Page 1

WARRANTY

Great Planes®Model Manufacturing Co. box guarantees this kit to be free from defects in both material and workmanship at the date of purchase.

This warranty does not cover any component parts damaged by use or modification.In no case shall Great Planes’liability exceed the original cost

of the purchased kit. Further, Great Planes reserves the right to change or modify this warranty without notice.

In that Great Planes has no control over the final assembly or material used for final assembly, no liability shall be assumed nor accepted for any

damage resulting from the use by the user of the final user-assembled product. By the act of using the user-assembled product, the user accepts all

resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to return this kit immediately

in new and unused condition to the place of purchase.

To make a warranty claim send the defective part or item to Hobby Services at the address below:

Hobby Services

3002 N. Apollo Dr.Suite 1

Champaign IL 61822

USA

Include a letter stating your name, return shipping address, as much contact information as possible (daytime telephone number, fax number, e-mail

address), a detailed description of the problem and a photocopy of the purchase receipt.Upon receipt of the package the problem will be evaluated as

quickly as possible.

READ THROUGH THIS MANUAL BEFORE STARTING

CONSTRUCTION. IT CONTAINS IMPORTANT

INSTRUCTIONS AND WARNINGS CONCERNING THE

ASSEMBLY AND USE OF THIS MODEL.

RV4PP03 V1.0 Entire Contents © Copyright 2004 Printed in USA

Champaign, IL

(217) 398-8970, Ext. 5

airsupport@greatplanes.com

INSTRUCTION MANUAL

Wingspan: 41-3/4 in [1060mm]

Wing Area: 368 sq in [23.7 dm

2

]

Airframe Weight: 11-1/2 oz [326 g]

Weight Ready to Fly: 18-1/2 to 22 oz [525–624g]

Wing Loading: 7.3–8.6 oz/sq ft [22.3–26.2 g/dm

2

]

Length: 38-1/4 in [972mm]

Radio: 4-channel with three micro servos

Motor: S-280 7.2 volt or 350 size, high power 7.2 volt

Page 2

INTRODUCTION.................................................................................2

SAFETY PRECAUTIONS...................................................................2

DECISIONS YOU MUST MAKE.........................................................3

Radio Equipment.........................................................................3

Speed Control .............................................................................3

Motor System..............................................................................3

Battery Recommendations..........................................................4

Performance Options ..................................................................4

Chargers......................................................................................5

Covering......................................................................................5

Building Board.............................................................................6

ADDITIONAL ITEMS REQUIRED......................................................6

Hardware & Accessories .............................................................6

Adhesives & Building Supplies....................................................6

Optional Supplies & Tools ...........................................................6

IMPORTANT BUILDING NOTES.......................................................6

DIE-CUT PATTERNS..........................................................................8

METRIC CONVERSIONS...................................................................8

BUILDING INSTRUCTIONS...............................................................9

BUILD THE T AIL SURFACES............................................................9

BUILD THE WING.............................................................................10

Build the Wing Panels...............................................................10

Join the Wing Panels.................................................................13

Build the Ailerons......................................................................14

BUILD THE FUSELA GE...................................................................16

Frame the Sides ........................................................................16

Finish the Fuselage ...................................................................18

Install the Pushrods...................................................................24

COVER THE MODEL .......................................................................26

Suggested Covering Sequence ................................................26

Add Washout.............................................................................26

FINAL ASSEMBLY...........................................................................27

Join the Tail Surfaces................................................................27

Hook Up the Controls................................................................28

Mount the Landing Gear ...........................................................28

Assemble the Gear Drive..........................................................29

MOUNT THE CANOPY, COWL & WHEEL PANTS ..........................30

PREPARE THE MODEL FOR FLYING ............................................32

Balance the Model ....................................................................32

Set the Control Throws..............................................................33

PREFLIGHT......................................................................................34

Charge the Transmitter Batteries ..............................................34

Identify Y our Model....................................................................34

Ground Inspection.....................................................................34

Range Check.............................................................................34

PERFORMANCE TIPS.....................................................................35

Cycle the Batteries....................................................................35

Examine the Propeller ...............................................................35

Motor Care ................................................................................35

Oil the Wheels ...........................................................................35

MOTOR SAFETY PRECAUTIONS ..................................................35

AMA SAFETY CODE (excerpts).....................................................35

FIND A SAFE PLACE TO FLY.........................................................36

FLYING .............................................................................................36

Takeoff.......................................................................................36

Flight..........................................................................................36

Landing......................................................................................37

ROG (Rise off Ground) Takeoff.................................................37

2-VIEW DRAWING...................................................Back Cover Page

FUSELAGE/WING PLAN...............................Center Pull-Out Section

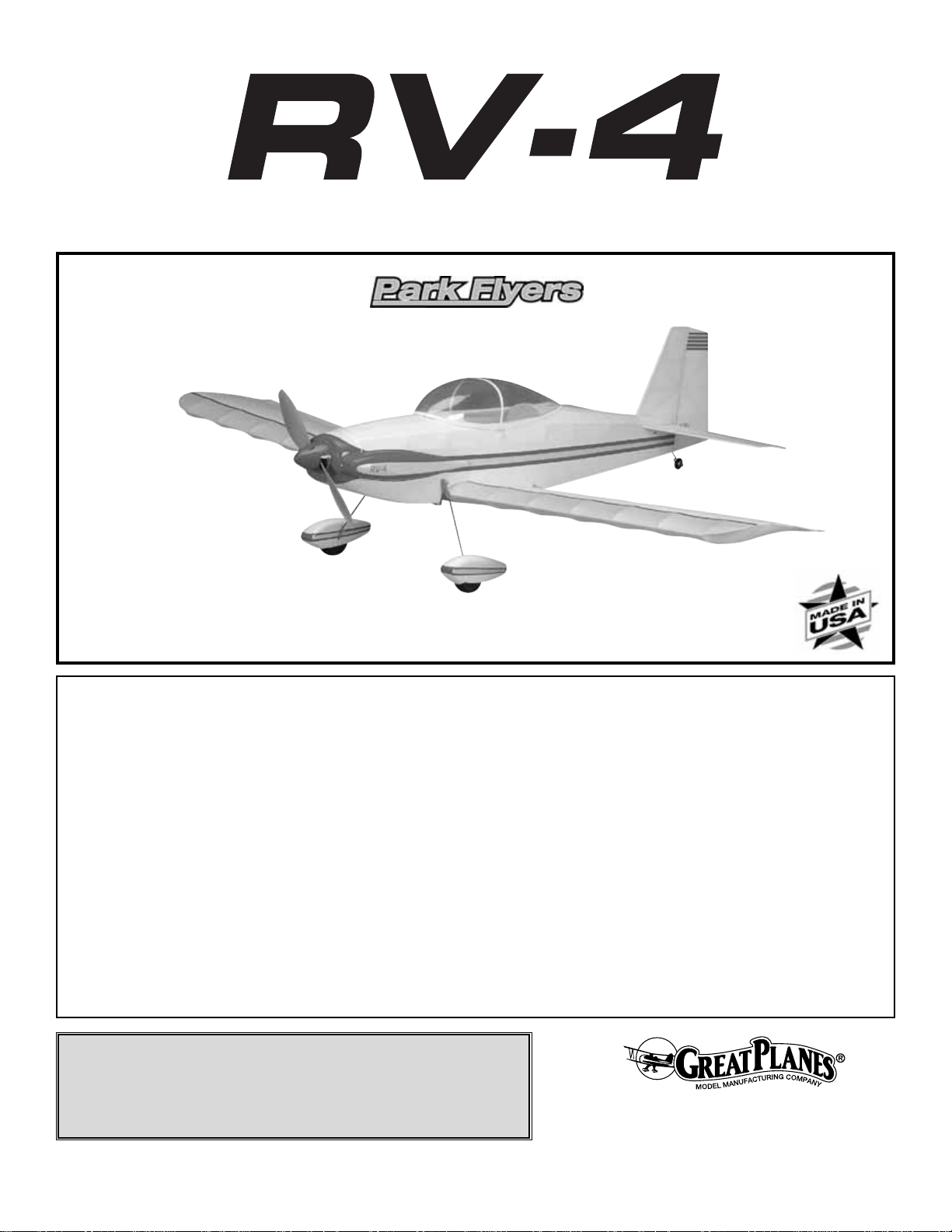

Congratulations and thank you for purchasing the Great

Planes RV-4 Park Flyer. The RV-4 Park Flyer is one in a

series of Park Flyers from Great Planes designed to be

flown in small areas. Park Flyers are a relatively new class

of small, lightweight, slow-flying, fast-b uilding models.Since

Park Flyers are small and fly slowly, little space is required.

A nearby park, schoolyard or vacant lot becomes an

impromptu flying site

(see “Find a Safe Place to Fly” on

page 36)

. Additionally, Park Flyers are perfect for those

evenings at the field when everybody else is packing up

their gear, the wind has died, and there is still enough light

to fly a small, slow model that can be kept close-in.

The RV-4 Park Flyer is a slow flying, low-wing model that is

relatively simple to build.It is a sport scale model of the full

size RV-4. However, if you have never flown an R/C model

before, learning to fly the RV-4 Park Flyer all by yourself is

not recommended. As with any airplane, you should find an

experienced modeler to help you with your first flights.

Information about R/C clubs and instructors is provided

later in this manual.

For the latest technical updates or manual corrections to the

RV-4 Park Flyer, visit the Great Planes web site at

www.greatplanes.com

. Open the “Airplanes” link, then

select the RV-4 Park Flyer kit. If there is new technical

information or changes to this model a “tech notice”box will

appear in the upper left corner of the page.

1. Even though the Great Planes RV-4 Park Flyer is small,

lightweight and flies slowly, if it is not assembled and

operated correctly it could possibly cause injury to yourself

or spectators and damage to property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as doing so

may result in an unsafe or unflyable model. In a few cases

the instructions may differ slightly from the photos.In those

instances the written instructions should be considered

as correct.

3.You must take time to build straight, true and strong.

4. You must use an R/C radio system that is in first-class

condition. This Park Flyer requires micro servos, a micro

receiver and a micro speed control able to handle 5 amps.

5.You must correctly install all R/C and other components

so that the model operates correctly on the ground and in

the air.

PRO TECT YOUR MODEL,Y OURSELF

& OTHERS...FOLLOW THESE

IMPORTANT SAFETY PRECAUTIONS

INTRODUCTIONTABLE OF CONTENTS

2

Page 3

6.You must check the operation of the model before every

flight to insure that all equipment is operating and that the

model has remained structurally sound. Be sure to check

connectors often and replace them if they show any signs

of wear or fatigue.

7. If you are not already an experienced R/C pilot, you

should fly the model only with the help of a competent,

experienced R/C pilot.

Remember:Take your time and follow directions to end

up with a well-built model that is straight and true.

Before starting to build, compare the parts in this kit with the

Parts List, and note any missing parts.Also inspect all parts

to make sure they are of acceptable quality. If any par ts are

missing, broken or defective, or if you have any questions

about building or flying this airplane, please contact Great

Planes at the address or telephone number below. If

requesting replacement parts, please provide the full kit

name, RV-4 Park Flyer, and the part numbers as listed in

the Parts List.

Great Planes Product Support:

3002 N Apollo Drive Suite 1

Champaign, IL 61822

Telephone: (217) 398-8970

Fax:(217) 398-7721

E-mail:

productsupport@greatplanes.com

If you’re an ine xperienced modeler, we recommend that

you get assistance from an experienced,

knowledgeable modeler to help you with assembly and

your first flights. If you’re not a member of a club, your

local hobby shop has information about clubs in your area

whose membership includes experienced pilots.

In addition to joining an R/C club, we strongly recommend

you join the AMA (Academy of Model Aeronautics). AMA

membership is required to fly at AMA sanctioned clubs.There

are over 2,500 AMA chartered clubs across the country.

