Page 1

KDD-PSU

POWER SUPPLY UNIT

Instruction Manual

071829803

FEBRUARY 2005

Page 2

KDD-PSU Power Supply Unit

Contacting Grass Valley

Region Voice Fax Address Web Site

North America (800) 547-8949

Support: 530-478-4148

Pacific Operations +852-2585-6688

Support: +852-2585-6579

U.K., Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany, Europe +49 6150 104 782 +49 6150 104 223

Copyright © Thomson Broadcast and Media Solutions All rights reserved.

Grass Valley Web Site

The www.thomsongrassvalley.com web site offers the following:

Sales: (530) 478-3347

Support: (530) 478-3181

+852-2802-2996

Grass Valley

P.O. Box 599000

Nevada City,

CA 95959-7900

USA

www.thomsongrassvalley.com

Online User Documentation — Current versions of product catalogs, brochures, data sheets, ordering

guides, planning guides, manuals, and release notes in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be found by searching our

Frequently Asked Questions (FAQ) database.

Software Downloads — Software updates, drivers, and patches can be downloaded.

2 Instruction Manual

Page 3

KDD-PSU Power Supply Unit

Table of Contents

1 Preface..............................................................................................................................................................7

1.1 About This Manual.....................................................................................................................................7

2 Regulatory Notices............................................................................................................................................9

2.1 Certifications and Compliances .................................................................................................................9

2.1.1 FCC Emission Control........................................................................................................................9

2.1.2 Canadian EMC Notice of Compliance................................................................................................9

2.1.3 FCC Emission Limits ..........................................................................................................................9

2.1.4 Certification and Compliance............................................................................................................10

3 Safety Summary..............................................................................................................................................13

3.1 Safety Terms and Symbols......................................................................................................................13

3.1.1 Terms in This Manual.......................................................................................................................13

3.1.2 Terms on the Product.......................................................................................................................13

3.1.3 Symbols on the Product....................................................................................................................14

3.2 Warnings..................................................................................................................................................15

3.3 Cautions...................................................................................................................................................16

4 Technical Specification....................................................................................................................................17

4.1 Power Supply...........................................................................................................................................17

4.2 Environmental Data .................................................................................................................................17

4.3 Mechanical Data......................................................................................................................................17

5 System Overview ............................................................................................................................................19

5.1 Introduction ..............................................................................................................................................19

5.2 DC Power Applications............................................................................................................................20

5.2.1 Standard Application for Redundancy..............................................................................................20

5.2.2 Control Panel Supply........................................................................................................................21

5.2.3 Multiple DC Power Supply................................................................................................................22

6 Installation.......................................................................................................................................................25

6.1 Pre-Installation Procedures......................................................................................................................25

6.1.1 System Survey..................................................................................................................................25

6.1.2 Line Voltage......................................................................................................................................25

6.1.3 Safety Requirements........................................................................................................................25

6.1.4 Installation Tasks..............................................................................................................................26

6.2 Mounting the Power Supply Unit..............................................................................................................27

6.2.1 General Rack Mounting Instructions ................................................................................................27

6.2.2 Rack Mounting Procedure................................................................................................................28

6.3 Rear Connectors......................................................................................................................................29

6.4 Pin Assignments ......................................................................................................................................31

6.4.1 48V DC Power Out...........................................................................................................................31

Instruction Manual 3

Page 4

KDD-PSU Power Supply Unit

7 Service Instructions........................................................................................................................................ 33

7.1 General.................................................................................................................................................... 33

7.2 Status LEDs ............................................................................................................................................ 33

7.3 Fuses....................................................................................................................................................... 33

7.3.1 Main Fuses....................................................................................................................................... 33

7.3.2 Internal Fuses on Board RY3781.....................................................................................................33

7.4 Fan Exchange .........................................................................................................................................34

Table of Figures

Figure 1 Redundant Power Supply for one Mainframe and one Control Panel.............................................. 20

Figure 2 Power Supply for Control Panel only ................................................................................................ 21

Figure 3 Separate Power Supply for Control Panel and Mainframe KayakDD-1............................................ 22

Figure 4 Separate Power Supply for Control Panel and Mainframe KayakDD-2............................................ 23

Figure 5 KDD-PSU Power Supply Unit with Mounting Accessories................................................................ 28

Figure 6 KDD-PSU Rear Connectors 1........................................................................................................... 29

Figure 7 KDD-PSU Rear Connectors 2........................................................................................................... 30

Figure 8 Mounting Overview............................................................................................................................35

4 Instruction Manual

Page 5

KDD-PSU Power Supply Unit

Instruction Manual 5

Page 6

KDD-PSU Power Supply Unit

6 Instruction Manual

Page 7

1 Preface

1.1 About This Manual

This KDD-PSU Manual provides installation, configuration, and service information for

the External Power Supply for the Thomson Grass Valley KayakDD Digital Production

Switchers. This manual is designed for technical personnel resp onsible for installing

and maintaining KayakDD-1 or KayakDD-2 systems.

KDD-PSU Power Supply Unit

Instruction Manual 7

Page 8

KDD-PSU Power Supply Unit

8 Instruction Manual

Page 9

KDD-PSU Power Supply Unit

2 Regulatory Notices

2.1 Certifications and Compliances

2.1.1 FCC Emission Control

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by Thomson Grass Valley can affect

emission compliance and could void the user’s authority to operate this equipment.

2.1.2 Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class B limits for radio noise emissions

from digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Le présent appareil numérique n’emet pas de bruits radioélectriques dépassant hors

des limites applicables aux appareils numériques de la classe B préscrites dans le

Règlement sur le brouillage radioélectrique édicte par le ministère des

Communications du Canada.

