Page 1

FIBRE CHANNEL NETWORKING

Installation Manual

071-8072-00

NOVEMBER 2000

PROFILE PDR100

PROFESSIONAL DISK RECORDERS

Page 2

Copyright Copyright © 2000 Grass Valley Group Inc. All rights reserved. Printed in the United

States of America.

This do cument m ay not be copied i n whole o r in part , or other wise repr oduced

except as sp ec ifi ca ll y permitt ed un de r U. S. co py r i gh t law, withou t the prior wr it ten

consent of Grass Valley Group Inc., P.O. Box 59900, Nevada City, California

95959-7900

Trademarks Grass Valley, GRASS VALLEY GROUP, Profile and Profile XP are either

registe red trad em arks or trad ema rk s of Gras s Va ll ey Gr oup in the Uni ted Stat es

and/or other countries. Other trademarks used in this document are either

registered trademarks or trademarks of the manufacturers or vendors of the

associated products. Grass Valley Group products are covered by U.S. and foreign

patents, issued and pending. Additi onal information regarding

Grass Valley Grou p's tradem arks and oth er propri etary right s may be fou nd at

www.grassvalleygroup.com.

Disclaimer Product options and specifications subject to change without notice. The

informati on in this manual is furnished for informatio nal use only, is subjec t to

chang e witho ut notic e, an d shou ld not b e cons trued as a com mitme nt by G rass

Valley Group. Grass Valley Group as sumes no res ponsibility or liability f or any

errors or inaccuracie s that may appear in this publication.

U.S. Government

Restricted Rights

Legend

Revision Status

Use, duplication, or disclosure by the United States Government is subject to

restrictions as set forth in s ubparagraph (c )(1)(ii) of t he Rights in Tech nical Data

and Comp ut er So ftwa re clau se at DFA RS 25 2.277 -7 013 or in su bpara gra ph c(1 )

and (2) of the Comm ercial Co mputer So ftware Re stricte d Rights cl ause at FAR

52.227-19, as applicable. Manufacturer is Grass Valley Group Inc., P.O. Box

59900, Nevada City, California 95959-7900 U.S.A.

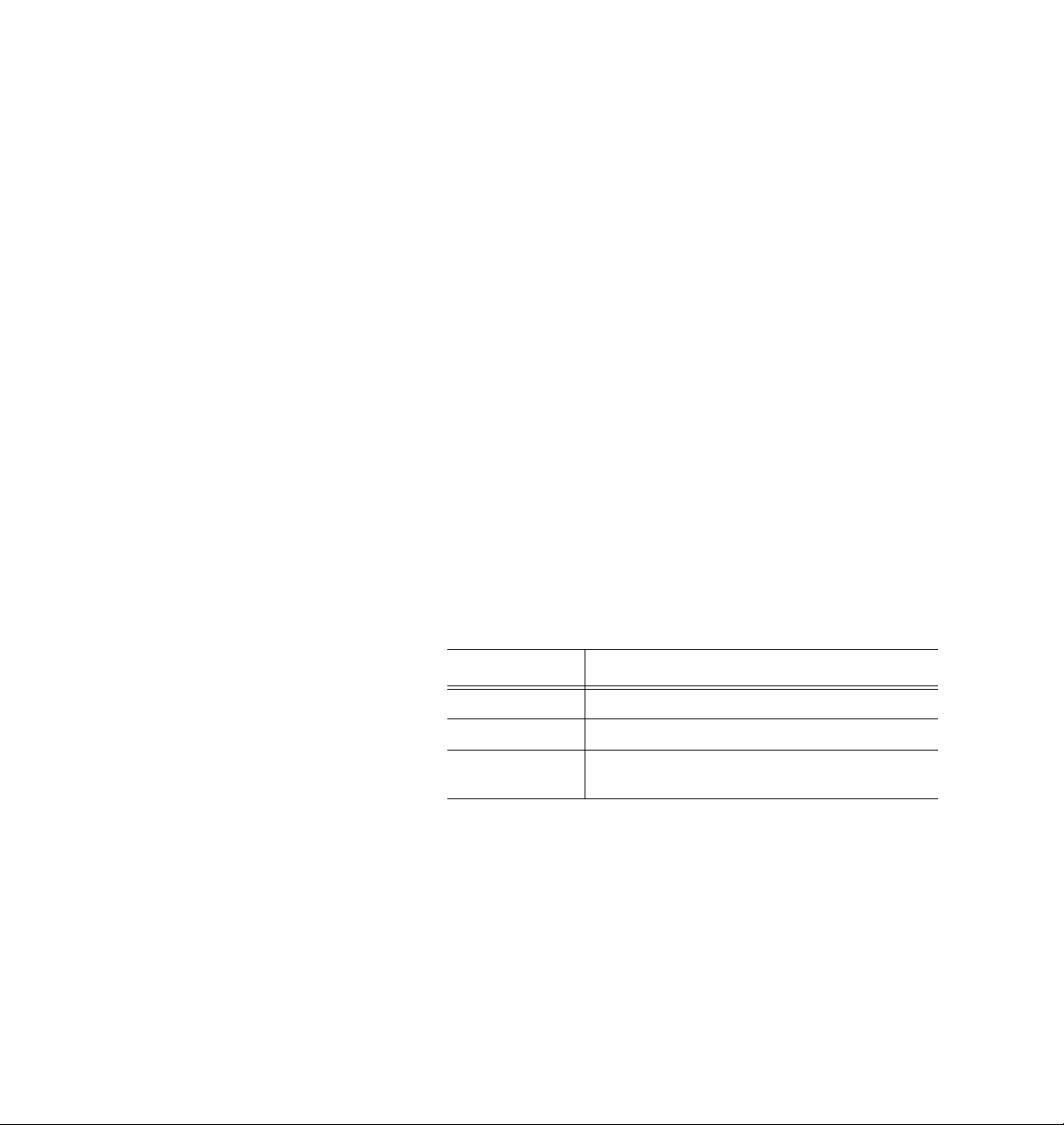

Rev Date Description

February 1997 Initial Issue, Manual P/N 070-9674-00.

September 1997 Move user information, roll P/ N to 070-9674-01.

November 2000 Revised Product Support contact information.

Part Number 071-8072-00.

Page 3

Contents

Grass Valley Group Product Support ............... ............ ............ ............ ......... ............ .. 7

General Safe ty Su mm ary............................... ........................................... .................. 8

Certifications and Compliances................................................................................... 11

Introduction.................................................................................................................. 13

Related Documents..................................................................................................... 13

System Requireme n ts.......... ........................................... ............................................ 14

Tools Required......................................................................... ................................... 14

Receiving Insp e ction of the Kit.... ..................... ........................................................... 15

Receiving Insp e ction.......... ................................... ............................................... 15

Unpacking Inspection.......................................................................................... 15

Fibre Channel Upgrade Kits................................................ .......... ....... .. ....... .......... .. .. 16

Fibre Channel Kit Description...................................................................................... 18

Fibre Channel Board................................................................ ....... ....... ..... ....... .. 18

Master Enhanced Disk Recorder Board ... ..... ..... ....... .. ..... ....... ..... .. ..... ....... ..... .. .. 18

Slave Enhanced Disk Reco r d er Board................................................................ 18

10/100 BaseT Ethernet Board ............................................................................. 18

PCI Interconnect Board ....................................................................................... 18

Front Panel Cable Assembly............................................................................... 19

LED Cable .................................................................................. ......................... 19

EMI Foam Gasket.............................................................................................. .. 19

Fibre Channel Cable...................................... ....... ....... ..... ....... ....... ..... ....... ....... .. 19

Ethernet Cable..................................................................................................... 20

Sticker Sets.......................................................................................................... 20

Accessori e s............ .................................................. ................................................... 21

Networking Overview................................................................................................... 23

Network Configurations....................................................................................... 23

Network Models................................................................................................... 23

Networking Several Profile Systems ............................................................ 24

Networking Sev eral Hubs ............................................................................ 25

Building a Fibre Channel Network ......................................................... .......... .. .. 26

Electro sta tic Precautio n s...... ..................... .................................................. ................ 27

Installation Procedures................................................................................ ............ .... 28

Preparing the Profile System............................................................................... 29

Enable the Network...................................................................................... 29

System Shutdo wn........................................................ ................................ 29

External Cab les Disconnect......................................................................... 30

Profile Chassis Removal..... ........................................... .............................. 30

Covers Removal .......... ................................................................................ 30

Board Retaine r Br a cke ts Removal......... ....... ............................................... 32

Removing Inter n a l Cable s................. ........................................................... 34

Removing Old Board s...................................... ............................................ 36

Board Location Guide.............................................. .......................................... .. 38

PDR 100 Fibre Channel Installation 3

Page 4

Contents

Video Router to Motherboard Relationship ........................................ ....... ... 38

Board I/O Requirements and Restrictions..................................... ..... ....... ... 38

Video Router I/O Connections...................................................................... 40

Selecting a Locat ion................................................. .................................... 42

Example 1...... ....... ........................................... .......................................... ... 43

Example 2...... ....... ........................................... .......................................... ... 46

Audio Clock Cabling............................................................................................. 48

Installing the Fibre Channel Upgrade........................................................................... 50

Installing the Ethernet 10/100 BaseT Board......................................................... 53

Installing the EDR Boards.................................................................................... 55

Installing the Fibre Channel Board..................................... .......... ....... ....... ....... ... 58

Reinstalling Internal Cables.................................................................................. 59

Installi n g th e PCI Interconnect Board.......... ............................ ............................. 60

Reinstalling Board Retainer Br a cke ts................................................................... 62

Installing EMI Compliance Components .............................................................. 64

Attaching Slot ID Stickers..................................................................................... 69

Replacing the Profile Covers................................................................................ 70

Reinstalling the Profile Chassis into the Rack...................................................... 71

Cable Connections................................................................................ ............... 71

Installation Verification................................. ................................................. ............... 72

Configuring the System.......... ............... ........................................................ ............... 73

System Set-up fo r Eth e rn e t...... .............. ........................................... ................... 74

Configuring the Ethernet Board for TCP/IP.......................................................... 75

Testing Your Ethernet Connection ....................................................................... 75

Configuring Your Fibre Channel Network............................................................. 76

If a Problem Occurs..................................................................................................... 77

