Page 1

Great Planes®Model Manufacturing Co. guarantees this kit to

be free from defects in both material and workmanship at the date

of purchase. This warranty does not cover any component parts

damaged by use or modification.In no case shall Great Planes’

liability exceed the original cost of the purchased kit. Further,

Great Planes reserves the right to change or modify this warranty

without notice.

In that Great Planes has no control over the final assembly or

material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of the

final user-assembled product. By the act of using the userassembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated

with the use of this product, the buyer is advised to return

this kit immediately in new and unused condition to the place

of purchase.

To make a w arranty claim send the def ectiv e part or item to Hobby

Services at the address below:

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign, IL 61822

USA

Include a letter stating your name, return shipping address, as

much contact information as possible (daytime telephone number,

fax number, e-mail address), a detailed description of the problem

and a photocopy of the purchase receipt. Upon receipt of the

package the problem will be evaluated as quickly as possible.

READ THROUGH THIS MANUAL BEFORE STARTING

CONSTRUCTION. IT CONT AINS IMPOR TANT

INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY AND

USE OF THIS MODEL.

CUB4P03 for GPMA0160 V3.0 Printed in USA Entire Contents © Copyright 2003

Champaign, IL

(217) 398-8970, Ext. 5

airsupport@greatplanes.com

INSTRUCTION MANUAL

Wingspan (Standard): 76.5 in [1,945mm]

Wingspan (Clipped): 61.5 in [1,560mm]

Wing Area (Standard): 820 sq in [58.9dm

2

]

Wing Area (Clipped): 653 sq in [42.1dm

2

]

Weight: 6.5-7.5 lbs [2950-300g]

Wing Loading: 18-21 oz/sq ft [55-64g/dm

2

]

Length: 49 in [1,245mm]

Radio: 4-channel transmitter with 4 standard servos

Engine: .40-.61 cu. in. [6.5-10cc] two-stroke

.48-.80 cu. in. [8-13cc] four-stroke

.40 SIZE!

WARRANTY

MADE IN

USA

Page 2

INTRODUCTION................................................................2

Precautions..................................................................3

DECISIONS YOU MUST MAKE ........................................3

Engine Selection..........................................................3

Wing Configuration ......................................................4

Muffler Selection..........................................................4

REQUIRED ITEMS ............................................................4

Required Accessories..................................................4

Adhesives & Building Supplies....................................4

Covering Tools .............................................................4

Optional Supplies & Tools............................................4

IMPORTANT BUILDING NOTES.......................................5

COMMON ABBREVIATIONS............................................5

TYPES OF WOOD.............................................................6

GET READY TO BUILD.....................................................6

DIE-CUT PATTERNS .........................................................6

TAIL FEATHERS ................................................................8

Build the Rudder..........................................................8

Build the Fin .................................................................9

Build the Stabilizer.......................................................9

Build the Elevators .....................................................10

Cut the Hinge Slots....................................................11

WING ASSEMBLY...........................................................11

Build the Wing Panels................................................11

Joining the Wing Panels ............................................15

Install the Aileron Linkage .........................................17

Install LE and TE Sheeting........................................18

Install Center Sheeting ..............................................20

Build the Ailerons .......................................................21

Install Ailerons ...........................................................22

FUSELAGE ASSEMBLY .................................................23

Prepare Fuse Parts....................................................23

Assemble Fuselage...................................................25

Install Engine Mount and Fuel Tank ..........................28

Final Fuselage Assembly...........................................29

Mount Stabilizer and Fin............................................30

Install Main Landing Gear..........................................32

Mount the Wing to the Fuse......................................33

Install Servos, Horns, and Pushrods.........................34

Control Throws...........................................................35

FINAL ASSEMBLY ..........................................................35

Install Wing Struts (Optional).....................................35

Install Receiver, Switch, and Battery.........................36

Install Cowl.................................................................37

Additional Fuelproofing..............................................38

Balance the Airplane Laterally...................................38

Final Sanding.............................................................38

Covering.....................................................................38

Apply Decals and Trim...............................................39

Glue the Hinges.........................................................39

Build the Cockpit Floor (Optional)..............................39

Painting the Pilot (Optional).......................................40

Building the Seats (Optional).....................................40

Build the Landing Gear Suspension (Optional).........40

Build the Dummy Engines .........................................41

Other Scale Details ....................................................42

Install the Windshield .................................................42

Install the Side Windows............................................43

Balance Your Model ...................................................43

Final Hookups and Checks........................................43

PREFLIGHT.....................................................................44

Charge the Batteries ..................................................44

Find a Safe Place to Fly............................................44

Ground Check the Model...........................................44

Range Check Your Radio...........................................44

Engine Safety Precautions ........................................44

AMA SAFETY CODE ......................................................45

FLYING.............................................................................45

2-VIEW DRAWING...........................................Back Cover

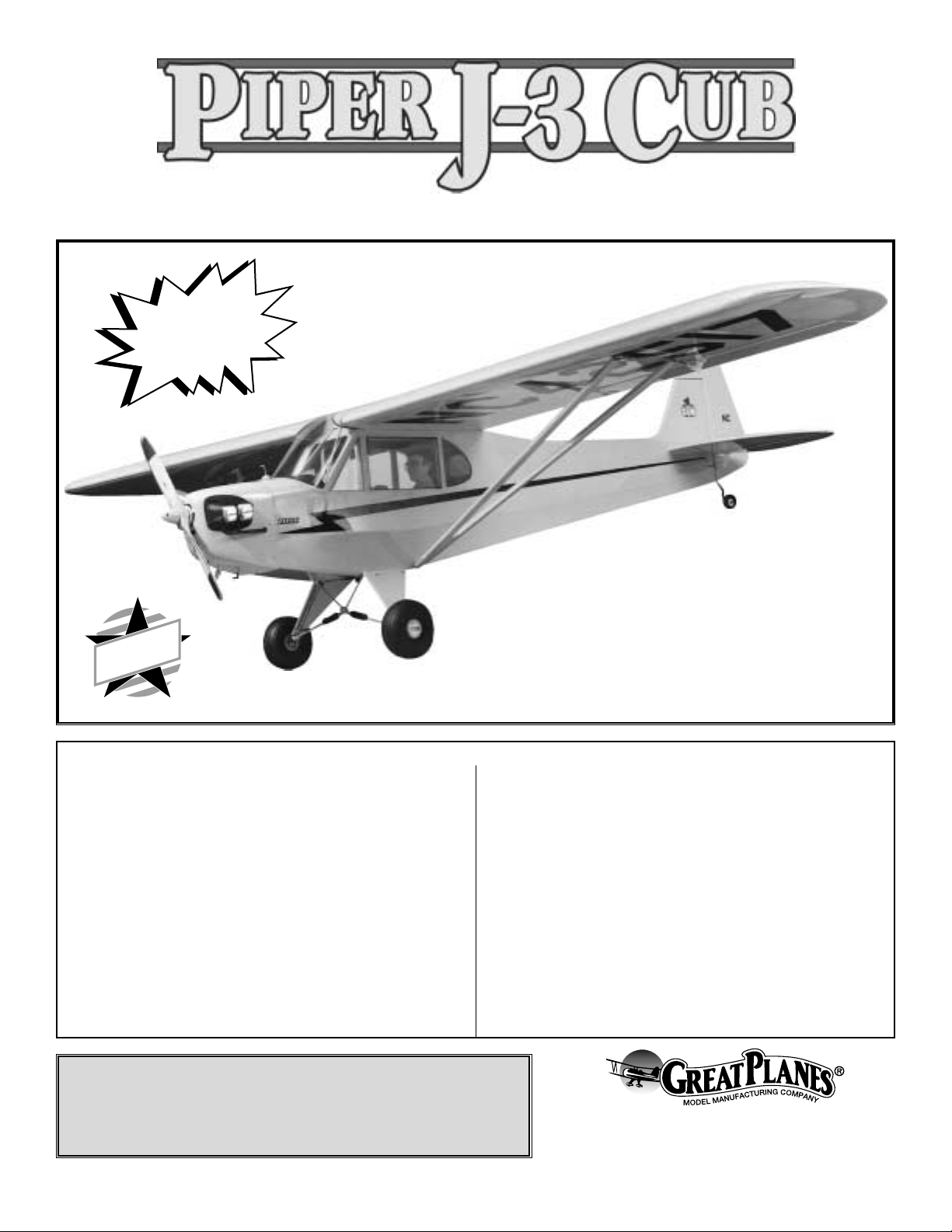

Thank you for purchasing the Great Planes Piper J-3 Cub!

This J-3 Cub kit is a 1/5.5 (18%) scale model of a full-size J-3

Cub and retains the real plane’s great flying characteristics.

You will find the J-3 Cub easy to build and fly, very

predictable and fairly aerobatic, yet it has no bad habits.

Although the model is sufficiently close to scale that it can

place well in sport-scale competition, traditional Great

Planes interlocking construction makes it simple to build a

great-looking and straight airplane that is sturdy enough to

take along every time you go to the flying field.

If you have chosen this kit as your first R/C model, it is

important that you find an experienced modeler to help you

throughout the building and flying of this plane. He should

thoroughly check the plane over bef ore flying it and help y ou

with the first flights.The J-3 Cub is a big airplane and lacks

the self-recovery characteristics of a good basic trainer

such as the Great Planes PT Series airplanes.On the other

hand, if you have already learned the basics of R/C flying

and you are able to safely handle a “trainer”airplane, the J-

3 Cub is an excellent choice.

Scale Model Research has photo sets and drawings of full

scale Piper Cubs available. These can help provide good

documentation for scale detailing and contests. Their

address is 3114 Yukon Avenue , Costa Mesa, CA 92626 and

their phone number is (714) 979-8058.

For the latest technical updates or manual corrections to the

Piper J-3 Cub .40, visit the web site listed below and select

the Great Planes Piper J-3 Cub .40.If there is new technical

information or changes to this kit a “tech notice” box will

appear in the upper left corner of the page.

http://www.greatplanes.com/airplanes/index.html

INTRODUCTION

TABLE OF CONTENTS

2

Page 3

1.Your Piper J-3 Cub .40 should not be considered a toy , b ut

rather a sophisticated, working model that functions very

much like a full-size airplane. Because of its performance

capabilities, the Piper J-3 Cub .40, if not assembled and

operated correctly, could possibly cause injury to yourself or

spectators and damage to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as doing

so may result in an unsafe or unflyable model. In a few

cases the instructions may differ slightly from the photos.In

those instances the written instructions should be

considered as correct.

3.You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in first-class

condition, and a correctly sized engine and components

(fuel tank, wheels, etc.) throughout the building process.

5. You must correctly install all R/C and other components

so that the model operates correctly on the ground and in

the air.

6.You must check the operation of the model before every

flight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

clevises or other connectors often and replace them if they

show any signs of wear or fatigue.

7. If you are not already an experienced R/C pilot, you

should fly the model only with the help of a competent,

experienced R/C pilot.

8.While this kit has been flight tested to exceed normal use,

if the plane will be used for extremely high stress flying,

such as racing, the modeler is responsible for taking steps

to reinforce the high stress points.

Remember:T ake your time and f ollo w the instructions to

end up with a well-built model that is straight and true.

Before starting to build, compare the parts in this kit

with the Parts List, and note any missing parts. Also

inspect all parts to make sure they are of acceptable

quality. If any parts are missing, broken or defective, or

if you have any questions about building or flying this

airplane, please contact Great Planes at the address or

telephone number below. If you are contacting us for

replacement parts, please be sure to provide the full kit

name (Piper J-3 Cub .40) and the part numbers as listed

in the Parts List.

Great Planes Product Support:

3002 N Apollo Drive, Suite 1

Champaign, IL 61822

Telephone: (217) 398-8970

Fax:(217) 398-7721

E-mail:

productsupport@greatplanes.com

You can also check our web site at

www.greatplanes.com

for the latest Piper J-3 Cub .40 updates.

If you have not flown this type of model before, we

recommend that you get the assistance of an experienced

pilot in your R/C club for your first flights. If you’re not a

member of a club, your local hobby shop has information

about clubs in your area whose membership includes

experienced pilots.

In addition to joining an R/C club, we strongly recommend y ou

join the AMA (Academy of Model Aeronautics). AMA

membership is required to fly at AMA sanctioned clubs.There

are over 2,500 AMA chartered clubs across the country.

Among other benefits, the AMA provides insurance to its

members who fly at sanctioned sites and events .Additionally,

training programs and instructors are available at AMA club

sites to help you get started the right way. Contact the AMA at

the address or toll-free phone number below:

The engine you select will determine where the throttle

pushrod is routed and also how the cowl is cut out, so it

is important that you have the engine close at hand

while building.

The recommended engine size range is as follows:

.40 - .61 cubic inch displacement 2-cycle

.48 - .80 cubic inch displacement 4-cycle

Engine Selection

DECISIONS YOU MUST MAKE

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

Tele: (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

http://www.modelaircraft.org

We, as the kit manufacturer, provide you with a top

quality, thoroughly tested kit and instructions, but

ultimately the quality and flyability of your finished model

depends on how you build it;therefore, we cannot in any

way guarantee the performance of your completed

model, and no representations are expressed or implied

as to the performance or safety of your completed model.

PRO TECT YOUR MODEL,YOURSELF

& OTHERS...FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

3

Page 4

For the best scale effect, an OS .48 Surpass 4-cycle is

ideal. For maximum aerobatics, an OS .70 Surpass 4-cycle

is all the power you will need.

This kit includes a Great Planes EM4070 engine mount

that fits most .40 - .60 2-cycle engines and most 40 - .70

4-cycle engines.

