Page 1

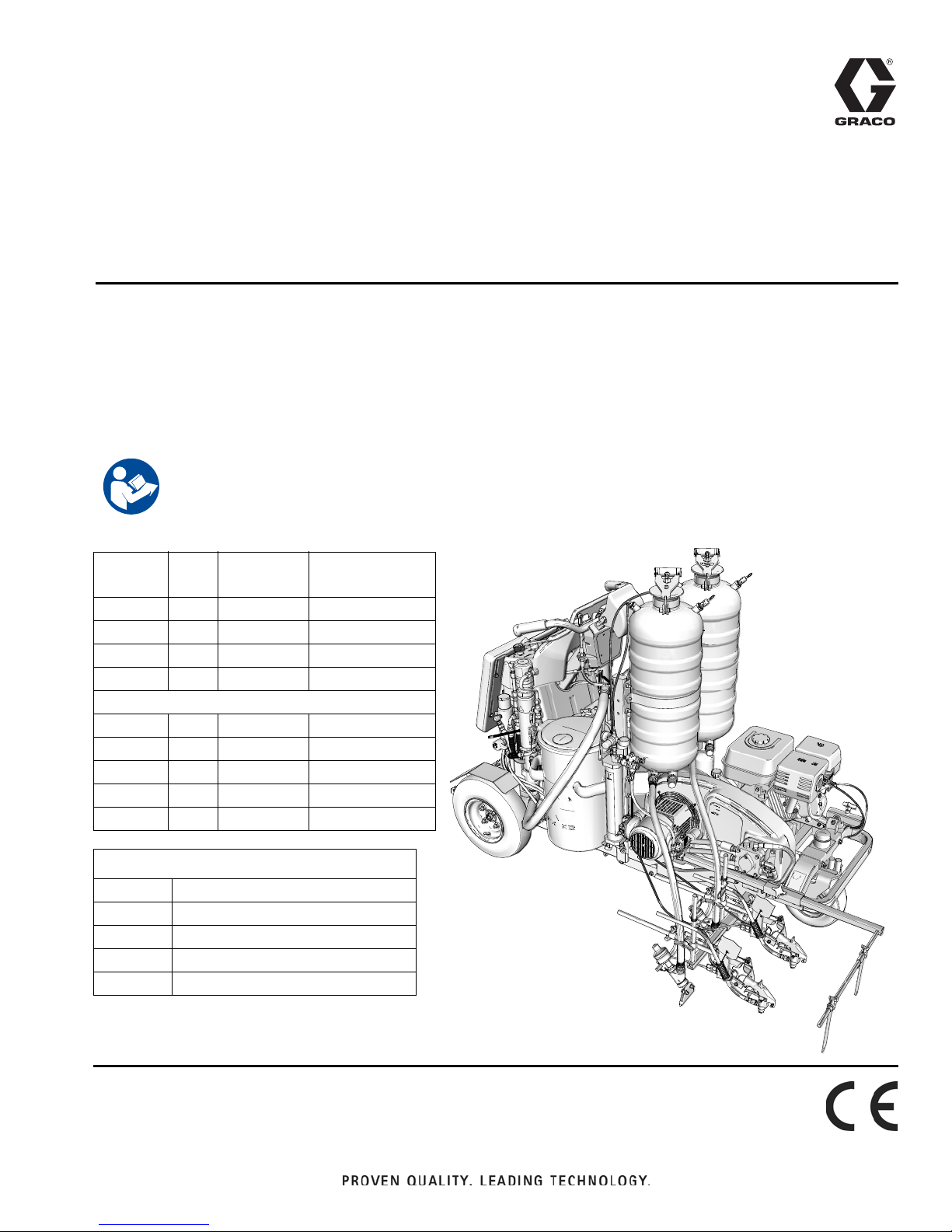

Operation

LineLazer V 250SPS and 250DC

Self-Propelled Line Striper

For the application of line striping materials.

For professional use only.

For outdoor use only.

Not for use in explosive atmospheres or hazardous locations.

Maximum Operating Speed: 10 mph (16 kph)

Maximum Operating Pressure: 3300 psi (22.8 MPa, 228 bar)

Important Safety Instructions

Read all warnings and instructions in this manual and in related manuals.

Be familiar with the controls and the proper usage of the equipment.

Save these instructions.

Pressurized

Model Guns

17H471 2 No LLV 250DC

17H472 3 No LLV 250DC

17H473 2 Yes - 2 Tank LLV 250DC

17H474 3 Yes - 2 Tank LLV 250DC

Bead System

Description

3A3393C

EN

17H466 1 No LLV 250SPS

17H467 2 No LLV 250SPS

17H468 1 Yes - 1 Tank LLV 250SPS

17J951 2 Yes - 1 Tank LLV 250SPS

17H469 2 Yes - 2 Tank LLV 250SPS

Related Manuals:

3A3394 Repair / Parts

311254 Gun

309277 Pump

3A3428 Auto-Layout Applications Methods

332230 Pressurized Bead System (PBS)

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

Page 2

Table of Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component Identification (LLV 250DC Shown) . . 7

Component Identification (Controls) . . . . . . . . . . . 8

Grounding Procedure

(For Flammable Flushing Fluids Only) . . . . . . 9

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 9

Setup/Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SwitchTip and Guard Assembly . . . . . . . . . . . . 12

Gun Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Install Guns . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Position Guns . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Select Guns (Standard Series) . . . . . . . . . . . . . 13

Gun Positions Chart . . . . . . . . . . . . . . . . . . . . . 14

Gun Arm Mounts . . . . . . . . . . . . . . . . . . . . . . . . 15

Change Gun Position

(Front and Back) . . . . . . . . . . . . . . . . . . . . . 15

Change Gun Position

(Left and Right) . . . . . . . . . . . . . . . . . . . . . . 15

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Gun Cable Adjustment . . . . . . . . . . . . . . . . . . . 16

Change Trigger Position . . . . . . . . . . . . . . . . . . 17

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Driving Instructions . . . . . . . . . . . . . . . . . . . . . . . . 19

Parking/Emergency Brake . . . . . . . . . . . . . . . . . 20

Drive Engagement . . . . . . . . . . . . . . . . . . . . . . . 20

Straight Line Adjustment . . . . . . . . . . . . . . . . . . 20

Handle Bar Height Adjustment . . . . . . . . . . . . . 21

Platform Storage Position . . . . . . . . . . . . . . . . . 21

Front Pad Adjustment . . . . . . . . . . . . . . . . . . . . 21

Smart Control Operation . . . . . . . . . . . . . . . . . . . . 22

Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Control Features . . . . . . . . . . . . . . . . . . . . . . . . 23

Main Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Striping Mode (LLV 250DC Shown) . . . . . . . . . 27

Measure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Layout Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Stall Calculator . . . . . . . . . . . . . . . . . . . . . . . . . 30

Angle Calculator . . . . . . . . . . . . . . . . . . . . . . . . 31

Setup/Information . . . . . . . . . . . . . . . . . . . . . . . 32

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Information (2) . . . . . . . . . . . . . . . . . . . . . . . . . . 34

World Symbol Key . . . . . . . . . . . . . . . . . . . . . . . . . 36

Hydraulic Oil/Filter Change . . . . . . . . . . . . . . . . . . 37

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Technical Specifications . . . . . . . . . . . . . . . . . . . . 38

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 42

2 3A3393C Operation

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard sym-

bols and warnings not covered in this section may appear throughout the body of this manual where applicable.

TRAFFIC HAZARD

Being struck by other vehicles may result in serious injury or death.

• Do not operate in traffic.

• Use appropriate traffic control in all traffic areas.

• Follow local highway and transportation regulations for traffic control (for example: Manual on Uniform Traffic Control Devices, U.S. Department of Transportation).

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or solvent flowing through the equipment can cause static sparking. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable and can

ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths

(potential static arc).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are present.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until you

identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that

injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any

part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while spraying,

follow the Pressure Relief Procedure for turning off the unit and relieving the pressure before removing

the nozzle tip to clean.

• Equipment maintains pressure after power is shut off. Do not leave the equipment energized or under pressure while unattended. Follow the Pressure Relief Procedure when the equipment is unattended or not

in use, and before servicing, cleaning, or removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3300 psi. Use Graco replacement parts or accessories that are rated

a minimum of 3300 psi.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

3A3393C Operation 3

Page 4

Warnings

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon monoxide

can cause death.

• Do not operate in an enclosed area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request Safety Data Sheet (SDS) from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety

hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for

compatibility.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow

the Pressure Relief Procedure and disconnect all power sources.

ENTANGLEMENT HAZARD

Rotating parts can cause serious injury.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pres-

sure Relief Procedure and disconnect all power sources.

4 3A3393C Operation

Page 5

Warnings

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read Safety Data Sheet (SDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited

to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

BATTERY HAZARD

The battery may leak, explode, cause burns, or cause an explosion if mishandled. Contents of an open battery can cause severe irritation and/or chemical burns. If on skin, wash with soap and water. If in eyes, flush

with water for at least 15 minutes and get immediate medical attention.

• Only use the battery type specified for use with the equipment. See Technical Data.

