Page 1

WARRANTY

Great Planes

®

Model Manufacturing Co. guarantees this kit to be free from defects in both material and workmanship at the date of

purchase. This warranty does not cover any component parts damaged by use or modification. In no case shall Great Planes'

liability exceed the original cost of the purchased kit. Further, Great Planes reserves the right to change or modify this warranty

without notice.

In that Great Planes has no control over the final assembly or material used for final assembly , no liability shall be assumed nor accepted

for any damage resulting from the use by the user of the final user-assembled product. By the act of using the user-assembled product,

the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to return this

kit immediately in new and unused condition to the place of purchase.

READ THROUGH THIS MANUAL BEFORE

STARTING CONSTRUCTION. IT CONTAINS

IMPORTANT WARNINGS AND INSTRUCTIONS

CONCERNING THE ASSEMBLY AND USE OF

THIS MODEL.

SPELP02 for Kit GPMA0535 V1.0

© Copyright 1999

P.O. Box 788 Urbana, IL 61803 (217) 398-8970

www.greatplanes.com

INSTRUCTION MANUAL

TM

Page 2

WARNING! THIS IS NOT A TOY!

This R/C kit and the model you will build is not a toy! It is

capable of serious bodily harm and property damage. IT IS

YOUR RESPONSIBILITY AND YOURS ALONE - to build

this kit correctly, to properly install all R/C components and

to test and fly the model only with experienced, competent

help in accordance with all safety standards and common

sense as set down in the Academy of Model Aeronautics

Safety Code. It is suggested that you join the AMA to

become properly insured before you attempt to fly this

model. IF YOU ARE JUST STARTING R/C MODELING,

CONSULT YOUR LOCAL HOBBY SHOP OR WRITE TO

THE ACADEMY OF MODEL AERONAUTICS TO FIND AN

EXPERIENCED INSTRUCTOR IN YOUR AREA.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

Thank you for purchasing the Great Planes SPIRIT ELITE

sailplane. Soaring offers a freedom that no other type of

flying can provide! With a little practice and some help from

mother nature, you will be able to defy gravity and enjoy

flights that can last for hours.

The SPIRIT ELITE’S wing uses the SA7035 airfoil at the root

blending to the SA7036 airfoil at the tip. This combination

gives the aircraft a superior Lift to Drag (L/D) ratio with

outstanding performance in higher wind conditions. This

advanced wing design incorporates flaps and ailerons to

provide the ultimate in control when using computer radio

mixing functions.

Take your time and follow directions to end up with a

well-built model that is straight and true.

❏ Radio having at least 4 channels (5 channels required

for crow mixing)

❏ Iron-on Covering Material (2 rolls)

❏ Latex Foam Rubber Padding (1/4” thick) (HCAQ1000)

❏ Hi-start or other Launching Device (DYFP8302)

❏ BB’s or Lead Shot for Balancing

❏ 2 oz. Thin CA Adhesive (GPMR6003)

❏ 1 oz. Medium or Thick CA Adhesive (GPMR6008)

❏ 5-Minute Epoxy (GPMR6045)

❏ Hand or Electric Drill

❏ Sealing Iron (TOPR2100)

❏ Heat Gun (TOPR2000)

❏ Razor Saw

❏ Hobby Knife, #11 Blades

❏ Screw Drivers

❏ T-Pins (HCAR5100)

❏ Straightedge

❏ Sandpaper (coarse, medium, fine grit)*

❏ Easy-Touch™Sander (GPMR6170)

❏ Plan Protector or Wax Paper (GPMR6167)

❏ Lightweight Balsa Filler (HCAR3401)

❏ 10-24 Tap, Tap Wrench

The SPIRIT ELITE kit has two different wing options: a

straight wing or a polyhedral wing. The straight wing is for

the more experienced sailplane pilot. It allows better

coordinated turn efficiency and much better handling in

cross winds. The polyhedral wing has more stability, turns

tighter with rudder, and is generally easier to fly. If you are a

novice sailplane pilot we recommend you build the

polyhedral option.

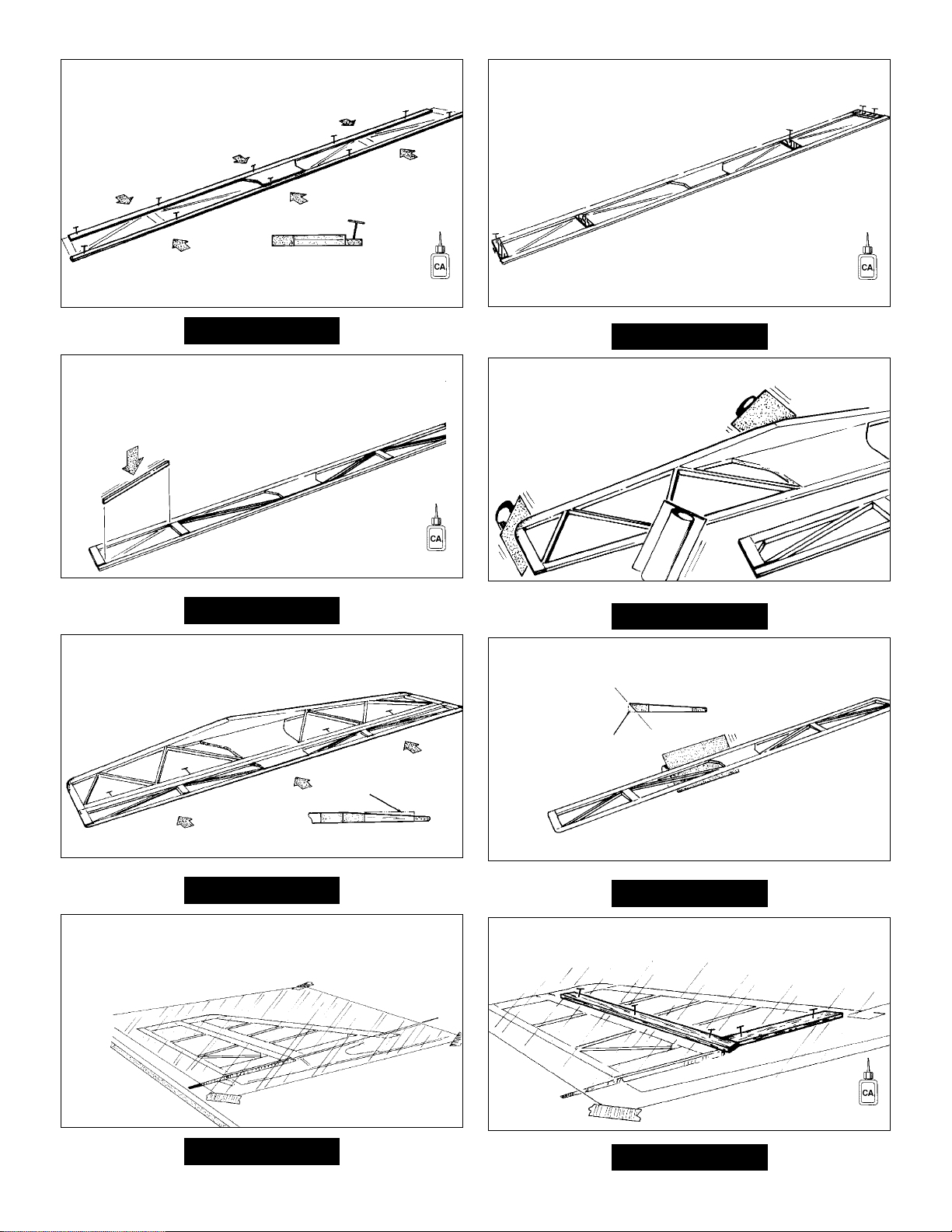

BALSA BASSWOOD PLYWOOD

1. Unroll the plan sheet. Reroll the plan inside out and let it

uncurl. This will help the plan lie flat.

2. Remove all parts from the box. Identify each part by

comparing it with the plan, parts list and die-cut parts page.

Write the part number or size on each piece to avoid

confusion later. Use the die-cut patterns shown on page 3

to identify and mark the die-cut parts.

3. If any of the die-cut parts are difficult to remove, use a

hobby knife to free them. Use your sanding block to lightly

sand the edges to remove any die-cutting irregularities.