This kit includes everything you need to build either the

standard or the clipped wing for your Cub. Both versions fly

extremely well and are equally easy to construct. The

standard wing makes the Cub a real “Floater” giving you

plenty of time to think about your maneuvers. The clipped

wing allows things to happen a bit quicker.Snaps, rolls and

spins can be performed faster and more precisely. Either

way, the model flies much like the real plane.

If you install a 2-cycle engine, we recommend using a

muffler that can be partially enclosed inside the cowl. The

muffler shown in the instruction book photos is a Slimline

#3217 Pitts Style Muffler for OS MAX .61SF and .60FP

engines. If you use a OS .40SF or .46SF use a Slimline

#3218 Pitts Style Muffler or similar. Most standard mufflers

will require an extension to clear the fuselage sides.

❏ Engine, prop nut, and suitable propellers

❏ 4-Channel radio with 4 standard ser vos

❏ 1/4" [6mm] R/C foam rubber (HCAQ1000)

❏ 10 or 12 oz. Fuel tank (GPMQ4104 or GPMQ4105)

❏ 3' [900mm] Standard silicone fuel tubing (GPMQ4131)

❏ 3-3/8" Main wheels, Cub Style (GPMQ4230)

❏ 1-1/4" Tail wheel (GPMQ4242)

❏ (4) 3/16" Wheel Collars (GPMQ4308)

❏ (2) 3/32" Wheel Collars (GPMQ4302)

❏ (2) Rolls Top Flite

®

MonoKote®covering (TOPQ0220,

Cub Yellow)

In addition to common household tools (screwdrivers, drill,

etc.), this is the “short list” of the most important items

required to build the Piper J-3 Cub .40.

We recommend

Great Planes Pro™CA and Epoxy glue.

❏ 2 oz. Thin Pro CA (GPMR6003)

❏ 2 oz. Medium Pro CA+ (GPMR6009)

❏ Pro 6-minute epoxy (GPMR6045)

❏ HobbyLite

™

balsa-colored balsa filler (HCAR3401)

❏ Plan Protector

™

(GPMR6167) or wax paper

❏ Dr ill bits: 1/16" [1.6mm], 5/64" [2.0mm], 3/32" [2.4mm],

7/64" [2.8mm], 1/8" [3.2mm], 9/64" [3.6mm],

11/64" [4.4mm], 3/16" [4.8mm], 1/4" [6.4mm]

❏ Small metal file

❏ Stick-on segmented lead weights (GPMQ4485)

❏ Silver solder w/flux (GPMR8070)

❏ #1 Hobby knife (HCAR0105)

❏ #11 Blades (100-pack, HCAR0311)

❏ Single-edge razor blades (10-pack, HCAR0212)

❏ Small T-pins (100, HCAR5100)

❏ Medium T-pins (100, HCAR5150)

❏ Sanding tools and sandpaper assor tment (see

Expert

Tip–Easy-Touch™Bar Sander

section on page 5)

❏ Top Flite

®

MonoKote®sealing iron (TOPR2100)

❏ Top Flite MonoKote heat gun (TOPR2000)

Here is a list of optional tools mentioned in the manual that

will help you build the Piper J-3 Cub .40.

❏ Pro Aliphatic resin (2 oz. [60g], GPMR6160)

❏ 2 oz. [57g] Spray CA activator (GPMR6035)

❏ CA applicator tips (HCAR3780)

❏ CA debonder (GPMR6039)

❏ Epoxy brushes (6, GPMR8060)

❏ Mixing sticks (50, GPMR8055)

❏ Mixing cups (GPMR8056)

❏ Razor plane (MASR1510)

❏ Builder’s triangle set (HCAR0480)

❏ 36" Metal r uler (HCAR0475)

❏ Cur ved-tip canopy scissors (for trimming plastic parts,

(HCAR0667)

Optional Supplies & Tools

Covering T ools

Adhesives & Building Supplies

Required Accessories

REQUIRED ITEMS

Muffler Selection

Wing Configuration

4

Page 5

❏ Pliers with wire cutter (HCAR0630)

❏ Robar t Super Stand II (ROBP1402)

❏ 18" x 24" [460 x 610mm] Builder’s cutting mat (HCAR0455)

❏ 16" x 48" [410 x 1220mm] Building board (GPMR6950)

❏ Masking tape (TOPR8018)

❏ Threadlocker

™

thread locking cement (GPMR6060)

❏ Denatured alcohol (for epoxy clean up)

❏ Z-bend pliers (HCAR2000)

❏ Rotar y tool such as Dremel

®

Moto-Tool

®

❏ Rotar y tool reinforced cut-off wheel (GPMR8200)

❏ Ser vo horn dr ill (HCAR0698)

❏ Dead Center

™

Engine Mount Hole Locator (GPMR8130)

❏ AccuThrow

™

Deflection Gauge (GPMR2405)

❏ Slot Machine

™

hinge slotting tool (110V, GPMR4010)

❏ CG Machine

™

(GPMR2400)

❏ Laser incidence meter (GPMR4020)

❏ Precision Magnetic Prop Balancer

™

(TOPQ5700)

EASY-TOUCH™BAR SANDER

A flat, durable, easy to handle sanding tool is a necessity f or

building a well finished model. Great Planes makes a

complete range of Easy-Touch Bar Sanders and replaceable

Easy-Touch Adhesive-backed Sandpaper.While building the

P-38 Profile, two 5-1/2" [140mm] Bar Sanders and two 11"

[280mm] Bar Sanders equipped with 80-grit and 150-grit

Adhesive-backed Sandpaper were used.

Here’s the complete list of Easy-Touch Bar Sanders and

Adhesive Backed Sandpaper:

5-1/2" Bar Sander (GPMR6169)

11" Bar Sander (GPMR6170)

22" Bar Sander (GPMR6172)

33" Bar Sander (GPMR6174)

44" Bar Sander (GPMR6176)

11" Contour Multi-Sander (GPMR6190)

12' roll Adhesive-backed 80-grit sandpaper (GPMR6180)

150-grit (GPMR6183)

180-grit (GPMR6184)

220-grit (GPMR6185)

Assortment pack of 5-1/2" strips (GPMR6189)

We also use Top Flite 320-grit (TOPR8030, 4 sheets) and

400-grit (TOPR8032, 4 sheets) wet-or-dry sandpaper for

finish sanding.

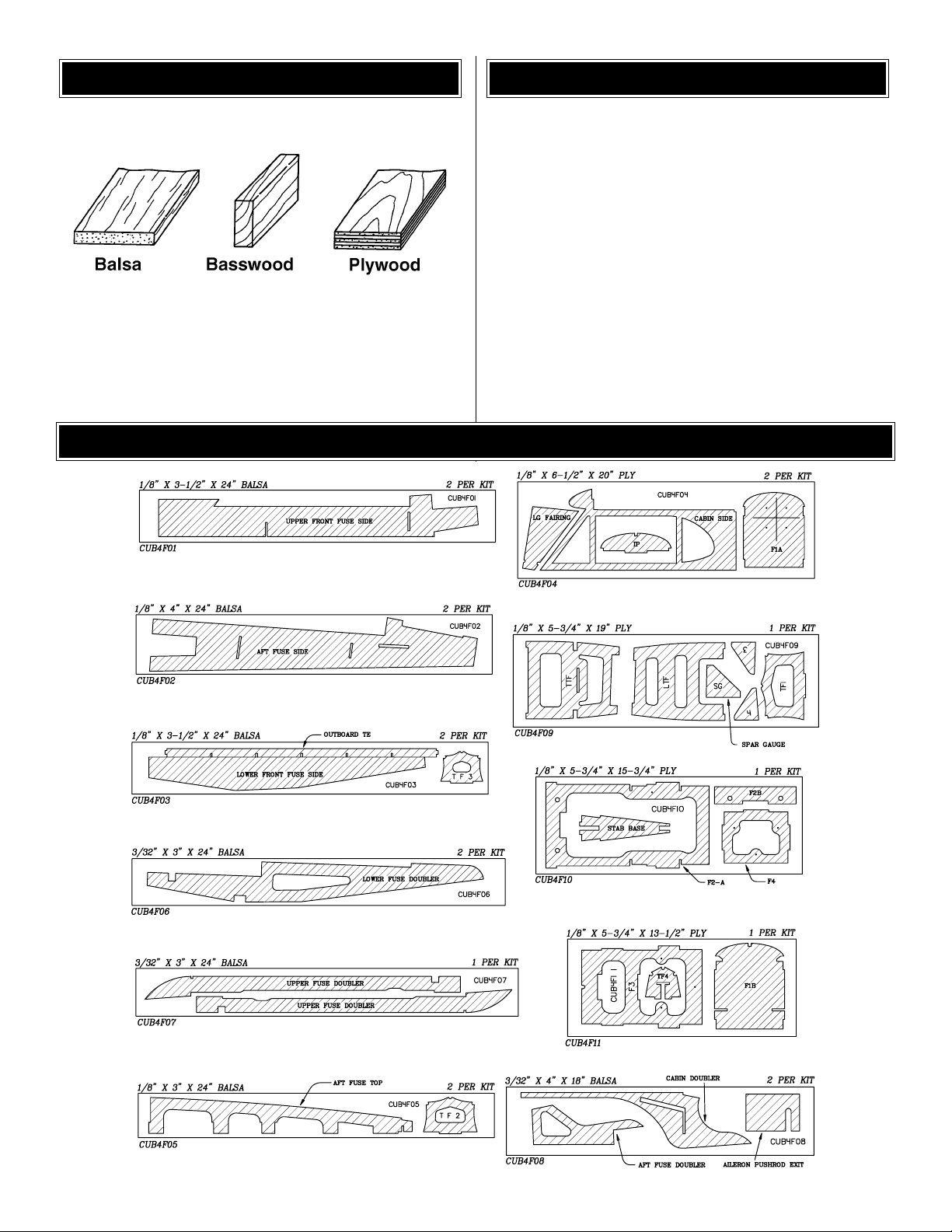

• There are two types of screws used in this kit:

Sheet metal screws are designated by a number and a length.

For example #6 x 3/4"

This is a number six screw that is 3/4" long.

Machine screws are designated by a number, threads

0per inch, and a length. SHCS is just an abbreviation for

“socket head cap screw”and that is a machine screw with a

socket head.

For example 4-40 x 3/4".

This is a number four screw that is 3/4" long

with forty threads per inch.

• When you see the term

test fit

in the instructions, it

means that you should first position the part on the

assembly without using any glue, then slightly modify or

custom fit the part as necessar y for the best fit.

• Whenever the term

glue

is written you should rely upon

your experience to decide what type of glue to use.When a

specific type of adhesive works best for that step, the

instructions will make a recommendation.

• Whenever just

epoxy

is specified you may use

either

30-minute (or 45-minute) epoxy or6-minute epoxy. When

30-minute epoxy is specified it is highly recommended that

you use only 30-minute (or 45-minute) epoxy, because you

will need the working time and/or the additional strength.

•

Photos

and

sketches

are placed before the step they

refer to. Frequently you can study photos in following steps

to get another view of the same parts.

Fuse = Fuselage

Stab = Horizontal Stabilizer

Fin = Ver tical Fin

LE = Leading Edge

TE = Trailing Edge

LG = Landing Gear

Ply = Plywood

" = Inches

mm = Millimeters

SHCS = Socket Head Cap Screw

COMMON ABBREVIATIONS

IMPORTANT BUILDING NOTES

5

Page 6

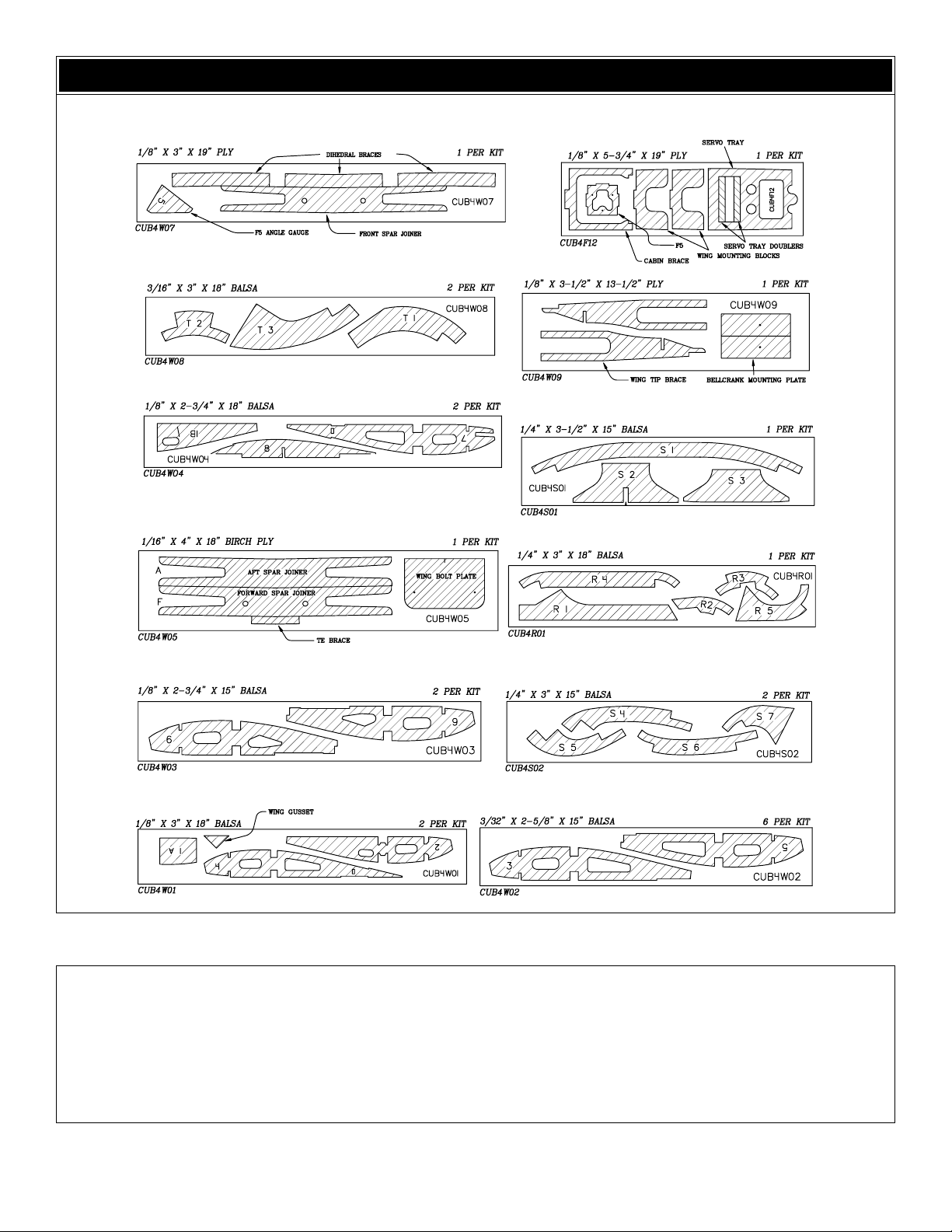

1.Unroll the plan sheet.Re-roll it inside out to make it lie flat.

