Page 1

INSTRUCTIONS-PARTS

LIST

308–422

This

manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

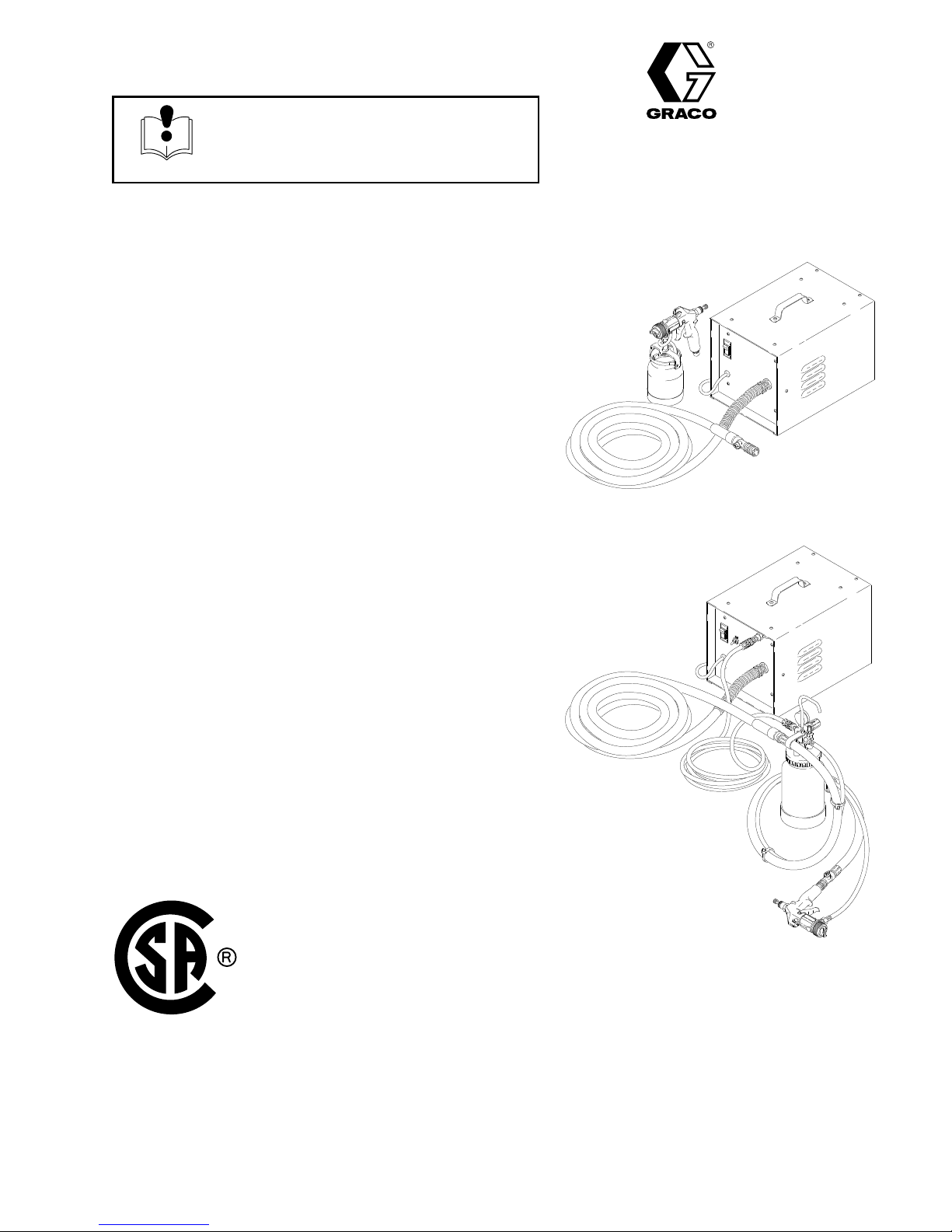

INSTRUCTIONS

Series

T

urbine Sprayers

120 VAC 50/60 Hz: Series 700 and 900

120 VAC 60 Hz: Series 800

Maximum Working Pressure:

Series 700 and 800: 5 psi (0.34 bar)

Series 900: 6 psi (0.41 bar)

Model

Complete Series 700 T

M73109, Series A

700, 800, and 900

urbine, with hose and turbine gun

Model M73111, Series A

Basic Series 700 T

urbine, without hose or gun

Series

Supersedes A

700 and 900

Rev. B

03015

Model M73154, Series A

Complete Series 800 T

urbine,

with remote 2 qt cup, hose, and turbine gun

Model M73157, Series A

Basic Series 800 T

urbine, without hose or gun

Model M73331, Series A

Complete Series 900 T

urbine, with hose and turbine gun

Model M73333, Series A

Basic Series 900 T

urbine, without hose or gun

Series 800

03016A

GRACO INC. P.O. BOX 1441

MINNEAPOLIS, MN

COPYRIGHT

Graco

Inc. is registered to I.S. EN ISO 9001

1994, GRACO INC.

55440–1441

Page 2

Table

Warnings 2.

General

Specifications 6

Dimensions 6

Setup 7

Shutdown 11

Maintenance 12

Troubleshooting 13

Repair 14

Parts 18

Accessories 24

Warranty Back

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Information5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cover

WARNING

FIRE AND EXPLOSION HAZARD

Symbols

Warning Symbol

WARNING

This

symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This

symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

Improper

result in a fire or explosion and serious injury

D

D

D

D

D

D

D

D

D

grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

.

Ground the equipment and the object being sprayed. Refer to

If there is any static sparking or you feel an electric shock while using this equipment,

ing immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

When flammable liquid is sprayed or used for flushing or cleaning the equipment, the turbine must

be placed at least 20 feet (6.1 m) away from areas where hazardous concentrations of flammable

vapors are likely to occur

Use additional air hose if necessary to ensure that the turbine is operated in a clean, dry

ventilated area.

Never place the turbine inside a spray booth! Use this equipment outdoors or in extremely well

ventilated areas.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Electrically disconnect all equipment in the spray area.

Extinguish all open flames or pilot lights in the spray area.

.

Grounding

on page 8.

stop spray-

, well

D

Do not smoke in the spray area.

D

Do not turn on or of

D

Do not operate a gasoline engine in the spray area.

f any light switch in the spray area while operating or if fumes are present.

Page 3

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment

D

This equipment is for professional use only

D

Read all instruction manuals, tags, and labels before operating the equipment.

D

Use the equipment only for its intended purpose. If you are not sure, call Graco T

tance at 1–800–543–0339.

D

Do not alter or modify this equipment.

