Page 1

WARRANTY

Great Planes Model Manufacturing Co.guarantees this kit to be free from defects in both material and workmanship

at the date of purchase.This warranty does not cover any component parts damaged by use or modification. In no case

shall Great Planes’ liability exceed the original cost of the purchased kit. Fur ther, Great Planes reserves the right

to change or modify this warranty without notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no liability shall be

assumed nor accepted for any damage resulting from the use by the user of the final user-assembled product.By the act

of using the user-assembled product, the user accepts all resulting liability.

If the buyers are not prepared to accept the liability associated with the use of this product,they are advised

to return this kit immediately in new and unused condition to the place of purchase.

READ THROUGH THIS INSTRUCTION MANUAL

FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS

AND WARNINGS CONCERNING THE ASSEMBLY

AND USE OF THIS MODEL.

FUNDP03 for GPMA0050 V1.1 Entire Contents © Copyright 2001

P.O.Box 788 Urbana, IL 61801 (217) 398-8970

productsupport@greatplanes.com

INSTRUCTION MANUAL

Printed In USA

Wingspan: 35 in

Wing Area: 350 sq in

Weight (Ready to Fly): 13-16 oz

Wing Loading: 5.3-6.6 oz/sq ft

Fuselage Length: 30 in

TM

MADE IN

USA

Page 2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . 2

DECISIONS YOU MUST MAKE . . . . . . . . . . . . . . . . . . . 3

Radio Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Motor System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Battery Recommendation . . . . . . . . . . . . . . . . . . . . . 4

Battery Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chargers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Covering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . . . . . . 4

Building Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Optional Supplies and Tools. . . . . . . . . . . . . . . . . . . 4

IMPORTANT BUILDING NOTES . . . . . . . . . . . . . . . . . . 5

Common Abbreviations . . . . . . . . . . . . . . . . . . . . . . 5

Types of Wood. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

DIE-CUT PATTERNS . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

GET READY TO BUILD . . . . . . . . . . . . . . . . . . . . . . . . . 7

BUILD THE WING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

BUILD THE AILERONS . . . . . . . . . . . . . . . . . . . . . . . . 10

BUILD THE TAIL SURFACES. . . . . . . . . . . . . . . . . . . . 10

Build the Fin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Build the Stab and Elevator . . . . . . . . . . . . . . . . . . 12

BUILD THE FUSELAGE. . . . . . . . . . . . . . . . . . . . . . . . 13

Prepare the Fuselage Tube . . . . . . . . . . . . . . . . . . 13

Build the Landing Gear (optional). . . . . . . . . . . . . . 14

Mount the Landing Gear . . . . . . . . . . . . . . . . . . . . 15

COVER THE MODEL . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Prepare the Model for Covering . . . . . . . . . . . . . . . 16

Cover the Wing and Ailerons . . . . . . . . . . . . . . . . . 16

Cover the Tail Surfaces . . . . . . . . . . . . . . . . . . . . . 16

FINAL ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mount the Control Horns . . . . . . . . . . . . . . . . . . . . 17

Mount the Stab and Fin . . . . . . . . . . . . . . . . . . . . . 17

Mount the Battery . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mount the Motor and Speed Control. . . . . . . . . . . . 18

Mount the Radio . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PREPARE THE MODEL FOR FLYING . . . . . . . . . . . . . 21

Set the Control Throws. . . . . . . . . . . . . . . . . . . . . . 21

Balance the Model. . . . . . . . . . . . . . . . . . . . . . . . . 21

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Charge the Batteries . . . . . . . . . . . . . . . . . . . . . . . 22

Identify Your Model . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ground Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 22

Range Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PERFORMANCE TIPS. . . . . . . . . . . . . . . . . . . . . . . . . 22

Cycle the Batteries. . . . . . . . . . . . . . . . . . . . . . . . . 22

Examine the Propeller . . . . . . . . . . . . . . . . . . . . . . 22

Motor Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

FIND A SAFE PLACE TO FLY . . . . . . . . . . . . . . . . . . . 23

MOTOR SAFETY PRECAUTIONS. . . . . . . . . . . . . . . . 23

AMA SAFETY CODE. . . . . . . . . . . . . . . . . . . . . . . . . . 23

FLYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Takeoff. . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

ROG Takeoff . . . . . . . . . . . . . . . . . . . . . . Back Cover

The Fundango is a fun to fly, aerobatic electric airplane that

can be flown in small spaces (see

Find a Safe Place to Fly

on page 23).Depending on your level of e xpertise, this plane

can either be a slow “Park Flyer” or an aerobatic model

capable of tight loops, inverted flight and fast rolls. Although

the Fundango uses only ailerons and elevator, with practice

you will be able to perform wing-overs and hammer-heads

which traditionally require a rudder.The Fundango was not

designed to look like a “real” airplane; instead it was

designed for exceptional aerobatic performance and we

think you'll agree that it meets this objective.

IMPORTANT: Though the Fundango is a small, lightweight

model that is capable of flying slowly, due to its aerobatic

design it is not intended for beginners.If you are new to R/C

airplanes, do not attempt to learn to fly with the Fundango.

You MUST learn to fly a trainer model first. Information about

R/C clubs and instructors is provided later in this manual.

1. Even though the Great Planes

Fundango

is a small,

lightweight model, if it is not assembled and operated correctly

it could possibly cause injury to yourself or spectators and

damage property.

2. Build the plane according to the plans and instr uctions. Do

not alter or modify the model, as doing so may result in an

unsafe or unflyab le model.In a few cases the instructions may

differ slightly from the photos. In those instances the plans

and written instructions should be considered as correct.

3.Take time to build straight, true and strong.

4. Use an R/C radio system that is in first-class condition. The

Fundango requires mini servos, a micro receiver and a micro

speed control that is capable of handling at least 15 amps.

5.You must properly install all R/C and other components so

that the model operates properly on the ground and in the air.

6. You must test the operation of the model before every

flight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

connectors often and replace them if they show signs of

wear or fatigue.

PRO TECT YOUR MODEL,Y OURSELF

& OTHERS...FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

INTRODUCTION

TABLE OF CONTENTS

2

Page 3

Remember:Take your time and follow directions to end

up with a well-built model that is straight and true.

If you're an inexperienced modeler, we recommend that

you get assistance from an experienced,knowledgeable

modeler to help you with assembly and y our first flights.

You'll learn faster and avoid risking your model before y ou're

truly ready to solo. Your local hobby shop has information

about flying clubs in your area whose membership includes

qualified instructors.

You can also contact the national Academy of Model

Aeronautics (AMA), which has more than 2,500 chartered

clubs across the country. Through any one of them,

instructor training programs and insured newcomer training

are available. Contact the AMA at the address or toll-free

phone number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

or via the Internet at http://www.modelaircraft.org

Before starting to build, compare the parts in this kit

with the Parts List and note any missing parts. Also

inspect all parts to make sure they are of acceptable

quality. If any parts are missing, broken or defective, or

if you have any questions about building or flying this

airplane, please call us at (217)398-8970 or e-mail us at:

productsupport@greatplanes.com.

If you are contacting us for replacement parts,please be

sure to provide the full kit name (Fundango) and the

part numbers as listed in the Parts List.

For the latest Fundango updates, you can also check

our web site at:

www.greatplanes.com

This is a list of items required to finish the Fundango that

must be purchased separately. For some of these items

there is more than one option which may require some

decision making ahead of time. Order numbers (in

parentheses) are provided for your convenience.

The Fundango requires three mini servos and a micro receiver .

Futaba®S3101 (FUTM0033) or Hobbico®CS-35 (HCAM0120)

micro servos and Hitec's®Feather Receiver (HRCL1535) are

suitable. The Feather Receiver comes without a receiver

crystal, so the crystal must be purchased separately.The order

number for the Hitec receiver crystal is HRCL23**. Substitute

the “**”with the channel number you require.For example, if the

transmitter you plan to fly your Fundango with is on channel 44,

order receiver crystal HRCL2344.

An electronic speed control with BEC (Battery Eliminator

Circuitry) is required.The BEC allows both the motor and the

radio system to be powered by the same battery (thus

eliminating an additional battery typically required to power

the radio).The Great Planes ElectriFly™C-20 High Frequency

Electronic Speed Control (GPMM2020) is recommended for

the Fundango. If you purchase the complete motor and gear

drive system, the speed control is included (refer to the

“Motor System” section that follows).

