Page 1

INSTRUCTION MANUAL

WARRANTY

Great Planes Model Manufacturing Co. guarantees this kit to be free from defects in both material and

workmanship at the date of purchase. This warranty does not cover any component parts damaged by use or

modification. In no case shall Great Planes' liability exceed the original cost of the purchased kit. Further, Great

Planes reserves the right to change or modify this warranty without notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the final user-assembled product. By the

act of using the user-assembled product, the user accepts all resulting liability.

If the buyers are not prepared to accept the liability associated with the use of this product, they are

advised to return this kit immediately in new and unused condition to the place of purchase.

Urbana, IL 61801 (217) 398-8970

Entire Contents © Copyright 1995

LEA4P03 V1.1

P.O.

Box

LEARJET is a registered trademark of LEARJET, INC.

788

Page 2

INTRODUCTION..............................................................2

PRECAUTIONS.................................................................3

DECISIONS YOU MUST MAKE........................................3

Engine and mount

Fixed or retractable landing gear.................................3

PREPARATIONS...............................................................3

Accessories and additional items................................3

Optional retracts. ........................................................4

Building supplies and tools..........................................4

Types

of

wood

Common abbreviations ...............................................4

What about adhesives?...............................................5

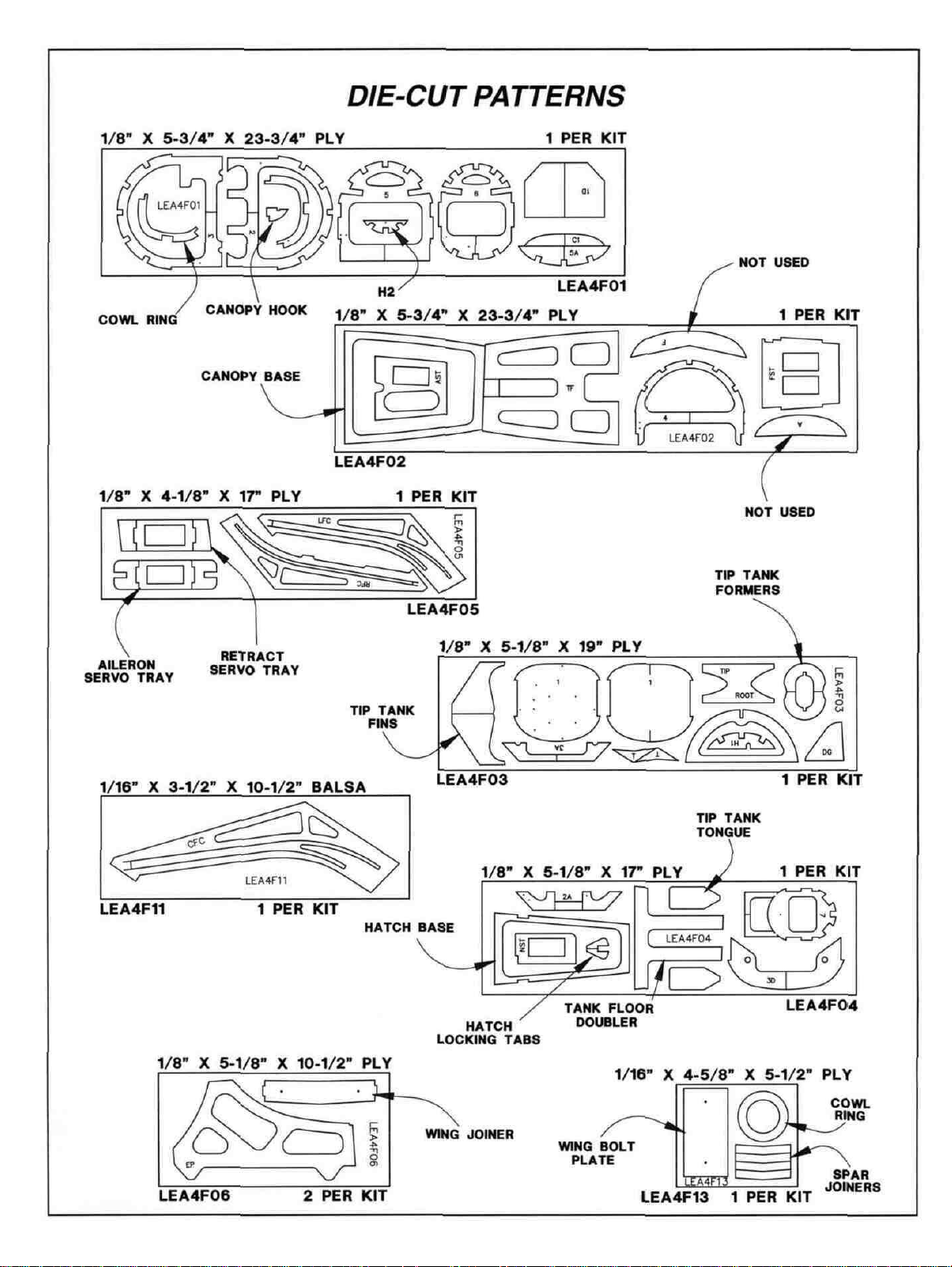

Die-cut patterns.....................................................6 & 7

Get ready to build ........................................................8

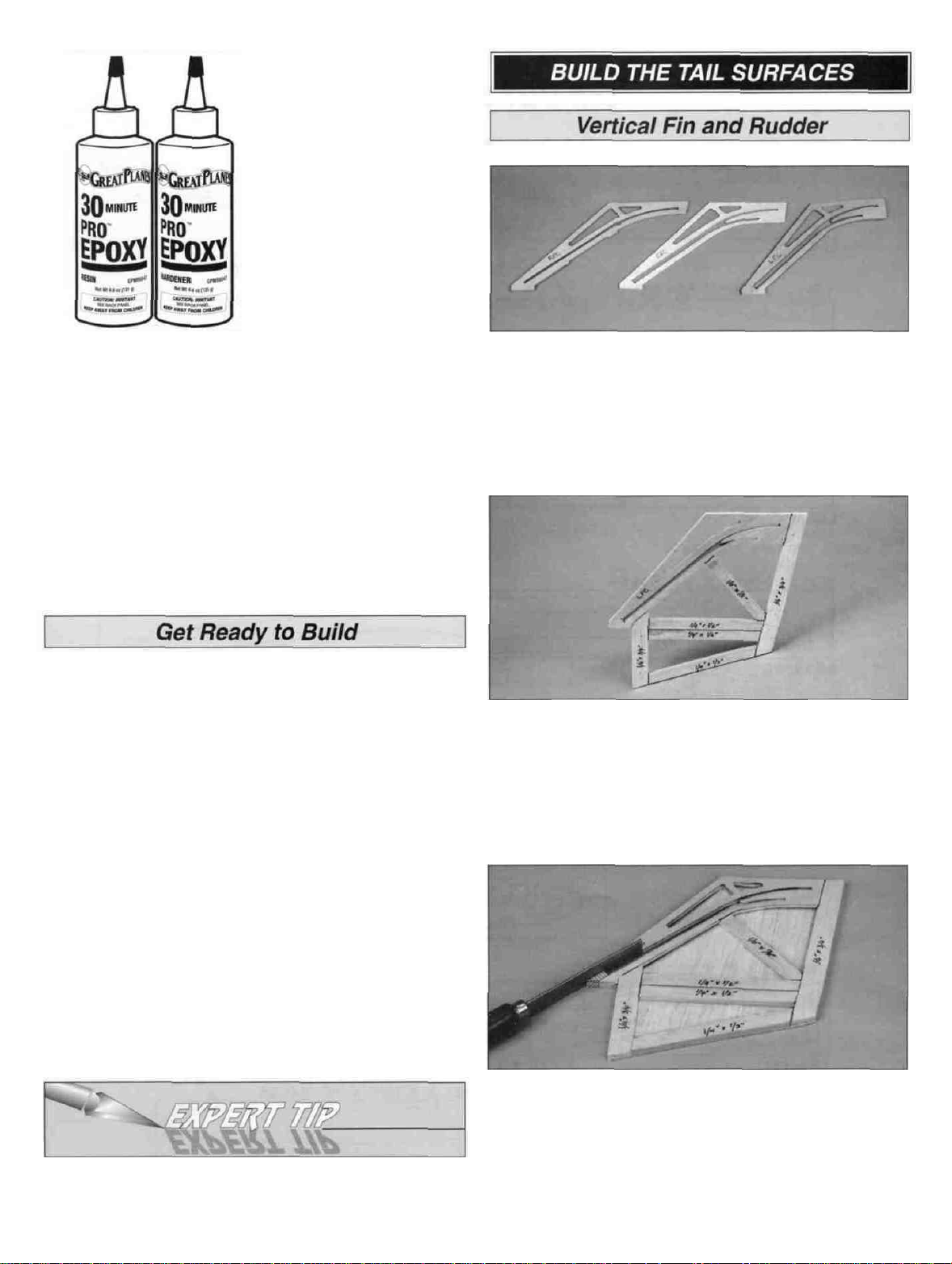

BUILD THE TAIL SURFACES...........................................8

Vertical fin and rudder

Stabilizer and elevators

BUILD

THE WING

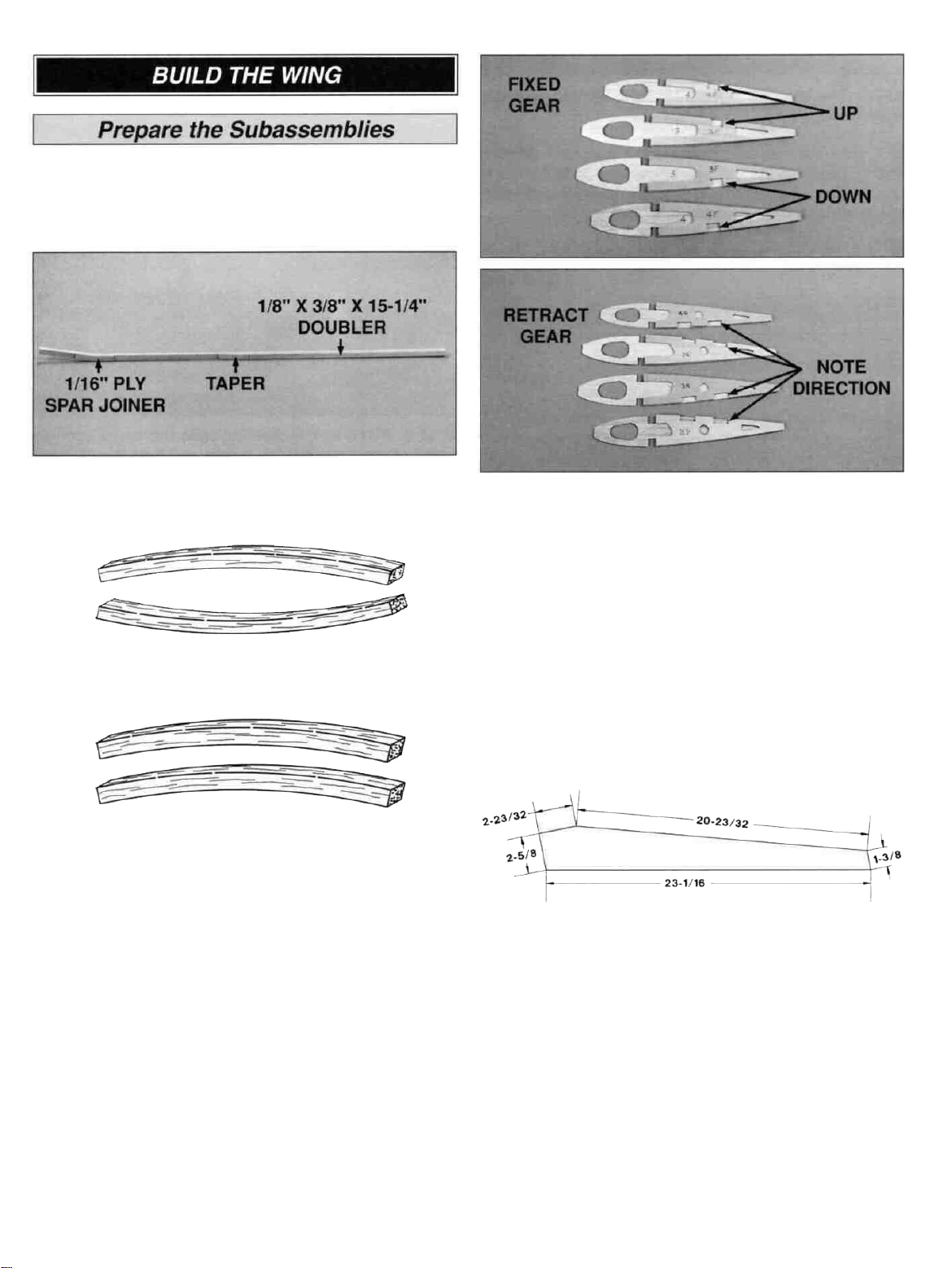

Prepare subassemblies.............................................11

Assemble the wings .................................................12

Completing the wing panels ......................................14

Join the wings............................................................16

Sand the leading edge ..............................................18

Assemble and install the tip tanks.............................18

BUILD THE FUSELAGE ................................................19

Frame the fuselage ...................................................20

Mount the engine ......................................................26

Install the canopy and cowl .......................................26

Mount the wing.............!............................................28

FINAL ASSEMBLY

Install the tail group ...................................................29

Assemble the engine nacelles...................................30

Balance the airplane laterally

FINISHING.......................................................................31

Fuel proofing .............................................................31

Final sanding before covering ...................................31

Applying MonoKote" covering ...................................31

Covering sequence ...................................................32

Painting .....................................................................32

Apply the decals . .....................................................32

INSTALL THE RADIO AND CONTROL SURFACES .....32

Install receiver and switch

Hinge and hook up the controls.................................33

Recommended control surface throws......................35

COMPLETE THE MODEL...............................................36

Install the

Install retractable

Install fixed landing gear............................................36

Install the nacelles and tip tanks

Balance the model

THE MAIDEN VOYAGE...................................................37

Balance the propeller ................................................37

Preflight .. . .. ............................................................38

Range check your radio ............................................38

Engine

AMA Safety Code......................................................38

