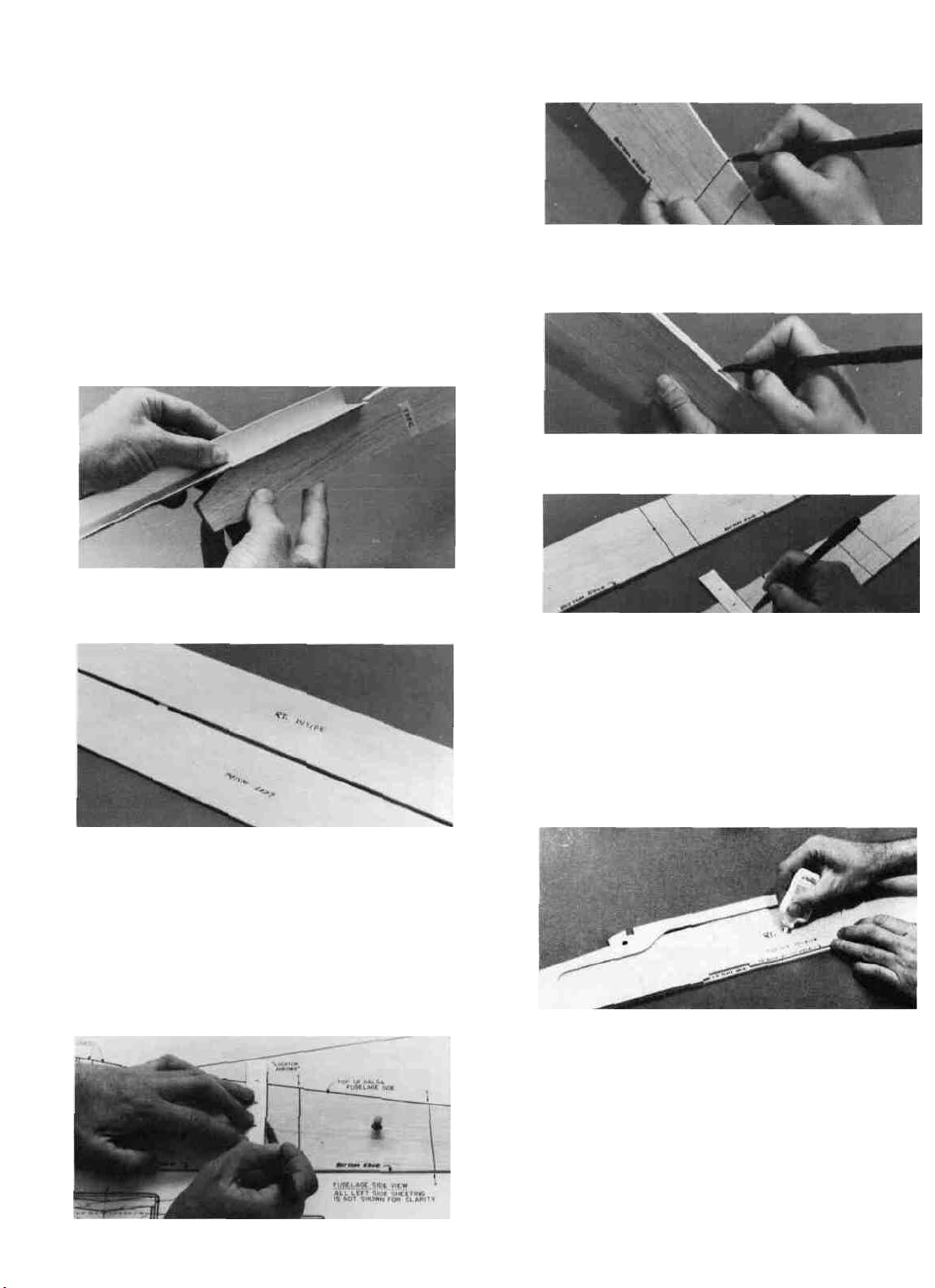

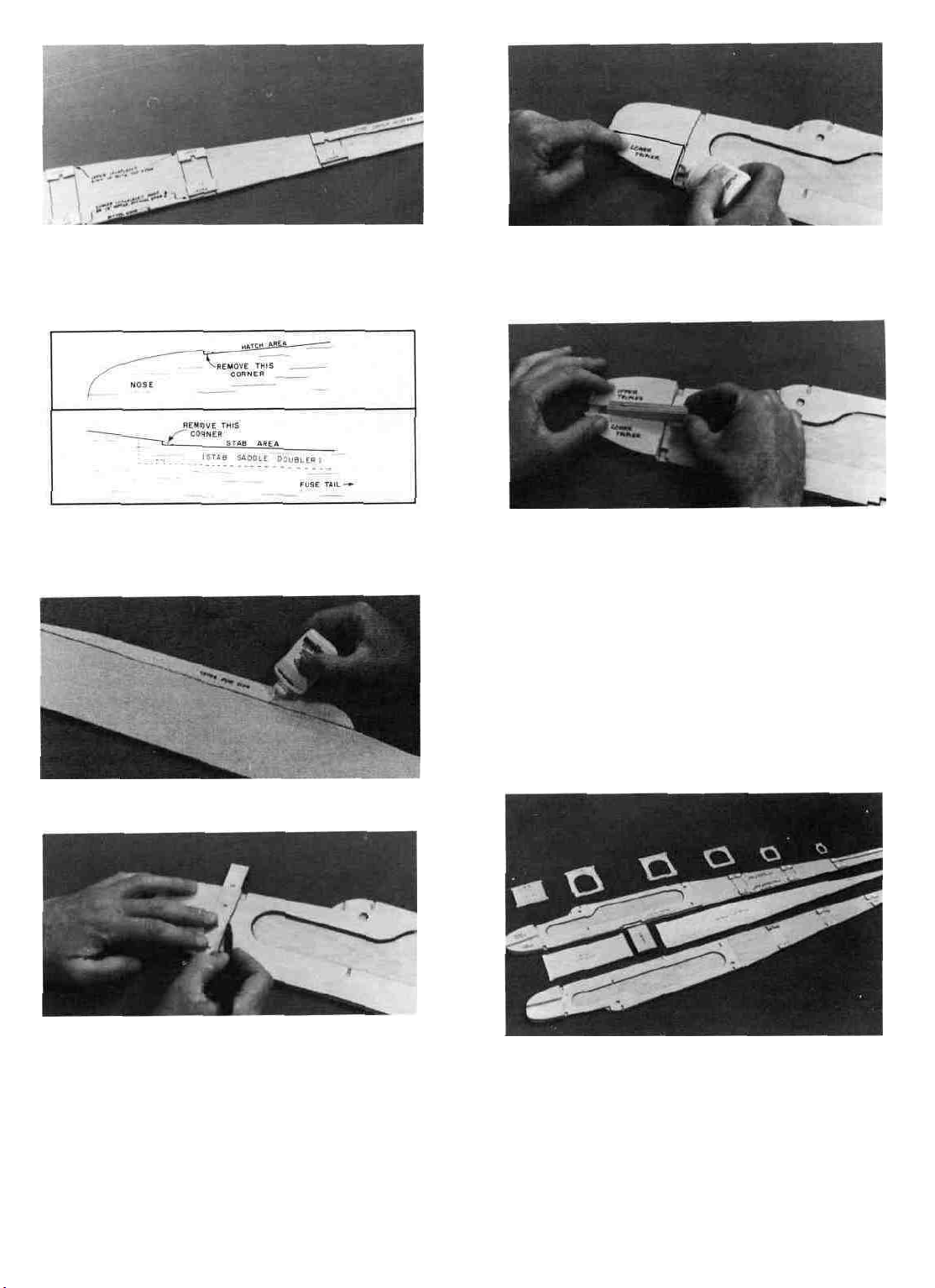

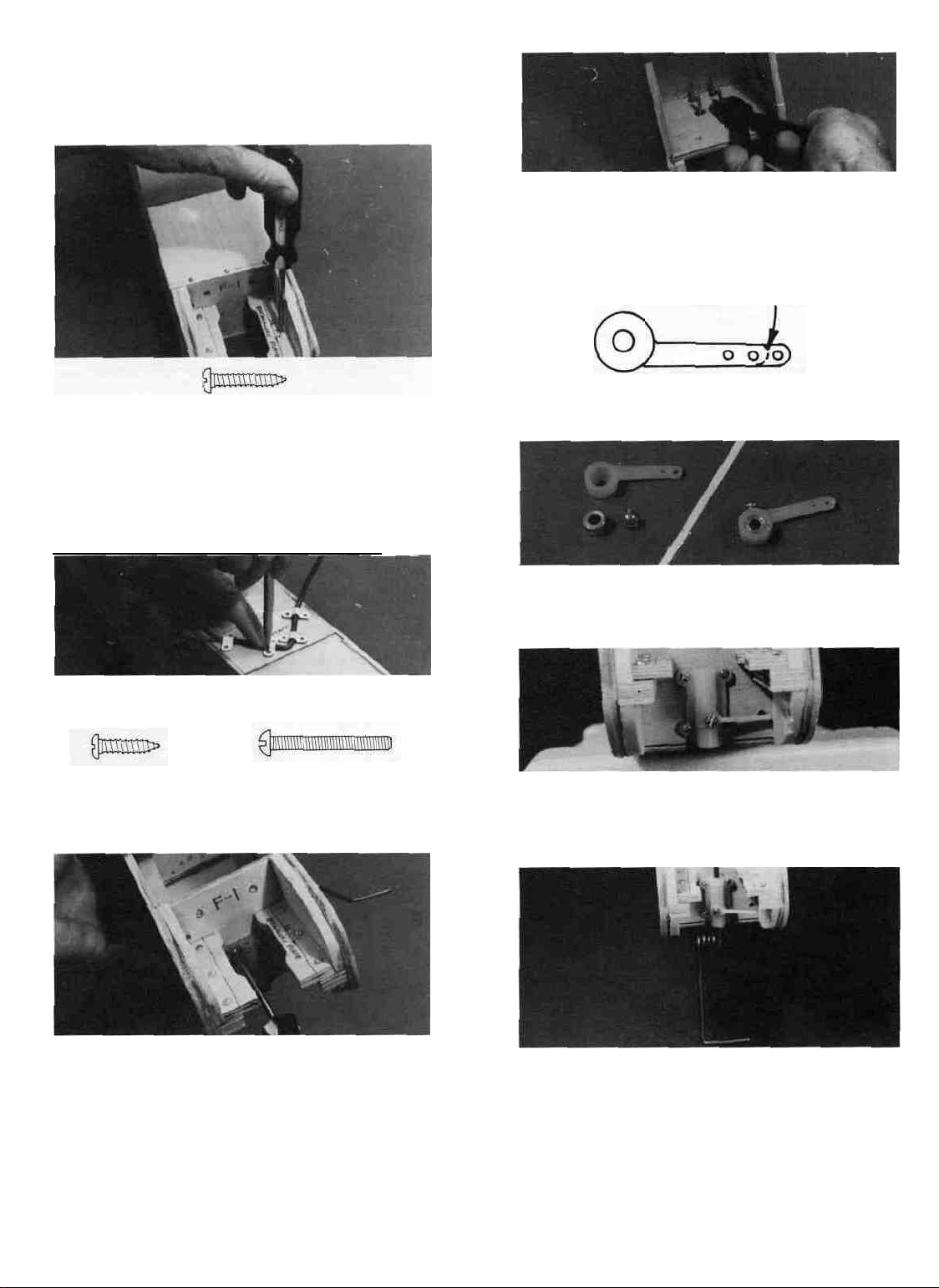

BUILD THE FUSELAGE SIDES

D 1. Take the two large 1/8" balsa fuselage sides

and put them together. Carefully line them up along

the bottom edge and the front. Tape them together

with a few pieces of masking tape along the bottom

edge to prevent them from moving. Now examine the

other edges to make sure the two fuselage sides are

exactly the same all around. If not, use a T-bar sander

with 100 grit sandpaper to lightly sand the edges to

match.

D 6. Remove the fuse side from the plan and make

small marks on the top and bottom edges, where the

lines end.

D 7. Put the two fuse sides together (inside to inside), and line them up carefully. While holding them

together, transfer the edge marks over to the left fuse

side edges as shown here.

D 8. Now draw lines on the left inside fuse side,

using the edge marks and a straight edge.

D 2. Now, with the tape still in place along the

bottom edge, let the two sides fall open and write

"Rt inside" and "Left inside" as shown here.

D 3. Tape the fuselage plan to your building surface.

D 4. Lay the right fuse (fuselage) side on the plan,

and carefully position it so the bottom edge and the

nose line up with the plan. Insert a few pins or tape

to hold it in place.

D 5. Using the "locator arrows", a straightedge

and a pen, draw six vertical lines on the fuse side as

shown. Press lightly to avoid damaging the balsa.

D 9. Lay the large 1/8" ply fuse doubler on the right

inside fuse side and position it to line up at the nose

and bottom edge. The part of the doubler which is

behind the L.G. plate area must be exactly 1/8"

above the bottom edge of the fuse side. Use a piece

of 1/8" balsa (such as the "windshield" piece) to check

this spacing. When you are satisfied that the doubler

is correctly lined up, apply thin CA glue all around

the edges while holding the doubler in place. Use

enough glue to make sure it flows under the plywood

to make a good bond.

D

10. Position

the

upper and

lower

"lock plates"

and

the stab saddle doublers on the right fuse side, using

the vertical guidelines previously drawn. The upper

lock plates and stab saddle doubler must be even with

