Page 1

READ THROUGH THIS INSTRUCTION

BOOKLET FIRST. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE BUILDING AND USE OF THIS

MODEL.

WARNING!

This R/C kit and the model you will build is not a toy! It is capable of serious

bodily harm and property damage. IT IS YOUR RESPONSIBILITY AND YOURS

ALONE — to build this kit correctly, properly install all R/C components and flying

gear (engine, tank, pushrods, etc.) and to test the model and fly it only with experienced, competent help in accordance with all safety standards and common

sense as set down in the Academy of Model Aeronautics Safety Code. It is suggested that you join the AMA and become properly insured before you attempt to

fly this model. IF YOU ARE JUST STARTING R/C MODELING, CONSULT YOUR

LOCAL HOBBY SHOP OR WRITE TO THE ACADEMY OF MODEL AERONAUTICS

TO FIND AN EXPERIENCED INSTRUCTOR IN YOUR AREA.

Academy of Model Aeronautics

5151 East Memorial Dr.

Muncie, IN 47302-9252

(800) 435-9262

PO BOX 721 URBANA ILLINOIS 61801

Page 2

TABLE OF CONTENTS

INTRODUCTION 2

PRECAUTIONS 3

KEEP IT LIGHT' 3

RADIO SELECTION 3

BATTERY SELECTION 3

BATTERY CHARGER SELECTION 3

PROPELLER SELECTION 3

SELECTION OF WHEELS 4

GLUES (ADHESIVES) 4

OTHER ITEMS REQUIRED 4

SUPPLIES AND TOOLS NEEDED 4

COMMON ABBREVIATIONS USED IN

THIS BOOK AND ON THE PLANS 4

PARTS IDENTIFICATION DRAWINGS 5

GET READY TO BUILD

FUSELAGE

PREPARE THE LANDING GEAR PLATE 7

PREPARE THE HATCH 7

PREPARE F1 9

PREPARE F2 9

MAKE THE FUSE SIDES 10

ASSEMBLE THE FUSELAGE 11

BUILD THE FIN 13

BUILD THE RUDDER 13

BUILD THE STABILIZER 14

BUILD THE ELEVATORS 15

MAKE THE HINGES 16

TEMPORARILY INSTALL HINGES 16

TEMPORARILY MOUNT CONTROL

HORNS 17

INSTALL SERVOS 18

INSTALL THE MOTOR AND SWITCH

HARNESS 19

INSTALL ON-OFF SWITCH PUSHROD 20

MOUNT THE RECEIVER SWITCH 21

CUT PUSHROD EXIT SLOTS 21

MOUNT THE STABILIZER 22

TRIAL FIT THE FIN AND RUDDER 22

MAKE THE PUSHRODS 23

INSTALL PUSHRODS 25

COMPLETING THE FUSELAGE 25

WING .................................. 27

..........

6

PREDICTING THE FINISHED FLYING

WEIGHT .. ............................. 30

COMPLETE THE STRUCTURE .......... 31

TRIAL FIT THE WING IN THE SADDLE 31

MOUNT THE ELEVATOR 31

MOUNT THE FIN 32

TRIAL FIT THE MOTOR BATTERY 32

COVERING ........................ 32

COVER THE FUSELAGE 32

ADD WASHOUT AT THE WING TIPS 35

ADD TRIM 35

FINAL ASSEMBLY ...................... 36

BALANCE YOUR MODEL 36

FINAL HOOKUPS AND CHECKS 37

PRE.FLIGHT ........................... 37

CHARGE THE BATTERIES 37

TEST THE MOTOR OPERATION 37

FIND A SAFE PLACE TO FLY 37

GROUND CHECK THE MODEL 38

RANGE CHECK YOUR RADIO 38

MOTOR SAFETY PRECAUTIONS 38

AMA SAFETY CODE 38

FLYING ................................ 38

TRIM OUT THE MODEL 39

YOUR FIRST FLIGHTS 39

THE TAKEOFF 39

FLYING WITH 3 CHANNELS 40

FLYING WITH 2 CHANNELS 40

LANDING 40

APPENDIX ............................. 40

PROPER CARE OF YOUR

THRUSTMASTER MOTOR 40

WHEN YOU BLOW A FUSE 41

HOW TO ACHIEVE THE BEST

PERFORMANCE FROM YOUR ELECTRICPOWERED MODEL 41

WEIGHT 41

THRUST 42

OTHER FACTORS 42

SUMMARY 43

PARTS

LIST

............................

44

INTRODUCTION

Hello' My name is Jim Schrmdt On behalf of

Great Planes Model Manufacturing thank you for

choosing the PT-Electnc I will show you step bystep how to build this airplane Follow these instructions as they are written and you will end up with

a great flying airplane, plus you will have learned

the basics of R/C model building

I'll try to make your building experience as

enjoyable and "snag free as possible If you have

any questions about building or flying this

airplane, please call us at (217) 398-8970 and we'll

be glad to help.

2

Page 3

PRECAUTIONS

1 You must build the plane according to the

plans and instructions. Do not alter or modify the

model as represented by the plans, as doing so may

result in an unsafe or unflyable model.

2 You must take time to build straight, true

and strong

3 You must use a proper R/C radio that is in

first class condition, the correct size motor and correct components (fuel tank, wheels, etc.) throughout your building process

4 You must properly install all R/C and other

components so that the model operates properly on

the ground

5. You must test the operation of the model

before the first and each successive flight to insure

that all equipment is operating and you must make

certain that the model has remained structurally

sound.

6. You must fly the model only with compe-

tent help from a well experienced R/C pilot if

you are not already an experienced and knowledgeable R/C pilot at this time.

We will give you tips throughout this book on

how to keep the structure light, and we urge you to

follow them

RADIO SELECTION

If you are a beginner, we recommend that

you purchase a radio system that has a built-in

Trainer

training for your first flights using the "buddy box"

system, in which two transmitters (yours and your

instructor's) are connected with a "trainer cord"

PT-Electnc, the ideal radio system is one that employs a small 225 mAh battery pack, a miniature

receiver and 2 or 3 "micro" servos, such as Futaba's

S-33 servos We have, however, done most of our test

flying using 3 standard Futaba S-38 servos and a

225 mAh battery pack, and this combination has

proven to be satisfactory

to use it, rather than purchasing a new one just to

save a couple of ounces, however, we do recommend

that you use a 225 mAh battery pack rather than

the 550 mAh pack that comes standard with most

radios Be aware, however, that a smaller battery

pack means fewer flights between charging.

System

Because weight is an important factor in the

If you already have a radio, we encourage you

If

you

do,

you

will

be able to receive

Note We, as the kit manufacturer, can provide

you with a top quality kit and great instructions,

but ultimately the quality and flyability of your

finished model depends on how you build it, therefore, we cannot in any way guarantee the performance of your completed model, and no representations

are expressed or implied as to the performance or

safety of your completed model.

Remember: Take your time and follow directions to end up with a well-built model that

is straight and true.

KEEP IT LIGHT!

Because the electric motor and motor battery

are relatively heavy, and because electric motors do

not produce as much thrust as glow engines (when

compared to their weight), it is essential that the

basic structure of the airplane be kept as light as

possible In doing so, you will help insure that the

finished airplane will not be too heavy to fly well

One way to prevent excess weight build- up is

to use only as much glue as needed for good glue

joints. Do not apply extra "fillets" of glue thinking

that it will make your plane stronger' All that extra

glue adds ounces to the weight of your plane, and

will detract from the performance.

Please make sure you select a radio system

that

is

on

a frequency

craft use only", and one that meets current FCC standards.

BATTERY SELECTION

The PT-Electnc was designed to fly with a standard 6-cell 7 2 volt 1200 mAh battery pack for motor

power, and it does so very well' If you want additional

power and a super climb rate, you may wish to use

a 7-cell 84 volt 1200 mAh pack ("flat" type) The

Thrustmaster switch harness uses a connector that

is made to fit batteries with "Kyosho"-type connectors We think the best all-around battery for the

PT-Electnc is the Kyosho 6-cell 1200 mAh Racing

Battery.

BATTERY CHARGER SELECTION

You may use any of the commercially available

battery chargers that are designed for charging 6 or

7 cell nicad battery packs Some chargers have a

"peak detector" which sense when the battery is fully

charged and automatically shut off at the right time

Some chargers operate from 110 volt house current,

12 volt DC (automobile battery), or both

PROPELLER SELECTION

(channel)

designated"

for

air-

The finished PT-Electnc, ready to fly, should

weigh-in right at 3 lbs (48 ounces) as an ideal weight

It will, however, perform quite well at weights up to

3-1/4 lbs We have successfully flown the PT-Electnc

at 3-1/2 lbs , but the performance was marginal

The propeller type size and pitch seem to affect

the performance of the PT-Electnc more than any

other single factor For use with the Thrustmaster

and similar motors we recommend the Grish 8x4

Nylon Propeller over any others we tested in direct

3

Page 4

drive operation You may wish to experiment with

various other prop sizes in nylon and wood, to best

match your motor, but the Gnsh 8 x 4 is the best

place to start

SELECTION OF WHEELS

Because weight is such an important factor in

electric powered models, we strongly recommend

that you purchase lightweight wheels, such as Dave

Brown "Lite Flite" wheels or Zinger lightweight

wheels

GLUES (ADHESIVES)

If you look at the "ITEMS NEEDED" list you

will see that we recommend only two basic types of

glue for building the PT-Electnc.-.CA glue and

epoxy.

CA (Cyanoacrylate) glues are great for model

building because they set fast Rather than pinning

glued joints together and waiting for hours while the

glue dries, CA glues will harden in a few seconds

while you hold the parts together Thin CA runs

right into a good fitting joint, so you can assemble

the parts first, then apply thin CA Thick CA is

more like syrup and it will not harden until you

press the two parts together squeezing the glue out

to a thin layer A related and very handy product is

CA Accelerator spray (Zip Kicker or Hot Shot),

and is used to instantly harden CA glue When using

CA glues " trial fit" the parts to make sure they

fit well before gluing because they don't give you

a second chance The most common mistake made by

new modelers is using too much CA glue Rather

than squeezing the bottle, it is usually sufficient to

touch the tip of the applicator spout to the joint being

glued and allow a few drops of CA to flow into the

joint.

If you need time to position glued pieces cor-

rectly or need extra strength, use epoxy glue Epoxy

is normally used in the firewall and motor mount

area and when gluing the two wing panels together.

Five

minute

epoxy

starts

to harden in 5 minutes)

is great for most applications If you need longer time

use 15 or 30 minute epoxy You need not use large

amounts of epoxy Squeeze out the amounts of epoxy

and hardener that your particular brand requires.

For example, some epoxies use equal amounts and

some use a 1 to 2 mixture Mix these together Coat

one piece with epoxy, squeegee the excess glue off

with scrap wood The epoxy glue will work better if

there isn't too much oozing out at the edges of the

glued piece Wipe off any of this excess glue with a

tissue.

In any case, glue is never a substitute for a

good-fitting joint, once the Joint is formed, use a

minimum amount of glue and wipe off the excess

with a tissue Clamp, pin or hold the Joint while the

glue is drying.

OTHER ITEMS REQUIRED

General:

Radio, Batteries (See above comments on these

items)

2- 2" Diameter Main Wheels

1- 1-3/4" Diameter Nose Wheel

6- 1/8" Wheel Collars

Iron-on Covering Material (Super Monokote or

Similar)

Roll of 1/8" x 1/4" self-adhesive foam wing seating tape (Rocket City #38, or Sonictronics

#232)

Foam Rubber Padding, 1/4" thick (Goldberg

#291 FR25 or similar)

SUPPLIES AND TOOLS NEEDED

2 oz - Thin CA Adhesive

1/2 oz - Thick CA Adhesive

Instant Glue Accelerator (optional)

2 5 oz - 30 Minute Epoxy

Hand or Electric Drill

Drill Bits 1/16", 5/64", 3/32", 7/64". 1/8", 11/

64",

1/4")

Sealing Iron (for covering)

Heat Gun (optional, for shrinking covering)

Hobby Saw (X-Acto Razor Saw)

X-Acto Knife, #11 Blades

Pliers

Screw Drivers

Flat File

T-Pins

Straightedge 01 Ruler

Masking Tape

Sandpaper (100 grit and 220 grit)

T-Bdi Sanding Block, or Similar

Waxed Paper

Lightweight Balsa Filler

COMMON ABBREVIATIONS USED IN THIS

BOOK AND ON THE PLANS:

Elev = Elevator

Fuse = Fuselage

LE = Leading Edge (front)

LG = Landing Gear

Lt = Left

Ply = Plywood

Rt = Right

Stab = Stabilizer

TE = Trailing Edge (rear)

" = Inches

Remember: Take your time and follow directions to end up with a well-built model that

is straight and true.