Among other benefits, the AMA provides insurance to its

members who fly at sanctioned sites and events .Additionally ,

training programs and instructors are available at AMA club

sites to help you get started the right way. Contact the AMA

at the address or toll-free phone number below:

This is a list of items required to finish the RV-4 Park Flyer

that must be purchased separately. For some of these items

there is more than one option which will require a bit of

decision making ahead of time. Order numbers (in

parentheses) are provided for your convenience.

For specific performance package options, see

“Performance Options”

later in this discussion.

The RV-4 Park Flyer requires a four-channel radio system

with a micro receiver and three micro servos.Futaba®S3103

or S3107 (FUTM0037, FUTM0025) or Hobbico®CS-5

(HCAM0090) micro servos are suitable.

An electronic speed control with BEC (Battery Eliminator

Circuitry) is required. The BEC allows both the motor and

the radio system to be powered by the same battery (thus

eliminating an additional battery typically required to power

the radio). Depending on the motor selected, the Great

Planes ElectriFly™C-10 or C-20 High Frequency Electronic

Speed Control (GPMM2010 or GPMM2020) are recommended

for the RV-4 Park Flyer.

There are several motor/gearbo x/prop/battery combinations

that give good performance with the RV-4 Park Flyer. Many

modelers do not realize that each component in this

combination is important. You can have a good

motor/gearbox/prop combination, but without the proper

battery, performance could be disappointing.

Standard, lower power 280 size motors, such as the Great

Planes ElectriFly T-280, are not recommended for the RV-4

Park Flyer.

Motor System

Speed Control

Radio Equipment

DECISIONS YOU MUST MAKE

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

Tele: (800) 435-9262

Fax (765) 741-0057

Or via the Internet at:

http://www.modelaircraft.org

Note: We, as the kit manufacturer, provide you with a top

quality kit and great instructions, but ultimately the quality

and flyability of your finished model depends on how you

build it; therefore, we cannot in any way guarantee the

performance of your completed model, and no

representations are expressed or implied as to the

performance or safety of your completed model.

3

Page 4

The RV-4 Park Flyer also flies well with the Great Planes

ElectriFly T-400 Ferrite Motor (GPMG0325). This motor

should be used with the Great Planes ElectriFly T-400 4.1:1

Gearbox (GPMG0226).The best prop is the APC 10 x 4.7

SloFlyer (APCQ5015). You will also need a 3mm prop

adapter (GPMQ4600).This combination gives less spirited,

but adequate performance, with much cooler motor

temperatures and longer motor lifespan.

The RV-4 Park Flyer flies in a very spirited manner with the

Great Planes ElectriFly S-280 Ferrite Motor (GPMG0305),

Great Planes ElectriFly S-280 5.0:1 Gearbox (GPMG0200)

and APC 10 x 4.7 SloFlyer Prop (APCQ5015). For this

combination you will also need a 3mm prop adapter

(GPMQ4600). With this motor you can also use the Great

Planes ElectriFly S-280 4.5:1 Gearbox (GPMG0201) or the

S-280 4.1:1 Gearbox (GPMG0202). An APC 9 x 6 SloFlyer

Prop (APCQ5013) would be a better prop with these

gearboxes. The Great Planes ElectriFly 8-cell 1050 mAh

NiMH Battery (GPMP0251) is not recommended with this

motor as the added run time could cause the motor to

overheat.This is a high power motor and adequate cooling

is important. Be sure to follow the cooling instructions on

page 31, steps 11 & 12 of this manual.Allow 10 – 15 minutes

of cooling time between flights.

An even more powerful motor for the RV-4 Park Flyer is the

Great Planes ElectriFly S-370 Ferrite Motor (GPMG0310).

This motor is nearly the same physical size as a 280-size

motor and can be used with the same components

recommended above for the S-280 motor. A 20-amp ESC

should be used with this motor and adequate cooling is

critical. It is best to limit this motor to a 7-cell 650 mAh

battery. With an 8-cell 1050 mAh battery, motor

temperatures can easily reach 240 degrees, which would

greatly reduce the lifespan of the motor. Be sure to follow

the cooling instructions on page 31, steps 11 & 12 of this

manual. Allow 20 minutes of cooling time between flights.

The RV-4 Park Flyer can be powered with brushless motors

as well. While these motors and their controllers are

expensive, they give outstanding performance with longer

flight times and cooler motor temperatures than the above

ferrite motors.

There are three kinds of battery packs used for electric R/C

models: nickel-metal hydride (NiMH), nickel-cadmium

(NiCd, pronounced ny-cad) and Lithium Polymer (Li-Po).

NiMH and Li-Po batteries are recommended for the RV-4

Park Flyer because they provide from two to six times the

capacity of a NiCd battery of the same size and weight.

However, it should be noted that NiMH and Li-Po cannot be

charged as fast as NiCds. Li-Po batteries also require a

special charger.

For NiMH and NiCd batteries, each individual cell that

makes up a battery is 1.2 volts.For a Li-Po battery each cell

is 3.7 volts.Batteries are also rated by their capacity in mAh

(milli-Amp-hours), or how much energy they store. A 650

mAh battery can supply 1

Ampere

for .65 hours (about 39

minutes). At a typical average park flyer power requirement

of 5 Amps, a 650 mAh battery will last about

7-1/2 minutes.

These are the battery packs recommended for the RV-4

Park Flyer:

GPMP0071 – 7-cell, 650 mAh NiMH pack

GPMP0072 –8-cell, 650 mAh NiMH pack

GPMP0250 –7-cell, 1050 mAh NiMH pack

GPMP0251 – 8-cell, 1050 mAh NiMH pack (for 400

size motor only)

KKMP9100 – Kokam 2-cell, 340 mAh Li-Po pack

KKMP7100 – Kokam 2-cell, 1500 mAh Li-Po pack

KKMP8100 – Kokam 3-cell, 1500 mAh Li-Po pack (for

400 size motor only)

Caution: Use extreme caution when using Li-Po batteries

with the S-280 and S-370 motors. Due to the very long r un

times these batteries can provide, overheating of these

motors will occur, resulting in VERY short motor life-spans.

The following performance packages are recommended for

the RV-4 Park Flyer.You may wish to experiment with other

combinations to obtain the performance level you find

most enjoyable.

Performance Options

At the time this manual was prepared, Lithium Polymer

batteries were becoming popular but were not widely

used. This model is ideally suited for these Li-Po

batteries. In particular, a two or three cell (7.4 or 11.1

volt), 1200 mAh or 1500 mAh pack would be ideal for this

model – providing much longer flight times and

considerably lighter weight of the ready to fly model.The

three cell pack will require careful power management as

it could easily damage the S-280 or S-370 motors due to

the higher than recommended voltage and capacity of

the battery. Full power should be used only for a very

limited time, with the majority of the flight at a reduced

power setting. In addition, the longer run times could

cause severe overheating of these motors. Therefore,

only a two cell Li-Po battery is recommended for use with

these motors.

Lithium Polymer batteries require a special charger. DO

NOT use a charger designed for other types of batteries.

Battery Recommendations

4

Page 5

Option 1, Good Performance

• T-400 Ferrite Motor (GPMG0325)

• T-400 4.1:1 Gearbox (GPMG0226)

• 10 x 4.7 SloFlyer Prop (APCQ5015)

• C-10 ESC (GPMM2010)

• 8-cell, 1050 mAh Battery (GPMP0251)

• 3mm Prop Adapter (GPMQ4600)

Option 2, Spirited Performance

• S-280 Ferrite Motor (GPMG0305)

• S-280 5.0:1 Gearbox (GPMG0200)

• 10 x 4.7 SloFlyer Prop (APCQ5015)

• C-10 ESC (GPMM2010)

• 8-cell, 650 mAh Battery (GPMP0072)

• 3mm Prop Adapter (GPMQ4600)

Option 3, Ballistic Performance

• S-370 Ferrite Motor (GPMG0310)

• S-280 5.0:1 Gearbox (GPMG0200)

• 9 x 6 SloFlyer Prop (APCQ5013)

• C-20 ESC (GPMM2020)

• 7-cell, 650 mAh Battery (GPMP0071)

• 3mm Prop Adapter (GPMQ4600)

If you are using Li-Po batteries it is critical that you use a

battery charger designed specifically for this type of battery .

Other types of chargers will not work properly and could

cause the battery to be overcharged, causing it to swell,

overheat and rupture – possibly causing a fire if the battery

is being charged near combustible material. If the batter y

becomes even warm, disconnect it immediately. NEVER

charge a Li-Po pack unattended. The Great Planes Tr iton

™

charger (GPMM3150) is a suitable charger for Li-Po

batteries.

Warning: Even with the proper charger, the

risk of a fire is much higher with Li-Po batteries, so

always charge these batteries away from combustible

materials and carefully monitor the charge process.

Proper charging of Lithium batteries is very important.

Consult your charger for charge procedures and for

precautions to observe.At a minimum these should include:

1. If the battery becomes damaged, as in a model crash,

immediately remove the battery and place it in a remote

area away from combustible materials. Monitor the

battery for at least 20 minutes. If the battery remains

cool, it is safe to transport. If the battery is physically

damaged, it should be disposed of.

2. If a soft sided battery, such as a Li-Po, is dented even

slightly it should be treated as a damaged battery and

immediately isolated as above.

3. Wear safety glasses when handling damaged batteries.

4. When charging lithium batteries, use a Protective

Charge Module that monitors individual cell voltage.

5. Whenever y ou charge a Lithium battery, ensure that the

charger is set to the correct number of cells. Double

check the setting, then triple check it!

6. Do not charge a Lithium battery while it is installed

inside a model.

7. Charge batteries in a well ventilated area.

8. Charge batteries away from combustible materials.

9. Charge batteries in an area with smok e and fire detectors.

10. Do not charge a Lithium battery at a rate higher than 1C.

11. Use a charger specifically designed for the type of

battery being charged.

12. Do not charge any battery inside a vehicle.

13. Do not wear jewelry or watches when working

with batteries.

14. Do not put batteries in your pocket.

15. Never charge batteries unattended.

The best type of charger for NiMH and NiCd batteries is a

peak charger, because it charges the batteries until they are

fully charged, then automatically switches to a trickle

charge mode. The Great Planes ElectriFly Peak Charger

(GPMM3000) is suitable for NiMH and NiCd batteries as

well as transmitter battery packs. The Great Planes Triton

charger (GPMM3150) is also suitable.

The following applies to NiMH and NiCd batteries only:

If you have another type of charger that is not a peak

charger, y ou will have to calculate the length of time it takes

to charge the batteries yourself, then turn the charger off

when the batteries are fully charged. Overcharging the

batteries may damage them. Before you can calculate the

time it takes to charge a battery pack, you first hav e to know

the charge rate you are going to use.Nickel-metal hydrides

should be charged at a rate of no more than 1/10 of their

capacity. For the 650 mAh batteries recommended for the

RV-4 Park Flyer, this would be a charge rate of

approximately 65 mAh. Divide the capacity of the battery

pack by the charge rate to calculate the charge time. A

discharged 650 mAh battery pack charged at 65 mAh will

take 10 hours to charge.

Charge rate/time recommendations for a fully

discharged pack:

• Charge a 650 mAh battery pack at 65 mAh for 10 hours.

• Charge a 1050 mAh battery pack at 100 mAh for 11 hours.

IMPORTANT: Monitor the temperature of the battery

frequently. If the batter y becomes warm, disconnect it from

the charger.

Note: The period required to charge the batteries in the

examples above is for discharged batteries. If the battery

you are going to charge is not discharged (and you are not

using a peak charger), connect it to the motor on your

model. Run the motor until the propeller is turning slowly,

thus discharging the battery.

