Page 1

INSTRUCTIONS

ti11821s

®

Matrix

5 & Matrix

Meter

For dispensing oils and antifreeze over wireless communication with a Matrix system.

For professional use only.

Not approved for use in European explosive atmosphere locations.

Maximum Working Pressure: 1500 psi (10 MPa, 103 bar)

Maximum Flow Rate:14 gpm (53.0 lpm)

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

NOTICE

This dispense valve is designed to dispense

petroleum-based lubricants and antifreeze only.

Do not dispense windshield washer solvent with

this dispense valve.

®

15

313046T

EN

Matrix 5 and Matrix 15 contain an RF device with the

following approval:

FCC ID: TFB-FREESTAR

IC: 5969A-FREESTAR

ABN 75082 447 194

Freestar3 ZFSM-101-3(LSR)

Page 2

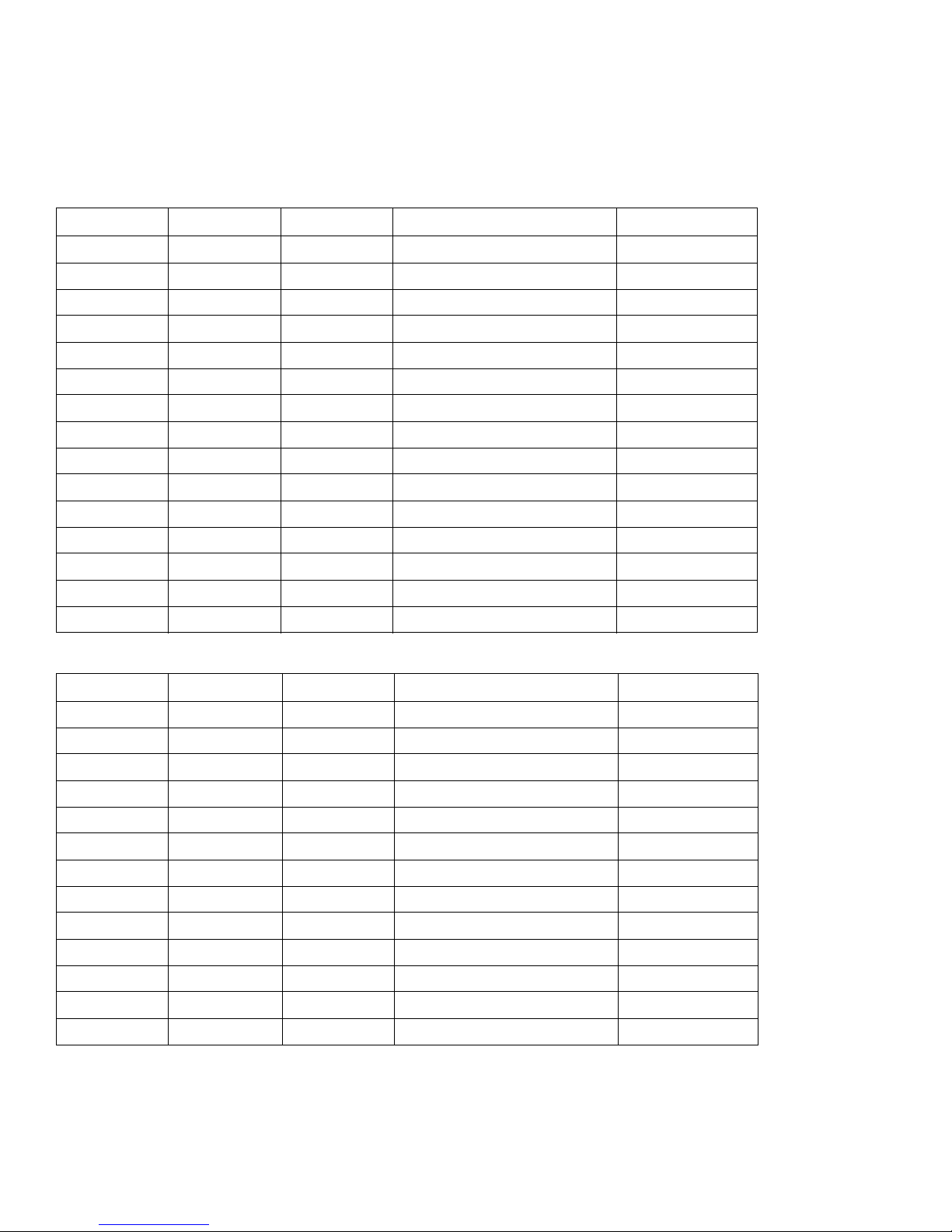

Models

Models

All meters are preset to Quarts in the Graco factory.

Matrix 5 Models

Model No. Swivel Extension Non-Drip Nozzle Fluid

256282 1/2” NPT(F) Rigid Automatic, Quick Close Oil, ATF

256482 1/2” NPT(F) Flexible Automatic, Quick Close Oil, ATF

256483 1/2” NPT(F) Gear Lube Quick Close Gear Lube

256484 1/2” NPT(F) Rigid Quick Close Antifreeze

256485 1/2” NPT(F) Flexible Quick Close Antifreeze

24H134 1/2” BSPP(F) Rigid Automatic, Quick Close Oil, ATF

24H136 1/2” BSPP(F) Flexible Automatic, Quick Close Oil, ATF

24H138 1/2” BSPP(F) Gear Lube Quick Close Gear Lube

24H140 1/2” BSPP(F) Rigid Quick Close Antifreeze

24H142 1/2” BSPP(F) Flexible Quick Close Antifreeze

24H135 1/2” BSPT(F) Rigid Automatic, Quick Close Oil, ATF

24H137 1/2” BSPT(F) Flexible Automatic, Quick Close Oil, ATF

24H139 1/2” BSPT(F) Gear Lube Quick Close Gear Lube

24H141 1/2” BSPT(F) Rigid Quick Close Antifreeze

24H143 1/2” BSPT(F) Flexible Quick Close Antifreeze

Matrix 15 Models

Model No. Swivel Extension Non-Drip Nozzle Fluid

256486 1/2” NPT(F) Rigid High Flow, Quick Close Oil, ATF, Antifreeze

256487 1/2” NPT(F) Flexible High Flow, Quick Close Oil, ATF, Antifreeze

256488 3/4” NPT(F) Rigid High Flow, Quick Close Oil, ATF, Antifreeze

257120 3/4” NPT(F) Flexible High Flow, Quick Close Oil, ATF, Antifreeze

257539 No Swivel No Extension No Nozzle Oil, ATF, Antifreeze

24H144 1/2” BSPP(F) Rigid High Flow, Quick Close Oil, ATF, Antifreeze

24H146 1/2” BSPP(F) Flexible High Flow, Quick Close Oil, ATF, Antifreeze

24H148 3/4” BSPP(F) Rigid High Flow, Quick Close Oil, ATF, Antifreeze

24H158 3/4” BSPP(F) Flexible High Flow, Quick Close Oil, ATF, Antifreeze

24H145 1/2” BSPT(F) Rigid High Flow, Quick Close Oil, ATF, Antifreeze

24H147 1/2” BSPT(F) Flexible High Flow, Quick Close Oil, ATF, Antifreeze

24H149 3/4” BSPT(F) Rigid High Flow, Quick Close Oil, ATF, Antifreeze

24H159 3/4” BSPT(F) Flexible High Flow, Quick Close Oil, ATF, Antifreeze

2 313046T

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

BATTERY SAFETY

The battery may leak, explode, cause burns, or cause an explosion if mishandled:

• You must use the battery type specified for use with the equipment.