Get Ready to Build

Types of Wood

WING OPTIONS

Supplies & Tools Needed

Other Items Required

INTRODUCTION

PROTECT YOUR MODEL,

YOURSELF & OTHERS

2

Page 3

3

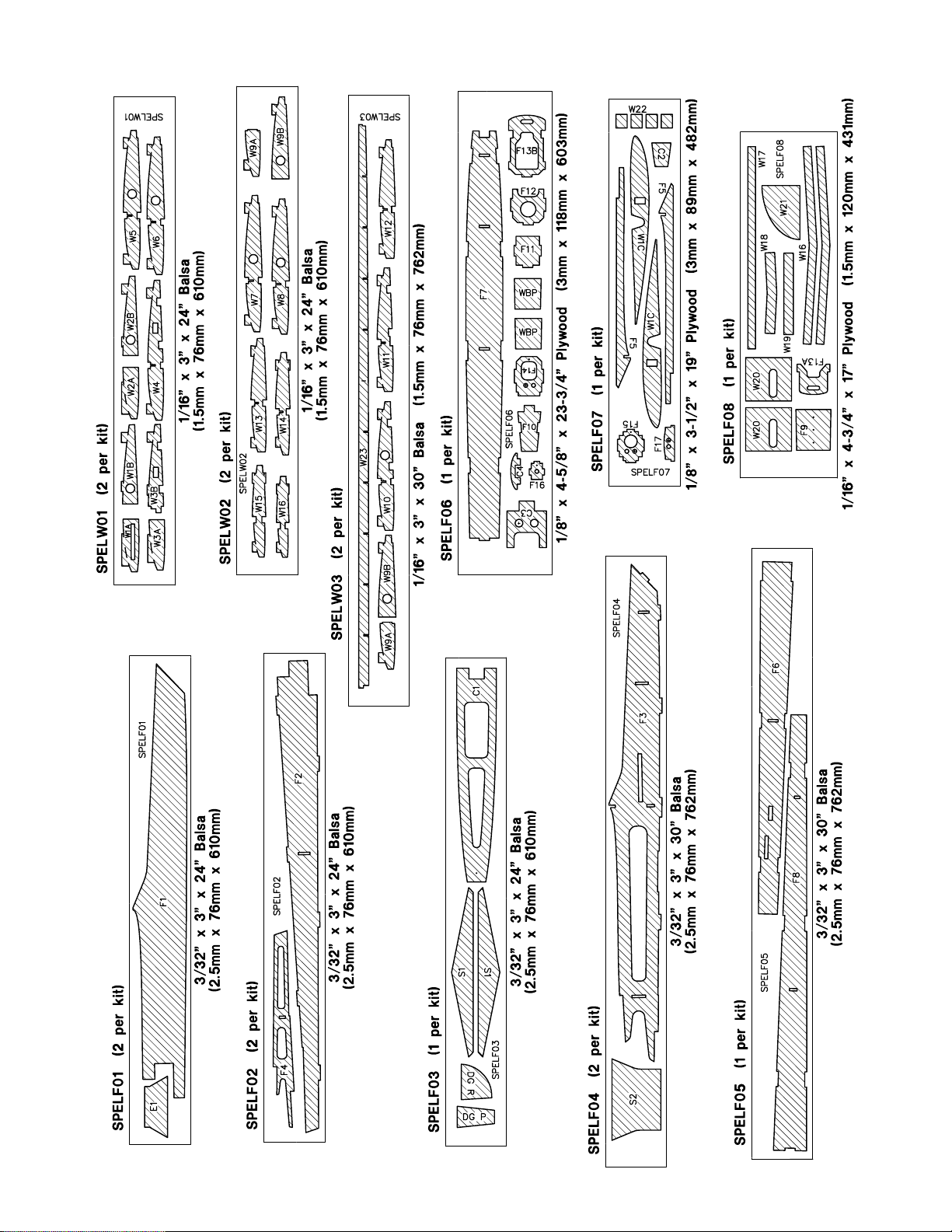

DIE-CUT PATTERNS

Page 4

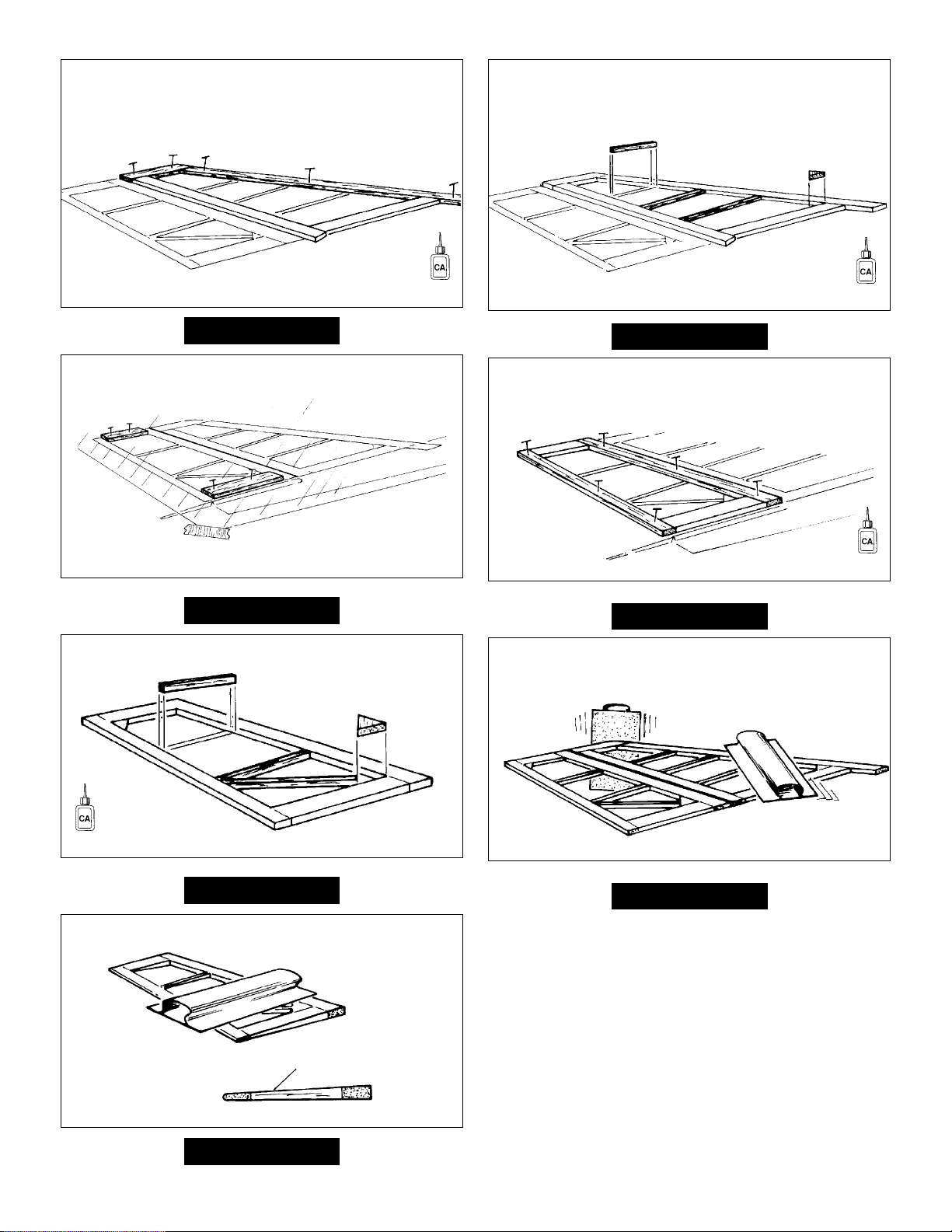

Step 8

Step 6

Step 4

Step 2

Step 7

Step 5

Step 3

Step 1

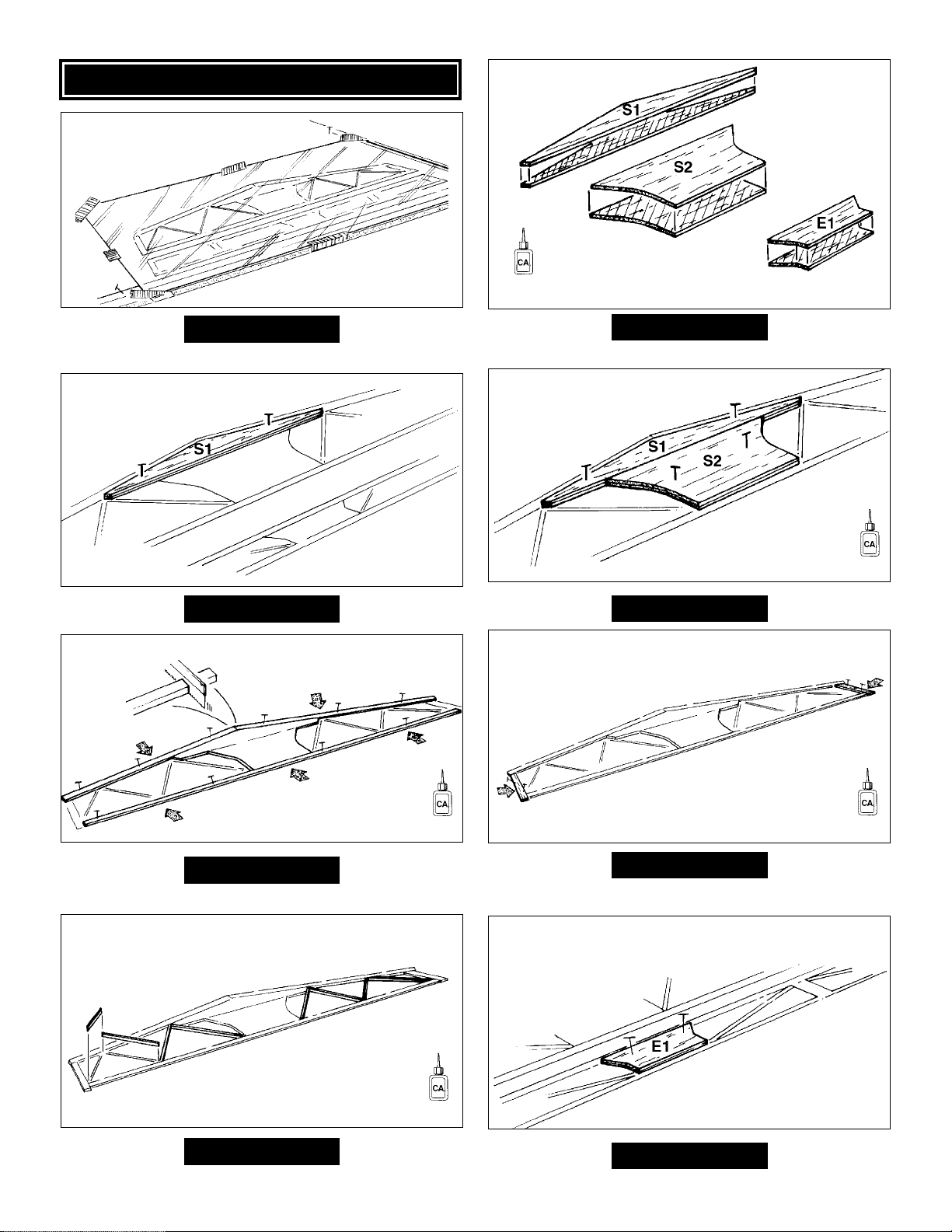

ASSEMBLE THE TAIL

4

Cover the stabilizer and elevator

plan with Great Planes Plan

Protector or wax paper.

Medium

(When you see this symbol use the suggested CA.)

(When you see this symbol use the suggested CA.)

Thin

Thin

Thin

Thin

Page 5

Step 16

Step 14

Step 12

Step 10

Step 15

Step 13

Step 11

Step 9

5

Thin

Thin

Thin

Thin

LE

SAND THE

ELEVATOR

BEVEL THE

LEADING EDGE (LE)

TE

