Graco GMAX 3400, GMAX II 3900, GMAX II 7900, TexSpray 5900HD, TexSpray 7900HD Operation

...

Operation

ti23055a

GMAX™ 3400, GMAX™ II 3900/5900/7900, and

3A6400A

TexSpray 5900HD/7900HD Airless Sprayers

For the application of architectural paints and coatings. For professional use only.

Not approved for use in European explosive atmosphere locations.

3300 psi (22.8 MPa, 228 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual and in gas engine manual before using

the equipment. Be familiar with the controls and the proper usage of the equipment.

Save these instructions.

Related Manuals:

Parts 3A6417

Honda Engine Manuals

EN

Model Standard ProContractor Lo-Boy Ironman

GMAX 3400 17E825

GMAX II 3900 17E827 17E826

GMAX II 5900 17E831 17E829

GMAX II 5900

Convertible

GMAX II 7900 17E836 17E834

TexSpray 5900HD 17E839

TexSpray 7900HD 17E841

GMAX 3400 17G997

GMAX II 3900 17G999 17E828 17G998

GMAX II 5900 17H810 17E832 17H808 17E833

GMAX II 7900 17H818 17E837 17H817 17E838

GMAX II 7900

Roof Rig

TexSpray 5900HD 17H819 17E840

TexSpray 7900HD 17H820 17E842 17E843

17E830

17E835

Contents

Contents

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electric Motor Warnings . . . . . . . . . . . . . . . . . . . 4

Internal Combustion Engine Warnings . . . . . . . . 5

Electric Motor/Internal Combustion Engine

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . 8

Standard Models (3400, 3900, 5900, 5900HD,

7900, 7900HD) . . . . . . . . . . . . . . . . . . . . . . . 8

ProContractor Models (3900, 5900, 7900, 5900HD,

7900HD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ironman Models (5900, 7900, 7900HD) . . . . . . 10

Lo-Boy Models (3900, 5900, 7900) . . . . . . . . . . 11

Convertible Models (5900) . . . . . . . . . . . . . . . . 12

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 13

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Grounding Procedure for Internal Combustion

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Grounding of Pails . . . . . . . . . . . . . . . . . . . . . . 14

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Convertible Models Only . . . . . . . . . . . . . . . . . . 16

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Switch Tip

Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Clearing Tip Clogs . . . . . . . . . . . . . . . . . . . . . . 19

WatchDog

™

Guard Assembly . . . . . . . . . . . . . . 18

™

Protection System (ProContractor and

Ironman units only) . . . . . . . . . . . . . . . . . . . 19

QuikReel

LED Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

LED Display Messages . . . . . . . . . . . . . . . . . . . . . 38

Pinion Assembly/Clutch Armature/Clamp . . . . . . 39

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 45

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 46

™

(ProContractor units only) . . . . . . . . . . . . . . . 20

(ProContractor and Ironman units) . . . . . . . . . . 21

Fluid Pump Runs Constantly . . . . . . . . . . . . . . . 31

Control Board Malfunction . . . . . . . . . . . . . . . . . 32

Control Board Malfunction (Steps) . . . . . . . . . . 33

Convertible Electric Motor Will Not Run . . . . . . 34

Convertible Electric Motor Will Not Run (Steps) 35

Convertible Electric Motor Runs -

No AC Output to Sprayer Control Board . . . 36

Pinion Assembly/Clutch Armature Removal . . . 39

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Clamp Removal . . . . . . . . . . . . . . . . . . . . . . . . . 40

Clamp Installation . . . . . . . . . . . . . . . . . . . . . . . 40

2 3A6400A

Warning

WARNING

120V US

Warning

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these

symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard

symbols and warnings not covered in this section may appear throughout the body of this manual where applicable.

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This product is equipped with a cord

having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding wire to

either flat blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes is the

grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely

understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a

qualified electrician.

• This product is for use on a nominal 120V circuit and has a grounding plug similar to the plugs

illustrated in the figure below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

• Extension Cords:

• Use only a 3-wire extension cord that has a grounding plug and a grounding receptacle that accepts

the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary, use 12 AWG (2.5

2

mm

) minimum to carry the current that the product draws.

• An undersized cord results in a drop in line voltage and loss of power and overheating.

