Page 1

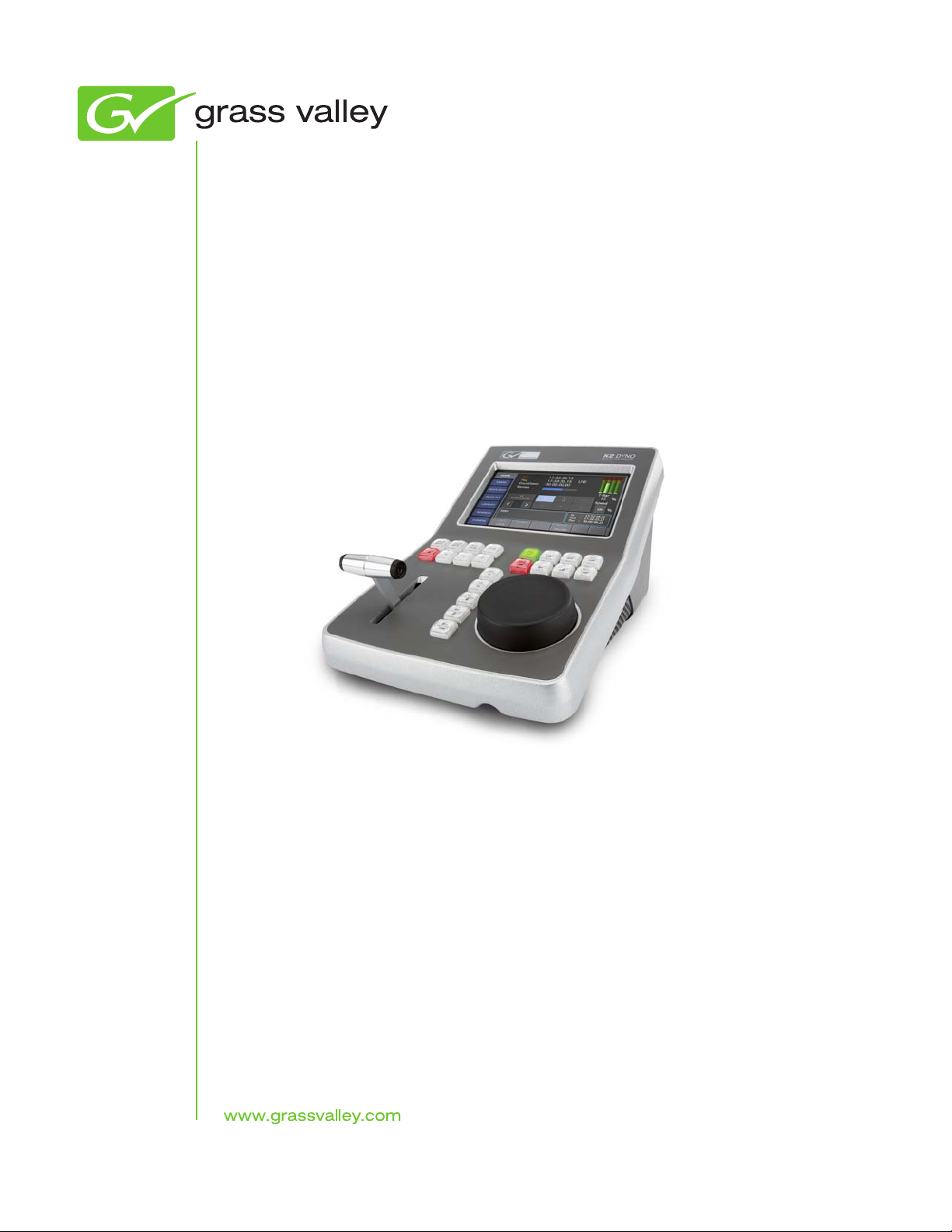

K2 Dyno

Replay Controller

Service Manual

071-8702-02

February 2012

Page 2

Affiliate with the N.V. KEMA in The Netherlands

CERTIFICATE

Certificate Number: 510040.001

The Quality System of:

Thomson Inc, and its worLdwide Grass Valley division affiliates DBA

GRASS VALLEY

Headquarters

400 Providence Mine Rd

Nevada City, CA 95959

United States

15655 SW Greystone Ct.

Beaverton, OR 97006

United States

10 Presidential Way

Suite 300

Woburn, MA 01801

United States

Kapittelweg 10

4827 HG Breda

The Nederlands

7140 Baymeadows Way

Ste 101

Jacksonville, FL 32256

United States

2300 So. Decker Lake Blvd.

Salt Lake City, UT 84119

United States

Rue du Clos Courtel

CS 31719

35517 Cesson-Sevigné Cedex

France

1 rue de l’Hautil

Z.I. des Boutries BP 150

78702 Conflans-Sainte

Honorine Cedex

France

Technopole Brest-Iroise

Site de la Pointe du Diable

CS 73808

29238 Brest Cedex 3

France

40 Rue de Bray

2 Rue des Landelles

35510 Cesson Sevigné

France

Spinnereistrasse 5

CH-5300 Turgi

Switzerland

Brunnenweg 9

D-64331 Weiterstadt

Germany

Carl-Benz-Strasse 6-8

67105 Schifferstadt

Germany

Including its implementation, meets the requirements of the standard:

ISO 9001:2008

Scope:

The design, manufacture and support of video and audio hardware and software products and

related systems

.

This Certificate is valid until: June 14, 2012

This Certificate is valid as of: June 14, 2009

Certified for the first time: June 14, 2000

H. Pierre Sallé

President

KEMA-Registered Quality

The method of operation for quality certification is defined in the KEMA General Terms

And Conditions For Quality And Environmental Management Systems Certifications.

Integral publication of this certificate is allowed.

KEMA-Registered Quality, Inc.

4377 County Line Road

Chalfont, PA 18914

Ph: (215)997-4519

Fax: (215)997-3809

CRT 001 073004

Accredited By:

ANAB

CERTIFICATE

Certificate Number: 510040.001

The Quality System of:

Grass Valley USA, LLC and its Grass Valley Affiliates

Headquarters:

400 Providence Mine Road

Nevada City, CA 95945

United States

15655 SW Greystone Ct.

Beaverton, OR 97006

United States

Brunnenweg 9

D-64331 Weiterstadt

Germany

Kapittelweg 10

4827 HG Breda

The Nederlands

2300 So. Decker Lake Blvd.

Salt Lake City, UT 84119

United States

Including its implementation, meets the requirements of the standard:

ISO 9001:2008

Scope:

The design, manufacture and support of video and audio hardware and software products and related

systems.

This Certificate is valid until: June 14, 2012

This Certificate is valid as of: December 23, 2010

Certified for the first time: June 14, 2000

H. Pierre Sallé

President

KEMA-Registered Quality

The method of operation for quality certification is defined in the KEMA General Terms And Conditions For

Quality And Environmental Management Systems Certifications. Integral publication of this certificate is allowed.

KEMA-Registered Quality, Inc.

4377 County Line Road

Chalfont, PA 18914

Ph: (215)997-4519

Fax: (215)997-3809

CRT 001 042108

ccredited By:

ANAB

A

Page 3

K2 Dyno

Replay Controller

Service Manual

071-8702-02

February 2012

Page 4

Contacting Grass Valley

International

Support Centers

Local Support

Centers

(available

during normal

business hours)

France

24 x 7

Australia and New Zealand: +61 1300 721 495 Central/South America: +55 11 5509 3443

Middle East: +971 4 299 64 40 Near East and Africa: +800 8080 2020 or +33 1 48 25 20 20

Europe

+800 8080 2020 or +33 1 48 25 20 20

Hong Kong, Taiwan, Korea, Macau: +852 2531 3058 Indian Subcontinent: +91 22 24933476

Asia

Southeast Asia/Malaysia: +603 7805 3884 Southeast Asia/Singapore: +65 6379 1313

China: +861 0660 159 450 Japan: +81 3 5484 6868

Belarus, Russia, Tadzikistan, Ukraine, Uzbekistan: +7 095 2580924 225 Switzerland: +41 1 487 80 02

S. Europe/Italy-Roma: +39 06 87 20 35 28 -Milan: +39 02 48 41 46 58 S. Europe/Spain: +34 91 512 03 50

Benelux/Belgium: +32 (0) 2 334 90 30 Benelux/Netherlands: +31 (0) 35 62 38 42 1 N. Europe: +45 45 96 88 70

Germany, Austria, Eastern Europe: +49 6150 104 444 UK, Ireland, Israel: +44 118 923 0499

Copyright © Grass Valley USA, LLC. All rights reserved.