fuel

safety

.......................................................3

.............................................................4

.................................................8

.............................................10

...........................................................11

..........................................................29

....................................30

.........................................32

tank

....................................................36

landing

precautions

fore

gear

..................................36

...............................37

and aft

.................................37

.........................................38

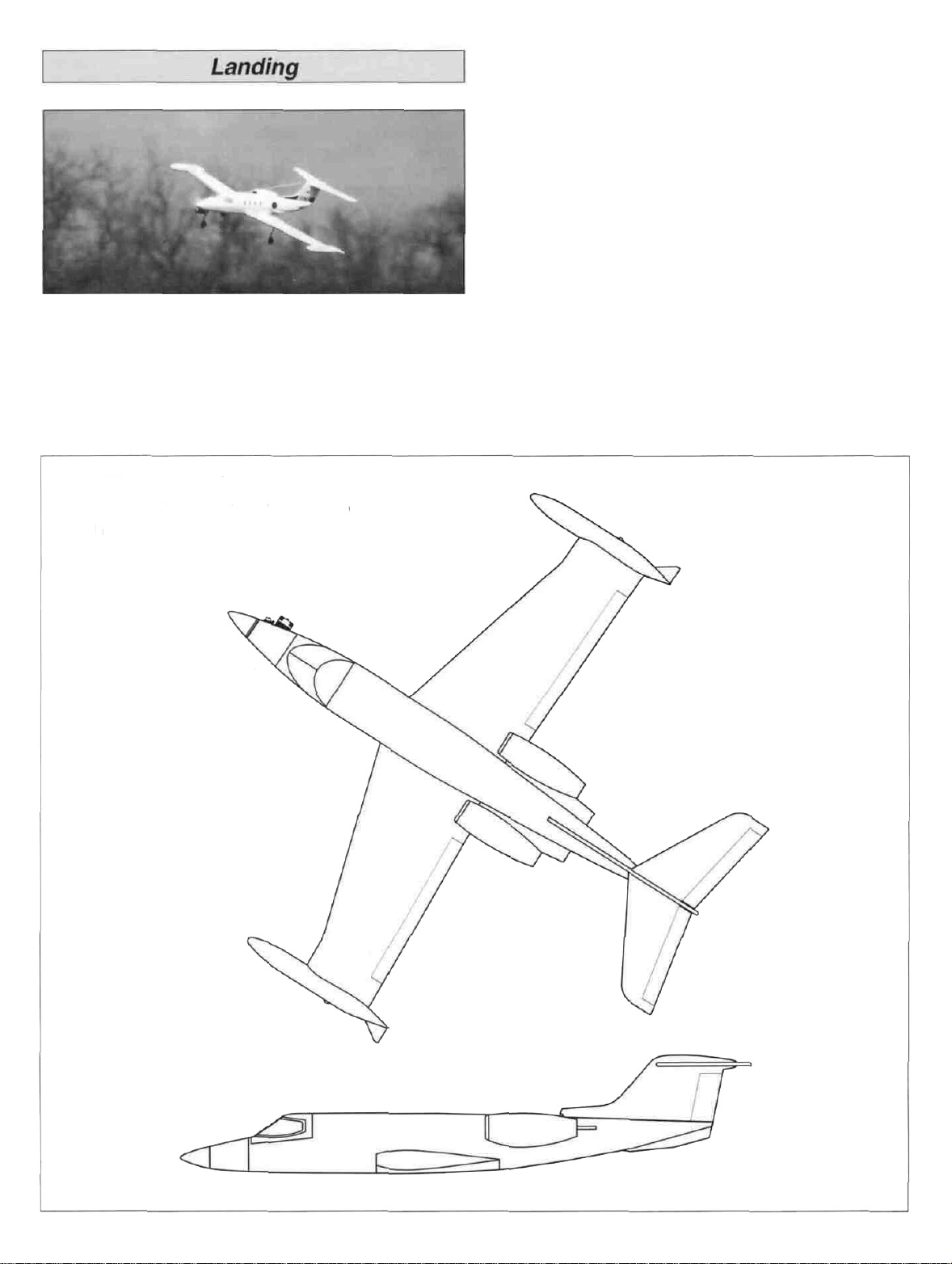

FLYING............................................................................39

Find a safe place to fly ..............................................39

Takeoff.......................................................................39

Flight......................................................................... 39

Landing......................................................................40

TWO VIEW DRAWING

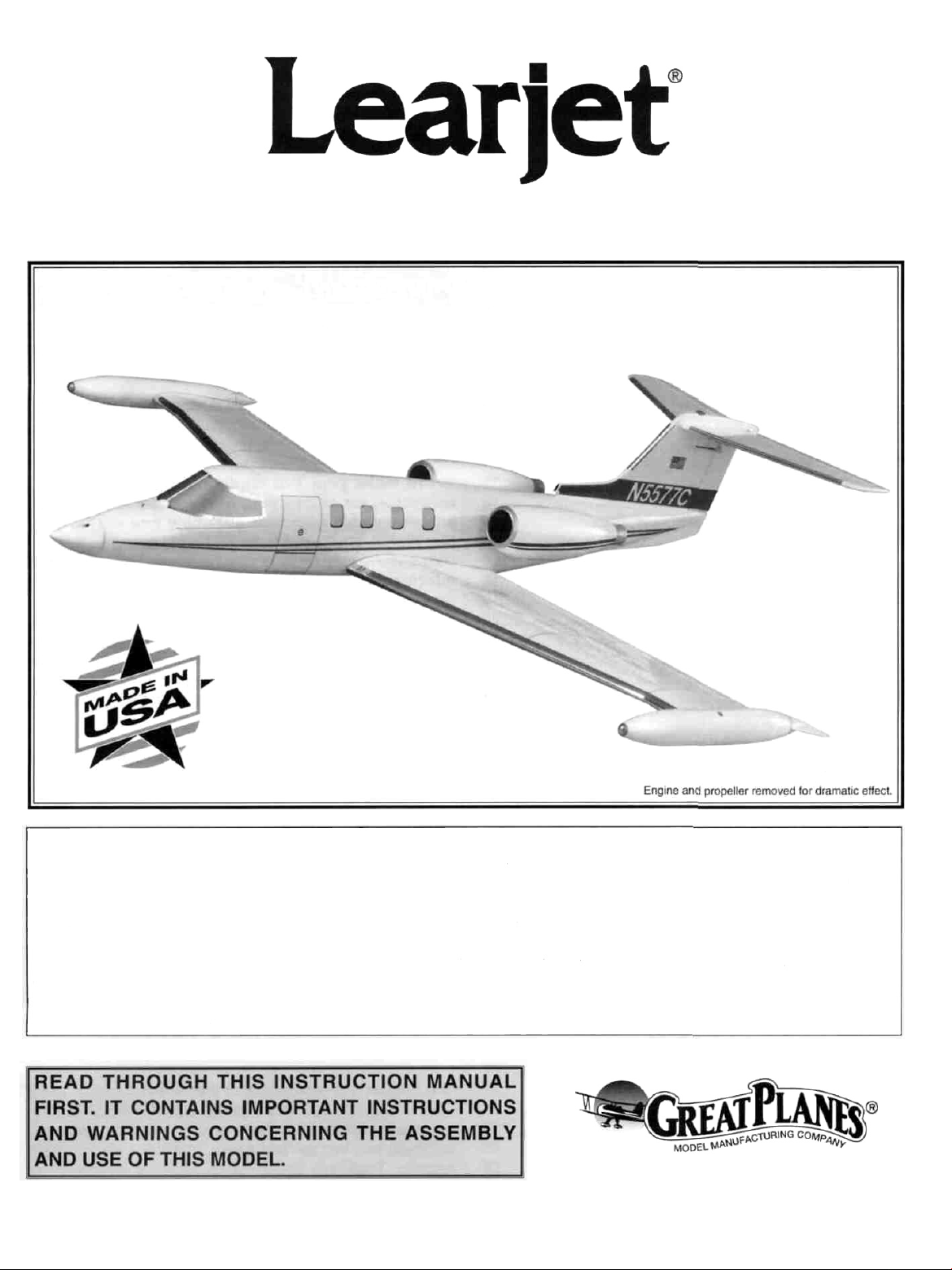

Your Great Planes Learjet is not a toy, but rather a

sophisticated, working model that functions very much like an

actual airplane.

Because of its realistic performance, the Learjet, if not

assembled and operated correctly, could possibly cause

injury to yourself or spectators and damage property.

To make your R/C modeling experience totally

enjoyable, we recommend that you get experienced,

knowledgeable help with assembly and during your

first flights. You'll learn faster and avoid risking your model

before you're truly ready to solo. Your local hobby shop has

information about flying clubs in your area whose

membership includes qualified instructors.

You can also contact the national Academy of Model

Aeronautics (AMA), which has more than 2,300 chartered

clubs across the country Through any one of them,

instructor training programs and insured newcomer training

are available.

Contact the AMA at the address or toll-free phone

number below.

Congratulations! Thank you for purchasing the Great

Planes Learjet!

This Learjet is a sport model of the full-size Learjet 35A. It

was designed by noted Ultra Sport'" modeler Jim

Feldmann It's easy to build and fly, predictable, fairly

aerobatic and has no "bad habits," making it a great sport

airplane. Traditional Great Planes quality and ruggedness

is evident throughout this kit, making this an airplane you'll

want to take along every time you go to the flying field.

....................................................40

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (317) 741-0057

2

Page 3

This is not a beginner's airplane! While the Learjet is

fairly easy to build and flies great, we must discourage you

from selecting this kit as your first R/C airplane It can be

fast, highly maneuverable and lacks the self-recovery

characteristics of a good basic trainer such as the Great

Planes PT Series On the other hand, if you have already

learned the basics of R/C flying and you are able to safely

handle a "trainer" airplane, the Learjet is an excellent

choice to improve your skills and learn new maneuvers.

Please inspect all parts carefully before starting to

build! If any parts are missing, broken or defective, or if

you have any questions about building or flying this

airplane, please call us at (217) 398-8970. If you are

calling for replacement parts, please reference the part

numbers and the kit identification number (stamped on

the end of the carton) and have them ready when calling.

1. You must build the plane according to the plan and

instructions. Do not alter or modify the model, as doing so

may result in an unsafe or unflyable model In a few cases

the plan and instructions may differ slightly from the

photos In those instances you should assume the plan

and written instructions are correct

Engine And Mount

The recommended engine size range is as follows'

40 - .50 cubic inch displacement 2-stroke.

This kit includes a Great Planes EM2840 engine mount

that fits nearly all 2-stroke engines in the recommended

range If you prefer, you may purchase a custom engine

mount for your engine, or you may choose to install

shock-absorbing, rubber-cushioned mounts.