There are several types of co v ering that may be used on the

RV-4 Park Flyer, and a few that are not recommended.Use

a covering suitable for lightweight models. Top Flite

®

Covering

Chargers

5

Page 6

EconoKote®and Coverite®CoverLite™are suitable for the

RV-4 Park Flyer.

EconoKote is similar to MonoKote®(used on most regularsize sport models), except EconoKote is lighter and does

not shrink as tightly, thus making it suitable for lightweight

structures such as that of the RV-4 Park Flyer. EconoKote

also has an adhesive on the back which is activated by the

heat of a model airplane covering iron.

Coverite CoverLite is another covering suitable for lightweight

structures (and is the covering that is on the model featured

on the box label). CoverLite has fibers embedded in the film

and is exceptionally strong, yet remains lightweight.It has no

adhesive on the back, therefore, you must apply an adhesive

to the structure before application. Use Coverite Balsarite

™

Fabric formula (COVR2500) for CoverLite. Do not use

Balsarite “film formula. ”

Transparent MonoKote film is also suitable for covering the

RV-4 Park Flyer, because it is lighter and does not shrink as

tightly as opaque MonoKote film.

Opaque MonoKote film is not recommended for the RV-4

Park Flyer because it is too heavy and shrinks too tightly f or

the structure to withstand.

Other lightweight covering materials for park flyer models

are being developed. Check with your hobby dealer for the

latest products.

You will need a flat board to lay over your workbench that you

can stick pins into.The back of a 2' x 4' ceiling tile or a section

cut from a sheet of Celotex®insulation board is ideal.

In addition to the items listed in the

“Decisions Y ou Must

Make”

section, following is the list of hardware and

accessories required to finish your RV-4 Park Flyer. Order

numbers are provided in parentheses.

❏ (1) 1-3/4" Spinner, Red (GPMQ4507)

❏ Cellophane tape (for hinges)

❏ Double-sided foam tape (for mounting servos)

(GPMQ4440)

The following is a “short list” of the most impor tant building

supplies required to build the RV-4 Park Flyer.

We

recommend Great Planes Pro™CA and Epoxy glue.

❏ 1 oz.Thin Pro CA (GPMR6002)

❏ 1 oz.Medium Pro CA+ (GPMR6008)

❏ CA glue tips (GPMR6033)

❏ Hobby knife (HCAR0105)

❏ #11 Blades (HCAR0211)

❏ Single-edge razor blades (HCAR0212)

❏ Small T-pins (HCAR5100)

❏ Builder’s triangle (HCAR0480)

❏ Electric drill and #68 (1/32"), 1/16" [1.6mm], 1/8"

[3.2mm] and 3/16" [4.8mm] drill bits

❏ Small Phillips and flat blade screwdrivers

❏ Pliers with wire cutter (HCAR0630)

❏ Great Planes Plan Protector

™

(GPMR6167) or wax paper

❏ HobbyLite

™

balsa-colored balsa filler (HCAR3401)

❏ Sanding tools and sandpaper assortment

❏ Sealing iron (TOPR2100)

❏ Razor saw

Here is a list of optional tools that will help you build the

RV-4 Park Flyer.

❏ Great Planes CG Machine

™

(GPMR2400)

❏ Top Flite Precision Magnetic Prop Balancer

™

(TOPQ5700)

❏ Top Flite Hot Sock

™

iron cover (TOPR2175)

❏ Straightedge with scale (HCAR0475)

❏ Cutting mat (HCAR0456)

❏ Masking tape (TOPR8018)

❏ CA Debonder (GPMR6039)

❏ Great Planes 5-1/2" [140mm] Bar Sander

™

(GPMR6169)

and 150-grit adhesive back sandpaper (GPMR6183)

❏ Top Flite 320-grit sandpaper (TOPR8030) and 400-grit

sandpaper (TOPR8032)

For the best performance, the RV-4 Park Flyer must be built

light.The model is designed for a light yet strong structure.

Because the finished model is so light, it does not require

the stronger structures you may be used to in other models.

It is not recommended that you strengthen the model as

doing so will add excess weight.

IMPORTANT BUILDING NOTES

Optional Supplies & Tools

Adhesives & Building Supplies

Hardware & Accessories

ADDITIONAL ITEMS REQUIRED

Building Board

6

Page 7

One of the best ways to insure light weight is to build neatly

and make good-fitting glue joints that require less glue.

Here are some tips to help you build neatly and light.

1. The easiest way to cut balsa sticks is with a single-edge

razor blade.To do so, position the stick over the plan, then

place the razor blade on the stick where you wish to cut it.

Press down lightly on the razor blade to mak e a mark where

the stick is to be cut.

2.Take the stick off the plan and cut it over a cutting mat or

a scrap piece of wood

(Okay, if you’re careful you could go

ahead and cut the stick right over the plan, but if y ou do , y ou

may cut through the plan protector, allowing the CA to soak

through and glue the structure to the plan)

.

3. Because of the small balsa sticks used in the tail, small

T-pins may be used to hold the sticks to your building board,

but only where necessary. Use small T-pins (HCAR5100)

or small straight pins found in craft stores.Do not stick pins

into the sticks near the ends, or the wood may split.

4. If you have difficulty with the T-pins splitting the small

sticks, an alternate method is to use the “crossed-pin”

technique. Insert the T-pins into the building board in a

crisscross fashion to hold the sticks to the plan.

5. Only a small amount of CA should be used to glue the

parts together. Use the included CA applicator tips to

control and pinpoint the amount of CA that comes from the

bottle. When the tip becomes clogged, cut the tip off and

continue. In addition to adding unnecessary weight, excess

CA is difficult to sand.If you require additional CA tips, order

number GPMR6033 (5).

6.When applying CA, be careful not to glue your fingers to the

structure. In the process of

un-sticking

your fingers you can

inadvertently damage the structure, thus requiring repairs and

adding weight

(not to mention the aggravation!)

.

7.Sanding requires a light touch to avoid damage.We found

the best method for sanding is to use light strokes in the

direction of the longest sticks. Be certain the sandpaper is

thoroughly bonded to the bar sander.Lifted edges will catch

the structure, causing damage.Use medium-grit sandpaper

such as 120 or 150-grit.

8. One of the best ways to insure a lightweight model is to

proceed slowly and build neatly. Good glue joints with minimal

adhesive are stronger, lighter and have a better appearance

than poor-fitting joints with too much CA.Of course, you should

take this approach with all of your projects!

9.Work over a flat surface .Cover the plan with Great Planes

Plan Protector™(GPMR6167) or wax paper so the parts will

not adhere to the plan.

7

Page 8

8

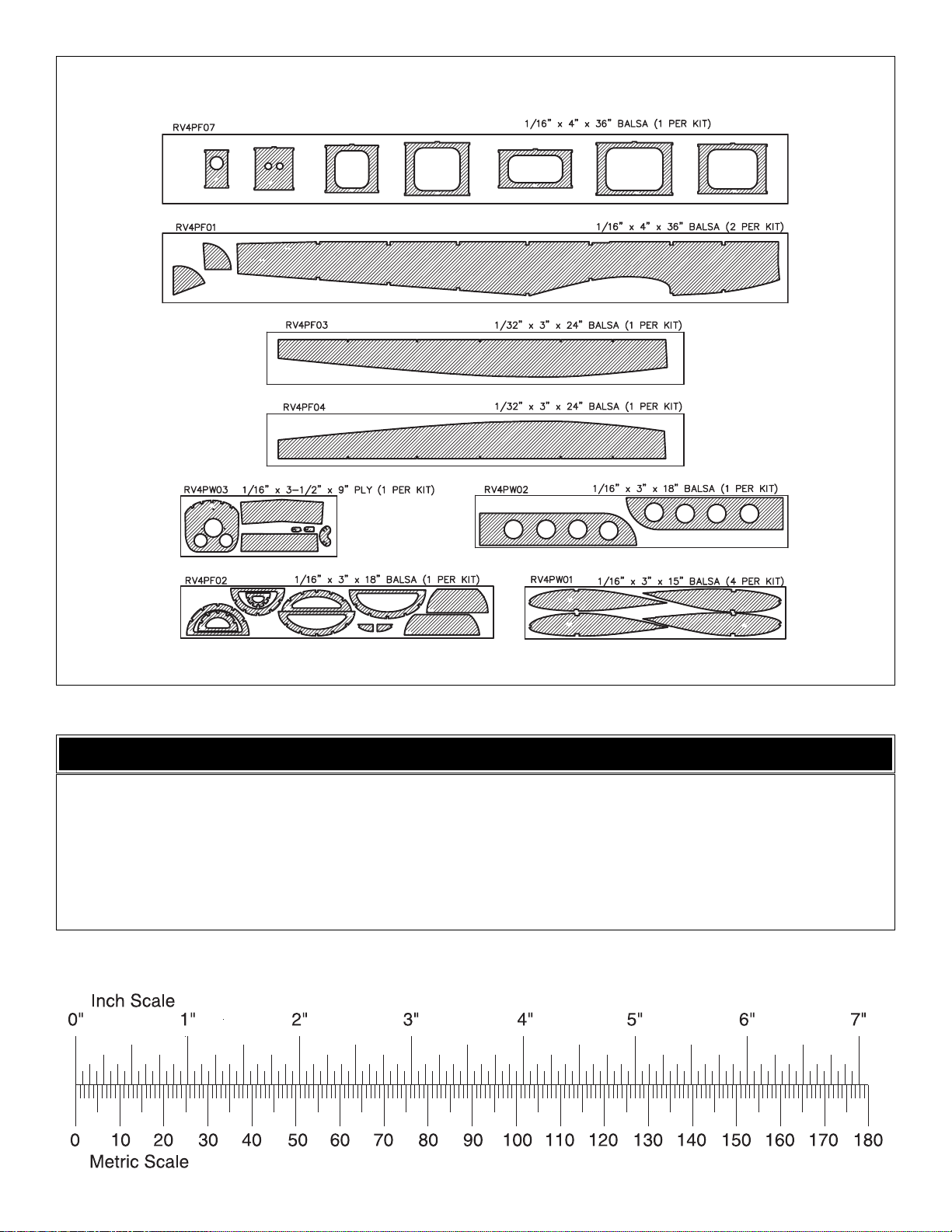

DIE-CUT PATTERNS

1/64" = .4 mm

1/32" = .8 mm

1/16" = 1.6 mm

3/32" = 2.4 mm

1/8" = 3.2 mm

5/32" = 4.0 mm

3/16" = 4.8 mm

1/4" = 6.4 mm

3/8" = 9.5 mm

1/2" = 12.7 mm

5/8" = 15.9 mm

3/4" = 19.0 mm

1" = 25.4 mm

2" = 50.8 mm

3" = 76.2 mm

6" = 152.4 mm

12" = 304.8 mm

18" = 457.2 mm

21" = 533.4 mm

24" = 609.6 mm

30" = 762.0 mm

36" = 914.4 mm

METRIC CONVERSIONS

Page 9

❏ 1. Unroll the plan sheets. Re-roll them inside-out so they

will lie flat. Place the fin/rudder portion of the fuse plan over

your flat building board, then cov er it with Great Planes Plan

Protector or wax paper so glue will not adhere to the plan.

Note: The bottom of the fin is difficult to see on the fuselage

plan. A separate drawing of the fin is located on the wing

plan and may be more useful for building the fin.

❏ 2.Find the four hardest 1/8" x 1/4" x 24" [3.2 x 6.4 x 610mm]

balsa sticks and set them aside for use as the wing spars.