4

Page 5

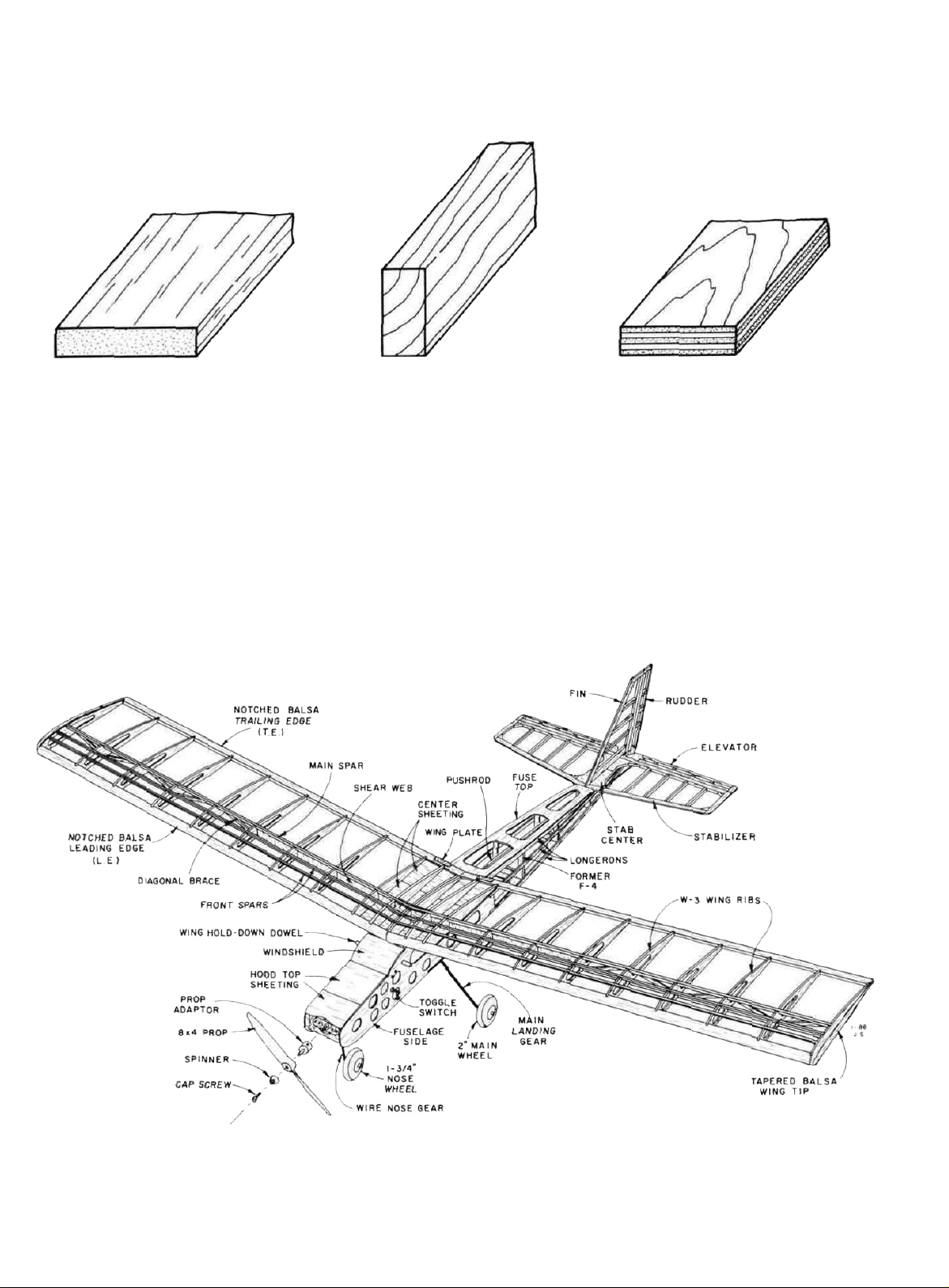

TYPES OF WOOD

BALSA BASSWOOD PLYWOOD

Study this perspective drawing to become familiar

with the parts of the PT-Electric.

5

Page 6

GET READY TO BUILD

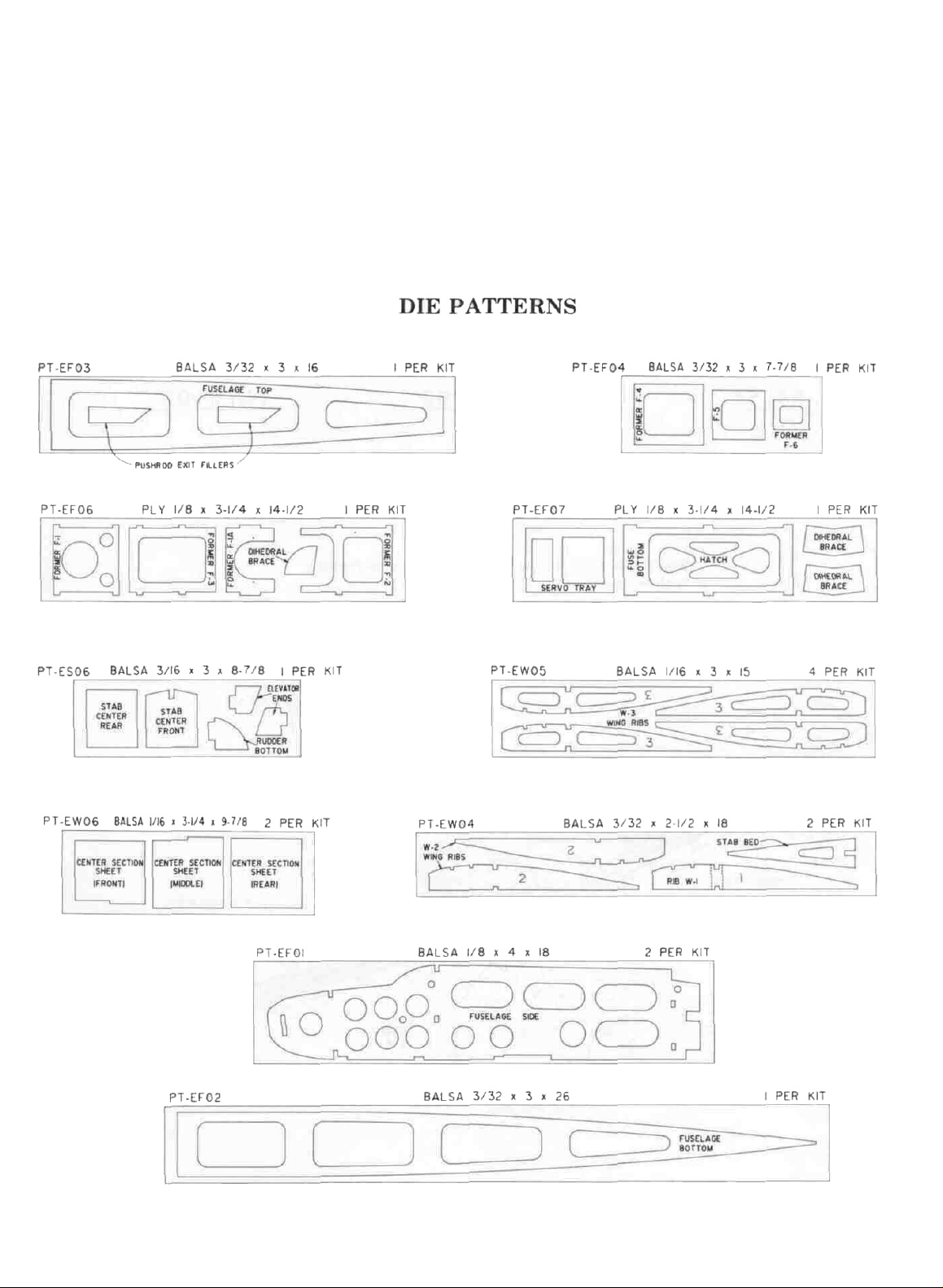

D 1. Unroll the plan sheet. Re-roll it inside out to make

it lie flat. Note: The fuselage plan is printed on Side

1 and the wing plan is printed on Side 2.

terns shown below to identify the die cut parts and

mark them before punching out. Save all scraps. If

any of the die-cut parts are difficult to punch out, do

not force them! Instead, first cut around the parts

with an Xacto knife.

D 2. Remove all parts from the box. As you do, figure

out the name of each part by comparing it with the

plans and the parts list. Using a felt tip pen, write

the part name or size on each piece to avoid confusion later. Be especially careful to identify the sticks

correctly, as there are several sticks having the same

width but differing thicknesses. Use the die cut pat-

NOTE: After punching out the die cut parts, use your

T-Bar or sanding block to lightly sand the edges to remove

any die-cutting irregularities.

D 3. As you identify and mark the parts, separate them

into groups, such as fuse (fuselage), wing, fin &

stab (stabilizer), and hardware.

6

Page 7

FUSELAGE

PREPARE THE LANDING GEAR PLATE

D 1. Find the following items: 3/16" x 1-27/32" x 2-3/4"

plywood landing gear plate, three nylon landing gear

brackets, six #2 x 3/8" screws, and the 1/8" wire

main landing gear.

#2x3/8" SCREW

LANDING GEAR STRAP

(NYLON)

D 5. File the screws off flush with the surface of the

landing gear plate to prevent damage to the battery

pack.

D 6. Drill several 1/4" holes in the landing gear plate

as shown on the plan. These holes are for lightness,

and provide cooling air exit for the battery compart-

ment.

D 2. Hold the landing gear on the ply plate in the

position shown on the plan and put the nylon brac-

kets in place. While holding, use a pencil down

through the bracket holes to mark the screw hole

locations.

D 3. Drill 1/16" pilot holes at the above locations.

TIP: Anytime you drill a hole in wood, use a T-pin to start

the hole (for accuracy), and use a scrap wood backing underneath. This will prevent splitting out the back side of

the wood and will protect your work surface. The landing

gear screws will go in easier if you lightly scrape the screws

on a bar of soap to lubricate the threads.

D 4. Temporarily attach the landing gear to the ply

plate using the #2 x 3/8" screws and nylon straps.

D 7. Remove the landing gear and sand the ply plate

smooth. Set the 6 screws aside in a bag marked "LG

SCREWS".

PREPARE THE HATCH

D 1. Find the following items 4 length of hinge strip

material, Die-cut 1/8" ply fuse bottom and hatch,

1/32" x 1- 3/4" x 2" ply, five #2 x 3/8" screws, and

the #2 washer.