• Sparking can occur when changing batteries. Only replace the battery in a non-hazardous location,

away from flammable fluids or fumes.

• Handle and dispose of battery properly - do not short circuit, charge, force over discharge, disassemble, crush, penetrate, incinerate, or heat the battery to a temperature exceeding 185° F (85° C).

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

313046T 3

Page 4

Warnings

WARNING

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

4 313046T

Page 5

Meter Overview

ti11824

5-Way Menu

Navigation Keypad

Unlocked

Locked

Meter Overview

Navigation and Modes

Meter Display

Adjusting Screen Contrast using ARROWS

On the Main Utility Setup Screen (page 6), use the

LEFT and RIGHT ARROWS to adjust the screen

contrast.

• Darken the Screen: Press the RIGHT ARROW

multiple times.

• Brighten the Screen: Press the LEFT ARROW

multiple times.

Asleep / Awake Mode

• Asleep: Battery-saving mode. In dispense mode,

the display goes blank after 5 minutes of inactivity.

• Awake: Display comes awake from sleep mode

when you press any ARROW or the center ENTER

button on the meter’s keypad or when you squeeze

the trigger to dispense fluid.

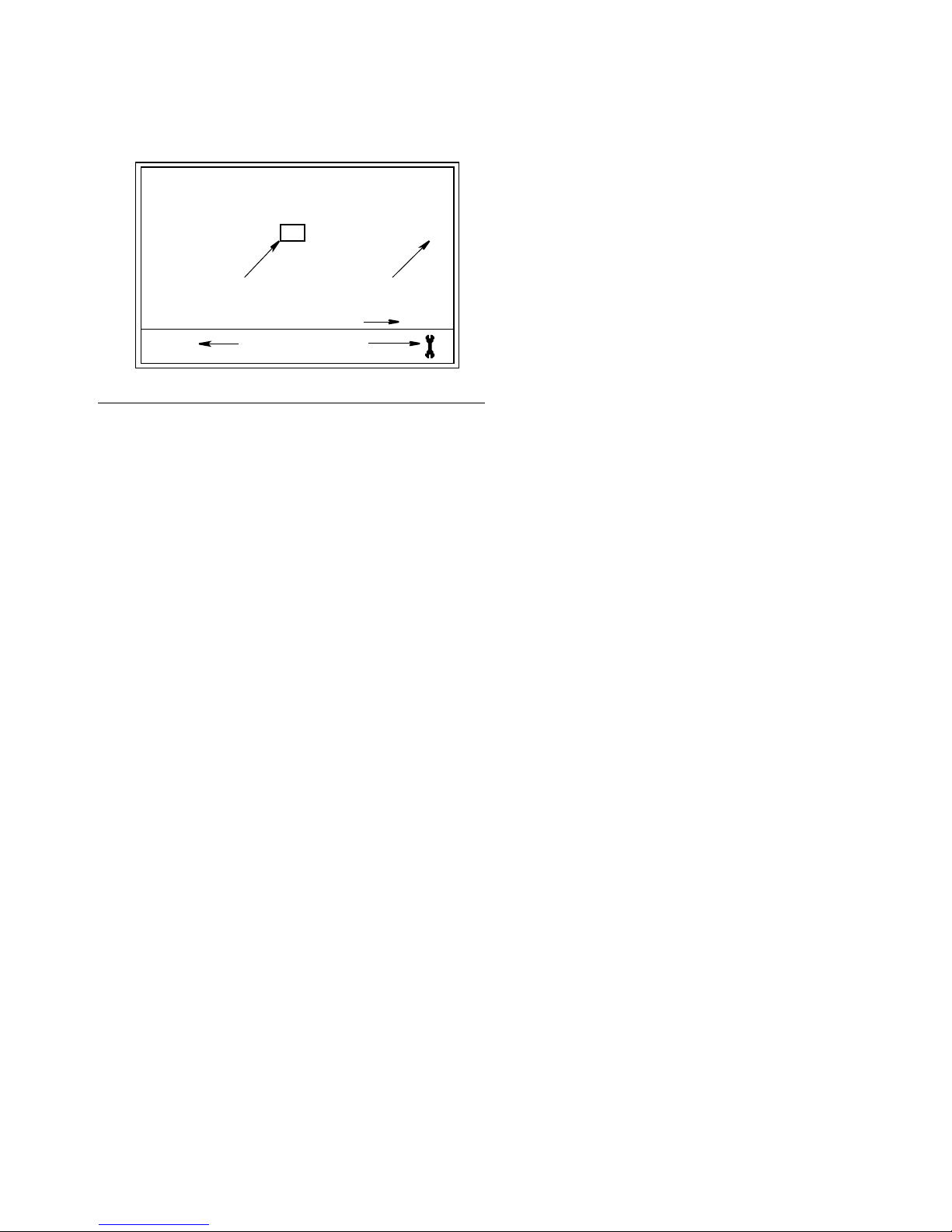

Locking and Unlocking Trigger

F

IG. 1

5-Way Menu Navigation Keypad (FIG. 1)

• Includes 4 direction ARROWS (UP, DOWN, LEFT,

RIGHT) and a center, ENTER button.

• Pressing the direction ARROWS allows user to

easily scroll through menus. To select/store your

selection, you must press the center, ENTER button

on meter’s keypad.

• Pressing and holding the direction ARROW down

allows user to scroll through menus quickly.

FIG. 2

The locking trigger feature allows the user to lock the

trigger in the dispense position as shown in F

release the lock, firmly squeeze the trigger to the

handle.

IG. 2. To

313046T 5

Page 6

Registering the Meter

(a)

(b)

ti11824a

REGISTER

RF TEST

UPGRADE

EMERGENCY

QUIT

3.01.001

ti12259a

Registering the Meter

Graco recommends registering the meter prior to

installation.

NOTE: Before registering the meter, use the Matrix PC

software to enter setup information pertaining to the:

• Transceiver,

• Tank Level Monitor (TLM),

• Tank Set Up,

and (optional)

• Pump Air Control (PAC).

Displaying Register Utility Screen

If this has not been done first, the software will display

an error when attempting to set up meter.

Main Utility Setup Screens (FIG. 4)

The Main Utility Screen displays a list of available Setup

Screens. This list also includes a link (QUIT) back to the

Operation Screens.

