Page 1

WARRANTY

Great Planes Model Manufacturing Co.guarantees this kit to be free from defects in both material and workmanship

at the date of purchase.This warranty does not cover any component parts damaged by use or modification. In no case

shall Great Planes’ liability exceed the original cost of the purchased kit. Fur ther, Great Planes reserves the right

to change or modify this warranty without notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the final user-assembled product.By the act

of using the user-assembled product, the user accepts all resulting liability.

If the buyers are not prepared to accept the liability associated with the use of this product,they are advised

to return this kit immediately in new and unused condition to the place of purchase.

READ THROUGH THIS INSTRUCTION MANUAL

FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

CUB1P05 V1.0 Entire Contents © Copyright 2000

P.O.Box 788 Urbana, IL 61801 (217) 398-8970

productsupport@greatplanes.com

INSTRUCTION MANUAL

TM

USA

MADE IN

IMPROVED

Page 2

SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . 2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

IF YOU’RE NEW TO ELECTRICS. . . . . . . . . . . . . . . . . . 3

Keep it Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

DECISIONS YOU MUST MAKE . . . . . . . . . . . . . . . . . . . 3

Radio Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Motor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chargers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PREPARATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Required Accessories . . . . . . . . . . . . . . . . . . . . . . . 4

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Building System. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Optional Supplies & Tools . . . . . . . . . . . . . . . . . . . . 5

Common Abbreviations . . . . . . . . . . . . . . . . . . . . . . 6

Types of Wood. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Metric Conversions . . . . . . . . . . . . . . . . . . . . . . . . . 6

Important Building Notes . . . . . . . . . . . . . . . . . . . . . 6

Die Patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

BUILD THE TAIL SURFACES. . . . . . . . . . . . . . . . . . . . . 8

Build the Fin and Rudder . . . . . . . . . . . . . . . . . . . . . 8

Build the Stabilizer and Elevator. . . . . . . . . . . . . . . . 8

Finish the Tail Surfaces . . . . . . . . . . . . . . . . . . . . . 11

BUILD THE WING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Build the Wing Panels . . . . . . . . . . . . . . . . . . . . . . 11

Join the Wing Panels . . . . . . . . . . . . . . . . . . . . . . . 14

Assemble and Install the Wing Tips . . . . . . . . . . . . 15

Build the Ailerons . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Finish the Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

BUILD THE FUSELAGE. . . . . . . . . . . . . . . . . . . . . . . . 19

Assemble the Fuselage Sides . . . . . . . . . . . . . . . . 19

Join the Fuselage Sides . . . . . . . . . . . . . . . . . . . . . 21

Sand the Fuselage. . . . . . . . . . . . . . . . . . . . . . . . . 27

Mount the Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mount the Stabilizer and Fin. . . . . . . . . . . . . . . . . . 29

Install the Dowel Stringers . . . . . . . . . . . . . . . . . . . 30

Mount the Landing Gear . . . . . . . . . . . . . . . . . . . . 31

Build the Motor Mount . . . . . . . . . . . . . . . . . . . . . . 32

Mount the Cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Construct the Wing Struts . . . . . . . . . . . . . . . . . . . 34

RADIO INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 34

Mount the Servos. . . . . . . . . . . . . . . . . . . . . . . . . . 34

Install the Nylon Control Horns . . . . . . . . . . . . . . . . 35

Make the Pushrods . . . . . . . . . . . . . . . . . . . . . . . . 35

BALANCE THE AIRPLANE LATERALLY. . . . . . . . . . . 37

FINISHING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Final Sanding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Covering the Model . . . . . . . . . . . . . . . . . . . . . . . . 37

Painting Your Model . . . . . . . . . . . . . . . . . . . . . . . . 38

FINAL HOOKUPS AND CHECKS . . . . . . . . . . . . . . . . 39

Install the Hinges. . . . . . . . . . . . . . . . . . . . . . . . . . 39

Install the Wheels. . . . . . . . . . . . . . . . . . . . . . . . . . 40

Install the Plastic Parts. . . . . . . . . . . . . . . . . . . . . . 40

Install the Motor Battery. . . . . . . . . . . . . . . . . . . . . 41

Reinstall the Radio System . . . . . . . . . . . . . . . . . . 41

BALANCE YOUR MODEL . . . . . . . . . . . . . . . . . . . . . . 42

FINISH THE RADIO INSTALLATION . . . . . . . . . . . . . . 43

INSTALL THE WING STRUTS . . . . . . . . . . . . . . . . . . . 43

SET THE CONTROL THROWS . . . . . . . . . . . . . . . . . . 44

PROPER CARE OF YOUR MOTOR . . . . . . . . . . . . . . . 44

PERFORMANCE TIPS. . . . . . . . . . . . . . . . . . . . . . . . . 45

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Charge the Radio Batteries . . . . . . . . . . . . . . . . . . 45

Balance the Propeller. . . . . . . . . . . . . . . . . . . . . . . 45

Find a Safe Place to Fly . . . . . . . . . . . . . . . . . . . . . 46

Ground Check the Model . . . . . . . . . . . . . . . . . . . . 46

Range Check Your Radio . . . . . . . . . . . . . . . . . . . . 46

AMA SAFETY CODE. . . . . . . . . . . . . . . . . . . . . . . . . . 46

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Radio Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

FLYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2-VIEW DRAWING. . . . . . . . . . . . . . . . . . . . . back cover

Your ElectriCub is not a toy, but rather a sophisticated,

working model that functions very much like an actual

airplane. Because of its realistic performance, the

ElectriCub, if not assembled and operated correctly,

could possibly cause injury to yourself or spectators and

damage property.

To make your R/C modeling experience totally

enjoyable, we recommend that you get experienced,

knowledgeable help with assembly and during your

first flights.You’ll learn faster and avoid risking your model

before you’re truly ready to solo.Your local hobby shop has

information about flying clubs in your area whose

membership includes qualified instructors.

You can also contact the national Academy of Model

Aeronautics (AMA), which has more than 2,500 chartered

clubs across the country. Through any one of them,

instructor training programs and insured newcomer training

are available. Contact the AMA at the address or toll-free

phone number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

or via the Internet at http://www.modelaircraft.org

PRO TECT YOUR MODEL,Y OURSELF

& OTHERS...FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

TABLE OF CONTENTS

2

Page 3

1. Build the plane according to the plan and instr uctions. Do

not alter or modify the model, as doing so may result in an

unsafe or unflyable model. In a few cases the plan and

instructions may differ slightly from the photos. In those

instances the plan and written instructions are correct.

2.Take time to build straight, true and strong.

3. Use an R/C radio system that is in first-class condition,

and a correctly sized motor and components (batteries,

wheels, etc.) throughout your building process.

4.You must properly install all components so that the model

operates properly on the ground and in the air.

5.You must check the operation of the model before every

flight to ensure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

nylon clevises or other connectors often and replace them if

they show signs of wear or fatigue.

Remember:Take your time and follow directions to end

up with a well-built model that is straight and true.

Please inspect all parts carefully before starting to

build! If any parts are missing, broken or defective, or if

you have any questions about building or flying this

airplane, please call us at:

(217) 398-8970

or e-mail us at:

productsupport@greatplanes.com.

If you are calling for replacement parts, please

reference the part numbers and the kit identification

number (stamped on the end of the carton) and have

them ready when calling.

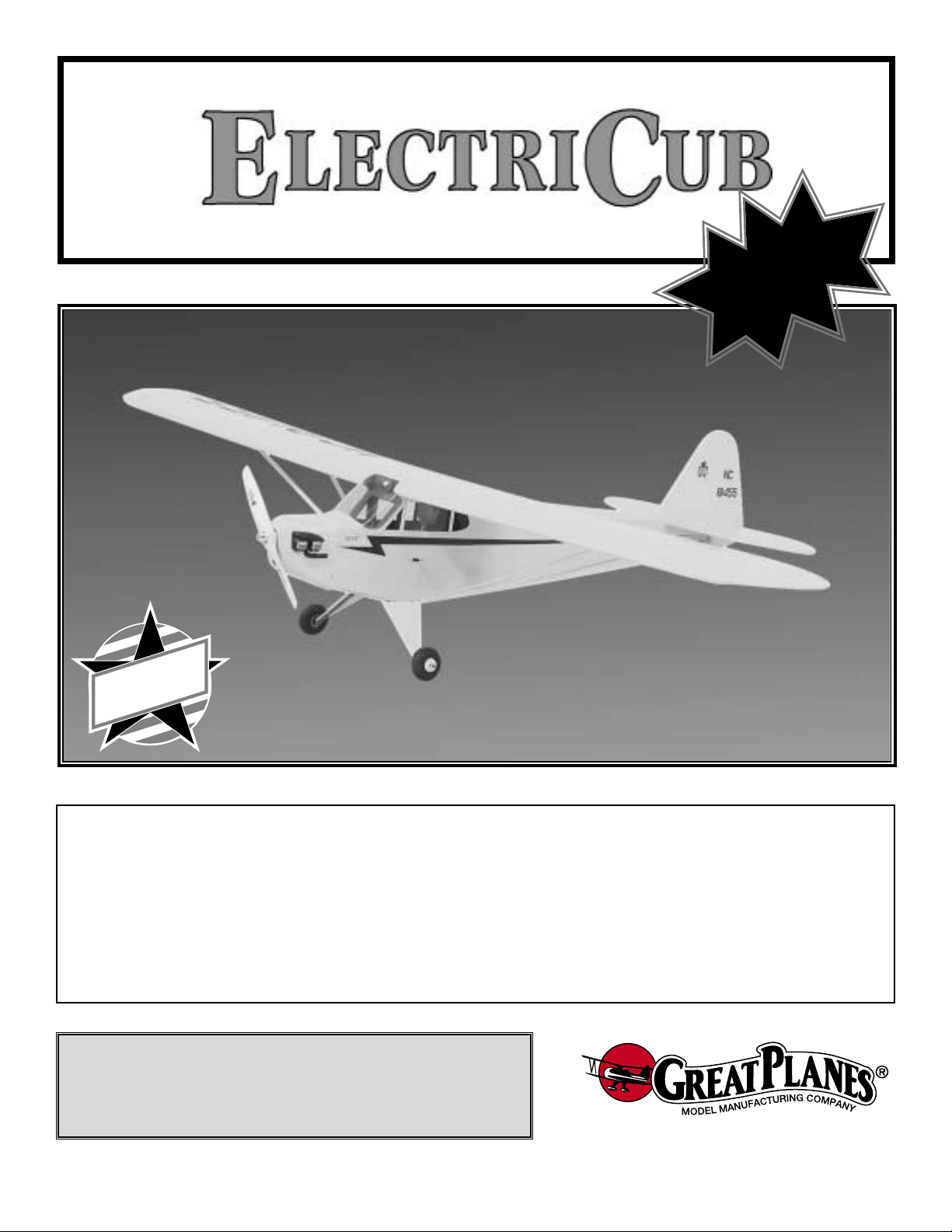

Since the original ElectriCub was introduced in 1987, electric

airplanes have grown in popularity and so has the technology.

Over the years modelers have told us what they would like to

see different on the ElectriCub. We've been listening! The

redesigned ElectriCub now comes with ailerons, clear windows

and is designed for mini servos.We've done extensive testing

of motors, gearbox es and props to find the best combination, at

the lowest price, for the new ElectriCub.

While the ElectriCub is easy to fly, it does not have the total

self-recovery and stability of a basic trainer like the Great

Planes series of PT basic trainers. Therefore, if you have

never flo wn an R/C airplane before , we strongly recommend

that you seek out the assistance of an experienced R/C pilot

who will be able to check out your construction and help you

with your first flights.We do know that once you have flown

the ElectriCub you will want to keep it in your vehicle for that

quick flight during your lunch break or to relax with a few

flights after work.

Keep It Light

Because the electric motor and motor battery are relatively

heavier than a glow engine, it is essential that the basic

structure of the airplane be kept as light as possible. In

doing so, you will help insure that the finished airplane will

not be too heavy to fly well.

One way to pre vent excess weight build-up is to use only as

much glue as needed for a good glue joint. Do not apply

extra “fillets” of glue thinking that it will make your plane

stronger! Extra glue could possibly add ounces to the

weight of your plane and detract from the performance.

We will give you tips throughout this book on how to keep

the structure light and we urge you to follow them.

