Page 1

Sportster

Instruction Manual

Bipe

40

Engine size

Wingspan 45 1/2"

Wing Area

Length 41 1/2"

Weight

Materials Needed to Complete

4

Channel radio Propeller Fuel tank

Engine Wheel collars Spinner

Fiberglass cloth/resin Wheels Covering

Engine mounting bolts Hinges Instant glue

Pushrods/clevises Wing bolts EPOXY

The Sportster Bipe

vides full aerobatic maneuverability, yet has enough wing area for docile low speed capability.

The parts are machine cut and sanded for accurate fit. Should you notice a difference in size between

plans and parts, it is usually because paper changes size with moisture.

Different types of glue may be used such

glue). Build on a flat surface for straight wings and fuselage.

Please read through this step

overall idea of the construction steps and t o avoid mistakes. Use the plan and parts list to identify the var

ious parts.

40

.35-.45

716 sq

5-61/2

was designed for sport flying. This biplane design with symmetrical wings pro

.

in.

Ibs.

the

Sportster:

as

epoxy, cyanoacrylate(instant glue) and aliphatic resin (white

-by-

step instruction manual before you start building soyou will have an

-

-

WAR

This R/C kit and the model you will build is not a toy! It is capable of serious

bodily harm and property damage.

-

ALONE

gear (engine, tank, pushrods, etc.) and to test the model and fly

enced, competent help in accordance with all safety standards and common

sense as set down in the Academy of Model Aeronautics Safety Code.

gested that you join the AMA and become properly insured before you attempt to

fly this model. I F YOU ARE JUST STARTING R/C MODELING, CONSULT YOUR

LOCAL HOBBY SHOP

TO

FIND AN EXPERIENCED INSTRUCTOR IN YOUR AREA.

to build this kit correctly, properly install all R/C components and flying

OR

WRITE TO THE ACADEMY OF MODEL AERONAUTICS

Academy of Model Aeronautics

1810 Samuel Morse Dr.

Reston, VA

22090

N

IT

I

N

G

IS

YOUR RESPONSIBILITY AND YOURS

PO

BOX

!

788

URBANA

it

only

lLLlNOlS61801

with experi

It

2171367

is sug

2069

-

-

Page 2

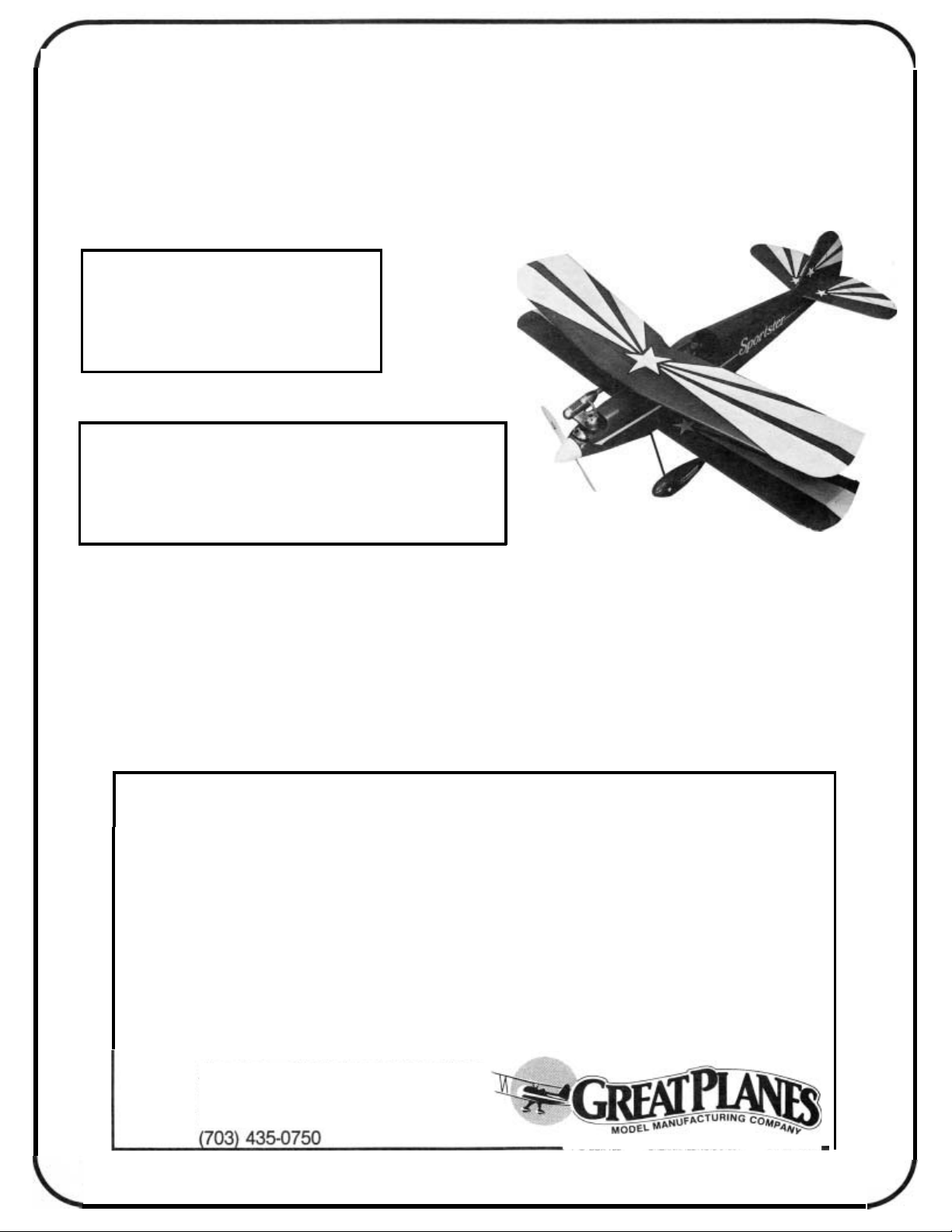

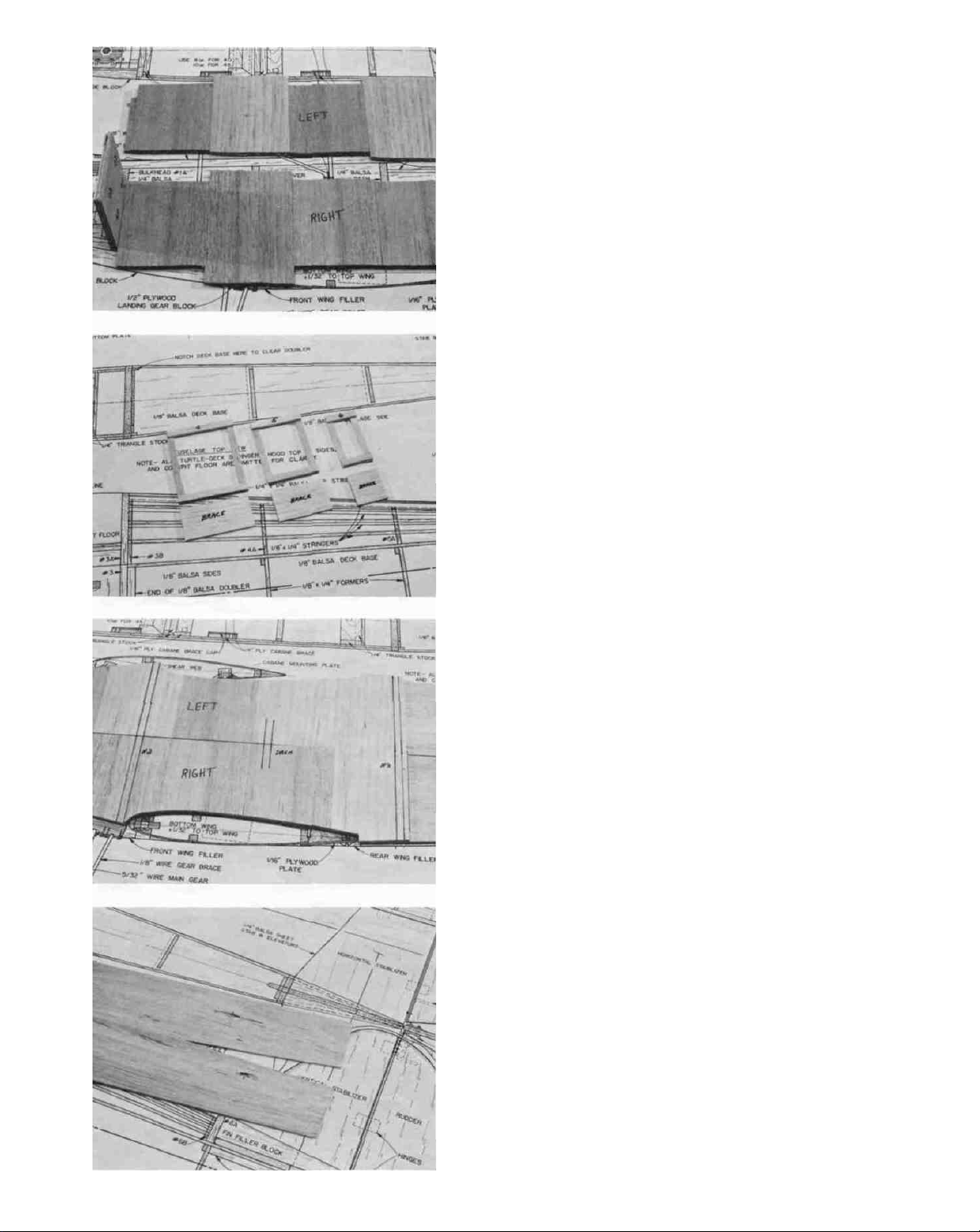

BUILDING THE TAIL

PREPARE THE FIN AND RUDDER

SECTION

Sandthe forwardand rear sectionsof the fin

sary for a good fit. Working over the plans, glue the fin section

pieces together. Sand both sides of the rudder.

