Page 1

NOTE – The rubber grommets are designed to absorb the

vibration energy from your engine. It is normal for them to

wear during usage.You should inspect the grommets for

excessive wear after the first five hours of operation and

every ten hours

thereafter (more often if excessive wear is

noted).

Replacement grommets are available at minimal

cost. You should replace the grommets when wear

becomes noticeable.

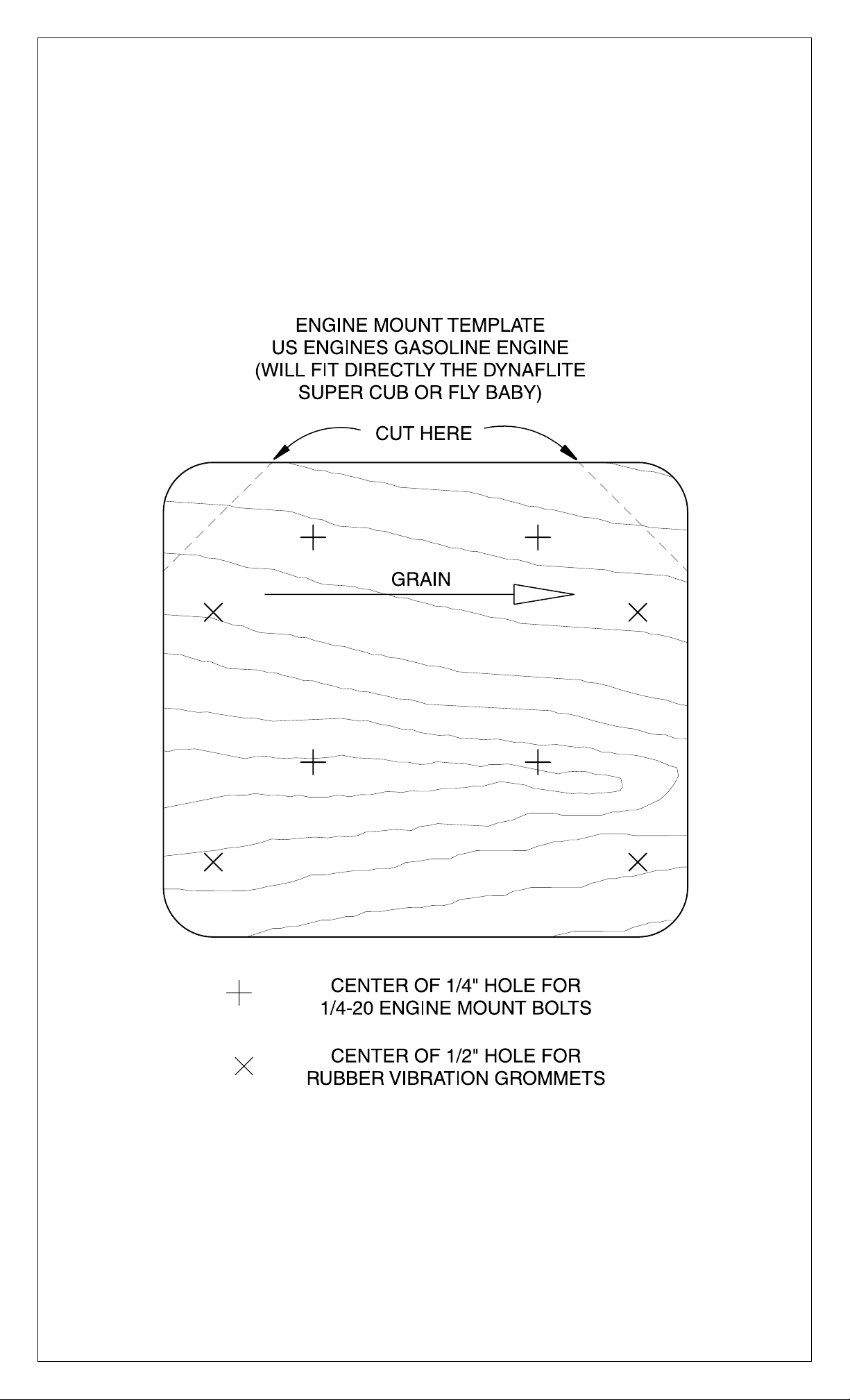

PREPARE THE ENGINE MOUNT:

❏

1.The 1/4" Birch Ply Mount has been designed for use

with a variety of models & engines.It ma y be necessary to

modify it for your particular application. For example, the

dashed lines on the upper corners of the enclosed

template, show where to cut off material to fit the

Dynaflite

™

Super Cub or Dynaflite Fly Baby.

❏ 2. Compare the Ply Mount with the side and top views

of the fuselage plan to determine if you will need to trim

the height or width of the mount, BUT DO NOT CUT

IT YET.