Radio Selection

Because weight is an important factor in the ElectriCub,

the ideal radio system is one that has a miniature

receiver, three mini servos such as Futaba®’s S3101

servos and an electronic speed control with BEC (Battery

Eliminator Circuitry such as the Great Planes Speed 300

GPMM2030). The electronic speed control with BEC

uses the motor battery , not a separate receiv er battery, to

power the receiver and servos. When the motor batter y

voltage reaches a preset voltage, the BEC on the speed

control stops the motor while still supplying power to the

receiver and servos.This setup can reduce the weight of

the plane by as much as 4 oz. However, the ElectriCub

will fly great with four mini servos, a 270 mAh receiver

battery and a micro switch. This setup is a great,

inexpensive way for the first-time electric pilot to try

electric flight. Once you’re hooked on the clean and quiet

advantages of electric flight, you can replace the micro

switch with a high quality electronic speed control.

DECISIONS YOU MUST MAKE

IF YOU'RE NEW TO ELECTRICS

INTRODUCTION

NOTE: We, as the kit manufacturer, provide you with a

top quality kit and great instructions, but ultimately the

quality of your finished model depends on how you build

it; therefore, we cannot in any way guarantee the

performance of your completed model, and no

representations are expressed or implied as to the

performance or safety of your completed model.

SAFETY PRECAUTIONS

3

Page 4

4

Items in parentheses (GPMQ4243) are suggested part

numbers recognized by most distributors and hobby shops

and are listed for your ordering convenience. GPM is the

Great Planes brand, TOP is the Top Flite®brand, HCA is the

Hobbico®brand and COV is the Coverite™brand.

❏ 4 Channel radio with 4 mini ser vos

❏ (2) 2" Ultralight Wheels (GPMQ4201)

❏ (1) 3/4" Tail wheel (GPMQ4240)

❏ (4) 1/8" Wheel collars (GPMQ4304)

❏ (1) 1/16" Wheel collar (GPMQ4300)

❏ (1 Roll) Double-Sided Foam Tape (GPMQ4440)

❏ (1) 1/6 Scale Pilot

❏ (2) Rolls covering film

❏Motor battery pack charger 900 AC/DC Charger (HCAP0125)

or 925 AC/DC P eak Detection Charger (HCAP0198)

❏ 1700mAh 8.4 volt NiCd battery pack (DTXC2071) or

2000mAh 8.4 volt NiCd battery pack (DTXC2076)

Required Accessories

PREPARATIONS

Chargers

A fully charged battery pack will provide an initial “surge”

of power during the first 15 to 30 seconds of the motor

run.Then the power output stays fairly steady for the next

several minutes before dropping off quickly. If you do not

charge your battery completely, it will not deliver that

surge necessary for a good takeoff and climb out.There

are three easy ways to “peak-charge” your battery pack.

1. The easiest way is with a “peak-detecting” battery

charger. This type of charger will automatically charge

your battery until it is fully charged.

2.The second method of charging your motor batteries is

to monitor the voltage of your battery pack with a

voltmeter.Your charger may have sockets into which you

may plug a voltmeter. If not, you may insert the probes

from the voltmeter into the rear of the battery plug,

making contact with the metal contacts. As your battery

charges, the voltage will gradually increase. When the

battery is fully charged, the voltage will start to drop.At

this point your battery is fully charged.

3.The third (and least reliable) method of “peak-charging”

your battery pack is by checking its temperature. As the

battery charges it will remain cool until it is fully charged.

When it reaches the fully charged state, it will rapidly

build up heat.You can feel this heat with your hand. As

soon as the pack starts to noticeably warm up,

disconnect it from the charger. Do not continue

charging if the battery pack is hot! Overcharging will

damage your battery pack and can result in an explosion.

Motor Selection

In testing the ElectriCub, many different motors were

evaluated. Some of them provided adequate thrust to fly

the ElectriCub satisfactorily. Some, however, gave such

marginal performance that the climb-out was very shallow

and flight times were short. Generally, a high perf ormance,

high power motor , like the Great Planes S-600™direct drive

motor, will give the ElectriCub a good climb rate and good

aerobatic capability, but will result in a relatively short run

time of 3 to 4 minutes.

The Great Planes T600r™reverse rotation motor with a

2.5:1 gear drive unit enables the motor to turn a larger,

more efficient propeller at a slower speed. This usually

results in more thrust for a better climb rate and longer

flight times up to 8 minutes. We consider this motor and

gear drive combination (GPMG0760) to be the system of

choice for the ElectriCub.See “Power Systems”on page 5.

Battery Selection

The ElectriCub was designed to fly on a 7-cell 8.4 volt

1700 - 2000 mAh flat battery pack. Even though the

ElectriCub will fly well on an inexpensive motor battery

pack, we recommend a battery pack that uses Sanyo®or

Panasonic®cells. These cells have a low internal

resistance which translates into more power and less heat.

If you are new to electric airplanes (or even cars and

boats) here is a short explanation of NiCd batteries. A

single cell NiCd battery supplies 1.2 volts with no load (not

powering anything). A 7- cell battery pack can supply 8.4

volts (1.2 volts x 7 cells = 8.4 volts).The cell rating in mAh

(milli-amp-hours) is the amount of current the battery can

supply. If a battery is rated at 1700 mAh, the battery can

supply 1.7 amps for 1 hour (or 1 amp for 1.7 hours).This

sounds great – flying for over 1-1/2 hours on a single

battery charge! The bad news is that to produce the power

needed to fly an airplane the size of the ElectriCub, the

motor draws from 15-25 amps. The current consumption

reduces the run time to 4-6 minutes.The good news is that

propellers become more efficient as the speed of the plane

increases.This lowers the current draw, allowing the plane

to fly longer on a single charge, sometimes up to 20%

longer. Also, if an electronic speed control is used, the

motor can be throttled back, increasing the flight time.Most

airplanes only need full throttle during takeoff.

We recommend the use of high quality battery packs.The

higher quality batteries usually have less internal resistance

than the average battery. The higher quality battery will

provide more power to the motor than the average battery.

In NiCd batteries, internal resistance transforms power into

heat. With less internal resistance, there is more power

available to the motor and less heat is generated.We hope

this helps explain NiCd batteries and why a high quality

battery should be used in the ElectriCub.

Page 5

Power Systems

Good: GPMG0755 S-600 Motor System

S-600 motor (GPMG0710)

8 x 4 propeller

Propeller adapter

Wiring harness with fuse and micro switch

Better: GPMG0760 T600GD System with Gear Drive

T600R reverse rotation motor (GPMG0700)

2.5:1 gearbox (GPMG0850)

Propeller adapter (GPMG0855)

10 x 8 propeller for electrics

Wiring harness with fuse and micro switch

Best: GPMG0760 T600GD ESC System with Gear Drive

and electronic speed control

T600r reverse rotation motor (GPMG0700)

2.5:1 gearbox (GPMG0850)

Propeller adapter (GPMG0855)

10 x 8 propeller for electrics

Speed 300 Electronic speed control with BEC and

auto cutoff (GPMM2030)

These are the building supplies that are required. We

recommended Great Planes Pro™CA and Epoxy glue.

❏ 1 oz. Thin Pro™CA (GPMR6002)

❏ 1 oz. Medium Pro CA (GPMR6008)

❏ 6-Minute Pro Epoxy (GPMR6045)

❏ 30-Minute Pro Epoxy (GPMR6047)

❏ Thread locking compound (GPMR6060)

❏ Balsa filler (HCAR3401)

❏ Plan protector (GPMR6167)

❏ Isopropyl rubbing alcohol (70%)

❏ Paper towels

❏ Sanding block and sandpaper (coarse, medium, fine)

❏ Hobby knife (HCAR0105)

❏ #11 blades (HCAR0211)

❏ Single-edge razor blades (HCAR0212)

❏ Razor saw

❏ Razor plane (MASR1510)

❏ Electr ic drill

❏ Dr ill bits - 1/16", 3/32", 7/64", 1/8", 5/32", 11/64", 3/16"

❏ Small Phillips and flat blade screwdrivers

❏ Pliers with wire cutter (HCAR0630)

❏ Sealing iron (TOPR2100)

❏ Heat gun (TOPR2000)

❏ T-Pins (HCAR5150)

❏ Straightedge with scale (HCAR0475)

❏ Cutting mat (HCAR0456)

❏ Builder’s triangle (HCAR0480)

❏ 10-24 Tap and Drill set

❏ Masking tape (TOPR8018)

❏ Panel line pen (TOPQ2510)

❏ CG Machine™(GPMR2400)

❏ Accu Throw™Deflection Meter (GPMR2405)

❏ CA Applicator tips (HCAR3780)

❏ CA Debonder (GPMR6039)

❏ Clevis installation tool (GPMR8030)

❏ Hot Sock™(TOPR2175)

❏ Cur ved-tip canopy scissors (HCAR0667)

❏ Top Flite Precision Magnetic Prop Balancer™(TOPQ5700)

❏ Slot Machine™motorized hinge slotting tool (GPMR4010)

❏ Precision hinge mar king tool (GPMR4005)

❏ Groove tube (GPMR8140)

Great Planes Easy-Touch Bar Sanders are made from

lightweight extruded aluminum and can be found at most

hobby shops.They are available in five sizes.

5-1/2” (GPMR6169) for those tight, hard-to-reach spots;

11” (GPMR6170) for most general purpose sanding;

22” (GPMR6172), 33” (GPMR6174) and 44” (GPMR6176)

for long surfaces such as wing leading edges. The Easy-

Touch Adhesive-Backed Sandpaper comes in 2” x 12’

rolls of 80-grit (GPMR6180), 150-grit (GPMR6183) and

220-grit (GPMR6185) and an assortment of 5-1/2” long

strips (GPMR6189) for the short bar sander.The adhesivebacked sandpaper is easy to apply and remove from your

sanding bar when it’s time for replacement.

Custom sanding blocks can be made from balsa or

hardwood blocks and dowels for sanding difficult-toreach spots.

On our workbench, we have three 11” Great Planes

Easy-Touch™Bar Sanders, equipped with #80, #150

and #220-grit sandpaper.This setup is all that is required

for almost any sanding task. We also keep some

#320-grit wet-or-dry sandpaper handy for finish sanding

before covering.

Optional Supplies and Tools

Tools

Building Supplies

5

Page 6

Elev = Elevator Fuse = Fuselage

LE = Leading Edge (front) LG = Landing Gear

Lt = Left Ply = Plywood

Rt = Right Stab = Stabilizer

TE = Trailing Edge (rear) " = Inches

1. Unroll the plan sheets, then reroll the plan inside-out to

make them lie flat.

2. Sort through the sticks and sheets, grouping them by

size. Masking tape can be used to bundle matching sheets

and sticks. Using a felt tip or ballpoint pen, lightly write the

part name or size on each piece or bundle. Refer to the

parts list and plan for sizes and quantities. Use the die-cut

patterns shown on page 7 to identify the die-cut parts and

mark them before removing them from the die sheet. Save

all leftovers.If any of the die-cut parts are difficult to remove,

do not force them! Instead, cut around the parts with a

hobby knife or lightly sand the back of the sheet. After

removing the die-cut parts, use your sanding block to lightly

sand the edges to remove any die-cutting irregularities.

3. As you identify and mark the parts, separate them into

groups, such as fuse (fuselage), wing, fin, stab (stabilizer)

and hardware.

4. Work on a flat surface. Cover the plan with wax paper or

Great Planes Plan Protector to prevent glue from sticking to

the plan.

5.When instructed to test fit parts, this means DO NOT USE

GLUE until you are satisfied that everything fits properly —

THEN glue the par ts together if instr ucted to do so.

6. Whenever the instructions tell you to glue pieces

together, use CA.When a specific type of glue is required,

the instructions will state the type of glue that is highly

recommended. When 30-minute epoxy is specified, it is

highly recommended that you use only 30-minute (or

slower) epoxy because y ou will need either the working time

and/or the additional strength.

7. The easiest way to cut balsa sticks is with a single-edge

razor blade or razor saw. Position the stick over the plan,

mark its size, then cut the part on a piece of leftover wood.

A modeling miter box works well for cutting square corners

and 45-degree gussets.

Zipper-top food storage bags are handy to store the small

parts as you sort, identify and separate them into

sub-assemblies.