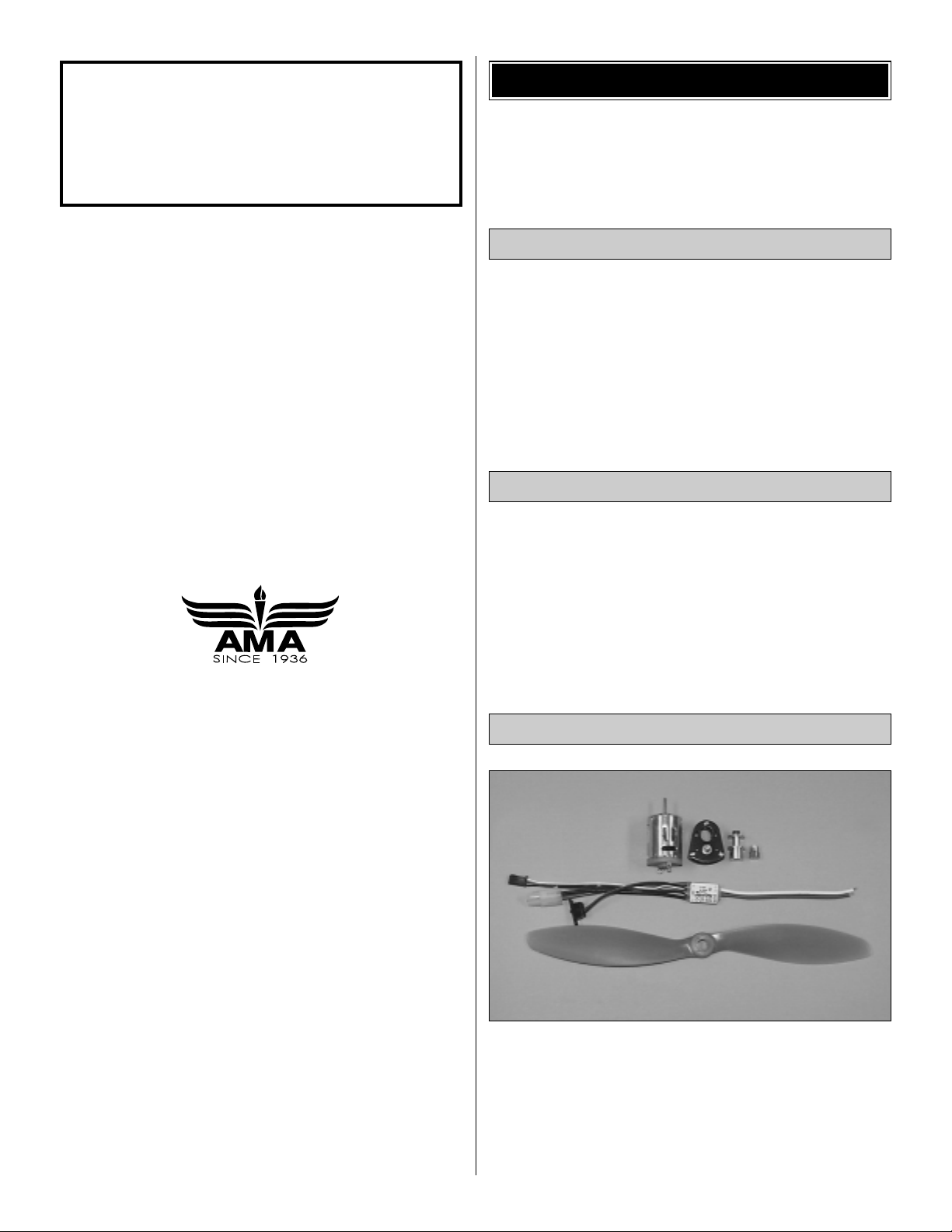

The Fundango is designed to use the Great Planes

ElectriFly T-400GD ESC motor system and gear drive for

electric flight (GPMG0400). This system includes a T-400

Ferrite Motor, S-400 3:1 ratio gearbox, 3mm prop adapter,

APC 10 x 7 propeller and the ElectriFly C-20 High

Frequency Electronic Speed Control w/BEC. The same

components are also available without the speed control by

ordering number GPMG0415.

Motor System

Speed Control

Radio Equipment

DECISIONS YOU MUST MAKE

Note: We, as the kit manufacturer, provide you with a

top quality kit and great instructions, but ultimately the

quality and flyability of your finished model depends on

how you build it; therefore, we cannot in any way

guarantee the performance of your completed model and

no representations are expressed or implied as to the

performance or safety of your completed model.

3

Page 4

4

Each individual Nicd or Nimh cell that makes up a battery is

1.2 volts. An 8-cell battery pack is 9.6 volts. Batteries are

also rated by their capacity in mAh (milli-Amp-hours), or how

much energy they store. A 600 mAh battery can supply 1

Ampere

for .6 hours (about 36 minutes).A 1200 mAh battery

pack has twice the capacity of a 600 mAh battery pack.

The battery pack recommended for the Fundango is the 8cell (9.6 volt) 600 mAh NiCd pack (HCAP6000).A 300 mAh

charger is included with the battery. If you already have a

charger, or if extra battery packs are required, the battery is

available separately (HCAP6005).

Do not attempt to fly the Fundango with 1200 mAh “sub-C”

battery packs, as they are too heavy.

ATTENTION: The product you have purchased is powered

by a rechargeable battery. At the end of its useful life, under

various state and local laws, it may be illegal to dispose of

this battery into the municipal waste system. Check with

your local solid waste officials for details in your area for

recycling options or proper disposal.

This product contains a chemical known to the State of

California to cause cancer and birth defects or other

reproductive harm.

The best type of charger to use is a peak charger, because

it charges the batteries until they are fully charged, then

automatically switches to a trickle charge mode. The

Hobbico Accu-Cycle™Plus (HCAP0270) is suitable for peakcharging the battery pack recommended.

The batteries may also be peak-charged by using a volt

meter to monitor the voltage while the batteries charge.The

voltage increases as the batteries charge.When the voltage

begins to decrease the batteries are fully charged (“peaked”).

The 9.6 volt 600 mAh battery recommended for the

Fundango may be charged at a rate no higher than 400

mAh. At this rate, it will take 90 minutes to charge a

discharged battery. If the battery is not discharged (and you

are not using a peak-charger), connect the battery to the

motor on your model. Run the motor until the propeller is

turning slowly, thus discharging the battery.

IMPORTANT: While charging, monitor the temperature of the

battery frequently .If the battery becomes warm, disconnect it

from the charger.

Though the Fundango is a small, lightweight model, it isn't a

floater, so using ultra-light coverings isn't a necessity. Some

weight can be saved by using Top Flite®EconoKote®or

Coverite™Micafilm™, but the overall savings is minimal and

has no noticeable effect on the way the Fundango performs.

Our prototypes covered with Top Flite MonoKote®film

performed very well.

In addition to the equipment listed in the “Decisions You

Must Make” section, following is the “short list” of the most

important building supplies required to build the Fundango.

We recommend Great Planes Pro™CA and Epoxy glue.

❏ 1/2 oz.Thin Pro CA (GPMR6001)

❏ 1/2 oz. Medium Pro CA+ (GPMR6007)

❏ Hobby knife (HCAR0105)

❏ #11 blades (HCAR0211)

❏ Single-edge razor blades (HCAR0212)

❏ Soldering Iron (HCAR0776)

❏ 60/40 Resin core solder (or other solder suitable for

electrical use)

❏ Approximately 3' of light string

❏ Small T-pins (HCAR5100)

❏ Builder's triangle (HCAR0480)

❏ Electric drill and drill bits: 1/16" [1.6mm], 5/64" [2mm] (or

1/16" [1.6mm]), 3/32" [2.4mm], 1/8" [3.2 mm], 5/16"

[7.9mm], #60 (.040") [1mm]

❏ Small Phillips and flat blade screwdrivers

❏ Pliers with wire cutter (HCAR0630)

❏ Great Planes Plan Protector (GPMR6167) or wax paper

❏ Sanding tools and sandpaper assortment

❏ Sealing Iron (TOPR2100)

❏ 70% Isopropyl rubbing alcohol (or water for bending

balsa sticks)

Here is a list of optional tools that may help you build

the Fundango.

❏T op Flite Precision Magnetic Prop Balancer™(TOPQ5700)

❏ Top Flite Hot Sock™iron cover (TOPR2175)

❏ Straightedge with scale (HCAR0475)

❏ Cutting mat (HCAR0456)

Optional Supplies and Tools

Building Supplies

ADDITIONAL ITEMS REQUIRED

Covering

Chargers

Battery Warning

Battery Recommendation

Page 5

❏ Masking Tape (TOPR8018)

❏ CA Debonder (GPMR6039)

❏ CA Applicator tips (GPMR6033)

❏ Great Planes 5-1/2" [140mm] Bar Sander (GPMR6169)

and 150-grit adhesive back sandpaper (GPMR6183)

❏ Top Flite 320-grit sandpaper (TOPR8030) and 400-grit

sandpaper (TOPR8032)

❏ Razor saw or Dremel®tool with cut-off wheel

❏ Medium T-Pins (HCAR5150)

For the best performance, the Fundango must be built light.

