Page 1

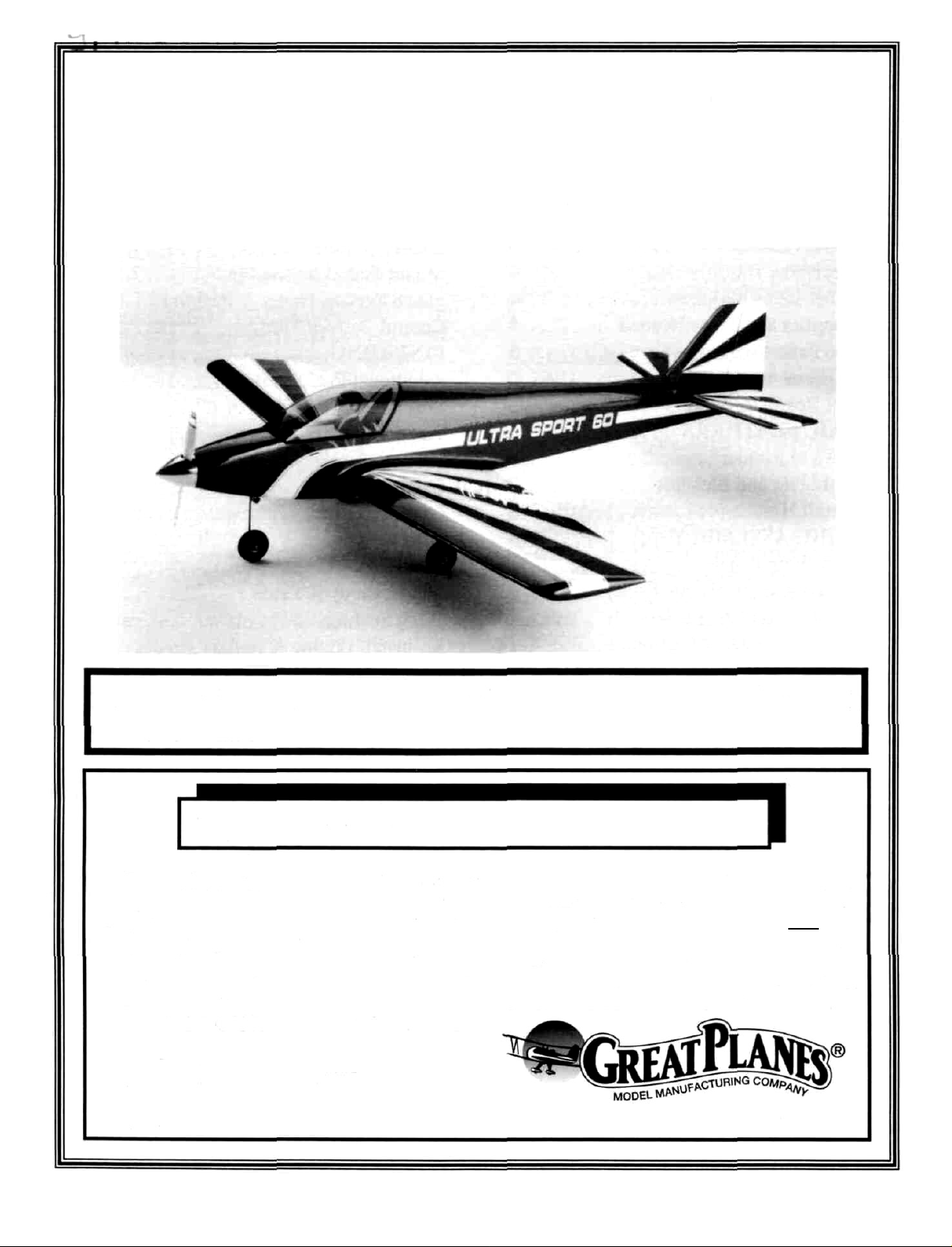

ULTRA SPORT 60

INSTRUCTION BOOK

PLEASE READ THROUGH THIS INSTRUCTION BOOKLET IN ITS ENTIRETY BEFORE BEGINNING

ASSEMBLY. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

WARNING! THIS IS NOT A TOY! THIS IS NOT A BEGINNER'S AIRPLANE!

This R/C kit and the model you will build is not a toy! It is capable of serious bodily harm and property

damage. IT IS YOUR RESPONSIBILITY AND YOURS ALONE to build this kit correctly, properly install

all R/C components and flying gear (engine, tank, pushrods, etc.) and to test the model and fly it only with

experienced, competent help, using common sense and in accordance with all safety standards as set down in the

Academy of Model Aeronautics Safety Code. It is suggested that you join the AMA to become properly insured

before you attempt to fly this model. IF YOU ARE JUST STARTING R/C MODELING. CONSULT YOUR

LOCAL HOBBY SHOP OR WRITE TO THE ACADEMY OF MODEL AERONAUTICS TO FIND AN

EXPERIENCED INSTRUCTOR IN YOUR AREA.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

(800)435-9262

P.O. BOX

788

URBANA, ILLINOIS 61801

(217)398-8970

Page 2

TABLE OF CONTENTS

INTRODUCTION ............. 3

Precautions

Abbreviations

Decisions

Other Items Required

Supplies and Tools Needed

Die Patterns

Types

of

Get Ready to Build

TAIL FEATHERS

Fin and Rudder

Stabilizer and Elevator

Install Hinges

WING ASSEMBLY

Join Wing Panels

Install Aileron Torque Rods

Sand

"Flats"

Fiberglass Center Section

Install Wing Tips

Install Ailerons

Install Wing Dowels

Install Wing Bolt Plate

Fill Landing Gear Slots

Installing Retracts

FUSELAGE ASSEMBLY

Prepare Fuse Sides

Assemble Lower Fuselage

Drill Engine Mount

Install Servos, Guide Tubes

Mount the Wing to the Fuse

Fit Fuel Tank, Fuelproofing

Install Turtle Deck

Assemble Nose Section

FINAL ASSEMBLY

Sand Fuselage

...................

.................

You

Must

Make

........

............

.......

...................

Wood

.................

.............

.............

................

...........

..................

............

...............

.......

on LE and TE

......

.........

...............

.................

............

...........

..........

..............

.......

..............

........

.............

.......

.......

.......

..............

..........

............

.................

3

3

4

4

4

5

6

6

6

6

7

8

8

13

13

14

14

15

16

16

17

17

17

18

18

19

21

22

23

25

25

27

30

30

Install Wing Fairings ............. 30

Install Wing Fillets

..............

31

Shape Fin Fillets ................ 32

Mount Stabilizer and Fin ......... 33

Install Servos, Horns & Pushrods ... 34

Control Surface Throws

FINISHING

...................

Additional Fuelproofmg

Seal

Off

Cockpit

Prepare Canopy

................

................

Balance Airplane Laterally

Final Sanding

Covering

Glue the Hinges

Install Pilot

..................

......................

................

....................

Glue Canopy in Place

Wing Seating

..................

Re-install Engine & Radio

Balance

Your

Model

Final Hookups and Checks

PRE-FLIGHT

Charge Batteries

.................

................

Find a Safe Place to Fly

Ground Check

Range Check

..................

..................

Engine Safety Precautions

AMA SAFETY CODE

FLYING

Takeoff

Flying

Landing

......................

.......................

........................

......................

FLIGHT TRIMMING

NOTES

PARTS LIST

......................

..................

2-VIEW DRAWING

..........

..........

........

............

........

.............

........

..........

........

..........

..........

............

35

36

36

36

36

36

37

37

37

38

38

38

38

39

39

40

40

40

40

40

40

41

41

41

41

41

42

45

46

48

2

Page 3

Please inspect all parts carefully before starting to

build! If any parts are missing, broken or defective, or if

you have any questions about building or flying this

airplane, please call us at (217) 398-8970 and we'll be glad

to help. If you are calling for replacement parts, please

look up the part numbers and the kit identification number (stamped on the end of the carton) and have them

ready when calling.

4. You mustproperly install all R/C and other components

so that the model operates properly on the ground and in the

air.

5. You must test the operation of the model before the first

and each successive flight to insure that all equipment is operating, and you must make certain that the model has

remained structurally sound. Be sure to check the nylon

clevises and horns often, and replace if they show signs of

wear.

INTRODUCTION

Congratulations! Thank you for purchasing the Great

Planes Ultra Sport 60! Jim Feldmann's original design was

featured as a construction article in the August, 1989 issue of

RC Modeler magazine, and has been hailed by many as "the

best sport flying airplane ever''! The design starts with the

legendary "Kaos" wing platform, and features modem

styling and state-of-the-art construction techniques. The

result is an ultra-stable, ultra-smooth flying airplane that does

what you want it to, no more and no less.

The Ultra Sport 60 is easy to build, totally predictable,

smooth-flying and has very docile stall characteristics, making it the ultimate sport airplane for the modeler who wants to

fly with a higher degree of precision. Because it naturally

tracks through maneuvers better than other sport airplanes,

you'll fly belter when you're flying an Ultra Sport 60.

This is not a beginner's airplane! While the Ultra

Sport 60 is easy to build and flies great, we must discourage

you from selecting this kit as your first R/C airplane. It is fast,

highly maneuverable, and lacks the self-recovery characteristics of a good basic trainer such as the Great Planes PT

Series airplanes. On the other hand, if you have already

learned the basics of R/C flying and you are able to safely

handle an ' 'aileron trainer'' airplane such as the Great Planes

Trainer Series or Big Stick Series airplanes, the Ultra Sport

60 is an excellent choice.

6. You must fly the model only with the competent help

of a well experienced R/C pilot if you are not already an

experienced and knowledgeable R/C pilot at this time.

Note: We, as the kit manufacturer, can provide you with a top

quality kit and great instructions, but ultimately the quality

and flyability of your finished model depends on how you

build it; therefore, we cannot in any way guarantee the

performance of your completed model, and no representations are expressed or implied as to the performance or safety

of your completed model.

Remember: Take your time and follow directions to end

up with a well-built model that is light, straight and true.

INSTRUCTIONS IN BOXES LIKE THIS ARE

VERY IMPORTANT AND SHOULD BE FOLLOWED CAREFULLY

PRECAUTIONS

1. You must build the plane according to the plans and

instructions. Do not alter or modify the model as represented

by the plans, as doing so may result in an unsafe or unflyable

model. In a few cases the plans and instructions may differ

slightly from me photos. In those instances you should

assume the plans and written instructions are correct

2. You must take time to build straight, true and strong.

3. You must use a proper R/C radio that is in first class

condition, the correct sized engine and correct components

(fuel tank, wheels, etc.) throughout your building process.