Sand the stabilizer smooth. Round

the leading edge (LE) and tips.

Cover the fin and rudder plan with

Great Planes Plan Protector or

wax paper.

Page 6

Step 22

Step 20

Step 18

Step 23

Step 21

Step 19

Step 17

6

Thin

Thin

Thin

Thin

Sand the fin and rudder smooth.

Round the LE of the fin.

SAND THE RUDDER TO A TAPER

Page 7

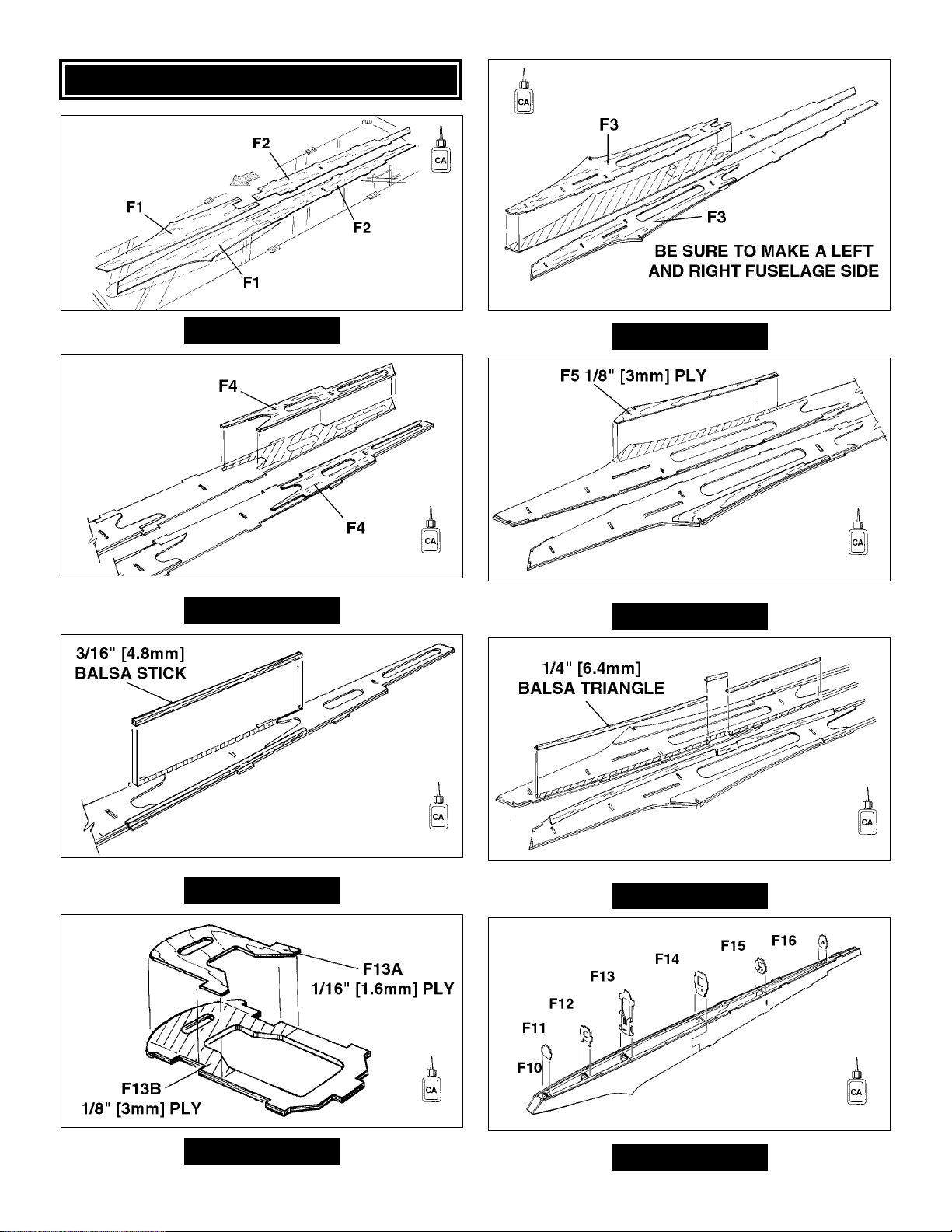

Step 8

Step 6

Step 4

Step 2

Step 7

Step 5

Step 3

Step 1

ASSEMBLE THE FUSELAGE

7

Make sure the pushrod tubes

fit easily into the guide holes

before installing

the formers.

Use rubber bands to

hold everything together.

Thin

Thin

Thin

Medium

Medium

Medium

Medium

Medium

Make sure the fuselage

lines up straight.

Cover the fuselage plan with

Great Planes Plan Protector

or wax paper.