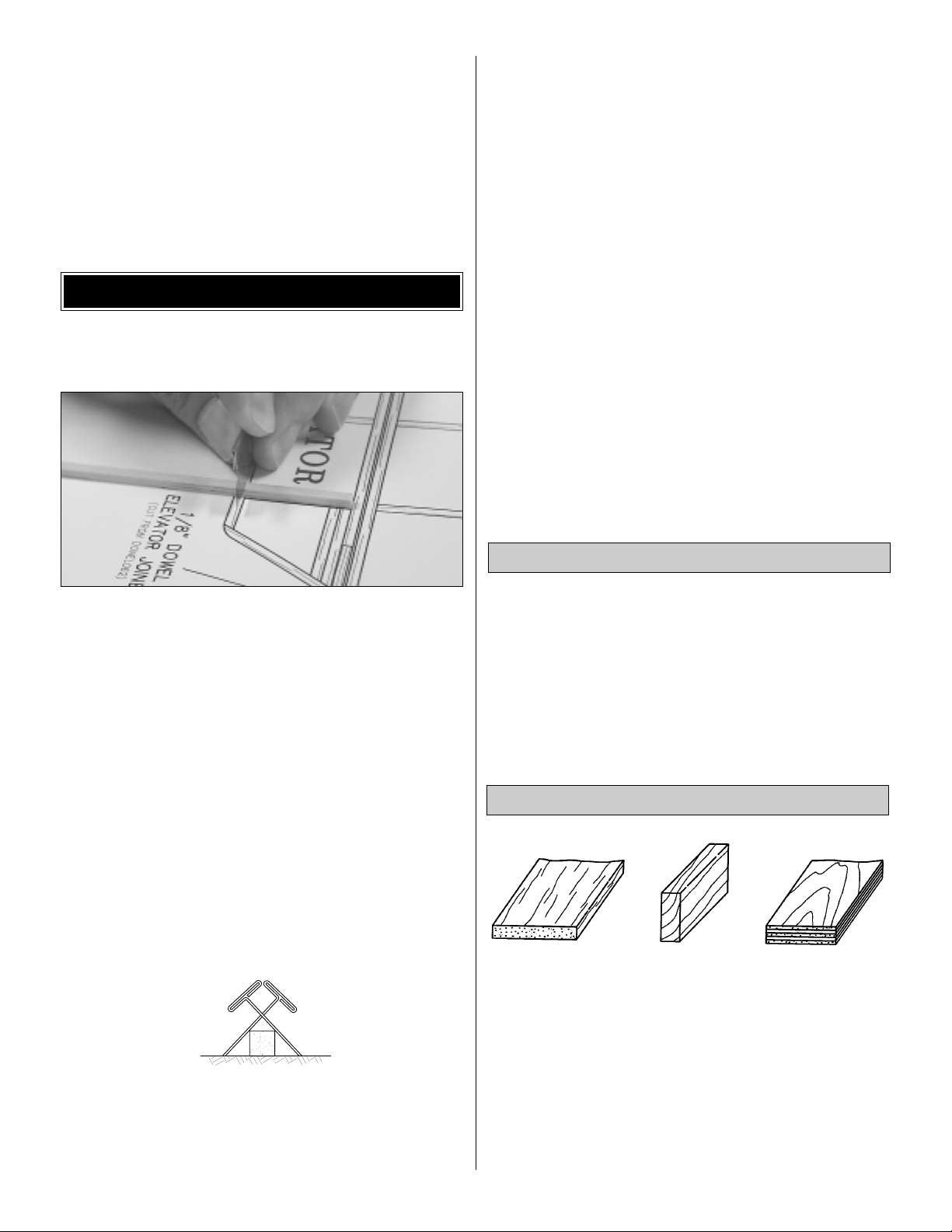

Here are some tips to help you build neatly and light.

1. The easiest way to cut balsa sticks is with a single-edge

razor blade.To do so, position the stick over the plan, then

place the razor blade on the stick where you wish to cut it.

Press down lightly on the razor blade to mak e a mark where

the stick is to be cut.

2.Take the stick off the plan and cut it over a cutting mat or

a leftover piece of wood

(Okay, if you're careful you could go

ahead and cut the stick right over the plan, but if y ou do, you

may cut through the plan protector and allow the CA to soak

through, gluing the structure to the plan).

3.Because of the small balsa sticks used in the tail, small Tpins may be used to hold the sticks to your building board,

but only where necessary.Use small T-pins (HCAR5100) or

small straight pins found in craft stores.Do not stick pins into

the sticks near the ends, or the wood may split.

4. If you have difficulty with the T-pins splitting the small

sticks, an alternate method is to use the “crossed-pin”

technique.Insert the T-pins into the building board in a crisscross fashion to hold the sticks to the plan.

5.When applying CA, be careful to not glue your fingers to the

structure. In the process of

unsticking

your fingers you can

inadvertently damage the structure, thus requiring repairs and

adding additional weight

(not to mention the aggravation!)

.

6. Sanding requires a light touch to avoid damage.We found

the best method for sanding is to use light strokes in the

direction of the longest sticks. Be certain the sandpaper is

thoroughly bonded to the bar sander.Lifted edges will catch

the structure causing damage. Use medium-grit sandpaper

such as 120 or 150.

7. One of the best ways to insure a lightweight model is to

build neatly. Good-fitting glue joints with minimal adhesive

are stronger, lighter and ha v e a better appear ance than poorfitting joints with too much CA.Of course, you should take this

approach with all of your projects! Use CA applicator tips

(GPMR6033) to control and pinpoint the amount of CA.

8. Build over a flat surface. Cover the plans with Great

Planes Plan Protector (GPMR6167) or wax paper so the

parts will not adhere to the plan.

Fuse = Fuselage

LE = Leading Edge (front)

TE = Trailing Edge (rear)

Stab = Stabilizer

" = Inches

Elev = Elevator

LG = Landing Gear

Ply = Plywood

Types of Wood

Common Abbreviations

IMPORTANT BUILDING NOTES

5

Page 6

1/64" = .4 mm

1/32" = .8 mm

1/16" = 1.6 mm

3/32" = 2.4 mm

1/8" = 3.2 mm

5/32" = 4.0 mm

3/16" = 4.8 mm

1/4" = 6.4 mm

3/8" = 9.5 mm

1/2" = 12.7 mm

5/8" = 15.9 mm

3/4" = 19.0 mm

1" = 25.4 mm

2" = 50.8 mm

3" = 76.2 mm

6" = 152.4 mm

12" = 304.8 mm

18" = 457.2 mm

21" = 533.4 mm

24" = 609.6 mm

30" = 762.0 mm

36" = 914.4 mm

6

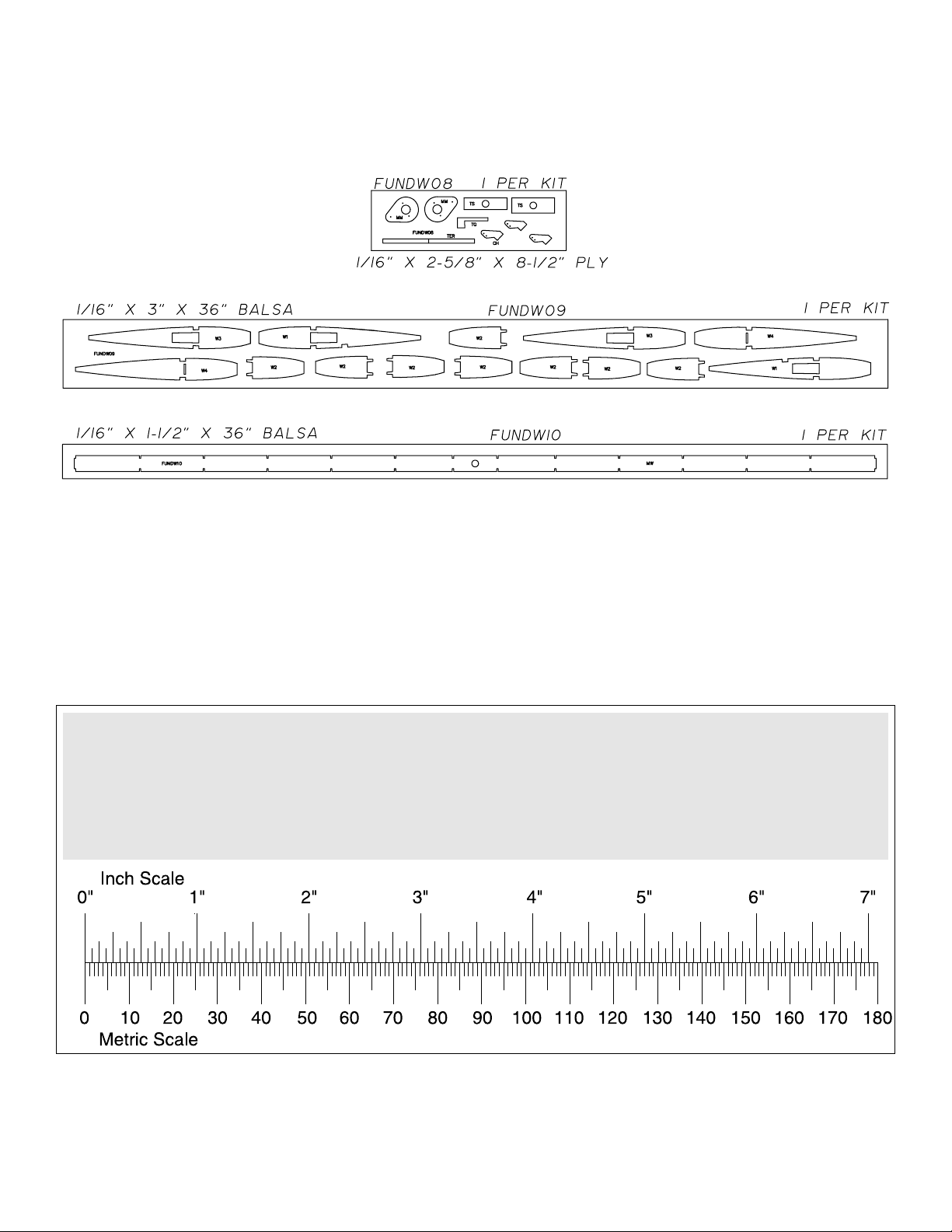

DIE-CUT PATTERNS

Metric Conversions

Page 7

❏ 1.Unroll the plan sheet. Re-roll it inside out to make it lie flat.