Fixed or retractable landing gear

The Great Planes Learjet includes prebent wire landing

gear for fixed installation To add to the sleek and realistic

appearance of your model in flight, you may want to

install retracts We have included instructions for both

installations However, you will need to purchase a set of

three mechanical retracts, two servos, and a "Y" harness

if you choose the retract option Pneumatic retracts may

be used in place of the suggested mechanical units if you

prefer

2. You must take time to build straight, true and strong.

3. You must use a proper R/C radio that is in first class

condition, the correct sized engine and correct

components (fuel tank, wheels, etc ) throughout your

building process.

4 You must properly install all R/C and other components so

that the model operates properly on the ground and in the air.

5. You must test the operation of the model before the first

and each successive flight to insure that all equipment is

operating, and you must make certain that the model has

remained structurally sound Be sure to check the nylon

clevises often, and replace if they show signs of wear.

6. You must fly the model only with the help of a

competent, experienced R/C pilot if you are not already

an experienced and knowledgeable R/C pilot at this time.

NOTE We, as the kit manufacturer, can provide you

with a top quality kit and great instructions, but ultimately

the quality of your finished model depends on how you

build it, therefore, we cannot in any way guarantee the

performance of your completed model, and no

representations are expressed or implied as to the

performance or safety of your completed model

Remember: Take your time and follow directions to end

up with a well-built model that is straight and true.

D Four or five channel radio with 4 to 6 servos

(optional retracts)

D 6" Servo extension cord

D Propellers (See engine instructions)

D 2-1/4" Jet spinner

(white GPMQ4542) (black GPMQ4540)

D 6 to 8 oz Fuel tank

(6 oz GPMQ4102 8 oz GPMQ4103)

D 2 oz Thin CA adhesive (GPMR6015)

D 2 oz Medium CA adhesive (GPMR6009)

D 1 oz Thick CA adhesive (GPMR6014)

D 6-Minute epoxy (GPMR6045)

D 30-Minute epoxy (GPMR6047)

D 1-3/4" Nose wheel (GPMQ4220)

D 2" Main wheels (GPMQ4221)

D 5/32" Wheel collars (6) (GPMQ4306)

D Model covering (2 - 3 rolls)

(Top Flite MonoKote" Covering)

D Medium fuel tubing (GPMQ4131)

D 1/2" thick Latex foam rubber padding (HCAQ1050)

D Sliver solder (recommended) (GPMR8070 w/flux)

D Switch & charge jack mount (optional) (GPMM1000)

D Fuel filter (optional) (GPMQ4150)

D Fuelproof paint

(see "Painting" section of instructions on page 32)

3

Page 4

D Tricycle retract gear - (HCAP4000)

D Retract servo (Futaba S136G or similar)

D Standard servo for nose gear retract

D Servo "Y" harness

D 1-1/4" x 5/32" Wheel axles (3) (GPMQ4280)

D 2-56 x 12" Threaded wire pushrods (2) (GPMQ3750)

D 2-56 x 36" Threaded wire pushrods (1) (GPMQ3716)

D Screw-Lock pushrod connector (3) (GPMQ3870)

D 4-40 x 1/8" Set screws

*ltems in parentheses (GPMQ1234) are suggested part

numbers recognized by distributors and hobby shops and

are listed for your convenience GPM is the Great Planes

brand, HCA is the Hobbico® brand, TOP is Top Flite

D Hand or electric drill *

D Drill bits 1/16", 3/32", 7/64" or #35, 1/8", #29 or

9/64", 3/16", #10 or 13/64", 15/64", 17/64" and 1/4"

D Sealing iron - (TOPR2100)

D Hot sock (optional) - (TOPR2175)

D Heat gun (optional) - (TOPR2000)

D Razor saw

D #1 knife handle - (XACR4305)

D #11 Blades - (HCAR0311 pkg of 100)

D Common and needle nose pliers

D Screwdrivers (phillips and flat)

D T-Pins - (HCAR5100 small, HCAR5150 medium,

HCAR5200 large)

D Straightedge - (Fourmost Non Slip FORR2149)

D Masking tape

D Sandpaper (coarse, medium, fine grit)

D Sanding blocks or Great Planes Easy-Touch"

Bar Sander (GPMR6170 -11" & GPMR6172 - 22")

D Waxed paper

D Lightweight balsa filler - (HCAR3401)

D 5/32" brass tube (optional)

D 1/8" brass tube (optional)

D Tap wrench

D 1/4-20 Tap - (GPMR8105 w/dnll bit)

D IsopropyI rubbing alcohol (70%)

D Dremel® Moto Tool® or similar w/sanding drum and

cutting burr (optional)

D Kyosho" curved scissors (optional) - (KYOR1010)

On our workbench, we have four 11" Easy-Touch Bar

Sanders, equipped with #50, #80, #150 and #220-gnt

sandpaper This setup is all that is required for almost

any sanding task Custom sanding blocks can be made

from balsa for sanding hard to reach spots We also keep

some #320-gnt wet-or-dry sandpaper handy for finish

sanding before covering

Great Planes Easy-Touch Bar Sanders are made from

light-weight extruded aluminum and can be found at

most hobby shops The sanders are available in two

sizes - 11" (GPMR6170) for most general purpose

sanding and 22" (GPMR6172) for long surfaces such as

wing leading edges We recommend using the 2-1/4"

wide self adhesive sandpaper sold in 12' rolls by Great

Planes The sandpaper is available in three different grit

sizes - #80-grit (GPMR6180), #150-grit (GPMR6183)

and #220-grit (GPMR6185) Standard sandpaper can be

attached by gluing it to the sander with rubber cement.

Apply the rubber cement to both the bottom of the sander

and the back of the sandpaper When both surfaces are

dry to the touch, press the sandpaper firmly onto the

sander Spray adhesive can be used for this purpose but

it's much harder to remove the sandpaper when you

need to replace it Use a knife blade for cutting

sandpaper, not your good scissors!

Balsa Basswood Plywood

Elev = Elevator

LE = Leading Edge (front)

Lt = Left

Rt = Right

TE = Trailing Edge (rear)

4

Fuse = Fuselage

LG = Landing Gear

Ply = Plywood

Stab = Stabilizer

" = Inches

Page 5

We understand that the caliber of modelers likely to build

the Great Planes Learjet may be rather high You may

already know all about the types of adhesives you like to

use However, due to its easy building features, many new

builders may try their hand at the Great Planes Learjet For

those modelers (experts may read along), we have

provided some explanation about the variety of adhesives

used during construction of a model.

Accelerator is a liquid chemical that

comes in a spray bottle for use in

speeding up the cure time of all CA

types It should be misted on, not

sprayed heavily on the joint Accelerator

may cause exposed CA to bubble and

sometimes change color If accelerator

is sprayed on too heavily it may weaken

the glue joint, so use it sparingly

Cyanoacrylate or CA glue has changed the way models

are built more than any other advance in modeling

technology In the good ol' days, model cement like

Ambroid, Duco, Comet and Sigment were the glues of

choice They all had a strong odor that could cause

dizziness, dried slowly (compared to CA) and became

brittle with age CA, on the other hand, is stronger, works

almost instantly and is bottled in three different viscosities

(thicknesses) CA is used for most glue joints, except where

epoxy is specified CA does emit rather strong fumes (some

say it's like tear gas) as it cures, so rule number one is to

work in a well ventilated area. All CA glues work best if

the joints are smooth and fit well.

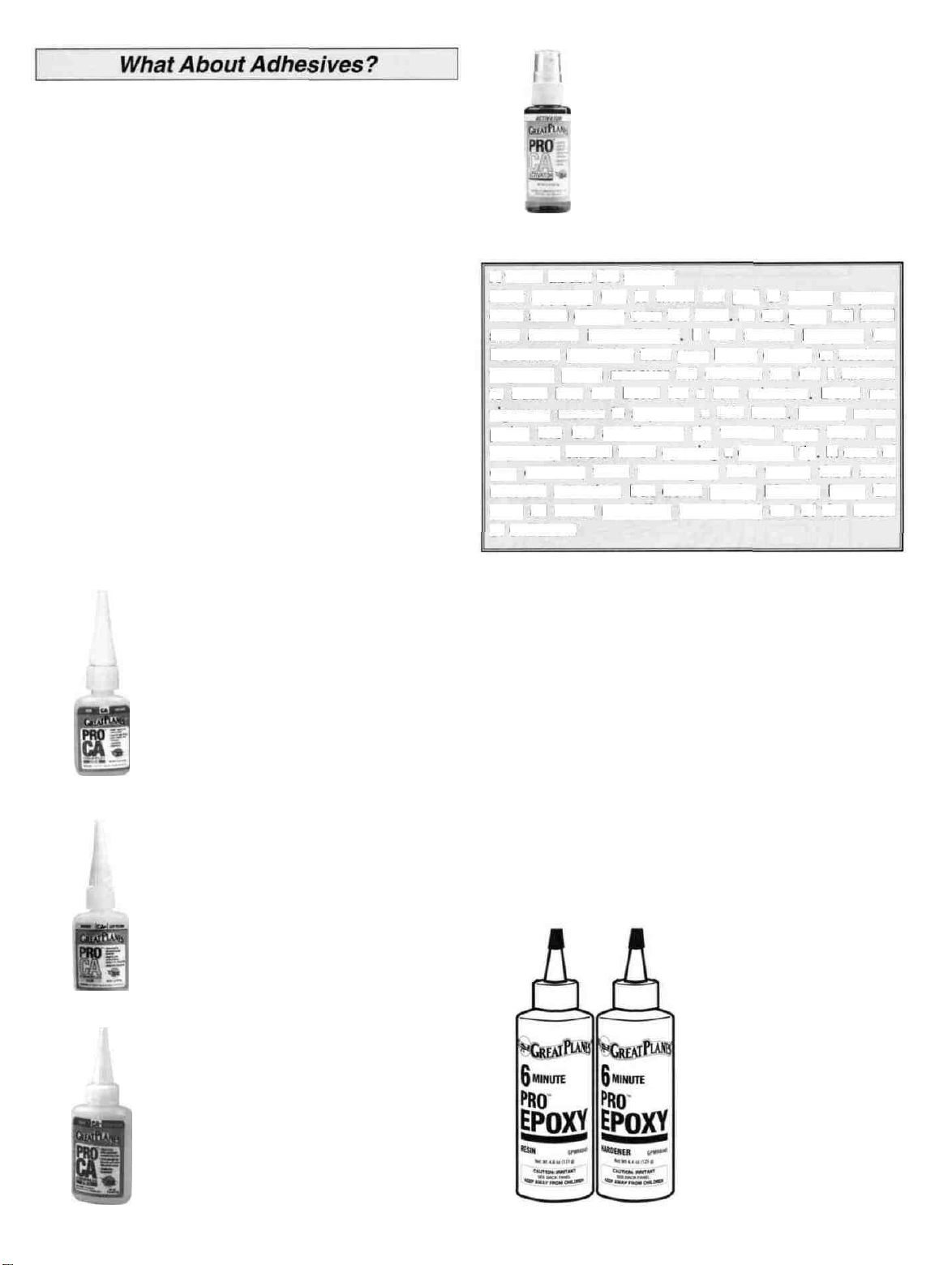

Thin CA is also known simply as CA This

is the adhesive that has revolutionized

model building because it allows you to

assemble the parts first, then apply the

adhesive The thin formulation flows or

"wicks" into the joints and sets almost

instantly, eliminating the need to hold

things together while the glue dries You

will often use Thin CA for the initial bond,

then follow with medium or thick CA for

extra strength, especially when gluing

plywood or hardwood.

CA+ is also known as medium or gap

filling CA CA+ is used for surface

gluing, filling small gaps between poorly

matched parts and for general purpose

applications It cures slower than thin CA,

allowing you to apply a bead to two or

three parts before assembly Curing time

without accelerator is 20-30 seconds.

CA- or thick CA is used when extra

positioning time is needed CA- is a great

gap filler and is also used to make fillets

when a little extra strength is required.

Curing time is about 1-2 minutes.

A word about CA safety!

After applying CA, to avoid the puff of strong vapors,

don't stand directly over the work All CA glues will bond

skin almost immediately If this should happen, CA

Debonder (available from your hobby dealer) or acetone

fingernail polish remover will dissolve the CA if allowed

to soak into the bond for a few minutes Don't use

vigorous means to separate a skin bond Never, never

point the CA applicator tip toward your face' Be

especially careful when opening a clogged tip In case of

eye contact, flush thoroughly with water, then seek

medical attention, but don't panic. Please, keep CA

(and all other modeling chemicals) out of the reach

of children!