the top edge of the fuse side. The three lower

lock plates

must

be positioned

1/8"

above

the

bottom edge of the fuse side. Use a piece of 1/8" balsa

as a spacer to aid in correct positioning of the bottom

lock plates.

Glue

these parts

in place

with thin

CA.

(See photo on next page.)

Page 8

D 11. Notice that the 1/8" balsa fuse side has two

slightly rounded corners at the front of the "hatch"

area and at the front of the "stab saddle" area. Using

an X-Acto knife, cut away these rounded comers to

match the doublers.

D 15. Use one of the 3/8" ply engine beams as a

spacer to position the 1/4" balsa upper tripler. Move

the upper tripler forward or back until it lines up

with the line you drew in Step 13.

D 12. Turn the fuse side over and lay the 1/8" balsa

upper fuse side in place on the doubler, lining up

the curved "windshield" edge. Apply glue all around

the edges of this upper fuse side.

LI 13. Draw a straight line connecting the front edge

of the front slots in the fuse doubler.

D 16. Remove the 3/8" ply spacer, then glue the upper

tripler in place with thin CA all around the edges.

D 17. Glue the fuselage doubler, upper and lower

lock-plates, upper fuse side, stab saddle doublers and

the 1/4" balsa triplers to the left inside fuselage side.

Be sure to follow the same procedure as set forth in

steps 9-16 when doing so, but don't make two Rt.

fuse sides!

D 18. Drill or cut out the 5/16" holes in the fuse sides

for the wing hold-down dowels. If you use a drill, lay

the fuse side on a wood block for a backing to drill

into, which will prevent the balsa from tearing.

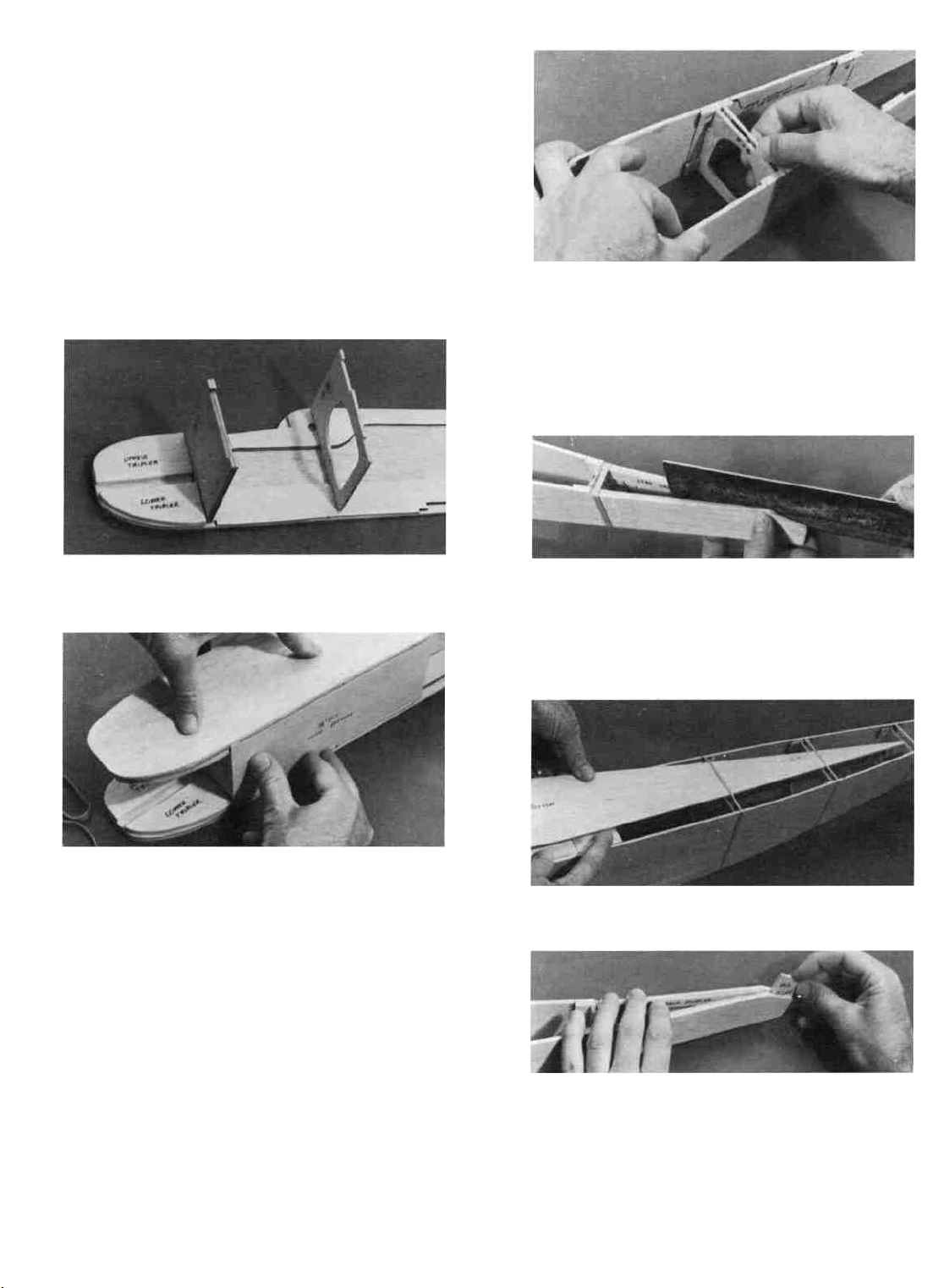

ASSEMBLE THE FUSELAGE

D 14. Lay the 1/4" balsa lower tripler in place on

the fuse doubler, and line it up with the line just

drawn and the edge of the doubler Glue the lower

tripler in place with thin CA all around the edges.

D 1. Before assembling the fuselage, make sure

that the following parts are set out within easy reach:

both fuse sides with doublers and triplers securely

glued on; formers F-l through F-6; 1/8" ply fuse bottom; 3/8" ply L.G. (landing gear) plate; 1/8" balsa

fuse bottom; the tapered balsa "fuse tail wedge" and

the six #62 rubber bands provided.

