Page 1

WARRANTY

Great Planes Model Manufacturing Co. guarantees this kit to be free from defects in both material and

workmanship at the date of purchase. This warranty does not cover any component parts damaged by use or

modification. In no case shall Great Planes' liability exceed the original cost of the purchased kit. Further, Great

Planes reserves the right to change or modify this warranty without notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the final user-assembled product. By the

act of using the user-assembled product, the user accepts all resulting liability.

If the buyers are not prepared to accept the liability associated with the use of this product,they are advised

to return this kit immediately in new and unused condition to the place of purchase.

READ THROUGH THIS INSTRUCTION MANUAL

FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

CAP4P03 V1.0 Entire Contents © Copyright 1998

P.O.Box 788 Urbana, IL 61801 (217) 398-8970

www.greatplanes.com

INSTRUCTION MANUAL

MADE IN

USA

Page 2

SAFETY PRECAUTIONS..................................................2

INTRODUCTION ...............................................................2

DECISIONS YOU MUST MAKE .......................................3

Engine Selection............................................................3

Exhaust System.............................................................3

Servo Selection..............................................................3

PREPARATIONS ..............................................................3

Required Accessories....................................................3

Building Supplies & Tools...............................................4

Optional Supplies & Tools ..............................................4

Building Notes ...............................................................5

Types of Wood................................................................5

Common Abbreviations..................................................5

Metric Conversions ........................................................5

Get Ready to Build.........................................................5

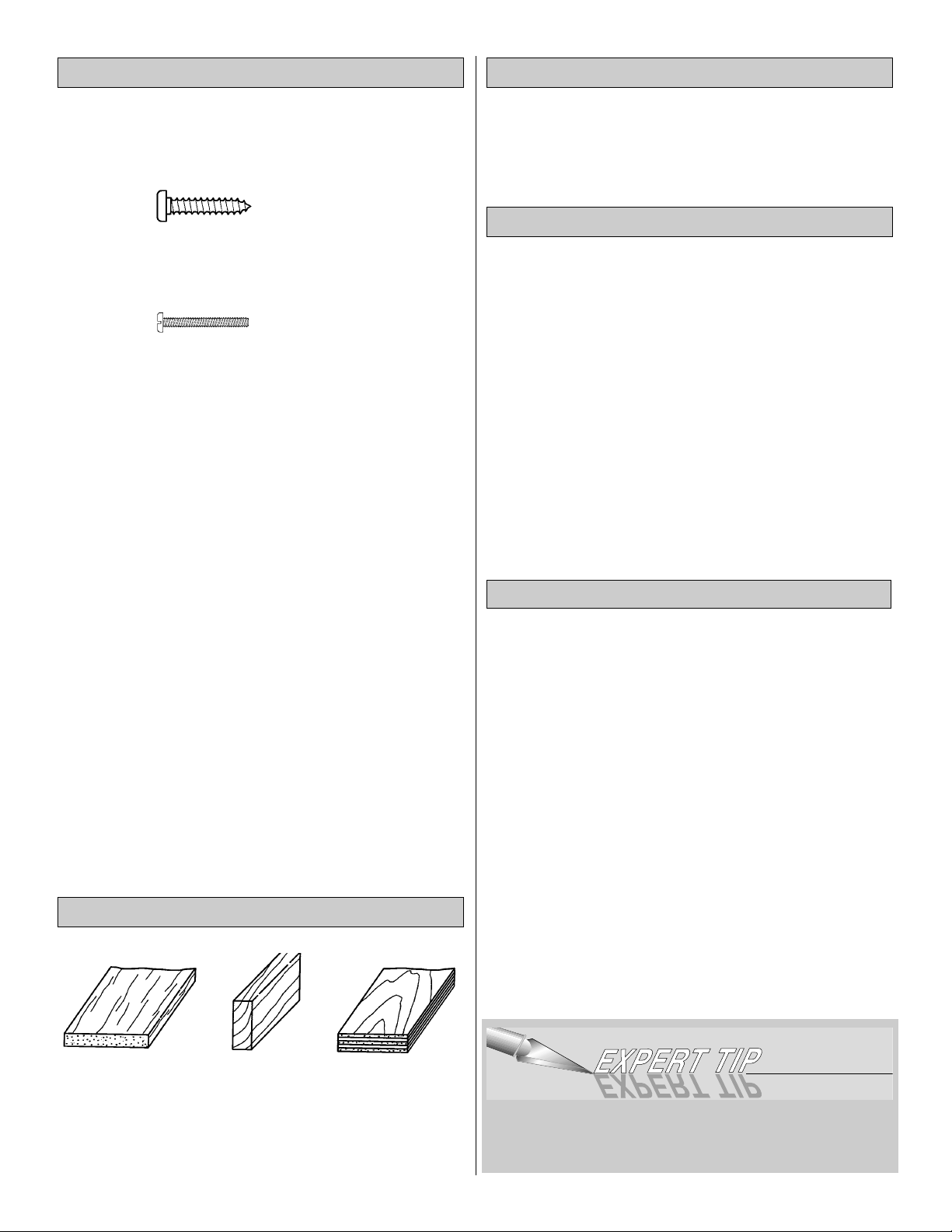

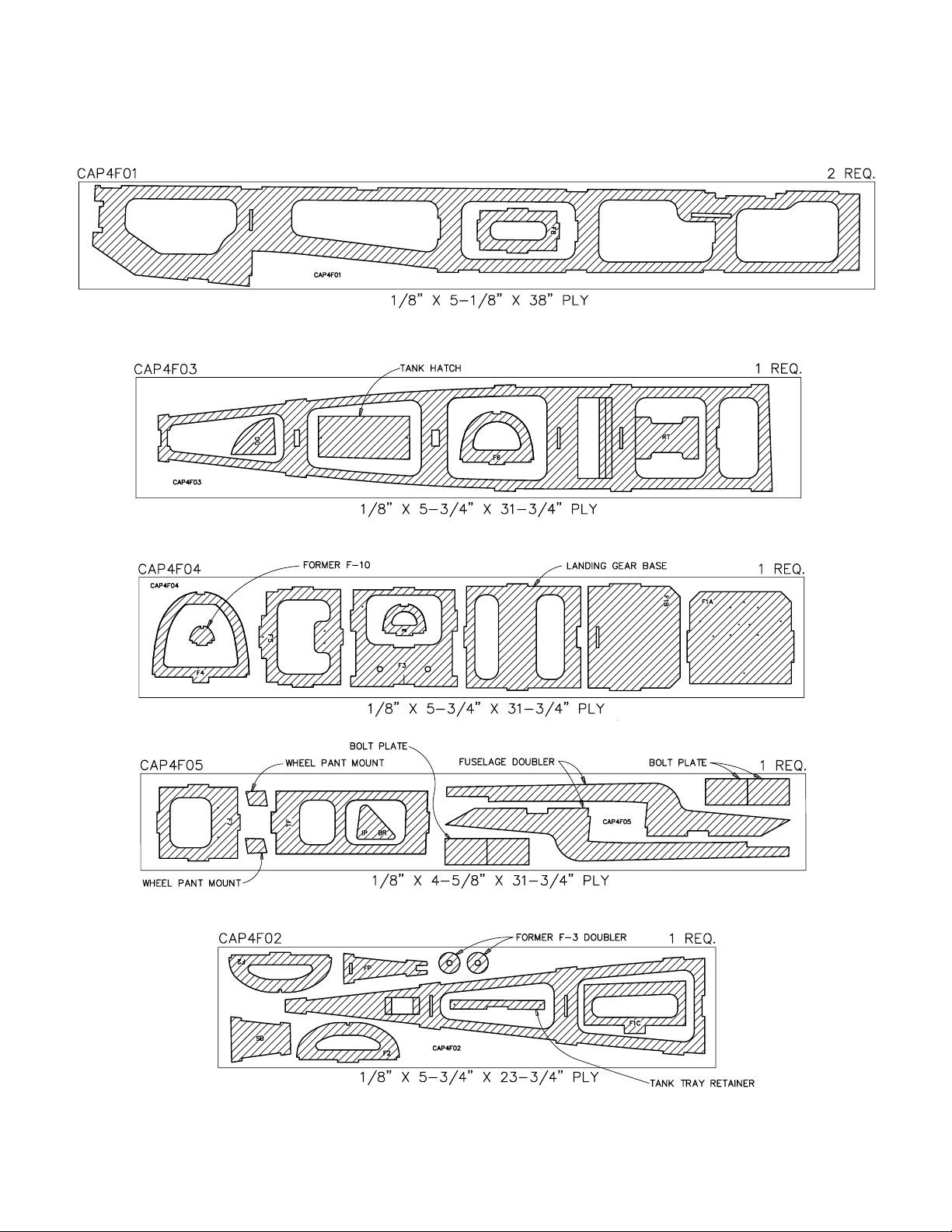

DIE-CUT PATTERNS .................................................6 & 7

BUILD THE T AIL SURF ACES............................................8

Build the Stab.................................................................8

Elevator Building Sequence...........................................9

Fin Building Sequence...................................................9

Rudder Building Sequence ............................................9

Hinge the Tail Surfaces ..................................................9

Finish the Tail Surfaces................................................10

BUILD THE WING............................................................11

Make the Wing Sheets.................................................11

Build the Wing Panels..................................................12

Join the Wing Panels....................................................15

Sheet the Wing.............................................................16

Build the Ailerons.........................................................16

BUILD THE FUSELAGE..................................................18

Assemble the Fuselage Former & Sides......................18

Assemble the Fuselage................................................20

Mount the Wing to the Fuselage..................................21

Build the Front Fuselage Deck.....................................25

Mount the Stabilizer to the Fuselage............................26

Build the Turtledeck......................................................27

Mount the Engine.........................................................29

Install the Battery & Tank .............................................30

Install the Servos and Make the Pushrods...................31

Add the Forward & Aft Wing Fairings...........................33

Assemble the Wheel Pants..........................................34

Assemble the Cowl ......................................................36

Prepare the Model for Covering...................................37

COVER THE MODEL.......................................................37

Covering Technique......................................................37

Suggested Covering Sequence ...................................37

BALANCE THE MODEL LATERALLY............................38

PAINTING........................................................................38

FINAL HOOK-UPS AND CHECKS.................................38

Join the Control Surfaces.............................................38

Install the Hardware.....................................................39

Attach the Canopy........................................................39

Set the Control Throws.................................................40

Balance the Model .......................................................40

PREFLIGHT.....................................................................41

Charge the Batteries....................................................41

Balance the Propeller...................................................41

Find a Safe Place to Fly...............................................41

Ground Check the Model.............................................41

Range Check the Radio...............................................42

Engine Safety Precautions...........................................42

AMA Safety Code.........................................................42

FLYING ............................................................................43

Takeoff..........................................................................43

Flight ............................................................................43

Landing ........................................................................43

TWO VIEW DRAWING.................................BACK COVER

Your CAP 232 is not a toy, but rather a sophisticated,

working model that functions very much like an actual

airplane. Because of its realistic performance, the CAP, if

not assembled and operated correctly, could possibly cause

injury to yourself or spectators and damage property.

If this is your first low wing sport model we

recommend that you get help from an experienced,

knowledgeable modeler with your first flights. You'll

learn faster and avoid risking your model before you're truly

ready to solo.Your local hobby shop has information about

flying clubs in your area whose membership includes

qualified instructors.

You may also contact the national Academy of Model

Aeronautics (AMA), which has more than 2,500 chartered

clubs across the country.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Congratulations and thank you for purchasing the Great

Planes CAP 232. The CAP is a rather "square" airplane

with well-defined lines. Coincidentally, this makes it

exceptionally easy to build and cover–especially for a semiscale sport model. Framing the model is very

straightforward, as most of the structure features

interlocking balsa and lite-ply. The turtledeck sheeting may

look a little intimidating but in actuality it is quite easy to

apply if you follow the instructions.

Flying the CAP 232 is a rewarding experience–as it should

be for such an aerobatic model! It doesn't take much

elevator or aileron throw to put the CAP through its paces.

When you have a feel for your CAP 232, the throws can be

increased to high rates (illustrated in the instructions) to

INTRODUCTION

PROTECT Y OUR MODEL,YOURSELF

& OTHERS...FOLLOW THIS

IMPORTANT SAFETY PRECAUTION

TABLE OF CONTENTS

2

Page 3

really showcase the aerobatic potential.The CAP performs

surprisingly well on a ball bearing Schneurle por ted .40,

but seasoned experts will surely want to get the most out of

the CAP by bolting on a .46 2-stroke or a .70 4-stroke.

We hope you enjoy building and flying your Great Planes

CAP 232 as much as we did the prototypes.

Please inspect all parts carefully before starting to build!

If any parts are missing, broken or defective, or if you

have any questions about building or flying this

airplane, please call us at (217) 398-8970. If you are

calling for replacement parts, please reference the part

numbers and the kit identification number (stamped on

the end of the carton) and have them ready when calling.