COMMON ABBREVIATIONS USED IN

THIS BOOK AND ON THE PLANS:

Elev = Elevator

Fuse = Fuselage

LE = Leading Edge (front)

LG = Landing Gear

Lt = Left

Ply = Plywood

Rt = Right

Stab = Stabilizer

TE = Trailing Edge (rear)

Tri = Triangle

= Inches

3

Page 4

DECISIONS YOU MUST MAKE NOW

ENGINE AND MOUNT SELECTION

The recommended engine size range is as follows:

.60 - .65 cubic inch displacement 2-cycle

.70 - .91 cubic inch displacement 4-cycle

The engine you select will determine how you build the

fuselage, so it is important that you have the engine close at

hand while building.

This kit includes the new Great Planes Adjustable

Engine mount. This mount will work on most .40-.60

2-Cycles and .40-.70 4-cycles. Cut or break the

"spreader bar" off each mount half. The surfaces

where the spreader bars were attached need to be

very smooth to allow the mount halves to fit together.

Snap the two mount halves together. Slide the mount

halves apart until the engine mounting lugs will sit

flat on the beams.

OTHER ITEMS REQUIRED

• Four-channel radio with 4 servos (additional channel and

retract servo required if retracts are being used).

• Propellers (see engine instructions and above engine

notes for recommended sizes).

• Spinner (2-3/4" diameter)

• Fuel Tank (11 to 14 ounce)

• Main Wheels* - 2 (2-1/2" dia. for fixed gear and retract)

• Nose Wheel* - 1 (2-1/2" diameter, required for trike

only)

• Tail Wheel - 1 (1" diameter, required for taildragger

only)

• 5/32" Wheel Collars - 4 or 6

• 3/32" Wheel Collars - 2 (required for taildragger only)

• Iron-on Covering Material

• Silicone Fuel Tubing

• Wing Sealing Tape (or silicone sealer ... see instructions)

• Latex Foam Rubber Padding (1/4" thick)

• Dubro "E-Z Connectors" (or equivalent) - 2

• Main Gear Retracts: (optional)

Mechanical: Dave Brown 2-Gear Main, or

equivalent

Pneumatic: Robart #605 90-degree mains, or

equivalent (requires #188 air control kit)

• Plastic Pilot (Williams Bros. 2-5/8" scale)

•"Lightweight wheels are recommended.

NOTE: If you choose to power your Ultra Sport 60 with a 4.

cycle engine, keep in mind that the RPM of your engine will

be considerably less than that of a 2-cycle engine; therefore,

you should select a higher pitch propeller to keep the speed

and overall performance roughly equivalent to that of a 2cycle engine. For example, an 11x7 or 11x8 prop would be

used with a .61 (2-cycle) engine; but an 11x11 prop may be

the best choice for a .91 4-cycle engine.

LANDING GEAR CONFIGURATION

The Ultra Sport 60 may be built with a "taildragger"

or "tricycle" landing gear configuration, and a retractable

main gear may be installed if you want to really ' 'clean up"

this airplane for ultra-smooth and precise aerobatics.

There is not. however, room for a nose gear retract;

therefore, if you want retracts, you'll have to use the "taildragger" configuration.

SUPPLIES AND TOOLS NEEDED

2 oz. Thin CA Adhesive

2 oz. Medium or Thick CA Adhesive

2.5 oz. 30-Minute Epoxy

Hand or Electric Drill

Drill Bits: 1/16". 5/64", 3/32", 7/64", 1/8", 9/64". 5/32",

13/64", 7/32". and 1/4"

Sealing Iron

Heat Gun

Hobby Saw (Xacto Razor Saw)

Xacto Knife, #11 Blades

Pliers

Screw Drivers

T-Pins

Straightedge

Masking Tape

Sandpaper (coarse, medium, fine grit)*

T-Bar Sanding Block, or similar

Waxed Paper

Lightweight Balsa Filler

1/4-20 Tap, Tap Wrench

Vaseline Petroleum Jelly

Isopropyi Rubbing Alcohol (70%)

3M "77" Spray Adhesive (optional)

Dremel Moto Tool or similar (optional)

*NOTE: On our workbench, we have four 11" T-Bar

sanders, equipped with #50, #80, #100 and #150-grit sandpaper. This setup is all that is required for almost any sanding

task. We also keep some #320-grit wet-or-dry sandpaper

handy for finish sanding before covering.

4

Page 5

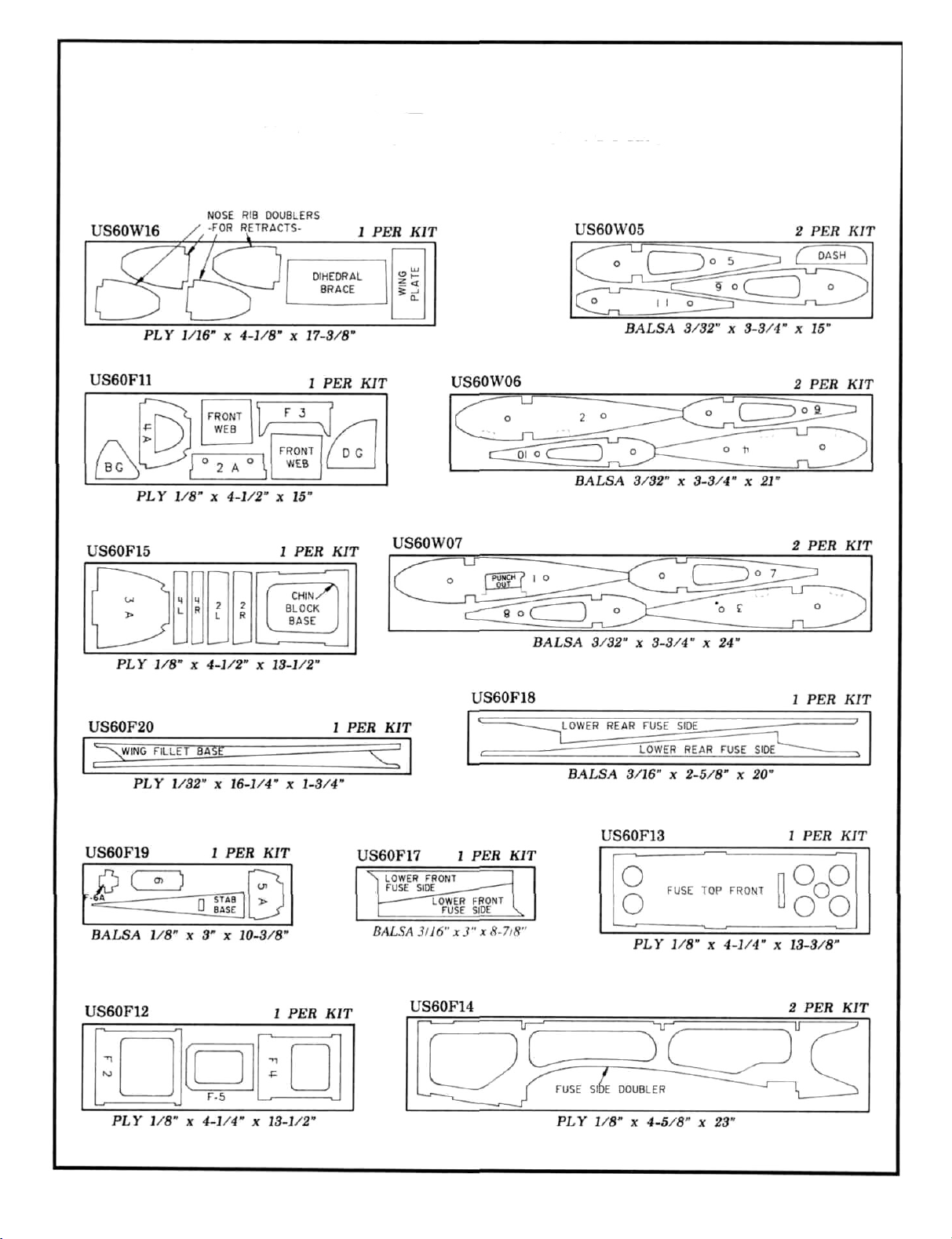

DIE DRAWINGS

Use this drawing to help you identify the die-cut parts

5

Page 6

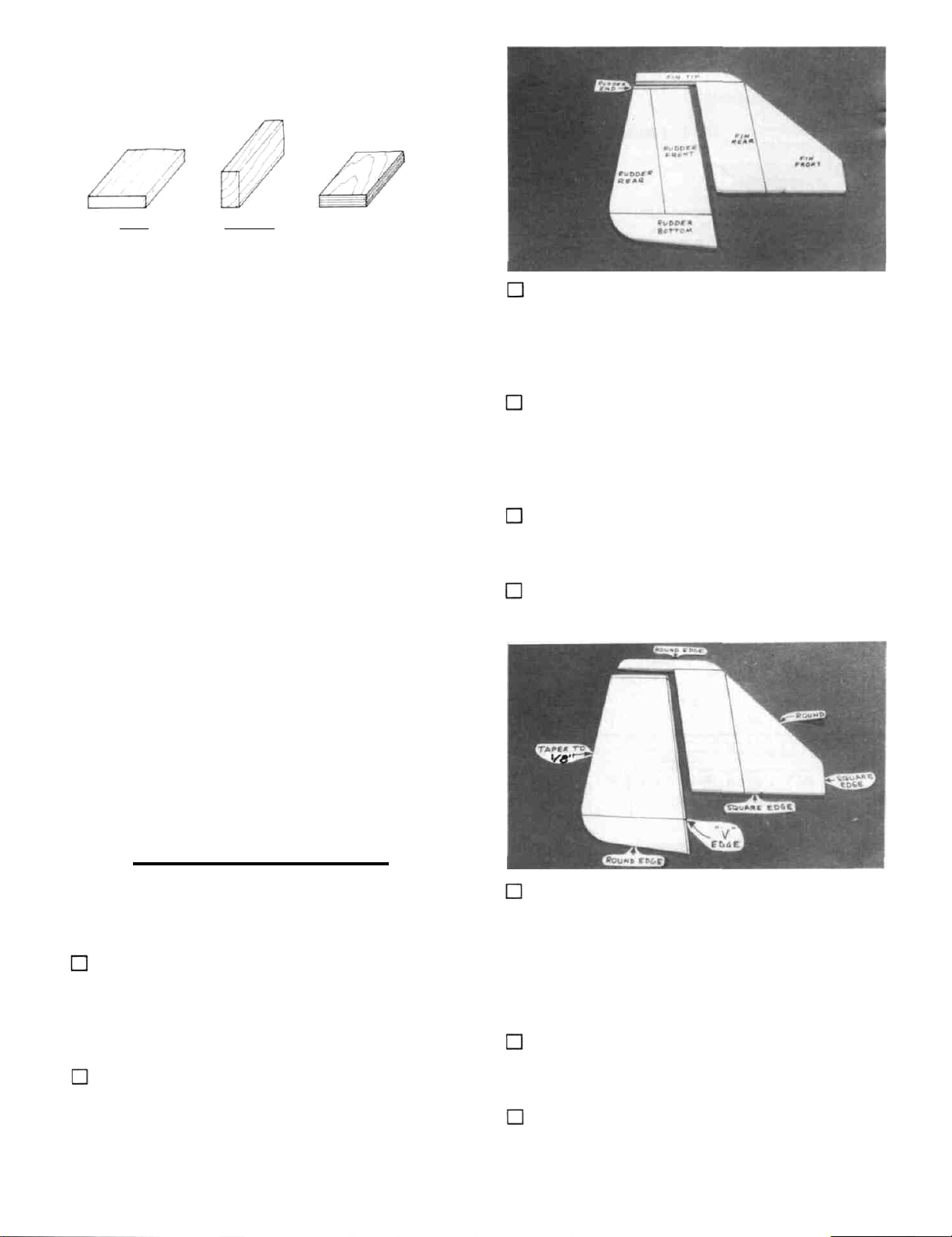

TYPES OF WOOD

BALSA

BASSWOOO

GET READY TO BUILD

1. Unroll the plan sheets. Re-roll them inside out to make

them lie flat. NOTE: You may cut the fuselage plan into two

sections for case of building on the "Bottom View," by

cutting along the "cut line" shown on the plan.