Page 9

Note: In the next steps you will assemble the

fuselage without glue! The interlocking parts enable you to do this so you can get everything together,

make sure the parts fit properly, check for straightness and make adjustments if necessary. Then you

will glue everything together by applying thin CA.

D 2. Make the "firewall" (Former F-l) by gluing

together the two 1/8" plywood parts which are marked

"F-l". Use 5 minute epoxy for this job. After the epoxy

has hardened, drill four 1/8" holes at the marks for

the nose gear bearing mounting holes.

D 3. Lay the right fuse side flat on the work surface.

Insert formers F-l and F-2 into their respective slots

in the right fuse side doubler.

D 8. Put F-5 and F- 6 in place in the lock-plate

notches and secure with rubber bands.

D 9. Note that the rear end of the stab saddle doublers touch, preventing the rear ends of the fuse sides

from coming together. Using your T-bar, sand the

rear portions of both the stab saddle doublers as

shown until the rear ends of the fuse sides nearly

touch.

D 4. While holding F-l and F-2 upright, lay the left

fuse side in place on these formers. Now put the 1/8"

ply fuse bottom in place in the slots provided.

D 5. Holding these five parts together with one

hand, slide two #62 rubber bands over the nose, leaving one around F-l and one around F-2.

Note: Notice that the fuselage has now become

somewhat rigid and square. Before proceeding make

sure that the tabs in F-l, F-2 and the fuse bottom are

properly inserted into the slots in the fuse doublers.

Position the fuselage in its normal (upright) position

while inserting the other formers in the next steps.

D 6. Put former F- 3 in place and secure by sliding

a rubber band around the fuselage from the rear.

D 7. Slide another rubber band around the fuse to

the F-4 location, pulling the fuse sides together. Now

work F-4 into place in the lock-plate notches.

(See photo at top of next column.)

D 10. Turn the fuselage upside down and place the

3/8" ply L.G. plate into the slots provided. Secure

with masking tape.

D 11. Now take the 1/8" balsa fuse bottom and carefully slide it in place, narrow end first, under the

rubber bands, starting at F-3.

D 12. Finally, insert the tapered balsa fuse tail

wedge, and secure with a small rubber band or masking tape.

D 13. Temporarily install the 3/8" ply engine beams

and the 1/4" ply breakaway plates. Hold in place with

masking tape. Now position your engine on the

breakaway plates and your fuel tank behind F-l.

Don't worry about exact fits at this time. While holding these parts in position, determine where to drill

the holes in F-l for the fuel lines and the throttle

pushrod. (See photo and notes on next page.)

Page 10

NOTE ON ENGINES: The engine mount

"breakaway plates" have been cut to an average width

which will permit mounting almost any engine you

choose. However, you may have to trim these plates

slightly to fit your engine. The best way to do this is

to sand or file away a little at a time from the inside

edges of both breakaway plates until your engine fits

between the plates.

NOTE ON FUEL TANK: The PT40 requires

any 6 or 8 oz. fuel tank of your choice. Most tanks

have three possible openings, one for fuel pick- up,

and two for the fill/vent lines. We recommend that

you only use two lines. Run one line from the "klunk"

pick-up to the fuel fitting on the engine carburetor

and the other to the "pressure tap" fitting on the

muffler.

D 14. Because you have not yet glued the fuse parts

together, you may now carefully remove F-l and drill

the holes for the fuel lines and throttle pushrod.

D 18. Check your assembly of the fuselage, making

sure that all former tabs are in their respective

notches and all parts are in place. Set the fuselage

assembly on the plan top view. Your fuse assembly

should line up with the plan within 1/16". If not,

something is wrong and you should try to straighten

it out. If the alignment is far off and you can't find

the problem, consult with an experienced model builder to correct the problem before proceeding.

D 19. Lay down a 50" long piece of waxed paper to

protect your building surface. Set the fuselage assembly upright (in its normal position) on the waxed

paper. With everything in its proper place, apply thin

CA glue to all the joints, around the formers and

along the bottom. Wait a minute for the glue to set,

then apply thick CA to the joints to make sure a

good bond exists, especially in the joints that do not

fit perfectly. Note: The use of "Zip Kicker" or other

CA glue accelerator will be helpful when using thick

CA to fill any large gaps.

D 20. Remove the rubber bands from the fuselage.

In the above step you may have glued the rubber

bands to the wood in some places. If so, just cut the

rubber away from the wood with an X-Acto knife.

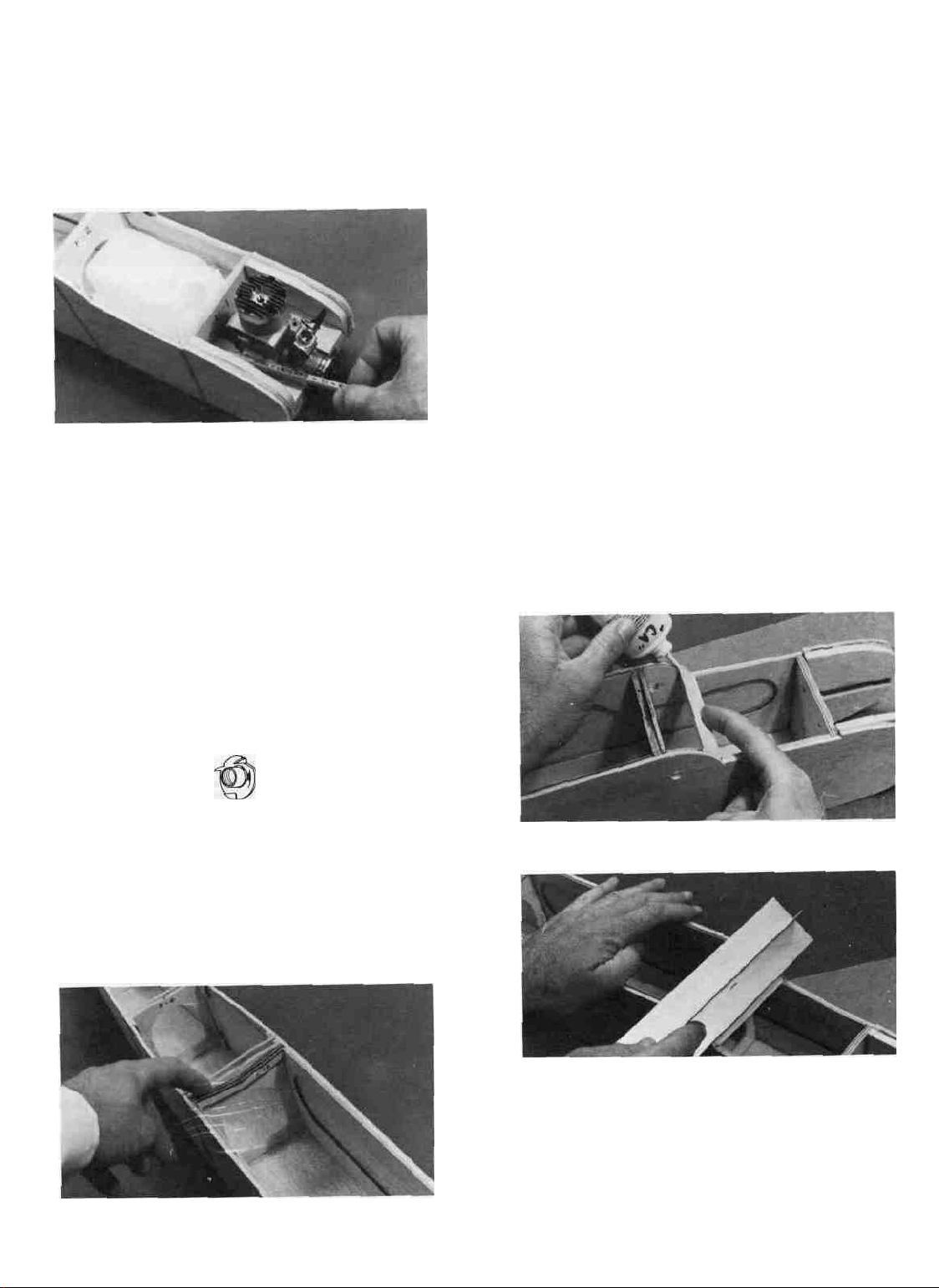

INSTALL THE WINDSHIELD

AND HATCH

D 1. Put the 1/2" balsa triangle windshield brace

in place and apply thin CA glue.

D 15. Insert four 4-40 blind nuts part-way into the

1/8" holes previously drilled. Insert them from the

back side of F-l. Apply one drop of thick CA glue

under the wide part of each nut, then immediately

press them firmly in place with a pliers or a vise.

4-40 BLIND NUT

D 16. Replace F-l back into the fuse.

D 17. By now you should have decided which wing

you are going to build, "Wing A" (without ailerons),

or "Wing B" (with ailerons). If you have chosen'

"Wing A", find the four F-2A wing saddles and put

them into the slots behind F-2 and in front of F-3. If

you have chosen "Wing B", use the F-2B saddles.

D 2. Sand the 1/2" balsa triangle to match the curve

on the fuse sides.

D 3. Sand the bottom edge of the l/8"balsa

windshield at an angle so it will rest flat on the fuse

sides.

D 4. Apply thick CA to the 1/2" balsa triangle, then

immediately place the windshield in position, holding the bottom against the triangle.

10 (See photo, top of next page.)

Page 11

D 5. Wet the top surface of the windshield so the

wood will bend without breaking.

D 6. Apply thick CA to the top of F-2 and the fuse

sides where the windshield will contact, then immediately bend the windshield down and hold until

the glue sets

D 7. Trim any excess windshield even with the back

edge of F-2.

D 8. Taper the rear edge of the 1/8" ply hatch to fit

the windshield as shown on the fuse plan side view.

D 9. Find the piece of 1/8" ply that you punched

out of F-5. This is used as the hatch tongue. Glue the

hatch tongue to the bottom of the 1/8" ply hatch with

thick CA. Let the hatch tongue extend about 1/2"

beyond the back edge of the hatch.