4 PDR 100 Fibre Channel Inst allation

Page 5

Figures

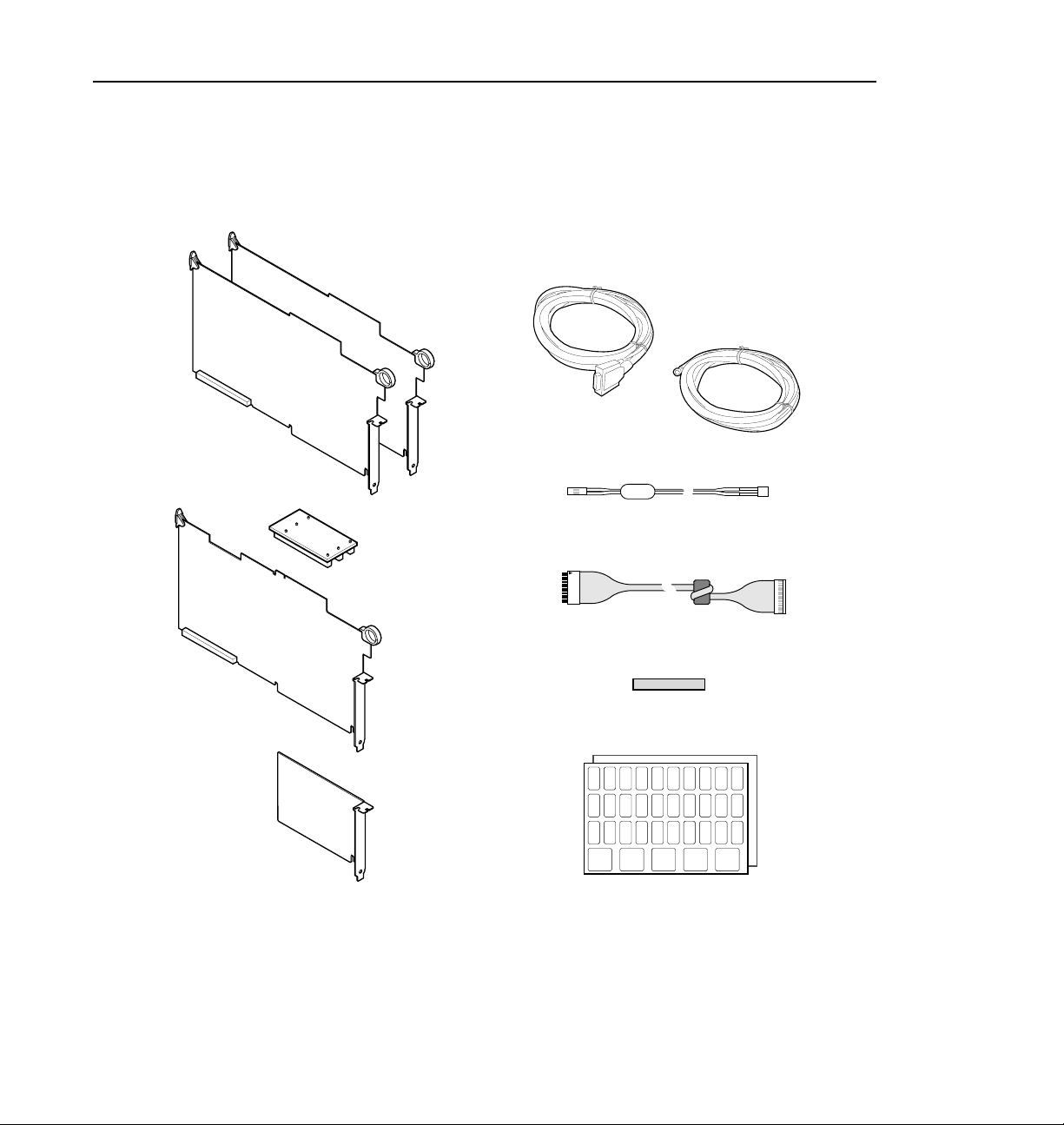

1 4-Channel Fibre Channel Kit Contents....................................................... 17

2 Example - Profile System Fibre Channel Connections...............................21

3 Fibre Channel and Ethernet Hubs ..............................................................22

4 Copper-to-Fiber Cable Adapter ............................... ....... ..... ....... .. .......... .. ..22

5 Basic Hub Connect ion s........ ......................................................................24

6 Using Several Hubs....................................................................................25

7 Point-to-point Fibre Channel Network Connection .....................................26

8 Profile Top Covers Re mo va l.......... .............................................................31

9 Board Retainer Brackets Removal .............................................................33

10 Internal SCSI Cables Removal...................................................................35

11 Typical Remova l of a Full Size Board...... ................................... ................36

12 Typical Remova l of a Shor t Bo a rd..............................................................37

13 Example of Audio Clock Cabling ................................................................49

14 Board Slot IDs (Rear Panel).......................................................................51

15 Slave EDR, Master EDR, and Fibre Channel Board Locations..................52

16 Short Board Installation Example (Top View).............................................54

17 Distinguishing Between Master and Slave EDRs.......................................56

18 Installi n g a Full Si ze Board Exa mp l e..........................................................57

19 SCSI Cable Connections............................................................................ 59

20 PCI Interconnection Board ..........................................................................60

21 PCI Interconnect Board Installation ............................................................ 61

22 Short Board Retainer Bracket and Extender ..............................................62

23 Board Retainer Bra cke t installat io n......... ............................ .......................63

24 Front Panel Cable Assembly......................................................................64

25 LED Cable Assembly................................................................................ ..65

26 Removing the Front Panel and Bezel....................................................... ..66

27 Installing the Front Panel and LED Cable Assemblies ............................... 67

28 Installing the EMI Gasket............................................................................ 68

29 Sticker Slot IDs for New Boards .................................................................69

30 Profile Cov er Replace me n ts... ....................................................................70

31 Diagnostics Window Board Recognition Example...................................... 73

Contents

PDR 100 Fibre Channel Installation 5

Page 6

Contents

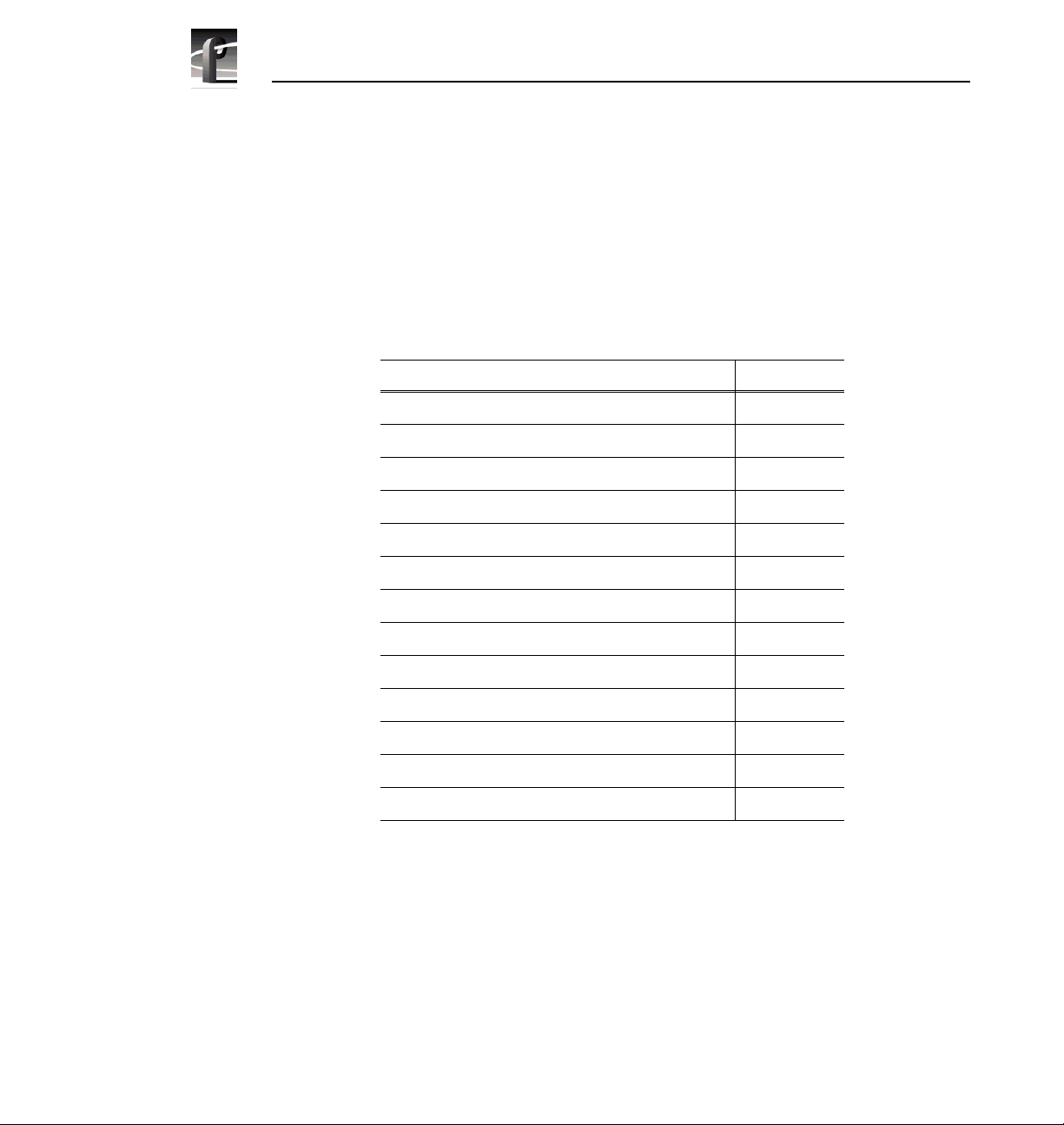

Tables

1 4-Channel Profile Fibre Channel Upgrade Kit Contents .. ...........................16

2 Fibre Channel Networking Accessories .....................................................22

3 Board I/O Requirements and Restrictions ..................................................39

4 Board location chart ...................................................................................41

5 Example 1 - Installing the Fibre Channel Upgrade .....................................45

6 Example 2 - Instal ling a Mix Effects Board ........ .........................................47

6 PDR 100 Fibre Channel Inst allation

Page 7

Grass Valley Group Product Support

You can get technical assist ance, check on the status of problems, or report new

problems by contacting our Produc t Support Group.

Unit ed States and Canada

Monday–Friday 5:30AM–5:00PM Pa cific Time

(800) 547-8949

Europe

Monday–Friday 9:00AM–5:30PM

France

Germany 49 221 1791 234 Other +44 1753 218 777

Italy 02 25086606

01 45 29 73 00

Asia and South America

Australia

- from overseas

Beijing 86-10-62351230

Brazil 55-11-3741-8422 Taiwan 886-2-27571571

Hong Kong 852-2585-6579

02-9888 0100

61-2-9888 0100

ext. 711

World Wide

24-hour Emergency Hotline (530) 478-4148 (Con tract and warr anty customers)

Worl d Wide Web http://www.grassvalleygroup.com/support//

FTP Site ftp.grassvalleygroup.com

E-mail profile-users@grassvalleygroup.com

United Ki ngdom 01628 405830

Japan 81-3-3448-3111

Korea 82-2-528-5299

Mexico 52-5-666-6333

Singapore 65-356-3900

PDR 100 Fibre Channel Installation 7

Page 8

PDR 100 Fibre Channel Installation

General Safety Summary

!

WARNING: These instructions are for use by qualified

service personnel only. To avoid personal injury, do not

perform any servicing unless you are qualifie d to do so.

Refer to all safety summaries before performing service.

Review the following safety precautions to avoid personal

injury and prevent damage to this product or any products

connected to it.

While using this product, you may need to access other parts

of the system. Read the general safety summary in other

system manuals for warnings and cautions related to

operating the system.

Injury Precautions

Do Not Service

Alone

Disconnect Power To avoid electric shock while servi cing, disconne ct the main

Use Care W h en

Ser vicin g Wit h

Power On

Do not perform inte rnal se rvice or a dju stment of this product

unless another person capable of render ing first aid and

resuscitation is pres ent.

power by means of the power cord.

Dangerous voltages or currents may exist in this product.

Disconnect power and remove battery (if applicable) before

removing protective panels, soldering, or replacing

components.

Avoid Exposed

Circuitry

Do Not Operate

Without Product

Covers in Place

8 PDR 100 Fibre Channel Inst allation

To avoid injury while servicing, remove jewelry such as

rings, watches, and other metallic objects. Do not touch

exposed connections a nd compone nts when p ower is pres ent.

