Page 1

Manzel® HP Lubricators

For precisely metered lubricant delivery at

pressures up to 60,000 psi.

DESCRIPTION

Manzel Force Feed Lubricators are precision metering pumps operating

within rugged cast iron reservoirs which contain the lubricant to be pumped.

Each pumping unit supplies a single point of lubrication. Lubricators may be

fur nished in single or multi-feed units for any number of points of lubrication.

They are available with various drive ar rangements, for a broad range of

lubricants, viscosities, and required line pressures. Each Manzel Lubricator

Pumping Unit is fitted with an integral sight feed showing the flow of lubricant

into each line.

Manzel High Pressure Lubricators are famous the world over for convenience,

positive protection, cost savings and reliability. They are specified by leading

equipment builders in the chemical and petrochemical industries in the United

States, Europe, Japan and South America.

“Dri-Vac” sealed pumping units may be easily removed for servicing without

dis-assembling the complete lubricator from the installation. Individual pumps

may also be added or changed to alter the number or pressure rating of

individual feeds.

Lubricant is pumped through the Sight Feed Chamber by means of negative

pressure, each drip tube indicating the amount of lubricant fed to each point

of lubrication. The individually sealed chambers are compatible with both

mineral oil and synthetic base lubricants.

Simple hand adjustment of the feed regulator knob provides regulation of feed

from a fraction of a drop to full pump capacity.

FEATURES

Operating pressures to 60,000 p.s.i., for lubricating compressor and •

circulator cylinder walls, heavily loaded bearings and other moving

parts.

Single plunger force feed principle also highly efficient for injecting •

lubricants and/or compatible fluids into high pressure systems.

Vacuum sight feeds on self-contained pumping units show output of •

lubricant to individual lubrication points.

All working parts are totally enclosed and self-lubricated.•

Individual pumping units easily removed for service.•

Feed rate infinitely variable from minimum to maximum with simple •

hand adjustment.

OPERATION

The crankshaft gives a vertical movement to the pump plunger through

the regulating lever. Pump displacement is controlled by the position of the

regulating lever fulcrum. When the feed regulator nut is turned clockwise to

its fur thest point, the graduated regulator rod will project its greatest distance.

The regulating lever fulcrum will then be at its highest point, and the plunger

will displace a maximum of fluid. Fluid displacement occurs in that portion of

the cylinder above the inlet port and is a function of plunger travel.

On the downstroke, the plunger creates a negative pressure in the cylinder,

positively seating the spring-loaded poppet discharge valve and opening

the inlet port from the sight chamber well. This causes the fluid in the sight

chamber well to flow into the depressurized pump cylinder, creating a

reduction of pressure in the sight feed chamber. As a result of this pressure

imbalance, a metered amount of fluid is forced up through the drip tube into

the sight well.

On the upstroke, the plunger closes the inlet port and the metered amount of

fluid is forced under system pressure over the poppet discharge valve to the

point of lubrication. The inlet port provides an annular ring around the plunger

and a channel to the Sight Feed Chamber. Any loss of lubri cant between

the plunger and cylinder on the discharge stroke returns to the Sight Feed

Chamber. Because of the pressure balance system, the volume being drawn

up from the reservoir is reduced. Hence, the amount seen leaving the drip

tube is equivalent to that entering the discharge line.

Mounting – Reservoirs have end mounting lugs as shown in outline drawings

on page 2. Mounting bases to accommodate com plete reservoir and drive

systems are also available.

Drive – Crankshaft drive is provided by a rotary power source whose output

speed is in the range of 3 to 36 rpm, usually elec tric motors combined with

individual speed reduction units (normally those that will accept NEMA flange

motor mounts). Multiple-drive arrangements use double extension output

shafts in the gear reduction units, for right and left drives. Parallel drive

systems are also possible through chain and sprocket devices.

Tandem drive arrangements are powered through driveshaft couplers. A

maximum of three high pressure lubricators may be driven by this method.

System Connections – It is recommended that each pumping unit be

installed with a Manzel High Pressure Check Valve in the discharge line

adjacent to the pump discharge connection, so that pump assembly may be

removed from reservoir without loss of lubricant in lines. The installation of a

second of these valves at the point of lubrication is always recommended to

prevent line drainage, and as a positive means of avoiding feedback of system

pressure to pump.