#2x3/8"

SCREW

7

Page 8

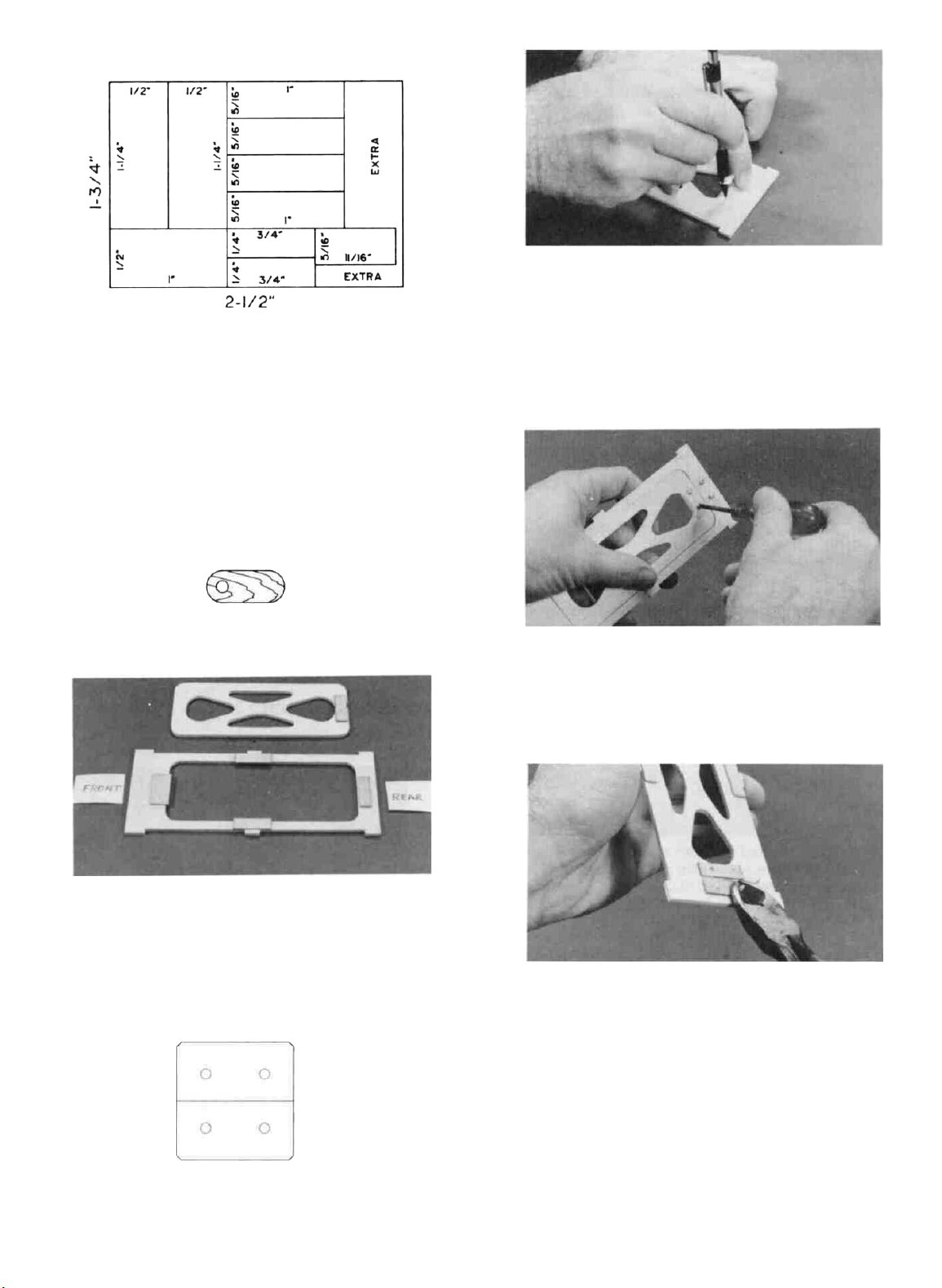

1/32" PLY CUTTING PATTERN

D 2. Using the pattern given here, mark the 1/32" x

1-3/4" x 2" ply plate for cutting. Cut out the small

pieces with a scissors or Xacto knife. The two 1-1/4"

x 1/2" pieces are the wing plates. Set them aside

until later. The two 1/4" x 3/4" pieces will be used

in the "PREPARE F-l" section.

D 3. From the 1/32" x 5/16" x 11/16" ply piece that you

previously cut, make the hatch locking tab according to the following sketch: (be sure to drill into a

wood backing to prevent splitting).

D 6. Lay the 1" hinge in place on the hatch and fuse

bottom, and mark the locations of the screw holes.

D 7. Drill 1/16" pilot holes at the marked locations.

HATCH LOCKING TAB

1/32 PLY

D 4. Using thin CA, Glue the remaining 1/32" ply pieces

to the 1/8" ply hatch and fuse bottom in the locations

shown on the plan. Note that the two side pieces and

the front piece extend 1/16" into the hatch opening.

D 5. Cut off a 1" length of hinge strip material and

drill four 3/32" holes as shown in the following

sketch.

D 8. Attach the hinge with four #2 x 3/8" screws.

D 9. Cut or file off the portion of the screws that would

protrude into the battery compartment. NOTE: Protect your eyes from flying metal when cutting off

screws.

HATCH HINGE

D 10. Drill a 1/16" pilot hole in the fuse bottom for the

hatch locking tab, at the location shown on the plan.

8

Page 9

D 11. Temporarily mount the 1/32" ply hatch locking

tab using a #22 x 3/8" screw and the #2 washer,

and cut off the portion of the screw that protrudes

into the battery compartment.

D 12. Check the operation of the hatch Sand the edges

of the hatch slightly to provide a close but non-binding fit.

D 13. Disassemble the above and set the hatch, hinge,

locking tab and screws aside until later.

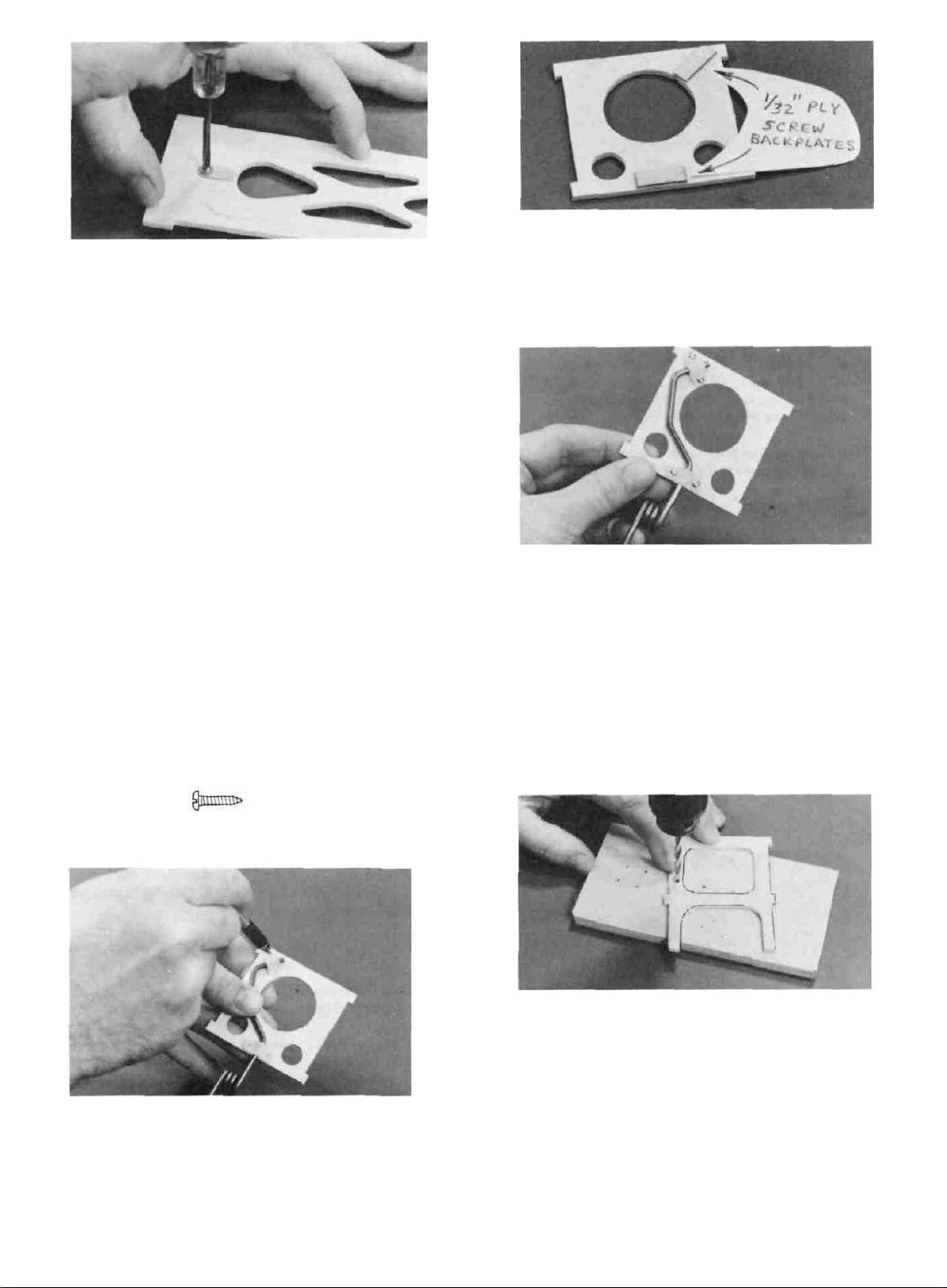

PREPARE F- 1

NOTE: The PT-Electric has a "fixed" (non-steering) nose

gear which you will rigidly attach to Former F-l. At first

you may

the airplane on the ground with this setup We just want

to assure you at this time that it actually does steer quite

well' Because there is very little weight on the nose wheel,

the wind moving past the tail of the airplane enables the

rudder to turn the airplane almost as if the nose wheel

were steerable.

D 1. Find the die- cut 1/8" ply former F-l, two nylon

be

thinking

landing gear brackets, four #2 x 3/8" screws, the

1/8" wire nose gear, and the two 1/32" x 1/4" x 3/4"

ply pieces which you previously cut.

that

it

will

not be possible to

steer

D 4. Glue the 1/32" ply screw backplates to the back

of F-l, using the pilot holes you previously drilled

to determine where to locate the ply backplates.

D 5. Now re-drill the pilot holes.

D 6. Temporarily mount the nose gear to F-l using the

nylon brackets and screws.

D 7 Disassemble the above parts, and set the nose

gear, brackets and screws aside until later.

PREPARE F-2

D 1. Find the die cut ply former F-2.

D 2. From the detail drawing of F-2 determine the lo-

cation of the on-off switch pushrod.

#2x3/8"

D 2. Study the detail drawing of F-l on the plan, and

position the nose gear and nylon brackets While

holding them in place, mark the locations of the

screw holes.

D 3. Drill 1/16" pilot holes at the marked locations.

SCREW

D 3. Drill an 11/64" hole in F-2 at the above location.

PREPARE F-4 AND F-5

D 1. Find the die-cut 3/32" balsa formers F-4 and F-5,

and the two 3/32" x 3/8" x 17-7/8" balsa sticks

D 2. Cut a 9-1/8" length from each of the 3/32" x 3/8"

x 17-7/8" sticks, mark them "Wing Saddle Dou-

bler", and set them aside.

9

Page 10

D 3. From one of the remaining 3/32" x 3/8" balsa sticks,

cut cross-braces for F-4 and F-5. Glue these crossbraces to the formers with thin CA as shown on the

plan. Use only a few drops of glue to avoid excess

weight build-up.

MAKE THE FUSE SIDES

D 1. Find the 1/8" die- cut balsa fuse sides and the

1/8" x 3/8" x 23-7/8" balsa sticks. Inspect the balsa

sticks and pick out the four straightest ones which

you will use for the middle and lower longerons.

D 2. Tape the fuse plan to your flat work surface, then

tape a piece of waxed paper over the fuse side view.

D D 5. From one of the remaining short 1/8" x 3/8" sticks,

cut the tail post to match the plan.

D D 6. Hold or pin the parts accurately in place on the

plan, then glue the middle and lower longerons to

the fuse side and to the tail post using thin CA.

D D 7. Cut a third 1/8" x 3/8" balsa stick to match the

upper longeron on the plan (the upper longeron

extends back to the rear edge of F-6), and glue it to

the fuse side and to the middle longeron.

D D 3. Accurately position one of the 1/8" balsa fuse sides

on the plan and hold it firmly in place with a heavy

book or with "shot bags" (A handy shot bag can be

made by partially filling a sock with lead shot or

BB's).

D D 4. Lay the middle and lower "longerons" (1/8" x 3/8"

sticks) in place and draw a straight line at the front

of the tail post. Cut the longerons off at these lines

using a razor saw.

D 8. While the fuse side is still in place on the plan,

use a straightedge and a pen to mark the locations

of formers F-4, F-5 and F-6. (Skip this step when

building the second fuse side.)

D D 9. Sand the fuse side smooth using a T-bar sander

with 100 grit sandpaper.

D 10. Now repeat steps 3-7 and 9 to build another

identical fuse side.

D 11. Put the two fuse sides together and line them up

at the front and the bottom edges. Then check to

make sure they are exactly the same all the way

around. Sand the edges as necessary until the two

fuse sides match. It is especially important that the

overall length be the same, so sand the tail post as

necessary.

10

Page 11

D 12. Lay the two fuse sides flat on the table, with the

bottom edges touching. Then, using a straightedge

and a pen, extend the former location lines onto the

fuse side that does not have them.

