Page 1

INSTRUCTION BOOK

PLEASE READ THROUGH TH I S INSTRUCTION BOOKLET IN ITS ENTIRETY BEFORE BEGINNING

ASSEMBLY. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY

AN D U S E OF T HI S MODEL.

WARNING! THIS IS NOT A TOY!

This R/C kit and the model you will build is not a toy! It is capable of serious bodily

harm and property

damage.

IT IS YOUR RESPONSIBILITY AND

YOURS

ALONE - to

build

this kit correctly, properly install all R/C components and to test the model and fl y it only with

experienced, competent help in accordance with all safety standards and common sense as set

down in the Academy of Model Aeronautics Safety Code. It is suggested that you join the AMA

to become properly insured before you attempt to fly this model. IF YOU ARE JUST STARTING R/C MODELING, CONSULT YOUR LOCAL HOBBY SHOP OR WRITE TO THE

ACADEMY OF MODEL AERONAUTICS TO FIND AN EXPERIENCED INSTRUCTOR IN

YOUR AREA.

Academy of Model Aeronautics

5151 Memorial Drive

Muncie, IN 47302

1-800-435-9262

P.O. BOX 788 URBANA, ILLINOIS 61801 217398-8970

Page 2

TABLE OF CONTENTS

INTRODUCTION

Precautions

..................

Other Items Required

Supplies and Tools Needed

Die Patterns

Abbreviations

Types

of

Wood

.............

..........

......

.................

................

...............

3

3

3

3

4

5

5

Decisions you must make now . . . 5

Get Ready to Build

TAIL FEATHERS

Build

the Fin and Rudder

............

.............

.......

5

6

6

Build the Stabilizer and Elevator . 7

Cut the Hinge Slots

...........

8

WING ASSEMBLY ............ 9

Build

the Inner Wing Panel

......

9

Build the Outer Wing Panel ..... 12

Join the Wing Panels

..........

14

Final Wing Assembly .......... 15

FUSELAGE ASSEMBLY

.......

19

Assemble Fuselage Sides ....... 19

Frame-up the Fuselage

Assemble the Canopy

FINAL ASSEMBLY

.........

..........

............

20

23

25

Balance the Airplane Laterally ... 25

Final Sanding

................

25

Covering .................... 25

Checking for Warps

Glue

the Hinges

Mount the

Tail

Assemble Pushrods

...........

..............

Surfaces

........

...........

26

26

27

27

Install Radio Gear

Control Throws

.............

...............

28

29

Install the Spoilers in the Wing . . . 29

Balance the Model

Final Hookups and Checks

............

......

29

30

PRE-FLIGHT ................. 31

Charge the Batteries

Find a Safe Place to Fly

Range Check

Your

...........

........

Radio

.......

31

31

31

Install the Wings .............. 31

AMA Safety Code .............. 31

General

Radio Control

.....................

................

31

31

FLYING ...................... 32

Trim Flights

Your

First Hi-Start Launch

First Flights

.................

......

..................

32

32

33

THERMAL FLYING ........... 33

Facts About Thermals

Thermal Soaring

Pointers for Contest

SLOPE SOARING

..........

..............

Flying

......

.............

33

34

35

35

Flying ...................... 35

Slope Landings ............... 36

POWERED LAUNCHING ...... 36

BALLASTING ................ 36

BUILDING NOTES ............ 36

PARTS LIST .................. 37

CONTEST PRACTICE CHART .. 39

2-VIEW DRAWING ............ 40

Please inspect all parts carefully before starting to build! If any parts are missing, broken or defective, or i f you

have any questions about building or flying this airplane, please call or write us at the address below and we will

be glad to help. If you are calling for replacement parts, please look up the part numbers a nd the kit identification

number (stamped on the end of the kit box) and have them ready when calling. Thank you.

Great Planes Model Mfg., Inc.

P.O.

Box

788

Urbana, IL 61801 (217) 398-8970

2

P.O.BOX

788

URBANA,

ILLINOIS

61801

217398-8970

Page 3

INTRODUCTION

OTHER ITEMS REQUIRED

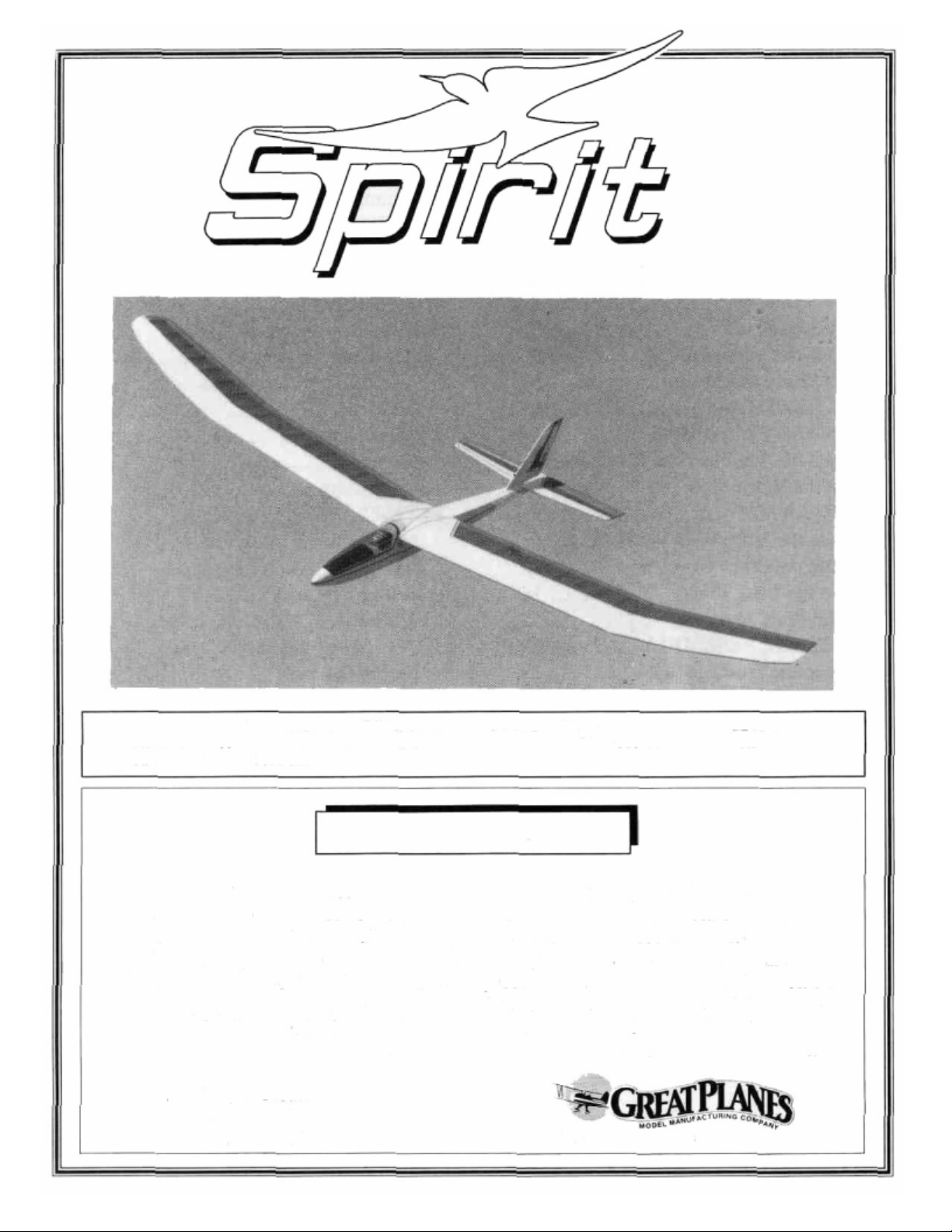

Congratulations! You are about to enter the exciting

world of silent flight. Soaring offers a freedom that no other

type of flying can offer! It is your knowledge and your

SPIRIT'S flying abilities in a fight against gravity. With a

little practice and some help from mother nature you will be

able to defeat gravity and enjoy flights that can last for hours

and cover many miles at incredible altitudes.

Thank you for purchasing the Great Planes SPIRIT

sailplane. It has been designed to give you many hours of

relaxing flying, and has also been engineered to provide a

truly enjoyable building experience.

PRECAUTIONS

1. You must build the plane according to the plans

and instructions. Do not alter or modify the model as doing

s o may result in a n unsafe or un-flyable model. In a few cases

the plans and instructions may differ slightly from the photos.

In those instances you should assume the plans and w r itten

instructions a r e correct.

2. You must take time t o build straight, true and strong.

3. You must use a proper R/C radio that i s in first class

condition.

4. You must properly install all R/C and other components so that the model operates properly on the ground and

in

the

air.

5. You must test the operation of the model before the first

and each successive flight to insure that all equipment is

operating, and you must make certain that the model has

remained structurally sound. Be sure to check the nylon

clevises often, and replace if they show signs of wear.

6. You must fly the model only with the competent

help of a well experienced R/C pilot if you are not already an

experienced and knowledgeable R/C pilot at th is time.

Note: We, as the kit manufacturer, can provide you

with a top quality kit and great instructions, but

ultimately the quality and "fly-ability" of your

finished model depends on how you build it; therefore, we cannot in an y way guarantee the performance of your completed model, and no representations are expressed or implied as to the performance

or safety of your completed model.

Remember: Take your time and follow direc-

tions to end up with a well-built model that is

straight and true.

Radio having at least 2 channels (a third channel is

required for optional spoilers)

Iron-on Covering Material (2 rolls)

Latex Foam Rubber Padding (1/4" thick)

#64 Rubber B an ds

Hi-start or other Launching Device

BB's or Lead Shot for Balancing

The Optional Spoilers Also Require:

1 - 3/16" x 1/4" x 36" Balsa Stick

2 - 30" Lengths of Braided Fishing Line

2 - 30" Lengths of 1/8" Plastic Tubing

The Optional Bolt-On Wing Also Requires:

1 - Small Sheet of 1/4" Birch Plywood

1 - Small Piece of 1/16" Birch Plywood

SUPPLIES AND TOOLS NEEDED

2 oz. Thin CA Adhesive

2 oz. Medium or Thick CA Adhesive

2.5 oz. 5-Minute Epoxy

Hand or Electric Drill

Drill Bits: 1/16", 5/64", 1/8", 9/64" (13/64" and 17/64"

for Wing Bolt Option)

Sealing Iron

Heat Gun

Razor Saw

Hobby Knife, #11 Blades

Pliers

Screw Drivers

T-Pins

Assorted Rubber Bands

Straightedge

Masking Tape

Cellophane Tape

Vinyl Tape

Sandpaper (coarse, medium, fine grit)*

T-Bar Sanding Block (or similar)

Waxed Paper

Lightweight Balsa Filler

1/4-20 Tap, Tap Wrench (for bolt on wing option)

Dremel Moto Tool or Similar (optional)

*NOTE: On our workbench, we have four 11" TBar sanders, equipped with #50, #80, #100 and

#150-grit sandpaper. This setup is all that is required for almost an y sanding task. We also keep

some #320-grit wet-or-dry sandpaper handy for

finish sanding before covering.