MOUNT THE ENGINE BEAMS AND

BREAKAWAY PLATES

D 1. Glue the 3/8" ply engine beams in place using

5 minute epoxy. With a tissue, wipe off any excess

epoxy that squeezes out when sliding the beams into

the slots. Allow the epoxy to fully cure before disturbing the beams.

D 2. Holding the 1/4" breakaway plate under the

3/8" ply beam, draw a line on the breakaway plate

to mark the edge of the beam.

D 10. Draw a guideline 1/8" back from the front edge

of the hatch. This is the centerline of the three hatch

hold down screws.

D 11. Holding the hatch firmly in position, drill three

1/16" holes along the guideline •

D 12. Remove the hatch and re-drill the holes in the

hatch only to 3/32". Then attach the hatch to the fuse

with three #2 x 3/8" screws. (See photo, top of next

column.)

D 3. Now place the breakaway plate on top of the

beam and while holding the plate firmly in place,

drill three 3/32" holes as shown, drilling down

through the breakaway plate and the beam. Do this

for both plates and beams.

11

Page 12

D 4. Remove the breakaway plates and re-drill the

holes in the breakaway plates only to 1/8".

D 5, Fasten the breakaway plates to the beams

using six #4 x 5/8" screws.

PREPARE THE NOSE GEAR

D 1. Referring to the steering arm drawing here,

cut off about 3/16" of the steering arm so it will clear

the fuse triplers. Drill out the end hole to 5/64"diameter for pushrod wire clearance.

TRIM 3/16" HERE

#4x5/8"

INSTALL THE LANDING GEAR

D 1. Turn the fuselage upside down and position

the 5/32" wire main L.G. (landing gear) on the ply

L.G. plate. Set the four nylon L.G. straps in place

and mark the location for the eight screw holes. Drill

3/32" (or slightly smaller) holes at the marks.____

D 2. Temporarily mount the main LG using the

nylon straps and the #4 x 1/2" screws.

#4x1/2"

D 3. Temporarily mount the nylon nose gear bearing

using four 4-40 x 1" bolts screwed into the 4-40 blind

nuts previously installed.

SCREW

SCREW

4-40x1" BOLT

D 2.Assemble the nose gear steering arm which

consists of a nylon arm, a 5/32" wheel collar and a

6-32 x 3/16" screw.

D 3. Place the steering arm assembly into the nose

gear bracket making sure that the wheel collar opening on the steering arm is down and the screw is

facing out.

11

D 4. Referring to the nose gear diagram on the plans,

slide the nose gear wire through the holes in the

nose gear bearing and wheel collar/steering arm.

Tighten the screw, making sure the steering arm is

at the angle shown on the top view of the fuselage.

D 4. If you are a young person, you should ask

an adult to help you with the following step:

Using a side cutter, cut off the excess bolt length

sticking out behind F-l. You must wear eye protec-

tion when doing this! Note: An alternate method

is to mark the bolts with an indelible marker, remove

them from F-l, and cut them off at the marks with

a side cutter, hacksaw or a Dremel cut-off wheel.

(See photo, top of next column.)

CUT THE NOSEGEAR PUSHROD

OPENING

D 1. Mark and drill a 1/8" hole through Former F-l

in the position shown on the F-l drawing on the plan.

This hole is for pushrod clearance.

See photo, top of next page

12

Page 13

CUT THE PUSHROD EXIT SLOTS FOR

THE RUDDER AND ELEVATOR

D 1. Find the location of the "Pushrod Exits" on

the fuselage plan (side view). Measure their locations

in relation to the fuse bottom and the back of F-6,

and transfer these measurements to your fuselage.

Note that the pushrod exit shown in dashed lines is

for the rudder pushrod exit on the left fuselage side.

D 2. Cut out the slots with an X-Acto knife.

This completes the fuselage construction for

now. Note that you have not yet installed the top

sheet. Set the fuselage assembly aside.

BUILD AND INSTALL THE "TAIL

FEATHERS"

Q 1. Working on waxed paper on a flat surface, glue

the 1/4" balsa fin front to the 1/4" balsa fin rear

using thin CA. Immediately wipe off any excess glue

to make sanding easier. Apply glue to both sides of

the joint.

D 3. Find the two 1/4" x 1/4" x 5-7/8" balsa pieces.

These are used for the ends of the stab and elevator.

Cut a 1-3/8" length from each of these pieces and

glue them to the ends of the elevator using thin CA

glue. Sand the ends even with the elevator using a

sanding block.

D 4. Take the two remaining pieces of 1/4" x 1/4"

balsa and glue them to the ends of the stab and sand

to blend in.

D 5. Round the corners of the fin, rudder, stab and

elevator as shown on the plan.

D 6. Sand the fin and stab smooth with a T-bar

sanding block and 100 grit sandpaper.

D 7. Put the elevator and stab together and sand

the tips to the same length.

D 8. Using a sanding block, sand the following to

a rounded shape: stab leading edge (excepting the

flat center portion), stab tips, elevator trailing edge

and tips, fin leading edge, fin tip, rudder trailing

edge and rudder tip.

D 9. Using a fine point felt tip marker, carefully

draw a centerlirie all along the stab trailing edge,

elevator leading edge, fin trailing edge and rudder

leading edge.

D 2. In the same manner, glue the stab (stabilizer)

front to the stab rear.

D 10. Using a T- bar sanding block with 100 grit

sandpaper, sand the elevator leading edge and rudder

leading edge to a "V" shape. Work slowly and care-

fully so you don't sand away too much balsa. When

you have finished, the centerlines you previously

drew should remain, and the "V" shape should look

like the sketch shown above the fin on the plan.

13

Page 14

MAKE THE HINGES

D 1. Take the 9" strip of hinge material and roughen

both sides with 220 grit sandpaper. This is best done

with a small piece of sandpaper held with your fingers, rather than a sanding block. Do not sand the

centerline of the hinge material.

D 2. Using a ruler and a ball point pen, draw lines

dividing the hinge material into eighteen 1/2" -wide

segments.

D 2. While holding the elevator in place against

the stab trailing edge, transfer the hinge locations

to the elevator leading edge.

D 3. Repeat the above process marking the hinge

locations on the fin and rudder. Don't forget to mark

the bottom hinge location on the rudder.

CUT THE HINGE SLOTS

D 3. Drill four 1/16" holes in each of the hinge segments as shown on the plan. Use a wood block as a

backing to drill into when drilling these holes.

D 4. Fold the hinge material back and forth a few

times on the centerline to "condition" the hinges.

D 5. Cut the hinges apart with a scissors on the

lines you previously drew. Also snip off a small piece

of each hinge comer.

D 1. Move the fin trailing edge close to the table

edge. Place a small piece of 1/8" plywood (from die-cutting scraps) next to the hinge slot location.

D 2. Hold your X-Acto knife straight on the scrap

wood and cut straight into the fin. The slots should

be about 1/2" deep (enough for half of the hinge to

fit into).

D 3. Trial fit by pushing the hinges (no glue) into

the slots to make sure you have cut the slots wide

enough and deep enough.

D 4. Repeat this process for the rudder, elevator

and stab.

MOUNT THE STAB ON THE FUSE

D 1. Remove the nylon nose gear bearing and the

main gear from the fuselage.

Note: You should end up with 18 hinges, 8 of

which you will use for the ailerons if you are building

the "B" wing.

MARK THE HINGE LOCATIONS

D 1. Lay the stab on the plan and mark the hinge

locations on the stab trailing edge (both sides are

the same).

D 2. Lay the stab on the plan and carefully line it

up with the outside lines. While holding it in this

position, lay a straight edge along the "fuselage cen-

terline" as shown on the plan. Draw the fuselage

centerline on the top of the stab with a fine point

marker. Work as carefully as you can when doing this!

(See photo, top of next page)

14

Page 15

D 3. With the fuse on a flat surface, lay the stab

in place on the fuselage in the stab saddle area with

the front of the stab touching the rear surface of F-6

and centered side-to-side.

D 4. While holding the stab firmly in place onto

the saddle, measure down to the flat work surface

from both ends of the stab. If one side is higher than

the other, sand the high side of the stab saddle with

your T-bar sanding block and 80 or 100 grit

sandpaper. Replace the stab in the saddle and recheck the measurements. Continue this process until

the stab is level within 1/16".

the stab slightly until both measurements are the

same within 1/16" .

E- When you finally have the stab accurately

aligned on the fuse, make four little "alignment

marks" on the stab where the leading and trailing

edge of the stab intersect with the outside edges of

the fuse sides. You will use these marks to quickly

and accurately position the stab when gluing it in

place. Now remove the stab.

F- Mix up a batch of epoxy and spread it on the

stab saddle and the back of F-6. Lay the stab in place

using the "alignment marks" for positioning. Before

the glue sets, re-check the measurements in step D.

Hold or pin the stab in place until the glue sets.

NOTE: READ THROUGH AND PRACTICE THE NEXT 6 STEPS (A-F) BEFORE PROCEEDING.

D 5. Now glue the stab securely to the stab saddle

with 5 minute epoxy. (You may perform this step with

5 minute epoxy, but a slower curing epoxy will give

you more time to make sure the alignment is correct.)

It is important that the stab be centered and square

on the fuselage; so, follow this procedure exactly:

A- With a ruler, measure to find the exact center

of the top of F-3. Stick a pin in at this point.

B- Also measure to find the center of the top

of F-6 and mark this point with a pencil.

C- Lay the stab in the saddle and line up the

"fuse centerline" (which you previously drew on top

of the stab) with the mark on F-6 and with the center

joint at the rear of the fuse.

MOUNT THE FIN TO THE STAB

Note: Probably the single most troublesome

cause of poor flying models is improper fin alignment.

Therefore, you should take the time and care necessary to do your "best when performing this next set

of steps. Read through the next five steps before

beginning!