This product may be covered by one or more U.S. and foreign patents.

United States/Canada

24 x 7

+1 800 547 8949 or +1 530 478 4148

Grass Valley Web Site

The www.grassvalley.com web site offers the following:

Online User Documentation — Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads — Download software updates, drivers, and patches.

4 K2 Dyno Service Manual

Page 5

Contents

Safety Summaries..............................................................................................7

Finding Information...........................................................................................25

Chapter 1 Product Description

Overview description...............................................................................................28

Dyno controller orientation........................................................................ ...... ........29

FRU functional descriptions ....................................................................................30

Base chassis ................................................. ..... ...... ...... ................................. ...30

Compact Flash boot media.................................................................................30

Jog knob.................................................. ...... ..... .................................. ...... ..... ...30

Plastic cover.......................................................................................................30

T-bar lever assembly..........................................................................................31

Type I Control panel UI board ............................................................................31

Type II Control panel UI board ...........................................................................31

Type II Encoder..................................................................................................32

LCD screen.......................................................................... ...... ..... ...... ...... ..... ...32

LCD screen inverter board .................................................................................32

Front I/O board........................................ ...... ..... .................................. ...... ..... ...32

Fan .....................................................................................................................32

USB board..........................................................................................................32

Motherboard.......................................................................................................32

Power supply......................................................................................................33

Status indicators......................................................................................................34

Rear panel indicators..........................................................................................34

System beep codes............................................ ...... ...... ................................. ...35

General specifications.............................................................................................35

Counter top installation............................................................................................36

Chapter 2 Service Procedures

Exporting log files (software version 2.x).................................................................37

Exporting log files (software version 1.x).................................................................37

Calibrating the control panel....................................................................................37

Upgrading software.................................................................................................38

Updating firmware (software version 2.x)................................................................38

Updating firmware (software version 1.x)................................................................38

Using recovery disk images ....................................................................................39

About the recovery disk image process..............................................................39

Creating a recovery disk image..........................................................................40

Restoring from a system-specific recovery disk image.......................................41

Restoring from a generic recovery disk image...................................................43

Replacing a Dyno controller....................................................................................44

Chapter 3 Troubleshooting problems

Step 1: Check configurations ..................................................................................48

Step 2: Check connections and external equipment...............................................48

Step 3: Identify problems using the startup sequence ............................................48

Step 4: Run hardware diagnostics ..........................................................................48

Run hardware diagnostics (software version 2.x)...............................................48

Run hardware diagnostics (software version 1.x)...............................................50

BIOS startup information.........................................................................................51

Shutdown/restart problems.....................................................................................51

Checking external equipment..................................................................................52

VGA display problems........................................................................................52

Keyboard and mouse problems..........................................................................52

BIOS startup............................................................................................................52

BIOS POST error messages............................................... ..... ...... .........................52

02 February 2012 K2 Dyno Replay Controller Service Manual 5

Page 6

Contents

Windows startup............................... ...... ...... ................................. ...... .................... 56

LCD screen problems ........................................................ ...... ..... ..........................57

Thermal problems................................................................................................... 57

Power supply problems........................................................................................... 57

Isolating functional problems................................................................................... 58

Chapter 4 Removing and replacing FRUs

Job knob removal.................................................... ..... ...... ...... ...............................60

Control panel UI board identification.......................................................................61

Job knob bearing assembly removal....................................................................... 62

Job knob replacement........................................................ ...... ...............................64

T-bar lever handle removal ..................................................................................... 64

Compact Flash boot media removal ....................................................................... 65

Top removal............................................................................................................66

Top unit cable removal Type I control panel UI board ............................................67

Top unit cable removal Type II control panel UI board ........................................... 68

Top replacement..................................................................................................... 69

T-bar lever assembly removal................................................................................. 69

Plastic cover removal..............................................................................................70

LCD screen inverter board removal........................................................................ 71

Type I control panel UI board removal....................................................................72

Type II control panel UI board removal...................................................................74

Type II encoder removal......................................................................................... 76

LCD screen removal ............................................................................................ ...77

Front I/O board removal..........................................................................................78

Fan removal............................................................................................................79

Motherboard removal.............................................................................................. 80

Cabling diagram with Type I control panel UI board............................................... 81

Cabling diagram with Type II control panel UI board..............................................82

USB board removal................................................................................................. 83

Power supply removal............................................................................................. 84

Appendix A Trademarks and Agreements

Trademarks.............................................................................................................86

Index......................................................................................................................87

6 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 7

Safety Summaries

Read the following sections for impor tant safety in formation.

• Safety Summary

• Sicherheit – Überblick

• Consignes desécurité

• Certificat ions and compliances

• ESD Protection

02 February 2012 K2 Dyno Replay Controller Service Manual 7

Page 8

Safety Summaries

Safety Summary

Read and follow the important safety information below, noting especially those

instructions related to risk of fir e, electric shock or injury to persons. Additi onal

specific warnings not listed here may be found throughout the manual.

Safety terms and symbols

Terms in this manual

Safety-rel ated statements may appe ar in this man ual in the foll owing form:

WARNING: Any instructions i n this manual that re quire opening

the equipment cover or enclosure are for use by qualified service

personnel only. To reduce the risk of electric shock, do not

perform any servicing other than that contained in the operating

instructions unless you are qualified to do so.

WARNING: Warning statements identi fy conditi ons or practices

that may result in personal injury or loss of life.

CAUTION: Caution statements identify conditions or practices

that may result in damage to equipment or other property, or

which may cause equipment crucial to your business

environment to become temporarily non-operational.

Terms on the product

These terms may appear on the product:

DANGER — A personal injury hazard is immediately accessible as you read the

marking.

WARNING — A personal injury hazar d exists but is not immediat ely accessible as you

read the marking.

CAUTION — A hazard to property, product, and other equipment is present.

Symbols on the product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the

equipment enclosure that may be of sufficient magnitude to

constitute a risk of elec tric shock.

Indicates that user, operator or service technician should refer to

product manual(s) for important operating, maintenance, or service

instructions.

This is a prompt to n ote fuse rating when rep lacing fuse(s). The fuse

referenced in the text must be replaced with one having the ratings

indicated.

8 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 9

Warnings

The following warning statements identify conditions or practices that can result in

personal injury or loss of life.

Dangerous voltage or current may b e present — Disconnec t power and remove battery

(if applicable) before removing protective panels, soldering, or replacing

components.

Do not service alone — Do not internally service this product unless another person

capable of rendering first aid and resuscitation is present.

Remove jewelry — Prior to servicing, remove jewelry such as rings, wat ches, and

other metallic objects.

Identifies a prote ctive grounding terminal wh ich must be connected

to earth ground prior to making any other equipment connections.

Identifies an external protec tive gro unding te rminal whi ch may be

connected to earth ground as a supple ment to an internal grounding

terminal.

Indicates that static sensitiv e components are pres ent which may be

damaged by electrostatic discharge. Use anti-static procedures,

equipment and surfaces during servicing.

Avoid exposed circuitry — Do not touch exposed connections, components or

circuitry when power is present.

Use proper power cord — Use only the power cord supplied or specified for this

product.

Ground product — Connect the grounding conductor of the power cord to earth

ground.

Operate only with covers and enclo sure panels in plac e — Do not opera te this pr oduct

when covers or enclosure panels are removed.

Use correct fuse — Use only the fuse type and rating specified fo r this product.

Use only in dry environment — Do not operate in wet or damp conditions.

Use only in non-explosive environment — Do no t ope rate th is pr oduct in a n explos ive

atmosphere.

High leakage current may be present — Earth connect ion of product is essenti al before

connecting power.

Dual power supplies ma y be present — Be ce rtain to plug each power s upply cord into

a separate bra nch circuit employ ing a separate service ground. Disconnect both power

supply cords prior to servicing.

Double pole neutral fusing — Disconnect mains power prior to servicing.

Use proper lift points — Do not use door latches to lift or move equipment.