•REGISTER

• RF TEST

•UPGRADE

• EMERGENCY

•QUIT

IG. 3

F

1. If you are on a Dispense Screen, to display the Main

Utility Screen, first hold down the RIGHT ARROW

(a) only, for a few seconds (F

2. Then at the same time, also hold down the center,

ENTER button (b) (F

until the Main Utility Screen shown in F

plays.

IG. 3). Hold both buttons down

IG. 3).

6 313046T

IG. 4 dis-

FIG. 4

3. Use the UP or DOWN arrow to move the cursor up

and down the list until it is over the REGISTER

option on the list.

4. Press the center ENTER button on meter’s keypad

to select the REGISTER option. The Register

Screen shown in F

IG. 5 displays.

Page 7

Registering the Meter

REGISTER

NETWORK ID 8 TRANS ID 6

REGISTERREGISTER

123F456A

ti12260a

D

A

B

C

E

REGISTER Screen

F

IG. 5

A. NETWORK ID: The unique Radio Frequency (RF)

assigned to components of the same operating system

in a specific facility. The unique NETWORK ID assigned

to the facility, prevents RF interference from other Matrix

Systems operating in the vicinity, at other locations.

There are 8 NETWORK ID’s available.

To setup a meter to receive the correct NETWORK ID

RF signal, use the UP or DOWN ARROWS to scroll, one

number at a time, through the NETWORK ID numbers

(1-8). When the correct NETWORK ID number assigned

to your facility is displayed in the field/box, press center

ENTER button on meter’s keypad to lock in the choice.

B. TRANS ID: The unique RF frequency assigned to a

specific transceiver in the operating system. Each

transceiver in the system has its own TRANS(ciever) ID

number assigned to it. An operating system can have

more than one transceiver. There are 8 TRANS ID’s

available.

To set up a meter to receive the correct TRANS ID RF

Signal, use the UP or DOWN ARROWS to scroll, one

number at a time, through the TRANS ID numbers (1-8).

When the number assigned to the transceiver you are

using displays in the field/box, press center ENTER

button on meter’s keypad to lock in the choice.

C. REGISTER /field: Sends message to Matrix PC

Software to register the meter with the operating

system.

D. WRENCH Icon: Returns user to Main Utility Screen.

Use the LEFT or RIGHT ARROWS to move the cursor

over the WRENCH Icon on the display. Then press

center, ENTER button on meter’s keypad, to confirm the

selection.

E. SERIAL Number: Unique meter ID.

Registering Meter with Matrix PC Software

1. The screen displays the NETWORK ID (A) and

TRANS(ceiver) ID (B) (F

the meter.

2. If the ID’s in both fields are correct and you do not

need to make any changes, use LEFT or RIGHT

ARROWS to move cursor over REGISTER (C).

Press center ENTER button on meter’s keypad. The

meter resets to it’s initial screen.

OR . . .

If the NETWORK ID or TRANS ID information

shown on the display is NOT correct:

a. Use LEFT or RIGHT ARROWS to move cursor

to NETWORK ID field and/or TRANS ID field.

b. When field you want to modify is selected, use

UP or DOWN ARROWS to scroll forward or

backward through the available NETWORK ID

or TRANS ID numbers.

c. When correct ID number displays, press center

ENTER button on meter’s keypad to confirm

your choice. If necessary, use LEFT or RIGHT

ARROWS to move cursor to the next field and

repeat this procedure.

d. When both the NETWORK ID and TRANS ID

fields display the correct information, use LEFT

or RIGHT ARROWS to move cursor over REGISTER. Press center ENTER button on the

meter’s keypad to complete meter registration.

IG. 5) currently assigned to

Use the LEFT or RIGHT ARROWS to move the cursor

over the REGISTER field/box on the display. Then press

center, ENTER button on meter’s keypad, to confirm the

selection.

313046T 7

Page 8

Registering the Meter

e. The meter resets and returns to it’s initial

screen.

NOTE: If the meter is not able to communicate with the

PC during registration, the message NO SIGNAL or NO

PC SIGNAL appears on the meter display.

NO SIGNAL message means:

• There is no RF signal between the PC and

Meter.

• The meter is out of the RF Signal range.

• The Transceiver does not have power.

• Either the NETWORK ID and/or TRANSCEIVER ID information is not correct in the

meter and the correct information must be provided.

NO PC SIGNAL message means:

• The Matrix Client isn’t running.

• The cable is not connected between the PC and

Transceiver.

f. After the information is programmed into the

electronic meter, the meter can be connected to

the dispensing hose.

NOTE: If the programmed parameters need to be

changed, the meter must be reprogrammed.

ti12405a

8 313046T

Page 9

RF Test

TEST RF

NETWORK ID 8 TRANS ID 6

START

123F456A

TEST RF

NETWORK ID 8 TRANS ID 6

START

123F456A

RETRIES = 0

GOOD SIGNAL

RF Test

An RF Test is performed before a Matrix System and

meters are installed at a site to evaluate the strength of

the RF signal and determine the number of Transceivers

that will be needed and where they should be installed

in the facility.

In order to perform this test, a test computer with the

Matrix PC software installed and a Transceiver are

located in the area of the shop that the installed

Transceiver will be located. The tester then uses a meter

to evaluate the strength of the RF Signal between the

Transceiver and meter at each potential meter location

throughout the shop.

REGISTER

RF TEST

UPGRADE

EMERGENCY

QUIT

3.01.001

4. Use RIGHT ARROW to move cursor over START

(F

IG. 7).

FIG. 7

5. Use center ENTER button to confirm the selection.

The meter sends an RF signal to the Transceiver.

If the signal is good on the following message displays on the meter screen (F

RETRIES: 0 (or 1-5)

GOOD SIGNAL

IG. 8):

IG. 6

F

1. On the Main Utility Screen, use the UP or DOWN

ARROWS to select the RF TEST option on the list.

Then press the center ENTER button on meter’s

keypad to confirm the selection.

To perform the RF TEST:

2. Holding the meter, walk around the shop to a potential meter installation work area.

3. Verify that the Network ID and Trans ID assigned to

the meter are correct. If they are not correct, you

must first register the meter. (See Registering the

Meter, page 6).

F

IG. 8

313046T 9

Page 10

Upgrade

TEST RF

NETWORK ID 8 TRANS ID 6

START

123F456A

RETRIES = 5

BAD SIGNAL

TEST RF

NETWORK ID 8 TRANS ID 6

START

123F456A

RETRIES = 0

NO PC SIGNAL

REGISTER

RF TEST

UPGRADE

EMERGENCY

QUIT

3.01.001

ti12408a

If the signal is weak or there is not a signal at all. one of

the following message appears on the meter screen

(F

IG. 9).

NOTE: The meter is programmed to try sending a signal

to the Transceiver 5 times before displaying the BAD

SIGNAL message.

Upgrade

This feature is used to modify the firmware software

used by the meter when a new and upgraded version of

the software is released or a new feature is added.