Epoxy

Great Planes has two epoxy formulations available for the

modeler Both offer exceptional strength and convenient

working times Use epoxy when the joint requires

exceptional strength, such as when installing the firewall,

when joining the wing panels, and when installing wing

hold-down blocks As with most epoxies, you mix equal

parts of resin and hardener, stir well then apply a thin film

to each part Parts should be clamped, pinned, taped or

weighted in place until fully cured Before the epoxy cures,

clean off any excess with a paper towel A word of caution

about mixing epoxy-don't use extra hardener in the

hopes of making the mixture harder or work faster Just

about all epoxies work best with exactly a 50/50 mix When

you increase the amount of hardener, you run the risk of

causing the cured epoxy to become either brittle or

rubbery-neither being as strong as a properly mixed batch.

6-Minute Epoxy is used

for simple, small gluing

applications where

elaborate alignment is not

required Working time

(before its too gooey to

use) is about 5 minutes,

handling time 15 minutes

and it's fully cured in about

1 hour

(Continued on page 8)

5

Page 6

6

Page 7

7

Page 8

30-minute epoxy is used

for extra strength (because

it can penetrate longer) and

where several parts must

be aligned and checked

before it cures. Working

time is about 25 minutes,

handling time 2 hours, and

it's fully cured in 8 hours.

Great Planes Pro" Wood Glue is an Aliphatic resin glue

that works well on all types of wood. It is non-toxic, virtually

odorless and dries clear. Some people are sensitive to CA

and epoxy fumes, so this is a good alternative for general

modeling use. Its only drawback is that it is slow to cure,

requiring the parts to be securely clamped, pinned or taped

while the glue dries.

Okay, you've got your work space ready, your tools are at

hand, and you know how to choose and use the right glue

for the job. Let's get started!

D 1. The fin core is made up of left and right die-cut 1/8"

plywood fin cores (LFC, RFC) and a die-cut 1/16" balsa

center fin core (CFC). Place the fin plan on your building

board and cover it with waxed paper. Place the 1/8" RFC

(with one slot) over the plan and glue the 1/16" center fin

core on top of it. Glue the 1/8" LFC (two slots) on top of the

center fin core.

D 1. Unroll the plan sheets. Reroll the plan sheets inside

out to make them lie flat.

D 2. Remove all parts from the box. As you do, determine

the name of each part by comparing it with the plan and the

parts list included with this kit. Using a felt-tip or ball point

pen, lightly write the part name or size on each piece to

avoid confusion later. Use the die-cut patterns shown on

pages 6 and 7 to identify the die-cut parts and mark them

before removing them from the sheet. Save all scraps. If

any of the die-cut parts are difficult to punch out, do not

force them! Instead, cut around the parts with a hobby

knife. After punching out the die-cut parts, use your T-Bar

or sanding block to lightly sand the edges to remove any

die-cutting irregularities.

D 3. As you identify and mark the parts, separate them

into groups, such as fuse (fuselage), wing, fin, stab

(stabilizer), and hardware.

Zipper-top food storage bags are handy to store your parts

as you sort, identify and separate them into subassemblies.

D 2. Sand the front and top edges of the fin core smooth,

then pin the core over the plan. Assemble the balsa fin

framework from 1/4" x 1/2" and 1/4" x 3/4" balsa sticks on

the core as shown on the plan. Note: The frame is thinner

than the fin core but this will not cause a problem. Do not

install the leading edge, dorsal fin or the 3/8" top and rear

pieces yet.

D 3. Remove the fin from the board, sand both sides

smooth (it's OK if the plywood core is a little thicker than

the balsa framing). Sheet the right side with 1/16" balsa

sheeting. Drill a 1/8" hole through the sheeting at the rear

end of the top slot and elongate the hole to fit the control

cable tubing. Cut away the fin core below the bottom of the

slots as shown on the plan.

8

Page 9

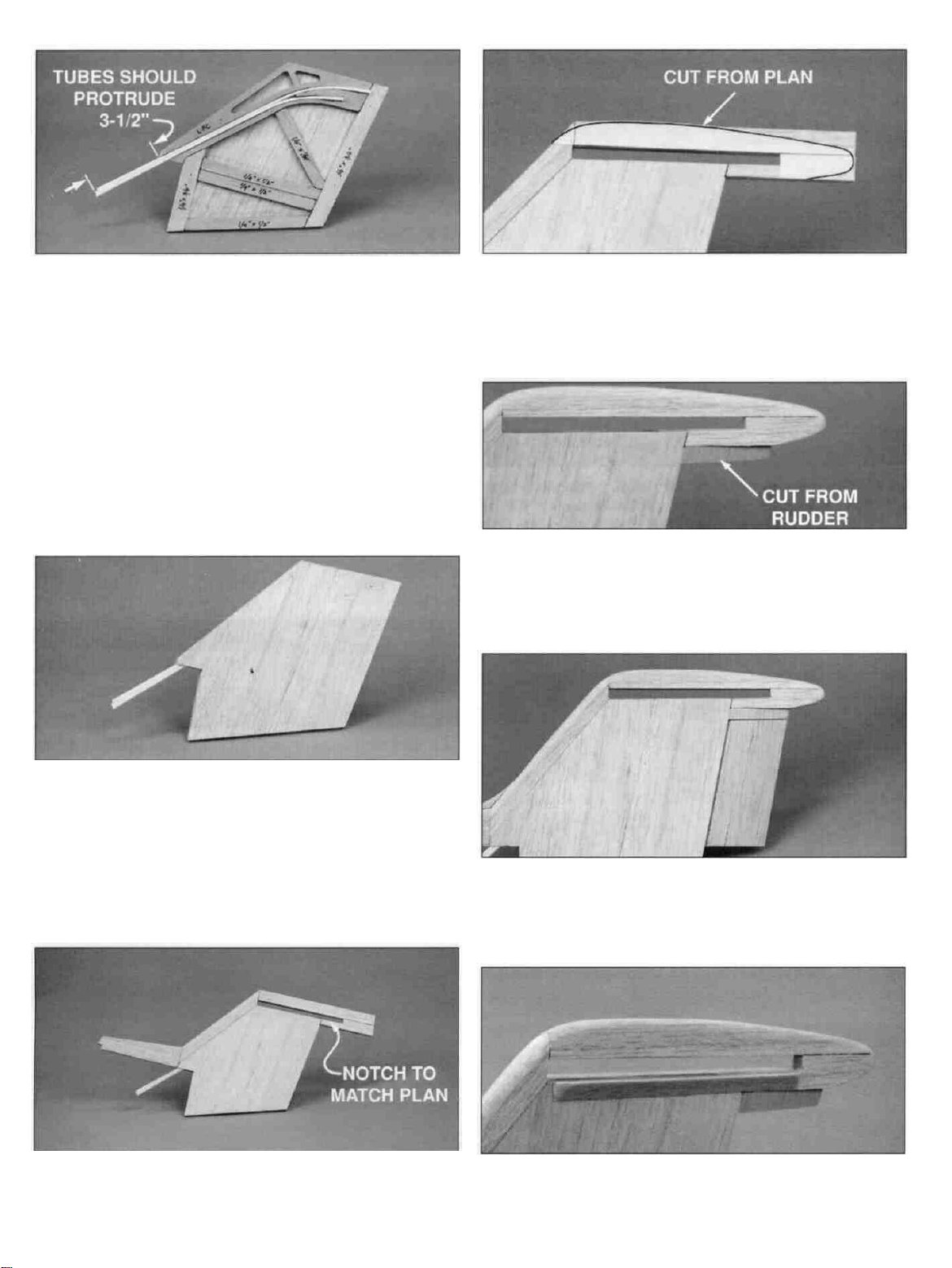

D 4. Cut three pieces of inner pushrod tube to match the

plan. Fit the right elevator cable tube in the top slot of the

fin core, up against the sheeting on the right side, with an

inch or so extending through the sheeting hole.

NOTE: LEAVE 3-1/2" OF ALL THREE TUBES

EXTENDING PAST THE BOTTOM OF THE FIN CORE. Fit

the left elevator cable tube in the same slot on top of the

right one, but have it exit on the left side. Fit the rudder

cable tube in the lower slot in the fin core exiting on the

left side as well. When you're happy with the fit, use thick

CA to hold the tubes in the slots.

D 7. Cut the fin top pattern from the plan, then glue it to

the top of the fin with spray adhesive or rubber cement.

Sand the edges of the fin top to match the pattern. Round

the top of the dorsal fin, front of the leading edge and top of

the

fin

top.

D 8. Sand one end of the shaped balsa rudder to match

the angle shown under the stab on the plan. Cut a 3/8"

piece from the sanded end to make the rudder filler. Glue

the 3/8" piece to the bottom of the fin's TE. Cut the rudder

to match the size and shape shown on the plan.

D 5. Sand the right elevator tube flush with the sheeting,

then pin the fin assembly back on the building board. Add

1/16" balsa sheeting on the open side, fitting the sheeting

around the rudder and left elevator tubes where they exit.

Sand the tubes flush with the sheeting.

D 6. Add the 3/8" x 3/4" balsa stick leading edge, trailing

edge (TE), top (notched to match the plan) and shaped

dorsal fin. Remove the assembly from the board.

D 9. Sand a "V" on the leading edge (LE) of the rudder to

match the cross-section on the plan. Use masking tape to

temporarily attach the rudder to the fin. The hinges will be

installed after covering.

D 10. Round the ends of two 6" long pieces of 3/8" balsa

tri-stock and glue them to the sides of the fin, flush with the

bottom of the stab slot.

9

Page 10

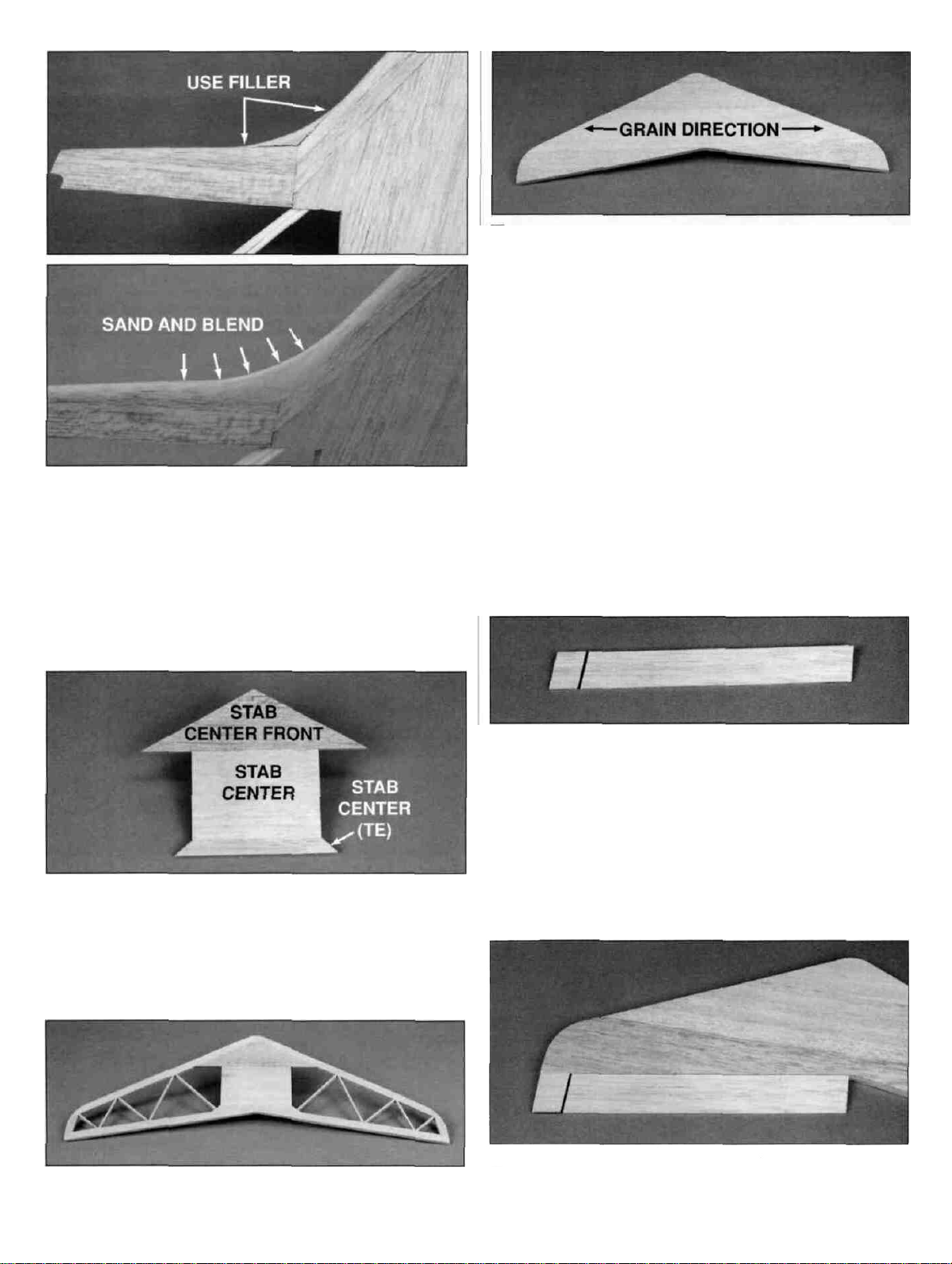

D 11. Cut a small piece of 3/8" scrap balsa stick to fit

between the top of the dorsal fin and the vertical fin. Shape

and sand this piece to match the plan. Use balsa filler

(HCAR3104).