2. Remove all parts from the box. As you do, figure out

the name of each part by comparing it with the plans and the

parts list. Using a felt tip pen, write the part name or size on

each piece to avoid confusion later. Use the die-cut patterns

shown on page 5 to identify the die-cut parts and mark them

before punching out. Save all scraps. If any of the die-cut

parts are difficult to punch out, do not force them! Instead,

first cut around the parts with an Xacto knife. After punching

out the die-cut parts, use your T-Bar or sanding block to

lightly sand the edges to remove any die-cutting irregularities.

3. Working on a flat surface covered with waxed paper,

glue the fin front to the fin rear, then glue on the fin tip. Sand

the front of the fin tip to blend with the fin, as shown on the

plan.

4. Using a T-bar or sanding block, sand both sides of

the fin smooth. Then sand the leading edge and top edge to

a rounded shape, as shown on the plan. Draw a centerline

along the trailing edge of the fin to mark the hinge line.

5. Glue the rudder front to the rudder rear. then glue

on the rudder bottom and rudder end.

6. Draw a centerline all around the edges of the rudder.

3. As you identify and mark the parts, separate them into

groups, such as fuse (fuselage), wing, fin and stab (stabilizer), and hardware.

"TAIL FEATHERS"

BUILD THE FIN AND RUDDER

1. Find the following parts: 5/16" balsa fin front, fin

rear, rudder front, rudder rear and rudder bottom. Compare

the parts to the plans to make sure you have the correct parts.

Also find the 5/16" x 5/8" x 5-3/4" balsa stick, and the 1/8" x

3/8" x 11-7/8 "balsa stick.

2. Cut the 1/8" x 3/8" x 11 -7/8" balsa stick into 5 pieces

having lengths of: 2-7/8", 2-7/8", 1-5/8", 1-5/8" and 2-3/4".

The 2-3/4" length is the rudder end. The remaining pieces

are the elevator ends.

7. Using a sanding block and coarse (50 or 80-grit)

sandpaper, sand both sides of the rudder to a taper as shown

on the plans. The trailing edge should end up approximately

1/8" wide and have a rounded shape. (Do not sand to a sharp

edge). Sand the bottom edge to a rounded shape. Sand the

leading edge to a "V-shape" as shown on the plan.

8. Hold the fin and rudder together and mark the fin tip

at the rudder trailing edge. Cut off the fin tip and sand it to

match the rudder as shown on the plan.

9. If you are building a'' taildragger'', check the plans

and mark the location of the tailgear on the rudder. Drill a

6

Page 7

7/64" hole in the rudder, and groove the rudder leading edge

to accept the tailgear wire and the nylon tailgear bearing.

DO NOT GLUE YET! (The hole is drilled slightly oversize

to allow for positioning, and to create a hard epoxy "sleeve"

around the wire).

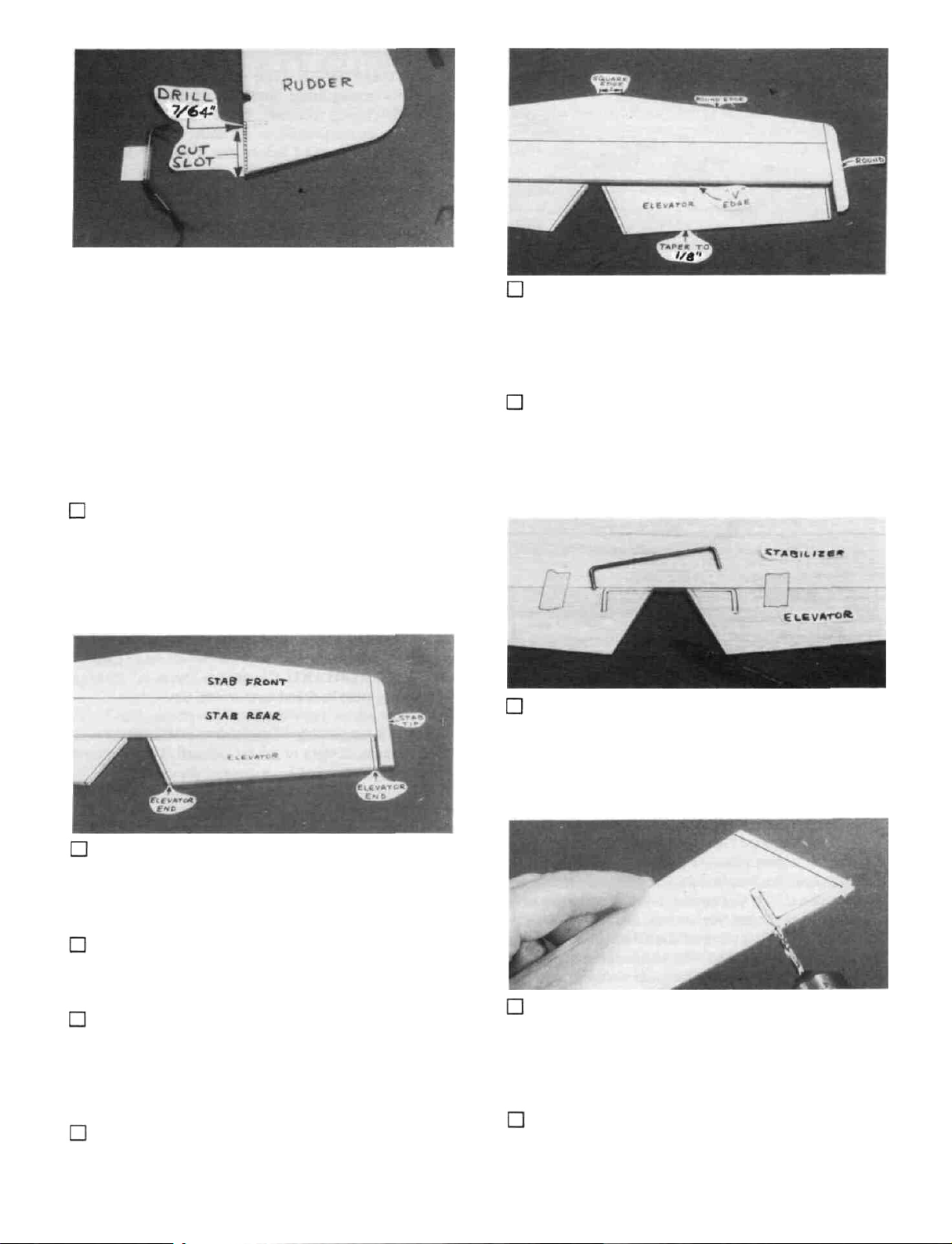

BUILD THE STABILIZER AND

ELEVATORS

1. Find the following parts: 3/8" balsa stab front, stab

rear and elevators. You'll also need the 3/8" x 5/8" x 11"

balsa stab tip stock, the 1/8" elevator ends that you previously cut, and the 1/8" wire elevator joiner.

6. Sand both sides of the elevators to a taper as shown

on the plans. The trailing edge should end up approximately

1/8" wide and have a rounded shape (do not sand to a sharp

edge). Sand the leading edge to a "V-shape" as shown on the

plan.

7. Temporarily tape the elevators to the stab, providing

1/16" clearance between the elevator end and the stab tip.

8. Lay the 1/8" wire elevator joiner in place on the

elevators and mark its outline using a fine point fell-tip pen.

2. Glue the stab front to the stab rear. Then glue on

the stab tips. Sand the front of the stab tips to blend with the

stab.

3. Glue the elevator ends to the elevators and sand to

blend.

4. Sand both sides of the stab smooth, then sand the

leading edge and lips to a rounded shape. (Leave the center

portion of the LE square). Draw a centerline along the

trailing edge of the stab to mark the hinge line.

5. Draw a centerline all around the edges of the eleva-

tors.

9. Accurately drill holes in the elevators for the 1/8"

wire joiner. Begin by drilling a 1/16" or 5/64" pilot hole, then

drill the final hole to a depth of 7/8" with a 9/64" drill bit.

(The hole is drilled slightly oversize to allow for positioning,

and to create a hard epoxy "sleeve" around the wire).

10. Using an Xacto knife, sharpen the inside of one end

of a 1/8" diameter brass tube and use it to cut grooves in the

7

Page 8

CAUTION!!!: You must use extreme care

when cutting hinge slots with an Xacto knife, to

avoid cutting yourself! If the balsa part breaks

while you are pushing on the knife, the blade could

go into your hand before you know it! A good

precaution is to wear leather gloves and always cut

away from your hand while performing the following steps.

leading edge of the elevators to accept the joiner wire.

11. Roughen the joiner wire with coarse sandpaper, then

clean the wire thoroughly with alcohol to remove any oily

residue.

12. Trial fit the joiner wire into the elevators, then glue

it in using 5-minute or 30-minute epoxy. Work plenty of

epoxy into the holes with a toothpick, then lay the elevator

leading edges along a straightedge to insure perfect alignment.

2. Cut the hinge slots on the accurate centerlines

which you previously drew, using an Xacto knife or a

slotting fork and slotting hook. The recommended procedure

for cutting hinge slots with an Xacto knife is given below.

A. Begin by carefully cutting a very shallow slit in the

trailing edge at the hinge location. This first cut is to establish your cut in the right place, so concentrate on

staying on the centerline and don't cut too deep!

B. Make three or four more cuts in the same line,

going slightly deeper each time. As you make these

additional cuts, work on going straight into the wood.

Continue this process while' 'wiggling'' the knife handle

back and forth until the blade has reached the proper

depth for the hinge.

