Page 1

Maxi-Flo® Pump Package

DESCRIPTION

Designed for machinery requiring oil lubrication, this self-contained,

easy-to-install package includes a reservoir, electric-motor-driven

positive displacement pump, gear motor, and a choice of two control

systems with a low-level switch as standard equipment.

Optional accessories are a pressure gauge and a high pressure switch

which, when used with MS or MJ series type divider valves, provide an

economical means of effectively monitoring system operation.

Note: Designing information for a Maxi-Flo system is available in

Bulletin No. L23110.

SPECIFICATIONS

Pump Output per Stroke 0.010 in3 (0.165 cm3)

Pump Output per min of OnTime

3

12 rpm @ 60 Hz 0.120 in

10 rpm @ 50 Hz 0.100 in

Max System Operating

Pressure

Atmosphere Relief Indicator

Rating

Lubricant Oil, 60-30000 SUS

Operating Temperature

Min 0ºF (-18ºC)

Max - Intermittent

Operation

Max - Continuous Operation 120ºF (49ºC)

Reservoir Capacity 4 pints (1.9 liters), 116 in

Pump Gearmotors 115V, 50/60 Hz, shaded pole, 12 rpm

Reservoir Low Level Switch 115 VAC, 10 Watt Load

500 psi (34 bar)

600 psi (41 bar)

140ºF (60ºC), 50% duty cycle or less)

output @ 60 Hz, 10 rpm @ 50 Hz, 0.13

amp running current, 0.185 amp inrush

current

(1.97 cm3)

3

(1.64 cm3)

3

(1890 cm3)

Compact Pump / Control Package for automatic,

low-pressure, centralized oil lubrication systems.

FEATURES / BENEFITS

Choice of (1) Solid-State Time Control, or (2) Remote Control •

matches unit to application.

Easy installation. Just four mounting bolts and one electrical •

connection.

Transparent reservoir provides visual indication of oil level.•

Manual run push-button simplifies line filling, system bleeding or •

purging, and/or testing system integrity.

Housing and reservoir are durable molded plastic.•

Lights indicate low level, operating and power on.•

Standard Control Systems

Time Control Solid State Timer, 115 VAC, 50/60 Hz,

cycle time from 1/2 minute to 32 hours,

adjustable On-Time of 12 sec to 13

minutes

NOTE: If the On-Time is set greater or

equal to "Total Cycle Time" the timer will

cause the pump to run continuously

Remote Control 115 VAC, 50/60 Hz, terminal strip for

connection to machine control system

Accessories

Pressure Gauge 0-1000 psi (0-69 bar), back mount, 1/8

NPTF

High Pressure Switch Factory set @ 550 psi (38 bar), 10

ampere contact rating @ 115 VAC

Page 2

Trabon® Maxi-Flo® Pump Package 13110

OPERATION

The pump gearmotor, energized by one of the three control units,

rotates an eccentric (A) connected to a rod that drives the pump

piston (B).

On the prime stroke, the piston opens the inlet port (C), allowing

oil from the reservoir to flow into the piston chamber. On the

power stroke, the piston motion closes the inlet port and forces

MOTOR COMPARTMENT

the oil through the spring-loaded check valve (D) and the outlet

port (E), and into the line to the divider valves. When "On", the

pump gearmotor rotates the eccentric at a fixed speed of one

pump strokes every 5 seconds on 60 hz, or one stroke every 6

3

seconds on 50 hz. The piston meters a fixed .010 in

(0.16 cm3) of

oil for every pump stroke. The total volume of oil delivered to the

system is determined by the frequency and length of "ON TIME"

that the pump is operated.