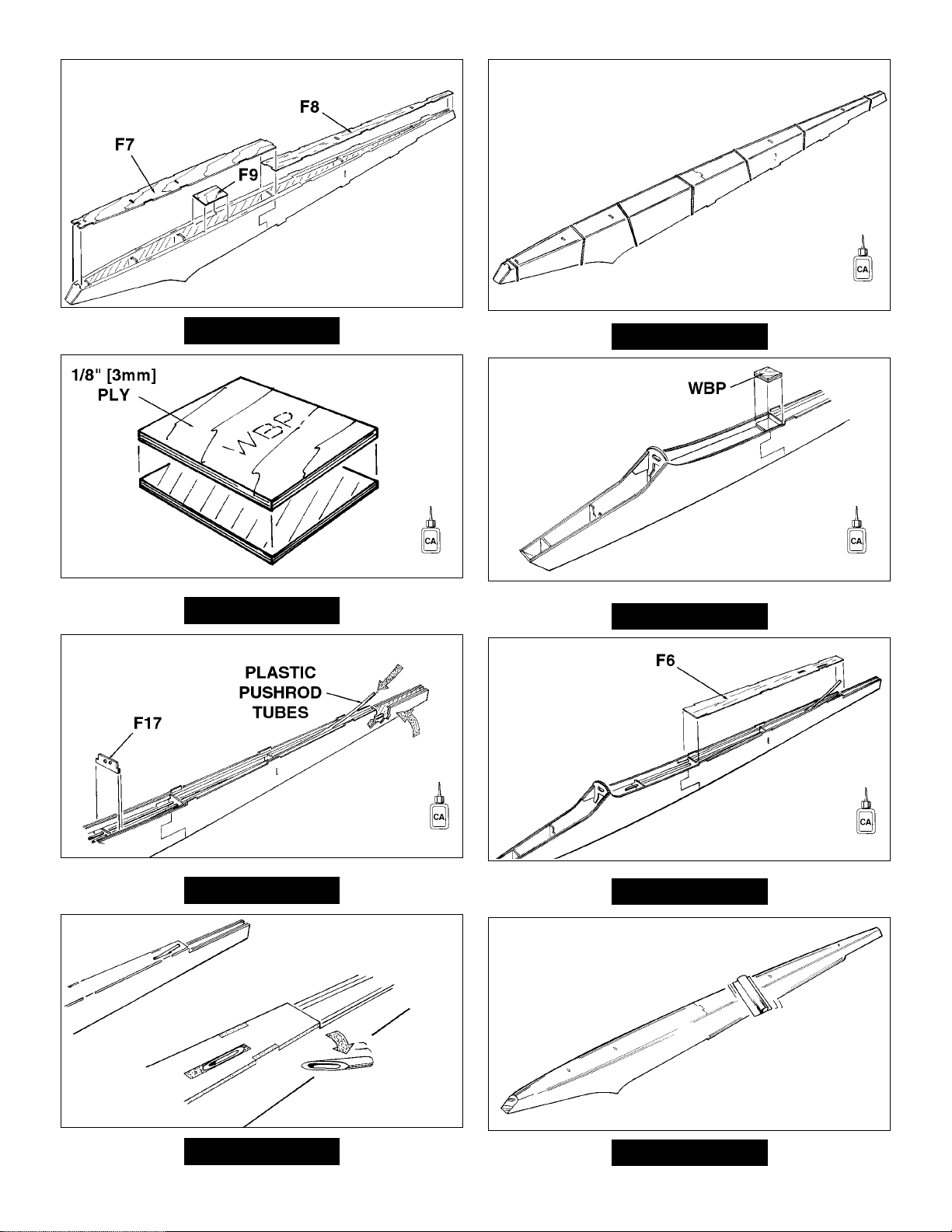

Page 8

Step 16

Step 14

Step 12

Step 10

Step 15

Step 13

Step 11

Step 9

8

Make sure the three punch

marks on F9, face the inside

of the fuselage.

Use rubber bands to hold the

fuselage together. Make sure

the fuselage is straight and

then glue.

Thin

Thin

Thin

Medium

Medium

Make sure the fuselage

is straight before gluing.

Sand entire fuselage smooth.

Round corners as shown on plan.

Trim off excess.

Slide in from back.

Page 9

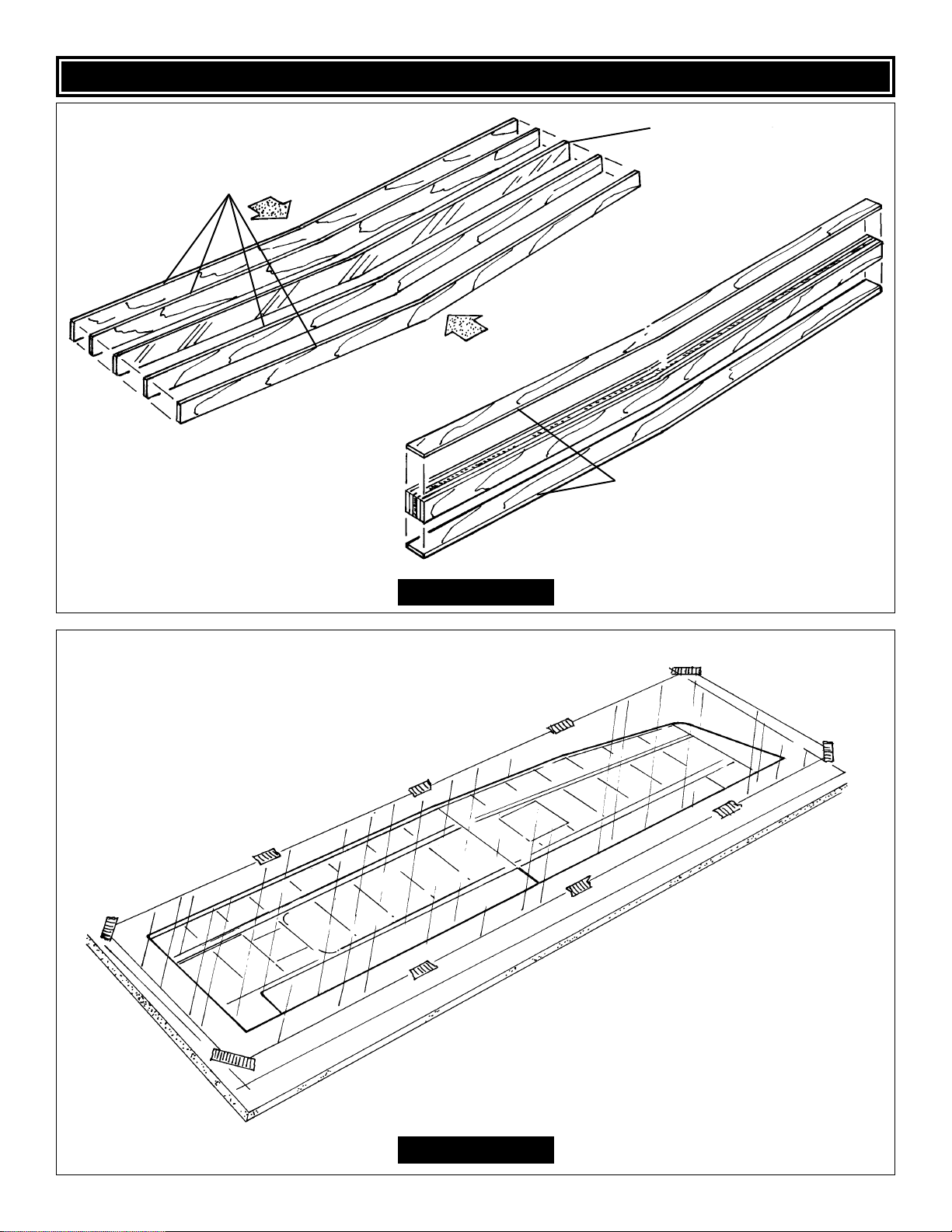

9

Glue and clamp the wing joiner

together using 30-minute epoxy.

Wipe off any excess epoxy before

it cures.

Cover the wing plan with

Great Planes Plan Protector

or wax paper.

1/16" [1.6mm] PLY

WING JOINERS

1/16" [1.6mm] PLY

JOINER CAPS

ALUMINUM JOINER

(Clean with alcohol)

Step 1

Step 2

BUILD THE WING

Page 10

10

1/8" [3.2mm ]

PLY JOINER BOX

W23

Step 3

Step 4

Step 5

Cut the 1/8" x 3/4" x 12-1/2"

[3.2mm x 19mm x 317mm]

plywood to make the joiner

box parts

Position the 1/8" x 5/16" x 40"

[3.2mm x 8mm x 1016mm]

spars over the plan.