IMPORTANT BUILDING NOTES

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

3/4" = 19mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

15" = 381mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762mm

36" = 914.4mm

1" = 25.4mm (conversion factor)

Metric Conversions

Types of Wood

Common Abbreviations

6

Page 7

7

NOT USED

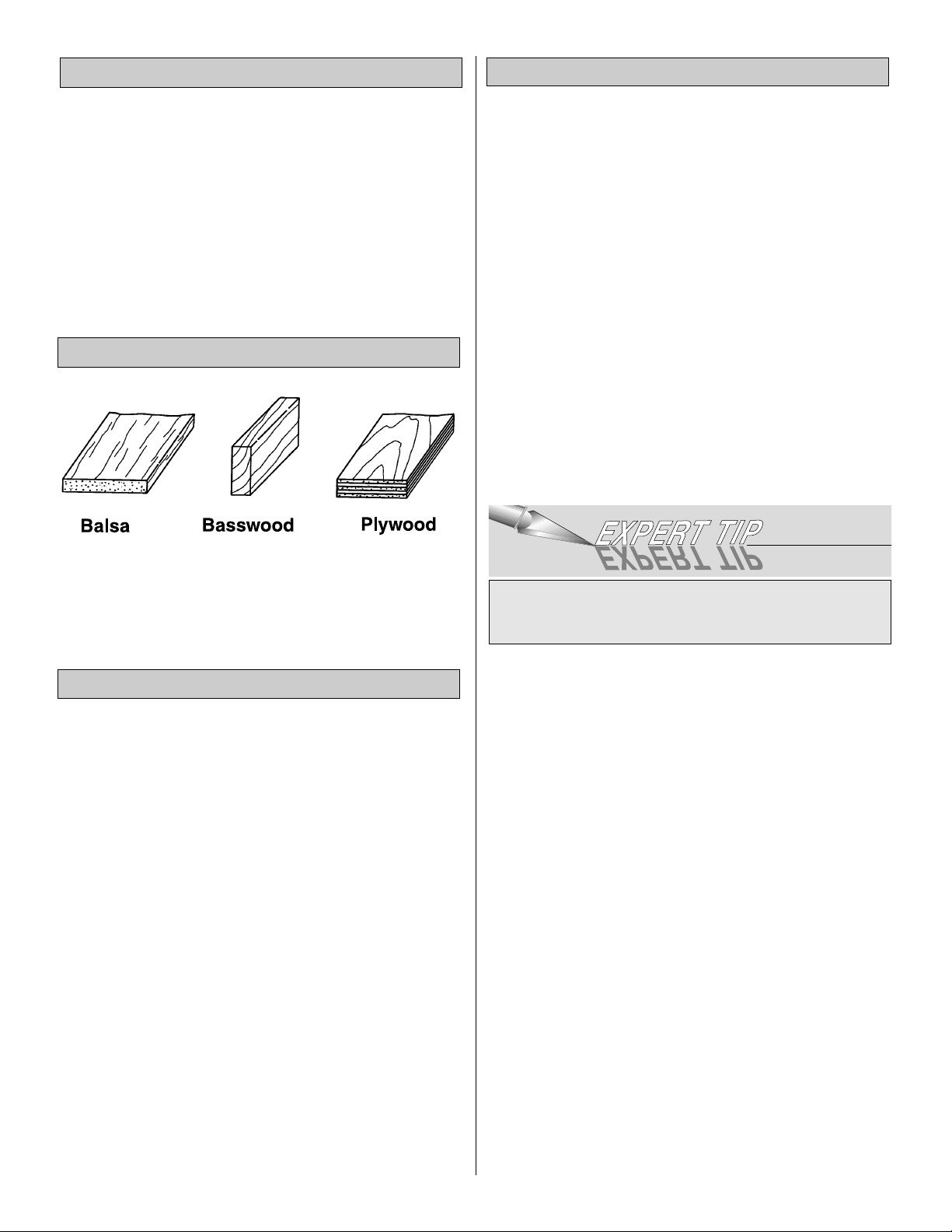

DIE-CUT PATTERNS

NOT

USED

NOT

USED

Page 8

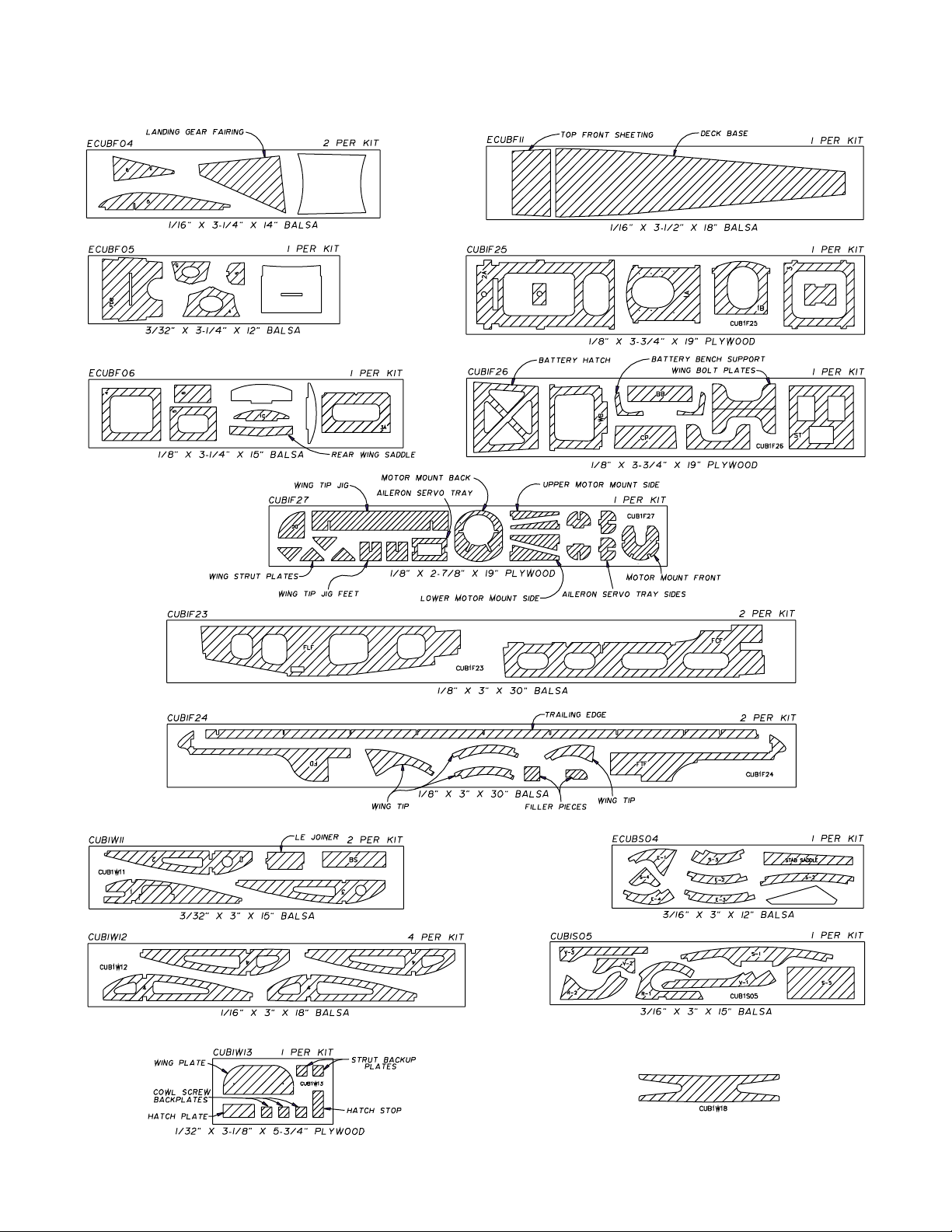

❏ 1. Cover the fin/rudder portion of the plan with wax paper

or Great Planes Plan Protector.

❏ 2. Pin the die-cut 3/16" balsa fin frame V-1, V-2 and V-3 in

position on the fuse plan, sanding the mating edges as required

for a good fit.Use thin CA to glue the fin frame together.

❏ 3. From one of the 3/16" x 3/8" x 30" balsa sticks, cut and

glue a fin base between V-1 and V -3 along the bottom of the fin.

❏ 4. From the 3/16" x 3/16" x 24" balsa stick, cut and glue

the fin rib to the frame.

❏ 5. Remove the fin from your building board.Inspect all the

glue joints and add CA to any joints that don’t look strong.

Fill any gaps with balsa sanding dust and a drop or two of

thin CA.

❏ 6. Build the r udder frame from the die-cut 3/16" balsa R-1

and R-2 frame pieces, a 3/16" x 3/8" x 30" balsa stick and the

small 3/16" x 3/8" x 5/8" hardwood tailgear support.

❏ 7. From the 3/16" x 3/16" x 24" balsa stick, cut and glue

the rudder ribs to the frame.

❏ 8.Remove the rudder from your building board.Inspect all

the glue joints and add CA to any joints that don’t look

strong.Sand the rudder and fin to shape using the fuse plan

as a guide. Sand both sides of the r udder and fin flat and

even.Be careful that you don’t sand any area too thin.

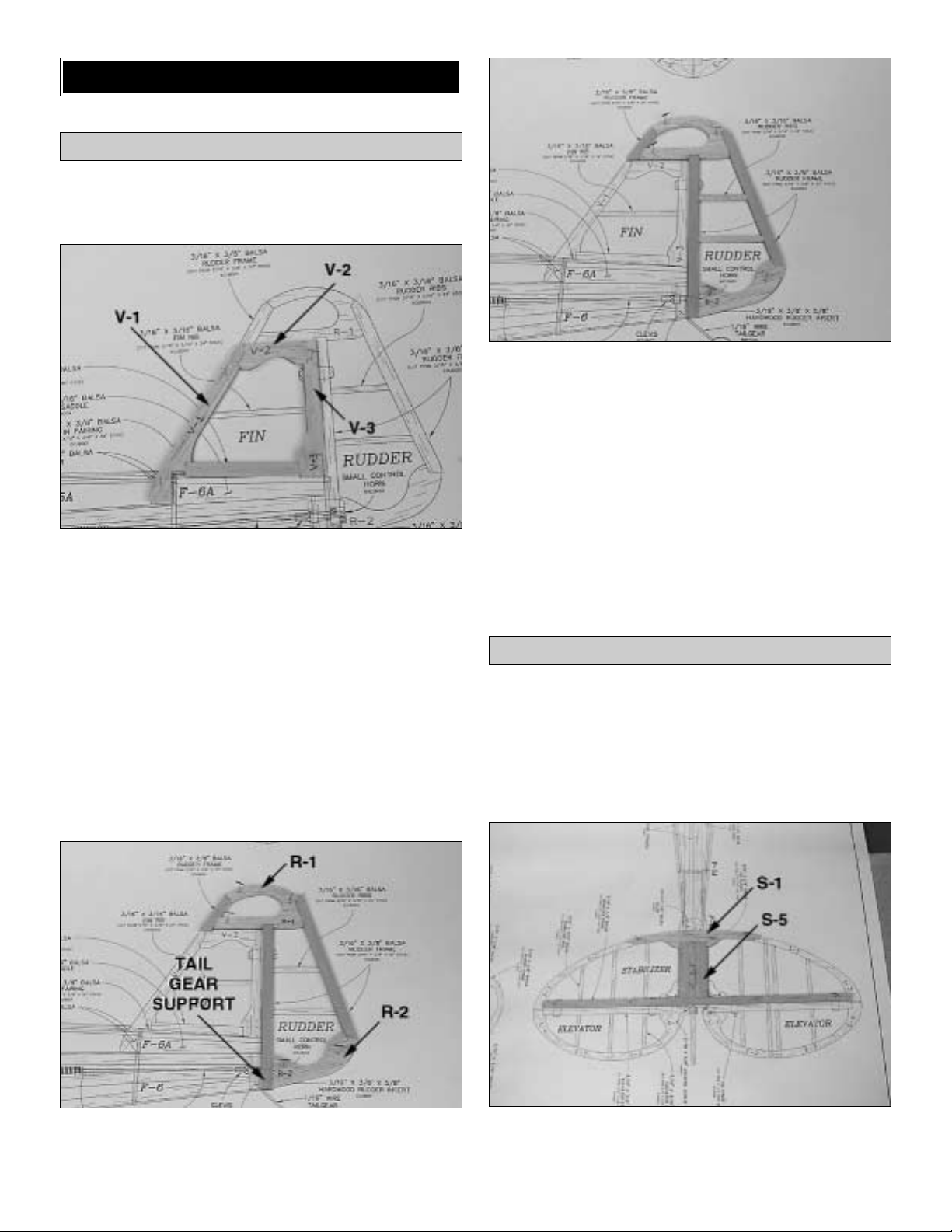

❏ 1. Cover the stabilizer/elevator portion of the plan with

wax paper or Great Planes Plan Protector.

❏ 2. From one of the 3/16" x 3/8" x 30" balsa sticks, cut the

stabilizer trailing edge to match the stabilizer plan. Pin the

stab TE over the plan.

❏ 3. Pin the die-cut 3/16" balsa leading edge S-1 and stab

center S-5 in position. Glue S-1 to S-5 and S-5 to the front

of the stab TE.

Build the Stabilizer & Elevator

Build the Fin & Rudder

BUILD THE T AIL SURF ACES

8

Page 9

❏ 4. Pin the die-cut 3/16" balsa stab frames S-2 and S-3 in

position. Glue S-2 and S-3 to S-1 and the stab TE.