2. Remove all parts from the box. As you do, figure out the

name of each part by comparing it with the plans and the

parts list included with this kit. Using a felt-tip or ballpoint

pen, lightly write the part name or size on each piece to

avoid confusion later. Use the die-cut drawings shown on

page 7 to identify the die-cut parts and mark them before

removing them from the sheet. Save all scraps. If any of

the die-cut parts are difficult to punch out, do not force

them! Instead, cut around the parts with a hobby knife.After

punching out the die-cut parts, use your Bar Sander or

sanding block to lightly sand the edges to remove any diecutting irregularities or slivers.

GET READY TO BUILDTYPES OF WOOD

6

DIE-CUT DRAWINGS

Page 7

7

1/64" = .4 mm

1/32" = .8 mm

1/16" = 1.6 mm

3/32" = 2.4 mm

1/8" = 3.2 mm

5/32" = 4.0 mm

3/16" = 4.8 mm

1/4" = 6.4 mm

METRIC CONVERSIONS

3/8" = 9.5 mm

1/2" = 12.7 mm

5/8" = 15.9 mm

3/4" = 19.0 mm

1" = 25.4 mm

2" = 50.8 mm

3" = 76.2 mm

6" = 152.4 mm

12" = 304.8 mm

18" = 457.2 mm

21" = 533.4 mm

24" = 609.6 mm

30" = 762.0 mm

36" = 914.4 mm

DIE-CUT DRAWINGS

Page 8

8

❏ 1. Tape waxed paper over the Rudder drawing on the

fuse plans. Remove the die-cut 1/4” balsa par ts R2,R3,R4

and R5 from CUB4RO1. Place all the parts over the plan in

their locations and check the joints for good fits.Use a T-bar

or other flat sanding block to make any necessary

adjustments.Pin the parts to the building board after proper

alignment and fitting has been done.

❏ 2. Cut the rudder LE from the 1/4" x 3/4" x 24" balsa

strip (CUB4SO3). NOTE: Look over the three CUB4S03’s

and mark the straightest one to be used later for the stab

TE. Fit the LE into the notch in R3 and against the edge of

R5. Cut the horizontal frame section from the 1/4" x 3/4"

balsa strip and fit it in position. Pin the LE and horizontal

frame section in place and securely glue all joints with thin

CA. Wipe any excess glue off with a paper towel before it

cures (this will make sanding much easier).NOTE:Leave all

the parts pinned to the building board.

❏ 3. Cut the four Ribs from the 3/16” x 1/4” x 24” balsa

stick (CUB4SO4). Fit the ribs into the rudder frame and

securely glue them in place with thin CA.

❏ 4. Remove the Rudder from the building board and

inspect all the glue joints on the bottom side.Add thin CA to

all the tight fitting joints and thick CA to any open joints.

NOTE: The process of re-gluing the joints on the bottom

side is necessary on the thick balsa parts. This will ensure

the complete wicking of the CA throughout the entire joint.

❏ 5. Place the Rudder on a flat work surface and lightly

sand both sides flat and smooth using a T-Bar or good flat

sanding block with medium grit sandpaper.

❏ 6. Carefully draw a centerline on the LE and TE of the

rudder. This will help you to maintain symmetry when

sanding these edges.

❏ 7. Using a flat sanding block, sand the top and theTE of

the rudder to a rounded shape. Sand the LE to a “V-shape”

as shown on the plans.

Build the Rudder

TAIL FEATHERS

Page 9

❏ 8. Check the plans and mark the location of the tailgear

on the rudder.Drill a 7/64” hole in the rudder 3/4” deep (the

hole is drilled slightly oversize to allow room to create a hard

epoxy “sleeve”around the wire).Then groove the rudder LE

to accept the tailgear wire.

Using a hobby knife, sharpen the inside of one end of a

1/8" diameter brass tube, and use it to cut the groove in

the LE of the rudder as shown below.

❏ 1. Tape waxed paper over the Fin drawing on the fuse

plans. Remove the 1/4” die-cut balsa R1 from (CUB4RO1).

Place R1 on the plan and pin in place.

❏ 2.Cut the remaining fin frame parts from the 1/4" x 3/4"

x 24" balsa strip (CUB4SO3). Pin the par ts in place and

make sure all the joints are good and tight.Securely glue all

the joints with thin CA. Note: The bottom end of the trailing

edge stops at the top edge of the horizontal stabilizer.

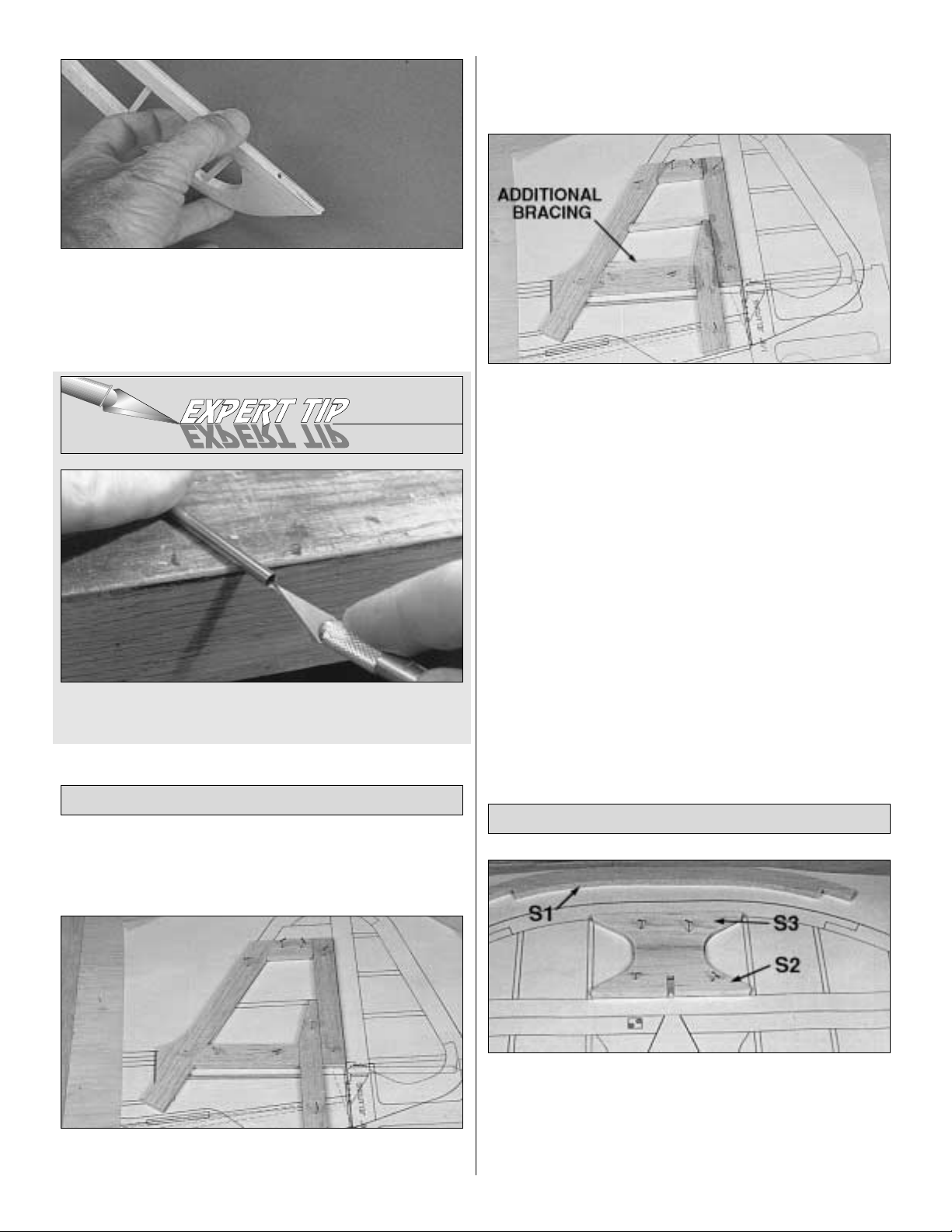

❏ 3. Cut three Ribs from the 3/16" x 1/4" x 24" balsa stick

(CUB4SO4).Fit one rib in place and glue it with thin CA.Add

two more ribs for additional bracing above the lower frame.

❏ 4. Remove the Fin from the building board and inspect all

the glue joints.Glue all the tight fitting joints on the bottom side

of the fin with thin CA and add thick CA to any open joints.

❏ 5. Place the Fin on a flat work surface and lightly sand

both sides flat and smooth.

❏ 6. Draw a centerline on the LE and TE of the fin. The

lines will assist you in the final shaping of the LE and hinge

positioning on the TE.

❏ 7. Sand the LE only to a rounded shape to match the

cross-section shown on the plans. NOTE: The trailing edge,

bottom edge and top edge must not be rounded or V -shaped.

Instead, just sand these edges flat and square.

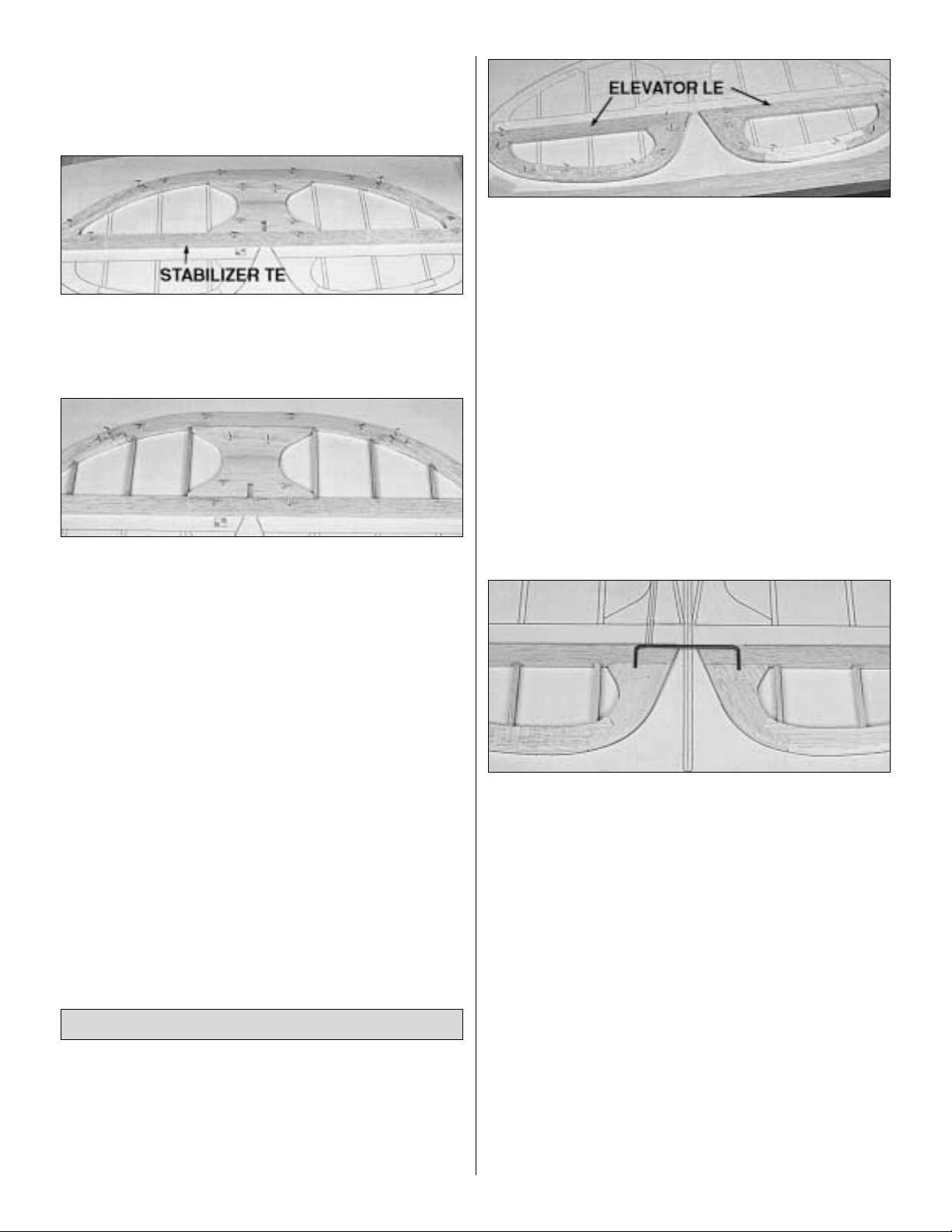

❏ 1. Tape waxed paper over the Stabilizer drawing on the

fuse plan.Remove the die-cut 1/4" balsa parts S1, S2 and S3

from (CUB4SO1) and the two S4’s from (CUB4S02). Place

S2 and S3 over the plan to check their fit together.Sand the

parts as necessar y to ensure a good fitting joint. Pin S2 and

S3 in place over the plans and glue them together.