3A6400A 3

Warning

WARNING

Electric Motor Warnings

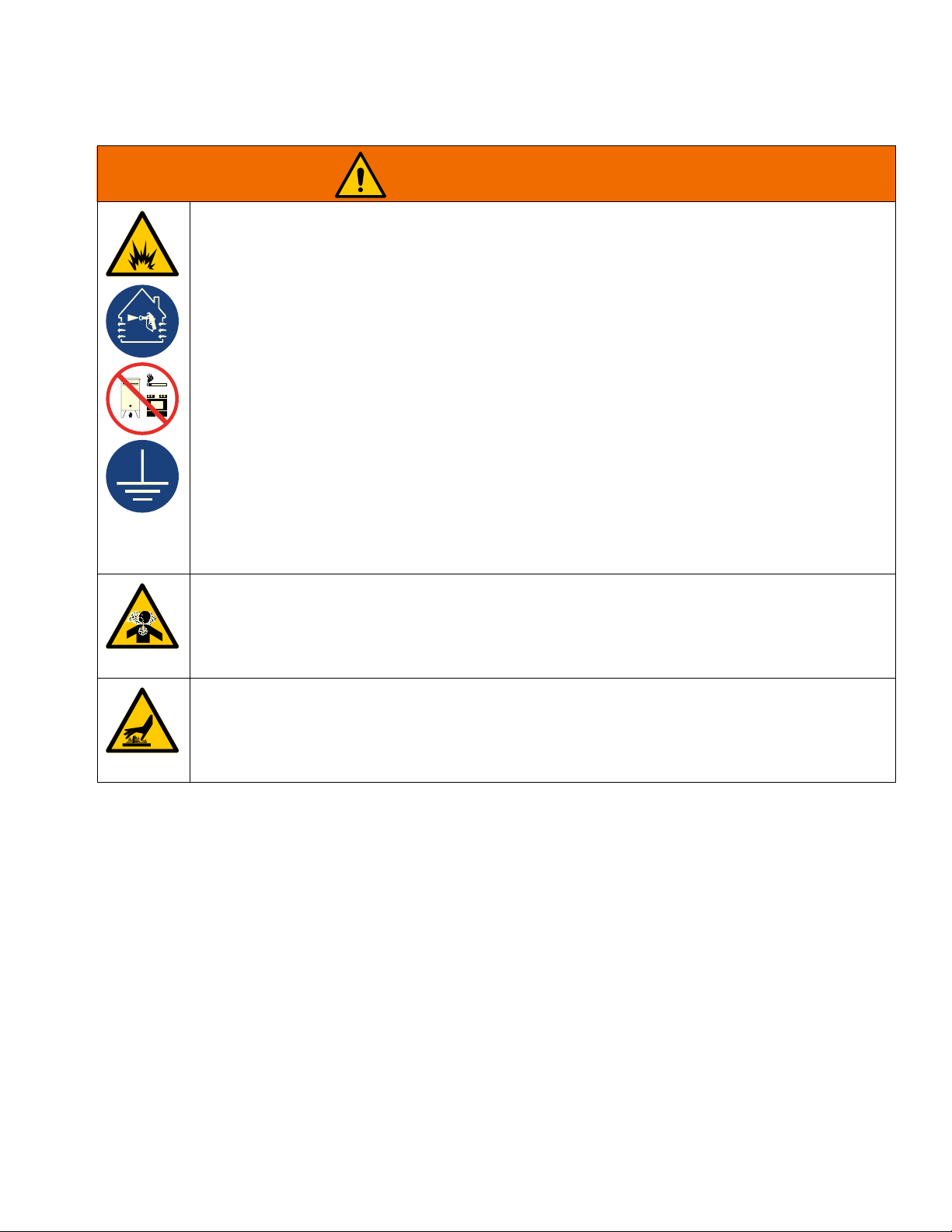

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition such as

cigarettes, motors, and electrical equipment.

• Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity

creates a risk of fire or explosion in the presence of paint or solvent fumes. All parts of the spray

system, including the pump, hose assembly, spray gun, and objects in and around the spray area

shall be properly grounded to protect against static discharge and sparks. Use Graco conductive or

grounded high-pressure airless paint sprayer hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge. Do not

use pail liners unless they are anti-static or conductive.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Do not spray flammable or combustible liquids in a confined area.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area.

• Sprayer generates sparks. Keep pump assembly in a well-ventilated area at least 20 feet (6.1 m)

from the spray area when spraying, flushing, cleaning, or servicing. Do not spray pump assembly.