D 1. At the front and back of the "fuse centerline"

which you previously drew on the top of the stab,

make accurate marks 1/8" right and left.

D 2. Using a straight edge and a fine point marker,

connect these marks, making two parallel lines, one

on each side of the fuse centerline.

D- Check the "squareness" of the stab by

measuring from the rear corners of both stab tips to

the pin in the center of F-3. Adjust the position of

15

Page 16

D 3. With the rudder attached to the fin by the top

three hinges (not glued in), trial fit the fin onto the

fuse. If the rudder is too long and touches the flat

work surface preventing the fin from resting on the

stab,

sand a small amount

D 4. Apply 5 minute epoxy to the bottom of the fin

and position the fin between the guidelines you previously drew. Slide the fin/rudder assembly forward

until the bottom of the rudder just touches the back

of the fuse. Wipe away any excess epoxy with a tissue.

D 5. Before the epoxy sets, check the squareness

of the fin with the stab, using a small carpenter's

off

the

bottom

of

the

rudder.

square or draftsman triangle. Hold position until the epoxy sets firmly.

D 8. Now temporarily assemble the elevator to

the stab and the rudder to the fin. Swing the rudder

from side to side and the elevator up and down. The

rudder and elevator must not touch in any position! If they do, carve or sand the notch in the rudder

to insure that they will not bind. In addition, make

sure no part of the fin interferes with the free upward

movement of the elevator.

Lay the fuselage assembly aside for now.

CHARGE YOUR NICAD BATTERIES

D 1. Read the instruction manual for your radio

system to become familiar with how to hook it up.

D 6. Find the two 4-7/8" lengths of l/4"balsa triangle

and sand the ends to a rounded (or pointed) shape

as shown on the plan. Trial fit these pieces in place

at the fin/stab joint. Later, when you are covering

the model (and before you cover the fin and stab)

cover the outer surface of these triangular pieces,

leaving about l/8"of excess covering all around the

edges. Then glue these pieces in place and iron down

the excess covering to the fin and stab

D 2. Charge your transmitter and receiver bat-

teries now so they will be ready when you need them.

Note: Charge the batteries for the time recom-

mended for the first charge...usually 18-24 hours.

BUILD THE WING PANELS

NOTE: Like the fuselage, the PT40 wing is

made to fit together without glue, so you can assemble all of the major parts and check to make sure

they are all lined up before applying thin CA to the

joints.Thick CA will be added after the thin CA has cured.

D 1. Turn the plan over to side 2, which shows the

wing. Tape or pin the plan to your flat work surface

so the "Right Wing Panel" is facing you. Cover the

right wing panel drawing with waxed paper (so you

won't glue the wing to the plan!).

D 2. The shaped and notched wing leading edge

(L.E.) and trailing edge (T.E.) are fastened together

by a thin layer of balsa. Separate them by folding

until the balsa breaks. Sand away the excess balsa

that remains along the edges after breaking them

apart, using a T-bar with 100 grit sandpaper.

D 7. You previously marked the four hinge loca-

tions on the rudder. Now transfer the bottom hinge

location over to the rear of the fuse. Cut the hinge

slot in the tapered balsa fuse tail filler.

(See photo, top of next column.)

16

Page 17

D 3. Before using the L.E. and T.E. pieces, you must

determine which pieces are to be used for the right

wing panel. Here's how:

A- We have drawn red lines on the top of each

piece.

B - Notice that the pieces are notched on one

end, but not on the other. The notched end goes toward

the wing tip, and the end without a notch goes toward

the center of the wing.

C- Take one of the L.E. pieces and lay it on the

right wing panel plan with the red line up. If the

notched end is on the right side (at the tip) you have

the correct L E.

D- Do the same thing to determine which T.E.

piece to use.

D 4 Tape one of the 3/8" x 1/2" basswood spars to

the plan, with the right end of the spar lined up with

the tip. The excess spar length must extend past the

wing centerline.Apply tape in 3 places, between the

ribs, near the ends and in the middle.

D 6. Insert the fronts of the ribs into the notches

in the balsa leading edge (L.E.).

D 7. Insert the backs of the ribs into the notches

in the balsa trailing edge (T.E.).

D 8. Adjust the position of the leading edge and

trailing edge left or right so they match the plan at

the right tip. Tape or pin them to the plan so they

don't move.

D 9. The tip rib should now match the plan exactly.

However, due to shrinkage or expansion of the paper,

the other ribs may not line up perfectly. That is OK,

because the notches in the L.E. and TE. are cut in

the right places. Before proceeding, make sure none

of the ribs are bowed (curved). If they are, straighten

them by sliding the center part right or left on the

spar.

D 10. Insert the top 3/8" x 1/2" spar into the top

notches in the ribs, so the right end is even with the

tip

rib.

D 11. Insert two of the 3/16" x 3/16" basswood spars

into the small notches in the top of the ribs, so the

right ends are even with the tip rib.

D 5. Remove the 3/32" balsa wing ribs from the die

cut sheets and slide 12 ribs into place on the bottom

spar, using the plan to get them close to their proper

position DO NOT PUT A RIB AT THE CENTER-

LINE.

D 12. Make sure that the ribs are all down onto the

plan and fully inserted into the notches in the L.E.

and

T.E.

17

Page 18

D 13. Apply thin Ca to all joints. After the thin CA

has cured, apply some thick CA to each joint.

D 14. Find the die-cut plywood sheets containing the

Dihedral Braces, Wing Braces, F-2's and Gauges

(PT40W14 & PT40W15). If you are building wing "A"

(without ailerons), punch out all the parts that apply to the

"A" wing. Compare each part with the drawings on page

6 and mark them with their correct letter and number (A-

1, A-2, etc.). If you are building the "B" wing, use only

the parts with a "B" on them.

D 15. Using the "dihedral gauge" (A or B, depending

on your wing choice), draw cut-off lines on the back

of the L.E. and the front and back of the spars and

T.E. (See the sketch on the plan showing how to do

this.) The point of the dihedral gauge must be

exactly on the centerline when marking the cutoff lines.

D 16. Using a razor saw (or any fine-toothed saw),

carefully cut off the L.E., spars and T.E. on the lines

you just drew.

Clamp or hold the parts until the glue hardens.

Set the right wing panel aside, and turn the

plan around so the left wing panel is facing you.

D 18. Build the left wing panel in the same manner

as you did the right panel, following steps 1 through

16.

JOIN THE WING PANELS

D 1. Lay the left wing panel flat on the building

surface or a large flat table. Place a sheet of waxed

paper under the "center" portion of the panel where

it will be joined to the right half.

D 2. Slide the right wing panel into position, so

the spars touch the spars of the left panel. Block up

the right tip with a stack of books The stack of books

must be 8" high for wing A and 5" high for wing B.

D 17. Using 5 minute epoxy:

Glue A-l or B-l to the back of the leading edge.

Glue A-2 or B-2 to the front of the main spars.

Glue A-2 or B-2 to the back of the main spars.

Glue A-3 or B-3 to the front of the trailing edge.

D 3. Check to make sure the L.E., spars and T.E.

are touching. If not, sand off any long ones slightly

until they all touch. Now slide the panels apart.

NOTE: PRACTICE THE NEXT STEP

"DRY" BEFORE ACTUALLY DOING IT!

D 4. Mix up a batch of epoxy (30 minute epoxy is

preferred here to give you more time, or 5 minute

epoxy may be used if you work quickly), and apply

it to the dihedral braces, L.E., spars and T.E. Slide

the panels together and wipe up the excess glue with

a tissue.

Make sure the wing panels remain in posi-

tion until the epoxy has fully hardened.

Remove any excess glue with a tissue.

NOTE: Skip to page 39 and add the

shear webs as described on that page.

18

Page 19

INSTALL THE CENTER RIBS AND

BOTTOM SHEETING

LI 1. After building the wing, you have two ribs

remaining. Lay these ribs, one at a time, on the drawing in the lower left comer of the wing plan. With a

straight edge and a pen, mark the four cut-off lines,

using the arrows as a guide.

D 2. Cut the ribs at the cut-off lines using a razor

saw.

D 3. Place the two "front parts" together and the

two "aft parts" together, and apply thin CA glue

around the edges.

D 6. Working on waxed paper, glue the bottom

sheeting to the inside edges of the ribs and dihedral

braces.

D 7. Turn the wing upside down and inspect the

bottom of the center section. If there are any major

gaps between parts, fill them with balsa dust (from

sanding) and apply thin CA.

D 8. Sand the bottom of the center section smooth

with a sanding block and 100 grit sandpaper.

At this point the bottom center section should

look like this:

INSTALL TAPERED TRAILING EDGE

(WING A ONLY)

D 4. Position these center rib parts in place in the

center of the wing and glue them to the L.E..spars

and T.E. You may use thin CA if the ribs fit perfectly;

otherwise use thick CA or epoxy.

D 5. From the sheet of 1/8" x 3" x 13" balsa, cut

rectangles to fit between the center rib and the 2nd

rib in both wing panels The easiest way to do this

is to lay the wing right on the 1/8" balsa sheet and

trace around the inside edge of the ribs and spars as

shown here.

Note: The following 7 steps apply only to wing

A (without ailerons). If you are building Wing B, skip

to the next section now.

D 1. Find the two tapered balsa T.E. pieces. They

are 1-3/16" wide and 30" long.

D 2. Place one of the trailing edge pieces against

the rear edge of the right wing panel on a flat surface.

If there is a 3/32" gap along the top edge, that means

the T.E. is upside down If so, turn it over.

D 3. Working on a flat surface covered with waxed

paper, hold the tapered T.E. firmly against the rear

edge of the Rt. wing panel with the left edge at the

wing centerline, and apply thin CA along the joint.

Make sure the wing and the T.E. are down flat on

the work surface when doing so.

Note: The grain of this bottom sheeting must

run in the same direction as the spars.