Build the Stabilizer

Build the Fin

9

Page 10

❏ 2. Position the S1 and the two S4’s over their locations

on the plans. Check the fits of the joints and sand them if

necessary. Pin them in place.

❏ 3.Cut the Stabilizer TE from the 1/4" X 3/4" X 24" balsa

strip (CUB4S03). Fit the TE between the S4’s and glue it in

place with thin CA.

❏ 4. Cut the Ribs from the 3/16" x 1/4" x 24" balsa stick

(CUB4S04). Fit the Ribs in the stabilizer frame and glue

them in place with thin CA.

❏ 5. Remove the stabilizer from the building board and

inspect all the glue joints. Glue all the tight fitting joints on

the bottom side of the stab with thin CA and add thick CA to

any open joints.

❏ 6. Place the stabilizer on a flat work surface and lightly

sand both sides flat and smooth.

❏ 7. Draw a centerline on the TE of the stabilizer. The

centerline will be used later to assist in positioning the hinges.

❏ 8. Sand the LE only of the stabilizer to a nice rounded

shape as shown on the plans.

❏ 1.Tape waxed paper over the Elevator drawing on the

fuse plan.Remove S5,S6,and S7 from the 1/4" die-cut balsa

sheet CUB4S02. Position the parts over the plans and

check the fit of the joints. Sand the parts as necessar y to

ensure good fitting joints. Pin the parts in place over the

plans and glue them together with thin CA.

❏ 2. Cut the Elevator LE from the 1/4" x 3/4" x 24" balsa

strip (CUB4S03) and pin it in place. Glue all the joints with

thin CA.

❏ 3. Cut the elevator Ribs from the 3/16" x 1/4" x 24" balsa

stick (CUB4SO4).Fit the ribs in the elevator frame and glue

with thin CA.

❏ 4. Remove the elevators from the building board and

inspect all the glue joints. Glue all the tight fitting joints with

thin CA and add thick CA to any open joints.

❏ 5. Place the elevators on a flat wor k surface and lightly

sand both sides flat and smooth using a T-bar or other good

flat sanding block.

❏ 6. Carefully draw a centerline all around the edges of

the elevators.

❏ 7. Temporarily pin the elevators to the plan. Lay the 1/8"

wire elevator joiner (WBNT194) in place on the elevators

and mark its outline using a soft leaded pencil. NOTE: Mark

the elevator joiner wire outline very lightly so that it will not

be seen through the covering material.

❏8.Accurately drill a 1/16" diameter pilot hole approximately

3/4" deep at each location. Then drill the final hole with a

9/64" drill bit to a depth of 7/8". (The hole is drilled slightly

oversize to allow for positioning, and to allow room to create

a hard epoxy “sleeve”around the wire.NOTE:The joiner wire

must be centered on the centerline of the stabilizer.The holes

must be drilled perpendicular to the LE and parallel to the top

and bottom surfaces of the elevators.

❏ 9. Use the shar pened 1/8" diameter brass tube to cut

grooves in the leading edge of the elevators to accept the

joiner wire.

❏ 10. Sand the LE to a “V”-shape and the entire TE to a

rounded shape.Check the plans for the proper cross-sections.

Build the Elevators

10

Page 11

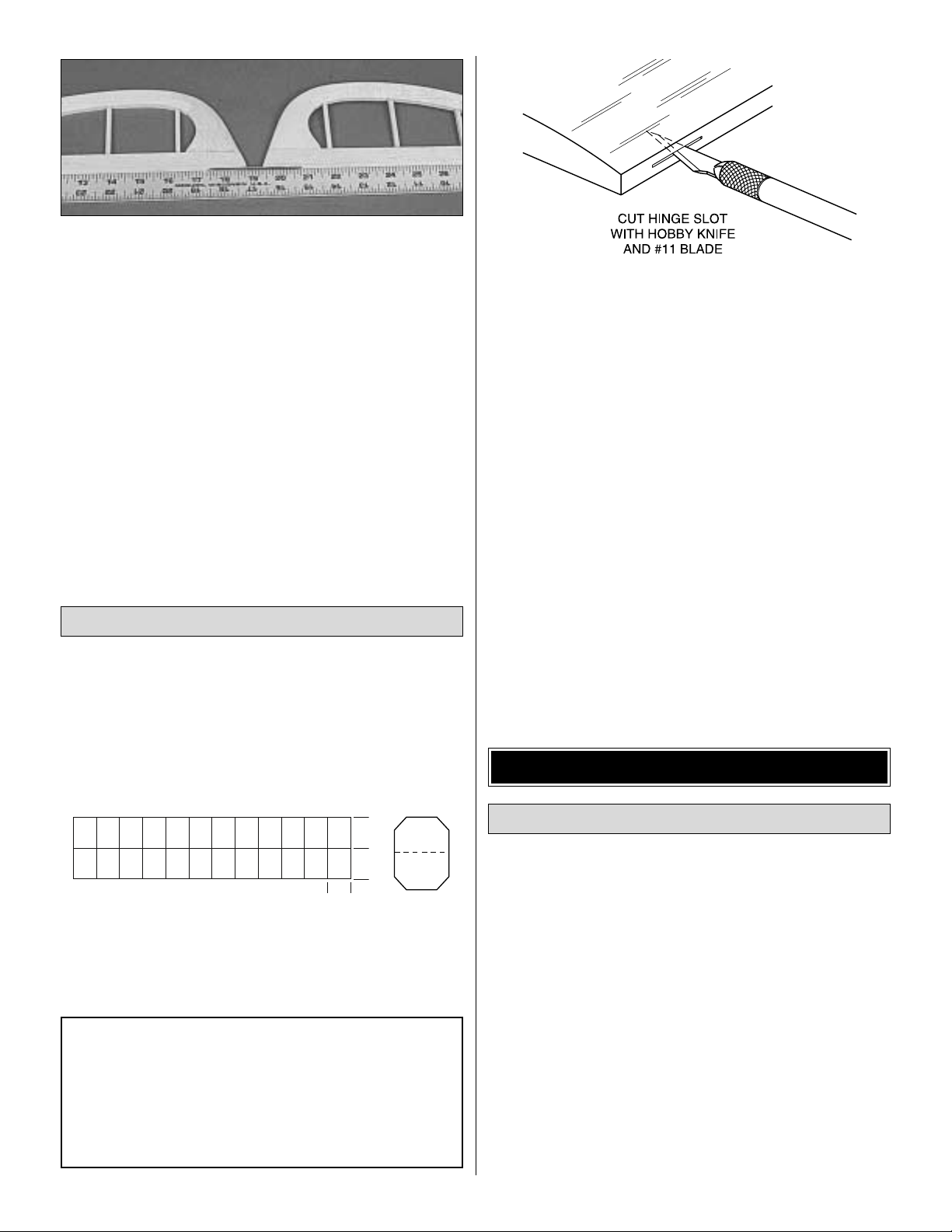

❏ 11.Test fit the joiner wire into both elevators.Position the

elevators against a straight edge to chec k f or str aightness of

the LE with the joiner wire installed. Adjust the holes if

needed to achieve a straight LE.

❏ 12. Roughen the joiner wire with coarse sandpaper,

then clean the wire thoroughly with alcohol to remove any

oily residue.

❏ 13.Glue the joiner in place using 30-minute epoxy.When

gluing, lay the elevators on a flat surface with the leading

edges along a straightedge to ensure perfect alignment.

NOTE: A strip of Ultra-Grip hinges are supplied in this

kit. If you choose to use the “pinned”-type hinges, you

should cut the hinge slots at this time. However, if you

choose to use the Ultra-Grip hinges that are furnished

in this kit, you may wait until after covering before

cutting the hinge slots. The strip of Ultra-Grip hinges

must be cut as shown in the sketch below.

❏ 1.Lay the rudder and elevators on the plan and mark the

hinge locations. Place the rudder against the fin TE and

transfer the marks over to the fin. Place the elevators

against the stab TE and transfer the marks over to the stab.

❏ 2. Cut the hinge slots on the centerlines which you

previously drew, using a hobby knife following the

recommended hinge slotting technique listed below. NOTE:

For pinned hinges use a slotting fork and slotting hook.

❏ A. Begin by carefully cutting a very shallow slit at the

hinge location. This first cut is to establish your cut in the

right place, so concentrate on staying on the centerline and

don’t cut too deep!

❏ B.Make three or four more cuts in the same line, going

slightly deeper each time. As you make these additional

cuts, work on going straight into the wood. Continue this

process while “wiggling” the knife handle back and forth

until the blade has reached the proper depth for the hinge.

❏ C.Trial fit the hinge into the slot. If the hinge is difficult

to push in, re-insert the knife and move it back and forth in

the slot a few times to enlarge the slot.

❏ 3. Inser t the hinges into the slots and trial fit the rudder

and elevators in place on the fin and stab. Do not glue the

hinges until after you have covered the model.

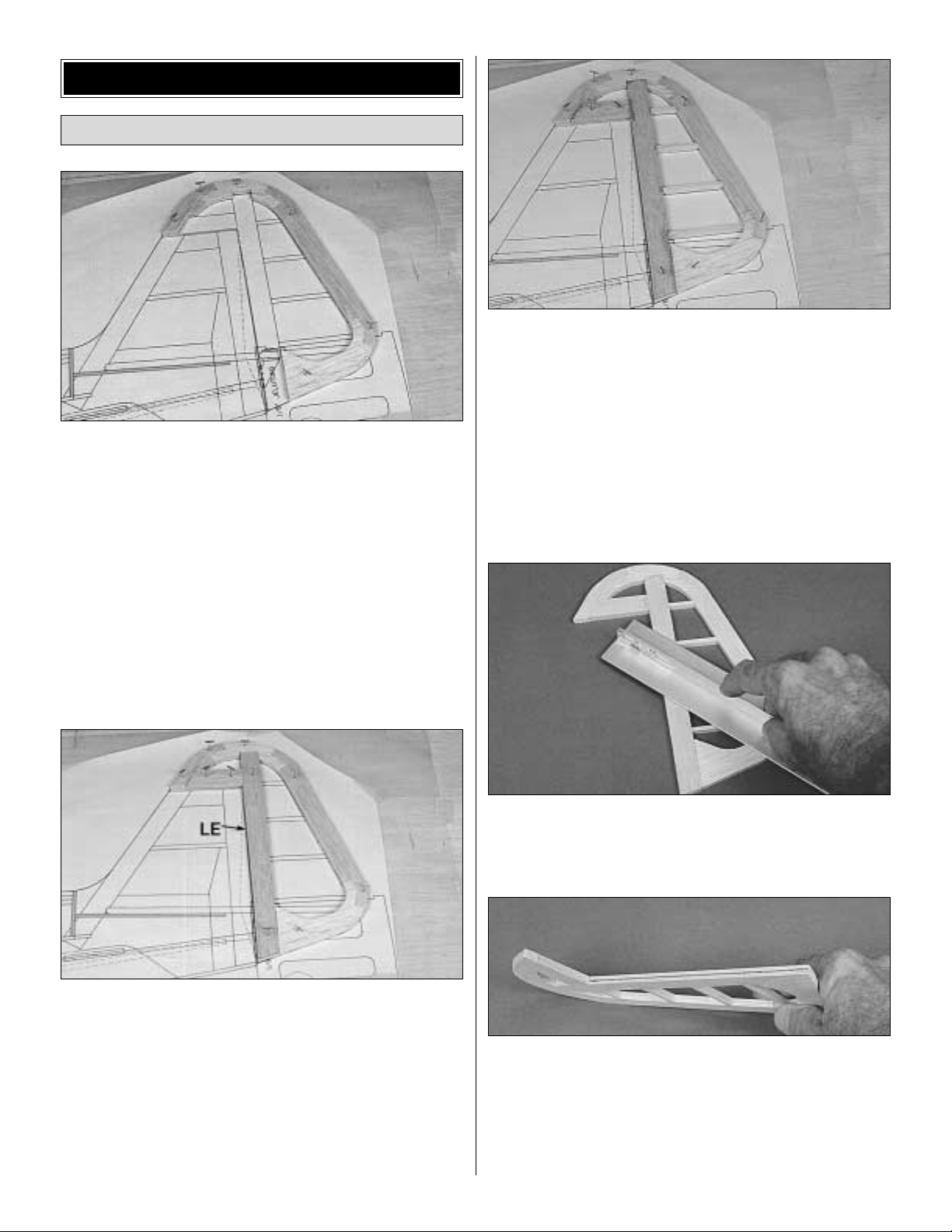

NOTE: It will be helpful to build the wing on a piece of

“Celotex” or other semi-soft (and flat) surface, into

which you may easily stick pins to firmly hold down the

wing parts while building, to avoid warps.