D

Check equipment daily

D

Do not exceed the maximum working pressure of the lowest rated system component. The Series

700 and 800 turbines have a working pressure of 5 psi (0.34 bar) and the Series 900 has a working

pressure of 6 psi (0.41 bar).

D

Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

fications

D

Do not use hoses to pull equipment.

D

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 82_C (180_F) or below –40_C (–40

D W

misuse can cause the equipment to rupture or malfunction and result in serious injury

.

. Repair or replace worn or damaged parts immediately

on page 6 for this information.

ear hearing protection when operating this equipment.

.

_F).

echnical Assis

.

-

Speci-

D

Do not lift pressurized equipment.

D

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D

Do not point the gun at anyone or at any part of the body

D

Do not put your hand or fingers over the gun fluid nozzle.

D

Do not stop or deflect leaks with your hand, body

D

Do not “blow back” fluid; this is not an air spray system.

D

Follow the

checking or servicing the equipment.

D T

ighten all fluid connections before operating the equipment.

D

Check the hoses, tubes, and couplings daily

Pressure Relief Procedure

on page 1

, glove or rag.

. Replace worn or damaged parts immediately

1 if the fluid nozzle clogs and before cleaning,

.

.

Page 4

TOXIC FLUID HAZARD

WARNING

Hazardous

inhaled, or swallowed.

D

Know the specific hazards of the fluid you are using.

D

Store hazardous fluid in an approved container

state and national guidelines.

D

Always wear protective eyewear

solvent manufacturer

D

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in the turbine spray system, which contains aluminum and/or galva

nized-coated parts. Such use could result in a serious chemical reaction, with the possibility of

explosion, which could cause death, serious injury

fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

. Dispose of hazardous fluid according to all local,

, gloves, clothing and respirator as recommended by the fluid and

.

, and/or substantial property damage.

CAUTION

CSA Certification of this sprayer is valid only when used with the following Graco hoses:

M71452 M71453

M71454 M71455

M71631 M71633

M71481 M71484

M71485 M71486

-

Manual

Changed

Also changed part numbers according to project 157F–07.

all model numbers from CX–7, CX–8, and CX–9, to Series 700, Series 800, and Series 900, respectively

Change Summary

.

Page 5

General

The

Series 700, 800 and 900 T

spray most coatings or finishes currently being used

for automotive refinish, industrial, aerospace, marine,

wood, plastic and architectural applications.

urbine Spray Guns can

Information

The contents of the Series 700 bare sprayer

M73111, includes:

D

1 Series 700 T

D

1 Sprayer Instruction Manual, 308–422

urbine Sprayer

, Model

, M73486

This spray gun typically utilizes 5 psi (0.34 bar) for

Series 700 and Series 800 and 6 psi (0.41 bar) for the

Series 900 inbound air pressure to produce high

quality paint finishes. The gun produces a cone of air

that carries and directs the paint from the gun to the

surface, minimizing overspray and increasing transfer

efficiency

clean air laws that are designed to reduce VOC (vola

tile organic compounds) emissions, eases paint

application by requiring fewer paint passes to obtain

coverage, and saves on both material and clean-up

time.

Refer to the turbine gun manual, 308–336, for more

information on the operation and use of the turbine

spray gun.

Unpack the Graco T

carton and inspect for any possible shipping damage.

If necessary

The contents of the Series 700 T

Model M73109, includes:

. This enables painters to comply with new

urbine Sprayer from the shipping

, call your distributor

.

urbine Sprayer

,

The contents of the Series 800 T

Model M73154, includes:

D

1 Series 800 T

D 1 T

D

D

-

D

D

D

D

The contents of the Series 800 bare sprayer

M73157, includes:

D

D

The contents of the Series 900 T

Model M73331, includes:

D

D 1 T

D

D

D

urbine Gun, M73225

1 25 ft. hose, M71452

1 2 qt. cup, M70962

1 25 ft. braided air hose, M71631

10 wire ties, M71

1 Sprayer Instruction Manual, 308–422

1 Gun Instruction Manual, 308–336

1 Series 800 T

1 Sprayer Instruction Manual, 308–422

1 Series 900 T

urbine Gun, M73200

1 25 ft. hose, M71452

1 Sprayer Instruction Manual, 308–422

1 Gun Instruction Manual, 308–336

urbine Sprayer

179

urbine Sprayer

urbine Sprayer

urbine Sprayer

, M73487

, Model

, M73487

urbine Sprayer

, M73488

,

,

D

1 Series 700 T

D 1 T

D

D

D

urbine Gun, M73200

1 25 ft. hose, M71452

1 Sprayer Instruction Manual, 308–422

1 Gun Instruction Manual, 308–336

urbine Sprayer

, M73486

The contents of the Series 900 bare sprayer

M73333, includes:

D

1 Series 900 T

D

1 Sprayer Instruction Manual, 308–422

urbine Sprayer

, M73488

, Model

Page 6

Specifications

PTFEPTFEPTFE

Power

Requirements

Series 700, Series 900

Series

800

.

. . . . . . . . . . . . . . . . . . . . . . .

Amps

@ 120 volts

Series 700

Series

Series

Power

CFM

unrestricted

Series 700, Series 800

Series

Turbine

Maximum T

Series 700, Series 800

Series

Cup

Series

Series

{

Extension

Locktite

tion.

.

. . . . . . . . . . . . . . . .

800

.

. . . . . . . . . . . . . . . .

900

.

. . . . . . . . . . . . . . . .

Cord

900

900

700, Series 900

800

is a registered trademark of the DuPont Corporation.

r

. . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stages3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

urbine Hose Length

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

cord must be 3-wire, 12 A

is a registered trademark of the Locktite Corpora

.

. . . . . . . . . .

No. 16 A

.

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

120 V

120 V

1 phase, 12A minimum

1 phase, 12A minimum

1 phase, 12A minimum

WG, 3 wire, 10 ft (3 m)

WG; 100 ft or shorter

ac, 50/60 Hz

ac, 60 Hz

101 cfm

1

15 cfm

40 ft (12 m).

60 ft (18 m).

1 qt (1 liter).

2 qt (2 liter).

.

-

Wetted

{.

Series 800 Air Compressor

CFM 0.4.

HP 1/30

PSI 30

Turbine

Series

Series

Series

Parts

Bare Spray Gun

Spray Gun Cups

2

Quart Accessory Remote

Pressure Pot

2-1/2

Gallon Accessory Remote

Pressure Pot

solvent–resistant

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping W

700

.

. . . . . . . . . . . . . . . . . . . . . . . . .

800

.

. . . . . . . . . . . . . . . . . . . . . . . .

900

.

. . . . . . . . . . . . . . . . . . . . . . . . .

Stainless Steel, Brass,

.

Hard-coated

.