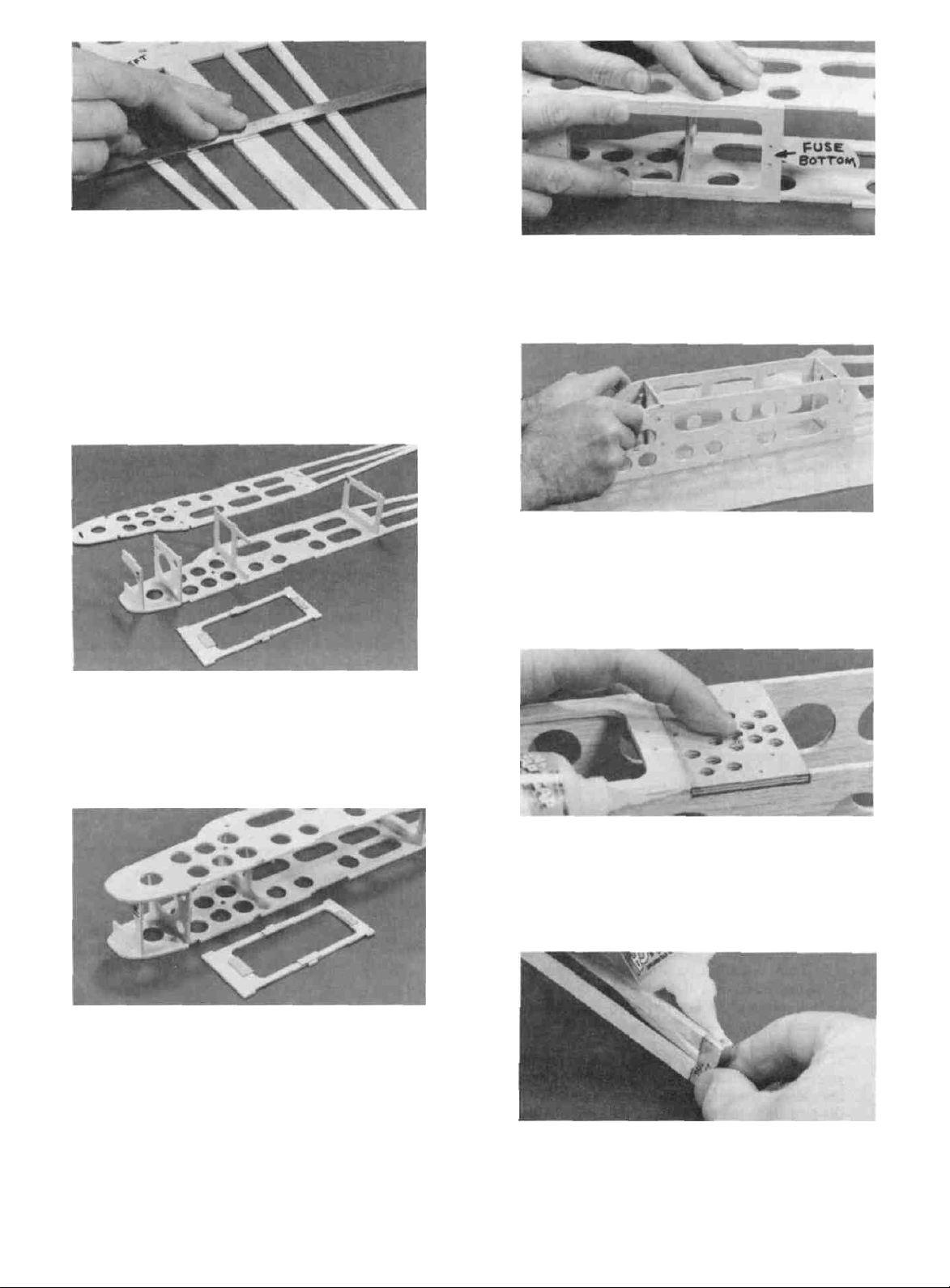

ASSEMBLE THE FUSELAGE

D 1. To begin, you'll need the following parts: The two

fuse sides you just built, Formers F-1A, F-l, F-2, F-3,

and the 1/8" ply fuse bottom.

D 2. Lay one of the fuse sides down flat on the table.

Insert the tabs of formers F-1A, F-l, F-2 and F-3 into

the slots in the fuse side. Check the plans and make

sure the formers are right side up. (Do not glue).

D 4. Press the 1/8" ply fuse bottom in place. Notice

that the interlocking parts automatically square-up

and align the front portion of the fuselage.

D 5. Lay a piece of waxed paper on your flat table, then

set the fuse assembly upright on the waxed paper.

Make sure that all tabs are fully seated into the

slots and notches. While holding the assembly to-

gether, apply thin CA glue to all joints.

D 3. Lay the left fuse side in place on the formers,

working the tabs into the notches. (Do not glue).

D 6. Turn the fuse upside down, and glue the 3/16" ply

landing gear plate in place in the notches in the

fuse sides (sand the ply plate, if necessary, for a good

fit). Add thick CA glue to the joint between the LG

plate and the 1/8" ply fuse bottom.

D 7. Turn the fuselage right side up, pull the tail posts

together, and apply thin CA glue to the tail posts.

11

Page 12

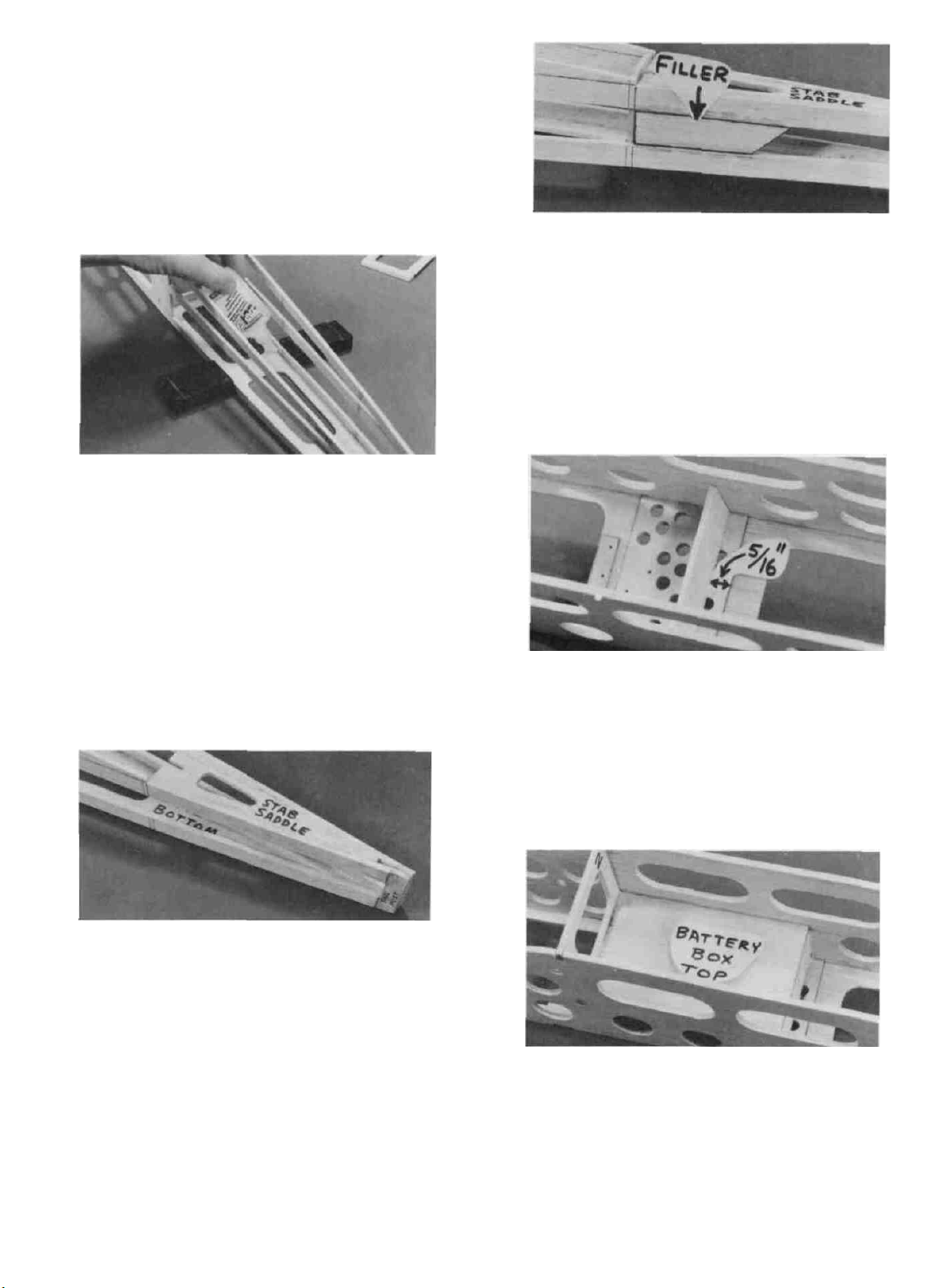

D 8. Now get the following parts together: Die-cut 3/32"

balsa fuse bottom, formers F-4, F-5 and F-6, and

the die-cut 3/32" balsa stab saddle.

D 9. Work the 3/32" balsa fuse bottom into place

between the bottom longerons. The front of the fuse

bottom must touch the rear of the landing gear plate.

With the fuse upright on a piece of waxed paper,

make sure the fuse bottom is even with the bottom edge of the fuse sides and bottom longerons,

then apply thin CA glue along the bottom joints,

pulling the bottom longerons together. Note: If you

have small hands and are unable to hold the stringers

together, you may use books or other square weights

to hold the longerons together.

D 12. Find the two die-cut 3/32" balsa pushrod exit

fillers, sand them to fit between the middle and lower

longerons just behind F-6. Glue them in place, flush

with the outside edge of the longerons.

D 13. Find the 3/32" x 1-1/4" x 2-1/2" balsa battery

box rear, and glue it to the landing gear plate, 5/16"

forward of the rear edge of the landing gear plate.

D 10. Slide the 3/32" balsa stab saddle into place be-

tween the middle longerons. The front edge of the

stab saddle must line up with the marks you made

for the rear edge of F-6. Make sure the top edge

of the stab saddle is even with the top of the

longerons, and glue it in place with thin CA.

D 11. Install formers F-4, F-5 and F-6 at the locations

you previously marked. Note: you may have to sand

the

sides

of

the formers

the formers to the fuse bottom, then pull the longerons together and glue them to the formers.

slightly

for a good

fit.

Glue

D 14. Find the 3/32" x 2-1/2" x 4-1/16" balsa battery

box top. Position it so the bottom front edge is even

with the bottom edge the cross-brace on F-2. Glue it

to F-2, the fuse sides and to the battery box rear.

12

Page 13

D 15. Find the two 3/32" x 3/8" x 9-1/8" balsa sticks

which you previously marked "Wing Saddle Dou-

bler". Sand the ends of these pieces slightly, to fit

between F-2 and F-3. Glue these doublers in place

with the edge flush with the top edge of the fuse sides.

NOTE: This completes the fuselage assembly for now.

Leaving off the top sheeting will make it easier to install

the other components later.