RESERVOIR

OUTLET PORT

ä

ä

ä

FIGURE 1

A

B

C

RELIEF

INDICATOR

PORT

D

E

Page 2

Page 3

Trabon® Maxi-Flo® Pump Package 13110

TOTAL CYCLE TIME

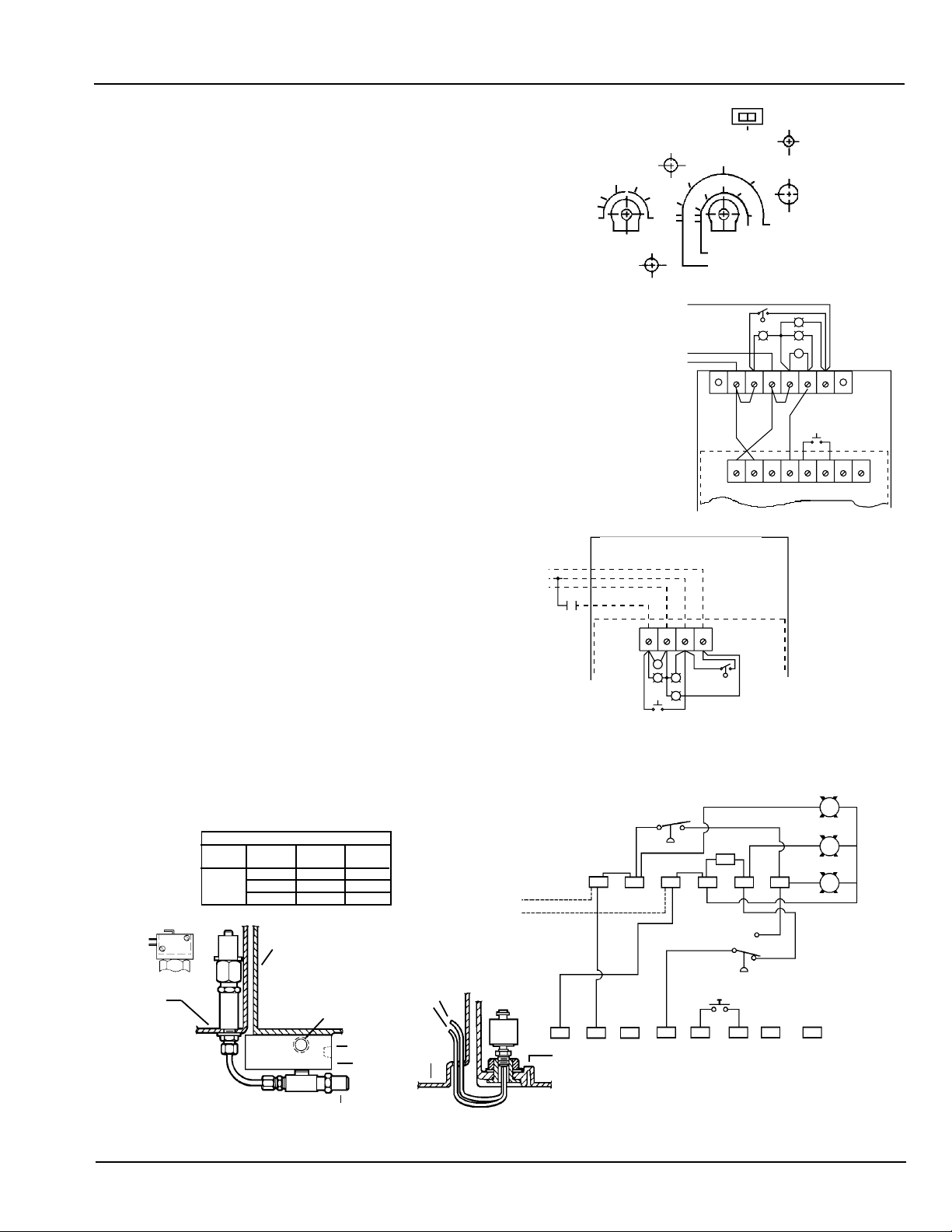

OPERATION WITH TIME CONTROL

Set the slide switch to either minutes or hours for cycle time.

Next, set the desired pump "ON TIME" using a screwdriver in the

slotted head of the scale marked "ON TIME MINUTES". Then in a

similar fashion, set the specific interval at which lube cycles are to

occur using the appropriate scale under "TOTAL CYCLE TIME".

"ON TIME" in minutes = Total output required per cycle time (cu.

in.) divided by 0.12 (60 hz) or 0.10 (50 hz) cu.in. per minute output

rate.

When power is applied, the timer activates the lube pump motor

and simultaneously begins timing of the "ON TIME" and "TOTAL

CYCLE TIME".

TIME CONTROL

ADJUSTMENTS

5

2

1

02

ON TIME MINUTES

TIME CONTROL WIRING

MINUTES HOURS

16

7

8

10

13

8

4

4

2

2

5

5

MINUTES

HOURS

LOW LEVEL

FAULT

L2

L1

24

16

24

30

TOTAL CYCLE

TIME

G

7 8 9 10 11 12

32

R

A

M

When the "ON TIME" is completed, the timer shuts off the pump

motor but continues timing the "TOTAL CYCLE TIME" until the

next cycle and "ON TIME".

Activation of the manual run button resets the cycle time to zero

and starts a lube cycle.

The pump will stroke once every 5 seconds at 60 hz and once

every 6 seconds at 50 hz of "ON TIME".

Note: If the "ON TIME" is greater than the "TOTAL CYCLE TIME",

the timer will cause the pump to run continuously.

OPERATION WITH REMOTE CONTROL

This unit permits connection of the pump motor to the lubricated

machine's control system, or to some other control system.

The pump motor "ON TIME" will be determined by the machine or

external system control. For most applications, it is recommended

that the pump operate a minimum of one stroke per lubrication

cycle.

DETAIL ON STANDARD AND OPTIONAL SWITCHES

SINGLE POLE SINGLE THROW

SW RATINGS - MAX RES. LOAD

AMPS AMPS

WATTS VOLTS AC DC

0-50 .2 0.05

10 120 .08 0.02

240 .04 N.A.

COMM.

N.O.

N.C.