• Do not smoke in the spray area or spray where sparks or flame is present.

• Do not operate light switches, engines, or similar spark producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

• Know the contents of the paints and solvents being sprayed. Read all Safety Data Sheets (SDSs)

and container labels provided with the paints and solvents. Follow the paint and solvent

manufacturer’s safety instructions.

• Keep a working fire extinguisher in the work area.

4 3A6400A

Internal Combustion Engine Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or

solvent flowing through the equipment can cause static sparking. To help prevent fire and explosion:

• Use equipment only in well-ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable

and can ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic

drop cloths (potential static sparking).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

are anti-static or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon

monoxide can cause death.

Warning

• Do not operate internal combustion engine in an enclosed area.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

3A6400A 5

Warning

WARNING

Electric Motor/Internal Combustion Engine Warnings

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious injury that can result in

amputation. In the event that injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks

with any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while

spraying, follow the Pressure Relief Procedure for turning off the unit and relieving the pressure

before removing the nozzle tip to clean.

• Equipment maintains pressure after power is shut off. Do not leave the equipment energized or

under pressure while unattended. Follow the Pressure Relief Procedure when the equipment is

unattended or not in use, and before servicing, cleaning, or removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3300 psi (228 bar, 22.8 MPa). Use Graco parts or accessories

that are rated a minimum of 3300 psi (228 bar, 22.8 MPa).

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Specifications in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For

complete information about your material, request Safety Data Sheets (SDSs) from distributor or

retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and

create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

6 3A6400A

Warning

WARNING

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death, serious

injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material

supplier for compatibility.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

RECOIL HAZARD

Gun may recoil when triggered. If you are not standing securely, you could fall and be seriously

injured.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

CALIFORNIA PROPOSITION 65

The engine exhaust from this product contains a chemical known to the State of California to cause

cancer, birth defects or other reproductive harm.

This product contains a chemical known to the State of California to cause cancer, birth defects or

other reproductive harm. Wash hands after handling.