. . . . . . .

.

. . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . .

finish, EPDM Gasket (standard)

eight

Aluminum, Polyethylene

Aluminum, Brass,

psi (1.03 bar)

(w/o

pkg, hose, or gun)

47 lb (21.3 kg)

Polyethylene

40 lb (18 kg)

46 lb (21 kg)

PTFE, r.

Aluminum

Steel with

hp

Turbine

Series 700, Series 800

Series

Diameter

900

.

. . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . .

Dimensions

5.7 in (144.78 mm)

7.2 in (182.88 mm)

Page 7

Setup

NOTE:

information on the operation and setup of the gun.

Refer to the turbine gun manual, 308–336, for

Connect the Fluid and Air Supply

1. Connect

2.

Connect the gun air supply hose (A) between the

turbine air outlet (D) and the gun air inlet. DO

NOT use a wrench to tighten connections; hand–

tighten only

3.

If using a spray gun cup (B),

the gun fluid inlet.

4.

For Series 800 only: If using an accessory remote

pressure pot (C),

between the gun fluid inlet and the remote pres

sure pot.

Connect the air hose (E) between the pressure pot

air inlet and the compressor air outlet (F).

the hose to the gun.

. See Fig. 1.

connect the fluid supply hose (G)

G

connect the cup to

Air Control V

(used to shut of

without shutting of

turbine)

A

NOTES:

D

The circled letters in Fig. 1 indicate hose line con

nections.

Only the Series 800 turbine unit includes a com

D

pressor for use with a remote pressure pot.

-

-

Connect to Electric Supply

1. Plug

2.

-

alve

f air

f

the sprayer power cord into a grounded

outlet.

If an extension cord is used, it must be 3-wire, 12

A

WG and 100 ft or less in length.

B

Air Control V

(used to shut of

air without shut

ting of

alve

f turbine)

f

-

A

B

Z

X

X

E

Y

G

Z

C

G

Z

E

Y

A

DF

Y

C

X

E

2-1/2 Gallon Remote Pressure Pot

Part No. M70604

Fig.

1

(see Accessories)

2 Quart Remote Pressure Pot

Part No. M70962

(see Accessories)

Series 800

T

urbine shown

04958

Page 8

Setup

Grounding

WARNING

FIRE

AND EXPLOSION HAZARD

Before operating the turbine sprayer

ground the system as explained below

Also read the section

SION HAZARD

1.

Turbine:

properly grounded outlet. Do not remove the

grounding prong from the power cord. Do not use

an adapter

2.

Extension cords:

wires and be rated for a minimum of 15 amps.

3.

Fluid supply container:

4.

Object being sprayed:

Plug the turbine power supply cord into a

.

Extension cords must have three

follow your local code.

follow your local code.

FIRE OR EXPLO

on page 2.

Prepare the Fluid

1. Always

includes color

2.

When using a turbine spray system, you need to

,

.

-

use a slower drying reducer or thinner to compen

sate for the faster drying time caused by the warm

air of the turbine.

strain the fluid before spraying; this

, reducer and hardeners if used.

-

Do not over reduce.

CAUTION

The performance of the turbine sprayer will vary

with the viscosity of the material. Unnecessary hose

length will cause the air pressure to drop.

Paint Reduction – Automotive Type Finishes

Reduce and catalyze all paint to manufacturer’s speci

fications. T

turbine systems, use a reducer one-step slower than

what is used for conventional air spray

Paint Reduction – Industrial or Domestic Coatings

Reduce and catalyze all paint to manufacturer’s speci

fications. If no reductions are given, first thoroughly

mix the fluid to be sprayed. Then gradually mix in the

proper reducer

correct spraying consistency

o compensate for the faster drying time of

.

, testing the fluid until you have the

.

-

-

T

o test the consistency:

thinned paint. When the paint stream running of

stir stick breaks into droplets, the first few drops should

be about one second apart.

Remove the stir stick from the

f the

Page 9

Fill the Cup or Remote Pressure Pot

Spray Gun Cup

WARNING

Setup

b.

2 Quart Remote Pot:

relief knob (1

pressure is completely relieved before remov

ing the cover

system again. See Fig. 3.

13) about one turn. W

. Close the knob before using the

T

urn out the pressure

ait until

-

The spray gun cup is pressurized by the gun’

supply. T

pressurized fluid or accidental spray from the gun,

always turn of

removing the spray gun cup.

Only fill the cup 3/4 full to help keep the air pressure

tube clean, then install the cover

has a latch (H) to secure it to the cup. The over-cup

has a ring with notches (J) that secures the cup hood

into place when locked in place on the cup.

H

Fig. 2

Accessory Remote Pressure Pot

o reduce the risk of serious injury from

f the air supply to the gun before

. The under-cup cover

s air

WARNING

The accessory remote pressure pots remain pres

surized until pressure is manually relieved. T

reduce the risk of serious injury from pressurized

fluid or accidental spray from the gun, always

relieve pressure in the pressure pot before loosen

ing or removing the cover

1.

Relieve the remote pressure pot pressure by

following these steps:

a. T

urn of

f the air supply to the pressure pot.

.

-

o

J

-

113

2 quart

Fig. 3

2. Remove

sure pot. Secure the cover

NOTE:

the cover threads with petroleum jelly

the pressure pot cover and fill the pres

.

2 quart remote pressure pot only:

.

lightly coat

CAUTION

If the 2 quart remote pressure pot is accidentally

tipped over or held at too great of an angle, fluid may

leak into the air regulator

this. If fluid does get into the regulator

immediately.

. T

ake precautions to avoid

, clean it

CAUTION

Do not tighten the pressure pot cover more than

hand-tight. Excessive tightening may damage the

cover gasket.

-

Page 10

Prepare the Surface to be Sprayed

To

achieve proper adhesion, make sure the surface to

be sprayed is completely clean.

Operating the Turbine

WARNING

Sparking

of the turbine motor

from flammable liquid, dust particles and other

flammable substances in the spray area, and

cause serious injury and property damage. Be sure

to follow the precautions below:

D

D

D

D A

can be expected in the normal operation

. Sparks could ignite fumes

When flammable liquid is sprayed or used for

flushing or cleaning equipment, the turbine must

be placed at least 20 feet (6.1 m) away from

areas where hazardous concentrations of

flammable vapors are likely to occur

Use additional air hose if necessary to ensure

that the turbine is operated in a clean, dry

ventilated area.

Never place the turbine inside a spray booth!

Use this equipment outdoors or in extremely

well ventilated areas.

void all ignition sources such as static electric

ity from plastic drop cloths, open flames such as

pilot lights, hot objects such as cigarettes, arcs

from connecting or disconnecting power cords

or turning light switches on and of

or remove all sources of ignition.

