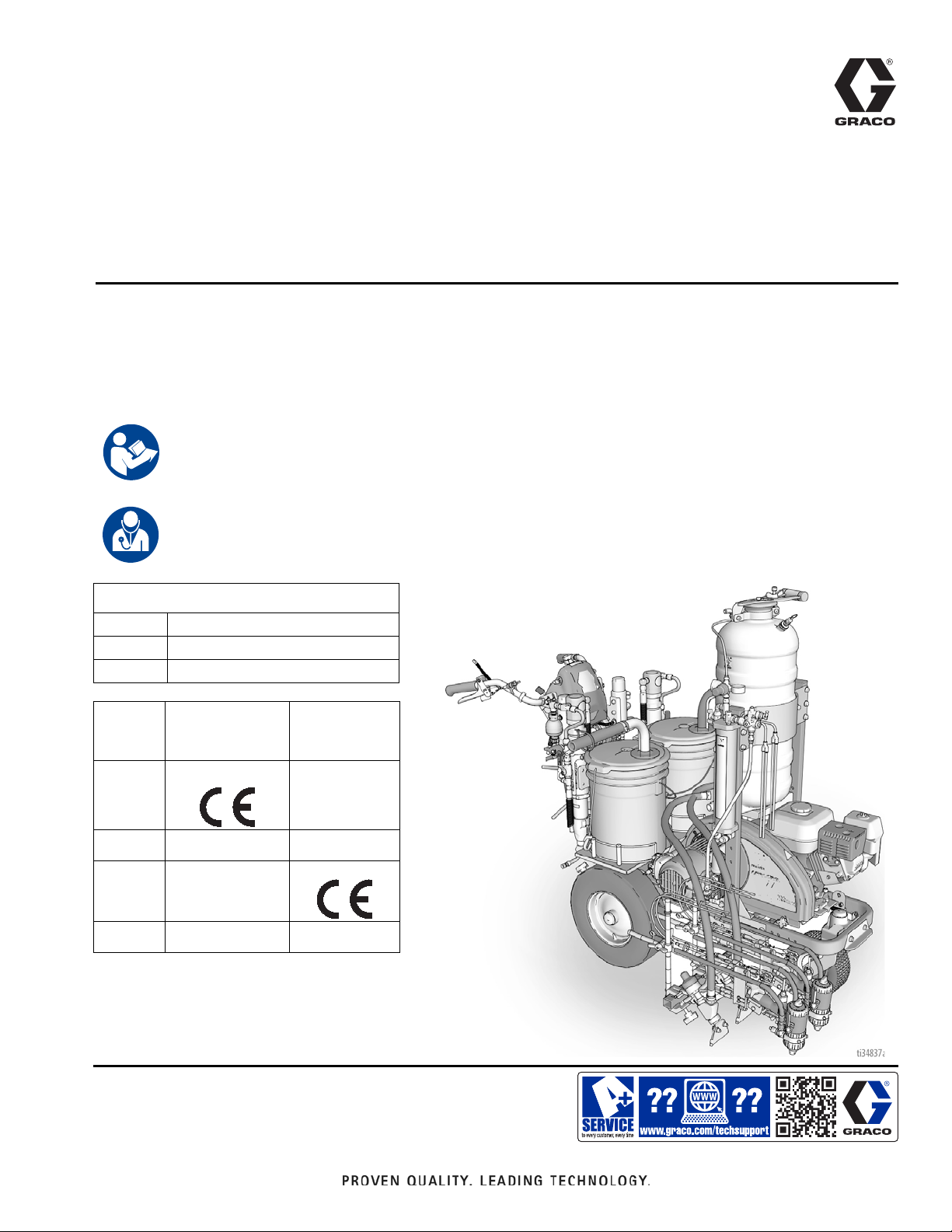

Operation, Repair, Parts

™

LineLazer

For the application of two component line striping materials.

For professional use only.

For outdoor use only.

Not for use in explosive atmospheres or hazardous locations.

Maximum Operating Pressure: 3300 psi (22.8 MPa, 228 bar)

Important Safety Instructions

Read all warnings and instructions in this manual and in related manuals before using the equipment.

Be familiar with the controls and the proper usage of the equipment.

Save these instructions.

Important Medical Information

Read the medical alert card provided with the gun. It contains injection injury treatment information

for a doctor. Keep it with you when operating the equipment.

V 200MMA 1:1 Airless Line Stripers

3A6466A

EN

Related Manuals:

309277 Pump

3A3428 Auto-Layout Applications Methods

332230 Pressurized Bead System

Model: HP Reflective

1 Auto Gun

1 PBS Tank

17Y234

17Y271

17Y513

17Y512

All auto guns can be actuated manually.

with laser

HP Reflective

2 Auto Guns

1 PBS Tank

with laser

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

Contents

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Tip Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Component Identification - LLV 200MMA . . . . . . . . . . . . . . . 8

Component Identification - Gun . . . . . . . . . . . . . . . . . . . . . . . 9

Piston Safety Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Loss of Air Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Grounding Procedure

(For Flammable Flushing Fluids Only) . . . . . . . . . . . . 12

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setup/Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Keep Components A and B Separate . . . . . . . . . . . . . . . 15

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Gun Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Install Guns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Position Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Manual Guns Selection . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Auto Guns Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Gun Positions Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Gun Arm Mounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Change Gun Position

(Front and Back) . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Change Gun Position

(Left and Right) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Trigger Sensor Adjustment . . . . . . . . . . . . . . . . . . . . . . . 22

Gun Cable Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Straight Line Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 24

Handle Bar Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Dot Laser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

For overnight shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . 28

LineLazer V LiveLook Display . . . . . . . . . . . . . . . . . . . . . . . 29

HP Auto Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Initial Setup (HP Auto Series) . . . . . . . . . . . . . . . . . . . . . 30

Striping Mode (HP Auto Series) . . . . . . . . . . . . . . . . . . . 32

Measure Mode (HP Auto Series) . . . . . . . . . . . . . . . . . . . 33

Layout Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Stall Calculator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Angle Calculator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Setup/Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

MMA Fusion Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Flush Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Clean Outside of Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Tip Guard Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Clean Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Clean Fluid Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Clean Mix Chamber Nozzle . . . . . . . . . . . . . . . . . . . . . . . 45

Clean Passages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Remove Tip Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Clean Impingement Ports . . . . . . . . . . . . . . . . . . . . . . . . 46

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Disassemble Front End of Fusion Gun . . . . . . . . . . . . . . 47

Reassemble Front End of Fusion Gun . . . . . . . . . . . . . . 47

Remove Mix Chamber & Side Seal Cartridges . . . . . . . . 48

Reassemble Mix Chamber & Side Seal Cartridges . . . . . 49

Dissassemble Check Valves . . . . . . . . . . . . . . . . . . . . . . 50

Reassemble Check Valves . . . . . . . . . . . . . . . . . . . . . . . 50

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Piston Safety Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Air Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

LineLazer V 200MMA 1:1 . . . . . . . . . . . . . . . . . . . . . . . . 53

Hydraulic Oil/Filter Change . . . . . . . . . . . . . . . . . . . . . . . . . 54

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Gun Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Gun Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Check Valve Filter Screen Kits . . . . . . . . . . . . . . . . . . . . 62

Drill Bit Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Drill Bit Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Air Purge Handle Cleanout Drill Kit . . . . . . . . . . . . . . . . . 63