Stabilizer & Elevators

D 3. Sand the completed framework smooth, then glue

1/16" x 3" balsa sheeting to the top surface.

D 4. Remove the stab from the board. Sand the bottom

side smooth, then sheet it with 1/16" x 3" balsa. Trim the

perimeter to the shape shown on the plan and sand the

assembly smooth. Sand the leading edge and tips round to

match the cross section on the plan but leave the TE flat.

D 1. Put the stab plan on your building board and cover it

with waxed paper. Pin the 1/4" shaped balsa stab center

front over the plan, then glue the 1/4" x 3" x 4-1/4" balsa

stab center to its aft edge. Cut the stab center (TE) from a

1/4" x 1/2" balsa stick to match the shape shown on the plan.

D 2. Assemble the stab frame from 1/4" x 1/2" balsa sticks,

then cut and glue the 1/8" x 1/4" balsa trussing in position.

D 5. Cut both ends of each shaped balsa elevator to the

angle shown on the plan, then cut a 1" piece from each

one. Glue these short pieces to the TE of the stab at the

tips, and sand to shape.

D 6. Sand a "V" on the LE of the elevators and trim the

inner ends to match the plan. Temporarily attach the

elevators to the stab with masking tape.

10

Page 11

D 1. Pin the wing plan to your building board and cover it

with waxed paper.

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

STRAIGHT WING

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

WARPED WING

D 2. Assemble the spars as follows: Pin one of the 1/4" x

3/8" x 30" balsa main spars down over one wing plan and

trim the outboard end at the centerline of W-9 (save the

off-cut piece for use in a moment). Locate a 1/8" x 3/8" x

15-1/4" balsa spar doubler. Sand 2-1/4" of one end of the

spar doubler to a taper (see plan). Glue the spar doubler to

the inboard end of the main spar so that the untapered end

is flush with the root end of the main spar. Trim the

off-cut piece of 1/4" x 3/8" to match the plan at the outboard

end of the main spar, then glue it in position. Glue the diecut 1/16" plywood spar joiner on top of the joint.

D 3. Remove this spar from the plan, then assemble a

second one over the same plan.

D 5. Decide whether you will be using fixed or retractable

landing gear. The rib doublers required for fixed or retract

gear are different. W-3F and W-4F are used for the fixed

gear and W-3R and W-4R are used for the retract gear.

Glue the appropriate doublers to the W-3 and W-4 ribs,

being sure that you make a left and a right of each one.

Cut the gear block notches out of each rib using the

notches in the doubler as a guide.

D 6. Align the shaped and notched leading edges (LE)

over the plan. Cut the LE in two at the centerline of W-9.

Save both pieces.

CUT LE SHEETING AS SHOWN (4 REQUIRED)

D 7. Using the plan and the pattern shown above, cut four

3/32" x 3-1/2" x 30" balsa LE sheets. Note: The aft edge of

the sheets should fall approximately along the middle of

the spar.

D 8. Glue the two die-cut plywood dihedral braces (DB)

together with 6-minute epoxy. Be sure they are perfectly

aligned along all edges. Clamp the pieces together while

the epoxy cures.

D 4. Build two more spars over the plan of the other

wing. This procedure will produce left and right top and

bottom spars.

D 9. After the DB epoxy has cured, lightly sand the edges

to remove any bumps. Drill a 1/4" hole through the DB

at each of the two punch marks. These holes are for the

wing dowels.

11

Page 12

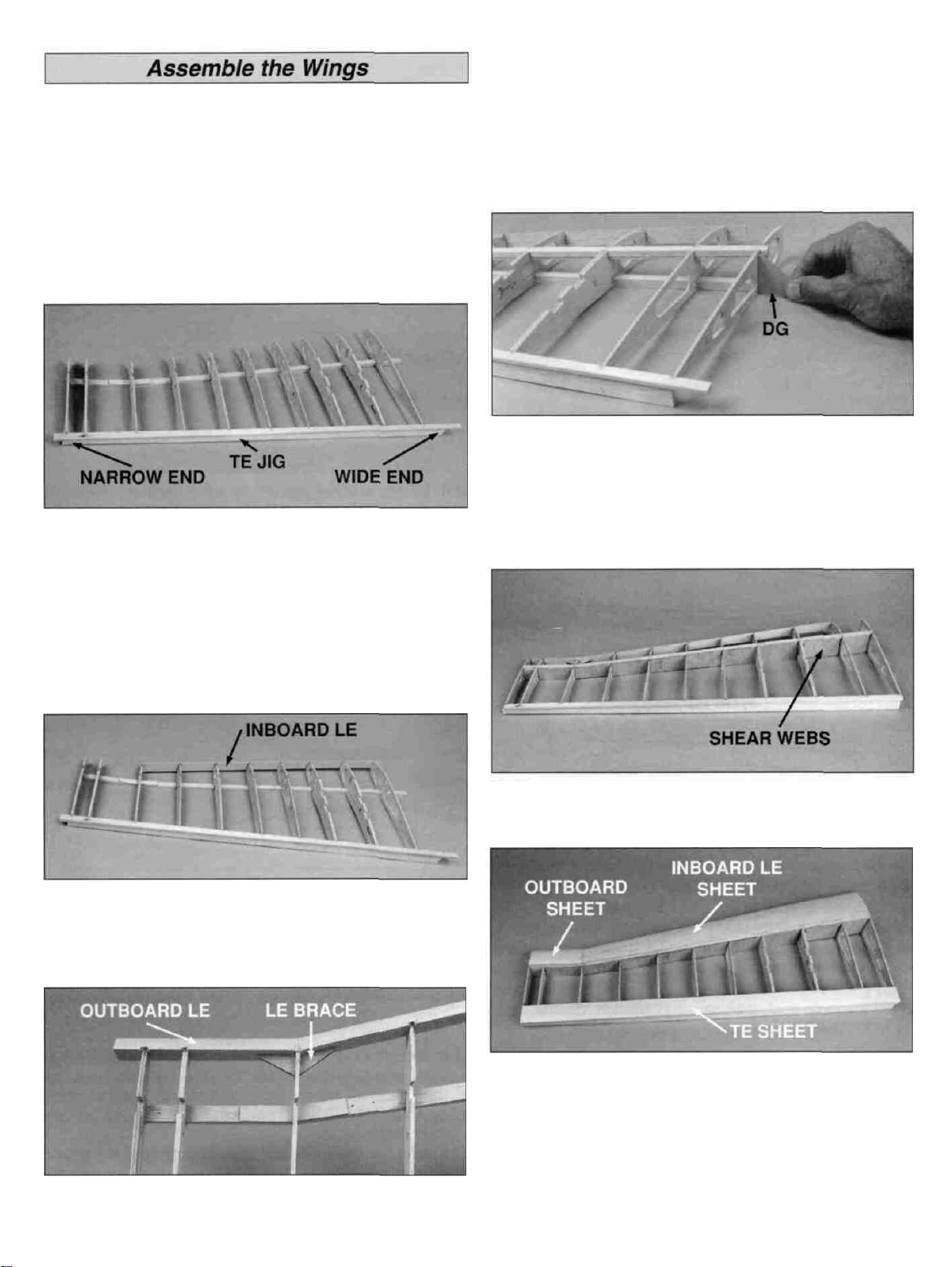

NOTE: The wings are built UPSIDE DOWN over the

opposite wing plan.

glue it in place on the forward edge of ribs W-9 through

W-11. Glue the die cut 1/8" plywood leading edge brace to

the back of the leading edge at W-9.

D 1. Start with the wing plan which shows your chosen

landing gear. Pin the trailing edge support jig to the board

over the plan, under the waxed paper. The wide end of the

jig is positioned at the root end of the wing.

D D 2. Carefully separate the leading and trailing edges

with a hobby knife.

D D 3. Pin the bottom spar down and glue W-2, W-6 and

W-11 to the spar, then glue the shaped and notched

trailing edge to those ribs. The ribs should be centered

vertically on the trailing edge and the trailing edge must be

kept level. (Since the trailing edge is tapered, it does not sit

flat on the support jig.) Pin the trailing edge to the support

jig. Add the rest of the ribs (except W-1). Be sure that the

rib doublers are on the correct side of W-3 and W-4 as

indicated on the plan.

D D 6. Fit and glue the second spar in position.

D D 7. Place W-1 in position (with the servo opening

pointing toward the building board) and hold the dihedral

gauge against the outer face to set the proper angle. Glue

W-1 in place. Cut both spars and the TE flush with W-1.

Trim the LE flush with W-2.

D D 4. Fit the inboard leading edge in place on ribs W-4

through W-9. The leading edge must extend an equal

amount above and below the ribs. Glue the leading edge in

place with thin CA.

D D 5. Sand the outboard leading edge (the short piece

you cut off) to fit against the inboard leading edge, then

D D 8. Fit and install 1/16" balsa shear webs in all rib

bays against the aft edges of the spars.

Refer to this photo for next three steps.

D D 9. Lightly sand the top of the ribs, spar and trailing

edge to remove any irregularities. Sand the forward edge

of the 3/32" inboard leading edge sheeting to match the

angle made by the ribs and the leading edge. The aft edge

of the sheet should fall on the centerline of the spar. When

satisfied with the fit, glue it in place.

12

Page 13

D D 10. Fit and glue the 3/32" x 1-1/4" x 30" trailing edge

sheeting in position across the aft edge of the wing.

D D 11. Sheet the outboard leading edge with the balsa

you trimmed off when cutting the LE sheets. Glue it in place.

D D 12. Slide the die-cut 1/8" ply tip tank tongue in place

through the slots in W-11 and W-10. Fit a 1/4" x 27/32" x 1"

balsa tip tank retainer block on top of the tongue between

W-10 and W-11 and carefully glue it to the two ribs.

Remove the tongue immediately so that you don't

accidentally glue it to the block. Glue a piece of scrap 3/32"

balsa on top of the hardwood block and sand it to match

the shape of the ribs.

D D 15. Fit the retract mechanism in place, trimming the

plywood mounting plates as required to allow the retract

to function properly. Drill 3/32" mounting holes and

temporarily install the retract with four #4 x 3/8" sheet

metal screws.

D D 13. Cut and install the tip sheeting (from left over

3/32" balsa) between W-10 and W-11.

Use the instructions that follow to install the landing gear

mounting rails of your choice (for fixed or retractable).

D D 14. Use 30-minute epoxy to glue the 1/4" x 3/4" x

3-5/8" plywood retract mounting plates into the slots in

W-3 and W-4.

D D 16. Use 30-minute epoxy to glue the 7/16" x 5/8" x

4-5/16" hardwood main gear block into the notches in W-3

and W-4. The inboard end should overhang W-3 by 3/4"

and the "groove" faces away from the building board.

D D 17. Use 30-minute epoxy to glue the 5/8" x 5/8" x 5/8"

hardwood landing gear torque block to the ungrooved side

of the main block, against the root face of W-3F. Glue the

5/8" wedge shaped landing gear gusset on the ungrooved

side of the main block, against the root face of W-4F with

30-minute epoxy.

13

Page 14

D D 18. Drill an 11/64" hole through the main gear block

and the torque block as shown on the plan. This hole must

be drilled perpendicular to the main gear block and parallel

to W-3F.