3

Page 4

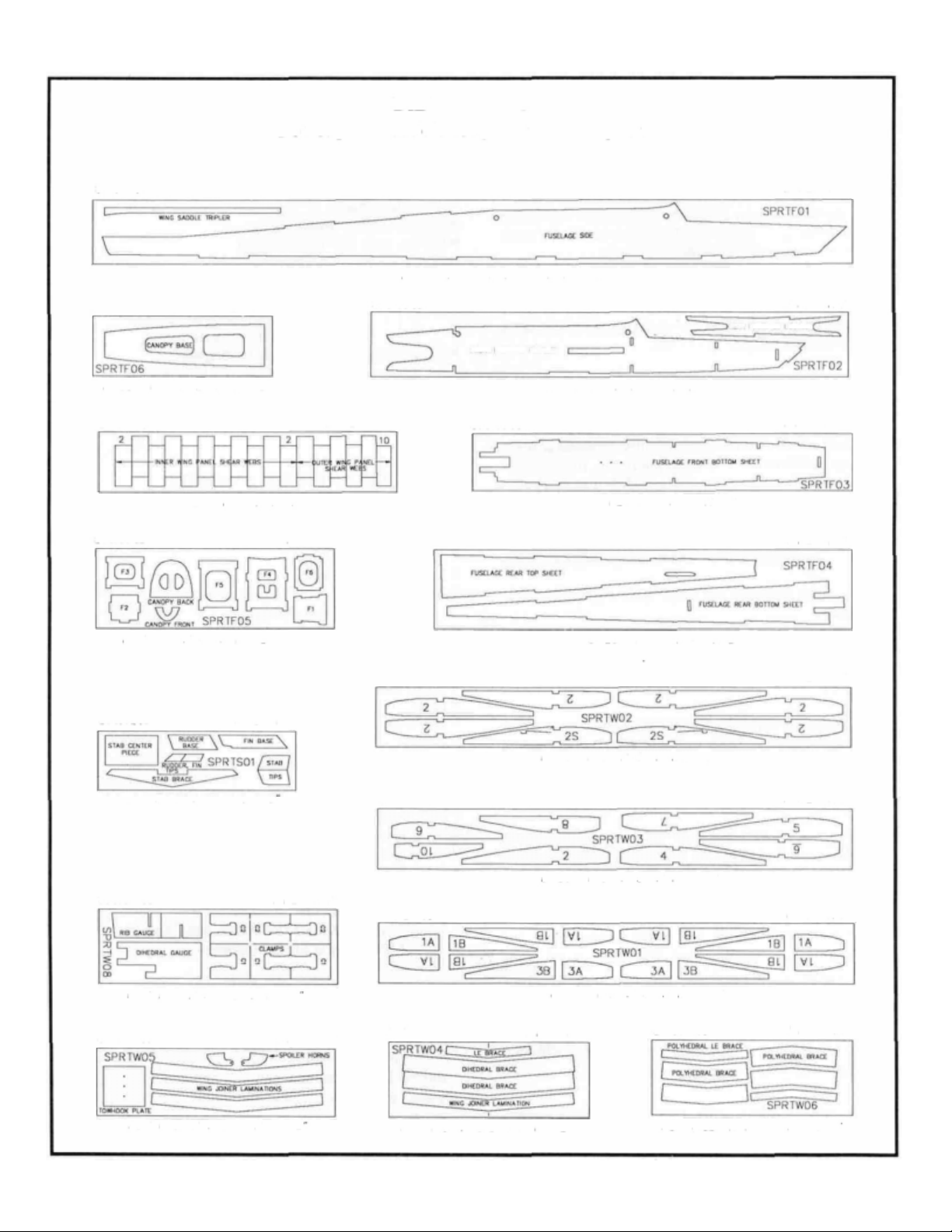

SPRTFO1

DIE PATTERNS

Do not punch out die-cut parts until ready to use!

BALSA 3/32" X 3-1/4" X 38-1/2"

2

PER

KIT

1

PER

SPRTF06

BALSA 1/8" X 3" X 9-7/8"

SPRTW07

BALSA 1/16" X 3" X 15"

SPRTF05 1 PER KIT

PLY 1/8" X 4" X 11-7/8"

SPRTS01

KIT

1

PER

KIT

2

PER

SPRTF02

KIT

SPRTW02

SPRTF04

FRONT FUSELAGE DOUBLER

BALSA 3/32" X 3-1/4" X 24"

SPRTF03

REAR FUSELAGE DOUBLER

PLY 1/8"

BALSA 3/32" X 4" X 21"

X

3"

X

19"

2

PER

I

PER

I

PER

2

PER

KIT

KIT

KIT

KIT

BALSA 3/16" x 3" x 9-7/8

SPRTW08

PLY 1/8" X 3-7/8" X 11-7/8

SPRTW05

PLY 1/16" X 3-3/8" X 11-7/8

I

PER

1

PER

KIT

KIT

BALSA 1/16" X 3" X 23-7/8"

SPRTW03

BALSA 1/16" X 3" X 23-7/8"

SPRTW01

BALSA 1/8" X 3" X 23-7/8"

SPRTW04 1 PER KIT

PLY 1/8" X 3-3/4 X 10-1/2"

4

2

PER

KIT

I

PER

KIT

SPRTW06 I PER KIT

PLY 1/32" X 3-1/4" X 9-3/4'

Page 5

COMMON ABBREVIATIONS USED IN

THIS BOOK AND ON THE PLANS:

TYPES OF WOOD

Elev

Fuse

LE

Lt

Ply

Rt

Stab

TE

= Elevator

= Fuselage

= Leading Edge (front)

Left

= Plywood

= Right

= Stabilizer

= Trailing Edge (rear)

" = Inches

DECISIONS YOU MUST

MAKE NOW

WING CONFIGURATION

The SPIRIT kit has three different wing options: a

two-piece rubber band on wing, a one-piece bolt on wing

or a one-piece rubber band on wing. The two-piece wing

is the easiest version to build and is recommended for

beginners. Some experienced sailplane pilots may prefer

the one-piece bolt on wing, bu t the large wing can present

transportion problems in todays small cars. The onepiece rubber band wing would be the next best choice for

beginners.

SPOILERS

The SPIRIT can be built either with or without

spoilers. Spoilers act as airbrakes and make it easier for

experienced pilots to precisely land on target during

contests. They can also be helpful in losing altitude

quickly. Due to the added complexity encountered when

installing spoilers, they are NOT recommended for first

time builders. If you a r e a beginner and may eventually

want spoilers, install just the spoiler tubing now and the

rest of the spoiler pans can be installed when you are

ready.

BALSA

BASSWOOD

PLYWOOD

GET READY TO BUILD

NOTE: It will be helpful to build on a piece of

"Celotex", or other semi-soft (and flat) surface,

into which you may easily stick pins to firmly hold

down the parts while building and to avoid warps.

1. Unroll the plan sheet. Re-roll the plan inside out and let

it uncurl while you read through this instruction book. This

will help the plan lay flat and get you acquainted with the

building process. NOTE: Because there are several op-

tions to consider when building the SPIRIT, you should

read the instruction book through before building and

then go back and cross off the steps you won't use to build

your model.

2. Remove all parts from the box. As you do, figure out the

name of each part by comparing it with the plans and the parts

list at the back of this book. Write the part name or size on

each piece to avoid confusion later. Use the die-cut patterns

shown on page 4 to identify the die-cut parts and mark them.

If any of the die-cut parts are difficult to punch out during

construction, do not force them! Instead, first cu t around the

parts with a hobby knife. After punching out the die-cut parts,

use your T-Bar or sanding block to lightly sand the edges to

remove any die-cutting irregularities.

INSTRUCTIONS IN BOXES LIKE THIS

ARE VERY IMPORTANT AND SHOULD

BE FOLLOWED CAREFULLY

5

Page 6

"TAIL FEATHERS"

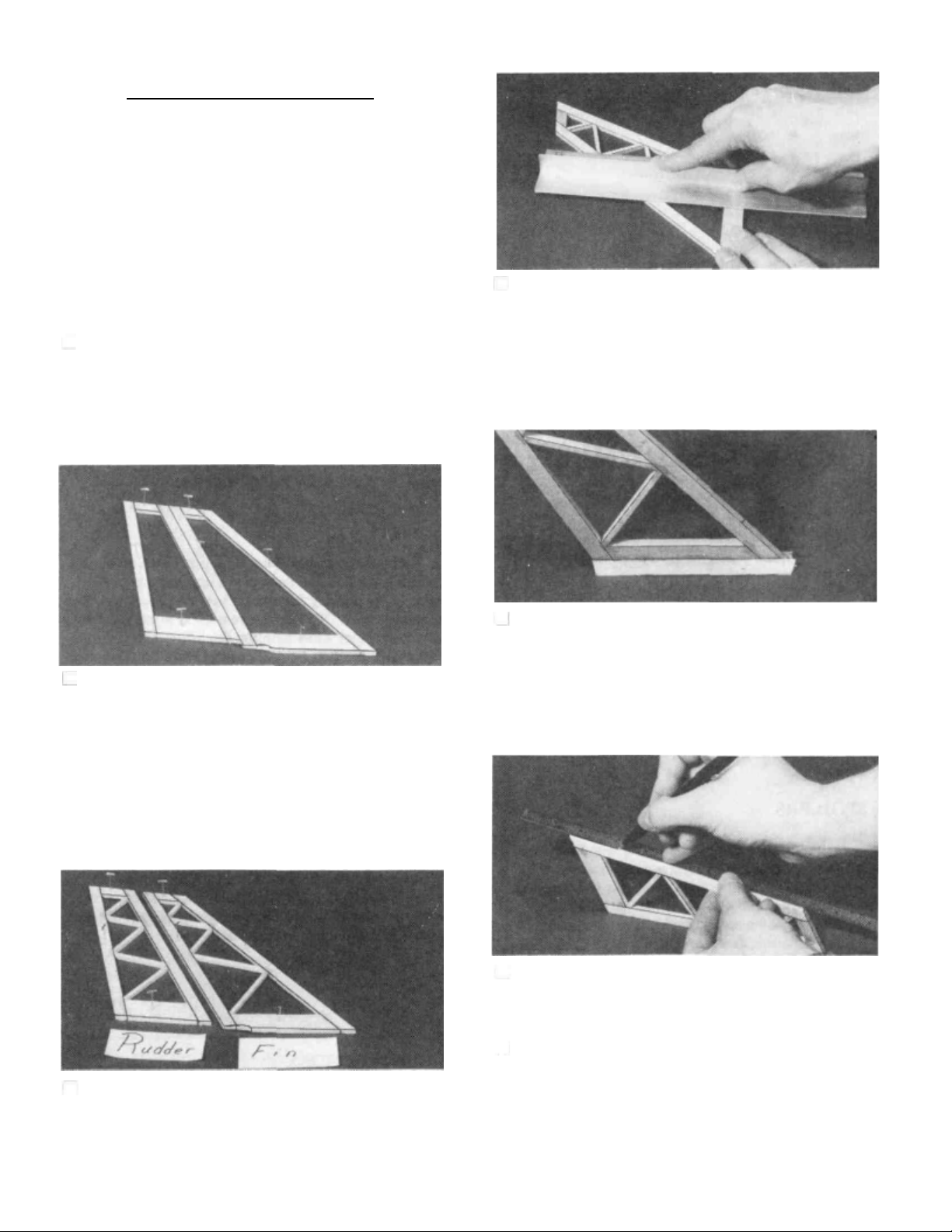

BUILD THE FIN A N D RUDDER

You'll need t he following parts:

SPRTS02 3/16" x 3/8" x 30" Balsa Stick

SPRTS03 1/8" x 3/16" x 30" Balsa Stick

SPRTS01 3/16" Die-Cut Tail Parts

SPRTF08 3/16" Balsa Triangle

D 1 . Tape or pin the plan down to your flat work surface.

Tape a piece of waxed paper over the f i n and rudder portion

of the plan (so you don't glue the parts to the plan).

D 4. Remove the fin and rudder assemblies from the plan

and examine them for any open or bad joints. Fill any gaps

with thick CA, then use your sanding block wi t h me dium grit

sandpaper to sand both sides of t he framework smooth.

D 2. Using the plan as a guide, cut pieces of 3/16" x 3/8"

balsa (from the 30" sticks, SPRTS02) to make the Rudder

and Fin Framework. NOTE: Cu t the Fin L.E., the Rudder

L.E. and the Rudder T.E. from a single SPRTS02 (This wil l

leave enough long pieces for the stab). Punch ou t the die-cut

Fin Tip, Rudder T ip, Fin Base and Rudder Base from

SPRTS01. Sand the edges if necessary and pin them in place

on the plan and glu e the parts together using thin CA glue.

NOTE: Do not glue the fin to the rudder!

D 3. From the 1/8" x 3/16" x 30" sticks (SPRTS03), cu t

the diagonal "ribs" to fit between the rudder and fin frame-

work, and glue them in place. NOTE: It is not necessary to

get these ribs in the exact position shown on the plan.

D 5. Cut two 4-1/8" lengths of 3/16" Balsa Triangle

from SPRTF08 and glue them along the bottom of the fin.

The bottom edges of the tria ngle should be flush with the

bottom of the fin.

D 6. Carefully draw a centerline all around the edges of

the rudder and fin (this will help to maintain symmetry when

sanding).

D 7. Using a sanding block and coarse (50 or 80-grit)

sandpaper, sand the leading edge of the rudder t o the V-shape

as shown on the plans (a small razor plane works great for

initial shaping). Sand the three remaining edges to a smooth

rounded shape. Sand the top and the leading edge of the fin

to a nice rounded shape*. NOTE: The trailing edge of the

6

Page 7

FIN must remain square, do not sand it! Sand the triangle

stock to blend with th e leading and trailing edges of the fin.

Also, cut or sand the bottom of the triangle stock to match the

contour of the 3/16" die-cut fi n bottom.