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

LineLazer V 200MMA 1:1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

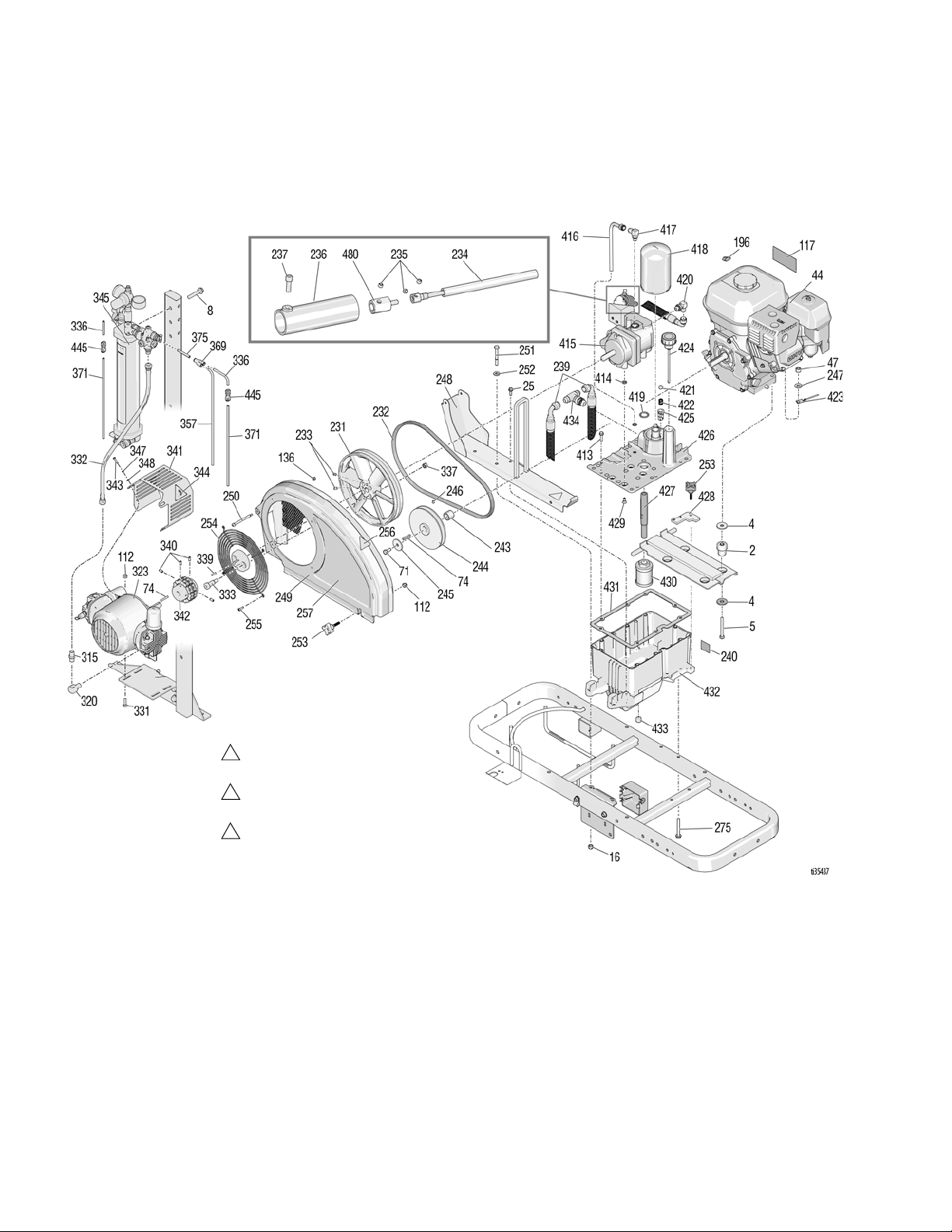

Parts Drawing - Frame Assembly . . . . . . . . . . . . . . . . . . . . 66

Parts List - Frame Assembly . . . . . . . . . . . . . . . . . . . . . . . . 67

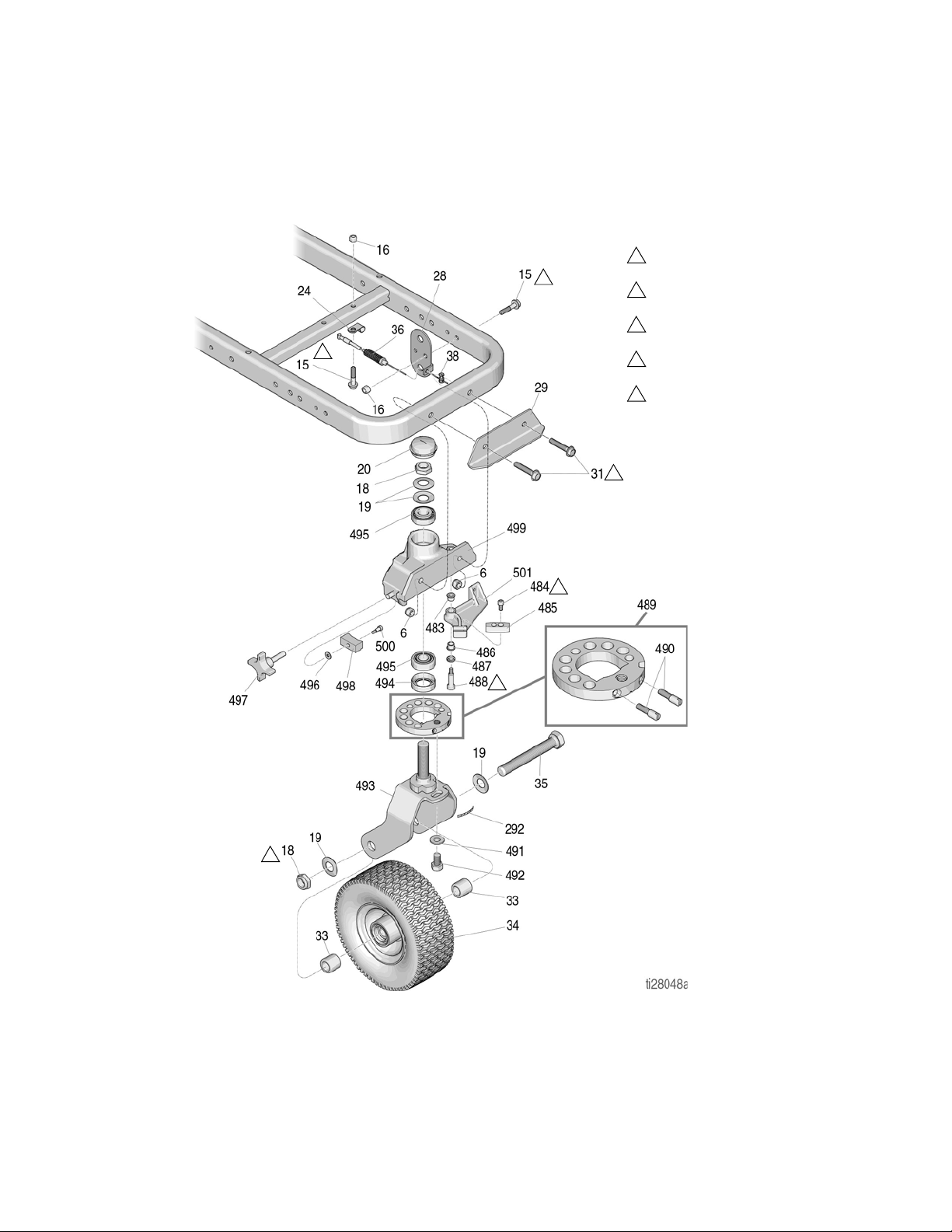

Parts Drawing - Gun Arm & Gun Trigger . . . . . . . . . . . . . . 68

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Gun Holder and Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Gun Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Cutaway View - Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Parts Drawing - Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Parts List - Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Detail Views - Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