D 4. Take the other tapered T.E. and determine

which side goes up, as in step 2.

D 5. Trial fit this piece in place against the rear

edge of the Left wing panel. You will probably notice

that there is a gap on the bottom, where the two T.E.

pieces come together. If so, sand the end of the T.E.

so it fits snugly against the end of the right T.E.

D 6. Glue the left tapered T.E. in place, as in step 3.

19

Page 20

D 7. With a razor saw, cut off the ends of the tapered

trailing edges even with the tip ribs.

INSTALL TRAILING EDGE, AILERONS

AND TORQUE RODS (WING B ONLY)

Note: The following 27 steps apply to wing B

(with ailerons). If you are building wing A, skip to

the next section now.

D 1. Find the two tapered balsa T.E. (trailing edge)

pieces. They are 1-3/16" wide and 30" long.

D 2. Place one of the T.E. pieces against the rear

edge of the right wing panel on a flat surface. If there

is a 3/32" gap along the top edge, that means the T.E.

is upside down. If so, turn it over.

D 3. Just below the right wing drawing (on the

plan), there is a separate drawing showing the aileron

details. Using this drawing as a guide, cut the tapered

T.E. into three parts. Label these parts: "Rt. inboard

T.E.", "Rt. Aileron" and "Rt. outboard T.E."

("Rt." is an abbreviation for "right".)

There are several ways to accomplish this, so

you may choose one of these:

A- File the groove with an 1/8" or 5/32" diameter

round file, available at hardware stores (this type

of file is normally used to sharpen small chain saw

teeth).

B- Cut the groove with a 5/32" outside diameter

brass tube. You can sharpen the tube by cutting

around the inside of one end with an X-Acto knife.

C- Cut the groove by running the T.E. piece

over a small table saw, with the blade set at the

height needed to cut a groove 5/32" deep.

D- Rout the groove out with a Dremel Moto

Tool and a 1/8" bit.

D 7. Turn the two inboard T.E. pieces upside down

as shown in the following photo, and measure 7/16"

out from the "wing centerline". At the 7/16" point,

cut a notch in both pieces with an X-Acto knife, pro-

viding free movement for the threaded portion of the

aileron torque rods.

D 4. Glue the Rt. outboard T.E. piece to the rear

edge of the right wing panel. The outer edge of the

T.E should be even with the tip as shown on the plan.

D 5. Repeat steps 1-4 for the left side, making the

"Lt. inboard T.E.", "Lt. Aileron" and "Lt. outboard

T.E." ("Lt." is an abbreviation for "left".)

D 6. Find the "aileron torque rods". You will

notice that there is a black nylon tube on each of the

bent rods. This nylon tube is called the "torque rod

bearing". You must now make a groove in the front

edge of each inboard T.E., so the torque rod bearing

may fit into the groove.

D 8. Roughen the surface of the nylon torque rod

bearings using a piece of 100 grit sandpaper.

D 9. Slide the nylon torque rod bearings as far as

they will go toward the threaded portion of the torque

rods.

D 10. With a toothpick, apply a small amount of

petroleum jelly (Vaseline, etc.) around the torque rod

where it enters the nylon bearing. This will help

prevent any excess glue from getting in and possibly

"locking up" the torque rod.

D 11. Place the torque rods into the grooved T.E.

pieces.

STOP! AT THIS POINT YOU MUST CAREFULLY STUDY THE PLANS AND PHOTOS TO

MAKE SURE YOU HAVE THE RIGHT TORQUE

ROD IN THE RT. INBOARD T.E., AND THE

LEFT TORQUE ROD IN THE LT. INBOARD T.E.

THE THREADED PORTION MUST COME OUT

THE BOTTOM, AND THE SHORT BENT END

MUST POINT TOWARD THE REAR.

20

Page 21

D 12. If the nylon bearing fits snugly into the groove,

you may use a few drops of thin CA to glue it in place.

If you have a loose fit, use thick CA or epoxy. DO

NOT GET GLUE INTO THE ENDS OF THE

NYLON BEARING TUBE!

D 13. Turn the wing upside down, with the trailing

edge facing you, and temporarily position the inboard

T.E. pieces against the back edge of the wing. You

will notice the gap between the pieces, caused by the

dihedral angle. Sand the ends of the inboard T.E.

pieces so they come together without a gap.

D 14. With the T.E. pieces taped in their proper position mark the location of the slots (where the

threaded portion comes out) on the back edge of the

wing as shown. Then remove the T.E. pieces and cut

slots in the back edge of the wing.

D 19. Sand the leading edge of the ailerons to a "V"

shape as shown on the plan.

D 20. Groove the leading edge of each aileron to

accept the torque rods.

D 21. Trial fit the ailerons onto the torque rods.

D 22. Cut or sand a small amount off both ends of

the ailerons to provide about 1/16" to 3/32" of clear-

ance at each end. (Remember....the ailerons will be

covered with Super Monokote or other covering material; therefore you must make some space at the

aileron ends so they don't tighten up after covering.)

D 23. Remove the ailerons and draw a centerline

down the back edge of the wing, in the aileron opening.

D 24. Place the ailerons on the wing plan and mark

the locations of the hinges on the leading edge of the

ailerons. Now put the ailerons back in place on the

wing and transfer the hinge location marks to the

back edge of the wing.

D 15. Glue the inboard T.E. pieces to the back of the

wing by carefully holding or taping the pieces in

place and applying thin CA in small drops along the

joints. Use care to avoid getting glue inside the nylon

bearings.

D 16. Mark a centerline all the way down the leading

edge of each aileron.

D 17. Hold the ailerons in place against the back

edge of the wing and mark the location where the

torque rods will enter the ailerons.

D 18. Drill a 3/32" hole in each aileron to accept the

torque rods.

D 25. Cut the hinge slots for the ailerons in the

same way that you did for the elevator and rudder.

D 26. Using 100 grit sandpaper, roughen the ends

of the torque rods that will go into the ailerons.

D 27. Trial fit the ailerons on the wing with the

hinges in place. DO NOT GLUE THE HINGES IN

UNTIL AFTER COVERING.

THE FOLLOWING INSTRUCTION

PHOTOS SHOW THE "B" WING (WITH

AILERONS), BUT THE PRINCIPLES APPLY

TO BOTH "A" AND "B" WINGS.

INSTALL THE WING TIPS

D 1. Sand the wing tips smooth and flat with your

T-bar and 100 grit sandpaper.

D 2. Find the two tapered balsa pieces that are

11-3/8" long. These are the wing tips.

D 3. Holding the wing and wing tip on a flat surface

covered with waxed paper (the narrow edge of the

tapered piece goes down), apply thin CA glue to the

joint.

(See photo, top of next page.)

21

Page 22

D 4. Carve and sand the wing tip to blend in with

the

tip rib, L.E. and

T.E.

D 5. Sand the front and rear comers to a rounded

shape as shown on the plan. Also sand the top and

bottom edges to a slightly rounded shape.

SAND THE WING SMOOTH

D 5. Apply thin CA glue around the edges, holding

the plates firmly in place until the glue sets.

TRIAL FIT THE WING IN THE SADDLE

D 1. Using your T-bar sander, sand the inside edge

of the plywood fuse side doublers at the same angle

as the F-2A or F-2B formers.

D 2. Lay the wing in place on the fuselage with

the T.E. resting against the front of F-3.

D 3. Notice that the center of the wing L.E. rests

on the top rear portion of the windshield, preventing

the wing from resting down onto the fuse sides. Mark

the area of the windshield that needs to be cut away.

D 1. Lightly sand the entire wing with your T-bar

and 100 grit sandpaper. Pay special attention to

blending the ribs in with the leading and trailing

edges and spars and removing any excess glue residue that would cause bumps when the covering is

applied later.

D 2. Now lightly sand the wing again with a Tbar and 220 grit sandpaper. After this step, the wing

should be very smooth and ready for covering.

INSTALL THE WING PLATES

D 1. Find the two pieces of 1/32" x 3/4" x 1-1/2"

plywood. These are the "Wing Plates" which protect

the trailing edge at the points where the wing hold

down rubber bands are fastened.

D 2. Working on the table edge, use a sanding block

to "feather" (taper) the edges of the wing plates.

Feather three edges of each plate, leaving one long

edge square.

D 3. Make marks on the T.E., 1" each way from the

wing centerline.

D 4. Put the wing plates in position on the T.E.

The edge of the plate that is not feathered goes to

the rear along the trailing edge. The 1" marks you

made in step 3 are where the plates begin.

D 4. Using an X-Acto knife and a sanding block,

carefully remove part of the windshield, a little at

a time, until the wing rests down flat on the fuse

sides. You may have to cut into F-2 slightly.

D 5. Find the two 5/16" diameter hardwood wing

hold down dowels that are 5-3/16" long. Round the

ends of these dowels slightly with sandpaper.

D 6. Insert the dowels into the holes in the fuse

sides. Enlarge the holes with a round file or drill, if

necessary.

22

DO NOT GLUE THE DOWELS IN PLACE

UNTIL AFTER THE FUSELAGE HAS BEEN

COVERED.

Page 23

D 7. Attach the wing to the fuselage with eight

#64 rubber bands. The bands should all be passing

over the plywood wing plates on the trailing edge ,

and the wing should be resting firmly down on the

fuselage sides.

D 8. With the wing attached to the fuse, and the

fuse bottom resting on a flat surface, measure from

both wing tips down to the flat surface. If the measurements differ by more than 1/8" , sand the wing

saddle area (a little at a time!) until the two measurements are nearly the same.