3A6400A 7

Component Identification

Component Identification

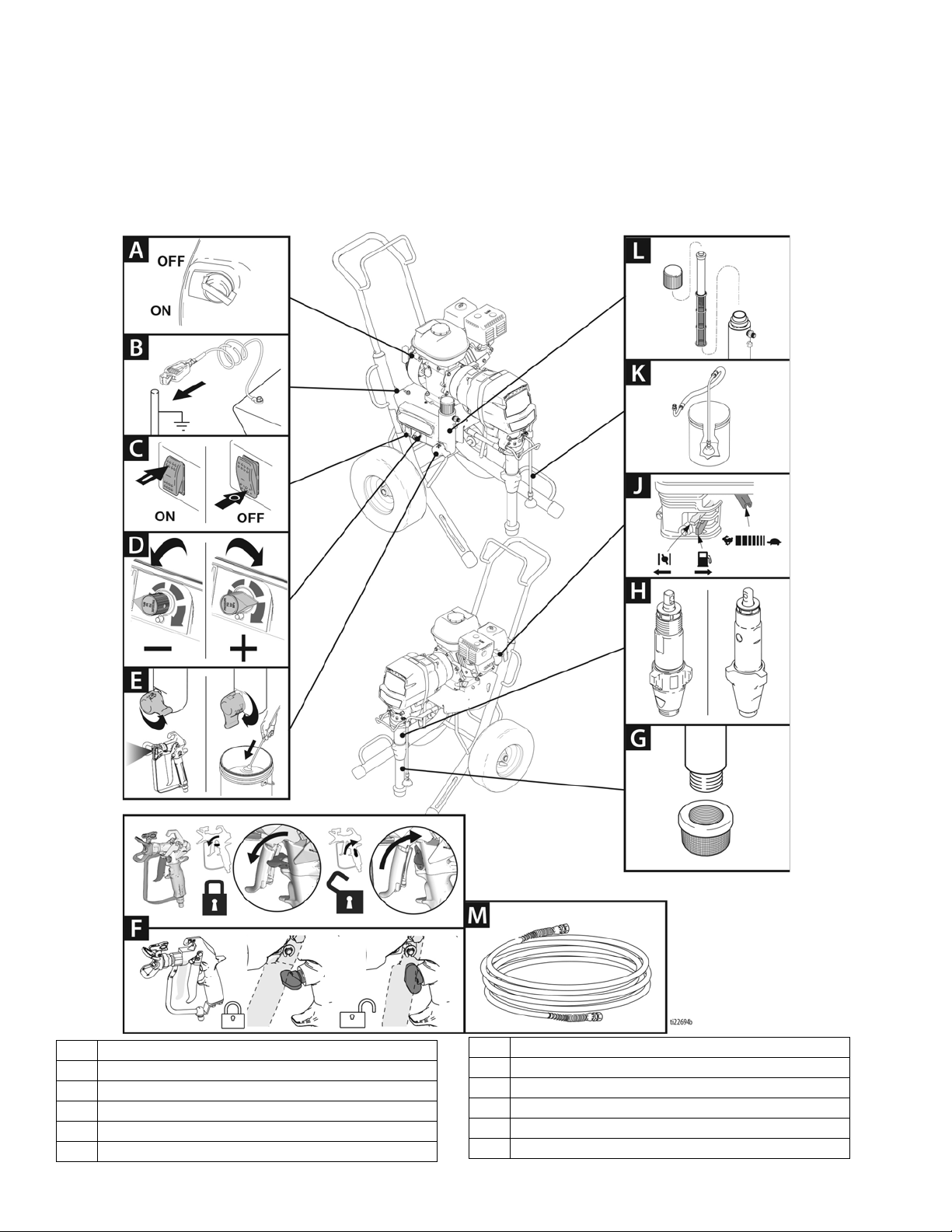

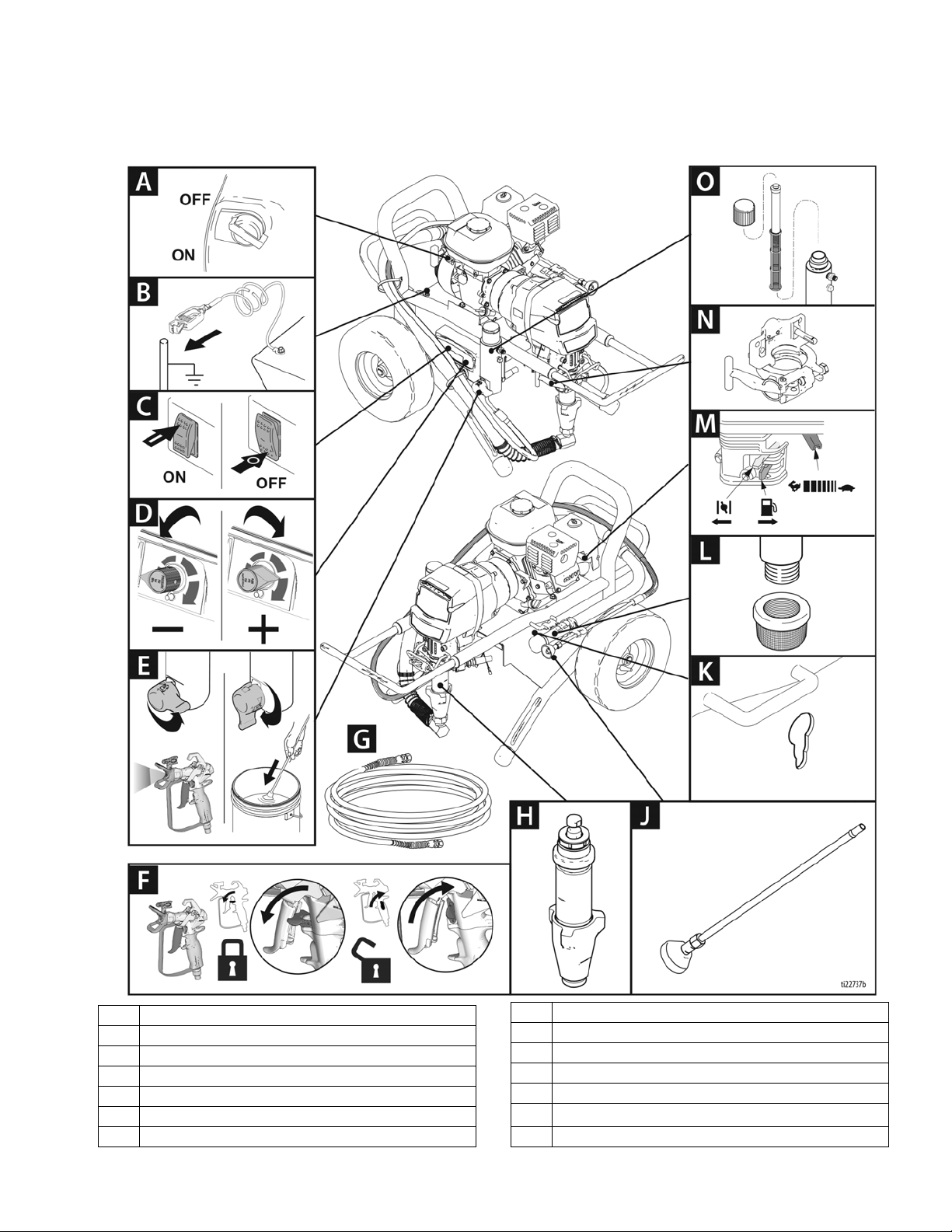

Standard Models (3400, 3900, 5900, 5900HD, 7900, 7900HD)

A Engine ON/OFF Switch

B Grounding Clamp

C Pump On/Off Switch