Avoid mechanical hazards — Allow all rotating devices to come to a stop before

servicing.

02 February 2012 K2 Dyno Replay Controller Service Manual 9

Page 10

Safety Summaries

Cautions

The following caution statements identify conditions or practices that can result in

damage to equipment or other property

Use correct power source — Do not operate this product from a power source that

applies more than the voltage specified for the product.

Use correct voltage setting — If this product lacks auto-ranging power supplies,

before applying power ensure that the each power supply is set to match the power

source.

Provide proper ventilation — To prevent product overheating, provide equipment

ventilation in accordance with installation instructions.

Use anti-static procedures — Static sensitive components are present which may be

damaged by electrostatic discharge. Use anti-static procedures, equipment and

surfaces during servicing.

Do not operate with suspected equipment failure — If you suspec t pro duct damage or

equipment failure, have the equipment inspected by qualified service personnel.

Ensure mains disconnect — If mains switch is not provided, the power cord(s) of this

equipment provide the means of disconnection. The socket outlet must be installed

near the equipment and must be easily accessible. Verify that all mains power is

disconnected before installing or removing power supplies and/or options.

Route cable properly — Route powe r cords and other cabl es so tha t they ar not likel y

to be damaged. Properly support heavy cable bundles to avoid connector damage.

Use correct power supply co rds — P ower cord s fo r this equipmen t, i f provi ded, me et

all North American electrical codes. Operation of this equipment at voltages

exceeding 130 VAC requires power supply cords which comply with NEMA

configurations. International power cords, if provided, have the approval of the

country of use.

Use correct replacemen t batter y — This pr oduct may conta in bat teri es. To r educe t he

risk of explosion, check polarity and replace only with the same or equivalent type

recommended by manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

Troubleshoot only to board level — Circuit boards in this product are densely

populated with surfac e mount technology (SMT) components and application specific

integrated circuits (ASICS). As a result, circuit board repair at the component level is

very difficult in the field, if not impossible. For warranty compliance, do not

troubleshoot systems beyond the board level.

10 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 11

Sicherheit – Über bl ick

Lesen und befolgen Sie die wichtigen Sicherheitsinformationen dieses Abschnitts.

Beachten Sie insbesondere die Anweisungen bezüglich

Brand-, Stromschlag- und Verletzungsgefahren. Weitere spezifische, hier nicht

a

ufgeführte Warnungen finden Sie im gesamten Handbuch.

WARNUNG: Alle Anweisungen in diesem Handbuch, die das

Abnehmen der Geräteabdeckung oder des Gerätegehäuses

erfordern, dürfen nur von qualifiziertem Servicepersonal

ausgeführt werden. Um die Stromschlaggefahr zu verringern,

führen Sie keine Wartungsarbeiten außer den in den

Bedienungsanleitungen genann ten Arbeiten aus, es se i denn, Sie

besitzen d ie entsprechende Qual ifikationen für diese Arbeiten.

Sicherheit – Begriffe und Symbole

In diesem Handbuch verwendete Begriffe

Sicherheitsrelevante Hinweise können in diesem Handbuch in der folgenden Form

au

ftauchen:

WARNUNG: Warnungen weisen auf Situationen oder

Vorgehensweisen hin, die Verletzungs- oder Lebensgefahr

bergen.

VORSICHT: Vorsichtshinweise weisen auf Situationen oder

Vorgehensweisen hin, die zu Schäden an

Ausrüstungskomponenten oder an deren Gegenständen oder zum

zeitweisen Ausfall wichtiger Komponenten in der

Arbeitsumgebung führen können.

Hinweise am Produkt

Die folgenden Hinweise können sich am Produkt befinden:

GEFAHR – Wenn Sie diesen Begriff lesen, besteht ein unmittelbares

Verletzungsrisiko.

WARNUNG – Wenn Sie diesen Begriff lesen, besteht ein mittelbares

Verletzungsrisiko.

VORSICHT – Es besteht ein Risiko für Objekte in der Umgebung, den Mixer selbst

oder andere Ausrüstungskomponenten.

Symbole am Produkt

Die folgenden Symbole können sich am Produkt befinden:

Weist auf eine gefährliche Hochspannung im Gerätegehäuse hin,

die stark genug sein kann, um eine Stromsch laggefahr darzustel len.

02 February 2012 K2 Dyno Replay Controller Service Manual 11

Page 12

Safety Summaries

Weist darauf hin, dass der Benutzer, Bediener oder

Servicetechniker wichtige Bedienungs-, Wartungs- oder

Serviceanweisungen in den Produkthandbüchern lesen sollte.

Dies ist eine Aufforderung, beim Wechsel von Sicherungen auf

deren Nennwert zu achten. Die im Text angegebene Sicherung

muss durch eine Sicherung ersetzt werden, die die angegebenen

Nennwerte besitzt.

Weist auf eine Schutzerdungsklemme hin, die mit dem

Erdungskontakt verbunden werden muss, bevor weitere

Ausrüstungskomponenten angeschlossen werden.

Weist auf eine externe Schutzerdungsklemme hin, die als

Ergänzung zu einem internen Erdungskontakt an die Erde

angeschlossen werden kann.

Weist darauf hin, dass es stati sch empfindlic he Komponenten gibt,

die durch eine elektrostatische Entladung beschädigt werden

können. Verwenden Sie ant i sta ti sc he Pr ozeduren, Ausrüstung und

Oberflächen während der Wartung.

Warnungen

Die folgenden Warnungen weisen auf Bedingungen oder Vorgehensweisen hin, die

Verletzungs- oder Lebensgefahr bergen:

Gefährliche Spannungen oder Ströme – Schal ten Sie de n Strom ab, un d entfe rnen Sie

ggf. die Batterie, bevor si e Schut za bdeckungen abnehmen, löten oder Kompone nte n

austauschen.

Servicearbeiten nic ht alleine a usführen – Führen Sie interne Servicearbeiten nur aus,

wenn eine weitere Person anwesend ist, die erste Hilfe leisten und

Wiederbelebungsmaßnahmen einleiten kann.

Schmuck abnehmen – Legen Sie vor Servicearbe iten Schmuck wie Ring e, Uhren und

andere metallische Objekte ab.

Keine offen liegenden Leiter berühren – Berühre n Sie bei eingesc haltete r Stromzuf uhr

keine offen liegenden Leitungen, Komponenten oder Schaltungen.

Richtiges Netzkabel verwenden – Verwenden Sie nur das mitgeliefert e Netzkabel ode r

ein Netzkabel, das den Spezifikationen für dieses Produkt entspricht.

Gerät erden – Schließen Sie den Erdleiter des Netzkabels an den Erdungskontakt an.

Gerät nur mit angebrachten Abdeckungen und Gehä useseiten betreiben – Sc halten Sie

dieses Gerät nicht ein, wenn die Abdeckungen oder Gehäuseseiten entfernt wurden.

Richtige Sicherung verwenden – Verwenden Sie nur Sicherungen, deren Typ und

Nennwert den Spezifikationen für dieses Produkt entsprechen.

Gerät nur in trockener Umgebung verwen den – Betreiben Si e das Gerät nicht in nassen

oder feuchten Umgebungen.

Gerät nur verwenden, wenn keine Explosionsgefahr besteht – Verwenden Sie dieses

Produkt nur in Umgebungen, in denen keinerlei Explosionsgefahr besteht.

12 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 13

Hohe Kriechströme – Das Gerät muss vor dem Ein schalten unbe dingt gee rdet werd en.

Doppelte Spannungsversorgung kann vorhanden sein – Schließen Sie die beide n

Anschlußkabel an getrennte Stromkreise an. Vor Servicearbeiten sind beide

Anschlußkabel vom Netz zu trennen.

Zweipolige, neutrale Sicherung – Schalten Sie den Netzstrom ab, bevor Sie mit den

Servicearbeiten beginnen.

Fassen Sie das Gerät beim Transport richtig an – Halten Sie das Ger ät beim Transpo rt

nicht an Türen oder anderen beweglichen Teilen fest.

Gefahr durch mechanische Teile – Warten Sie, bis der Lüfter vollständig zum Halt

gekommen ist, bevor Sie mit den Servicearbeiten beginnen.