❏ 5. From the 3/16" x 3/16" x 24" balsa stick, cut and glue

the stab ribs to the stab frame.Glue the 3/16" die-cut balsa

stab gussets S-4 to the stab TE and S-5.

❏ 6. Remove the stab from your building board. Inspect,

glue and sand as you did with the fin.

❏❏7.From a 3/16" x 3/8" x 30" balsa stick, cut the elevator

leading edge to length and pin it over the elevator plan.Pin

and glue the die-cut 3/16" balsa elevator frame E-1 through

E-4 to the LE.

❏❏8.From the 3/16" x 3/16" x 24" balsa stick, cut and glue

the elevator ribs to the frame.

❏ 9. Repeat steps 7 and 8 to build the second elevator half.

❏ 10. Remove the elevators from your building board.

Inspect, glue and sand as you did with the fin.

❏ 11. Pin both elevators in position over the plan. Lay the

3/32" elevator joiner wire on top of the elevators in the

position shown on the plan. Use a pencil to lightly mar k the

outline of the joiner wire on the elevators.

❏ 12. Using a straightedge, extend the side lines of the

elevator joiner outline forward to the leading edge.Also, use

a Precision Hinge Marking Tool to draw a centerline on

the leading edge. Using these lines, you can determine

exactly where to drill the holes for the elevator joiner wire.

9

Page 10

❏ 13. Drill a 3/32" hole into the leading edge of both

elevators. As you drill each hole, keep the drill aligned with

the top and bottom surface of the elevator and reference

lines you made in the previous steps.

❏ 14. Refer to the Expert Tip that follows or use a Great

Planes Groove Tube™to cut a 3/32" groove in the leading

edge of both elevators to recess the joiner wire.

❏ 15.Temporarily join the elevators with the joiner wire.The

joiner wire will be easier to install if you chamfer (bevel) the

ends a little. If necessary, “tweak” the joiner wire so the

elevators are parallel and la y flat on y our building tab le when

the joiner wire is installed. If you found it necessary to

“tweak” the joiner wire, use a felt-tip pen to mark it so you

can install the joiner wire in the same orientation when you

permanently join the elevators.

❏ 16. Lay the elevators and stab over the plan and lightly

mark the hinge locations on the LE of the elevators and the

TE of the stab. Repeat the process to mark the hinge

locations on the LE of the rudder and TE of the fin.

To cut the hinge slot, place the blades onto the wood

where you want the slot. Lightly press the teeth into the

wood.When you are satisfied with the location, press the

button on the handle and the blades will cut easily into the

balsa wood.

We have simplified the task of cutting hinge slots with the

introduction of the Great Planes Slot Machine™. This

simple electric tool cuts a perfect width slot for use with

CA hinges.

B. Use the sharpened tube to carefully gouge the leading

edge of the elevators.You’ll have to make several passes

to make the recess deep enough for the joiner wire.

A. Use a #11 knife blade to sharpen the inside of a piece

of 3/32” brass tube. Roll the tube as you carve the end.

HOW TO CUT A GROOVE FOR A JOINER WIRE

10

Page 11

11

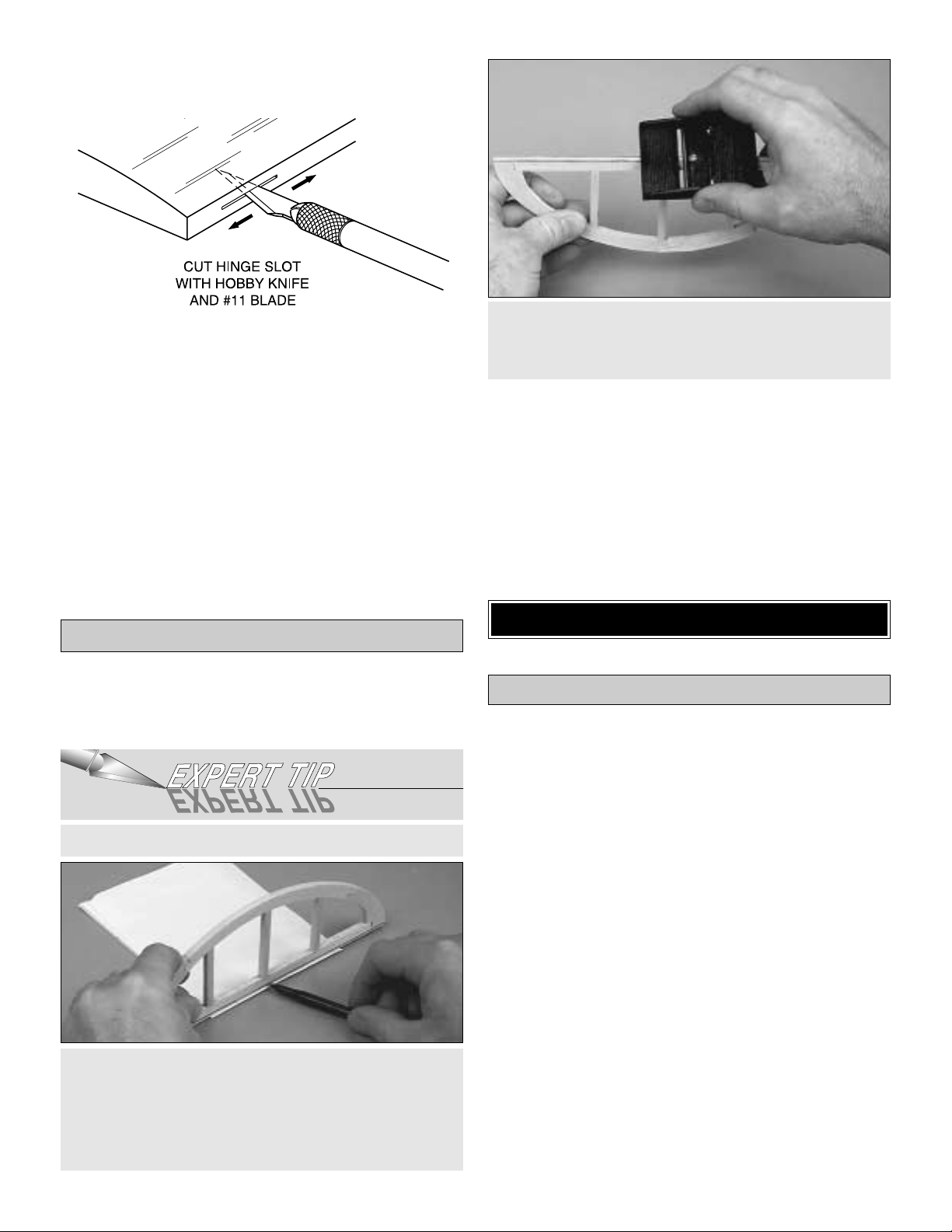

If you choose not to purchase a Slot Machine™you can

make the slots by following these instructions.

❏ 17. Cut the hinge slots in the elevators, stabilizer, fin and

rudder using a Hobby Knife with a #11 blade. Begin by

carefully cutting a very shallow slit at the hinge location to

accurately establish the hinge slot.Make three or four more

cuts, going a little deeper each time. As you cut, slide the

knife from side to side until the slot has reached the proper

depth and width for the hinge.

❏ 18. Cut the 3/8" x 1" hinges for the elevator and rudder

from the supplied 2" x 9" hinge material, then snip off the

corners. Temporarily join the elevators to the stab and the

rudder to the fin with the hinges, adjusting any hinge slots if

necessary so they all align.Do not glue in the hinges until

you are instructed to do so.

❏ 1. Refer to the Expert Tip that follows and shape the

leading edge of the elevators and rudder to a “V” as shown

on the plan.

❏ 2. Use the same procedure to bevel the leading edge of

the rudder.

❏ 3. Temporarily attach the elevators to the stab and the

rudder to the fin. Use your bar sander to round the entire

perimeter of the elevator, stab, rudder and fin (do not round

the bottom edge of the fin where it will be glued to the stab

and fuse).

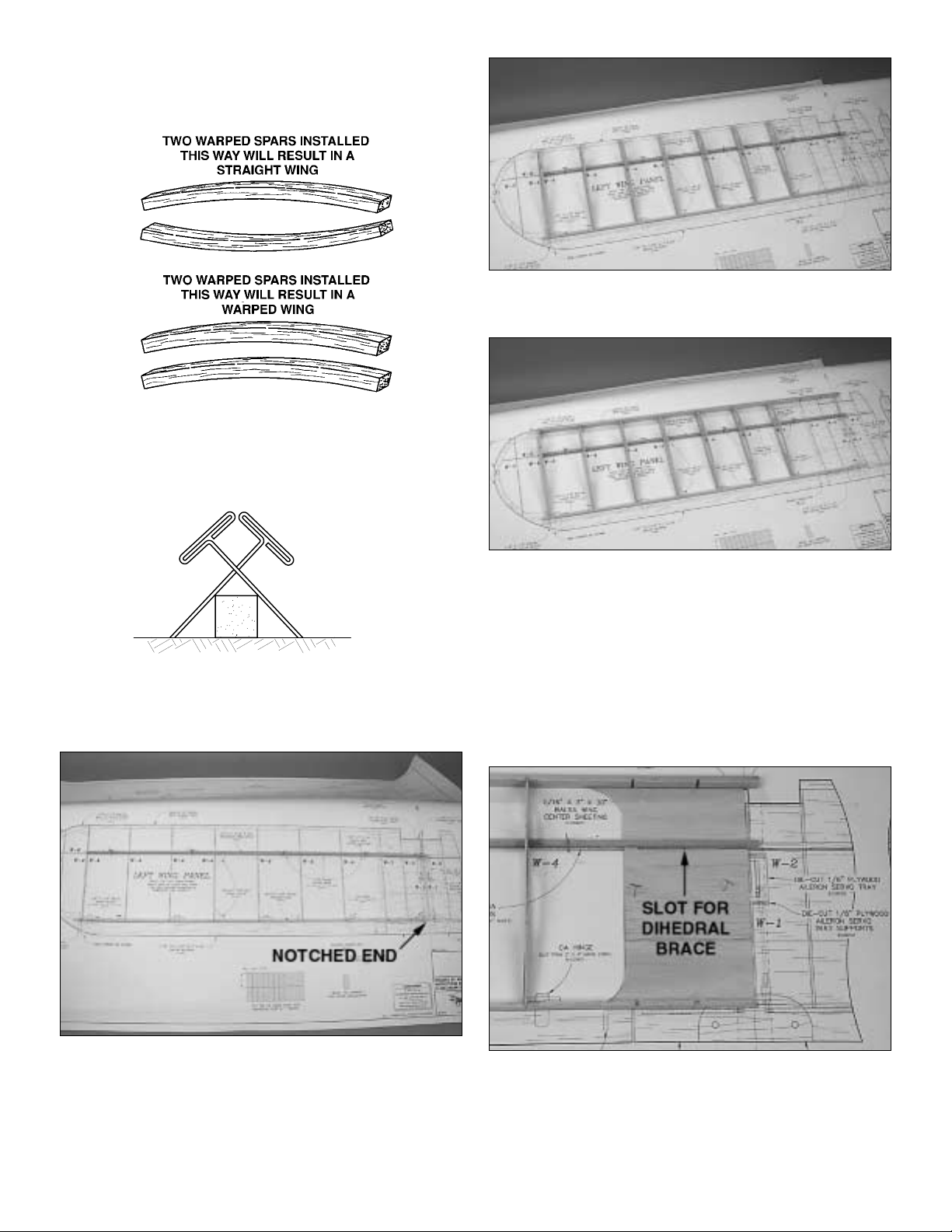

Start by building the left wing panel right side up over the

left wing panel plan so your progress matches the photos.

❏ 1. Set aside two of the hardest and straightest 1/4" x 1/4"

x 13" balsa sticks for use later to make pushrods.

❏ 2.The shaped and notched balsa wing leading edges are

fastened together by a thin web of balsa.Separate the LE’s

by folding them until the balsa web breaks. Sand away the

excess balsa that remains along the edges, using a sanding

bar with 150-grit sandpaper. Before using the leading edge

you must determine which one to use for the left wing panel.

Here’s how:

A.We have drawn a red line on the top of each piece.

B.The pieces are notched on one end but not on the other.

The notched end goes toward the wing tip.

C. Position one of the leading edge pieces on the left wing

panel plan with the red line up.If the notched end is on the

left side (at the tip) you have the correct piece. (When

building the right wing panel the red line must be up, with

the notched end on the right side, at the tip).

Build the Wing Panels

BUILD THE WING

B.Using the “bevel to”lines and the centerline as a guide,

make the “V” on the leading edge of the elevators with a

razor plane or your bar sander with 150-grit sandpaper.