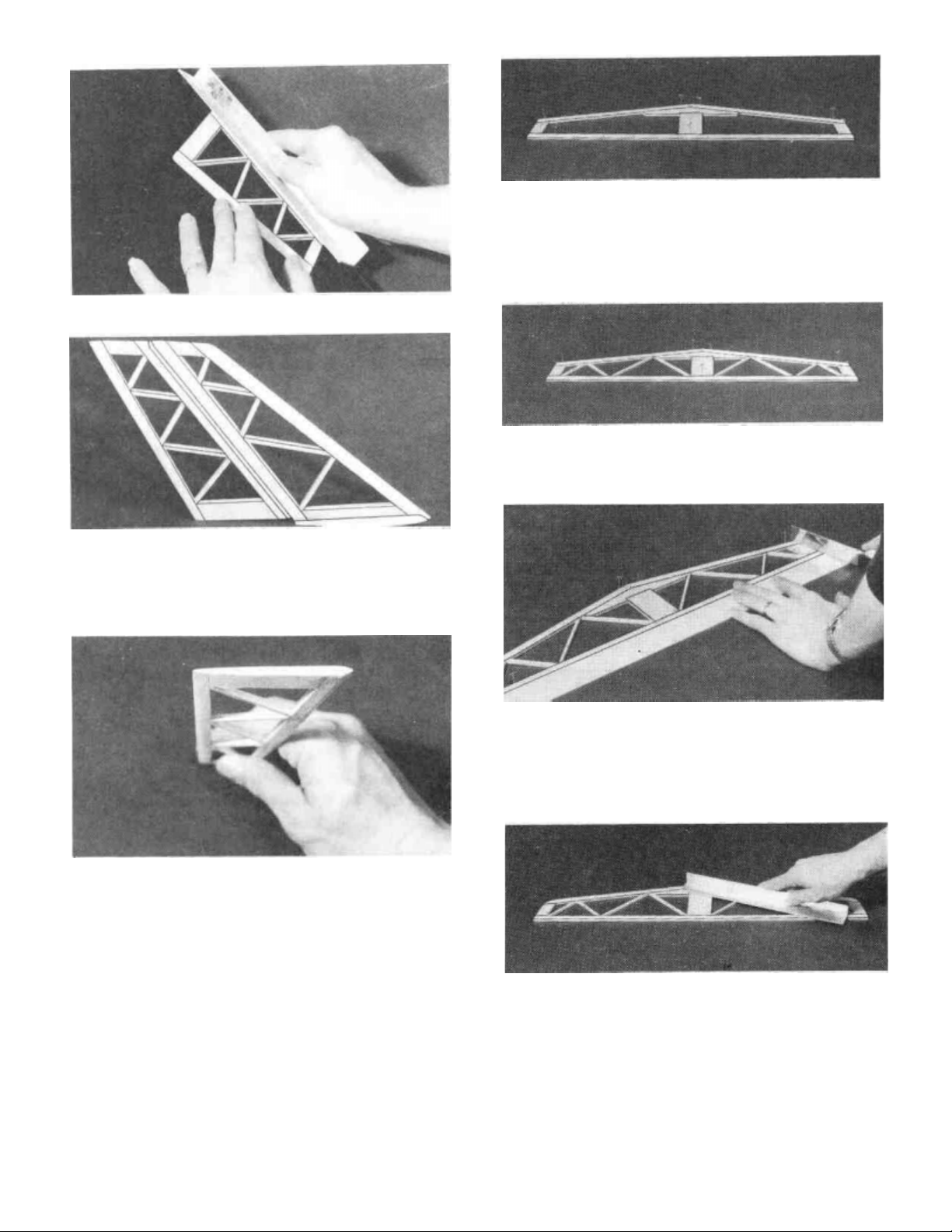

D 1. Tape waxed paper over the stabilizer drawing on the

plan. In the same manner as the rudder, cut the 3/16" x 3/8"

balsa pieces and using the die-cut Stab Tips, Stab Center

and Stab Brace from SPRTS01, assemble the stab framework using thin CA glue.

D 2. Cut the 1/8 " x 3/ 16" "ribs" to length and glue them

in place.

* MAXIMUM PERFORMANCE TIP - Sand both sides of

the rudder to a taper as shown on the plans. This requires a

little more work but will help to reduce drag and thus increase

performance of the sailplane.

BUILD THE STABILIZER AND ELEVATOR

You'll need the following parts:

SPRTS02 3/16" x 3/8" x 30" Balsa Sticks

SPRTS03 1/8" x 3/16" x 30" Balsa Sticks

SPRTS01 3/16" Die-Cut Tail Parts

SPRTS04 Tapered Elevator

D 3. Pin or tape the elevator (SPRTS04) in place behind

the stab and use your razor saw to cut the ends off t o match the

stab.

D 4. Remove the stab from the plan and examine it for

any open or bad joints. Fill any gaps with thick CA, then use

your sanding block with medium grit sandpaper to sand both

sides smooth. Draw a centerline around the stab edges.

D 5. Tape the elevator to the stab using masking tape and

sand the leading edge of the stab, the stab tips and the elevator

tips to a smooth rounded shape. The tips of the elevator

should blend in nicely with the stab lips.

7

Page 8

D 6. Remove the elevator and draw a center line down its

leading edge. Use yo ur sanding block to sand the same Vshape as you did on the rudder. The trailing edge should also

be sanded to a smooth rounded shape.

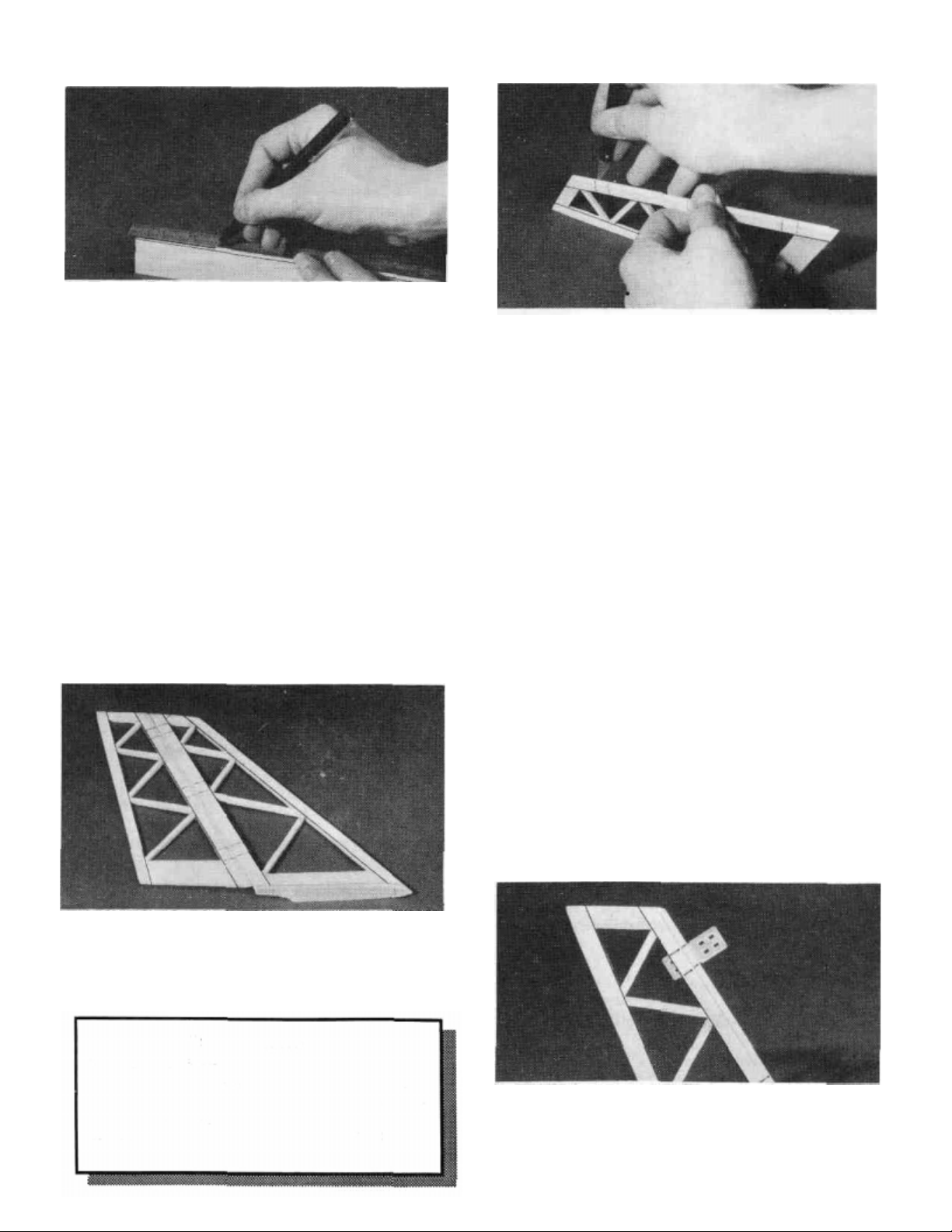

D 2. Draw accurate centerlines down the trailing edge of

the stab and the fin. Cut the hinge slots on these lines using

a hobby knife or a slotting fork and slotting hook. (The

recommended hinge slotting technique is listed below).

CUT THE HINGE SLOTS (Do not glue)

NOTE: One-piece molded polypropylene hinges

are supplied in this kit. If you choose to use these

hinges or the "pinned"-type hinges, you may cut

the hinge slots at this time. However, if you choose

to use the one-piece hinges tha t are paper covered

for CA glue installation, you may wait until after

covering before cutting the hinge slots.

A. Begin by carefully cutting a very shallow slit at

the hinge location. This first cut is to establish your cut

in the right place, so concentrate on staying on the

centerline and don't cut too deep!

B. Make three or four more cuts in the same line,

going slightly deeper each time. As you make these

additional cuts, work on going straight into th e wood.

Continue this process while "wiggling" the knife

handle forward and backward until the blade has reached

the proper depth for the hinge.

C. Trial fit the hinge into the slot. If the hinge is

difficult to push in, re-insert the knife and move it back

and forth in the slot a few times to enlarge the slot.

D 3. IMPORTANT! Condition or "break-in" the

hinges by folding them back and forth several times.

D 1. Lay the rudder and elevators on the plan and mark

the hinge locations. Place the rudder against the fin TE and

transfer the marks over to the fin. Place the elevator against

the stab TE and transfer the marks over to the stab.

CAUTION!!!: You must use extreme care when

cutting hinge slots with a hobby knife, to avoid

cutting yourself! If the balsa part breaks while you

are pushing on the knife, the blade could go into

your hand before you know it! A good precaution is

to wear leather gloves while performing the following steps.

D 4. Insert the hinges into the slots and trial fit the rudder

and elevator in place on the fi n and stab. Do not glue the

hinges until after you have covered the model.

8

Page 9

WING ASSEMBLY

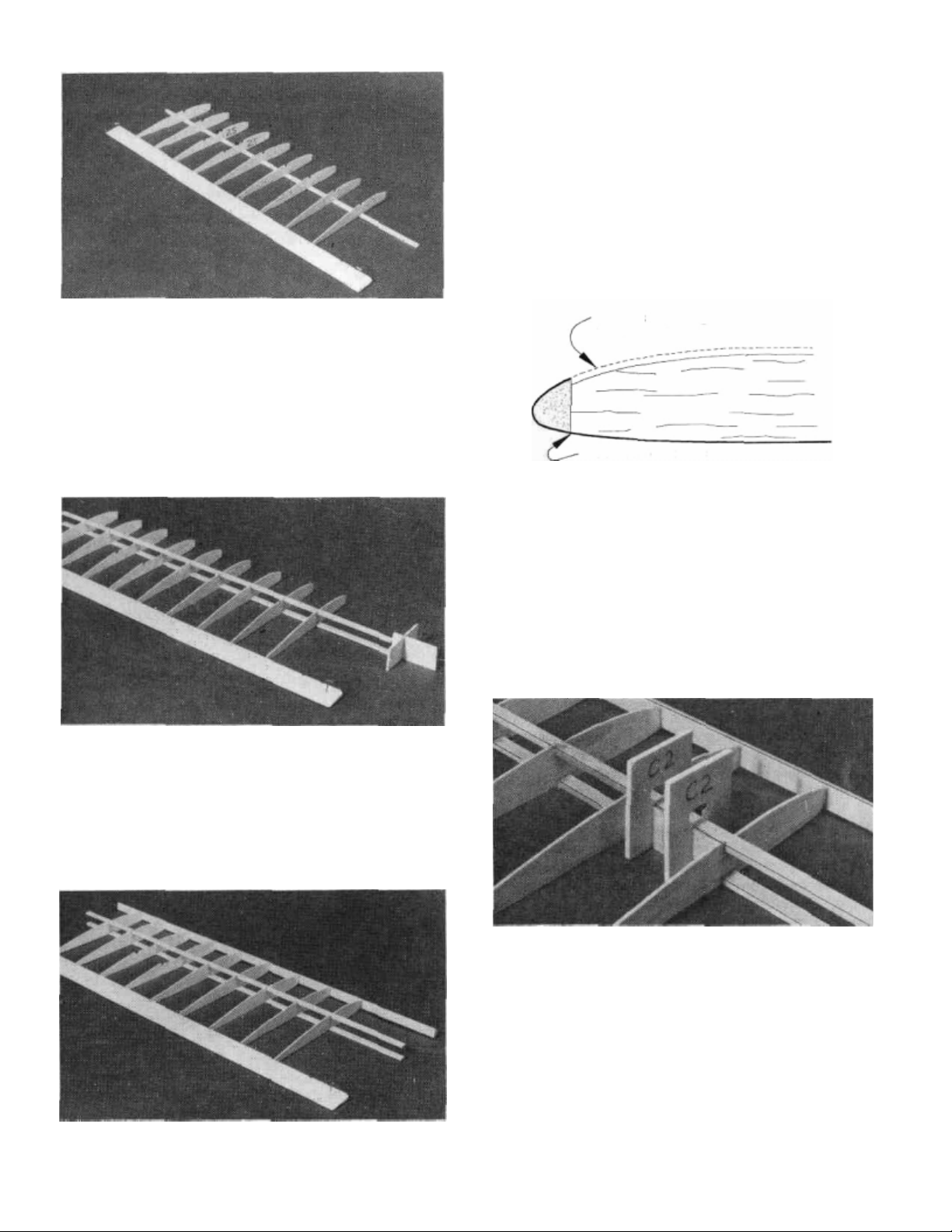

BUILD THE INNER WING PANELS

D 4. Carefully punch out all the die-cut 1/16" Balsa W2

and W2S Wing Ribs. Sand the edges slightly to remove any

die-cutting irregularities.