NOTE: You may build one of two different wings from

this kit. The standard scale wing or the clipped wing

version.You will need to decide now which version you

would like to build. Regardless of your decision, the

wings LE's and TE's will require trimming. Carefully

study the LE and TE trim diagram on the wing plan. Lay

the LE and TE directly over the plan and trim

accordingly. No change to the plans is necessary for the

standard scale wing. If you decide to build the clipped

wing version, cut the plans on the dashed lines. Slide

the outer halves of each wing panel over the inner

halves and match the registration marks between the

Build the Wing Panels

WING ASSEMBLY

CAUTION!!!: You must use extreme care when

cutting hinge slots with a hobby knife, to avoid

cutting yourself! If the balsa part breaks while you

are pushing on the knife, the blade could go into

your hand before y ou know it! A good precaution is

to wear leather gloves while performing the

following steps,and always cut

away

from yourself .

Cut the Hinge Slots

11

1"

1"

3/4"

Page 12

first two #3 ribs. Keep the plans aligned and tape the

inner and outer halves together. The plans are now

ready to use for the clipped wing version.

❏1.T ape the plan to your flat work surface .Align a straightedge

on the wing centerline and draw a continuous line extending out

past the leading and trailing edges.Do this for both the right and

left wing panel plans. This centerline will be used at various

times during the wing construction. Cover the wing drawing with

waxed paper (so you won’t glue the wing to the plan!).

❏ 2. Before using the 3/8" x 3/8" x 33-1/2" bass woodSpars

(CUB4W06), examine them carefully for possible

imperfections.Look for knots, soft spots, diagonal grain and

any other imperfections. If possible, position each spar so

the imperfections are on the outer half of the wing panel

(toward the tip), where they will be least affected by high

stress. If the spars are warped slightly, try to “balance them

out” by installing the warped spars in opposite directions.

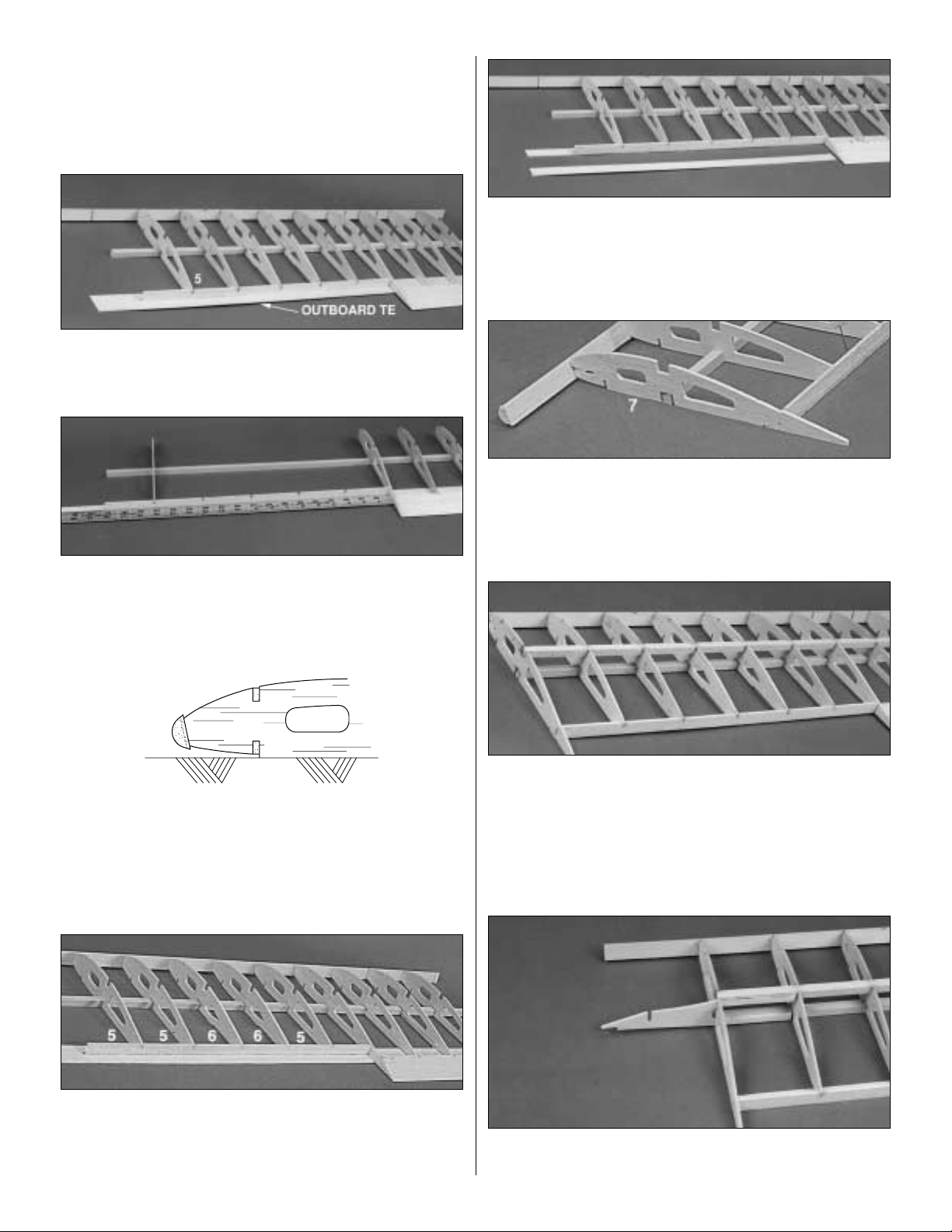

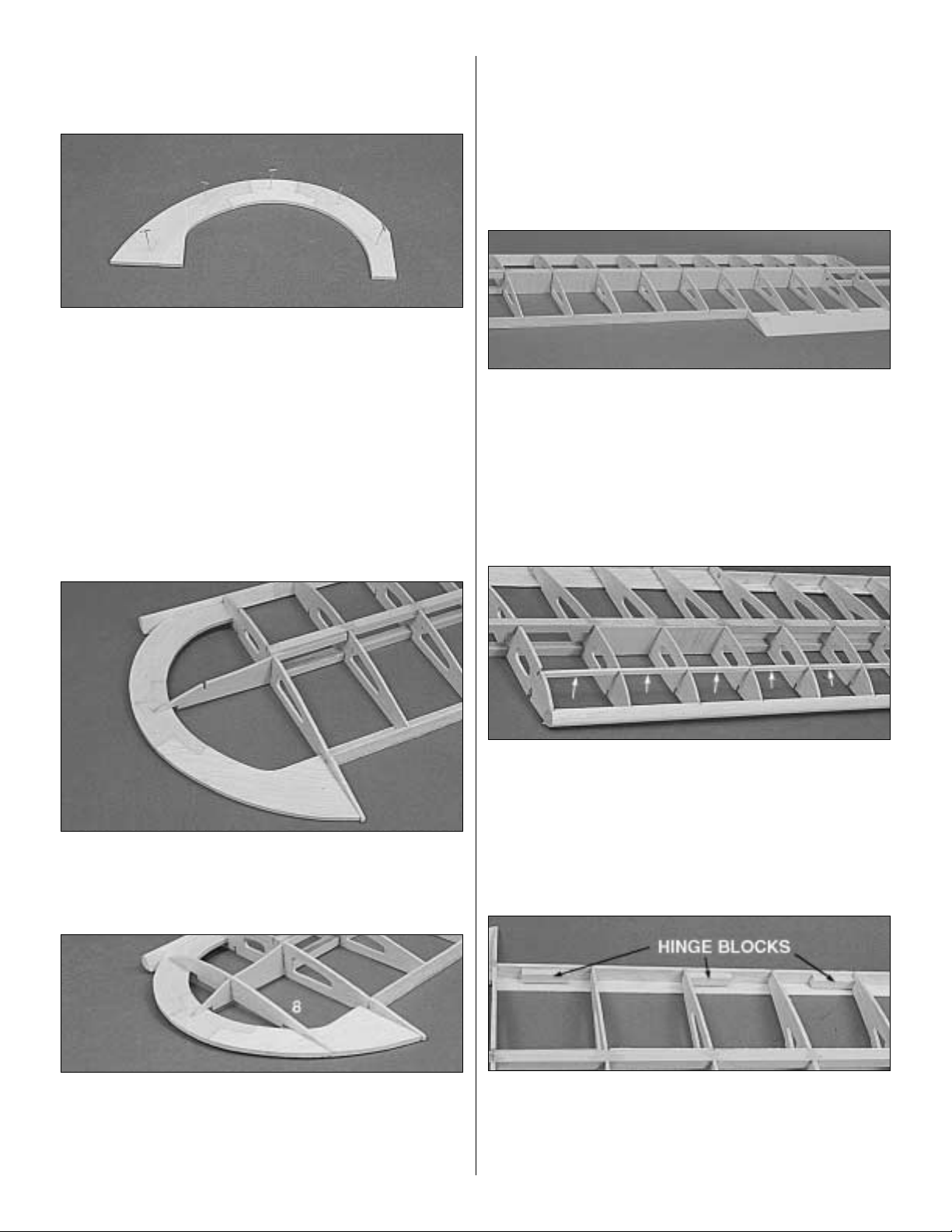

❏ 3. Carefully punch out all the die-cut 3/32" balsa #3 and

#5 ribs (CUB4W02) and the die-cut 1/8" balsa #2, #4,#6, #7

and #8 ribs (CUB4W01, CUB4W03 and CUB4W04). Sand

the edges slightly to remove any die-cutting irregularities.

❏❏4. Place one of the 3/8" x 3/8" x 33-1/2" Basswood

Spars (CUB4W09) on the wing plan and pin the spar down

with crossed T-pins as shown in the follo wing sk etch.NOTE:

Align the end of the spar with the outboard edge of rib #7.

The spars are cut slightly too long, and the excess will be

cut off later at the center of the wing.

❏❏5. Place the 1/16" x 1-3/8" x 36" balsa TE Sheeting

(CUB4W13) on the plans but do not pin it yet.Align one end

of the sheeting with the wing centerline.

❏❏6. Place three of the #3 ribs and one of the #4 r ibs on

the spar in their locations shown on the plans, but do not

glue. Slide the TE sheeting to the forward edge of the

notches in the bottom of the ribs. The TE sheeting is used

only as a shim for the rib ends at this point.

❏❏7.Carefully check the notches on the TE (CUB4W11).

The 1/8" wide notches are to be positioned over the #1 and

#2 rib locations on the plans. Align the outboard end of the

TE with the aft end of the #4 rib.Insert the aft ends of the #3

ribs into the notches in the TE.Make sure the ribs are down

against the sheeting and building board and glue the ribs to

the spar and the TE with thin CA.The TE sheeting should

hold the ribs 1/16" above the work surface.

❏❏8. Slide the bottom sheeting back against the TE and

align it with the inboard end of the TE. Glue the bottom

sheeting to the TE and the ribs.

NOTE: Follow steps 4 through 30 to build the LEFT

wing panel, then repeat these steps to build the

RIGHT wing panel.

12

T-Pin

Spar

Work Surface

Page 13

❏❏9. Carefully inspect the notches in the die-cut 1/8"

balsa Outboard TE (CUB4F03). The 1/8" wide notches are

to be aligned with the #6 rib locations. Insert the tab on the

die-cut outboard TE into the slot at the aft end of the #4 rib,

with the notches facing up.

❏❏10.Place the outboard #5 rib on the spar at the proper

location and insert the aft end of the rib into the proper notch

in the outboard TE.Do not glue yet!

❏❏11. Use a straightedge to keep the outboard TE straight

as shown in the photo and glue it to the bottom TE sheeting with

thin CA. Be careful not to glue the straightedge to the sheeting.

❏❏12. Position the notched LE so the 1/8" wide notches

are near the #2, #4, #6, #6 and #7 positions. Place it on the

ribs so the ribs are centered vertically on the LE to allow for

the LE sheeting which will be installed later.Glue it in place

with thin CA.

❏❏13. Install the remaining #5 and #6 ribs. Glue them to

the LE, the spar, the outboard TE and the bottom TE

sheeting. Make sure they are centered on the LE and down

against the bottom TE sheeting.

❏❏14.Trim the bottom sheeting in the aileron area, along

the #4 rib and the outboard TE to the end of the sheet.

Maintain a straight cut past the #7 rib location.You may want

to slide a thin piece of hard plastic under the bottom sheeting

to avoid cutting into the plans when making this cut.

❏❏15.Position the #7 rib in place over the plans and onto

the tab at the end of the outboard TE.Glue the rib to the LE,

the front and top edges of the spar, the outboard TE and

the bottom TE sheeting.Trim the bottom sheeting even with

the outboard edge of the #7 rib.

❏❏16. Insert the 3/8" x 3/8" basswood Top Spar

(CUB4W09) into the notches in the ribs. Align the end of the

spar to the outboard edge of the #7 rib. Glue the spar to all

the ribs, with the spar against the front of the notch in the #7

rib.Make sure the top surface of the spar is level with the top

edges of the ribs. NOTE: Check to make sure the spar is

positioned properly to ensure a straight wing (see step 2).

❏❏17. Install a die-cut 1/8" plywood Wing Tip Brace

(CUB4W09) at the rear of the spars through the notches in

13

Page 14

the #7 rib. Align the top notch in the wing tip brace with the

#8 rib on the plans and glue the brace in place. Make sure

the “legs” of the brace are parallel with the spars.

❏❏18. If you are currently building the left wing panel,

assemble the wing tips over the right wing panel plan.Place

the die-cut 3/16" balsa Wing Tip parts T1, T2 and T3

(CUB4W08) over the plans and check all joints for proper

fits. Sand the par ts if necessary for good fitting joints. Pin

them in place and glue the pieces together with thin CA.

❏❏19. Remove the Wing Tip from the building board and

inspect all the glue joints on the bottom side. Add thin CA to

all the tight fitting joints and add thick CA to all the open joints.

❏❏20. Place the Wing Tip on a flat work surface and

lightly sand both sides flat and smooth.