A. Place the leading edge of one of the elevators on your

work surface and use your pen to mark a “bevel to” line

on both sides, about 3/32” high.

Note: You will probably have to adjust the height of the

elevator with card stoc k so your “be vel to”line is not too high.

HOW TO BEVEL THE LEADING EDGES

Finish the Tail Surfaces

Page 12

12

❏❏3. Cover the left wing panel plan with wax paper or

Great Planes Plan Protector.

❏❏4. Match the 3/16" x 3/16" x 26-1/4" basswood main

spars so any warps will counteract each other.

❏❏5. Pin one of the main spars in position over the plan,

aligning one end of the main spar with the outside edge of

the tip rib W-4.

❏❏6. Pin one of the die-cut 1/8" balsa trailing edges,

notches facing up, in position over the plan. The TE is

notched at one end and not the other.The notched end goes

toward the wing root (wing center).

❏❏7. Glue two of the die-cut 1/16" balsa W-4 ribs together

to make the tip rib.

❏❏8. Place the W-4 ribs onto the main spar and into the

notches in the trailing edge.

❏❏9. Carefully inser t the W-4 ribs into the notches in the

leading edge. Note: Do not be concerned if the ribs do not

line up exactly with the plan. Sometimes the humidity will

cause the plan to expand or contract.Just make sure to line

everything up with the outside edge of the last rib. The

notches will provide the proper spacing.

❏❏10. With the ribs, LE and TE flat against the building

surface, glue the W-4 ribs to the spar, LE and TE.

❏❏11. From a 1/16" x 3" x 30" balsa sheet, cut the wing

center sheeting to fit between the TE and main spar and

the LE and main spar. Make sure to leave a 1/16" slot, for

the dihedral brace, in the sheeting at the back of the main

spar.Pin the sheeting in position. Then, glue the sheeting to

the main spar, LE and TE.

Page 13

13

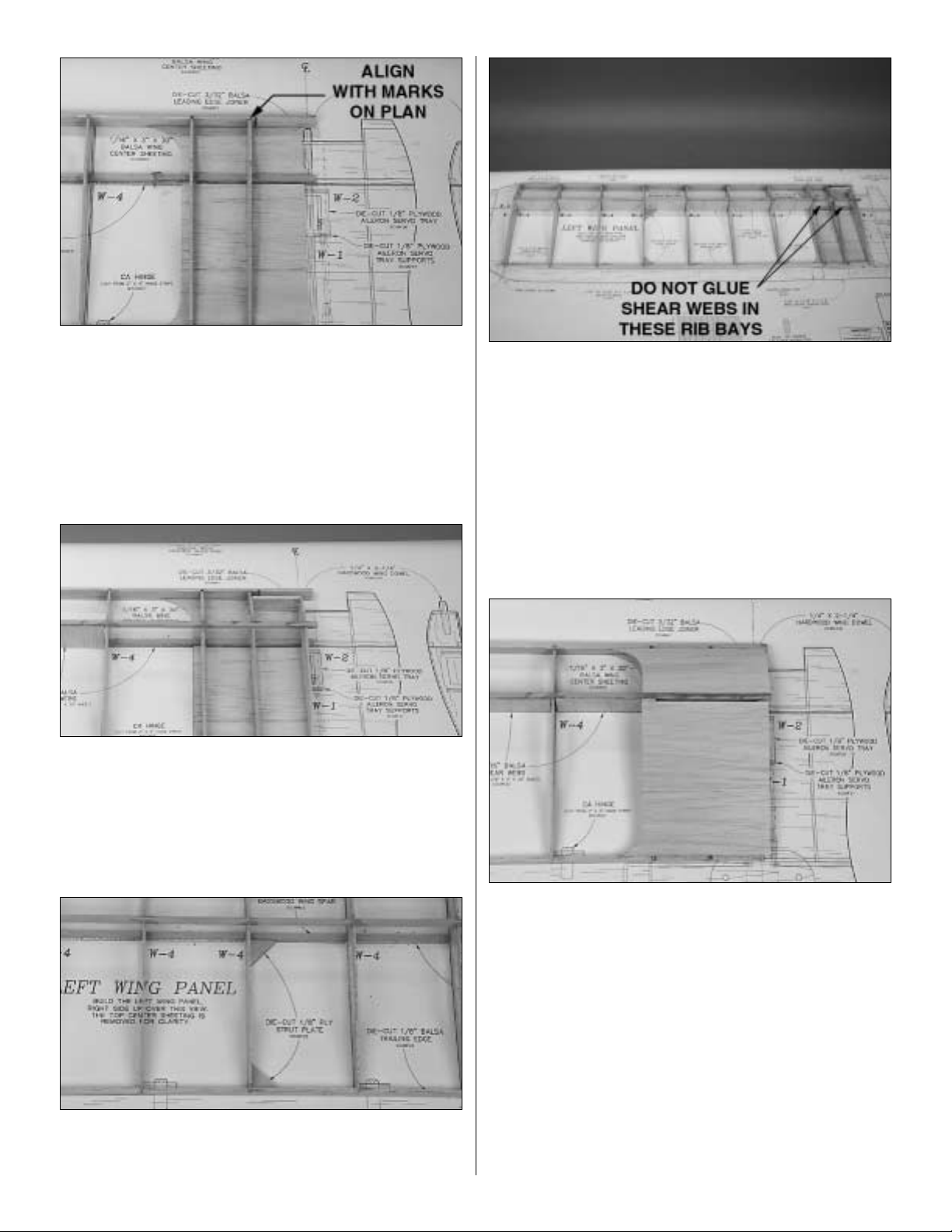

❏❏12. Position the die-cut 3/32" balsa ribs W -2 and W-3 in

position. Important: Rib W-2 does not fit into the notch in the

LE. Rib W-2 fits into the notch in the TE and aligns with the

alignment marks on the wing plan in front of the LE. Glue

only W-3 to the LE, TE, main spar and center sheeting.

❏❏13. Position the top 3/16" basswood spar in the rib

notches with one end flush with the outside edge of the tip

rib and glue to all the ribs except W-2.

❏❏14. Position the die-cut 3/32" balsa rib W-1 in place

between the main spars, with the bottom edge flat against

the center sheeting. Use the die-cut 1/8" ply dihedral

gauge to set the rib at the proper angle (see the drawing on

the wing plan). Position the die-cut 3/32" balsa LE joiner

between ribs W-1 and W-2. When you have W-1, W-2 and

the LE joiner positioned properly, glue them in place.

❏❏15. Glue the two die-cut 1/8" ply wing strut plates in

position.The wing strut plates must be flat on the table, flush

with the bottom of the wing.

❏❏16. From the 1/16" x 3" x 30" balsa sheet, cut and glue

vertical grain shear webs to the spars in the locations

shown on the plan.It is not necessar y for the shear webs to

be glued to the ribs. Make sure they are glued securely to

the wing spars. Do not install shear webs in the rib bays

between ribs W-1 and W-3.

❏❏17.Carefully sand the top of the LE joiner flush with the

top of ribs W-1 and W-2.

❏❏18. From a 1/16" x 3" x 30" balsa sheet, cut pieces to

make the top center section sheeting (don’t forget the 1/16"

notch for the dihedral brace). When satisfied with the fit,

apply medium CA to the top of the ribs and press the

sheeting in place. Note: If the balsa sheeting supplied in

your kit is difficult to bend over the front portion of the ribs

without cracking, wet the top surface of the sheeting with

water.The water will soften the wood, making it much easier

to bend.

❏❏19. From one of the remaining 1/4" x 1/4" x 13" balsa

sticks, cut four 1" long hinge blocks.Glue the hinge blocks

in position, centered on the TE.

Page 14

14

❏❏19. Remove the wing from your building board. Use a

razor saw to trim the LE and top and bottom center sheeting

flush with rib W-2 and the LE joiner. Trim and sand the top

and bottom main spars and center sheeting flush with the

side of rib W-1.Sand the TE flush with the tip rib W-4.

❏❏20. Sand the top and bottom of the LE and TE flush

with the ribs.

❏ 21. Now, go back to step 2 and build the right wing panel.

Remember! Build it over the right wing plan.

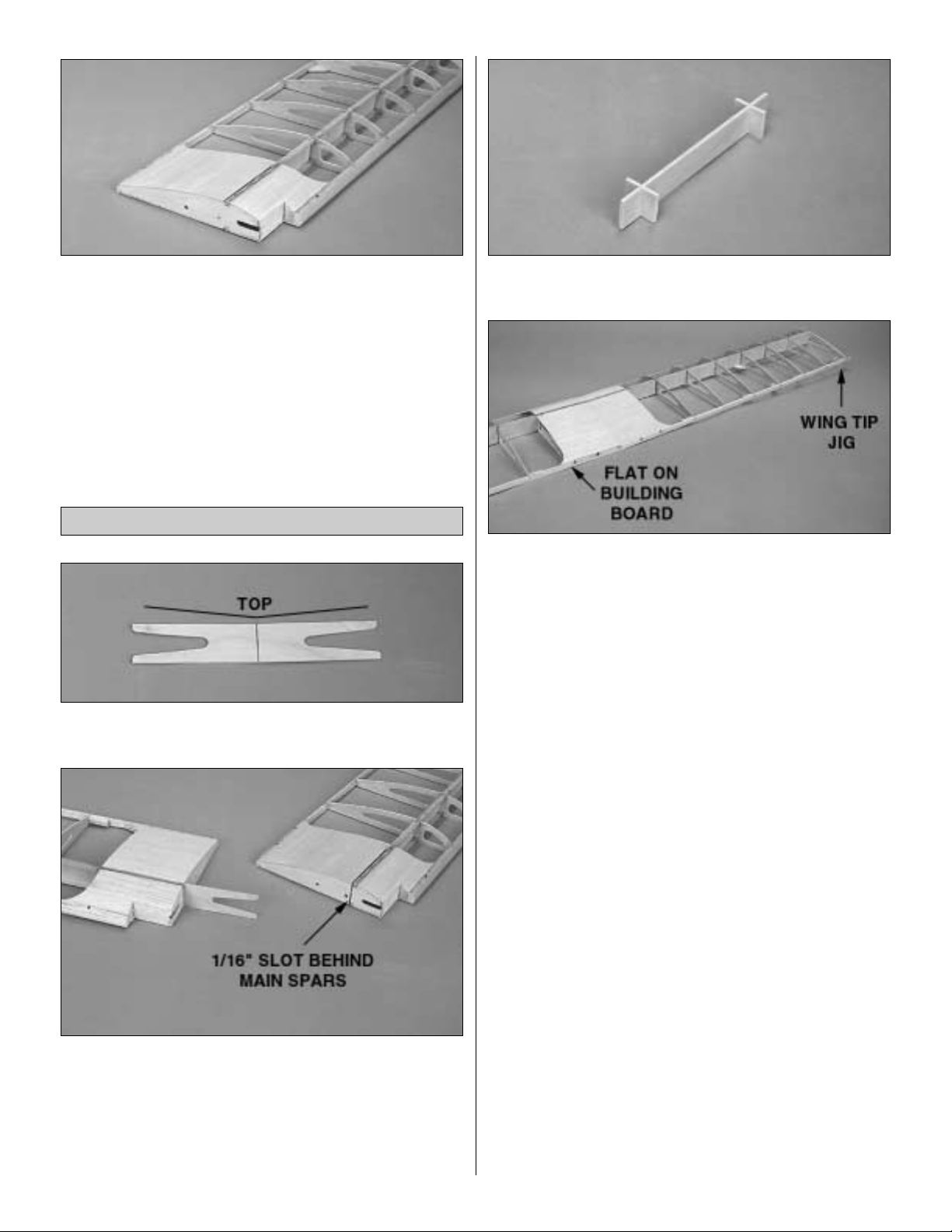

❏1. Draw a centerline on the die-cut 1/16" ply dihedral brace.

The top of the dihedral brace has a slight "V" shape.

❏ 2. Using a razor saw, carefully cut a 1/16" slot in ribs

W-1, just behind the main spar.Trial fit the dihedral brace in

the slots.

❏ 3. Sand the bottom of both wing panels near the center, to

remove any excess glue on the spars or sheeting that may

prevent the wing from resting flat on your building board.

❏ 4.Assemble the die-cut 1/8" ply wing tip jig and wing tip

jig feet.

❏ 5. Trial fit the wing halves together with one wing half flat

on your building board and the wing tip jig under the tip rib

of the other wing panel. Use a sanding bar to sand the

center joint as necessary until the wing halves fit together

without any gap.