You'll need the following parts:

SPRTW01 1/8" Die-Cut Balsa Wing Ribs

SPRTW02 1/16" Die-Cut Balsa Wing Ribs, W2, W2S

SPRTW03 1/16 " Die-Cut Balsa Wing Ribs, W2, W4-W10

SPRTW04 1/8" Die-Cut Plywood Dihedral Braces

SPRTW07 1/16" Die-Cut Balsa Shear Webs

SPRTW08 1/8" Die-Cut Plywood Clamps and Gauges

SPRTW10 Shaped Balsa Leading Edge

SPRTW 11 Shaped, Notched Balsa Inner Trailing Edge

SPRTW13 1/8" x 5/16" x 23-1/2" Basswood Spars

SPRTW17 1/16" x 3" x 24" Balsa Wing Sheeting

NOTE: The wing is designed to be built as a twopiece wing; however, we also describe how to build

a one-piece wing which can be either held on with

rubber bands or 1/4 - 20 nylon wing bolts (not

included).

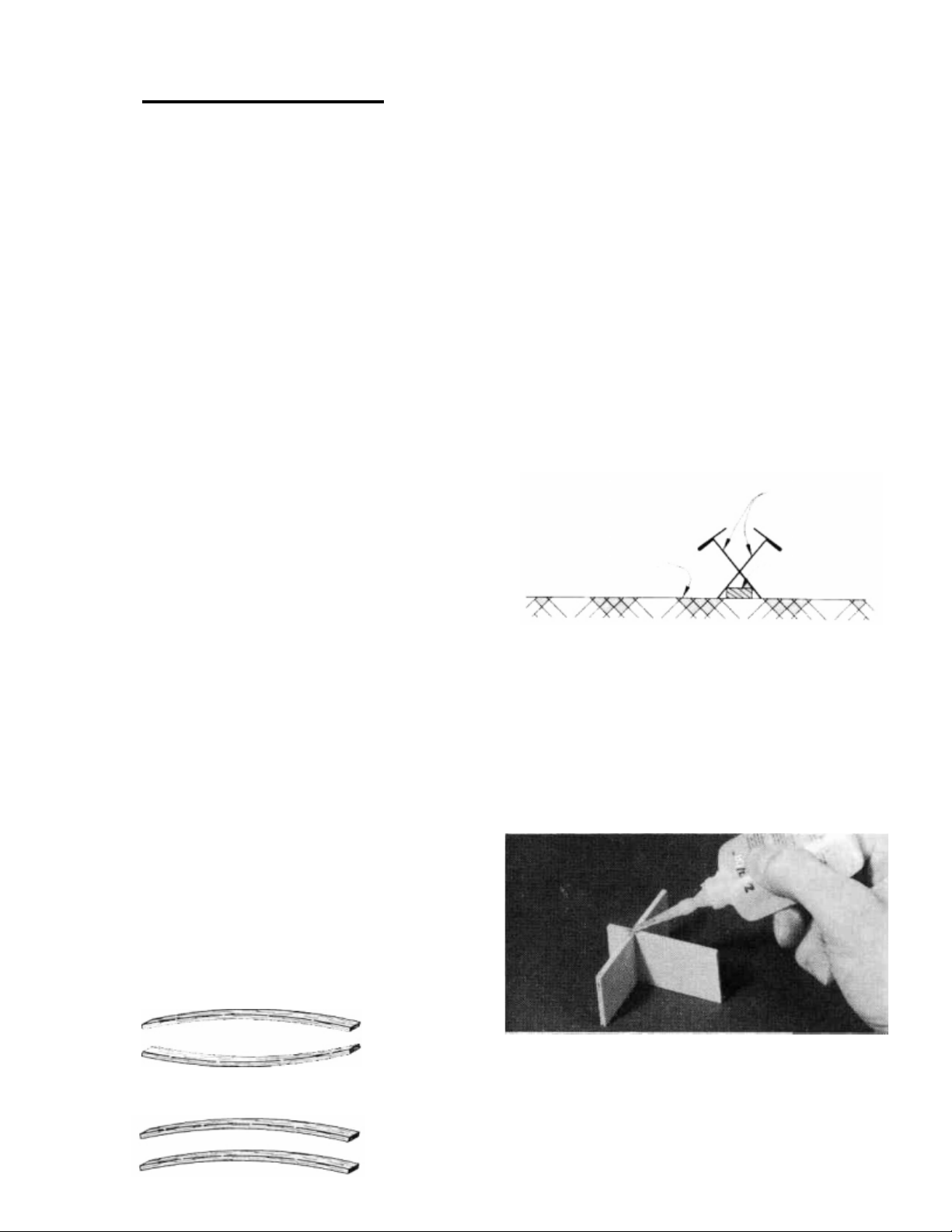

D 1. Tape the plan to your flat work surface, and cover

the wing drawing wi th waxed paper. NOTE: If your work

space is limited, you may c ut the wing drawings apart from

the rest of the plans.

NOTE: Follow step 5 below through step 7 on page

15 to build the LEFT wing panel, then repeat these

steps to build the RIGHT wing panel.

DD 5. Pin one of the notched balsa Inner Trailing

Edges (SPRTW 1 1 ) to the plan lining up the notches in the T E

with the notches on the the plan.

DD 6. Place one of the 1/8" x 5/16" x 23-1/2" Basswood

Inner Spars (SPRTW13) on the wi ng plan and pin the spar

down with crossed T-pins as shown in the following sketch.

NOTE: The spars ma y be cu t slightly oversize, the excess

will be cu t off later.

T-Pins

Work Surface

Spar

D 2. The Shaped Wing Leading Edges (SPRTW10) are

fastened together by thin strips of balsa. Separate them by

carefully cutting between the LE'S. Sand away the excess

balsa that remains along the edges after cutting them apart,

using a sanding block with 100-grit sandpaper.

D 3. Before using the 1/8" x 5/16" x 23-1/2" Basswood

Spars (SPRTW13), examine them carefully for possible

imperfections. Look for knots, soft spots, diagonal grain and

any other imperfections. If possible, position each spar so the

imperfections are on the outer half of the wing panel (toward

the tip), where they will b e least affected by high stress. If the

spars are warped slightly, "balance them out" by installing

the warped spars in opposite directions (see sketch).

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

STRAIGHT WING

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

WARPED WING

DD 7. Place the seven W-2 ribs (from SPRTW02 and

SPRTW03) and the two W-2S ribs (from SPRTW02) on the

spar in their approximate positions, work the ribs into the

notches on the trailing edge bu t do not glue anything yet.

DD 8. Punch out the two Rib Gauge Pieces from the

1/8" die-cut plywood sheet (SPRTW08) and assemble them

using CA. Notice that one end of the gauge is slanted at a 5

degree angle for positioning the end ribs. The other 3 ends are

perpendicular and can be used to keep parts 90 degrees to the

work surface.

9

Page 10

edges are NOT symmetrical. Refer to one of the section

views on the plans to determine which way they should be

installed. Carefully hold the leading edge against one o f t he

end W-2 ribs and note that i t i s wider than the front of th e rib.

This i s because the 1/16" balsa leading edge top sheeting will

be added later. Align the lower surface of the leading edge

with the bottom of the rib and glue it in place with a drop of

thin CA. Lift up the other end of the leading edge, align it with

the bottom of the opposite end W-2 and glue it with a drop of

thin C A . Go down the line and glue the remaining ribs to th e

leading edge one at a time so you can make sure they are

aligned.

DD 9. Make sure the ribs are properly positioned accord-

ing to the plans and glue them in place using thick CA at the

spar joint and a drop of thin CA at the trailing edge joint. Use

the square end of the rib gauge to keep the ribs perpendicular

to the work surface. NOTE: if you are installing spoilers,

cut out the embossed area on the two W2S ribs and make

sure you install these ribs in the proper locations.

DD 10. Trial fit the top 1/8" x 5/16" x 23-1/2" Basswood

Inner Spar (SPRTW13) into the notches in the ribs by

carefully pushing the spar completely down into the notches.

Make sure the lop spar i s lined up lengthwise with the bottom

spar. Remove the spar and glu e it in place by applying thick

CA to the notches before the spar is put back in place.

1/16" sheeting will

be added later

-Bottom of rib should

be flush with bottom

of leading edge.

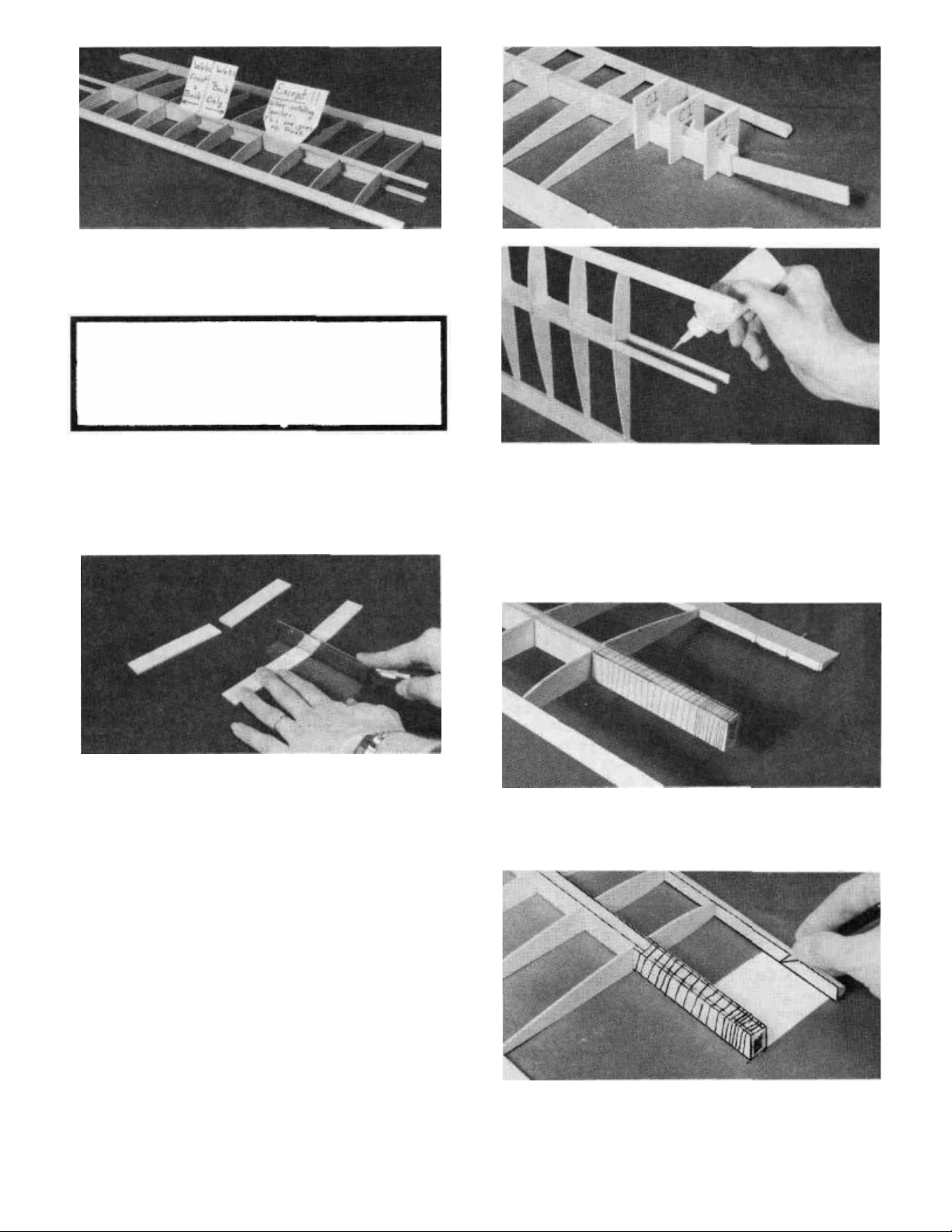

DD 12. Locate the 1/16" Balsa Die-Cut Shear Web

She et (SPRTW07) and notice th at all of the shear webs are

not t he same. The webs between the number 2's are for use

on the inner panel. The webs between the 2 and the 1 0 are for

the outer panel and each one of these is a different size so keep

them in the sheet until they are ready to be used. Punch out

all of the "2" shear webs.