.

, well

f. Extinguish

Setup

1. T

NOTE:

period of time, turn it of

automatically.

2.

NOTE: To adjust the spray gun pattern, see the

turbine gun manual 308–336.

Series 800 Cold W

T

urbine Spray Model Series 800 has a diaphragm

compressor

diaphragm will become stiff in cold weather

enough, the stif

sor to start (the unit will hum). If this occurs, follow

these steps:

1. T

2.

3.

-

4.

5.

6.

urn the turbine on a few minutes before you start

spraying to allow for warm-up time.

When the turbine is not in use for an extended

f. The turbine does not shut of

Be sure the turbine filter is clean before operating.

See page 12 to check and clean the filter

eather Operation

. When this compressors is new

f diaphragm will not allow the compres

urn the turbine and compressor of

Unplug the turbine from the power source.

Loosen the four main filter screws and remove the

filter; replace the main filter and pre-filter if they

are dirty

Hand spin the cooling fan on the compressor for a

few revolutions.

Reassemble the turbine.

Plug in the turbine and turn compressor on. The

compressor should start.

.

.

, the

. If cold

f.

f

-

10 308-422

Page 11

Shutdown

Pressure Relief Procedure

WARNING

PRESSURIZED

The equipment stays pressurized until pressure is

manually relieved. To reduce the risk of a serious

injury from pressurized fluid, accidental spray from

the gun, or splashing fluid, follow the

lief Procedure

D

are instructed to relieve the pressure,

D

stop spraying,

D

check or service any of the system equipment,

D

or install or clean the fluid nozzles.

1.

When spraying is finished, release the gun trigger

and turn of

2. T

urn of

f the turbine sprayer

EQUIPMENT HAZARD

Pressure Re

whenever you:

f the air supply to the gun.

.

b.

2 Quart Remote Pot:

relief knob (1

pressure is completely relieved before remov

ing the cover

system again.

See Fig. 4.

-

13) about one turn. W

. Close the knob before using the

113

T

urn out the pressure

2 quart

ait until

-

WARNING

The turbine hose outlet may be hot. Carefully

check the hose end before removing the hose.

3.

If using a remote pressure pot,

by following these steps:

a. T

urn of

f the air supply to the pressure pot.

relieve its pressure

Fig. 4

NOTE: Elevate the spray gun and pull the trigger

will allow the fluid in the fluid hose to drain back into

the remote pressure pot.

4.

Clean the spray gun and cup as instructed in the

turbine gun manual, 308–336.

. This

308-42211

Page 12

Maintenance

Daily

Check

the main turbine filter daily for cleanliness.

The turbine systems are lifetime lubricated. The only

maintenance required is filter cleaning and replace

ment.

The turbine main filter and pre-filter must be clean at

all times to provide suf

and atomize the fluid. Check the filters weekly

mum. Replace the pre-filter as required.

ficient air flow to cool the motor

-

, mini

CAUTION

Do not operate the turbine sprayer without the filter

installed.

-

NOTE: To check the filter

place a piece of paper against the air intake filter

air intake holds the paper in place, the filter is okay

T

o clean the main filter:

1. T

urn of

f and unplug the turbine.

2.

Loosen the four main filter screws. See Fig. 5.

3.

Remove the main filter and clean it by following

one of the following three methods:

D T

ap the filter gently on a flat surface, dirty side

down.

D

Direct compressed air (100 psi [7 bar] maxi

mum) through the filter panel in the opposite

direction of the arrows on the side of the filter

D

Soak the filter for 15 minutes in water and a

mild detergent. Rinse the filter until it is clean.

Air dry the filter; do not use compressed air

, turn on the turbine and

. If the

WARNING

T

o avoid damage to the turbine and possible elec

tric shock, never install a damp filter in the turbine.

.

Main

filter

screws

03072

Fig. 5

Series 800 T

urbine shown

Weekly

-

.

Check the hose for cracks, leaks, and holes. Replace,

if necessary

.

Annually or 600 Hours (whichever comes

first)

.

-

Replace

sprayer operation. If the brushes are not replaced,

motor failure will occur

NOTE:

center perform the motor brush replacement. See the

procedure on page 16.

the motor brushes 600 hours after turbine

.

It is recommended that an authorized service

12 308-422

Page 13

Troubleshooting

PROBLEM CAUSE SOLUTION

Remote Container Pressurization

(Series

to

800) Compressor fails

start

No

fluid delivery

Cold weather operation.

. Check for leaks at the container gasket,

2

quart lid, and 2 1/2 gal pot wing nuts.

Check for air flow from male quick–disconnect at compressor outlet (approx.

1/4 CFM).

Turn

pressure regulator clockwise. Look

for

pressure on gauge. (If no pressure on

gauge,

Check

needle

Check

Check if fluid pickup tube is unplugged.

Tighten.

Blow

Check container for material.

See Cold W eather Operation instructions,

check air line and fittings).

hole in tank lid under regulator or

valve 2 Qt lid. Clean if necessary

for obstructions.

out and clear material hose.

page 10.

.

T

urbine fails to start

Poor atomization

Red Rocker Circuit Breaker

Switch Trips

Power supply

Dirty filter

Extension cord too long.

Hose length too long.

Check filter

Excessive high ambient temperature.

Excessive brush wear

Excessive current draw

.

.

.

.

.

Cycle red rocker switch.

Clean filter

Replace with shorter extension cord (do

not exceed 100 ft). Extension cord must

3-wire, 12 A

be

Replace with shorter hose. See Accessories

Clean filter and replace as necessary

Move turbine to cooler area.

Remove turbine wrapper and:

. Check for free motor rotation,

. Check brush wear

. Replace motor brushes if necessary

Return to authorized service center

.

WG.

for shorter hose and P/N.

.

,

.

.

308-42213

Page 14

WARNING

Turn

of

f turbine and unplug power for the following

procedures.

T

urbine Switch Replacement (Red Rocker Circuit

Breaker)

o remove the turbine switch (3), wedge a large

1. T

flat blade screwdriver between the top of the

switch and the turbine face plate. See Fig. 6.

2.

Push down firmly on the switch. Pry the switch out

far enough so the two top switch locking tabs are

visible.

While maintaining outward pressure on the switch,

3.

push down on the two locking tabs with a small flat

blade screwdriver until they release. The switch

will pop out.

4.

Disconnect the two wires and remove the switch.

5.

Reinstall by connecting wires to the new switch.

Snap the switch into place.

Repair

6.

7.

rapper Removal

W

Remove the cabinet wrapper by following these steps.

1.

2.

3.

4.

5.