To avoid electric shock or fire hazard, do not operate this

product with covers or panels removed.

Page 9

Product Damage Precautions

Do Not Operate in

Wet/Damp

Conditions

Do Not Opera te i n an

Explosive

Atmosphere

To avoid electric shock, do not op erate this pr oduct in we t or

damp conditions.

To avoid injury or fire hazard, do not operate this pro duct in

an explosive atmosphere .

Product Damage Precautions

Use the Proper

Voltage Setting

Provide Proper

Ventilation

Do Not O p er ate If

You Suspect

Product Failures

Ensure that the line selec tor is in the proper position for the

power source before applying power.

Prevent product overhea ting by providing proper vent ilation.

If you suspect there is damage to this product, have it

inspected by qualifie d servic e personnel.

Safety Terms and Symbols

Terms in This

Manual

These terms may appear in this manual:

!

!

WARNING: Warning statements identify conditions or

practices that can result in personal injury or loss of life.

CAUTION: Caution statements identify conditions or

practices tha t can result in damage to the equipment or other

property.

PDR 100 Fibre Channel Installation 9

Page 10

PDR 100 Fibre Channel Installation

Terms on the

Product

Symbols on the

Product

!

These terms may appear on the product:

DANGER indicates a personal injury hazard imme diately

accessible as you read the marking.

WARNING indicates a personal injury hazard not

immediately accessible as you read the marking.

CAUTION indicates a hazard to property, including the

product.

The following symbols may appear on the product:

DANGER high voltage

Protective ground (eart h) ter minal

ATTENTION – refer to manual

10 PDR 100 Fibre Channel Install ation

Page 11

Certifications and Compliances

Certifications and Compliances

FCC Emission

Control

Canadian EMC

Notice of

Compliance

This equipment has bee n tested and found to co mply with the

limits for a Class A digital de vice, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against ha rmful interference when the equipment

is operated in a comm ercial environment. This equip m en t

generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with this installation

manual, may cause harmful interf erence to radio

communications. Oper ation of t his equipment in a residential

area is lik ely to cause harmful interference in which case the

user will be requi red t o corr ect the interference at his or her

own expense. Changes or modifications not expressly

approved by Grass Valley Group can affect emission

compliance and could void the user’s author ity to operate this

equipment.

This digital appar atus does not exceed the Class A limits f or

radio noise emissions from a digital apparatus set out in the

Radio Interferenc e Regulations of the Canadian Department

of Communications.

Le présent appareil num érique n’émet pas de bruit s

radioélectriques dépassant les li mites applicables aux apparei ls

numériques de la classe A préscrites dans le Règlement sur le

brouillage radioélectrique édicté par le ministère des

Communications du Canada.

EN55022 Class A

Warning

For products that comply with Class A. In a domestic

environment, this product may cause radio interference , in

which case the user may be required to take adequate

measures.

PDR 100 Fibre Channel Installation 11

Page 12

PDR 100 Fibre Channel Installation

Certification

Category Standard

Safety Designe d /te s te d fo r co m p liance with:

UL1950 – Sa fety of Inf ormation Technolo gy Equipm ent, in cluding E lectric al

Business Equipment (Third Edition, 1995)

IEC 950 – Safety of Information Technology Equipment, including

Electrical Business Equipment (Second edition, 1991)

CAN/CSA C22.2, No. 950-95 – Safety of Information Technology

Equipment , including Electrical Business Equipment

EN60950 – Safety of Information Technology Equi pm ent, inclu ding

Electrical Business E quipment (includes Appendix ZB)

12 PDR 100 Fibre Channel Install ation

Page 13

PDR 100 Fibre Channel Installation

Introduction

Fibre Channel adds high speed video networking capability to Profile systems,

allowing clips to be transferred between Profile systems. This manual contains

instructions on how to install the Fibre Channel kit in your PDR100. The

instructions include:

• Related documents.

• System Requirements.

• Receiving inspecti on of the Fibre Channel Kit.

• Kit Contents.

• Installation Proc edure

• Configuring the system for Ethernet.

• Verifying that the Fibre Channel is correctly installed.

Once you have installed the Fibre Channel upgrade, your Profile system must be

configured t o use the F ibre C hannel network. Se e the Pr ofile Family User Manual

for Fibre Channel configuration and use information.

NOTE: The Fibre Channel upgrade should only be installe d by qualified

personnel.

Related Documents

Profile Rele ase N o tes

Profile Family User Guide

PDR100 Installation Manual

PDR100 Service Manual

PDR 100 Fibre Channel Installation 13

Page 14

PDR 100 Fibre Channel Installation

System Requirements

The system requirements for installing and using the PDR100 Fibre Channel

upgrade are:

• Window NT operating system V3.51 or higher.

• Profile System Software V2.1 or higher.

• An Ethernet LAN board.

Tools Required

Tools required, but not supplied, to install the kit are:

• Torx screwdriver with T10 and T15 tips.

• Static discharge wri st strap.

14 PDR 100 Fibre Channel Install ation

Page 15

Receiving Inspection of the Kit

Receiving Inspection

After receiving the Fibr e Channel upgrade kit, carefully inspect the container. If

any damage is noted, contact the shipping agent immediately.

Unpacking Inspection

Grass Valley Group has made every effort to ensure that you receive a complete

and intact kit. Carefully unpack the kit and check the contents against the invoice

or shipping manifest. If any discrepancies are found, notif y your Grass Valley

Group representative immediately.

Inspect each component for any signs of damage. Especially note that cables are

not kinked and that con nector pins are not br oken or bent. I f any damage i s found,

notify your Grass Valley Group representative immediately and DO NOT

proceed further unless instructed to do so.

Receiving Inspection of the Kit

PDR 100 Fibre Channel Installation 15

Page 16

PDR 100 Fibre Channel Installation

Fibre Channel Upgrade Kits

There are two Fibre Channel upgrade kits f or the PDR100: one for a 4-channel

Profile system and the other for a 2-channe l Profile system.

The Fibre Channel upgr ade kit for a 4-channe l Profile syste m consists of the items

listed in Table 1 and shown in Figure 1.

Table 1. 4-Channel Profile Fibre Channel Upgrade Kit Contents

Name Part Number

Fibre Channel Board 672-1462- X X

Master EDR Board 671-3795-X X

Slave EDR Board 671-3757-XX

10/100 Base T Ethernet Boar d 118-9403- X X

PCI Interconnect Board 671-3794-XX

Front Panel Cable Assy w/Fer rite Bead 174-3459- XX

LED Cable Assy w/F errite Bead 174-3471-X X

Gasket, EMI Foam 348-1543-XX

5M Fibre Channel Copper Cable 174-3629-X X

5.49M Ethernet 10/100 BaseT Cable 174-3738- XX

Standard Sticker Set 334-8982- X X

Fibre Channel Sticker Set 334-9461- X X

Installation Manual 070-9674-XX

The 2-channel upgr ade kit consists of all the items listed in Table 1 and shown in

Figure 1 except the EDR Slave board.

16 PDR 100 Fibre Channel Install ation

Page 17

Fibre Channel Upgrade Kits

Enhanced Disk

Recorder Boards

PCI Board

Fibre Channel

Board

5 meter Fibre

Channel Cable

5.49 meter

Ethernet Cable

LED Cable

Front Panel Cable

EMI Gasket

Label Sets

10/100 Base T

Board

Figure 1. 4-Channel Fibre Channel Kit Contents

PDR 100 Fibre Channel Installation 17

9674-1

Page 18

PDR 100 Fibre Channel Installation

Fibre Channel Kit Description

The Fibre Channel upgr ade provides for connect ivity and high speed data t ransfers

between Profile systems. A LAN network (or Ethernet hub) and a Fibre Channel

hub are required to connect groups of grea ter than two Profile systems and, in

general, one set of hu bs is requ ired fo r each g roup of Profile systems to be

connected.

Fibre Cha nn e l Boa r d

The Fibre Channel (FC) board is a networkin g device which uses the Fibre

Channel Arbitrated Loop ( FCAL) protocol. The FC board is compatible with the

Peripheral Component I nterc onnect (PCI) local bus. With the on-boar d Gigabau d

Link Module (GLM), the FC board provides the functionality to network

numerous Profile systems.

Master Enhanced Disk Recorder Board

The Master Enhanced Disk Recorder (MEDR) board provides high bandwidth

data transfe rs from disk to and from video channels and the Fibre Channel board.

Additionally the i960 enhancements include a Global PCI, a Local PCI (LPCI),

and the i960 processor.

Slave Enhanced Disk Recorder Board

The Slave Enhanced Disk Recorder (SEDR) board is the same as the MEDR with

the following exceptions:

• It does not have the i960 processor section.

• Arbitration, interrupt, and clock lines are from the MEDR.

10/100 BaseT Ethernet Board

This board provides the Ethernet connection for the Profile system.

PCI Interconnect Board

This is a passive 3-conne ctor boa rd which provi des local bus connection betwee n

the Master ED R bo ard , the Slav e EDR , an d the FC board. It is attached to

connectors on the top edges of these boards.

18 PDR 100 Fibre Channel Install ation

Page 19

Front Panel Cable Assembly

This is a r eplac ement c able wit h an at tached ferr ite bea d to in sur e that your Profi le

system remains EMI compliant. Replacement of this cable is only necessary on

Profile systems with serial n umbers lower than B041685.

LED Cable

This is a r eplac ement c able wit h an at tached ferr ite bea d to in sur e that your Profi le

system remains EMI compliant. Replacement of this cable is only necessary on

Profile systems with serial n umbers lower than B041685.

EMI Foam Gas ket

This is EMI foam gasket is ins talled to insure that yo ur Profile system remains EM I

compliant. Installation of this gasket is onl y necess ary on Profile sys tems with

serial numbers lower than B041685.

Fibre Cha nn e l Cab le

The cable connecting the Profile system to a Hub is a 5 meter, copper wire cable

with a DB-9 connect or on each end. Note that other lengths of cable are available

from your Grass Valley Group representative. Also note that for distances greate r

than 25 meters, quality will begin to deteriorate and a fiber-optic cable with

copper-to-fi ber adapters is then recommended.

Front Panel Cable Assembly

NOTE: Minimum cable distances should be used to redu ce signal degradation

and error rates.

PDR 100 Fibre Channel Installation 19

Page 20

PDR 100 Fibre Channel Installation

Ethernet Cable

The Ethernet cable is a 5.49 mete r standard Ethe rnet cable with RJ-45 connectors

on each end.

Sticker Sets

A standard set of stic kers and a Fibre Channel set of stickers are provided so that

your Profile board IDs at the back of the chassis can be updated after the

installation of the Fibre Channel kit.

20 PDR 100 Fibre Channel Install ation

Page 21

Accessories

A Profile Video Network requires a n Etherne t Local Ar ea Network (LAN) to

communi cate co m mand and status info rm at ion b et ween s ystems. If your Profile

systems are not connected to an existing LAN, Grass Valley Group recommends

Ethernet connecti on to a LAN hub or switch.