CUT THE HINGE SLOTS IN THE FIN AND RUD

DER; CUT OUT RUDDER FOR JOINER CLEAR

ANCE

Draw centerlines down the trailing edge of the fin

and the leading edge of the rudder. Mark and cut the hinge

slots. Two hinges are used above the stabilizer. The third hinge

should be just below the stab and above the tail wheel strut

tab. Cut out part of the rudder leading edge for elevator joiner

wire clearance. Wait to shape the leading edge until the hole

is drilled for the tail wheel tiller arm later.

if

neces

-

-

-

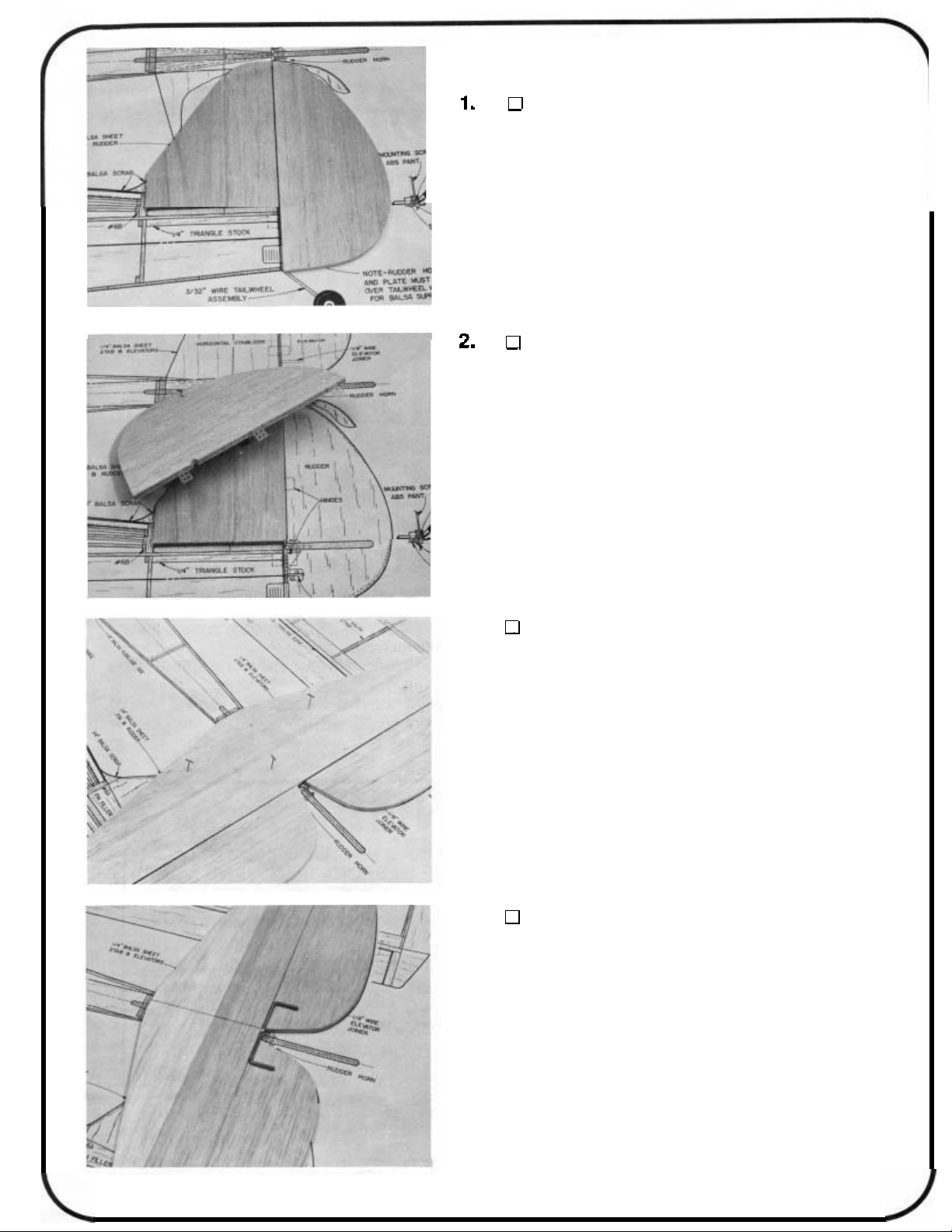

3.

the stab

sides of the stab and elevator halves.

4.

the stab and a centerlinedown the leadingedges of the elevator

halves. Mark the center of the elevator joiner wire. Align the

stab, elevator and joiner wire and mark the hole locations for

the joiner wire arms on the centerline of the elevator leading

edge. Drill the holes.

GLUE STAB PARTSTOGETHER; SAND THE STAB

AND ELEVATORS

Check the fit and sand the forward and rer parts of

so

they fit together well. Glue them together. Sand both

DRILL HOLES IN THE ELEVATOR HALVES FOR

ELEVATOR JOINER WIRE

Draw a front to back centerline down the top side of

2

Page 3

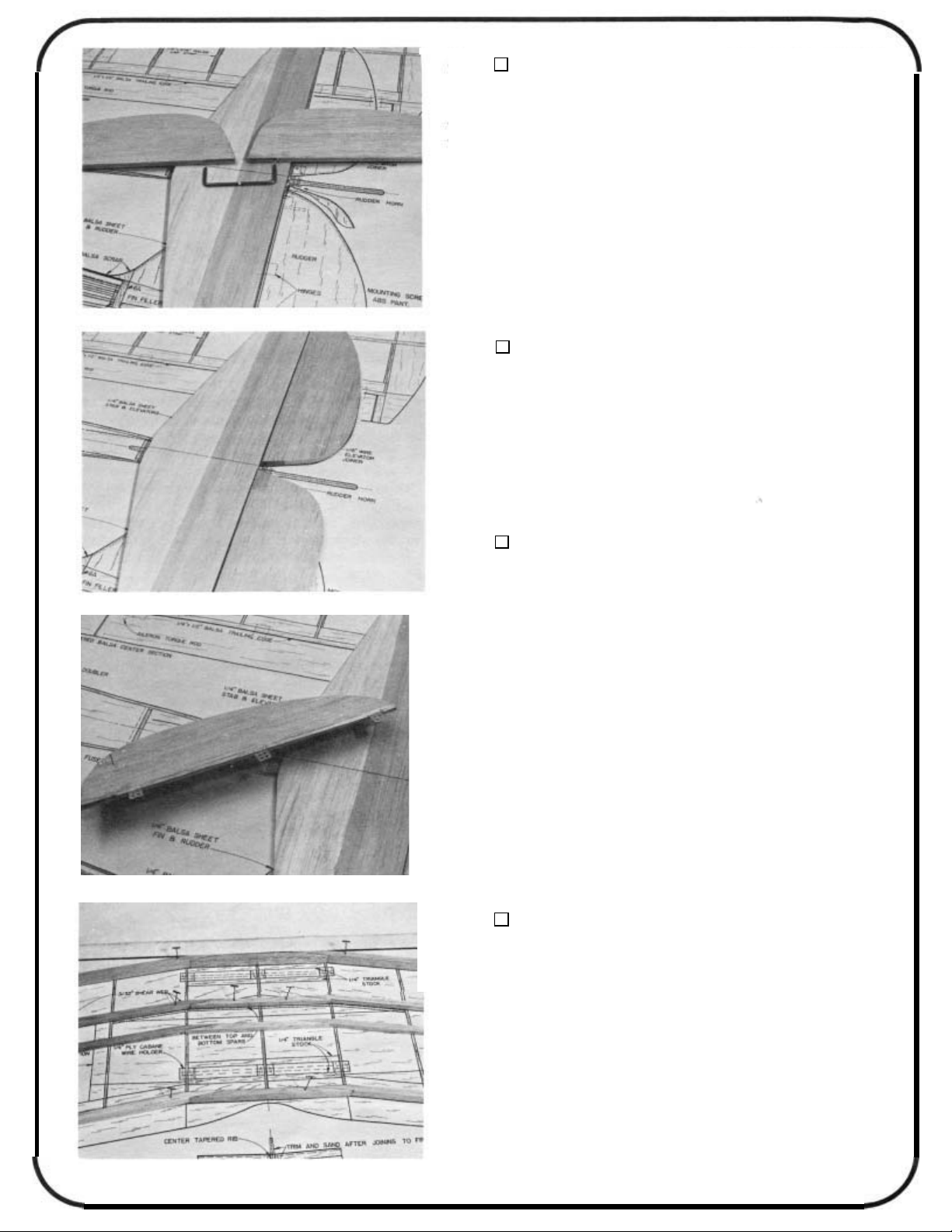

5.

the hole

the leading edge of the elevator.

GROOVE OUT THE ELEVATORS

WIRE CLEARANCE

Cut a groove in the elevator leading edge inside of

so

when the joiner wire is installed it will be flush with

FOR

Do

both elevator halves.

JOINER

6.

elevator halves. Check to make sure that this assembly is

aligned properly. Bend the joiner arms

fit.

DO NOT GLUE THE JOINER WIRE TOTHE ELEVATOR

HALVESUNTILAFTERTHE PIECESARE COVERED LATER.

7.

halves as you did with the fin and rudder. See the plans for

locations. Shape the leading edges of the elevator halves to a

V’.

READ THIS FIRST BEFORE YOU START BUILDING THE

WING PANELS: It is very important that you build straight wings

with nowarps or twists or you will get some flying characteristics

you didn’t expect! Bevery careful when you align the ribs, spars,

leading edges, trailing edges and sheeting at the various steps

below. All these parts should be in their correct positions before

you glue them in place. Hold or pin the parts in place, then

glue. Use the following instructions to help you build the wing

straight and warp free.