Product info – www.greatplanes.com

E-mail – productsupport@greatplanes.com

1. Build the plane according to the plans and instructions.

Do not alter or modify the model, as doing so may result in

an unsafe or unflyable model. In a few cases the plans and

instructions may differ slightly from the photos. In those

instances the plans and written instructions are correct.

2.Take time to build straight, true and strong.

3. Use an R/C radio system that is in first-class condition,

and a correctly-sized engine and components (fuel tank,

wheels, etc.) throughout your building process.

4. You must properly install all components so that the

model operates properly on the ground and in the air.

5.You must check the operation of the model before every

flight to ensure that all equipment is operating, and that the

model has remained structurally sound. Be sure to check

nylon clevises or other connectors often and replace them if

they show signs of wear or fatigue.

6. If you are not already an experienced R/C pilot you must

fly the model only with the help of a competent, well

experienced R/C pilot.

Remember:Take your time and follow directions to end

up with a well-built model that is straight and true.

Items in parentheses (OSMG2691) are suggested part

numbers recognized by distributors and hobby shops and

are listed for your ordering convenience. GPM is the Great

Planes brand, TOP is the Top Flite®brand, and HCA is the

Hobbico®brand.

❏ 4 Channel Radio with 4 Servos

❏ Engine -

See

Engine Selection above

❏ Muffler -

See

Exhaust System above

❏ Spare Glow Plugs (O.S.#8 for most 2-stroke engines,

OSMG2691)

❏ Propeller (Top Flite

®

Power Point™) we found that a

11x4 on the O.S. .46FX and the 13x6 on the O.S. .70

Surpass worked the best.

❏ Top Flite Super MonoKote

®

covering (Approximately 2

rolls);

See

Covering (page 37)

Required Accessories

PREPARATIONS

Engine Selection

There are several engines that will work well in your CAP

232, but for unlimited performance we recommend a

hot

2-stroke such as an O.S.®.46FX or SuperTigre™GS-45. If

you prefer a 4-stroke, an O.S. .70 Sur pass™is the ticket.

Your choice of 2-stroke or 4-stroke will determine the

location of the throttle servo and throttle pushrod exit on the

firewall, so plan ahead.

Exhaust System

If you choose to use a 2-stroke engine, you will need an

in-cowl muffler for the best appearance. On our prototype

CAP 232 with the O.S. .46FX we used the Slimline #3218

Pitts Muffler (SLIG2218) without the exhaust extension kit.If

you prefer to use an exhaust extension kit, you can always

purchase #8012 (SLIG5012) for this exhaust. On our

prototype CAP 232 with the O.S. 70 Sur pass, we used the

O.S.short flex pipe (0SMG2684) and the included muffler to

make the exhaust e xit in the scale location.

Servo Selection

During our extensive testing of the CAP 232, we found that

the CAP performs very well with standard Futaba®S3003

servos on all surfaces. However, for all-out 3D aerobatics,

the seasoned expert will want to consider high performance

servos such as the Futaba 9001 for elevator and rudder.

The additional torque, speed and centering capabilities of

these servos will provide crisper performance in everything

from slow rolls to hammerheads, torque rolls, knife edge

loops and beyond.

DECISIONS YOU MUST MAKE

NOTE: We, as the kit manufacturer, provide you with a

top quality kit and great instructions, but ultimately the

quality of your finished model depends on how you build

it; therefore, we cannot in any way guarantee the

performance of your completed model, and no

representations are expressed or implied as to the

performance or safety of your completed model.

PRECAUTIONS

3

Page 4

❏ Fuelproof paint;

See

Painting (page xxxx)

❏ Medium Fuel Tubing (GPMQ4131, 3')

❏ 1/4" Latex Foam Rubber Padding (HCAQ1000)

❏ 1/16" Foam Wing Seating Tape (GPMQ4422)

❏ 10 oz.Fuel Tank (GPMQ4104)

❏ (2) 2-1/2" Wheels (GPMQ4223)

❏ (1) 3/16" Wheel Collar (GPMQ4308)

❏ (2) 3/32" Wheel Collars (GPMQ4303)

❏ 2-1/2" Spinner (GPMQ4517 – red)

❏ Pilot (Williams Bros. 1/5 Scale Spor tsman Pilot used

in prototype, WBRQ2626)

❏ Fueling System (Great Planes Top Fueler,

™

GPMQ4160)

❏ Pacer Formula 560 Canopy Glue

❏ 1" Tail wheel (GPMQ4241)

These are the building tools, glue, etc. that we recommend

and mention in the manual.

We recommended Great

Planes Pro™CA and Epoxy

❏ 2 oz.Thin CA (GPMR6003)

❏ 2 oz.Medium CA+ (GPMR6009)

❏ CA Accelerator (GPMR6035)

❏ 30-Minute Pro Epoxy (GPMR6047)

❏ Building Square (HCAR0480)

❏ Plan Protector (GPMR6167)

❏ #1 Hobby Knife Handle (HCAR0105)

❏ #11 Blades (HCAR0311, 100 qty.)

❏ Razor Saw

❏ Small T-pins (HCAR5100)

❏ Medium T-pins (HCAR5150)

❏ Masking Tape

❏ Electric Power Drill

❏ 1/4-20 Tap (GPMR8105, drill bit included)

❏ Drill Bits:1/16", 3/32", 7/64", 1/8", 5/32", #18 or

11/64", 3/16", #10 or 13/64" (unless purchased with

1/4-20 Tap listed above), 7/32", 1/4", 17/64"

❏ Pliers

❏ Monofilament String for aligning wing and stabilizer

❏ Screwdrivers (Phillips and Flat Blade)

❏ HobbyLite

™

Balsa Filler (HCAR3401)

❏ Sealing Iron (TOPR2100)

❏ Bar Sander or Sanding Block and Sandpaper (coarse,

medium, fine grit)

❏ Microballoons

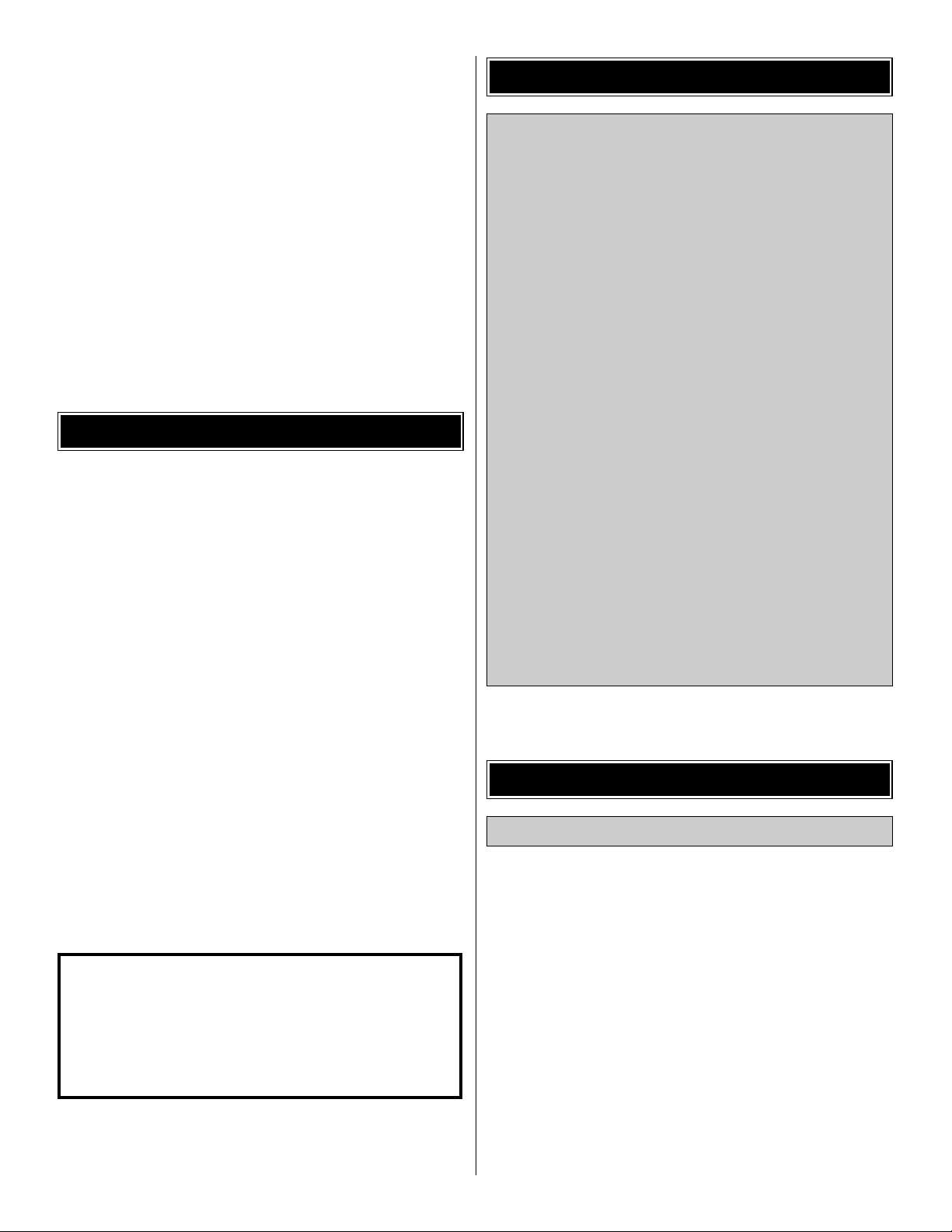

In our busy work shop we use the Great Planes

Easy-Touch

™

Bar Sanders equipped with Great Planes

#80, #150 and #220-grit Easy-Touch Adhesive-Backed

Sandpaper. Great Planes Easy-Touch Bar Sanders are

made from lightweight, rigid, extruded aluminum and can

be found at most hobby shops.

They are available in three sizes–5-1/2" (GPMR6169) and

11" (GPMR6170) for most general purpose sanding and

22" (GPMR6172) for long surfaces such as wing leading

edges. The Easy–Touch Adhesive-Backed Sandpaper

comes in 2" x 12' rolls of 80-grit (GPMR6180), 150-grit

(GPMR6183), 220-grit (GPMR6185) and an assortment

pack of 5-1/2" long strips (GPMR6189) for the short Bar

Sander. The adhesive backed sandpaper is easy to apply

and remove from your sanding bar when it's time

for replacement.

This setup is all that is required for almost any sanding

task. Custom sanders can be made from balsa or

hardwood blocks and sticks for sanding difficult to reach

spots. We also keep some #320-grit wet-or-dry sandpaper

for finish sanding just before covering.

❏ 1 oz.Thick CA- (GPMR6014)

❏ 6-Minute Pro Epoxy (GPMR6045)

❏ CA Applicator Tips (HCAR3780)

❏ Epoxy Brushes (GPMR8060)

❏ Epoxy Mixing Sticks (GPMR8055, qty. 50)

❏ CA Debonder (GPMR6039)

❏ Hot Sock (TOPR2175)

❏ Trim Seal Tool (TOPR2200)

❏ Heat Gun (TOPR2000)

❏ Single Edge Razor Blades (HCAR0312, 100 qty.)

❏ Razor Plane (MASR1510)

❏ Straightedge (Fourmost Non Slip, FORR2149)

❏ 1/8" Brass Tube, see page 17, step 10

❏ 5/32" Brass Tube, see page 33, step 15

❏ Denatured or Isopropyl Alcohol (for epoxy clean-up)

❏ Dremel MultiPro

™

or similar w/Sanding Drum, Cutting

Burr, Cut-off Wheel

❏ Kyosho

®

Curved Scissors for trimming Cowl, Wheel

Pants and Canopy (KYOR1010)

Optional Supplies and Tools

Building Supplies and Tools

4

Page 5

5

There are two types of screws used in this kit:

Sheet metal screws are designated by a number and

a length.

For example #4 x 3/4"

Machine screws are designated by a number, threads per

inch and a length.

For example 4-40 x 3/4"

When you see the term “test fit” in the instructions, it

means you should first position the part on the assembly

without using any glue, then slightly modify the part as

necessary for the best fit.

Whenever just “epoxy” is specified you may use

either

30-minute epoxy or6-minute epoxy. When 30-minute epoxy

is specified it is highly recommended that you use only

30-minute (or slower) epoxy because you will need either

the working time and/or the additional strength.

Several times during construction we refer to the “top” or

“bottom” of the model or a part of the model. For example,

during wing construction we tell you to “glue the top main

spar” or “trim the bottom of the former.” It is understood that

the “top” or “bottom” of the model is as it would be when the

airplane is right side up and will be referred to as the “top”

even if the model is being worked on upside down,

i.e.

the

“top” main spar is always the “top”main spar even when the

wing is being built upside down.

Elev = Elevator Fuse = Fuselage

LE = Leading Edge (front) LG = Landing Gear

Ply = Plywood Stab = Stabilizer

TE = Trailing Edge (rear) " = Inches

1. Unroll the plan sheets. Reroll the plans inside out to

make them lie flat.