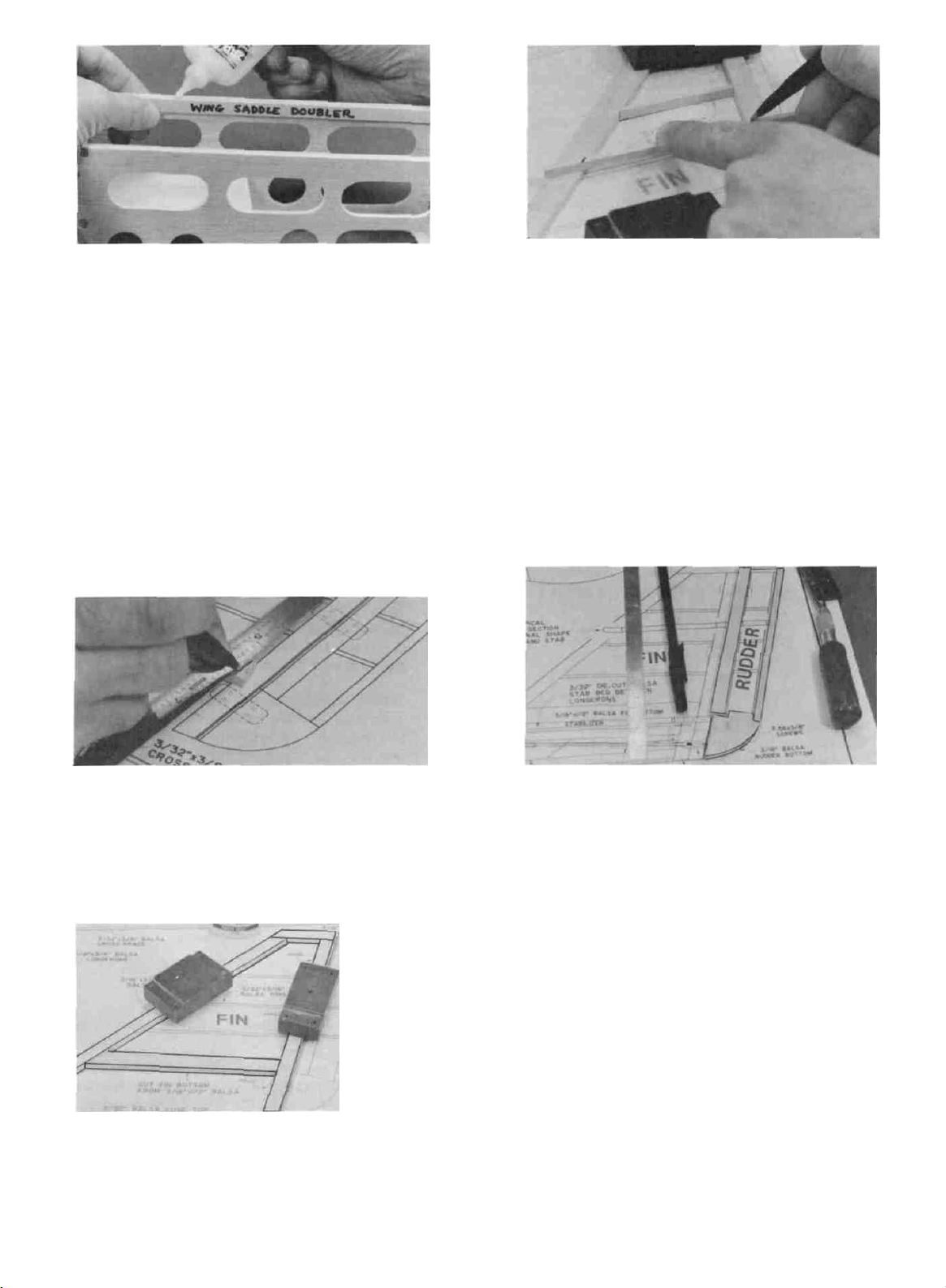

BUILD THE FIN

1. Find the following parts: 3/16" x 1/2" x 5-1/2" balsa

stick, five 3/16" x 3/8" x 24" balsa sticks, and a 3/32"

x 3/16" x 24" balsa stick. Select the straightest 3/16"

x 3/8" x 24" balsa stick and set it aside for later use

as the stabilizer trailing edge.

D 4. From the 3/32" x 3/16" x 24" balsa stick cut ribs

to fit between the framework, as shown on the plan.

Glue the ribs to the framework.

D 5. Sand both sides of the fin smooth using your T-bar

and 100 grit sandpaper. Sand the leading edge and

top of the fin to a rounded shape as shown in the

typical cross-section.

BUILD THE RUDDER

1. You'll need the following parts: Die-cut 3/16" balsa

D

rudder bottom, 3/16" x 3/8" x 24" balsa stick, 3/16"

x 3/16" x 24" balsa stick, and a 3/32" x 3/16" balsa

stick.

2. Working over the separate FIN drawing on the

D

plan, mark and cut the balsa sticks to make the

outer framework of the fin.Begin by laying one of

the sticks in place, then use a straightedge to mark

the cut-off lines. Cut the stick off with a razor saw,

then proceed to the next part.

3. Hold or pin the parts over the plan and glue the

D

outer framework pieces together with thin CA, working on waxed paper to prevent gluing to the plan.

13

2. In the same manner as the fin, cut the outer

D

framework pieces for the rudder.

3. Glue the outer framework and the rudder bottom

D

together with thin CA. Be sure to work on waxed

paper to avoid gluing the parts to the plan!

4. From the 3/32" x 3/16" balsa stick, cut ribs to fit

D

between the rudder leading edge and trailing edge.

Glue the ribs in place.

5. Sand both sides of the rudder smooth and flat.

D

Sand the upper rear corners of the rudder to a round

shape as shown on the plan. Sand the trailing edge

and rudder bottom to a rounded shape as shown in

the typical cross-section.

Page 14

D 6. Draw a centerline down the full length of the

rudder leading edge, then use your T-bar sander to

sand the leading edge to a "V" shape as shown in

the typical cross-section.

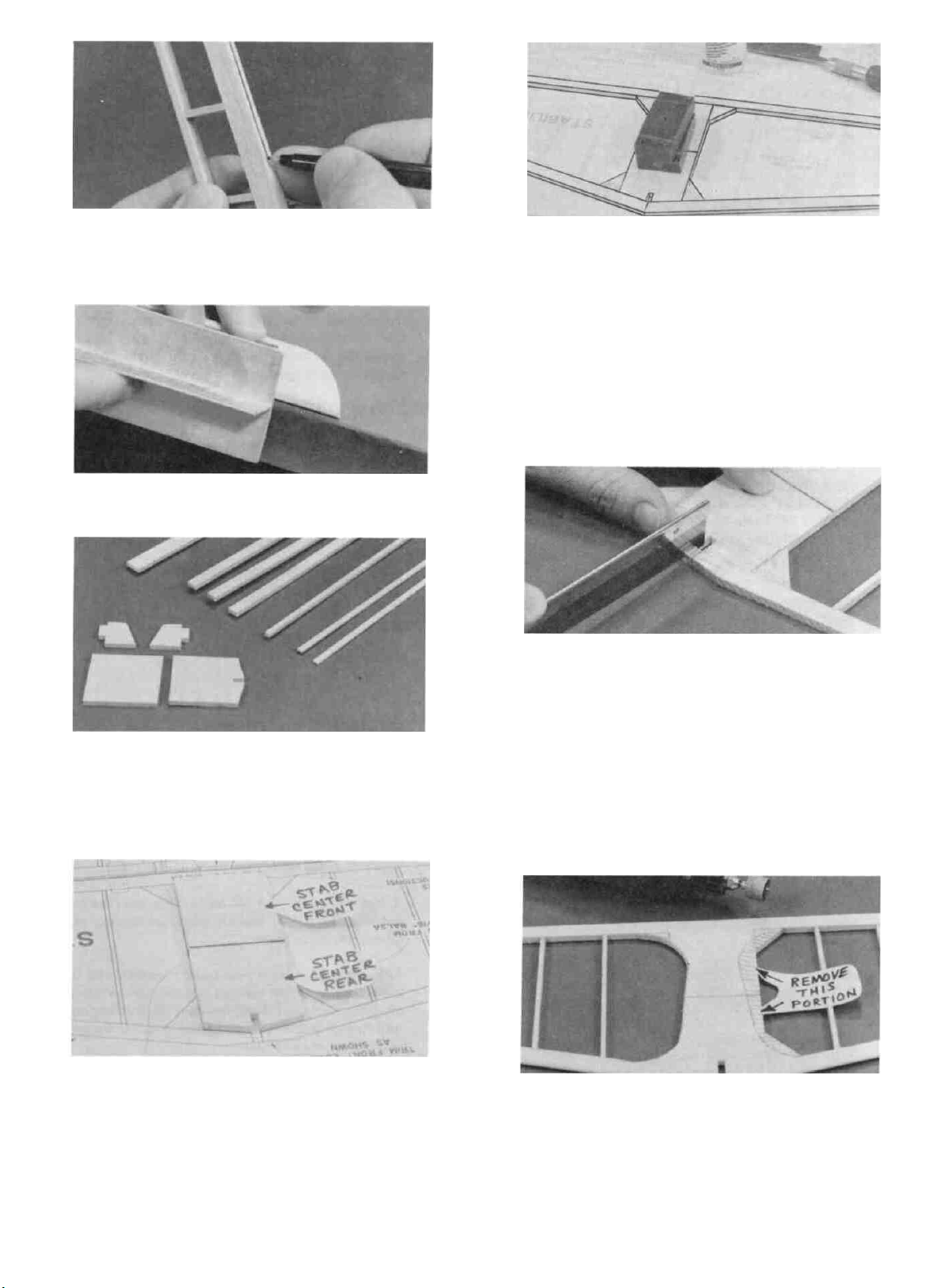

BUILD THE STABILIZER

D 3. From 3/16" x 3/8" balsa sticks, cut the outer

framework pieces and glue them together. Note:

The straightest 3/16" x 3/8" balsa stick should be

used for the trailing edge.

D 4. Cut the triangular corner braces from the 3/16"

x 5/8" x 7" balsa stick and glue them in place.

D 5. Cut the stabilizer ribs from the 3/32" x 3/16" balsa

sticks and glue them in place.

D 6. Cut out the fin notch in the leading edge, and trim

the front edge as shown on the plan.

D 1. Get the following items together: Die-cut 3/16"

balsa stab center front and stab center rear, 3/16"

x 3/8" x 24" balsa sticks, 3/32" x 3/16" x 24" balsa

sticks, and the 3/16" x 5/8" x 7" balsa stick. (Note:

The photo also shows the elevator parts).

2. Tape a piece of waxed paper over the separate

STABILIZER drawing on the plan, then lay the

die-cut 3/16" balsa stab center pieces on the plan

and pin in place. NOTE: These die-cut pieces may

have irregular edges, so you should sand the edges

with your T- bar first, until they fit the plan exactly.

Edge glue these stab center pieces together with thin

CA.

D 7. Sand both sides of the stabilizer smooth with your

T-bar, then sand the stabilizer leading edge and ends

to a rounded shape as shown in the typical cross-section.

NOTE: If the 3/16" balsa stab center pieces supplied in

your kit are soft balsa (easily dented with your fingernail),

do not perform the next step.

D 8. Now you may lighten the stabilizer by trimming

the stab center along the dashed line as shown on

the stabilizer drawing. Use your ruler to transfer

the trim lines from the plan to your stabilizer, then

use a Dremel Moto Tool sanding drum or a piece of

sandpaper wrapped around a dowel to sand away the

excess balsa.

14

Page 15

BUILD THE ELEVATORS

D 1. You'll need the following parts: Die-cut 3/16" balsa

elevator ends, 3/16" x 3/8" x 24" balsa stick, 3/16"

x 3/16" x 24" balsa stick, the remaining 3/32" x 3/16"

balsa stick, and the 3/32" wire elevator joiner.

ELEVATOR JOINER WIRE

D 7. Use a pin to start a pilot hole in the elevator

leading edge (on the centerline you previously

marked). The hole will be located in the middle of

the wire outline you drew in the above step. (See

photo).

D 2. Working on waxed paper over the plans, cut the

outer framework pieces and glue them together

and to the die- cut elevator ends.

D 3. Cut the elevator ribs from the 3/32" x 3/16" balsa

stick, and glue in place.

D 4. Sand both sides of the elevators smooth with your

T-bar, then sand the trailing edge and ends to a

rounded shape as shown in the typical cross-section.

D 5. Draw a centerline down the full length of the

elevator leading edge, then use your T-bar to sand

the leading edge to a "V-shape as shown on the

typical cross-section.

D 8. Drill a 7/64" diameter hole into the elevators at

the holes you started in the above step. (Drilling

slightly oversize will permit some adjustment when

joining the elevators).

D 9. Clean all oily residue from the wire elevator

joiner using a tissue dampened with alcohol or a

degreasing solvent. Then roughen the wire with

coarse sandpaper (so the glue will stick to the wire).

D 6. Position the elevators over the plans and lay the

3/32" wire elevator joiner on top of the elevators.

Then use a pen to mark the outline of the wire on

the elevators.

D 10. Use the threaded end of one of the 12" pushrod

wires to "file" a groove in the elevator leading edge.

Make the groove deep enough to fully accept the

joiner wire.

15

Page 16

D 11. Insert the joiner wire into both elevator halves,

then lay the assembly down on a piece of waxed

paper on a flat surface. Place a straightedge along

the leading edge of both elevators.

D 12. When you have the elevators lying flat on the

surface and both leading edges in a straight line,

apply thin CA glue where the joiner wire enters the

elevators and hold until the glue has set.

D 13. Inspect the assembly and apply thick CA to any

gaps around the joiner wire.

MAKE THE HINGES

D 1. You'll need the following: The remaining piece of

hinge strip material, a piece of 220 grit sandpaper,

a ruler, scissors and a 1/16" drill.

