Page 1

Model HP-15 High Pressure Lubricators

DESCRIPTION

The high pressure lubricator comprises one to six

integral sight and pump assemblies in a cast iron

reservoir. The unit is designed for direct connection to an

electric motor/speed reducer power source. A “Manzel”

terminal check valve is recommended in the lubrication

system. When required to maintain proper oil viscosity,

the reservoir can be fitted with an optional steam or

electric heater.

SPECIFICATION

Plunger Diameter .................................................... 1/4 Inch

Maximum Operating Pressure ............................ 18,000 psi

Maximum Pumping Rate...... .008 in

Based on SAE 40 Oil — (approx. 4 drops)

Minimum Pump Rate .. .001 in3 (.017 cc) at max. pressure

Reservoir Heating (optional) ................... Stream or Electric

Lubricant Viscosity ................................... 100 to 5000 SUS

Operating Temperature................................ -20

3

(0.133 cc) per stroke

O

F to 120OF

OPERATING

Oil Level —

When necessary, completely fill the lubricator reservoir

with clean filtered lubricant. Three sight glasses, provided in the reservoir at various levels, permit observation

of fluid level. Oil level should not be allowed to drop

below the bottom sight glass. During the initial filling, the

vent plugs at the top of the pump sight glasses should

be removed. This allows lubricant to rise in the drip tube

up to the level of the oil in the reservoir and reduces the

priming required at start up.

Pump Priming —

If the sight well on the pump does not contain oil, the

pump should be primed. Pumps may be primed while

the lubricator shaft is rotating as follows:

a. Adjust the pumping rate to the maximum setting by

turning the adjustment nut on the indicator stem as

far as possible in a clockwise direction.

b. Remove the vent plug on top of the sight glass and fill

the housing sight well with oil to 3/8 inch below the

discharge of the drip tube.

c. Replace the vent plug. Check the sight glass to insure

that it is properly seated against the O-ring to prevent

air leakage into the sight well.

d. Readjust the pumping rate to the desired delivery.

Pumping Rate —

The pumping rate is indicated at the drip tube inside the

sight glass. During the pump suction stroke, fluid is

drawn into the pump from the sight well. This creates a

partial vacuum in the sight well, permitting atmospheric

pressure in the lubricator reservoir to force an amount of

oil equal to the pump displacement through the drip tube

into the sight well. The rate is adjustable for each pump

assembly by means of the pump regulator which varies

the stroke of the positive displacement, reciprocating

pump assembly.

Caution —

The drip tube flow rate is accurate after the pump has

operated long enough to stabilize the pressure inside the

sight well. There is a time lag at start-up, low pumping

rates, and during pump rate changes. Allow sufficient

time to insure an accurate rate indication.

Regulating Pump Rate —

The pumping rate can be varied infinitely within the range

of minimum to maximum by means of the graduated

pump regulators which project through the reservoir

cover. The regulators are easily adjusted by hand during

the pump suction stroke. Maximum pumping rate is

achieved when the adjustment nut on the sight indicator

stem is turned in a clockwise direction as far as it can

go. In this position the sight indicator stem projects the

maximum distance indicating maximum pumping stroke.

When the adjusting nut is turned in a counter-clockwise

direction, delivery reduces, because of a reduction in

pump stroke, until minimum delivery is obtained.

Note —

To retain the hydraulic seal between the plunger and the

cylinder walls, minimum delivery must not go below 1/2

drop, .001in

3

(0.017 cc) per pump stroke.