DD 11. Position a Pre-shaped Leading Edge

(SPRTW10) in place over the plans. NOTE: These leading

DD 13. Trial fit one of the webs in place between the first

two W-2 ribs. You may have to sand it slightly to get it to fit.

Glue the shear web in place on the back of the spars using

thick CA. The webs should be centered (up and down)

between the spars. It is important to do a good job of gluing

these in place as they are responsible for most of the wing's

strength. C-2 Clamps from the 1/8" Die-Cut Plywood Sheet

SPRTW08 can be used to help hold the webs in place while

the glue cures.

DD 14. Install the remaining balsa shear webs. Note that

the webs are only installed between the ribs already glued in

place. Three webs are also installed on the front of the spars

10

Page 11

in the first three rib "bays". NOTE: if you are installing

spoilers in the wing or may add them in the future, install

the web between the two W2S ribs on the FRONT of the

spars to make room for the spoiler horn.

IF YOU ARE BUILDING A ONE-PIECE

WING, SKIP AHEAD TO "BUILD THE

OUTER WING PANEL" ON PAGE 12. STEPS

1 5 THROUGH 22 ARE FOR A 2-PIECE WING

ONLY.

DD 15. Locate the 1/8" die-cut sheet (SPRTW04) that

contains the Dihedral Braces, the Leading Edge Brace and

the Wing Joiner Lamination. Line a ruler up with the two

embossed cut marks and draw a line across both of the

dihedral braces.

DD 16. Punch out the two dihedral braces and cut them in

half with a razor saw along the lines you jus t drew. Note:

these braces are supplied in one piece for the bolt on wing

option. Also punch out the wing joiner lamination from that

sheet and set it aside for the next step. The leading e d ge brace

is not used in a two-piece wing.

DD 17. Punch out the three C1 clamps from the 1/8" diecut plywood sheet (SPRTW08). Test f i t two of the dihedral

brace "halves" to the "root" (inner) end of the inner panel

spars. One brace should be installed on the front of the spars

and the other on the back. The edge that you cut with the razor

saw should be near the end of the spars and it should be placed

s o that i t slants in at the top (towards the middle o f the wing).

Use the C1 clamps to hold the braces in place and test fit the

wing joiner lamination into the box formed. This "box" will

be referred to as the "joiner box". The wing joiner lamination is used to make sure the spars remain the correct distance

apart. (See photo at the top of the next column.)

DD 18. Remove the clamps and apply a bead of epoxy

along the spar edges (thick CA will also work b ut be very

careful to get things aligned properly before the glue cures).

Install the braces and hold in place wi th the C1 clamps. A

goo d glue joint is important here but be careful not to get any

excess glue inside the box formed by these braces or the wing

joiner will not fit ins ide. Also test the size of the joiner box

with the joiner lamination while th e glue is curing.

DD 19. Tightly wrap the joiner box with a strong thin

thread and then soak it with thin C/A. This will add a lot of

strength to the joiner box. Do not overlap the thread or allow

it to build up too thick.

DD 20. Locate one of the 1/16" x 3" x 30" Balsa Sheets

(SPRTW 17) and cut it into 6 pieces 2-3/8" long. Slide one of

the sheets in place in front o f the joiner box and trim to fit. Use

11

another sheet to shim up the frontedge (See sketch nextpage).

Glue it in place with thick CA.

Page 12

1/16"

balsa

scrap

Shaped

balsa LE

1/16" balsa

bottom sheet

Spars

Work Surface

DD 20 . Glue another piece to the rear of the joiner box and

then cut a third piece to fit behind the second and glue it in

place.

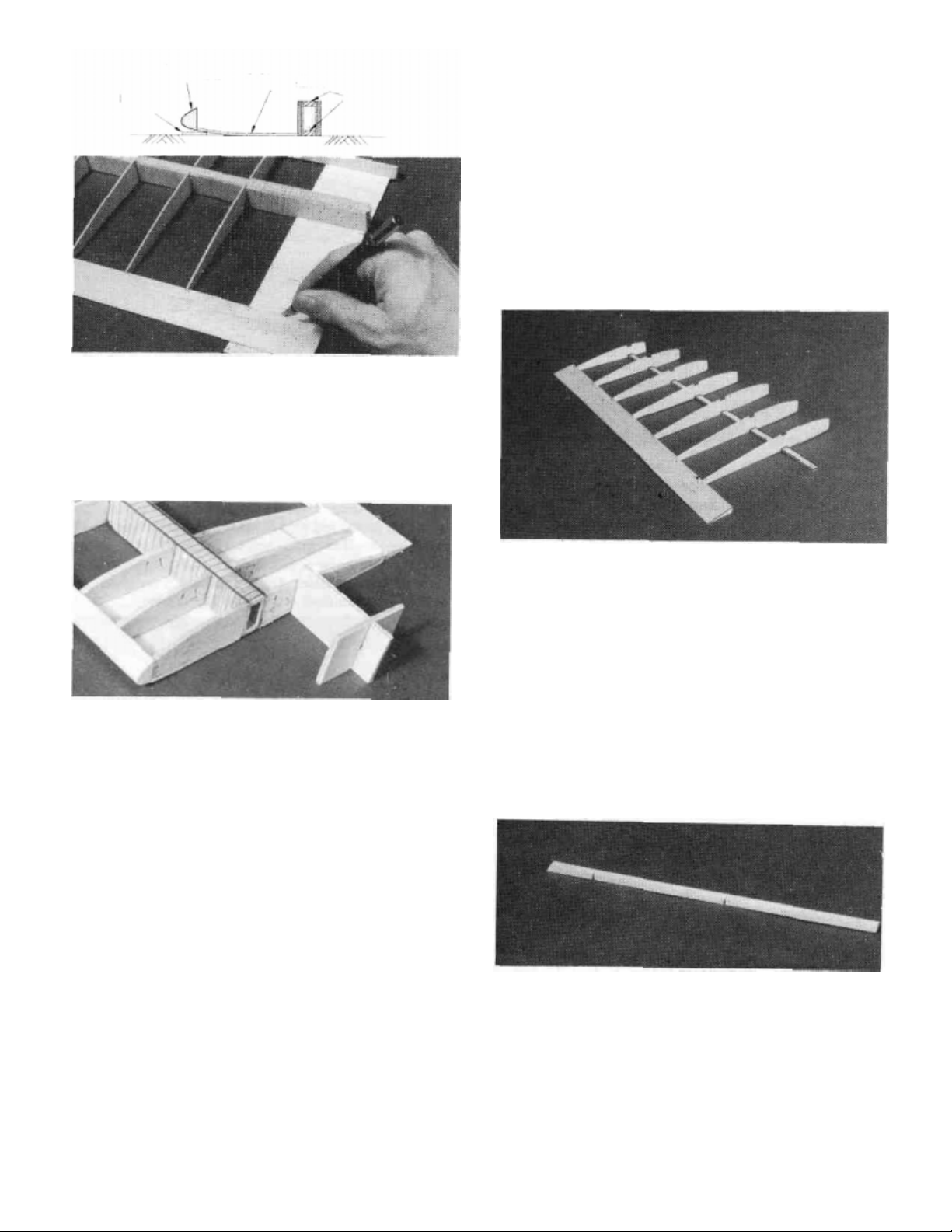

DD 1. Lay one of the Outer Trailing Edges

(SPRTW 1 2) in place over the plan and cut it to length just past

the last notch. Align th e notches in the trailing edge with th e

notches on the plans and pin it in position. NOTE: The un-

notched end of this trailing edge will be used later if you

are installing spoilers.

DD 2. "Cross pin" one of the 1/8" x 5/16" x 15-1/8"

Basswood Outer Spars (SPRTW 14) in place.

DD 2 I.Punch out three W1A ribs and three W1B ribs from

the l/8"die-cut balsa rib sheet(SPRTW01). Tes t

fit

these ribs

into position. A little sanding may be necessary to make them

fit properly. Glue these ribs into place using thick CA. The

end rib should be tilted in at the top using the slanted end of

the rib gauge to give it the correct angle.

DD 22. Cut and sand the leading edges, trailing edges and

spars to their correct length. Lay the panel over the plans to

determine the correct lengths.

BUILD THE OUTER WING PANEL

You'll need the following parts:

SPRTW03 1/16" Die-Cut Balsa Wing Ribs W4 - W10

SPRTW07 1/16" Die-Cut Balsa Shear Webs

SPRTW10 Shaped Balsa Leading Edge

SPRTW 12 Shaped, Notched Balsa Outer Trailing Edge

SPRTW14 1/8" x 5/16" x 15-1/8" Basswood Outer Spars

SPRTW15 7/8" Shaped Balsa Wing Tip Block 12

DD 3. Punch out the 1/16" (W4-W10) Tip Ribs ou t of

one of the SPRTW03 die-cut sheets. Glue the ribs in place

with a thick C A at the spar joint and a drop of thin CA at the

trailing edge joint. Use the rib gauge to keep the ribs

perpendicular.

DD 4. Trial fit the top 1/8" x 5/16" x 15-1/8" Basswood

Outer Spar in place by carefully pressing the spar int o the

notches until it is flush with the top of the ribs. Remove the

spar and apply thick C A to the notches. Replace the spar and

allow the glue to cure.

DD 5. Lay one of the remaining Pre-Shaped Leading

Edges over the LEADING EDGE TEMPLATE at the top

rig h t comer of the plans. Use this drawing as a reference to

cut the leading edge to length and to cut the relief notches. It

is a good idea to cut the leading edge approximately 1/4"

longer on both ends to be on the safe side. It can be cut to

the correct length after it is installed. The relief notches do

not need to go all the way through the leading edge but should

go within 1/8" of doing so. NOTE: You must make a

"Right" and a "Left" L.E.

Page 13

DD 6. Carefully bend the leading edge to the angle

shown on the plans and position it against the ribs. The bends

should be at ribs W6 and W9. Align the leading edge with the

top and bottom edges of the ribs and glue it in place starting

at ribs W6 and W9.

DD 7. Locate the remaining 1/16" Die-Cut Shear Webs

from sheet (SPRTW07). NOTE: These remaining shear

webs are actually tapered to match the taper of the wing.

DD 8. Punch out the remaining 6 shear webs and lay

them end to end so that the end of one web is the same siz e as

the end of the one next to it as shown in the sketch below. This

is the order and direction they will be installed in the wing.

The thinnest web goes between ribs W9 & W10 and the

thickest web goes between ribs W4 & W5.

NOTE TAPER OF WEBS

W9-WIO W8-W9 W7-W8 W6-W7 W5-W6 W4-W5

DD 11. Glue the 7/8" x 1-1/4" x 6-1/4" Tapered Wing

Tip Blocks (SPRTW15) to W10 with thick CA. The sketch

below and the cross sections on the plan shows how the block

should be attached to get the correct tip shape.

DD 9. Glue the webs into their respective places using

thick CA. The thinnest end of each web goes towards the tip

of the panel. The C-2 clamps can be used to help hold the

webs in place while the glue cures.

DD 10. Cut and sand the trailing edge, spars and leading

edge flush with rib W 10. Also cut these to the correct length 1 3

at the other end using the plans as a guide.

DD 12. Carve and sand the wing tip to blend in with rib

W10. Be careful not to change the shape of W10 while

sanding the tip. There are three section views on the left wing

plan to show you the desired shape.

Page 14

DD 13. Apply several drops of thin CA to the rear portion

of the balsa wing tip. Allow the glue t o soak into the wood and

cure. The glue will help harden the wood and protect it from

damage.

JOIN THE INNER AND OUTER WING

PANELS

sand the leading edge, spars and trailing edge so they are all

even and of the correct length.

NOTE: The SPIRIT'S wing is designed to be

just under the legal maximum projected wing

span for 2-meter sailplanes (approximately

78-3/4"). Be very careful when joining these

panels to get t he right amount of dihedral and

to keep the panels the correct length or you

could very easily build a wing that is too long

for competition in the 2-meter class.

DD 1. Prop up the outer panel 2-5/8" (from the work

surface to the bottom of W10) using the lower notch of the

Dihedral Gauge (from SPRTW08) next to rib W9. Use a

sanding block to carefully sand the leading edge, spars and

trailing edge to achieve vertical surfaces on each. Check your

progress by occasionally setting the panel on the plans to

make sure you are not sanding any "sweep" (forward or

backward tilt) into the wing.