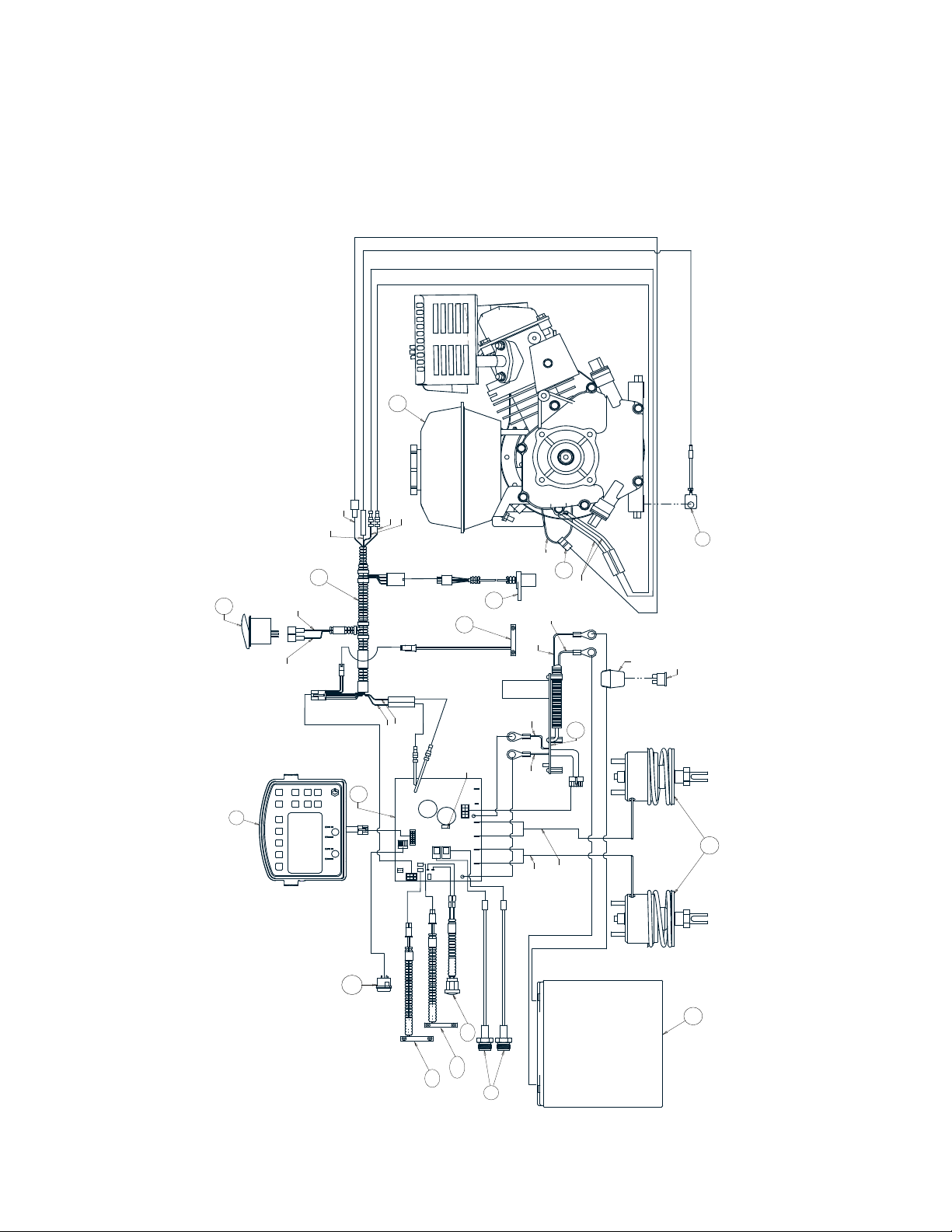

Parts Drawing - Handle/Controls . . . . . . . . . . . . . . . . . . . . . 74

Parts List - Handle/Controls . . . . . . . . . . . . . . . . . . . . . . . . . 75

Parts Drawing - Filters A & B . . . . . . . . . . . . . . . . . . . . . . . . 76

Parts List - Filters A & B . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Parts Drawing - Fluid Pumps A & B . . . . . . . . . . . . . . . . . . 78

Parts List - Fluid Pumps A & B . . . . . . . . . . . . . . . . . . . . . . 79

Parts Drawing - Engine & Compressor . . . . . . . . . . . . . . . . 80

Parts List - Engine & Compressor . . . . . . . . . . . . . . . . . . . . 81

Parts Drawing - EZ Align Swivel Wheel . . . . . . . . . . . . . . . 82

Parts List - EZ Align Swivel Wheel . . . . . . . . . . . . . . . . . . . 83

Parts Drawing - Pressure Tank . . . . . . . . . . . . . . . . . . . . . . 84

Parts List - Presssure Tank . . . . . . . . . . . . . . . . . . . . . . . . . 85

Accessories - Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Stainless Steel Side Seal Kits . . . . . . . . . . . . . . . . . . . . . 86

Polycarballoy Side Seal Kits . . . . . . . . . . . . . . . . . . . . . . 86

Gun Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Lubricant for Gun Rebuild . . . . . . . . . . . . . . . . . . . . . . . . 87

Grease Cartridge for Gun Shutdown . . . . . . . . . . . . . . . . 87

Flushing Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Solvent Flush Canister Kit . . . . . . . . . . . . . . . . . . . . . . . . 87

Solvent Flush Pail Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Gun Cleaning Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