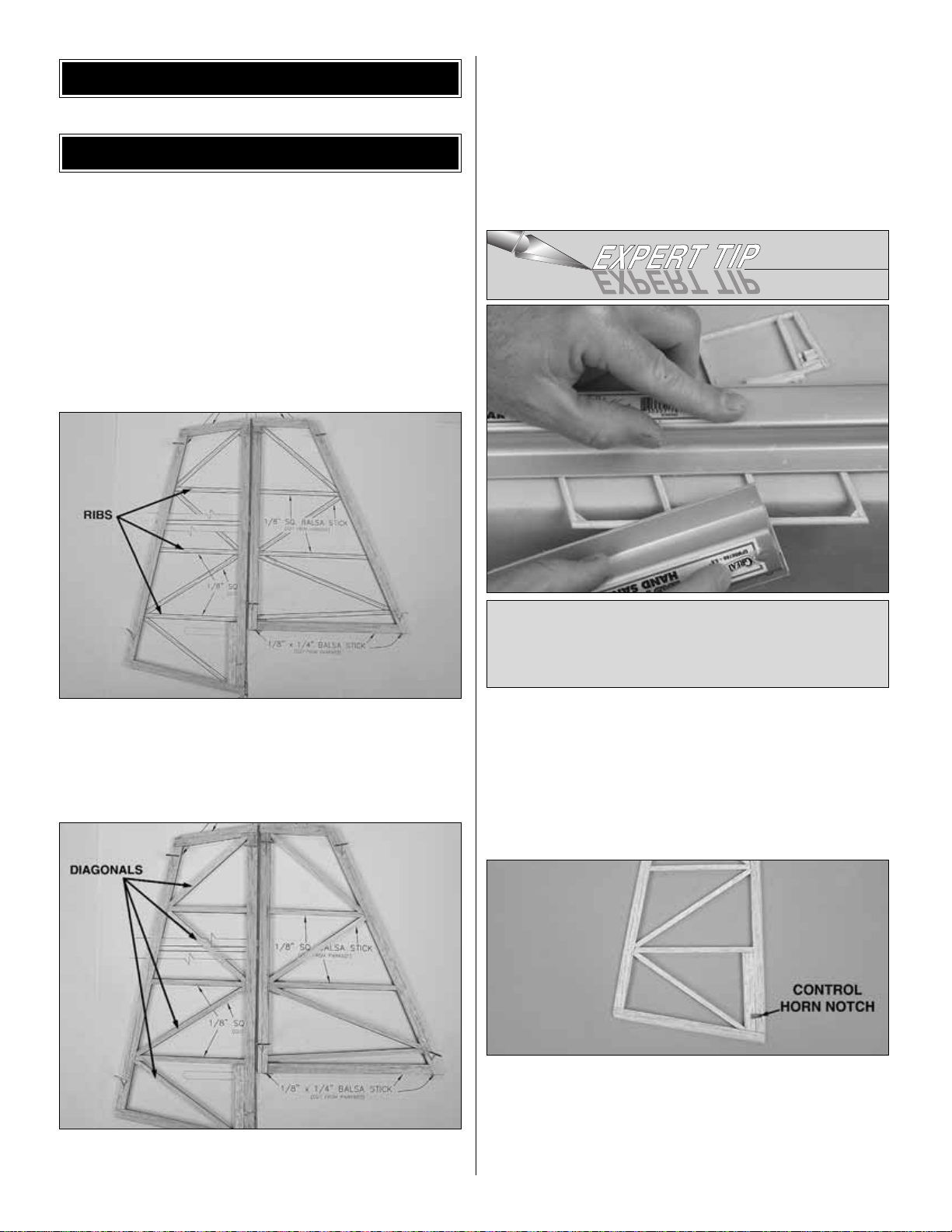

❏ 3. Build the fin and rudder framework from two 1/8" x

1/4" x 24" [3.2 x 6.4 x 610mm] balsa sticks.Hint: Start with

the longest pieces first. If you accidentally cut one piece too

short, use it for a shorter piece somewhere else, thus

minimizing wasted material.

❏ 4. Add the fin and rudder ribs and diagonal braces

from two 1/8" x 1/8" x 24" [3.2 x 3.2 x 610mm] balsa sticks.

❏ 5. Remove the fin and rudder from the plan. Use a bar

sander with 150-grit sandpaper to carefully sand both sides

of the fin and rudder flat and even. Round the corners as

shown on the plan.Refer to the Expert Tip that follows, then

round the leading edge, top of the fin, trailing edge and top

of the rudder.

❏ 6. Sand a bevel on the leading edge of the rudder as

shown in the cross-section on the plan.

❏ 7. Use a #11 blade to cut the notch in the rudder where

shown on the plan for the laser-cut 1/16" [1.6mm] plywood

control horn. The control horn will be installed into the

notch on the right side of the r udder, but do not glue it into

place until the pushrods are installed during

“Hook Up the

Controls.”

The rudder control horn has an “R” printed on it.

To round the edges of the tail pieces, place one of them

on your workbench so the edge you are rounding extends

just beyond the edge of the bench. Use a bar sander to

hold it down. Use another bar sander to do the sanding.

BUILD THE T AIL SURF A CES

BUILDING INSTRUCTIONS

9

Page 10

❏ 8.Build the stab and elevators from five 1/8" x 1/4" x 24"

[3.2 x 6.4 x 610mm] and two 1/8" x 1/8" x 24" [3.2 x 3.2 x

610mm] balsa sticks. Be sure to notch the leading edge of

both elevators where the bass w ood joiner stic k goes.Do not

join the elevators with the 1/8" x 1/8" x 3" [3.2 x 3.2 x 76mm]

basswood stick until instructed to do so.

❏ 9. The same as you did the fin and rudder, remove the

stab and elevators from the plans, sand the stab and

elevators flat and even, then round the corners where

shown on the plan.Round the tips of the stab and elevators .

Round the leading edge of the stab and the trailing edge of

the elevators. Bevel the leading edge of both elevators as

shown in the cross-section on the plan.

❏ 10. Use a #11 blade to cut the notch in the left elevator

where shown on the plan for the laser-cut 1/16" [1.6mm]

plywood control horn.The control horn will be installed into

the notch on the bottom of the left elevator, but do not glue

it into place until the pushrods are installed during

“Hook

Up the Controls.”

❏ 11.Use a bar sander with 150-grit sandpaper to bevel the

1/8" x 1/8" x 3" [3.2 x 3.2 x 76mm] basswood elevator

joiner to match the leading edge of the elevators.

❏ 12. Pin both elevators to the plan upside-down. Check the

fit of the elevator joiner and trim if necessary. Use medium CA

to securely glue the elevator joiner to the left elevator only

.

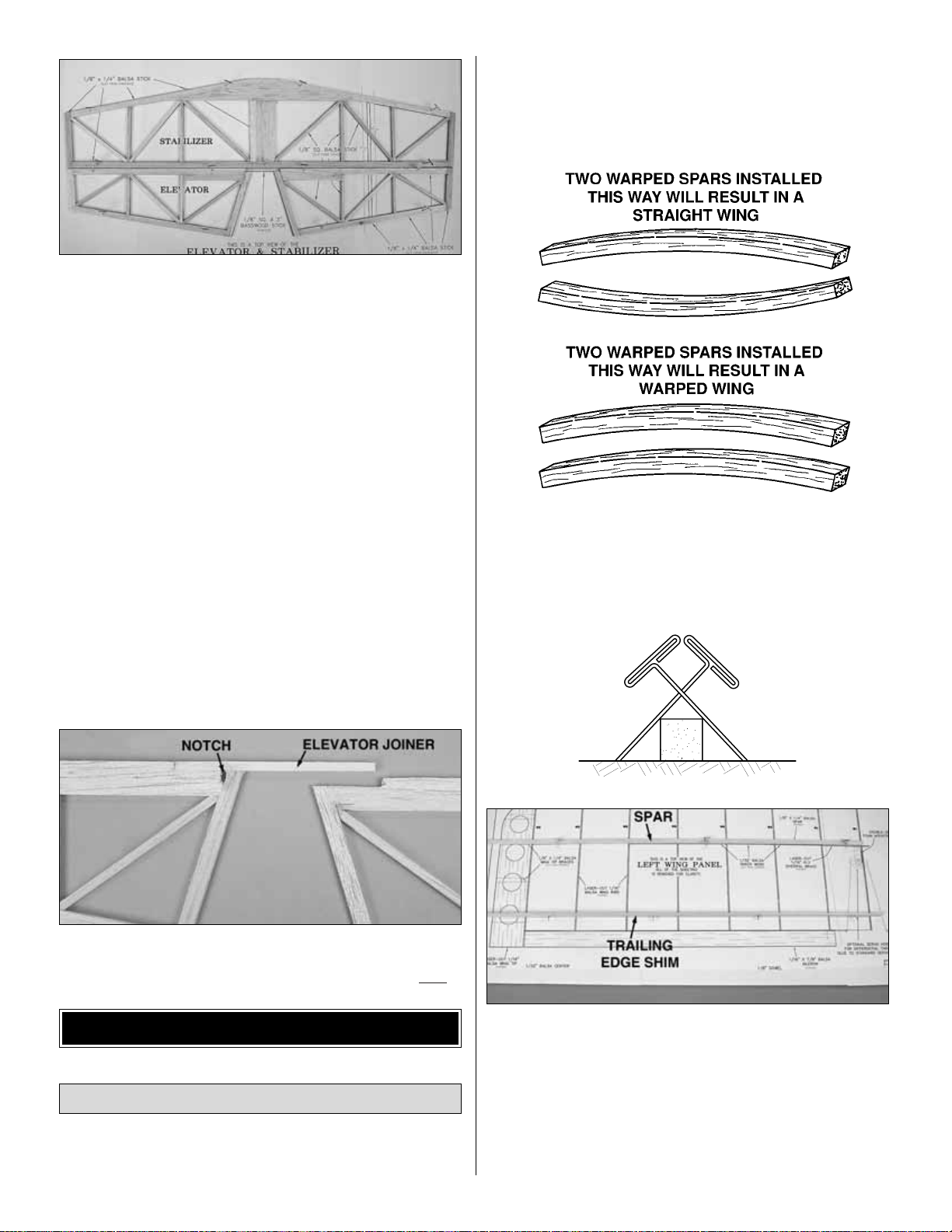

Start by building the left wing panel first so your progress

matches the photos.