Page 2

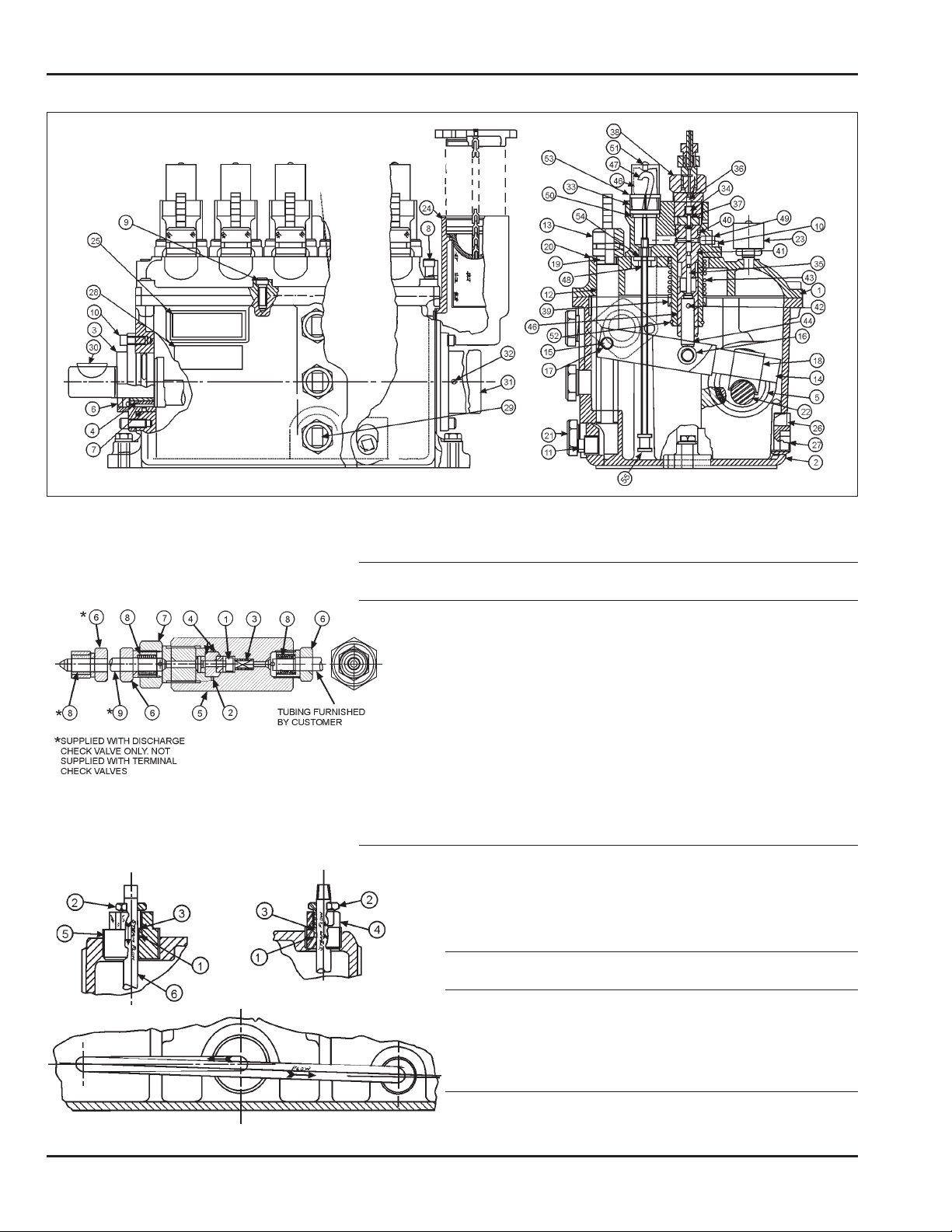

Manzel® HP-15 High Pressure Lubricator

Figure 1.

Bulletin 40230

Figure 2.

Figure 3.

Check Valve Parts List

Figure & Part Quantity Usage

Index No. Number Description Required Code

2- 463-280-001 LINE CHECK VALVE ASSEMBL Y, 1 D

3/8” O.D. Tube

2- 463-280-011 DISCHARGE CHECK VAL VE, ....... 1 E

ASSEMBLY, 3/8” Tube

-1 463-920-000 VALVE, Check ................... 1

-2 463-910-000 SEAT, Check valve ................... 1

-3 458-005-130 SPRING, Check valve ................... 1

-4 439-007-010 GASKET, Check valve ................. 2

-5 463-860-880 BODY, Check valve ................... 1

-6 446-010-010 NUT, Check valve ................... 2 D

-6 446-010-010 NUT, Check valve ................... 3 E

-7 463-860-870 BODY, Check valve ................... 1

-8 446-000-010 COLLAR, Check valve ................. 2 D

-8 446-000-010 COLLAR, Check valve ................. 3 E

-9 446-055-000 NIPPLE, Check V alve ................... 1 E

NOTE: This check valve for 3/8” tube. Other sizes available. Refer to factory for

parts list details.