D Pressure Control

E Prime Valve

F Gun Trigger Lock

8 3A6400A

GStrainer

HPump

J Engine Controls

K Drain Hose

L Easy Out Pump Filter

MHose

Component Identification

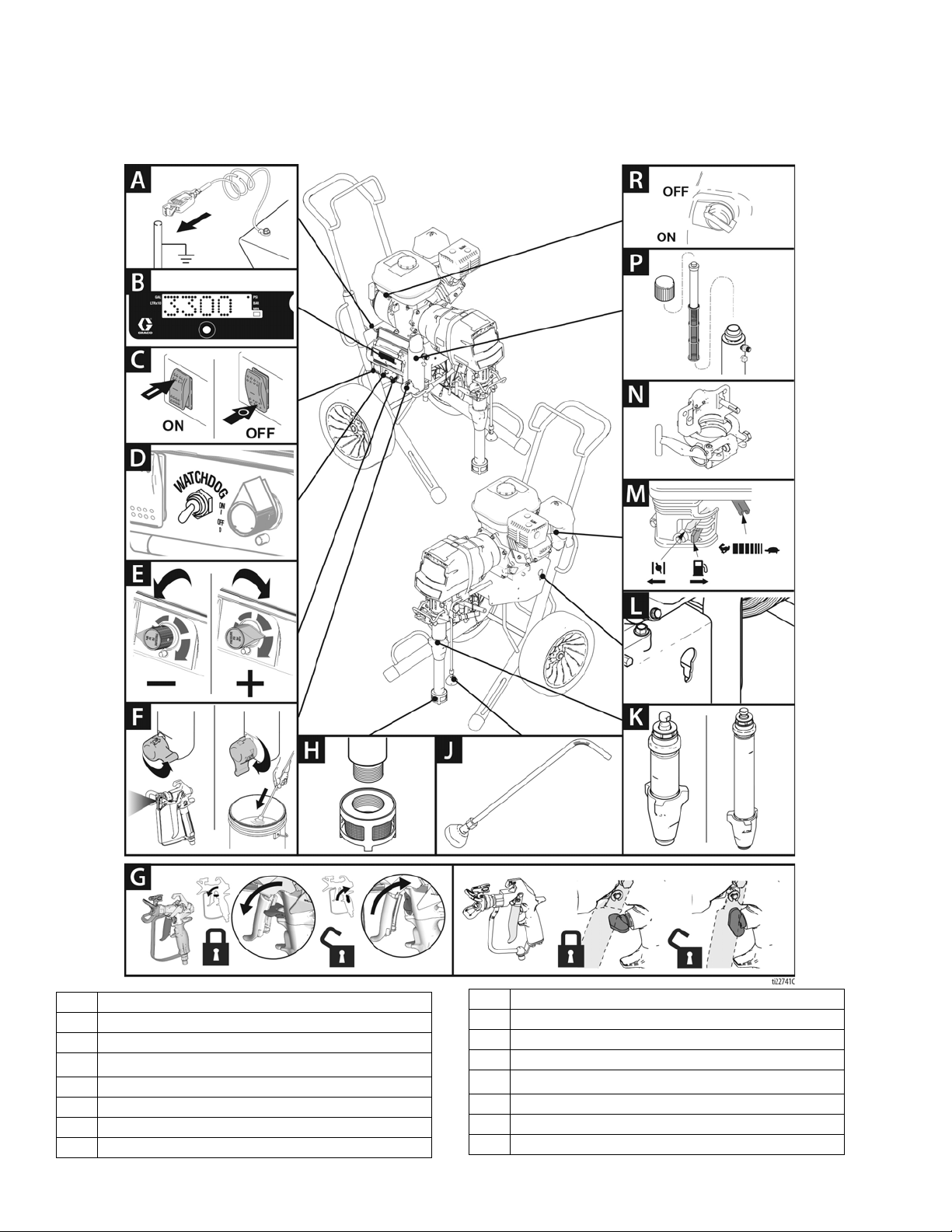

ProContractor Models (3900, 5900, 7900, 5900HD, 7900HD)