D 4. Drill four 1/16" holes in each of the hinge segments

as shown on the plan. Use a wood block as a back-

ing when drilling these holes. After drilling,

lightly sand the hinges again to remove any rough

edges caused by drilling.

D 5. Fold the hinge material back and forth a few

times to "condition" the hinges.

D 6. Cut the hinges apart with a scissors on the lines

you previously drew. Also snip off a small piece of

each corner.

D 2. Take the strip of hinge material and roughen both

sides with 220 grit sandpaper. This is best done with

a small piece of sandpaper held with your fingers,

rather than a sanding block. Do not sand the cen-

terline of the hinge material.

D 3. Using a ruler and a ball point pen, draw lines

dividing the hinge material into seven 3/8"-wide

segments.

HINGE

TEMPORARILY INSTALL HINGES (Do not glue the

hinges at this time).

D 1. You'll need the seven hinges you just made, plus

an Xacto knife with a No. 11 blade.

D 2. Draw an accurate centerline on the trailing edge

of the fin and stabilizer.

16

Page 17

D 3 Lay the fin and stabilizer on the plan and mark

the hinge locations on the trailing edges.

D 4 Now, while holding the elevators in place against

the stabilizer trailing edge, transfer the hinge locations over to the elevator leading edge Repeat this

process to mark the hinge locations on the rudder.

D 7 After you have cut about halfway into the wood,

you can push the blade all the way through, while

"wiggling" the knife handle back and forth Continue to pivot the knife while moving the blade to

both ends of the hinge location.

D 8 Trial fit the hinge into the slot If the hinge is

difficult to push in, re-insert the knife and move it

back and forth in the slot a few times to enlarge the

slot.

D 9 Repeat the above process to cut slots at all the

hinge locations in the fin, rudder, stabilizer and

elevators.

D 10 Assemble the rudder to the fin and the elevators

to the stabilizer (DO NOT GLUE), and check the

operation of the hinges

NOTE: The hinges supplied with this kit are thin enough

that they can be inserted into a slot made with an Xacto

knife Most other hinges require you to use a hinge slotting

tool The following steps describe how to easily cut the

hinge slots with an Xacto knife.

D 5. Begin by carefully cutting a very shallow slit in

the fin trailing edge at the hinge location This first

cut is to establish your cut in the right place, so

concentrate on staying on the centerline and don't

cut too deep!

D 6 Make three or four more cuts in the same line,

going slightly deeper each time As you make

these additional cuts, work on going straight into

the wood.

D 11 Cut off the portion of the bottom rudder hinge

that protrudes in front of the 3/16" x 3/8" fin trailing

edge Note: Be sure to use this hinge in the same

location later when making the final assembly

TEMPORARILY MOUNT CONTROL HORNS

D 1 You'll need Two nylon control horns, four 2-56

x 3/8" machine screws, a 3/32" drill and a small

screwdriver

2-56 SCREW

NYLON HORN AND NUT PLATE

17

Page 18

D 2 Use an Xacto knife to separate the nylon screw

backplates from the nylon horns.

D 7. Insert two 2-56 screws through the nylon horn

and through the holes you drilled Then screw them

into the nylon nutplate which originally came attached to the horn Tighten the screws until they

are snug, but do not crush the wood by over-

tightening.

D 8. Repeat the above process to install the nylon con-

trol horns on the elevator. NOTE: When marking

the locations for drilling, you must hold the

nylon horn on the BOTTOM of the elevator!

INSTALL SERVOS

D 3. Lay the rudder on the fuselage plan side view and

determine where the nylon control horn should be

located Holding one of the nylon horns in place on

the left side of the rudder, use a pencil to mark

through both holes in the horn

D 4. Remove the rudder from the fin, and remove the

hinges.

D

5.

Start

pilot

holes with a pin

then drill the holes with a 3/32" drill

D 6. Harden the balsa in the control horn area by

putting a drop of thin CA into each hole After the

glue has set, re-drill the holes and sand the surface

smooth.

at

the

marked

locations,

NOTE The following instructions and photos describe how

to install Futaba S-48 servos in your PT-Electnc If your

radio equipment is different from that shown in the photos,

you may have to use a slightly different method to mount

your servos properly Be sure to read the instruction

manual for your radio before beginning this section.

If you have difficulty with the radio installation, ask an

experienced model builder for assistance

Special Note: Most radio systems sold today have "servo

reversing switches" on the transmitter, which enable the

modeler to install the servos without first checking to

determine which direction the servos rotate After the installation has been completed, the modeler merely flips

the switches on the transmitter to make the servos rotate

in the desired direction Many of the older systems, however, do not have servo reversing instead they include

one or two "reverse" or "left-handed" servos which rotate

in a direction opposite that of the other servos When installing the servos of a system that does not have servo reversing, you must plan ahead to use the "reverse" servos

where they are needed.

D 1 Prepare the servos by installing the four rubber

grommets into each servo, then inserting the brass

eyelets up into the grommets.

D 2 Place the servos into the die-cut 1/8" plywood

servo tray provided, and position them so they are

not touching the sides of the openings Note: If you

have only two servos, they will be used for elevator

and rudder control only (no servo-activated on-off

switching)

18

Page 19

D 3. Holding the servos in place, use a pencil to mark

down through the brass eyelets onto the plywood.

Remove the servos and drill 1/16" holes at each of

the marks.

D 4. Study the plan to determine where the servo tray

goes. Glue the servo tray to the fuse sides and to

F-3 with thin CA. Then apply thick CA on top and

bottom of the tray to lock it in place.

D 2. Note that we have punched the locations of the

four screw holes in F-1B Drill 1/8" holes at these

four locations. Be sure to use a wood backing

when drilling to prevent damaging the part you are

drilling.

D 3. Mount F-1B onto the front of the motor with the

two M3 x 6 metric screws.

D 5. Now install the servos into the tray using the

screws provided with your radio.

INSTALL THE MOTOR AND SWITCH HARNESS

D 1. You'll need the following: Electric motor and

switch harness, die- cut 1/16" ply F-1B, two M3 x

6 (metric) screws, and two #4 x 1/2" screws.

M3x6

SCREW

#4x1/2"

SCREW

D 4. Drill two 5/64" holes in F- 1A at the punched

locations. (These are pilot holes for the #4 x 1/2"

mounting screws).

D 5. Insert all the switch harness components through

the large hole in F-l, then slide the motor into place.

Secure F-1B to F-1A with the two #4 x 1/2" screws.

19

Page 20

D 6. Remove the nut and the washers from the toggle

switch. Insert the threaded barrel of the toggle

switch through the 1/4" hole in the fuse side, then

secure it with a nut on the outside.

D NOTE: The toggle switch in the photo is shown

incorrectly. It should be rotated 180 degrees, as

it is shown on the plan, to operate correctly.

Correct operation of the toggle switch means

that pushing the switch forward is "on", and

pushing the switch backward is "off.

INSTALL ON-OFF SWITCH PUSHROD

(Not required for 2-channel operation)

NOTE: If you wish to fly the PT- Electric with a 2channel radio (rudder and elevator control only), just

wrap masking tape around the micro switch to hold

it in the "closed" position, and proceed to the next

section.

D 3. Insert the plastic outer pushrod sleeve through

the hole you previously drilled in F-2 and glue it

securely to F-2 with thin CA, followed by thick CA.

The tube should protrude only about 1/4" in front of

F-2.

D 4. Grasp the 1" threaded rod in the middle with a

pliers, and screw the nylon clevis onto one end and

the plastic pushrod onto the other end.

D 1. You'll need the following parts: 4-1/4" long plastic

outer pushrod sleeve, 6-3/8" long inner plastic

pushrod, 2-56 threaded rod 1" long, and a nylon

clevis.

NYLON CLEVIS

2-56 x I" THREADED ROD

D 2. Roughen the outside surface of the plastic pushrod

sleeve with 100 grit sandpaper (so the glue will stick

better).

D 5. Insert the plastic inner pushrod into the outer

sleeve and attach the nylon clevis to the servo arm.

(You may have to drill the servo arm with a 5/64"

drill bit to fit the clevis pin).

D 6. Temporarily hook up your radio system. (Be sure

to read the radio instruction manual regarding

proper hookup and battery charging procedures).

D 7. Study the fuse plan side view and note the position

of the micro switch. Now hold the micro switch

against the fuse side in this approximate position.

Operate the throttle servo and observe how the push

rod contacts the micro switch. Move the micro

switch around until the pushrod "clicks" the micro

switch only when the throttle stick is pushed almost

fully forward.

20

Page 21

D 8 When you have determined the correct position

for the micro switch, draw a line around the switch

on the fuselage side for reference.

D 9 Holding the micro switch in place, push a pin

through both holes in the micro switch and out

through the fuselage sides

D 10 Now drill two 3/32" holes through the fuselage

side at the pin holes Then mount the micro switch

with the two 2-56 x 5/8" screws and nuts

MOUNT THE RECEIVER SWITCH

D 1 Remove the face plate from your receiver switch

and hold it against the outside of the fuselage as

shown in the photo Make sure the switch will be

located above the battery box, and clear of the

on-off switch pushrod!

D 2 Mark the locations of the screw holes and the

rectangular switch hole, using the faceplate as a

guide

NOTE: Before proceeding, read " Peak Battery

Charging " in the appendix at the back of this book.

NOTE: Remove the propeller from the motor before

testing your electrical system in the next step!

D 11 When you have the motor and switch harness

installed, you may check its operation by hooking

up the motor battery* and activating the toggle

switch The motor should begin running when the

transmitter throttle stick is pushed forward to full

throttle, and stop when the stick is pulled back With

the toggle switch in the "off position, you should

not be able to turn the motor on with the throttle

stick In order for this safety feature to be effec-

tive, you should always keep the toggle switch

in the "off position until just before you are

ready to fly.

D 3. Drill 3/32" holes for the switch mounting screws.

D 4 Use an Xacto knife to cut out the rectangular

switch hole

D 5. Mount the switch to the fuse side and check the

operation (Pushing the switch toward the front

of the airplane is "on"),

CUT PUSHROD EXIT SLOTS

D 1 Study the plan and note the location of the elevator

and rudder pushrod exit slots(they are in the same

location on both sides of the fuselage) Using a ruler,

transfer the locations of these slots from the plan to

the fuselage, marking the front and rear of each slot.

*NOTE The motor battery must have a Kyosho-type connector to mate properly with the Thrustmaster switch harness If your battery connector is not compatible, you'll

have to change connectors

D 2 Drill 1/8" holes in the 3/32" balsa fillers at the

front and rear of the pushrod exit locations

21

Page 22

D 3. Use an Xacto knife to cut out the slots, between

the holes.

D 4. Sand the fuse sides smooth in the area of the push-

rod exit slots.

MOUNT THE STABILIZER

D 1. Sand the stab saddle area of the fuselage with

your T-bar to remove any excess glue.

D 2. Accurately measure and mark the exact center

of the top of former F-3 as a reference mark. Stick

a pin in at this point.

D 4. Line up the 3/16" notch in the front of the

stabilizer with the 3/16" notch in the stab saddle.

Tack glue the front of the stabilizer to F-6 with only

one drop of thin CA.

D 5. Measure from your reference mark in the center

of F-3 to both rear corners of the stab, and adjust

the position of the stab until the measurements are

equal. Holding the stab in this position, apply thin

CA to the stab/fuse joint at the rear of the stab. Also

add more CA at the back of F-6 to lock the stab in

place.

D 3. While holding the stab firmly in place onto the

saddle, measure down to the flat work surface from

both ends of the stab. If one side is higher than the

other, sand the high side of the stab saddle with your

T-bar sander and 100 grit sandpaper (Sand only a

little at a time!). Replace the stab in the saddle and

re-check the measurements. Continue this process

until the stab is level within 1/16".

D 6. Now turn the fuse upside down, and apply thin

CA glue all along the stab/fuse joints.

D 7. Temporarily attach the elevator to the stab with

the hinges.

TRIAL FIT THE FIN AND RUDDER

(Do not glue!!)

D 1. Temporarily attach the rudder to the fin with the

hinges (do not glue).

22

Page 23

D 2. Set the fin in place on the stab to check the fit

and alignment. If the fin TE does not match the fuse

tail post, you may sand a little off the lower front

corner of the fin LE to permit the fin to slide forward

until it contacts the tail post. Also, with the fin resting down on the stab, the bottom of the fin and rudder

must not protrude below the bottom of the fuse. If

they do, sand them off.