2. Remove all parts from the box. As you do, determine the

name of each part by comparing it with the plan and the

parts list included with this kit. Using a felt-tip or ballpoint

pen, lightly write the part name or size on each piece to

avoid confusion later. Use the die-cut patterns shown on

pages 6 and 7 to identify the die-cut parts and mark them

before removing them from the sheet. Save all scraps. If

any of the die-cut parts are difficult to punch out, do not

force them! Instead, cut around the parts with a hobby

knife. After punching out the die-cut parts, use your bar

sander or sanding block to lightly sand the edges to

remove any die-cutting irregularities or slivers.

3. As you identify and mark the par ts, separate them into

groups, such as fuse (fuselage), wing, fin, stab (stabilizer)

and hardware.

Zipper-top food storage bags are handy for storing your

parts as you sort, identify and separate them into

sub-assemblies.

Get Ready to Build

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

3/4" = 19mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

15" = 381mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762mm

36" = 914.4mm

1" = 25.4mm (conversion factor)

Metric Conversions

Common Abbreviations

Balsa Basswood Plywood

Types of Wood

Building Notes

Page 6

6

DIE-CUT PATTERNS

Page 7

7

DIE-CUT PATTERNS

Page 8

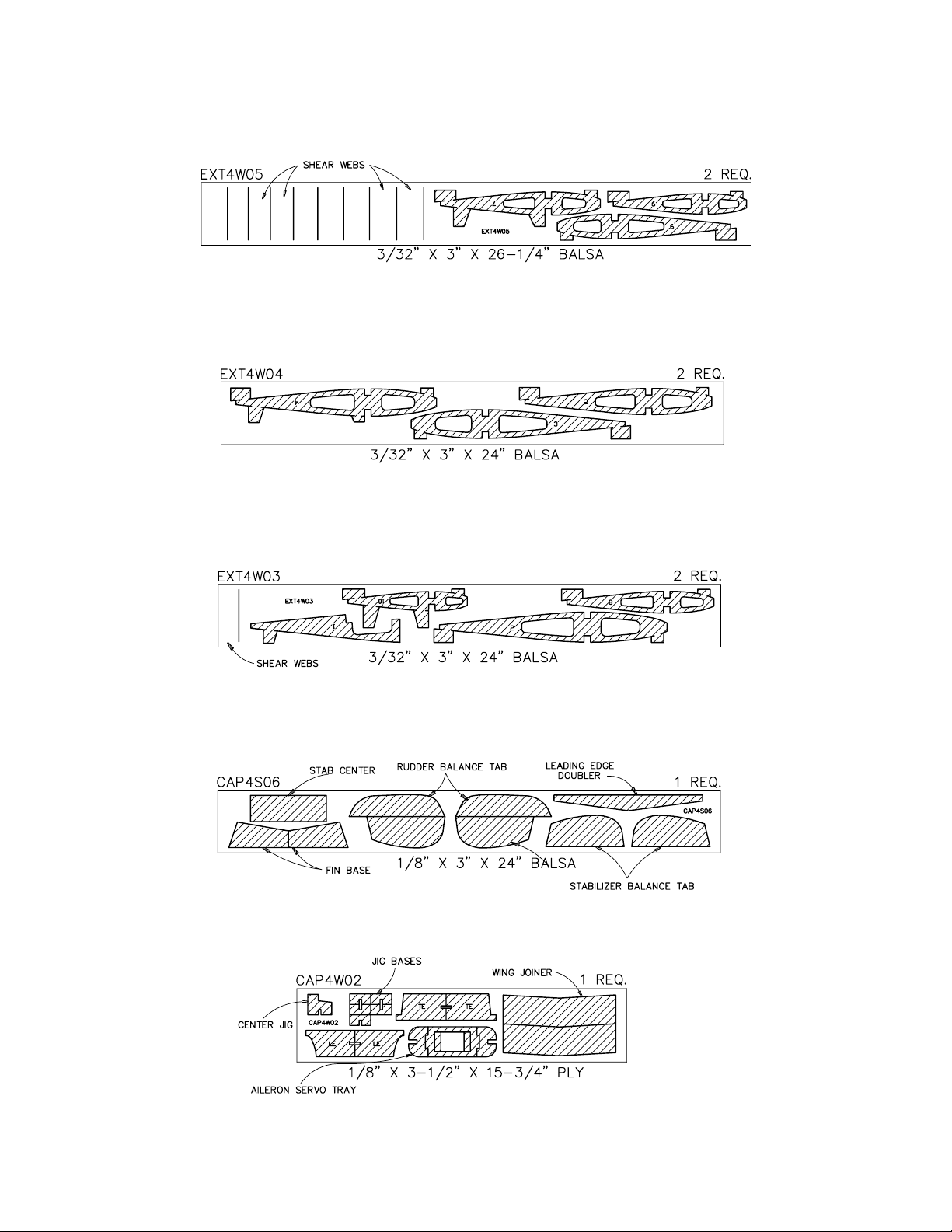

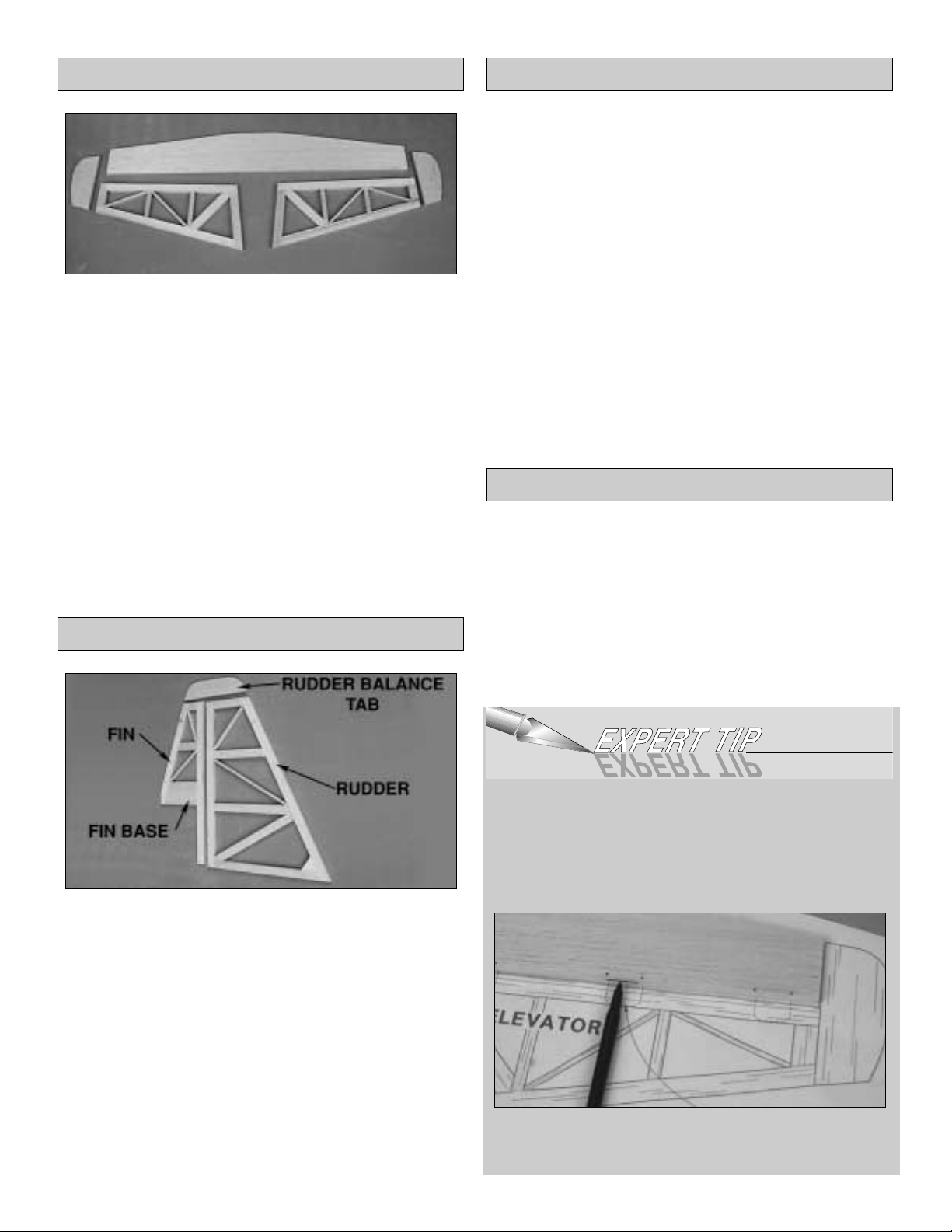

❏ 1. Cover the stab portion of the plan with wax paper or

Plan Protector. Pin the die-cut 1/8" balsa stab LE doubler

in position over the plan. Glue the die-cut 1/8" balsa stab

center to the LE doubler with medium CA.

❏ 2. Using two of the 1/8" x 1/2" x 24" balsa sticks, cut and

fit the stab LE, TE, and tips.

Hint: Use a straightedge as a guide to make sure the stab

TE is straight before pinning in place. Glue the stab LE's,

TE, and tips in place with thin CA.

❏3.From the 1/8" x 1/4" x 24" balsa stick, fit and glue the four

cross braces in place. Do the same with a 1/8" x 1/8" x 30"

balsa stick to finish the remaining cross bracing.

❏ 4. Use your bar sander or a large sanding block and

220-grit sandpaper to sand the entire top and bottom

surface of the stab framework until it is flat and even. Be

careful while sanding so you do not over-thin any one

particular area of the stab or gouge the stab cross braces

by snagging the sandpaper on them.

❏❏5. Using medium CA, glue one 1/16" x 3" x 24" balsa

sheet to one side of the stab framework, aligning the

sheeting parallel to the TE of the stab. Give the CA ample

time to cure before lifting the assembly off the work bench.

❏❏6. Place the sheeted side of the stab on your bench and

trim the sheeting around the outer edges of the framework.

❏7.Repeat steps 5 and 6 to sheet the other side of the stab.

❏ 8. Place the sheeted stab back in place over the plan

and, using the dotted lines as a reference, draw a line on

the stab. Trim the leading edge of the stab on the line you

just drew.

There, that was kind of fun wasn't it? Let's continue to build

the elevators, fin, and rudder.

❏ 9. Make two laminated elevator balance tabs from the

four 1/8" die-cut balsa pieces.Make one rudder balance tab

from the two die-cut pieces.

❏ 10. Build the elevators, fin and rudder from the 1/4" thick

balsa sticks (unlike the 1/8" sticks you used for the stab).

Recommended building sequences follow.

Note: Do not glue the elevator or rudder balance tabs in

place until the leading edges are beveled.

Note: Refrain from using excessive accelerator. Even hours

after it's sprayed on, residual accelerator can prematurely

and unexpectedly cure the CA you use later on nearby glue

joints. Unless you must handle or remove the part from your

building board right away, we recommend using no

accelerator at all.

Build the Stab

BUILD THE T AIL SURFACES

8

Page 9

A.1/4" x 1/2" LE pin in place

B.1/4" x 1/2" Root rib pin and glue

C.1/4" x 1/2" elevator tip rib fit and glue

D.1/4" x 1/2" TE fit and glue

E.1/4" x 1/4" ribs fit and glue

F. 1/8" x 1/4" diagonal ribs fit and glue

G.1/4" x 1/2" diagonal rib fit and glue

H.Remove the elevator from the plan and inspect all the

glue joints.Add CA where necessary.

I. Sand flat and smooth with bar sander and 220-grit

sandpaper. Note: Do not glue the laminated balance

tab in position until

after

you bevel the leading edge

of the elevator as instructed on page 11. This will

make it easier to sand the bevel.

J. Build the other elevator the same as the first.

A.Laminate the two die-cut 1/8" balsa Fin Bases

together and pin them in place.

B.1/4" x 1/2" TE

C.1/4" x 1/2" Fin tip

D. 1/4" x 1/2" LE (cut taper so it fits against F-9 as

shown on the plan)

E.1/4" x 1/2" center rib

F. 1/4" x 1/8" diagonal ribs

G. Remove the fin from your building board and inspect all

the glue joints. Add CA where necessary. Use your bar

sander to sand the top of the leading and trailing edges

even with the tip of the fin.Sand the bottom of the leading

edge even with the base. Sand the entire fin flat and

smooth with your bar sander and 220-grit sandpaper.

A.1/4" x 1/2" LE

B.1/4" x 1/2" Rudder bottom

C.1/4" x 1/2" TE

D.Two 1/4" x 1/2" ribs

E.One 1/4" x 1/2" diagonal rib

F. Two 1/8" x 1/4" diagonal ribs

G. Remove the rudder from your building board and

sand the top, the LE and TE so they are flush.

Note: Do not glue the laminated balance tab in

position until

after

you bevel the leading edge of the

rudder as instructed on page 11. This will make it

easier to sand the bevel.

H.Inspect all the glue joints. Add CA where necessary.

❏ 1. Place the stab over its location on the plan and

lightly

mark the hinge locations on the trailing edge with a ball

point pen. Mark the hinge locations on the elevators in the

same manner.