2.1.3 FCC Emission Limits

This device complies with Part 15 of the FCC 47 Rules. Operation is subject to the

following two conditions: (1) This device may no cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesirable operation.

Instruction Manual 9

Page 10

KDD-PSU Power Supply Unit

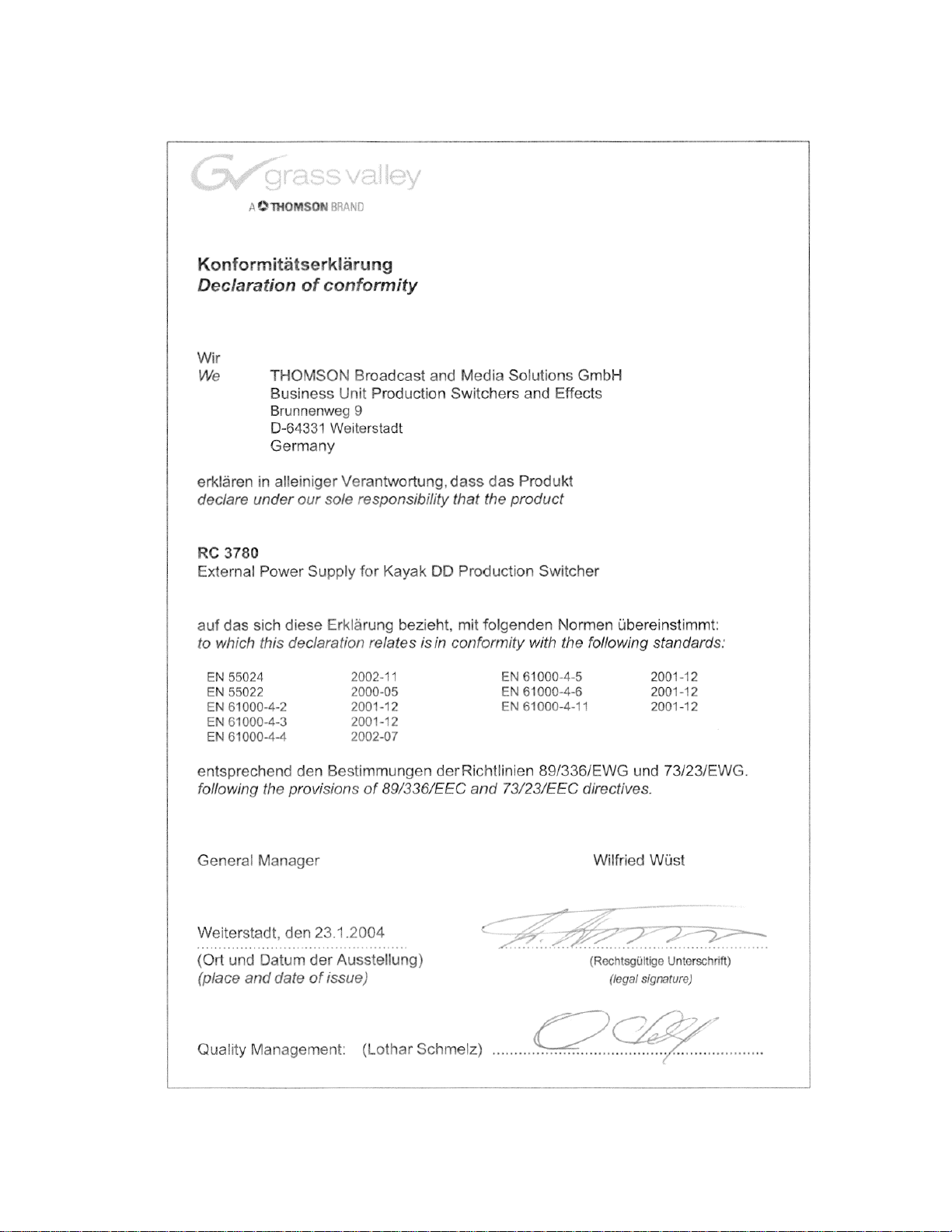

2.1.4 Certification and Compliance

This product has been evaluated for Electromagnetic Compatibility under the E N

55103-1/2 standards for Emissions and Immunity and meets the requirement s for

E1/E2 environment.

This product complies with Class B. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate measures.

This product has been evaluated and meets the following Safety Certification

Standards:

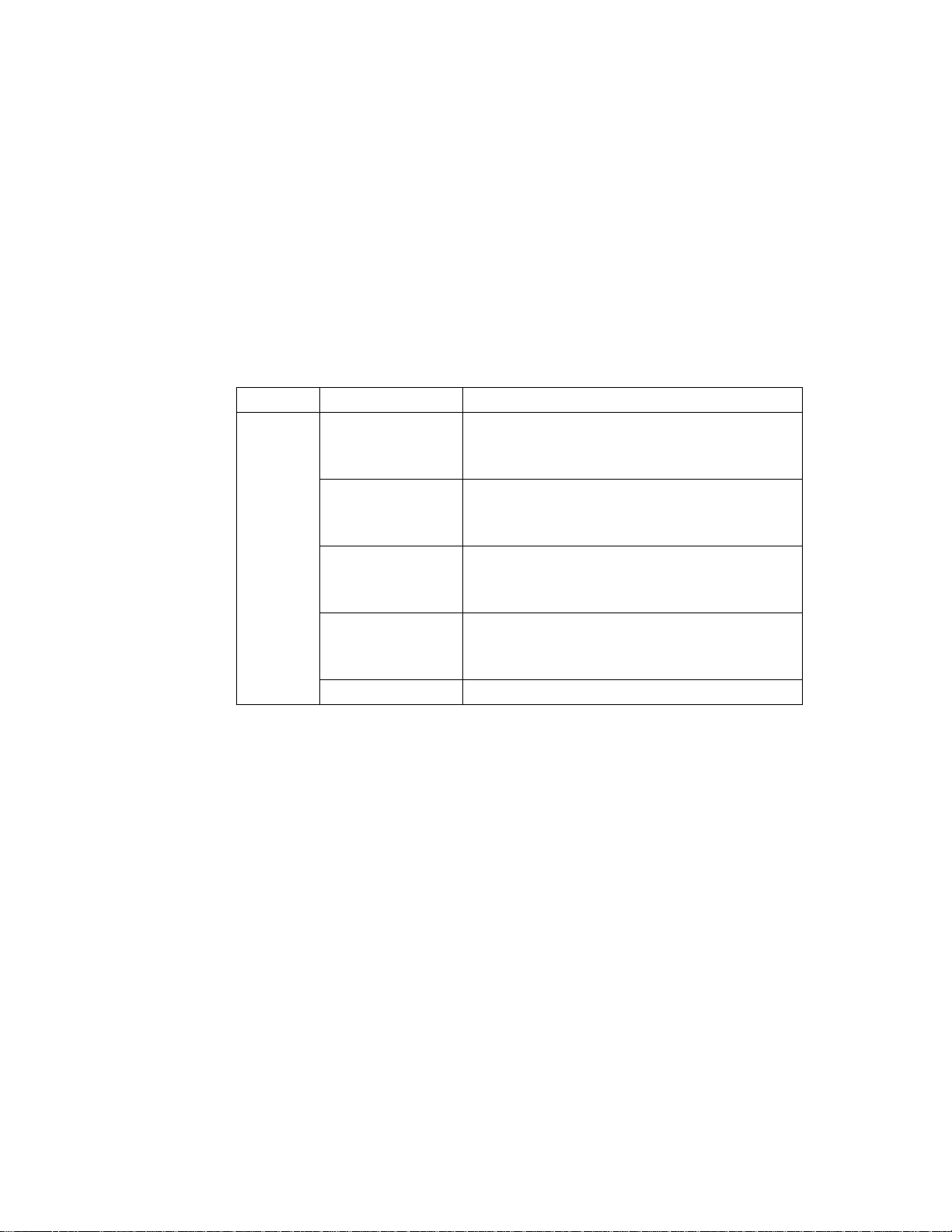

Category Standard Designed/tested for compliance with

Safety ANSI / UL60950

IEC 60950

73/23/EEC Low Voltage Directive

CAN/CSA C22.2,

No. 60950-00

Europe:

EN 60950

Safety of Information Technology Equipment,

including Electrical Business Equipment.

Safety of Information Technology Equipment,

including Electrical Business Equipment

Safety of Information Technology Equipment,

including Electrical Business Equipment.

Safety of Information Technology Equipment,

including Electrical Business Equipment.