C. Trial fit the hinge into the slot. If the hinge is

difficult to push in, re-insert the knife and move it back

and forth in the slot a few times to enlarge the slot

3. IMPORTANT! Condition or "break-in" the hinges

by folding them back and forth several times.

4. Insert the hinges into the slots and trial fit the rudder

and elevators in place on the fin and stab. Do not glue the

hinges until after you have covered the model.

INSTALL THE HINGES (Do not glue)

NOTE: One-piece molded polypropylene hinges are sup-

plied in this kit. If you choose to use these hinges or the

"pinned"-type hinges, you may cut the hinge slots at this

time. However, if you choose to use the one-piece hinges that

are paper covered for CA glue installation, you may wait until

after covering before cutting the hinge slots.

1. Lay the rudder and elevators on the plan and mark

the hinge locations. Place the rudder against the fin TE and

transfer the marks over to the fin. Place the elevators against

the stab TE and transfer the marks over to the stab. Note:

Heavy duty hinges should be used on the rudder if you are

building a taildragger.

WING

NOTE: The following instructions explain how to build the

wing on a flat surface, directly on the plans. An alternate

method is to use a Great Planes Wing Jig (available from your

local hobby dealer). Many expert modelers prefer to use a

wing jig for high performance airplanes, as it helps to insure

a straight, warp-free wing, especially if you do not have a

workbench or building board that is perfectly flat. If you

choose to use the Wing Jig, please read the instructions that

are included with the jig before beginning.

8

Page 9

BUILD THE WING PANELS

NOTE: It will be helpful to build the wing on a piece of

"Celotex" or other semi-soft (and flat) surface, into which

you may easily stick pins to firmly hold down the wing parts

while building, to avoid warps.

1. Tape the plan to your flat work surface, and cover

the wing drawing with waxed paper (so you won't glue the

wing to the plan!). NOTE; If your work space is limited, you

may cut the left and right wing half drawings apart.

2. The shaped and notched wing leading edges (LE)

and trailing edges (TE) are fastened together by thin strips of

balsa. Separate them by folding until the balsa breaks. Sand

away the excess balsa that remains along the edges after

breaking them apart, using a T-bar with 100-grit sandpaper.

3. Before using the 1/4" x 1/2" x 30" hard balsa spars,

examine them carefully for possible imperfections. Look for

knots, soft spots, diagonal grain and any other imperfections.

If possible, position each spar so the imperfections (if any) are

on the outer half of the wing panel (toward the tip), where they

will be least affected by high stress. If the spars are warped

slightly, try to "balance them out" by installing the warped

spars in opposite directions (see sketch).

NOTE: If you will be installing a retractable landing gear,

disregard Steps 6 and 7.

6. Note that the wing plan shows two alternate loca-

tions for the main landing gear blocks. Note also that Ribs

W-2, W-3 and W-4 have partial cutouts for each of the two

locations. If you are building your plane as a taildragger, cut

out the front notches in these ribs. If you are building your

plane with a tricycle gear, cut out the rear notches. (If you I

|will be installing retracts, do not cut out any of the notches).

7. Glue the die-cut 1/16" ply landing gear doublers to

ribs W-2, W-3 and W-4. Be sure to glue them to the correct

side of the ribs, as shown on the plan (make a right and a left

set). Sand the doublers even with the edge of the ribs.

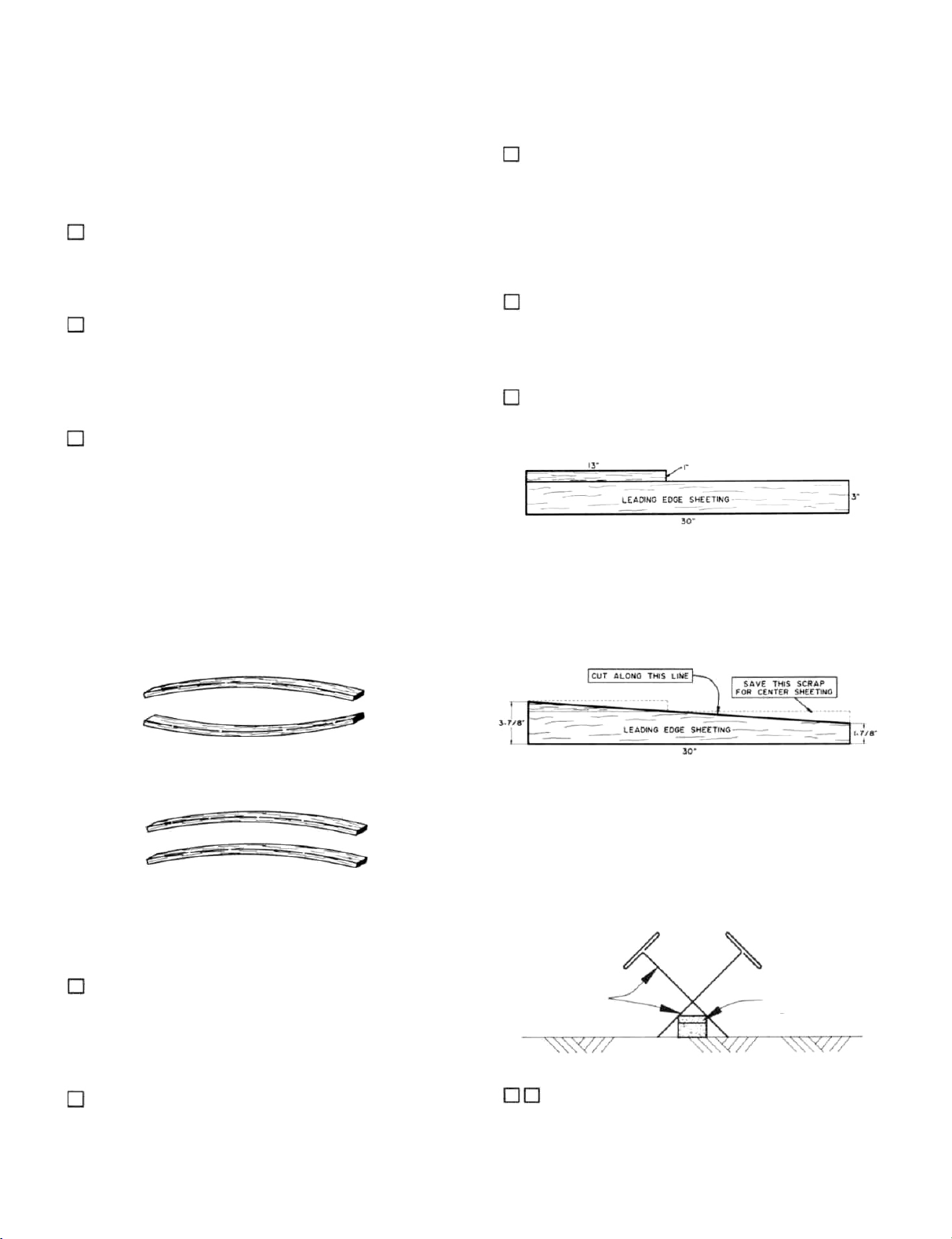

8. Prepare the leading edge sheeting as follows: Edge

glue the 3/32" x 1" x 13" balsa sheets to the 3/32" x 3" x 30"

balsa sheets as shown here ...

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

STRAIGHT WING

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

WARPED WING

4. Find the four 1/8" x 1/2" x 14-1/2" balsa spar

doublers. Sand one end of each spar doubler to a taper as

shown in the "Wing Spar Detail" on the plan. Glue the spar

doublers to the spars, and sand off any excess glue.

Now measure and mark the balsa sheeting (see sketch

below), then cut the angle in the sheeting, cutting along a

metal straightedge for accuracy.

NOTE: Follow steps 9 through 34 to build the RIGHT

wing panel, then repeat these steps to build the LEFT wing

panel

T-Pins

Spar

5. Carefully punch out all the die-cut 3/32" balsa wing

ribs. Sand the edges slightly to remove any die-cutting

irregularities.

9. Pin one of the spars to the plan with the spar

doubler up and toward the root NOTE: The spars are cut

slightly too long. Center the spar on the plan so an equal

amount protrudes on both ends.

9

Page 10

10. Place the ribs on the spar in their approximate

position, but do not glue. NOTE: Make sure ribs W-2,

W-3 and W-4 are installed with the LG notches down, and

W-l is installed with the servo opening pointing up.

Cut first slot to

angle of dihedral gauge

NOTCHED LEADING

EDGE

11. Examine the shaped, notched leading and trailing

edges. Notice that the notches at one end of each LE and TE

are only 2-5/8" apart. These are the notches for W-l and

W-2. Also notice that all notches in the LE and TE are

vertical; however, rib W-l will be installed at a slight angle

using the Dihedral Gauge. Therefore, you should now

modify the notch for W-l by cutting it to the angle of the rib.

You may determine the approximate angle of the cut by

holding the Dihedral Gauge (DG) against the LE as shown

above.

CENTER L.E. VERTICALLY

ON FRONT OF RIBS

L.E.

16. Make sure the ribs are fully down on the plan and

all ribs are inserted into the LE notches. Angle rib W-l

slightly using the dihedral gauge (DG). Glue W-1 to the TE,

LE and bottom spar. Glue all other ribs to the LE and bottom

spar.

12. Insert the rear ends of the ribs into the notches in

the TE, then block up the TE with the 1/4" balsa TE Jig

supplied. NOTE: The narrow end of the TE jig is at rib

W-ll. Pin the jig to the building surface.

13. Pin the TE to the TE Jig, making sure the ribs line

up with the plan.

14. Glue ribs W-2 through W-ll to the TE. (Apply

glue sparingly, to avoid gluing the TE to the TE Jig).

15. Insert the front ends of the ribs into the notches in

theLE. NOTE: Position the LE as shown at the top of the

next column.

17. Glue the top spar in place, making sure you do not

change the angle of W-l.

18. Glue the pre-cut 3/32" balsa vertical grain shear

webs to the rear edge of the spars in all rib bays except

between ribs W-l and W-2. NOTE: You may wish to trial

fit, mark, and trim each web before gluing in. NOTE: The

webs must be securely glued to the spars, but it is not

necessary to glue the webs to the ribs.

19. You will now make a "pocket" for the 1/16" ply

dihedral brace by installing a 3/32" balsa web 1/16" behind

the spars. Sand one of the 3/32" x 2-3/16" x 2-1/2" balsa

horizontal grain webs for a good fit between W-1 and W-2.

(See photo at top of next page.)

10

Page 11

Using the 1/16" ply dihedral brace as a temporary spacer,

glue the 3/32" web to W-l and W-2.

23. Prepare the 3/32" balsa leading edge sheeting by

sanding the front edge to a slight bevel so it will fit snugly

against the back of the leading edge.