Similarly, connecting more than two Profile systems to a Fibre Channel Network

requires the use of a Fibre Channel hub or switc h. In addit ion, each Profil e s ystem

more than 25 meters f rom the Fibr e C hannel hub, switch o r an other P rofil e syst em

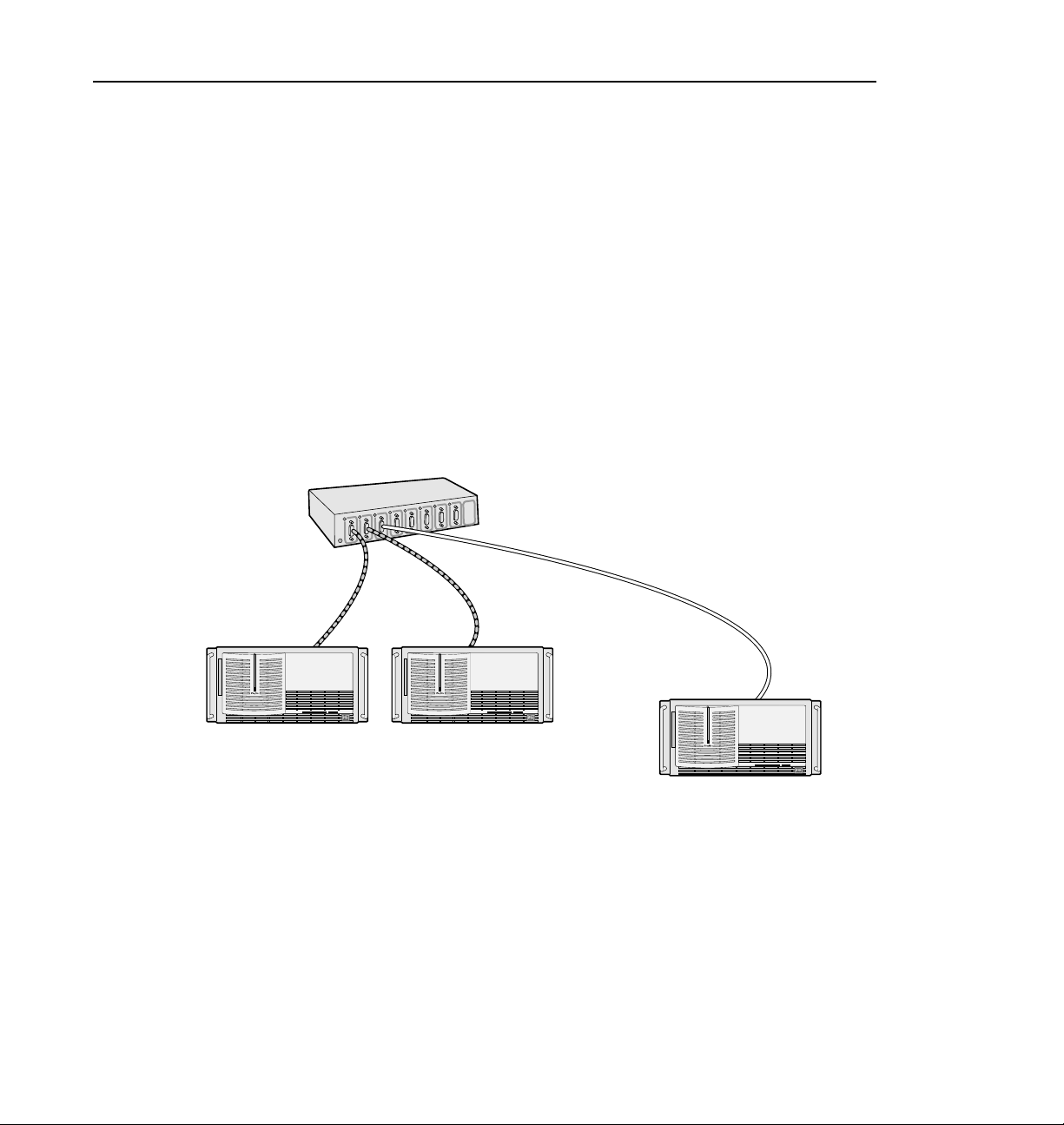

needs a fiber-optic cable and copper-to-fiber cable adap ters. Figure 2 shows an

example of connecting Profile systems up to and more than 25 meters apart.

Up to 25m

(use copper cable)

Accessories

Fibre Channel Hub

From 25m to 500m

(use fiber-optic cable)

Profile1 Profile2

0033-8

Profile3

Figure 2. Example - Profile System Fibre Channel Connections

The hubs, switches, and the adapters are not part of this Fibr e Channel kit, but m ay

be purchased separate ly by contac ting your Grass Valley Group representative.

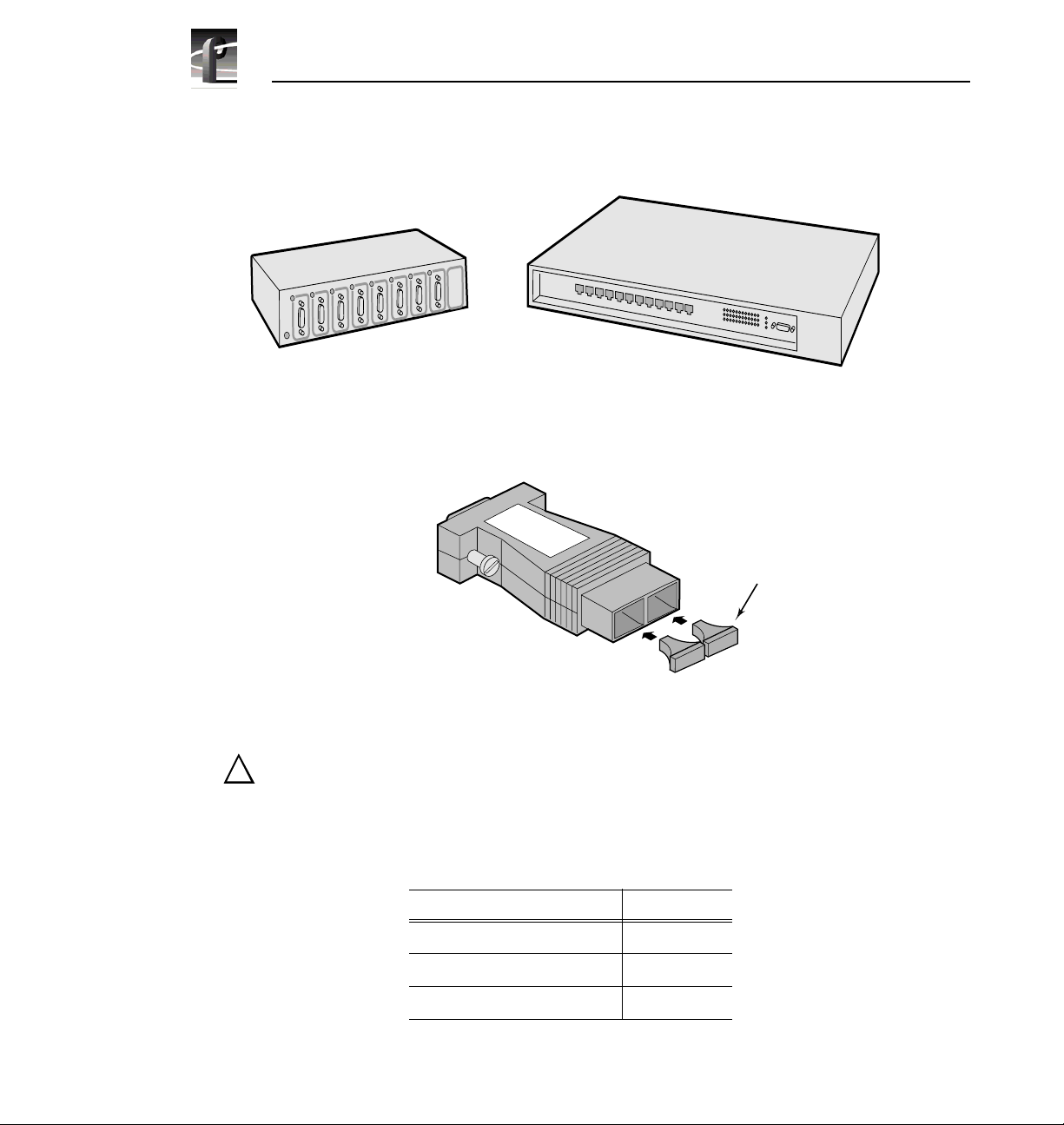

Figure 3 shows the two hubs and Figure 4 shows a copper-to-fiber cable adapter.

Table 2 lists the Hub and Adapte r part numbers.

PDR 100 Fibre Channel Installation 21

Page 22

PDR 100 Fibre Channel Installation

.

Fibre Channel Hub

Figure 3. Fibre Channel and Ethernet Hubs

9674-21

Figure 4. Copper-to-Fiber Cable Adapter

Ethernet Hub

Fiber-optic

Connector

Covers

9674-2

CAUTION: The laser diode in the Copper-to-Fiber Cable Adapter is made

!

from Gallium-Aluminum-Arsenide. Check with your local environmental

authorities for proper disposal of a malfunctioning adapter.

Table 2. Fibre Channel Netw orking Accessories

Name Part Number

Ethernet Hub PNETHUB

Fibre Channel Hub PNFCHUB

Cable Ada pter, Co pper- to-Fi ber PNF0MIA

22 PDR 100 Fibre Channel Install ation

Page 23

Networking Overview

This section contain s information about networking Profile systems and Ethernet.

Network Configurations

Ethernet and Fibre Channel provide two types of networking. Etherne t provides a

path for command and status signals from one device to another. It also allows

Windows NT file transfers between devices.

Fibre Channel provide s connectivity for high speed media data transfers between

Profile system s .

Using Fibre Channel to network groups of greater than two Profile systems

requires an existing Ethernet network (LAN) or an Ethernet hub and a Fibre

Channel hub.

Network Models

The following discusses two example s of Ethernet and Fibre Channel networking.

The first example shows connect ion of several Profile systems with an Etherne t

hub (or existing Ethernet network) and a Fibre Channel hub. The second example

of Ethernet and Fibre Channel networking shows connection of several hubs.

Networking Overview

PDR 100 Fibre Channel Installation 23

Page 24

PDR 100 Fibre Channel Installation

Networking Several Profile Systems

Hubs provide an easy and efficient method for the connection and disconnection

of machines without rewiri ng. I f you want to connect more than two Profile

systems togethe r for video ne tworking, you will need t o connect each sys tem to an

Ethernet hub or an existing Ether net network and a Fibre Channel Hub. Figure 5

shows an example of this networking.