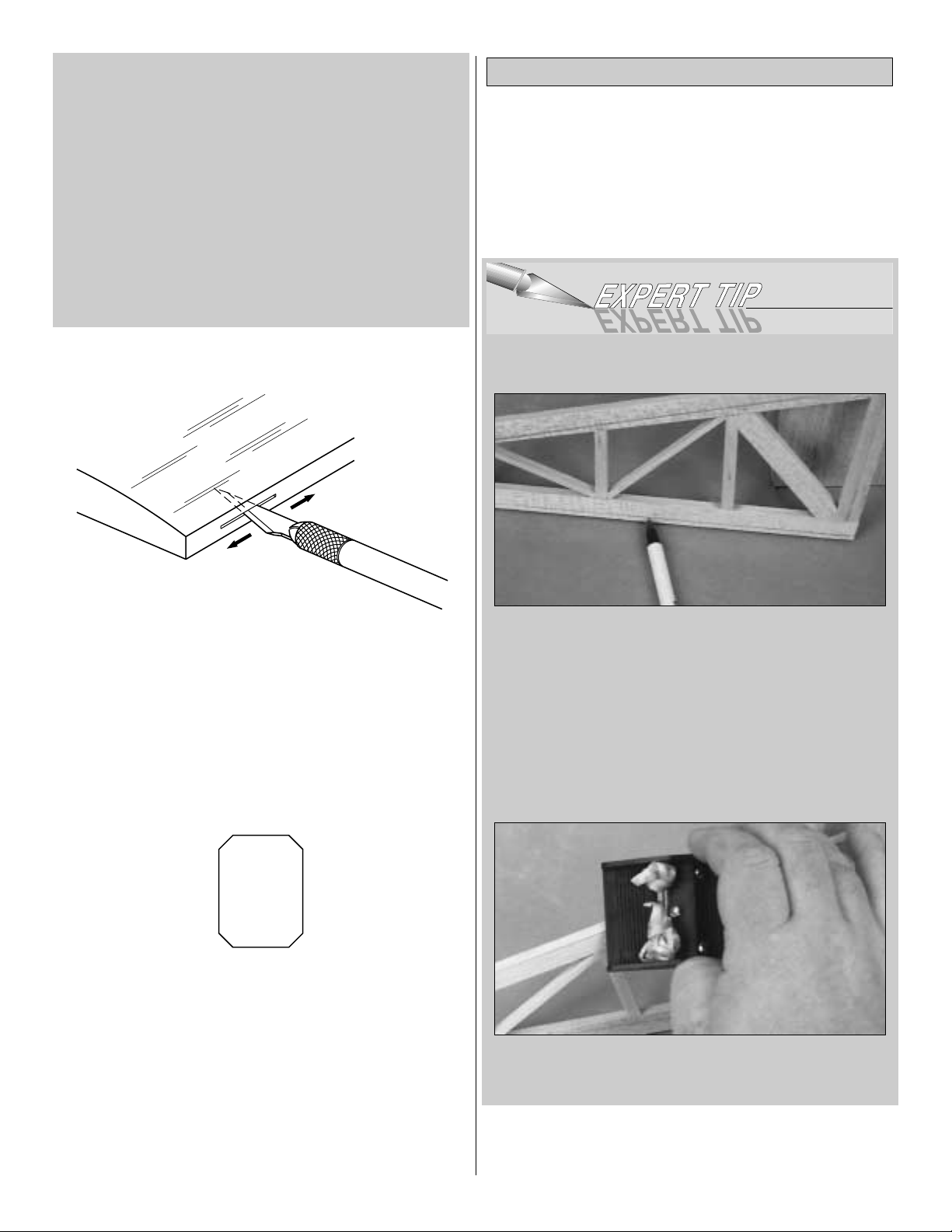

HOW TO MARK THE HINGE SLOTS

It's important that the hinge slots are centered and parallel to

the part you are hinging. The best way to start is by accurately

marking the hinge slots.We'll start with the stabilizer.

A. Lay the stabilizer and a ballpoint pen on a flat surface.

Mark a “test line” on the trailing edge of the stab, away from

the hinge locations you marked earlier.

Hinge the Tail Surfaces

Rudder Building Sequence

Fin Building Sequence

Elevator Building Sequence

9

Page 10

B.Flip the stab over and mark another line in the same location

as the first.If you see only one line, then it is on center.Proceed

and mark the hinge slots at each hinge location. If you see two

lines you will have to adjust the height of the stab until you can

mark only one centerline.

C. Use playing cards or business cards to adjust the height

of the stabilizer until you can mark the centerline. Mark the

hinge slots at each hinge location.

D. Use the same technique to mark the centerline along the

entire length of both elevators.

❏ 3. Cut the hinge slots in the elevator and stabilizer using

a #11 blade.Begin by carefully cutting a very shallow slit at

the hinge location to accurately establish the hinge slot.

Make three or four more cuts going a little deeper each

time. As you cut, slide the knife from side to side until the

slot has reached the proper depth and width for the hinge.

❏ 4. Cut 3/4" x 1" hinges for the elevators and rudder from

the supplied 2" x 9" hinge material, then snip off the

corners. Temporarily join the elevators to the stab with the

hinges adjusting any hinge slots if necessary so they all

align. Do not glue in the hinges until you are instructed

to do so.

❏ 5. Retur n to step 1 and use the same procedures to

hinge the rudder and fin.

❏ 1. Shape the leading edge of the elevators to a “V” as

shown on the plan.

HOW TO BEVEL THE LEADING EDGES

A. Place the leading edge of one of the elevators on your

work surface and use your ballpoint pen to mark a “bevel

to” line on both sides about 3/32" high.

Note: You will probably have to adjust the height of the

elevator with card stock (as you did while marking the hinge

slots) so your “bevel to” line is not too high – making too

sharp of a “V.”

B. Using the “bevel to” lines and the centerline as a guide,

make the “V” on the leading edge of the elevators with a

razor plane or your bar sander and 150-grit sandpaper.

❏ 2. Use the same procedure to bevel the leading edge of

the rudder.

Finish the Tail Surfaces

10

CUT HINGE SLOT

WITH HOBBY KNIFE

AND #11 BLADE

Page 11

11

❏ 3. Use the plan to make sure the balance tabs are

properly aligned.Then, using medium CA, glue the balance

tabs to both of the elevators and the rudder.

❏ 4. Use your bar sander and 150-grit sandpaper to round

the tail surfaces as shown on the fuse plan.

That's about it for the tail surfaces. They're a little more

work than sheet surfaces but they are much lighter, just

about as strong, and are a nice piece of craftsmanship.

Clean off your work bench and get ready for the wing!

Now while you have a nice clean work bench, let’s start the

wing by making the sheeting.

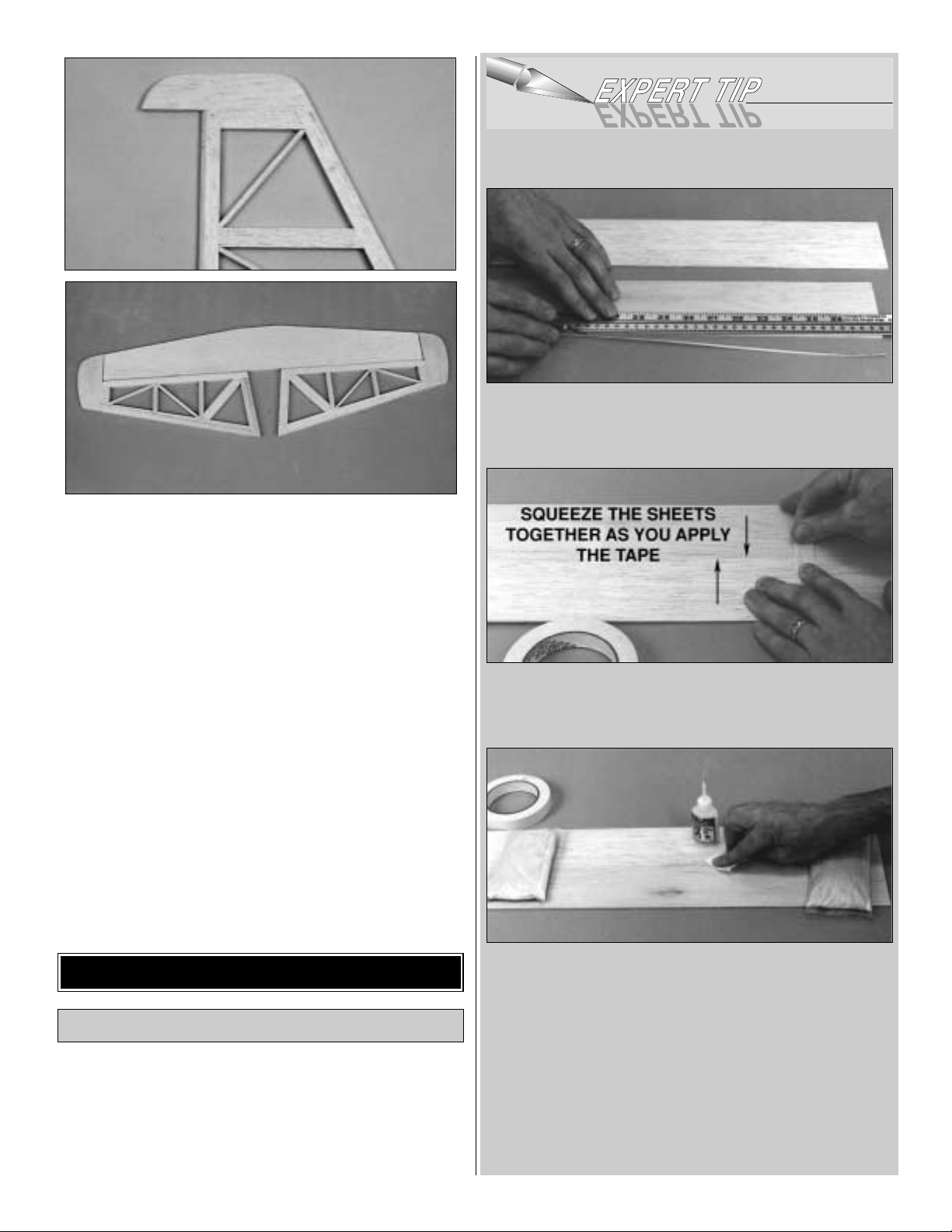

❏❏1. Glue two 3/32" x 3" x 30" balsa sheets together to

make one 6" wide sheet for the top and bottom leading

edge wing sheeting for one wing half.

HOW TO MAKE WING SHEETS

A. Use a metal straightedge as a guide to trim one edge of

both sheets.

B. Use masking tape to tightly tape the two sheets together

joining the trimmed edges.

C. Turn the sheet over and place weights on top of the

sheet to hold it flat. Apply thin CA spar ingly to the seam

between the two pieces, quickly wiping away excess CA

with a paper towel as you proceed.

D. Turn the sheet over and remove the masking tape, then

apply thin CA to the seam the same way you did for the

other side.

E. Sand the sheet flat and smooth with your bar sander and

150-grit sandpaper.

Make the Wing Sheets

BUILD THE WING

Page 12

❏❏2. Cut the sheet as shown in the photo to make a top

and a bottom LE wing sheet.

❏ 3. Repeat steps 1 and 2 to make the two leading edge

wing sheets for the other wing half.

We’ll start by building the right wing panel upside down over

the left wing panel plan so your progress matches the photos .