When this is required, your Graco distributor will contact

you to arrange the upgrade.

FIG. 10

Emergency

F

IG. 9

6. After the final area has been tested, use the LEFT

ARROW to move the cursor to the Wrench Icon.

Press the center ENTER button on meter’s keypad

to confirm the selection and return to the Main Utility

Screen.

If the communication link between the meter and PC is

lost due to power loss or the computer crashing, the

meter will continue to function if it is placed in

Emergency Mode.

REGISTER

RF TEST

UPGRADE

EMERGENCY

QUIT

3.01.001

IG. 11

F

1. On the Main Utility Screen, use the UP or DOWN

ARROWS to select the EMERGENCY option on the

list. Then press the center ENTER button to confirm

the selection.

10 313046T

Page 11

2. The Emergency Screen appears. The cursor is

already in position for entering the first number of

the Emergency Code. Use the UP or DOWN

ARROWS to scroll through the numbers 0-9 until the

first number of the unique Emergency Code

assigned to that meter appears in the field.

EMERGENCY MODE

2122

Emergency

F

IG. 12

ENTER

QUIT

3. Use the center ENTER to confirm the selection. The

cursor moves to the next field.

4. Repeat steps 2-3 until all 4 numbers have been

entered. After the 4th number of the Emergency

Code is entered the cursor automatically moves to

the ENTER on the display.

5. Press the center ENTER button to confirm the

selection.

6. The Dispense Screen displays on the meter.

NOTE: When the meter is put in Emergency Mode:

• All pending work orders will be deleted from the

work order queue in the meter. They will have to be

entered again by the System Administrator on the

PC.

• New work orders cannot be added at the meter.

313046T 11

Page 12

Installation

B

D

E

C

A

ti11010a

ti11822

Installation

Typical Installations (FIG. 13)

The typical installation shown in FIG. 13 is only a guide.

It is not a complete system design. Contact your Graco

distributor for assistance in designing a system to suit

your needs.

NOTICE

The dispense valve is not designed for in-line

installation.

ITEM DESCRIPTION

A Electronic metered dispense valve

B Fluid shut-off valve

CHose

D Hose reel fluid inlet hose

E Hose reel

A Thermal Relief Kit (not shown) is required. The kit

required will vary by pump selected.

Mounting Bracket (FIG. 14)

Mounting Bracket Kit 249440 is available for resting the

dispense valve on a console.

FIG. 14

F

IG. 13

12 313046T

Page 13

Installation

ti12303a

Oil Bar (FIG. 15)

An Oil Bar Kit is available for mounting one to three

meters. See your Graco Distributor or contact Graco

Customer Service for ordering details.

Grounding

FIRE HAZARD: Conductive metal surfaces on the

meter must not make contact with any positively

charged metal surface, including (but not limited to),

the starter solenoid terminal, alternator terminal or

battery terminal. Such contact could cause electrical

arcing and a fire.

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

Pump: Follow manufacturer’s recommendations.

F

IG. 15

Pressure Relief Procedure

This equipment will stay pressurized until the pressure

has been manually relieved. To reduce the risk of

serious injury from pressurized fluid, accidental spray

from the dispense valve or splashing fluid, follow this

Pressure Relief Procedure when ever you:

• Are instructed to relieve pressure.

• Check, clean or service any system equipment.

• Install or clean fluid nozzles or filter.

1. Turn off power supply to the pump or close

upstream ball valve.

2. Open nozzle. Trigger the dispense valve into a

waste container to relieve pressure.

Air and fluid hoses: Only use electrically conductive

hoses. Check electrical resistance of hoses. If total

resistance to ground exceeds 29 megohms, replace

hose immediately.

Air compressor: Follow manufacturer’s

recommendations.

Fluid supply container: Follow local code.

To maintain grounding continuity when flushing or

relieving pressure: hold a metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

Pre-Installation Procedure

1. Relieve pressure, page 13.

2. Close the shut-off valve (B, F

IG. 13).

3. Open any bleed-type master air valves and fluid

drain valves in the system.

4. Leave the drain valve open until you are ready to

pressurize the system.

313046T 13

3. Ground the hose and reel or console, page 13.

Leave at least two threads bare when using PTFE

tape. The bare threads ensure a ground is maintained.

Page 14

Installation

31

ti10983a

32

a

Installation Procedure

NOTICE

• If this is a new installation or if the fluid lines are

contaminated, flush the lines before you install the

metered valve. Contaminated lines could cause the

valve to leak.

• Never dispense compressed air with meter. Doing

so will damage meter.

Flushing

If this is an existing installation, go to Installing Meter

section, page 14. The following procedure, Steps 1-5

are the Flushing Procedure.

1. Close the fluid shut-off valve (B, F

each dispense position.

2. Make sure:

• the main fluid outlet valve at the pump is closed,

• the air pressure to the pump motor is adjusted,

and

• the air valve is open.

IG. 13, page 12) at

1. Relieve pressure, page 13.

FIG. 16

2. Slide the swivel boot (32) back, over the hose, small

end first to access the swivel fitting (a).

3. Apply thread sealant to the male threads of the hose

fitting. Thread the hose fitting into the meter swivel

(31). Use two wrenches to tighten securely (F

IG.

16).

NOTE: Make sure you let the sealant cure to the

manufacturer’s recommendations before circulating fluid

through the system.

3. Slowly open the main fluid valve.

a. Place the hose end (with no dispense valve

connected) into a container for waste oil.

b. Secure the hose in the container so it will not

come out during flushing.

c. If you have multiple dispense positions, first

flush the dispense position farthest from the

pump and work your way toward the pump.

4. Slowly open the shut-off valve (B) at the dispense

position. Flush out a sufficient amount of oil to

ensure that the entire system is clean; then close

the valve.

5. Repeat Step 4 at all other positions.

Installing Meter (FIG. 16)

14 313046T

Page 15

Installation

20

a

c

b

ti10615A2

20

33

a

b

Installing Tube Extension (FIG. 17)

IG. 17

F

1.

a. Loosen nut (a).

b. Thread extension (20) into housing (b) until it

bottoms out.

c. Align extension (20) with meter housing and

handle (c).

d. Firmly tighten nut (a).

Installing Nozzle (FIG. 18)

NOTE:

• Only tighten nozzle with wrench on flats of the

nozzle bushing.

• Do not disassemble the bushing from noz-

zle. Disassembly will affect performance of the

nozzle.

2. Open automatic twist lock nozzle and all fluid

shut-off valves. Start pump to pressurize system.

3. To ensure dispensing accuracy, purge all air from

the fluid lines and dispense valve before you use it.

4. Set the system flow to the desired flow rate.

Impact Guard Kit (24W327)

Impact Guard Kit, 24W327 is available. This guard

provides additional protection for the meter housing and

bezel.