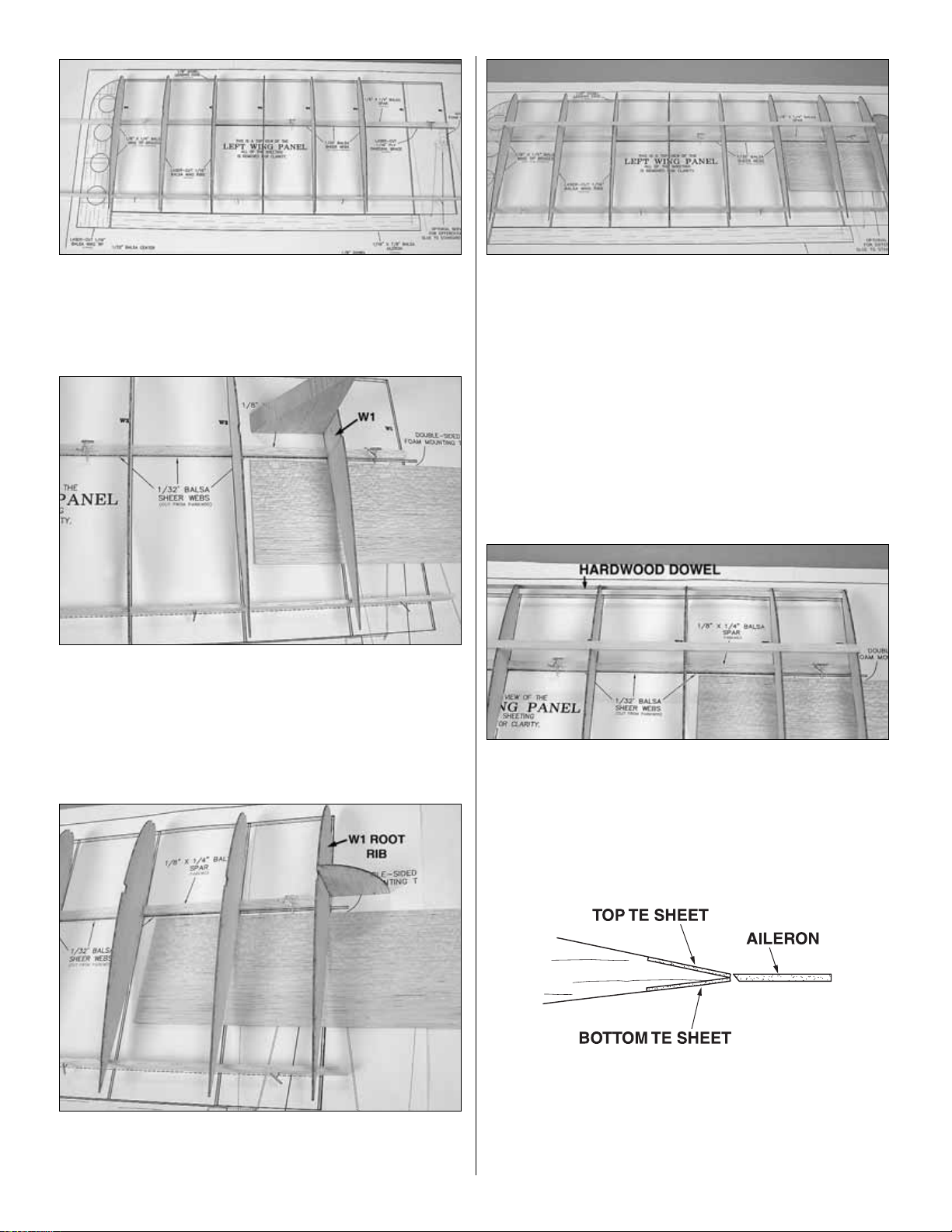

❏ ❏ 1. Cover the left wing panel plan with Great Planes

Plan Protector or wax paper.

❏ ❏ 2. Find the four hardest 1/8" x 1/4" x 24" [3.2 x 6.4 x

610mm] balsa sticks you set aside earlier. Match the balsa

main spars so any warps will counteract each other.

❏ ❏ 3. Pin one of the main spars in position over the plan,

aligning one end of the main spar with the outside edge of

the root rib W-1.

❏ ❏ 4. Pin the 1/8" x 3/8" x 24" [3.2 x 9.6 x 610mm] balsa

trailing edge shim in position over the plan, aligning the aft

edge of the stick on the dashed line. The shim should be

standing up with the 1/8" [3.2mm] edge on the table.

Build the Wing Panels

BUILD THE WING

10

Page 11

❏ ❏ 5. Starting at the wing tip, glue six laser-cut 1/16"

[1.6mm] balsa W2 ribs over the main spar, perpendicular to

the building board.Important: Pin the rear of the ribs firmly

to the TE shim.

❏ ❏ 6. Temporarily place a sheet of 1/32" [0.8mm] balsa

sheeting on the plan 1/4" [6.4mm] aft of the spar as shown

in the above photo. This will space the W1 ribs properly on

the spar. Glue a laser-cut 1/16" [1.6mm] balsa W1 rib in

place over the main spar as shown in the photo.

❏ ❏ 7. Position a W1 root rib in place over the main spar.

Use the die-cut 1/16" [1.6mm] dihedral gauge to set the rib

at the proper angle before gluing it to the main spar.

❏ ❏ 8.Position the top 1/8" x 1/4" x 24" [3.2 x 6.4 x 610mm]

balsa main spar in the rib notches with one end flush with

the outside edge of the W1 root rib. Glue the spar to all of

the ribs except the W1 root rib .Make sure all ribs, except the

root rib, are perpendicular to the table as you glue each rib

to the top spar.

❏ ❏ 9.Using the dihedral gauge, check that the root rib is still

at the correct angle. Glue the root rib to the top main spar.

Note: Save the dihedral gauge to set the angle of F5A.

❏ ❏ 10. Cut one of the 1/8" x 24" [3.2 x 610mm] hardwood

dowels to length so that it fits in the notches at the front of

the wing ribs, from the root to the tip rib. Glue the dowel to

the ribs.

❏ ❏ 11.Locate a 1/32" x 3/4" x 24" [.8 x 19 x 610mm] balsa

sheet.The sheet should fit in the notches at the trailing edge

of the wing ribs.When the wing is complete, it will blend with

the bottom trailing edge sheet when it is installed later.The

above sketch shows how the completed assembly will look.

11

Page 12

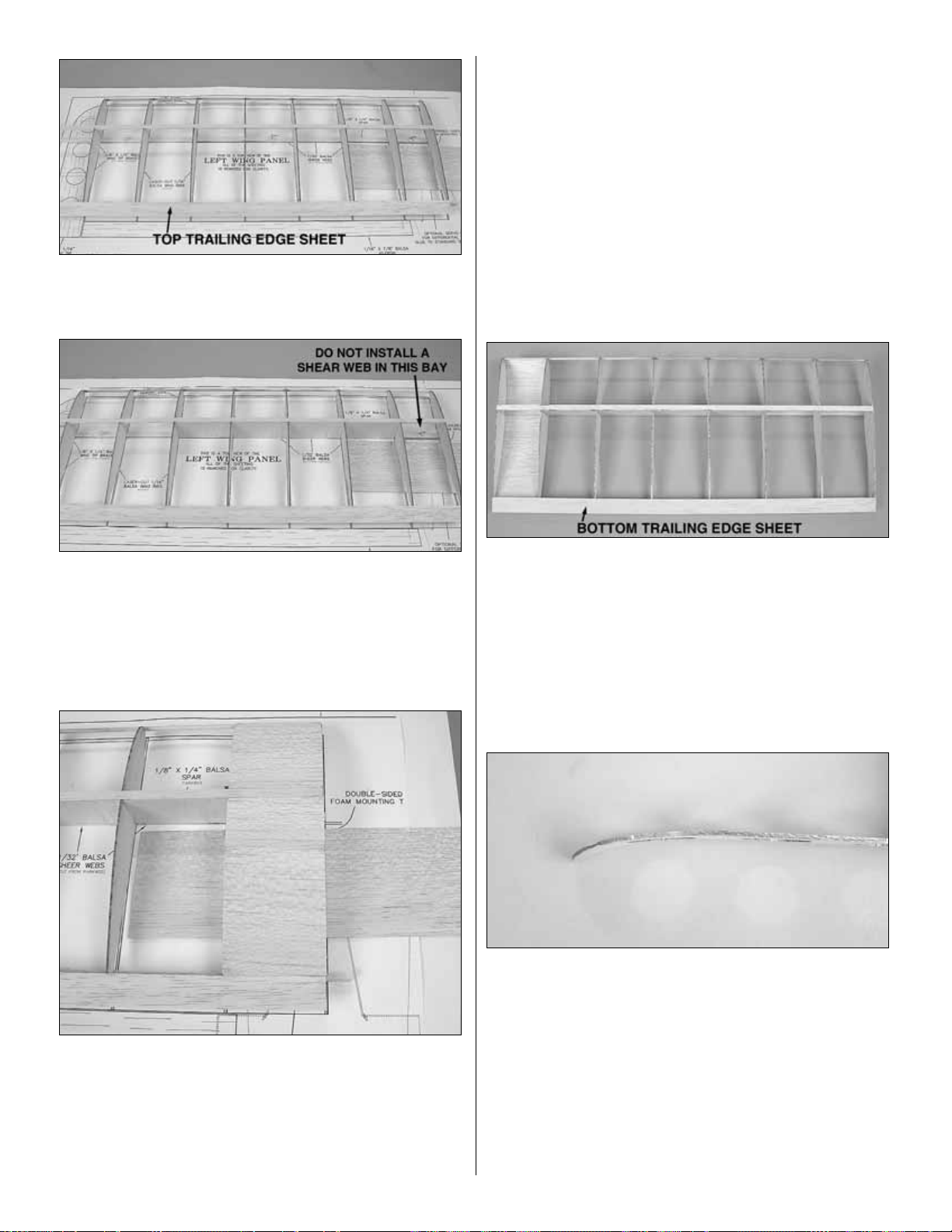

❏ ❏ 12. Glue the top trailing edge sheet to the top of the

wing ribs.

❏ ❏ 13. From a 1/32" x 3" x 15" [0.8 x 76 x 380mm] balsa

sheet, cut and glue shear webs, with the grain running

vertically , to the top and bottom spars in the locations shown

on the plan. It is not necessary for the shear webs to be

glued to the ribs at this time, but make sure they are glued

securely to the wing spars. Do not install shear webs in

the rib bay between the W1 ribs.

❏ ❏ 14. From a 1/32" x 3" x 15" [0.8 x 76 x 380mm] balsa

sheet, cut pieces to make the top center sheeting to fit

between the wing spar and trailing edge sheet and between

the wing spar and the leading edge dowel.Remove any pins

that may be under the area to be sheeted. When satisfied

with the fit, apply medium CA to the top of the W1 ribs and

press the sheeting in place.

❏ ❏ 15. Carefully sand the top center sheeting flush with

the wing spar, leading edge dowel and trailing edge sheet.

❏ ❏ 16. Remove the wing from your building board and

carefully sand off any glue blobs. Cut and sand the wing

spars, leading edge and trailing edge sheeting flush with the

wing tip rib and root rib.

❏ ❏ 17. Reinforce any glue joints that look weak. Glue the

shear webs to each rib. Remember, use glue sparingly to

minimize weight gain.

❏ ❏ 18. Glue a 1/32" x 3/4" x 24" [.8 x 19 x 610mm] balsa

bottom trailing edge sheet to the bottom of the wing ribs

and to the top trailing edge sheet.Trim the sheet even with

the tip and root ribs.

Before proceeding, read steps 19 through 25 to become

familiar with how the wing tip will be installed.

❏ ❏ 19.Prepare the laser-cut 1/16" [1.6mm] balsa wing tip

by carefully bending the forward part of the tip along the

embossed lines.You must do this gently to avoid breaking

part of the tip off. Do not bend along the two short lines that

are used to align the tip with the top wing spar.

Caution: On the left wing tip the embossed lines should be

on top of the wing tip. On the right wing tip the embossed

lines should be on the bottom of the wing tip. Hold the tip

against the wing to determine which way to bend for the

wing tip you are doing!

12

Page 13

❏ ❏ 20.Align the two short embossed lines on the wing tip

with the top main spar. Spot glue the wing tip to the end of

the wing spar with a small drop of thin CA.

❏ ❏ 21. From a leftover 1/8" x 1/4" [3.2 x 6.4mm] balsa

stick, cut a wing tip brace 2-1/4" [57mm] long. Bevel the

ends of the brace to fit the wing tip as shown in the photo

above. A straightedge can be used along the top spar to

hold the wing tip even and level with the top of the wing.

When satisfied with the fit, glue the brace in place. Hint:

First spot glue the brace to the W2 rib, then glue the end of

the brace to the wing tip while using the straightedge to hold

the wing tip level.

❏ ❏ 22. Glue the rear of the wing tip to the top edge of rib

W2. Make two more wing tip braces and glue them in place

where shown on the plan.

❏ ❏ 23. Glue the front of the wing tip to the top edge of rib

W2. Make one more wing tip brace and glue it in place

where shown on the plan.

❏ ❏ 24.Use a sanding block and 150-grit sandpaper to blend

the wing tip, wing tip braces and the W2 rib together smoothly.

❏ 25. Return to step 1 and build the right wing panel.