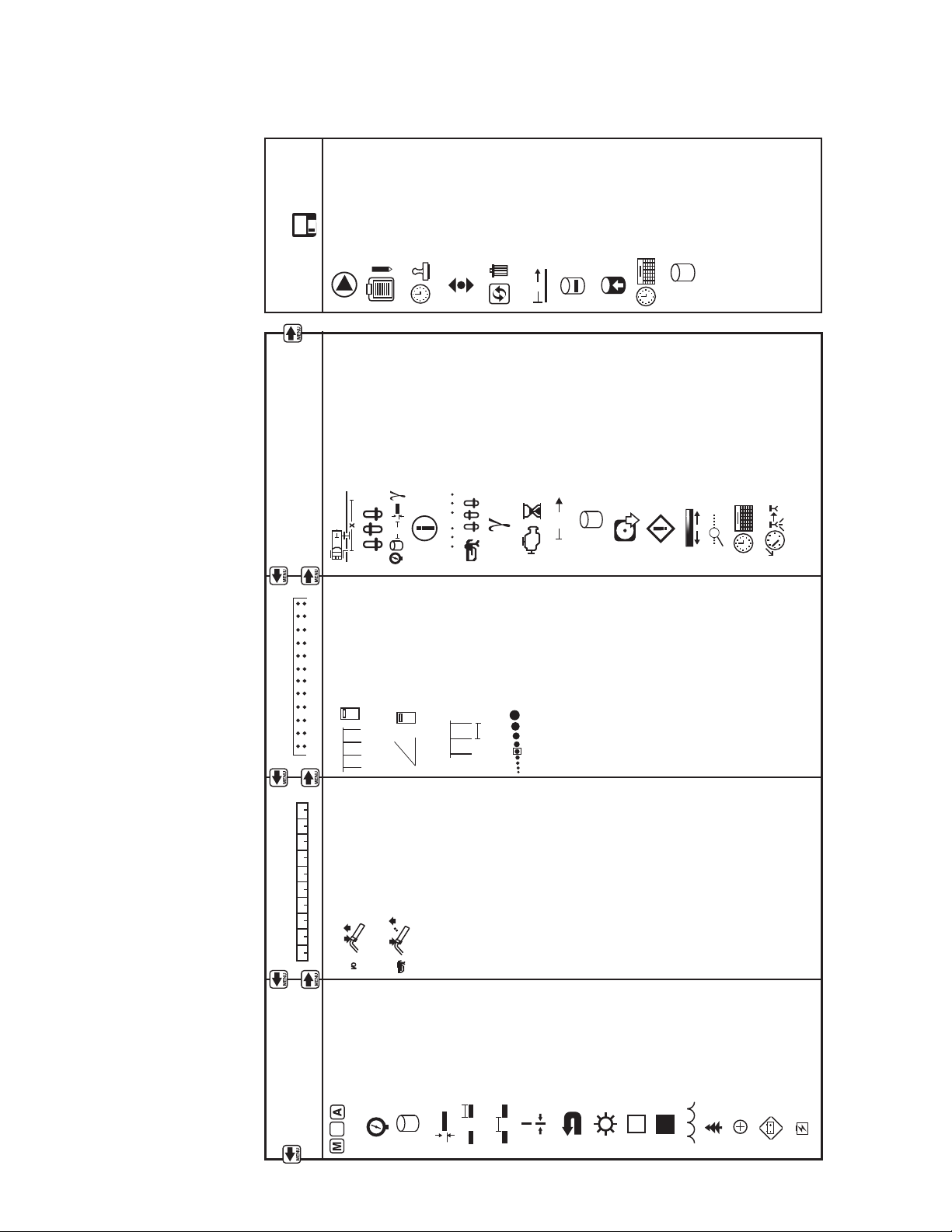

World Symbol Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

CALIFORNIA PROPOSITION 65 . . . . . . . . . . . . . . . . . . 90

Technical Specifications - Gun . . . . . . . . . . . . . . . . . . . . . . 91

End of Product Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2 3A6466A Operation, Repair, Parts

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard sym-

bols and warnings not covered in this section may appear throughout the body of this manual where applicable.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or solvent flowing through the equipment can cause static sparking. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable and can

ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths

(potential static arc).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are present.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until you

identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that

injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any

part of the body.

• Always use the spray tip guard. Do not spray without spray tip guard in place.

• Use Graco spray tips.

• Use caution when cleaning and changing spray tips. In the case where the spray tip clogs while spraying,

follow the Pressure Relief Procedure for turning off the unit and relieving the pressure before removing

the spray tip to clean.

• Equipment maintains pressure after power is shut off. Do not leave the equipment energized or under pressure while unattended. Follow the Pressure Relief Procedure when the equipment is unattended or not

in use, and before servicing, cleaning, or removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3300 psi. Use Graco replacement parts or accessories that are rated

a minimum of 3300 psi.

•

Always engage the piston safety lock when not spraying. Verify the piston safety lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

3A6466A Operation, Repair, Parts 3

Warnings

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon monoxide

can cause death.

• Do not operate in an enclosed area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request Safety Data Sheets (SDSs) from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety

hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for

compatibility.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pres-

sure Relief Procedure and disconnect all power sources.

ENTANGLEMENT HAZARD

Rotating parts can cause serious injury

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pres-

sure Relief Procedure and disconnect all power sources.

4 3A6466A Operation, Repair, Parts

Warnings

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited

to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

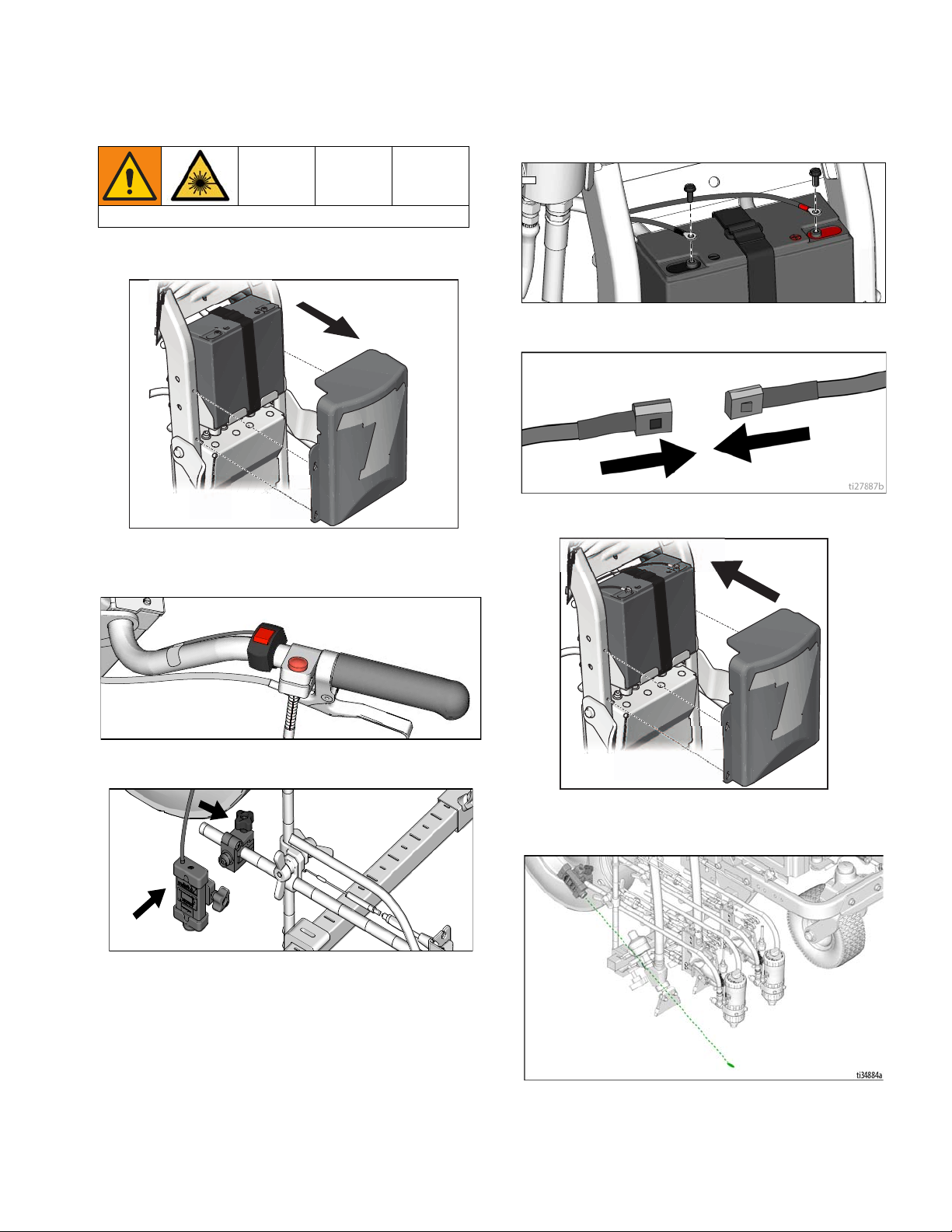

BATTERY HAZARD

The battery may leak, explode, cause burns, or cause an explosion if mishandled. Contents of an open battery can cause severe irritation and/or chemical burns. If on skin, wash with soap and water. If in eyes, flush

with water for at least 15 minutes and get immediate medical attention.