Vorsicht

Die folgenden Vorsichtshinweise weisen auf Bedingungen oder Vorgehensweisen

hin, die zu Schäden an Ausr üstungsko mponente n oder anderen Gegenstände n führen

können:

Gerät nicht öffnen – Durch das unbefugte Öffnen wird die Garantie ungültig.

Richtige Spannungsquelle verwenden – Betreiben Sie das Gerät nicht an einer

Spannungsquelle, die eine höhere Spannung liefert als in den Spezifikationen für

dieses Produkt angegeben.

Gerät ausreichend belüften – Um eine Überhitzung des Geräts zu ve rmeiden , müss en

die Ausrüstungskomponenten entsprechend den Installationsanweisungen belüftet

werden. Legen Sie kein Papier unter das Gerät. Es könnte die Belüftung behindern.

Platzieren Sie das Gerät auf einer ebenen Oberfläche.

Antistatische Vorkehrungen treffen – Es gi bt stati sch empfindl iche Komponenten, d ie

durch eine elektrostatische Entladung beschädigt werden können. Verwenden Sie

antistatische Prozeduren, Ausrüstung und Oberflächen während der Wartung.

CF-Karte nicht mit einem PC verwenden – Die CF-Karte ist speziell formatiert. Die auf

der CF-Karte gespeicherte Software könnte gelöscht werden.

Gerät nicht bei eventuellem Ausrüstungsfehler betreiben – Wenn Sie einen

Produktschaden oder Ausrüstungsfehler vermuten, lassen Sie die Komponente von

einem qualifizierten Servicetechniker untersuchen.

Kabel richtig verle gen – Verlegen Sie Netzkabel und andere Kabel so, dass Sie nicht

beschädigt werden. Stützen Sie schwere Kabelbündel ordnungsgemäß ab, damit die

Anschlüsse nicht beschädigt werden.

Richtige Netzkabel verwenden – Wenn Netzkabel mitgeliefert wurden, erfüllen diese

alle nationalen elektri schen Normen. Der Betri eb dieses Geräts mit Spann ungen über

130 V AC erfordert Netzkabel, die NEMA-Konfigurationen entsprechen. Wenn

internationale Netzkabel mitgeliefert wurden, sind diese für das Verwendungsland

zugelassen.

Richtige Ersatzbatterie verwenden – Dieses Gerät enthä lt eine Batter i e. Um die

Explosionsgefahr zu verringern, prüfen Sie di e Polarität und taus chen die Batterie nur

gegen eine Batterie desselben Typs oder eines gleichwertigen, vom Hersteller

empfohlenen Typs aus. Entsorgen Sie gebrauchte Batterien entsprechend den

Anweisungen des Batterieherstellers.

02 February 2012 K2 Dyno Replay Controller Service Manual 13

Page 14

Safety Summaries

Das Gerät enthält keine Teile, die vom Benutzer gewartet werden können. Wenden

Sie sich bei Problemen bitte an den nächsten Händler.

14 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 15

Consignes desécurité

Il est recommandé de lire, de bi en comprendre et s urtout de respe cter les in formations

relatives à la sécurité qui sont exposées ci-après, notamment les consignes destinées

à prévenir les risques d’incendie, les décharges électriques et les blessures aux

personnes. Les avertissements complémentaires, qui ne sont pas nécessairement

repris ci-dessous, mais pré sents da ns toute s les se ctions du manue l, sont éga leme nt à

prendre en considération.

AVERTISSEMENT: Toutes les instructions présentes dans ce

manuel qui concernent l’ouverture des capots ou des logements

de cet équipement sont destinées exclusivement à des membres

qualifiés du personnel de maintenance. Afin de diminuer les

risques de décharges électriques, ne procédez à aucune

intervention d’entre t ien autre que celles contenues dans le

manuel de l’utilisateur, à moins que vous ne soyez habilité pour

le faire.

Consignes et symboles de sécurité

Termes utilisés dans ce manuel

Les consignes de sécurité présentées dans ce manuel peuvent apparaître sous les

f

ormes suivantes :

AVERTISSEMENT: Les avertissements signalent des conditions

ou des pratiques suscepti bles d’occas ionner des bles sures graves,

voire même fatales.

MISE EN GARDE: Les mises en ga rde signalent des conditions

ou des pratiques suscept ibles d’ occasionner un endommagement

à l’équipement ou aux installations, ou de rendre l’équipement

temporairement non opérationnel, ce qui peut porter préjudice à

vos activi tés.

Signalétique apposée sur le produit

La signalétique suivante peut être apposée sur le produit :

DANGER — risque de danger imminent pour l’utilisateur.

AVERTISSEMENT — Risque de danger non imminent pour l’utilisateur.

MISE EN GARDE — Risque d’endommagement du produit, des installations ou des

autres équipements.

Symboles apposés sur le produit

Les symboles suivants peut être apposés sur le produit :

Signale la présence d’une tension élevée et dangereuse dans le

boîtier de l’équipement ; cette tension peut être suffisante pour

constituer un risque de décharge électrique.

02 February 2012 K2 Dyno Replay Controller Service Manual 15

Page 16

Safety Summaries

Signale que l’utilisateur, l’ opérateur ou le technicien de

maintenance doit faire référence au(x) manuel(s) pour prendre

connaissance des instructions d’utilisation, de maintenance ou

d’entretien.

Il s’agit d’une invite à prendre note du calibre du fusible lors du

remplacement de ce dernier. Le fusible auquel il est fait référence

dans le texte doit être remplacé par un fusible du même calibre.

Identifie une borne de protection de mise à la masse qui doit être

raccordée correctement avant de procéder au raccordement des

autres équipements.

I dentifie une borne de protection de mise à la masse qui peut être

connectée en tant que borne de mise à la masse supplémentaire.

Signale la présence de compo sants sensi bles à l’él ectrici té stati que

et qui sont susceptibles d’être endommagés par une décharge

électrostatique. Utilisez des procédures, des équipements et des

surfaces antistatiques durant les interventions d’entretien.

Avertissements

Les avertissements suivants signalent des conditions ou des pratiques susceptibles

d’occasionner des blessures graves, voire même fatales :

Présence possible de tensions ou de courants dangereux — Mettez hors tension,

débranchez et retirez la pile (le cas échéant) avant de déposer les couvercles de

protection, de défaire une soudure ou de remplacer des composants.

Ne procédez pas seul à un e intervention d’entre tien — Ne réalisez pas une intervention

d’entretien interne sur ce produit si une personne n’est pas présente pour fournir les

premiers soins en cas d’accident.

Retirez tous vos bijoux — Avant de procéder à une intervention d’entretie n, retirez

tous vos bijoux, notamment les bagues, la montre ou tout autre objet métallique.

Évitez tout contact avec les circuits exposés — Évitez tout contact avec les

connexions, les composants ou les circuits exposés s’ils sont sous tension.

Utilisez le cordon d’alimentation approprié — Utilisez exclusivement le co rdon

d’alimentation fourni avec ce produit ou spécifié pour ce produit.

Raccordez le produit à la masse — Raccordez le conducteur de masse du cordon

d’alimentation à la borne de masse de la prise secteur.

Utilisez le produit lorsque les couvercles et les capots sont en place — N’utilisez pas

ce produit si les couvercles et les capots sont déposés.

Utilisez le bon fusible — Utilisez exclusivement un fusible du type et du calibre

spécifiés pour ce produit.

Utilisez ce produit exclusivement dans un environnement sec — N’utilisez pas ce

produit dans un environnement humide.

Utilisez ce produit exclu siv eme nt dans un environnement non explosible — N’utilisez

pas ce produit dans un environnement dont l’atmosphère est explosible.

16 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 17

Présence possible de courants de fuite — Un raccordement à la masse est

indispensable avant la mise sous tension.

Deux alimentations peuvent être présentes dans l’équipement — Assurez vous que

chaque cordon d’alimen tation est raccordé à des circuits de ter re séparés. Débranc hez

les deux cordons d’alimentation avant toute intervention.

Fusion neutre bipolaire — Débranchez l’alimentation principale avant de procéder à

une intervention d’entretien.

Utilisez les points de levage appro priés — Ne p as u ti li ser les verrous de la po rt e po ur

lever ou déplacer l’équipement.

Évitez les dangers méca nique s — Laissez le ventilateur s’arrêter av ant de p rocéder à

une intervention d’entretien.