1. Install the bezel guard (a) over the meter bezel as

shown in F

2. Then install the housing guard (b) over the nozzle/extension and onto the meter and bezel guard

(a) as shown in F

IG. 19.

IG. 19.

F

IG. 18

1.

a. Thread new nozzle (33) onto extension (20).

b. With an open-end adjustable wrench on flats of

nozzle bushing, tighten firmly.

313046T 15

FIG. 19

Page 16

Setup

MOBIL

1

5W-20

ENTER

PIN CODE

2122

ti12255a

Setup

Battery Indicator

A battery icon appears on the upper right corner of most

Setup and Dispense screens. When the batteries are

fully charged, the battery will be completely filled in. As

the battery discharges, the amount of battery that is

filled in will decline. For example, the battery in F

at about 50%.

NOTE: The meter’s operating parameters are controlled

by the Matrix PC Software and setup by the System

Administrator. See the Matrix 3 Software instruction

manual for these instructions.

Meter Calibration

IG. 20 is

F

IG. 20

Meter calibration is performed using the Matrix PC

software. Refer to the Matrix 3 Software instruction

manual for this procedure.

Security Modes

When the meter was originally programmed by the

system administrator, one of the following security

choices was entered:

•PIN Code

• Parts Room Authorization

• System Monitoring

Prior to dispensing, it may be necessary to complete

one of the following security procedures, depending on

the security mode set by the system administrator.

PIN Code (FIG. 21)

1

MOBIL

5W-20

PIN CODE

2122

ENTER

FIG. 21

PIN Code (Personal Identification Number) means that

a four digit number must be entered at the meter before

every new dispense to obtain dispense authorization.

To use a meter with PIN Code security:

16 313046T

1. Use the UP or DOWN ARROWS to select the first

PIN Code number field.

Page 17

Setup

MOBIL

1

5W-20

REQUEST

AUTHORIZATION

REQUIRED

ti12256a

MOBIL

1

5W-20

REQUEST

PLEASE WAIT

AUTHORIZATION

REQUIRED

ti12257a

2. Press the UP or DOWN ARROWS to scroll through

the numbers 0-9. When the correct numeral

appears in the field, press center ENTER button on

meter’s keypad to select the number. After a number

is entered, the cursor automatically moves to the

right, to the next number field.

3. Continue this process until the complete, 4-digit PIN

Code has been entered.

4. After the last number is entered, the cursor moves

over ENTER. Press center ENTER button on the

meter’s keypad to send the PIN Code entry to the

PC.

5. The PC recognizes the PIN Code entered, and

authorizes the meter to begin the dispense.

Parts Room Authorization (FIG. 22)

2. After sending the request, the message PLEASE

WAIT appears at the top of the screen as shown in

F

IG. 23.

FIG. 23

3. You will not receive a message at the meter saying

the Parts Room Administrator has authorized the

meter to begin the dispense.

There are two ways to determine when the meter is

ready:

F

IG. 22

This mode provides highest level of security and

requires a Parts Room Administrator to authorize each

dispense. Before each dispense the meter displays the

message: AUTHORIZATION REQUIRED. To send an

authorization request to the Parts Room Administrator:

1. Move cursor to select the REQUEST on the display

and push the center ENTER button on meter’s keypad to send the authorization request to the Parts

Room.

• Press the center ENTER button to select

REQUEST again. If the meter has received

authorization from the Parts Room Administrator, the meter display will change to either the

Dispense Screen or, if the meter was programmed to process work orders, the Work

Order Enter/Select screen will appear (see

Work Orders and Job Numbers, page 18).

OR

• Wait for the meter to fall asleep. When you

press any button to wake it up, if the meter has

been authorized for the dispense, the Dispense

Screen will display.

NOTE: The Parts Room Administrator can choose to

reject the dispense request. If a request is rejected, the

PLEASE WAIT message on the display will be replaced

with REJECTED and the meter will not be allowed to

dispense.

System Monitoring

When system monitoring is selected, no security

authorization is required prior to making a dispense. Any

amount of fluid dispensed is automatically sent by the

meter to the PC where it is recorded for future reference.

313046T 17

Page 18

Setup

ENTER W.O

CANCEL ENTER

1 2 3 4 5 6 7 8

W E B

ti12271a

ti12404a

MOBIL

1

5W-20

SELECT ENTER NEW

ti12270a

Work Orders and Job Codes

Refer to the Matrix 3 Software manual for instructions on

creating and sending Work Orders and Job Codes using

the PC and/or Global Work Orders.

The System Administrator can program the meter to

process work orders using one of the following methods:

• Work Order/Job Code at the PC only

• Work Order/Job Code at the PC and Meter

Work Orders can have a maximum of (8) characters.

The Job Code can have a maximum of (3) characters.

The Work Order number is separated from the Job

Code with a dash (-) (F

IG. 24).

On the meter, use the UP or DOWN ARROWS to scroll

through the list of entered work orders.

MOBIL

SELECT

5W-20

1

FIG. 25

On meters configured to enter Work Orders and Job

Codes at the PC and meter, the screen shown in F

IG. 26

displays before the Dispense Screen.

Work orders entered at the meter appear at the

beginning of the Work Order list on the meter and are

placed ahead of Work Orders previously entered on the

PC.

F

IG. 24

The numbers, 0 - 9; alphabet characters, A - Z; and

period (.), forward slash (/) and dash (-) or space

characters can be used when assigning a Work Order or

Job Number. One Work Order can require more than

one service.

NOTE: One naming convention that can be

implemented for identifying different services on a Work

Order is adding an extension to the end of the order

number (i.e., 123456.oil, 123456.atf).

On meters configured to enter Work Orders and Job

Codes at the PC only, the screen shown in F

displays before the Dispense Screen.

The meter can receive any number of work orders. New

work orders added at the PC will appear at the end of

the work order list.

IG. 25

IG. 26

F

18 313046T

Page 19

Setup

ti12257a

MOBIL

1

5W-20

SELECT ENTER NEW

(a)

(b)

ti12270

ENTER W.O

CANCEL ENTER

1 2 3 4 5 6 7 8

W E B

To Display PC Created Work Order on the

Meter:

The screen shown in FIG. 27 (a) (meters set to receive

Work Orders and Job Numbers from the PC only) or (b)

(meter set to receive Work Orders and Job Numbers

from the PC or created at the meter), displays before a

dispense can be made by the meter.

To view the Work Orders in the Work Order Queue:

1. Use the UP or DOWN ARROWS to display the work

orders.

2. When the work order that applies to the vehicle you

are servicing appears on the display, press the

ENTER button to start a dispense.

MOBIL

5W-20

1

Creating Work Order at the Meter (FIG. 28)

Using the UP ARROW displays the numbers, 0 - 9 and

then alphabet letters, A - Z. By using the DOWN

ARROW when the blank field is displays will also

provide the period (.) ; forward slash (/); dash (-)

characters; or space can be used.

To enter a new work order at the meter:

1. Use the LEFT ARROW to position the cursor over

ENTER NEW.