Ethernet Hub

Profile1

Profile2

Profile3

0033-9

Figure 5. Basic Hub Connections

Fibre Channel Hub

24 PDR 100 Fibre Channel Install ation

Page 25

Network Models

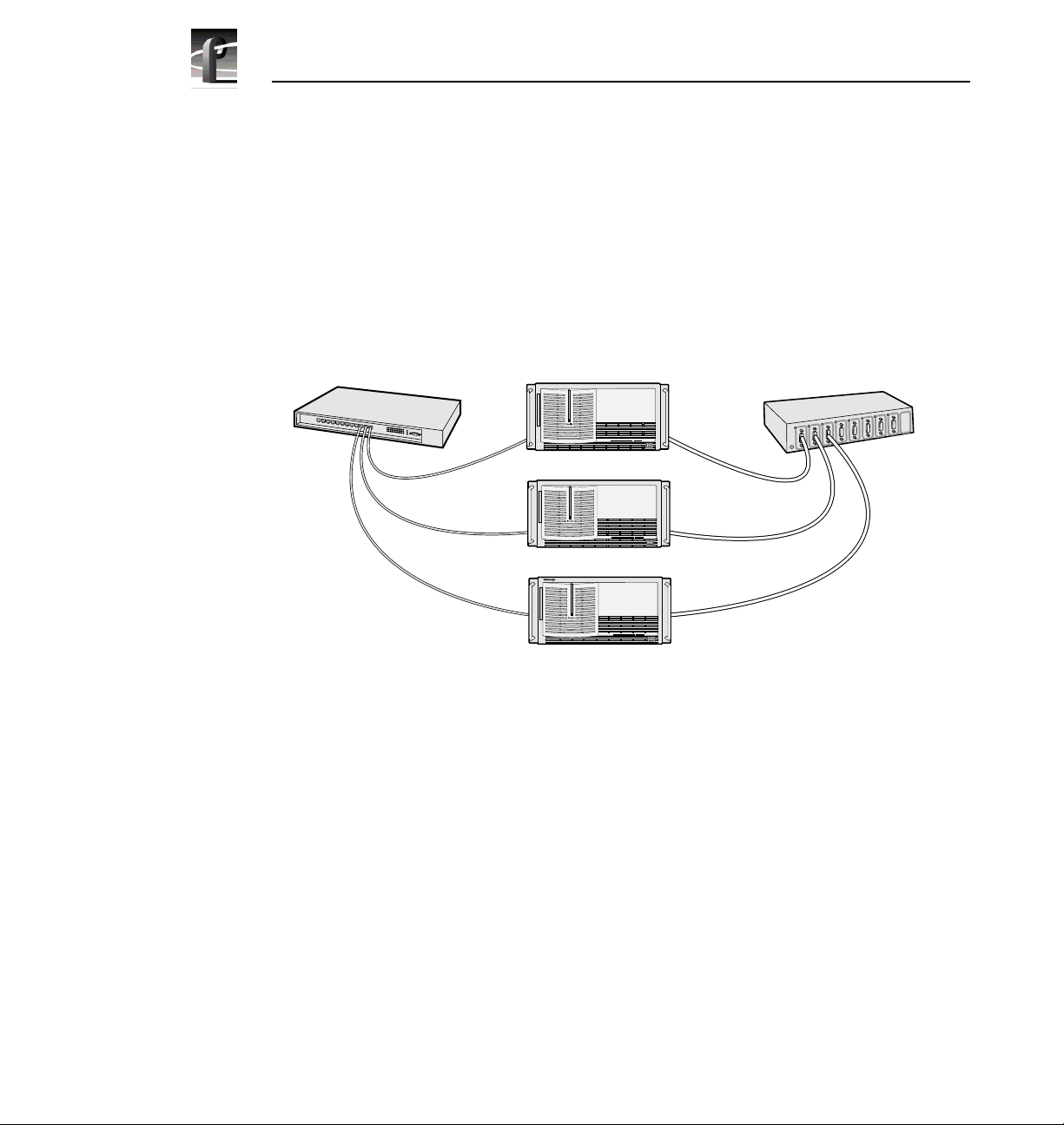

Networking Several Hubs

Connecting hubs together provides a way to add more and more systems to the

network. Large Fibre Channel networks will probably not perform as well as

smaller ones due to bandwidth lim itati ons. Figure 6 shows a simple use of several

hubs.

Ethernet Hub 1

Ethernet Hub 2

Profile1

Profile2

Profile3

Profile4

Profile5

Profile6

Fibre Channel Hub 1

Fibre Channel Hub 2

0033-10

Figure 6. Using Several Hubs

PDR 100 Fibre Channel Installation 25

Page 26

PDR 100 Fibre Channel Installation

The number of hu bs re quire d depends o n th e number of conne ction s sup porte d by

each hub. Remember that one of the connections is needed to connect to the next

hub. You must use appropriate cables fo r the distance between devices.

Building a Fibre Channel Network

The simplest network connect ion is the point-to-point connection shown in

Figure 7. This method allows you to conn ect two Profile systems togeth er, which

is the ideal installation fo r initial setup to ensure that all components are working

and correctly config ured be fore adding additional Profile systems to your Fibre

Channel network.

Profile1

r

b

i

F

n

e

n

c

o

t

C

t

e

n

r

e

h

t

E

a

h

C

e

o

C

l

e

n

n

i

o

n

e

c

n

t

i

n

o

n

Profile2

0033-11

Figure 7. Point-to-point Fibre Channel Network Connection

The Ethernet connection shown in Fi gure 7 links the two LAN cards in each

Profile system. These cables may be twisted pairs up to 30 meters in length

The Fibre Channel connection shown in Figure 7 links the two Fibre Channel

cards in the two systems. This cable can be:

• Copper cable up to 25 meters.

• Multi-mode optical cabl e with a copper-to-fiber adapter up to 500 meters.

26 PDR 100 Fibre Channel Install ation

Page 27

Electrostatic Precautions

Electrostatic Precautions

!

CAUTION: This product contains components that are highly sensitive to

electrostatic discharge. To protect these components from damage and to

maintain product reliability, take the following precautions when handling

the circuit boards.

• Handle all circuit boar ds in a static -protected area capable of cont rolling

static charge on c onductive materia ls , people, and non-con ductive mate ria ls.

Static-prote cted areas include non-static table tops and non-static floor mats.

• Use a static discharge wrist strap when handling circuit boards.

• Handle the circuit board s only by the edges. Avoid touching the printed wires

on the back of the circuit board as much as possible.

• Leave the board in its static-shielded bag until you are ready to install the

board.

PDR 100 Fibre Channel Installation 27

Page 28

PDR 100 Fibre Channel Installation

Installation Procedures

!

WARNING: These procedures should only be performed by qualified se rvice

personnel.

The procedures listed below take you step-by-step through the installation of the

Fibre Channel upgrade.

• Preparing the Profile system for the upgrade.

• Installing the upgr ade.

• Verifying post-i nstallation operability.

NOTE: Unless otherwise instructe d, do not discard any items removed from

the Profile sys tem.

28 PDR 100 Fibre Channel Install ation

Page 29

Prep aring the Profile System

Before you can inst all, tes t, and operate the Fibre Channe l upgrade, Prof ile System

Software version 2.1 or higher must be insta lled and te st ed for o perabili ty, and the

tasks liste d below. In add ition to these task s, mak e sure t hat your video d ata i s

backed up.

• Enable the network

• System shutdown.

• Power off.

• Power cord and External cables disconnect.

• Profile system removal from the rac k .

• Covers removal.

• Board brackets removal.

• Removing the old Mast er Disk Recorder boa rd and, if installed, the old Slave

Disk Record er bo ard .

A board location guide and audio clock cabling information is included to as sist

you if you must move boards around in order to instal l the Fibre Channel upgra de.

Preparing the Profile System

Enable the N etwork

Network service s must be r unning r egardle ss of whether or no t yo u cur rently ha ve

a LAN board installed. To enable the network, from a Command Prompt, type in:

netenabl and then press

Return.

System Shut dow n

To shut your Profile system down without loss of data, you will need to:

• Shut down the Profile Applicat ion software.

• Close any other processes whic h may be running.

• Close Windows NT.

• Switch power off.

PDR 100 Fibre Channel Installation 29

Page 30

PDR 100 Fibre Channel Installation

External Cables Disconnect

NOTE: Making a diagram or note of cable connecti ons wil l make it e asier to

reconnec t the cab les .

Disconnect the power cord, all cable s, and any SCSI te rminators from the Profile

rear panel.

Profile Chassis Removal

To remove the Prof ile chassi s from the equ ipment rack:

!

!

WARNING: Unless the equi pment rack is adeq uat el y anch o r ed, th e rac k

could tip when the Profile chassis is extended on the rack slides. To avoid

possible injury to person nel or damage to the equipm ent, make sure th e rack

is firmly anchored before exte nding the Profile chassis on the rack slides.

1. Loosen the Pr ofile chassis retaining screw which secures the Profile chassis

to the rack.

2. Use the Profile chass is front panel handles to sli de the chassis out of the rack

until the rack slide locks engage.

WARNING: The Profile chassis is too heavy for one person to remove from

an equipment rack. To avoid possible injury to personnel or damage to the

equipment, get help when removing the Profile chassis from the rack.

3. Being sure to fully support the Prof ile chassis, depress the slide locks and

slide the chassis out free of the rack and place on a flat level surface with

enough room to work around it.

Covers Removal

There are two covers which need to be removed to gain access to the board area:

the disk drive top cover and the board area top c over. The disk drive cover acts as

a hold down for the board area cover and therefore must be removed first. See

Figure 8.

NOTE: If your PDR100 has been upgraded to 9GB disk drives, it will have

more disk drive cover screws than shown in Figure 8.

30 PDR 100 Fibre Channel Install ation

Page 31

Preparing the Profile System

1. Use the Torx tool with the T10 tip to remove the top screws and use the T15

tip to remove the side screws, if present, which secure the disk drive cover

Ê

to the chassis and remove the cover.

2. Use the Torx tool with the T10 tip to remove the screws which secure the

Ë

board area cover

.

2

1

9496-1

Figure 8. Profile Top Covers Removal

PDR 100 Fibre Channel Installation 31

Page 32

PDR 100 Fibre Channel Installation

Board Retainer Brackets Removal

There are two re tainer brackets l ocated in the board area that must be removed in

order to remove circuit boards. One is slotted so that it holds full size boards in

place and helps maintain their ali gnment. Although the other bracket holds short

boards in place, it must also be removed to remove any full siz e boards. This

bracket has extenders which may be moved to adapt to the locations of any short

boards. See Figure 9 for locations and removals of the two board retaine r brackets.

To remove the board hold-down bracket s, r efe r to Figure 9 and:

1. Use the Torx tool with the T10 bit to remove retaining sc rew

slotted bracket from the side of the Prof ile chassis.

2. Lift bracket

3. Use the Torx tool with the T10 bit to remove retaining sc rew

middle of the short board bracket.

4. Lift bracket

Ë

up and out of the chassis.

Í

up and out of the chassis.

Ê

for the top

Ì

from the

32 PDR 100 Fibre Channel Install ation

Page 33

Preparing the Profile System

3

4

1

2

9674-13

Figure 9. Board Retainer Bracket s Rem oval

PDR 100 Fibre Channel Installation 33

Page 34

PDR 100 Fibre Channel Installation

Removing Internal Cables

The internal cables you remove dep ends on whether you have 2-channel or a

4-channel PDR100 (see Figure 10).

For a 2-channel PDR100:

• Remove the SCSI A Cable connector

board.

For a 4-channel PDR100:

• Remove the SCSI A cable connector

board.

• Remove the SCSI B cable connector

• Remove the short ribbon cable

Recorder board an d the Slav e D isk Recorder board .

It may be necessary to move boards around to accommodat e the slot requirements

for the Fibre Channel board and the new EDR boards. If moving boards a round

requires re moval of any int ernal cables, Gra ss Vall ey Gro up re commends making

a diagram of the internal cable connections prior to moving an y boards to make it

easier to reconnect internal cables. Refer to the “Board Location Guide” on

page 38 and “Audio Clock Cabling” on page 48 for additional information.

Ì

from the Master D isk Recorder

Ê

Ê

from the Master Disk Recorder

from the Slave Disk Recorder board.