Mises en garde

Les mises en garde suivantes signalent les conditions et les pratiques susceptibles

d’occasionner des endommagements à l’équipement et aux installations :

N’ouvrez pas l’appareil — Toute ouverture prohibée de l’appareil aura pour effet

d’annuler la garantie.

Utilisez la source d’alimenta tion adéqu ate — Ne bra nchez pa s ce pr oduit à une so urce

d’alimentation qui utilis e une tensi on supérieu re à la tens ion nomin ale spéci fiée pour

ce produit.

Assurez une ventilation adéquate — Pour éviter toute surchauffe du produit, assurez

une ventilation de l’équipement conformément aux instructions d’installation. Ne

déposez aucun document sous l’appareil – ils peuvent gêner la ventilation. Placez

l’appareil sur une surface plane.

Utilisez des procédures antis tatiques - Les composants sensi bles à l’électrici té statique

présents dans l’équipement sont susceptibles d’être endommagés par une décharge

électrostatiq ue. Utilisez des pr océdures, des équi pements et des surf aces antistat iques

durant les interventions d’entretien.

N’utilisez pas la carte CF avec un PC — La carte CF a été spécialement formatée. Le

logiciel enregistré sur la carte CF risque d’être effacé.

N’utilisez pas l’équipemen t si un dysfonction nement est susp ecté — Si vo us suspectez

un dysfonctionnement du pr oduit, fai tes inspec ter cel ui-ci par un membre qualif ié du

personnel d’entretien.

Acheminez les câbles correctement — Acheminez les câbles d’alimentation et les

autres câbles de manière à ce qu’ils ne risquent pas d’être endommagés. Supportez

correctement les enroul ements de câbles afin de ne pas endomma ger les connecteur s.

Utilisez les cordons d’alimentation adéquats — Les cordons d’alimentation de cet

équipement, s’ils sont fournis, satisfont aux exigences de toutes les réglementations

régionales. L’util isat ion de cet é quipement à des tens ions dé passa nt les 130 V e n c. a.

requiert des cordons d’alimentation qui satisfont aux exigences des configurations

NEMA. Les cordons internationa ux, s’ils sont four nis, ont reçu l’approba tion du pays

dans lequel l’équipement est utilisé.

02 February 2012 K2 Dyno Replay Controller Service Manual 17

Page 18

Safety Summaries

Utilisez une pile de remplacement adéquate — Ce produit renferme une pile. Pour

réduire le risque d’explosion, vérifiez la polarité et ne remplacez la pile que par une

pile du même type, recommandée par le fabricant. Mettez les piles usagées au rebut

conformément aux instructions du fabricant des piles.

Cette unité ne contient aucune partie qui peut faire l’objet d’un entretien par

’utilisateur. Si un problème survient, veuillez contacter votre distributeur local.

l

18 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 19

Certifications and compliances

Canadian certified power cords

Canadian approval includes the products and power cords appropriate for use in the

North America power network. All other power cords supplied are approved for the

country of use.

FCC emission control

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his

own expense. Changes or modifica tions not expr essly a pproved by Grass Val ley can

affect emission compliance and could void the user’s authority to operate this

equipment.

Canadian EMC Notice of Compliance

This digital apparatus does not exceed the Class A limits for radio noise emissions

from digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les

l

imites applicables aux appareils numériques de la classe A préscrites dans le

Règlement sur le brouillage radioélectrique édicté par le ministère des

Communications du Canada.

EN55103 1/2 Class A warning

This product has been evaluated for Electromagnetic Compatibility under the EN

55103-1/2 standards f or Emissions and Immuni ty and meets the r equi re me nt s for E4

environment.

This product complies wit h Class A (E4 environment). In a do mestic environment this

pr

oduct may cause radio interference in which case the user may be required to take

adequate measures.

FCC emission limits

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions : (1) This device may not cau se harmful interference , and (2)

this device must accept any interference rece ived, including interference that may

cause undesirable operation.

02 February 2012 K2 Dyno Replay Controller Service Manual 19

Page 20

Safety Summaries

Laser compliance

Laser safety requirements

Laser safety

This product may contain a Class 1 certified laser device. Operating this product

ou

tside specifica tions or alteri ng its or iginal design may resul t in haza rdous ra diation

exposure, and may be cons idered an act of mod ifying or new manufact uring of a laser

product under U.S. regulations contained in 21CFR Chapter 1, subchapter J or

CENELEC regulations in HD 482 S1. People perfo rming s uch an a ct ar e req uired by

law to recertify and reidentify this product in accordance with provisions of 21CFR

subchapter J for distribution within the U.S.A., and in accordance with CENELEC

HD 482 S1 for distribution within countries using the IEC 825 standard.

Laser safety in the United States is regulated by the Center for Devices and

iological Health (CDRH). The laser safety r egulations are published in t he “Laser

Rad

Product Performance Standard,” Code of Federal Regulation (CFR), Title 21,

Subchapter J.

The International Electrotechnical Commission (IEC) Standard 825, “Radiation of

ser Products, Equipment Classifica tion, Require ments and User ’s Guide,” gov erns

La

laser products o utside the United States . Europe and member nations of the European

Free Trade Association fall under the jurisdiction of the Comité Européen de

Normalization Electrotechnique (CENELEC).

Safety certification

This product has been evaluated and meets the following Safety Certification

Standards:

Standard Designed/tested for compliance with:

ANSI/UL 60950-1 Safety of Informatio n Technology Equipment,

IEC 60950-1 with CB

cert.

CAN/CSA C22.2 No.

60950-1

BS EN 60950-1 Safety of Informatio n Technology Equipment,

including Electrical Business Equipment

(Second edition 2007).

Safety of Information Technology Equipment,

including Electrical Business Equipment

(Second edition, 2005).

Safety of Information Technology Equipment,

including Electrical Business Equipment

(Second edition 2007).

including Electrical Business Equipment

2006.

20 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 21

ESD Protection

Electronics today ar e more suscep tibl e to elect rosta tic dis cha rge (ESD) damag e than

older equipment. Damage to equipment c an occur by E SD fields that ar e smaller th an

you can feel. Implementing the information in this section will help you protect the

investment that you have made in purchasing Grass Valley equipment. This section

contains Grass Vall ey’s rec ommended ESD guid elines t hat shoul d be followe d when

handling electrostatic discharge sensitive (ESDS) items. These minimal

recommendations are based on the information in the “So urc es of ESD and Risks”

area. The in formation in “Grounding Requirements for Personnel” on page 22 is

provided to assist you in selecting an appropriate grounding method.

Recommended ESD Guidelines

Follow these guidelines when handling Grass Valley equipment:

• Only trained personnel that are connected to a grounding system should handle

ESDS i

• Do not open any prot ective bag, bo x, or speci al shippi ng packagi ng until you hav e

been grounded.

Note: When a Personal Gro unding strap is unavailab le, as an abso lute minimum,

ouch a metal object that is touching the floor (for example, a table, frame, or

t

rack) to discharge any static energy before touching an ESDS item

tems.

• Open the anti-static packaging by sl it ti ng a ny existing adhesive tapes. Do not tear

the tapes off.

• Remove the ESDS item by holding it by its edges or by a metal panel.

• Do not touch the component s of an ESDS item unle ss it is absolut ely nec essar y to

configure or repair the item.

• Keep the ESDS work area clear of all noness ential it ems such as co ffee cups, p ens,

wrappers and pers onal items as th ese i te m s c an discharge stati c. If you need to set

an ESDS item down, place it on an anti-static m at or on the a nti-static p ackaging.

Sources of ESD and Risks

The following information identifies possible sources of electrostatic discharge and

can be used to help establish an ESD policy.

Personnel

One of the largest sources of static is personnel. The static can be released from a

pe

rson’s clothing and shoes.

Environment

The environment in cludes t he humidit y and flo ors in a work area . The humidi ty le vel

must be controlled and shoul d not be allowed to fluctuat e over a broad range. Relative

humidity (RH) is a major part in determining the level of static that is being generated.

02 February 2012 K2 Dyno Replay Controller Service Manual 21

Page 22

Safety Summaries

Work Surfaces

Equipment

Materials

Grounding Requirements for Personnel

For example, at 10% - 20% RH a perso n walking across a carpe ted floor can develo p

35kV; yet when the rel ativ e humidi ty i s incr eased to 70% - 80%, t he p erson can only

generate 1.5kV.