2. Press center ENTER button on the meter’s keypad

to select the ENTER NEW option.

3. The cursor automatically is positioned on the first

field of the Enter Work Order screen. Use the UP or

DOWN ARROWS to scroll through the list of numbers, letters and characters or a field can be left

blank.

F

IG. 27

SELECT

FIG. 28

4. When the number, letter or character you want to

use displays, press the center ENTER button on

meter’s keypad to confirm the selection. The cursor

automatically advances to the next field.

5. Repeat this procedure for all Work Order and Job

Number fields on the display.

After the last field has been completed, the cursor

will automatically move to the CANCEL.

6. To Cancel the new Work Order and Job Number

you just created on the meter, press the center

ENTER button on meter’s keypad to select the Cancel option.

313046T 19

To Select the new Work Order and Job Number you

just created on the meter, use the LEFT ARROW to

move the cursor to ENTER on the display. Press the

Page 20

Setup

center ENTER button on the meter’s keypad. This

new work order now appears as the first item in the

Work Order Queue.

7. The work order selection screen displays. You can

either select the work order you just created or use

the UP or DOWN ARROWS to scroll through the list

of all work orders in the queue until you find the

work order that applies to the vehicle you are servicing.

MOBIL

5W-20

1

12345 - 12

SELECT

F

IG. 29

8. Use the LEFT or RIGHT ARROWS to move cursor

to SELECT. Press the center ENTER button on the

meter’s keypad to confirm the work order selection.

20 313046T

Page 21

Dispense

MOBIL

1

5W-20

0.00

QTS

ACTIVATE

Dispense

The meter dispense options are determined by the

System Administrator at the time the meter is

programmed. Meter dispense options include:

• Manual Dispense Mode

• Preset Dispense Mode

• Restricted Preset Dispense Mode

• Fixed Preset Dispsense Mode

NOTE: To change the meter from one mode to another,

you must edit the meter’s profile.

Manual Dispense Mode

To dispense fluid in this mode:

1. If necessary, enter the PIN Code or Parts Room

Authorization request (16 and 17) and, if the meter

is set to use Work Orders and Job Codes, select or

add a Work Order (page 18).

2. The Manual Dispense Screen (F

Press the center ENTER button on the meter’s keypad to select ACTIVATE. You will hear a loud click at

the meter indicating it is now ready to begin dispensing fluid

MOBIL

1

IG. 30) displays.

5W-20

4. When you have finished the dispense, press the

center ENTER button on the meter’s keypad to

select END (F

FIG. 31

The meter sends the dispense report to the PC.

IG. 31).

MOBIL

0.00

5W-20

1

QTS

END

Preset Dispense

To dispense fluid in this mode:

1. If necessary enter the PIN Code or Parts Room

Authorization request (pages 16 and 17) and, if the

meter is set to use Work Orders and Job Codes,

select or add a Work Order (page 18).

2. The Preset Dispense Screen displays. Press the

center ENTER button on the meter’s keypad to

0.00

ACTIVATE

F

IG. 30

3. Pull the trigger to begin the dispense. The meter

counts up until you release the trigger.

313046T 21

QTS

select the ACTIVATE. You will hear a loud click at

the meter indicating it is now ready to begin dispensing fluid.

IG. 32

F

Page 22

Dispense

MOBIL

1

5W-20

2.25

QTS

STOP

4.5xxxxxxxxxxxxxxxxxxxxxxxx

3. The display changes to show the Preset Amount.

The UP or DOWN ARROWS can be used to

increase or decrease this amount. If you change

the amount you must press the center ENTER

button on the meter’s keypad to confirm the new

amount before you begin dispensing fluid.

MOBIL

0.00

5W-20

1

QTS

20.0

20.0

FIG. 33

4. Pull the trigger to begin the dispense. The meter

counts up from 0. The progression bar also provides

a visual display of the dispense.

NOTE: If at any time before reaching the preset dispense amount, you want to stop the dispense, STOP on

the bottom of the screen can be selected.

b. PRESET - returns meter to PRESET mode and

continues the current preset dispense where it

was stopped.

c. END - ends the dispense and sends final report

to PC.

STOPPED

4.50

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

TOP OFF

FIG. 35

5. When the preset amount has been dispensed the

meter will click loudly and release the trigger, stopping the dispense.

6. You now have the option to choose either:

• TOP OFF if you need to add additional fluid.

The amount of top off allowed can be limited

during meter programming.

PRESET

QTS

END

IG. 34

F

The screen shown in F

RIGHT ARROW and center ENTER s to select one of

three options:

a. TOP OFF - the dispense can be continued in

TOP OFF mode (see description of TOP OFF,

on this page.

IG. 35 displays. Use the LEFT or

OR . . .

• END to finish the dispense and send the dis-

pense report to the PC.

TOP OFF

DONE

QTS

IG. 36

F

4.50

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

TOP OFF

END

22 313046T

Page 23

1. To TOP OFF, press the center ENTER button on the

meter’s keypad to select TOP OFF on the display

(the cursor will automatically be positioned over this

option when the meter clicks off).

2. Squeeze trigger to dispense additional fluid.

The amount dispensed on the display will continue

to count up. Unless there is a preset limit on the

amount you are allowed to top off and you have

reached the limit, you can squeeze the trigger again

to dispense more fluid.

To end the TOP OFF release trigger. The cursor will

be over the END option on the display.

3. Use the center ENTER button on the meter’s keypad to select END on the display.

The meter sends the dispense report to the PC.

Dispense

END

If you do not need to dispense additional fluid, use the

LEFT ARROW to move the cursor to END on the

display. Press center ENTER button on the meter’s

keypad to confirm the selection.

The meter sends the dispense report to the PC.

Restricted Preset Dispense

When meters are programmed in restricted preset

mode, workorders are required for proper operation. The

specified dispense value cannot be increased, only

decreased. The functionality of this feature is identical to

Preset Dispense Mode except that the preset value can

only be decreased with the DOWN ARROW.

Fixed Preset Dispense

When meters are programmed in fixed preset mode,

Global workorders and workorder entry at the meter are

required for proper operation. The specified dispense

valve cannot be increased or decreased. The

functionality of this feature is identical to Preset

Dispense Mode except that the preset valve cannot be

modified.

313046T 23

Page 24

Troubleshooting

Troubleshooting

• Relieve pressure, page 13, before you check or repair the meter. Be sure all other valves, controls and pump

are operating properly.

• When calling for Technical Assistance you may be asked to provide the Software Version that is being used by

your meter. Refer to F

Problem Cause Solution

Battery dead icon is present. Batteries are low. Replace batteries, page 27.

Display does not activate.

Cannot read display Contrast is set too high or too low to

IG. 5, page 7, item E for help determining where this information is shown on your meter.

Batteries are defective. Replace batteries, page 27.

Electronic control is malfunctioning. Replace the electronic bezel assem-

bly. Order Kit 255886.