❏ 2. Remove all parts from the box. As you do, figure out the

name of each part by comparing it to the plans, the die page and

the parts list. Save all leftovers. If any of the parts are difficult to

remove from their die sheets, do not force them. Instead, cut

around the part with a hobby knife. After removing the parts,

lightly sand the edges to remove any die-cutting irregularities.

❏ 1. Place the wing portion of the plan over your flat

building board. Cover the wing plan with Great Planes Plan

Protector or wax paper.

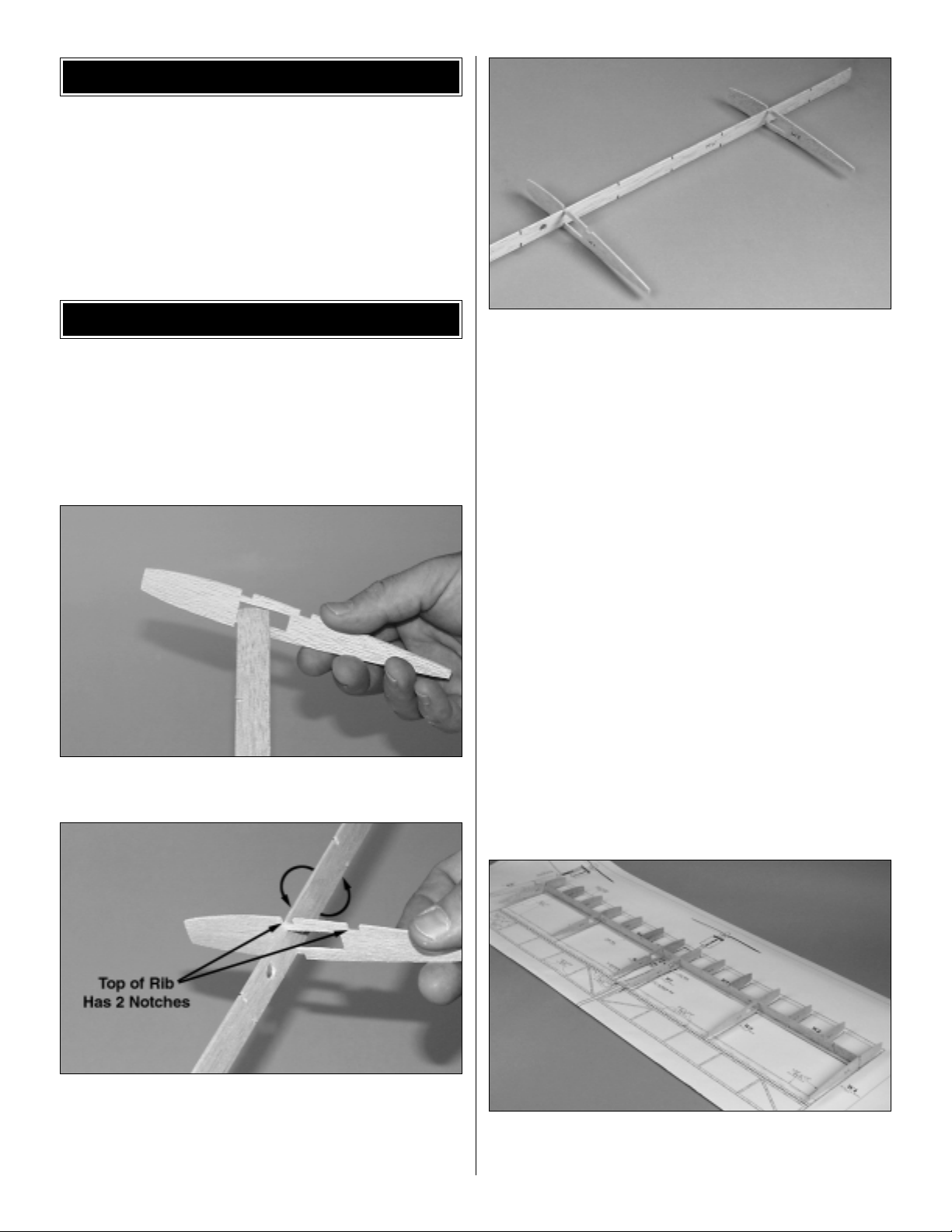

❏ 2.Locate the die-cut 1/16" [1.6mm] balsa ribs W1 through

W4, the main web (MW) and the die-cut 1/16" [1.6mm]

plywood parts.

❏ 3. Inser t the right end of the main web into the opening

in rib W1 as shown.

❏ ❏ 4. Place rib W1 into the notch shown on the plan by

twisting it into position on the main web.W1 should be lined up

with the spar notch.The top of the rib is the side with two spar

notches. Be certain the rib is on the main web with these

two notches up. Glue W1 perpendicular to the main web.

❏ ❏ 5.Using the same procedure, insert W3 onto the main

web as shown on the plan. Glue W3 perpendicular to the

main web.

❏ 6. Repeat steps 3, 4 and 5 for the left side of the wing.

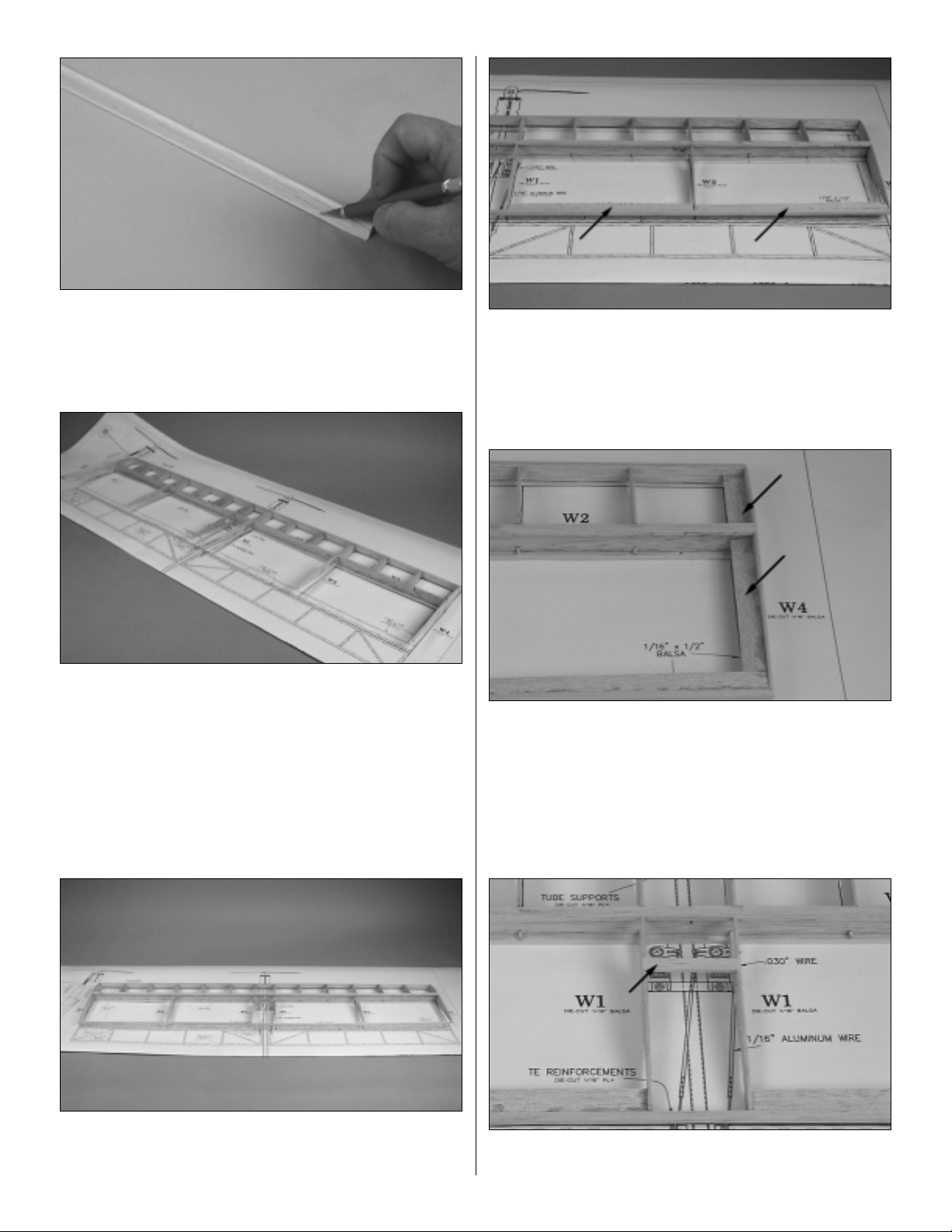

❏ 7. Locate the two 1/8" x 1/4" x 36" [3.2 x 6.4 x 910mm]

balsa sticks and cut them to 35" [889mm] in length. These

make up the top and bottom spar.