A Grounding Coil

B Smart Control 3.0 Display

C Pump ON/OFF Switch

D

WatchDog

E Pressure Control

F Prime Valve

G Gun Trigger Lock

HStrainer

3A6400A 9

TM

Switch

JDrain hose

KPump

L Rod Pull Feature

M Engine Controls

N

ProConnect

P Filter

R Engine ON/OFF Switch

S QuikReel

TM

II Pump Clamp

Component Identification

Ironman Models (5900, 7900, 7900HD)

A Grounding Coil

B Smart Control 3.0 Display

C Pump ON/OFF Switch

D

WatchDog

E Pressure Control

F Prime Valve

G Gun Trigger Lock

H Heavy Duty Strainer

10 3A6400A

TM

Switch

J Drain Hose

K MaxLife Pump

L Rod Pull Feature

M Engine Controls

N

ProConnect

P Easy Out Pump Filter

R Engine ON/OFF Switch

S Hose (not shown)

TM

II Pump Clamp

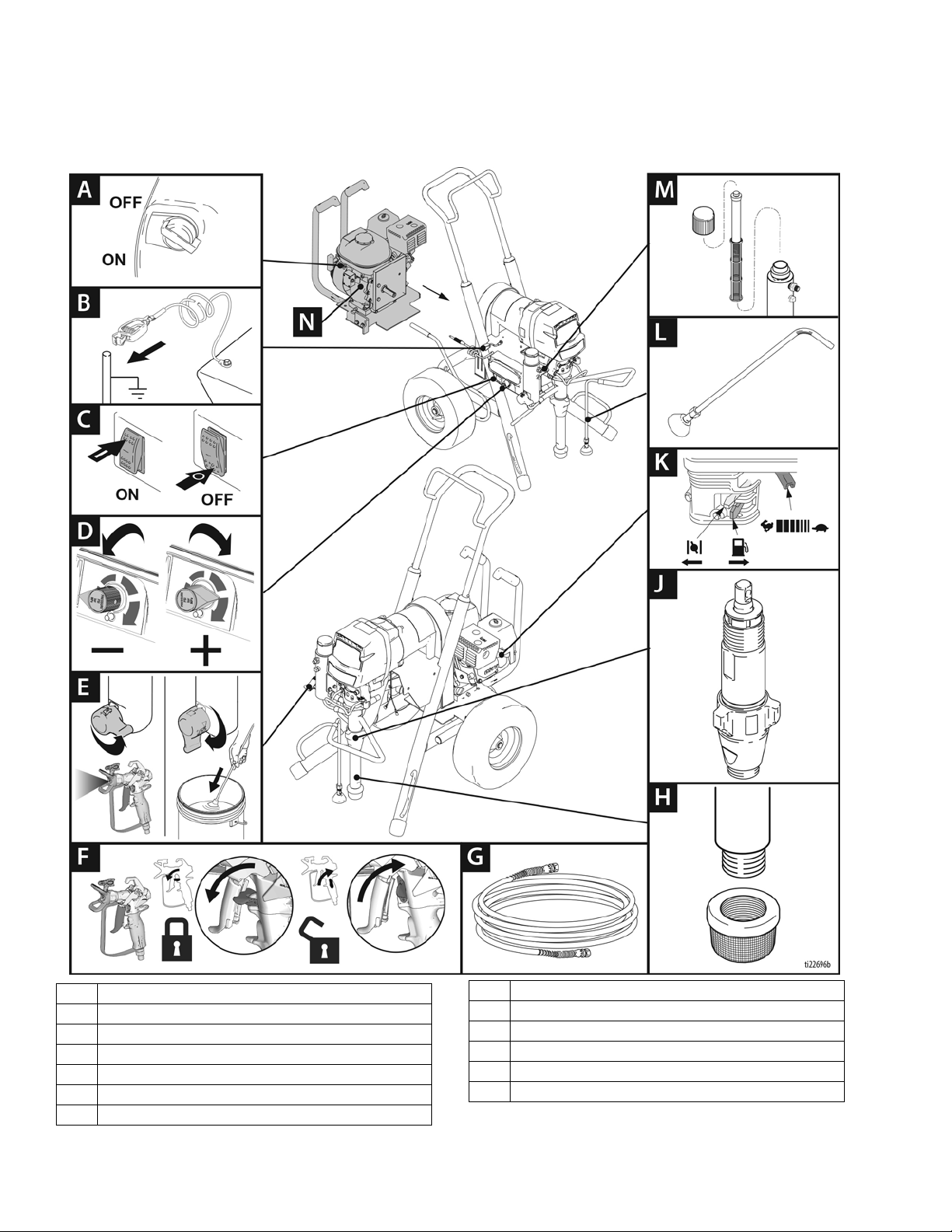

Lo-Boy Models (3900, 5900, 7900)

Component Identification

A Engine ON/OFF Switch

B Grounding Coil

C Pump ON/OFF Switch

D Pressure Control

E Prime Valve

F Gun Trigger Lock

GHose

3A6400A 11

H Pump

J Drain Hose

K Rod Pull Feature

LStrainer

M Engine Controls

N

ProConnect

O Easy Out Pump Filter

TM

II Pump Clamp

Component Identification

Convertible Models (5900)

A Engine ON/OFF Switch

B Grounding Coil

C Pump On/Off Switch

D Pressure Control

E Prime Valve

F Gun Trigger Lock

GHose

12 3A6400A

HStrainer

JPump

K Engine Controls

L Drain Hose

M Easy Out Pump Filter

NPower Pack

Pressure Relief Procedure

ti5787a

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Engage trigger lock.

2. Turn gas engine ON/OFF siwtch to OFF. For

Convertible Models with electric motor, turn electric

motor ON/OFF switch to OFF, and unplug power

cord to electric motor.

3. Disengage trigger lock. Hold metal part of gun firmly

to side of grounded metal pail, and trigger gun to

relieve pressure.

4. Engage gun trigger lock.

5. Turn prime valve down to DRAIN position. Leave

prime valve down until ready to spray again.

6. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved:

Grounding

Grounding Procedure for

Internal Combustion Engine

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

To ground sprayer: Attach sprayer grounding clamp to