Cut the spars at rib 9.

Leave

1/4" [6.4mm]

overhang.

Cut the W23 balsa

shear web at rib 9.

Page 11

11

SPAR

W8

W7

W6

W5

W4

W23

3/16" [4.8mm] SQUARE

BALSA RIB JIGS

W2A

W2B

W3B

W3A

1/8" [3.2mm] JOINER

BOX FRONT

1/8" [3.2mm] JOINER

BOX AFT

Step 6

Step 7

Step 8

Shim the spar up from the

table using 1/16" [1.6mm]

balsa. (Use leftover pieces

from the rib die sheets.)

Use pieces of the 3/16" x 3/16"

balsa sticks as rib jigs to hold

the ribs in place for the steps

that follow.

Clamp the 1/8" [3.2mm] joiner

box front and joiner box aft to

the spars.

Add ribs 2A&B.

Add ribs 3A&B.

BUILD THE

INBOARD PANEL

Thin

DO NOT GLUE THE

JOINER BOX YET!

Page 12

12

70%

ISOPROPYL

ALCOHOL

Step 10

Use 30-minute epoxy to glue the

joiner box to the spars.

Before the glue cures, insert the

wing joiner several times to get a

good fit and to push out excess

glue. When satisfied, pull out the

joiner and wipe clean.

Coat the wing joiner with

isopropyl alcohol so the

epoxy won't stick.

DGR

DGR

W1B

W1A

Align the rib between the

dashed lines on the plan.

Align the rib between the

dashed lines on the plan.

Use the dihedral gauge to

set the angle.

1/16" X 3/8" X 42"

[1.6mm X 9.5mm X 1067mm]

SUB LE

1/8" X 1/2" X 42"

[3.2mm X 12.7mm X 1067mm]

BALSA WING TE

Step 9

Center the TE on the ribs.

Line up the LE.

Step 11 Step 12

Thin

Thin Thin

Page 13

13

1/16" X 3" X 24"

[1.6mm X 76mm X 610mm]

BALSA SHEET

1/16" X 3/8" X 42"

[1.6mm X 9.5mm X 1067mm]

BALSA TE SHEETING

Step 15

The sheeting should line up

with the back edge of the spar.

Make sure the structure stays

flat on the table.

Fill in any gaps with

1/16" [1.6mm] balsa.

Sand the sheeting

so it doesn’t bulge

at the cloth.

3/16" X 3/8" X 5-1/2"

[4.8mm X 9.5mm X 140mm]

BASSWOOD RAILS

2-3/4" [70mm]

2-3/4" [70mm]

Step 16

DGP

W9B

W9A

FIBERGLASS

CLOTH

POLYHEDRAL WING

Use the polyhedral gauge

only if you are building

the polyhedral wing.

Cut the fiberglass cloth into four 4” [100mm] pieces.

Attach part of the fiberglass cloth to the spars

using thin CA. You will finish this

step after you remove the

panel from the table.

STRAIGHT WING

Align ribs W9A and W9B

straight up and down

over the plan.

Step 13 Step 14

Thin

Thin

Medium

or

aliphatic

wood

glue

Medium

Cut the rails in half.

Page 14

14

1/16" X 3" X 24"

[1.6mm X 76mm X 610mm]

BALSA SHEET

W20 1/16" [1.6mm]

PLY HATCH

Step 17

Use the ply hatch as a

template for cutting the

hole for the flap servo.

Cut from 1/16" X 3" X 24"

[1.6mm X 76mm X 610mm]

BALSA SHEET

Step 18

Step 19

Remove the wing from the

table. Cut off the jig tabs

and sand smooth.

Step 20

Wrap the fiberglass cloth tightly around the joiner

box and glue it in place. Cut off any excess.

1/16" X 3" X 24"

[1.6mm X 76mm X 610mm]

BALSA SHEET

Step 21

Glue the top sheeting in place.

1/16" X 3/8" X 42"

[1.6mm X 9.5mm X 1067mm]

BALSA SHEETING

Medium

Medium

Thin

Medium

or

aliphatic

wood

glue

The cloth will cause the

sheeting to bulge. sand the

sheeting to compensate.

Page 15

15

1/16" X 3" X 24"

[1.6mm X 76mm X 610mm]

BALSA SHEET

Step 22

Install the top center sheeting.

Step 23

Sand the root and the

outer ribs smooth.

Bevel the leading edge so the balsa

will follow the shape of the rib.

Cut 2-1/2" [63.5mm] from one of the 1-3/4" x 24"

[44.4mm x 610mm] balsa triangles and glue in

place at the wing root.

Trim off and sand the leading

edge smooth.

Finish the slot in W1A

for the wing dowel.

Epoxy the wing

dowel and W1C

to the wing root.

Step 24 Step 25

Medium

Page 16

16

Step 26

Cut the spars straight with rib 9.

Position the 1/8" [3.2mm]

spars over the plan.

1/8" [3.2mm]

BUILD THE

OUTER PANEL

Step 27

W11

W10

W23

W12

W13

W14

W15

W16

1/16" [1.6mm]

SHIMS

Make rib jigs from

the 3/16" [4.8mm]

square sticks.

Step 28 Step 29

1/16" X 3/8" X 42" [1.6mm X 9.5mm X 1067mm]

BALSA LE

(Left over from the inner panel.)

1/8" X 1/2" X 42" [1.6mm X 9.5mm X 1067mm]

BALSA TE

(Left over from the inner panel.)

Thin

Thin

Page 17

17

Step 30

1/16" X 3" X 24"

[1.6mm X 76mm X 610mm]

BALSA SHEETING

1/16" X 3/8" X 42"

[1.6mm X 9.5mm X 1067mm]

BALSA TE SHEETING

1/16" [1.6mm]

PLY HATCH

Install the servo rails.

Cut from 3/16" x 3/8" x 5-1/2" basswood.

Install 1/16" [1.6mm] balsa sheeting

around the servo hatch.

Step 31 Step 32

Step 33

Cut a small gusset from

3/8" [9.5mm] balsa.

Medium

or

aliphatic

wood

glue

Medium

Thin

Thin

Page 18

18

W9A

W9B

Trim excess sheeting.

Step 34 Step 35

1/16" X 3" X 24"

[1.6mm X 76mm X 610mm]

BALSA SHEETING

Step 36

1/16" X 3/8" X 42"

[1.6mm X 9.5mm X 1067mm]

BALSA TE SHEETING

Step 37

Trim off the excess sheeting

and sand smooth.

Sand the root and

tip ribs smooth.

Thin

Page 19

19

Step 38

Join the tip panel to the root panel

using epoxy and the straight

W19 1/16" [1.6mm] ply joiner.

Sand the root and

tip ribs smooth.

W19

STRAIGHT WING

Step 40

Shape the LE as

shown on the plan.

Glue the 1/4" x 7/16" x 42"

[6.4mm x 11mm x 1067mm]

balsa LE to the wing panels.

Step 39

Join the tip panel to the root

panel using epoxy and the

W18 1/16" [1.6mm] ply joiner.

Use the (DGP) gauge

under the W16 rib to

help set the height.

W18

POLYHEDRAL WING

Page 20

20

Bevel the LE so the balsa will

follow the shape of the rib.

Glue and shape the balsa

wing tip to the tip panel.

Cut 2-1/2" [63.5mm] from a

1-3/4" x 24" [44.4mm x 610mm]

balsa triangle.

Step 41 Step 42

1/16" [1.6mm]

PLY WING BOLT

PLATES

Make an aileron and a flap from the leftover

1-3/4" [44.4mm] balsa triangles. Bevel their

leading edges as shown on the plan.

Step 43

Step 44

Drill two 5/32" [4mm] holes

through the wing and into

the fuselage.

Align the wing to the fuselage.

3/4”

[19mm]

7/16”

[11mm]

Step 45 Step 46

AILERON

FLAP

Medium Medium

Medium

Page 21

21

Carefully tap the two holes. Reinforce the

threads with thin CA and retap.

Enlarge the holes

in the wing.

Step 47 Step 48

10-24 TAP

Build the canopy.

Glue the plywood C2 doubler

to C1 balsa canopy base.

Glue the canopy parts

together. Be carful not to

glue them to the fuselage.

Trim and sand C1 and

C3 to fit your

Step 1 Step 2

C1

C1

C3

C4

C2

Drill a 1/8" [3mm] hole into the nose block. Glue in

the 1/8" x 1" [3mm x 25.4mm] dowel into the canopy

base. Do not glue the dowel to the fuselage.