D D 19. Fit the 5/32" music wire strut into the blocks and

fill the unused slot at either end of the main block with

scrap balsa. Remove the strut.

D D 20. Remove the wing from the board and check all

glue joints. Add a glue fillet to any joint that needs it. Sand

off any imperfections before proceeding.

D D 26. Cut and glue 3/32" x 3/8" balsa cap strips to the

top of ribs W-5 through W-9.

D D 27. Sheet the wing center section with 3/32" x 3"

balsa cut from a 36" sheet.

D D 28. Remove the wing from the board and sand the

sheeting flush with W-1, W-11 and the trailing edge. Rough

sand the leading edge to shape.

D D 21. With the wing "right side up," pin (or weight) the

spar to the building board. Tack glue the die-cut 1/8" ply TE

jigs, J1 and J11, to the bottom of the TE at ribs W-1 and W-

11. Pin or weight the aft portion of the wing to be sure the TE

jigs and main spar are touching the building board. Add a 5/8"

shim of balsa under the trailing edge center to prevent the TE

from bowing downward.

D D 22. Glue the top 3/32" x 1-1/4" x 30" balsa TE sheet

in position.

D D 23. Glue the inboard and outboard LE sheeting in

position. Be sure the TE jigs, shim and spar remain in

contact with the building board.

D D 24. Insert the tip tank tongue and fit a 1/4" x 27/32" x

1" hardwood upper retainer block on top of the tongue

between W-10 and W-11. Glue this block between the ribs,

and remove the tongue immediately. Glue scrap balsa to the

top of the block, then sand it to match the top of the ribs.

D D 25. Install the 3/32" tip sheeting (from left over

3/32" balsa).

D D 29. Turn the wing panel over and sheet the bottom

center section with 3/32" x 3" balsa. The sheeting must be

fitted around the main gear block or the retract mechanism

if using retracts.

Okay, clean up your building board, then build the second

wing panel over the other wing plan.

D 1. Cut a 3" piece from each 21" long tapered balsa

aileron. Check that the taper of the aileron stock matches

the shape of the airfoil. Glue the 3" pieces to the aft edge

of each wing panel, at the tip.

14

Page 15

D 2. Check that the taper of the 1 -3/8" x 6" balsa center

TE piece matches the shape of the airfoil.

NOTE: When installing the center trailing edge pieces

make sure they line up with the top and bottom surface of

the wing.

If necessary, sand the aft edge of the wing to correct the

problem. Trim and sand the ends to match the angles on

the wing plan. Cut a notch in the top surface of a balsa

center TE piece 1/2" from the root end. Fit an aileron

torque rod assembly into the groove with the threaded end

protruding through the notch. Prepare another center TE for

the other wing panel. Be sure to make a left and a right

side as shown.

D 4. Cut the ailerons to fit between the center TE and the

tip TE. Hold the aileron in position, then mark the location

of the torque rod arm. Drill a 1/8" hole, 3/4" deep, into the

LE of the aileron at the mark. Cut a groove for the torque

rod to fit into the aileron's LE. Sand the leading edge of

both ailerons to a "V" as shown on the plan.

D 5. Finish cutting out the aileron servo opening (and

retract servo opening if using retracts) that is partially

die-cut in both W-1 ribs. Mark the location of the servo

opening(s) on the top surface of both wing panels but don't

cut out the sheeting until after the wing has been joined.

D 3. Sand the mating root surfaces of the center TE pieces

to allow for the dihedral angle. Roughen the nylon torque

rod tubes with coarse sandpaper, then apply a dab of

petroleum jelly to the exposed wire at both ends of the

tube. Use 6-minute epoxy to glue the nylon torque rod

tubes into the center TE, then, before the epoxy cures, glue

the center TE assemblies to the aft edge of each wing at

the root with the threaded ends protruding through the top

of the wing. Be sure that the taper of the trailing edge

matches the shape of the airfoil.

D 6. Insert the landing gear strut wire into the retract

mechanism. Measure and cut the main retract struts to

4-7/16" long (measured from the surface of the wing).

Install the 2" main wheels (not included, GPMQ4221)

using adjustable 1-1/4" x 5/32" wheel axles (not included,

GPMQ4280) and 5/32" wheel collars (not included,

GPMQ4306). Verify that there is no toe-in or toe-out when

the retracts are extended, then tighten the locking screws.

15

Page 16

D 7. Slowly retract each strut and wheel, cutting away

the bottom center sheeting and ribs for clearance as you

go. Enlarge the diameter of the wheel well hole to 2-1/2"

keeping the hole centered on the retracted wheel.

D 2. If needed, sand the leading edge sheeting even with

the front edge of W-1.

D 8. The wheel well liners can be made from proper

sized foam or paper coffee cups, or from vertical grain

1/16" balsa sheeting wrapped around an appropriately

sized glass jar and glued to form a cylinder. Glue the

wheel wells in place, then trim the edges to match the

bottom sheeting.

D 9. Use a 12" long x 1/4" drill bit to drill a hole from the

retract servo opening, through the wheel well liners, to

the retract mechanism.

D 3 Before using any glue,trial fit the wings together using

the die-cut plywood dihedral brace (DB). The wing roots

(W-1) should fit together smoothly, and the dihedral brace

should contact both spars and also locks into both W-2s.

The dihedral brace is mounted perpendicular to W-1, not

parallel to the spars (see plan for exact position) Be sure

the "V" shaped edge of the dihedral brace is toward the

bottom of the wing. Apply 30-minute epoxy to the mating

surfaces of the W-1 ribs, dihedral brace and inner edges of

the center TE. Clamp or pin the wings together while the

epoxy cures.

NOTE: When the epoxy has cured, look at (DB) from the

leading edge and add additional epoxy to fill any visible gaps.

D 1 Finish cutting out the partially die-cut section

between the spars on both W-1 ribs.

D 4. Fit and install the 1/2" x 1-7/16" x 5" balsa center

leading edge block. We suggest using a liberal amount of

thick CA when you glue it in position.

16

Page 17

D 5. Draw a horizontal line across the front of the center

leading edge block. Mark the centerline of the wing on the

front of the block. Make a mark 1-3/4" on each side of the

centerline. These marks show the position of the 1/4" wing

dowels. Drill a 17/64" hole through the block at each of

the marks.

D 6. Carve and sand the top and bottom edges of the

block to follow the airfoil contour but leave the front

surface flat.

Applying Fiberglass Cloth

A. Center one end of the fiberglass cloth on the trailing

edge of the wing, then apply several drops of thin CA to

hold it in position. Roll the loose end of the fiberglass cloth

onto a pencil, then use the pencil as a handle to stretch

the cloth over the wing toward the leading edge. Apply a

few more drops of thin CA to the LE to hold the cloth in its

"stretched tight" position.

B. Make a squeegee by wrapping a 2" wide piece of stiff

cardboard with a plastic sandwich bag or similar material.

Perform the following operation in a well ventilated

area with a fan directing air flow away from you.

C. Starting at the trailing edge, flow thin CA into the cloth.

Smooth the cloth down with the squeegee as you work

toward the leading edge. Avoid standing directly over the

work as the CA fumes can be quite irritating to your eyes

and nose.

D. Allow the CA to cure naturally without using any

accelerator. When thoroughly cured, lightly sand the

edges with 150-grit sandpaper to remove any ridges.

E. Just before you cover your model, fill the weave and

blend the edges with the wing using balsa filler. Sand the

dried filler with 220-grit sandpaper and recoat if necessary.

D 7. Round one end of each 1/4" x 4" wing dowel and

chamfer the other end (to make it easier to insert). Test fit

the dowels into the wing to be sure that they pass easily

through the leading edge block and the dihedral brace.

Glue them in place with 30-minute epoxy.

D 8. Apply 3" wide fiberglass cloth to the center joint on

the top and bottom of the wing. We prefer to adhere the

cloth with thin CA to save weight, but resin or thinned epoxy

will work just as well. Read the Expert Tip that follows

before performing step #8.

D 9. NOTE: The aileron and retract servo trays are slightly

different in size - the aileron servo tray is the smaller one.

Center the die-cut plywood aileron servo tray on top of the

wing at the marks you made in siep 5 of the previous

section (Completing the wing panels). Mark the outside

perimeter of the tray, then cut the wing sheeting from inside

the lines. Refer to the wing plan to locate the retract servo

tray opening. Mark and cut the sheeting for the retract

servo tray.

17

Page 18

D 10. Insert the die-cut 1/8" plywood aileron servo tray

supports into the opening on the top of the wing, then fit

the servo tray onto the supports. Glue the assembly to the

inside of the wing with thin CA followed by a fillet of thick

CA. If installing retracts, repeat this operation for the die-cut

1/8" ply retract servo tray.

D 1. Trim the four plastic tip tank halves to the embossed

cut lines.

NOTE: Each piece has one half of a lap joint.

D 2. Sand the edges smooth. Roughen the inside surface

of the wing tip recess with coarse sandpaper.

D D 3. Carefully cut out the plastic from the inside of the

slot in the middle of the rib recess.

D D 4. Insert a die-cut ply tip tank former into the notches

of the tank rib. Insert the die-cut tip tank tongue (tapered

end first) through the rib slot into the notch of the former.

Align all parts "straight and true," then securely glue

them together.

D 11. Draw a center line on the die-cut 1/16" plywood

trailing edge reinforcing plate across the narrow

dimension. Glue the plate to the bottom of the wing, with

the centerlines on the wing and plate in alignment. Be sure

the punch marks are on the side that shows. You will need

to see them later.

1. Use the die-cut plywood leading edge gauge to check

the curvature of the LE along its length. The wide end of

the gauge is used at the root and the narrow end is used at

the tip. If necessary, touch up the LE with a sanding block

to conform to the gauge.

D D 5. Insert the tip tank tongue through the slot in the

tank and test fit the assembly on the wing tip. Be sure to

match the right tank with the right wing tip and the left

tank with the left wing tip.

D D 6. Remove the wooden support assembly, then apply

6-minute epoxy to only the rib. Slide the tongue back into

position through the tank (while on the wing) and allow the

epoxy to cure. Do not get any epoxy onto the tongue as the

tank must be removable.

18

Page 19

D D 7. Hold the tank in position while you carefully drill a

3/32" hole through the center of the mounting blocks and

tank tongue from the bottom of the wing. Try not to drill

through the top of the wing.

D D 8. Enlarge the opening of the entrance hole to 3/16"

diameter x 1/8" deep. This will hide the head of the cap

screw when it's installed.

D D 9. Glue the outside of the tip tank to the assembled

inner half.

D D 10. Cut a 1/8" wide slot in the "outside" aft end of the

tip tank centered between the top and bottom edge of the

tank. Test fit the die-cut plywood tip tank fin into the slot.

Round off the LE and TE of the fin with sandpaper.

D 1. Pin the side view fuselage plan to your building board

and cover it with waxed paper. Assemble the die-cut 1/8"

balsa front and rear fuselage sides over the plan, then

add the die-cut 1/8" balsa front and rear doublers.

D 2. Turn the fuselage side upside-down, cover it with

waxed paper, then assemble the fuselage side and its

doublers over it. Remove both sides from the board and

sand them so they match exactly. Cut 1/8" off the front of

the right side only. This will set the proper amount of right

thrust in the firewall.

D 3. Mark the former positions on the inside of both fuselage

sides, then remove the side view plan from the board.

D 11. Glue the fin into the slot at the aft end of the tank,

then repeat steps 2 thru 9 for the other tip tank.

D 12. If you will be painting the tip tanks, fill the joints with

automotive body filler (Bondo®). When the filler has cured,

wet sand the seam smooth.

This completes the assembly of the wing for the time being.

Looks like a jet wing, eh? Clean off your workbench, take a

break, then let's get on with the fuselage. You can sleep later.

D 4. Assemble the three piece firewall (with the punch

marks forward) using 6-minute epoxy. Glue the two F-1s

together and also F-1D to the aft side of the F-1s. Using the

plan and punch marks as guides, carefully drill holes for

the engine mount, fuel lines, throttle cable and, if using fixed

gear, the nosegear steering cable. Mark the top front of the

firewall now, so you won't make a mistake later. Install four

4-40 blind nuts on the back of the firewall assembly.

19

Page 20

d 5. After referring to the fuselage plan, drill the

pushrod guide tube holes at each of the punch marks on all

of the formers. Use a 1/8" drill bit for the nosewheel

steering guide tube and a 3/16" bit for the outer throttle

guide tube.

NOTE: Do not drill any holes in F-7 at this time.