Ë

connected b etw een the Mast er D isk

34 PDR 100 Fibre Channel Install ation

Page 35

Preparing the Profile System

3

1

2

9674-9

Figure 10. Interna l SCSI Cables Rem oval

PDR 100 Fibre Channel Installation 35

Page 36

PDR 100 Fibre Channel Installation

Removing Old Boards

If you currently have a 2-channel PDR100 system, you must remove the Master

Disk Recorder board. I f you curr ently have a 4- channel syst em, you must re move

the Master Disk Recorder and the Slave Disk Recorder boards. Also, for both

2-channel and 4-channel systems, if you currently have an Ethernet 10 BaseT

board, you must remove that board.

To remove the old Master and, if installe d, Sl ave Disk Recorder boards:

1. Use the Torx tool with the T15 tip to remove the screws which secure each

board to the rear panel (see Figur e 11 for an example).

2. Use the extraction lever on the front of each boa rd and the extracti on ring at

the back of each board to lift the circuit board free of the connectors on the

motherboard.

1

Figure 11. Typical Removal of a Full Size Board

36 PDR 100 Fibre Channel Install ation

2

9040-13

Page 37

Preparing the Profile System

If necessary to remove an Ethernet 10 BaseT board, which is a short board, see

Figure 12 for an example and:

1. Use the Torx tool with the T15 tip to remove the board bracket retaining

screw from the inside of the rear panel.

2. Carefully but firmly gra sp the boar d and lift it straight up and out of the

chassis. Note that you may ha ve to remove an adjacent full size board in order

to safety grasp the Ethernet 10 BaseT board.

Figure 12. Typical Removal of a Short Board

PDR 100 Fibre Channel Installation 37

9674-18

Page 38

PDR 100 Fibre Channel Installation

Board Location Guide

This board location guide ide ntifies the inputs and outputs of each Profi le board

currently avail able for a PDR100, as well as the input and output connections on

the Video Router connectors on the motherboard. Use this information when:

• you add a new circuit board to the Profile system and need to select a slot

into which you can install it;

• you need to move boards around to meet requirements for new boards.

As you move boards around, remember that some circuit boards must occupy

specific slots , while others can be installed in almost any slot a s long as their I/O

requirements are met.

This section provides a simple approach to board location. It explains the

relationship bet ween the motherboard a nd Video Router connect ors and provide s

tables, charts and examples to as sist you in installing boards.

Video Router to Motherboard Relationship

The Video Router provides and controls video data to twelve connectors on the

motherboard. These video dat a connectors are align ed with the main motherboard

connectors for slo ts J5 through J16. Since the Ref Gen board must oc cupy J16 to

provide the necessary system clocks, this discussion excludes J16.

When choosing a slot for a board, the major constraint on a slot is how the board

connects to the Video Router. Not all boa rds requir e the same nu mber of video I/O

connections, and not all video data connectors provide the same number of video

I/O connections. Therefore, you must know how many input and output

connections the board need s, and the slot available that meets those needs.

Board I/O Requirements and Restrictions

Table 3 lists each of the boards which may be installed in the Profile system and

the recommended slots, possible alternatives, and restrictions for each board.

Note that if more than one slot is recommended or possible for a board, those slots

are listed in the order of preference.

38 PDR 100 Fibre Channel Install ation

Page 39

Table 3. Board I/O Requirements and Restrictions

Board Location Guide

Board Video Router

Connection

Requirements

Inputs Outputs

CPU n/a n/a J1 None Reserved for PC card only

VGA n/a n/a J2 None ISA only

LAN n/a n/a J3 None EISA only

SCSI n /a n/a J4 None EISA only

RefGen n/a n/a J16 None Reference genlock

RS-422 n/a n/a J17 None EISA only

Master Disk

Recorder

Slave Dis k

Recorder

Analog

Compos ite In

Analog

Composite

Decoder

Four Ch annel

Analog Out

Analog

Composite

Monitor Out

Analog

Compos ite I/O

Serial Digital I/O 2 2 any slot J5-J15 any open slot if board in adjacent slot does

CAV In None 1 any slot J5-J15 any open slot if board in adjacent slot does

Fibre Channel None None J13 None Must be adjacent to Master Disk Recorder.

Mix Effe cts 6 2 J6 J7 Only J6 and J7 have 5 dedicated inputs;

Audio Signal

Processing

Board (ASPB)

2 2 J14 Non e Must be adja cent t o Slave Disk R ecorder and

2 2 J15 None Must be adjacent to Mas ter Disk Re corder.

None 1 any slot J5- J 15 Any open slot if board in adjacent slot does

None None any slot J4-J15 Must be adjacent to Analog Composit e In.

4 None J11,J12 J6,J7 Only J6, J7, J11, and J12 have 4 (or more)

4 None J11,J12 J6,J7 Only J6, J7, J11, and J12 have 4 (or more)

2 2 any slot J5-J15 any open slot if board in adjacent slot does

None None any slot J5-J15 Cables must be able to reach video boards

Recommended

Slots

Other

Possible

Slots

Comments

Fibre Channel (if insta lled).

not use the same sha red rout e r poi nt s. Mu st

be adjacent to the Analog Composite

Decoder.

May be installed in J4 since it does not

require any router connections.

inputs. If in J11 or J12, board must be able to

get a s hare d in pu t (t he 4 t h) fr om an adj ace nt

slot (J1 0 or J1 3).

inputs. If in J11 or J12, board must be able to

get a s hare d in pu t (t he 4 t h) fr om an adj ace nt

slot (J1 0 or J1 3).

not use the same sh ared rout er points.

not use the same sh ared rout er points.

not use the same sh ared rout er points.

PCI Interconnect required.

board must be ab le to get a sha red i nput ( the

6th) fr om an adjacent slot (J5 or J8).

or additional ASPB. Second ASPB

nece ss a r y for 32 channels of audio.

PDR 100 Fibre Channel Installation 39

Page 40

PDR 100 Fibre Channel Installation

Video Router I/O Connections

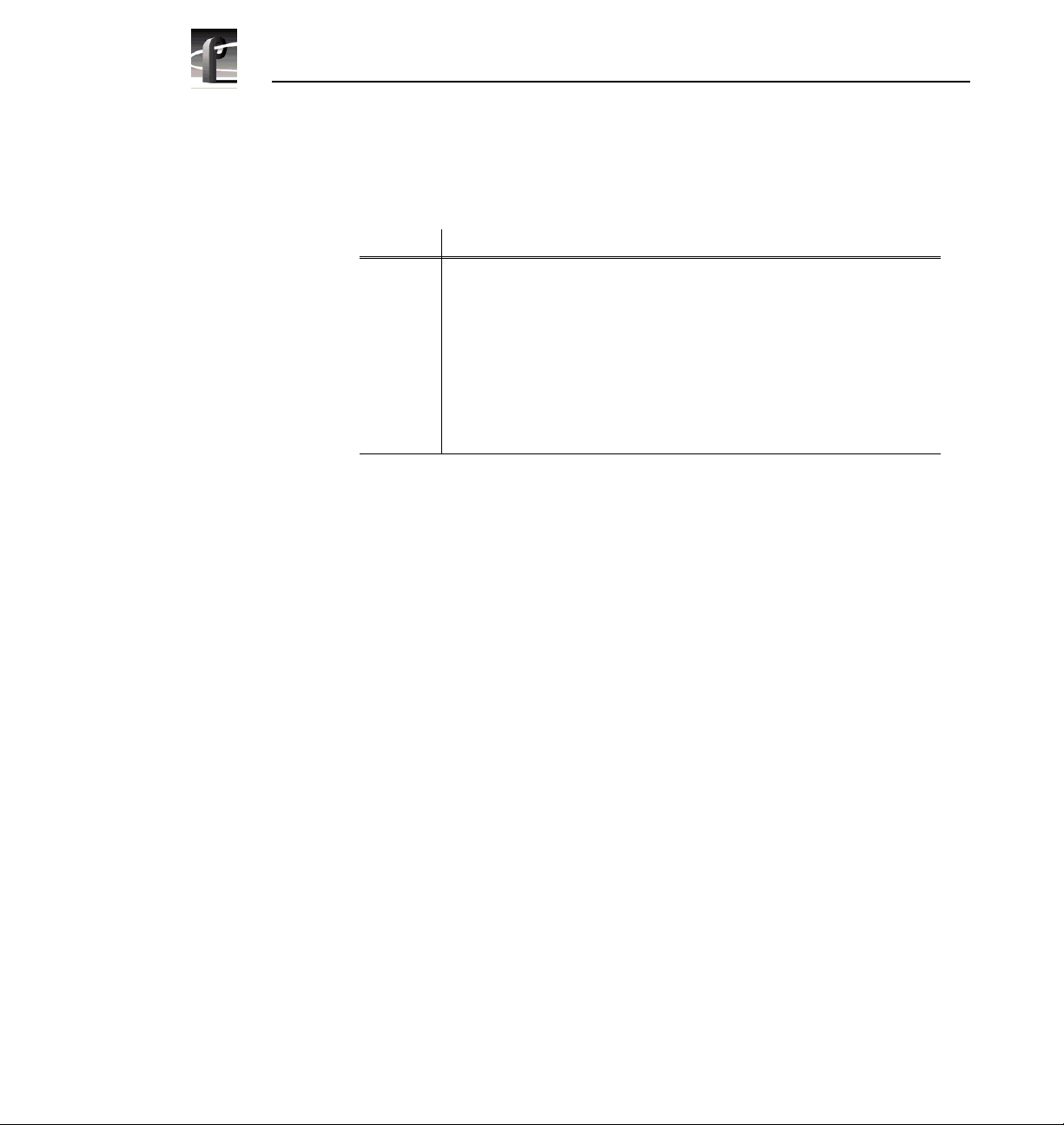

Now let’s look at th e Video Router connections available at slots J5-J15. Table 4

is a board location chart with the Video Router input and output connections. In

the table:

• The Slots column lists each slot on the motherboard connected to the Video

Router.

• The Board column is where you e nter the boards curren tly installed and the

name of the board you want to install.

• The Inputs column identifi es data input connections to the slots (boards)

from the Video Router. The numbers in the blocks correspond to the order

input connections are assigned at the Video Router connector.

• The Outputs column identifies data output connections from the slots

(boards) to the Video Router. The numbers in the blocks correspond to the

order output connecti ons are assigned at the Video Router connector.

• The shaded blocks in the d iagram indicate Video R outer conn ections sha red

between slots. A shar ed connec tion is avail abl e to eithe r slot, but not both at

the same time.

For instance :

• The shaded blocks between slots J5 and J6, slots J7 and J8, slo ts J10 and J11,

and slots J12 and J13 indicate shared input connections.

• The shaded blocks between slots J8 and J9, slots J10 and J11, and slots J12

and J13 indicate shared output c onne ctions.

40 PDR 100 Fibre Channel Install ation

Page 41

Table 4. Board location chart

Slot Board Input Output

J5

1

23

J6

J7 1 1

2

3

42

5

6

J8

J9 1

22

J10 1 1

2 34

J11

J12 1 1

22

3

4 34

J13

J14 1 1

23

J15 1 1

23

1

2

62

5

4

31

2

1

21

12

34

43

2

4 43

32

2

11

2 43

12

2

2

Board Location Guide

1

1

PDR 100 Fibre Channel Installation 41

Page 42

PDR 100 Fibre Channel Installation

Selecting a Location

Here’s how to use the tables to select a location for a board.

1. In the Board Location C hart, Tab le 4, enter the board name and, referring to

Board I/O Requ irements a nd Restrictio ns, Table 3, put a check mark i n each

input and output block u sed by each board cu rrently inst alle d in your Profil e

syst e m. Start with the 1 block for each board.