Step 3 Step 4

BALSA NOSE BLOCK

1/8" [3mm]

DRILL BIT

Medium

Thin

Thin

FINISHING

Page 22

22

Trim the plastic canopy to fit the canopy

frame and fuselage.

Sand the nose block to shape.

(See plan)

Step 5 Step 6

Drill 3 holes in F9 - 1/16"

[1.6mm] ply tow hook mount.

Press in the three

blind nuts.

Step 7 Step 8

SMALL

RUBBER

BAND

4-40 TOW

HOOK

CENTERLINE

MARKING

TOOL

4-40

WASHER

4-40 NUT

# 2 X 3/8" [9.5mm] SCREW

1/8" [3mm]

DRILL BIT

Mark a center

line on the fin

and rudder.

Carefully cut hinge

slots at the locations

shown on the plan.

Cut two 3/4" x 1" [19mm x 25.4mm] hinges

from the 2" x 9" [50.5 x 228.5mm] hinge strip.

Step 9 Step 10

HINGE THE RUDDER

Medium

DO NOT

GLUE

YET.

Page 23

Fuselage and Tail:

1. 1/4” strips at stab as described above

2. Stab bottom

3. Stab Top

4. Fin Left and Right

5. Rudder Left and Right

6. Elevator bottom and top

7. Fuselage bottom

8. Fuselage left and right

9. Fuselage top

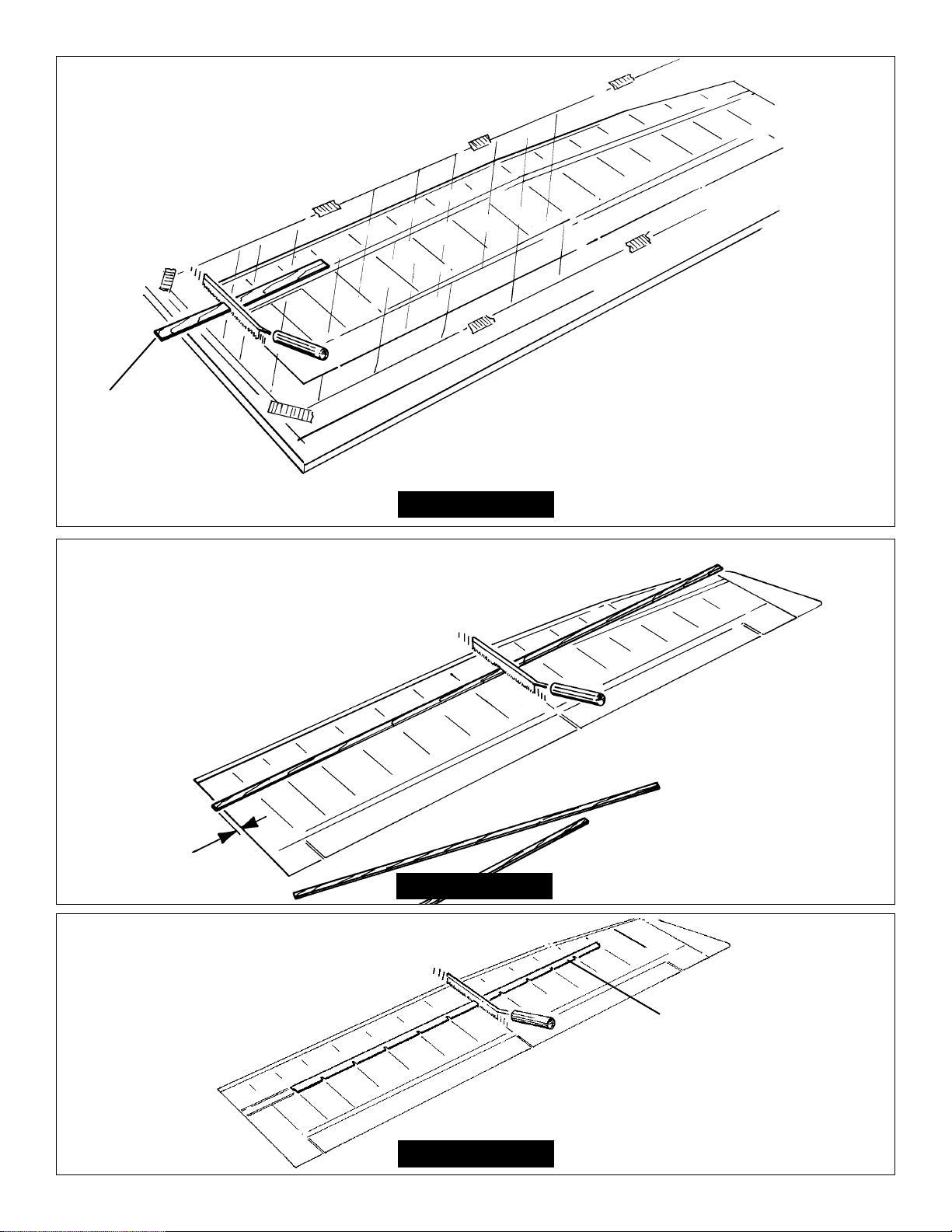

Wing:

1. Ailerons and Flaps bottoms and tops

2. Bottom right, followed by the bottom left

wing panel. (If building the polyhedral wing,

cover the inner and outer panels separately.

3. Top right, followed by the left wing panel.

23

Bevel the leading edge

of the rudder as shown

on the plan.

Hold the flaps and ailerons

in place and mark the

locations for the control

horn plate (W22).

Step 11 Step 12

Step 13

Cut out the balsa and

glue in the W22 ply

control horn plate.

The plate should be

flush with the balsa.

Step 14

Preparing The Surface

Most of the model should be rough-sanded by now, with all edges

sanded and rounded following the cross-section views on the

plans. If not, do so now. Fill all dents, seams, low spots and

notches with HobbyLite

™

balsa colored filler. After the filler has

dried, use progressively finer grades of sandpaper to even and

smooth all the edges, seams and surfaces. Remove all the balsa

dust from the model with compressed air or a vacuum with a brush

and a tack cloth.

Covering Technique

Cover the model with Top Flite MonoKote film, using the

suggested covering sequence that follows.

Some modelers prefer to cover the top and bottom of the ailerons

with one strip of MonoKote film. This is done by covering the bottom

first, then wrapping the MonoKote film up over the leading edge.

Apply 1/4” wide strips of MonoKote film in the corners where the

stab and fin meet the fuselage. Proceed to cover the stab with

pre-cut pieces that meet in the corners and overlap the 1/4” strips.

Never cut the covering on the stab and fin after it has been

applied except around the leading and trailing edges and the tips.

Modelers who do this may cut through the covering and into the

wood. This will weaken the structure to a point where it may fail

during flight.

S

UGGESTED COVERING SEQUENCE

COVERING

Medium

Page 24

24

STAB

ELEVATOR

MONOKOTE OR

STRONG TAPE HINGE

Fold back the elevator and

apply monokote or strong

tape to the underside.

Step 17Step 16

Installing CA Hinges for the Rudder

The Rudder in this kit is attached using two CA hinges

where shown on the plans.

It is best to leave a very slight hinge gap, rather than closing it up tight. This will prevent the Glue from wicking along

the hinge line. Insert a small pin through the center of each hinge to keep the hinge centered while you install the

control surfaces.

Step 15

DRILL A 3/32" HOLE

1/2" DEEP, IN CENTER

OF HINGE SLOT

TEMPORARY PIN

TO KEEP HINGE

CENTERED

ASSEMBLE, THEN APPLY 6 DROPS

OF THIN CA TO CENTER

OF HINGE, ON BOTH SIDES

Page 25

25

MONOKOTE OR

STRONG TAPE HINGE

Use a triangle to align the

fin 90

o

to the stab. Glue in

place with epoxy.

Position the fin so it is straight with the

fuselage. Remove the covering where

the fin rests on the fuselage.

Install the flaps and

ailerons with MonoKote

or strong tape hinge.

Step 20Step 19

# 2 X 3/8" [9.5mm]

FLAT HEAD SCREWS

Cut servo blocks from the 3/16" x 3/8" x 2"

[4.8mm x 9.5mm x 50.8mm] basswood.

Drill small pilot

holes for the

servo screws.

Drill pilot holes

for the screws.

Install the servos

to the blocks.