NOTE:

Reinstall the hose on the “out” side of the com

pressor.

Replace the main filter

Remove the four filter screws. Remove the main

filter

. Clean and replace the filter if necessary

Remove the four remaining top wrapper screws.

Do not remove handle screws.

Remove one screw from each side of the wrap

per.

Remove the four remaining bottom wrapper

screws. Do not remove the rubber feet.

Gently pry loose and remove the wrapper from the

cabinet.

The wrapper is sealed with caulk.

.

-

.

-

Locking Tabs

3

Fig. 6

Series 800 Compressor Replacement

1.

Remove the four main filter stop screws and

remove the main filter

necessary).

Remove the air hose from the “out” side of the

2.

compressor.

Locate and remove the three compressor hold–

3.

down screws.

4.

Remove the ground screw

remove the compressor

Rewire and install the new compressor

5.

removable LoctiteR on the compressor screws and

tighten the screws. Do not overtighten the rubber

bumpers.

14 308-422

. (Clean or replace filter as

. Clip the lead wires and

.

. Apply

03728

Filter

Screws

Wrapper

Screws

Side

Fig. 7

Power Cord Replacement

Remove the cabinet wrapper by following the

Removal

The power cord may now be replaced.

Series 800 Compressor T

ment

Remove the cabinet wrapper by following the

Removal

The compressor toggle switch (Series 800) may now

be replaced.

procedure.

procedure.

Series 900 shown

oggle Switch Replace

Screws

03067

Wrapper

-

Wrapper

Page 15

Repair

Turbine/Motor

The Series 700 and 800 turbine replacement kit

M73525 contains: T

spacer (16), foam fan seal (83), ground ring terminal

(7) red butt connector (not shown, used on series 800

only) and 2 switch connectors (8)

The Series 900 turbine replacement kit M73526 con

tains: T

foam fan seal (83), ground ring terminal (7) and 2

switch connectors (8)

Remove the cabinet wrapper by following the steps in

the W

list exploded view for disassembly

Note:

1.

2.

3.

urbine unit (62), rubber bottom spacer (16),

rapper Removal procedure. Reference the parts

the wrapper is sealed with caulk.

The motor may now be replaced.

Remove the upper motor mount (42) by removing

the five screws that retain it.

Remove the ground wire (green) and switch wires

(black & white).

Replacement

urbine unit (62), rubber bottom

-

.

Be sure to install the ground wire to the grounding

7.

stud on the lower motor mount.

8.

Replace the upper motor mount and the five

screws that retain it.

9.

Install the new fan seal gasket (83) on the top of

the upper motor mount

10.

Replace the wrapper and filter system.

Motor

Black

61

60

Green

White

8

White

7

8

9

Green

Black

Rocker

Switch

Power

Cord

Note:

Series 800 only

approximately 2 in. from the three wire crimp connec

tor.

4.

Install (crimp) the female switch connectors or red

butt connectors on the new turbine as shown in the

appropriate wiring diagram. The round ring con

nector always goes on the green wire.

Note:

On Series 800 only

(attached to the three wire crimp connector) back

approximately 3/8 in. and install the red butt connector

5.

Remove the old motor from the lower mount by

removing the three bolts (54). The nuts are at

tached to the lower mount, a holding wrench is not

required.

6.

Reinstall the new turbine (62) and pad (16).

Note:

Application of removable Loctiter is recom

mended on the threads of the three bolts (54).

Note:

Do not over tighten the three bolts (54) securing

the turbine to the lower motor mount, damage to the

turbine may occur

, clip the neutral lead (white)

-

-

, strip the white neutral wire

-

-

.

Series 700 shown

Fig. 8

Compressor

Motor

22

61

60

8

.

6

White

Black

Green

Fig. 9

Green

White

79

12

Series 800 shown

White

Rocker

Switch

Black

Green

Black

Black

Power

Cord

T

Switch

78

8

78

Black

oggle

03733A

308-42215

Page 16

Motor

Black

Repair

Motor Brush Replacement

NOTE:

performed by an authorized service center

1.

It is recommended that this procedure be

.

Follow the steps for removing the motor in the

Motor Replacement procedure.

Green

White

White

Fig.

10

2.

On the Series 700 and 800 turbine motor

the two retaining clips and plastic fan cover

Rocker

Switch

7

8

9

Series 900 shown

Green

Black

8

Power

Cord

03735A

On the Series 900 turbine motor

3.

clips out of the top of the motor for brush replace

ment.

4.

Remove the brushes. Check the commutator for

excessive wear

5.

Reassemble the new motor brushes using reverse

order

. Keep lead wires from all rotating parts and

the motor frame.

.

, lift the retaining

CAUTION

Do not run the motor with the air inlet or outlet

sealed of

6.

7.

f.

Reinstall the motor in the reverse order

After running the motor for 30–45 minutes at

full–rated voltage, the motor will return to full

performance.

, remove

.

-

.

16 308-422

Page 17

Notes

308-42217

Page 18

Parts

for Series 700

35

34

33

26

93

39

38

37

20

43

36

60

62

42

8

21,

51

7

28

29

31

30

83

50

8

54

53

45

27

26

3

16

6

5

9

7

4

84

93

10

59

17

88

85

24

25

94

86

04959A

18 308-422

Page 19

Parts

Ref

No.

3 M70657

4 M70601

5 106013

6 107260 CONNECT

7 102799

8 M70760

9 107266 CONNECT

10 M73044 PLA

16 M73323 P

17 M70773 W

20 M73043 WRAPPER 1

21 M73024

24 M70763 BUMPER 4

25 M70775 SCREW

26 M70774 SCREW

27 M73048 PLA

28 M70859 FIL

29 M70757 FIL

30 M71558 FIL

31 M70607 FIL

33 M71628

34 M70872 NUT

35 M70874 W

36 M71246 O-RING 1

37 M71262

Part No.

Description Qty

SWITCH, rocker 12A

CORD, power

FITTING, strain relief

OR, female

TERMINAL, ground ring

SWITCH, connector

OR, male

TE, face

AD, turbine mount

ASHER, 1/4

DECAL, RH

, 8–32x5/8

, black oxide, 8–32x1/2

TE, bottom

TER, stop

TER, foam stop

TER KIT

TER, pre

FOAM, die cut

, cabinet handle

ASHER, 3/16x1

FITTING, air outlet

, main

, female

for Series 700

20

Ref

No.