10 Instruction Manual

Page 11

KDD-PSU Power Supply Unit

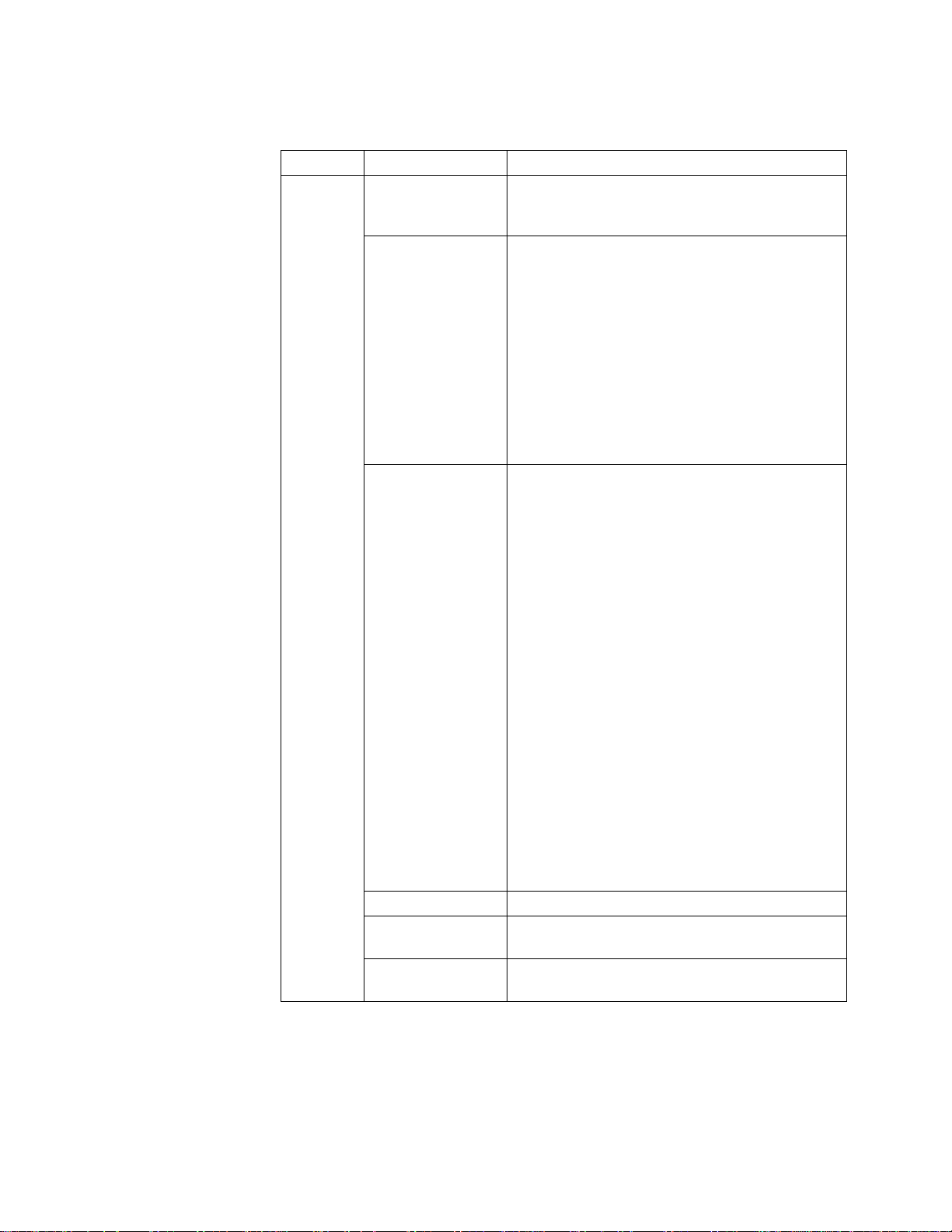

Category Standard Designed/tested for compliance with

EMI

EMC Directive

89/336/EEC via

Audio, Video and Entertainment Lighting

Control for the European Community.

EN 55103-1 and 2

EN 55103-1

standards

Electromagnetic compatibility.

Product family standard for audio, video, audiovisual and entertainment lighting control

apparatus for professional use.

Part 1 Emissions, Environment E1/E2

EN 55022: Class B Radiated and Conducted

Emissions

EN 61000-3-2: Power Line Harmonic

Emissions, Radiated Magnetic Field Emissions,

Peak Inrush Current

EN55103-2

standards

Electromagnetic compatibility--Product family

standard for audio, video, audio-visual and

entertainment lighting control apparatus for

professional use.

Part 2 Immunity, Environment E1/E2

EN 50082-1: Immunity

EN 61000-4-2:

Electrostatic Discharge “ESD” Immunity

EN 61000-4-3:

Radiated RF Electromagnetic Field Immunity

EN 61000-4-4:

Electrical Fast Transient/Burst “EFT” Immunity

EN 61000-4-5: Surge Immunity

EN 61000-4-6: Conducted RF Immunity

EN 61000-4-11: Voltage Dips, Short

Interruptions and Voltage Variations

Annex A - Radiated Magnetic Field Immunity

Note: This only applies to assemblies sensitive

to magnetic fields

US FCC Class B CISPR Pub. 22 (1985)

Canada FCC

Industry Canada

Australia &

New Zealand:

AS/NZS 3548

Instruction Manual 11

Page 12

KDD-PSU Power Supply Unit

12 Instruction Manual

Page 13

3 Safety Summary

Read and follow the important safety information below, noting especially those

instructions related to risk of fire, electric shock or injury to persons. Additional specific

warnings not listed here may be found throughout the manual.

WARNING!

Any instructions in this manual that require opening the equipment cover or

enclosure are for use by qualified service personnel only. To reduce the

risk of electric shock, do not perform any servicing other than that contained in

the operating instructions unless you are qualified to do so.

3.1 Safety Terms and Symbols

3.1.1 Terms in This Manual

Safety-related statements may appear in this manual in the following form:

WARNING!

Warning statements identify conditions or practices that may result in personal

injury or loss of life.

CAUTION!

Caution statements identify conditions or practices that may result in damage

to equipment or other property, or which may cause equipment crucial to

your business environment to become temporarily non-operational.

KDD-PSU Power Supply Unit

3.1.2 Terms on the Product

The following terms may appear on the product:

DANGER!

A personal injury hazard is immediately accessible as you read

the marking.

WARNING!

A personal injury hazard exists but is not immediately accessible

as you read the marking.

CAUTION!

A hazard to property, product, and other equipment is present.

Instruction Manual 13

Page 14

KDD-PSU Power Supply Unit

3.1.3 Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the equipment enclosure that

may be of sufficient magnitude to

constitute a risk of electric shock.

Indicates that user, operator or service technician should refer to product manual(s) for

important operating, maintenance, or service instructions.

This is a prompt to note fuse rating when replacing fuse(s).

The fuse referenced in the text must be replaced with one having the ratings indicated.

Identifies a protective grounding terminal which must be connected to earth ground

prior to making any other equipment connections.

Identifies an internal Protective Bounding Conductor (PBC) terminal proper earthing of

metal parts auf the unit (EN 60950 / 1.1.13.9).

Indicates that static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static

procedures, equipment and surfaces during servicing.

14 Instruction Manual

Page 15

3.2 Warnings

The following warning statements identify conditions or practices that can result in

personal injury or loss of life.

WARNING — To reduce the risk of electrical shock, do not remove cover or back. No

user-serviceable parts inside. Refer to qualified service personnel.

• Dangerous voltage or current may be present — Disconnect power and remove

battery (if applicable) before removing protective panels, soldering, or replacing

components.

• Do not service alone — Do not internally service this product unless another

person capable of rendering first aid and resuscitation is present.

• Remove jewelry — Prior to servicing, remove jewelry such as rings, watches, and

other metallic objects.

• Avoid exposed circuitry — Do not touch exposed connections, components or

circuitry when power is present.

• Use proper power cord — Use only the power cord supplied or specified for this

product.