• Replace battery only in well-ventilated area and away from flammable or combustible materials, including

paints and solvents.

• Do not dispose of battery in fire or heat above 50°C (122°F). The battery is capable of exploding.

• Do not throw into fire.

• Do not expose battery to water or rain.

• Do not disassemble, crush, or penetrate the battery.

• Do not use or charge a battery that is cracked or damaged.

• Follow local ordinances and/or regulations for disposal.

CALIFORNIA PROPOSITION 65

The engine exhaust from this product contains a chemical known to the State of California to cause cancer,

birth defects or other reproductive harm.

This product contains a chemical known to the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

3A3393C Operation 5

Page 6

Warnings

Battery Disposal

Do not place batteries in the trash. Recycle batteries according to local regulations. To find a recycling location in the

USA and Canada call 1-800-822-8837 or go to www.call2recycle.org.

i2

6 3A3393C Operation

Page 7

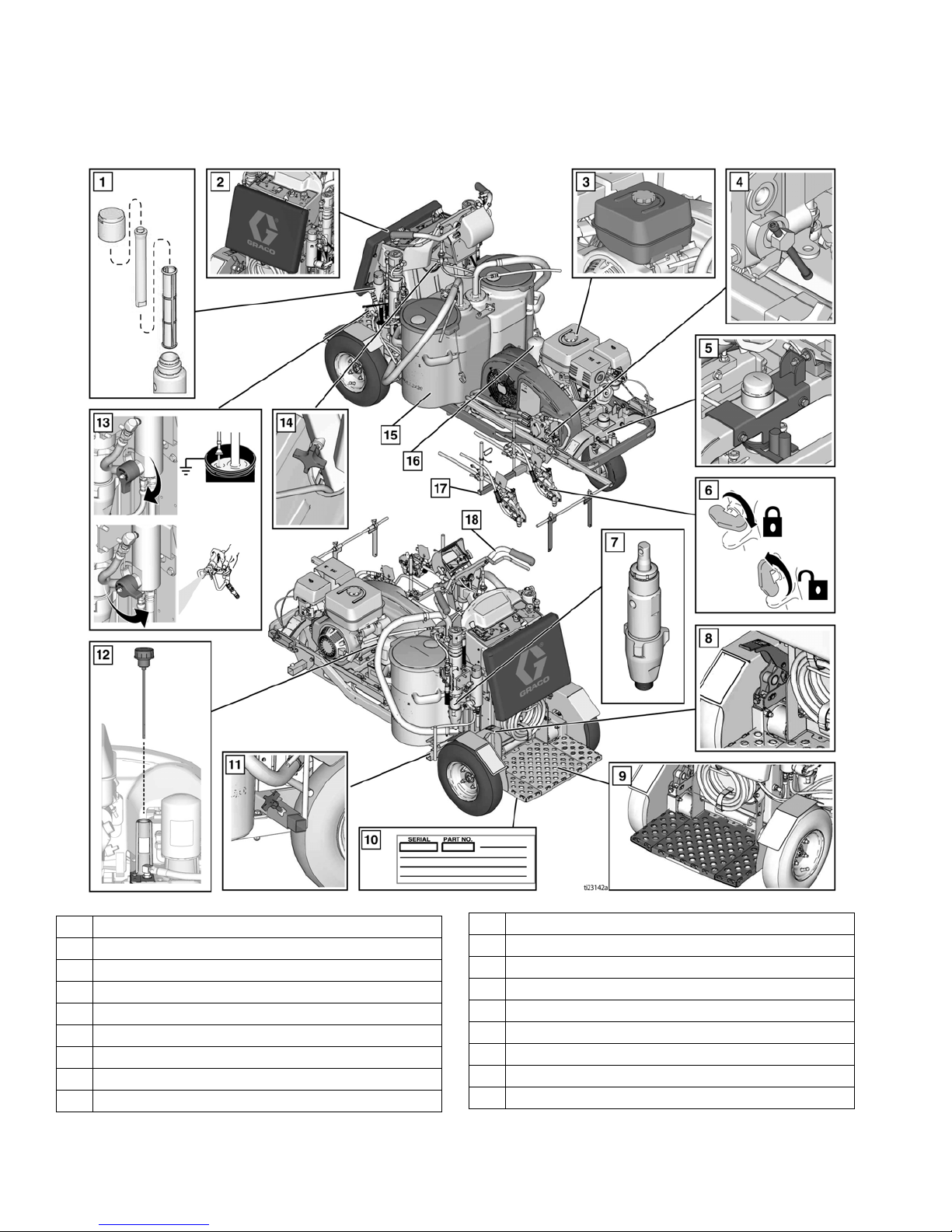

Component Identification (LLV 250DC Shown)

Component Identification (LLV 250DC Shown)

1 Paint filter, both sides

2 Adjustable pad

3 Engine fuel cap

4 Wheel motor bypass valve

5 Straight line adjuster

6 Gun trigger lock

7 Displacement pump, both sides

8 Brake

9 Operator platform

*LLV 250SPS has only 1 paint hopper and 1 pump.

3A3393C Operation 7

10 Serial label under operator platform

11 Rear gun arm mount, both sides

12 Hydraulic fill cap/dipstick

13 Prime/drain valve, both sides

14 Handle bar height adjustment knob

15 Two paint hoppers (15 gallon/56 liter)

16 Hydraulic oil filter

17 Front gun mount, both sides

18 Steering handle

Page 8

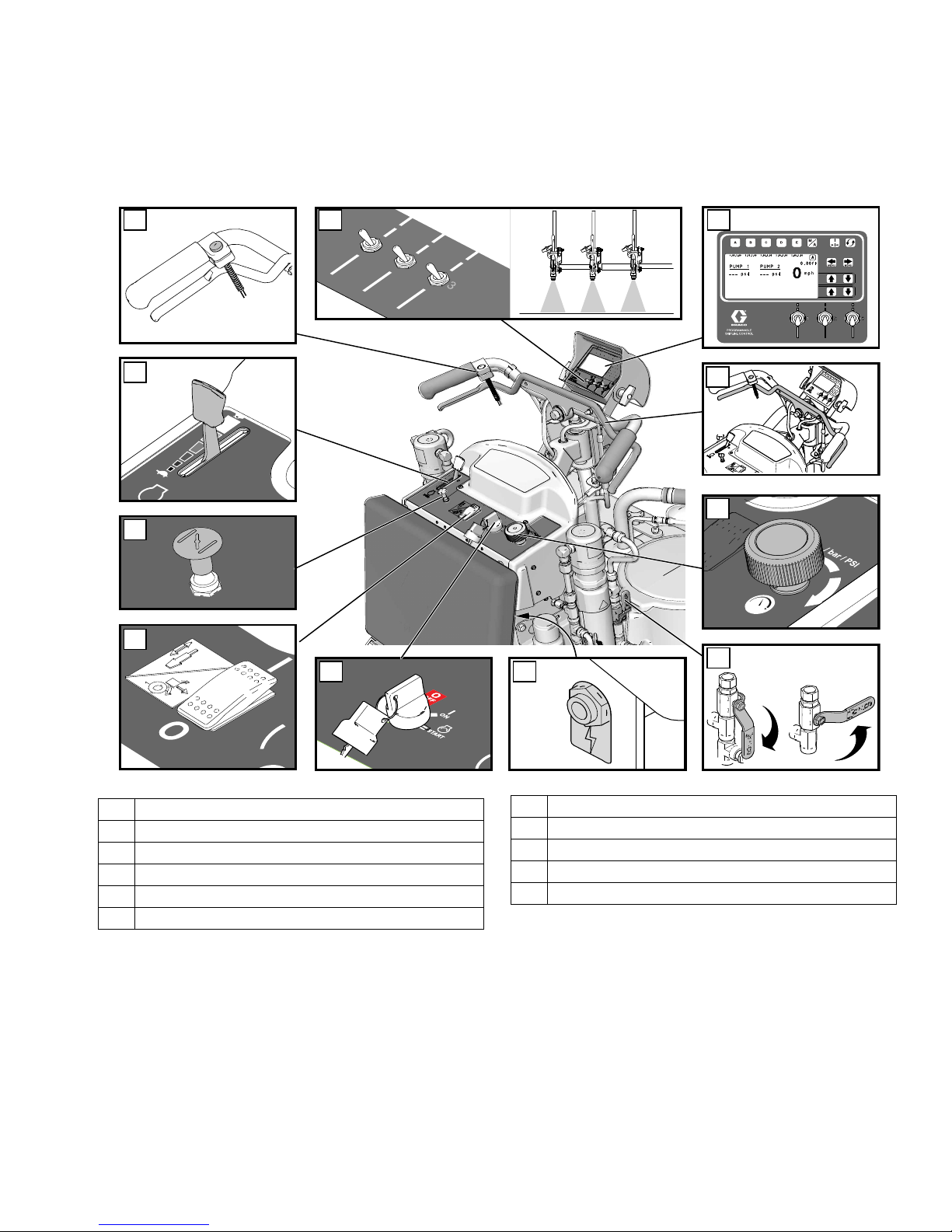

Component Identification (Controls)