Transceiver not connected to PC Check USB connection between

Transceiver and PC and reconnect if

loose of disconnected.

Adjust contrast. See Adjusting

be viewed in work area

Screen Contrast Using LEFT or

RIGHT ARROWS, page 5.

1. Relieve pressure, page 13.

2. Clean or replace filter. Order Fil-

Filter is clogged.

Pump pressure is low. Increase pump pressure.

Twist lock nozzle not fully open. Aim nozzle into bucket or rag. Fully

Slow or no fluid flow.

Shut-off valve is not fully open. Fully open shut-off valve.

Foreign material is jammed in the

meter housing.

Displayed dispensed amount is not

accurate.

Meter leaks from cover/control. Poor seal at metering cover chamber. Contact your Graco distributor for

Unit needs to be calibrated for the

fluid that is being dispensed.

ter Kit 255885.

3. If the problem remains, contact

your Graco distributor for repair

or replacement.

open nozzle.

Do not trigger meter when nozzle

is closed! If you do accidentally trig-

ger the meter with the nozzle closed,

point nozzle into a waste bucket and

open the nozzle to relieve pressure

and expel built up fluid.

Contact your Graco distributor for

repair or replacement.

Calibrate the meter for the fluid that is

being dispensed.

repair or replacement.

24 313046T

Page 25

Problem Cause Solution

Meter leaks from twist lock nozzle.

• It is important to distinguish

between the two causes of this

problem. A new nozzle will NOT

correct a fluid leak caused by a

faulty valve.

Meter leaks from swivel.

Unit does not stop dispensing when

assumed preset amount is dispensed.

Troubleshooting

Twist lock nozzle has a damaged

seal.

Valve has damaged or obstructed

Replace nozzle. See Step 1 in Installation Procedure, page 15.

Clean valve stem o-rings.

seals.

Poor swivel/hose connection. Apply PTFE tape (leave a minimum 2

engaged threads uncovered for electrical continuity) or sealant to threads

of hose and tighten the connection.

See Step 3 in Installation Procedure,

page 14.

Poor swivel/meter housing connec-

Torque the fitting to 20-25 ft.-lbs.

tion.

Swivel seals have deteriorated and

Replace swivel.

leak.

Valve is dirty or seals are defective. Clean valve or replace valve seal.

Low battery. Replace batteries, page 27.

Solenoid not functioning (Preset

Replace solenoid.

only).

313046T 25

Page 26

Troubleshooting

Error Codes

Error codes are listed below. Even in an error condition

the unit keeps track of the amount dispensed. With any

error code displayed you must end a dispense.

Error Code Cause Solution

Switch Error: Error occurred with

pick-up in internal gear.

Error 2

or

Ensure that your flow rate is not

higher than 14 gpm (37.8 lpm). For

further assistance, contact your

Graco distributor.

Error 4

Error 7

Unit was dropped or unit encountered

excessive vibration during shipping.

Flow has continued after it should

have shut off.

or

Flow has occurred in lockout condition.

CAP ERROR: Error has occurred in

control.

End Dispense

End Dispense

Replace electronic bezel assembly.

Order Kit 255886.

26 313046T

Page 27

Service

ti10984a

47

Battery

Orientation

(b)

(a)

Replacing the Battery

• Only use the size and type of batteries specified in

this manual.

Batteries required to meet life expectancy:

•Energizer E91

• Be sure to follow the correct polarity when

installing batteries in the battery compartment

(F

IG. 37). Reversed batteries may damage this

meter.

• Do not mix different types of batteries together or

old batteries with fresh ones. Always replace all 4

batteries with 4, fresh, new batteries.

Service

To change the battery:

1. Press firmly on battery compartment cover. Using a

flat screwdriver turn latch screw counter-clockwise

1/2 turn.

2. Remove the battery compartment cover and batteries.

3. Install new batteries. See F

IG. 37 for battery orienta-

tion.

FIG. 37

4. Replace cover. The cover is designed to only fit on

battery compartment one way. The notch (a) on

cover fits into slot (b) on compartment. (F

.

F

IG. 38

IG. 38).

5. Press down firmly on cover. Using a flat screwdriver

turn latch screw clockwise 1/4 turn.

313046T 27

Page 28

Notes

Notes

28 313046T

Page 29

Meter Parts

Meter Parts

(

Ref Part Description Qty

2 115477 SCREW, mach, torx pan hd 6

3 255889 KIt, repair, trip rod, includes 3a-3c

and instruction manual 312944

3a BALL,5 MM, carbide 3

3b ROD 1

3c SPRING, compression 10.67 mm 1

5 120812 O-RING, seal 1

6 15K418 TRIGGER, meter 1

7 15K443 ARM, trip 1

8 15K446 PLATE, ratchet 1

9 15K464 GUARD, bumper 1

11 HOUSING, meter 1

12 15W093 SOLENOID 1

15 15K602 SPRING, torsion 1

17 255197 MODULE, battery 1

18 255886 KIT, repair, electronic bezel,

includes 18a and instruction man-

ual 312942

18a LABEL, control, overlay 1

19 120850 PIN, dowel M4 2

24 16F811 KIT, repair, valve and seal,

includes 24a-24f and instruction

manual 312939

24a SPRING, compression 6.1 x 76mm 1

24b CARTRIDGE, valve 1

24c STEM, valve 1

31 247344 SWIVEL, straight, 1/2-14 NPT,

includes 31a (used with 256282,

256482, 256483, 256484, 256485,

256486, 256487)

247345 SWIVEL, straight, 3/4-14 NPT

includes 31a (used with 256488 &

257120)

24H097 SWIVEL, straight, 1/2-14 BSPT

includes 31a (used with 24H135,

24H137, 24H139, 24H141,

24H143, 24H145, 24H147)

24H099 SWIVEL, straight, 3/4-14 BSPT

includes 31a (used with 24H149 &

24H159)

24H098 SWIVEL, straight, 1/2-14 BSPP

includes 31a (used with 24H134,

24H136, 24H138, 24H140,

24H142, 24H144, 24H146)

24H100 SWIVEL, straight, 3/4-14 BSPP

includes 31a (used with 24H148 &

24H158)

31a 105765 O-RING 1

32 15T366 BOOT, swivel, 3/4” hose,NPT and

BSPT, black (standard with meter)

15T367 BOOT, swivel, 3/4” hose,NPT and

BSPT, red

15T368 BOOT, swivel, 3/4” hose,NPT and

BSPT, blue

Ref Part Description Qty

15T369 BOOT, swivel, 3/4” hose, NPT and

1

BSPT,green

15T370 BOOT, swivel, 3/4” hose,NPT and

BSPT, yellow

125961 BOOT, swivel, SD, BSPP, black 1

126115 BOOT, swivel,SD, BSPP,, red 1

126116 BOOT, swivel, SD, BSPP, blue 1

126117 BOOT, swivel, SD, BSPP, green 1

126118 BOOT, swivel, SD, BSPP, yellow 1

34 255885 KIT, filter, includes 34a-34c 1

34a KIT, filter, wire, 40 mesh 10

34b PACKING, o-ring (not included on

257539)

34c SPACER, strainer 10

47 121413 BATTERY, pkg, 4 count, alkaline,

1

AA (page 27)

49 15T259 LABEL, CE 1

51 15T603 GUARD, right 1

52 15T604 GUARD, left 1

53 117436 SCREW, thd forming 2

1

Replacement Danger and Warning labels, tags and

cards are available at no cost.