Cover the hatch

with Monokote.

Glue in place

with Medium

CA or epoxy.

Step 22Step 21

A=A AA

AA

A=A

Step 18

Align the stabilizer so that it is parallel

with the wing.

When satisfied with the fit,

glue in place with epoxy.

Page 26

26

Step 24

1" [25.4mm]

THREADED WIRE

INNER PUSHROD TUBE

NYLON CLEVIS AND

CLEVIS RETAINER

Step 25

1" [25.4mm]

THREADED WIRE

METAL CLEVIS

NYLON BACKPLATE

NYLON CONTROL HORN

2-56 X 3/8" [9.5mm] BOLT

2-56 X 3/8" [9.5mm] BOLT

Wrap the receiver and

battery in foam.

Line up the control horns

with the pushrods. Attach

the control horns to the

elevator and rudder.

Install the switch inside the

fuselage, next to the receiver.

Step 23

Page 27

NOTE: This section is VERY important and must not be

omitted! A model that is not properly balanced will be

unstable and possibly unflyable.

1. The balance point (Center of Gravity) is 3-1/4” (82mm)

from the Leading edge. This is the balance point at which

your model should balance for your first flights. Later, you

may wish to shift the balance up to 1/2”(13mm) behind this

point to change the flying characteristics. Moving the CG

forward will add stability but it will decrease the overall

performance of the sailplane. Moving the balance back

makes the model more agile with a lighter and snappier

“feel” and improves the sailplane’s response to air currents.

However, it will also make the model less stable and can

cause the sailplane to “tuck under” or dive when its flying

speed increases.

2. With the wing attached to the fuse, and all parts of the

model installed (ready to fly), lift the model by picking it up

with your fingertips. If the tail drops when you lift, the model

is “tail heavy” and you must add weight to the nose to

balance. If the nose drops, it is “nose heavy” and you must

add weight to the tail to balance. The model should hang with

a slight nose down attitude. Add BB’s or lead to the nose.

1. The tow hook should be in the front hole for the first

flights. After the first flights the tow hook can be moved back

to the middle hole for most flying conditions. For contest

flying you may want to try the rear hole as it can help

achieve a higher launch. But be careful as the sailplane will

be less stable and more apt to “Pop Off’ the line.

If you are not thoroughly familiar with the operation of R/C

models, ask an experienced modeler to check to see you

have the radio installed correctly and all the control surfaces

do what they are supposed to.

TRIMMING FLIGHTS

It is a good idea to do a couple of trim flights before each

flying session to make sure the plane is still in trim and the

radio is working properly.

Hold the SPIRIT ELITE under the wing with the nose

pointed slightly down and directly into the wind. Launch the

model with the wings level and the nose pointing at a spot

on the ground about 50 feet in front of you. If the sailplane

is launched with the nose up or launched too hard it will

climb a few feet, stall and fall nose first straight down. With

the nose pointed down slightly the sailplane will accelerate

down until it picks up enough flying speed, then level off and

glide forward. Adjust the trims on your transmitter to get the

plane to fly straight ahead in a smooth glide path.

FLYING

TOW HOOK LOCATION

Use these control throws for your first flights.

ELEVATOR: 1/2” (13mm)

RUDDER: 2” (50mm)

FLAPS: 1-3/8” (35mm) down

AILERONS: 3/4” (19mm) up, 3/8”(9.5mm) down

CONTROL SURFACE THROWS

BALANCE THE MODEL

27

Page 28

HI-START LAUNCH

A hi-start is the most common way to launch your SPIRIT

ELITE. Follow the directions that came with the hi-start and

lay it out directly into the wind. Place the stake at the far

upwind edge of the flying field so the parachute will blow

back onto the flying field.

Hook the parachute up to the tow hook. Pull the plane back

approximately twice as far as the rubber is long or whatever

the hi-start instructions recommend.

Hold the plane above your head with the wings level and the

nose pointed slightly up and directly into the wind. Give the

plane a push forward to get it flying and it will climb up like

a kite. You should not have to touch the elevator during the

launch. Use the rudder stick to keep it going straight up.

You will find the ailerons are not very responsive during the

first part of the launch. As the rubber relaxes the plane will

fly off the hi-start.

FIRST FLIGHTS

Use these flights to get the “feel” of the controls and the

SPIRIT ELITE’S flying characteristics. Adjust the trims on

your transmitter (a little at a time) until the plane will fly

straight and level with the transmitter sticks in their neutral

positions. If you built the polyhedral wing, rudder alone is

enough to perform smooth turns. If you built the straight

wing, you will need to coordinate ailerons with rudder for

smooth turns.

The SPIRIT ELITE is a very gentle plane that flys well in

light to moderate winds. Practice coordinating ailerons and

rudder until you can get a tight turn that is relatively flat.

Bank the sailplane with rudder and ailerons first, then add

elevator to pull it around. When setting up to land, point the

nose into the wind just downwind of where you want to land.

Line up with your landing spot and slowly feed in flaps (or

Crow). Add more or less flaps to control your descent angle

and speed so you end up hitting the spot.

There are several types of mixing the Spirit Elite can take

advantage of if you have a “computer radio”.

Launch Camber: Lowering the flaps and ailerons during the

launch will produce a steeper climb giving you better altitude.

A good place to start is about 15 degrees of flap and 5

degrees of aileron drop (The flaps will drop about three times

more than the ailerons). This automatically puts some

washout in the wing which adds stability for arrow straight

launches. If you don’t have a switch for launch camber, just

use the flaps for launch.

Crow: This is used to lose altitude quickly and to control your

glide for spot landings. This mixing is tied to the flap stick

(throttle)and allows the ailerons to come up as the flaps drop.

Be sure to use plenty of aileron differential when using

CROW mixing because the ailerons become less effective at

very high angles of deflection. Also use maximum rudder

coupling at full CROW. If you don’t have CROW capabilities

just use flaps and make sure you have full rudder throw when

the flaps start coming down. It is a good idea to get lined up

on the spot before dropping the flaps very much because the

rudder will become sluggish with the flaps down at slow

speeds. Note: You will need to mix in a little down elevator

with the flaps to keep the plane tracking straight.

Aileron/Rudder Coupling - This is used to allow the

sailplane to make efficient, non-slipping, non-skidding turns.

You will need to experiment to find the proper amount of

throw required to do this but 1” (25mm) of rudder throw at full

aileron is probably a good place to start.

Elevator/Camber Coupling - This is a neat type of mixing

allows the TE (ailerons and flaps) to respond to the elevator.

When properly set up, this can be very useful when floating

around in light air or when trying to thermal very tightly. This

mixing can change the flying characteristics of the plane so

start off small and get used it. A good place to start would be

1/8” (3mm) of TE drop at full up elevator.

Controlling the Wing Trailing Edge (Camber): The wing

camber is usually controlled by a 3-position switch. The traditional

way of setting this switch is to have: the middle position set to

neutral camber, one direction for reflex (the entire TE raises about

1/16”( 1.5mm)) and the other direction for positive camber (the

entire TE drops about 3/32”(2.5mm)). This way of programming

the switch is great for good thermal-days or days with a lot of wind

where you might need the reflex capability for zooming up wind.

The other way we set this switch is to have the “back” position for

neutral camber, the middle position for a slight amount of positive

camber (1/32”(1mm) - 1/16”(2mm)), and the forward position for

more positive camber (3/32”2.5mm - 1/8”(3mm)). The middle

position can be used once good air is located or when trying to

gain a few extra seconds of air time. Normally the L/D will not be

as great as neutral camber but the sailplane will float better. The

forward position is when the sailplane is low and encounters lift,

don’t panic, just hit the switch. The SPIRIT ELITE will really slow

up and will thermal “on a dime”. This set-up is great for duration

type flying without a lot of wind.

ADVANCED FEATURES

28

Page 29

Thermals are a natural phenomenon that happen outside,

by the millions, every single day of the year. Thermals are

responsible for many things including forming several types

of clouds, creating breezes, and distributing plant seeds and

pollen. If you have ever seen a dust devil (which is nothing

more than a thermal that has picked up dust), you have

seen a thermal in action. Their swirling action is very similar

to that of a tornado but much gentler. Most thermals have

updrafts rising 200-700 feet per minute but have been

known to produce updrafts of over 5,000 feet per minute

These strong thermals can rip a plane apart or carry the

plane out of sight before the pilot can get out of the updraft.