(Assembles right side-up over the plan)

Note: The firewall is lower than the bottom of the fuselage

sides, so in order to install it at the proper time, the

fuselage must be built with the nose extending beyond

the left side of your building board. Pin the fuselage top

view plan to the board, with F-1 extending about an inch

past the edge of the board.

Important: Unless specified differently, all fuselage formers

are made from die-cut 1/8" plywood. Be sure that the die

stamped numbers on each former face the nose of the

model or the pushrod routing holes will not line up.

D 1. With the right fuselage side held flat on your building

board, glue F-3 in place, perpendicular to the fuselage side.

Be careful, when installing all of the fuselage formers, that

you position them correctly (see plan).

D 4. Pull the rear of the fuselage sides together and hold

them with rubber bands. Glue F-7 into place and pin the

support leg on the bottom of F-7 to the board, again making

sure that the former is centered over the plan.

D 5. Cut a 1" length from the 1/4" x 3/4" balsa left over

from the fin frame. Taper it to a wedge shape to fit between

the fuse sides at the aft end of the fuse. Remove the rubber

bands holding the rear of the fuselage sides together and

place the wedge between the sides. Measure carefully

with a 90 degree triangle to be sure the aft ends of the

sides are directly above the centerline shown on the plan,

then glue the wedge in place with thin CA. Trim the top and

bottom of the wedge flush with the fuse.

D 6. Glue in formers F-6 and then F-5, centered over the

plan and pinned to the board. Pin the fuselage sides to the

board at F-5.

D 2. Turn this assembly upright and pin F-3 in its proper

location over the plan, then glue the left fuselage side to

F-3. NOTE: All formers have a centerline embossed on the

bottom end. Use these marks to align the formers over the

fuse plan.

D 3. Glue F-4 in place between the fuselage sides. Be

sure to seat F-4 all the way to the top of the "long" notch.

D 7. Hold the front of the fuselage sides together with

rubber bands while you glue F-2 in place. Slide the die-cut

1/8" ply tank floor into position with the embossed letters

pointing toward the top of the fuse. Glue the tank floor to

F-2 only - not to the fuse sides. (See next photo.)

D 8. Fit the firewall assembly between the front of the

fuselage sides. Sand an angle on the edges of the firewall

to match the angle of the fuselage sides when they are

20

Page 21

pulled in to meet it Wet the fuselage sides from F-2

forward, but keep the water away from the gluing surfaces.

Glue the firewall in place with 30-minute epoxy, then run a

bead of thick CA along the top edges of the tank floor Use

rubber bands or clamps to hold the sides together until the

epoxy cures Pin the fuselage sides to the board as close to

the firewall as you can to help keep the firewall centered

D 9 Without gluing, fit the 1/4" x 1/4" x 36" balsa top

stringers in the notches from F-2 to F-7 Mark the position

of F-4 on each stringer Cut halfway through the stringers

from the bottom so that they will make a clean bend at F-4

Glue all five stringers in place

D 11 Install the 3/32" x 3" x 13-1/8" forward top sheeting

from F-2 to F-4 Glue the first sheet to the top of the

fuselage side doubler and then trim it so that it extends to

the middle of the second stringer Wet the balsa if

necessary, then glue this sheet down Sheet the other

side. Fit and install the top sheet between them.

D 12 Install the 3/32" x 3" x 19-1/8" aft top sheeting the

same way as the forward sheeting, except that you may

find it easier to trim the side sheets roughly to shape before

gluing them to the top of the fuse doubler.

D 10 Center, then glue the 3/32" x 1-1/16" x 2" balsa

fillers between the stringers on both sides of F-4 Sand the

front and rear portions of the fillers and the tops of the

stringers so that the sheeting will lie flat on top of them

Sheeting a rounded surface.

Wet the outside of a balsa sheet, then flex it with the

grain for a minute or two to soften it up and start a curve

Align the sheet with the fuse side, then temporarily hold it

in place with clothespins

Mark the sheet for cutting Always trim the sheet to the

center of the appropriate stringer to allow for a gluing

surface for the next piece of sheeting

Apply medium or thick CA to all frame parts that the

sheet will contact. Roll the sheet into position, starting

along the lower edge Hold it in position by hand and with

clothespins until the CA cures Wick thin CA along the

top seam, wiping off the excess before it cures Repeat

for the other side of the fuse It's best to sheet alternate

sides to avoid building in a twist.

D 13 Trim and sand the top sheeting flush with F-2 and

F-7, then remove the fuse from the building board Cut a

3/8" diameter hole through the top sheeting and center

stringer 1" in front of F-7 for the tail surface pushrod tubes

NOTE: Before performing the following step, lightly draw a

centerline along the top of the fuse using the top center

stringer locations at F-2 and F-7 for reference.

D 14 Insert the completed vertical fin into the rear of the

fuselage Shim the rear of the fin so that it is centered

between the fuselage sides IMPORTANT: Carefully

check that the fin is lined up fore and aft with the

centerline of the fuselage Hold a 36" straightedge along

one side of the fin, then adjust the fin so that the

straightedge is parallel to the centerline on top of the fuse.

Be sure that the fin is perpendicular to the building board.

Mark the fin's position on the back of F-7, then pin it firmly

in place.

21

Page 22

D 15. Fit the 1" x 1" x 9-1/2" balsa top aft fuse fairing

blocks in place on both sides of the fin. Mark and sand the

forward ends of the blocks so they fit flush with F-7. Glue

the blocks to the rear of F-7 and the top of the fuselage

sides, but not to the fin. Use glue carefully so that you

don't accidentally glue the fin in place. Remove the fin

immediately after this step.

an Easy-Touch" Bar-Sander will smooth out the lines and

flat spots. Don't try to shave too much wood at one time

and check your work regularly. You can always remove

wood, but it's difficult to put it back.

D 17. Glue a the 1/4" x 3/8" x 2-1/4" balsa filler between

the rear top blocks to fill the gap behind the fin.

D 16. Carve and sand the fuselage and fairing blocks to

shape (see Expert Tip that follows). Use the cross sections

on the plan as a guide and make sure there are no flat

surfaces left. This is the key to a fuselage that will appear

round, even if it isn't.

SHAPING BALSA BLOCKS

D 18. If you will be using retracts, cut out the scored part

in the front of the tank floor and install the die-cut 1/8" ply

tank floor doubler (TFD) on the top side.

D 19. Trim and sand 3/8" balsa tri-stock reinforcements

to fit behind the firewall and both sides of the fuse. Glue

them in place.

D 20. Put the fuselage upside-down in a Styrofoam"

cradle* so that you can work on it without marring the top

surfaces. Cut off the support crutch from the bottom

of

F-7.

*HINT:A Styrofoam ice chest is cheap and can be cut to fit,

or you can purchase a Robart Super Stand which is

specifically made for this purpose.

A long carving blade in a heavy duty handle (A) is the

best tool to create the rough shape as a large amount of

wood can be easily removed. Once the blocks are

"roughed in," use a razor plane (B) to fine tune the

shape. Finally, coarse, medium, and fine sandpaper on

D 21. Sand a bevel on the wide end of the die-cut 1/8" ply

forward servo tray that corresponds to the angle at F-6

(see side view of fuse plan). Using the bottom view plan as a

guide, glue the forward and the die-cut 1/8" plywood rear

22

Page 23

servo tray in place between F-6 and F-7. NOTE: Don't block

the pushrod holes in F-6 with the servo tray. The rear servo

tray must be glued to the top edge of the aft doubler and not

to the stringers.

D 22. Glue the die-cut 1/8" balsa wing saddle triplers in

place. If you are using retracts, install the die-cut 1/8"

plywood nose retract servo tray.

MOUNTING SERVOS

The proper way to mount a servo is as follows:

A. Insert a rubber grommet into each of the four

servo notches.

B. Insert a metal eyelet from the bottom side of the rubber

grommet. This way the wide portion of the eyelet will be

in contact with the servo tray when mounted.

C. Test fit the servo in the tray, and enlarge the openings

so the servo will not touch the tray. The rubber

grommets will isolate the servo from the hard vibration

of the airplane's structure.

D. Position the servo, then mark the location of the

mounting holes. Drill pilot holes with a 1/16" bit at

each mark.

E. Use the servo screws supplied with your radio to mount

the servo(s) in the servo tray. Tighten the screws until

they just touch the top of the metal eyelet.

D 23. Glue F-2A to the bottom of F-2. Be sure the control

cable tube holes are on the right side. Glue F-3A to the

bottom of F-3 and then glue F-3D to rear of F-3 and F-3A.

Glue F-5A to the bottom of F-5.

D 24. Cut and fit the 1/8 x 1/4 x 6-1/4" balsa hatch triplers

to the fuselage sides along the hatch opening. With

reference to the plan, install all of the fuselage servos and

the forward control pushrods. (See Expert Tip that follows.)

D 25. Install the retractable nose gear if you will be using

one. Follow the routing on the plan to install the 3/16 OD

throttle and 1/8" OD nosewheel steering guide tubes.

Insert the cable and flexible pushrod, then check to see

that there is no binding. When everything is working

smoothly, glue the tubes in place at each former.

D 26. If you are using retracts, make the retract pushrod

from 2-56 threaded pushrod wire (not included,

GPMQ3716) and a nylon clevis. Install an adjustable 5/32"

axle on the gear strut as shown on the plan and install the

nosewheel with two 5/32" wheel collars (not included,

GPMQ4150). Hook up the steering cable and the retract

pushrod, then install the retract servo and cycle the retract

to be sure everything is working properly. Remove the gear

strut but leave the retract mechanism in place.

23

Page 24

D 27 If you would like to use a larger capacity fuel tank than

the recommended 8 ounce size, run two 1/8" aluminum

tubes along the right side of the fuselage from just behind the

nose retract servo tray to the middle of the fuselage

NOTE: In order to obtain reliable engine performance you

will need to install an auxiliary fuel pump to deliver fuel to the

engine The larger tank should be mounted on cross

members (not supplied) in the fuse, centered on the CG

During final assembly connect the tank and engine to the

aluminum tubes with standard fuel tubing

D 28. Insert the vertical fin into its slot in the fuselage.

Carefully check its alignment and pin it in place Fit the rear

bottom blocks in place on either side of the fin and glue

them to the rear of F-7 and the top of the fuselage sides,

but

not to the

fin.

D 31 Put the die-cut 1/8" ply hatch base in place between

F-6 and F-7 Glue the die-cut 1/8 ply hatch formers H-1

and H-2 (make sure punch mark faces forward) to the

hatch base using F-6 and F-7 to set the correct angles Be

careful not to glue the hatch into the fuselage Cut out the

section of the hatch base which corresponds with the notch

in H-1 to allow for the nose wheel pushrod guide tube.

D 29 Glue a 1/4" x 3/8" x 9-1/2" balsa filler strip between

the rear blocks to fill the gap The filler strip should be flush

with the edge of F-7 and touch the side sheeting at the aft

end of the fuse Remove the fin immediately after this step

to be sure it isn't accidentally glued in place.

D 30 Carve and sand the rear bottom blocks to shape

Use the bottom of F-7 and the plan as a guide to the

correct shape (See Expert Tip on page 22 )

D 32 Glue the two die-cut 1/8" ply locking tabs to the

bottom of the hatch with the wide end toward the front Notch

the forward end of the servo compartment tripler to match

the locking tabs, allowing the hatch to seat properly Drill

1/16" pilot holes through the fuse sides into the locking tabs.

Before flying, secure the hatch with two #2 x 3/8" screws.

D 33 Drill through the punch mark in H-2 into F-7 with a

1/8" bit angled downward at about a 5 degree angle.

Remove the hatch Round one end of the 1/8" x 1" hatch

dowel Insert the dowel into H-2 so that it extends 3/16"

from the rear, then mark it on the inside of H-2 Install the

hatch, then glue the dowel in position to the inside of H-2

using your mark to obtain the correct depth After the CA

has cured, cut off the excess dowel on the inside of

the hatch.

24

Page 25

D 34. Remove the hatch from the fuselage and sand the

sides of the hatch base to an angle that matches the

contour of H-1 and H-2. Install three 1/4" x 1/4" x 6-3/4"

balsa stringers, and sand off any rough edges.

out the sheeting between the pin marks. Extend the slots

on both sides of the two formers so that the forward edge is

18-3/8" from F-2 and the overall length of the slot is 8-1/4".

Test fit the die-cut ply pylons into the slots and make

adjustments as necessary. IMPORTANT: Both pylons must

be the same distance from F-2. Don't worry about the

thickness

of

the pylons as we

still

have to sheet them.