1

1

1

1

1

1

1

1

1

1

1

10

1

313046T 29

Page 30

Meter Parts

34a

34b

34c

24b

24c

7

24a

15

6

19

8

3

18

52

51

53

2

34

3a

3b

3c

11

49

5

9

18a

12

17 / 47

32

31

31a

Torque to 15-25 IN. LBS

3

Torque to 20-30 FT. LBS

5

5

3

5

ti10617b

30 313046T

Page 31

Nozzle (33) and Extension (20) Kits

ti11826

ti11827

ti11825

ti11827

ti11831

ti11830

ti11826

ti11828

ti11825

ti11828

Part No. Description Fluid Type

Nozzle (33) and Extension (20) Kits

255852*

255853*

255854

Automatic, quick close, non-drip nozzle with

rigid extension.

Automatic, quick close, non-drip nozzle with

flexible extension

Quick close, non-drip nozzle with rigid

extension

Oil, ATF

Oil, ATF

Gear Lube

255855*

255856*

Quick close, non-drip nozzle with rigid extension

Quick close, non-drip nozzle with flexible

extension

*Used for dispensing 5gpm (22.7 lpm) or less.

313046T 31

Anti-freeze

Anti-freeze

continued on page 32

Page 32

Nozzle (33) and Extension (20) Kits

ti11826

ti11829

ti11825

ti11829

Part No. Description Fluid Type

255857

255858

High flow, quick close, non-drip nozzle with

rigid extension

High flow, quick close, non-drip nozzle with

flexible extension

Oil, ATF,

Anti-freeze

Oil, ATF,

Anti-freeze

32 313046T

Page 33

Nozzle (33) Kits

255459* Automatic, quick-close non-drip, nozzle Qty Oil

• BODY, nozzle 1

• O-RING, packing 1

• SPRING, compression 1

• O-RING, packing 1

• STEM, nozzle, valve 1

• SEAT, valve 1

255460* Quick close, , non-drip, quick-close nozzle Anti-freeze

• BODY, nozzle 1

• SPRING, compression 1

• O-RING, packing 1

• STEM, nozzle, valve 1

• O-RING, packing 1

• SEAT, valve 1

255461

255470 Quick close, non-drip nozzle Gear Lube

High flow, quick close, non-drip, high-flow

nozzle

• STEM, nozzle 1

• BODY, nozzle 1

• O-RING, packing 1

• O-RING, packing 1

• O-RING, packing 1

• Housing 1

• Body, nozzle 1

• O-RING, packing 1

• O-RING, packing 1

• Plug, Hollow, hex 1

Oil and Antifreeze

Nozzle (33) and Extension (20) Kits

*Used for dispensing 5gpm (22.7 lpm) or less.

Thermal Relief Kits (page 5)

Part No. Description PSI (bar) Rating

112353 Diaphragm pump for fuel dispense, valve only 50 psi (3.4 bar)

235998

237601 Fire-Ball 425, 3:1 600 psi (41 bar)

313046T 33

Mini Fire-Ball

™

225, 3:1

600 psi (41 bar)

Page 34

Nozzle (33) and Extension (20) Kits

Part No. Description PSI (bar) Rating

237893 Mini Fire-Ball 300, 5:1 and Fire-Ball 425, 6:1 900 psi (62 bar)

Mini Fire-Ball 300, 5:1 and Fire-Ball 425, 6:1

248296

(same as 237893 without bung adapter and

900 psi (62 bar)

swivel. Includes 6-foot hose)

238899 Diaphragm pump 150 psi (10.4 bar)

240429 Fire-Ball 425, 10:1 1600 psi (110 bar)

248324

Fire-Ball 425, 10:1 (same as 240429 minus bung

adapter and swivel. Includes 6-foot hose)

1600 psi (110 bar)

34 313046T

Page 35

Technical Specifications

Technical Specifications

Flow range* . . . . . . . . . . . . . . . . . . . . . 0.1 to 14 gpm (0.4 to 53 lpm)

Maximum Working Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1500 psi (103.4 bar)

Units of Measure . . . . . .pints, quarts, gallons, liters (factory set to quarts)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 pounds (2.26 kg)

Dimensions (without extension) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 inches (33 cm)

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.75 inches (9.5 cm)

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.75 inches (14.6 cm)

Units of measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . factory set in quarts

maximum totalizer amount = 999,999 gallons or liters

maximum recorded dispensed volume = 999.99 units

maximum preset volume = 999.9 units

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2-14 npt or 3/4-14 npt

Outlet . . . . . . . . . . . . . . . . . . 3/4-16 straight thread o-ring boss

Operating temperature range . . . . . . . . . . . . . . . . . . . . . 4 °F to 158°F (-16°C to 70°C)

Storage temperature range . . . . . . . . . . . . . . . . . . . . -40°F to 158°F (-40°C to 70°C)

Battery** . . . . . . . . . . . . . . . . . . . 4AA alkaline or lithium batteries

Expected battery life in typical shop environment 6 months

Wetted parts . . . . . . . . . . . . aluminum, stainless steel, PBT/PC, zinc,

nitrile rubber, CS

Fluid compatibility . . . . . . . . . . . . . . antifreeze, gear oil, crankcase oil, ATF

Meter pressure loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 psi @ 10 gpm

Accuracy† . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +/- 0.5 percent

RF Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2405-2480 MHz

RF Transmit Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10dBm/10mW

*Tested in 10W motor oil. Flow rates vary with fluid pressure, temperature and viscosity.

**Battery required to meet life expectancy: Energizer

† At 2.5 gpm (9.5 lpm), at 70°F (21°C), with 10-weight oil and 1 gallon dispensed. May require calibration; out-of-box

accuracy is +/- 1.25 percent.

313046T 35

®

Alkaline E91.

Page 36

Graco 7-Year Meter and Valve Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period from the date of sale as defined in the table below, repair or replace equipment covered by this

warranty and determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in

accordance with Graco’s written recommendations.

Graco 7-Year Meter and Valve Extended Warranty

Components Warranty Period

Structural Components

Electronics

Wear Parts - including but not limited to o-rings, seals and valves

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within one (1) year past the warranty period, or two (2)

years for all other parts.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou in

de ou en rapport, directement ou indirectement, avec les procédures concernées.

7 years

3 years

1 year

tentés, à la suite

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 313046

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

www.graco.com

Revised May 2018

Loading...

Loading...