Page 2

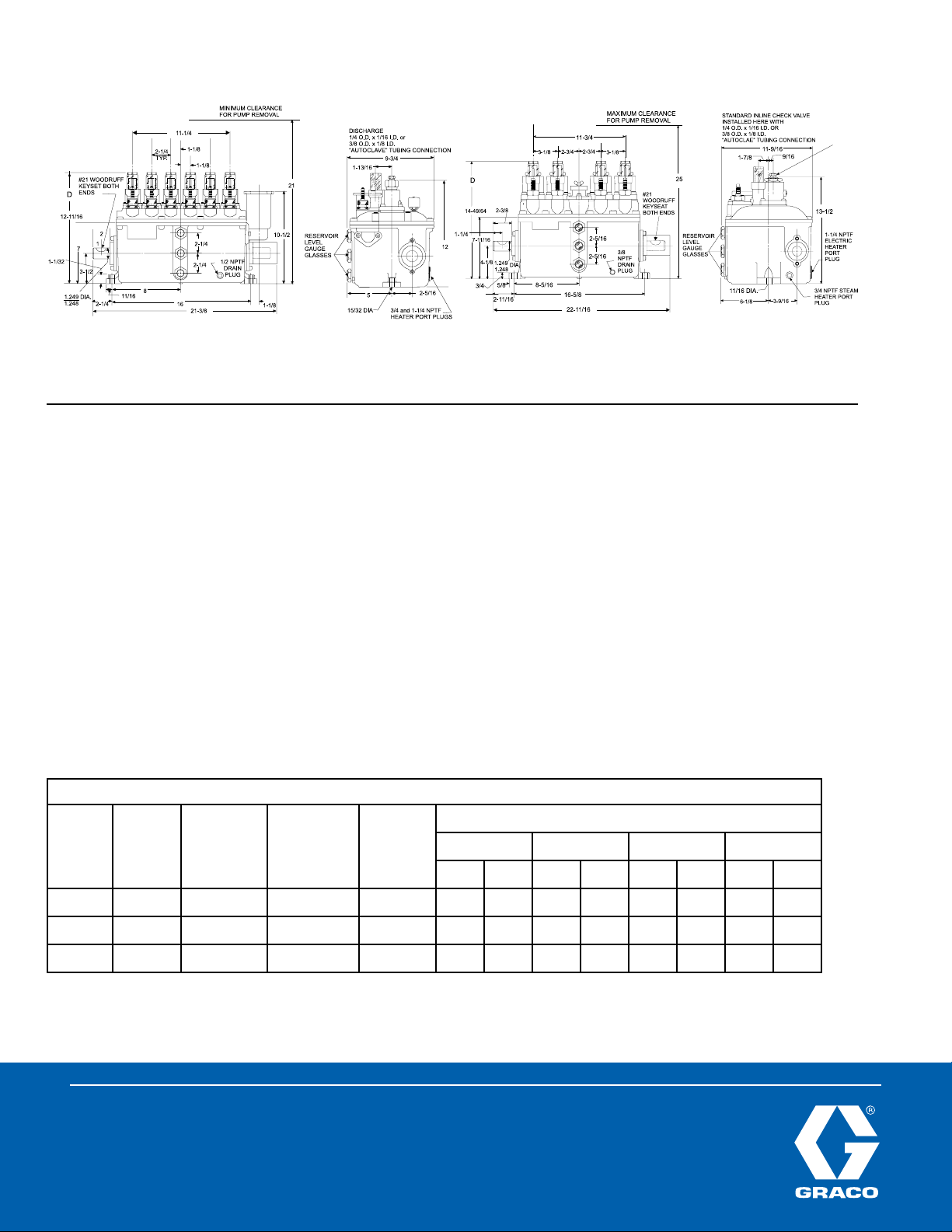

Manzel Model HP-15 Manzel Model HP-50, HP-60

Front View End Front Front View End Front

Reservoir Capacity 7 qts. from Centerline of Top Gauge Glass to Centerline

of Bottom Gauge Glass.

OPERATION

Lubricant Types and Viscosities — Manzel HP Lubricators are suitable for

use with mineral oil or synthetic base lubricants with viscosities in the range

of 100 to 5,000 SUS under pumping conditions.

Heaters and Other Accessories — Both electrical and steam heater

assemblies for low ambient temperatures and/or high viscosities are available

on special order.

Also available are low level, low level/shaft rotation alarms and auto fill

devices.

Finish — The exteriors of all pumping units are Parco-Lubrited, as well as

the inside and outside of the cast reservoir and its cover. This makes painting

unnecessary, and eliminates many of the problems of handling synthetic

lubricants.

Service — Pumping units include a hardened cylinder and plunger which are

lapped to a selective fit. It is therefore recom mended that pumps be returned

to the factory for service. To insure uninterrupted equipment operation, spare

pumps should be available.

(Continued)

LUBRICATOR CHARACTERISTICS

Model

Number of

Feeds

Maximum

Operating

Pressure

Reservoir

Capacity

(Quarts) (1)

Plunger

Diameter

(Inches)

Reservoir Capacity 9 qts. from Centerline of Top Gauge Glass to Centerline

of Bottom Gauge Glass.

MATERIALS OF CONSTRUCTION

Reservoir and Cover — Heavily ribbed cast iron.

Cylinder — Hardened alloy steel, precision-honed.

Plunger — Hardened alloy steel, precision-ground and fitted.

Valves — Poppet type, flat face, hardened and ground alloy steel.

Valve Seats — Hardened and ground alloy steel.

Driveshaft — Integral crankshaft type, hardened, ground and polished alloy

steel, machined from solid bar.

Bearings — Bronze bushed, high load capacity, long-life, self-lubricating

type.

Regulating Lever — Forged steel.

Pumping Unit Displacements [2]

Drops / Stroke Cu. In./ Stroke C.C. / Stroke Strokes / Min.

Max. Min. Max. Min. Max. Min. Max. Min.

HP-15 1 to 6 18,000 7 1/4 4 1 .008 .002 .133 .033 36 3

HP-50 1 to 4 50,000 9 1/4 4 1 .008 .002 .133 .033 36 3

HP-60 1 to 4 60,000 9 1/4 4 1 .008 .002 .133 .033 36 3

[1] Usable reservoir Capacity, as measured from centerline of top gauge glass to centerline of bottom gauge glass (see drawings).

O

[2] All displacements are based on SAE 30 oil (500 SUS at 100

equal 1 cu. in., 30 drops equal 1cc.

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

F.) at room temperature. Volumetric equivalents of drops are: 14,115 drops equal 1 pint, 490 drops

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

©2006-2009 Graco Inc. Form No. L51030 Rev. B 4/09 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Loading...

Loading...