• Only use the battery type specified for use with the equipment. See Technical Data.

• Replace battery only in well-ventilated area and away from flammable or combustible materials, including

paints and solvents.

• Do not dispose of battery in fire or heat above 50°C (122°F). The battery is capable of exploding.

• Do not throw into fire.

• Do not expose battery to water or rain.

• Do not disassemble, crush, or penetrate the battery.

• Do not use or charge a battery that is cracked or damaged.

• Follow local ordinances and/or regulations for disposal.

ELECTRIC SHOCK HAZARD

Hazardous voltage is present in control box while engine is running.

• Turn off engine before servicing equipment.

3A6466A Operation, Repair, Parts 5

Warnings

Important Laser Information for Units with Laser Option

LASER LIGHT HAZARD: AVOID DIRECT EYE CONTACT

Eye exposure to Class IIIa3/3R levels of laser light can potentially present an eye (retinal) injury hazard,

including spot blindness or other retinal injury. To avoid direct eye exposure:

• Never look directly in to a laser beam or point the beam into the eyes of others, even at long distances.

• Never shine the laser at mirror like surfaces which can cause specular reflections of the beam.

• Always set the laser at a height and angle that prevents the beam from shining into people’s eyes.

• Immediately terminate laser emissions if personnel, animals or reflective objects approach the beam.

• Always turn off laser when unattended.

• Do not remove any warning labels from the laser.

• Only properly trained laser operators are to use this product.

• Never allow beams to be aimed toward traffic, vehicles, or heavy equipment. Even when not damaging at

long distances, the high brightness of lasers can distract or disrupt vehicle operations.

• Never point a laser at an aircraft or law enforcement personnel. This is considered a felony in most locations, with the possibility of jail time, heavy fines or both.

• Do not disassemble laser product. Return to factory for all service procedures.

• Laser must be turned OFF when cleaning the lens, so as not to create unwanted laser refraction.

LASER RADIATION HAZARD

Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

• Do not attempt to open or disassemble the laser housing under any circumstances. Doing so may cause

exposure to potentially hazardous levels of laser radiation.

• No serviceable parts within. Unit is factory sealed.

FIRE AND EXPLOSION HAZARD

Connecting directly to a generator source can create a short or sparking under certain conditions.

• Only connect GL1700 to a dedicated 12 volt DC battery source.

Battery Disposal

Do not place batteries in the trash. Recycle batteries according to local regulations. To find a recycling location in the USA

and Canada call 1-800-822-8837 or go to www.call2recycle.org.

6 3A6466A Operation, Repair, Parts

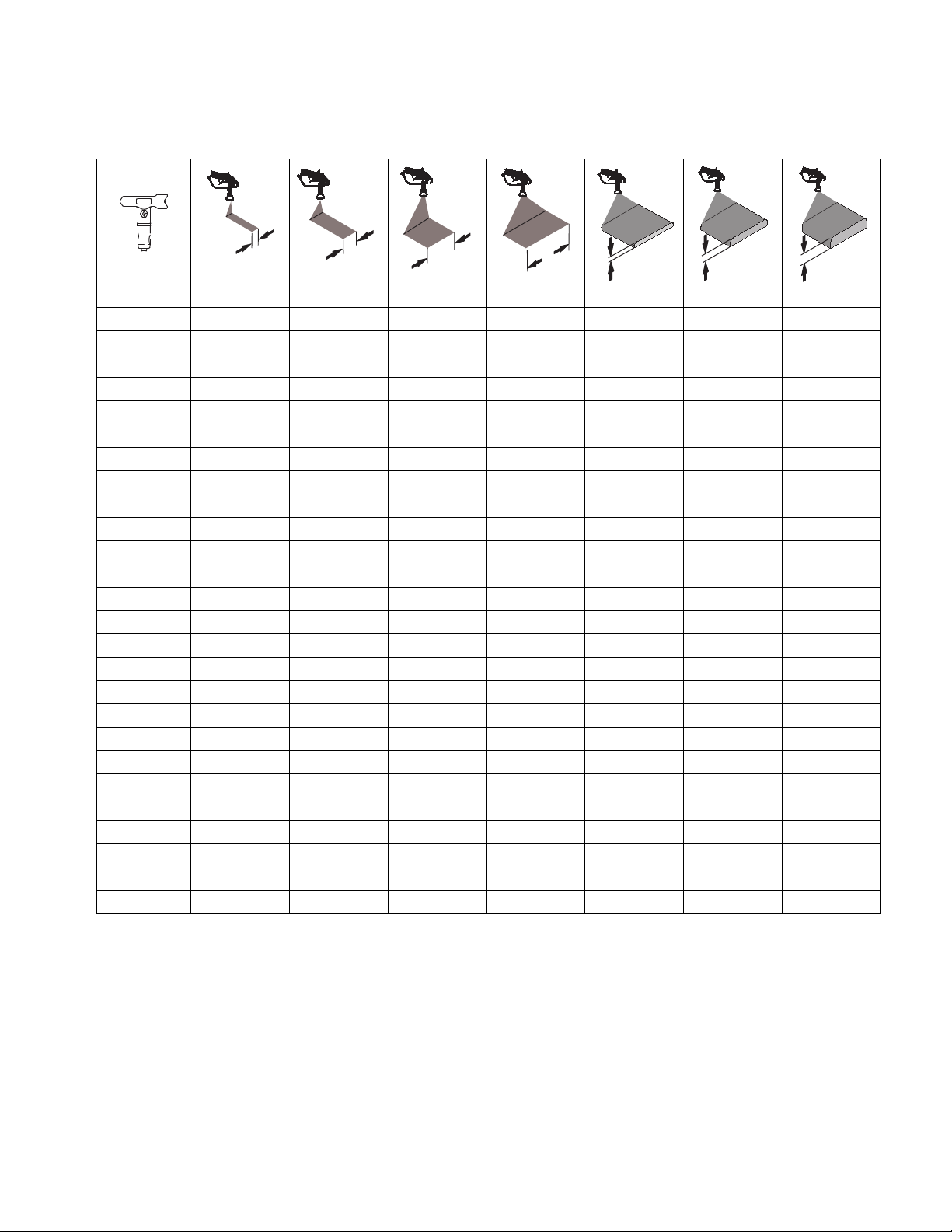

Tip Selection

ti27606a

ti27606a

in.

(cm)

ti27505a

in.

in.