MOTOR

COMPARTMENT

NOTE:

NONADJUSTABLE PRESSURE SWITCH FACTORY

SET @ 550 PSI

ä

OPTIONAL HIGH PRESSURE SWITCH

RESERVOIR COMPARTMENT

ä

SINGLE POLE DOUBLE THROW

10 AMPS - 115/230 VAC

1/8-27 NPSF (GAUGE

PORT)

7 AMPS - 6-30 VDC

ä

ä

STANDARD 600 PSI

RELIEF INDICATOR

LUBE OUTLET

1/8-27 NPSF

PUMP

ä

LOW LEVEL SWITCH WIRE LEADS

CONNECTED TO TERMINAL STRIP

ä

ä

MOTOR

COMPARTMENT

ä

LOW LEVEL SWITCH

SPST N.C. (Held Open)

REMOTE CONTROL WIRING

7 8 9 10 11 12

FAULT

L1

L2

USER CONTROL

REMOTE

CONTROL

HIGH PRESSURE

SWITCH WIRING

7

8

L1

L2

2

ä

1

RESERVOIR

COMPARTMENT

3

When installing optional high 1.

pressure switch, remove factory

jumper #4 to #11.

During normal operation, pressure 2.

switch N.C. contact is closed and

pump motor will operate when timer

calls for a lube cycle (red fault llight

off).

1 2 3 4

M

A

G

R

MANUAL

RUN

LOW LEVEL

9

4

1 2 3 4 5 6

INPUT

115 /230

REMOTE

CONTROL

LOW LEVEL

M

10 11

HIGH PRESS

N.O.

SWITCH

COMM.

MANUAL RUN

5

6

High pressure condition causes 3.

switch contacts to transfer

interrupting power to pump motor

and applying power to red fault light

and fault output (red fault light on).

LOAD

3 AMPS

12

N.C.

7

MANUAL

RUN

MAN

RUN

8

NOT

USED

G

A

R

Page 3

Page 4

DIMENSIONS Inches (mm)

5.9

(150)

ä

ä

ä

6.44

(164)

ä

0.75

(19.1)

0.84 DIA.

HOLE FOR 1/2"

CONDUIT

FITTING TYP.

2 PLACES

RESERVOIR

DRAIN

PLUG

MANUAL

RUN

BUTTON

ä

ä

1.75

(44.5)

2.28

ä

(58)

ä

FOR STANDARD 5/16

SCREWS 0.34 DIA.

MTG. HOLES TYP. 4

PLACES

ä

ä

2.25

(57)

6.44

(164)

3.56

(90.4)

ä

0.62

ä

ä

(15.7)

RELIEF INDICA-

TOR (600 PSI)

ä

TRABON

Maxi-Flo

ä

ä

ä

ä

ä

Pump Package

AMBER

RED

GREEN

10.5

(265)

10.625

(269.87)

11.375

(288.96)

FILL CAP

ä

LUBE

OUTLET

1/8-27 NPSF

SHOWN WITH

OPTIONAL GAUGE

ä

ä

9.5

(241)

ä

ä

ä

GENERAL INSTRUCTIONS

Maximum pump pressure is 500 psi. Damage may result if

pump is operated in excess of 600 psi. Relief valve automatically

relieves output to atmosphere at 600 psi.

Fill reservoir with clean, filtered oil - never allow pump to operate

on an empty reservoir.

To drain reservoir, remove the rubber plug at the bottom extreme

right hand end of reservoir.

Maxi-Flo pump should be cleaned with a mild detergent.

Do not use more than 20 inch pounds of torque on the pump

mounting bolts.

Note: The Maxi-Flo package was not designed for use in outdoor

applications. Do not install unit where it will be constantly

exposed to direct sunlight and water.

Graco endorses the SAE recommendation of ISO 18/14 (ISO 4406) oil

cleanliness for most bearing applications. Some high speed bearing

may require cleaner oil. Consult the bearing manufacturer for recommendation.

COMPONENT ORDERING

Description Part No. Old Part No.

Maxi-Flo Package

w/Time Control for 115 VAC, 50/60 Hz,

Matched Pump Gearmotor

w/Remote Control for 115 VAC, 50/60 Hz,

Matched Pump Gearmotor

*Optional Accessories

High Pressure Switch 564376 521-500-330

Gauge (0-1000psi) 558899 493-020-241

Service Parts

Timer Replacement Board, 115 VAC 558031 572-142-590

Replacement 115 VAC Gearmotor 557641 521-500-650

Replacement Pump 563374 521-500-220

Replacement Low Level Switch 557826 541-603-002

Replacement Reservoir/Timer Housing Kit 563930 560-002-130

Replacement Relief Indicator 563375 521-500-400

* Available for field installation only. Terminal strip supplied with high

pressure option kit.

563379 521-500-910

563376 521-500-430

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

©2006-2009 Graco Inc. Form No. L13110 Rev. B 2/09 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Loading...

Loading...