Static is generated as personnel move (or as equipment is moved) across a floor’s

s

urface. Carpeted and waxed vinyl floors contribute to static build up.

Painted or vinyl-covered tables, chairs, conveyor belts, racks, carts, anodized

su

rfaces, plexiglass covers, and shelving are all static generators.

Any equipment commonly found in an ESD work ar ea, such as solder guns, heat guns,

bl

owers, etc., should be grounded.

Plastic work holders, foam, plastic tote boxes, pens, packaging containers and other

i

tems commonly found at workstations can generate static electricity.

The information in this section is provided to assist you in selecting a grounding

method. This information is taken from ANSI/ESD S20.20-2007 (Revision o f ANSI/

ESD S20.20-1999).

Product Qualification

Personnel Grounding

Technical Requirement

Wrist Strap System* ANSI/ESD S1.1 (Section 5.11) < 3.5 x 107 ohm

Flooring / Footwear System –

Method 1

Flooring / Footwear System –

Method 2 (both required)

Product qualification is normally conducted during the initial selection of ESD

control products and materials. Any of the following methods can be used: product

specification review, independent laboratory evaluation, or internal laboratory

evaluation.

Compliance Verification

Personnel Grounding

Technical Requirement

Wrist Strap System* ESD TR53 Wrist Strap Section < 3.5 x 107 ohm

Flooring / Footwear System –

Method 1

Test Method Required Limits

ANSI/ESD STM97.1 < 3.5 x 107 ohm

ANSI/ESD STM97.1 < 109 ohm

ANSI/ESD STM97.2 < 100 V

Test Method Required Limits

ESD TR53 Flooring Section and

ESD TR53 Footwear Section

< 3.5 x 10

7

ohm

22 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 23

Personnel Grounding

Technical Requirement

Flooring / Footwear System –

Method 2 (both required)

Test Method Required Limits

ESD TR53 Flooring Section and

ESD TR53 Footwear Section

< 1.0 x 109 ohm

* For situations where an ESD garment is used as part of the wrist strap grounding

path, the total syste m res is ta nce, including the person , gar me nt , and g rounding cord,

7

must be less than 3.5 x 10

ohm.

02 February 2012 K2 Dyno Replay Controller Service Manual 23

Page 24

Safety Summaries

24 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 25

Finding Information

This service manual provides procedures for servicing the K2™ Dyno™ Replay

Controller to the field-replaceable unit level. Use this manual to isolate problems to a

board or module, such as the Power Supply, and to make repairs through module

exchange.

How this manual is org anized

This manual is or ganized around the tasks required to service the Dyn o controller. The

following describes the chapters included in this manual:

Chapter 1, Pro

and status indicators of the Dyno controller.

Chapter 2, Ser

repair.

Chapter 3, Tr

diagnosing and correcting the cause of the problem. Use this information if you are

ving trouble with your Dyno controller.

ha

Chapter 4, Removi

replacing field replaceable hardware components.

duct Description — Describes the key features, system components,

vice Procedures — Contains pr ocedure s for period ic main te nance an d

oubleshooting problems — Cont ains problem descriptions with s teps for

ng and replacing FRUs — Cont ains procedures for removing and

Getting more information

The following sections help you find the information you need in product manuals

and elsewhere.

K2 documentation

Read the following descriptions to locate the information you need.

K2 Dyno Replay System Quick Start Guide — You receive this guide in the product

packaging with your K2 Dyno Replay Controller. The Quick Start Guide provides

step-by-step ins tallat ion instr uctions f or basic in stall ation and operation of the repl ay

system, which includes the K2 Dyno Replay Controller and the K2 Summit

Production Client.

Release Notes — The release notes contain the latest information about the software

shipped on your s ystem. There are K2 Release Not es and K2 Dyno Replay Contro ller

Release Notes. The information in release notes includes software upgrade

instructions, software specifications and requirements, feature changes from the

previous releases, and any known problems.

K2 Documentation Set — Except for the release notes, the full set of support

documentation, includi ng this manual, i s available in t he K2 Documentation Se t. You

can find the K2 Documentati on Set on the Grass Vall ey website . The following URL

allows you to browse by K2 Dyno software version:

http://www.grassvalley.com/dl/k2_dyno

The K2 Documentation Set includes the following documents:

• K2 Dyno Replay System Quick Start Guide — As described above.

•

K2 Dyno Replay Controller User Manual — Describes Dyno controller applications

and provides instructions for configuring and operating the product.

02 February 2012 K2 Dyno Replay Controller Service Manual 25

Page 26

Finding Information

• K2 Dyno Replay Controller Service Manual — Contains information on servicing and

•

•

•

•

•

•

•

maintenance.

K2 Summit Production Client Quick Start Guide — The Quick Start Guide provides

step-by-step installation instructions for basic installation and operation of K2

systems, including recording and playing clips.

K2 AppCenter User Guide — Describes K2 applications and provides instructions

for configuring and operating the product.

K2 System Guide — Contains the product specifications and step-by-step

instructions for modifying system settings.

K2 Cabling Guide — Contains diagrams for cabling the devices of the K2 Storage

Area Network.

K2 SAN Installation and Service Manual — Contains installa tion, configura tion, and

maintenance procedures for shared storage options.

RAID Instruction Manuals — There is an Instruction Manual for each type of RAID

storage device that can be a par t of a K2 system. These manuals contain procedur es

for configuring and servicing the device.

K2 Client Service Manual — Contains information on servicing and maintenance.

NetCentral documentation

The NetCentral product has its own documentation set, described as follows:

•

NetCentral Quick Star t Guide — Pr ovides an overview o f the i nstalla tion proc ess to

quickly set up and run NetCentral.

•

NetCentral Installation Guide — Identifies requirements and procedures to correctly

set up servers and devices, as well as provides detailed instructions to install and

configure NetCentral software.

•

NetCentral User Guide — Describes how to use the NetCentral Manager to monitor

devices.

•

NetCentral Help — From the NetCentral inter face acce ss on-line help. Selec t Help |

NetCentral Help Topics

.

Also find information about monitoring a specific product in that product’s manuals.

Grass Valley Web Site

This public Web site contains all the latest manuals and documentation, and

additional support information. Use the following URL.

http://www.grassvalley.com.

26 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 27

Chapter 1

Product Description

Topics in this section include the following:

•“Overview description” on page 28

•“Dyno controller orientation” on page 29

•“FRU functional descriptions” on page 30

•“Status indicators” on page 34

•“General specifications” on page 35

•“Counter top installation” on page 36

02 February 2012 K2 Dyno Replay Controller Service Manual 27

Page 28

Chapter 1 Product Description

Overview description

The Dyno controller is a compact slow-motion controller designed for sports

production and other live event production. It features a touch-screen interface,

external VGA screen, high-speed Gigabit Ethernet connection, USB connectors,

T-bar lever, jog knob, and switcher quality buttons.

The Dyno controller recor ds and plays using in dustry standard f iles. It connect s to the

ummit Production Client for media storage. It can also be connected to a K2

K2 S

SAN. It supports a networke d environment us ing standard Gigabit Ether net networks

for file sharing.

The Dyno controller provides a variety of features including speed, editing, effects,

ti-user operation, an efficient user interface, and immediate content packaging.

mul

Interface tools include thumbnail icons, status indicators, specialized windows, and

drag-and-drop operations for speedy and easy use.

Refer to the K2 Dy

controls, applications, and subsystems.

no Replay Controller User Manual for descriptions of features,

28 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 29

Dyno controller orientation

Front I/O board

Power supply

T-bar lever assembly

Control panel UI board

LCD screen

Plastic cover

Jog knob

Motherboard

Fan

Compact Flash

boot media

USB board

LCD screen

inverter board

The following illu strat ion sh ows the l ocati on of Fi eld Repl aceabl e Unit s (FRUs ) and

other components in the Dyno controller.

Dyno controller orientation

The Type I control panel UI board with integrated encoder is shown. The Type II

ontrol panel UI board i s in a similar posit ion. With the Type II control panel UI b oard

c

there is a also a Type II encoder (not shown) that is a separate unit, rather than being

integrated into the board.