❏ 6.When satisfied with the fit, apply 30-minute epoxy to

the dihedral brace, main spars and ribs W-1. Do not apply

epoxy within 1/4" of the wing dowel slot in W-1. You need to

avoid getting epoxy in the slot. Slide the two wing halves

together with the dihedral brace in place.With the two wing

halves aligned, use masking tape to hold the wing halves

together. Wipe off any excess epoxy with a paper towel

dampened with rubbing alcohol. Weight one of the wing

halves down flat on your building board, with the other wing

half supported by the wing jig positioned at the wing tip.

Allow the epoxy to cure before moving the wing.

Note: While waiting for the epoxy to cure, let’s continue with

assembling the wing tips.

Join the Wing Panels

Page 15

❏ 1. Cover the wing tip portions of the wing plan with wax

paper or Great Planes Plan Protector.

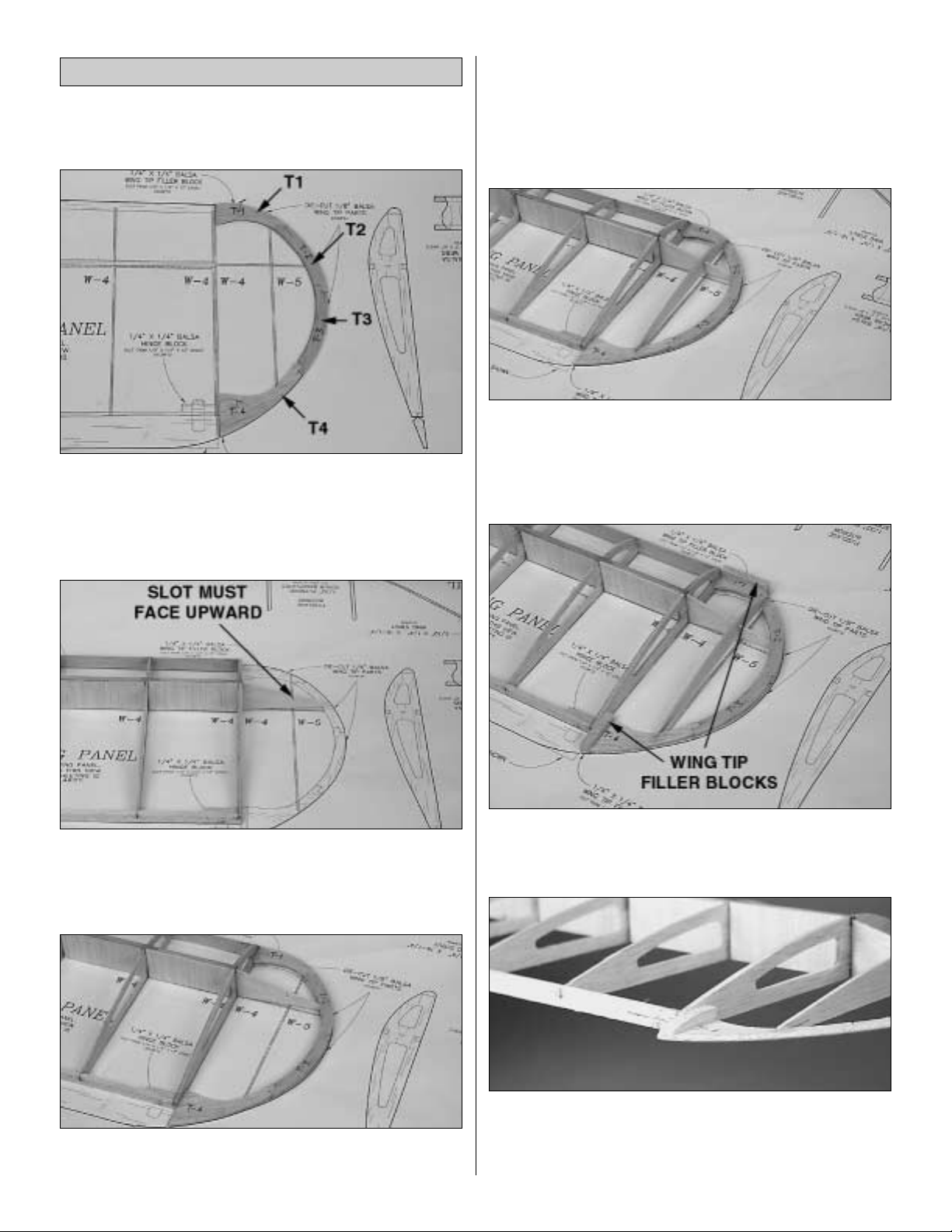

❏❏2. Assemble the wing tip from the die-cut 1/8" balsa

parts T-1, T-2, T-3 and T-4. There are two of each part (one

for each wing tip). Position the wing tip parts over the plan

and glue them together.Fill any gaps with medium CA, then

sand smooth.

❏❏3. With one of the wing panels flat on your building

table, glue the die-cut 1/16" balsa wing tip brace W-6 to the

end of the spars and tip rib W-4. The slot in W-6 must be

facing upward.

❏❏4. Trial fit the wing tip assembly against the end of the

LE and TE. Center the LE of the wing tip on the end of the

wing LE. The TE of the wing tip should rest on the building

table.Sand off the end of W-6 until it just touches the inside

edge of the wing tip.

❏❏5. With the wing tip centered on the LE and resting on

the table at the TE, glue the wing tip to the LE, TE and W-6.

❏❏6. Trial fit the die-cut 1/16" balsa rib W-5 in the notch in

W-6.Sand the rib if necessary for a good fit and glue in place.

❏❏7. Sand the front and rear of W-5 to blend into the

rib contour.

❏❏8. From a 1/4" x 1/4" x 13" balsa stick, cut and glue

wing tip filler blocks on the top and bottom of the wing tip

LE and on the top of the wing tip TE.

❏❏9. Use a sanding bar to blend the filler blocks into the

wing tip.Round the edges of the wing tip.

❏ 10. Go back to step 2 and assemble the other wing tip.

Assemble & Install the Wing Tips

15

Page 16

❏ 1. Cut the tapered and grooved balsa center trailing

edges to the length shown on the plan.Bevel them so they

join as shown on the plan. Test fit the center TE’s on the

wing. Note: The center TE is positioned on the wing with

the 90 degree edge at the bottom of the wing.

❏ 2. Place the center TE’s over the wing plan and mark the

location of the aileron torque rods.To clear the torque rods,

cut notches at the marks on the bottom of the center TE’ s .Test

fit the torque rods in the center TE’s to check for clearance.

❏ 3. Turn the wing upside-down and position the center TE’s

on the wing TE with the torque rods installed. Mark the

location of the notches on the bottom of the wing’s TE. Cut

notches in the wing TE at the marks.Test fit the center TE’s

with the torque rods installed, checking that the notches align

and are large enough to allow the torque rods to move freely.

❏ 4.Use coarse sandpaper to scuff the nylon tube bearing

on the aileron torque rods so that the glue will adhere better.

❏ 5. To prevent gluing the torque rod to the nylon tube

bearing, apply petroleum jelly on the torque rod at the ends

of the nylon tube bearing.

❏ 6.Use 30-minute epoxy to glue the nylon tube bearings in

the center TE’s and the center TE’s to the TE of the wing.

Tape the center TE’s to the wing so that the bottom of the

center TE’s are aligned with the bottom of the wing. Use a

paper towel dampened with rubbing alcohol to wipe off any

excess epoxy before it cures.

Build the Ailerons

16

Page 17

❏❏7. Position the left aileron on the trailing edge of the

wing. Mar k the end of the aileron where it meets the wing

tip.Cut the aileron approximately 1/8" shorter than the mark.

This will allow the aileron to move freely after the MonoK ote

®

covering is applied.

❏❏8. Position the aileron on the wing with a 1/16" gap at

each end.Mark the location of the torque rod on the aileron.

❏❏9.Use a drafting square or triangle to extend the marks

to the LE of the aileron. Mark an accurate centerline on the

entire LE of the aileron and the TE of the wing.

❏❏10. Use the centerline and the marks for the torque rod

as a guide to drill a 7/64" hole in the aileron for the torque

rod. Use the Great Planes Groove Tube or a sharpened

brass tube to cut a groove for the torque rod in the LE of the

aileron.

❏❏11. Test fit the aileron on the wing to make sure the

torque rod fits and there is approximately 1/16" clearance

between both ends of the aileron and wing.

❏❏12. Mark the location of the hinges on the aileron and

wing. Cut the hinge slots in the aileron and wing. Cut four

3/8" wide hinges from the supplied hinge strip. Insert the

hinges in the aileron and fit the aileron to the wing. Do not

glue the hinges at this time.

❏❏13.Sand the tip of the aileron to blend with the wing tip.

❏❏14. Remove the aileron from the wing. Mark the “bevel

to” lines and shape the LE of the aileron to a “V” as shown

on the plan.

❏ 15. Go back to step 7 and fit the right aileron to the wing.

17

Page 18

❏ 1. Use a pen to draw a centerline on the die-cut 1/16"

plywood wing plate. Use a sanding bar to bevel the front

and sides of the wing plate to a sharp edge.

❏ 2. Lightly sand the entire wing smooth. Sand very

carefully in the center section area when removing the

excess glue around the center joint (remember , the sheeting

is only 1/16" thick).

❏ 3. Use 6-minute epoxy to glue the wing plate on the top

of the wing, aligned with the centerline and flush with the

wing center TE.Use masking tape or clamps to hold it tight

against the wing sheeting until the epoxy cures.

❏ 4. Read “Fiberglassing Tips” that follow this step.The

included strip of fiberglass tape is used to reinforce the

center of the wing.The remaining fiberglass tape is used to

reinforce the ends of the wing struts.With the wing upside-

down, use thin CA to glue the fiberglass tape to the center

sheeting starting at the TE and working toward the LE.Then

glue the tape on the top of the wing from the front edge of

the wing plate to the LE. Cut off the excess tape.

❏ 5. Use a sanding bar to carefully “feather” the edges of

the glass tape into the center sheeting. Lightly sand the

surface of the glass tape to remove the roughness, but do

not sand through the weave. A light coat of balsa filler can

also be used to blend the glass tape to the center sheeting.

❏ 6. On the bottom of the wing, draw a line 3/16" back from

the aft edge of the wing spar.

❏ 7. Align the die-cut 1/8" ply aileron tray with the line,

centered on the wing joint.Trace around the aileron tray.

Fiberglassing Tips: If you spray a very light mist of 3M

“77”spray adhesive on the center section (only where the

glass tape is to be applied), you can press the glass tape

in place before applying the thin CA glue.Hold the spray

can at least 16" away from the wing and give it just a

short burst. You may also use a piece of wax paper to

press the glass tape firmly down to the wood immediately

after applying the CA.

Finish the Wing

18

Page 19

❏ 8. Trim the 1/16" balsa sheeting along the outline of the

aileron tray. Cut out the aileron servo opening in ribs W-1.

❏ 9. Glue the die-cut 1/8" ply aileron tray supports on the

end of the aileron tray, perpendicular to the tray.

❏ 10. Insert the aileron tray into the opening in the wing and

glue in position. Cut a small hole in the wing sheeting next

to the aileron tray to route the servo wire out.

❏❏1.With wax paper or Plan Protector positioned over the

fuse plan, pin the die-cut 1/8" balsa forward lower

fuselage (FLF), forwar d center fuselage (FCF) and upper

fuselage (FTF) in position over the plan and glue together.

❏❏2. From the 1/8" x 3/8" x 24" balsa sticks, carefully cut

the three longerons and the tail post to match the plan.

Glue the longerons to the forward fuselage and glue the tail

post to the ends of the longerons.

❏❏3. From the 1/8" x 1/4" x 24" balsa stick, cut and glue

the two side window frames to the forward center and

upper fuselage sides.

Assemble the Fuselage Sides

BUILD THE FUSELAGE

19

Page 20

❏❏4. Use a pen to mark the location on the longerons for

formers F-4, F-5 and F-6.

❏ 5. Remove the fuselage side from the plans. Return to

step 1 and build the second fuselage side.

❏ 6. Place the two fuse sides together and check that they

match up all the way around. If they are not identical, pin

them together and use a sanding bar to make them match.

❏ 7. Lightly sand both sides of the fuselage sides to remove

any excess glue.

❏ 8. Lay the fuse sides next to each other so they mirror

each other.Mark one fuse side left side and one right side.

❏ 9.To provide right thr ust in the firewall, trim 3/32" off the

front of the right fuselage side.

❏ 10. Align and glue the die-cut 1/8" balsa wing saddle

doublers to the inside of both fuse sides with the top and front

of the doubler aligned with the top and front of the fuse side.

❏ 11. Cut the 1/4" x 1/4" x 12" basswood servo tray rail

in half.