❏ 8.Pin one of the spars in place over the plan.This will be

the bottom spar.

❏ 9. Place the main web with the two W1 and two W3 ribs

onto the bottom spar. Carefully align the ribs in place over

the plan. Be sure that each rib is perpendicular to the

building surface.

❏ 10. Glue rib W4 to the main web at each end of the

bottom wing spar.

❏ 11. Glue each of the W2 half-ribs to the main web.

❏ 12. Make sure that ribs W1, W3, W4 and the main web

are in contact with the bottom spar. Glue the r ibs and the

main web to the bottom spar with thin CA.

BUILD THE WING

GET READY TO BUILD

7

Page 8

❏ 13. Use a hobby knife with a #11 blade to remove the

flashing from the shaped 36" balsa leading edge. NOTE:

The leading edge is symmetrical – there is no

top

or

bottom

.

❏ 14. Cut the leading edge to a length of 35" [889mm].

❏ 15. Beginning on the right side of the wing, glue the

leading edge to rib W4 with medium CA.Position the leading

edge so it is centered on the rib.When the glue has set, glue

the leading edge to W4 on the left side of the wing.Continue

to glue the leading edge to each of the W2 and W3 ribs for

the entire length of the wing, making sure that each rib is

centered on the leading edge.

❏ 16.Position and glue the top spar in place in the notches

on the top of the wing above the main web.

❏ 17.Cut one of the 3/16" x 3/16" x 36" [4.8 x 4.8 x 910mm]

balsa sticks to a length of 35" [889mm] to make the wing

trailing edge.Glue the trailing edge to ribs W1, W3 and W4.

❏ 18. Cut both 1/16" x 1/2" x 24" [1.6 x 13 x 610mm] balsa

TE supports to fit between W1 and W3 and between W3

and W4.Do this for the left and right side of the wing, gluing

them into place. Be certain the supports are centered

vertically on the TE.

❏ 19. Fit the remaining 1/16" x 1/2" x 24" [1.6 x 13 x

610mm] balsa stick between the trailing edge and the

leading edge at rib W4. When you are satisfied with the fit

glue them into place. Do this for both the left and right end

of the wing.

❏ 20. Glue the 1/8" x 1/4" x 2" [3.2 x 6.4 x 51mm] balsa

servo support into the two remaining notches on ribs W1.

8

Page 9

❏ 21. Locate both die-cut 1/16” [1.6mm] plywood tube

supports. Glue the narrower support to the back of the

leading edge in the center of the wing.

❏ 22. Glue the remaining tube suppor t to the back of the

main web. Be sure the hole in the main web and the rear

tube support align.

❏ 23. Push a T-pin through the exact center of the tube

support on the back of the LE, all the way through the

leading edge. This will be your

pilot hole guide

for drilling a

hole through the leading edge.

❏ 24. Drill a 1/8" [3.2mm] pilot hole through the pin hole

guide. Once you are satisfied that the pilot hole is through

the center of the forward tube support, drill a 5/16" [7.9mm]

hole through the leading edge.

❏ 25. Lightly and carefully sand the entire wing. The wing

is light and too much force could damage it.

❏ 26. Test fit the fiberglass fuselage tube into the wing.

Make any adjustments to the mounting holes needed for the

tube to slide through the wing. Cut a 5/16" [7.9mm] opening

in the trailing edge of the wing to allow the tube to pass

through it. This opening must be exactly centered between

the W-1 ribs.

9

Page 10

❏ ❏ 1.Make the frame of the aileron as shown on the plan

from a 3/16" x 3/16" x 36" [4.8 x 4.8 x 910mm] balsa stick.

❏ ❏ 2. Cut the cross supports from a 1/8" x 3/16" x 36"

[3.2 x 4.8 x 910mm] balsa stick. Glue the cross supports in

place using the plan as a guide.

❏ ❏ 3.From a leftover piece of 3/16" x 3/16" [4.8 x 4.8mm]

balsa stick, cut the control horn support brace to the

shape shown on the plan.

❏ ❏ 4. Glue the control horn suppor t brace to the aileron

as shown on the plan.Do not glue the control horn in place.

The control horn will be glued in after the aileron is covered.

❏ 5. Repeat steps 1 – 4 for the left aileron.

❏ 1. Cover the fin area of the plan with Great Planes

Plan Protector.

❏ 2. Make the bottom of the fin and the center fin post

from the 3/16" x 3/16" x 36" [4.8 x 4.8 x 910mm] balsa stick.

Pin the parts to your building board as you proceed.

❏ 3. Fit and glue the rest of the cross-brace structure from

one of the 1/8" x 3/16" x 36" [3.2 x 4.8 x 910mm] balsa

sticks. Place a few pins around the structure to suppor t it.

This will be helpful as you move through the steps of

wrapping the laminated frame of the fin.

Build the Fin

BUILD THE T AIL SURF ACES

BUILD THE AILERONS

10

Page 11

❏ 4. Inser t T-pins into the building board following the line

of the inside perimeter of the fin. This will help guide the

balsa laminate that will create the fin.

❏ 5. Use Isopropyl Alcohol or water to wet one side of the

three 1/16" x 3/16" x 24" [1.6 x 4.8 x 610mm] balsa sticks

allowing them to soften, so they can be bent around the T-pins.

Allow the sticks to sit for a few minutes before proceeding.

❏ 6.Glue the balsa sticks in place.Begin by gluing one end

of the stick to the fin using medium CA. Work the stick

around the fin using the T-pins as a guide. As you proceed,

glue the stick to the wooden structure. Carefully work the

balsa stick around the fin.

❏ 7. Repeat this process for the second and third stick,

gluing each one to the other.

❏ 8. Trim the excess strips to match the shape of the fin.

After the balsa has completely dried, lightly sand the fin.

❏ 9.Round the perimeter of the fin by sanding as shown on

the plan sheet.

Laminating is an interesting and fun way to make a strong,

yet lightweight structure. Now that you know how to do it,

you should be able to do the same thing to the horizontal

stab and elevator in much less time. Let's get started!

11

Page 12

❏ 1.Cover the stab and elevator area of the plan with Great

Planes Plan Protector.

❏ 2. Cut the stab trailing edge and the elevator leading

edge from the 3/16" x 3/16" x 36" [4.8 x 4.8 x 910mm] balsa

stick, then pin them to the plan.

❏ 3. Build the cross-brace structure in the same manner as

the fin from 1/8" x 3/16" x 36" [3.2 x 4.8 x 910mm] balsa

sticks. The elevator control horn brace should be made

from leftover 3/16" x 3/16" [4.8 x 4.8mm] the same as the

control horn braces for the ailerons. Do not glue the control

horn in place at this time. It will be installed after the elevator

is covered. Place a few pins around the structure to support

it and insert T-pins into the building board following the line of

the inside perimeter of the fin. This will help guide the balsa

laminate that will create the frames of the stab and elevator.

❏ 4. Locate three 1/16" x 3/16" x 36" [1.6 x 4.8 x 910mm]

balsa strips. These will be wrapped around the stab and

elevator the same way that you did the fin. Be sure you

follow the same steps for wetting the wood as was done for

the fin.

❏ 5. Wet the wood and allow it soften for a few minutes.

Glue the balsa laminate in place.Begin by gluing one end of

the strip to the stab at the location shown in the photo.

❏ 6.Work the strip around the perimeter of the stab and the

elevator. When you get back to the point where you first

glued the strip you will have to cut off the e xcess balsa stick.

This will allow you to complete the laminate wrap.

❏ 7. Repeat the process for the second and third balsa

laminate strips, gluing them to one another.

❏ 8. After the balsa has dr ied, lightly sand the structure.

The entire perimeter should be rounded to match the crosssection on the plan.

Build the Stab and Elevator

12

Page 13

❏ 9. Use a hobby knife to separate the stab and elevator.

❏ 10. Use a sanding bar to bevel the leading edge of the

elevator to the shape shown on the elevator cross-section

on the plan.

That's it for the tuff stuff! Now you can move ahead with the

process of assembling the plane.

❏ 1.Use a razor saw or a Moto-Tool with a cut-off wheel to cut

the fiberglass fuselage tube to a length of 24-5/8" [625.5mm].

Refer to this photo for the following two steps.

❏ 2.Wrap one end of the tube with 5" [130mm] of masking

tape.This will be the aft end of the fuselage tube.Mark a line

on the tape 4-7/8" [124mm] from the end of the tube.

❏ 3. From the mark you made, draw a line parallel with the

tube to the end of the tube. Draw a second line parallel with

the line you just made the thickness of the fin. (This should

be 3/16" [4.8mm], but may be less because of sanding.)