❏ 3. Using the SIDE VIEW of the fuselage, place your

engine at the proper location and orientation. Be sure to

align the

center of the crankshaft with the thrust line shown

on the

plans. Place the Ply Mount against the back of the

engine.Move the Ply Mount up or down to obtain the best

location for mounting it to the fuselage. Mark the Ply

Mount for the vertical height of the engine mounting bolts.

Also, mark the location of the Ply Mount on the firewall.

❏ 4. Use the TOP VIEW of the fuselage to place your

engine at the proper location and orientation. Be sure to

align the center of the crankshaft with the thrust line

shown on the plans, noting any thrust angle.Place the Ply

Mount against the back of the engine.Mo v e the Ply Mount

left or right to obtain the best location for mounting it to the

fuselage. Mark the Ply Mount for the horizontal location

of the engine mounting bolts. Also, mark the location of

the Ply Mount on the firewall.

❏ 5. Mark the center line locations of the holes to be

drilled for the engine mount bolts, BUT DO NOT DRILL

THEM YET .

❏ 6. Determine how you will mount the Ply Mount to the

aircraft firewall, keeping in mind that the grommets will

cause the Ply Mount to be spaced 1/4" from the firewall.

On Many airplanes it will simply be a matter of bolting it

directly to the firewall with the supplied bolts. On others

you may need to build spacers onto the firewall. If you

have not yet mounted the firewall in the aircraft, you may

be able to adjust it to better fit the Ply Mount.

MOUNT THE ENGINE TO THE PLY MOUNT:

You are now ready to drill the engine mounting holes in

the Ply Mount. Remember the old carpenters saying ‘Measure twice, cut once’.

❏ 1. Dr ill 1/4" holes at the locations you marked for the

engine bolts.

❏ 2. Mount the engine to the Ply Mount using 1/4-20 x 1" bolts

and 1/4" flat washers (Not Supplied).

MOUNT THE ENGINE AND PLY MOUNT TO THE

FIREWALL:

You must now determine where to drill the holes for the

mounting bolts. When doing so, keep in mind the

clearances needed for the rubber grommets.If your mount

comes with pre-drilled holes, skip to Step 4.

❏ 1. Place the Engine/Ply Mount on the firewall using the

reference marks you made earlier.The Ply Mount will not

fit directly against the firewall as the engine mounting bolts

are on the rear of the Ply Mount.

❏

2. Referring to the plans, double check the location

again.

Determine the best location for the mounting bolts,

then mark the Ply Mount for the mounting bolts. Remember

that the rubber grommets will be mounted to the front and

rear of the Ply Mount and could conflict with parts of the

engine. Also keep in mind any parts of the airplane

structure that could conflict with the mounting bolts or

blind nuts.

❏

3. Drill 1/2" holes in the Ply Mount at the locations you marked.

❏ 4. Install the eight rubber grommets in the Ply Mount.

Place the Engine/Ply Mount back on the firewall and mark

the location of the holes to be drilled in the firewall.

❏

5. Drill 5/16" holes in the firewall at the locations you

marked. Install the 1/4-20 blind nuts in these holes.

NOTE - The engine bolt heads on the rear of the Ply

Mount

will touch the firewall.Mark the firewall where the

bolt heads

touch.

❏

6.You will need to cut or drill clearance holes where the

engine bolts touched the firewall. Either partially dr ill into

the firewall with a 1/2" drill or use a Dremel

®

MultiPro™tool

to hollow out a clearance area.

❏ 7.Bolt the Engine/Ply Mount to the firewall using the

1/4-

20 x 1-1/4" bolts and 1/4" flat washers. If you had to

install spacers on the firewall, you may need to obtain

longer bolts.

ENGINE SIDE VIEW

Parts List

Part# Qty. Description

PLYS018................(1)............................1/4" Birch Ply Mount

SUB2000 ..............(1)..............................Hardware Subpack

Hardware Subpack (includes the items listed below):

SCRW114 ............(4) ............................1/4-20 X 1-1/4" Bolt

WASHER03 ..........(4)..................................1/4" Flat Washer

NUTS020 ..............(4) ................................1/4"-20 Blind Nut

RBUSH01..............(8) ..................................Rubber Bushing

Large Engine

Isolation Mount

™

ASSEMBLY INSTRUCTIONS

Great Planes Model Manufacturing

P.O.Box 788

Urbana, Illinois 61803

(217) 398-8970

© 1997 V1.2

The Large Engine Isolation Mount™provides a simple

but effective w a y to mount your large gas or glo w engine.

It is effective at dampening normal engine vibration,

which in turn will extend the life of both your airplane and

your radio system. It will also effectively reduce noise

due to vibration.

Caution – Proper balancing of your propeller is

essential. This engine mount system WILL NOT

compensate for an out of balance propeller. The rubber

grommets are designed to work under normal engine

vibration and will be quickly damaged under heavier

than normal vibration.

Printed In USAGPMG2000P01

Page 2

Loading...

Loading...