2. Look in the Board I/O Requirements and Restric tions, Table 3, to see the

input and output requirements and both the recommended slot and

alternative slots for the board you want to install.

3. Look in the B oard Location Chart, Ta ble 4, for a slot with the r equired Vide o

Router connections avai lable. Starting with the 1 block, put an “X” in each

block that correspond s to an input and output r equirement for the board. If

the recommended slot is occupied, or there are not enough input or output

blocks avail abl e, lo ok at the al te rnat iv e slo ts.

4. If all input and output requirements for the board match the available ones

for the slot , write the b oard name in the Boa rd column for the slot and in stall

the board.

NOTE: If you can’t find an open slot with the I/O which meets the I/O

requirements of the board you want to instal l, y ou will have to move boards

around. You can use the Boa rd I/O Requiremen ts and Restri ction s table an d

the Board Locat ion Chart to experim e nt with various board locations be fore

deciding on one.

The following examples de monstrate how to u se the Board I /O Requirements and

Restrictions, Table 3, and the Board Location Chart, Table 4.

42 PDR 100 Fibre Channel Install ation

Page 43

Board Location Guide

Example 1

This example shows how to use the Board I/O Requirements and Restrictions,

Table 3, and the Board Loca tion Chart, Table 4, to install a Fibre Channel upgrade

into a 4-channel PDR100 with two Serial I/O boards and four Audio I/O boards.

In all likelihood, you will have to move boards before you can install the Fibre

Channel upgrade. Move the boards bef ore using the Board Location Chart. For this

example:

1. Move the Serial I/O in slot J8 to slot J7.

2. Move the Audio I/O board in slot J9 to slot J8.

3. Move the Audio I/O board in slot J10 to slot J9.

4. Move the Serial I/O in slot J11 to slot J10.

5. Move the Audio I/O board in slot J12 to slot J11.

6. Move the Audio I/O board in slot J13 to slot J12.

7. Now fill in the Board Location Chart.

a. For the Serial I/O in slot J7, which requires two inputs and two outputs:

- Write Serial I/O in Slot 7.

- Put check marks in the 1 and 2 Input blocks for J7.

- Put check marks in the 1 and 2 Output blocks for J7.

b. For the Audio I/O boards in slots J8 and J9, which requi re no Video Router

connections:

- Write Audio I/O in Slot J8 and Slot J9.

c. For the Serial I/O in slot J10, which requires two inputs and two outputs:

- Write Serial I/O in Slot 10.

- Put check marks in the 1 and 2 Input blocks for J10.

- Put check marks in the 1 and 2 Output blocks for J10.

d. For the Audio I/O boards in slots J11 and J12, which require no Video

Router connections:

- Write Audio I/O in Slot J11 and Slot J12.

PDR 100 Fibre Channel Installation 43

Page 44

PDR 100 Fibre Channel Installation

8. From the Board I/O Requirements and Restri ctions, Table 3, note that:

a. The Slave EDR board requires two inputs and two outputs and must be

adjacent to the Mast er E DR b o ard.

b. The Master EDR boar d requires two inputs and two outputs and must be

adjacent to both the Slave EDR and the Fibre Channel boa rds.

c. The Fibre Channel board does not require inputs or outputs but must be

adjacent to the Mast er E DR b o ard.

9. Looking at your Board Location Chart reveals that slots J13, J14, and J15

meet requirements for all three boards.

10. For the Slave EDR board:

- Put Xs in the 1 and 2 Input blocks for J13.

- Put Xs in the 1 and 2 Output blocks for J13,

- Write Slave EDR in the Boards column for Slot J13, and install the board.

11. For the Master EDR board:

- Put Xs in the 1 and 2 Input blocks for J14.

- Put Xs in the 1 and 2 Output blocks for J14.

- Write Master EDR in the Boards column for Slot J14, and install the bo ard.

12. Write Fibre Channel in the Boards column for slot J15 a nd install the board.

• Your Board Location Chart would the n look similar to Table 5, “Example 1

- Installing the Fibre Channe l Upgrade,” on page 45.

44 PDR 100 Fibre Channel Install ation

Page 45

Table 5. Example 1 - Installing the Fibre Channel Upgrade

Slot Board Input Output

J5

J6

J7 Serial Digital I/O 1

J8 Analog Audio I/O

J9 Analog Audio I/O 1

J10 Serial Digital I/O 1

J11 Analog Audio I/O

J12 Analog Audio I/O 1 1

J13 Fibre Channel

J14 Master Enhanced

Disk Recorder

J15 Slave Enhanced

Disk Recorder

1

23

2

3

42

5

6

22

2

22

3

4 34

1 X 1 X

2 X 3

1 X 1 X

2 X 3

1

2

62

5

4

31

2

1

3

1

3

3

3

21

12

34

43

1

3

3

3

2

3

34

4 43

32

2

11

2 43

12

2 X

2 X

Board Location Guide

1

1

PDR 100 Fibre Channel Installation 45

Page 46

PDR 100 Fibre Channel Installation

Example 2

If you next want to install a Mix Effects board:

1. From the Board I/O Requirements and Restrictions table, note that the Mix

Effects board require s six inputs and two outputs and that the first

recommended slot is J7 with slot J6 another possibility.

2. Looking at your Board Location Chart , you see tha t slot J7 is occupied but

that slot J6 is open and although it only has five Inputs, t he 6th Input can be

the input shared with J5, which is open.

3. On your Board Location Chart for the Mix Effects boa rd :

- Put Xs in the 1-5 Input blocks for J6.

- Put an X in the shared Input block for J5.

- Put Xs in the 1 and 2 Output blocks for J6.

4. Write Mix Effects in the Board column for slot J6 and ins tall the board.

• Your Board Location Chart would the n look similar to Table 6, “Example 2

- Installing a Mix Effects Boar d,” on page 47.

46 PDR 100 Fibre Channel Install ation

Page 47

Table 6. Example 2 - Installing a Mix Effects Board

Slot Board Input Output

J5

J6 Mix Effects

J7 Serial Digital I/O 1

J8 Analog Audio I/O

J9 Analog Audio I/O 1

J10 Serial Digital I/O 1

J11 Analog Audio I/O

J12 Analog Audio I/O 1 1

J13 Fibre Channel

J14 Master Enhanced

Disk Recorder

J15 Slave Enhanced

Disk Recorder

1

23

2

3

42

5

6

22

2

22

3

4 34

1 X 1 X

2 X 3

1 X 1 X

2 X 3

1

2

X 6 X 2

X 5

X 4

X 3 X 1

X 2

X 1

3

1

3

3

3

21

12

34

43

1

3

3

3

2

3

34

4 43

32

2

11

2 43

12

2 X

2 X

Board Location Guide

1

1

PDR 100 Fibre Channel Installation 47

Page 48

PDR 100 Fibre Channel Installation

Audio Clock Cabling

This section provides some general rules about audio clock cabling. Audio clock

signals from the appropr iate video board synchronize the audio to the video during

Record. Internal cabling between connectors on the top of the video boards and

connectors on the top of the audio board s provide the clock signals to the audio

boards.

In general, the video board in the lowest numbered slot provides the audio clock

signal to an Audio I/O board, the video board in the next lowest numbered slot

provides the audio clock signal to another Audio I/O board, etc.

Figure 13 shows an example of internal audio clock cabling. In Figure 13, Serial

I/O boards, installed in slots J 7 and J10, are the only v ideo boards. The audio c lock

cable connect io n s are:

• Channel 1 of the Seria l I/O board in slot J7 t o Audi o 1 (PLAY) on t he Audio

I/O in slot J8

• Channel 2 of the Seria l I/O board in slot J7 t o Audi o 2 (PLAY) on t he Audio

I/O in slot J9

• Channel 1 of the Serial I/O board in slot J10 to Audio 3 (RECORD) on the

Audio I/O in slot J11

• Channel 2 of the Serial I/O board in slot J10 to Audio 4 (RECORD) on the

Audio I/O in slot J12

• PLAY from all four Audio I/O boards to the system clocks on the RefGen

board.

Note that Figure 13 is an example with video boards only in slot s J7 and J10. If

you have other video boards in lower numbered slots, you will have to determine

how you want to set your system up. You will have to remove any unused clock

cables and you may have to move boards around to accommodate your setup.

Also note that you must be su re to connect audio sources associated with a video

board to the correct XLR connectors on the audio bre akout box.

48 PDR 100 Fibre Channel Install ation

Page 49

Audio Clock Cabling

J17 J13J16

Ref Gen

J11 J9

J15 J14 J6J7

Play

Record

J12

Audio 4

J10

Serial I/O

Audio 3

J8

Audio 1

Audio 2

Ch. 2

Ch. 1

Serial I/O

J5

J4 J3

9674-30

Figure 13. Example of Audio Clock Cabli ng

PDR 100 Fibre Channel Installation 49

Page 50

PDR 100 Fibre Channel Installation

Installing the Fibre Channel Upgrade

Figure 14 identifies the board slot IDs and Figure 15 shows the locations a nd slot

IDs for the Slave EDR, Master EDR, and Fibre Channel boards. Installing the

Fibre Channel upgrade consists of the tasks listed below.

• Installing the 10/100 Base T board, the Slave and Master EDR boards, and

the Fibre Channel board.

• Reinstalling board hold- down brackets.

• Reconnecting interna l cable s.

• Installing the PCI Inte rconnect board.

• Installing EMI complianc e components, if necessary.

• Replacing the Profile cov ers.

• Replacing the Profile chassis into the rack.

• Connecting/rec onnecting external cables and power cord.

NOTE: After board relocation s, the slot ID stickers on the bott om rear panel

will no longer be valid. If you need new ID stickers, contact your Grass Valle y

Group representativ e.

50 PDR 100 Fibre Channel Install ation

Page 51

Installing the Fibre Channel Upgrade

J17 J13J16

J15 J14 J6J7

Figure 14. Board Slot IDs (Rear Panel)

J12

J11 J9

J10

J8

J5

J4 J3 J2

J1

9674-19

PDR 100 Fibre Channel Installation 51

Page 52

PDR 100 Fibre Channel Installation

Figure 15. Slave EDR, Master EDR, and Fibre Channel Board Locations

Slave (J13)

Master (J14)

Fibre Channel (J15)

9674-16

52 PDR 100 Fibre Channel Install ation

Page 53

Installing the Ethernet 10/100 BaseT Board

Installing the Ethernet 10/100 BaseT Board

The Ethernet 1 0/100 BaseT board is a short board, which must be installed in slot

J3. See Figur e 16 for an installati on example a nd i nstall th e 10/100 baseT b oard as

follows:

1. If you did not have an Ethernet board, use the Torx tool with the T15 tip

remove the slot blank from J3.

2. Slip the 10/100 BaseT board into the board area ali gning it with the

connectors in the mother board at the bottom panel and the rear panel cutout

for J3.

3. Ensure that the board contacts a re corr ectly aligned with the motherboard

connectors and firmly press down on the board until it is fully seated. Screw

holes in the board bracket should a li gn with the two bracket mounting scr ew

holes, one on the inside and one on the outside of the rear pa nel.

4. Use the Torx tool with the T15 bit to secure the 10/100 BaseT boar d bracket

to the rear pa nel with the screw removed either when the old Ethernet board

was removed or when the slot blank was removed (step 1).