Steam Heater Components

Figure & Part Quantity

Index No. Number Description Required

3-1 422-050-120 “O” RING SEAL ................... 2

-2 410-701-860 SEAL NUT ................... 2

-3 439-079-030 SEAL GLAND ................... 2

-4 437-700-380 PLUG, 3/4” open ................... 1

-5 437-700-390 PLUG, 1-1/4” open ................... 1

-6 433-700-500 STEAM HEA TER TUBE ................. 1

NOTE: Steam and electric heaters available for all lubricators. Refer to

the factory for detail parts other than those shown above.

Page 2

Page 3

Manzel® HP-15 High Pressure Lubricator

HP-15 Lubricator Assembly Parts List

Figure & Quantity

Index No. Part Number Description Required

1- 469-838-091 RESERVOIR ASSEMBLY............................ REF.

-1 471-638-030 · COVER, Reservoir .................................... 1

-2 469-838-030 · BODY, Reservoir ....................................... 1

-3 402-040-120 · BEARING, Shaft ........................................ 2

-4 402-114-320 · BUSHING, Bearing..................................... 2

-5 402-114-330 · BUSHING, Reservoir ................................. 2

-6 423-010-160 . SEAL, Shaft .............................................. 2

-7 422-012-270 . “O” Ring Bearing ....................................... 2

-8 419-150-090 . SCREW , Cover end ................................... 4

-9 419-150-060 · SCREW , Cover side .................................. 8

-10 419-150-040 · SCREW, Bearing........................................ 4

-11 412-130-160 . PLUG, Drain hole ....................................... 1

-12 453-030-130 . ROD, Feed adjusting ................................. 6

-13 410-700-730 . NUT, Feed adjusting .................................. 6

-14 453-040-050 . LEVER, Actuating...................................... 6

-15 411-700-270 . PIN, Lever.................................................. 12

-16 402-172-040 . ROLLER, Pin .............................................. 6

-17 418-010-140 . RING, Pin.................................................... 24

-18 484-110-020 . SHOE, Lever ............................................. 6

-19 418-090-230 . RETAINER, W asher ................................... 6

-20 439-077-110 . WASHER, Friction ..................................... 6

-21 438-010-030 . SIGHT GLASS, Reservoir ......................... 3

-22 465-920-030 . CRANKSHAFT........................................... 1

-23 542-847-000 . BREA THER ................................................ 1

-24 473-040-131 . FILLER ASSEMBL Y ................................... 1

-25 457-008-321 . NAMEPLATE .............................................. 1

-26 412-140-060 . PLUG, 1-1/4” Heater opening ................... 1

-27 412-140-040 . PLUG, 3/4” Heater opening ....................... 1

-28 457-002-232 . PLATE, Operating instructions.................. 1

-29 438-028-060 . REFLECTOR, Gauge glass........................ 3

-30 409-010-290 . KEY, Woodruff.......................................... 1

-31 471-680-090 . COVER, Shaft end .................................... 1

-32 415-110-060 . SCREW, Shaft end cover .......................... 1

1- 362-390-325 . PUMP UNIT, HP-15 ................................... 6

-33 477-140-100 . HOUSING, Pump ........................................ 1

-34 463-160-071 . VALVE ASSEMBLY................................... 1

-35 477-020-511 . CYLINDER ASSEMBL Y ............................. 1

-36 458-005-140 . SPRING, Pump valve ................................. 1

-37 422-040-120 . GASKET, Valve ......................................... 2

-38 410-700-750 . NUT , Housing............................................. 1

-39 484-170-020 . RET AINER, S pring...................................... 1

-40 422-042-120 . “O” RING, Cylinder..................................... 1

-41 422-040-180 . “O” RING, Cylinder..................................... 1

-42 411-700-260 . PIN, Spring retainer ................................... 1

-43 458-005-200 . SPRING, Plunger........................................ 1

-44 475-070-010 . PUSHER, Plunger....................................... 1

-45 484-010-110 . SLEEVE, Pusher........................................ 1

-46 438-036-070 . SIGHT , V acuum ......................................... 1

-47 433-700-020 . TUBE, Oil drip ............................................ 1

-48 433-701-153 . TUBE ASSEMBL Y , Suction........................ 1

-49 503-485-000 . PLUG ......................................................... 1

-50 422-042-130 . “O” RING, Vacuum sight............................ 1

-51 437-700-770 . PLUG, Vent................................................ 1

-52 418-010-360 . RET AINER, Housing................................... 1

-53 410-701-840 , NUT, Hold down ........................................ 1

-54 422-041-120 . “O” RING, Suction Tube ............................ 1

-55 473-020-471 . SUCTION STRAINER

*Site Glass Kit - 438-036-061.