TRIAL FIT THE JOINER WIRE

Temporarily install the elevator joiner wire into the

if

necessary for a perfect

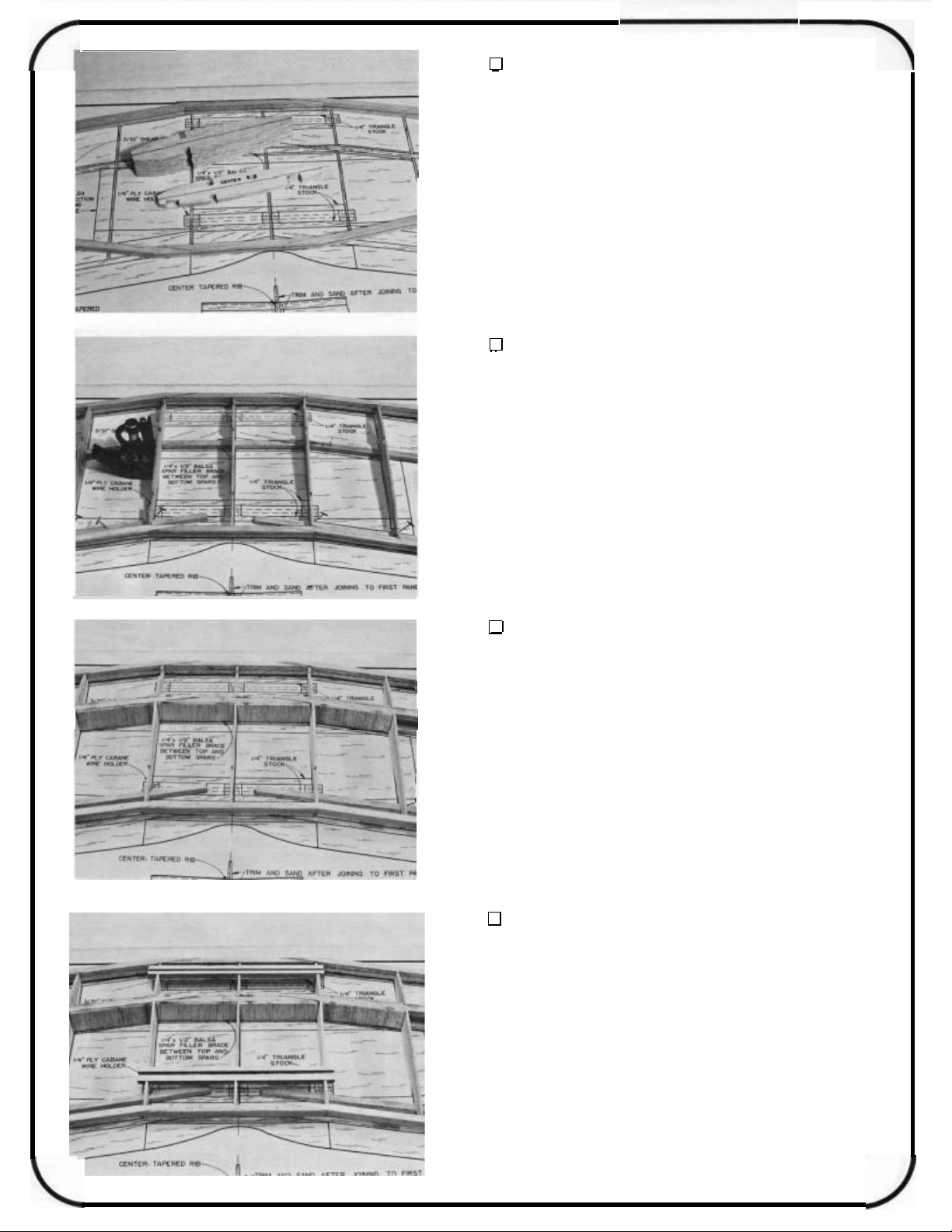

CUT HINGE SLOTS FOR THE STAB AND

ELEVATOR

Mark and cut the hinge slots for the stab and elevator

Remember: Anyone can build a wing. Only

can build a straight wing.

BUILDING

Start the top wing by building twospars from 1/4 x

1/4 x 24 balsa, aleadingedge from 1/4 x1/2 x 24 balsa and

a trailing edge from1/4x

on the plan. Cut the parts, fit them together and then glue

overtheplan. The top wing is builtin one piece. You will

build the top wing upside down at first. Use epoxy when

you gluethese pieces together in this step.

3

THE

TOP

1/4 x 24

WING

balsa. U se waxedpaper

a

careful builder

Page 4

2.

top wing rib. Note that the three center ribs have2 extra notches

for the cabane mounting plate. Draw rib alignment centerlines

down the back of the leading edge and the front of the trailing

edge.

PREPARE THE RIBS

Draw a rib alignment line down the center of each

3.

down) over the waxed paper covered plan. Place the ribs on

the spar. Align the ribs at the positions shown on the plans.

Make sure that the three center ribs have the cabane notches

"up"

extra 1/4 x 1/4

drew on the ribs are parallel to the building board. When the

ribs are aligned correctly, and at 90 degrees to the building

board, glue the ribs

with the line on the leading edge. Glue the ribs

edge. Line up the trailing edge line

ribs

4.

two end center ribs for the 1/4 x 9/16 balsa spar filler brace.

Glue in the 1/4 x 9/16 filler brace pieces from the center rib out

past the spar scarf joint on both sides of the center rib. Glue

in the bottom spar. Now cut shear web pieces from 3/32 x 3

24 balsa to fit between the spars at the rib bays shown on the

plan. The wing should still be shimmed up with the extra spars

throughout the building process. Use epoxy in this step.

ALIGN AND GLUE RIBS, LEADING EDGE AND

TRAILING EDGE TO TOP SPAR

Pin the top spar (the wing will be built (upside

as shown. Shim up the trailing edges of the ribs with the

x

24 spars, making sure the centerlines you

to

the spar. Line up the lines on the ribs

to

the leading

to

the rib lines and glue the

to

the trailing edge.

GLUE IN SPAR FILLER BRACE, BOTTOM SPAR

AND SHEAR WEB

Cut out the area between the spar notches on the

x

I

5.

wire holders with epoxy into the slots in the htree center ribs.

Make sure the cabane holders are flush with the top edges of

the ribs.

4

ADD THE CABANE HOLDERS

Glue in the two plywood 1/4 x 1/2

x

6 1/2 cabane

Page 5

6.

on the 1/16

x

24 trailing edge sheeting and the 1/16x3x15 center section

sheeting. Do not glue the sheeting

you will cut away this sheeting later. Cut cap strips from 1/16

3/16x36 balsa and glue them in place over the rib edges.

ADD THE SHEETING AND CAP STRIPS

Cut the sheeting to fit first then glue in place. Glue

x

2-1/8x24 leading edge sheeting, the 1/16x7/8

to

the cabane holders as

x

7.

down

pieces

on the plan. Glue this 1/4 tri

holder. Also cut tri stock

.

ribs on top ofthe cabane holders. Glue these braces in place.

ADD 1/4 TRI STOCK BRACES

After the glue is dry, turn the wing over and pin it

to

the building board. Use 1/4x36 triangle stock and cut

to

fit along the length of the cabane holders as shown

to

the sheeting andtothe cabane

to

fitoneither side of the three center

\

8.

the1/16

center section sheeting. Glue onthe1/16

ADDTHE REST OFTHE SHEETING

x

Glue on the1/16

x

7/8

x

24trailingedge sheeting and the 1/16x3

2-1/8x24leading edge sheeting,

x

x

3/16cap strips.

15

9.

andthe3/8

to

fit first and then glue them in place. Now cut the curve in the

center trailing edge as shown on the plan and in the photo.

5

ADDTHETRAILINGEDGE

x

Addthetapered3/8

x1x

6taperedcentertrailingedgepiece.Cutparts

1x24balsa trailing edgestock

Page 6

BUILDING

line. Also draw centerlines down the 1/4

and the 1/4

bottom to the bottom wing at this point.

THE

PREPARE WING RIBS

Mark all bottom wing ribs with a rib alignmentcenter-

x

1/2x24 trailing edge pieces. There is no top or

BOTTOM

WING

x

1/2x24 leadingedge

2.

the left panel first. Use the extra spar as a shim at the trailing

edge as you did with the tio wing. Pin the bottom spar over the

plans. Align the ribs to the spar, shim up the trailing edges of

the ribs and glue the ribs

hold down block as a spacer for location of ribs #1 and #2.

(Note: These hold downs are the same size as the ones that

glue into the fuselage later.) Do not glue the hold down block

in place yet.

3.

(leading edge, trailing edge and top spar). Use epoxy to glue

the hold down in place. Glue the balsa 1/4

the hold down and sand the it

GLUE THE RIBS TO THE SPAR

Build the right and left wing panels separately. Build

to

the spar. Use the 1/4x7/8

ADD LEADING EDGE, TRAILING EDGE, TOP

SPAR, HOLD DOWN AND FILLER

Align the above parts first and then glue in place

x 5/8 x

to

the shapeofthe rib contour.

x

3

3

filler above

wing

4.

ADD THE SHEETING

x

Glue on the 1/16

leading edge sheeting, the 1/16

edge sheeting and the 1/16 x 3

sheeting. Cut cap strips from 1/16

and glue them in place.

6

x 7/8 x

x

15 center section

x

2-118x24

24 trailing

3/16x36 balsa

Page 7

5.

it to the board and glue in the balsa filler on the other side of

the holddown. Sand it to shape. Add the leadingedge sheeting,

the trailing edge sheeting and the center section sheeting. Add

the cap strips. This completes the left wing panel for now. Re

move the panel from the building board when it is dry. Now

build the right wing panel by following steps 1 through

ADDTHE SHEETINGAND FILLER ONTHEOTHER

OF

SIDE

When the glue is dry, turn the wing panelover, realign

THE WING PANEL

5.

INSTALLING THE WING TIPS

-

1.

Do not cut

top and bottom wingslpanels. The tips should be centered on

the tip rib and the leading edge centerline. The wing tips for

the top wing will have to sanded to an angle at the top to fit

against the leading edge. Cut the tip brace pieces from the 114

scrap provided (1/4

lower end of the wing tips, top and bottom. Sand this filler to

shape later after hinging and installing the ailerons. Sand the

leading edge to the rounded shape shown on the plans. Cut

off

the spars and sheeting even with the root rib on the panels.

Cut

the inside

GLUE THE WING TIPS TO TOP AND BOTTOM

WING PANELS

Cut

off

the sheeting and spars even with the tip rib.

off

the leading edge! Glue the wing tips on both the

x

3x11-7/8). Add the filler piece at the

the inner tip filler from some scrap balsa and add to

of

the tip. Shape

it

to

match the ailerons and

tip filler blocks.

INSTALLING THE CENTER

TRAILING EDGE (BOTTOM WING)

I.

panels and down the leading edges of the center sections. Cut

a groove along the centerline in the tapered

balsa center section pieces for the aileron torque rods. Notch

the center sections for backward torque rod arm movement.

Glue the brass sleeves of the torque rods into the blocks with

epoxy. Make right and left assemblies. Also notch the trailing

edge of the wing panelfor forward movementof the torque arms.

MAKE CENTER SECTlON/TORQUE ROD AS

SEMBLIES

Draw a centerline down the trailing edges of the wing

5/8

x

1-3/4x3-1/2

-

2.

rod

so

to move. Glue the rod/center sections to the wing panels up

the centerlines.

GLUE THE CENTER SECTIONS TO THE WING

PANELS

Use vaseline at the ends of the tube of the torque

you don't glue the wire to the wing. The rod must be free

Page 8

JOINING

GLUE THE CENTER RIB TO THE LEFT WING

PANEL

THE

BOTTOM

WING PANELS

With the wing panels

balsa center rib

sure the wider edge of the center rib is down and that the

leading edge and trailing edge are centered on the tapered rib.