• Ground product — Connect the protective grounding conductor of the power cord

to earth ground.

• Operate only with covers and enclosure panels in place — Do not operate this

product when covers or enclosure panels are removed.

• Use correct fuse — Use only the fuse type and rating specified for this product.

• Use only in dry environment — Do not operate in wet or damp conditions.

• Use only in non-explosive environment — Do not operate this product in an

explosive atmosphere.

• High leakage current may be present — Earth connection of product is essential

before connecting power.

• Dual power supplies may be present — Be certain to plug each power supply

cord into a separate branch circuit employing a separate service ground.

Disconnect both power supply cords prior to servicing.

• Double pole neutral fusing — Disconnect mains power prior to servicing.

• Use proper lift points — Do not use door latches to lift or move equipment.

• Avoid mechanical hazards — Allow all rotating devices to come to a stop before

servicing.

KDD-PSU Power Supply Unit

Instruction Manual 15

Page 16

KDD-PSU Power Supply Unit

3.3 Cautions

The following caution statements identify conditions or practices that can

result in damage to equipment or other property:

• Use correct power source — Do not operate this product from a power source

that applies more than the voltage specified for the product.

• Use correct voltage setting — If this product lacks auto-ranging power supplies,

before applying power ensure that the each power supply is set to match the

power source.

• Provide proper ventilation — To prevent product overheating, provide equipment

ventilation in accordance with installation instructions.

• Use anti-static procedures — Static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static procedures, equipment

and surfaces during servicing.

• Do not operate with suspected equipment failure — If you suspect product

damage or equipment failure, have the equipment inspected by qualified service

personnel.

• Ensure mains disconnect — If mains switch is not provided, the power cord(s) of

this equipment provide the means of disconnection. The socket outlet must be

installed near the equipment and must be easily accessible. Verify that all mains

power is disconnected before installing or removing power supplies and/or options.

• Route cable properly — Route power cords and other cables so that they are n ot

likely to be damaged. Properly support heavy cable bundles to avoid connector

damage.

• Use correct power supply cords — Power cords for this equipment, if provided,

meet all North American electrical codes. Operation of this equipment at voltages

exceeding 130 VAC requires power supply cords which comply with NEMA

configurations. International power cords, if provided, have the approval of the

country of use.

• Use correct replacement battery — This product may contain batteries. To

reduce the risk of explosion, check polarity and replace only with the same or

equivalent type recommended by manufacturer. Dispose of used batteries

according to the manufacturer’s instructions.

• Troubleshoot only to board level — Circuit boards in this product are densely

populated with surface mount technology (SMT) components and application

specific integrated circuits (ASICs). As a result, circuit board repair at the

component level is very difficult in the field, if not impossible. For warranty

compliance, do not troubleshoot systems beyond the board level.

16 Instruction Manual

Page 17

KDD-PSU Power Supply Unit

4 Technical Specification

4.1 Power Supply

Line voltage 100V-240V AC +/-10%,

power factor corrected

Line frequency 50/60Hz +/- 5%

Power consumption max. 375W

Leakage current < 2 mA at 250V AC

DC-OUT 2x 48V DC, total 6A max

EXT BATT IN 12V … 24V, 0.5A

RAM Recorder

buffer voltage: 7V DC, max 300mA. (Only with ext. battery input or AC In)

4.2 Environmental Data

Storage temperature -20°C to +70°C (-4°F to 158°F)

Operating temperature +5°C to +40°C (41°F to 104°F)

Relative humidity ≤ 95% non-condensing

Electromagnetic

environment E2 (according to EN55103-1, -2)

4.3 Mechanical Data

Height 1RU 44 mm (1.73 in ch)

Width 482 mm (19 inch)

Depth 240 mm (9.45 inch)

Weight 2.8 kg (6.2 lb)

Instruction Manual 17

Page 18

KDD-PSU Power Supply Unit

18 Instruction Manual

Page 19

5 System Overview

5.1 Introduction

KDD-PSU Power Supply Unit

Wide range AC power supply providing redundant power for KayakDD production

switcher. Power output is sufficient for two KayakDD-1 or one KayakDD-2 system.

External battery voltage can be connected in order to provide uninterrupted buffer

voltage for RAM Recorder option.

The package contents:

• 1pc KDD-PSU External Power Supply Unit

• 1pc AC power cord

• Rack mount accessories

• Instruction Manual

There are two lengths of cable to the KayakDD mainframe available:

• 5m (KDD-PS U-CABLE5)

• 20m (KDD-PSU-CABLE20)

To connect a KayakDD Control Panel to the second DC output the following cables

can also be used:

• 20m (KDD-PSU-CABLE20)

• 50m (DCP WR -50)

• 100m (DCP WR-100)

NOTE!

In order to ensure the RAM Recorder buffer voltage, the cable length is

limited to 20m. The standard KayakDD DC cables are not suitable for buffer

voltage supply!