02 February 2012 K2 Dyno Replay Controller Service Manual 29

Page 30

Chapter 1 Product Description

FRU functional descriptions

The Field Replaceable Units (FRU s) describ ed in this section are as follows:

• “

Base chas sis”

• “Compact Flash boot media”

• “Jog knob”

• “Plastic cover”

• “T-bar lever assembly”

• “Type I Control panel UI board”

• “LCD screen”

• “LCD screen inverter board”

• “Front I/O board”

• “Fan”

• “USB board”

• “Motherboard”

• “Power supply”

For procedures, refer to Chapter 4, Removi

Base chassis

For some serious system faults or for mechanical damage, the entire Dyno controller

can be replaced as a base chassis FRU. Refer to “Replacing a Dyno controller” on

page 44.

Compact Flash boot media

The Compact Flash b oot media conta ins the sys tem drive, also known as the C: dr ive.

The C: drive contains application and operating system files.

Refer to “Compact Flash boot media removal” on page 65 for procedures.

Jog knob

The jog knob is 60mm, weighted, and rubber encased with tactile relief.

Refer to “Job knob removal” on page 60 for procedures.

Plastic cover

ng and replacing FRUs.

The plastic top cover provides the finished work surface with access holes for

controls.

Refer to “Plastic cover removal” on page 70 for procedures.

30 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 31

T-bar lever assembly

This is the complete mechanism which includes the front panel T-bar lever and the

unit in which it is housed. In case it is damaged or otherwise inoperable, it can be

replaced separately.

Refer to “T-bar lever assembly removal” on page 69 for procedures.

Type I Control panel UI board

This board provides the front control panel user interface for the Dyno controller,

including the following functionality:

• 21 backlit, tri-color, momentary contact tactile buttons in 3 banks

•

Jog knob interface and encoder

• USB interface to PC Motherboa rd

• Push Button Matrix Scanner, for 21 top panel buttons

• T-bar lever A /D interface

• SPI Port to LCD screen Con troller

T-bar lever assembly

• LED driver interface

• Button LED Dimming

• Embedded Program Flash and SRAM memory

• Display Inte rface

• LCD screen controller

Refer to “Type I control panel UI board removal” on page 72 for procedures.

Type II Control panel UI board

This board provides the front control panel user interface for the Dyno controller,

including the following functionality:

• 21 backlit, tri-color, momentary contact tactile buttons in 3 banks

•

Jog knob interface

• USB interface to PC Motherboa rd

• Push Button Matrix Scanner, for 21 top panel buttons

• T-bar lever A /D interface

• SPI Port to LCD screen Con troller

• LED driver interface

• Button LED Dimming

• Embedded Program Flash and SRAM memory

• Display Inte rface

• LCD screen controller

02 February 2012 K2 Dyno Replay Controller Service Manual 31

Page 32

Chapter 1 Product Description

Refer to “Type II control panel UI board removal” on page 74 for procedures.

Type II Encoder

This unit provides the jog knob functionality for the Dyno controller:

Refer to “Type II encoder removal” on page 76 for procedures.

LCD screen

The LCD touch screen is a 178mm (7in.) color flat panel displ ay overlaid with a touch

screen that translates finger contact into mouse-type USB control information. The

display is a 800 x 480 resolution, 18 Bit Panel.

Refer to “LCD screen removal” on page 77 for procedures.

LCD screen inverter board

This board takes in a DC voltage and outputs a very high AC voltage to power the

display backlight. It is mounted on the rear of the LCD touch screen housing.

Refer to “LCD screen inverter board removal” on page 71 for procedures.

Front I/O board

The front I/O connector board provides a headphone jack and volume control for

audio monitoring, two fr ont pa nel USB 2.0 p orts, a nd a spe aker ( left channe l). When

the headphone jack is active, it mutes the speaker.

Refer to “Front I/O board removal” on page 78 for procedures.

Fan

The fan provides cooling for the Dyno controller chassis. The fan is installed in the

rear of the Dyno controller chassis and it is temperature controlled.

Refer to “Fan removal” on page 79 for procedures.

USB board

The USB board provides the USB connec tions on the rear panel . It features a four port

USB 2.0 Hub, ATX power management, and a rear fan control.

Refer to “USB board removal” on page 83 for procedures.

Motherboard

The motherboard hosts the CPU and other components that provide the basic

computer functionali ty f or t he c ont rol le r. I t pr ovi de s the Power and Service LEDs, a

Compact Flash slot, and rear panel connectors as follows:

• 2 Giga-bit Ethernet

•

15 pin (D-conn) VGA

• DB-9 serial port.

Refer to “Motherboard removal” on page 80 for procedures.

32 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 33

Power supply

The Dyno controller power supply has a fan wi th automatic s peed control . The power

supply has protection for over voltage, over current, over temperature, and short

circuits. It is an ATX Power supply of 180 Watts.

Refer to “Power supply removal” on page 84 for procedures.

Power supply

02 February 2012 K2 Dyno Replay Controller Service Manual 33

Page 34

Chapter 1 Product Description

!

Status indicators

The following sections describe the visual and audible indicators that communicate

the current operating status and system health of the Dyno controller.

Rear panel indicators

100-240 V~

4A 50-60Hz

RS-232

Power LED

This LED indicates status as foll ows:

Off:

The standby switch is set to Off and the Dyno controller is not operational.

WARNING: The power standby switch does not turn off power to the

stem. To turn power off the system must be disconnected from the

sy

power source.

Steady on (green):

The standby switch is set to On and the Dyno controller is either

in the startup process or has competed the startup process and is operational.

Drive access LED

This LED indicates status as foll ows:

Flickering (amber):

The system drive is being accessed by data read/write

operations.

Off:

No drive access is occurring.

LAN connector indicator codes

Power

LED

Drive

access

LED

LAN

connector

indicators

The motherboard has two RJ-45 LAN conne ctors that include integrat ed status LEDs .

T

he LEDs are oriented a s follows:

Green

34 K2 Dyno Replay Controller Service Manual 02 February 2012

Green/Yellow/Orange

Page 35

The meanings of the LED states are described in the following table:

LED LED state Status Condition

Green Green On The adapter is connected to a valid link partner

Green/Yellow/

Oran

ge

If a LAN connector is faulty, you must replace the motherboard.

System beep codes

If there are no errors present the Dyno controller does not emit any audible beeps

during startup process or otherwise. If an error occurs during Power On Self Test

(POST), the BIOS might issue one of the following beep codes:

System beep codes

Green flashing Data activity

Off No link

Off 10 Mbps

Green 100 Mbps

Yellow 10000 Mbps

Orange flashing Identify

Error Beep Code Description

One long and two short beeps A video error has occurred and the BIOS cannot

A single long beep, repeated. A DRAM error has occurred.

General specifications

Characteristic Specification

Power AC universal power s uppl y, 10 0-1 30 VA C, 200-2 40 V AC, 50 o r

60 Hz. Typical power consumption, 100 watts

Dimensions Dimensions: leng th = 12 .6 in. (316 mm);

width = 8.25 in. ( 210 mm); he ight = 7.4 in. (187 mm) (Al l approx.)

Weight 5 kg (11 lbs.)

Temperature range Operating: 0°C to 40°C (32°F to 104°F); Storage: -20°C to 60°C

(

-4°F to 140°F)

Humidity range 10% to 90% (relative humidity)

initialize the vide o screen to display any additional

information.

02 February 2012 K2 Dyno Replay Controller Service Manual 35

Page 36

Chapter 1 Product Description

Counter top installation

Use the following specifications for a custom installation in a counter top.

36 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 37

Chapter 2

Service Procedures

Topics in this section include the following:

•“E

xporting log files (software version 2.x)” on page 37

•“Exporting log files (software version 1.x)” on page 37

•“Calibrating the control panel” on page 37

•“Upgrading software” on page 38

•“Updating firmware (software version 2.x)” on page 38

•“Updating firmware (software version 1.x)” on page 38

•“Using recovery disk images” on page 39

•“Replacing a Dyno controller” on page 44

Exporting log files (so ftwa r e ve rs io n 2.x)

In version 2.x, the K2 Dyno Replay application no longer exports logs. Logs are

stored on the K2 Summit Production Client or Solo.