earth ground.

Air and fluid hoses: Use only electrically conductive

hoses with a maximum of 500ft. (150 m) combined hose

length to ensure grounding continuity. Check electrical

resistance of hoses. If total resistance to ground

exceeds 29 megaohms, replace hose immediately.

Spray gun: Ground through connection to a properly

grounded fluid hose and pump.

a. VERY SLOWLY loosen the tip guard retaining

nut or the hose end coupling to relieve pressure

gradually.

b. Loosen the nut or the coupling completely.

c. Clear the obstruction in the hose or tip.

3A6400A 13

Grounding

Grounding Procedure for

Electric Motor (Convertible

Models only)

The equipment must be grounded to reduce the risk

of static sparking and electric shock. An electric or

static spark can cause fumes to ignite or explode. An

improper ground can cause electric shock. A good

ground provides an escape wire for the electric

current.

This sprayer is equipped with a power cord that has a

ground wire and an appropriate grounding plug.

If using the electric motor, plug must be plugged into an

actual outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided; if it does not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Grounding of Pails

Solvent pails used when flushing: Follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a non-conductive

surface, such as paper or cardboard, which interrupts

grounding continuity.

ti25360a

Always ground a metal pail: connect a ground wire to

the pail. Clamp one end to the pail and the other end to

a true earth ground such as a water pipe.

To maintain ground continuity when sprayer is

flushed or pressure is relieved: hold metal part of

spray gun firmly to the side of a grounded metal pail

then trigger the gun.

Power Requirements

Convetible is only in USA or Canada.

• 100-120 VAC, 50/60 Hz, 15A, 1 phase.

Extension Cords

Use an extension cord with an undamaged ground

contact. If an extension cord is necessary, use a 3-wire,

12 AWG (2.5 mm²) minimum.

NOTE: Smaller gauge or longer extension cords may

reduce sprayer performance.

ti24585a

14 3A6400A

Loading...

Loading...