3

on

off

ti23143a

1 2 3

4

5

6

78

9

10

11

Component Identification (Controls)

1

2

7 12V accessory jack

8 Engine key switch, OFF - ON - Start

9 Engine clutch switch

10 Engine choke

11 Engine throttle

1 Gun trigger control

2 Gun 1, 2, 3 selector

3 Display

4 Forward/reverse lever

5 Pressure control

6 Hydraulic pump valve, both sides

8 3A3393C Operation

Page 9

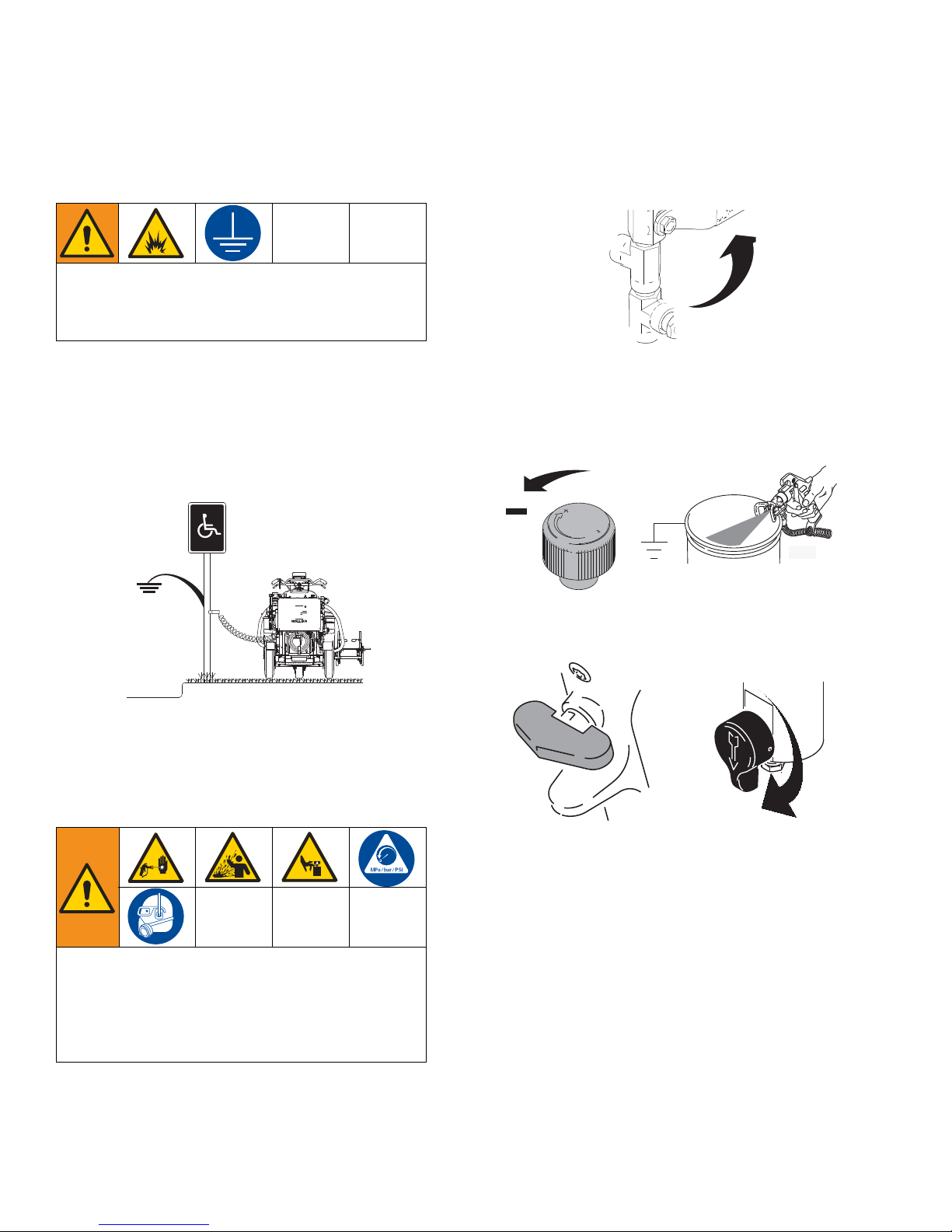

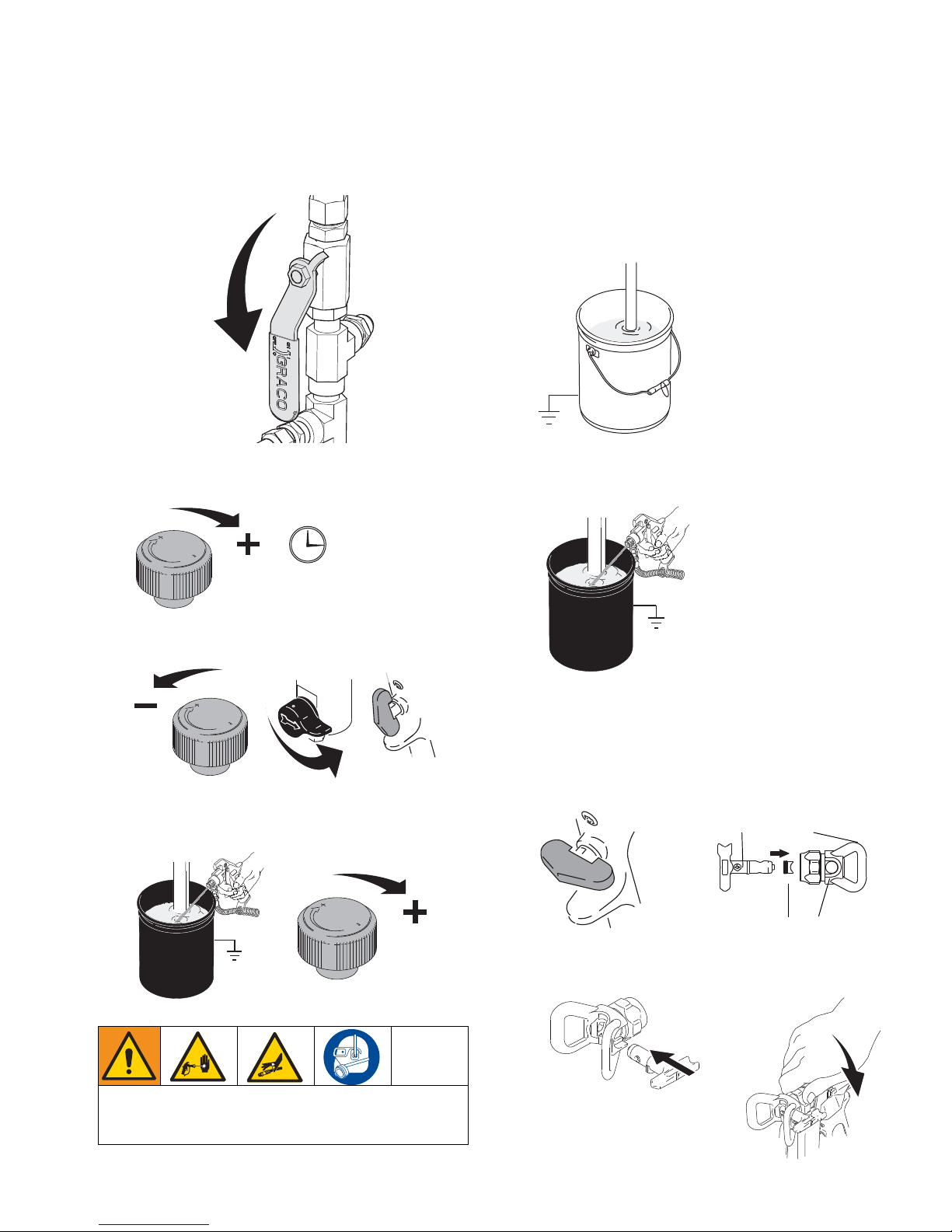

Grounding Procedure (For Flammable Flushing Fluids Only)

ti23146a

ti23

ti3441a

ti6473a

Grounding Procedure

(For Flammable Flushing Fluids

Only)

This equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

1. Position striper so that the tires are not on pavement.

2. Striper is shipped with a grounding clamp. Grounding clamp must attach to grounded object (e.g.

metal sign post).

1. Perform Grounding Procedure if using flammable

materials.

2. Set pump valve(s) to OFF (250

valve; 250

DC has two pump valves). Turn engine

SPS has one pump

OFF.

3. Turn pressure control to lowest setting. Trigger all

guns to relieve pressure.

ti3305a

3. Disconnect grounding clamp after flushing is completed.

Pressure Relief Procedure

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

PAINT

4. Engage all gun trigger locks. Turn prime valve(s)

down (250

SPS has one prime valve; 250DC has two

prime valves).

ti3324a

5. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved:

a. VERY SLOWLY loosen the tip guard retaining

nut or the hose end coupling to relieve pressure

gradually.

b. Loosen the nut or coupling completely.

c. Clear the obstruction in the hose or tip.