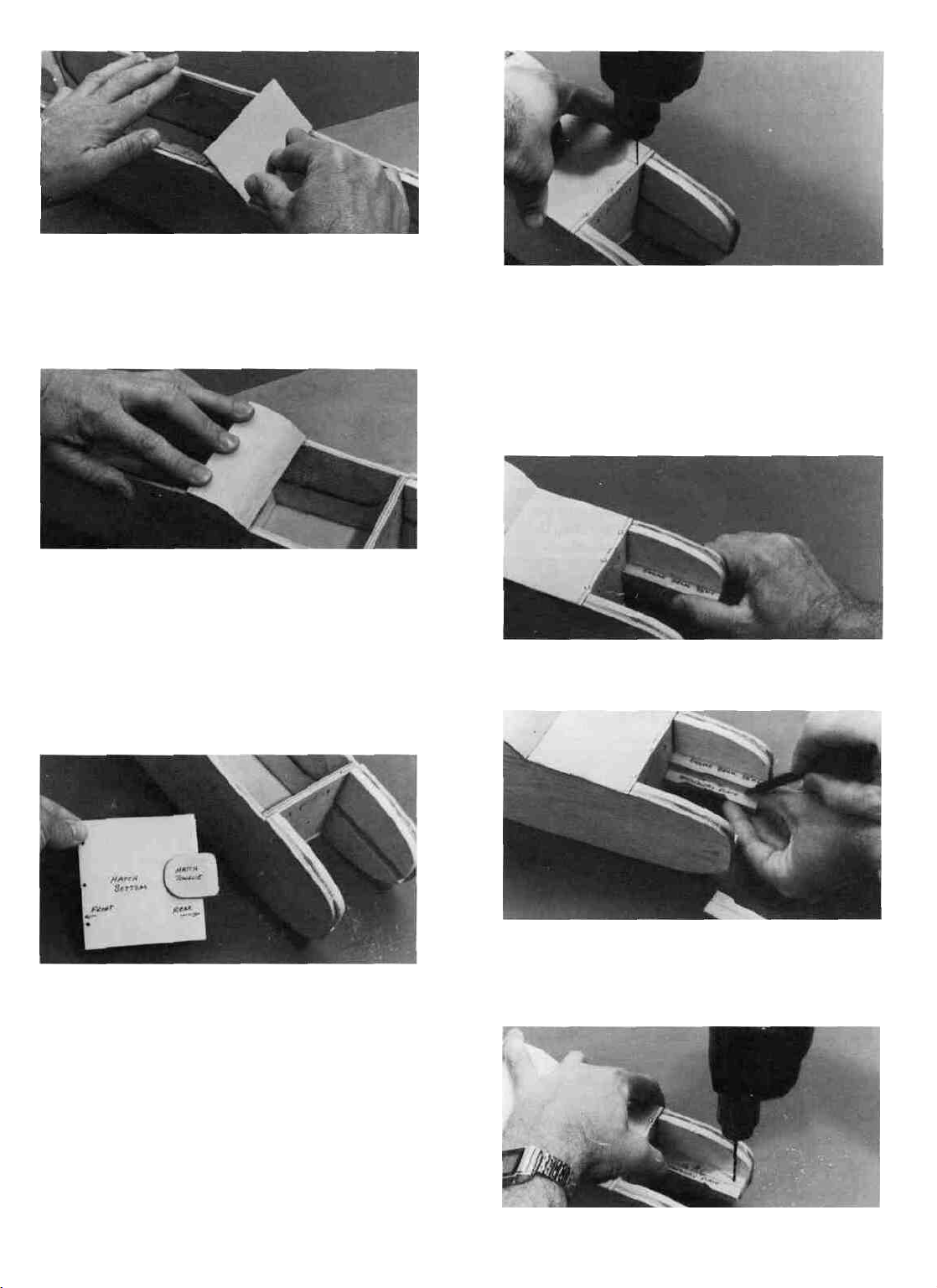

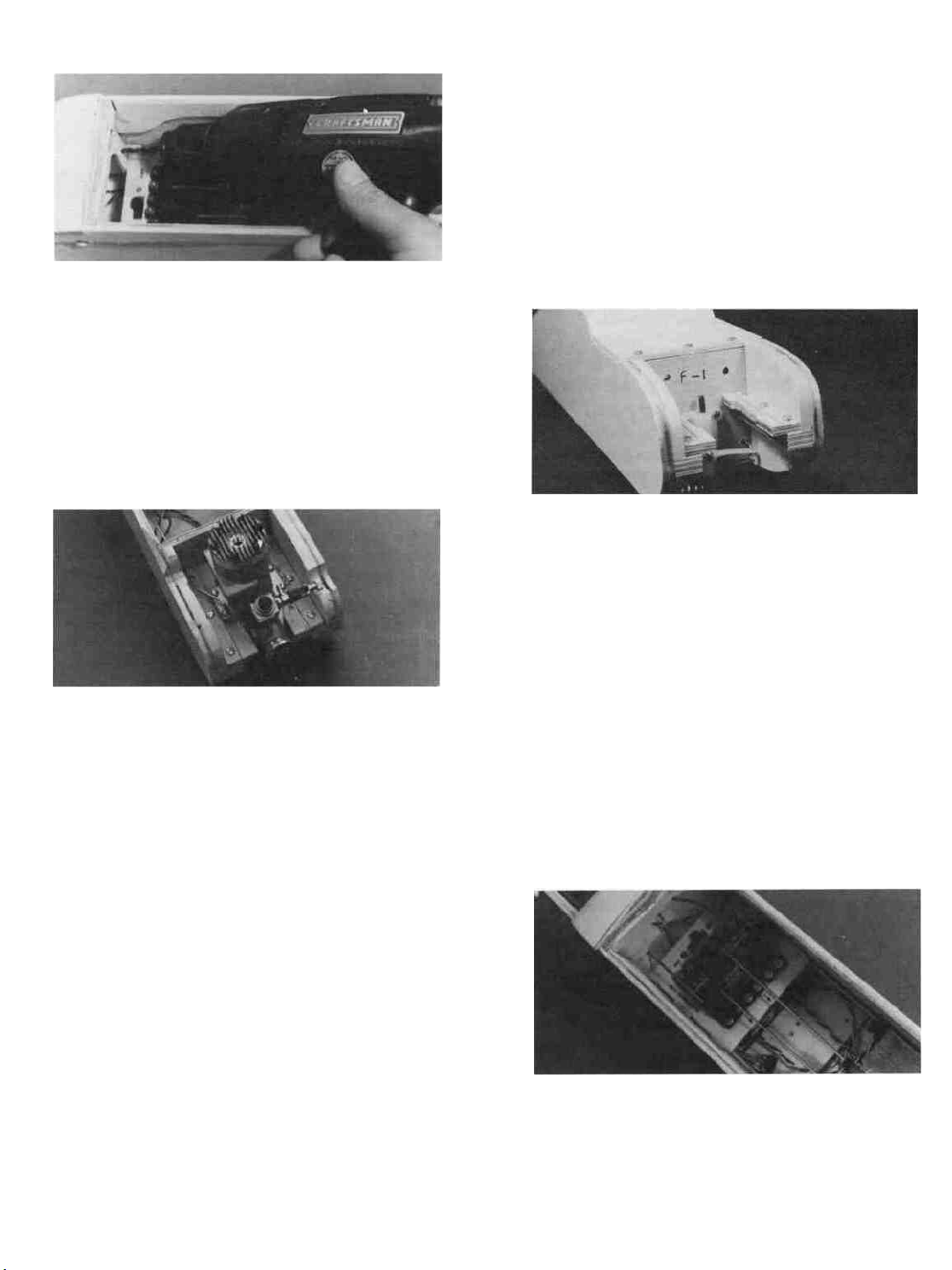

MOUNT THE ENGINE

Note: There are many different engines that

will be OK for mounting in the PT40 and the engine

mounting system that is used makes it possible for

you to install any engine you choose as long as it is

within the following range: .25-.40 2-cycle, or .35-.45

4-cycle. The following photos show installation of the

O.S. Max .40 FP engine. The plans also have draw-

ings of the K&B .40 (2-cycle) and the O.S. Max .40

FS (4-cycle). Depending on your engine, you may have

to use a slightly different method to end up with a

good solid mount. If you have any trouble, be sure to

ask an experienced model builder for assistance.

D 1. You should already have the breakaway plates

screwed (but not glued) to the engine beams. The

breakaway plates have also been cut out so your en-

gine can fit down between them. If not, do so now.

D 4. Remove the muffler and again put the engine

in place on the breakaway plates. This time, however,

you must carefully position the engine so it is pointing straight ahead. Also, the engine must be far

enough forward to allow the propeller to turn freely

without touching the front of the fuse sides.

D 5. Holding the engine in this position, use a pencil to mark the location of the engine mounting holes

on the breakaway plates. Note: For this step, it is

helpful to have a "mechanical pencil" with the lead

extended, which enables you to mark straight down

through the engine mounting holes.

D 6. Drill 1/8" holes through the breakaway plates

at the marked locations.

D 7. Install 4-40 blind nuts in the bottom of the

holes you just drilled, as follows:

D 2. Put the engine in place on the breakaway

plates. Mark the area of the fuse side that must be

cut away to clear the needle valve. Cut this area away

now, using a round file, Dremel Moto Tool or a small

saw.

D 3. Now install the muffler onto the engine, put

the engine in place on the breakaway plates, mark

and cut away enough of the fuse side to provide clearance for the muffler.

23

A-Push the blind nut in part way with your

finger.

B- Apply a drop of thick CA around the base

of

the

nut.

C- Immediately squeeze the nut in, using a

pliers or a vise.

Page 24

D 8. Screw the breakaway plates down tightly to

the engine beams, and notice two things...

A-Looking at the bottom, do the blind nuts extend into and between the breakaway plate and the

engine beam?

B-Do the blind nuts stick out into the area

where the engine goes, preventing the engine from

being lowered into place?

vos without first checking to determine which direction the servos rotate. After the installation has been

completed , the modeler merely flips the switches on

the transmitter to make the servos rotate in the desired direction. Many of the older systems, however,

do not have servo reversing...instead they include one

or two "reverse" or "left-handed" servos which rotate

in a direction opposite that of the other servos. When

installing the servos from a system that does not

have servo reversing, you must plan ahead to use

the "reverse" servos where they are needed.