3/32" Balsa

L.E. Sheeting

Bevel this

edge

NOTE: It will be helpful to have the following items handy

for the next step... thin CA, thick CA, a wet cloth, masking

tape and T-pins. Read through the following step and go

through a "dry run" before actually gluing.

20. Glue the die-cut 1/8" ply front web to the front

edge of the spars between ribs W-1 and W-2.

NOTE: In the next steps, maintain straightness by keeping

the wing down on the flat surface and on the TE Jig.

21. Lightly sand the lops of the ribs to blend with the

notched trailing edge; then glue one of the 3/32" x 1-3/4" x

30" balsa trailing edge sheets in place. NOTE: The edge of

the TE sheet may not be exactly straight, but just position the

sheet so it slightly overlaps the TE, and any overlap can be

sanded off later.

24. Position the leading edge sheeting at the rear edge

of the notched LE so there is an equal amount protruding on

both ends of the wing. Using thin CA, glue the front (beveled)

edge of the leading edge sheeting to the back edge of the

leading edge. Now wet the top surface of the sheeting so it

will bend easier. Apply thick CA glue to the top edge of the

ribs and to the front half of the spar, then immediately bend

the sheeting down onto the ribs and spar. Hold the sheeting

down with masking tape, pins and your hands until the glue

has set.

22. Before applying the leading edge sheeting in the

next step, use your T-bar to lightly sand off the edges of the

shear webs and smoothly blend the ribs to the spar.

25. Using the 3/32" x 3" x 8-13/16" balsa sheets, glue

the top center section sheeting in place as shown on the plan.

(Use the scraps trimmed from the LE sheeting for the aft

pieces).

11

Page 12

NOTE: If you are installing retracts, disregard steps 26

through 29.

26. Remove the wing from the building board and

trial fit the long grooved hardwood LG block into the notches

in ribs W-2, W-3 and W-4 (see the landing gear detail drawing

on the wing plan for proper positioning). File the notches if

necessary for a good fit. Now use epoxy to securely glue the

block in place.

27. Epoxy the 7/16" x 5/8" x 7/8" hardwood block to

the LG block and to the 1/16" ply doubler on rib W-2, as

shown on the plan and in the photo, then epoxy the small

hardwood block to the other end of the LG block and to the

1/16" ply doubler on rib W-4.

Photo of finished wing with retract mechanism removed.

NOTE: If you will be installing retracts, now is the time to

glue in the 1/16" ply die-cut rib doublers to the front portion

of ribs W-3 and W-4. (Make sure the front rib doublers are on

the outboard side of W-3 and the inboard side of W-4). This

is also the time to install the 1/4" x 13/16" x 2-11/16" ply

retract mounting rails on the bottom of the wing, in the

location shown on the plan. Lock and strengthen the joints

between the 1/4" ply rails and the 1/16" ply rib doublers by

gluing 1/4" balsa triangle stock to these joints. You should

also now do some planning and trial fitting of the retract and

pushrod, customizing the installation as necessary [to|

accommodate your retracts. Installing retracts requires

careful planning and a lot of trial fitting: therefore, you should

take the time now to plan out your installation.

31. With the wing upside down, again use the TE jig

to support the TE. Then install the bottom TE sheeting, LE

sheeting and Center Section sheeting, cutting and fitting the

sheeting around the LG block as necessary. IMPORTANT

NOTE: To insure a straight wing, you must pin or weight

the TE securely down on the TE jig while the bottom

sheeting is glued in place!

28. Drill a 5/32" hole down through the grooved LG

block and the 7/8" block. Line up the drill so you are drilling

straight down through the middle of the 7/8" block.

29. Trial fit the 5/32" diameter main landing gear

wire into the landing gear block at this time. Cut or file the

groove and hole in the landing gear block as necessary for a

good fit

30. Using a razor saw and a sanding block, carefully

cut off and sand all excess sheeting, spars, LE and TE even

with W-l and W-ll.

32. From the 3/32" x 3/8" x 30" balsa sticks, cut and

glue cap strips to all exposed ribs, top and bottom. HINT:

For easier positioning of the cap strips, first mark the location

of each rib on the LE and TE sheeting.

33. Trim the sheeting flush with ribs W-l and W-ll

and sand the entire wing panel smooth. Sand the leading edge

to smoothly blend with the LE sheeting (see the note on the

following page).

12

Page 13

IMPORTANT: The shape of the leading edge

will affect the way this airplane performs snap rolls

and spins. A blunt, rounded leading edge will

"soften" the stall, making the plane very docile

when flying slowly, enabling it to flare nose-high for

very slow landings; however, this may cause the

plane to be a little sluggish when trying to enter a

snap roll or spin. A sharper leading edge will help

the plane enter snap roll and spin maneuvers more

crisply, while sacrificing only a little of the low

speed stability. The leading edge has been approximately pre-shaped to the sharper cross-section, so

try to maintain the same LE radius when sanding to

blend with the LE sheeting. To avoid tip stalls,

make sure the leading edges of both wing panels

have the same shape.

NOTE: 30-minute epoxy is strongly recommended for the

wing joining process.

3. Mix up a batch of 30-minute epoxy and push some

into the dihedral brace slots. Smear epoxy on the spar ends,

and on both sides of the 1/16" ply dihedral brace. Slide the

dihedral brace in place, push the wing panels together and

immediately proceed to the next step.

34. Mark and cut out a 1/16" slot in W-l just behind

the spars, for the dihedral brace.

35. Now go back and repeat Steps 9 through 34 to build

the left

wing panel.

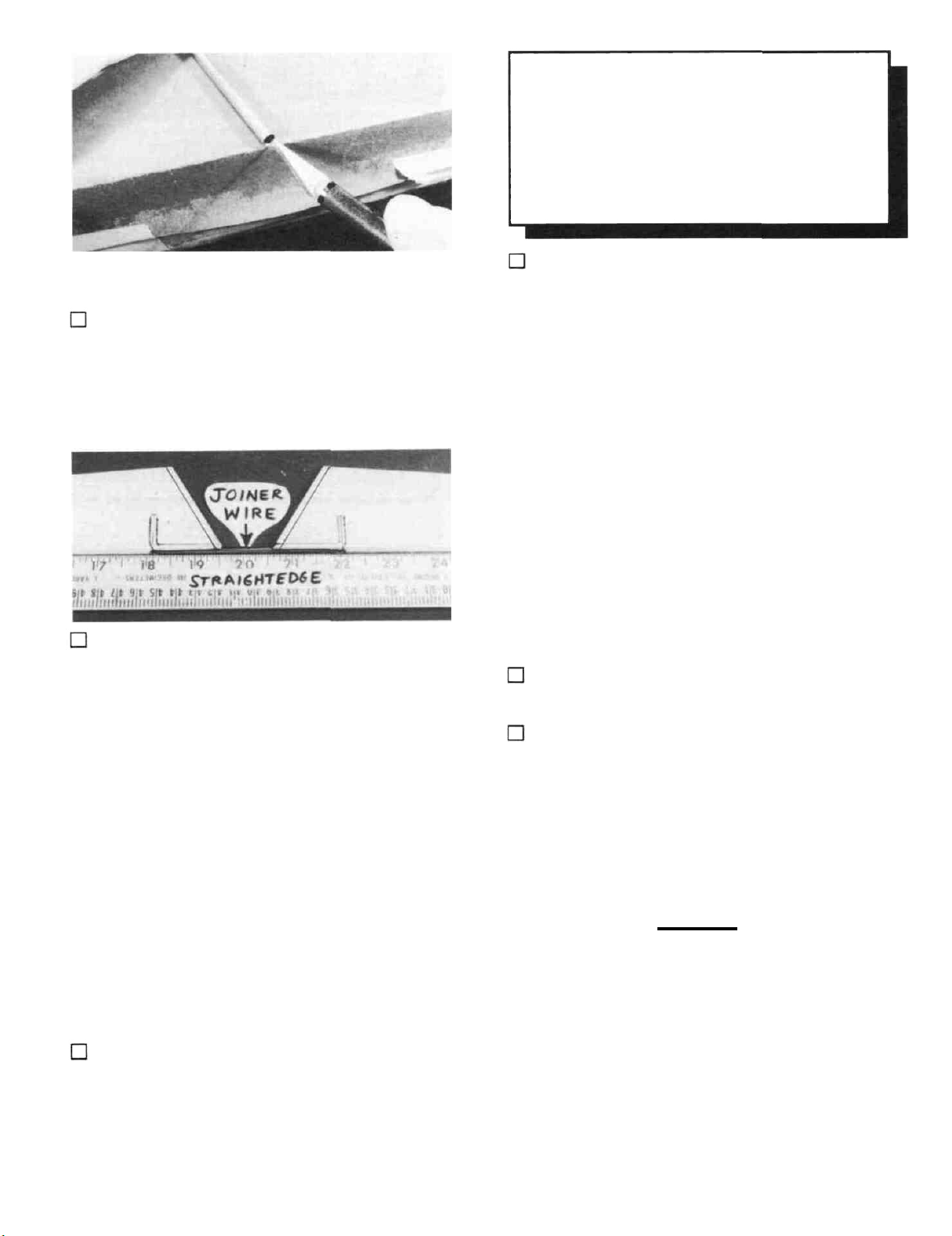

JOIN THE WING PANELS

NOTE: Read steps 1 through 4, then make a "dry run"

through these steps before actually proceeding.

1. Lay a piece of waxed paper down and place the two

wing panels, right side up, so that the W-l ribs are together.

Using the 1-1/8" x 1-9/16" x 9-3/4" balsa wing tip blocks,

block up both wing tips 1-1/8-inch. Sand the wing panels at

the center so they will fit together without a gap.

2. Trial fit the 1/16" ply dihedral brace to make sure

it will readily slide into place. (The photo for this step is at the

top of the next column).

4. With the wing tips blocked up 1-1/8 inch, carefully

align the LE and TE of both wing panels at the center and,

while holding them in correct alignment, apply thin CA glue

to "lock'' the panels together. Do not apply CA glue to any

area that is already coated with epoxy. Allow the epoxy to

fully harden before disturbing the wing.

5. Sand the wing joint smooth all around.

INSTALL AILERON TORQUE RODS

1. Roughen the short end of the aileron torque rods

with 100-grit sandpaper, and file the same end to a wedge

shape. (See sketch on next page).

13

Page 14

File end to

wedge shape

pieces in place with epoxy. HINT: Use masking tape to hold

these pieces to the wing TE, to aid in correct positioning.

2. Roughen the surface of the plastic bearing tubes

with 100-grit sandpaper.

3. Clean the torque rods and bearing tubes with alco-

hol.

4. Find the two grooved, tapered balsa center trailing

edge pieces. Lay them on the plan, mark and cut them off to

match the plan for length and angle at the centerline.