5

Use

_

minute epoxy.

2.

it about

block

surfaces.

1/8"

so

that the center rib edges are flush with the wing sheeting

to

the root end of the left wing panel. Make

SAND THE CENTER RIB TO THE WING PANEL

CONTOUR

Rough cut the center rib to the wing airfoil, leaving

oversize. Sand the remainder away with a sanding

"up"

, glue the wedge-shaped

3.

ing and trailing edges of the panels.

make sure the leading edge of the wing is straight. Block up

the wing

slow set epoxy. See the drawing on the plan.

wing is upside down

the wing over and mark the aileron servo well location. Add the

1/16x2

I

4.

JOINTHEWING PANELS; ADDTHEWING PLATES

Join the wing panels upside down. Line up the lead-

Use a straight edge to

7/8"

at the center and glue the panels together using

Remember the

at

this point! When the glue is dry, turn

x

3-1/4

DO

plywoodwing plateto the bottomof the wing.

GLASS THE CENTER SECTION OF THE WING

NOT OMIT

THIS

STEP!

Doingsomay result in a wing failure during flight!

Coat the

minuteepoxy and use

area

where the wings werejoined with

a

4

"

wide strip

of

6

oz.

5

glass or nylon

cloth to reinforce the center joint. Saturate the cloth with

off

epoxy and then wipe

should cover both the top and the bottom

When the epoxy is

any extra epoxy. The cloth strip

of

the wing joint.

dry,

sand the center section lightly

without sanding into the glass cloth.

Page 9

PREPARE THE AILERONS

Cut the aileron stock

length and draw a centerline down the leading edge of the

ailerons. Mark and drill the torque rod holes. Groove the aileron

for torque rod clearance. Make right and left ailerons.

2.

the wing trailing edge. Shape the leading edge

to a

the fit. Final sand the wing tips to match the aileron contour at

neutral. Do not permanently hinge the ailerons until after they

are covered.

CUTTHE HINGE SLOTS; FINAL SAND THE AILE-

RONS

Mark and cut the hinge slots into the ailerons and

“V’.

Temporarily install the ailerons with hinges to check

(5/8 x

17-1/2 tapered stock) to

of

the ailerons

LEFT

BUILDING

,

,

1.

“left”. Cut out part of the wing saddle area at the rear as shown

on the plan.

STOP!

the instructions on installationof 4

this instruction book.

2.

Firewall. Mark the “top” of the firewall (the bottom has a slight

angle). Mark the position of the motor mount. Mark and drillthe

holes for the motor mount

in positions in these holes you drilled. Temporarily place the

mount on the firewall with the screws. Cut the screws

,

back of the firewall

Notch a hole in Bulkhead # 2 for the throttle linkage. Prepare

Bulkhead #3 by drilling holes for the outer pushrod housings.

PREPARE THE FUSELAGE SIDES

Mark the inside of the fuselage sides “right” and

If

you plan to install a 4-cycle engine, read and follow

PREPARE THE BULKHEADS

Locate the 1/4

THE

so

FUSELAGE

-

cycle engines at the end of

x 3

x 2-3/4

4-40

they won’t get in the wayofthe fuel tank.

plywood Bulkhead

screws. Put the 4-40 blind nuts

#1,

off

the

in

9

Page 10

3. D GLUE THE DOUBLERS TO

Using Bulkhead #1 as a spacer, install the 1/8" balsa

doublers crossgrain on the inside of the fuselage sides. Cut the

doubler pieces from 1/8 x 3 x 36 balsa first, position and then

glue in place. Use slow set epoxy or thick cyanoacrylate. The

doubler should extend 1/4"beyond the position of bulkhead #3.

Trim the doublers to the fuselage contour.

Note:

Be careful

to use what is left in the next step.

4. D BUILD THE THREE REAR FORMERS

Use the plans as a guide and cut the balsa to size. Glue the

parts together to make the three formers. Make push rod braces

from scrap 1/8 x 3 x 36 left over from the doubler stock in the

step you just did. The widths of the braces are the same as

that of each of the formers. The braces will be installed when

the pushrods are installed

engine instructions if you plan to install a 4-cycle?

when

Make Formers #4,5 and 6 from 1/8 x 1/4 x 36 balsa.

you

later. STOP!

cut the

THE

FUSELAGE SIDES

doubler

stock

as you

Did you read the 4-cycle

need

D MARK BULKHEAD POSITIONS

Mark the positions of bulkheads #2 and #3 on the

fuselage sides. Also

#2 and #3. Mark the positions of the cabane blocks now if you

wish.

6. D DRILL PUSHROD EXIT HOLES

Mark and drill the holes in the fuselage sides for the

pushrod exits for the elevator and rudder. See the plans for

suggested positions of the pushrods to estimate the hole positions. A piece of brass tubing sharpened on the inside with an

X-Acto knife blade makes a neat, clean angled hole for tubestyle pushrods.

mark

the

position

of

the balsa dash between

10

Page 11

FIT THE WING TO THE FUSELAGE

Pin the fuselage sides together perfectly lined up.

Check the fit to the wing saddle cutout by placing the fuse sides

if

on the wing. Custom sand

wing incidence.

necessary but do not change the

8.

for a better glue joint. Pin the right fuse side to your work surface.

Position the bulkheads correctly (the angle

and glue them in place at

NOTE: The straight edge at the top of the fuselage side is called

the Fuselage Reference Line and will be used later to align the

wing and stab to the fuselage.

9.

down over the top view of the plans. Make sure the flat side is

resting flat on the building board and that the bulkheads are

aligned to the plans. Pin the fuselage in place. Glue the left

fuse side to bulkheads

side is also flat to the building board. Clamp or pin the fuselage

in place until the glue is dry.

SAND FUSELAGE TAIL; GLUE BULKHEADS

AND #3 TO THE RIGHT FUSELAGE

Slightly sand the insides of the fuse sides at the tail

90

degrees to the fuse side.

GLUE LEFT FUSELAGE SIDE TO THE BUL

KHEADS

Align the fuselage sidelbulkhead assembly upside

#2

and # 3 making sure the left fuse

SIDE

is

at the bottom)

#2

-

10.

like the hold down plates in the bottom wing. Glue the front

hold down to Bulkhead

the balsa 1/8

at the rear of the wing saddle. Glue the rear hold down to the

false bulkhead and doublers. Glue 1/4"triangle stock to the top

and bottom of both holddown plates. Use 1/4 tri

11

GLUEINTHE HOLD DOWN PLATES

x

7/8

x

The hold down plates are 1/4

#2

and the fuse side doublers. Glue

x

3/4x3 false bulkhead to the fuse side doublers

3 plywoodjust

x

36 balsastock.

Page 12

GLUE IN BULKHEAD

Realign the fuselage upside down over the plans

and glue the fuse sides

the bulkhead is flat on the building board and that the front of

the bulkhead is facing forward.

to

bulkhead#1

.

Makesurethe top of

12.

of the firewall. Extend the throttle linkage hole through the tri

stock.

13.

thedoublerasshown on the plans. Thedeckbase should butt

to

up

worksurface.Markthe location ofFormers #4, #5 and

Check the fit ofthe formers and glue themtothe deck base

making sure they are

ADD 1/4" TRI BRACING

Add three pieces of 114 triangle stock along the back

GLUE FORMERS TO DECK BASE

Notch the 1/2

the doubler. Pin the deck base over the plans to your

balsadeckbaseatthecornerstoclear

90

degreestothe base.

#6.

14.

overthedeck base. Use a pushrod housing and markthe loca

tion

housing follows asstraight a path aspossiblefrombulkhead

#3 to

the housings

ina tube style pushrods areshown here but other typesmay

be used.

12

PREPAREFORMER BRACES

HOUSINGS

Temporarilyput the fuselage/bulkhead assembly

of

the housing holes inthe former braces. Make surethe

the exit. Drill the holesinthe braces. Temporarilyinstall

to

check your work. Remove the housings.. Tube

FOR PUSHROD

-

Page 13

15.

deck base former

sides of the deck base and the sides of the formers. The deck

base glues to the rear of bulkhead

DO NOT GLUE THE FUSELAGE SIDESTOGETHER ATTHE

TAIL UNTIL THE NEXT STEP!

GLUE THE FUSELAGE TO THE DECK BASE

Gluethe fuselagesides/bulkhead

assembly. Fuselage sides are glued to the

#3.

assembly to the

16.

Use the rudder hinge slot as a guide to placement.

the area open where the tail wheel strut mounting tab will

glue later,

17.

braces to the formers. Rough up the housings with sandpaper

intheareasofBulkhead#3

cyanoacrylate glue, glue both elevator and rudder housings in

place except at Bulkhead

servosare installed.You may trimthe housingsat the exits now.

GLUE THE HINGE/FUSELAGE TAIL;GLUE

THE FUSE SIDES TOGETHER ATTHE TAIL

Glue the rudder hinge just below the stab location.

Keeping

glue the fuse sides together at the tail.

GLUE PUSHROD BRACES TO FORMERS; GLUE

PUSHROD HOUSINGS TO BRACES

Usingthe pushrod

housings as guides, glue the

,thebraces and theexits.Using

#3.

This will be glued later when the

18.

deckbase between former #6 andthetail. Angle

of

the tri stock at the tail for a good glue joint.

13

GLUE IN

Glue 1/4"

1/4

BRACING ATTHE TAIL

triangle stock at the bottom sides of the

-

cut the ends

Page 14

ADD THE LANDING GEAR BRACES

x

Glueinthe grooved 1/2

block at the bottom ofbulkhead

along the frontofbulkhead #2

block.Cut the braces from1/2"

main gear now but do not install until after the model isfinished.

-

Thewider

Note

positioned toward the front of the model for main gear place

ment. The brace fits into the smaller slot.

slot

(groove)inthe landing gearblockis

1-5/16x3

#2.

Addthe 1/2 trianglestock

andthe top ofthe landing gear

x

6stock.Youmaysolderthe

-

1/2landinggear

-

20.

and over the plans, alignthe chin block to the front of the landing

gear block and gluethe chin block to the fuselage. (The fuselage

is notshown aligned

21.

cross

3

x

and work your way back, gluing one piece at a time. Leave the

last section of sheeting out until the tail wheel bracket is installed

later. When the glue is dry, remove the fuselage from your

building board and sand the bottom sheeting to shape.

GLUE THE CHIN BLOCK TO THE FUSELAGE

90

With the fuselage still at

to

theplansinthe photo.)