Instruction Manual 19

Page 20

KDD-PSU Power Supply Unit

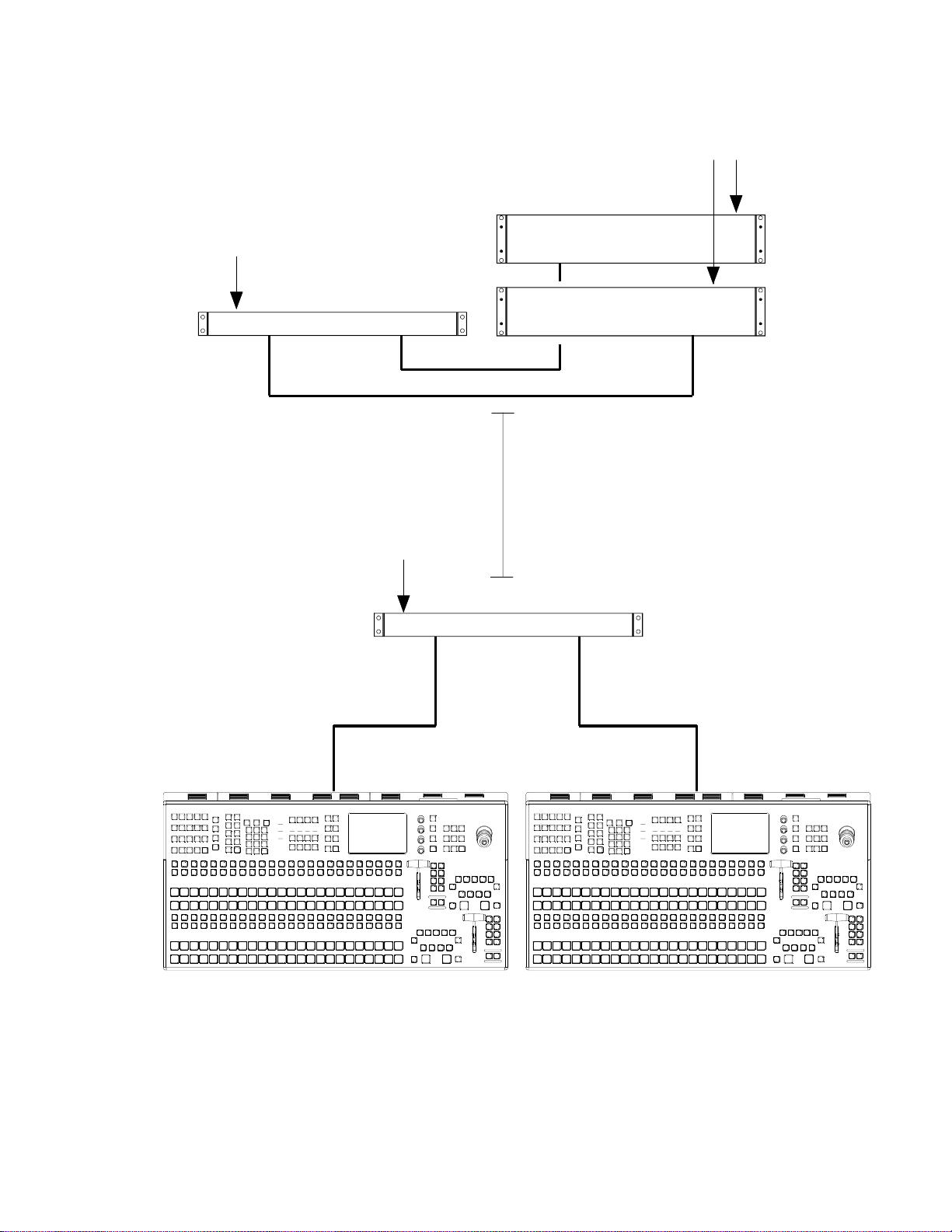

5.2 DC Power Applications

Note! The DC cables in the diagrams below are not included!

5.2.1 Standard Application for Redundancy

AC1

Redundant Power Supply Unit

KDD-PSU

Ext. Battery In

12-24V

Other cable available:

Cable 20m (with RAM buffering)

Cable 20m (w/o RAM buffering)

Cable 50m (w/o RAM buffering)

Cable 100m (w/o RAM buffering)

AC2

Mainframe

KayakDD-1

KayakDD-2KayakDD-2

20m cable

5m cable

Other cables

available:

Cable 50m

Cable 100m

KayakDD-2

KayakDD-1

Figure 1 Redundant Power Supply for one Mainframe and one Control Panel

20 Instruction Manual

Page 21

5.2.2 Control Panel Supply

KDD-PSU Power Supply Unit

AC2

Mainframe

KayakDD-1

KayakDD-2KayakDD-2

Distance more than 100m

Control Panel

AC1

Panel Power Supply Unit

KDD-PSU

5m cable

Other cables available:

Cable 20m

Cable 50m

Cable 100m

Figure 2 Power Supply for Control Panel only

KayakDD-1

or

KayakDD-2

Instruction Manual 21

Page 22

KDD-PSU Power Supply Unit

5.2.3 Multiple DC Power Supply

2x AC2

Mainframe 1

KayakDD-1

AC1

Redundant Power Supply Unit

KDD-PSU

NOTE!

Redundancy is ensured in case of a

failure in one of the two internal power

supply units (n+1 Redundancy).

AC3

5m cable 5m cable

Mainframe 2

KayakDD-1

5m cable

5m cable

Other cable available:

Cable 5m (with RAM buffering)

Cable 20m (with RAM buffering)

Cable 20m (w/o RAM buffering)

Cable 50m (w/o RAM buffering)

Cable 100m (w/o RAM buffering)

Distance more than 100m

Panel Power Supply Unit

KDD-PSU

Control Panel 1

Control Panel 2

Figure 3 Separate Power Supply for Control Panel and Mainframe KayakDD-1

22 Instruction Manual

Page 23

Mainframe 1

KayakDD-2

KDD-PSU Power Supply Unit

2x AC2

AC1

Redundant Power Supply Unit

KDD-PSU

NOTE!

Redundancy is ensured in case of a

failure in one of the two internal power

supply units (n+1 Redundancy).