3A3393C Operation 9

Page 10

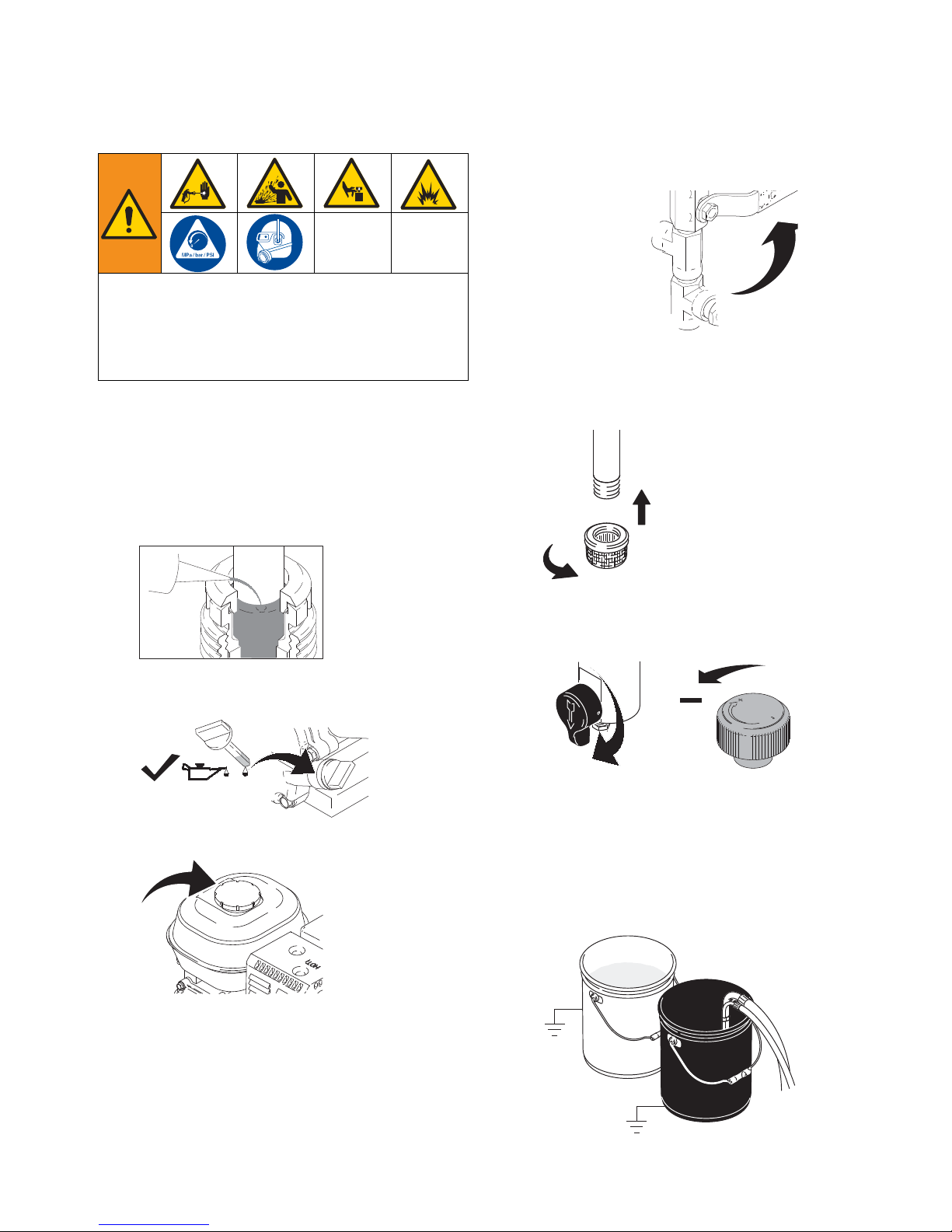

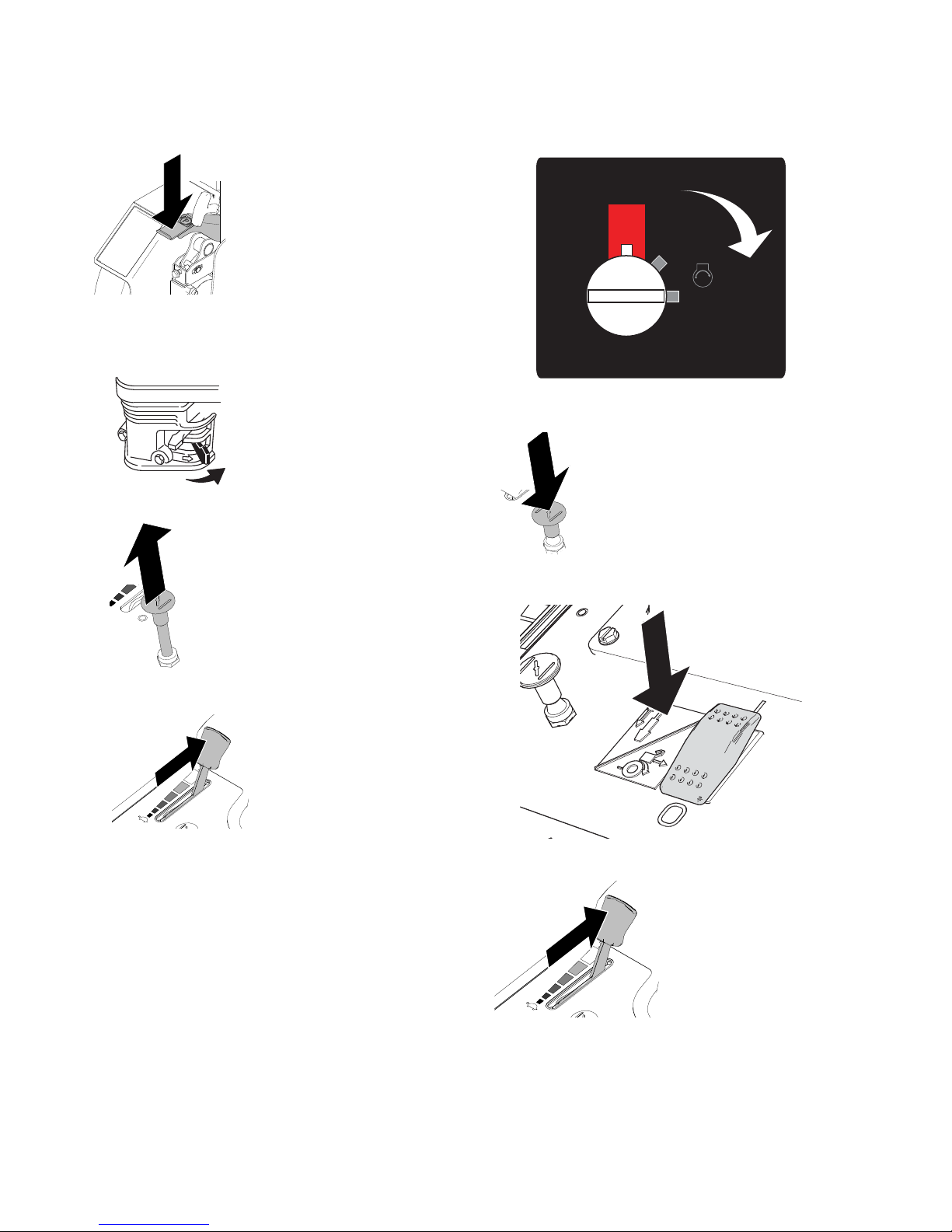

Setup/Startup

ti3308a

ti3309a

ti23

ti6473a

ti3441a

Setup/Startup

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before cleaning, checking, or servicing the equipment.

1. Perform

Pressure Relief Procedure

, page 9.

2. Perform Grounding Procedure (For Flammable

Flushing Fluids Only), page 9 if using flammable

materials.

3. Fill throat packing nut with Throat Seal Liquid (TSL)

to decrease packing wear.

6. Set pump valve(s) to OFF (250

valve; 250

DC has two pump valves).

SPS has one pump

7. If removed, install strainer(s).

ti3430a

8. Turn prime valve(s) down (250

valve; 250

DC has two prime valves). Turn pressure

SPS has one prime

control counterclockwise to lowest pressure.

4. Check engine oil level. Add SAE 10W-30 (summer)

or 5W-30 (winter). See engine manual.

5. Fill fuel tank.

NOTE: Minimum hose size allowable for proper

sprayer operation is 3/8 in. x 11 ft (9.5mm x 3.3m).

9. Place siphon tube set(s) in grounded metal pail partially filled with flushing fluid. Attach ground wire to

true earth ground. Use water to flush water-base

paint and mineral spirits to flush oil-base paint and

storage oil.

ti3310a

PAI N T

FLUSH

10 3A3393C Operation

Page 11

Setup/Startup

ti18550a

ti3312a

ti18561a

ti18568a

O

I

OFF

ON

START

ti23147a

ti18563a

ti23792a

ti18568a

10. Apply brake.

11. Start engine:

a. Move fuel valve to open.

b. Move choke to closed.

d. Turn engine key switch clockwise to START.

e. After engine starts, move choke to open.