D 1. Prepare the servos (3 are required if you built

Wing A, 4 if you built Wing B) by installing the four

rubber grommets into each servo, then inserting the

brass eyelets up into the grommets.

D 2. Place the servos in the 1/8" plywood servo tray

provided, and space them out so they are not touching

each other or the sides of the opening.

D 9. If your answer to A is yes, remove the breaka-

way plates and carefully cut away the top layer of

plywood on the engine beam, in the area where the

blind nut was hitting.

D 10. If your answer to B is yes, use a flat file to file

away the portion of the blind nut that is sticking out

into the engine area.

D 11. Now re-install the breakaway plates. Then

mount the engine to the breakaway plates with the

four 4-40 bolts provided. Note: Later when you install

the engine the final time (before flying), make sure

you slip the small lockwashers on the 4-40 bolts

before mounting the engine.

INSTALL THE SERVOS

Note: The following instructions and photos de-

scribe how to install Futaba S-28 servos in your PT40.

If your radio equipment is different from that shown

in the photos, you may have to use a slightly different

method to mount your servos properly. Be sure to

read the instruction manual for your radio before

beginning this section. If you have difficulty with the

radio installation, ask an experienced model builder

for assistance.

SPECIAL NOTE: Most radio systems sold

today have "servo reversing switches" on the trans-

mitter, which enable the modeler to install the ser-

D 3. Holding the servos in place, use a pencil to

mark down through the brass eyelets onto the

plywood. Remove the servos and drill 1/16" holes at

each of the marks.

D 4. Insert the switch into the slot provided in the

servo tray and mark the locations of the screw holes.

Drill 3/32" holes for the switch mounting screws. Reinstall the switch. Note: Install the switch such that

sliding the switch toward the right fuselage side

turns the radio off.

D 5. Place the plywood servo tray into the fuselage

to rest on top of the lower portion of the plywood fuse

side doublers in the position shown on the plan.

Check to determine how it fits. Note that the switch

slot should be in the front. Sand the sides of the servo

tray if necessary for a good fit between the balsa fuse

sides.

SPECIAL NOTE : If your battery pack is the flat

type (as shown on the fuse plan side view), it will fit

nicely under an 8 oz. fuel tank in the front compartment. If your battery pack is the square type you

will either have to use a 6 oz. fuel tank or place the

battery behind F-2. If this is the case, allow room

for the battery behind F-2 by mounting the servo

tray 1-3/4" behind F-2.

D 6. Remove the tray. Apply 5- minute epoxy to

the top of the lower portion of the plywood fuse side

doublers where the tray will rest, then lay the servo

tray in place and allow the epoxy to harden.

24

Page 25

D 7. "Lock" the servo tray in place by gluing a few

scraps of 1/8" ply (from the die- cutting scrap) to the

fuse side and the top of the servo tray using thick

CA as shown here.

D 8. Put the servos into the tray and screw them

down with the screws provided with your radio.

Tighten the screws "finger tight , not wrench tight".

D 9. Make a single servo mount as described below,

for the aileron servo. This is only required for Wing

B. If you built Wing A, skip to the next section.

From 1/8" plywood die-cutting scraps, cut one

piece 1-1/8" wide x 2-7/16" long. Also cut two pieces

3/8" wide x 1-3/16" long, with the wood grain running

the long way. From the 3/8" x 5/8" x 2-1/2" balsa provided, cut two triangular servo rail braces. Use the

pattern shown here:

D 13. Screw the aileron servo to the mount using

the screws provided with your radio.

INSTALL NYLON CONTROL HORNS

D 1. Find the set of two nylon control horns and

cut them apart with an X-acto knife. Also find the

four 2-56 screws that are 5/8" long.

Glue the above five parts together to make the

single servo mount. Study the plan to see how they

go together.

D 10. While holding the servo in place on the rails,

mark the location of the four mounting holes through

the brass eyelets onto the plywood. Drill 1/16" holes

at these marks.

D 11. Attach a large servo wheel to your 4th servo.

D 12. Determine from the plan (See the "Bottom of

Wing" detail) exactly where this aileron servo mount

should be located. Lay the mount in place on the

bottom of the wing and using a felt-tip marker, draw

a dark line around the base of the servo mount. DO

NOT GLUE THE SERVO MOUNT TO THE WING

UNTIL AFTER COVERING.

2-56 x 5/8" SCREW

D 2. Remove the rudder and elevator from the fin

and stab. Remove the hinges.

D 3. Lay the rudder on the fuselage plan side view

and determine where the nylon control horn should

be located. Holding one of the nylon horns in place

on the left side of the rudder, use a pencil to mark

through the holes in the horn.

D 4. Drill 3/32" holes through the rudder at the

marks you just drew.

D 5. Repeat steps 3 and 4, locating and drilling

holes in the elevator. Note: When marking the lo-

cations for drilling, you must hold the nylon horn

on the BOTTOM of the elevator!

25

Page 26

D 6. Temporarily mount the control horns on the

rudder and elevator. (Note that the elevator horn is

mounted on the bottom, and the rudder horn is

mounted on the left side.) To do this, insert two 2-56

screws through the holes in the horn and through

the holes you drilled. Then screw them into the nylon

"nutplate" which originally came attached to the

horn.

D 7. Re-install the rudder and elevator onto the fin

and stab, but do not glue in the hinges.

PUSHRODS

D 6. Take one of the 12" threaded wires, attach a

clevis and bend the wire to match the drawing of the

elevator rear pushrod wire (top view). At the front

end of this wire drawing, note that the wire makes

a 90 degree bend and goes into the dowel. Make this

bend now, and cut the wire off.

D 1. Get the following parts together before starting:

2- 1/4" diameter hardwood dowels, 25" long

6- 12" long wire, threaded one end

2- small nylon aileron clevis connector

2-

nylon aileron clevis

4- standard nylon clevis

10 feet of kite string or strong thread (not

supplied)

D 2. Write "elevator pushrod" on one of the 1/4" x

25" dowels, and "rudder pushrod" on the other.

D 3. Lay the elevator pushrod dowel on the fuselage

top view. Note that the front pushrod wire attaches

to the top of this dowel, and the rear wire attaches

to the right side. To avoid confusion later, draw lines

l-3/8"long on the dowel where the wires will be at-

tached.

D 4. Use the threaded end of one of the wire push-

rods to "file" grooves in the dowel where you drew

the lines. The grooves need not be deeper than 1/2

the thickness of the wire.

D 7. Round both ends of the dowel slightly to help

prevent the possibility of it "hanging up" on something.

D 8. With 100 grit sandpaper, roughen the end of

the wire that will be glued to the dowel.

D 9. Insert the wire into the hole and the groove

in the dowel. Apply a couple drops of thin CA to hold

in place.

D 10. Wrap kite string or strong thread around the

wire and dowel as shown on the plan, then apply

thick CA onto the string.

D 11. After cutting the pushrod wire to length in

step 6, you should have a straight piece of wire remaining that has a length of about 6-1/2 inches. Make

a short 90 degree bend in one end of this rod.

D 12. Roughen the end of the rod near the bent end

using sandpaper.

D 13. Insert this rod into the hole and groove in the

front end of the elevator pushrod dowel, wrap with

thread and apply thick CA.

D 5. Drill 5/64" holes through the dowel, 1-3/8" in

from each end, at the end of the grooves you made

in step 4.

26

D 14. Following a similar method as given in steps

3-13, make the "Rudder Pushrod". Note that the

groove in the front of the rudder pushrod is on the

top of the dowel while the groove in the rear is on

the left.

D 15. Remove the nylon clevises from the rear ends

of the elevator and rudder pushrods.

D 16. Insert the pushrods into the fuselage through

the openings in Formers 3-6 and out through the

slots in the fuse sides that you previously cut.

Page 27

D 17. Screw the nylon clevises back on the rear ends

of the pushrods. Pry the clevises open with a screw-

driver and hook them up to the outer holes in the

nylon elevator and rudder horns. Twist the pushrods

slightly, so the rods come out of the fuse side slots

without binding.

D 18. Temporarily hook up the receiver, battery

pack, switch and servos. Read the instruction man-

ual for your radio to learn how to do this.

D 19. Center the "trim tabs" on your radio transmitter for the elevator, aileron and rudder controls. The

trim tab for the throttle should be pushed all the

way forward.

D 20. Turn on the transmitter and receiver so the

servos rotate to their normal "centered" positions.

Now turn off the receiver and transmitter (in that

order).

D 21. With the rudder centered (straight with the

fin) lay the front part of the rudder pushrod across

the hole in the servo wheel where it will attach. Using

an indelible marker, make a small mark on the push-

rod at the hole location.

B-Bend up with pliers.

C-Finish Z-bend.

D 24. Now you may re-install the pushrods and insert the Z-bends into the servo wheels. Note: To do

this you must remove the servo wheel from the servo,

drill out the hole in the servo wheel to 5/64" diameter,

work the Z- bend into the hole, and replace the servo

wheel on the servo.

D 25. Turn the radio on, and check the movement

of the elevator and rudder. To re-center the elevator

and rudder, turn the clevis on the rear end of the

pushrod.

D 22. Center the elevator and mark the pushrod

where it goes across the hole in the elevator servo

wheel.

L_] 23. Remove the elevator and rudder pushrods from

the fuselage and make "Z"-bends in the pushrods at

the marks you just made. Here's how...

A-Bend down with pliers.

D 26. From die-cutting scrap, cut two pieces of 1/8"

plywood 1/4" wide and 2-3/4" long. Glue these "pushrod braces" to the front of F-4, above and below the

pushrod dowels, as shown in the drawing of F-4 on

the bottom of the fuse plan.

D 27. To provide adequate movement to move the