❏ 4. CAUTION:Wear eye protection for this step! Use a

Dremel®tool with a cut-off wheel or a razor saw to cut the

tube on the lines to create a slot for the fin.Hint: Cut the slot

a bit narrow to begin with, so the fin will fit well.

❏ 5. Test fit, but do not glue the fin into the slot. Make

adjustments if necessary.

❏ 6. Sand the 1/4" x 2" [6.3 x 50mm] wooden dowel until it

will fit into the front end of the fuselage tube. Be sure to

leave a little room for glue. Fit the dowel into the tube, flush

with the end of the tube and permanently glue it into position

with thin CA.

❏ 7.Slide the fuselage tube into the wing. Position the wing

so the leading edge of the wing is 2-1/4" [57mm] from the

front of the tube. Do not glue it in place yet!

Prepare the Fuselage Tube

BUILD THE FUSELAGE

13

Page 14

❏ 8. Lay the bottom of the wing flat on the bench.

IMPORTANT! The top of the wing is the side that has the two

servo rails.Temporarily place the fin into the slot at the end of

the tube. Rotate the tube until the fin is 90 degrees to the

bench.Use a triangle to verify that the fin is set at 90-degrees.

❏ 9. Once you are satisfied with the placement, use CA to

glue the fuselage tube to the wing at the leading edge, the

main web and the trailing edge.

❏ 10.Locate the die-cut 1/16" [1.6mm] ply top and bottom

trailing edge reinforcement. Glue one to the top of the

trailing edge and one to the bottom of the trailing edge as

shown in the photo. Apply them at the same time and use

your fingers to apply equal pressure to the top and bottom

at the same time. Any gap you have can be filled with

medium or thick CA and hardened with CA accelerator.

❏ 11. Hold the die-cut 1/16" [1.6mm] ply engine thrust

gauge on the top of the fuselage tube. Sand the front of the

tube to match the angle of the gauge to provide the correct

motor down thrust.

Landing gear is optional on the Fundango.With gear, handlaunching is not necessary as the plane can take-off and

land on hard surfaces. The landing gear also protects the

propeller on rough landings. The gear does, however, add

weight and drag. If you fly over grassy areas you may

consider omitting the gear. Soft landings in the grass are

done easily without damaging the propeller.

❏ 1. Cut the 1/16" x 30" [1.6 x 760mm] wire into three

pieces of 15-5/8" [397mm], 6" [152mm] and 9" [230mm].

❏ 2. Bend the 15" [380mm] wire as shown on the landing

gear template on the plan.

❏ 3. Use a felt-tip pen to mark the wire 1" [25mm] from the

top as shown in the drawing. Bend the wire back at a 90

degree angle.

❏ 4.Cut the gear in half as shown in the photo and the drawing.

Build the Landing Gear (Optional)

14

Page 15

❏ 5. Now there is a left and right main landing gear.

❏ 6. Bend the 6" [152mm] wire as shown on the

cross-

brace

template on the plan.

❏ 7. Bend the tail skid from the remaining piece of 9"

[230mm] wire as shown on the plan. Use a needle nose

pliers to make the circular bend in different spots until you

have formed the curved end. Cut off the excess wire.

❏ 1. Cover the front 2" [50mm] of the fuselage tube with

masking tape, so you can mark where to drill the holes for

the landing gear.

❏ 2. Use a ballpoint pen to mark the tube 1" [25mm] and

1-1/16" [27mm] from the end. Be certain the marks are on

the tube so that when the holes are drilled and the landing

gear is mounted, the wings will be level when the model is

resting on the gear.

❏ 3. Drill 1/16" [1.6mm] holes all the way through the

fuselage tube at the marks you made.

❏ 4. Inser t the landing gear into the tube. Wrap the gear

and the tube tightly with string or thread (not included in the

kit). Saturate the string with thin CA.

❏ 5.Attach the cross-brace 1-3/8" [35mm] above the bend in

the axle. Wrap the joints tightly with string or thread and

saturate with thin CA.

❏ 6. Drill a 1/16" [1.6mm] hole for the tail skid 6" [152mm]

from the aft end of the tube.

Mount the Landing Gear

15

Page 16

❏ 7. Attach the tail skid the same way you did the landing

gear with string and CA.

❏ 8. Mount the wheels and secure them with the two

nylon retainers.

❏ 1. If you haven't done so already, sand all wood parts of

the model smooth with 320-grit, then 400-grit sandpaper.

❏ 2. Use compressed air (be careful!), a dust brush or a

tack cloth to remove balsa dust from the model.

❏ 3. Determine what material you will be covering the

model with. If using Top Flite EconoKote or MonoKote, the

model is ready to cover. If using Coverite Micafilm, coat the

areas to be covered with Coverite Balsarite (COVR2500).

Be certain you use the formula for Micafilm (fabric) and not

the formula for regular film covering.

The following procedure must be followed to assure a

straight, strong wing.

❏ 1. Cover the bottom, then the top of the wing, but do not

shrink the covering until instructed to do so.Do your best

to minimize wrinkles without applying heat, thus reducing the

amount of shrinking that will be required later on.

❏ 2.Cover the bottom, then the top of both ailerons the same

way. Do not shrink the covering until instructed to do so.

❏ 3. Cut both 3/4" x 1" [9 x 25mm] hinge strips into (12)

hinges as shown on the plan.

❏ 4. Use a hobby knife to cut 1/8" [3mm] hinge slots in the

trailing edge of the wing and the leading edge of the ailerons

where shown on the plan.

❏ 5. Join the ailerons to the wing with the hinges. Apply 3

drops of thin CA to each side of each hinge.

❏ 6.Proceeding slowly, heat the top and bottom of one side

of the wing to shrink the covering. Heat each side a little at

a time, so the top and bottom shrink simultaneously. Use

only enough heat to remove the wrinkles. Avoid fully

shrinking and tightening the covering. After the wrinkles

have disappeared, use a covering iron to bond the covering

to the ribs, to the servo mounting rails, to the aileron crossbraces and to the control horn brace.

❏ 7. Use the same procedure to remove the wrinkles from

the other side of the wing and the ailerons.

❏ 8.Trim the covering from the servo mounting rails and the

control horn braces in the ailerons.

❏ 1.Cover both sides of the fin, shrinking the covering evenly

and only as much as necessary to remove the wrinkles.

❏ 2. Cover the stab and the elevator.

❏ 3. Join the elevator to the stab with the hinges, then heat

the covering evenly on both sides to remove the wrinkles.

Cover the Tail Surfaces

Cover the Wing and Ailerons

Prepare the Model for Covering

CO VER THE MODEL

16

CUT HINGE SLOT

WITH HOBBY KNIFE

AND #11 BLADE

ASSEMBLE, THEN APPLY 3 DROPS

OF THIN CA TO CENTER

OF HINGE, ON BOTH SIDES

Page 17

❏ 1. Dr ill two #60 (.040") [1mm] holes through the punch

marks in the die-cut 1/16" control horns.

❏ 2. Glue the control horns into position in each of the

ailerons and the elevator, making sure they are vertical to

the control surface.

❏ 1. Slide the stab and elevator onto the fuselage tube.

Make sure you hav e a good fit betw een the tube and the slot

in the stab. Sand or shim the stab as needed to get a good

fit. Be sure that the elevator moves up and down freely

without any binding when the stab is mounted.

❏ 2. Make sure that the stab is parallel with the wing as

shown in the photo above .Glue the stab to the fuselage tube

with medium CA.

❏ 3. Slide the fin into the slot in the rear of the fuselage

tube. Be sure that the fin is 90 degrees to the stab and

parallel with the fuse, then glue the fin into the slot.

❏ 1. Drill a 5/64" [2mm] hole for the battery hook through

one side of the fuselage tube between the leading edge of

the wing and the landing gear.

(If you don't have a 5/64"

[2mm] drill bit you could use a 1/16" [1.6mm] drill bit, but

you'll have to enlarge the hole with a hobby knife.)

❏ 2.Make the battery hook from .074 x 2" [1.9 x 50mm] wire.

Mount the Battery

Mount the Stab and Fin

Mount the Control Horns

FINAL ASSEMBLY

17

90˚

90˚

Page 18

❏ 3. Use medium CA to glue the hook into the hole you

drilled in the fuselage tube.

❏ 4. Hook two #64 rubber bands around the fuselage tube

behind the wing, then connect them to the battery hook.

Mount the battery pack between the wing and the rubber

bands. Later, the exact location of the battery will be

determined to balance the model.

❏ 1.Glue both die-cut 1/16" [1.6mm] plywood motor mounts

together to form a 1/8" [3.2mm] motor mount.

❏ 2.Drill a 1/8" [3.2mm] hole though the three punch marks

in the motor mount.

❏ 3.Drill a 3/32" [2.4mm] hole into the center of the wooden

dowel in the front of the fiberglass pushrod.

❏ 4.Attach the motor mount to the front of the fuselage with

a #4 washer and a #4 x 1/2" [3.2mm] screw.

❏ 5. Use electrical solder to tin the end of the white and

blue wires coming from the speed control.Do not use silver

solder as it is not suitable for electrical purposes and the flux

will corrode the wires.