38 M70870

1

39 M70873 SCREW

1

42 M73009 MOUNT

1

43 M70776 NUT

1

45 M73019 SP

1

50 113400 SCREW 3

2

51 M73025

1

53 M70764 O-

1

RING 3

1

54 M73021 BOLT

6

59 M71012 MOUNT

60 M73503

1

61 M71185 SCREW

62 M73525* MOT

4

82 186620

83 M73362 GASKET

1

84 M71452

1

85 M71681** VAL

4

86 M70402 DISCONNECT

1

88 M70721

1

93 M71603

2

94

2

2

*

gaskets, and electrical connectors. Motor Brush Kit M73521

1

is also available. Purchase separately

** V

Part No.

Motor Kit M73525 includes: motor

alve Kit M71681 includes air valve and o–ring.

Description Qty

HANDLE,

, cabinet handle

, turbine upper

, hex

ACER, 2.9

DECAL, LH (not shown)

, 1/4–20x4.00

, turbine lower

WIRE, green/yellow

, self–tapping

OR KIT

LABEL, ground (not shown)

HOSE, turbine, 25 ft

VE, turbine air

O-RING, hose

LABEL, Danger/W

GUN, T

Manual, 308–336

, Series 700, 120V

, fan seal

, quick

arning 1

urbine, see Gun Instruction

, ground wire connectors,

.

1

2

1

2

3

1

3

1

1

1

1

1

1

1

1

1

1

1

61

60

Green

White

White

8

9

Motor

7

Green

Black

Black

Rocker

Switch

8

6

Power

Cord

03732A

308-42219

Page 20

Parts

for Series 800

35

34

33

93

26

89

31

24

25

32

27

26

M70962

(see

page 24)

38

39

30

29

42

21,

51

20

37

58

2

1

3

89

1

61

60

62

6

36

43

16

28

83

50

54

53

45

59

17

8

5

7

4

84

52

10

92

85

95

96

04960A

Page 21

Parts for Series 800

Ref

No.

1 M70603

2 M70811

3 M70657

4 M70601

5 106013

6 M70759 CONNECT

7 102799

8 M70760

10 M73045 PLA

12 M71143

16 M73323 P

17 M70773 W

20 M73043 WRAPPER 1

21 M73026

24 M70763 BUMPER 4

25 M70775 SCREW

26 M70774 SCREW

27 M73285 PLA

28 M70859 FIL

29 M70757 FIL

30 M71558 FIL

31 M70607 FIL

32 M71535 {

33 M71628

34 M70872 NUT

35 M70874 W

36 M71246 O-RING 1

37 M71262

38 M70870

39 M70873 SCREW

42 M73009 MOUNT, motor

43 M70776 NUT

Part No.

Description Qty

SWITCH, toggle

SWITCH, plate

SWITCH, rocker 12 amp

CORD, power

FITTING, strain relief

OR, red butt

TERMINAL, ground ring

SWITCH, connector

TE, face

HARNESS, 14 in wire

AD, turbine mount

ASHER, 1/4

DECAL, RH

, 8–32x5/8

, black oxide 8–32x1/2

20

TE, bottom

TER, stop

TER, foam stop

TER KIT

, main

TER, pre

COMPRESSOR KIT

,

Series 800, 120V

FOAM, die cut

, cabinet handle

ASHER, 3/16x1

FITTING, air outllet

HANDLE,

, cabinet handle

, upper

, hex

Ref

No.

1

45 M73019 SP

1

50 113400 SCREW 3

1

51 M73027

1

52 M71136 WASHER 3

1

53 M70764 O-RING 3

1

54 M73021 BOLT

1

58 M70673

2

60 M73503

1

61 M71185 SCREW

1

62 M73525 *MOT

1

78 M71187

6

79 M70810 CONNECT

82 186620

1

83 M73362 GASKET

84 M71452

4

85 M70721

89 M70691

1

92 M70402 DISCONNECT

1

93 M71603

4

95 M71631

1

1

96

1

2

*

2

gaskets, and electrical connectors. Motor Brush Kit M73521

2

is also available. Purchase separately

1

** Unloader Kit M70691 includes unloader valve, hose, hose

1

clamps and fitting M70809.

Part No.

Description Qty

ACER, 2.9 in.

DECAL, LH (not shown)

, 1/4–20x4.00

COUPLING, parker #207P–4

WIRE, green/yellow

, self–tapping

OR KIT

WIRE, black

OR, crimped

LABEL, ground (not shown)

, fan seal

HOSE, turbine, 25 ft

O-RING, hose

**UNLOADER KIT

LABEL, warning/danger

HOSE, compressed air

disconnect, 25 ft

GUN, turbine, see Gun Instruction

Manual, 308–336

Motor Kit M73525 includes: motor

, Series 800, 120V

, quick

, ground wire connectors,

.

2

1

{

Compressor Kit, M71535, includes compressor

3

wire, and electrical connectors.

3

1

3

1

1

1

1

2

2

1

1

1

1

1

1

1

, with quick

1

1

, ground

Compressor

Green

8

White

Black

12

61

60

Green

White

79

Motor

White

Green

Black

Black

Rocker

Switch

Black

Black

Power

Cord

Toggle

Switch

78

8

78

03733A

308-42221

Page 22

Parts

for Series 900

35

34

33

26

93

39

38

20

82

62

36

37

31

30

29

28

21,

51

8

7

8

42

50

54

17

53

45

17

83

27

44

43

26

3

16

59

6

5

7

9

4

84

10

85

87

86

24

25

94

04961A

Page 23

Parts

Ref

No.

3 M70657

4 M70601

5 106013

6 107260 CONNECT

7 102799

8 M70760

9 107266 CONNECT

10 M73046 PLA

13 M71179

16 M73039 P

17 M70773 W

20 M73043 WRAPPER 1

21 M73028

24 M70763 BUMPER 4

25 M70775 SCREW

26 M70774 SCREW

27 M73048 PLA

28 M70859 FIL

29 M70757

30 M71558 FIL

31 M70607 FIL

33 M71628

34 M70872 NUT

Part No.

Description Qty

SWITCH, rocker 12 amp

CORD, power

FITTING, strain relief

OR, female

TERMINAL RING, ground

SWITCH, connector

OR, male

TE, face

WIRE, tie (not shown)

AD, turbine mount

ASHER, 1/4

DECAL, R.H.

, 8–32x5/8

, black oxide, 8–32x1/2

TE, bottom

TER, stop

FOAM, filter stop

TER KIT

TER, pre

FOAM, die cut

, cabinet handle

, main

for Series 900

16

Ref

No.

35 M70874 W

1

36 M71246 O-RING 1

1

37 M71262

1

38 M70870 HANDLE 1

1

39 M70873 SCREW

2

42 M73011 MOUNT, motor

2

43 M70776 NUT

1

44 M70789 SCREW

1

45 M73020 SP

1

50 113400 SCREW 3

1

51 M73029

6

53 M70764 O-RING 3

54 M70770 BOLT

1

59 M73010 MOUNT, motor

62 M73526* MOT

4

82 186620

83 M73037 GASKET

1

84 M71452

1

85 M71681** VAL

4

86 M70402 DISCONNECT

1

87 M70721

1

93 M71603

2

94

2

Part No.