DD 2. With the inner panel flat on the work surface,

DD 3. Test fit the inner and outer panels together over

the plan to make sure the leading edges, spars, and trailing

edges all meet up nicely when t he tip panel is blocked up the

required 2-5/8" at the bottom of rib W 10 (Use the lower notch

of the dihedral guage at W9 as shown on the plans to obtain

the correct angle). Sand a ny ends if needed to make everything fit well.

DD 4. With the dihedral gauge in place. Apply thick CA

or epoxy to the leading edge, trailing edge and spar joints to

"tack glue" the two panels together. Hold everything in

place until th e glue has cured.

DD 5. Punch out two of the 1/32" Plywood Polyhedral

Braces from the die-cut sheet (SPRTW06) and test fit them

in place against the front and back of the spars. Sand them if

needed to achieve a good fit .

DD 6. When satisfied with the fit apply a generous bead

of epoxy or thick CA to the spars and install the braces on both

sides of the spars. Use the die-cut C2 clamps (from

SPRTW08) to hold everything in place. The photo at the top

of the next page shows this procedure.

14

Page 15

DD 7. Glue the 1/32" Plywood Polyhedral LE Brace

(from SPRTW06) in place against the leading edges. Install

ribs W3A and W3B between the inner and outer panels using

thick C A as shown in the photo. A little sanding may be necessary to achieve a good fit. Use the rib gauge to tilt the ribs

to the proper angle.

D 2. Use either epoxy or thick CA to glue one of the 1/16"

laminations to the 1/8" laminations. Apply as much pressure

(clamps, clothespins, weights, etc.) as possible while the glue

is curing and be sure to accurately line up the two pieces.

Next, glue this lamination assemby and the other 1/16" lamination, one on each side, to the aluminum joiner using epoxy

(The alumium joiner and the 1/8" Lamination should be i n th e

middle). Clamp together until the glue cures.

D 8. Now go back to step 5 on page 9 and assemble the

other half of the wing.

FINAL WING ASSEMBLY

IF YOU ARE BUILDING A ONE-PIECE

WING SKIP AHEAD TO STEP 4

D 1. Punch out three of the 1/16" an d one of the 1/8" Plywood Wing Joiner Laminations (SPRTW05 / SPRTW04)

and find the aluminum joiner. Lightly sand the edges of each

to remove any high spots.

D 3. Sand the edges of the finished "wing joiner" to

remove any glue globs and test fit it in the wi ng joiner box.

Some sanding may be required to get a nice smooth but not

loose fit.

IF YOU ARE BUILDING THE TWO.

PIECE WING SKIP AHEAD TO STEP 15

D 4. Prop up one wing half 2" (as measured from the work

surface to the bottom of rib W3) and sand the root (Inner) en d

of the trailing edge, spars and leading edges to achieve

vertical surfaces as you did earlier for the outer panels. Do the

same for the other wing panel.

D 5. Test fit the two inner panels together by laying one

panel flat on the work surface and propping up the other

panel 4" (at the bottom of ri b W3). Use the dihedral gauge

next to the last W2 rib to achieve the correct angle. Make sure

that each spar, etc. j u s t touches the opposite spar, etc. of the

other panel. Carefully sand the longest ends until a good joint

15 is achieved between each member.

Page 16

D 6. Punch out all four of t he Wing Joiner Laminations,

the Dihedral Braces and the Leading Edge Brace from the

die-cut sheets SPRTW04 an d SPRTW05. Test f it all of the

pieces in place and sand them if necessary to make them fit

nicely. The wing joiner laminations a re installed between the

spars and arc sandwiched in place by the dihedral braces. The

C1 clamps can be used to hold ev e rything in place.

place using thick CA. It should be centered (up and down) on

the leading edge because 1/16" sheeting w i ll be added later.

D 9. Locate one of the 1/16" x 3" x 24" Balsa Sheets

(SPRTW17) and cut it into 6 pieces 2-3/8" long. Slide one of

the sheets in place in front o f the dihedral brace, trim it to fit

and glue it to the LE and the dihedral brace with thick CA.

D 10. Glue another piece to the rear of the dihedral brace.

then cut a third piece to fit behind the second and glue it in

place.

D 7. When satisfied with the fit, mix up a batch of epoxy

(30 minute cure time is ideal, 5-minute is too fast), coat the

joiner laminations with a layer of epoxy and install the joiner

laminations between the spars. Quickly apply some epoxy to

the dihedral braces and hold them in place using the C1

clamps. Also apply some glue to the leading and trailing

edges and pin them together to keep them aligned with one

another. Wipe off any excess epoxy that may have squeezed

out before it cures. After the glue cures sand off any glue

globs that may have formed.

D 8. Glue the 1/8" Plywood Leading Edge Brace in

IF YOU ARE BUILDING A ONE-PIECE

WING THAT WILL BE ATTACHED

WITH RUBBER BANDS, DISREGARD

STEPS # 11,12,13 and 14 and instead just

glue all six W1A and W 1 B ribs in place.

D 11. Punch out six W1A ribs and six W1B ribs from the

1/8" d i e-cut balsa rib sheet (SPRTW01). Test fit these ribs

into position. A little sanding may be necessary to make them

fit properly. Glue all six W1B ribs into place using thi ck CA

(the two center W1B ribs arc glued together). Glue the outer

two W1A ribs into place but the remaining four W 1 A ribs will

not be added until later.

D 12. Cut a piece of 1/4" birch plywood (not included) to

fit between the leading edge and the spars. It will be called the

Front Wing Bolt Plate and should b e approximately 2-1/8"

x 2-5/16". Glue the wing bolt plate in place with either epoxy

or thick CA. Add strips of 3/16 triangle stock wherever

possible along the joints to help reinforce it.

D 13. Glue a W1A rib to each side of the wing bolt plate.

Trim the other two W1A ribs to fit together on top of the wing

bolt plate and glue them in place. Cut out a section of these

two W 1 A ribs to clear the wing bolt as shown in the sketch on

the top of the next page.

16

Page 17

-Cut W1A Rib and Leading Edge Sheeting

away to clear Nylon Wing Bolt

D 14. Add a 5/16" x 1" x 7/8" balsa filler block (not

included) on each side of the middle W1B ribs near the

trailing edge and sand them flush with the top of the ribs.

and act as a lunge for the gluing process. Press the sheeting

into place and trim it flush with the back edge of the spar using

a modeling knife and straightedge.

STEPS 15 - 18 APPLY TO ALL WING

CONFIGURATIONS

D 15. Set the 1/16" x 3" x 24" Balsa Leading Edge

Sheeting (SPRTW17)in place on the inner panel. The outer

end of the sheeting should cover rib W3A. Cut off the excess

sheeting even with rib W1A. Sand the top L.E. of the ribs if

necessary to allow the sheeting to be flush with the L.E.

D 16. With the 1/16" sheeting in place against the leading

edge apply several strips of masking tape to hold it in place

D 17. Lift the sheeting up and apply a bead of thick CA

along the top spar. Quickly press the sheeting down into place

and hold until the glue h as cured. A straight strip of wood the

length of the panel can be a big help when trying to hold the

sheeting down evenly.

D 18 . Apply a small bead of thin CA between the pieces of

masking tape along the leading edge. When al l of the glue has

cured, remove the tape, flip the wing over and securely glue

the sheeting to the ribs using thin CA as shown in the photo

at the top of the next page. Poke some pin holes in the center

sheeting where the center W1A rib is and apply a drop of thin

CA to each hole.

17

Page 18

IF YOU ARE NOT INSTALLING

SPOILERS SKIP TO STEP 28

D 19. Cut one 6-1/4" long spoiler from the UNNOTCHED scrap end of each Outer Panel Trailing Edge

(SPRTW12). Also cut two pieces of 3/16" x 1/4" balsa

6-9/32" long, four pieces 1-1/4" long, two pieces 1" long and

two pieces of 1/16" x 1/8" balsa 6-9/32" long. This wood is

not supplied in the kit bu t can be purchased at your local

hobby dealer. Set half of the pieces aside for the other side of

the wing.

D 23. With the spoiler in place, glue the 3/16" x 1/4" x

1-1/4" pieces of balsa to ribs W2. These are the spoiler rests

and should be positioned so they hold the spoiler flush with

the top surface of the wing. NOTE: It is important that th e

spoiler sit flush with the top of the wing o r it will unnecessarily disrupt the airflow over the wing.

D 24. Drill 1/8" holes in the ribs as indicated on the plans an d

snake a 1/8" diameter nylon tubing (Inner pushrod tube or

antenna tube, not included) through th e ribs. Cut a 1/ 8 " wide,

1/8" deep notch in the middle of the 3/16" x 1/4" x 1" piece of

balsa and glu e i t to t h e bottom of the 3/16" x 1/4" x 6-9/32"

piece trapping the end of the spoiler tube in the notch as

shown in the photo.

D 20. Glue the 1/16" x 1/8" x 6-9/32" piece of balsa to th e

back edge of the sheeting between the W2 ribs as shown on

the plans and in the photo.

D 21. Glue the 3/16" x 1/4" x 6-9/32" piece of balsa in its

notch on the W2S ribs. It should also be glued t o the W2 ribs

at the ends and it should be flush wi t h the TOP of the ribs.

D 22. Test fit the spoiler in its bay and sand it if necessary

to achieve a 1/32" gap around the sides and trailing edge. Use

a strip of masking tape to temporarily hinge the spoiler in

place.

D 25 . If you are using the spoiler setup shown o n th e plans,

the spoiler tube should exit the bottom of the wing just behind

the wing joiner box and the nylon tube should protrude

approximately 4 " to help the spoiler string clear the servos in

the fuselage. Drill a 1/8" hole in th e bottom center section

sheeting for the tube, insert the tube in place and glue the lube

to every rib and the sheeting using thick CA.

18

Page 19

these sheets to match the contour of the wi ng and be careful

not to add much to the wingspan with these extra sheets.

D 30. Sand three edges (two short and one long edge) of

each 1/16" Plywood Wing Protector (SPRTW18) to a taper

as shown on the plans and glue them in place on top of each

trailing edge. They should be oriented so the unsandcd edge

is flush with the back of the trailing edge an d they should be

placed 9/16" a way from the root of th e wing. These wi ll

protect the wing trailing edge from being dented.

Wing Protectors

FUSELAGE ASSEMBLY

D 26. Drill a 1/16" hole in each 1/16" Die-Cut Plywood

Spoiler Horn (SPRTW05) at the indentation. Cut a 1/16"

wide slot in the spoiler for the spoiler horn using a razor saw

(a hack saw blade wil l also work fine) and glue the horn in

place. It should be flush with the top surface of the spoiler as

shown on the plans. This completes the assembly of the

spoilers until after the wing is covered.

D 27. Assemble the spoiler on the other wing panel.

STEPS 28 AND 29 APPLY TO ALL WING

CONFIGURATIONS.

You'll need the following items:

SPRTF01 3/32" Balsa Fuselage Sides, Wing Saddle Tripler

SPRTF02 3/32" Balsa Fuselage Doublers

SPRTF03 1/8" Plywood From Fuselage Bottom

SPRTF04 1/16" Balsa Rear Fuselage Sheeting

SPRTF05

SPRTF07 1/8" Square x 24" Balsa Stringer

SPRTF08 3/16" x 30" Balsa Triangle

SPRTW05 1/16" Plywood Towhook Plate

1/8" Plywood Formers

ASSEMBLE FUSELAGE SIDES

D 1. Pin or tape the fuselage plan to your flat work

surface and cover it with waxed paper. Pin one of the 3/32"

Die-Cut Balsa Fuselage Sides (SPRTF01) down ABOVE

the FUSELAGE SIDE VIEW so y ou can use the plan for

reference. This is going to be the LEFT fuselage side.

D 28. Use the remaining piece of 1/16" balsa sheeting to

sheet the top inboard center section out past rib W1B as

shown in the photo. Thick CA should be used for this step.

Pre-cut the sheeting t o fit first near the spars, and cut a second

piece to fit between the first piece and the trailing edge. Glue

these in place and if you built a two-piece wing, sand the

sheeting flush with the W1A and W1B ribs at the wing root.

D 29. If you built a two-piece wing, trial fit the two wing

halves together using th e plywood wing joiner. Sand the root

of each panel if necessary to achieve a nice close joint

between the two wings. If there are large gaps, glue a sheet

of 1/16" balsa to the root of the panels to fill the gaps. Sand

DD 2. Trial fit one of the 3/32" Die-Cut Balsa Front

Fuselage Doublers (SPRTF02) onto th e 3/32" Balsa Fuselage Side. The doubler should line up with the fuselage where

the canopy wi ll sit. The arrows i n t he photo point out this

area. Spread a thin layer of thick CA on the doubler and glue

it to the fuselage side.