Remember! Build it over the right wing plan.

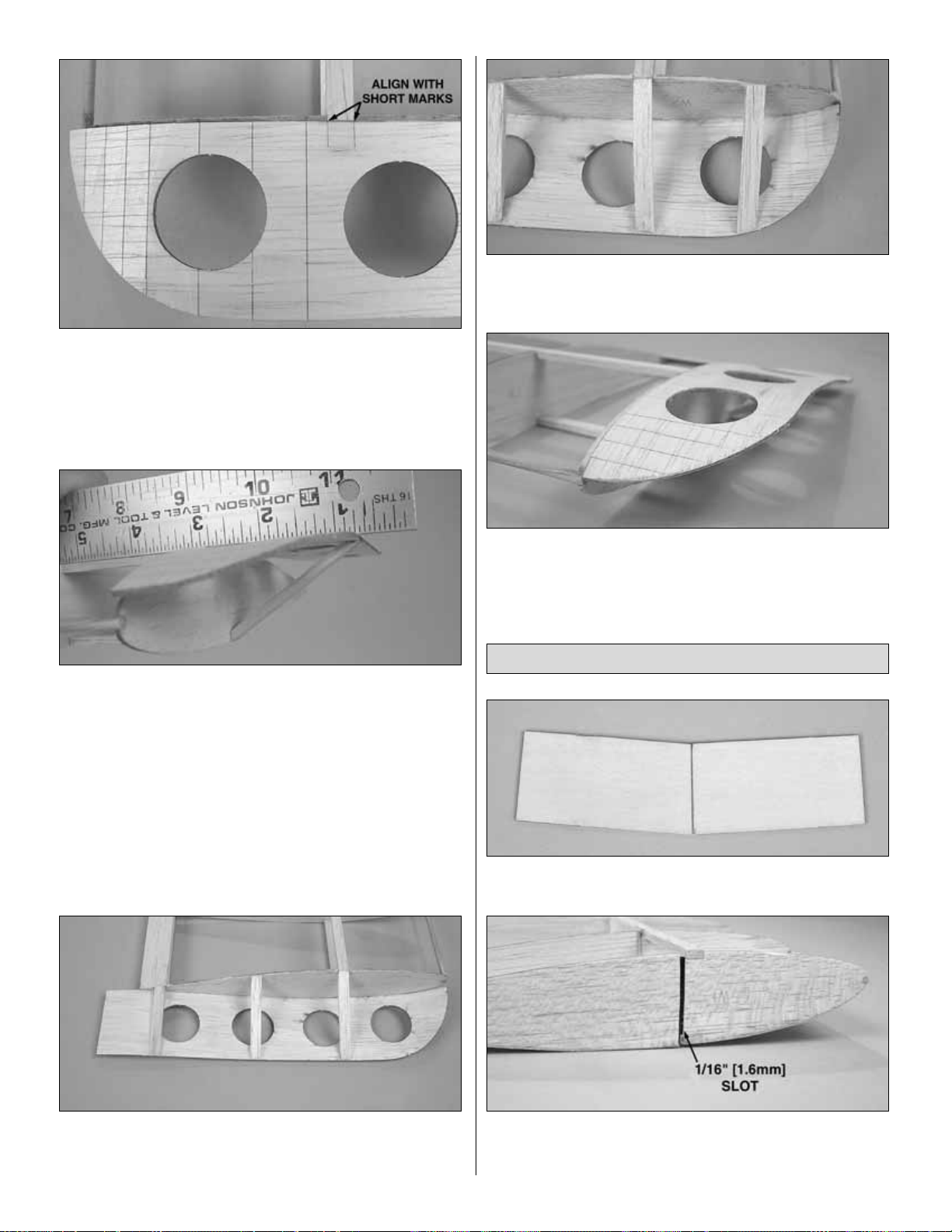

❏ 1. Draw a centerline on the laser-cut 1/16" [1.6mm] ply

dihedral brace.

❏ 2. Using a razor saw and hobby knife, carefully cut a

1/16" [1.6mm] slot in root rib W1, just behind the main spar,

on both wing panels.Test fit the dihedral brace in each slot.

Join the Wing Panels

13

Page 14

❏ 3.Test fit the wing halves together.With one wing half flat

on your building board, block-up the wing tip of the other

wing half so that it is 2-5/8" [67mm] off of your building

board. Use a bar sander to sand the center joint as

necessary until the wing halves fit together without any gap.

Note: Do not be concerned if your wing does not have

exactly 2-5/8" [67mm] dihedral. No adjustment is needed if

it is within 1/4" [6.4mm].

❏ 4. When satisfied with the fit, glue the ply dihedral brace

into the left wing panel with medium CA. Be sure the

dihedral brace is securely glued to the two main spars.After

the CA has hardened, tack-glue the right wing panel to the

ply dihedral brace with a small drop of thin CA. Do not glue

the root ribs together yet. With one wing panel flat on your

building board and the wing tip of the other wing half

blocked up as before, check that you have the same

measurement as in the above step. When satisfied with the

fit, wick more thin CA along the dihedral brace, securely

gluing it to both main spars in the right wing panel.

❏ 5. Align the trailing edges and glue them together with thin

CA. Glue the root ribs together from the spar to the trailing

edge by wicking thin CA between them. Glue the leading

edges and the rest of the root ribs together with thin CA.

❏ 6.Sand the leading and trailing edges of the wing joint flush.

❏ 7. Sheet the bottom of the center-section with a 1/32" x

3" x 15" [0.8 x 76 x 380mm] balsa sheet. If you are careful,

this can be done as a continuous strip across the full width

of the center-section, as shown in the above photo.

❏ 8. Fill any dings and uneven areas on the wing with light

weight balsa filler. Sand the wing smooth in preparation

for covering.

❏ ❏ 1. Using the drawings on the wing plan, follow the

procedure below to make a right aileron torque rod from

one of the .030" x 20" [.76 x 508mm] wires.

❏ ❏ A. Cut 1" [25mm] from one end of the .030" x 20" [.76

x 508mm] wire and clamp it in a vise.Make a loop near one

end of the remaining wire by pulling it around the wire

clamped in the vise.

❏ ❏ B .Cut the excess wire from the loop, then use the dra wing

on the plan to make the next bend as shown in the photo.

Build the Ailerons

14

Page 15

❏ ❏ C. Locate one of the 1/16" x 12" [1.6 x 305mm]

aluminum tubes. Cut two 9/16" [14mm] aileron torque rod

bearings from the tube.De-burr the holes in the tube with a

#11 knife blade. Install one of these pieces on the wire.

Make the final bend, then cut the wire to the length shown

on the plan. Be cer tain the horizontal portion of the torque

rod, that goes into the aileron, is perpendicular to the

vertical portion of the rod.

Remember: When you make the left torque rod, the bends are

in different directions and the length will be 1-1/8 [28.5mm].

❏ ❏ 2.Cut one of the 1/16" x 7/8" x 17" [1.6 x 22 x 430mm]

balsa ailerons to the length shown on the wing plan. Drill a

#68 (or 1/32") [0.8mm] hole into the leading edge of the

aileron where shown on the plan for the aileron torque rod.

❏ ❏ 3. Cut a notch in the leading edge of the aileron

between the hole you drilled and the end to accommodate

the torque rod. Glue the torque rod to the aileron with

medium CA.

❏ 4. Retur n to step 1 and make the left aileron torque rod

and aileron the same way.

Refer to these photos for the following five steps.Note:

You may want to delay the following steps until after the

model is covered.

❏ 5. Temporarily tape both ailerons to the wing.

❏ 6. Glue the laser-cut 1/16" [1.6mm] ply servo horn to the

plastic servo horn included with your servo.With this servo

horn, the ailerons will travel up more than down, reducing

adverse yaw, which is the tendency for the nose of the

model to turn away from the direction of banked turns.

❏ 7. Cut the top sheeting for the aileron servo, so that the

servo can be mounted to the left side of the center rib, aft of

the wing joiner and spar.

❏ 8. Clean the aileron servo case with a tissue dampened

with alcohol or other suitable solvent. Mount the aileron

servo to the side of the center rib with double-sided foam

mounting tape (GPMQ4440, not included).

Note: For a more secure bond to the wing rib, first coat the

rib with a thin layer of medium CA where the tape will be

applied.Sand the hardened CA to remove any irregularities.

❏ 9. Use the remainder of the .030" [.76mm] wire you used

for the torque rods to make the ailer on pushr ods.Note that

the pushrods are connected to the torque rods with a

“Z-bend” on both ends. If you do not have Z-bend pliers, or

do not know how to make a Z-bend with regular pliers, f ollo w

the procedure below. (For clarity, larger wire than was

supplied with this kit was used in the photos.)

❏ A. Make the first 90° bend near one end of the wire.

❏ B. Hold the wire in the pliers as shown.

15

Page 16

❏ C. Make the second 90° bend downward.

❏ D.Make the final 90° bend (twist) upward to form the “Z.”

❏ E. Cut the excess wire near the end.

Note: This procedure does not work for all types of wire, but

will work on the thin music wire supplied with this kit.

❏ 10. Connect the aileron ser vo to the aileron torque rods

with the pushrods you just made.

❏ 11. If you need to tweak the linkage slightly to center the

ailerons, you can make a slight bend in the aileron torque rod.

❏ 12. After the model is covered, glue the aileron torque

rod bearings to the trailing edge of the wing with medium

CA. Coat the torque rod with a film of oil or Vaseline®to

prevent CA from adhering to the torque rod.

❏ 1. Glue a 1/8" x 1/8" [3.2 x 3.2mm] balsa stick to the top

and bottom on one side of formers F2 to F8. Note: The side

with the sticks on it is now the front.

Frame the Sides

BUILD THE FUSELAGE

16

Page 17

❏ 2. Use thin CA to glue the die-cut 1/16" [1.6mm] left and

right fuselage top deck pieces together. Hold the pieces

together tightly while applying CA glue to the joint a couple

of inches at a time, wiping excess CA from the joint before

it hardens. Lightly sand the top deck smooth.

❏ 3. Use a straightedge and a hobby knife to trim the front

edge of one of the die-cut 1/16" [1.6mm] balsa fuselage

sides along the cut line. Mar k the inside of that fuse side

with an “R,” designating it as the right side. Note: The cut

line is not straight and angles about halfway down the side.

❏ 4. There are die-cut markings for the pushrod exit slots

on the rear of the fuselage sides.Cut out the lower rear slot

on the right fuselage side. Cut out the upper forward slot

on the other fuselage side, which now becomes the left

side. Note: The marked slots can be difficult to see. Cut the

slots according to the dimensions shown in the above photo .

❏ 5. Cover the bottom view of the fuse plan with Plan

Protector or wax paper. Pin the die-cut 1/16" [1.6mm] balsa

fuselage top deck over the bottom view of the fuselage plan.

Important: The front of the top deck should be aligned with

the rear of F1.The fuselage sides will extend 1/16" [1.6mm]

forward of the top deck.

❏ 6. Fit former F4 and the fuse sides to the fuse top.When

satisfied with the fit, glue F4 to the fuse top and sides.Note:

Make certain the right fuse side is on the right, and the left

fuse side is on the left (Remember, you are building the

fuselage upside-down.)

❏ 7.Working forward one former at a time, glue formers F3

and F2 to the fuse top and sides.

17

Page 18

❏ 8. Working aft one former at a time, glue formers F5, F6

and F7 to the fuse top and sides. Glue the fuse sides to the

fuse top.

❏ 9. Glue former F8 into position between the fuselage sides.

❏ 10.Glue the laser-cut 1/16" [1.6mm] ply landing gear mount

to the fuselage where shown on the side view of the plan.