IMPORTANT NOTE: Improper fin alignment is one of

the most common causes of poor flying airplanes. The fin

absolutely must line up with the centerline of the

airplane! Therefore, use care in the following steps to

mount the fin properly.

MAKE THE PUSHRODS

D 1. You'll need the two 1/4" x 1/4" x 12-1/2" balsa

sticks, two 12" steel rods threaded on one end, two

nylon clevises and some strong thread (not included).

NYLON CLEVIS

STEEL PUSHROD WIRE

D 2. Clean the oily residue off the pushrod wires using

a tissue dampened with alcohol or degreaser.

D 3. Remember the mark you made in the center of

F-3? Now measure 3/32" left and right of that mark

and make two more reference marks. Now lay a

straightedge along the left side of the fin, with one

end of the straightedge on the left mark on F-3. Ad-

just the position of the fin until it matches the

straightedge.

D 4. Holding the fin in this position, draw lines on the

stab center on both sides of the fin for future reference. Double check this by laying the straightedge

along the right side of the fin and holding it on the

right mark on F- 3.

D 3. Draw a line 1-inch long on each end of both 1/4"

x 1/4" sticks as shown in the photo.

D 4. Use the threaded end of one of the wire pushrods

to "file" grooves in the balsa sticks where you drew

the lines. The depth of the grooves should be about

1/2 the thickness of the wire.

DO NOT glue the fin to the stab at this time!

D 5. Drill 5/64" holes through the sticks at the end of

the grooves you made in the above step.

23

Page 24

D 6. Screw a nylon clevis on the threaded end of both

steel pushrod wires. Screw it all the way on, until

the wire is visible inside the clevis (about 17 full

turns). Note: The wire will be easier to hold if you

grasp it with a pliers.

D 7. Lay the wires on the fuse plan (top view), and use

a pliers to bend the wires to match the drawings of

the elevator and rudder pushrods. Notice where the

wire makes a 90-degree bend and goes into the stick

and mark that location on the wire. Make this bend

now and cut off the excess wire.

D 10. Insert the wires into the holes and slots in the

1/4" x 1/4" balsa sticks, and glue in place with thin

CA.

D 8. Take the straight wires that you cut off, and make

a short 90-degree bend in one end of each of them.

D 9. Use sandpaper to roughen the four ends of the

wires that will be glued into the balsa sticks.

D 11. Use your T-bar to sand the ends of the balsa

pushrods to a rounded and somewhat pointed shape,

as shown on the plans and in the photos. This will

reduce the chance of the pushrod binding against

something inside the fuselage.

D 12. Wrap the ends of the pushrods with strong

thread, as shown on the plan, apply thick CA to the

threads and smooth it out with a piece of waxed

paper. Allow to harden.

24

Page 25

INSTALL PUSHRODS

D 1. Remove the nylon clevises from the pushrods.

D 2. Insert the pushrods, threaded end first, through

the openings in F-3, F-4, F-5 and F-6, then out

through the pushrod exit slots you previously cut.

Note: You may have to bend the wire slightly to

allow it to pass out through the exit slots. If so,

straighten the wire after it is out.

D 3. Screw the nylon clevises back onto the threaded

rods, then snap the clevises onto the nylon horns on

the rudder and elevator.

D 4. With the elevator, rudder and servos in the neutral

position, mark the front of the pushrod wires where

they cross the hole in the servo output wheels or

arms.

COMPLETING THE FUSELAGE

D 1. Remove the following items from the fuselage:

F-1B, Motor, Switch harness, receiver, radio switch,

radio battery, servos, pushrods, horns and hinges.

Note: If it seems strange to you to now remove these

items, please be assured that this will make it much

easier to perform the next steps, and it will be very

easy and fast to re-install these items later.

D 2. Carefully sand the top edges of F-3, F-4, F-5 and

F-6 until they are even with the top longerons, being

careful not to gouge into the upper longerons.

D 5. Remove the clevises and remove the pushrods from

the fuselage and make "Z"-bends* in the wires at

the marks you just made.

*NOTE: You can make a "Z"-Bend with a regular pliers

(practice on a scrap first), or you may use a special "Z"-bend

pliers (available through your hobby shop). There are a

couple of alternatives to making Z-bends which you may

want to consider: 1. Use a solder-on clevis on the servo

end of the pushrod or 2. Use a Dubro No. 121 E-Z Connec-

tor to attach the pushrod to the servo arm.

D 6. Cut off the excess wire.

D 3. Trial fit the die-cut 3 32" balsa fuse top. It fits

against the front of the stab, and extends forward to

the front edge of F-3. Glue the fuse top in place.

D 4. Find the 3 32" x 2-1/4" x 2-3'4" balsa windshield

and glue it to the fuse sides at the bottom front corners, using thin CA. Allow to harden.

25

Page 26

D 5. Bend the windshield around the curve of the fuse

sides and over the top of F-2. Glue the windshield

in place. Trim the windshield even with the rear

edge of F-2. NOTE: If the windshield is hard balsa,

it will bend easier if you first wet the top surface

with water or alcohol.

D 6. Sand the top of F-l to match the top edge of the

fuse sides.

D 7. From the 1/16" x 3" x 6" balsa sheet, cut two pieces

of cross-grain sheeting and glue them to the top

of the fuse in front of the windshield (this is called

the "hood top").

D 10. SAND, SAND, SAND! Using your T-bar sander

with 100 grit sandpaper, sand the top and bottom

corners of the fuselage to a rounded shape as shown

in the former detail drawings on the plan (do not

round the fuselage corners in the wing saddle area).

Sand the fuselage sides, top, and bottom until they

are very smooth.

D 8. Carve a rounded area in the front of the sheeting

to provide clearance for the motor.

D 9. Apply lightweight filler compound to all gaps,

gouges and rough areas of the fuselage, and allow

to

dry.

D 11. DO NOT OMIT THIS STEP! Accurately weigh

the following items on a postage scale: Fuselage,

hatch, fin, rudder, stab, elevator and pushrods. These

items should have a total weight of no more than 7

ounces. If they are heavier than 7 ounces, that

means the balsa in your kit is slightly harder and

heavier than normal, you have used too much glue,

or you have not done enough sanding. If so, you

should make every effort to lighten the structure by

doing more sanding and by enlarging the lightening

holes in the 1/8" balsa fuse sides.

26

Page 27

WING

NOTE The PT-Electnc wing is made to fit together without glue, so you can assemble all of the major parts and

check to make sure they are all lined up before applying

thin CA to the joints

D 1. Turn the plan over to side 2, which shows the

wing Tape the plan to your flat work surface so the

"Right Wing Panel" is facing you Cover the right

wing panel drawing with waxed paper (so you won't

glue the wing to the plan!).

D D 4 Pin one of the 3/16" x 3/16" x 28" hardwood spars

to the plan, with the right end of the spar lined up

with the tip (The excess spar length extends past

the wing centerline)

D 2 The shaped and notched wing leading edges

(LE) and trailing edges (TE) are fastened together by thin layers of balsa Separate them by

folding until the balsa breaks Sand away the excess

balsa that remains along the edges after breaking

them apart, using a T-bar with 100-gnt sandpaper.

NOTE: Save several of the thin little balsa scraps

which will be used in step 8.

D 3 Before using the L E and T E pieces, you must

determine which pieces are to be used for the right

wing panel Here's how

A- We have drawn red lines on the top of each piece

D D 5 Accurately position the three die-cut 1/16" balsa

center section sheets on the plan and pin them in

place Notice the pre-cut openings for the dihedral

braces Edge glue the two rear sheets together with

thin CA, and glue them to the spar.

D D 6. Put the two W-2 ribs and the eight W-3 ribs in

place on the spars (do not glue).

D D 7. Lay the trailing edge in place with the end lined

up with the outside edge of the tip rib on the drawing

(the excess length extends beyond the wing centerline), and work the ribs into the notches (do not

glue).

D D 8 Lay down some of the 1/32" balsa scraps from step

2 between the ribs at the L E (these will raise the

L.E. 1/32" off the table).

B- Notice that the pieces are notched on one end, but

not on the other The notched end goes toward the

wing tip, and the end without a notch goes toward the

center of the wing.

C- Take one of the L E pieces and lay it on the right

wing panel plan with the red line up If the notched end

is on the right side (at the tip) you have the correct L.E.

D- Do the same thing to determine which T E piece

to use.

D D 9 Lay the leading edge in place and line up the end

with the outside edge of the tip rib on the drawing

(the excess length extends beyond the wing centerline) Work the ribs into the notches REMEMBER:

The L E is 1/32" above the table, supported by the

balsa scraps.

27

Page 28

D D 10. Set the W-l rib in place (do not glue), then lay

the top spar in place.

D D 11. Set W-l at the proper angle, using the die-cut

1/8" ply dihedral gauge. NOTE: The edge of W-l

must line up with the wing centerline(which

should also be the edge of the 1/16" balsa bottom

sheeting).

D D 12. Make sure that the ribs are all down onto the

plan and fully inserted into the notches in the L.E.

and T.E. Also make sure that the spars are seated

snugly down into the notches in the ribs. Check all

parts for correct alignment (especially rib W-l),

then apply thin CA glue to all joints.

D D 15. Find the stack of 1/16" balsa shear webs. Cut

one of the webs to fit between the two W-2 ribs and

glue it to the back of the spars. Also glue webs to

the spars in the next three rib bays. (See the detail

drawing showing the webs and braces on the wing

plan).

D D 13. From the 5-1/2" length of 1/4" balsa triangle,

cut pieces to fit between the ribs in the first two rib

bays. Glue these pieces to the bottom sheeting and

the L.E. as shown on the plan and in the photo.

D D 14. Lay two of the 1/8" x 1/8" x 28" balsa sticks in

the front spar notches, with the ends of the sticks

flush with the outside edge of the tip rib. Make sure

the spars are fully down into the notches, then apply

thin CA to all joints.

D D 16. From one of the 1/16" x 1/4" x 18" balsa sticks,

cut diagonal braces and glue these braces to the

spars as shown on the detail drawing.

D D 17. Sand the leading edge, spars and trailing edge

even with the tip rib, using your T-bar sander.

28

Page 29

D D 18. Find the two tapered balsa pieces that are 9-1/8"

long. These are the wing tips. Glue one of these

tapered balsa wing tips to the tip rib (the narrow

edge of the tapered wing tip goes down).

D D 19. Carve and sand the wing tip to blend with the

tip rib. Sand the front and rear corners to a rounded

shape as shown on the plan. Also sand the top and

bottom edges to a slightly rounded shape.

D 22. On rib W-l, draw lines 1/8" in front and back of

the spars.

D 23. Working very carefully and slowly with a razor

saw, cut out 1/8" strips in W-l in front and back of

the spars. Do this in both wing panels to provide

openings for the dihedral braces. Note: It is OK if

the part of W-l between the spars is broken out.

D D 20. Using a razor saw, carefully cut off the leading

edge, spars and trailing edge flush with rib W-l.

Then sand smooth and flat using a T-bar.

D 21. Turn the plan around so the Left Wing Panel

drawing is facing you, and repeat steps 4 through

20 to build the left wing panel in the same manner.

D 24. Check the spars in the area you just cut out. If

any wood or glue remains attached to the spars, sand

it off with your T- bar.

Page 30

D 25 Working on a flat table, place the two wing panels

together at the center Block up both wing tips 3-1/2"

with stacks of books, then trial fit the die-cut 1/8"

ply dihedral braces at the center Enlarge the open-

ing in W-l and the bottom sheeting if necessary to

allow the dihedral braces to fit without forcing them

in.

PRACTICE THE NEXT STEP "DRY" BEFORE

ACTUALLY DOING IT!

D 26 Place waxed paper under the wing center joint,

then mix up a batch of epoxy (30-minute epoxy is

preferred here to give you more time), and apply it

to the dihedral braces and spars Slide the wing

panels together, clamp the dihedral braces to the

spars with clothespins, and wipe up the excess glue

with a tissue While you are waiting for the epoxy

to harden, apply thin CA along the joint where the

two W-l ribs come together Make sure the wing

panels remain undisturbed until the epoxy has

fully hardened.

D 27. After the epoxy has hardened, examine the center

joint and fill any gaps with balsa dust and CA glue.

D 28. Sand the center section and the entire wing

smooth with your T- bar sander NOTE: When sand-

ing the wing, you must be very careful not to change

the shape of the wing by accidentally sanding into

the wing ribs.