12. Set engine clutch switch to ON.

c. Set throttle to fast.

13. Set throttle to desired setting.

3A3393C Operation 11

Page 12

Setup/Startup

ti23793a

15 SEC.

ti3442a

ti6472a

3304c

ti3441a

ti3442a

ti3322b

ti6638a

A

B

C

D

ti3325a

ti3327a

14. Set pump valve(s) ON (250SPS has one pump

valve; 250

DC has two pump valves). Pumps are now

active.

15. Increase pressure control enough to start pump.

Allow fluid to circulate for 15 seconds.

18. Inspect fittings for leaks. If leaks occur, turn sprayer

OFF immediately. Perform Pressure Relief Proce-

dure. Tighten leaky fittings. Repeat Startup, steps

1 - 17. If no leaks, continue to trigger gun until system is thoroughly flushed. Proceed to step 18.

19. Place siphon tube in paint pails.

ti3316a

PAINT

20. Trigger all guns again into a flushing fluid pail until

paint appears. Assemble tips and guards.

16. Turn pressure down, turn both prime valves horizontal. Disengage gun trigger lock.

17. Hold all guns against a grounded metal flushing pail.

Trigger guns and increase fluid pressure slowly until

pumps run smoothly.

SwitchTip and Guard Assembly

1. Engage trigger lock. Use end of SwitchTip (A) to

press OneSeal (B) into tip guard (D), with curve

matching tip bore (C).

ti3324a

2. Insert SwitchTip in tip bore and firmly thread assembly onto gun.

High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. Do not stop

leaks with hand or rag.

12 3A3393C Operation

Page 13

Gun Placement

ti27777a

ti27778a

line pattern

Continuous

line

disengages

gun

ti27881a

Gun1Gun2Gun

3

Gun1Gun2Gun

3

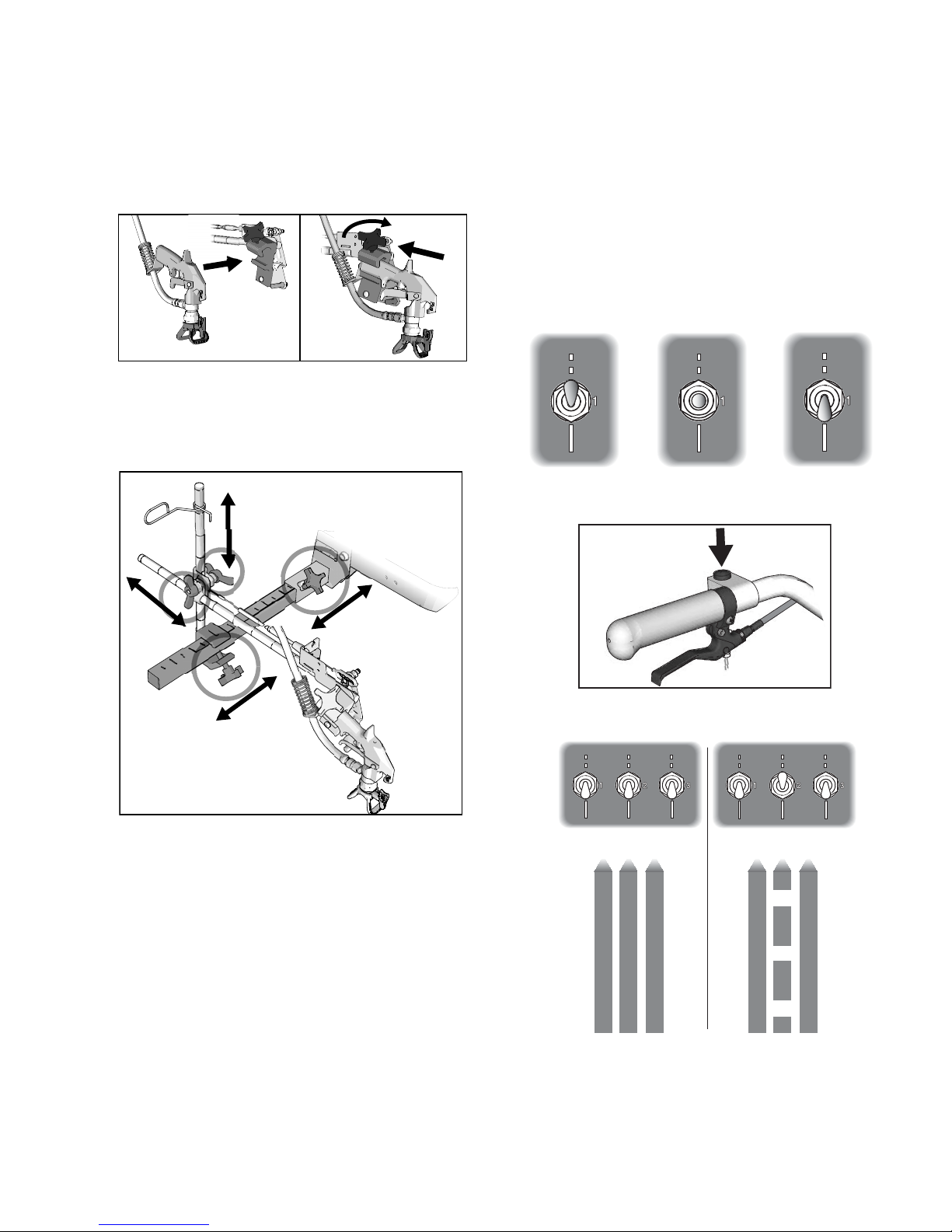

Gun Placement

Install Guns

1. Insert guns into gun holder. Tighten clamps.

Position Guns

2. Position guns: up/down, forward/reverse, left/right.

See Gun Positions Chart, page 14 for examples.

Select Guns (Standard Series)

3. Use the three gun selector switches to determine

which guns are active. Each gun selector switch has

3 positions: programmed line pattern, OFF, and

continuous line.

OFF position

Programmed

ti23814a

4. Use the gun trigger control to actuate guns.

2 Examples:

ti23813a

3A3393C Operation 13

Page 14

Gun Placement

1

2

3

4

5

6

7

ti23154a

Gun Positions Chart

1 One line

2 One line up to 24 in. (61 cm) wide

3 Two lines

4 One line with two line highlight (250

5 Two lines with three line highlight (250

6 One gun curb

7 Two gun curb

DC only)

DC only)

14 3A3393C Operation

Page 15

Gun Placement

ti18556a

ti18555a

ti28200a

ti28201a

ti28202a

ti28203a

ti28205a

ti28205a

Gun Arm Mounts

This unit is equipped with front and rear gun arm mounts

on either side.

Change Gun Position

4. Tighten gun arm knob into gun arm mounting slot.

NOTICE

Make sure all hoses, cables, and wires are properly

routed through brackets and do NOT rub on tire.

Contact with tire will result in damaged hoses, cables,

and wires.

Change Gun Position

(Left and Right)

Removal

1. Loosen vertical gun arm knob on gun arm mounting

bar and remove.

(Front and Back)

1. Loosen gun arm knob and remove from gun arm

mounting slot.

2. Slide gun arm assembly (including gun and hoses)

out from gun arm mounting slot.

3. Slide gun arm assembly into desired gun arm

mounting slot.

ti28204a

2. Assemble mounting bar on opposite side of the

machine.

3A3393C Operation 15

Page 16

Gun Placement

ti28206a

+

ti18987a

ti27804a

ti18997a

ti23151a

ti18998a

ti19000a

ti23152a

Installation

1. Install vertical gun mount onto gun bar.

NOTE: Make sure all hoses, cables, and wires are

properly routed through brackets.

Gun Cable Adjustment

Adjusting the gun cable will increase or decrease the

gap between the trigger plate and the gun trigger. To

adjust trigger gap, perform the steps below.

2. Install exposed cable through cable bracket slot.

3. Insert plastic cable retainer into cable bracket hole.

4. Install cable end onto trigger plate pin and install

clip.

1. Use wrench to loosen locking nut on cable adjuster.

2. Loosen or tighten adjuster until desired result is

achieved. NOTE: More thread exposed means less

gap between gun trigger and trigger plate.

3. Use wrench to tighten locking nut on the adjuster.

Adding Gun Cable

This line striper is equipped with three gun actuators.

Each gun actuator is capable of operating two cables.

For additional (3 to 6 guns) gun installation, attach cable

to the desired actuator rod.

1. Select cable end with adjuster.

5. Route cable around unit and up through cable holes

behind hose mount.

6. Route cable end loop through rectangular hole in

bracket and insert plastic cable retainer into the

actuator bracket. Install cable end onto actuator rod

and install clip.

16 3A3393C Operation

Page 17

Change Trigger Position

ti23153a

ti18989a

ti18990a

ti18993a

ti18991a

ti18992a

ti23153a

Gun Placement

Removal

1. Remove both hand grips from handle bar (spraying

compressed air into end of handle grip works well

for this).

2. Use an allen wrench to loosen bolt on trigger

mounting clamp.

Installation

1. Route trigger wire to other side of handle bar. Make

sure wire is routed behind steering column, through

wire slot on steering plate, and into wire clamp on

handle bar.