PDR 100 Fibre Channel Installation 53

Page 54

PDR 100 Fibre Channel Installation

Figure 16. Short Board Installation Example (Top View)

54 PDR 100 Fibre Channel Install ation

9674-11

Page 55

Installing the EDR Boards

See Figure 17 to distinguish between the Master EDR board and the Slave EDR

board, where the Master EDR contains the i960 Controller. See Figure 14 for slot

IDs and Figure 18 for an example of installing a full size board. To inst all the EDR

boards, proceed as follows:

1. If you have a 2- channe l PDR100, start at step 5, o therwi se continue t o step 2.

2. Slip the Slave EDR board into the board slide at the front of the board area

for slot J13 aligning it with the e dge-board connectors in the motherboard at

the bottom panel and the rear panel cutout for J13.

3. Ensure that the board contacts a re corr ectly aligned with the motherboard

connectors and firmly press down on the board until it is fully seated. Screw

holes in the board bracket should a li gn with the two bracket mount ing scr ew

holes, one on the inside and one on the outside of the rear pa nel.

4. Use the Torx tool with the T15 bit to secure the Slave EDR board bracket to

the rear panel with the two screws previously removed, but do not fully

tighten until afte r the PCI Interconnect board has been install ed.

5. Slip the Master EDR board into the board slide at the front of the board area

for slot J14 aligning it with the e dge-board connectors in the motherboard at

the bottom panel and the rear panel cutout for J14.

Installing the EDR Boards

6. Repeat step 3 and 4.

PDR 100 Fibre Channel Installation 55

Page 56

PDR 100 Fibre Channel Installation

Master EDR Slave EDR

i960

Figure 17. Distinguishing Between Master and Slave EDRs

9674-23

56 PDR 100 Fibre Channel Install ation

Page 57

Installing the EDR Boards

9674-7

Figure 18. Installing a Full Size Board Exam ple

PDR 100 Fibre Channel Installation 57

Page 58

PDR 100 Fibre Channel Installation

Installing the Fibre Channel Board

The Fibre Channel boa rd must be installe d in slot J15, ad jacent to the Maste r EDR

board. To install the Fibre Channel board, refer to Figure 14 and Figure 15

(page 52) for loca tion, and Figure 18 (page 57) for installation information and

proceed as follows:

1. Slip the Fibre Channel board into the board slide at the front of the board area

for slot J15 ali gning i t wit h the edge-boa rd c onnector s in t he motherboa rd at

the bottom panel and the rear panel cutout for J15.

2. Ensure that the board contacts a re corr ectly aligned with the motherboard

connectors and f irmly press down o n the board until i t is f ully se ated. S crew

holes in the board bracket should align with the two brack et mounting screw

holes, one on the inside and one on the outside of the rear pa nel.

3. Use the Torx t ool wi th t he T15 bit to secur e the Fibre Chann el board bracket

to the rear panel with the two screws provi ded, but do not fully tighten unti l

after the PCI Interconnect board has been installed.

58 PDR 100 Fibre Channel Install ation

Page 59

Reinstalling Internal Cables

Figure 19 shows ins tal lation o f the SCSI cable conne ctors. R efer to Fi gure 19 and:

Reinstalling Internal Cables

1. Connect the cab le label led SCSI A (

on the Master EDR board.

2. For a 4-channel PDR100, connect the cable labelled SCSI B (

Figure 19) to the heade r connector on the Slave EDR.

3. From your diagram, reconnect all other previously removed interna l cables.

in Figure 19) to the header connector

Ê

in

Ë

2

1

Figure 19. SCSI Cable Connections

PDR 100 Fibre Channel Installation 59

9674-17

Page 60

PDR 100 Fibre Channel Installation

Installing the PCI Interconnect Board

The PCI Interconnect board has thr ee conn ectors which attach to edge-board

contacts on the Sl ave EDR, the Maste r EDR , and the Fi bre Ch a n ne l board s . Se e

Figure 20.

J1

Index Notch

Master

J2

J3

9674-15

Figure 20. PCI Interconnection Board

The PCI board connector s are keyed to ensure correct orientation and the bottom

of the board identifies the connec tors as J1, J2, and J3. J2 is further identifie d as

MASTER. To install the PCI board, refer to Figure 21 and proceed as follows:

1. Hold the PCI with the connectors pointing down and the connector

identifica tion s tow ard s the rear of the Profile chas s is.

2. Align the PCI connector s so that J1 is over the Slave EDR header connector,

Master J2 over the Master EDR header connector, and J3 over the Fibre

Channel header connect or, and the connector keys are over the index notc hes

on the boards.

60 PDR 100 Fibre Channel Install ation

Page 61

Installing the PCI Interconnect Board

9674-10

Figure 21. PCI Interconnect Board Installation

3. Attach the PCI boar d by gent ly but firmly pre ssi ng down until t he PCI bo ard

is fully seated on all three b oard s .

4. Tighten the screws which secure the EDR boards and the Fibre Channel

board to the chass is .

PDR 100 Fibre Channel Installation 61

Page 62

PDR 100 Fibre Channel Installation

Reinstalling Board Ret ainer Brackets

Before re-inst alling the short board retainer bra cket, check it against the lay- out of

the boards. Ensure that an extender is in every location where a short board is

installed and that none are in locations where full sized boards are installed.

NOTE: To prevent damage to the Analog Composite Monitor board, if

installed, ensure that an extender is not installed at the Analog Composite

Monitor board location.

To move a short board b racket extender, refer to Fig ure 22 and procee d as follows:

1. Use the Torx tool with the T15 bit and remove extender retaining screw

Ê

from the bracket.

2. Move the extender to the desired location on the bracket.

3. Ensure that the extender align ment nub is in the hole on the bracket and

Ë

replace retaini ng screw

1

Figure 22. Short Board Retainer Bracket and Extender

.

2

9674-6

To re-install the shor t board reta iner bracket, refer to Figur e 23 and proceed as

follows:

1. Insert bracket

Ê

into the board area and ensure that the extenders are on the

top edge of all short boards.

62 PDR 100 Fibre Channel Install ation

Page 63

Reinstalling Board Retainer Brackets

2. Use the Torx tool with the T10 bit to replace brack et retaining screw Ë.

2

1

4

3

9674-14

Figure 23. Board Retainer Bracket installati on

To reinstall the full siz e board retainer bracket refer to Figur e 23 and proceed as

follows:

1. Place bracket

Ì

over the boards.

2. Align the full size boa rds to the co rrect br acket s lots (see ins ert i n Figur e 23)

and carefully seat the bracket onto the boards.

PDR 100 Fibre Channel Installation 63

Page 64

PDR 100 Fibre Channel Installation

3. Use the Torx tool with the T10 bi t to r eplace bracket r etaining sc rew Í at the

side of the Profile chassis.

Installing EMI Compliance Components

NOTE: This procedure is only necessary if your PDR100 serial number is

below B041650.

To ensure that your PDR100 remains compliant with EMI standards with the

Fibre Channel upgrade installed, you must:

1. Remove two cables be hind the front panel and replace them with the cables

included in this upgrade kit.

2. Install a gasket inside the rear panel behind the power supply.

The following procedures explain how to perform these modifications.

To replace the ca b le s:

The front panel cable assembly, Figure 24, and the LED cable assembly,

Figure 25, are on the bezel behind the front panel.

Figure 24. Front Panel Cable Assembly

64 PDR 100 Fibre Channel Install ation

9674-25

Page 65

Installing EMI Compliance Components

Figure 25. LED Cable Assembl y

Figure 26 shows removal of the front panel and bezel.

9674-24

1. Refer to Figure 26 and remove the PDR100 handles (

front panel metal pl ate (

in Figure 26) to access the two cables on the bezel .

Ë

in Figure 26) and

Ê

PDR 100 Fibre Channel Installation 65

Page 66

PDR 100 Fibre Channel Installation

Figure 26. Removing the Front Panel and Beze l

66 PDR 100 Fibre Channel Install ation

Page 67

Installing EMI Compliance Components

2. Refer to Figures 24, 25, and 27 and replace the front panel and LED cable

assemblies.

3. Refer to Figure 26 and reinstall the front panel metal plate, be zel, and

handles.

9674-28

Figure 27. Inst alling the Front Panel and LED Cable Assemblie s

PDR 100 Fibre Channel Installation 67

Page 68

PDR 100 Fibre Channel Installation

To install the EMI foam gasket:

1. Use the Torx tool with the T15 tip to remove the screws which secure the

power supply to the side of the chassis.

2. Refer to

in Figure 28 and slide the power supply toward the front of the

Ê

chassis approximately 1 inch.

3. Remove the protective str ip from the adhesive on the EMI gasket.

4. Carefully slip the gasket into the chassis between the power supply and the

rear panel and attach it to the chassis just below the power cord connector

cut-out as shown at

in Figure 28.

Ë

5. Slide the power supply back into its or iginal position and secure it to the

chassis with the screws previously removed.

2

1

Figure 28. Installi ng the EMI Gasket

68 PDR 100 Fibre Channel Install ation

9674-29

Page 69

Attaching Slot ID Stickers

Two sets of self-a dhesive stickers are inc luded as part of the Fib re Channel kit. One

set is for the new boards. The other set allows you to r e-ide ntify sl ots as a res ult of

any board m ovement wh ich wa s nece ssar y due to instal lation of t he F ibre Channel

kit. Figure 29 shows the locations for the new stickers. If you need additional or

different stickers, contact your Grass Valley Group representative.

Attaching Slot ID Stickers

9674-22

Fibre

Channel

EDR

Master

Figure 29. Sticker Slot IDs for Ne w Boards

EDR

Slave

10/100 Base T

Ethernet

PDR 100 Fibre Channel Installation 69

Page 70

PDR 100 Fibre Channel Installation

Replacing the Profile Covers

See Figure 30 and replace covers as follows:

1. Set board area cover

replace the twelve cover screws; eight on top and four from the side.

2. Set disk drive cover

tips to replace the cover with the screws previously removed.

NOTE: Your PDR100 may have more disk drive cover scre ws than sh own in

Figure 30.

Ê

in place and use the Torx tool with the T10 bit to

Ë

in place and use the Torx tool with the T10 and T15

1

2

Figure 30. Profile Cover Replacements

70 PDR 100 Fibre Channel Install ation

9674-12

Page 71

Reinstalling the Profile Chassis into the Rack

Reinstalling the Profile Chassis into the Rack

To reinstall the Profile chassis into the equipment rack:

WARNING : Un les s the eq uip m ent rac k is adequa t ely a nch o red , it coul d tip

when the Profile chassis is extended on the rack slides. To avoid possible

injury to pe rsonnel or dama ge to the equip ment, make sure the rack is firmly

anchored before extending th e Profile chassis on the rack slides.

WARNING: The Profile chassis is too heavy for one person to install in an

equipment rack. To avoid possible injury to personnel or damage to the

equipment, get help when re-installing the Profile chassis into the rack.

1. Being sure to fully suppo rt the Profile chassi s, slide it into the rac k slides until

the slide locks engage.

2. Depress the slide locks and slide the Profile chassis completely into the rack.

3. Tighten the retaini ng screw to secure the Profil e chassis in t he rack.

Cable Connections

1. If you are using more than two Profile systems, connect the 5 meter Fibre

Channel cable from the Fibre Channel board connector on the rear panel to

the Fibre Cha nnel hub. Se e the Fibre Channel Hub m anual for inst ructions on

how to install the Fibre Channel Hub.