D 37. Glue three 1/4" x 1/4" x 6-3/4" stringers between F-5

and F-6 and sheet this area with moistened 3/32" x 3" x

6-3/4" balsa. After the sheeting has dried thoroughly, install

the hatch and sand the entire rear portion of the fuselage

bottom to shape.

D 35. Glue a 3/32" balsa sheet to the outside edge of the

hatch base. Wet the outside of the sheet, bend it around

and trim it to end at the middle of the center stringer. Glue it

in place. Repeat for the other side, then when the sheeting

has dried completely, sand the front and back ends flush

with the hatch formers.

D 38. Fit the 1/4" plywood wing bolt plate in the notches

in the wing saddle triplers, up against F-5. Use 30-minute

epoxy to glue this part in position. Add 1/4" balsa triangle

reinforcements between the wing saddle triplers and the

top of the plate at both ends.

D 36. Locate the dummy engine nacelle pylon positions

by inserting pins through the sheeting from the inside of the

fuse at the notched sections of formers F-5 and F-6.

Remove the pins, then use a straightedge and knife to cut

D 39. Fit one die-cut 3/16" balsa lower fuse corner to each

side of the fuselage between F-3 and F-1. Sand an angle on

the convex (curving outward) side so that it will fit flush on

the bottom edge of the fuselage side doubler. Glue these

pieces in place, then fit and glue a second pair of fuse

comers on top of the first. Using four pieces here instead of

two makes the required twist much easier to achieve.

25

Page 26

D 40. Remove the retract mechanism. Trim and sand the

tops of the F-8s flush with the top of F-1 D, F-2A and F-3A,

then glue the 1/2" x 4" x 13" balsa front bottom block in

place. If you are using retracts, cut a clearance hole for the

retract mechanism in the block. HINT: To locate the position

of the retract mechanism, push a sharpened piece of wire

through the retract screw holes in the tank floor out through

the bottom of the block. Align the retract mechanism over

the holes, then mark its shape. Carve off the overhanging

portions of the fuse bottom and roughly create the

rounded shape.

bars were attached must be smooth to allow the mount

halves to fit together. Trim the flashing from any rough

edges if necessary. Assemble the mount halves as shown.

D 2. Temporarily install the engine mount on the firewall

using four #4 flat washers and four 4-40 x 1" machine

screws. Don't tighten the screws completely until after the

engine has been positioned.

D 3. Position the engine on the engine mount. Slide the

engine mount halves apart until the engine mounting lugs

will sit flat on the rails. Adjust the mount up and down until

the tic marks on the mount are centered on the horizontal

reference line on the firewall. After adjusting the mount,

tighten the 4-40 screws to hold it firmly in position.

D 41. If you are using retracts, reinstall the retract unit,

axle and wheel. Slowly retract the gear while you cut away

the portions of the bottom block which interfere. A template

has been provided on the fuse plan for reference. Cycle the

retract a few times to be sure that everything works

correctly, then remove the retract assembly.

The Great Planes adjustable engine mount is simple and

convenient to use. It may be used to mount most .20 - .40

two-stroke and .26 - .48 four-stroke engines. Nose gear

bearings for 5/32" diameter wire are incorporated in the

mount.

D 4. Position the engine so that the backplate of a spinner

will be 4" (102mm) in front of the firewall. Carefully mark

the engine mounting holes on the rails with a sharpened

piece of wire or a pencil lead.

D 5. Remove the engine and engine mount from the fuse.

Use a centerpunch or sharpened nail to "dimple" the marks

on the rails, then drill a 7/64" hole through the rails at each

punch mark. If you have access to a drill press, this is the

best tool for the job. However, if you are using a hand held

electric drill, try to keep the bit perpendicular to the rails.

Test fit the engine but don't screw it permanently in position

just yet.

REMOVE

D 1. Cut or break the "spreader bar" from each mount half.

Carefully trim any extra material left by the spreader bar

from each mount half as the surface where the spreader

D 1. Protect the edges of the fuse and formers with waxed

paper, then fit the die-cut 1/8" ply canopy base between F-

1 and F-2. Glue the die-cut 1/8" ply C-1 and C-2 to the

canopy base using F-1 and F-2 to set the proper angles. Be

careful not to glue the canopy base to the fuselage.

26

Page 27

D 2 Sand the sides of the canopy base to an angle to

match the shape of C-1 and C-2 Tack glue the canopy

frame into the fuselage, then trim the canopy (starting

outside the cut lines) to fit When satisfied, remove the

canopy and frame from the fuselage, then glue the canopy

and frame together.

D 3 Glue the die-cut plywood canopy hook inside of the

canopy frame at the notched location in C-2 Fit and glue

two 1/4" x 3" balsa sticks (cut from 6" piece) to the bottom

of the canopy frame to prevent the canopy from moving

sideways The canopy is held in position by a rubber band

(not included) looped around the cross piece on former

F-2 and then attached to the plywood hook.

D 7 Position a straightedge between F-1 and the spinner,

then draw the angle of the cowl on the edge of each

mounting block Remove the spinner Sand the tops of the

blocks to the lines you drew Mark the centerline of each

block on a piece of tape wrapped around the fuse

D 4 After referring to the plan, glue the die-cut plywood

firewall cowl ring to the front of F-1 NOTE: The cowl ring

is "inside" the perimeter of F-1 by about 1/16" to allow for

the thickness of the cowl material

D 5 Use 6-minute epoxy to glue the five 1/2" x 1/2" x 1/4"

hardwood cowl mounting blocks into the notches of the

cowl ring

D 6 Install the engine with four #6 x 3/4" sheet metal

screws that have been provided with this kit Install a

Learjet 2-1/4" spinner (not included, GPMQ4542) on the

prop shaft.

D 8 Cut the opening at the front of the cowl and trim the

rear edge to along the "cut line " Cut out the engine access

hole on the side of the cowl following the cut lines Position

the cowl on the fuse and make adjustments to the engine

opening as required Sand the edges of the mounting

blocks if needed for a good fit.

D 9 Reinstall the spinner and prop then adjust the cowl to

clear the back of the spinner by 1/16" Securely tape the

cowl in position, then drill 1/16" (1 6mm) holes through the

cowl into the mounting blocks (using the centerlines you

drew in step 7) for the #2 x 3/8" cowl mounting screws

NOTE: A 1/16" plywood spinner ring has been included to

shim the front of the cowl if needed.

D 10 Cut the cowl as necessary to allow clearance for the

muffler, then remove the cowl and engine in preparation for

final sanding.

27

Page 28

D 3. Bolt the wing to the fuselage using the supplied 1/4" x

2" nylon bolts.

D 1. With the fuselage upside-down in the foam cradle, fit

the wing in the wing saddle. The wing dowels should slide

easily into the holes in F-3D, and there should be no gaps

between the wing and the saddle at the front or the rear.

Check that the wing tips measure the same distance from

the tip of the tail. When the fit is right, mark the center of

the trailing edge on the bottom sheeting as a guide for the

next step.

D 4. Trim the plastic belly pan to the embossed perimeter

cut line. Test the belly pan on the wing, then carefully make

adjustments to the edges to obtain a good fit*. Sand a

bevel on the inside of the edges that will contact the

surface of the wing.

* Fill any gap between the fuse formers and belly pan with

left over balsa.

D 5. With the wing mounted on the fuse, glue the belly pan

in position using a mixture of 30-minute epoxy and Top Flite

Microballoon filler (TOPR1090). Use 4 parts of the filler to

1 part of epoxy. Apply a bead of the mixture to the inside

surface of the belly pan, then quickly position the part and

secure it with tape while the epoxy cures. Be careful not to

glue the wing to the fuse.

D 2. Drill through the punch marks in the trailing edge

reinforcing plate with a 13/64" bit. These holes must extend

all the way through the wing and the wing bolt plate and

must be perpendicular to the surface of the wing. Do not

allow the wing to move out of alignment while you are

drilling these holes. Now run a 1/4-20 tap through the

holes. Remove the wing and drill out the holes in the wing

to 1/4". Apply a few drops of thin CA to the threads in the

wing bolt plate, and after the CA has completely cured, run

the tap through them again.

D 6. Cut out the wing bolt holes on the plastic belly pan

using the cut lines as a guide. Enlarge the holes in the wing

fairing to 1/2" diameter. Insert the supplied 1/2" x 6"

cardboard tube into one of the holes centered on a wing

bolt. Glue the tube to the outside of the belly pan with thin

CA. Do not allow CA to contact the wing bolt or your wing

may become permanently attached. Cut off the tube just

above the surface of the belly pan.

D 7. Repeat step 6 for the other bolt hole. Turn the tube

over to provide a squared off end at the bolt's location. Cut

off the excess tube material.

D 8. Remove the wing bolts, then drip a few drops of thin

CA down the inside of the tubes to attach them to the inside

of the wing. Do not reinstall the wing bolts until you are

sure the CA is fully cured!

D 9. Sand the top edges of the tubes flush with the contour

of the belly pan.

28

Page 29

The following 3 steps are critical to the way your

Learjet flies, so take your time and work carefully.

D 4. Block up your model so that the wing root is level and

has 0 degrees of incidence. We recommend the use of an

incidence meter for this important step. If you can't obtain

an incidence meter, you can accomplish the same objective

if you insert a pin in the center of the leading and trailing

edges, then exactly equalize the distance from the

workbench to the pins.

D 1. Mount the wing, then without gluing, insert the fin

into the tail slot. Slide the stab into position, centering it

visually on both sides of the fin. Use string to measure the

distance from each stab tip to a pin centered on top of F-2.

The distance to the pin must be equal from each stab tip.

D 2. Mark the top of the stab with reference lines on both

sides of the fin.

D 3. Position the model so that you can "sight" it several

feet from the front and rear. Look at the relationship

between the stab tips and the top of the wing - the

distance must be equal. If not, sand the high side of the

slot in the fin to correct the situation. When satisfied,

remove the stab, then use 6-minute epoxy to glue it in

position using your reference marks for alignment. Before

the epoxy cures, recheck your alignment from all points

of reference.

D 5. Once the wing angle is set, check the incidence of the

stab - it must be 0 degrees as well. Once again use an

incidence meter or the pin measurement technique. If the

stab does not measure 0 degrees, adjust the angle of the

fin up or down in its slot to remedy the problem. NOTE:

The base of the fin may need to be sanded slightly to allow

enough movement. Sand (or shim) the bottom of the dorsal

fin, if needed, to obtain a good fit with the top of the fuse.

Draw reference lines on the fin (along the top of the fuse)

once the correct angle is established.

D 6. Use 30-minute epoxy to glue the fin into the fin slot at

the marked angle. Be sure to check the incidence angle

once again before the epoxy cures

D 7. Center and glue the shaped 1/4" balsa ventral fin to

the bottom of the fuse flush with the aft end as shown on

the fuse plan.

29

Page 30

D 5. Roughen the mating surfaces with coarse sandpaper

then glue the left, right and front pieces together with thin CA.

D 1. Sheet both die-cut 1/8" plywood nacelle pylons on

both sides with 3/32" x 3" balsa. Be sure the grain direction

runs from the inboard edge to the tip. Trim and sand the

sheeting to the shape of the die-cut pylons.

D 2. Insert the pylons into the slots in the fuse, then cut two

pylon trailing edge pieces from the remaining balsa rudder

stock to the shape shown on the plan. Sand the edges for a

nice fit with the fuse sides. Glue the TE pieces to the

pylons only. We will glue them to the fuse after the model

is covered.

D 3. Trim the six pieces that comprise the dummy engine

nacelles to the embossed cut lines. Sand the edges smooth.

Without gluing, fit the parts together, then designate the left

and right nacelles. Open the two nacelles.

D 6. If you will be painting the nacelles, now would be a

good time to fill the joints with automotive body filler (Bondo).

Wet sand the seams smooth before priming and painting.

NOTE: Do not confuse this procedure with "checking

the C.G." or "balancing the airplane fore and aft." That

very important step will be covered later in the manual.

Now that you have the basic airframe nearly completed,

this is a good time to balance the airplane laterally (sideto-side). Here is how to do it:

D 1. Temporarily attach the wing and engine (with muffler)

to the fuselage.

D 4. Cut a pylon access slot in only the two pieces that

will be closest to the fuselage following the embossed cut

lines on the inside surface of the nacelles. Do not cut the

slots in all four pieces or you will have slots showing on

the outside of the nacelle.