AC3

5m cable 5m cable

Mainframe 2

KayakDD-2

5m cable

5m cable

Other cable available:

Cable 5m (with RAM buffering)

Cable 20m (with RAM buffering)

Cable 20m (w/o RAM buffering)

Cable 50m (w/o RAM buffering)

Cable 100m (w/o RAM buffering)

Distance more than 100m

Panel Power Supply Unit

KDD-PSU

Control Panel 1

Control Panel 2

Figure 4 Separate Power Supply for Control Panel and Mainframe KayakDD-2

Instruction Manual 23

Page 24

KDD-PSU Power Supply Unit

24 Instruction Manual

Page 25

6 Installation

This section describes the installation and setup of KDD-PSU Power Supply Unit.

6.1 Pre-Installation Procedures

Before you physically install the KDD-PSU Power Supply Unit, familiarize yourself with

the tools required, physical specifications, and safety and power requirements covered

in this section.

6.1.1 System Survey

Check all parts received against the packing list enclosed with your shipme nt, and

examine the equipment for any shipping damage. Immediately report any missing or

damaged items to the carrier and to your Thomson Grass Valley Service

Representative.

KDD-PSU Power Supply Unit

6.1.2 Line Voltage

KDD-PSU components utilize wide-ranging power supplies whi ch accommodate 100 240V. No switch settings are required, nor are any possible.

6.1.3 Safety Requirements

To prevent injury or equipment damage, read, understand, and follow all installation

safety precautions.

WARNING!

Electrical potential is still applied to some internal components even when power to the

frame is off. To prevent electrical shock when working on this equipment, disconnect

the AC line cords from the AC source before working on any internal components.

Residual voltage may be present immediately after unplugging the system; wait thirty

seconds to allow capacitors to discharge before working on the system.

Instruction Manual 25

Page 26

KDD-PSU Power Supply Unit

6.1.4 Installation Tasks

After completing the Pre-Installation procedures, the recommended installation

tasks given in this section are:

1. Unpack the equipment,

2. Install the KDD-PSU Power Supply Unit

3. Connect all cables between KayakDD devices,

4. Connect the power cables.

Power up and configuration is covered in detail in the next sections of this manual.

26 Instruction Manual

Page 27

6.2 Mounting the Power Supply Unit

6.2.1 General Rack Mounting Instructions

• The maximum ambient temperature for this unit is 40°C (104°F).

• Installing the unit in a closed or multi-unit rack assembly, together with other units

could increase the maximum ambient for this unit.

• If the unit is installed in a rack, no ventilation openings should be blocked or

otherwise covered. Ensure a sufficient amount of airflow. Airflow through KayakDD

(front view) is from the left side of the frame to the right side of the frame.

• Mounting of the unit in the rack should be such that a hazardous condition is not

achieved due to uneven mechanical loading.

• When connecting the unit to the supply circuit be sure that the supply circuit of the

rack is not overloaded. For ratings see chapter Technical Specifications.

• The unit must be grounded to a good earth ground using a wire as specified by the

local electrical code. This wire is attached to the protective earth connector on the

rear.

• When connecting the unit in a closed or multi-unit rack assembly together with

other units be sure that the summation of the touch (leakage) currents for each

power supply circuit is not higher than 3.5 mA . In this case the rack must be

permanently connected with an earth terminal. Earth connection is essential before

connecting supply voltage! For details see chapter Technical Specifications.

The Power Supply Unit frame has to be mounted in a rack using the delivered

accessories and screws.