❏❏21. Sand the front edge of the Wing Tip to match the

angle of the LE.Test fit the wing tip into the slot at the front of

rib #7 and align the aft end of the wing tip with the aft end of rib

#7. Glue the wing tip to the LE, the wing tip brace and rib #7.

❏❏22.Insert rib #8 into the notch in the wing tip brace so

the ends of the rib rest on the wing tip.Align the rib over the

plans and glue it in place. Sand the top and bottom outside

edges of the wing tip to remove the sharp corner where the

leading edge sheeting will be attached later.

❏❏23. Install rib #2 by sliding it in between the spars and

twisting it into place. Center it on the LE and glue it with thin

CA. Do not glue it to the spars yet! Note: Maintain a 1/16"

gap between the bottom edge of the rib and the work surface

to allow for the center sheeting which will be installed later.

Use a scrap piece of 1/16" balsa to hold the rib up off the

work surface.

❏❏24. Securely glue eight (six for the clipped wing Cub)

of the pre-cut 1/16" x 2-7/8" x 1-7/16" balsa vertical grain

shear webs (CUB4W20) to the rear surface of the spars,

starting between the two #5 ribs near the wing tip end of the

wing and working towards the center of the wing.Medium or

thick CA works best for this. Securely glue a shear web to

the front surfaces of the spars in the two rib bays between

the #3 r ibs as shown in the next photo.

❏❏25.Install the 1/8" x 1/4" x 33-1/2" balsa T op Forwar d

Spar (CUB4W12) in the forward rib notches, starting with

the #7 rib. Press the spar down fir mly into the notches and

glue it in place with thin CA. Trim the forward spar and LE

even with the inboard side of the #2 rib and even with the

outboard side of the #7 rib.

❏❏26.Position f our 1/4" x 3/8" x 1-1/2" balsa Hinge Blocks

(CUB4W21) against the Outboard TE at the locations shown

on the plans and glue them in place with CA. Notice that they

are centered vertically on the outboard TE and not placed

down against the bottom TE sheeting.

14

Page 15

❏❏27. Place the die-cut 1/8" balsa triangular Gusset

(CUB4W01) in the corner formed by the #4 rib and the

tapered TE.Securely glue it in place.

(Photo taken at a later stage of completion.)

❏❏28. Glue the 1/2" x 3/4" x 1" basswood Wing Strut

Mounting Blocks (CUB4W22) to the outboard side of the

second #6 rib.They should be flush with the bottom of the rib

and positioned as shown on the plans.Cut four 1" long pieces

of 3/8" balsa Triangle (CUB4W24) and glue one piece on top

of each mounting block. There are six of these blocks

included in this kit, two of which are (CUB4F20). The strut

mounting blocks must be down flat on the building surface

when gluing it to the rib.The front block will be flush with the

bottom of the rib, but the aft block will be 3/32" below the

bottom edge of the rib because the balsa sheeting has not yet

been installed in the bellcrank bay.

❏❏29. Use the die-cut 1/8" ply Spar Gauge (CUB4F09)

to mark where to cut the spars and TE off. Hold the gauge

flat against the work surface and line it up with the centerline

on the plans. Mar k along the almost vertical edge and then

cut the spars off along these lines. This will make the top

spar slightly shorter than the bottom spar to allow for the

dihedral angle.In addition to the spars, mark and cut off the

bottom TE sheet and the tapered TE at the wing centerline.

❏❏30.Remove the wing panel from the work surface and

install the 1/8" x 1/4" x 33-1/2" Bottom Forward Spar

(CUB4W12) following the same procedure used in step 25.

❏ 31. Go back to step 4 and build the other wing panel.

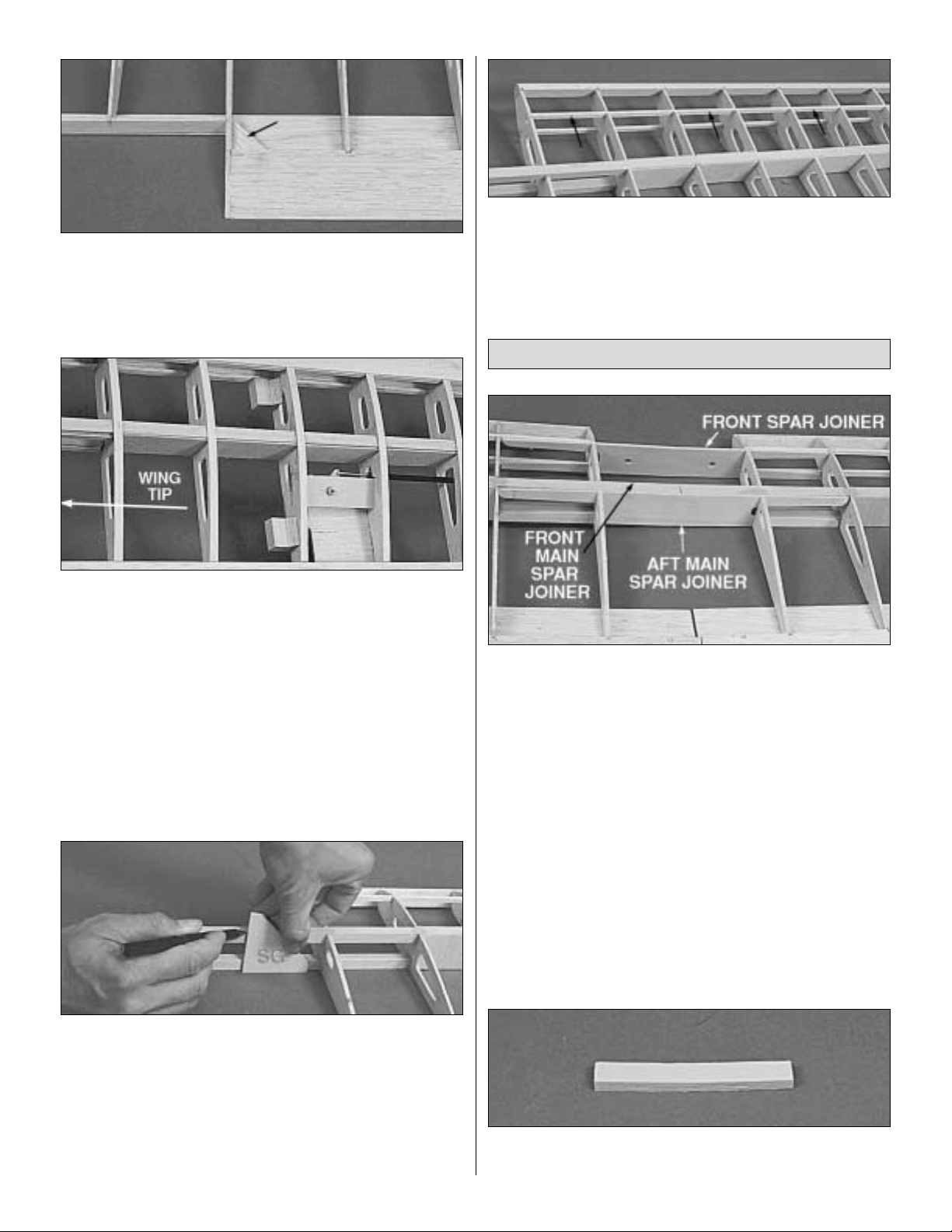

❏1. Using the die-cut 1/8" ply Front Spar Joiner(CUB4W07)

and the die-cut 1/16" ply Forward and Aft Main Spar Joiners

(CUB4W05), test fit (DO NOT GLUE) the two wing panels

together. With the center of the wings resting on the work

surface, block up both wing tips 5/8" (1/2" for the clipped wing)

as measured from the work surface to the bottom of rib #7.

Check the fit of the spars and the TE to make sure they meet

up nicely without producing any sweep in the wing. Take the

panels apart and sand the spars or TE’s if necessary to achieve

the correct alignment. NOTE: The holes in the die-cut 1/8"

plywoodFront Spar Joiner and the holes in the die-cut1/16" ply

Forward Main Spar Joiner must be centered on the centerline

of the wing.Make sure you trim the ends of the spar joiners as

needed to allow the wing panels to come together and the

spars to touch. It is typical to have to trim 1/16"from the ends

of the joiners.It is also likely likely that you will have to deepen

the notches in the #2 ribs slightly to allow the joiners to slide

fully into place.

❏ 2. Glue the three die-cut 1/8" plywood Dihedral Braces

(CUB4W07) together as shown in the photo.

Joining the Wing Panels

15

Page 16

❏ 3.Tr ial fit the dihedral brace between the main spars of

the wing. Sand the edges of the dihedral brace if necessary

to get it to fit without forcing the spars apart.

❏ 4. IMPORTANT: Use a good quality non-brittle epoxy

for this task,such as Great Planes Pro 30-minute Epo xy.

Place waxed paper on the work surface and mix up a batch

of epoxy. Apply it to the top and bottom of the dihedral brace,

the spar joiners, the spars, spar ends and the ends of both

TE’s.Apply plenty of epoxy, to fully fill all voids at the center

of the wing. Slide the spar joiners and the dihedral brace

into one wing panel first. Slide the other wing panel into

place and wipe off any excess epo xy. Immediately proceed

to the next step.

❏ 5. Block up each wing panel 5/8" (1/2" for the clipped

wing) as measured from the work surface to the bottom of rib

#7. Carefully align the spars and the TE of both wing panels.

Clamp the spar joiners to the spars and wipe off any excess

epoxy with a paper towel.Allow the epoxy to fully harden

before disturbing the wing and removing the clamps.

Wipe out any excess epoxy in the holes in the forward main

spar joiner.

❏ 6. Securely glue the remaining four 1/16" balsa vertical

grain shear webs to the front and back sides of the main

spar joiners between the #2 and #3 ribs.

❏ 7. Install the two #1B ribs as shown in the photo.The top

surface of each rib should be flush with the top surface of

the spars.

❏ 8. Round off one end of each 1/4" x 3" hardwood Wing

Dowel (DOWEL017). Slightly chamfer the other end of each

dowel.Slide the chamfered end of both dow els into the wing

and securely glue them to both spar joiners with either thick

CA or epoxy.

❏ 9. Install the two #1A ribs as shown in the photo.The top

surface of each rib should be flush with the top surface of

the spars.

16

Page 17

❏ 10. Glue the die-cut 1/16" ply TE Joiner (CUB4W05) in

place between the #1B ribs as shown in the photo.

❏ 11. Glue the 5/16" x 3/8" x 1" basswood Aileron Servo

Rails (CUB4W22) to the inboard sides of both #1B ribs as

shown on the plans.Line up the front edge of each servo rail

with the embossed angled line near the back of the pushrod

hole in the ribs.The embossed line will be on the wrong side

of one rib, but you can still eye it while positioning the servo

rail. NOTE: If you are using a servo smaller than a Futaba

S148, you may need to glue a spacer between the servo

rails and the ribs to correctly space the rails to fit your servo.

❏ 12. Cut all the arms except one off of a large servo horn

and mount the Threaded Ball (SCRW058) in the outer hole

of the arm as shown in the photo. Install the arm on the

servo so it is perpendicular to the servo (neutral position).

(Wing is upside down in photo.)

❏ 13. Hold your aileron servo in position against the servo

rails and mark where to drill the mounting holes. Drill 1/16"

holes at each mark and mount your servo using the screws

provided with the servo. NOTE: The screws are installed

from the bottom side of the servo lugs.

❏ 14.Drill a 1/8" hole at the punch mark on each die-cut 1/8"

plywood Bellcrank Mounting Plate (CUB4W09). Assemble

the 90 degree nylon bellcranks on each plate as shown in the

sketch above. NOTE: The outer holes in each bellcrank must

be drilled with a #49 (5/64") drill to ensure a good slop-free

fit to the .074" diameter pushrod wires. Apply epoxy to the

bellcrank nut and bolt to prevent them from loosening

but do not get epoxy on the bellcrank.

❏ 15. Position the bellcrank mounting plates in the notches

provided in the #6 ribs with the bellcranks on the bottom

side of the wing and securely glue them in place.

❏ 16. Cut two 24" long pieces of Threaded Pushrod Wire

from the two .074" x 35" pushrod wires that are threaded on

both ends (WIRES10). NOTE: Save the remaining pieces

of pushrod wire for another step.

Install Aileron Linkage

17

Page 18

❏17.Cut eight pieces of the Inner Pushrod T ube (PLTB004)

approximately 1/4" long to make the pushrod wire spacers.

Slide four spacers on each of the 24" long pushrod wires.

Space them out on the wire as shown on the wing plan.Add a

very small drop of thin CA to each spacer to hold it in place.

Thread each 24" long pushrod wire completely into the Nylon

Double Ended Ball Link (NYLON55). Now back each wire

out three full turns.

(Wing is right side up in photo.)

❏ 18. Slide the aileron pushrod assembly into the wing

and snap the double ended ball link onto the metal ball.

❏ 19. With the servo arm in its neutral position, adjust each

bellcrank so it is oriented as shown on the plans.Mark where

each pushrod crosses the outer hole in each bellcrank. Be

careful to not move the servo arm while marking the wires.Cut

off each pushrod wire 5/16" outside the marks you just made.

❏ 20.Cut the 36" long Outer Pushrod Tube (PLTB011) into

two 18" long pieces. Scuff up the outer surface of each

pushrod tube with 150 grit sandpaper so the glue will

adhere better. Slide the 18" long outer pushrod tubes over

each aileron pushrod wire.

❏ 21.Unsnap the nylon double ended ball link and slide the

pushrod assembly part way out of one wing panel.Bend that

pushrod wire 90 degrees at the mark you made earlier.Try to

keep the double ended ball link oriented properly during this

bending process so you won’t have to twist the wires later to

get them into the bellcranks.Slide the pushrod assembly out

the other wing panel and bend that wire 90 degrees also.