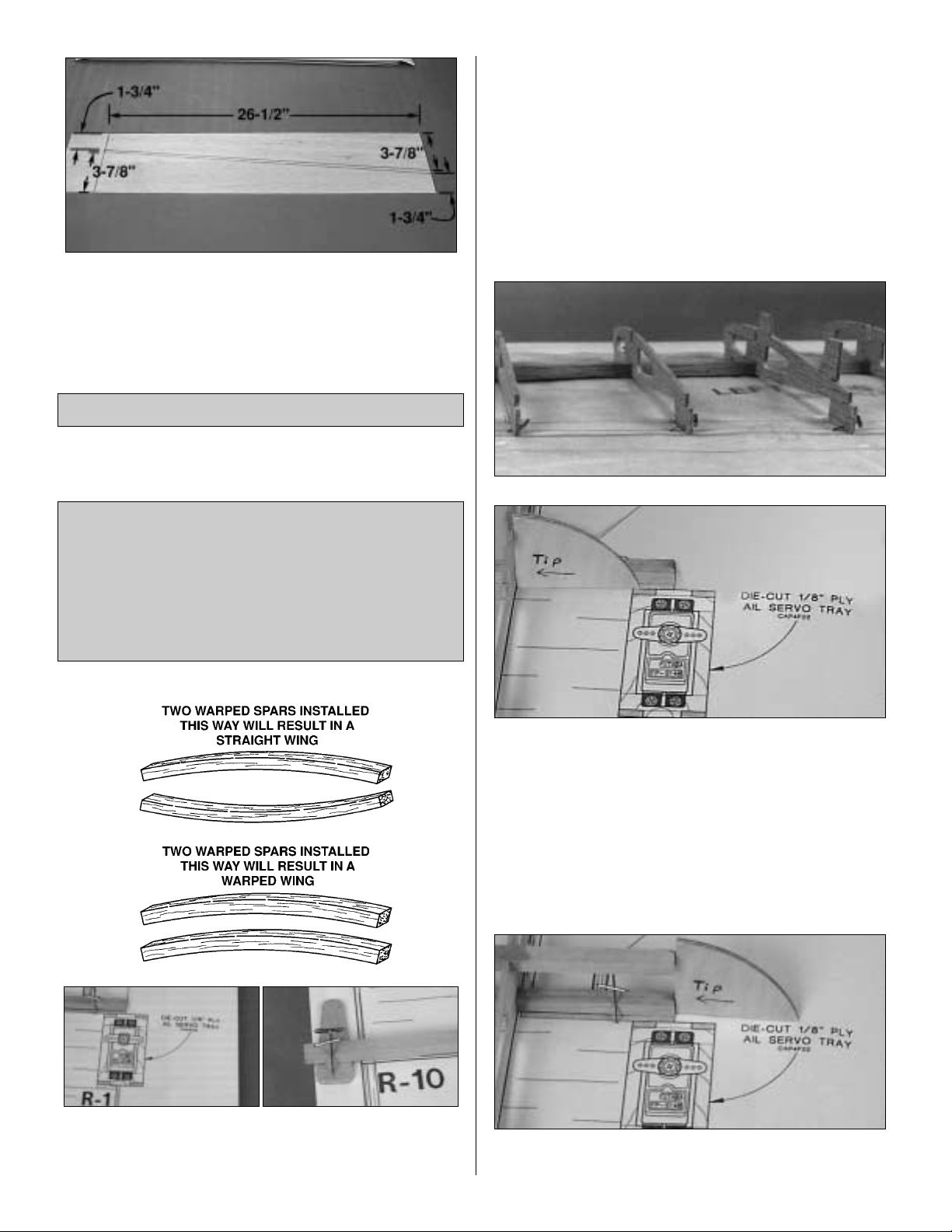

❏❏1. Using two large T-pins, cross pin the root end of a

5/16" x 5/16" x 30" basswood main spar over its location on

the plan so it lines up with the wing centerline. This is the

top spar. Cross pin the tip of the spar to the plan with a

piece of 3/32" leftover balsa under the spar past the

location of rib R-10.

❏❏2. Place (do not glue) the die-cut 3/32" balsa wing

ribs R-2 through R-10 on the top spar over their locations

on the plan. Note: The short jig tabs on every rib, should

be contacting the plan.

❏ 3. Using the dihedral gauge to set rib R-2 at the proper

angle, pin the jig tabs in place with small T-pins. Again

using the dihedral gauge, pin ribs R-2 through R-10 to your

building board over their location on the plan.

Note: Inser t the T-pins at an angle from the rear, so they

can be removed after the trailing edge and bottom sheeting

are glued in position.

❏❏4. Place a 5/16" x 5/16" x 30" spar in the notches of the

ribs, using the dihedral gauge to locate this bottom spar.

Note: Due to the decreasing thickness of the wing

towards the tip, the top

main spar

is not pinned directly

to the building board. Instead, the

ribs

are securely

pinned to the building board. You must follow the

instructions closely on where to insert the T-pins in the

ribs so you do not conceal them under the sheeting,

making it very difficult to remove the wing from the

building board.

Build the Wing Panels

12

Page 13

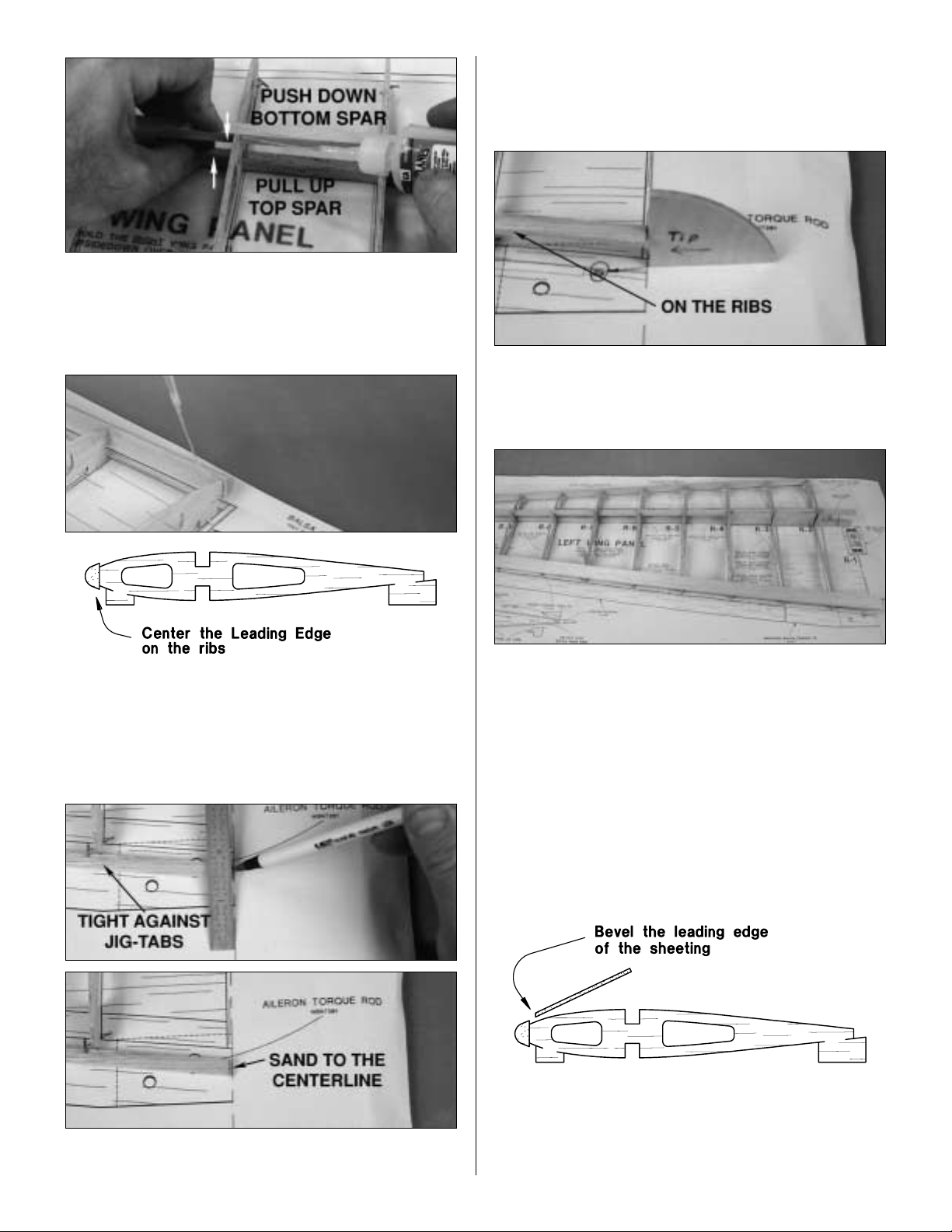

❏❏5. Glue the main spars to the ribs with thin CA. As

you glue each rib to the spars, simultaneously

pull

the top

spar up into the rib and

push

the bottom spar down into the

rib to make sure the spars are fully seated in the notches.

Make sure all the jig tabs are contacting the work surface.

❏❏6. Lightly r un a sanding bar across the front of the r ibs

to check alignment. Position the shaped leading edge (LE)

on the front of the ribs.The LE should be centered on all the

ribs and the root end should extend past rib R-2 by about

1/16". Make sure all the jig tabs are contacting the work

surface.Use thin CA to glue the LE to the front of the ribs.

❏❏7. Place the 30" balsa shaped trailing edge (TE)

against the rear of the rib tabs and flat on the work bench.

Mark the root end so that it lines up with the centerline of

the wing.Take the TE off your work bench and sand the TE

to the mark you made.

❏❏8. Using the dihedral gauge to correctly position the

TE, use thin CA to glue the trailing edge (TE) to the ends of

the ribs.

❏❏9. Starting at ribs R-8 & R-7, test fit the die-cut 3/32"

cross grain balsa shear webs to the front of the spars.

Note that the shear webs increase in height as they get

closer to the root. Glue them in place with medium CA.

There are two additional shear webs for the rib bays

between ribs 2 & 3 and 3 & 4. Glue these to the back of the

spars between these ribs with medium CA.

❏❏10. Use medium CA to glue the 3/32" x 7/8" x 30"

trailing edge sheeting to the TE and ribs so the end

extends past the wing centerline by approximately 1/8".

❏❏11. Without gluing, fit one of the leading edge sheets

to the bottom of the wing panel by sanding a bevel on the

front edge of the sheet so it matches the leading edge of

the wing.

13

Page 14

❏❏12. Before you glue the LE sheeting in position,

remove the T-pins from the front jig tabs in the wing ribs.

❏❏13.Wet the outside of the leading edge sheeting so it

will bend easier. (Hint: a 50/50 mix of water and alcohol or

ammonia helps break down the wood fibers so the sheet is

even easier to bend). Run a bead of medium CA down the

leading edge of the sheeting. Position the front of the sheet

against the LE of the wing and use accelerator to hold it

there.Wet the sheet once more if needed.

❏❏14. Carefully lift the sheeting away from the ribs.

Working quickly, apply a bead of medium or thick CA to the

top of each rib where the sheeting contacts the spar.

Pull

the sheeting back toward the main spar as you

press

it

down to the ribs and spar. Use masking tape, T-pins or

weights to hold the sheeting to the ribs until the CA cures.

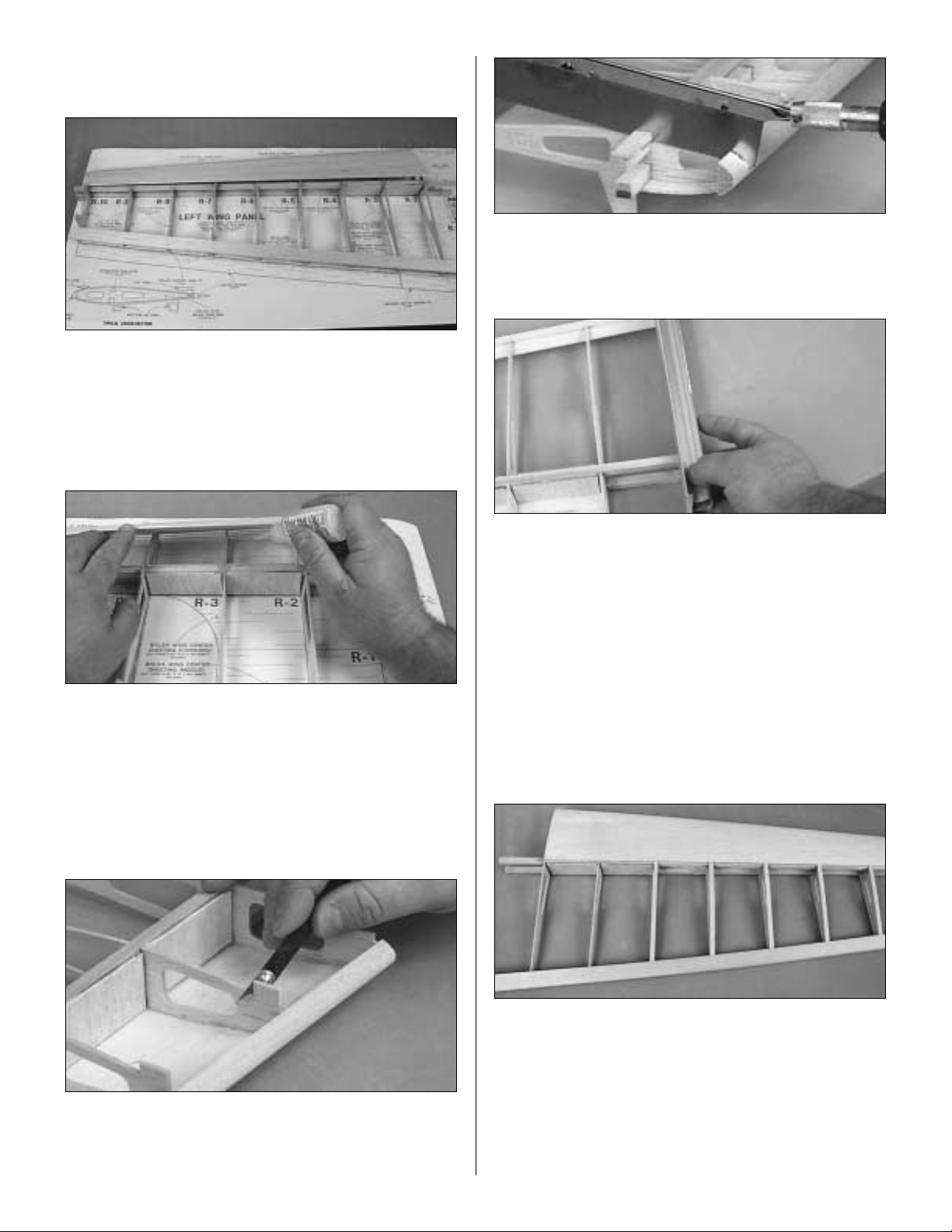

❏❏15. Remove the T-pins, then flip the wing half over on

your building board.