Description Qty

ASHER, 3/16x1

FITTING, air outlet

, cabinet handle

, upper

, hex

, 1/4 x 20 x 3/4

ACER, 2.6

DECAL, LH

, 1/4–20x3.5

, lower

OR KIT

LABEL, ground (not shown)

, fan seal

HOSE, 25 ft

VE, turbine air

, quick

O-RING, hose

LABEL, warning/danger

Gun, turbine, see Gun Instruction

Manual, 308–336

2

1

2

1

3

4

3

1

3

1

1

1

1

1

1

1

1

1

Green

White

White

*

Motor Kit M73526 includes: motor

gaskets, and electrical connectors. Motor Brush Kit M73522

is also available. Purchase separately

alve Kit M71681 includes air valve and o-ring.

** V

Motor

Black

Rocker

8

7

8

9

Green

Black

6

Switch

Power

Cord

, ground wire connectors,

.

03735A

Page 24

Accessories

2-1/2

Gallon (9.46 liter) Pressure Pot M70604

(Series 800 only)

50 psi (3.5 bar) Maximum Inlet Air Pressure

2-1/2 gallon (9.46 liter) capacity

an air pressure regulator and gauge and a pressure

relief valve.

201

216

217

202

212

204

205

NOTE:

2 1/2 Gal

(9.46 liter) Paint

T

ank Liner (5

pak) M70695

, steel tank. Includes

221

208

209

203

207

212

2

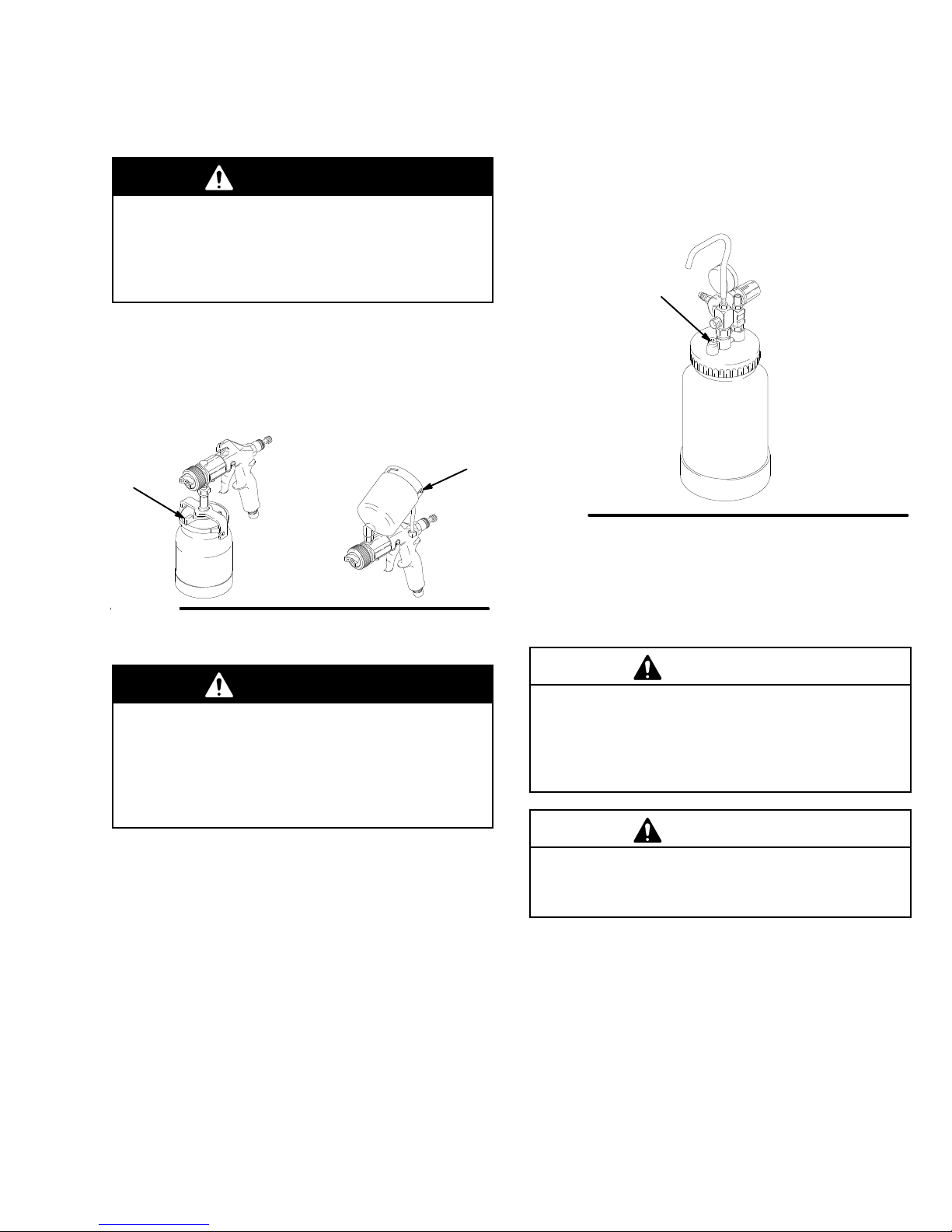

Quart (1.94 liter) Pressure Pot M70962

(Series 800 only)

50 psi (3.5 bar) Maximum Inlet Air Pressure

2 quart (1.94 liter) capacity

, aluminum cup.

Includes an air pressure regulator and gauge, pressure

relief valve, and rigid hook handle.

WARNING

Do not use 1,1,1-trichloroethane, methylene chlo

ride, other halogenated hydrocarbon solvents or

fluids containing such solvents in the turbine spray

system, which contains aluminum and/or galva

nized-coated parts. Such use could result in a

serious chemical reaction, with the possibility of

explosion, which could cause death, serious injury

and/or substantial property damage.

*109

118

101

121

124

120

119

114

-

-

,

103

102

123

122

128

Ref.

No. Part No. Description Qty.

201 104655 PRESSURE GAUGE 1

202 151519

203 M70687 COUPLING 1

204 M70676 O-RING 1

205 M70686 PRESSURE RELIEF VALVE 1

207 M70616 GASKET

M70617 GASKET

208 M70678 WING NUT 5

209 M70677 WASHER 5

212 M71433 T

216 169969 QUICK DISCONNECT

217 104815 PRESSURE REGULATOR 1

221 M71639 HANDLE 1

REDUCER, 1/4 to 1/8

, standard; EPDM

, solvent resistant; Thiokol

(optional–must order separately)

ANK, paint, 2-1/2 gallon (9.5 liter),

with cover

, black powder coat

, male

04957

109

112

126

127

Ref.