5. Trial fit the torque rods into the center TE pieces.

Determine from the plan where to cut the clearance notches,

which will permit the torque rod horns to travel freely. Also

cut small clearance notches in the wing TE. Note: The

torque rod horns must exit the TOP of the wing!

SAND "FLATS" ON LE AND TE

1. Study the wing plan near the wing centerline. Note

that the center portion of the LE and TE must be sanded flat.

2. Sand approximately 5/32" into the LE at the centerline, and approximately 3/32" into the TE at the centerline.

(The flats will end up approximately 4-1/2" wide at the LE,

and 2" wide at the TE).

FIBERGLASS THE CENTER SECTION

6. Slide the plastic bearings toward the threaded end of

the torque rods, then use a toothpick to apply a small amount

of petroleum jelly to the ends of the plastic tubes (to help

prevent glue from getting inside and locking up the torque

rods).

7. Use 5-minute epoxy or thick CA to glue the plastic

bearing tubes into the grooves in the center TE pieces. Wipe

off any excess glue and allow it to harden.

8. Trial fit the trailing edge / torque rod assemblies

onto the wing trailing edge. Sand the center trailing edge

pieces slightly where they join, for a good fit. Glue these

NOTE; Because of the high stresses in the center of this

wing, Fiberglass reinforcement is REQUIRED. Please do

not omit this important section!

NOTE: If you have previous experience with applying

fiberglass, feel free to use your favorite method, providing

that it results in a strong bond between the glass cloth and the

wood. If this is your first time, we offer the following

suggested method, which is the fastest and easiest we have

seen.

1. Make location marks for the fiberglass reinforce-

ment cloth, 2" each way from the wing centerline.

14

Page 15

2. Trial fit the 4" wide fiberglass cloth in place.

can use a scissors or a paper punch to cut holes in the glass

cloth for the aileron torque rod horns.

You

trailing edge with a sharp Xacto knife followed by a sanding

block.

9. After the glue has set, trim the excess cloth at the

3. Wrap small pieces of masking tape around the

threaded portion of the aileron torque rods to protect them

from the spray adhesive in the next step.

4. Spray a very light mist of 3M "77" Spray Adhesive

on the center section in the area to be glassed. Hold the spray

can at least 12" away from the surface when doing this to

avoid a heavy buildup. The purpose of this is only to give the

wood a little "tackiness". If you apply loo much spray it

could result in a poor glue bond. Allow the spray to dry for

5 minutes before proceeding to Step 5.

10. Carefully sand the edges of the glass cloth with a T-

bar sander with 80 or 100-grit sandpaper. Also, lightly sand

the surface of the glass cloth with a piece of sandpaper held

in your fingers to remove any rough spots. WARNING:

When sanding fiberglass, wear a dust mask to avoid

breathing airborne glass fibers.

INSTALL WING TIPS

NOTE: The wing tips will be carved from the 1-1/8" x

1-9/16" x 9-3/4" balsa blocks.

1. Draw a centerline on the ends of the wing and on the

wing tip blocks.

5. Beginning at the trailing edge, lay the glass tape in

place on the wing. Gently press the cloth in place, working

out all the wrinkles. The "77" spray adhesive should hold

the cloth down to the surface, but will permit you to lift and

reposition the cloth if you make a mistake. Keep working

forward along the top of the wing, around the leading edge,

and along the bottom of the wing, ending at the trailing edge.

Do not attempt to wrap the glass cloth around the trailing

edge.

6. Working outdoors or in a very well-ventilated area

apply thin CA glue to the glass cloth. Begin by running a

bead of glue down the center of the glass cloth strip, then

continue applying the glue in lines until all the cloth has been

secured. Run the thin CA out 1/4" beyond the edges of the

glass cloth to help protect the balsa sheeting when sanding

later. WARNING: This operation produces a larger than

normal quantity of CA fumes, so adequate ventilation is a

must!

7. Inspect the surface of the glass cloth. If any areas are

not glued down, apply a couple more drops of CA glue and

press down with a piece of waxed paper until the glue sets.

8. To make sure the glass cloth is fully "wetted out"

and bonded to the balsa, you may apply more thin CA, a few

drops at a time, and spread it out with a piece of waxed paper.

2. Securely glue a wing tip block to the left end of the

wing, and tack glue a wing tip block to the right end of the

wing, lining up the centerlines you previously drew. You will

later break only the right lip loose and hollow it out.

3. Cut, carve and sand the wing tips to the appropriate

shape as shown on the plan. HINT; Use 50-grit sandpaper

and a sharp wood chisel or razor plane to speed up this

operation. NOTE: Leave the tips oversize in the area of the

ailerons, for now.

15

Page 16

4. Cut the right wing tip loose from the wing and use

a Dremel Moto Tool to hollow out the wing tip. (This will

help to compensate for the weight of the engine head and

muffler).

5. Now securely glue the right wing tip in place.

to make room for the torque rod bearings. Trial fit the ailerons

onto the torque rods and cut or file as necessary until they fit.

Cut 2" off Aileron stock

and glue permanently to TE

6. Cut 2" off one end of the tapered ailerons and glue

the 2" pieces permanently to the trailing edge as shown in the

sketch. This moves the aileron away from the turbulence

caused by the tip vortex. Make sure you carefully line up this

piece with the top and bottom surfaces of the wing.

INSTALL AILERONS

NOTE: Do not glue the aileron hinges until after your model

has been covered.

1. Draw an accurate centerline along the LE of the

tapered balsa ailerons and the wing TE,

2. Check the length of your ailerons against the actual

aileron openings and trim the ailerons as necessary. You

should provide approximately 1/16" gap at each end of the

ailerons.

6. Lay the ailerons on the plan and mark the hinge

locations on the ailerons. Use two hinges near the tips. Place

the ailerons against the wing TE and transfer the marks over

to the wing.

7. Cut the hinge slots in the ailerons and wing TE using

an Xacto knife or hinge slotting tool.

8. IMPORTANT! Condition or "break-in" the hinges

by folding them back and forth several times,

9. Sand the leading edge of the ailerons to the same

"V"-shape as shown on the wing rib detail drawing.

10. Insert the hinges into the slots and trial fit the

ailerons in place on the wing. Do not glue the hinges until

after you have covered the wing.

There should be no hinge gap!

3. Lay the ailerons in place in the openings, with the

torque rods resting on lop of the ailerons. Mark the torque

rod locations on the top of the ailerons.

4. Drill a 7/64" hole in the ailerons at the torque rod

locations, starting at the leading edge centerline and drilling

straight in to the proper depth. (The hole is drilled slightly

oversize to allow for positioning, and to create a hard epoxy

"sleeve" around the wire).

5. Use the sharpened 1/8" diameter brass tube to cut a

groove in the leading edge of the ailerons to accept the

torque rods. Cut these grooves a little larger at the beginning,

11. Now is a good lime to finish the wing tips. Tape the

ailerons on in the neutral position, and sand the wing tips to

blend with the ailerons.

INSTALL WING DOWELS

1. Mark a horizontal centerline on the flat which you

sanded on the wing LE. Also mark a vertical centerlineon the

die-cut 1/8" ply former F-2A (the Wing Dowel Plate).

16

Page 17

2. Holding the die-cut 1/8" balsa F-2A on the leading

edge, in the exact center of the wing, mark the dowel

locations through the dowel plate holes.

3. Remove F-2A and double check to make sure the

dowel locations are both the same distance from the wing

center joint

4. It is important that you now drill the dowel holes

accurately! To insure accurately positioned holes, begin by

drilling small (1/8") holes in the center of the marked locations. Then gradually increase drill bit sizes until you have

finally drilled the holes to 1/4" diameter. The final holes you

drill must extend 3-3/4" into the wing to penetrate the front

webs. NOTE: Try to drill straight in.

3. Sand the wing bolt plate flush with the wing TE.

FILL LANDING GEAR SLOTS

1. Temporarily install the main LG wires.

2. Check the plan for the location of the nylon landing

gear straps and temporarily install them, using #2x3/8 sheet

metal screws.

NYLON LANDING

GEAR STRAP

#2X3/8" SHEET

METAL SCREW

5. Sand one end of each wing dowel to a rounded or

pointed shape. This is the end that will be inserted. Do not

sand the other end at this time.

6. Trial fit the dowels into the dowel holes, and trial fit

the dowel plate over the dowels. If the dowels fit too tightly,

you may enlarge the holes slightly using a round file, or you

may sand the dowels down slightly. Do not glue the dowels

in place at this lime.

INSTALL WING BOLT PLATE

1. Mark a centerline on the die-cut 1/16" x 3-15/32" x

1-5/8" ply wing bolt plate.

notched LG blocks and sand flush with the surface of the

wing. This will aid in covering later.

INSTALL RETRACTS (OPTIONAL)

NOTE: Hardware for retract installation is not included in

the

kit

1. Study the retract drawings on the plan. and the

I installation instructions provided with your retracts, and plan

your retract installation before proceeding,

2. Position the wing boll plate on the bottom of the

wing, and line it up with the wing TE and centerline. Glue it

in

place.

Photo shows finished wing with retract installed.

2. Cut an opening in the bottom LE sheeting for the

17

Page 18

retract mechanism. Cut a clearance slot in rib W-3 for the LG

wire. Cut an opening in the bottom LE sheet and in rib W-2

for the wheel well.

FUSELAGE ASSEMBLY

3. lEnclose the wheel well by running vertical grain

1/16" balsa between the bottom and top sheeting; or you may

make the wheel well from an appropriately-sized styrofoam

cup.

of the spars) for your retract servo, and bend and fit a pushrod

to run between the servo and the retract mechanism. Run the

pushrod just under the top LE sheeting until it passes over the

wheel well, then make two 90-degree bends and connect it to

the retract mechanism.

5. Temporarily mount yourretract servo and trial fit all

retract components. Test the operation of your retracts

making sure they operate freely and reliably. Also make sure

they

"lock"

in

both the up and down positions.

PREPARE FUSE SIDES

1. Lay one of the shaped 3/16" balsa fuselage sides in

place on the fuselage plan side view. Carefully position the

fuse side so the front edge lines up with the front ofF-1 on the

plan. Tape or pin the fuse side so it can't move. NOTE: The

fuse side may be a little longer at the rear than indicated by the

plan. This is as it should be.

2. Carefully position the die-cut 3/16" balsa lower

front fuse side so the rear edge lines up with the front of the

wing saddle opening on the plan (the rear edge ofF-2A). You

may have to lightly sand the top edge of the die-cut 3/16"

balsa for a good fit against the bottom edge of the fuse side.

Edge glue the lower front fuse side to the fuse side. NOTE:

Use waxed paper under the balsa to avoid gluing to the plan.

Photo shows

6. Blend the bottom sheeting as neatly as possible

around the retracts.