Order this kit if your present

pumps have plastic site feeds.

Bulletin 40230

(added to pumps made after 1/98) ......... 1

Page 3

Page 4

SERVICE

Lubricator operation can be checked by observing the

drip tube. If the correct pumping rate is maintained, no

servicing is required other than periodic replenishment of

the reservoir. If the sight glass well pumps dry or no flow

is observed, check the following points until the cause is

determined and corrected.

a. Check the vent plug for proper sealing. Any

nicks or cracks in the rubber plug will cause

an air leak into the sight glass.

b. Check shaft rotation. If the lubricator shaft is

not rotating, determine the cause and repair

as necessary.

c. Check oil level and viscosity. Be sure the

reservoir is filled with oil, and if necessary

heat the reservoir to maintain viscosity at the

correct level for the desired flow.

d. Check pump priming. If necessary, prime the

pump in accordance with the “Operating

Instructions”.

e. Check the feed adjustment and readjust if the

pumping rate is too low.

f. Check the actuating linkage for proper

operation. If defective, isolate the broken part

and repair or replace as required.

If none of the above steps isolate the malfunction, the

cause is in the pump assembly. The following items

should be checked before removing the pump assembly

from the cover.

a. Check the sight for inward leakage due to a

crack in the sight glass, improper sight glass

seating, or a defective O-ring. Repair as

required.

If the sight glass fills with lubricant proceed as follows:

a. Remove the vent plug and allow the lubricant

to pump down to the proper level. Replace the

vent plug. The pump should operate normally.

b. If the sight glass continues to fill with

lubricant check all terminal check valves for

proper operation. If the valves are operating

properly, remove and clean the pump

assembly, then reinstall the pump in the

system and check operation.

c. If the sight glass still fills with lubricant it may

be caused by temperature variation.

1). When the unit is not operating,

remove the vent plug and allow the

lubricant to pump down to the proper

level. Replace the vent plug. The pump

will now function properly. The sight

glass may fill with fluid without affecting

the operation of the lubricator as long as

the drip tube remains above the

lubricant level to show the rate of

pumping.

2). When the unit is operating, the sight

level will vary depending on temperature

variations. If the level falls to less than 1/4

inch above sight glass flange, add

lubricant to the proper level (3/8 inch

below the discharge of the drip tube)

through the vent hole. If the level is too

high, remove the vent plug and allow the

unit to pump down before replacing the

vent plug.

Other servicing that may be required is listed below:

b. Check for an obstruction in the drip tube and

remove if found.

If the above steps do not isolate the malfunction, disconnect the discharge tubing and remove the pump assembly which is attached to the cover with four screws.

Caution —

Exercise extreme care if equipment is operating.

Rotating equipment can cause serious injury. Faulty

pumps should be returned to the factory for repair as

they contain a selectively fitted cylinder and plunger. A

spare pump should be on hand for use during emergencies when a pump is being repaired.

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice

a. Periodic cleaning of the lubricator is desirable

to eliminate contamination that may have

occurred in the oil. To accomplish this,

remove all pumping units and clean the

pumps and reservoir by brushing loose all

foreign matter, dipping in solvent and

thoroughly drying.

b. If external leakage is observed, determine the

cause (loose bolts, defective gaskets, or

seals) and repair as required.

Call today for product information or to request a demonstration.

1.800.USA.LUBE

®2006 Graco Inc. Bulletin 40230, March 2002. Printed in U.S.A.

All other brand names or marks are used for identification purposes and are trademarks of their respective owners.

(1-800-872-5823) or visit us at www.lubriquip.graco.com.

Loading...

Loading...