(cm)

ti27507a

in.

ti27605a

Tip Selection

ti27506a

286321

286323

286325

286327

286331

(cm)

3-4 (7-10)

3-4 (7-10)

3-4 (7-10)

3-4 (7-10)

3-4 (7-10)

(cm)

286423 4-5 (10-13)

286425 4-5 (10-13)

286427 4-5 (10-13)

286429 4-5 (10-13)

286433 4-5 (10-13)

286525 5-6 (13-15)

286527 5-6 (13-15)

286529 5-6 (13-15)

286531 5-6 (13-15)

286533 5-6 (13-15)

286535 5-6 (13-15)

286627 6-8 (15-20)

286629 6-8 (15-20)

286631 6-8 (15-20)

286633 6-8 (15-20)

286635 6-8 (15-20)

286729 8-10 (20-25)

286735 8-10 (20-25)

286831 8-12 (20-30)

286833 8-12 (20-30)

286835 8-12 (20-30)

286935 9-12 (23-30)

ti27508a

ti27509a

ti27510a

Tips smaller than a 0.021 orifice may result in poorly mixed material or frequently clogged tips.

3A6466A Operation, Repair, Parts 7

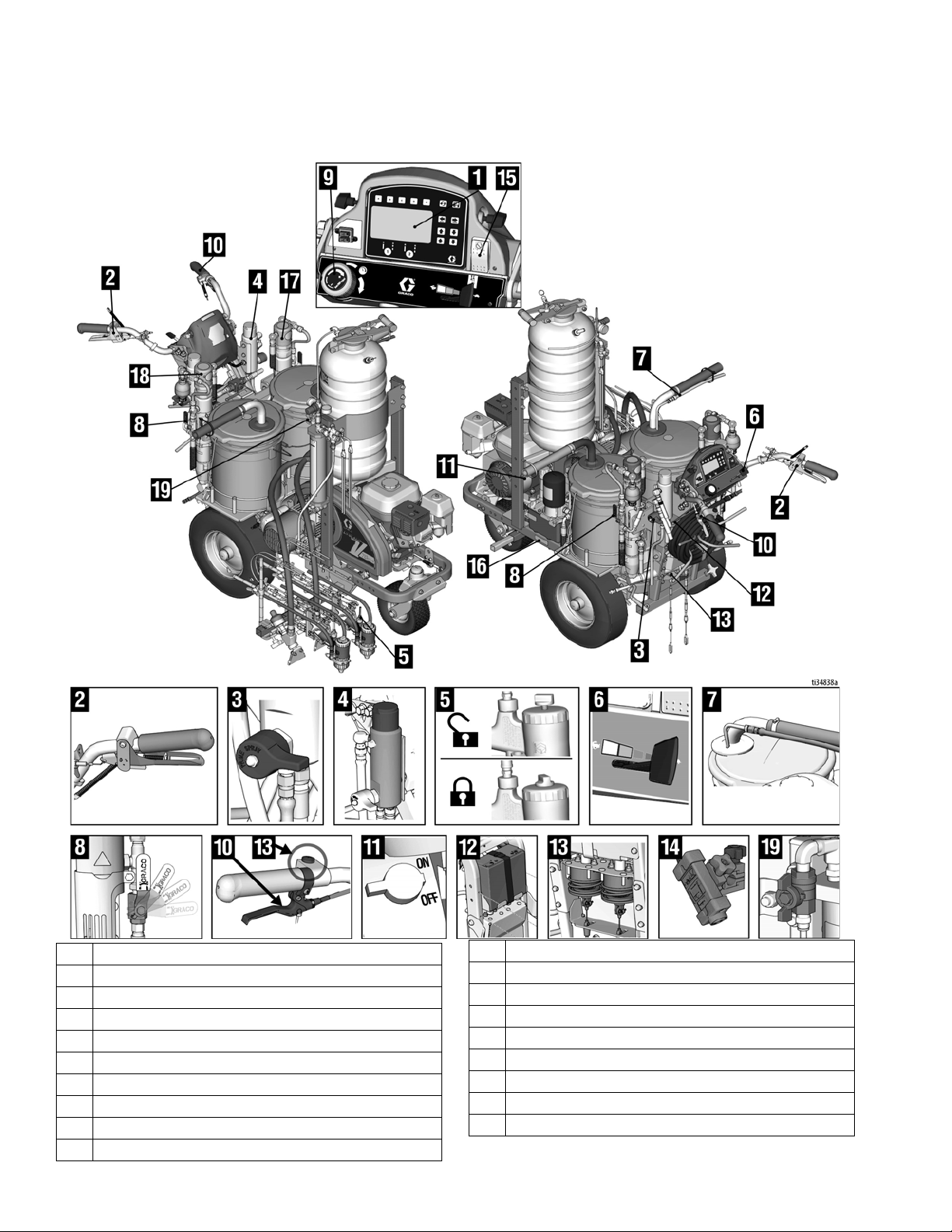

Component Identification - LLV 200MMA

Component Identification - LLV 200MMA

1 Display

2 Spray Gun Control

3 Prime/Spray Valve

4 Filter Manifold

5 Piston Safety Lock

6 Engine/Controls

7 Drain and Siphon Tubes

8 Pump ON/OFF Valve

9 Pressure Control

10 Turn Control

8 3A6466A Operation, Repair, Parts

11 Engine STOP

12 12 Volt Battery

13 Gun Actuator

14 Layout Laser

15 Engine Kill Switch

16 Identification Label

17 A side Fluid Pump

18 B side Fluid Pump

19 Purge Air Valve

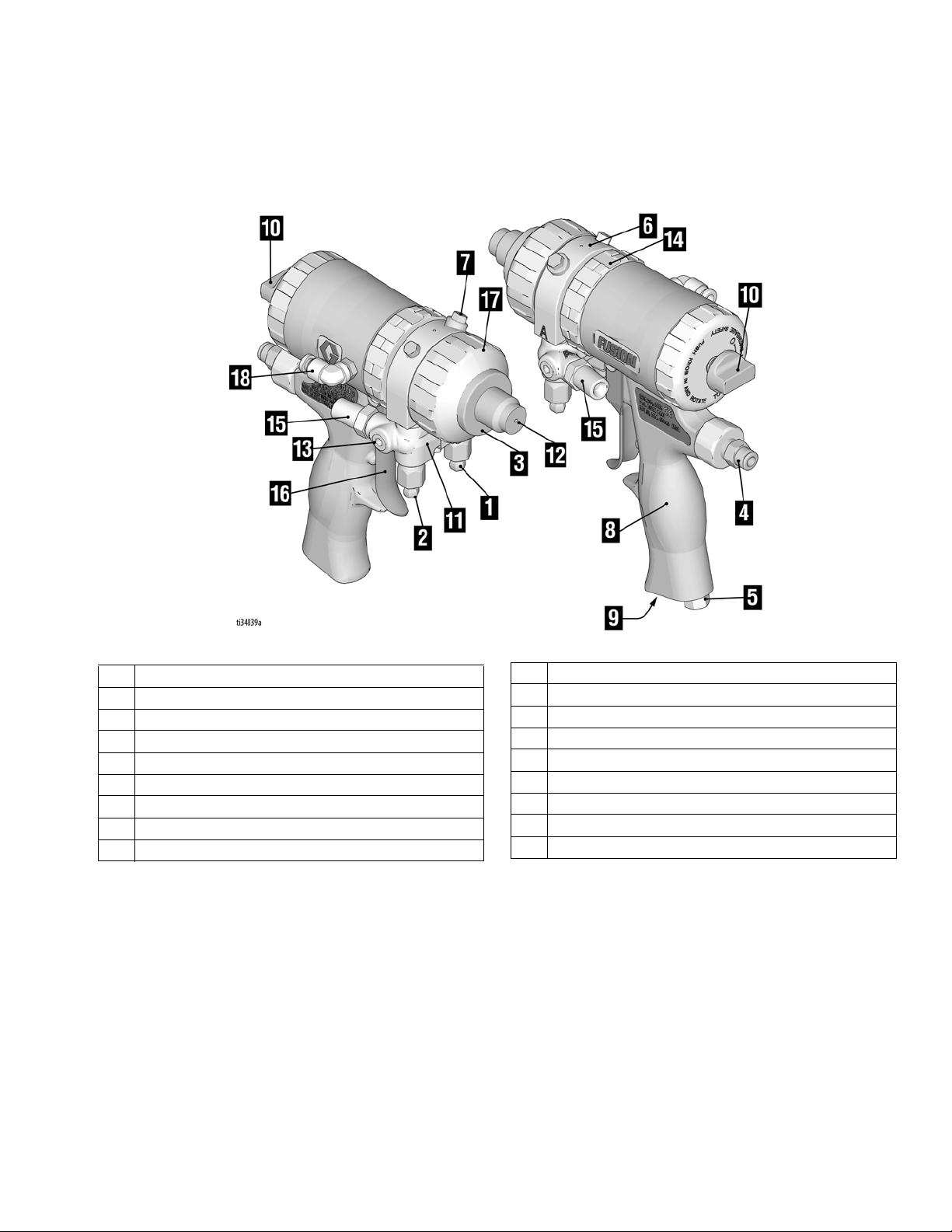

Component Identification - Fusion Gun