No. Part No. Description Qty.

101 104655 PRESSURE GAUGE 1

1

102 M70727 SAFETY VALVE 1

103 104815 PRESSURE REGULATOR 1

109 M71144 POT

112 M71425 GASKET KIT

1

114 M70725 FITTING 1

118 169969 QUICK DISCONNECT

1

119 M71491

120 M71470

121 M70854 HOSE CLAMP 1

122 110440

1

123 189557 RESTRICTOR 1

1

124 M70399 QUICK DISCONNECT

126 M71681 AIR VAL

127 M70402 QUICK DISCONNECT 1

128 M72842 FITTING, air pressure stem 1

*NOTE: Handle is shipped loose, inside the 2 qt container

, 2 quart (1.94 liter), aluminum

, polyethylene (5 pak)

, male

HOSE, fluid; 60 in. long; 1/4 in. ID

HOSE, air; 54 in. (1.37 m) long

FITTING. tee

, male

VE KIT (o–ring and valve)

02951A

1

1

1

1

1

1

1

1

.

Page 25

Accessories

NOTE: See selection charts in the gun turbine manual,

308–336, to order fluid sets.

Lubricant 111–265

One 4 oz. (1

lubricant for fluid seals and wear areas.

#4 Ford V

Used to measure viscosity of fluid.

1 Quart Cup Lid M70610

Fits on 1 qt under–cup for air tight storage of fluid.

1 Quart Cup M71667

1 quart under-cup.

1 Quart Cup Gaskets M70425

5 pack of polyethylene gaskets for use with 1 quart

under-cup.

1 Quart Under-Cup Assembly M71660

Complete 1 quart under-cup assembly

13 gram) tube sanitary (non-silicone)

iscosity Cup M70702

.

Automotive User Kit M70705

For use with automotive finishes. Includes:

Part No.

M70559

M70647

M70425

M70464

M70395

–

T

rail Around Dolly M70700

Lightweight and mobile platform with wheels; for use

with Series 700, Series 800, and Series 900.

45 Degree Elbow M70593

Attaches between gun and turbine air hose; increases

maneuverability.

Y Fitting Kit M70611

Creates two air connections; allows for two–gun

operation.

Series 800 1/4 in. ID Compressor Air Hose (with

Female Quick Disconnect)

PVC, Maximum W

Part No.

M70665

M71631

Description

1.0/0.05 mm Fluid Set

1.2/0.7 mm Fluid Set

1 Quart Under-cup Gaskets (5-pack)

Fluid Strainer

Upper Air Pressure Hose

Parts Box with Compartments

orking Pressure: 150 psi (10.3 bar)

Length

20 ft

25 ft

(Extension)

(Replacement)

Cup Check V

T

o help prevent the cup from depressurizing after the

air is shut of

Fluid Strainer M70464

Install on the end of the cup or pressure pot fluid tube

to strain the fluid and help eliminate surface blemishes

and plugged tips. 100 mesh screen.

Blow Gun M70703

For dusting and drying. With quick disconnect.

Contractor User Kit M70704

Used for fine finish materials and heavier bodied

materials (latex). Includes:

Part No.

M70562

M70582

M70425

M70464

M70395

–

alve M71007

f.

Description

1.0 mm Fluid Set

2.0 mm Fluid Set

1 Quart Under-cup Gaskets (5-pack)

Fluid Strainer

Upper Air Pressure Hose

Parts Box with Compartments

3/8 in. ID Paint Fluid Hose

LDPE, Maximum W

Part No.

M71482

M71481

M71484

M71486

M71485

Material Hose Connector M70693

For use with 3/8 in. paint fluid hose.

3/4 in. ID T

PVC, Maximum W

Part No.

M71452

M71453

M71454

M71455

3/4 in. ID T

Spring

PVC, Maximum W

Part No.

M71460

M71461

M71462

M71463

M71464

urbine Air Hose with Spring

urbine Air Hose Extension without

orking Pressure: 175 psi (12 bar)

Length

15 ft

25 ft

30 ft

40 ft

50 ft

orking Pressure: 100 psi (6.9 bar)

Length

25 ft

30 ft

40 ft

50 ft

orking Pressure: 100 psi (6.9 bar)

Length

10 ft

15 ft

20 ft

25 ft

30 ft

Page 26

Notes

Page 27

Notes

Page 28

The

WARRANTY

Graco

warrants all equipment manufactured by it and bearing its name to be free from defects in material and workmanship on

the date of sale

warranty,

tive.

ommendations.

This warranty does not cover

misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility with Graco

equipment of structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, instal

lation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor

for verification of the claim. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any

defect in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts,

labor and transportation.

DISCLAIMERS AND LIMITATIONS

The terms of this warranty constitute purchaser’s sole and exclusive remedy and are in lieu of any other warranties (express or

implied),

liabilities, including product liabilities, based on negligence or strict liability

tial damages or loss is expressly excluded and denied. In no case shall Graco’

Any action for breach of warranty must be brought within two (2) years of the date of sale.

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment proven defec

This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’

including warranty of merchantability or warranty of fitness for a particular purpose

Graco Warranty and Disclaimers

by an authorized Graco distributor to the original purchaser for use. As purchaser’s sole remedy for breach of this

s written rec-

, and Graco shall not be liable for

, any malfunction, damage or wear caused by faulty installation,

, and of any non–contractual

. Every form of liability for direct, special or consequen

s liability exceed the amount of the purchase price.

-

-

-

EQUIPMENT NOT COVERED BY GRACO WARRANTY

Graco makes no warranty

respect to accessories, equipment, materials, or components sold but not manufactured by Graco. These items sold, but not

manufactured by Graco (such as electric motor

Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

TO

PLACE AN ORDER

1–800–328–0211 T

, and disclaims all implied

, switches, hose, etc.) are subject to the warranty

Graco

, contact your Graco distributor

oll Free

warranties of merchantability and fitness for a particular purpose

, if any

, of their manufacturer

Phone Number

, or call this number to identify the distributor closest to you:

, with

.

Sales

Foreign Offices:

Belgium, Canada, England, Korea, Switzerland, France, Germany

Offices:

GRACO INC. P.O. BOX 1441

PRINTED

IN U.S.A. 308–422 June 1994 Revised January 1996

Atlanta, Chicago, Detroit, Los Angeles

MINNEAPOLIS, MN

, Hong Kong, Japan

55440–1441

Loading...

Loading...