Reposition the pushrod assembly in the wing and snap the

double ended ball link onto the servo. Insert each bent

portion of the wire into the two bellcranks and secure them

with a nylon Snap Keeper (NYLON91) as shown in the

photo.Remove the aileron servo from the wing for now.

NOTE: In the next steps, maintain straightness

by keeping each wing panel down against a

flat surface while it is being sheeted.

❏ 1. Use your T-bar or other good flat sanding block to

lightly sand the top edges of the ribs to smoothly blend

them to the forward spar. Also remove any glue bumps or

other irregularities along the leading and trailing edges.

Install LE and TE Sheeting

18

Page 19

❏2. Prepare the 1/16" x 1-1/2" x 36" balsa Top Leading Edge

Sheeting (CUB4W25) by sanding the front edge to a slight

bevel so it will fit snugly against the LE (check by trial fitting).

❏ 3. Position the LE sheeting against the rear edge of the

LE moving it left or right until it is just overlapping the #2 rib.

Using thin CA, glue the front (beveled) edge of the LE

sheeting to the LE.

❏ 4. Prop up the wing on its LE as shown in the photo.

Apply a generous drop of thick CA to the top edge of each

rib and allow it to flow down to the LE. Also apply a

generous bead of thick CA to the top of the forward spar.

Immediately lay the wing panel down on a flat surface and

bend the LE sheeting down onto the ribs and forward spar.

Hold the sheeting down with something flat (like a T-Bar or

flat block of wood) until the glue cures. It is important to

keep the wing flat until the glue has cured or you may

build a warp into the wing!

❏ 5. Wet the LE sheeting with a wet paper towel from rib #7

to the end of the sheet. Form the sheeting down against the

wing tip and glue along the LE and the edge of the wing tip.

Hold the sheeting against the wing tip until the glue sets.

Tr im the sheeting even with the wing tip.

❏ 6. Place the 1/16" x 1-3/8" x 36" Top TE sheeting

(CUB4W13) in place against the tapered TE so the inboard

end of the sheeting is even with the wing centerline. Cut a

notch in the TE sheeting at rib #7 to allow it to sit down onto

the rib. Securely glue the sheeting in place and then tr im it

along the outboard TE and rib #7 just as you did for the

bottom TE sheeting.

❏ 7. Lightly sand the bottom edges of the r ibs to smoothly

blend them to the bottom forward spar. Also remove any glue

bumps or other irregularities along the leading and trailing

edges. Note: DO NOT sand off the bottom of the rib behind

the forward spar , because a “Step”must be maintained at the

aft edge of the spar for the 1/16" sheeting.Examine the cross

section on the wing plan before proceeding.

❏8. Install the 1/16" x 1-1/4" x 36" balsa Bottom LE Sheeting

(CUB4W26) following the same sequence you used on the top

LE sheeting.

❏ 9.Wet and form the bottom leading edge sheeting at the

wing tip like you did the top leading edge sheeting.Glue the

sheeting to the LE and the wing tip, then trim the sheeting

and sand the entire tip as shown in the photo.

19

Page 20

❏ 1. Use a sanding block to sand off any excess epoxy on

the top and bottom of the spars in the center of the wing.

Also lightly sand both the tops and bottoms of each rib to

remove any glue bumps or other irregularities.

❏ 2. Mark a center line on one of the 1/16" x 3" x 14-7/8"

balsa Center Sheets (CUB4W14) lay the sheet against the

back edge of the leading edge sheeting and mark the edge

of the sheet on the ribs and spars. Remove the sheet and

apply thick CA to the ribs and spars. Press the sheeting

down and hold it in place until the glue sets.

❏ 3.Slide a second piece of top center sheeting up against

the first piece and glue it in place.Cut a third piece to fill the

gap between the second piece and the TE and glue it in

place. Save the scrap from the third piece.

❏4. Use a 2-1/2" diameter circle template or the outline drawn

on the plans as a guide for cutting a smooth radius at each

corner of the top center sheeting as shown in the photo.Sand

the edges smooth with a piece of fine (220 grit) sandpaper.Use

extreme caution to avoid cutting into the spars!

❏ 5. Trim a piece of the 1/16" x 3" x 14-7/8" center wing

sheeting to fit between the spar and the bottom LE

sheeting. It also must fit between the first two #3 ribs as

shown in the photo.

❏ 6. Glue the remaining piece of center wing sheeting

behind the spar and use the scrap left over from the top of

the wing to fill in to the TE. This sheeting also must fit

between the first two #3 ribs. Cut out between the #1B ribs

for access to the aileron servo.

❏ 7. Cut the Cap Strips from the 1/16" x 1/4" x 30"

(CUB4W15) balsa sticks to fit between the LE sheeting and the

TE sheeting, and glue them to the top of each exposed rib.

Install Center Sheeting

20

Page 21

❏ 8. Sand the front and side TOP edges of the die-cut 1/16"

plywood Wing Bolt Plate (CUB4W05) to a feathered edge.

Leave the TE square.The top of the wing bolt plate has the

embossed centerline and punch marks on it. Align the

embossed centerline with the centerline of the wing and

securely glue the wing bolt plate to the top of the wing TE so

the punch marks are showing.

❏1.T ape wax ed paper over the aileron section of the wing plan.

❏❏2. Position the 3/32" x 2-11/32" x 18" balsa Aileron

Base (CUB4W16) over the aileron view on the wing plan

and carefully mark the rib locations on both sides of the

aileron base using the guides printed on the plan.

❏❏3. Slide the Aileron Base into the groove of the 3/8"

x 5/8" x 18" grooved balsaAileron LE (CUB4W17).Position

the base so it is perpendicular to the face of the LE and glue

it in place with thin CA.

❏❏4. Cut the Aileron Ribs from the 3/32" x 1/4" x 30"

balsa stick (CUB4W18). Glue the ribs to both sides of the

ailerons lining them up with the rib locations you marked

earlier. Make sure the ribs are perpendicular to the aileron

base and tight against the LE.

❏❏5. Use a razor plane and a T-bar or other good flat

sanding block to shape the ribs to the cross section shown

on the wing plan. As you can see on the cross section, the

ribs should taper to nothing near the TE of the aileron.

❏ 6. Repeat steps 2 - 5 to make a 2nd aileron.

❏ 7. Draw an accurate centerline along the LE of the

ailerons and the wing TE.Use a razor plane and a sanding

block to shape the Aileron LE to the “V” shape shown on

the aileron cross-section view on the wing plan. Sand the

ends of the ailerons if needed.

❏ 8. Designate one aileron as Left and write an “L” on it

somewhere. Write an “R” on the other one. Test fit the Left

aileron into the left wing panel and check to make sure there

is approximately a 1/16" gap at both ends of the aileron.Sand

the ends or add scrap balsa to the ends of the ailerons to

adjust the width of this gap.Do the same for the Right aileron.

❏ 9. Glue the 1/4" x 1" shaped balsa Aileron Control Horn

Mounting Block (CUB4W19) in place as shown on the

Build the Ailerons

21

Page 22

plans. This goes on the bottom of each aileron. Sand it to

match the shape of the ribs.

NOTE: Do not glue the aileron hinges until after your

model has been covered.

❏ 1. Lay the ailerons on the plan and mark the hinge

locations on the ailerons. Center the ailerons in the wing

panels and transfer the marks over to the wing TE.

❏ 2. Cut the hinge slots in the ailerons and wing TE using a

hobby knife .(The suggested procedure was given on page 11).

❏ 3. Insert the hinges into the slots and trial fit the ailerons

in place on the wing. Do not glue the hing es until after

you have covered the wing. NOTE:There should not be

any hinge gap!

❏ 4. Position a Small Nylon Control Horn (NYLON03) on

each aileron as shown in the photo and on the wing plan.

Mark where to drill the mounting holes and remove the

control horn.

❏ 5. Drill a 3/32" hole at each mark and temporarily install

the control horns using the 2-56 x 5/8" machine screws

(SCRW002) and the nylon nutplates.You may have to cut

the aileron LE away slightly on the top to clear the control

horn nut plate. Use either thick CA or epoxy to glue the

nylon nutplate to the aileron, but do not get glue on the

screws.Cut the excess screw off flush with the nutplate.

❏ 6. Reinstall the aileron servo and snap the double ended

ball link in place. Screw a Nylon Clevis (NYLON17) with a

clevis retainer onto the threaded end of the scrap .074"

diameter pushrod wire section until the threads can be seen

inside the clevis. Snap the clevis into the outer hole of the

control horn and allow the pushrod to lay on top of the

bellcrank. Tape the aileron in its neutral position. NOTE:

Slide the silicone clevis keeper onto the base of the clevis.

❏ 7. With the aileron servo in its neutral position, mark

where the pushrod crosses the outer bellcrank hole. Cut the

pushrod off 5/16" past that mark and then make a 90 degree

bend at the mark. Insert the bent par t into the bellcrank and

secure it with a nylon snap keeper .Assemble the pushrod for

the other aileron following the same procedure.

❏ 8. Cut eight 1/4" wide x 1" long pieces of scrap 3/32" or

1/8" balsa to use as aileron pushrod braces. Position them

Install Ailerons

22

Page 23

against the aileron pushrod outer tube and glue them to

several of the ribs as shown in the photo.Securely glue the

outer pushrod tube wherever possible.

❏ 9. Adjust the length of the aileron pushrods if necessary

(by twisting the clevises) to bring both ailerons into their

neutral positions at the same time.

❏ 10. Position the die-cut 3/32" balsa Aileron Pushrod

Exit (CUB4F08) in the notches on the bottom of the #6 ribs.

Glue it in place and sand it to blend with the TE

❏❏1.Pin or tape the fuse plan to a flat surface and cover

it with waxed paper.Trial fit a die-cut 1/8" balsa Upper Front

Fuse Side (CUB4F01), Aft Fuse Side (CUB4F02) and

Lower Fuse Side (CUB4F03) together as shown in the

photo. Sand them as necessary to achieve a good fit and

glue them together with thin CA. HINT:You can also check

the alignment of these parts using a straight edge along the

lower aft edge of the assembly. Wipe off any excess glue

with a paper towel (before it cures).

❏❏2. Glue a die-cut 1/8" ply Cabin Side (CUB4F04) to

the fuse side.

❏❏3. Remove the fuse side from the plans and inspect

the glue joints for gaps, adding thick CA glue to any open

joints. Sand the glue joints smooth on both sides using a

T-bar and 150-grit sandpaper.

❏ 4. Repeat steps 1 - 3 to build the other fuse side. Place

the two assembled fuse sides together and sand the edges

as necessary to make the two sides identical.

❏❏5. Glue a die-cut 3/32" balsa Lower Fuse Doubler

(CUB4F06) to the fuse side. The front and lower edges of

the doubler should be flush with the edges of the fuse side.

❏❏6. Glue a die-cut 3/32" balsa Upper Fuse Doubler

(CUB4F07) in place.The front and top edges of the doubler

should be flush with the edges of the fuse side.

❏❏7. Glue a die-cut 3/32" balsa Aft Fuse Doubler

(CUB4F08) in place. It should line up with the fuse sides as

shown in the photo.

❏ 8.Go back to step 5 and add the remaining doublers to the

other fuse side. Be sure to make a Right and a Left side!

Prepare Fuse Parts

FUSELAGE ASSEMBLY

23

Page 24

❏ 9. Test fit the two die-cut 1/8" balsa Aft Fuse Tops

(CUB4F05) together. Sand them if necessary to achieve a

good fit and glue them together as shown in the photo.

❏ 10. Use the aft fuse top to help position the die-cut 3/32"

balsa Cabin Doublers (CUB4F08) as shown in the photo.

The aft edge of the vertical slot (where the arrow is pointing)

should be even with the aft edge of the cabin. Glue the

doublers in place with thin CA.

❏ 11. Locate the die-cut 1/8" ply Former F1A (CUB4F04)

and the die-cut 1/8" ply Former F1B (CUB4F11). Securely

epoxy F1B to F1A so they are aligned with each other and

the punch marks on F1A are showing.The kit has two F1A

formers only one is used in the kit disregard the other.

❏ 12. If you are going to use the engine mount supplied

with the kit, drill a 5/32" hole through the firewall at each of

the four engine mount punch marks.If you are going to use

a different mount, center it on the embossed lines and mark

and drill the mounting holes.

❏ 13. Glue one of the 1/8" x 2-3/8" x 2-3/8" ply Firewall

Doublers (CUB4F18) to former F1B so that it is centered over

the engine mount holes as shown in the photo.After the glue

cures, drill the engine mount holes through the firewall doubler

as well.Note: There are two Firewall Doublers included in this

kit only one of them is used at this time (the other one may be

needed later depending on the size of your engine.

❏ 14. Insert the #6-32 Blind Nuts (NUTS003) into the

engine mounting holes on the doubler. Tap the blind nuts in

place with a hammer.Apply epoxy or thick CA to the blind nut

flanges and the doubler to hold them in place.NOTE: Do not

allow the glue to enter the threaded portion of the blind nuts.

❏ 15. Glue the die-cut 1/8" ply F2B (CUB4F10) to the die-cut

1/8" ply F2A (CUB4F10) as shown in the photo.It is important

to line up the wing dowel holes as precisely as possible.Drill

a 3/16" hole at each of the punch marks on F2A.

❏ 16. Align the two die-cut 1/8" ply Wing Mounting Blocks

(CUB4F12) with each other and securely glue the two together.

❏ 17. Drill a 3/16" hole at each of the punch marks on

formers F3, F4, and F5.