❏ 6.Solder the blue wire (negative) on the speed control to

the tab on the motor that has a red dot (positive).Solder the

white wire (positive) to the other tab on the motor

(negative). Note: The speed control is connected to the

motor “backwards” due to the gear reduction, which would

otherwise cause the propeller to turn backwards.

Mount the Motor and Speed Control

18

Page 19

❏ 7. Mount the motor and gear box to the motor mount as

shown, using the screws included with the system.

❏ 8. Make a tapered 3/16" spacer from leftover balsa and

glue it to the fuselage under the aft end of the motor as

shown on the plan.

❏ 9.Secure the back of the motor to the fuselage with nylon

tape or a tie wrap (not included).

Final motor connections will be done when the servos and

receiver are installed.

The Hitec Feather Receiver is shown in these instructions.

❏ 1. If you haven't yet done so, trim the covering from the

servo bay as shown.

❏ 2. Connect the aileron servo to slot number one on the

receiver, the elevator to number two and the speed control

to number three.

❏ 3.Insert the receiver into the servo bay opening along side

of the fuselage. (If you are using a larger receiver you can

mount it outside the wing and secure it with rubber bands.)

❏ 4.Drill 1/16" [1.6mm] holes in the servo rails for mounting

the servos. Add a drop of thin CA to the holes and allow to

harden. Mount the servos to the rails.

Now let's make the pushrods!

❏ 5. Cut the 1/16" x 24" [1.6 x 610mm] aluminum tube into

one 17-1/4" [438mm] piece and two 3-3/8" [86mm] pieces to

make the pushrod tubes. Hint: The tubing is easily cut by

placing the edge of your hobby knife blade on the tube, then

rolling the tube back and forth until it cuts through.

❏ 6. Cut the .03" x 10" [.76 x 254mm] wire into four 1-1/2"

[38mm] pieces and two 3" [76mm] pieces.

Mount the Radio

19

Page 20

❏ 7. Place a couple of drops of medium CA on the end of

one 3-3/8" [86mm] pushrod tube. Insert a 1-1/2" [38mm]

wire into the tube approximately 1/2" [13mm]. Allow the CA

to harden, or give it a “spritz”of CA accelerator.Do the same

at the other end of the tube. Repeat for the other 3-3/8"

[86mm] tube.These pushrods will be for the ailerons.

❏ 8. Follow the same procedure for the 17-1/4" [438mm]

tube, inserting the 3" [76mm] wire 1/2" [13mm] into each end

of the tube.This will be the elevator pushrod.

❏ 9.Make a Z – bend at one end only of all three pushrods

as shown.

❏ 10.Using the servo horns supplied with your servos, make

one

single

servo arm and one

twin

servo arm as shown.

❏ 11. Center the aileron servo and mount the twin servo

arm to it.

❏ 12. Insert the aileron pushrods that have the Z-bend into

the aileron control horns.

❏ 13. Center the aileron, then mark the end of the pushrod

wire where it attaches to the servo.Make another Z- bend at

the mark and insert it into the ser vo horn. Do this for both

aileron servos.

❏ 14.Use the same procedure to install the elevator pushrod.

❏ 15. Mount the speed control and the on/off switch to the

top of the fuselage with double-sided foam mounting tape

(not included).

❏ 16. Extend the receiver antenna to the back of the

fuselage and hold it to the stabilizer with cellophane tape.Be

certain there is no way that the antenna can reach the

propeller! Never coil-up the antenna, nor cut it.The antenna

length is tuned to a certain radio frequency.

20

Page 21

❏ 1. For safety, remove the propeller from the motor. Move

the throttle stick to the off position. Connect the charged

battery to the speed control. Turn on the transmitter, then

follow the instructions that came with your speed control to

turn on the receiver.

❏ 2.Center the trims on the transmitter.Operate the servos

by moving the control sticks. Check that the servos respond

in the correct direction as shown in the diagram. If

necessary, use the servo reversing function in your

transmitter to get the controls to respond correctly.

❏ 3. Operate the controls with the transmitter and use a

ruler to measure the throws. Use the ATV function in the

transmitter to set the control throws according to the chart

that follows.If your transmitter does not have dual rates, set

up the Fundango on the low rate settings.After you become

accustomed to the way the Fundango flies, you may begin

increasing the throws until you get to the high-rate settings.

❏ 4. Switch off the transmitter and disconnect the batter y.

Note:This section is VERY important and must NOT be

omitted! A model that is not properly balanced will be

unstable and possibly unflyable.

❏ 1. Use 1/8"-wide tape or a felt-tip pen to accurately mark

the balance point on the top of the wing on both sides of the

fuselage.The balance point (CG) is located 3-1/16" [78mm]

from the leading edge as shown in the sketch and on the

plan.This is the balance point at which the Fundango should

balance for your first flights. If, after initial trim flights you

have become accustomed to the way the Fundango flies,

you may wish to experiment by shifting the balance point

3/16" [5mm] forward to 1/2" [13mm] back to change the

flying characteristics.Moving the balance point forward may

improve the stability and make the model easier to fly, but it

may not climb as rapidly and will be less aerobatic. Moving

the balance aft makes the model more maneuverable and

aerobatic, but it could be too difficult to control if you are not

an experienced pilot. In any case, start at the balance point

recommended and do not at any time balance the model

outside the recommended range.

Balance the Model

These are the recommended control throws:

High rate Low rate

Elevator: 2" [51mm] up 1" [25mm] up

2" [51mm] down 1" [25mm] down

Ailerons: 1-1/8" [29mm] up 1/2" [13mm] up

1-1/8" [29mm] down 1/2" [13mm] down

IMPORTANT: The Fundango has been extensively

tested.These are the control throws at which it flies best.

If, after you become comfortable with the way the

Fundango flies, you would like to adjust the thro ws to suit

your taste, that is fine.However , on the high-rate settings

the Fundango can already do all the maneuvers “in the

book,”so there shouldn't be any requirement to increase

the throws. Doing so could make the model too difficult

to control, so remember, “more is not always better.”

Warning: Whenever the model is not being flown or set

up, the battery should be disconnected.

Set the Control Throws

PREPARE THE MODEL FOR FLYING

21

3-CHANNEL RADIO SETUP

(STANDARD MODE 2)

ELEVATOR MOVES UP

4-CHANNEL

TRANSMITTER

RIGHT AILERON MOVES UP

LEFT AILERON MOVES DOWN

4-CHANNEL

TRANSMITTER

MOTOR TURNS

4-CHANNEL

TRANSMITTER

3-1/16"

Center of Gravity:

3-1/16" From Leading Edge

Total Range: 2-7/8" to 3-9/16"

Page 22

❏ 2.With the battery mounted to the fuselage, lift the model

upside-down at the balance point.If the tail drops, the model

is “tail heavy” and you must shift the battery pack forward to

balance the model. If the nose drops, it is “nose heavy” and

you must shift the battery aft to balance the model.

❏ 3. Shift the battery pack until the model balances at the

balance point recommended. Use narrow masking tape or a

felt-tip pen to mark the location of the battery pack on the

bottom of the wing. Be certain this is where you always

mount the battery pack when it's time to fly so the model will

be properly balanced.

Follow the transmitter battery charging procedures in your

radio's instruction manual.Charge the transmitter batteries the

night before you go flying and at other times as recommended

by the radio manufacturer.

Charge the motor battery following the instructions that

came with the battery charger and the guidelines in the front

of this manual.

No matter if you fly at an AMA sanctioned R/C club site or if

you fly somewhere on your own, you should always have

your name, address, telephone number and AMA number

on or inside your model. It is required at all AMA R/C club

flying sites and AMA sanctioned flying events. Fill out the

identification tag on the center spread of this manual and

place it on or inside your model.

Before you fly you should perform one last overall inspection

to make sure the model is truly ready to fly and that you

haven't ov erlook ed anything.If you are not thoroughly familiar

with the operation of R/C models, ask an experienced

modeler to perform the inspection. Check to see that you

have the radio installed correctly and that all the controls are

connected properly. The motor must also be checked by

confirming that the prop is rotating in the correct direction and

the motor sounds like it is reaching full power. Make certain

all control surfaces are secure, the pushrods are connected,

the controls respond in the correct direction, radio

components are securely mounted and the C.G.is correct.

Ground check the operational range of your r adio bef ore the

first flight of the day. With the transmitter antenna collapsed

and the receiver and transmitter on, you should be able to

walk at least 100 feet away from the model and still have

control. Have an assistant stand by your model and, while

you work the controls, tell you what the control surfaces are

doing. Repeat this test with the motor running at various

speeds with an assistant holding the model, using hand

signals to show you what is happening. If the control

surfaces do not respond correctly, do not fly! Find and

correct the problem first. Look for loose servo connections

or broken wires, corroded wires on old servo connectors,

poor solder joints in your battery pack or a defective cell, or

a damaged receiver crystal from a previous crash.

NOTE: It is possible for the motor to cause interference.If you

experience a range problem or notice the servos “glitching,”

install an additional .01 µF capacitor between the motor

leads, then repeat the range check with the motor running.