ADDTHEBALSA BOTTOM SHEETING

With all pins removed from the inside of the fuselage,

-

grain sheet the bottom rear of the fuselage. Use 3/32

24

balsa and cut pieces to fit. Start at the false bulkhead

degrees to the board

x

22.

to

match the plans. Mark the locations of thestringersonformers

3Aand6A by referring

of3A.Glueformer6Bto the frontof 6A.Drawthe location lines

forthe cockpit floor onthe back ofthedashandonthefront

ofthe 3A/3B

14

PREPARE TOP FORMERS 1ATHROUGH 3B

Preparethe fuselage top formers bynumberingthem

to

the plans. Glue former 3B totheback

assembly.

Page 15

23.

and

a slight angle sothe top blockwillmate squarely when glued.

Trialfit the assembled fuel tank.Carve out a section offormer

2Aforfueltank clearance

permanently,plug all fuel lines

lines.

ADDFORMERS 1AAND 2A

Glueformers 1A

2.

Whentheglueis dry sand the tops ofthese formers

and2Ato the

if

necessary.Ifyouleavethetankin

so

balsadustdoes not enter the

tops

ofbulkheads 1

to

24. ADDTHEDASHANDFORMERS3N3B

Pinthe hood top inplace

thedash. Put the cockpit floor inposition

placementofthe dash on the fuseside.Gluethe dash

fuse sides. Do not glue on thehood top yet.Glueformer3A/3B

to the fuselage at the rear ofthe cockpit on top ofbulkhead#3.

todetermine the heightof

todetermine the

to

the

.

25. GLUE IN THE COCKPIT FLOOR

Glueinthe balsa cockpit floorbetween

the dash and former 3A/3Bon thelinesyoudrewearlier.

26.

led into the fuselage. Cut the sheeting out over the cabane wire

holders in the top wing. With the wing level on your work surface

and the bottom side of the wing up, place the cabanes into the

slots

each other. Wrapthe wire bracesto the cabanes with the copper

wire provided. With the cabanes

the bottom (nearest the wing) wire wrapped end of the cabane

on both sides. Then solder the

losing the alignment

SOLDER THE CABANE WIRE

top

The cabanes for the

in the holders. The bent ends of the cabanes should face

to the wing.

wing are permanently instal

90

degrees to the wing, solder

top

wire wrapped end without

-

.

15

Page 16

27. PREPARE SMALL CABANE BLOCKS

Clearance holes will have to be cut in the small

cabane blocks for cabane wire clearance. Place the blocks on

the cabane wire ends. The blocks should line up with the top

of

the fuselage. Clamp the blockstothe fuselage.Do

the

blocks

yet!

not

glue

28.

fuselage side) parallel

be right side up. Place the top wing onto the cabanes. Line up

the top wing to the work surface and the fuselage as shown in

the drawings. Distance A should equal distance A, B should

equal B and C should equal C. When the top wing is properly

aligned, mark the positions of the cabane brace blocks in the

fuselage. Use slow set epoxy and glue the blocks in place. Fill

in the areas around the wires in the blocks with epoxy. Glue on

the 1/16 x 112

the alignment before the glue sets up.

When the glue is dry,

in the wing with silicone. Put car wax or similar material on the

cabane wires and placethe wing backon the cabanes. Remove

the excess silicone that may ooze out

that you added makes a good seat for the wires and cuts down

on vibration. After the wing is covered later, you will attach the

top wing to the cabanes with the aluminum plates and the #2

x

3/8 screws provided. Ttie plates should be flush with the wing

sheeting. Note

ment when you apply the silicone to the cabane slots. The wires

should still touch the bottom of the slots in the holders; the

silicone fills in around the sides of the wires in the slot.

ALIGN THE TOP WING TO THE FUSELAGE

Align the Fuselage Reference Line (top side of the

to

the work surface. The fuselage should

x

1-112 plywood cabane brace caps. Recheck

fill

in the

slots

in the cabane wing holders

of

the slot. This silicone

-

Make sure you do not disturb the wing align

-

29.

0

to be twisted slightly

easy to twist the balsa as required,

both pieces of the balsa sheets. Place one end in a vise and

twist the other end somewhat more than is required. Hold or

clamp this end until the wood dries (about 15 minutes). Note

that the twist inthe right piece

PREPARETHEBALSAHOOD SIDE PIECES

-

The 1/4x 1

3/8 x 17-1I2 balsa hood side pieces need

to fit the front of the fuselage. To make it

"

paint"some ammonia on

is

oppositethat of the left piece.

30. GLUE ON THE HOOD SIDE PIECES

so

so

they

they

Sand the bottoms of the hood side pieces

will mate squarely with the fuselage sides. Notch out the side

fill

pieces for cabane wire clearance. You can

holes later. Glue the side pieces from the front of former 3A/3B

to beyond former 1A i n the following manner.To preventatwisted

fuselage, glue both pieces at the same time, a little at a time,

starting at former 3A/3B. Also make sure the hood side pieces

extend outside former 3A/3B and the fuse sides slightly

can be sanded to contour later.

16

in these notched

Page 17

31.

top of the formers

SAND THE TOPS OF THE HOOD SIDE PIECES

Sand the tops of the hood side pieces flush with the

so

the hood top will mate squarely.

32.

glue it on as it is a little difficult to sand in that area after the

hood top is glued on. Glue the hood top in place. Trim the hood

sides at the cockpit as shown on the plans.

33.

the back of the fuselage. Mark the position of former 6A/6B.

Remove the stab. Glue 6A/6B in place.

GLUE ON THE HOOD TOP; SAND HOOD SIDES

AT COCKPIT

Trim the hood top at the cabanes first before you

ADDFORMER6A/6B

Pin the stabilizer in place

so

the stab is aligned with

34.

stringertofitbetweenformers3A/3Band6A/6B.Gluethe

stringer in place.

-17-

GLUE ON TOP STRINGER

Use the 1/4

x

1/4x16 balsa stock and cut the top

Page 18

35.

a straight edge alongthe top stringer. Placeand gluetheformers

so

they mate with the top stringer and and are centered from

side to side.

ADD FORMERS 4A AND 5A

Locatethe positionsof formers4A and 5A by placing

36.

to fit. Start by gluing at 6A/6Bfirst, checking with a straight

edge first, and then gluing

37.

depending on your engine) for the throttle linkage clearance.

Using

excess epoxy at the chin block joint. Carve and rough sand the

hood top, hood sides and chin block

side pieces. The next few photos will helpyou

needed. Don’t take

next to see where you need clearance.

ADD THE TURTLE DECK STRINGERS

x

Use the 1/8

PREPARE AND GLUE IN THE SIDE NOSE

BLOCKS; FINAL SAND THE FUSELAGE FRONT

Groove the inside of the nose side block (right or left

5

minute, glue the nose side blocks in place. Remove

1/4x16 balsa stock and cut stringers

to

5A, 4A and 3A/3B.

to

the shape of the nose

to

see the shape

too

much

off

until you mount the engine

38.

provided. Place the engine on the mount. Cut away areas of

the engine compartment

Check for binding of the throttle arm. Mark and drill the holes

in the mount for engine mount bolts. Tap the holes for bolts and

nuts or use self

The engine has no down thrust or right thrust.

18

TEMPORARILY MOUNT THE ENGINE TO THE

Temporarily install your mount with the 4

so

the engine rests flat on the mount.

-

tapping bolts to hold the engine on the mount.

-

40 bolts

Page 19

39.

of the 2

washer should extend 1/16 to 1/8 inches forward of the filler

block. Cut away areas on the block for engine clearance. The

placement of these parts depends on what brand spinner you

will use. Inspect your spinner backplate and locate the block

accordingly. When you are sure of the placement, glue the crossgrain nose filler block in place. Sand the front of the nose

the frontofthe filler block and the front of the nose side pieces

are even. Glue the 1/16 plywood spinner ring in place on the

filler block using your engine and spinner backplate as a guide

for placement. The engine shaft should be centered in the hole

in the spinner ring.

ADD NOSE FILLER BLOCK AND SPINNER RING

Using your engine as a guide, locate the placement

-

1/4 x 2-1/4 x 1/2 nose filler block. The engine thrust

so

40.

along the bottom sides of the engine compartment and behind

the filler block. Use 3/8 x 12triangle stock for this step. Custom

fit these pieces

Now sand and carve the nose of the fuselage to the shape of

the spinner ring.

ADD 3/8

TO

Remove the engine and add the 3/8 triangle stock

TRI

STOCKTOTHE NOSE; SAND NOSE

SHAPE

so

they gluetothe firewall and nose filler block.

.

41.

the plan for placement. Drill a hole in the bottom of the engine

compartment just in fron of the firewall for fuel drainage.

DRILL FUEL LINE HOLES AND A DRAIN HOLE

Drill the holes in former 1A for the fuel lines. See

42.

you did before by making sure the Fuselage Reference Line is

parallel to the work surface. Now align the stabilizer to the

fuselage in the following manner: A

the stab bed at the end of the fuselage. Line up the stab centerline to the fuse centerline. B

point at the centerof the top of the firewall area. Each measure

ment should be the same. CMeasure from each stab tip to

the work surface. Each measurement should be the same. D-

To

make sure you have zero degrees incidence,measure from

the center of the leading edge to the work surface. Measure

from the center of the trailing edge to the work surface. These

distances should be the same. When the stabilizer is aligned,

do not glue in place but go on to the next step.

19

ALIGN THE STABILIZERTOTHE FUSELAGE

First align the fuselage to your flat work surface like

-

Draw a centerline down

-

Measure from each stab tip to a

-

Page 20

43.

up the angle of the top stringer. Then sand them

of the stringers. Shaping and sanding is easy if you tack glue

scraps of balsa the thickness of the stab and fin to the fuselage.

Trim the scrap even with the fuse sides and stringer line, then

tack glue the blocks in place and razor plane and sand them

to

shape. When ready, break the blocks loose and remove and

discard the scrap. Use epoxy and glue the stabilizer to the

fuselage. Glue the fin to the stab at

aligned on the stab centerline. Glue the fin

degrees to the stab and aligned on the stab centerline. Glue

the prepared fin filler blocks in place with

move excess epoxy.