❏❏12. Draw a line on the inside of the fuse sides, 1/4"

above the joint between the forward lower fuse and the

forward center fuse.

❏❏13.T emporarily install the die-cut 1/8" plywood former

F-3 in position on the fuse side. Glue the 1/4" x 1/4" servo

tray rail to the fuse side, aligning its bottom edge with the

line drawn in step 12 and former F-3. Do not glue the rail

to F-3.

20

Page 21

21

❏❏14. Position the fuse side over the plan and glue the

die-cut 1/8" plywood battery bench support to the inside of

the right fuse side.When assembling the left side, position the

fuse over the plan and mark the location of the battery bench

support on the outside of the fuselage.Then, transfer the lines

to the inside of the fuselage and install the bench support.

❏❏15. Glue the die-cut 3/16" balsa stab saddle to the top

of the longeron. Make sure the front of the stab saddle

aligns with the mark for the aft edge of former F-6.

❏ 16. Return to step 12 and repeat the steps to assemble

the left fuse side.

❏ 17.Transfer the marks for the formers to the other side of

the longerons on the fuse sides.

❏ 1. From the leftover 1/4" x 1/4" balsa stick (don’t use the two

that have been set aside f or making the pushrods) cut and glue

reinforcements to both sides, at the bottom of the die-cut 1/8"

plywood former F-2A. Make sure the sticks are flush with the

end of the tabs.

❏2. From the leftover 1/8" x 3/8" balsa stick, cut tw o pieces the

full width of the die-cut 1/8" balsa formers F-4 and F-5.Glue

the sticks to the aft side at the top and bottom of the formers.

❏ 3. Install former F-2A on the right fuse side so that the

embossed F-2A faces forw ard.Make sure F-2A is inserted into

the notches completely. Use a building square to hold F-2A

perpendicular to the fuse side while gluing the former in place.

❏ 4. Glue the die-cut 1/8" plywood former F-3 to the right

fuse side. Use a building square to hold F-3 perpendicular

to the fuse side while gluing the former in place.

❏ 5. Join the right fuse side to the left, keying formers F-2

and F-3 to the left fuse side.Lay the fuse on its left side and

glue F-2 and F-3 to the left fuse side, making sure they are

perpendicular to the fuse side. It may help to prop up the aft

end of the right fuse side while performing this step.

Join the Fuselage Sides

Page 22

22

❏ 6. Pull the tail posts together and use a bar sander to

lightly sand the inside edges of the tail posts to an angle.

Align the fuse over the fuselage top view, checking the tail

posts for the proper width.Carefully line up the tail post and

glue them together. Note: A small misalignment here will

throw the aft end out of line, so double-check before gluing.

❏ 7.Test fit the die-cut 1/16" balsa aft deck base between

the forward center fuse sides and the stab saddle.Trim the

aft end of the deck base for a good fit.

❏ 8. Pin the aft deck base to the plan top view (note that the

front of the deck base is flush with the front of F-3).Use the

former locator marks and draw the former location lines on

the aft deck base.

❏ 9.Trial fit former F-4 between the longerons at the former

location lines (the cross braces face aft).Note that the sides

of F-4 and the cross braces will have to be sanded to a

slight taper to make good contact with the longerons.

Remove F-4 and sand as required f or a good fit.Do not glue

F-4 to the longerons.

10. Repeat the above process to properly taper the sides of

F-5 and F-6.

❏ 11. Position F-4 between the former location lines on the

aft deck base. Adjust the position of F-4 so it is centered

between the edges of the aft deck base.Glue F-4 to the aft

deck base, perpendicular to the aft deck base.

❏ 12. Repeat the procedure, gluing F-5 and F-6 to the aft

deck base.Remove the deck base from the plan.

❏ 13. Pin the fuselage over the plan top view. Make sure

former F-3 and the tail post are aligned with the plan.Check

that the sides of the tail posts are perpendicular to the

building board.

Page 23

23

❏ 14.Trial fit the aft deck base and formers on the fuse. At

each former, make sure the deck base seats completely on

the top longeron. Lightly sand the bottom of the formers

as needed.

❏ 15. Glue the aft deck base to the top edge of former F-3.

While applying pressure on the aft deck base at F-4, glue

the top longeron to the aft deck base at F-4. Repeat the

process at F-5 and F-6. Then, proceed to glue the top

longeron to the rest of the aft deck base.

❏ 16.Again, check that the tail post is perpendicular to the

building board (when viewed from the rear).Glue the middle

longerons to the formers.Temporarily apply weight to the aft

deck base so that F-4, F-5 and F-6 are against the building

board. Glue the bottom longerons to the formers.

❏ 17. Turn the fuse upside-down and apply glue along the

joints between the aft deck base and F-4, F-5 and F-6.

❏ 18. Carefully sand the bottom of the fuse flat.

❏ 19. Glue the die-cut 1/8" plywood battery bench back

and the die-cut 3/32" balsa battery bench seat to the

battery bench suppor ts.

❏ 20. Position the fuse upside-down on your building board.

Check that the tail post is perpendicular to the building

board (when viewed from the rear).Sheet the bottom of the

fuse with 1/16" x 3" x 30" balsa sheet, applied cross-grain,

starting at the rear edge of the landing gear plate opening

and proceeding to the tail post. Note: A good way to do this

is to lay the sheet across the fuselage and mark the edge of

the longerons on the bottom of the sheet Remove the sheet

and cut along the mark with a hobby knife, allowing a little

extra that will be sanded off later.

❏ 21.Use a sanding block to sand the bottom sheeting flush

with the sides of the fuse.

❏ 22. Using epoxy, glue the die-cut 1/8" plywood F-1B to the

back of F-1A. This is now called the firewall. Remember, the

side with the embossed “1A”and "1B" is the front of the firewall.

❏ 23. After the epoxy cures, drill 3/32" pilot holes through

the firewall at each of the eight punch marks.

❏ 24. Make a mark 3/32" from one front corner of the die-cut

3/32" balsa front deck base.Trim the end of the front deck

base at an angle to allow for the right thrust in the firewall.

Page 24

24

❏ 25.T rial fit the die-cut 1/8" plywood cabin brace in former

F-2 and the fuse sides. Lay the front deck base in position

and then the firewall assembly, pulling the front of the fuse

together with rubber bands. Sand the front deck base, as

necessary, for a good fit.

❏ 26. Glue the cabin brace to the fuse sides and F-2.

❏ 27. Glue the front deck base to the fuse sides and

cabin brace.

❏ 28. Use 6-minute epoxy to glue the firewall to the fuse

sides and the front deck base. Wipe off any excess epoxy

with a paper towel dampened with rubbing alcohol.Hold the

fuse sides tightly against the firewall until the epoxy sets.

❏ 29. Glue the die-cut 1/8" balsa former F-1C to the front

deck base.

❏ 30. Trial fit the die-cut 1/16" balsa top front sheet,

sanding as necessary. Glue the front sheet to the firewall,

F-1C and the front deck base.If the front sheet is hard balsa

and difficult to bend, wet the top surface of the sheet with

warm water before bending around the formers.

❏ 31. From the leftover 1/8" x 1/4" balsa stick, cut side

window frames to fit flush with the front of the cabin brace.

❏ 32.Fit the 3/16" plywood landing gear plate between the

fuse sides. Use 6-minute epoxy to glue the landing gear

plate to the fuse sides and the bottom of former F-2.

To reduce weight, before installing the top front sheet cut

lightening holes in the front deck as shown on the plan.

Page 25

❏ 33. From the 1/4" x 1/4" x 5-7/8" balsa triangle stick, cut

and glue three pieces to fit in the lower front corner of the

fuse. Sand the tr iangles flush with the bottom of the fuse.

❏ 34. Glue the three die-cut 1/32" plywood cowl screw

backplates to the inside of the fuse sides and top

front sheeting. See fuselage plan side view.

❏ 35.From leftover 1/16" balsa (use a piece from a die-cut

sheet), cut a 1/2" x 1-1/2" piece. Glue the piece to the aft

end (wide end) of the die-cut 1/8" plywood battery hatch.

Sand the aft end of the battery hatch to match the angle on

the front of the landing gear plate.

❏ 36. Glue the die-cut 1/32" x 5/8" x 1-1/2" plywood

hatch plate to the balsa strip on the aft end of the battery

hatch.The hatch plate should extend about 1/8" past the

aft edge.

❏ 37. Glue the die-cut 1/32" x 1/2" x 1-1/4" plywood hatch

stop to the aft end of the die-cut 1/8" plywood chin plate so

that it extends 1/8" behind the aft edge.

❏ 38. Position the battery hatch and chin plate on the fuse,

using the battery hatch as a spacer to determine the

location for the chin plate.While holding the chin plate firmly

in position, remove the battery hatch and apply thin CA

around the chin plate to secure it in place.

❏ 39. From leftover 1/32" plywood, make the hatch locking

tab as shown in the sketch.

25

DRILL 3/32"

HOLE

(ACTUAL SIZE)

1/32" PLYWOOD

Page 26

❏ 40. Center the hatch locking tab on the aft edge of the

chin plate. Mark the location of the screw hole on the chin

plate and drill a 1/16" pilot hole.

❏ 41.Attach the hatch locking tab to the chin plate with a #2

washer and #2 x 3/8" sheet metal screw.

Note: The hatch locking tab is designed to keep the battery

hatch closed during flight, yet it allows quick access to the

front compartment for easy insertion and removal of the

motor battery. You must adjust the tab screw for

sufficient friction so it will not allow the battery hatch to

open during flight. Periodically check and re-tighten the

screw if necessary.

❏ 42. Glue the die-cut 1/8" balsa former F-3A to the rear

edges of the upper fuse sides and the aft deck base.

❏ 43. Glue the die-cut 1/8" balsa rear wing saddle into the

slots in the wing saddle doublers, flush with the top of the

wing saddle.

❏ 44.Use epoxy to glue the three die-cut 1/8" plywood wing

bolt plates together.Use clamps to hold the plates together

until the epoxy cures.

❏ 45.Lightly sand the edges of the wing bolt plate to remove

any excess epo xy.Test fit the wing bolt plate into the slots in

the fuse sides, sanding as necessary to provide a good fit.

When satisfied with the fit, use epoxy to glue the wing bolt

plate to the fuse.

To reduce the weight of the wood structure, you can

enlarge the lightening holes by 1/16" in the lower fuselage

sides. A drum sander or a piece of sandpaper wrapped

around a dowel makes quick work of it.

26

Page 27

❏ 46. Using the marks for formers F-4 and F-5 on the side of

the longerons, draw lines across the top of the aft deck base.

❏ 47.Glue the die-cut 3/32" balsa formers F-4A and F-5A

between the lines, perpendicular to the aft deck base.

❏ 48. Glue the die-cut 3/32" balsa former F-6A to the front

of the stab saddle and the aft deck base.

❏ 49. From leftover 1/8" balsa (soft balsa preferred) cut two

pushrod exit plates to the approximate shape as shown.

❏ 50.Fit and glue the pushrod exit plates in front of former

F-6, between the upper and middle longerons.

❏ 1. Fill any small gaps in the fuselage with balsa filler.

❏ 2. Use a sanding bar to sand the fuse sides and bottom

smooth. Sand the top front sheeting and chin plate flush

with the firewall.

❏ 3. Sand the lower corners of the chin plate, battery hatch,

landing gear plate and bottom sheeting to a slightly rounded

shape as shown on the plan.

❏ 4. Lightly sand the front top sheeting to blend into the

fuse sides.

❏ 5. Sand the wing saddle area slightly to remove any

excess glue.

Sand the Fuselage

To reduce the weight of the plane, you may cut large

lightening holes in the aft deck base (between the

formers). Leave approximately 3/8" of material along the

sides and 3/4" near the formers.

27

Page 28

❏ 1. Position the wing in the wing saddle and visually align

it with the fuselage.The center joint of the wing should align

with the hole in former F-2.

❏ 2.Transfer the hole location onto the wing LE joiner and

carefully cut out the hole to fit the 1/4" wing dowel.

❏ 3. Round both ends of the 1/4" x 1-1/2" wing dowel. Use

epoxy to glue the wing dowel in the LE joiner and the slot in ribs

W-1.Make sure the dowel is perpendicular to the LE joiner and

protrudes 1/2" out of the forward wing joiner.

❏ 4. After the epoxy cures, reinstall the wing on the fuse.

Use epoxy to glue the die-cut 1/8" plywood wing dowel

doubler to the front of former F-2. Before the epoxy cures,

carefully remove the wing from the fuse.