2. Install trigger assembly onto desired handle bar.

3. Remove trigger assembly from handle bar.

3. Use allen wrench to tighten bolt on trigger mounting

clamp.

4. Replace hand grips.

3A3393C Operation 17

Page 18

Cleanup

TI3371A

ti6269a

ti3322b

Cleanup

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

1. Perform Pressure Relief Procedure, page 9.

2. Remove guard and SwitchTip from all guns.

4. Clean filter, guard and SwitchTip in flushing fluid.

TI3375A

FLUSH

5. Place siphon tube set in grounded metal pail partially filled with flushing fluid. Attach ground wire to

true earth ground. Perform Startup steps 11 - 17

(see page 11) to flush out paint in sprayer. Use

water to flush water-base paint and mineral spirits

solvent (also called white spirit) to flush oil-base

paint.

3. Unscrew cap(s), remove filter(s). Assemble without

filter.

6. Hold gun against paint bucket and pull trigger until

water or solvent appears.

7. Move gun to solvent or water bucket. Hold gun

against bucket and pull trigger until the system is

thoroughly flushed.

8. Fill pump with Pump Armor and reassemble filter,

guard and SwitchTip.

9. Each time you spray and store, fill throat packing

nut with TSL to decrease packing wear.

18 3A3393C Operation

Page 19

Driving Instructions

ti23155a

ti23156a

ti23157a

ti23158a

ti23159a

Driving Instructions

Perform startup see, Setup/Startup, page 10.

Use the handle bars of the LineStriper to control all

motion during operation. In addition to steering the

LineStriper, the handle bars also control forward and

reverse movement by pulling the forward/reverse

control lever.

NOTE: Make sure wheel motor bypass valve is

engaged (see page 20).

To move forward: Disengage brake and slowly pull

control lever on right side of handlebar.

To stop: Release control lever and allow it to return to

center.

To turn right and left: Turn the handle bar right or left

to steer the LineStriper.

To move in reverse: Slowly pull control lever on left

side of handlebar.

3A3393C Operation 19

Page 20

Driving Instructions

ti18550a

+

ti18565a

ti18548a

+

ti18576a

ti18586a

ti18585a

ti18591a

ti18592a

Parking/Emergency Brake

This unit is equipped with a parking brake. Always

engage parking brake when not in operation. Brake may

also be used to slow machine in an emergency situation.

1. Step down on the brake lever to engage parking

brake.

2. Lift brake lever up with foot to disengage parking

brake.

Straight Line Adjustment

The front wheel is set to center the unit and allow the

operator to form straight lines. Over time, the wheel may

become misaligned and will need to be readjusted. To

re-center the front wheel, perform the following steps:

1. Loosen two bolts on the wheel alignment plate.

2. If striper arcs to the right, turn adjuster screw

clockwise.

NOTE: Adjust screw for more or less braking force.

Drive Engagement

The wheel motor bypass valve allows the operator to

disengage the wheel tension and push the unit around.

Rotate one complete turn counter-clockwise to

disengage.

3. If striper arcs to the left, turn adjuster screw

counter-clockwise.

4. Test-drive the striper. Repeat steps 2 and 3 until

striper drives straight. Tighten two bolts on wheel

alignment plate to lock the new wheel setting.

20 3A3393C Operation

Page 21

Driving Instructions

ti23160a

ti23161a

ti23162a

ti18560a

ti18566a

ti23163a

Handle Bar Height Adjustment

1. Loosen handlebar height adjuster lock.

2. Raise or lower handlebars to desired height.

2. To lower stand, pull pin and lower stand.

Front Pad Adjustment

1. Loosen four bolts.

2. Slide pad up or down to desired position.

3. Tighten handlebar height adjuster lock.

Platform Storage Position

1. Raise stand and pin self-locks.

3. Tighten four bolts.

3A3393C Operation 21

Page 22

Smart Control Operation

Smart Control Operation

Menu Tree

(LLV 250DC Shown)

22 3A3393C Operation

*LLV 250SPS displays information for only 1 pump.

Page 23

Control Features

ti23788a

Smart Control Operation

1

23

4 5

9

Ref. Switch / Indicator Explanation

1

Menu Controls

2

Menu Control

3

M/A button

4

Line Width button

5

Reset button Resets values to zero.

6

MENU arrow buttons Used to switch between menus, adjusting values and resetting values.

7

Arrow buttons Used in conjunction with the menus to adjust on-screen values.

8

Arrow buttons Used in conjunction with the menus to adjust on-screen values.

9

Paint gun switches

1, 2 and 3

Provides menu specific commands as displayed on LCD screen. Provides skipline paint and

space distance storage for instant change. Press and hold button to store pattern. Selects preset

values “Favorite” or sub-menus.

Selects preset values or exits and returns to previous menu

Selects MANUAL or AUTOMATIC mode

Input line width for MIL (thickness) calculation

Mode, Measure Mode, Layout Mode, and Setup/Information Menus.

Enables/disables paint guns 1, 2 and 3. Up – skip line. Center – off. Down – continuous line.

.

.

6

7

8

.

Scrolls through Striping

Adjusts adjacent values displayed.

Adjusts adjacent values displayed.

3A3393C Operation 23

Page 24

Smart Control Operation

Main Menus

Use MENU buttons to scroll thorough the four

main menus.

Striping Mode

Measure Mode

See Striping Mode (LLV 250DC Shown), page 27 for

features.

LLV 250

LLV 250

DC shown

SPS displays information for only 1 pump.

Layout Mode

Setup/Information

See Measure Mode, page 28 for features.

See Layout Mode, page 29 for features.

LLV 250

LLV 250

DC shown

SPS displays information for only 1 pump.

24 3A3393C Operation

See Setup/Information, page 32 for features.

Page 25

Smart Control Operation

ti18713a

ti18714a

ti18715a

Initial Setup

The initial setup prepares the striper for operation based

on a number of user entered parameters. Language

selections and the units of measure selections can be

set before you start or changed later.

Language

From Setup/Information select appropriate language by

pressing until the language is outlined.

SI Units

Pressure = bar (MPa available)

Volume = liters

Distance = meters

Line thickness = micron (g/m

2

available)

Paint Specific Gravity = Use UP and DOWN arrows

to set specific gravity. Required to determine paint

thickness.

NOTE: All units can be changed individually at any

time.

Calibration

1. Check rear tire pressure 55 ± 5 psi (379 ± 34 kpa)

and fill if necessary.

2. Remove and rotate calibration bar.

ENG = English

SPA = Spanish

FRE = French

DEU = German

RUS = Russian

WORLD = Symbols see World Symbol Key, page

36.

NOTE: Languages can also be changed later.

Units

Select appropriate units of measure.

3. Insert calibration bar face down.

4. Tighten knob.

US Units

Pressure = psi

Volume = gallons

Distance = feet

Line Thickness = mil

3A3393C Operation 25

Page 26

Smart Control Operation

ti18716a

25 ft

1 FT 2 FT 3 FT 4 FT 5 FT 6 F

ti27831a

ti18564c

ti18717a

26 FT 27 FT 28 FT 29 FT 30 FT 31 F25 FT

ti27832a

ti18564c

5. Extend steel tape to distance greater than 26 ft.

(8m).

6. Press to select Setup/Information.

7. Press for Calibration. Set TRAVEL DIST to 25

ft (7.6m) or longer. Longer distances ensure better

accuracy, depending on conditions.

\

9. Push gun trigger control to start calibration.

10. Move striper forward. Keep unit aligned with steel

tape.

11. Stop when chosen part of unit aligns with 26-ft (8m),

or distance entered, on steel tape (25-ft./ 7.6m distance).

8. Align part of the unit with 1 foot (30.5cm) on steel

tape.

26 3A3393C Operation

12. Push gun trigger control to complete calibration.

• Calibration is not complete when the exclamation

symbol is displayed.

• Calibration is finished when the check mark symbol

is displayed.

13. Calibration is now complete.

Go to Measure Mode and verify accuracy by measuring

the tape (see Measure Mode, page 28).

Page 27

Striping Mode (LLV 250DC Shown)

12

5

6

7

34

ti23819a

1

9

8

Smart Control Operation

2

3

Ref. Description

Select a “Favorite”, press for less than one second.

1

Save a “Favorite”, press and hold for more than

three seconds.

Cycles between Manual or Automatic Mode.

Manual Mode: Press and hold gun trigger control

to stripe.

2

Automatic Mode: Press and release gun trigger

control to start striping. Press and release button

again to stop.

3 Line width button for MIL (thickness) calculation.

4 Resets “Job” values to zero.

5 Total line length sprayed.

6 Paint and Space length adjustment buttons.

7 Paint and Space distance that is sprayed if a

switch is set to skip line.

8 MIL thickness. While spraying “Instant MIL avg” is

displayed. When stopped total “Job MIL avg” is

displayed.

9 Five skip line favorites

*LLV 250SPS displays information for only 1 pump.

Ref. Description

1 Exits and returns to the Striping Mode Menu.

2 Select switch 1, 2, or 3.

3 Line Width Adjustment, if switch is operating more

than one gun add the line widths together.