PREPARE THE FIN FILLER BLOCKS; GLUE ON

THE STAB, FIN AND FIN FILLER BLOCK

to

Prepare the fin filler blocks by cutting them

to

the contour

90

degreestothe stab and

to

the stab at

5

minute epoxy. Re

pick

90

44. ADD DORSAL FIN AND FILLER PIECES

Use scrap balsa and custom make the dorsal fin

piece and filler pieces. Glue the dorsal fin

top stringer. Glue the filler pieces between the top stringer and

the next stringer on each sdie of the dorsal fin. These filler

pieces are used to anchor the covering material later.

to the fin and

1/4"

-

45.

plans. Use

piece of bottom sheeting. Mark and drill the hole for the tail

wheel tiller arm in the rudder. Also groove the rudder leading

edge below the hole for the nylon bearing clearance. Shape

the leading edge of the rudder

FINAL

1.

by placing the fuselage reference line parallel

face. Align the bottom wing tothe fuselage bymakingthe follow

ing measurements: A-Center the wing side to side in the sad

dle. The distance from the fuselage side tothe wing tip on each

side should be the same. &The wing tip to stab tip distance

should be the same on both sides. &Wing tip to work surface

and top wing tip to bottom wing tip distance should be the same

on both sides. D

+

1/32"to the top wing. This means that the leading edge of

the bottom wing should be 1/32" closer to the top wing than

the trailing edge of the bottom wing is. When the wing is in the

correct position, mark the fuselage and wing

the wing exactly the same again.

ADD TAIL WHEEL STRUT; FINISH RUDDER

Glue the tail wheel strut in place as shown on the

5

minute and clamp the tail until

to

a

"V"

ASSEMBLY

ALIGN THE BOlTOM WING TO THE FUSELAGE

AND TOP WING

Align the fuselage upside down

-

The bottom wing has a positive incidence

dry.

Add the last

.

to the work surface

to

the work sur

so

you can position

of

-

-

-

20

Page 21

2.

aligned to the fuse, drill two

hold down plates in the leading edge of the wing and one hold

in the trailing edge of the wing. Drill the rear hole at an angle

so

the bolt head will rest flat on the trailing edge. Drill these

pilot holes through the hold downs in the fuselage at the same

time you drill through the wing. Remove the wing. Drill and tap

the holes in the fuselage hold downs for

bore the leading edge holes in the wing

rest flat against the hold downs in the wing.

DRILLAND TAP WING BOLT HOLES IN THE WING

AND FUSE

Withe fuse aligned to the work surface and the wing

11/64

pilot holes through the wing

-

20

1/4

bolts. Counter-

so

that the bolts will

3.

on the bottom of the wing even with the fuselage sides. Cut the

fairings to width. Sand to shape by placing sandpaper on the

wing and working the fairings back and forth.

4.

wing bolt heads to pass through. Install the wing bolts and glue

the fairings in place with

any epoxy on the wing bolts and not to glue the wing to the

fuselage!When the glue is dry, sand the fairings to the fuselage

contour.

SAND THE WING FAIRINGS TO SHAPE

Prepare to install the wing fairings by drawing lines

GLUE THE FAIRINGS

THE FUSELAGE CONT

Drill holes through the fairings large enough for the

5

minute epoxy. Be careful not to get

PLACE; SAND THEM TO

IN

OUR

5.

want to add a pilot, paint the cockpit area and/or add an instru

ment panel. Fuelproof the engine compartment by coating all

the balsa and ply parts with resin or epoxy. Now final sand the

entire model.

21

FINISH COCKPIT AREA: FUELPROOF FUSE;

FINAL SAND MODEL

Finish the cockpit area any way you wish. You may

-

Page 22

6.

hardwood into the radio compartment. Install the rudder,

elevator and throttleservo directly to the hardwood rails or install

the servo tray that comes with your radio. Position the battery

and receiver (wrapped in foam rubber for protection) as shown

on the plan. Install the

wires or tubes into the pushrod housings for the rudder and

elevator. Also install a cable type pushrod and its outer tube for

the throttle linkage.

INSTALL RADIO COMPONENTS

Glue servo rails made from scrap plywood or

switch. Install the inner pushrod

on/off

7.

enough of the wing sheeting, center rib and root ribs to allow

the placement of the servo as deeply as possible inside the

wing. Glue hardwood rails (from scrap) as shown in the photo

or use the tray that came with your radio. Drill small pilot holes

in the rails for the servo screws.

8.

so

no binding occurs with the other servos. Installthreaded wire

pushrods with

to the aileron torque rod arms with the nylon connectors, wheel

collars and screws provided and clevises of your choice. This

end of the linkage is therefore adjustable.

CUTTHE SERVOWELL IN THE TOP OFTHE BOT

TOM WING

The well is located directly behind the spars. Cut out

INSTALL AILERON SERVO AND LINKAGE

Mount the servo as deep into the wing as you can

“Z’

bends at the servo. Connect the pushrods

-

9.

bly into the slots in the bottomofthe landing gear plate.

Place

straps over the brace and mark the hole positions on the

landing gear plate. Drill pilot holes for the

Put the screws in place.

10.

gine mount unless you already have. Attach the enginel

muffler to the mount.

INSTALL

Place the soldered maingear and braceassem

3

landing gear straps over the main gear and

INSTALLTHE ENGINE AND MUFFLER

Attach the muffler to the engine. Install the en

THE

MAIN GEAR

#2

x

3/8

screws.

11.

ready. Assemble the tank per manufacturer’s directions.

Feed extra long fuel lines through the front of former 1A

2

into the tank compartment. Attach the lines to the tank

and pull the tank into position. Cut the fuel lines to length

and attach them to the engine.

12.

while you are covering. Make sure the model is all final

-

sanded and clean (use a tack cloth or rag to pick up any

dust). Use heat shrink covering material and cover your

Sportster Bipe. Follow the instructions available with the

covering. When the model is completely covered, reinstall

INSTALLTHE FUELTANK

if

Install the tank now

COVERTHE MODEL

Remove any equipment that will be in the way

you haven’t donesoal-

Page 23

13.

INSTALL ALL CONTROL SURFACES AND

CONTROL HORNS

Flex the hinges back and forth a few times and

then glue the hinges into the rudder and fin slots; at the

same time glue the tiller arm of the tail wheel into the

rudder leading edge. Lightly sand both surfaces of the

hinges, put epoxy into each hinge

2-56

place the hinge in place. Use

and attach the nylon horn

to

the rudder over the tail wheel

screws and backplate

slot and

tiller arm position for extra support. Glue the elevator joiner

to

wire

the elevators. Glue the hinges to the elevators and

stabilizer in the same manner as above. Attach the nylon

to

elevator horn and backplate

2-56

elevator with

screws. Glue the aileron torque arms

the bottom of the right

into the ailerons as you glue the hinges into the ailerons

and wing trailing edge.

14.

INSTALL THE CANOPY

Cut the canopy on the cut lines scribed in the

plastic. You can dye the canopy using Rit dye. Follow the

instructions on the box. Remove the canopy from the dye

when the desired tint is achieved. Glue the canopy to the

fuselage with cyanoacrylate glue. Seal the edge with strip

ing tape.

15.

ASSEMBLE THE WHEEL PANTS

Cut and trim the wheel pant halves on their

parting lines that you find on the inside of the pants. You

-

can score this line with an X

Acto knife and break on the

line or simply cut on the line with a knife.

Sand the edges of the wheel pants smooth. An

to

do

easy way

this is to lay your sandpaper down on a

flat surface and move the pants over the sandpaper. This

way you are assured of a straight, flat edge when you

finish.

Cut a starter hole in one half of each pant in

the area of the wheel opening

to make it easier

to

cut out

the opening later after the halves are glued together. Cut

the starter hole at the join line. Using cyanoacrylate (in

stant glue), join the two halves together. Note that there

to

is a right and a left half

the wheel pant. Make sure you

have a good fit before you glue the two halves together.

When the halves are joined, sand lightly along the join

line on the outside of the pant

to get a smooth appearance.

16.

side of each wheel pant. Drill a clearance hole at this

location for your gear wire or axle bolt. See Figure

Do this by temporarily placing the wheel pant on the gear

Position the pant

level or in the correct position for your model. Mark the

positionof the brass plate on the gear and on the outside

of the pant. Remove the wheel pant! Solder the brass

plate

solder the other brass plate in the same manner.

of the wheel pant opposite the brass plate on the gear,

Temporarily put the wheel pant back on the gear to find

this position. The ply plate is used as a backup plate for

the brass plate

up. When you have the correct positions for the ply plates,

use

wheel pants. Let the ply plates dry.

pants.

holes through the wheel pants and the ply back up plate

for the

attaching the screws provided, wheels and wheel collars

to hold the wheels

remove the assembly from the gear. See Figure

-

’

-AXLE

HO

Figure 1

MOUNT THE WHEEL PANTS AND WHEELS

Mark the position of the axle hole on the innei

Mark the positionof the brass plateon the gear

so

it does not touch the ground and

to

the gear using Sta-Britesilver solder. Positionand

1/8

Posiiton the

so

do a good job of lining these two plates

5

minute epoxy and glue themtothe inside of the

plywood plate on the inside

Drill the axle hole through the ply plates in the

Using the brass plate as a guide, drill two pilot

#2

x

3/8”

screws.

Trial fit the wheel pant assembly

to the gear by

to the gear. If all is in the correct position,

LANDING GEAR

WHEEL

WHEEL

PANT

COLLARS

TAPE

L

E

1.

is

2.

Use your wheel and measure and mark the

to

area

be cut out of the pant for the wheel opening. Cut

out this area.

Findthe tape locations on the insideof the pant

in Figure

60-100

coarse sandpaper and sand the

1.

Use

areas where you will put the tape.

Reinforce the inside of the wheel pants with

fiberglass tape. Cut the tape into one inch squares. You

should have eight pieces of tape when you finish cutting.

5

Use

minute epoxy and piece of tape at each of the

places you sanded before. Let the tape hang out of the

off

wheel opening. Cut the excess

when the epoxyis dry.

BRASS PLATE

WHEEL

Figure

2

Paint the wheel pants. First, sand lightly with

wet/dry

320-400

sandpaper but use it dry. Use

K&B

or automotive primer. Sand the primer after it is dry. You

to

need only

sand the primer lightly. Put on the final coat

of paint. Spraying works the best for the final coat but

brushing the paint will give you good results also.

23

primer

Page 24

18.

of the fuselage and attach it

NOT cut the antenna wire!

19.

rudder pushrods

other ends maybe attached by "

and does not need

end of the throttle cable and attach it

arm. Attach the other end of the cable

with a connector of your choice. The servos and linkages

should not interfere with eachother. Set the control surface

throws as shown on the plan.

SPORTSTER BlPE FOUR-CYCLE CONVERSION INSTRUCTIONS

“4

the 4-cycle fun. Whether you wanttojust “putter” around the sky, or loop, roll and snap, the Sportster/4-Cycle

combination is unbeatable!