24

Page 25

❏ 1.Test fit Former F2 in place on the left fuse side so that

F2B is in front of F2A. Press it down into its slots and use a

90 degree triangle to keep it perpendicular to the fuse side.

Glue it in place with thin CA.

❏ 2.Test fit die-cut 1/8" ply Former F3 (CUB4F11) in place

on the left fuse side and use the die-cut 1/8" ply F3 Angle

Gauge (CUB4F09) to properly slant it backwards. Make

sure to install the former in the proper direction (see plans).

Tack glue it in place with thin CA but do not glue the angle

gauge in place. Note: You may have to sand off part of the

lower tabs on the sides of F3 to permit the edge of F3 to rest

fully down on the fuse side along its full length. If the tab

protrudes through the fuse side it will contact the workbench

before the edge of F3 contacts the fuse side.

❏ 3. Position die-cut 1/8" ply Formers F4 (CUB4F10) and

F5 (CUB4F12) in their respective slots on the left fuse side.

Use the die-cut F4 (CUB4F09) and F5 (CUB4W07) angle

gauges to slant them backwards. Tack glue F4 and F5 in

place with thin CA.Do not glue the angle gauges to the fuse

side. Do not apply glue to the joints near the TOP of former

F3, because you will later (step 6) have to spread the fuse

sides to install the wing mounting block.

❏ 4. Position the right fuse side in place so all four formers

key into their slots. Tack glue the fuselage side to the

formers. Do not apply glue to the joints near the TOP of

former F3, because you will later (step 6) have to spread the

fuse sides to install the wing mounting block.

❏ 5. Slide the 3/32" balsa aft fuse top that you assembled

earlier into place and allow the formers to key into their

notches.Make sure the fuselage is symmetrically lined up with

the top and glue the top to the fuse sides and the formers.

Glue the aft portion of the cabin doubler to the aft fuse top

❏ 6. Slide the laminated Wing Mounting Block into the

notch in the cabin side doublers and lock the tab into F3.

Securely glue it in place with epoxy. As you glue the wing

mounting block in place, also securely glue the upper portion

of Former F3 to the fuse sides.

❏ 7. Place the die-cut 1/8" ply Lower Tank Floor (LTF)

(CUB4F09) into the bottom notches of former F2.Make sure

the embossed letters are towards the top of the fuselage

since this former helps set the correct right thrust. Glue the

lower tank floor at the rear tabs only.

Assemble Fuselage

25

Page 26

❏ 8. Inser t the top tab of the die-cut 1/8" ply Cabin Brace

(CUB4F12) into the notch at the bottom of former F2B.

Insert the die-cut 1/8" ply Top T ank Floor (TTF) (CUB4F09)

with the embossed “TTF” facing upward, rear tabs into the

top notches of former F2. Allow the cabin brace legs to key

into their notches in the top tank floor.Glue the top tank floor

at the F2 notches only. LTF and TTF lay on the ledges

formed by the fuselage doublers.

❏ 9. Press the firewall all the way onto the tabs at the front

of both tank floors. Make sure it is properly seated on the

tabs as this sets the correct amount of right thrust. Glue the

firewall to the tank floors only.

❏ 10. Use good, stout hardwood sticks and multiple rubber

bands to pull the fuse sides together. As you add rubber

bands the fuse sides will gradually come together until they

mate with F1.Make sure these parts fit together properly first,

trimming as necessary, then remove some of the bands, Mix

up some epoxy and apply it to the edges of the firewall and

tank floors and add bands to pull the sides back into place.

Wipe off any excess epoxy before it cures. Immediatel y

proceed to the next step.

❏11.Go over all the joints , gluing them securely with medium

CA. Pay special attention to all glue joints that involve Former

F2.The arrows in the photo show the joints that require special

attention.Apply a fillet of 5-minute epoxy to the joint where the

Cabin Brace meets F2 and F2B.It is essential to have secure

glue joints in these areas, as these components form the

structure that holds the wing on. Avoid excessive buildup of

glue in the areas where the side windows will be installed.T rim

and sand off the tab at the top of the Cabin Brace where it

protrudes behind F2.

❏12.Press the die-cut 1/8" ply Instrument Panel (CUB4F04)

into the slot on the top of the top tank floor.Hold it perpendicular

to the tank floor and glue it in place. Note: Two Instrument

Panels are included in this kit, only one is required.

❏ 13. Cut three Stringers from the 3/16" x 3/16" x 24"

balsa stick (CUB4F14) to fit between the firewall and the

instrument panel. Glue them in place with thin CA.

26

Page 27

❏14.Cut two 4-3/4" long sheets from the 3/32" x 3" x 12" balsa

Nose Sheeting (CUB4F16).Glue one piece of sheeting to the

right fuselage side and stringer so the corner of it is against the

cabin side. Do not bend it around the firewall yet. Fir mly apply

two or three 15" long pieces of strapping tape to the sheeting.

Wet the outside of the nose sheeting with a paper towel and

allow it to soak for about 5 minutes .Carefully pull the strapping

tape around and stick it to the other fuselage side.Mark where

the sheeting crosses the middle of the center stringer and

release the strapping tape.Pull the strapping tape back enough

to allow you to cut the sheeting on your marks. Pull the tape

back to the other fuse side and glue the sheeting in place.

❏15.Apply the remaining piece of nose sheeting on the other

half of the nose, using the same technique described above.

The nose sheeting must join at the middle of the center

stringer.Trim the nose sheeting even with the instrument panel

and the front of the fuselage sides.

❏16.Cut four 2" long pieces of 1/4" balsaT riangle(CUB4F24)

and securely glue two of them to the front of the firewall, against

the fuse sides and between the doublers as shown in the photo .

Glue the other two to the backside of the firewall, similar to the

two pieces in front.

❏ 17. Place the die-cut 1/8" ply Servo Tra y (CUB4F12) in

the fuselage on the ledges of the lower fuselage doublers as

shown.If you are using a lighter 2-cycle engine, glue the tray

as shown in the photo. If you are using a 4-cycle engine,

slide the tray back against former F3 and glue it in place.

Glue the two servo tray doublers (which were die-cut inside

the servo tray opening) to the bottom of the servo tray at

the front and back of the servo opening. NOTE: Do not glue

the servo tray too far forward or you will not be able to get

the receiver battery in under the lower tank floor.

❏18.Scuff up the outside of the two 24" long Outer Pushrod

Tubes (PLTB011) with 150 grit sandpaper to help the glue

stick to them. Slide them through the rudder and elevator

pushrod holes in formers F3, F4, F5 and out through the slots

in the fuselage sides. Position the tubes so they extend past

the fuselage side approximately 2"(to allow for trimming later).

Cut the front of the tubes off approximately 2" forward of

former F3. If you would like to install a pushrod tube to route

the receiver antenna inside the fuselage, slide another tube

(not included) through the holes at the bottom of each former.

It should extend to the aft edge of the fuselage sides.Securely

glue the tubes to each of the formers and the fuse sides.

❏ 19. Position the antenna tube near the bottom corner

where the fuselage sides come together and glue it in place.

27

Page 28

❏ 20. Insert the die-cut 1/8" ply Top Deck Former #4

(CUB4F11) into its slot at the tail end of the balsa aft fuse

top. Slide the die-cut 1/8" ply Stab Base into its position

behind TDF #4 so that it keys into the former. Pull the

fuselage sides in to meet the former and stab base, and

securely glue the stab base only in place. (Note: Do not

glue TDF #4.) Remove the turtle deck former for now.

❏ 21. Go back and securely glue all formers by applying

more thin CA, if needed, and then thick CA to each joint.

Note:The 1/8" Firewall Doubler (spacer) is used, as needed,

to position the engine at the desired distance from the

firewall.Depending on your engine size, you may ha ve to use

two or even three spacers to achie v e the correct spacing.Y ou

may cut the extra die-cut firewall (CUB4F04) to 2-3/8" x 23/8" and use it as an extra spacer.The plans show the thrust

washer at 5", but 5-1/8" is best.Do not glue these spacers in

at this time. When you later fit the cowl, you may decide to

adjust the fore-aft position of the engine slightly.

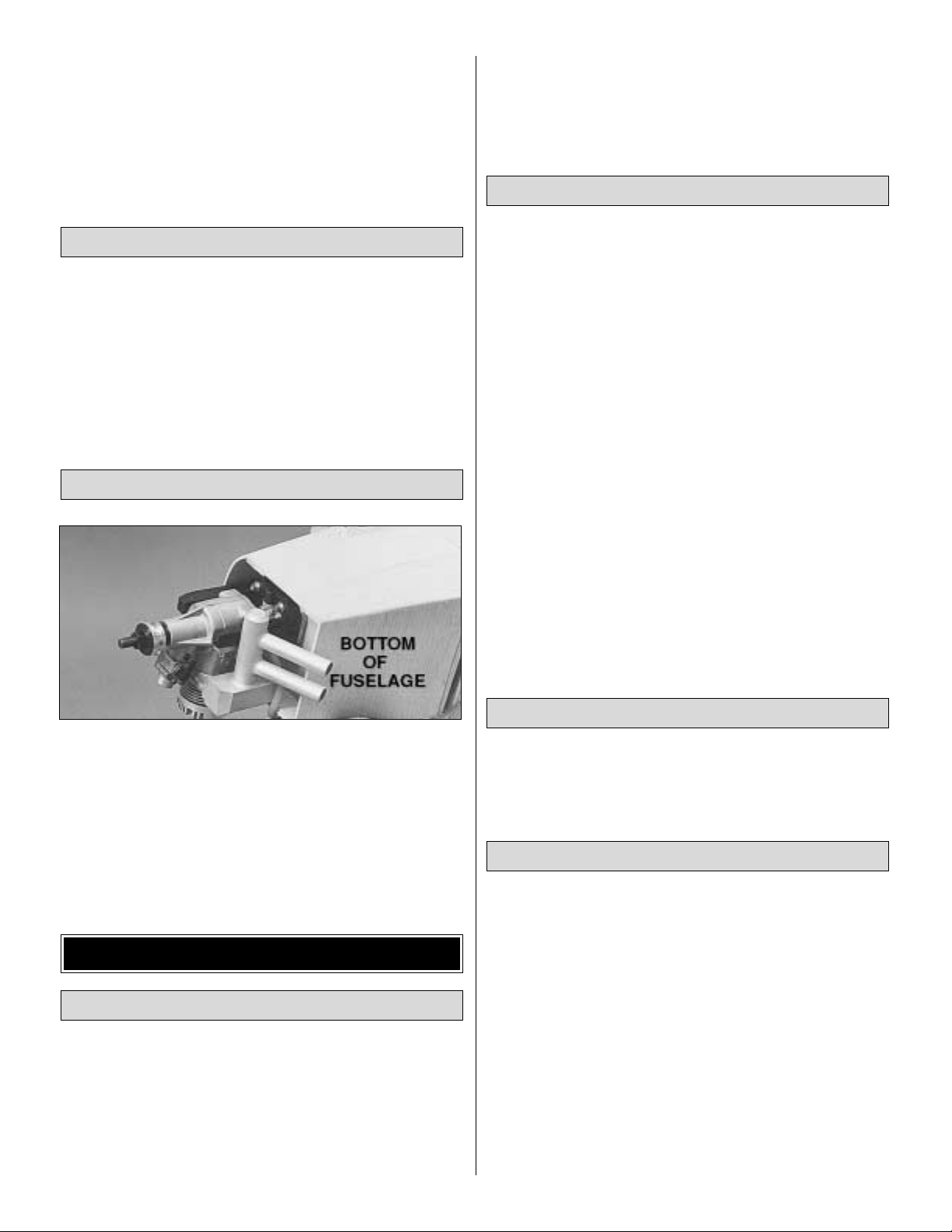

NOTE:If you are using a 4-Cyc le Engine,skip to step #3.

❏ 1. Draw two lines on the 1/8" x 2-3/8" x 2-3/8" Firewall

Doubler (CUB4F18) that extend from one corner across to

the diagonal corner as shown in the photo. This spacer is

not required for most 4-cycle engines.

❏ 2. Place the left side of the engine mount on the mount

spacer and center it on the diagonal lines you just drew.Mark

the mounting holes on the diagonal lines and then drill a 3/16"

hole at each mark. NOTE: You will not glue this doubler to the

firewall. It is used as a spacer only. Later, if you decide to

change to a 4-cycle engine, you can easily remov e the spacer .

❏ 3. Determine whether you want your engine side mounted

or inverted. We recommend side mounting, but an inverted

engine may allow you to use tw o dummy engines on the cowl.

Screw the mount to the firewall using the 6-32 x 1" machine

screws (SCRW008) provided. If you are using a 2-cycle

engine, place the 1/8" spacer you just drilled between the

mount and the firewall.

❏ 4. Set the engine on the engine mount and measure from

the firewall to the front of the thrust washer .Adjust the engine

on the mount until the front of the thrust washer is 5-1/8"

[130mm] away from the face of the firewall. Mark the

mounting hole locations on the mount. Remove the engine

from the mount and accurately drill 7/64" (or #36) holes.

NOTE: If you have access to a drill press, use it for drilling

these holes to insure that they are drilled vertically.

❏ 5. Now you may use one of the following methods to

attach your engine to the mount:

❏ Method 1: Screw the #6 x 3/4" sheet metal screws

(SCRW018), provided in the kit, through the engine

mounting flange and into the mount. When first installing

these screws, put a drop of oil into each screw hole.

❏ Method 2: Cut threads in the holes you just drilled

using a 6-32 tap and tap wrench. If you use this method

you’ll have to supply your own bolts (6-32 x 1" socket head

cap screws) for attaching the engine to the mount.

Install Engine Mount and Fuel Tank

28

Page 29