Operating in Striping Mode

Striper must be running and clutch engaged before activating gun trigger control.

1. Make sure engine is running and clutch switch is

engaged.

2. Use gun selector switches to select guns and line

type.

3. Activate gun trigger control to began spraying.

In Automatic Mode the striper has a low speed shutoff

value of 0.6 MPH (1.0 kilometer/hour). The low speed

shutoff value can be adjusted or disabled. See Informa-

tion, page 33.

In Automatic Mode the will flash when gun trigger

control is pressed to signal mode is active.

3A3393C Operation 27

Page 28

Smart Control Operation

ti23825a

MEASURE MODE

I/O

....

0.00

'

0.00

'

0.00

'

0.00

'

0.00

'

0.00

'

....

1

Measure Mode

Measure Mode replaces a tape measure to measure

distances when laying out an area to be striped.

1. Use to select Measure Mode.

Ref. Description

1 Hold to reset values to zero.

2. Press and release gun trigger control. Move striper

forwards or backwards. (Moving backwards is a

negative distance.)

ti18564b

3. Press and release gun trigger control to end measured length. Up to six lengths are viewable.

The most recent measured length is also saved as the

measured distance in the Stall Calculator display. See

Stall Calculator, page 30.

Press and hold gun trigger control at any time to apply a

dot. If trigger is held while striper is moving, a dot is

marked every 12-inches (30.5cm).

28 3A3393C Operation

Page 29

Smart Control Operation

1 2

ti23820a

4

5

3

ti18564b

Layout Mode

Layout Mode is used to calculate and mark parking lot

stalls.

1. Use to select Layout Mode.

*LLV 250SPS displays information for only 1 pump.

Ref. Description

1 Opens Stall Calculator Menu.

See Stall Calculator, page 30.

2 Opens Angle Calculator Menu.

See Angle Calculator, page 31.

3 Distance between dots laid by striper

4 Adjust stall size/dot spacing width.

5 Adjust dot size.

2. Press and release gun trigger control and move

striper forward.

3. Striper default is to place a dot every 9.0 ft (2.7m) to

mark the stall size. Stall size is adjustable.

4. Dots are laid down until gun trigger control is

pressed and released again.

An indicator before and after Layout Mode on the

screen alternately flash when gun trigger control is

pressed to signal mode is active.

3A3393C Operation 29

*LLV 250

SPS displays information for only 1 pump.

Page 30

Smart Control Operation

1 2 3

4

5

ti23821a

Stall Calculator

Stall Calculator is used to set the stall size. The striper

divides the measured length by the stall size to determine the number of stalls that will fit in the length measured.

1. Use to select Layout Mode. Press to

open Stall Calculator Menu.

Ref. Description

1 Opens Angle Calculator Menu.

See Angle Calculator, page 31.

2 Exits and returns stall size to Layout Mode.

3 Measured distance.

4 Calculated # of stalls. Changing the number of

stalls will change the stall size.

5 Stall size. Changing stall size changes the calcu-

lated # of stalls.

2. The most recent length measured in Measure Mode

is displayed or press gun trigger control to start a

new measurement. Press again to stop measuring.

Stall size and calculated number of stalls are both

adjustable.

3. Press to return to Layout Mode. The Stall size

is saved and displayed on the Layout Mode screen.

4. Press and release gun trigger control to start marking dots. Press and release gun trigger control again

to stop.

30 3A3393C Operation

Page 31

Smart Control Operation

1 2

3

4

5

ti23822a

ti23832a

Angle Calculator

Angle Calculator is used to determine the offset value

and dot spacing value for a layout.

1. Use to select Layout Mode. Press to

open Angle Calculator Menu.

Ref. Description

1 Opens Stall Calculator.

2 Exits and returns to Layout Mode.

3Select θ, h, or x.

4 Adjust the parameter selected.

5 Calculated offset and dot spacing.

3. Measure and mark the offset distance (z) calculated

for the first stall.

4. Press to return to Layout Mode. The dot spac-

ing value (m) is saved and displayed as stall size on

the Layout Mode screen.

2. Dot spacing (m) and offset (z) are calculated based

on the parameters entered:

θ - Stall angle

h Depth of stall

x Stall size (width)ll

3A3393C Operation 31

5. Press and release gun trigger control to start marking stall size dots. Press and release gun trigger

control to stop marking.

Page 32

Smart Control Operation

Setup/Information

Use to select Setup/Information.

Press to select Language.

See Language, page 25.

See Calibration, page 25.

See Units, page 25.

See Information, page 33.

See Marker Layout Mode, page 35.

32 3A3393C Operation

Page 33

Information

Use to select Setup/Information. Press to

open Information Menu.

Smart Control Operation

Displays and logs life data and striper information.

Logs last four error codes that occurred.

Code Description

02 = Over pressure on sensor #1

03 = No transducer #1 detected

22 = Over pressure on sensor #2

23 = No transducer #2 detected

Set time and date using arrow keys.

Use to enable or disable low speed shutoff when

in Automatic Mode.

Use up and down arrows to adjust low speed shutoff

value.

See Information (2), page 34.

3A3393C Operation 33

Page 34

Smart Control Operation

DIAGNOSTICS (1)

12.45V

1 O

2

E

A E

O

O

E

O

O

O

O

DIAGNOSTICS (2)

ti24040a

ti24041a

ti24043a

ti24044a

t

5a

Information (2)

Use to select Setup/Information. Press to

open Information Menu. Press to open Information

(2) Menu.

Set low speed limit (X) and high speed limit (Y). If you

travel outside of these speeds while striping the striper

will beep. Fast beep if traveling above the limit and a slow

beep if traveling below the limit.

Adjust screen contrast to the desired value.

Used for Troubleshooting.

Membrane Switch Wheel Sensor

Gallon Counter Gun Switches

ti24039a

Used for Troubleshooting.

Clutch Solenoids

34 3A3393C Operation

Caution Guns will Spray

i2404

Page 35

Smart Control Operation

1

2

3

ti23823a

8.00 ft. 8.00 ft.

4.00 ft.

4.00 ft.

16.00 ft.

48.00 ft.

4.00 ft.4.00 ft.

ti23812a

Marker Layout Mode

The Measure Mode feature sprays a dot or a series of

dots to mark an area.

1. Use to select Setup/Information. Press

to open Marker Layout Mode.

Ref. Description

1 Exits and returns to Information Menu.

2 Select value to change.

3 Adjust spacing value.

4. Set gun switch to skip line.

5. Press gun trigger control to start marking dots.

Press gun trigger control again to stop.

ti18564b

An indicator before and after Marker Mode on the

screen alternately flash when gun trigger control is

pressed to signal mode is active.

2. Use arrow keys to set up a marker pattern.

3. Marker layout example shows a typical lane layout

for reflective markers. Set space sizes up to eight

consecutive measurements. By leaving zeros in any

space, Marker Layout Mode will skip to the next

measurement in a continuous loop.

Some other uses of Marker Layout Mode are:

• Multiple spaced handicap stall layout

• Double line stalls

3A3393C Operation 35

Page 36

World Symbol Key

LL250 GLOBAL SYMBOL KEY

MENU SCREENS

STRIPING MODE MEASURE MODE

LAYOUT MODE SETTINGS/DATA

MANUAL OR

AUTOMATIC MODE

PRESSURE

GALLONS/LITERS

LINE THICKNESS

PAINT LENGTH

SPACE LENGTH

LINE WIDTH

SWITCH 1

SWITCH 2

SWITCH 3

EXIT

PRESS TO START/STOP

HOLD TO SPRAY A DOT

STALL CALCULATOR

ANGLE CALCULATOR

STALL WIDTH

DOT SIZE SELECTOR

CALIBRATE

UNITS

INFORMATION

& LIFE DATA

LANGUAGE SELECTION

MARKER LAYOUT MODE

SPECIFIC GRAVITY

ENGINE HOURS

TOTAL DISTANCE

TOTAL GALLONS

SOFTWARE REV

ERROR CODES

BEEP MODE

CONTRAST

DIAGNOSTICS

TIME AND DATE

LOW SPEED SHUTOFF

I/O

....

....

ENG SPA FRE GLOBAL

ș

÷

x

+

÷

x

+

-

1 2 3 4 5 6 7 8 9 10

X'

X'

A

ti23824a

World Symbol Key

36 3A3393C Operation

Page 37

Hydraulic Oil/Filter Change

ti2271a

Hydraulic Oil/Filter Change

Removal

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

1. Perform Pressure Relief Procedure, page 9.

2. Place drip pan or rags under sprayer to catch

hydraulic oil that drains out.

3. Remove drain plug. Allow hydraulic oil to drain.

4. Unscrew filter slowly - oil runs into groove and

drains out rear.

Installation

1. Apply a light film of oil on filter gasket. Install drain

plug and oil filter. Tighten oil filter 3/4 turn after gasket contacts base.

2. Fill with five quarts of Graco hydraulic oil 169236 (5

gallon/20 liter) or 207428 (1 gallon/3.8 liter).