Component Identification - Fusion Gun

1 A Side Fluid Valve

2 B Side Fluid Valve

3 Spray Tip Adapter

4 1/4” Air Push-to-Connect for Actuation

5 Muffler

6 Fluid Housing

7 Grease Fitting (under cap)

8 Handle

9 Optional Air Inlet

10 Piston Safety Lock

11 Gun Fluid Manifold

12 Mix Chamber Nozzle

13 Fluid Inlets (optional) (A Side Shown)

14 Lock Ring

15 Fluid Inlet (A Side Shown)

16 Trigger

17 Front Retaining Ring

18 1/4” Air Push to Connect for Purge

3A6466A Operation, Repair, Parts 9

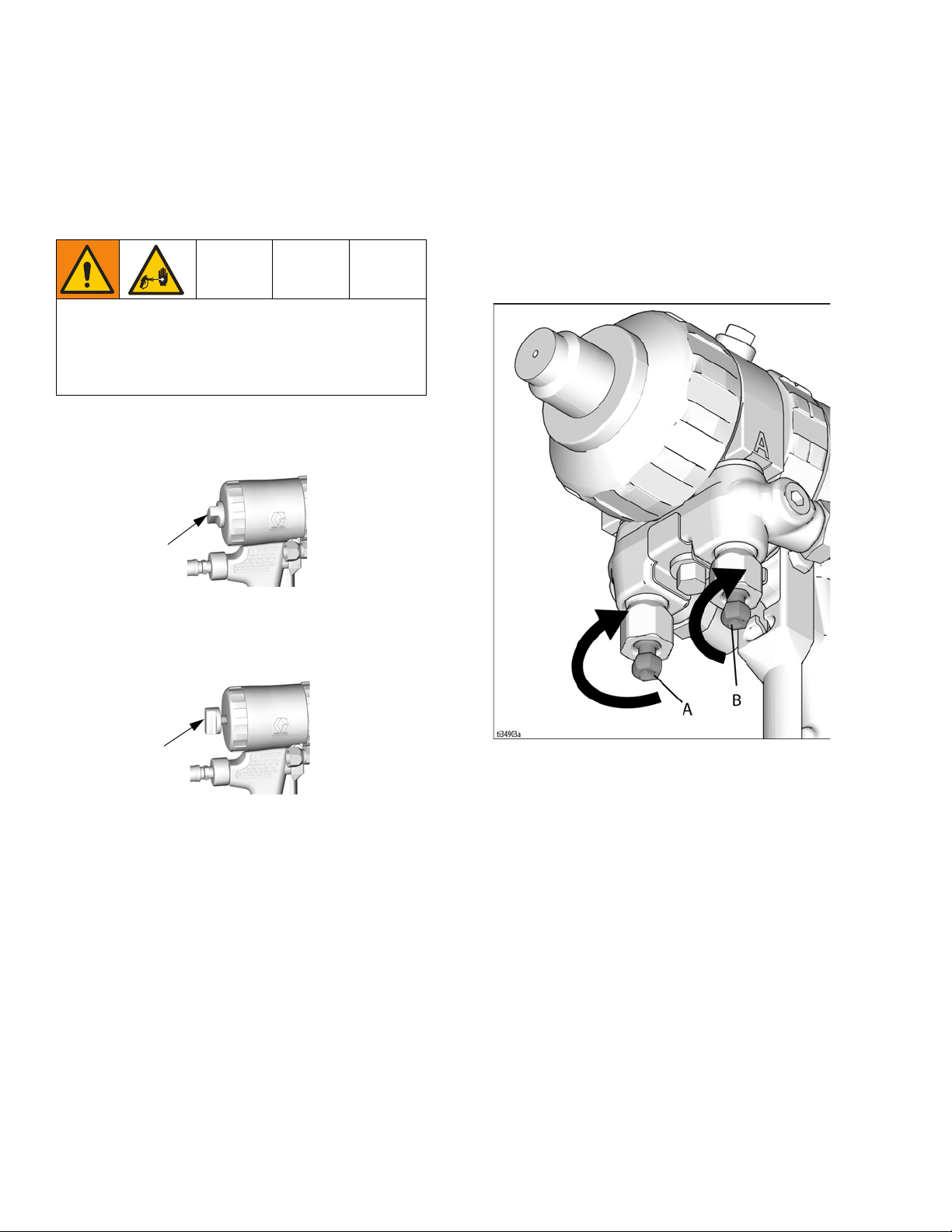

Piston Safety Lock

TI2409A

Engaged

TI2410A

Disengaged

Piston Safety Lock

Engage piston safety lock whenever you are handling

the gun out of the holder and the gun is under pressure,

to avoid accidental triggering.

RISK OF INJECTION

To help prevent serious injury from oressurized fluid,

such as skin injection, splashing fluid and moving

parts, engage the piston safety lock when handling

the gun out of the holder.

To engage piston safety lock: push knob in and turn

clockwise. If engaged, gun will not actuate.

Loss of Air Pressure

In event of loss of air pressure, gun will continue to

spray. To shut off gun, do one of the following:

• Push in Piston Safety Lock, page 10.

• Close fluid valves A and B.

To disengage piston safety lock: push knob in and

turn counterclockwise until it pops out. There will be a

gap between knob and gun body.