KDD-PSU Power Supply Unit

Instruction Manual 27

Page 28

KDD-PSU Power Supply Unit

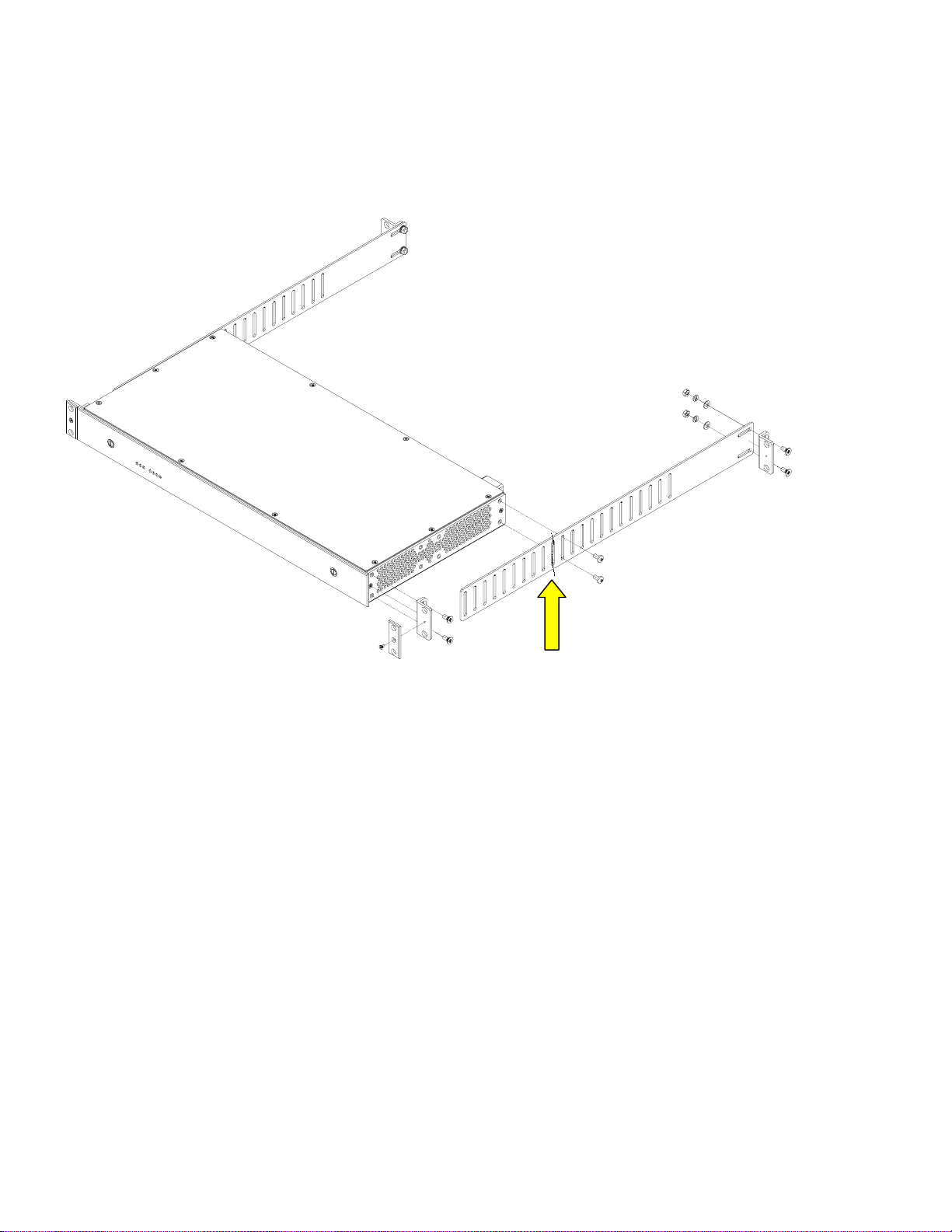

6.2.2 Rack Mounting Procedure

Figure 5 KDD-PSU Power Supply Unit with Mounting Accessories

Cut fastening metal so that

the ventilation openings are

not covered!

28 Instruction Manual

Page 29

6.3 Rear Connectors

KDD-PSU Power Supply Unit

Figure 6 KDD-PSU Rear Connectors 1

Jack Designation Note

J1 AC POWER IN

AC POWER IN

Mains connector (IEC-320, CEE-22) for power supply.

Operating Voltage: 100V-240V AC +/-10% wide-

range

Caution!

Double-pole or neutral fusing.

After operation of the protective device, parts of

the equipment that remain under voltage might

represent a hazard during servicing.

Caution!

For continued protection against risk of fire,

replace only with same type and rating of fuse!

2x 8A /T H 250V

Power switch

Instruction Manual 29

Page 30

KDD-PSU Power Supply Unit

Figure 7 KDD-PSU Rear Connectors 2

Jack Designation Note

J2 EXT. BATT IN

12V ... 24V DC

Terminal strip for connection to external battery for

buffering the RAM-Recorder data

J3 12V DC OUT

J4

DC POWER

J5

For future use!

Two output connectors for DC Power Supply.

(High current D-Sub, male).

Output voltage: 48V/ total 6A max

Earth Terminal

Earth terminal for grounding.

30 Instruction Manual

Page 31

6.4 Pin Assignments

6.4.1 48V DC Power Out

Socket Pin Signal

D-Sub Female

Pin 1Pin 2

Pin A2

Pin A1

Pin 3Pin 5

KDD-PSU Power Supply Unit

A1 48 V (+)

A2

1 GND

2 Return Sense

3 +7V (RAM Recorder)

4 -

5 Future use

48 V (−)

Instruction Manual 31

Page 32

KDD-PSU Power Supply Unit

32 Instruction Manual

Page 33

7 Service Instructions

7.1 General

WARNING — To reduce the risk of electrical shock, do not remove cover or back.

No user-serviceable parts inside. Refer to qualified service personnel.

7.2 Status LEDs

The status LEDs on the front of the KDD-PSU shows the state of the external and

internal voltages and the operating state of the internal fans:

AC On = AC Power OK

Ext.Batt On = External battery voltage is OK

Fans On = Both internal fans are OK

Off = One or both internal fans don’t run

48V-1 On = 48 V DC output 1 is OK

48V-2 On = 48 V DC output 2 is OK

12V On = 12V DC power supply for external Hub is OK (for future use)

7V On = 7V DC power for RAM Recorder buffering is OK

KDD-PSU Power Supply Unit

7.3 Fuses

• Double pole neutral fusing — Disconnect mains power prior to servicing.

• Use correct fuse — Use only the fuse type and rating specified for this product.

7.3.1 Main Fuses

Fuse type: 2x T 8A / H 250V

Manufacturer: WICKMANN 181, SCHURTER SPT 0001.2513

Order no.: 003 117 300 214

7.3.2 Internal Fuses on Board RY3781

T1, T2 F 7A / 250 V

Manufacturer: LITTLEFUSE 312007 or SCHURTER FSF 0034.5143

Order no.: 003 117 301 010

Instruction Manual 33

Page 34

KDD-PSU Power Supply Unit

7.4 Fan Exchange

The exchange of the fan can be carried out as follows:

• Demount the upper cover sheet

• Unplug the fan connection cable

• Pull the fan upwards. The fan in not fastened with screws!

• Insert the new fan in the same way.

• Do no damag e the connection cable when inserting the fan.

• Plug the fan connection cable

• Mount the upper cover sheet

to prevent bearing damage

do not touch the rotor !

34 Instruction Manual

Page 35

KDD-PSU Power Supply Unit

I

N

O

T

U

A

C

Figure 8 Mounting Overview

Instruction Manual 35

Page 36

KDD-PSU Power Supply Unit

36 Instruction Manual

Loading...

Loading...