19

Page 20

DD 3. Glue the 3/32" Die-Cut Balsa Rear Fuselage

Doubler (SPRTF02) in place making sure it lines up with the

fuselage sides at the rear of the doubler where the arrows in

the photo arc pointing.

DD 4. Glue one of the 3/32" Die-Cut Balsa Wing

Saddle Triplers (SPRTF01) in place on lop of the front

fuselage doubler. Do not let the tripler overlap the notches for

the formers.

FRAME-UP THE FUSELAGE

D 1. Lay a piece of waxed paper over t he FUSELAGE

TOP

VIEW. Assemble but do not glue

Plywood Front Fuselage Bottom (SPRTF03) and the 3 / 3 2 "

Die-Cut Balsa Rear Fuselage Bottom (SPRTF04) together

over the FUSELAGE TOP VIEW on the plans. The 1/8"

plywood bottom should be installed with the three towhook

hole marks DOWN so you can tell where to drill the towhook

holes after the fuselage is assembled. Make su re th e bottoms

are aligned with the plan and that both pieces are pushed

firmly against the work surface to even up the bottoms. If the

joint is a nice tight fit, apply thin CA to the joint. If the joint

is a little loose, tak e the bottoms apart, apply thick CA and

reassemble them.

glue

yet

1/8"

Die-Cut

DD 5. Cut one of the 1/8" Square Balsa Stringers

(SPRTF07) to fi t between the notch for former F5 and the rear

doubler and glu e it in place making sure it is lined up flush

with the lop edge of the fuselage side (excluding the tabs).

Cut another 1/8" sq. balsa stringer to fit along the bottom

between the rear doubler and the notch for former F5 and glue

it i n place. Make sure it is lined up flush with the bottom edge

of the fuselage side (excluding the tabs).

D 6. Go back to step 2 and assemble the RIGHT fuselage

side. The easiest way to do this is to pin the other fuselage side

upside down above the one you just built as shown in the

photo. MAKE SURE YOU ARE NOT BUILDING TWO

IDENTICAL SIDES, THEY SHOULD BE THE OPPOSITE OF EACH OTHER.

D 2. Trial fit all of the 1/8" Plywood Formers (except

Fl) in the respective notches in the fuselage bottom and sand

them if needed to make them fit properly. Use thick CA to

"Tack" glue the formers in place. The notches in the

fuselage sides will align the formers correctly.

D 3. Align the fuselage sides with the fuselage bottom

and position the formers so they will key into the notches.

Remove the assembly from the work surface and use rubber

bands to hold it all together.

D 4. Check the fit of the 1/16" Plywood Tow-hook Plate

(SPRTW05) in its slot between formers F4 and F5. Enlarge

the slot if needed to make the plate fi t and glue it to the

20

Page 21

fuselage bottom with thick CA. Use the fuselage sides to help

position it.

joints and around former F 6 . Take your time apply ing the thin

CA and be sure to get the bottom and the sides pressed

together nicely. Thick CA can then be added to these joints

to add strength.

D 7. Pull the front fuselage sides together and trial fit the

1/8" Plywood Former F1 in place. Apply t hick CA to the

front fuselage bottom and the formers, install F1 and pull the

fuselage sides together. A few rubber bands can be used to

help hold the assembly while the glue cures.

D 5. Spread the fuselage sides ou t and apply thick CA to

formers F4 and F5 and the fuselage bottom between them.

Reassemble, check to make sure the sides are pressed firmly

against the formers and the bottom is ful l y seated against the

sides, and allow the glue to cure.

D 6. Pull the rear fuselage sides together and make sure

that the sides are pressed firmly against former F 6 and that the

bottom is fully seated against the fuse sides. A couple of C2

clamps can be used to hold the tail of the fuselage together and

rubber bands will help around the formers. Apply a couple of

drops of thick CA on the back edge of the rear fuselage

doubler and a bead of thin CA along the bottom sheeting

D 8. Trial fit the 3/32" Balsa Rear Top Fuselage Sheet

(SPRTF04) in place*, and when satisfied wit h its fit apply a

bead of thick CA along the 1/8" balsa stringers, the fuselage

doublers and the fuselage sides and glue it in place. *NOTE:

The top sheeting should be installed s o the rudder pushrod

cut-out is on the le ft side of the fuse. Check the plans for

the proper orientation.

D 9. Cut the 3/16" Balsa Triangle (SPRTF08) into th e

following lengths:

two pieces - 4-5/8" long

four pieces - 2" long

two pieces - 4-1/16" long

two pieces - 2-7/8" long

one piece - 1-1/4" long

21

Page 22

These pieces should be glued wi th thick CA. They are

pressed into t he corner between t h e fuselage bottom and the

fuselage doubler in th e following places:

Glue the 4-5/8" pieces behind the towhook plate.

Glue the 2" long pieces on top of and in front of the

towhook plate.

Glue the 4-1/16" long pieces between formers F3 and F4.

Glue the 2-7/8" long pieces between former F2 and F3.

And glue the 1-1/4" long piece along the bottom between

formers F1 and F2 to seal the gap there.

inside

of

the

fuselage)

CA around the outside edge of each blind nut (be careful not

to get glue inside the blind nut!).

with a hammer and put a drop

of

thick

IF YOU ARE NOT BUILDING A

BOLT-ON WING SKIP AHEAD TO

"ASSEMBLE THE CANOPY".

D 10. Sand the fuselage sides and bottom flush with the

front of former F1 and glue the Shaped Balsa Nose block

(SPRTF10) in place with thick CA. The bottom of the nose

block should overlap the fuselage bottom by about 1/32" to

allow for sanding to final shape.

D 11. Drill three 9/64" (1/8" is light but will work) holes in

the 1/8" plywood bottom for the towhook. There should be

three indentations to show you where to drill. Gently Tap the

three 4-40 Blind Nuts (NUTS001) into the holes (from the

D 12. Cut two pieces of 1/4" birch plywood (not included)

which will be drilled and tapped for the wing bolts. The front

piece should be approximately 2-1 /32" x 1" and the rear piece

should be approximately 2" x I". You will want t o measure

your fuselage to make the parts fit properly. You should cut

the wing saddle tripler away s o the blocks can glue directly to

the fuselage doubler. Securely glue these in place with thick

CA or epoxy. Glue triangle stock around each one for extra

strength.

D 13. Glue a 1/16" Plywood Rear Wing Bolt Plate (not

included) on top of the wing trailing edge to protect it from

being crushed by the rear wing bolt (see the wi ng plan top

view for the approximate size and shape).

22

Page 23

D 14. Insert the 1/4" wing dowels in the holes in the

fuselage and temporarily rubber band the wing in position on

the fuselage and use a string as shown in the sketch to make

sure it is on straight. Make a couple of marks on t he wing a n d

fuse to help you make sure it stays in position while drilling

the wing bolt holes.

D 1. Trial fit the 1/8" Plywood Canopy Back

(SPRTF05) and the 1/8" Plywood Canopy Front

(SPRTF05) in place in the Formed ABS Cockpit

(SPRTF12). Sand them if necessary for a good fi t and then

glue them in place with thick CA.

D 15. Drill a 13/64" hole through the wing and 1/4" ply

plate in the fuse approximately 1" behind the front of the

leading edge.

in front of the rear of the trailing edge as shown on the

FUSELAGE SIDE VIEW of the plans.

D 16. Remove the wi ng and enlarge the two holes in the

wing to 17/64". Use a 1/4 - 20 tap to thread the holes in the

fuselage blocks. Test fit the wing i n place with 1/4 - 20 nylon

bolls (not included). Cut the 1/16" top sheeting away to clear

the front wing bolt.

Drill

another 13/64" hole

approximately

1-1/4"

ASSEMBLE THE CANOPY

You'll need the following items:

SPRTF06 1/8" Balsa Canopy Base

SPRTF05 1/8" Plywood Canopy Front and Back

CANPY044 Clear Canopy

SPRTF12 Formed ABS Cockpit

D 2. Sand the bottom edges of the canopy front and back

flush with th e bottom of the cockpit. Be careful not to sand

through the cockpit. A small flat file works well for the front

former.

D 3. Check the fit of the 1/8" Balsa Canopy Base

(SPRTF06) in the cockpit. Sand the sides of the base until it

will easily fit into the cockpit. When satisfied with the fit glue

it in place w i th thick CA.

D 4. Cut and sand off the extra cockpit material flush

with the edges of the canopy back, canopy base, and canopy

front. Saturate the front edge of the canopy base with thin CA

and allow it to soak in and cure. This is where the canopy hold

down dowel wil l rest. Sand the front and back edges of the

base flush with the Canopy Front and the Canopy Back.

D 5. Paint the cockpit with the color scheme of your

choice. Test the paint you are going to use on a piece of the

plastic you cut off to make sure it will not affect the plastic.

Regular plastic model paints usually work well for this. Do

not paint the edges of the cockpit where the canopy will attach

or the glue will no t hol d a s well. Striping tape can be used to

cover that seam. Lightly sand the edges to help the canopy

23 adhere.

Page 24

D 6. The canopy may have a Plastic Film on either or both

sides. Check for t his and remove it if you find one. Tint the

Canopy (CANPY044) if you wish, using powdered clothing

dye that you can buy at the grocery store (Rit, etc). Use very

warm water (warmer than you can leave your hand in) but do

not use very hot water or the canopy may deform. The

warmer the water and the longer you leave the canopy in the

dye, the darker the tint will be. Liquid dyes do not seem to

work as well.

D 7. Set the cockpit inside the canopy and line the cockpit

up with the scribe lines in the canopy. The scribe lines are

only for reference while positioning the cockpit, do not try to

get the cockpit to fit the scribe lines. Glue the canopy to the

cockpit using CA. Use the glue very sparingly by holding th e

cockpit in place inside the canopy and apply glue a drop at a

time to the seam. The glue will seep in along the seam and

provide a nice clean glue joint. Work you r w a y around the

canopy and don't get in a hurry or you may get too much glue

in there and it wi l l r u n d o wn th e ca nopy. Be careful not to

twist or move the cockpit once y o u start gluing it in place.

D 10. Measure up along the nose block 1/4" from the

fuselage side and make a mark. Do this on both sides of the

nose block and then draw a line across between the two

marks. Measure to the middle o f thi s line and make another

mark. Drill a 1/8" diameter hole about 1" deep at approximately the angle shown on the plans right where you made the

last mark.

D 8. Trim the canopy flush with t h e base and the front but

do not trim the back yet! A small pair of scissors works well

for trimming the canopy. Temporarily mount the wing in

place on the fuselage. VERY CAREFULLY trim the back

of the canopy, A LITTLE AT A TIME, to fit over the wing.

Take your time and use the outlines on the plans and the wing

for guides.

D 9. Test fit the canopy onto the fuselage. You can sand

the edges of the canopy slightly or you can sand the fuselage/

nose block if needed to get it to fit properly. You can also add

a layer of balsa to the back edge of the nose block to take up

any extra gap if needed.

D 11. Insert the 1/8" diameter Canopy Hold Down

Dowel (DOWEL033) into the hole and slide the canopy into

place to make sure it fits nicely. The dowel should hold the

canopy down against the fuselage. If it is too loose you can

either enlarge the hole slightly and move th e dowel down or

you can build up th e top surface of the canopy base with thin

plywood and/or thick CA. Glue the dowel in place wit h at

least 1/4" extending.

D 12 . Cut two pieces of 1 / 8 x 3/1 6" balsa (from SPRTS03),

one 1-7/8" long and the other 1-1/4" long. Wedge the longer

piece between the fuselage sides above the receiver compart-

24

Page 25

merit and wedge the other one between the sides in the weight

compartment. These pieces arc called the Canopy Aligners.

Lift the aligners so that they are slightly above the sides.

Apply a small drop of thick CA to the middle of each aligner

and carefully slide the canopy into place. Push down on the

canopy to force the aligners against the canopy base (with t he

canopy aligned with the fuselage sides) and hold it until the

glue has cured (a couple of minutes). Carefully remove the

canopy and securely glue the aligners to the canopy base with

more CA.

D 13. Apply a couple strips of masking tape around the

front of the canopy to protect the plastic and install the canopy

on the fuselage. Use a razor plane, hobby knife or sanding

block with coarse grit sandpaper to rough carve the nose

block to shape.

plane fore and aft". That very important step

will be covered later in the manual.

Now that you have the basic airframe nearly completed,

this is a good time to balance the airplane laterally (side-to-

side). Since the wing is the major factor on a sailplane, we

will only be concerned with it. Here is how to do it:

1. Set t he wing o n a flat surface and hold i t s o that both

wing tips are level. Let go of the wing and notice which wing

tip drops. Do this several times and if the same wing tip keeps

dropping push a thumb tack or small nail through rib W 1 0 into

the wing tip that keeps rising.