Thermals are formed by the uneven heating of the earth and

buildings, etc. by the sun. The darker colored surfaces

absorb heat faster than the lighter colors which reflect a

great deal of the sun’s energy back into space. These

darker areas (plowed fields, asphalt parking lots, tar roofs,

etc.) get warmer than the lighter areas (lakes, grassy fields,

forests, etc.). This causes the air above the darker areas to

be warmer than the air over the lighter areas and the more

buoyant warm air rises as the cooler, denser air forces its

way underneath the warmer air. As this warm air is forced

upward it contacts the cooler air of the higher altitudes and

this larger temperature difference makes the thermal rise

quicker. The thermal is gradually cooled by the surrounding

cooler air and its strength diminishes. Eventually the

thermal stops rising and any moisture contained in the once

warm air condenses and forms a puffy cumulus cloud.

These clouds, which mark the tops of thermals, are usually

between 2000 and 5000 feet high.

As the glider approaches a thermal, the wing tip that

reaches the rising air first will be lifted before the opposite

wing tip. This causes the plane to “bank” and turn away from

where we would like the plane to go. The best way to get

back in is to continue the bank and turn 270 degrees

straight into the thermal.

When you are thermal soaring, try to fly as smoothly and

straight as possible. Trim the plane to fly in a straight line

and only touch the controls when you have to. Watch the

sailplane carefully and it will tell you what it is encountering.

When the sailplane flys directly into a thermal it will either

start rising or stop sinking. Either case is reason enough to

start circling. Fly straight until you feel like you are in the

strongest lift, then fly a couple of seconds farther so your

circle will be centered in the strongest lift. Thermals travel

with the wind, so be careful that you don’t get too far

downwind that you can’t get back. If you find yourself getting

too high, don’t dive the plane to get out of the lift. Sailplanes

are very efficient aircraft and they will build up a lot of speed

and could “blow up” in the rough air of a thermal. The

easiest way to lose altitude is to apply full rudder and full up

elevator. This will put the plane into a tight spin that will not

over stress the airframe but it will enable it to lose altitude

very quickly. This is especially helpful if the sailplane gets

sucked into a cloud or it gets too high to see.

As you might expect, with all this air rising, there is also air

sinking. This air is the sailplane pilot’s nightmare that can

really make soaring challenging. “Sink” is usually not as

strong as the thermals in the same area but sometimes can

be. Because of this, it is important you do not let the

sailplane get too far downwind.

Watch the birds! - Thermals suck up small insects many

birds love to eat. A bunch of swallows flying around in one

area may indicate a thermal. Soaring birds (hawks, vultures,

eagles etc.) are the best thermal indicators. They not only

show you where the thermal is but they also show you

where the center is. These “Masters of the sky” will often fly

right along with sailplanes.

Practice those landings! - Most thermal contests are won

or lost during the landing. Establish a particular landing

pattern and try to stick to it for all landings. Learn to shift

your pattern to account for the wind and particular flying

field characteristics. Flaps can be very useful during contest

landings. They allow you to bring the sailplane in for a

landing higher or faster than normal to guard against any

last minute sink or gusts and dump the extra altitude and

speed at the last second. They can also be used to help

THERMAL SOARINGFACTS ABOUT THERMALS

29

Page 30

control your skid. Flaps will stop the plane from sliding a

little quicker. You can also “steer” the plane while it is sliding

along the ground. Don’t expect to be able to “horse it

around” but you can gain valuable inches by using the

rudder to guide it towards the spot as it slides to a stop. Be

very careful not to “ground loop” the plane since you will

lose your landing points if the plane flips over.

To be able to slope soar, you need a slope with a smooth

piece of land (or water) out in front of it and a breeze

blowing pretty close to straight up the slope. The higher and

steeper the hill or cliff the better. Also the larger and

smoother the land out in front the better. The air flowing

towards the hill, is forced up and can generate a very large

area of lift. Behind the hill is a large area of turbulent air that

can be very dangerous to try to fly in. The faster the wind is

blowing the stronger the lift and turbulence will be.

To fly off a slope, stand near the edge and throw the

sailplane (nose down) into the wind. As the sailplane flys out

into the “band” of lift it will begin to gain altitude. Turn and fly

parallel to the slope and make all of your turns into the wind

(especially when you are close to the slope). You will be

surprised at the altitude you can gain just from slope lift.

Thermals will often be “popped loose” by these slopes. If

you catch a thermal and follow it downwind, be very careful

to stay high enough to make it back to the slope without

flying through the turbulent air. Landings can be very tricky

on some slopes. On gentle slopes you can often fly very

close to the top of the slope and “slide” into the top of the

slope without encountering any turbulent air. On steeper

slopes you may have to be a little more aggressive to get

the plane out of the lift. In any case it is a good idea to plan

your landing before you launch your plane.

In strong wind conditions, you may want to add ballast

(weight) to the sailplane to increase its wing loading which

increases its normal flying speed. Increasing the weight of

your sailplane does not change its “glide ratio” but it does

make it fly faster which makes it sink a proportional amount

faster. Because of this faster sink rate, you need to be very

cautious when ballasting for a thermal contest. In duration

type contests only use ballast on very windy days that also

have a lot of thermal activity. Center the weight directly on

the center of gravity of the plane so you can add ballast

without having to re-balance the plane. When learning to

ballast your plane, start out small and work your way up.

Have fun and Good lift!!

BALLAST

SLOPE SOARING

30

Page 31

Spirit™100.

Keep your costs in check and still enjoy high-performance

features with the Great Planes Spirit 100. Interlocking

construction makes it beginner-easy to build. Two wing

options—the proven Spirit wing with S-3010 airfoil, or an

advanced version with a highly efficient S-7037 airfoil, plus

flaps and ailerons for greater control—enable fliers of all

skill levels to enjoy its versatile performance. The advanced

wing enables experienced sailplane pilots to use crow

mixing and offers complete camber-changing capability for

superior thermalling!

• Huge 100" wingspan for extra-smooth

flight!

• Two wing options in one easy-to-build kit.

• High performance without high cost.

GPMA0550

Wingspan: 100 in (2530mm)

Wing Area: 946 sq in (61 sq dm)

Weight: 3-4 lb (1420-1840g)

Wing Loading: 8-10 oz/sq ft (23-31 g/sq dm)

Fuselage Length: 51.5 in (1310mm)

Requires: 2-4 channel radio with 2-5 servos (use 3-channel

31

Spectra™Electric Sailplane

Electric motor power and a 78.5" span, triple-taper wing with

modified Selig 3010 airfoil give the Spectra outstanding

climbing ability...while the model's clean, aerodynamic

design helps you stretch your soaring times by moving

easily from thermal to thermal. The kit's easy assembly

(using the photo-illustrated manual), durability and forgiving

flight make it great for beginners. Includes hardware,

canopy , molded cockpit, Goldfire 550 motor system and 8x4

prop. Add Great Planes' scimitar style 8x4 Nylon Folding

Propeller (GPMQ1690) to minimize drag.

• A 2-meter electric that climbs from 0-500

feet in 60 seconds!

• Suitable for any skill level, with easy kit

assembly, smooth flight characteristics and a

durable airframe.

• Powered by an included Goldfire

550 motor system.

GPMA0540

Wingspan: 78.5 in (1995mm)

Wing Area: 676 sq in (43.6 sq dm)

Weight: 48-52 oz (1360-1470g)

Wing Loading: 10 oz/sq ft (31 g/sq dm)

Fuselage Length: 38 in (965mm)

Requires: 2-3 channel radio, 6-7 cell battery & charger

Perfect choices for every sailplane pilot.

Their quiet flight keeps your airfield's neighbors happy. Getting into action is clean, quick and easy. And the best reason

of all to fly a Great Planes sailplane? Their performance is awesome—right out of the box!

Extend your airtime indefinitely with a Great Planes sailplane...there's always more as close as the next thermal! Like the

Spirit Elite, the Spirit 100 and Spectra both offer fast, easy assembly , made even more enjoyable by Great Planes' perfectly

interlocking wood parts, photo-illustrated instruction manuals and premium quality hardware. Both include canopy and

molded cockpit.

Page 32

BUILDING NOTES

Kit Purchased Date: _______________________

Where Purchased:_________________________

Date Construction Started: __________________

Date Construction Finished: _________________

Finished Weight: __________________________

Date of First Flight: ________________________

FLIGHT LOG

PRINTED IN USA

Loading...

Loading...