EXTEND THE RADIO ANTENNA

Run the antenna out of the radio compartment

to

the front of the fin. DO

CONNECT ALL LINKAGES (PUSHRODS),

CONTROL SURFACES, CHECK RADIO OP

ERATION AND SET THE THROWS

Attach clevises to the ends of the elevator and

so

they are adjustable at the tail. The

Z"

bends or other method

to

be adjustable. Attach a clevis to the

to

the engine throttle

to the throttle servo

The Sportster Bipe is a natural for 4-cycle experimentation. The unique looks of the Bipe just screams

-

Cycle” and the lightweight air-frame and symmetrical airfoil means the Sportster design will make the most

20.

on the plan.

around until the model balances at the point shown.

additional balance weight is needed, add lead weights

the nose ortail to get the proper balance. Range check

your radio at your flying site as per your manufacturer’s

recommendations. Recheck your wing and stab align

ments. Makesure the rudder is90degrees to the fuselage.

Check

ment is in good condition.

RANGE CHECK

CHECK THE CENTER OF GRAVITY; RE

CHECK ALL ALIGNMENTS

Your model should balance at the point shown

If

it doesn’t, move the battery and/or receiver

to see that all hardwareis secure and that all equip

YOUR

RADIO SYSTEM;

21. TRIMTHEMODEL

Make your first flights, with the help of an experi

enced modeler/flyerifthis is your first model. The model

to

may need some trim changes or adjustments

surfaces after the first flight. Adjust the control surfaces

at the clevises until the model flies correctly.

the control

-

If

to

-

-

-

of

-

cycle engines offer many benefits-their quiet, realistic sound is pleasing to modelers and non-mod-

Four

elers alike. Hightorque allows the use of high pitch or large diameter propellersfor a newstyle of flight characteristics.

They are also very fuel efficient for economical operation.

-

On the other side of the coin, 4 cycles are larger and heavier than equivalent power 2

means some special care must be taken

farther back than normal. We’ll help you with that task with these instructions.

CHOOSING YOUR ENGINE

It’s

difficulttosay what the optimum engine size is for your Sportster Bipe. The old rule of thumb was

to

choose a 4-cycle engine with 1-1/2 times the 2-cycle displacement for equivalent horsepower. But recent

advancements by engine manufacturers have brought the power of 4 cycles way up and the weight of the engines

down. One good example is the Enya .46 Four Cycle. This engine weighs just a fraction more than most 2

.40’s and it produces comparable power and thrust.

For the Sportster Bipe, you can choose between a .40 and

flight performance. A .60 provides plenty of thrust, but with a significant increase in weight and size. The

fit, but it’s going to betight. Seethe full size drawings followingof the Enya .46 and the

A

CHOOSING

-

cycle use. The Hayes AL-40 will fit the Enya .46. The AL-60 will fit the OS FS-61. Tatone produces aluminum

for 4

mounts that are predrilled for individual engines.

gives a beam mount system that is extremely rigid but makes removal of the mount a little more cumbersome.

BUILDING PROCEDURE

MOUNT

Low weight and rigidity are important in 4 cycle mounting. Hayes and Tatone both make good mounts

Both brandsare lightweight.To improve rigidity, we recommendinstalling afront bulkhead.This essentially

to avoid a nose

-

heavy airplane, such as moving the firewall and radio

.60 size four cycle. A .40 will give docile

0SFS

-

61mountedin the Bipe.

cycles. That

-

cycle

.60 will

Following are new steps that refer

to

book. Refer

part of this book.

BUILDING THE FUSELAGE

these steps here as you build your model. Step numbers here refertothe step numbers in the front

to

4

cycle installation

24

to

replace the steps in the front part of this

Page 25

MOUNT

Page 26

HAYES

AL-60

Page 27

2.

position. The thrust line of the engine should be in the same position as shown on your plan. Drill holes and install

blind nuts. Temporarily install mount and trim the mount bolts that extend into the tank compartment. Drill hole for

throttle pushrod to carburetor, making sure the throttle pushrod does not interfere with tank.

PREPARE

Mark the top of the firewall. Mark the centerline of the engine on the firewall and center the mount in

THE

FIREWALL

Next bolt the engine

leaving sufficient room for engine and/or carburetor clearance. Make sure you don’t put in any right or left thrust.

Then measure the distance from the back of the firewall tothe thrust washer. To do this, place the engine

and mount on a flat surface and put a straight edge across the thrust washer. Measure back from this straight

to

edge

measuring this distance

of the model.

the back of the mount. This is distance

so

I

2

-

CYCLE ENGINE

GREAT PLmES MOUNT

AND

to

its

mount.Ifyou use a Hayesmount, position the engine as far back as possible

“B”.

Refer to the drawings and the chart shown here. We are

we can determine how far back to move the firewallsothe engine will fit into the nose

Figure

1

.

I

4-CYCLE ENGINE

&D

HAYES MOUNT

I

Now let’s figure out how far back tomove the firewall from the normal 2-cycle position. We have already

“A”

figured out for you the

used into account.

to

distance

the above measurement.

Distance

If

B

(length of

your4cycle

engine and

distance of the Sportster Bipe which is 3-3/4”. The chart below also takes the spinner

you use a different spinner then mentioned, just measure your backplate depth and add that

Distance

A

(length of 2cycle

Minus

engine/mount and

spinner back plate)

mount

SPORTSTER

Basically all we’ve done here istomeasure how long your new mount and engine is, allow for some

spinner backplate space, and subtract the distance shown on the plan

The result gives you the distance you have

BIPE

B

B

B

3-3/4”

3-29/32“

3-7/8”

to

move the firewall back. See Figures 3 and 4 also.

(CB

Spinner)

(Dubro Spinner)

(Goldberg Spinner)

?

(Distance to

Equals

move firewall

back)

(A)

from the distance you measured

?

?

?

(B)

.

27

Page 28

Let’s do an exampletoshow this. Refertothe drawing showing the OS FS-61 in the Bipe. We are going

to use a Goldberg Spinner. Our “B” measurement is

5-1/8

rear of the mount. By looking at the information in Chart

from our distance B. The result is

1-1/4.

We move the firewall back

(measure from the front of the thrust washertothe

1,

we know that we havetosubtract 3-7/8 (Distance A)

1-1/4.

Example

:

B

-

A

?

5-1/8

-

3-7/8

1-1

Work Area: Your

Your

B

A

Move Firewall

Back

HARD SCRAP BALSA

3.

MARK NEW FIREWALL

POSITION;

Mark the new position of the firewall on the inside

parallel

to the front of the fuse sides. Using the firewall as a spacer, install the

the inside of the fuse side. Custom cut these pieces

TO

BOTTOM

SIDE VI

OF

FIREWALL TO FILL ANY GAP

1/8“

(VERTICAL GRAIN)

EW

GLUE ON DOUBLERS

of each Fuselage side. Make sure vour line is perfectly

to

fit. Do not glue the firewall in at this time. Use epoxy glue

BALSA DO

UBLER

I’

1/8

balsa doublers crossgrain on

Figure

3

or thick CA to glue the doublers in place. The doubler should extend past Bulkhead #3. Carefully trim the doublers

to

the fuse side shape.

11.

GLUE FIREWALL IN CORRECTED POSITION

Draw the corrected bulkhead #1 position on the top view of the plans. Next still working over the plans,

,

glue bulkhead #1

5)

scrap balsa filler blocks, vertically grained, forward of bulkhead#1. Sand the blocks flush with the fuse sides.

1/4

Add

37.

balsa filler below the firewall later when you remove the fuselage from the building board.

GLUEONTHE BALSA NOSE SIDE PIECES

the firewall, in place. Then add 3 / 8 (or

Check for adequate width clearance for your engine.

to cut away part of the

need

can custom make 3 / 8 balsa sides and

1/2

nose side pieces and 3 / 8 scrap filler pieces in the engine mount area. Or you

1/8

filler pieces as shown in Figure5.Now follow step 37 in the front of

1/4

depending on your mount width-see Figures 4 and

If

your 4-cycle and mount is over

2-1/4

wide, you’ll

this book and glue in the side pieces.

if

Next,

1/8

plywood. Once the front bulkhead is epoxied in, drill the front of this bulkhead mount for 4-40 bolts. Then tap

the mount and install 4

desired, add a front bulkhead as shown on the full sized drawings. Make this bulkhead from

-

40 bolts.

I

I

\

\

Figure

4

FUSFl AGF TOP VlFW

28

Page 29

IF

MWNT

WIDTH

EXCEEDS T HE SPACE AVAILABLE

-

. .

Figure

5

GENERAL INFORMATION

of

Center

gravity:A nose heavy airplanecan be a problem! Make sure you check the CG locationduring

construction with the radio components installed. You may need to put the radio as far back in the compartment

as

possible. This will avoid having to carry tail weight.

Props:Always start with the manufacturer’s instructions (especially for break in) for prop selection. Read their

4

instructions carefully because

at a lower RPM and produce greater torque than equivalent displacement 2

cycles use entirely different diameter and pitch propellers because they operate

-

cycles.

You may find that after operating your sportster with recommendedprops that you’ll want to experiment

with other props. It is amazing how much you can change flight characteristics of a model by changing props.

If

you are looking for higher flight speeds from your Bipe than you are getting from the average recom

mended prop, consider reducing the diameter and/or blade area slightly and increasing the prop pitchtobring the

to

RPM back

x

5, 12 x 6, 11x7, 11x6, 10

13

performance. Larger props will provide slower speeds

racy Sportster. For faster speed, we found that a 10

the normal range. For example,with our Enya .46 equippedSportster Bipe,the instructions recommend

x

6,

10 x 7 or 10

x

8

props. We started with an 11x7 propeller which gave us fair

...

fine for big biplanes

-

1/2x7-1/2 propeller added approximately 10 mphtothe

...

but not what we wanted from our

straight and level flight which help make vertical maneuvers crisper due to a faster entry speed. There is a trade

x

off, however, as the engine idle was somewhat higher due to the lower mass of the wood 10-1/2

Four

-

cycles like flywheel weight from large diameter props. This made the plane land a little faster than with the

x

6. The prop we used was a prop designed for .60 size pattern engines, a Max Daily (Radio South) propeller.

11

A similar prop is also available from DW Products. Their addresses are:

.

7-1/2 propeller.

-

Radio South DW Products

180

E.