❏ 11. Use a sheet of 1/32" x 3" x 15" [0.8 x 76 x 380mm]

balsa to sheet the bottom rear of the fuselage. Start at

former F5 and cut and glue only the first two pieces. The

remainder of the sheeting will be installed after the servos

are installed.

❏ 12. Remove the fuselage from the plan. Reinforce any

glue joints that look weak.Lightly sand the fuselage smooth.

❏ 13.Cut two 1" [25.4mm] pieces from a leftover 1/8" x 1/4"

[3.2 x 6.4mm] balsa stick. Glue a piece to each side of the

fuselage on top of the ply landing gear mount.

❏ 1. Locate the laser-cut 1/16" [1.6mm] ply former F1.

Draw a line across the top of the former on the front, as

shown in the photo. Note that the hole for the gearbox is

offset to the right as seen in the above photo.

❏ 2. Cut three 1/2" [13mm] pieces from a leftover 1/8" x 1/4"

[3.2 x 6.4mm] balsa stick.Glue a piece over each of the screw

holes on the rear of F1. Position them as shown in the photo.

Finish the Fuselage

18

Page 19

❏ 3. Cut four 1" [25.4mm] pieces from a leftover 1/8" x 1/4"

[3.2 x 6.4mm] balsa stick.

Before proceeding, read steps 4 thru 9.This will give you a

better understanding of how to proceed.

❏ 4. Check the fit of former F1 to the front of the fuselage.

The top deck should end 1/16" [1.6mm] aft of the front

edges of the fuselage sides. With F1 in place, the top deck

should be against the rear of F1. Note: It may be necessary

to trim the fuse sides to match the width of the firewall.

❏ 5. Glue F1 to the upper part of the left fuselage side.The

line drawn across the top of F1 should be aligned with the

top of the fuselage side. Align F1 accurately with the slope

on the upper part of the fuselage side.The lower part of the

fuselage side angles forward slightly. Do not glue F1 to the

lower part of the fuselage side. Glue the top deck to the

fuselage side as well.

❏ 6. Glue one of the 1" [25.4mm] strips that you cut earlier

to the fuselage side and the rear of F1.

❏ 7. Glue F1 to the upper part of the r ight fuselage side.

The line drawn across the top of F1 should be aligned with

the top of the fuselage side. Make sure F1 is aligned

accurately with the slope on the upper part of the fuselage

side. Do not glue F1 to the lower part of the fuselage side.

Glue another 1" [25.4mm] strip to the right fuselage side

and the rear of F1.

❏ 8. Prepare two of the 1" [25.4mm] balsa strips as shown

in the photo. Sand a curve along one side to match the

curve of the lower part of F1. Sand an angle along the side

of this curve. Study steps 9 and 10 to get a better idea of

how the strip should be shaped. This piece is fitted into

place in step 10, but it will help to have the part sanded to

shape first.

The lower front of the right fuselage side will now be glued

to the curved part of F1. The fuselage side must first be

wetted for it to bend around this curve.We have found the

best solution for this is 70% isopropyl alcohol (rubbing

alcohol), which will soak in rapidly and dry quickly. This

looks difficult, but if you proceed as instructed it works well.

19

Page 20

❏ 9.Wet the outside of the sheeting where it curves around

the bottom of F1. Slowly bend the fuselage side along the

curve. If it begins to crack, moisten the area with more

alcohol. Once you get the wood to bend along the curve,

soak some thin CA into the joint between the right fuselage

side and F1. Continue to hold pressure on the joint, even

after the CA has hardened.

Note: Put some wax paper or plan protector between your

thumb and the fuselage side so you don’t glue yourself to

the model.

Caution: Do not squeeze the joint too tightly or you will

break the fuselage side.

❏ 10.While still holding the joint tightly, fit and glue the strip

you prepared in step 8 to the back of F1, along the side of

the fuselage. It does not have to fit tightly. Soak some thin

CA onto the area, keeping the strip in place. After the thin

CA hardens, fill any gaps with medium CA. Do not release

pressure on the joint until after the medium CA has fully

hardened. CA accelerator will speed the process.

❏ 11. In the same way, glue the left fuselage side to former

F1.Before doing so, glue the die-cut reference cut lines with

some thin CA. As you glue the side in place, it may crack at

the bottom of the cut line. Once the side is glued in place

any cracks can be sanded smooth and filled with lightweight

balsa filler.

❏ 12. Carefully sand the fuselage sides even with the front

of former F1. Do not push the sandpaper back and forth

across the joint.Rather, push the sandpaper across the joint

towards the center of the former. Be careful not to snag the

opposite fuselage side.

❏ 13. Cut six 2" [51mm] sticks from the 1/8" x 3/8" [3.2 x

9.6mm] balsa stick.Working one at a time, glue three sticks

to the inside of each fuse side to create a gluing surface for

the bottom sheeting.

20

Page 21

❏ 14. Sand the sticks flat so that the bottom sheeting can

be glued in place.

❏ 15. Using the 1/16" x 3" [1.6 x 76mm] balsa sheet, sheet

the bottom front of the fuselage. Start by gluing a sheet

beginning at the ply landing gear mount.

❏ 16. Sand the contour of the fuselage front to blend into

former F1. Fill any gaps with lightweight balsa filler.

❏ 17.Place the fuselage upside-down over the bottom view

of the plan. Mark the location of formers F2A, F3A, F4A,

F5A, F6A and F7A on the left and right fuselage sides.

Transfer the marks to the top deck of the fuselage. Note on

the side view that formers F4A and F5A are not located over

F4 and F5.

❏ 18. Glue the die-cut 1/16" [1.6mm] balsa formers F2A

thru F8A to the fuselage top deck. Formers F2A, F3A, F6A,

F7A and F8A are glued perpendicular to the top deck. Use

the die-cut 1/16" [1.6mm] balsa F3A gauge to establish the

correct angle of F4A. Use the die-cut 1/16" [1.6mm]

dihedral gauge to set the angle of F5A.

❏ 19. Using three 1/8" x 1/8" x 24" [3.2 x 3.2 x 610mm]

balsa sticks, cut, fit and glue the stringers to the forward part

of the fuselage. Star t with the bottom stringer, which goes

from F1 to F5A. Use the remainder of this stick to do the

stringer above it. Use the third stick to do the top center

stringer, saving the remainder of the stic k f or the top stringer

on the aft part of the fuselage.

❏ 20. Using five 1/8" x 1/8" x 24" [3.2 x 3.2 x 610mm] balsa

sticks, cut, fit and glue the stringers to the aft part of the

fuselage. Start with the two bottom stringers on each side,

which go from F5 to the rear of F8.

21

Page 22

❏ 21. Use a leftover 1/8" x 1/8" [3.2 x 3.2mm] balsa stick to

reinforce the trailing edge of the fuse sides and where the

horizontal stab will be mounted. This will provide additional

gluing area.

❏ 22. Temporarily pin the hor izontal stab to the fuselage,

making sure it is centered.

❏ 23.Hold the fuselage on the wing and check that the stab

is level with the wing.Lightly sand the stab mount as needed

to make it level with the wing.

❏ 24. Glue a filler stick cut from leftover 1/8" x 1/4" [3.2 x

6.4mm] balsa to the top of the fuselage, 3/16" [5mm] behind

the stab.Be careful not to glue the stab to the fuselage.

❏ 25.Tack glue a leftover 1/8" x 1/8" [3.2 x 3.2mm] balsa stic k

across the front of the stab saddle area of the fuse.

❏ 26. Tack glue a 1/8" x 1/8" [3.2 x 3.2mm] balsa stick

centered on top of the sticks glued in the last two steps.

❏ 27.Cut the 3/4" x 3/4" x 12" [19 x 19 x 305mm] balsa stick

in half, making two 6" [152.5mm] pieces.Tack glue these to

the sticks as shown.

❏ 28. Using a razor plane and progressively finer grades of

sandpaper, shape the fillet blocks until they blend into and

follow the contour of the fuselage.

❏ 29. Cut the fillet blocks and false stab/fin off the aircraft.

Remove the sticks used to represent the stab and fin.

22

Page 23

❏ 30. Being careful not to glue the stab or fin, glue the stab

fillets to the fuse using the fin and stab spacers. Note: The

stab and fin will be installed after the model is covered.

❏ 31.From a 1/8" [3.2mm] dowel, cut a 4-3/4" [120mm] rear

wing hold-down dowel and a 5-3/4" [146mm] front wing

hold-down dowel. Round the ends for a neat appearance.

❏ 32. Drill 1/8" [3.2mm] holes in the sides of the fuselage

for each dowel where shown on the plan and insert each

dowel into the fuselage.

Caution: If the rear dowel is too low, it will interfere with the

aileron pushrods. If the front dowel is too low, it will not

provide proper shock absorption for the landing gear.

❏ 33. Cut four 5/8" [16mm] long blocks from a leftover 1/8" x

1/4" [3.2 x 6.4mm] balsa stick.Glue a block to the inside of the

fuselage side under each dowel end to reinforce the area.

Note: Remove the dowel first so you don’t glue the dowel

in place.

❏ 34. Glue the small laser-cut 1/16" [1.6mm] balsa braces

to the fuselage top deck midway between formers F4A and

F5A. These braces are used only to provide additional

support for the canopy and do not need to be even with the

fuselage sides or the stringer.

If you would like to b lend the leading and trailing edge of the

wing with the bottom of the fuselage, continue with step 36.

Otherwise, go to

“Install the Pushrods”

on page 24.

Adding these fairings will only add a slight amount of weight

to the model.

❏ 35. Cut a 3-3/4" [95mm] fairing strip from a leftover 1/8"

x 1/4" [3.2 x 6.4mm] balsa stick. Sand a taper on the ends

of the stick as shown in the above photo.

❏ 36. Glue the fairing strip to the bottom of the fuselage

behind the trailing edge of the wing.

23

Page 24

❏ 37. Blend the fairing strip to the fuselage bottom with

some lightweight balsa filler.

❏ 38. Using a leftover piece of 1/16" [1.6mm] balsa

sheeting, cut a piece 4-3/8" [111mm] long. Notch one side

of this piece as shown in the above sketch.

❏ 39. Place the piece on the leading edge of the wing,

against the fuselage. Mark the sheet where it needs to be

cut flush with the bottom of the fuselage.

❏ 40. Tack glue this filler strip to the leading edge of the

wing, being careful not to glue it or the wing to the fuselage.

Remove the wing and reinforce the glue joint.

❏ 41. Using a leftover piece of 1/32" [0.8mm] balsa sheet,

cut a piece 4-3/8" x 1-1/2" [111 x 38mm]. Glue this piece to

the filler strip and the bottom wing sheeting.

❏ 42. Use leftover 1/32" [0.8mm] balsa to cut, fit and glue

filler strips to the end of the sheeting.

For the following steps make sure the horizontal stab and

vertical fin are pinned in place on the fuselage.

❏ 1. Use a tissue dampened with denatured alcohol or

other suitable solvent to clean the servo cases so the

mounting tape will adhere.Use double-sided foam mounting

tape (GPMQ4440, not included) to mount the elevator and

rudder servos to the fuse sides where shown on the plan.

Install the Pushrods

24

Page 25

❏ 2. Thoroughly clean the remaining .030" x 20" [.76 x

508mm] wire with alcohol or similar solvent, then scuff it with

320-grit sandpaper so glue will adhere.

❏ 3.Cut 5" [127mm] from the wire. Make a “Z” bend on one

end and a slight bend on the other end. See the drawing on

the fuselage plan.This is a control horn pushrod end.

❏ 4. Use pliers to inser t this pushrod end 1" [25.4mm] into

a 1/16" x 12" [1.6 x 305mm] aluminum pushrod tube. Use

thin CA to glue the pushrod end into the pushrod tube.