2. Perform this test several times until the wing balances or the same wing ti p does not drop every time and then

glue the tacks or nails in place with a drop of thin CA.

FINAL SANDING

Check over the entire structure carefully, inspecting for

any poorly glued joints, gaps and "dings". Apply additional

glue and/or balsa filler as necessary, then sand the entire

structure smooth using progressively finer grades of sandpaper. Sand the fuselage corners to a rounded shape as shown

on the cross sections of the plans.

COVERING

D 14. Use your sanding block with medium and then fine

grit sandpaper to smooth out the nose block and fair it in with

the canopy and the fuselage.

FINAL ASSEMBLY

BALANCE THE AIRPLANE LATERALLY

There are many different types of covering materials

available these days but the iron-on type coverings are by far

the easiest to use and in most cases the best suited for the job.

There are also several different brands of iron-on coverings

available. We recommend you use Top Flite Super

Monokote for covering your SPIRIT due to thi s covering's

higher strength. Sailplanes, which usually have higher

"aspect ratio" wings (long and thin), gain a great deal of

strength from the covering. This is evident b y gently twisting

the wing before and after it is covered, it is hard to believe the

difference. Because of this, the higher strength coverings are

best suited for sailplanes.

The following are some covering tips we have learned

over the years but you should follow the instructions in-

cluded with your covering material.

• Sand the surfaces as smooth as possible before starting to

cover the plane. The finished covering job wil l only be as

smooth as the surface you started with.

• Use a fresh single-edge razor blade or hobby knife blade

and replace the blade as soon as it starts showing signs of

dulling.

SPECIAL NOTE: Do not confuse this procedure

with "checking the C.G." or "balancing the air-

• Set the iron to the proper temperature by first applying a

25 "test strip" on a scrap of balsa.

Page 26

• Work outward, start by tacking the covering in place at the

comers and then start in the middle and work your way out to

the comers, gently pulling any wrinkles out as you go.

• Securely seal al l edges! Make sure the edges are firmly

sealed down to prevent the covering from pulling away at the

seams when shrinking the panel.

wing

17. Top of left

and TE)

18. Top of right wing panels (overlap covering 1/4" a t

LE and TE)

19. Spoilers if installed

panels (overlap covering

l/4"at

LE

NOTE: When covering the fin, begin by applying

a 1/2" wide strip of covering on each triangle. Next,

cover the rest of the fin with pre-cut pieces that have

a straight edge to overlap (1/8"+ overlap) the strips

you previously applied. This is a tip you should

remember as it makes it a lot easier to cover

"compound" curves.

Because the fin has to glue on top of the stab and the stab

has to glue to the fuse you do not want to cover where these

surfaces will glue to each other. The following instruction

will explain how to do this.

D 1. Position the stabilizer on the fuselage and aligned

with the fuselage using the procedure at step 3 on page 27.

Hold it in place and mark along the fuselage/stabilizer joint

with a felt pen to show where not to cover.

D 2. Position the fin in place on top to the stab. Make sure

it is centered and pointing straight ahead, and mark around the

base with a felt tip pen.

D 3. When applying the covering to the top and bottom

surfaces of the stab, do each side with two pieces of covering.

Do not cover between the lines. Cut the covering to fit around

the lines before you iron it in place. Also do not cover each

surface of the slab with one sheet of covering and then cut the

covering away between the lines. Doing this leaves "cut

lines" in the wood and greatly weakens the stab structure.

CHECKING FOR WARPS

This is a very important step and should be done every

once in a while throughout the flying season. A sailplanes

wing is most efficient when it is not twisted or warped at all.

"Washout" (wing trailing edge twisted up at the tip) helps

make a poor wing design fly belter by adding some stability

(preventing stalls) at slow speeds but it cuts down on the wing

efficiency at normal speeds. The SPIRIT'S wing is designed

to fly well at slow speeds without a ny washout and therefore

we recommend you check to make sure the wings are "flat"

using the following procedure.

D 1. Set the wing so an inner panel is resting on a flat

surface. Any warp (twist) will show up by cau s ing a comer

of the panel to rise off of the work surface.

D 2. To remove the warp, gently twist the win g in the

opposite direction while a helper glides an iron or heat gu n

over the covering on both the top and the bottom of the panel

to re-shrink the covering. Hold the twist until the covering

cools and then recheck for warps. It may take several trys to

get a warp o ut but it is worth it as you w ill end up with a

sailplane that flies straight and true and responds to air

currents like a high performance sailplane should.

D 3. Follow the same procedure to check all four wing

panels and then go back and double check them. Sometimes

you put a warp in one panel while trying t o fix another. You

should also look at the tail surfaces as they too can warp.

Recommended Covering Sequence:

1. Strips as described in above note

2. Fin left side

3. Fin right side

4. Rudder left side

5. Rudder right side

6. Bottom of elevator

7. Top of elevator

8. Stab bottom right side

9. Stab bottom left side

10. Stab lop right side

11. Stab top left side

12. Fuse bottom

13. Fuse sides

14. Fuse top

15. Bottom of left wing panels (inner and outer)

16. Bottom of right wing panels (inner and outer)

GLUE THE HINGES

D 1. Lay the rudder and elevator on the plans and mark on

the leading edge o f each part the locations of the hinges. Now

use a sharp hobby knife to cut slits in the covering at the hinge

locations. Trial fit the hinges t o make sure you have'' found''

the slots which you previously cut. In the same manner, slit

the covering at the hinge locations in the stab and fin TE.

D 2. When gluing the hinges it is important that plenty of

glue gets inside the hinge slot. If you just put glue on the

hinge, most of it will be wiped off as the hinge is inserted into

the slot. A good way of getting glue into the slot is to scoop

up some epoxy with a plastic soda straw, then pinch the end

of the straw, insert it into the slot, and squeeze the straw to

force the glue into the slot. Apply epoxy to the hinges, insert

26

Page 27

them into place (up to the middle of th e hinge) and wipe away

all excess epoxy with a tissue (for best results dampen the

tissue with rubbing alcohol).

MOUNT THE TAIL SURFACES

D 1. Use your sanding block with medium grit sandpaper

to chamfer (slightly round) the ends of the 1/4" Hardwood

Wing Dowels (DOWEL030) Insert the 1/4" wing dowels in

the holes and secure with thick CA. (Omit this step if you are

using a bolt-on wing.)

place on the rudder and elevator with a drop of thin CA. Use

the plans as a reference for positioning the horns (Rudder on

the left, elevator on the bottom). Drill two 3/32" holes

through the control surfaces using the control horns as guides.

Temporarily mount the horns with the 2-56 x 3/8" Screws

(SCRW001) and the Nylon Nutplates which were attached to

the horns, 2-56 X 3/8" Screw

D 3. Cut 4-1/4" off both threaded ends of the 36" Wire

(WIRES 17) and then cut two pieces 12" long from the

remaining piece of wire. Bend them as shown on the plans

except without the Z-bends. The Z-bends are not bent until

later. Wipe off each wire using a paper towel dampened with

rubbing alcohol to remove any oil.

D 2. Rubber band or bolt the wing onto the fuselage

making sure it is square and centered with respect to the

fuselage.

D 3. Position the stabilizer on the fuselage and measure

to get it centered and properly aligned. Glue the stabilizer to

the fuselage with either thick CA or epoxy. Check its

alignment with the wing while the glue is curing to make sure

they are level with each other.

D 4. Cut the pushrods from the 1/4" Square Balsa Sticks

(SPRTF09). The elevator pushrod should be 17-3/4" long an d

the rudder pushrod should be 15-1/4" long.

D 5. Drill a 5/64" hole 2-1/4" in from both ends of each

pushrod.

D 4. Position the fin in place on top of the stab. Glue the

fin in place on top of the stab and fuse using either thick CA

or epoxy. Check to make sure it is pointing straight at the nose

and is vertical (90 degrees) to the stab.

ASSEMBLE PUSHRODS

D 1. Harden the balsa in the area of the control horns (o n

both sides of the control surfaces) by poking several holes

with a pin, then apply thin CA glue and allow it to so ak in and

cure.

D 2. Tack glue the Nylon Control Horns (NYLON03) in

D 6. Use either a hobby knife, razor plane or coarse

sandpaper to taper three sides on each end of both pushrods.

The taper should start about 1-1/2" from the end. (One of the

sides wit h the 1/16" holes should remain flat).

D 7. Insert one threaded piece of wire into each pushrod.

Insert the 12" pieces of wire into the other end of each

27

Page 28

pushrod. Tack glue the wires in place with a couple drops of

CA. Firmly wrap the end of the pushrod with strong thread

and apply thick CA to hold everything in place as shown on

the plans and in the photo.

two servo horns you cut earlier with the arms facing opposite

directions as shown on th e plans. Operate the transmitter

sticks to make sure the servo horns turn freely without hitting

each other or the fuselage sides. If they do, cut or sand them

until they will operate freely. Turn off the receiver first and

then the transmitter.

INSTALL RADIO GEAR

D 1. Slide one of the 1/4" x 3/8" Basswood Servo Rails

(SPRTF11) into its slot in the fuselage doubler. Slide it all the

way forward and glue it in place wit h thick CA. Slide the

other servo rail into place and then slide it all the way to the

back. Do not glue it yet! Position one of your servos in place

and use it to position the rear servo rail. Do not push the rear

servo rail up tight against the servo but rather leave about a

3/32" gap between the servo "body" and the rear servo rail.

This will give you enough room to put the servos in and out

without removing the rails. Glue the rear servo rail in place.

D 2. Position both of the servos together in the middle of

the rails and mark where the holes for the servo mounting

screws should be drilled. Remove the servos and drill 1/16"

holes where the marks are. Install the servos, with the wires

exiting forward, using the servo mounting screws that came

with the radio.

D 3. Cut three "arms" off of two X-type servo horns

using wire culling pliers or a razor saw as shown in the

following sketch.

D 5. Screw a Nylon Clevis (NYLON17) onto the

threaded portion of each pushrod. Slide the pushrods into t he

fuselage. The rudder pushrod exits the top of the fuselage just

in front and to the left of the fin. The elevator pushrod exits

the hole in th e rear of the fuselage. Snap th e nylon clevises

into the outermost hole in the servo horns. The rudder

pushrod goes to the left servo and the elevator pushrod goes

to the right servo. With the control surfaces in their neutral

position, use a fe lt tip marker to make a small mark on each

pushrod wire where they cross the holes in the control horns.

Remove the pushrods from the fuselage and make a Z-bend in

each wire with the first bend starting where the marks are.

Nylon Clevis

(Airplane shown not covered ,for reference)

D 6. Cut any excess wire off 1/4" past the Z-bend and

reinsert the pushrods into the fuselage. Remove the nylon

control horns from the elevator and rudder and install the

horns onto the pushrods. Both pushrods should connect to the

control horns through the second hole from the inside. Rein-

stall the control horns to the elevator and rudder. Adjust the

nylon clevis or the bends in the wire until the control surfaces

are at neutral when the servo horn is perpendicular to the

centerline of the fuselage.

D 4. Read and follow the instructions that came with your

radio to install o r charge the batteries and get the servos ready

for mounting. Plug the servos and the battery pack into the

receiver and turn on the transmitter first and then the

receiver. Adjust the trim levers to their neutral positions and

allow the servos to return to their neutral positions. Install the

D 7. If you are installing spoilers, mount the spoiler servo

between formers F3 and F4. It can be mounted on servo rails,

or on its side with servo tape. C ut 3 arms off of an X-type

servo horn as you did for the tail surfaces and mount a #2 x

3/8" (not included) screw in the outer hole. Adjust the servo

and your transmitter so the hom is almost pointing towards

the rear of the plane when your transmitter stick is in the

"spoilers closed" position. The horn should rotate towards

the front o f the plane when the transmitter stick is moved to

the "spoilers open" position. Which way the transmitter

stick moves to open the spoilers is up to you. Both directions

are used by todays pilots.

28

Page 29

D 8. Pack the receiver in at least 1/4" of foam and install

it in between formers F3 and F4. If you are installing spoilers,

mount the receiver behind the rudder and elevator servos.

The receiver antenna can run down through the fuselage but

try to route it as far away from the servos and servo wires as

possible. Allow the excess antenna to trail from the fuselage.

DO NOT CUT THE ANTENNA!

INSTALL THE SPOILERS IN THE WING

(OPTIONAL)

D 1. Thread a 30" long piece of braided fishing line

through the spoiler tubing in the wing.

D 9. The receiver switch can be taped to former F3 with

double sided foam tape. Because the canopy is so easy to

remove, there is no need for the switch to be accessible from

the outside (this helps cut down on aerodynamic drag and

accidental shut-offs during launching as well).

D 10 . The battery pack should be wrapped in 1/4" of foam

also and it should be positioned between formers F2 and F3.

D 11. Hook up your radio system and test the operation of

all controls. The controls should move smoothly without any

binding or looseness.

CONTROL THROWS