Burgess

Pensacola, FL 32503

Fuel Tank: For simplicity, we recommend a

2

line tank for your Sportster Bipe.Ifyou can’t easily reach the fuel

5634 Crystal

Ct.

Santa Rosa, CA 95404

line for fueling purposes, you might consider using one of the Dubro fueling valves. This will save extra plumbing

that could leak or cause problems. Most 4 cycles have a small enough venturi that muffler pressure is unnecessary.

Don’t forget the crankcase drain line. A lot of excess fuel comes out of the pressurefitting. Make sure this drainage

exits your fuselage. Treat it as though it were a separate exhaust.

Flying:Other than the obvious difference, you’ll notice one other big difference from your first take off

to

with a four cycle equipped Sportster Bipe:You’ll need to add more right rudder than normal

counter the increased

torque on acceleration during takeoff. Also, you may be surprised how big an effect the larger propeller may have

on abrupt change maneuvers such as a square loop. Because there is more mass to the propeller, it has a larger

gyroscopic force. When you change directions in maneuverslike a square loop,you mayfind that the plane changes

-

heading. This may be a result of gyroscopic precession and/or P

larger diameter

cause problems with ground handling. Use sometoe

4

cycle props and with slower speeds generally encountered with these engines.

Also don’t forget to have a slight amount of toe

-

in, add some rudder and your takeoffs will be in a straight line.

-

factor.These factors become more prevalent with

in with your main wheels. Toe out and

lot’s

of torque can

GOOD LUCK AND GREAT FLYING!

29

Page 30

SPORTSTER BlPE 40 PARTS LIST

PARTNUMBER

BALO19 3 BalsaTriangle1/4x36

BAL047

BAL053

BAL072

BAL073

BAL084

CANPY017

MM40U

SB4OFO1

SB4OFO2

SB4OFO3

SB40F04

SB4OFO5

SB40F10

SB4OF30

SB40F35

SB40F36

SB4OPO1

SB40P02

SS4OWO7

SB4OWO8

SB40W10

SB40W11

SB40W17

SB4OW18

SB4OW19

SS4OFO7

SS4OFO9

SS4OF29

SS40R01

SS40R02

SS40R03

SS40SO1

SS40S02

SS40S03

SS40W09

RIBS010

RIB0047

RIB0048

RIBS049 1 Sub Pack

RIB0049 1/16 Balsa3132 Ribs

SB40A01

PLY3001 1 Plywood Spinner Ring

SB4OF14

SB40F17 4 Plywood 1/I4x 7/8x 3

SB4OF32 4 Plywood 1/4Cabane

SB4OF33 4 Plywood 1/16

SB4OW12

SB4OW15 1 Plywood 1/16x2x3-1/4

SB40A02 1 Sub Pack

SB4OF34 1 Balsa118x3/4x3

SS4OF16 1 Balsa2

SS4OF18 1 Balsa 1/4 Former1A

SS4OF19 1 Balsa 1/4 Former2A

SS4OF20 1 Balsa 1/4 Former3A

SS4OF21 1 Balsa1/4 Dash

QTY

DESCRIPTION

Balsa 1/8x1/4x36

1

Balsa1/16x3x30

5

Balsa1/8x3x36

Balsa 1/16 x 3/16 x 36

5

Balsa 3/32 x 3 x 24

Canopy

Motor Mount

Balsa 1/8 Fuselage Side

Balsa 1/8 Deck Base

1

Plywood 1/4 Bulkhead #1

1

1

Plywood114Bulkhead#2

1

Balsa 1/4 x 3 x 3

Balsa 1/2 Side Block

2

Balsa 1

1

1

1

1

1

4

2

1

1

1

1

2

1

1

1

1

1

3 Balsa3/32 NotchedRibs

1 Parts Bag-Fuselageand

1

2 Plywood1/4Cabane Brace

/8 x 3 x 4

BalsaTriangle112

Balsa5/8 Chin Block

Plans

Instruction Book

Balsa Front

Balsa 3/16 x 3-3/4x 3

Balsa3/16WingTip

Balsa 5/8 Center Trailing Edge

BalsaTapered318Center Trailing Edge

Balsa 114x 3 x 11-7/8

Balsa1/4x9/16x9-7/8 Spar Filler

Balsa 3/8 x 3

Balsa 114x

BalsaTriangle318 x 12

Balsa114

Balsa 114Fin Rear

Balsa 1/4Rudder

Balsa 114Stabilizer Front

Balsa

1/4Stabilizer

Balsa 114Elevator

BalsaTaperedCenter Rib

Sub Pack

RibSet

Balsa3/32Ribs

RibSet

Wing

Parts

Plywood 1/2 Landing

Gear Block

Wing Hold Down

Brace (Short)

Brace Cap

(Long)

Wing Plate

Wing Parts

FalsaBulkhead

-

Nose Filler Block

-

11/16 Bulkhead #3

-

1/2 Cockpit Floor

x 6

-

1/2 x 11 HoodTop

1

-3/8 x 17-112 Hood Side

Fin Front

Rear

-

Upper Wing

-

Lowerwing

x

1/2x1-1/2

-

Fuselageand

1/4x2-1/4x 1/2

-

3/4 Wing Fairing Rear

Wing Tip Filler

30

PARTNUMBER

SS4OF22 1 Balsa 1/8 Former4A

SS4OF23 1 Balsa 1/8 Former 5A

SS4OF24 1 Balsa 1/4 Former6A

SS4OF25

SS4OF26

SS4OF28

SS40W13 4 Balsa1/4x5/8x3

SB40MO1

NUTS001

NYLON03

NYLON09

NYLON10

NYLON13

SCRW002

SCRWOO3

SCRWO15

SCRW024

WBNT002

WBNTOO9

WBNTlOl

WHCLOO4

WIREF12

SB40M02

METAL009 2 Metal Cabane Mounting

WBNT080

WBNT081 1 Wire 5/32 Main Gear

WBNT082 2 Wire 1/8 Cabane

WBNT089 1 Wire 1/8 Main Gear Brace

SB40W01

SB40W02 8 Balsa 1/4x 1/4x24

SB4OWO3 3 Balsa 1/4 x 1/2x24 LE

S

B40W04 4 Balsa 1/16x2-1/8x24 LE

SB4QW05 4 Balsa1/16X7/8X24TE

SB40W20

SB40W14 1 Sub Pack

SB40W02 4 Balsa 1/4

SB4OWO3 4 Balsa 1/4x 1/2x24LE

SB4OWO4 4 Balsa 1/16x 2

SB4OWO5 4 Balsa 1/16x 7/8x 24TE

SB40W06 2 BalsaTapered5/8x 17

SS4OF31

SS4OFl1 1 Balsa 1/4X1/4X16Stringer

SS4OF12 8 Balsa1/8x 1/4x 16Stringer

WPMDU 1 Wheel PantsSet

GLTP001 1 FiberglassTape 8"

METAL007 2 Brass Plate

SCRW024 4 # 2

WPNT002 2 ABSWheel Pant

QTY

DESCRIPTION

1

Balsa118Former 3 8

1

Balsa1/8 Former6B

2 Balsa 5/8 Stailizer

FillerBlock

Leadina EdgeFiller

1 Sub Pack-iardware

5

MetalGear Hold

DownStraps

-

40 Blind Nuts

44

2 Nylon Control Horn

2 Nylon Hinges

2

Nylon Aileron Connector

3 Nylon1/4

42

-

4 4-40x1Bolt

-

24

18 #2

1 Wire 3/32 AileronTorque

RodSet

1

Wire3/32TailWheel

Assembly

1

Wire Elevator Joiner

2 3/32Wheel Collar

1 WrapWire

1 Sub Pack GearICabane

Wire

Plate

2 Wire Cabane Brace

.

1 Sub Pack-Topwing Parts

Spars/TE

Sheeting

Sheeting

2 Balsa3/8x 24Tapered

Trailing Edge

Wing Parts

Sheeting

Sheeting

Aileron

1 Sub Pack

-

20 Wing Bolt

56 x 5/8 Screw

40x1/8 Set Screw

x

3/8 Screw

-

Bottom

x

1/4x 24 Spars

-

-

Strinaers

x

3/8Screw

1/8 x 24 LE

-

1/2

Page 31

I

Use trim MonoKote and these

letters to create your trim

scheme

on

your Sportster.

Page 32

GREAT PLANES PRODUCT IMPROVEMENT SHEET

INSTRUCTIONS FOR BALANCING YOUR SUPER SPORTSTER

The recommended balance point for the Super Sportsters is

shown on the plan, and is located approximately

leadingedge. However, allSportsters have been thoroughlytest flown as

far back as

range from

total wing chord, as shown in the sketch).

36%,

and found to becompletely stable throughout theentire

29%

to

36%.

(These numbers represent a percentage of the

Total

Wing

Chord

29%

back from the

Balance

Points

If,

add several ouncesof nose weight to balance it at the location shownon

the plan, it

rather than adding a lot of weight.

the airplane will become more responsive to elevatorcontrol; therefore,

you

table

is measured at the widest part of the elevator, as shown in the sketch.

when balancing

is

preferable to balance farther

should reduce the maximum elevator

of

"

Recommended Maximum Elevator Throws."Theelevator throw

your

Super

Sportster,

As

you balance farther aft, however,

you

find it necessaryto

aft,

up to

36%

throw

in accordance with t he

(theaft limit),

The best way to balance your Super Sportster is to make a

Balancing Stand from a square

Mark the foreand aft limitsof thebalance range on the top

both sides of the fuselage), and place the airplane upside down on the

balancing stand as shown in the sketch (empty fuel tank). Move th e

airplane forward

If

it balances outside the

location of radio components

balances within the range.

frontof the recommended range, then adjust the linkages toyour elevator

to provide themaximum throwlisted in the

below.

If

maximum throw listed in the

of the range, set your elevator for the maximum throw listed in the

column.

or

aft on the stand until it balances with the stab level.

itbalances near the middle of the range, set your elevator for the

of

1

/4"

plywood and two

29%

to

36%

range, you must either shift the

or

add weight to the nose ortail until

Stab

must

be level

29%

-

30%

column in the table

33%

column.Ifit balances nearthe aft limit

3/8"

dowels.

of

the wing (on

36%

I

it

Measure Throw

Here

MEASUERED BACK FROM THE LE

WARNING!

OF

BOTTOM

If

you balance

WNG

your

Super Sportsteraft of the plan

location but fail to reduce the maximum elevator throw, the

of

elevatormayovercontrolthe pitch

in unwanted stallsand

"

snap rolls"!

the airplane,and mayresult

Loading...

Loading...