3. Check oil level.

3A3393C Operation 37

Page 38

Technical Specifications

Technical Specifications

LineLazer V 250DC (Models 17H471, 17H472)

U.S. Metric

Dimensions

Height (with handle bar down) Unpackaged - 50.5 in.

Width Unpackaged - 33.0 in.

Length (with platform down) Unpackaged - 73.5 in.

Weight (dry - no paint) Unpackaged - 752 lbs

Noise (dBa)

Sound Power per ISO 3744: 103.1

Sound Pressure measured at 3.3 feet (1m): 86.5

Vibration (m/s2) (8 hours daily exposure)

Hand Arm (per ISO 5349) 1.6

Whole Body (per ISO 2631) 0.4

Power Rating (Horse Power)

Power Rating (Horse Power) per SAE J1349 11.9 HP @ 3600 rpm 8.8 kW @ 3600 rpm

Maximum Delivery 2.5 gpm 9.5 lpm

Maximum Tip Size

1 gun

2 gun

3 gun

Inlet paint strainer 16 mesh 1190 micron

Outlet paint strainer 50 mesh 297 micron

Pump inlet size 1 in. NSPM (m)

Pump outlet size 3/8 NPT (f)

Hydraulic reservoir capacity 1.25 gallons 4.73 liters

Maximum hydraulic pressure 1825 psi 124 bar

Maximum working pressure 3300 psi 228 bar, 22.8 MPa

Maximum forward speed 10 mph 16 kph

Maximum reverse speed 6 mph 9.7 kph

Electrical Capacity 14 A @ 3600 rpm

Starting Battery 12V, 33Ah, Sealed lead acid

Packaged - 63.5 in.

Packaged - 45.0 in.

Packaged - 78.0 in.

Packaged - 890 lbs

.055

.039

.033

Unpackaged - 128.3 cm

Packaged - 161.3 cm

Unpackaged - 83.8 cm

Packaged - 114.3 cm

Unpackaged - 186.7 cm

Packaged - 198.1 cm

Unpackaged - 341 kg

Packaged - 404 kg

Wetted Parts: PTFE, Nylon, polyurethane, V-Max,

UHMWPE, fluoroelastomer, acetal, leather, tungsten

carbide, stainless steel, chrome plating, nickel-plated

carbon steel, ceramic

38 3A3393C Operation

Page 39

Technical Specifications

LineLazer V 250DC with Pressurized Bead System (Models 17H473, 17H474)

U.S. Metric

Dimensions

Height (with handle bar down) Unpackaged - 55.7 in.

Width Unpackaged - 33.0 in.

Length (with platform down) Unpackaged - 73.5 in.

Weight (dry - no paint or beads) Unpackaged - 864 lbs

Noise (dBa)

Sound Power per ISO 3744: 105.9

Sound Pressure measured at 3.3 feet (1m): 89.1

Vibration (m/s2) (8 hours daily exposure)

Hand Arm (per ISO 5349) 2.4

Whole Body (per ISO 2631) 0.4

Power Rating (Horse Power)

Power Rating (Horse Power) per SAE J1349 11.9 HP @ 3600 rpm 8.8 kW @ 3600 rpm

Maximum Delivery 2.5 gpm 9.5 lpm

Maximum Tip Size

1 gun

2 gun

3 gun

Inlet paint strainer 16 mesh 1190 micron

Outlet paint strainer 50 mesh 297 micron

Pump inlet size 1 in. NSPM (m)

Pump outlet size 3/8 NPT (f)

Hydraulic reservoir capacity 1.25 gallons 4.73 liters

Maximum hydraulic pressure 1825 psi 124 bar

Maximum working pressure 3300 psi 228 bar, 22.8 MPa

Maximum forward speed 10 mph 16 kph

Maximum reverse speed 6 mph 9.7 kph

Electrical Capacity 14 A @ 3600 rpm

Starting Battery 12V, 33Ah, Sealed lead acid

Packaged - 63.5 in.

Packaged - 45 in.

Packaged - 78.0 in.

Packaged - 1002 lbs

.055

.039

.033

Unpackaged - 141.5 cm

Packaged - 161.3 cm

Unpackaged - 83.8 cm

Packaged - 114.3 cm

Unpackaged - 186.7 cm

Packaged - 198.1 cm

Unpackaged - 392 kg

Packaged - 455kg

Wetted Parts: PTFE, Nylon, polyurethane, V-Max,

UHMWPE, fluoroelastomer, acetal, leather, tungsten

carbide, stainless steel, chrome plating, nickel-plated

carbon steel, ceramic

3A3393C Operation 39

Page 40

Technical Specifications

LineLazer V 250SPS (Models 17H466, 17H467)

U.S. Metric

Dimensions

Height (with handle bar down) Unpackaged - 55.7 in.

Width Unpackaged - 33.0 in.

Length (with platform down) Unpackaged - 73.5 in.

Weight (dry - no paint or beads)

Noise (dBa)

Sound Power per ISO 3744: 105.9

Sound Pressure measured at 3.3 feet (1m): 89.1

Vibration (m/s2) (8 hours daily exposure)

Hand Arm (per ISO 5349) 2.4

Whole Body (per ISO 2631) 0.4

Power Rating (Horse Power)

Power Rating (Horse Power) per SAE J1349 11.9 HP @ 3600 rpm 8.8 kW @ 3600 rpm

Maximum Delivery 2.5 gpm 9.5 lpm

Maximum Tip Size

1 gun

2 gun

3 gun

Inlet paint strainer 16 mesh 1190 micron

Outlet paint strainer 50 mesh 297 micron

Pump inlet size 1 in. NSPM (m)

Pump outlet size 3/8 NPT (f)

Hydraulic reservoir capacity 1.25 gallons 4.73 liters

Maximum hydraulic pressure 1825 psi 124 bar

Maximum working pressure 3300 psi 228 bar, 22.8 MPa

Maximum forward speed 10 mph 16 kph

Maximum reverse speed 6 mph 9.7 kph

Electrical Capacity 14 A @ 3600 rpm

Starting Battery 12V, 33Ah, Sealed lead acid

Packaged - 63.5 in.

Packaged - 45 in.

Packaged - 78.0 in.

Unpackaged - 666 lbs

Packaged - 769 lbs

.055

.039

.033

Unpackaged - 141.5 cm

Packaged - 161.3 cm

Unpackaged - 83.8 cm

Packaged - 114.3 cm

Unpackaged - 186.7 cm

Packaged - 198.1 cm

Unpackaged - 302.1 kg

Packaged - 348.8 kg

Wetted Parts: PTFE, Nylon, polyurethane, V-Max,

UHMWPE, fluoroelastomer, acetal, leather, tungsten

carbide, stainless steel, chrome plating, nickel-plated

carbon steel, ceramic

40 3A3393C Operation

Page 41

Technical Specifications

LineLazer V 250SPS with Pressurized Bead System (Models 17H468, 17J951, 17H469)

U.S. Metric

Dimensions

Height (with handle bar down) Unpackaged - 55.7 in.

Width Unpackaged - 33.0 in.

Length (with platform down) Unpackaged - 73.5 in.

Weight (dry - no paint or beads)

Noise (dBa)

Sound Power per ISO 3744: 105.9

Sound Pressure measured at 3.3 feet (1m): 89.1

Vibration (m/s2) (8 hours daily exposure)

Hand Arm (per ISO 5349) 2.4

Whole Body (per ISO 2631) 0.4

Power Rating (Horse Power)

Power Rating (Horse Power) per SAE J1349 11.9 HP @ 3600 rpm 8.8 kW @ 3600 rpm

Maximum Delivery 2.5 gpm 9.5 lpm

Maximum Tip Size

1 gun

2 gun

3 gun

Inlet paint strainer 16 mesh 1190 micron

Outlet paint strainer 50 mesh 297 micron

Pump inlet size 1 in. NSPM (m)

Pump outlet size 3/8 NPT (f)

Hydraulic reservoir capacity 1.25 gallons 4.73 liters

Maximum hydraulic pressure 1825 psi 124 bar

Maximum working pressure 3300 psi 228 bar, 22.8 MPa

Maximum forward speed 10 mph 16 kph

Maximum reverse speed 6 mph 9.7 kph

Electrical Capacity 14 A @ 3600 rpm

Starting Battery 12V, 33Ah, Sealed lead acid

Packaged - 63.5 in.

Packaged - 45 in.

Packaged - 78.0 in.

Unpackaged - 778 lbs

Packaged - 916 lbs

.055

.039

.033

Unpackaged - 141.5 cm

Packaged - 161.3 cm

Unpackaged - 83.8 cm

Packaged - 114.3 cm

Unpackaged - 186.7 cm

Packaged - 198.1 cm

Unpackaged - 352.9 kg

Packaged - 415.5 kg

Wetted Parts: PTFE, Nylon, polyurethane, V-Max,

UHMWPE, fluoroelastomer, acetal, leather, tungsten

carbide, stainless steel, chrome plating, nickel-plated

carbon steel, ceramic

3A3393C Operation 41

Page 42

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2016, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A3393

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision

C, April 2018

Loading...

Loading...