Exporting log files (so ftwa r e ve rs io n 1.x)

1. In the K2 Dyno Replay ap plication on the K2 Dyno Rep lay Controller LCD scr een,

select the

2. Touch

3. Configure settings as follows:

• Verbose Level — Sets the l og output level. A more detailed log is out put as you

in

• Output Folder — Specifies the folder to which the log is output.

• Gathering From — Sets the source(s) from which a log is col lected. If you select

Local Only, a log for operations, only on the K2 Dyno Replay Controller that

you are currently working on, is output. If you select Session, a log for

operations on all the con tr oll er s i s output even when multiple K2 Dyno Re pla y

Controllers are connected.

CONFIG tab.

< or > and then select LOG.

crease the value.

Calibrating the control panel

You can adjust the LED brightness of th e button an d the idle of the T-Bar/JOG knob

to suit your environment or preferences.

1. To start the diagnostics tool, double-click C

• In software version 2.x, it is located in c:/program files/Grass

Valley/Dyno.

ontrollerDiag.exe.

• In software versi on 1.x, it is located i n c:/program files/K2Dyno. You

02 February 2012 K2 Dyno Replay Controller Service Manual 37

Page 38

Chapter 2 Service Procedures

can also access the tool by pressing the Shift, Fn, and Next buttons at the same

time.

The calibration screen appears on the LCD screen.

2. Set items as follows:

Touch this… To make this adjustment:

TOUCH PANEL Corrects the touch panel. Touching the panel displays cross-shapes at the upper

LCD BRIGHT Adjusts the sc reen brightness. Touch </> to adjust.

LED BRIGHT Adjusts the button brightness. Touch </> to adjust.

left and lower right corners of the screen. To uch them to correct the touch panel,

respectively.

T-BAR

JOG Sets the idle of the JOG knob. Touch </> to adjust. The idle becomes smaller as

Load Default Touch to restore the default settings.

Save & Exit Saves the settings and exits the calibration screen.

Exit Discards the settings and exits the calibration screen.

Sets the idle of the T-Bar. Operate the T-Bar to move it to the position you want to

se

t as 0%, and then touch “0%”. Sim ilarly, touch “100%” at the position to set as

“100%”

y

ou decrease the value.

Upgrading software

When you receive your Dyno controller from Grass Valley, it has all necessary

software in stalled. For procedures to upgrad e software on the Dyno controller, refer

to the K2 Dyno Replay Controller Release Notes for the version to which you are

upgrading. Also refer to K2 Release Notes to upgrade related software on the K2

Summit Production Client.

Updating firmware (software version 2.x)

With software vers ion 2.x or higher , firmware is au tomatical ly in stalled when the K2

Dyno software is inst alled. If a new b oard is installe d, the K2 Dyno Replay Co ntroller

automatically updates the firmware.

When upgrading Dyno software from version 2.x or higher, the Dyno Replay

C

ontroller automatically checks for updated firmware and upgrades it along with the

software.

Updating firmware (software version 1.x)

1. Copy the update file to a USB memory.

• For instructions on how to obtain the update file, see the latest release notes.

2. Attach the USB memory to the K2 Dyno Replay Controller.

3. As soon as the K2 Dyno Replay Controller starts up, press the

buttons at the same time.

38 K2 Dyno Replay Controller Service Manual 02 February 2012

Fn, Shift, and A

Page 39

• You can also start the firmware updater by double-clicking

Controlle r Updater.e xe in c:/program files/K2Dyno.

4. Click Update.

Using recovery disk images

• If you click

program was installed.

5. Select the update file in the USB memory, and then click

Backup, the current program is backed up to the folder where the

Using recovery disk images

Procedures in this section are as follows:

• “A

bout the recovery disk image process” on page 39

• “Creating a recovery disk image” on page 40

• “Restoring from a system-specific recovery disk image” on page 41

About the recovery disk image process

You can create a disk image of the Dyno controller system drive and restore from the

image. This simplifie s the proces s of rebuildi ng a system in a disaster-recovery

scenario.

NOTE: This process is not intended as a means to backup and restore media.

When you receive your Dyno controller new from the factory, you a receive a

stem-specific disk image for that particular Dyno controller. This factory image is

sy

stored on a bootable USB Recovery Flash Drive. Also on the Recovery Flash Drive

is the Acronis True Image software necessary to create and restore a disk image.

Open.

After your Dyno controller is installed, configured, and running in your system

nvironment, you should cr eate new recovery dis k images to capture se ttings changed

e

from default. These “fi r st birthday” images are the baseline recovery image for the

Dyno controller in i ts life in your facility. The re is enough dis k space on the Reco very

Flash Drive to store the first birthday image along with the factory image.

02 February 2012 K2 Dyno Replay Controller Service Manual 39

Page 40

Chapter 2 Service Procedures

You should likewise create a new recovery disk image after completing any process

that changes system software or data, such as a software upgrade. In this way you

retain the ability to restore your Dyno controller to a recent “last known good” state.

NOTE: The recovery disk image process is an “off-line” process. Do not attempt

his process while media access is underway.

t

The recove ry disk image process that you shou ld follow is summarize d in the

ollowing steps.

f

At the Dyno controller first birthday…

1. Boot from the Recove ry Flash Drive..

2. Create a recovery disk image for the Dyno controller.

At milestones, such as software upgrades…

1. Boot from the Recove ry Flash Drive..

2. Create a recovery disk image for the Dyno controller.

3. Copy the disk image to another location, such as a network drive.

If you need to restore the Dyno controller…

1. Boot from the Recove ry Flash Drive..

2. Read the disk image from the Recovery Flash Drive or from the location that you

s

tored the disk image.

Use the following procedures to implement the recovery disk image process as

ne

cessary.

Creating a recovery disk image

Do the following at the local Dyno controller to create a disk image:

1. Make sure that media access is stopped.

2. If you have not already do ne so, connect keyboard, monit or, and mouse to the Dyno

c

ontroller.

3. Insert the Recovery Flash Drive into a USB port and restart the machine.

The machine boots from the Flash drive. The Acronis True Image program loads.

4. In the Acronis True Image main window, click

The Create Backup Wizard opens.

5. On the Welcome pa ge, click

The Partitions Selection page opens.

6. Select the

(C:) partition and then click Next.

Next.

Backup.

If a “…choose full backup mode…” message appears, click

OK.

The Backup Archive Location page opens.

7. In the tree view select

Removable Drive (A:) as the location to which you are writing

the disk im age.

40 K2 Dyno Replay Controller Service Manual 02 February 2012

Page 41

Restoring from a system-specific recovery disk image

8. Enter the name of the image file you are creating. Create the file name using the

Dyno controller hostna me and the date. Name the file with the .tib extension. For

example, if the hostname is Dyno1, in the File name field you would have

E:\Dyno1_20091027.tib. Cli

The Select Backup Mode page opens.

ck Next.

9. Select

Create a new full backup archive. Click Nex t.

The Backup Creation Options page opens.

10.Do not change any settings on this page. Click

Next.

The Archive Comment page opens.

11.If desired, enter image comments, such as the date, time, and software versions

c

ontained on the image you are creating. Click

Next.

The “…ready to proceed…” page opens.

12.Verify that you ar e creating a n image from the C: drive and writing t o the A:\ dri ve.

Cl

Proceed.

ick

If a “…insert next volume…” message appears, click

OK.

The Operation Progress page opens and displays progress.

13.When a “Backup archive creation has been successfully completed” message

ap

pears, click

14.Click

Operations | Exit to exit the Acronis True Image program.

OK.

The Dyno controller restarts automatically.

15.Remove the Recovery Flash Drive while the Dyno controller is shutting down.

Restoring from a system-specific recovery disk image

Use this procedure to acce ss an imag e created f rom a specifi c system and r estore that

image to the same specifi c syst em from whi ch it wa s creat ed. This can be t he fac tory

image stored on the bootable USB Recovery Flash Drive or an image you created to

capture settings changed from default.

Before restoring fr om a recovery disk imag e, ma ke s ure t h at th e Dyno controller has

ccess to the image fr om whi ch you are restorin g. You can restore fro m an image on

a

the Recovery Flash Driv e, from a network connected drive, or from anothe r connected

USB drive.

1. Make sure that media access is stopped.

2. If you have not already do ne so, connect keyboard, monit or, and mouse to the Dyno

c

ontroller.