❏❏16. Use a sharp hobby knife to remove the tabs from

the top of the wing. Use a sanding block with 220-grit

sandpaper to clean the edges of the ribs where the tabs

have been removed.

❏❏17. Using a razor saw, trim the spars, LE, TE, LE

sheeting, and TE sheeting flush with R-10.Also trim the LE

and LE sheeting flush with the edges of R-2.

❏❏18. Using the spars and the TE as a guide, sand off

the TE sheeting at the root of the wing.

Note: DO NOT SAND the shaped TE or the spars.

❏ 19. Glue the TE and LE sheeting onto the top of the

wing following the same procedures you used on the

bottom of the wing. (Steps 10-14)

❏ 20. Trim and sand the TE and LE sheeting using the

same procedures you did on the bottom of the wing.

(Steps 16-18)

❏❏21. From the 3/32" x 1/4" x 24" balsa sticks, cut cap

strips and use medium CA to glue them to the top and

bottom of ribs R-4 thru R-10.

Note: Do not put cap strips on R-2 or R-3, as they will be

sheeted after the wing halves are joined.

❏ Repeat steps 1 through 21 to build the left wing panel

over the right wing drawing on the plan.

14

Page 15

Note: The designer wishes to assure you that the specified

dihedral is correct. Although somewhat out of scale, this

dihedral angle is required to eliminate roll coupling, thus

providng you with a more neutral airplane. A side benefit of

the dihedral is better low speed stability.

❏ 1. From the 1/8" die-cut ply pieces make the five wing

jigs as shown in the photo above.

❏ 2. Without using any glue, test join the wing panels on

the jigs as shown. Make sure the ends of the spars and

TE’s join without any gaps.

❏ 3. Place wax paper under the center of the wing to catch

excess epoxy. When satisfied with the fit, glue the dihedral

braces to the spars with 30-minute epoxy by spreading a

film of epoxy on

both

the spars

and

the dihedral braces,

followed by C-clamps to hold them in place. Once the

C-clamps are tightened, wipe away excess epoxy before it

cures. Place weights on top of your wing to hold it in place

on the jigs.

❏ 4. Glue the TE’s together with thin CA.Do not disturb the

wing until the epoxy cures.

❏ 5. Trim the tabs off of both R-1 wing ribs. Laminate the

two R-1's together with medium CA.

❏ 6. Glue the laminated R-1 in place aligning the bottom of

the rib with the bottom of the spars.

Join the Wing Panels

15

Page 16

❏ 1. Use medium CA to glue the die-cut 1/8" ply aileron

servo tray and supports in position.Glue the die-cut 1/8" ply

aileron servo tray doublers to the bottom of the aileron servo

tray. Test fit your aileron servo and adjust the notch in rib R-1,

if needed, so the aileron servo will fit.Remove the servo.

❏ 2. Cut the 3/32" x 3" x 36" balsa sheet into one 17-1/4"

long sheet and one 18-3/4" long sheet. Cut the 17-1/4"

piece in half, making two 8-5/8" long pieces. Cut the

18-3/4" piece in half, making two 9-3/8" long pieces.

❏ 3. Cut a curve on the end of one of the sheets, using the

plan as a guide. The curve does not have to be an exact

match. Use that one as a template to mar k and cut the

three other sheets.

❏ 4. Fit and glue the two 8-5/8" long pieces to the top of

the wing.

❏ 5. Fit and glue the two 9-3/8" long pieces to the bottom

of the wing.

❏ 6. Cut pieces from a 3/32" x 3" x 30" balsa sheet to

cover the middle portion on the top and bottom of the wing.

❏ 7. From the remaining 3/32" x 3" x 30" balsa sheet, cut a

7" long piece. Using that 7" piece, cut and fit the aft center

section sheeting.

❏ 8. Using leftover 3/32" balsa, sheet the forward center

section over both top and bottom spars .Sand the sheeting

flush with the dihedral joiner.

❏ 1. Bevel the ends of the tapered, grooved balsa center

trailing edges so they join as shown on the plan. Test fit

the center TE's on the wing.

Build the Ailerons

Sheet the Wing

16

Page 17

❏ 2. Place the center TE's over the wing plan and mark the

location of the aileron torque rods. Cut notches at the

marks to clear the torque rods. Test fit the torque rods to

make sure the notches allow enough clearance.

❏ 3. Position the center TE's on the wing TE with the

torque rods installed, then mark the location of the notches

on the wing TE. Cut the notches in the wing TE at the

marks you made. Test fit the center TE's with the torque

rods to make sure the notches align and are large enough

to allow for proper aileron deflection.

❏ 4. Use coarse sandpaper to scuff the nylon tube

bearings on the aileron torque rods so the glue will stick.

❏ 5. Use 30-minute epoxy to simultaneously glue the nylon

bearing tubes in the center TE's and glue the center TE's to

the wing. IMPORTANT: Before gluing, use a tooth pick to

apply a dab of petroleum jelly to the ends of the nylon tubes

to keep the epoxy out.Tape the TE's edges to the wing until

the epoxy cures. Wipe away excess epoxy before it cures

and do not let epoxy get into the nylon bearing tubes.

❏❏6. Position the left aileron on the trailing edge of the

wing, then mark the location of the torque rod. Using a

straightedge, mark the end of the aileron where it meets the

wing tip.

❏❏7. Cut the aileron approximately 1/16" shor ter than

the mark you made at the tip so it will fit in the wing.

❏❏8. Use a draftsman's square to extend the torque rod

marks to the front of the aileron, then use the "centerline

technique" we've shown you before to mark the centerline

on the entire leading edge of the aileron.

❏❏9. Use the centerline and the marks you made earlier

as a guide to drill a 1/8" hole, 3/4" deep in the aileron for the

torque rod.

❏❏10. Refer to the Exper t Tip that follow, then cut a 1/8"

groove in the leading edge of the aileron.

HOW TO CUT A GROOVE FOR AILERON TORQUE ROD

A. Use a #11 knife blade to sharpen the inside end of a

piece of 1/8" brass tube. Roll the tube as you

carve

the

end. If you have a file or a cut-off wheel it helps to sharpen

the outside of the end of the tube as well.

17

Page 18

B. Use the shar pened tube to

carefully

gouge the leading

edge of the aileron.You'll have to make a few cuts to make

the recess deep enough for the torque rod.

❏❏11. Test fit the aileron to the wing to make sure the

torque rod fits and there is approximately 1/16" clearance

between the aileron and the root of the wing with the

aileron aligned at the tip.Make adjustments if necessary.

❏❏12. Mark the location of the hinges on the aileron and

the wing. Cut the hinge slots.Without using glue, test fit the

aileron to the wing with the hinges.

❏❏13. Remove the aileron from the wing. Mark the

"bevel to" lines and shape the leading edge of the aileron to

a "V" as shown on the plan the same way you did for the

elevator and the rudder.

❏ 14. Perform the same steps to shape the right aileron

and fit it to the wing.

❏ 15. Sand approximately 5/16" into the TE at the

centerline. (The flat will end up approximately 4-3/4" wide).

❏ 16. Use lightweight balsa filler such as HobbyLite to fill

glue joints or dents in the wing. After the filler has fully dried

use your bar sander to sand the wing using progressively

finer grades of sandpaper so it is smooth and all the joints

are blended.

❏ 1. Use 30-minute epoxy to glue the firewall formers

F-1A and F-1B together. Make sure the embossed label on

F-1A is facing UP and the edges and tabs on both formers

are aligned. Wipe away excess epoxy before it cures. From

now on this assembly will be referred to as thefirewall.

Note: If the formers are warped, simply clamping them

together may not "cancel out" the warps. It is best to clamp

the formers to a table or a flat board until the epoxy cures.

❏ 2. Use a straightedge and a ball point pen to draw a line

across the

tab

connecting the notches in the front of only

one of the fuselage sides. Use the line as a guide to

remove the tab with a #11 knife blade. On the inside

surface, label this as the RIGHT fuselage side.

Assemble the Fuse Formers & Sides

BUILD THE FUSELAGE

18

Page 19

❏ 3. Lay the other fuselage side next to the right side as

shown in the photo and label it on the inside as the LEFT.

It is important that you lay the fuselage sides in a mirrored

position to insure that you build a right and a left half.

❏ 4. Use medium CA to accurately glue a fuselage

doubler to the inside of the right fuselage side. Make sure

the doubler aligns with the fuselage side where the arrows

indicate in the photo.

❏ 5. Glue the left fuselage doubler to the left fuselage side

in the same manner.

❏ 6. Drill a 3/16" hole through each of the punch marks in

formers F-3, F-5 and F-7

Hint: Place the formers on a scrap piece of wood and

press down as you drill the hole so the former does not

split when the drill goes through.

❏ 7. Draw center lines connecting the outer punch marks

on the firewall. Drill 5/32" holes for the engine mount bolts

at the four engine mount punch marks. Drill a 3/16" hole for

the throttle pushrod at the punch mark. Drill two 7/32" holes

for the fuel line.

❏ 8. Press four supplied 6-32 blind nuts into the holes on

the back of the engine mount. Gently tap the blind nuts with

a hammer to fully seat them into the firewall. Add a few

drops of thin CA around the blind nuts to secure them.

❏ 9. Align the F-3 doublers over the die-cut holes in F-3,

and glue them in place using medium CA.

19

Page 20

❏ 1. Pin the die-cut fuse top in position over the fuselage

bottom view on the plan.Make sure the front of the fuse top

lines up with the firewall on the plan, as this sets the

right thrust.

❏ 2. Pin the die-cut fin plate in place, using the die-cut

stab base to correctly locate it. After you have the fin plate

pinned in position, remove the stab base.

❏ 3. Place formers F3, F5, F7 and F8 in position on the fuse

top.The doublers on F3 face forw ard, to ward the nose.

❏ 4. Fit the left fuse side to the formers and fuse top. Do

not glue.

❏ 5. Fit the right fuse side to the formers and fuse top.

❏ 6. Fit the fuse bottom in place. Note: the landing gear

base does not get installed until after the wing is mounted.

❏ 7. Using a square, check that the fuse sides are

perpendicular to the work bench. Using thin CA, glue each

former to the fuse top, bottom and sides. Double check

every former to make sure it is square.

Note: The interlocking construction this Great Planes kit

allows you to quickly assemble the fuselage upside down

on the plan while maintaining alignment.You will be fitting

most of the die-cut fuselage parts together before

applying glue. Do not use any glue until instructed to

do so.

Assemble the Fuselage

20

Page 21

21

❏ 8. Glue the fuse sides to the fuse top and bottom with thin

CA.Leave the fuse assembly pinned to your work surf ace.

❏ 9. Fit two of the die-cut 1/8" ply bolt plates in place on

the fuse and mark as shown in the photo.

❏ 10. Using medium CA, laminate the two marked plates

onto the two unmarked plates.

❏ 11. Mark 1/16" down on the TE of each laminated block.

Using your bar sander, sand a taper between the two lines.

❏ 12. Using 6-minute epoxy, securely glue the wing bolt

blocks in place.

❏ 1. Sand the entire wing saddle area lightly until the fuse

side doublers and fuse sides are flush.

❏ 2. Trial fit the wing on the fuse. If the wing is slightly too

large (front to rear) to fit into the saddle, sand the TE of the

wing slightly until it fits.

❏ 3. Center the wing side to side as follows:Stick a T-pin in

F-3 aligned with the center mark. Tie a piece of string

around the T-pin. Pull the string to the wing tip and put a

piece of masking tape on the string at the wing tip. Mark an

arrow on the tape, then slide the tape on the string so the

arrow aligns with the wing tip. Swing the string over to the

other tip and see if it aligns with the other wing tip. If

necessary, shift the wing and mark the location of the tip by

adjusting the position of the tape on the line. Do this until

the arrow on the string aligns with both tips. Measure down

from the bottom of both tip ribs to the flat surface. If the

measurements are not equal (within 1/16"),sand the saddle

until the wing sits level.

❏ 4. While holding the wing firmly in place, drill 1/4" holes

through the front and back dihedral braces as shown.

Remove the wing from the fuse.

Mount the Wing to the Fuselage

Page 22

❏ 5. Slightly round one end of a 1/4" x 1-1/8" wing dowel.

Using 6-minute Epoxy, glue the dowel in the wing leaving

3/8" protruding from the front of the dihedral brace.

❏ 6. Allow ample time for the epoxy to cure. Then, fit the

wing back onto the fuse, drill the second dowel hole,

remove the wing, and glue the second dowel in place.

Time to use your string again.

❏ 7. Stick the T-pin through the center of the aft end of the

fuselage bottom. Pull the line to the TE of the wing tip and

move your tape to that point. Swing the string over to the

other tip and see if it aligns with the same point. If

necessary shift the wing and mark the location of the tip by

adjusting the position of the tape on the string. Do this until

the arrow on the string aligns with both tips.