❏ 5.Make another pushrod end from a 4-1/4" [108mm] wire

just the same as the first and insert it into the other end of

the pushrod tube, but do not glue it in. See the drawing on

the fuselage plan.This will be the elevator pushrod.

❏ 6. Make sure the pushrod end that is not glued into the

tube fits tightly and will not easily slide in and out. It will be

permanently glued in after the model has been set up and

the exact length of the pushrod has been determined.

Refer to this photo for the following four steps. Note:

The photo shows how the completed installation will look.

❏ 7. Cut a slot in the fuselage at the rear of the horizontal

stab for the 1/8" [3.2mm] elevator joiner, installed in the left

elevator. Insert the joiner in the slot and check that the

elevator will move freely once installed. Temporarily hinge

the left elevator to the stab using clear cellophane tape.

❏ 8. Insert the elevator pushrod into the fuse through the

slot in the left side. The pushrod end that is not glued into

the tube should be at the servo end.

❏ 9. Connect the front of the pushrod to the ser vo arm, then

mount the servo arm to the elevator servo. Connect the other

end of the pushrod to the outer hole in the elevator control horn,

then insert the control horn into the slot in the elevator.

❏ 10. Slide the pushrod end in or out of the pushrod tube

until the elevator is centered when the servo is centered.

❏ 11. Make the rudder pushrod and join the rudder to the

fin the same way. The r udder pushrod should be inserted

into the inner hole of the rudder control horn.

Note:The photo shows how the completed installation will look.

❏ 12. The pushrods should be braced at the locations

shown on the plan. This photo shows the bracing installed

25

Page 26

just forward of F6. Use a leftover piece of 1/8" x 1/4" [3.2 x

6.4mm] balsa for the main brace. Cut notches in the brace

where the pushrods cross it. Hold the pushrods in the

notches with leftover 1/8" x 1/8" [3.2 x 3.2mm] balsa. Be

careful not to glue the pushrods to the braces.

❏ 13. In a similar manner, install pushrod bracing where

shown on the plan at the rear of the fuselage. This photo

shows the bracing between F7 and F8.

❏ 14. Sheet the bottom rear of the fuselage with the

remaining 1/32" [0.8mm] balsa sheeting.

❏ 15. Remove the servo arms from the top of the servos.

Pull the pushrods into the fuselage so that the rear ends do

not extend out of the fuselage.

❏ 16.Remove the stab and fin from the fuselage.Reinforce

the glue joints of stringers that were tack glued into place.

Sand the stringers even with F4 and F5. Sand all str ingers

to a smooth contoured shape. Sand the sheeting even with

the fuselage sides.

❏ 1. If you haven’t done so already, sand all par ts of the

model smooth with 320-grit, then 400-grit sandpaper.

❏ 2. Use compressed air (be careful!), a dust br ush or a

tack cloth to remove balsa dust from the model.

❏ 3. Determine what material you will be covering the

model with. If using Top Flite EconoKote, the model is ready

to cover. If using Coverite CoverLite, coat the areas to be

covered with Coverite Balsarite Fabric Formula

(COVR2500). Be certain you use the fabric formula for

CoverLite, and not the formula for regular film covering.

❏ 4. Follow the suggested covering sequence to cover

the model.

Important: Do not shrink the covering until both sides of

each part are covered.This will reduce the tendency for the

surfaces to twist.

Tail Surfaces:

❏ 1.The bottom, then the top of the stabilizer

❏ 2.Bottom, then top of elevators

❏ 3.Fin

❏ 4.Rudder

Fuselage:

❏ 1.Bottom

❏ 2.Sides and top

Wing:

❏ 1.The bottom of the wing

❏ 2.Top of the wing

❏ 3.Ailerons

Note: It may be easier to cover the wing tips separately,

after the rest of the wing has been covered.

❏ 1. After all the tail pieces are covered, inspect the stab

and fin for twists. If necessar y, lightly twist the part in the

opposite direction and apply heat to the covering until you

can get it flat.

An important characteristic of most air planes is their ability

to resist stalling, or to stall gently. Simply stated, a stall is

when the wing no longer produces lift–basically the model

quits flying until it regains airspeed. A stall can occur when

attempting to climb too rapidly, or when the model r uns out

of airspeed (such as when trying to land too slowly). One

way to prevent or delay a stall is to add “washout” to the

wing. Washout is an upward twist at both wing tips, so that

the trailing edge is higher than the leading edge. If the

trailing edges are raised slightly, or are at a lower angle then

the rest of the wing, the outer portion of the wing will

continue to produce lift (fly) even though the rest of the wing

has quit flying, thus resisting a stall. Because the RV-4 Park

Flyer is designed to be light, it would be difficult to build this

required twist into the wing during construction. The

following procedure explains how to add washout, which is

common for lightweight structures such as this.

❏ 1. Start with the r ight wing panel. Holding the middle of

the wing in one hand, twist the trailing edge of the right wing

tip upward. The amount of washout to shoot for is 1/8"

[3.2mm], so begin by twisting about 1/2" [13mm] (because

the wing will “spring” par tway back to its original position

after re-shrinking the covering in the next step).

Add “Washout”

Suggested Covering Sequence

CO VER THE MODEL

26

Page 27

❏ 2. Note the wrinkles in the covering while holding the

wing.Have an assistant heat the covering on the top and the

bottom until the wrinkles disappear. Allow the covering to

fully cool before letting go.

❏ 3. Add washout to the left wing panel the same way.

❏ 4. Check the wing periodically to be sure the washout

remains. Twist and shrink the covering as necessary to

retain the washout.

❏ 1. Mount the wing to the fuse with two #64 rubber bands

(when it’s time to fly the RV-4 Park Flyer, use four #64

rubber bands). Trim the front edge of the aft fuse bottom

sheeting and cut notches in former F5 to accommodate the

aileron torque rods. If you have to cut much of the former,

use a leftover 1/8" x 1/8" [3.2 x 3.2mm] balsa stick to cut and

glue a reinforcing piece behind F5.

❏ 2. Use a small pin to poke several holes through the

covering in the top and bottom of the stab where it will be

glued to the fuselage. These holes will absorb the CA that

will be used to glue the fin to the stab and will make for a

stronger glue joint.

❏ 3. Place the stab in the fuse, making sure it is centered

as shown in “A” = “A” in the photo above. Hint: If the

covering on the stab is transparent, align the sticks on both

sides of the center stick with the fuse.

❏ 4.View the model from the rear and see if the stab is le v el

with the wing as shown in “B” = “B.” If the stab is not level

with the wing, carefully sand the “high side” of the fuse until

you can get the stab to align.

❏ 5. Use a string or tape measure to align the stab. Put a

pin in the center of the top of former F1. Tie a loop in one

end of the string and place it over the pin. Put some tape

over the string with a mark on it. Swing the str ing from side

to side and adjust the stab as required until the stab is

aligned properly.

❏ 6. When satisfied with the alignment, glue the stab in

place with thin CA.

❏ 7. Inser t the vertical fin in the fuselage. Use a builders

square to get the fin perpendicular to the stab. Make sure

Join the Tail Surfaces

FINAL ASSEMBLY

Note: For a small, lightweight model such as the RV-4

Park Flyer, it is not critical to get exactly 1/8” [3.3mm] of

washout. However, it is important that

some

washout be

present in both wing tips. Do your best to achieve the

washout recommended, but don’t spend hours trying to

do so.A slight variance in both wing tips is acceptable, as

long as neither of the wing tips have any “wash-in.”

27

Page 28

the fin is aligned with the rear of the fuselage.Glue the stab

to the fuse with thin CA. The photo shows the rudder

installed on the fin, but your model will not have the rudder

installed yet.

❏ 8. Place the rudder over the plans and mark the location

of the tail wheel wire where it mounts on the rudder. Drill a

1/16" [1.6mm] hole in the leading edge of the rudder for the

wire. Notch the leading edge of the rudder for the wire to fit

into.Insert the tail wheel wire in the rudder and make sure it

is aligned correctly. Make sure the model will track correctly

on the ground with the rudder centered. Glue the tail wheel

wire into the rudder with thin CA.

❏ 1.Before proceeding, charge the motor battery (and your

transmitter if needed).When it’s time to set up the radio you

won’t have to stand by while the batteries are charging.

❏ 2.Cut the covering from the elevator and rudder pushrod

exit slots near the aft end of the fuse.Push the rear ends of

the pushrods out the slots in the rear of the fuselage.

Refer to this photo for the following four steps.

❏ 3. Install the left elevator on the fuselage. Insert the

elevator joiner in the slot behind the stab and check that the

elevator will move freely once installed. Hinge the left

elevator to the stab using clear cellophane tape as sho wn in

the sketch that follows.

❏ 4. Connect the front of the elevator pushrod to the servo

arm, then mount the servo arm to the elevator servo.Connect

the other end of the pushrod to the outer hole in the elevator

control horn, then insert the control hor n into the slot in the

elevator. Glue the control horn into place with thin CA.

❏ 5. Slide the pushrod end in or out of the pushrod tube

until the elevator is centered when the servo is centered.

❏ 6. Hinge the right elevator to the stab using clear cellophane

tape. Glue the 1/8" [3.2mm] elevator joiner to the right elevator

with thin CA. Make sure the left and right elevators are aligned

before gluing the joiner into place. Be careful not to glue the

joiner or the elevator to the stab or fuselage.

❏ 7. Install the rudder to the fin with clear cellophane tape.

The rudder pushrod should be inserted into the inner hole of

the rudder control horn.

❏ 8. If you have not done so already, attach the ailerons to

the wing with cellophane tape the same as you did the

elevators and rudder. Follow the instructions on page 14,

“Build the Ailerons”

for pushrod installation.

❏ 1. Install the supplied 3/4" [19mm] tail wheel on the tail

wheel wire. Hold it in place with a white nylon retainer.

❏ 2. Install the supplied 2" [51mm] wheels on the 3/32"

[1.6mm] wire landing gear. Secure the wheels with the

supplied wheel collars and set screws.

Mount the Landing Gear

Hook Up the Controls

28

Page 29

❏ 3. Mount the landing gear to the fuse with a #14 rubber

band on each side. Both rubber bands must be stretched

enough to wrap around the gear and dowel at least two times.

❏ 4. Cut four 1" [25.4mm] pieces from a leftover 1/8" x 1/8"

[32. x 3.2mm] balsa stick. Glue the pieces in front of and

behind the landing gear as shown in the photo.

Follow these assembly instructions for the Great Planes

ElectriFly motor and S-280 gear drive. If you are using

another type of gear drive and motor, follow the instructions

that came with the unit.

❏ 1. Use denatured alcohol or other solvent to clean the

motor shaft. Roughen the shaft with 320-grit sandpaper so

glue will adhere.

Note: If you are using the Great Planes ElectriFly S-370

motor, you should lightly file the knurling on the motor shaft

to make installation of the pinion gear easier. Wrap the

motor in a plastic bag to prevent metal filings from entering

the motor.

❏ 2. Apply a small amount of the green locking glue to the

motor shaft. Press the pinion gear onto the motor shaft using

a small hammer, base of a large screwdriver or something

similar.Depending on how tight the fit is, you may have to tap

the gear into place. While doing this, do not rest the base of

the motor on your workbench, but support the motor shaft with

a piece of hardwood. This way, the pressure applied to the

gear will not displace the armature in the motor.

Note: If you are using the Great Planes ElectriFly S-370

motor, it is easier to press the gear into place between the

jaws of a vise. Be careful not to damage the capacitors

installed on the back of the motor. Follow the instructions

supplied with the motor.

❏ 3. Press the motor by hand as far as it will go into the

gear drive unit.Draw a pencil line around the motor where it

aligns with the rear of the gear drive unit.Back the motor out

about 1/16" [1.6mm]. Spin the gear dr ive output shaft with

your fingers to insure that the gear drive and motor move