For the longest flight duration and to get the most from a new

battery, the battery should be cycled. “Cycling” a battery

means to fully charge (“peak” charge) the battery, then to

discharge it. Many batter y chargers have peak charging and

automatic discharging capabilities. If you do not have a

charger that is able to discharge batteries, you can discharge

the battery yourself by running the motor with the propeller

attached until the propeller spins slowly. Charge and

discharge the battery 3 or 4 more times on the ground before

flying. Be sure to remove the battery from the airplane

between each cycle and allow it to cool before recharging.

Use 400-grit sandpaper to remove imperfections along the

edges of the propeller.For the best performance, use a Top

Flite Precision Magnetic Prop Balancer™(TOPQ5700) to

balance the propellers (this is a necessity on glow-powered

engines, but less critical on small electric models).

Examine the Propeller

Cycle the Batteries

PERFORMANCE TIPS

Range Check

Ground Inspection

Identify Y our Model

Charge the Batteries

PREFLIGHT

22

Page 23

1. “Break-in” the motor by running it at 1/4 throttle without the

propeller for at least ten minutes.This will ensure that the motor

will provide full power f or the first flight and will extend the ov erall

life of the motor.Install the propeller onto the gear box shaft.

2.Using multiple battery packs for successive flights may cause

the motor to become excessively hot, thus causing damage.

Allow the motor to cool for at least 10 minutes between flights.

Though the Fundango is a “Park Flyer,” the best place to fly

any model is at an AMA chartered club field. Club fields are

set up for R/C flying making your outing safer and more

enjoyab le.We recommend that you join the AMA and a local

club so you can have a safe place to fly and have insurance

to cover you in case of a flying accident.The AMA address

and telephone number are in the front of this manual.

If there is no club or R/C flying field in your area, find a

suitable site that is clear of trees, telephone poles, buildings,

towers, busy streets and other obstacles. Since you are not

flying at a sanctioned AMA site, be aware that there may be

others like yourself who could be flying nearby.If both of your

models happen to be on the same frequency, interference

will likely cause one or both of the models to crash. An

acceptable minimum distance between flying models is five

miles, so keep this in mind when searching for a flying site.

In addition to obstacles, it is important to be aware of people

who may wander into the area once you begin flying.At AMA

club flying sites it is a severe rule infraction to fly over others.

You should avoid flying over people no matter where you fly.

R/C models tend to attract onlookers whose numbers can soon

multiply forming small, uncontrolled crowds. Onlookers pose

two main problems.First is the danger of actually crashing your

model into a person, causing injury .Second is the distraction of

those who ask you questions while you are trying to

concentrate on flying.To minimize or avoid this problem, have

an assistant standing by who can spot people who wander into

your flying site (so you can av oid flying ov er them) and who can

perform “crowd control”if people start to gather.

Note: Failure to follow these safety precautions may result

in severe injury to yourself and others.

Get help from an experienced pilot when learning to

operate motors.

Use safety glasses when running motors.

Do not run the motor in an area of loose gravel or sand;the

propeller may throw such material in your face or eyes.

Keep your f ace and body as well as all spectators a wa y from

the path of the propeller as you start and run the motor.

Keep items such as these away from the prop: loose

clothing, shirt sleeves, ties, scarfs, long hair or loose objects

(pencils, screw drivers) that may fall out of shirt or jacket

pockets into the prop.

The electric motor and battery used in the Fundango are very

powerful and the spinning propeller has a lot of momentum;

therefore, if you touch the propeller while it is spinning it may

inflict severe injury. Respect the motor and propeller for the

damage they are capable of and take whate ver precautions are

necessary to avoid injury. Always disconnect and remove the

motor battery until you are ready to fly again and always make

sure the switches are turned off before connecting the battery.

Be aware that the motor may suddenly start when you attach

the battery. Please keep away from the prop when attaching

the battery.

Read and abide by the following Academy of Model

Aeronautics Official Safety Code:

1. I will not fly my model aircraft in competition or in the

presence of spectators until it has been proven to be

airworthy by having been pre viously successfully flight tested.

2. I will not fly my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

airpor t operator. I will give right of way to and avoid flying in

the proximity of full scale aircraft. Where necessary an

observer shall be utilized to supervise flying to avoid having

models fly in the proximity of full scale aircraft.

3.Where established, I will abide by the safety rules for the

flying site I use and I will not willfully and deliberately fly my

models in a careless, reckless and/or dangerous manner.

7. I will not fly my model unless it is identified with my name

and address or AMA number, on or in the model.

1.I will have completed a successful radio equipment ground

check before the first flight of a new or repaired model.

2. I will not fly my model aircraft in the presence of

spectators until I become a qualified flyer, unless assisted

by an experienced helper.

3.I will perform my initial turn after takeoff away from the pit,

spectator and parking areas and I will not thereafter perform

Radio Control

General

AMA SAFETY CODE (EXCERPTS)

MOTOR SAFETY PRECAUTIONS

FIND A SAFE PLACE TO FLY

Motor Care

23

Page 24

maneuvers, flights of any sort or landing approaches over a

pit, spectator or parking area.

4. I will operate my model using only radio control frequencies

currently allowed by the F ederal Comm unications Commission.

IMPORTANT: The Fundango is a great park flyer that flies

smoothly and predictably, yet is surprisingly aerobatic. It

does not, however, possess the self-recovery characteristics

of a primary R/C trainer and should only be flown by

experienced RC pilots. If you know how to fly, but are not

experienced with aerobatic models, seek the assistance of a

competent, experienced R/C pilot who can check your model

for airworthiness and help you fly it.

The Fundango is capable of performing a broad range of

aerobatics - from simple loops and rolls to impressive rolling

circles. Have Fun!

Whether you have b uilt your Fundango with or without landing

gear, hand-launching is recommended for the first few flights

until you get the model properly trimmed and set up for flight.

Tur n on the transmitter and plug the battery into the speed

control. Turn on the receiver by following the instructions

that came with the speed control.

IMPORTANT: Confirm that the transmitter operates the

controls by moving the sticks and watching the surfaces

respond. Occasionally, electric models have been launched

with the transmitter turned off or the battery disconnected

from the speed control!

When ready to launch, an assistant should hold the model

by the sides of the battery pack just behind the landing gear

and raise the model above his head. Point the model into

the wind.With the pilot

(that would be you!)

standing behind

the plane, fully advance the throttle to start the motor. As

soon as the motor is at full power , the hand-launcher should

gently toss the plane into the air at a level or slightly noseup attitude. Be certain the model is being launched into the

wind and be immediately ready to make corrections to keep

the airplane flying straight, level and into the wind.

When the model has gained adequate flying speed under its

own power, gently pull the elevator stick back until the

airplane starts a gradual climb. Be gentle on the elevator

and don't panic. If you pull too hard and notice the model

losing speed, release the elevator stick and allow the model

to regain airspeed.

Continue a gradual climb and establish a gentle turn (away

from other people) until the model reaches an altitude of 75

to 100 feet.

Fly on low control rates until you have become accustomed

to the Fundango. If you find that the model is a bit of a

handful, throttle back to slow it down, allowing time to think

clearly and react.

Once at a comfortable altitude, the first priority is to adjust

the trims so the model flies straight and level.Continue to fly

around, executing turns and making mental notes (or having

your assistant take notes for you) of what additional

adjustments or C.G. changes may be required to fine tune

the model so it flies the way you like.

Before it's time to land, climb to a safe altitude and cut the

throttle to an idle and note how the model reacts. Do this a

few times so y ou know what to expect when it's time to land.

After you've gotten a f e w trim flights under your belt and you

are comfortable with the way the Fundango flies, you can

“cut it loose” and start flying some aerobatic maneuvers.

Remember to keep your maneuvers at a safe altitude until

you know what to expect.

The Fundango lands about the same as any other model, it

just requires much less space! When it's time to land, fly a

normal (but smaller) landing pattern and approach. Keep a

few clicks of power on until you are over the runway

threshold.This model does not stall hard on landing and will

3-point

nicely. If flying without landing gear, land with the

throttle off to avoid a prop strike.

If you have built the Fundango with landing gear you may take

off from a smooth surface—it probab ly won't takeoff from grass .

After you have trimmed the Fundango for flight and have

become familiar with its characteristics, you may execute

ROG takeoffs. Taking-off on the low rate settings is

recommended. Place the model on the r unway pointing into

the wind. Typically, with most R/C models it is best to

advance the throttle smoothly and allow the plane to build

up as much speed as possible before lifting off. However,

with the Fundango it is best to get the model into the air

quickly. To do this, advance the throttle rapidly and allow the

model to lift from the runway as soon as it reaches flying

speed—which should be about fifteen feet or less.You will

have little directional control until the model is in the air, but

if taking off into the wind the model should track fairly

straight on its own. Once in the air establish a climb the

same as when you were hand-launching.

Best of luck and happy flying!

ROG (Rise Off Ground) Takeoff

Landing

Flight

Takeoff

FLYING

Page 25

B C

Page 26

D A

2-View

Use these 2-views( or photocopy them)

to design your trim scheme.

Loading...

Loading...