❏ 8. Now that the wing is accurately aligned, glue the wing

bolt plate in place on the wing, being careful not to glue the

wing to the fuse.

Note: The punch marks in the wing bolt plate are closer to

the TE of the bolt plate.

❏ 9. Holding the wing firmly in place, drill 13/64" holes

through the punch marks in the bolt plate, drilling through

the wing and the laminated bolt blocks. Try to drill straight

in, perpendicular to the bolt plate. Note: Do not allow the

wing to move while drilling.

❏ 10. Remove the wing and re-drill the holes in the wing

only to 17/64".

❏ 11. Use a 1/4-20 tap and a tap wrench to cut threads in

the laminated bolt blocks in the fuselage.

❏ 12. Harden the threads in the bolt blocks with thin CA,

then re-tap the threads after the glue is completely dry.

We are almost ready to unpin the fuse from the building

board -- just a few more steps.

22

Page 23

❏ 13. Glue the 1/4" ply landing gear rail in position with

6-minute epoxy.

❏ 14. Glue the landing gear base in place with thin CA.

❏ 15. Center the landing gear between the tabs on the

landing gear base, and drill 13/64" holes through the landing

gear base and rail, making sure the gear does not shift.

❏ 16. Install 8-32 blind nuts supplied with this kit into the

landing gear rail from inside the fuselage. Use the 8/32" x

3/4" socket head cap screws through the landing gear to

pull the blind nuts into position.

❏ 17. Glue F1C in place with thin CA.

Finally. It’s time to un-pin the fuse from your work table.

❏ 18. Double check all of the glue joints. Reinforce with

medium CA as needed.

❏ 19. Install the wing onto the fuse.

❏ 20. Cut the 3/16" x 1-3/4" x 10" balsa stick in half,

making two 5" wing root spacers. Use a playing card or

business card to shim between the spacers and the fuse.

Use medium or thick CA to glue the balsa wing root

spacers to the wing.

Note: It may be necessary to sand the spacers slightly

thinner, or to apply filler to result in a 1/32" gap between the

spacers and the fuse.

23

Page 24

❏ 21. After the filler has fully dried, remove the wing from

the fuselage. Cut and sand the spacers and the filler to

match the contour of the wing.

❏ 22. Cut a 36" plastic outer pushrod tube in half,

making two 18" lengths. Sand the outside of the tubes with

coarse sandpaper so the glue will stick.

❏ 23. Install the tubes through the guide holes in the

formers. Approximately 1" of the tubes should protrude

outside the slots at the aft end of the fuse.

❏ 24. Glue the tubes into the slots at the end of the

fuselage with microballoons and epoxy. Completely fill the

slot with the microballoons and epoxy so it can be sanded

flush later.Glue the tubes to the formers with medium CA.

❏ 25. After the epoxy has cured, use your bar sander and

150-grit sandpaper to sand the outer pushrod tubes and

epoxy filler flush with the fuselage sides.

❏ 26. Glue the stab base in place with thin CA.

❏ 27. Use 30-minute epoxy to glue the firewall in position.

Use masking tape or clamps to hold the firewall until the

epoxy cures.

❏ 28. From the 3/8" x 3/8" x 12" balsa triangle , cut two

pieces 1-1/4" long. Glue them in place on top of the

laminated wing bolt blocks with 6-minute epoxy.

❏ 29. From the remaining 3/8" x 3/8" balsa triangle, cut

pieces to fit and glue them to the back of the firewall with

6-minute epoxy.

24

Page 25

❏ 30. Sand the fuselage sides flush with the firewall. Sand

the bottom of the firewall flush with F1C.Sand the bottom of

F1C flush with the landing gear base.

Note:The front and the rear of the front deck use the same

pieces (F-2), but the front F-2 is 90 degrees to the fuse

and the rear F-2 must to be set at an angle using the IP

(instrument panel) gauge.

❏ 1. Using a 90 degree triangle for alignment, glue the

front die-cut 1/8" plywood F2 in place.

❏ 2. Use the IP gauge while gluing the rear die-cut 1/8"

plywood F2 in place.

❏ 3. From the 1/8" x 1/4" x 30" balsa stick, cut an 8" piece

for the front deck main stringer. Glue this stringer into the

notches in both F2's.

❏4.From the 1/8" x 1/8" x 30" balsa stick, cut two 7-1/8" long

gluing stringers. Use a straightedge held on top of both F2's to position the right gluing stringer. With medium CA,

attach the gluing stringer to the right side of the main stringer.

❏ 5. Glue the left gluing stringer in place on the left side of

the main stringer.

❏ 6. From the same 1/8" square balsa, cut two more

pieces 7-5/8" long. Glue these in place at the bottom

corners of both F-2's on both sides.

❏ 7. Edge glue two 3/32" x 3" x 18" balsa sheets together.

Use your draftsman’s square to mark a centerline, then cut

the two sheets in half, making two 6" x 9" sheets.Cut each

piece so that it measures 9" x 3-1/2" as shown in the photo,

making the front deck sheeting.

Build the Front Fuselage Deck

25

Page 26

❏ 8. Use medium CA to glue the front deck sheeting to the

main stringer, keeping it down tight against the gluing

stringer.Do not try bending the sheeting yet.

❏ 9. Wet the sheet with the water and alcohol solution, then

carefully test bend it into position. Some tr imming may be

necessary to get a good fit. Apply more water and alcohol if

needed to bend the sheet. Apply medium CA to the formers

and to the bottom gluing stringer, and press the front deck

sheeting in place.Use masking tape to hold it in place.

❏ 10. After the water has evaporated remove the tape. Fit

and glue the other sheet to the fuselage.

❏ 11. Use your bar sander and 150-grit sandpaper to sand

the sides and top of the front deck sheeting so they are

even with the fuse sides. Trim the ends of the sheeting so

they are flush with both F-2's.

❏12.Sand the main stringer so it blends with the sheeting.

❏ 1. If you have not already done so, make sure the stab

and fin are final sanded to a smooth finish, as it will be a little

more difficult to do so after they are glued to the fuselage.

❏ 2. Mount the wing to the fuselage, then position the stab

on the fuselage.Stand about six to ten feet behind the model

and see if the stab is even with the wing. If necessary, use

your bar sander to make adjustments by sanding the stab

base until the stab is in alignment with the wing.

❏ 3. Accurately measure the trailing edge of the stabilizer

and use a ball point pen to lightly mark the center. Use the

same procedure to mark the center of the fin plate where

the trailing edge of the stab will contact it.

Mount the Stabilizer to the Fuselage

26

Page 27

❏ 4. Place the stab on the stab base with the center marks

aligned, then use a large T-pin to pin only the trailing edge

of the stab to the stab base.

❏ 5. Stick a T-pin through the forward fuse deck sheeting

above F2 in the center of the middle stringer, then use the

"pin and string technique" to accurately align the stab with

the fuselage. Once the stab is accurately aligned, pin the

LE of the stab to the stab base.

❏ 6. Carefully tur n the fuselage over and use a ball point

pen to lightly mar k where both fuselage sides contact the

bottom of the stab.

❏ 7. Remove the stab from the stab base but leave the

T-pins in the stab. Apply a film of 30-minute epoxy to the

stab base and to the stab between the lines you marked

indicating the fuselage sides.

❏ 8. Reposition the stab on the stab base and reinsert the

T-pins into the same holes. Use the string to confirm the

stab alignment. Then, use weights, more T-pins or clamps

to hold the stab in position.Wipe away excess epoxy before

it cures. Recheck alignment. Do not disturb the model until

the epoxy cures.

❏ 1. Glue the die-cut 1/8" ply “backrest”(F4) to the fuse top,

using the “backrest gauge”(BR) to set it at the correct angle.

Note: The gauge is used only for setting the angle (do not

glue the gauge in).

❏ 2. Use a square to position and glue the die-cut 1/8" ply

formers F-6, F-9, and F-10 vertically, at 90 degrees to the

fuse top.

❏ 3. Glue the remaining 1/8" x 1/4" balsa main stringer to

the top of the turtle deck formers. Be sure to keep it

centered on F-4, F-6, F-9 and tight in F-10. After the glue

cures cut the stringer flush with the rear of F-10 and the

front of F-4.

❏ 4. Glue the four 1/8" x 1/8" balsa gluing stringers in

place as you did on the front deck, using a straightedge.

Build the Turtledeck

27

Page 28

❏ 5. Edge glue three 3/32" x 3" x 18" balsa sheets

together, making a 9" x 18" sheet.

❏ 6. Prepare the two tur tle deck sheets by cutting the

balsa sheet you made in step 5 to the sizes shown in

the sketch.

❏ 7. Glue both turtle deck sheeting pieces to the fuse top

as shown.

Note: The grain runs parallel to the top stringer, NOT the

fuse top.

❏ 8. Wet the outside of the sheeting with your water and

alcohol solution. Wrap the sheeting around the formers and

tape it in place. Let the sheeting dry before trying to fit the

sheeting to the main stringer.

❏ 9. Now that the sheeting has conformed to the turtle

deck shape, trim the top edge so that the sheeting fits tight

against the gluing stringer. Glue the sheeting to the gluing

stringer, main stringer, and formers.

❏ 10. Sand the sheeting flush with the rear of F9 and the

front of F4.

❏ 11. Cut the 5/8" x 1" x 8-7/8" balsa stick into two 4" long

fin fillets. Hold the 1/4" x 1" x 4" balsa dummy fin

centered on and vertical to the fin base. Mar k THE FIN

BASE on both sides with a pen.

Note: It is VERY IMPORTANT that the dummy fin align with

the centerline of the fuse. A good way to check this is to

sight down the dummy fin, aligning it with the main stringer

on the turtle deck.

28

14"

1-1/16"

17"

5-1/4"

Page 29

❏ 12. Glue one side of the fin fillet to the fuse top and

former F-9. DO NOT GLUE it to the dummy fin. Allow the

glue to dry thoroughly before gluing the other fin fillet

in place.

Note: The dummy fin is only used as a temporary spacer,

so don't glue it in place.

❏ 13. Carve and sand the fin fillets and dummy fin to blend

smoothly with the fuse sides and the turtle deck.

Note: Masking tape around the stab at the root will make it

less prone to nicks while sanding the fillets.

❏ 14. If you have not already done so, final sand the fin.

Remove the dummy fin and put the fin in its place. Before

gluing, double check to make sure the fin aligns with the

fuse centerline. Glue the fin in place with 30-minute epoxy.

Use clamps to hold the fuse sides tight against the fin until

the epoxy has thoroughly cured.

❏ 1. Cut the "spreader bar" from the supplied Great Planes

engine mount, then use a hobby knife to remove any

flashing left over from the molding process so the halves fit

together well.

❏ 2. Temporarily mount the engine mount to the firewall

with four 6-32 x 1" Phillips head machine screws and #6 flat

washers. Do not tighten the screws all the way, because

you still need to adjust the mount.

❏ 3. Place your engine on the mount and slide the halves

in or out until the engine fits properly. Position the mount so

the molded-in "tick marks" are equally spaced on both

sides of the horizontal centerline you drew. When the

engine mount is adjusted and positioned, tighten the

mounting screws.

❏ 4. Position the engine on the mount so the front of the

drive washer (or the back of the spinner) is 4-7/8" away

from the firewall. Mark and drill 7/64" engine mounting

holes for the #6 x 3/4" engine mounting screws. Mount

the engine.

Mount the Engine

29

Page 30

HOW TO ACCURATELY MARK AND DRILL THE ENGINE

MOUNTING HOLES ON THE ENGINE MOUNT

A. Use C-clamps to hold the engine in position.

B. Heat the end of a shar pened wire rod and mark the center

of the engine mounting holes on the engine mount.It just takes

a little pressure from the heated rod to dimple the plastic.

C. Remove the engine, then use a pin vise or an electric

drill to start the holes with a 1/16" drill bit.

D. Remove the engine mount from the fuselage. Use a drill

press or your hand held electric drill to drill the 7/64" holes.

Optional: Modelers who prefer to mount their engine with

machine screws instead of sheet metal screws should drill

the engine mounting holes with a #36 drill, and tap the

holes with a 6-32 tap. 6-32 x 3/4" screws (not supplied)

are recommended.

❏ 1. Assemble the fuel tank per the manufacturer’s

instructions. Connect approximately 12" of fuel tubing to the

fuel pick-up fitting on the tank and 12" of fuel tubing to the

pressure fitting.

❏ 2. Attach the battery and the tank to the die-cut 1/8" tank

floor (TF) with nylon tape as shown in the photo. Make sure

the embossed labelTF is towards the tank.

Note: If you are using the OS .46 FX engine, the battery

should be installed on the tank mount as shown. If you are

using the OS .70 Surpass, then install the battery on a

left-over piece of 1/8" ply at the location shown on the plan.

❏ 3. Attach the receiver, wrapped in foam, to the 1/8"

die-cut receiver tray (RT) with nylon tape.