D 29 Find the two 1/32" x 1-1/4" x 1/2" plywood pieces

These are the wing plates which protect the trailing

edge from damage by the wing hold-down rubber

bands.

D 30 Working on the table edge, use a sanding block

to "feather" (taper) the edges of the wing plates

Feather three edges of each plate, leaving one long

edge square.

D 31 Make marks on the T E 1-inch each way from

the wing centerline

D 32 Put the wing plates in position on the T E The

edge of the plate that is not feathered goes to the

rear along the T E The 1-inch marks you made in

step 31 are where the plates begin

D 33 Apply thin CA glue around the edges, holding

the plates firmly in place until the glue sets.

D 34. DO NOT OMIT THIS STEP! Accurately weigh

the wing on a postage scale It should have a total

weight of no more than 5 ounces. If it is heavier

than 5 ounces, there is not much you can do other

than some light sanding of the leading and trailing

edges and the wing tips Do not sand the hardwood

spars, as this could weaken the wing Proceed to the

next section.

PREDICTING THE FINISHED FLYING WEIGHT

At this time you should try to accurately predict

what the final weight of your PT-Electnc will be Remember that you are shooting for a target weight of 48

ounces or less with a 6-cell 1200 mAh motor battery, and

50 ounces or less with a 7- cell 1200 mAh motor battery

If it looks like your airplane will be only 1 ounce overweight, don't worry about it, as you will probably be satisfied with the flight performance If, however, you predict

a final weight that will be 3 ounces or more overweight,

you should take another look at the components you will

be installing in your airplane (servos, battery, wheels), to

see where you can reduce weight. I'll talk more about this

later

Here is a sample weight computation:

Fuselage, etc (see p 26 step 11) 7.0 oz.

Wing 5.0

Wire landing gear and all hardware 2 0

6 #63 rubber bands 0.25

Wheels (lightweight) 1.5

Thrustmaster motor, harness, prop

and spinner 9.5

Receiver, switch, 3 standard servos, 225 mAh

receivel bdtteiy 8.75

6-cell 1200 mAh motor battery 11.5

Covering material 3 0

TOTAL 48.5 oz.

30

Page 31

COMPLETE THE STRUCTURE

TRIAL FIT THE WING IN THE SADDLE

D 1. Using your T-bar sander, sand the wing saddle

area to approximately the same angle as the wing.

MOUNT THE ELEVATOR

NOTE: This section requires that you begin covering

your airplane. Before doing so, please study the instructions that are provided with the covering material.

D 2. Use a sanding block to lightly sand the ends of

the 1/4" hardwood wing hold-down dowels to re-

move the sharp cut edges.

D 3. Insert these dowels into the holes in the fuselage

(do not glue). NOTE: If the dowels fit too tightly,

enlarge the holes with a 1/4" or 17/64" drill bit.

D 4. Lay the wing in the saddle and hold it down with

two #63 rubber bands* (provided). Check the fit

of the wing in the saddle. It should rest snugly and

evenly onto the saddle. If not, sand the saddle slightly

for a good fit. *NOTE: When actually flying your

PT-Electric, you must use SIX #63 rubber bands

for wing hold-down.

D 1. Cut a 3/4" x 18" strip of covering material (Top

Flite "Super Monokote" or similar). Iron this strip

to the stabilizer trailing edge, overlapping equally

onto the top and bottom of the stab.

D 2. Using an Xacto knife, slit the covering in the areas

of the hinge slots. NOTE: You can find the hinge

slots by holding the elevator against the stab T.E.

D 3. Now cover the entire elevator by covering the

bottom first, then the top.

D 5. Measure down from both wing tips to your flat

building surface. If the measurements differ by more

than 1/8", you must sand the wing saddle slightly

until the measurements are the same.

D 4. Insert the hinges into the slits in the stabilizer

trailing edge, and glue these hinges to the stab by

applying thin CA glue around the hinges. Wait a

few minutes, then grasp each hinge and pull to make

sure the glue has penetrated and bonded the hinge

to the wood.

31

Page 32

D 5 Slit the covering on the elevator in the areas of

the hinge slots NOTE: You can find the hinge slots

by holding the elevator against the stab T E and

marking the location of the hinges NOTE: For the

next step you'll need the following 30-mmute epoxy,

a plastic soda straw, rubbing alcohol and some tissues

D 6 Mix up a batch of 30-mmute epoxy Force some

epoxy up into a soda straw by pushing the straw into

the puddle of epoxy several times Pinch the end of

the soda straw and insert it approximately 1/16' into

one of the elevator hinge slots Squeeze the straw

to force epoxy into the hinge slot Repeat this process

to get epoxy into all of the elevator hinge slots, then

push the elevator onto the hinges Carefully wipe

away all excess epoxy with a tissue dampened with

alcohol Do not disturb the elevator until the epoxy

has

fully

hardened__

MOUNT THE FIN

D 1 Hold the fin in place on the stabilizer and line it

up with the marks you previously made Check to

make sure the fin is perpendicular to the stab, using

a draftsman's triangle or a carpenter's square Apply

a couple drops of thin CA to tack glue the fin in

place

D 2 Double check the fin alignment (it must line up

with the fuselage centerline), then apply thin CA

all along the fin/stab joint Also glue the bottom of

the fin TE to the fuselage tail post, and glue the

front of the fin L E to F-6

TRIAL FIT THE MOTOR BATTERY

D 1 Cut several pieces of 1/4" foam rubber and glue

them to the inside of the battery compartment in the

locations shown on the plan Don't forget the piece

of foam that goes on the hatch, as this is the piece

that holds the battery up in the compartment

D 2 Insert your 6 or 7 cell 1200 mAh motor battery

through the hatch opening and into the battery compartment to check the fit Add or remove foam rubber

as necessary for a good snug fit

COVERING

D 1 Preparation: Before covering, make a final

thorough check to make sure the entire model has

been sanded smooth The covering material probably

will not hide imperfections in your structure, so now

is the time to fix them Then vacuum the model dust

free, using a soft brush attachment on your vacuum

cleaner Finally vacuum your entire work area until

it is dust-free Remove the hatch, rudder, elevator,

hinges, radio, batteries, servos, pushrods, motor,

switch harness and landing gear from your model

D 2 Using Top Flite "Super Monokote" (we used

white and metallic blue on our prototypes) or any

other good quality covering film and following the

manufacturer's instructions, cover your model in the

following sequence

COVER THE FUSELAGE

D 1 Stab TE (previously done)

D 2 Elevator bottom (previously done)

D 3 Elevator top (previously done)

32

Page 33

D 4. 1/2" strips of covering at joint between bottom of

stab and fuse.

D 5. 1/2" strips at joint between stab and fin.

D 7. Use a pin to poke "vent holes" in the bottom rear

corners of the stab to allow air to escape when cover-

ing the top. (Also do this before shrinking the fin,

rudder and wing covering).

D 8. Stab top

D 9. Shrink the stab covering, top and bottom

D 10. Fin left side and T.E.

D 11. Fin right side (overlap around T.E.)

D 12. Shrink fin covering, both sides

D 6. Stab bottom

D 13. Hold rudder against fin and mark hinge locations

on fin. Slit covering at slots.

D 14. Rudder left side and L.E.

D 15. Rudder right side (overlap around L.E.)

D 16. Shrink rudder covering, both sides

D 17. Slit covering at rudder hinge locations

D 18. Hatch bottom

D 19. Fuse bottom

33

Page 34

D 20. Fuse sides

D 21. Fuse top behind wing

COVER THE WING

D 26. Wing tips

D 22. 1/2" strip at base of windshield

D 23. Windshield

D 24. Fuse top in front of windshield

D 27. Wing bottom left (overlap centerline 1/4")

D 28. Wing bottom right (overlap covering 1/2")

D 29. Wing top left (overlap centerline 1/2" and iron

covering to the side of rib W-l

D 30. Shrink covering on left wing panel, top and bot-

tom

25. Iron the covering down around all openings that

D

are to be cut out, then use a sharp Xacto knife to

carefully cut the covering from the following openings: Pushrod exit slots, Wing hold-down dowel holes,

Toggle switch hole. Landing gear plate air exit holes,

Landing gear mounting screw holes, Micro switch

mounting screw holes, Elevator and rudder control

horn mounting screw holes, and the Radio switch

and switch mounting screw holes.

D 31. Wing top right (overlap covering 1/4")

34

Page 35

D 32. Shrink covering on right wing panel, top and

bottom

ADD WASHOUT AT THE WING TIPS

SPECIAL NOTE: One important flying charac-

teristic of the PT-Electnc is its ability to recover "handsoff* from a steeply banked turn This is made possible by

building the wing with DIHEDRAL and WASHOUT

Washout is intentional and measured wing twist You will

add washout to each wingtip by twisting the wing panels

so the trailing edge will be higher than the leading

edge at both wing tips. Here's how to do it...

D 1 Place the wing on your workbench with half of

the wing extending off the edge Lay some magazines

(or a "shot bag" as shown in the photo) on the wing

near the center, to hold it down.

D 5 Depending on what type of covering you have used,

you may find that, in time, some of the washout may

disappear Check it after an hour and repeat the

above process if necessary Also, re-check it periodically before you go Hying, because THIS IS A VERY

IMPORTANT REASON FOR THE STABILITY

OF YOUR PT-ELECTRIC.

ADD TRIM

D 2 Now grasp the wing tip and twist it so the trailing

edge goes up and the leading edge goes down As you

twist you will notice ripples forming in the covering

While holding this twist, use a heat gun to "reshrink" the covering Heat both the top and bottom

When you let go of the tip, you will see that the wing

will retain some of the twist.

D 3 Place the twisted wing panel back on your flat

work surface While holding the center of the wing

down on the surface, measure how far the trailing

edge is raised at the tip.

D 4 You must continue twisting and re- shrinking

until the trailing edge is 1/2-inch off the surface at

both tips. As an aid in getting this height correct,

you may make a small wood block 1/2" high by gluing

together pieces of scrap wood Keep this block handy

while twisting and heating, to check your progress

D 1 Add trim using covering film or self-adhesive trim

material or decals NOTE: We recommend that you

keep your trim scheme as simple as possible for ease

of application and to avoid weight build-up.

D 2 You may paint F-l, F-1A, F-1B and the motor

compartment area with any kind of hobby enamel.

(On our prototype we used Testers flat blue enamel)

35

Page 36

FINAL ASSEMBLY

D 1 In the same manner as the elevator, install the

rudder hinges by first inserting them into the fin

trailing edge and applying thin CA glue NOTE:

Remember that you previously cut off part of the

bottom rudder hinge, so you must find that hinge

and use it in the right place

D 2 Force 30-minute epoxy into the rudder hinge slots

with a plastic soda straw, and push the rudder onto

the hinges Wipe away all excess epoxy with a tissue

dampened with alcohol

D 10 Route the receiver antenna along the right side

of the fuselage and out through a small hole drilled

through the fuselage top rear and through F-3

NOTE: The antenna hole must enter the radio compartment approximately 5/16" below the top of F-3

so the antenna will not be pinched by the wing T E.

(See the antenna drawing on the fuselage plan).

D 11 If your lightweight wheels are the foam type with

square edges, you may sand them to a rounded (more

streamlined) shape using a sanding block

D 12 Install the main wheels and nose wheel using

1/8" wheel collars (not supplied) on both sides of

each wheel A small drop of oil on each axle will help

the wheels turn freely

BALANCE YOUR MODEL

NOTE: This section if very important and must not

be omitted!

D 1 With the wing attached to the fuselage, all parts

of the model installed, including the 6 or 7-cell

motor battery, gently turn the model upside down

D 3 Re-install the servos and the radio switch

D 4 Wrap the 225 mAh receiver battery in foam rubber

and insert it into the area between the battery box

rear and the servos

D 5 Mount the receiver to the top of the battery box

in the location shown on the plan using the square

of double-sided foam tape (provided) Plug the

servo wires into the receiver (The rudder servo

must be plugged into the aileron channel for 2

or 3-channel operation).

D 6 Re-install the control horns, pushrods, main land-

ing gear and nose gear NOTE: To attach the elevator

and rudder pushrods to the servo wheel, remove the

servo wheel from the servo, drill a 5/64" hole in the

servo wheel if necessary, woik the Z-bend into the

hole in the servo wheel, then replace the servo wheel

onto the servo

D 7 Re-install the motor, switch harness and

aluminum prop hub (secure the hub by tightening