1. Use polyester resin or 30-minute epoxy thinned with

finished

wing with

retract

installed.

alcohol to fuelproof the entire retract well area.

3. Carefully position the die-cut 3/16" balsa lower

rear fuse side so the vertical front edge lines up with the rear

of the wing saddle opening on the plan (the front edge of

F-4). Edge glue the lower rear fuse side to the fuse side.

4. Trim and sand off the die-cut "bumps" from the

front and rear portion of the lower rear fuse side, blending

with the upper fuse side.

5. Sand the fuse side smooth on both sides using a Tbar and 100-grit sandpaper, then repeat the above steps to

make the other fuse side.

18

Page 19

6. Find the two die-cut 1/8" ply fuselage doublers and

the four die-cut 1/8" ply firewall spacers. Note that the

spacers are marked "2 L", "2 R". "4 L", and "4 R".

Use the #2 firewall spacers if you will be install-

ing a 2-cycle engine such as the OS Max 61 SF.

Use the #4 firewall spacers if you will be install-

ing a small 4-cycle engine, such as the OS FS 70

Surpass.

If you will be installing a larger (longer) 4-cycle

engine, such as the OS FS 91 Surpass, do not use any

firewall spacer on the right side, and use the 1/8" x

1/8" x 3-5/8" hardwood stick as a firewall spacer on the

left side.

PLAN IT OUT! It is important that the fuse doubler and fuse

side line up along the top edge and the front of the wing

opening. While holding in position, apply thin CA glue

around all the notches and lightening holes, then around the

edges. Make sure you apply sufficient glue so it flows under

the doubler to produce a strong bond. NOTE: The narrow

and wide firewall spacers will automatically position the

firewall to result in 2-degrees of right engine thrust.

9. Glue the tapered balsa tail filler to the aft end of one

of the fuse sides and sand it even with the top and bottom

edges.

10. From the 1/4" balsa triangle, cut pieces to fit be-

tween the tail filler and the rear of F-4, along the bottom

inside of both fuse sides. Glue in place.

7. Edge glue the appropriate firewall spacers to the

front edge of the fuselage doublers. Note that the spacers are

not the same size. They will automatically set the engine at

the required 2-degrees right thrust.

8. Carefully position the fuselage doublers on the fuse

sides, making a RIGHT and a LEFT side. The doubler with

the smaller firewall spacer goes on the right fuselage side ..

11. Sand the aft ends of the balsa triangle to a taper,

which will permit the fuse sides to be pulled together at the aft

end. NOTE: The taper shown in the photo is approximate

and may have to be modified during assembly.

ASSEMBLE LOWER FUSELAGE

1. Tape the fuselage plan to your workbench and cover

the Fuse Bottom View with waxed paper.

NOTE: The fuselage is assembled upside down.

2. Pin or tack glue (using 3M "77" Spray Adhesive)

the 1/8" die-cut balsa stab base accurately in position on the

plan. Align the front edge of the stab base with the line on the

plan.

19

Page 20

3. Accurately position the two pre-cut 1/4" x 1/2" balsa

cross-braces on the plan, and pin them in place behind F-4

and F-5. Note: The front cross-brace (at F-4) extends only

out to the doublers.

the plan and hold it securely in place with pins, tape or

weights (or you may spray it lightly with 3M "77" spray

adhesive, to hold it firmly but temporarily down on the plan).

7. Trial fit (do not glue) the following parts together

Fuse top, fuse sides, die-cut 1/8" ply F-2. F-3, F-4 and the

die-cut 1/8" ply Chin Block Base. Check the fit of all parts

and trim, file or sand as necessary for a good fit. Pull the aft

ends together and re-sand the 1/4" triangles if necessary.

4. Trial fit formers F-4 and F-5 to the front of the Cross-

braces (the formers are upside down), and sand the edges of

the formers slightly to match the angle of the fuse sides. Glue

the formers to the cross-braces, making sure that each

former is installed perpendicular to the building surface.

5, Insert F-6 upside down in the rear of the slot in the

stab base. Sand the edges of F-6 slightly to match the angle

of the fuse sides. Align F-6 perpendicular to the stab base and

glue it in place.

8. Once you have everything fitting properly, re-as-

semble the above parts, using clamps, pins. tape and weights

to hold everything together and flat on the workbench. Make

sure F-2 is pushed as far forward as possible, and F-4 is

pushed as far aft as possible. There should be waxed paper

underneath to prevent gluing the fuse to the plan. Apply thin

CA glue to the joints, then follow with thick CA glue in any

joints that are not tight fitting.

9. Sand the bottom of the fuse to remove any excess

glue, and to provide a flat surface for the sheeting.

6. Accurately position the 1/8" die-cut ply fuse top on

pieces of cross-grain sheeting to the bottom of the fuse,

beginning at the front of F-4 and running to the aft end of the

fuse.

11. Now you may remove the fuselage from the work

surface and sand the edges of the bottom sheeting flush with

the fuse sides.

20

Page 21

12. Find the 1/4" ply wing hold-down block and trial fit

it into the notches in the fuse side doublers, sanding as

necessary for a good fit. Glue the hold-down block in place

securely, using 30-minutc epoxy, then cut pieces of 1/4"

balsa triangle and glue them in place above and below the

hold-down block. Sand the triangles flush with the wing

saddle.

13. The 1/4" ply firewall (F-l) location and size will

vary, depending on which engine you install. The location

has been set by the firewall spacers. The firewall supplied in

your kit is the correct size if you are installing a .91 4-stroke

engine; however, if you are installing a smaller engine, such

as a .70 4-stroke or a .61 2-stroke, you will have to cut the

firewall down to the correct size. The fuse plan shows the

firewall sizes and engine mounting required for the three

locations. Cut the firewall to size and sand the sides and

bottom at an angle to match the fuse. Trial fit to make sure it

will fit correctly before proceeding to the next step.

15. Use 30-minute or 5-minute epoxy to securely glue

F-l to the fuse sides, holding with clamps or tape until the

glue has firmly set. NOTE: Before the glue sets. double

check to make sure F-1 is properly aligned with the top and

bottom edges of the fuselage, and fully back against the

firewall spacers. After the glue has fully hardened, sand off

the front of the fuse sides flush with the front of F-l.

16. Cut pieces of 3/8" balsa triangle to fit around the aft

edges of F-1, and glue them in place.

14. Before installing the firewall (F-l), you may drill

F-l for your engine mountand install the 6-32 blind nuts. You

may cut out the appropriate F-l drawing from the plans, tape

it to F-l and use it as a guide for drilling the four 5/32" holes.

If you will be using a mount not shown on the plans you'll

have to determine the correct mounting position. Note that

the mount should not be positioned on the vertical and

horizontal centerlines of F-1, but should be offset slightly

above the centerline and slightly toward the left side. (When

taking measurements off the plan, keep in mind that the plan

shows the bottom view of the airplane). Drill the holes and

install the blind nuts on the back ofF-1, pressing them in with

a pliers or a vise.

6-32

Blind Nut

DRILL ENGINE MOUNT

(Great Planes MM60L mount)

1. Place the engine pointing straight ahead on the

mount and mark the mounting hole locations on the mount.

At the marked locations, accurately drill 7/64" (or #36) holes.

NOTE: If you have access to a drill press, use it for drilling

these holes to insure that they are drilled vertically.

2. Now you may use one of the following methods to

attach your engine to the mount:

Method 1: Screw the #6 x 1" sheet metal screws

(provided in the kit) through the engine mounting flange and

into the mount. When first installing these screws, put a drop

of oil into each screw hole.

21

#6 x 1" Screw

Page 22

Method 2: Cut threads into the holes you just drilled

using a 6-32 tap and tap wrench. If you use this method you'll

have to supply your own bolts (6-32 x 1" socket head cap

screws) for attaching the engine to the mount. NOTE; 8-32

hardware is recommended if you are installing a 4-cycle

engine.

INSTALL SERVOS AND PUSHROD GUIDE

TUBES

NOTE: Although you may choose to wait until later, this is

the best time to install the pushrod guides, because the

fuselage is wide open and it is very easy to work inside.

IMPORTANT: Before proceeding, plan your servo and

pushrod installation. Especially note which side of the

fuselage the throttle pushrod and nose gear pushrod (if any)

will be located. Remember that the throttle arms of 2-cycle

and some 4-cycle engines are on opposite sides. It will be

helpful to actually sketch your pushrod locations on the plans

with a pencil. It is desireable for the throttle pushrod (and the

nosegear steering pushrod) to run along the sides of the

fuselage. It is also desireable (but not essential) for the rudder

and elevator pushrods to cross inside the fuselage, to avoid

any sharp bends.

the brass tube method gives a much neater cut). Determine

the location of these holes from the plans. You may chuck

this brass tube in an electric drill to aid in getting through

F-6.

5. Insert the plastic pushrod tubes through the holes

you just cut and through formers F-6, F-5 and F-4.

1. Set the fuselage upside down on blocks at least

1-inch high.

2. Trim the 3/16" x 1/2" x 3-5/8" ply servo rails to fit

between the fuse side doublers in the locations shown on the

plan. Temporarily mount your servos to the rails, then glue

the rails to the fuse side doublers. Lock the rails in place by

gluing scraps of plywood on the top and bottom of the rails.

3. Sand the outer surface of the pushrod guide tubes

with 100-grit sandpaper to provide a surface to which the glue

will adhere.

4. Use an Xacto knife to sharpen one end of a piece of

3/16" (outside diameter) brass tubing, then use this tubing to

cut the pushrod exit holes (you may use a 3/16" drill bit, but

6. Route the pushrod tubes according to your

radio installation plan. Temporarily insert the 34"

pushrod wires into the tubes and hold them in the

correct position at the servo end. Keep the tubes as

straight as possible. Glue the tubes to the fuse sides

at the rear exit points using thin CA glue. Use scraps

of 1/8" balsa to anchor the tubes to F-5. Do not anchor

the tubes to F-4 at this time, to allow for slight

adjustment of their positions later.

7. Cut off the tubes at the exit points and sand them

flush with the fuse sides using a sanding block.

8. Temporarily install the engine mount, nosegear

(and nosegear steering arm if you are building a tricycle

configuration).

9. Cut 1/4" off the end of the steering arm, then drill

a 3/16" hole in F-l, just above the outer hole of the arm.

NOTE: The drill should be aimed toward the rudder servo to

avoid tight bends in the pushrod. The photo for this step is at

the top of the next page.

5/32" Collar

Steering Arm

Cut

off

end

6-32 x 1/4" Screw

22

Page 23

10. With the engine resting on the mount, plan the

throttle pushrod routing. The pushrod should be located as

close as possible to the fuse sides (to allow room for the fuel

tank), and the guide tube should not have any tight bends.

Drill a 3/16" hole in F-l for the throttle pushrod guide tube.