❏ 4. Fit the TF in the fuse as shown. The front tab fits in

the slot in the bottom of the firewall and the rear tab fits in

the slot in F-3. Attach the die-cut 1/8 ply tank floor retainer

to F-3 with two #2 x 3/8" sheet metal screws.

Note: This method of mounting the tank makes it easy to

remove the tank and battery. However, after final assembly

it will be necessary to first remove the throttle and elevator

servos to remove the tank.

Install the Battery & Tank

30

Page 31

31

❏ 5. Install the die-cut 1/8" ply tank hatch with two #2 x

3/8" sheet metal screws.

❏ 1. Use coarse sandpaper to roughen the outside of the

throttle pushrod tube so glue will stick. Use medium CA to

glue the pushrod outer tube into F3 and the firewall.Cut the

pushrod outer tube flush with the outside of the firewall.

❏ 2. Bend and cut the 17-1/2" throttle pushrod wire to fit

your engine installation using the drawing on the fuselage

plan as a guide.Install a nylon clevis and insert the pushrod

through the guide tube. Make adjustments to the bends in

the wire so the pushrod aligns with the carburetor arm on

the engine, then temporarily connect the clevis to the carb

arm. Temporarily mount the muffler and make sure the

throttle pushrod will not interfere with the muffler. Make

adjustments to the bends in the wire if necessary.

❏ 3. Place the throttle servo in the servo tray. Temporarily

install the brass Screw Lock Pushrod Connector into the

throttle servo arm, then adjust the bend in the throttle

pushrod if necessary and fit it into the connector. When

satisfied with the fit of the pushrod, mount the servo to the

servo tray with the screws provided with the radio system.

❏ 4. Cut 11" off one end of one of the 35" wire pushrods.

Cut 13" off the end of the other 35" wire rod. Set the short

pieces aside and save them for the aileron pushrods.

Thread a nylon clevis about 20 turns onto the end of one of

the long rods, then remove the backing plate from a nylon

control horn and connect the clevis to the horn using the

outer hole. Make another pushrod assembly from the other

long rod with a clevis and control horn, in the same manner.

❏ 5. Inser t the pushrods into the pushrod tubes. Position

the control horns on the elevators as shown in the sketch

and on the plan. Use a ballpoint pen to mark the location of

the control horn mounting holes and drill 3/32" holes

through the elevators at the marks. Temporarily mount the

control horns to the elevators with the backing plates and

2-56 x 5/8" screws.

Install the Servos & Make the Pushrods

Page 32

❏ 6. With the elevator servo set in place, the servo control

horn centered and the control surfaces in their neutral

position, use a felt tip pen to mark where the longer

pushrod crosses the mounting holes in the servo arm.

❏ 7. Disconnect the clevis from the control horn on the

wire you marked. Make a 90 degree bend at the mark you

made. Temporarily install a nylon Faslink™on this pushrod,

then cut the wire so it slightly protrudes out of the Faslink.

Hint: If you prefer to bend and cut the pushrod out of the

fuselage remove the pushrod, make the 90 degree bends

and cut the wire. Unscrew the clevis and reinstall the

pushrod in the guide tube from the front. Screw the clevis

back on.

❏ 8. Slide two 5/32" wheel collars onto the pushrod.

Connect the pushrod to the servo with the Faslink.

Note: If necessary, enlarge the hole in the servo arm with a

hobby knife (or a #48 drill for precision). Let the pushrod

locate the servo in the servo tray. Screw the elevator servo

in place.

❏ 9. While keeping both elevators centered, connect the

two elevator pushrods to each other with the two 5/32"

wheel collars and 6-32 x 1/4" set screws as shown in the

photo. We recommend using thread locking compound on

the set screw threads.

❏ 10. Mount the rudder servo in the fuse as shown. Mount

the 2-56 ball link to the rudder servo arm with the 2-56 nut

provided. The ball link must extend toward the fuse as

shown.Secure the nut with thread locker or thin CA.

❏ 11. Cut 1-1/4" off the unthreaded end of the 6" rudder

pushrod, making a final length of 4-3/4". Screw the nylon

ball link socket fifteen turns onto the rudder pushrod. Snap

the ball link onto the ball on the servo arm. Temporarily

slide the solder clevis onto the rudder control horn and fit it

in place on the rudder with the rudder pushrod inser ted into

the clevis. Center the rudder and the servo horn and mark

the pushrod with a felt tip pen where it enters the clevis.

❏ 12. Remove the solder clevis from the control horn, and

remove the servo arm from the servo with the pushrod

attached. The pushrod must be cleaned (but don't wipe off

your mark) before soldering. Rubbing alcohol works well for

this. Silver solder the clevis to the pushrod using the mark

you made as a reference.

32

Page 33

❏ 13. Reattach the ser vo arm with the pushrod to the

servo. Mount the control horn the same way as the

elevators with two 2-56 x 5/8" screws.

❏ 14. Mark the location of the tail gear wire on the rudder

and the nylon tail gear bearing on the fuselage.

❏ 15. Remove the rudder and drill a 7/64" hole 5/8" deep

in the leading edge at the mark you made for the tail gear

wire. Cut a groove in the rudder for the nylon tail gear

bearing (use a 5/32" brass tube sharpened at one end to

cut the groove the same way you did for the ailerons). Test

fit the tail gear wire in the rudder.

❏ 16. Cut a slot in the trailing edge of the fuse at the marks

you made for the nylon tail gear bearing. Without using any

glue, join the rudder to the fin with the tail gear wire.

❏ 17. Mount the aileron servo in the wing.Screw the nylon

torque rod connectors on the torque rods until they are

3/4" from the wing.

❏ 18. Use the 11" and 13" wire rods cut from the 35"

pushrods to make the aileron pushrods. Connect the

pushrods the same way you did for the elevator with the

nylon clevises and Faslinks.

❏ 1. Using a leftover 1/4" x 1/2" balsa stick, make the

forward and the aft wing fairings, and glue them in place.

Sand the fairings flush with the sides of the fuse.

Add the Forward & Aft Wing Fairings

33

Page 34

❏ 2. Mount the wing to the fuse. Using your sanding bar,

shape the fairings to the contour of the wing. Be careful not

to sand into the wing.

Note: It is easier to sand one side of the aft fairing with one

wing bolt removed.When the first side is done, put the wing

bolt back in place and remove the wing bolt on the

unsanded side.

❏❏1. Trim one matching set of wheel pant halves along

the molded in cut lines. Notice that the top of the outer pant

goes over the lip of the inner pant and the bottom of the

inner pant goes over the lip of the outer pant.You can use a

hobby knife to carefully score along the cut lines and flex

the plastic until the excess breaks free, or use small

scissors to cut along the lines. Kyosho curved plastic

cutting scissors (KYOR1010) work extremely well for this

and make the job a cinch. For now, don't worry about

accurately cutting out the opening in each wheel pant

half–just cut an approximate opening for the wheels.

❏❏2. Use your bar sander to carefully true the edges of

the overlapping pieces of the wheel pant halves so when

you glue them together the seam will be as small and

straight as possible. Notice that the front and rear of the

pant halves do not overlap and are "butt glued" together.

Use 150 or 220-grit sandpaper to remove the flashing and

thoroughly roughen all areas that are to be glued including

the indentation on the inside of both inner pant halves.

❏❏3.Test fit the wheel pant halves and make adjustments

where necessary for the best possible fit.

❏❏4. Join two wheel pant halves and carefully spot glue

them together in just a few places with thin CA.Start by spot

gluing the top, then the front and rear where the two halves

just butt together. After the halves are joined, securely glue

them together along all seams with thin CA.

Note: Do not use CA accelerator on the ABS plastic as it

may develop cracks and/or keep the paint from adhering.

❏❏5. Use your hobby knife (or a Moto-Tool with a sanding

drum) to cut out the wheel openings.

Hint: Make the wheel openings wide as this will make

installing the wheels and axles easier and cause less

interference with the wheels upon landing and takeoff. You

can see the size of the wheel openings in the following photo.

❏❏6. Use medium CA to glue the die-cut 1/8" plywood

wheel pant mounts to the inside of each wheel pant.

❏❏7. Use a metal file to chamfer the edges and corners

of the aluminum landing gear so it will neatly fit in the

recess of the wheel pant. Position the wheel pant on the

aluminum landing gear, then use a felt tip pen to accurately

mark the location of the axle mounting hole.

Assemble the Wheel Pants

34

Page 35

❏❏8. Dr ill a 3/16" (11/64" or #18 for precision) hole in

the wheel pant at the mark. Back up the wheel pant mount

with a piece of scrap wood so you do not split it as the drill

goes through.

❏❏9. Most 2-1/2" wheels are made to fit 5/32" axles, but

the 8-32 screws supplied in this kit for the axles require a

larger hole. If the wheel does not roll freely on the

8-32 x 1-1/2" SHCS "axle," enlarge the wheel hub with an

11/64" (#18 for perfection) drill.

❏❏10. Test fit the wheel in the wheel pant using the

following procedure:

A. Install an axle in a wheel.Thread an 8-32 nut about 1/8"

onto the axle.

B. Insert the wheel in the pant with the end of the screw

inserted in the plywood wheel pant mount and the head of

the screw sticking out of the wheel pant.

Note: When you reinstall the wheel after the wheel pant

has been painted, put masking tape on the bottom of the

pant so the screw will not scratch it.

C. Use a 9/64" hex wrench to screw the axle through the

wheel and the wheel pant until the wheel goes all the way

in and the axle goes through the pant mount.

D. Adjust the tightness of the nut with hemostats or needle

nose pliers.

❏❏11. Temporarily mount the wheel pant to the landing

gear with another 8-32 nut on the axle.

❏ 12. Perform the same procedure to assemble and

temporarily mount the other wheel pant to the landing gear.

❏ 13. Before painting the wheel pants, fill the seams with

putty filler such as Squadron White Putty or resin filler such

as Bondo.®We use Bondo most of the time as it cures

quickly and is easy to sand, but usually it must be

purchased in large quantities. Squadron putty works well

but it takes overnight to dry and usually requires at least

two applications because it shrinks as it dries.

❏ 14. After the filler cures, wet sand the wheel pants with

400-grit sandpaper to prepare them for primer.

35

Page 36

❏ 1. The cowl is assembled in a manner similar to the

wheel pants. Cut the cowl along the cut lines, then use your

bar sander to true all the edges. For now, the opening in the

front cowl piece only needs to be roughly cut out. Use

coarse sandpaper to roughen all the overlapping areas so

the glue will stick.

❏ 2. Tape the three pieces together, then wick a small

amount of thin CA along the seams of the overlapping

joints. After the CA has cured, remove the tape and make

sure you have thoroughly glued the two pieces together by

inspecting the glue joints and adding thin CA if necessary.

❏ 3. Use a sharp hobby knife (or a Moto-Tool with a sanding

drum) to accurately cut the air openings at the front of the

cowl and the air exit at the bottom rear of the cowl.

❏ 4. Use 30-minute epoxy to glue a 1" strip of fiberglass

cloth across the glue joint inside the front of the cowl.

❏ 5. Fit the cowl over the engine, then mount the spinner

backplate on the engine. Align the cowl so there is

approximately a 1/8" gap between the backplate of the

spinner and the cowl.T ape the cowl to the fuse.

❏ 6. Making one hole at a time and checking to be sure the

cowl still lines up with the spinner back plate, drill one 3/32"

hole through the cowl and the fuse side at one of the locations

shown on the plan. Using a #4 x 1/2" screw attach the cowl to

the fuse. Do the same for the other three cowl mounting

screws, checking alignment bef ore drilling each one.

❏ 7. Remove the spinner backplate and the cowl from the

fuselage. Use a drop of thin CA to harden the screw holes

in the fuse.

❏ 8. Use thin cardboard or plastic to make templates for

the cutouts in the cowl for the glow plug driver and the

needle valve. Tape the templates to the fuselage behind

where the cowl will mount to the fuse, accurately indicating

the position of the glow plug and needle valve.

Assemble the Cowl

36

Page 37

❏ 9. Remount the cowl, leaving the templates you made

attached to the fuse. Mark the holes for the needle valve

and the glow plug driver on the cowl. Remove the cowl and

cut the holes for the needle valve and glow plug driver.

❏ 10. Cut four 1" x 1" pieces of fiberglass cloth. Use

30-minute epoxy to glue one piece to the inside of the cowl

at each cowl mounting hole. After the epoxy cures, re-drill

the holes with a 1/8" drill bit.

❏ 11. Fill the seams and other imperfections in the cowl as

described in the preceding Wheel Pants section. Wet sand

the entire cowl with 400-grit sandpaper to prepare it

for priming.

❏ 1. Disconnect and remove all the pushrods and remove

the hinges and control horns from the ailerons, elevators,

and rudder. Remove the engine mount and any other

hardware you may have installed.

❏ 2. Most of the model should be rough-sanded by now

with all the tabs and rough edges sanded even. Fill all

dents, seams, low spots, and notches with HobbyLite Balsa

Colored Filler.

❏ 3. After the filler has dried, use progressively finer grades

of sandpaper to even all the edges and seams and smooth

all surfaces. Remove all balsa dust from the model with