❏ 5. Place the wing in the wing saddle and visually align it

with the fuselage. Use a tape measure to measure the

distance from the corner of the aileron bay to the center of

the tail post. Then, measure the distance from the other

aileron bay and check if the distances are the same.Adjust

the wing until both distances are equal. When the wing is

perfectly aligned, make reference marks on the wing

trailing edge and former F-3A to help keep the parts aligned

during the next step.

❏ 6. Tape the wing in position so that it cannot move. Use a

5/32" (or #25) drill bit to drill a hole through the wing and wing

bolt plate.Two small 90-degree triangles will help you to align

the drill perpendicular to the top surface of the wing.Important:

Do not allow the wing to shift during this procedure.

❏ 7. Remove the wing and use a 13/64" drill bit to enlarge

the holes in the wing only.

❏ 8.Use a #10-24 tap to cut threads into the wing bolt plate.

After cutting the threads, put a couple of drops of thin CA on

28

Page 29

the threads in the wing bolt plate. After the CA has fully

cured, thread the tap back through the holes to clean up the

threads.Bolt the wing to the fuse with two nylon 10-24 wing

bolts, checking the fit.

❏ 9. Trim the clear windshield along the embossed “cut

lines.” Then, tape it in position on the front of the cabin.

❏ 10. With the wing installed, note the gap between the LE

of the wing and the windshield. Install shims made from

1/16" balsa sheet to reduce the gap to 1/32" on each side.

❏ 1. To aid in alignment, draw an accurate centerline on

the top of the stabilizer. This centerline should be in the

middle of S-5 and perpendicular to the TE.

❏ 2.Mount the wing on the fuse. Center the stabilizer on the

stab saddle, aligning the centerline of the stab with the

centerline of the fuse. From a few feet behind the fuselage,

view the stabilizer , checking that the stabiliz er is parallel with

the wing. If not, remove the stabilizer and sand the saddle

slightly.The front of the stab may need to be sanded slightly

so that the stab TE is flush with the aft end of the fuse.When

satisfied with the fit, use 30-minute epoxy to glue the stab to

the fuse. Double-check the stab alignment while the

epoxy is curing.

❏ 3. Set the fin in position on the stab. The fin TE must line

up with the aft edge of the fuselage tail post. If the fin is too

far forward, sand V-1 slightly to allow the fin to slide back

until the TE lines up properly. Also, the bottom of V-1 may

need to be sanded to allow the fin to seat on the stab.

❏ 4. Measure 1/8" on each side of the stab centerline and

draw two lines parallel with the stab centerline.

Mount the Stabilizer & Fin

29

Page 30

❏ 5. Set the fin in place, using the lines as a guide. Sight

down the fin, checking that it is in line with the centerline of

the fuselage. It is very important that the fin be aligned with

the centerline of the fuse.If it is not, the plane will be difficult

to trim. Use a square to check that the fin is perpendicular

to the stab. Use 30-minute epoxy to glue the fin to the stab

and aft deck base.

❏ 6. You previously cut the hinge slots in the rudder and fin

TE. Mar k the location of the bottom rudder hinge on the

fuselage tail post.

❏ 7 Cut the hinge slot in the fuse tail post and trial fit the

bottom rudder hinge in place.

❏ 1. Position one of the 1/8" diameter dowels in the center

notches of F-3A, F-4A, F-5A and F-6A. Sand the aft end of

the dowel at an angle to match the angle of the fin LE.Glue

the dowel in place. Then, cut off the forward end of the

dowel flush with the front of F-3A.

❏ 2. In a similar manner, cut and glue the other two 1/8"

dowels in position.

Note: If you examine the fuse plan you will notice that there

are 1/8" balsa filler pieces in the area in front of the fin.The

purpose of these pieces is to make the fuse easier to cover

and enhance the scale appearance.

❏ 3. Fit and glue the die-cut 1/8" balsa filler pieces

between the dowel stringers and fin and the dowel stringers

and aft deck base.

❏ 4. From a leftover piece of 3/16" balsa, cut a piece to fit

between the fin LE and the top dowel stringer. Glue it in

place and sand the top edge to a rounded shape to match

the fin LE.

Install the Dowel Stringers

30

Page 31

31

❏ 5. From a leftover 1/8" x 3/8" stick, cut a piece

approximately 4-1/4" long to fit on the side of the fin, from

former F-6A to the TE of the fin. Cut the piece in half

diagonally to make two fairings.

❏ 6. Sand the top surface of the fairings to a rounded shape.

❏ 7.Test fit the fairings in place.The forward edge should be

flush with the top of former F-6A. When satisfied with the fit,

glue the fairings in place on both sides of the fin/stab joint.

❏ 8. Apply balsa filler to any gaps around F-6A to blend the

fairings into the fin and stab.

❏ 9. From leftover 1/8" balsa, make gussets to fit at the joint

between the outside dowel stringers and former F-3A.

❏ 1. Turn the fuse upside-down and position the 1/8" wire

main landing gear on the 3/16" ply landing gear plate as

shown on the plan.T ac k glue it in place with a drop of thin CA.

❏ 2. Position the three nylon landing gear straps over the

main landing gear as shown on the plan. Mark the screw

hole locations on the landing gear plate.

❏ 3. Drill a 1/16" diameter pilot hole at each location

you marked.

❏ 4.Temporarily secure the main landing gear to the landing

gear plate with the landing gear straps and six #2 x 3/8" screws.

To reduce the weight of the plane, we recommend drilling

several 1/4" diameter holes through the landing gear

plate.Be careful to not drill through former F-2 or close to

the landing gear straps.

Mount the Landing Gear

Page 32

32

❏ 5. On the LE of the rudder, drill a 1/16" hole, centered

in the LE of the tailgear support, 3/8" from the bottom of

the rudder.

❏ 6. Use the threaded end of one of the threaded pushrod

wires to file a small slot in the LE of the tailgear support for

the 1/16" tailgear wire.Test fit the tailgear wire in the rudder.

Do not glue it in place until after the rudder is covered.

❏ Important: If you will be installing a motor with a diameter

of 1-29/64" (such as a Great Planes S-600 motor with a flux

ring) sand the raised area of the die-cut 1/8" plywood motor

mount sides flat.

❏ 1. Drill a 1/8" hole at each of the punch marks on the die-cut

1/8" plywood motor mount back and motor mount front.

❏ 2.Glue the two lower motor mount sides perpendicular to

the motor mount back.

❏ 3. Glue the two upper motor mount sides perpendicular

to the motor mount back.

❏ 4. Glue the motor mount front, flush with the motor

mount sides.

❏ 5. Use medium CA to reinforce all the glue joints on the

motor mount.

❏ 6.If you will be using an S-600 direct drive motor, test fit

the motor in the motor mount and secure it with two 3mm x

6mm machine screws and a rubber band at the rear.

Build the Motor Mount

Page 33

33

❏ 7. If you will be using a Great Planes T-600R Reverse

Rotation motor with a Great Planes 2.5:1 gear drive, test fit

the motor and gear drive in the motor mount and secure it

with three rubber bands, two behind the gear drive and one

at the back of the motor mount.

❏ 8. Use four #4 x 1/2" sheet metal screws to temporarily

attach the motor mount to the firewall.The direct drive setup

is mounted in the top holes.The gear drive setup is mounted

in the second set of holes, from the top.

❏ 1.Carefully trim the cowl along the mold seam at the back

of the cowl. Use a hobby knife or Curved-Tip Canopy

Scissors to cut out the propeller shaft hole and the vent

holes in the front of the cowl.Also cut out the cooling air exit

hole on the bottom of the cowl.

❏ 2.There are three small indentations near the rear edge

of the cowl, one on top and one on each side, toward the

bottom.These are the mounting screw hole locations. Drill a

3/32" diameter hole at each location.

❏ 3. With your electric motor mounted, slide the cowl into

position. Make sure the propeller shaft is centered in the

hole and there is approximately 1/16" clearance between

the front of the prop adapter and the cowl. Mark the cowl

screw hole locations on the fuselage.

❏ 4. Drill 1/16" diameter pilot holes in the fuse for the cowl

screws. Temporarily mount the cowl to the fuse with #2 x

3/8" sheet metal screws.Do not over-tighten the screws.

Mount the Cowl

Page 34

34

❏ 5. Cut out the dummy engines and exhaust pipes.Test fit

them on the cowl.The cylinder heads should line up with the

prop shaft of the real motor.Trim and sand as required for a

good fit.We waited until after the cowl and dummy engines

were painted before gluing them together.

❏ 6. Since you are cutting out plastic par ts, cut out the two

hub caps also. Test fit them on your 2" main wheels (not

included). When satisfied with their fit, set them aside until

after they are painted.

Note: The wing struts are optional (for scale like appearance)

and are not required for flying. They do, however, add

strength to the wing and do not seem to noticeably reduce

the performance.

❏ 1. Sand the 3/32" x 1/4" x 16-1/4" hardwood sticks to an

airfoil shape as shown on the wing plan.

❏ 2.Working over the wing strut drawing on the wing plan,

make two sets of struts as shown. Note that where the

struts join you must cut one of the struts off at an angle

before gluing them together.

❏ 3. Reinforce the ends of the struts by wrapping small

pieces of fiberglass around the struts and applying CA

glue. Sand the str uts smooth.

❏ 4. Drill 1/16" diameter pilot holes in the ends of the struts

where shown for the mounting screws.

Note: The struts will be mounted to the wing and fuse after

the plane is covered.

Note: The Electr iCub was designed to use mini servos on

all control surfaces.If you are installing an electronic speed

control, the throttle servo, receiver battery (if the speed

control has BEC and auto cutoff) and the toggle switch can

be omitted.

❏ 1. Prepare the servos by installing the rubber grommets

and brass eyelets into each servo.

❏ 2. Place the ser vos into the die-cut 1/8" plywood servo

tray and position them so they do not touch the sides of the

openings. Mark the servo mounting holes on the servo tray.

Remove the servos and drill 1/16" pilot holes at the marks.

Mount the servos to the servo tray using the mounting

screws provided with the servos.

❏ Note: If an electronic speed control is used, assemble the

speed control tray and mount it in the top opening in former

F-2A. The speed control can be held in place with a piece

of V elcro®applied to the top of the tray and the bottom of the

speed control.

❏3.Mount the receiver switch on the side of the fuse.We found

a good place for the switch is just behind f ormer F-2A along the

joint between the bottom fuse side and middle fuse side.

Mount the Servos

RADIO INSTALLATION

Construct the Wing Struts

Page 35

❏ 4. Wrap the receiver and receiver battery (if used) in 1/4"

foam rubber.

❏ 5. Temporarily position the receiver and receiver battery

on the fuse bottom, in front of former F-3.Later, the receiver

battery may be moved forward or aft to balance the plane.

Plug the receiver battery into the receiver switch.

❏ 6. If you are installing one of the Great Planes motor

packages with the switch harness, mount the toggle switch

on the side of the fuselage.

❏ 7. Place the servo tray in the fuse. Do not attach it to the

servo tray rails. It will be attached later, allowing it to be

moved forward or aft to balance the plane. Plug the servos

and receiver switch into the receiver.

❏ 8. Cut and sand one of the servo control wheels to a

“cam” shape, similar to that shown on the plan. Clean the

micro switch and the top of the throttle servo case with

rubbing alcohol. Mount the micro switch to the top of the

throttle servo case with double-sided foam tape in such a

way that when you advance the transmitter throttle stick to

full throttle (pushed towards the top of the transmitter), the

servo wheel will activate the micro switch. When satisfied

with the operation of the switch, secure the switch to the

servo by wrapping with a narrow strip of strapping tape.

❏ 9. Charge the motor battery following the instructions

included with your charger.

❏ 10. Make sure the propeller is removed before testing

your motor system. Plug the motor battery into the switch

harness and activate the toggle switch. The motor should

begin running when the transmitter throttle stick is pushed

forward to full throttle and stop when the stick is pulled bac k.

With the toggle switch in the off position, you should not be

able to start the motor with the throttle stick. In order for

this safety feature to be effective, you should always

keep the toggle switch in the “off”position until you are

ready to fly.

NOTE: If you are using an electronic speed control,

install it at this time following the instructions provided

with the speed control. Test run the motor and speed

control to make sure it operates properly.

❏ 11. Unplug and remove the motor battery from the plane.

❏ 1. Separate the nylon control horns from the nut plates.

❏ 2.Lay the rudder on the fuse plan side view and determine

the location for the nylon control horn. While holding one of

the control horns in position on the left side of the rudder,

mark the mounting hole location on the rudder.

❏3.Drill a 3/32" diameter hole through the rudder at each mark.

❏ 4. Mount the control horn on the r udder with two 2-56 x

3/8" machine screws and the nylon nut plate.

❏ 5. Repeat the process to mount the control hor n on the

bottom right side of the elevator.