3. Insert the die-cut 1/8" ply F-2A in place against the

back of F-2 (do not glue).

4. Insert the 1/4" wing dowels into the wing so they

stick out only 1/8".

5. With the fuselage upside down on a flat surface, trial

fit the wing into the wing saddle. If the wing is slightly too

large (front to rear) to fit into the saddle, sand the rear edge of

the saddle and the wing trailing edge slightly until it fits.

11.

Drill or carve holes in F-2 and F-3 for the guide

tubes. Cut the remaining 36" plastic pushrod guide tube in

half and trial fit the tubes in the fuselage. (Also see the photo

on page 35.)

12. Sand the plastic pushrod guide tubes with 100-grit

sandpaper, then glue them in place. Trim and sand the tubes

flush with the front of F-l.

13. Cut the pushrod wires (supplied) to the required

lengths and temporarily install the throttle and nose gear

pushrods. NOTE: A 34" wire, threaded one end, is supplied

for the throttle pushrod, and a 19" wire (no threads) is

supplied for the nosegear pushrod.

14. Now remove the pushrod wires, engine, engine

mount and servos.

MOUNT THE WING TO THE FUSE

1. Sand the top surface of the fuse to remove any excess

glue so the fuse will lie flat on the workbench.

2. Sand the entire wing saddle area lightly until the fuse

side doublcrs and fuse sides are flush.

Measurements must be equal

6. Carefully align the wing in the saddle as follows:

If you have drilled the dowel holes accurately, the wing

should now be centered, side to side. Measure down from the

bottom of both tip ribs to the flat surface. If the measurements

are not equal (within 1/16"), sand the saddle slightly until the

wing sits level in the saddle. Also measure from the rear

comer of each wing tip to the tail end of the fuselage. These

measurements must also agree within 1/16". If not, shift the

wing slightly until they do. With the wing in this position you

may now check the wing incidence using an "incidence

23

Page 24

meter" or by measuring down to the flat surface from the

center of the leading and trailing edges. The measurements

should be the same (zero degrees incidence). CAUTION: If

your flat surface is not level, you will get erroneous incidence

readings! If you are working on a flat surface that is not level,

you must set the wing incidence the same as your flat surface.

7. After making the necessary corrections to align the

wing, tack glue F-2A to F-2 with a couple drops of CA. Also

make alignment marks on the wing TE and the front ofF-4

so you may easily re-align the wing later.

8. Remove the wing and securely glue F-2A in place by

flowing thin CA into the wing dowel holes and around the

edges. Follow up with thick CA in any gaps around the edges.

12. Holding the wing firmly in place, drill 13/64" holes

at the locations you marked in step 11, drilling down through

the 1/16" ply wing bolt plate and through the 1/4" ply holddown block in the fuselage. Try to drill straight in, perpendicular to the 1/16" ply bolt plate. IMPORTANT!: Do not

allow the wing to move while drilling!

13. Remove the wing and re-drill the holes in the wing

only to 1/4".

9. Drill 1/4" holes through F-2 using the holes in F-2A as

a guide.

10. Use a pliers to grasp the ends of the wing dowels and

pull them out. Now you may slightly round (or chamfer) the

ends of the dowels for easier insertion into F-2A. Mix up a

batch of 30-minute epoxy, use a long stick to work some

epoxy into the dowel holes, smear epoxy on the dowels, then

re-insert the dowels into the wing, leaving them protrude

3/8". Wipe away all excess epoxy, then allow the epoxy to

fully harden.

11. Study the wing plan to determine where the wing

bolt holes are to be drilled. By measuring, transfer the locations to the wing bolt plate on the bottom of the wing. After

marking the bolt locations, replace the wing in the saddle and

re-align it accurately, as in step 6.

1/16" WING BOLT PLATE

13/16"

14. Use a 1/4-20 tap and a tap wrench to cut threads

the ply hold-down block in the fuselage.

15.

Harden the threads in the hold-down block with thin

CA glue, then re-tap the threads after the glue is completely

dry.

16. Trial fit the wing to the fuse using the two 1/4-20

nylon bolts provided. You may cut the bolts off to their proper

length, so they protrude about 1/4" below the hold-down

block in the fuselage.

1/4 - 20 Nylon Wing Bolt

17. Later you will apply foam wing seating tape or

silicone sealer to the wing saddle. To allow space for this

wing cushion material, you may sand the saddle slightly in

the areas where the wing touches the saddle, to provide a

small gap.

in

Drilling locations

18. Sand off the bottom edge of F-2 and F-2A flush with

the bottom of the chin block base. And, while you're at it,

24

Page 25

sand the entire fuse bottom, forward ofF-2A, in preparation

for installation of the chin block.

FIT FUEL TANK and FUELPROOF TANK

COMPARTMENT

1. Assemble your 11 to 14 oz. fuel tank. Werecommend bending the brass tubes as shown in the photo to prevent

them from cutting through the silicone fuel lines if pressed

against the firewall. (Try not to' 'kink'' the tubes when bending, however).

2. Try sliding the tank in through F-2. If the opening is

not large enough, sand or file the opening until the tank slides

in easily.

3. Temporarily install the engine mount and note how

far the mounting screws protrude into the fuel tank compartment. Remove the screws and cut them off so they do not

protrude more than 1/8" (to prevent puncturing the fuel tank).

5. Now remove the engine mount and fuelproof the

inside of the fuel tank compartment and the front of F-l by

brushing on a coat of polyester resin or 30-minute epoxy

thinned with alcohol. NOTE: Later when installing the nose

pieces, you will fuelproof the chin block before installing it.

6. You may permanently install the fuel tank at this

time, or you may wait until the plane is nearly completed. If

you do it now it will be easier to feed the fuel lines through

F-1, and to make sure there are no kinks in the lines; however,

you'll have to work around them while completing the nose.

When you install the tank, be sure to cushion it from vibration

and prevent it from moving by surrounding the tank on all

sides (and front) with latex foam rubber. Leave a few inches

of extra fuel tubing in front of F-l (you can cut off the excess

later). The photo shows how to route the fuel tubing to

prevent kinking.

INSTALL TURTLE DECK

4. Drill two holes (7/32" or size to fit your fuel tubing)

near the top of F-l for your fuel tubing vent and fill lines. The

location of these holes will depend somewhat upon the type

of engine you are using, etc. It is OK to drill the holes in the

upper left and upper right comers, but we prefer drilling both

holes in the upper right comer (as viewed from the rear) for

easier access.

You'll need the following pans: Die-cut 1/8" ply F-3A,

F-4A. and Backrest Gauge (BG); die-cut 1/8" balsa F-5A

and F-6A; two 1/4" x 1/4" x 27" balsa turtle deck stringers;

two 3/32" x 3-1/4" x 28-1/4" balsa turtle deck sides; the 1/2"

x 2-3/8" x 26" balsa turtle deck top block and a roll of

masking tape.

1. Glue the die-cut 1/8" ply "backrest" (F-3A) to the

fuse top, using the "backrest gauge" (BG) to set it at the

25

Page 26

correct angle. NOTE: The gauge is used only for setting the

angle (do not glue the gauge in).

2. Glue F-4A to the front of F-4.

Glue F-5A to the front of F-5.

Glue F-6A to the front of F-6 (insert the F-6A tab

through the slot in the stab base).

7. Glue the bottom edge of the sheeting to the top of the

fuse sides.

3. Glue the 1/4" x 1/4" x 27" balsa stringers to the

formers. HINT: If F-3A is slightly warped, you may

straighten it during this step by twisting it straight while

gluing the stringers. Trim and sand the ends of the stringers

flush with the front of F-3A and the rear of F-6A.

4. Use a sanding block to sand the sides of the stringers

to blend with the formers (see the cross-section drawings on

the plan). Also use a long sanding block to sand the stringers

and the tops of the formers in a straight line from F-3A to

F-6A.

5. Prepare the turtle deck sides by cutting the two

3/32" x 3-1/4" x 28-1/4" balsa sheets to the angle shown in the

following sketch.

8. Wet the outside surface of the sheering with a damp

rag to permit easier bending. Apply thick CA glue to the

edges of the formers and the stringers, then immediately bend

the sheeting around the formers and onto the stringers.

HINT: This requires about 5 sets of "hands," so use several

long pieces of masking tape to pull the sheering together;

then, working a small section at a time, add CA and press the

sheeting to the stringers.

9. Trim and sand the sheering flush with the front of

F-3A and the rear of F-6A.

6. Trial fit one edge of the sheeting down onto the top

of the fuse side. Sand the edge of the sheering if necessary,

for a good fit

10. Using a long T-bar or sanding block with 80-grit

sandpaper, sand the sheering and stringers flush with the top

edges of the formers.

26

Page 27

NOTE: The turtle deck is designed to be as light as possible,

while still providing sufficient durability for normal use. If

your airplane will be handled by "ham-fisted" people who

like to squeeze hard when holding the airplane in the turtle

deck area, you may want to add an extra 1/4" x 1/4" balsa

stringer on the inside of the turtle deck sheeting, between

F-3A and F-4A, about halfway down.

HINT: For a super-smooth and uniform finish on your turtle

deck, cut a 2-1/4" x 11" strip of 320 or 400-grit wet-or-dry

sandpaper, and work it like a "shoe-shine cloth" across the

top of the turtle deck.

11. Glue the 1/2" x 2-3/8" x 26" balsa turtle deck top

block to the tops of the formers, stringers and sheeting, then

trim the ends of the top block flush with F-3A and F-6A.

HINT: In the next step it will be helpful in keeping the

top block symmetrical if you first mark a centerline on the

top of the top block from front to back (this is a line from the

centerline of F-3A to F-6A).

ASSEMBLE THE NOSE SECTION

1. Find the 1/4" x 1/4" x 10" balsa cockpit sides. Cut

off one end of each stick at an angle to fit the front edge of the

backrest (F-3A).

2. Glue the cockpit sides to the top edge of the fuse

sides and to F-3A. The outside edge of the cockpit sides

should be flush with the outside edge of the fuse sides.

3. Measure, mark and sand off the cockpit sides according to the sketch. Then sand the top front comers of the

fuse sides on the same angle, to blend with the cockpit sides.

12. Carve and sand the top block to blend smoothly with

the sheeting (see the cross-sections on the plan). HINT: Use

a razor plane (or a sharp wood chisel) and a sanding block

with 50-grit sandpaper for rough shaping the top block.

4. Attach the engine mount to F-l, and attach the

engine to the mount Remove the nose gear.

5. From a scrap of 1/32" ply, cut four small pieces and

tack glue them to the 1/16" ply spinner ring as shown, using

a very small amount of thick CA (these will be removed

later). IMPORTANT NOTE: If you have chosen to use

shock-absorbing rubber engine mounts, then you must provide more space between the spinner ring and the spinner

27

Loading...

Loading...