10 3A6466A Operation, Repair, Parts

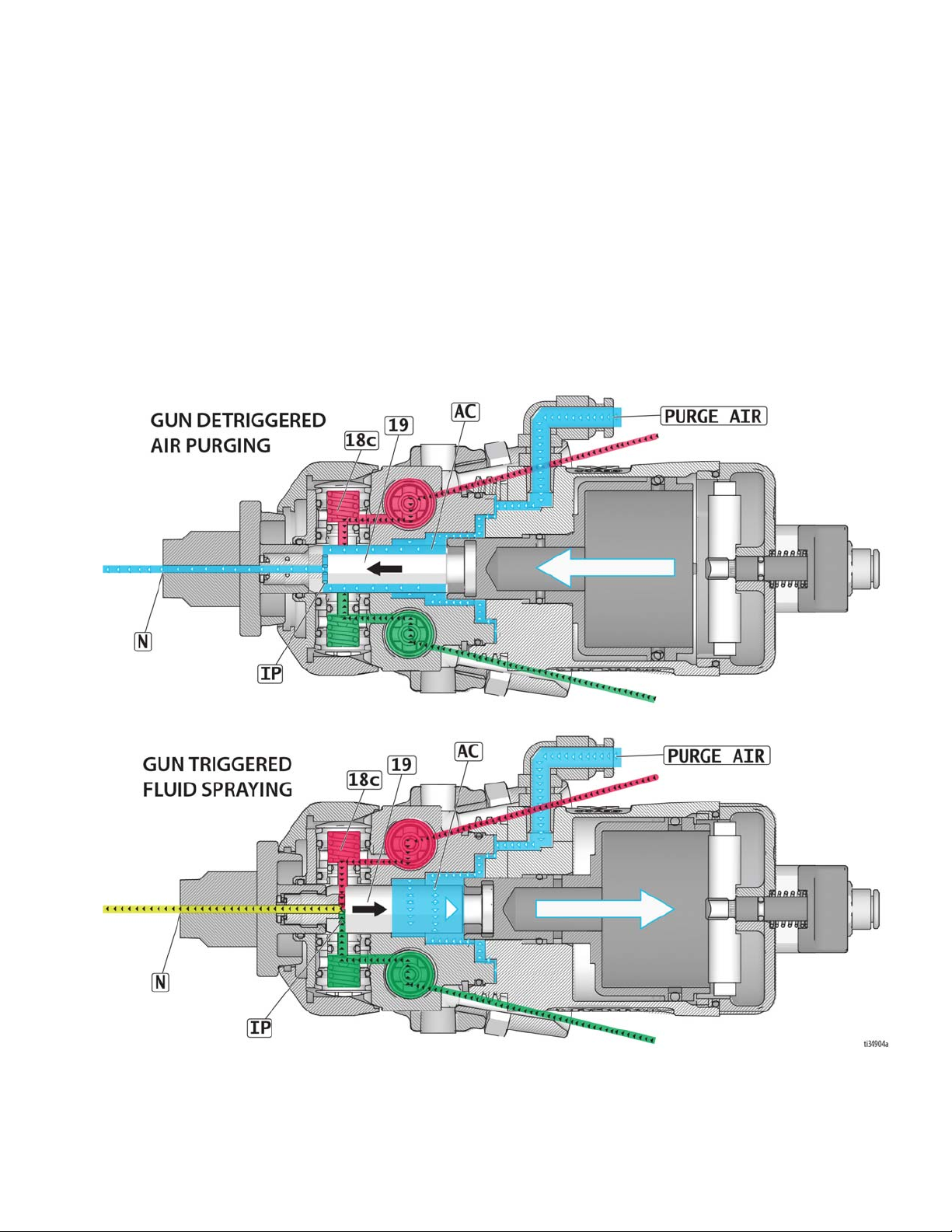

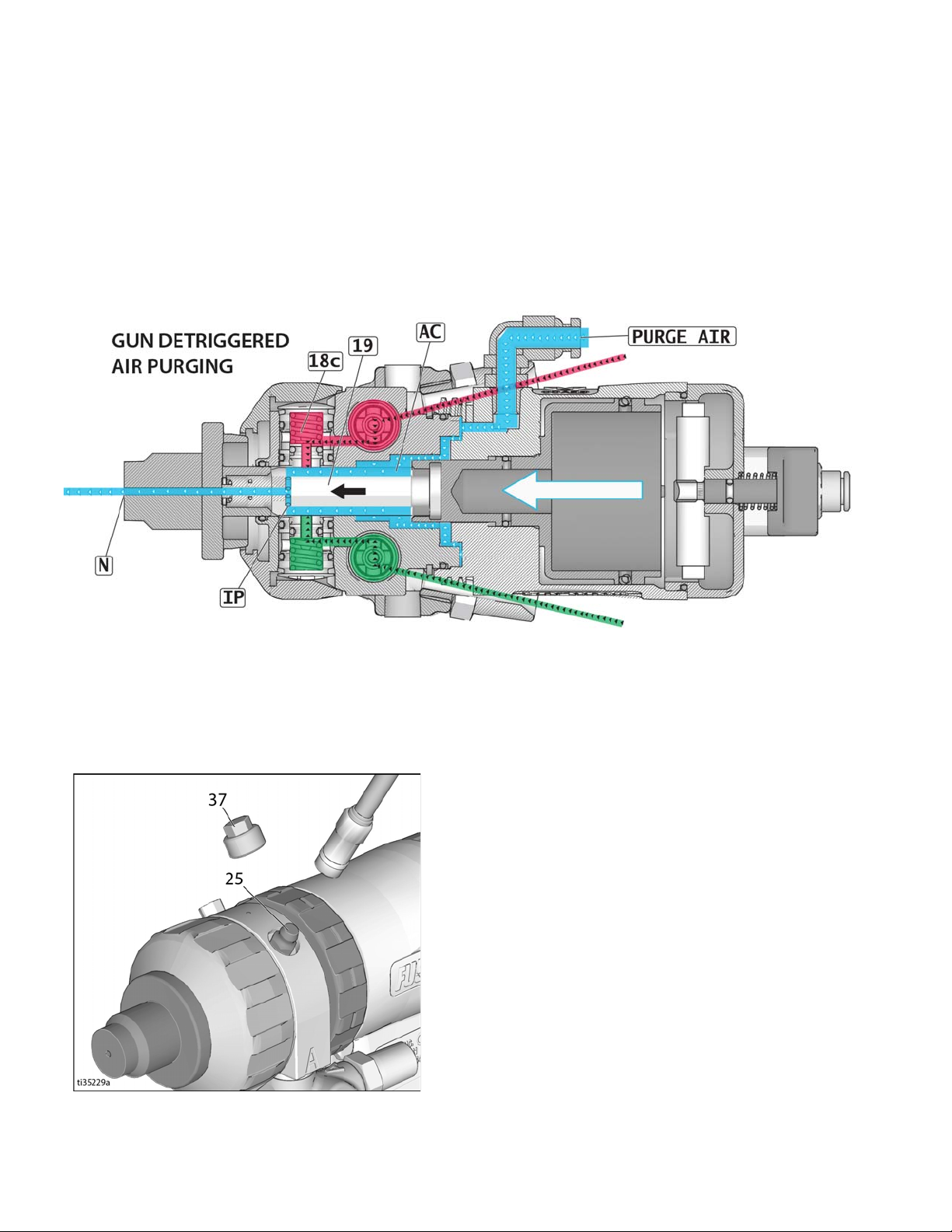

Theory of Gun Operation

Theory of Gun Operation

Gun Triggered (Fluid Spraying)

Mix chamber (19) moves back, shutting off purge air

flow. Impingement ports (IP) align with fluid ports of side

seals (18c), allowing fluid to flow through mix chamber

nozzle (N).

NOTE: Flow paths are not shown to scale, for clarity.

See Parts List, pages 70-72, for part numbers and reference locations.

Gun Detriggered (Air Purging)

Mix chamber (19) moves forward, shutting off fluid flow.

Impingement ports (IP) open to air chamber (AC), allowing purge air to flow through mix chamber nozzle (N).

See page 28 for use of grease fitting.

3A6466A Operation, Repair, Parts 11

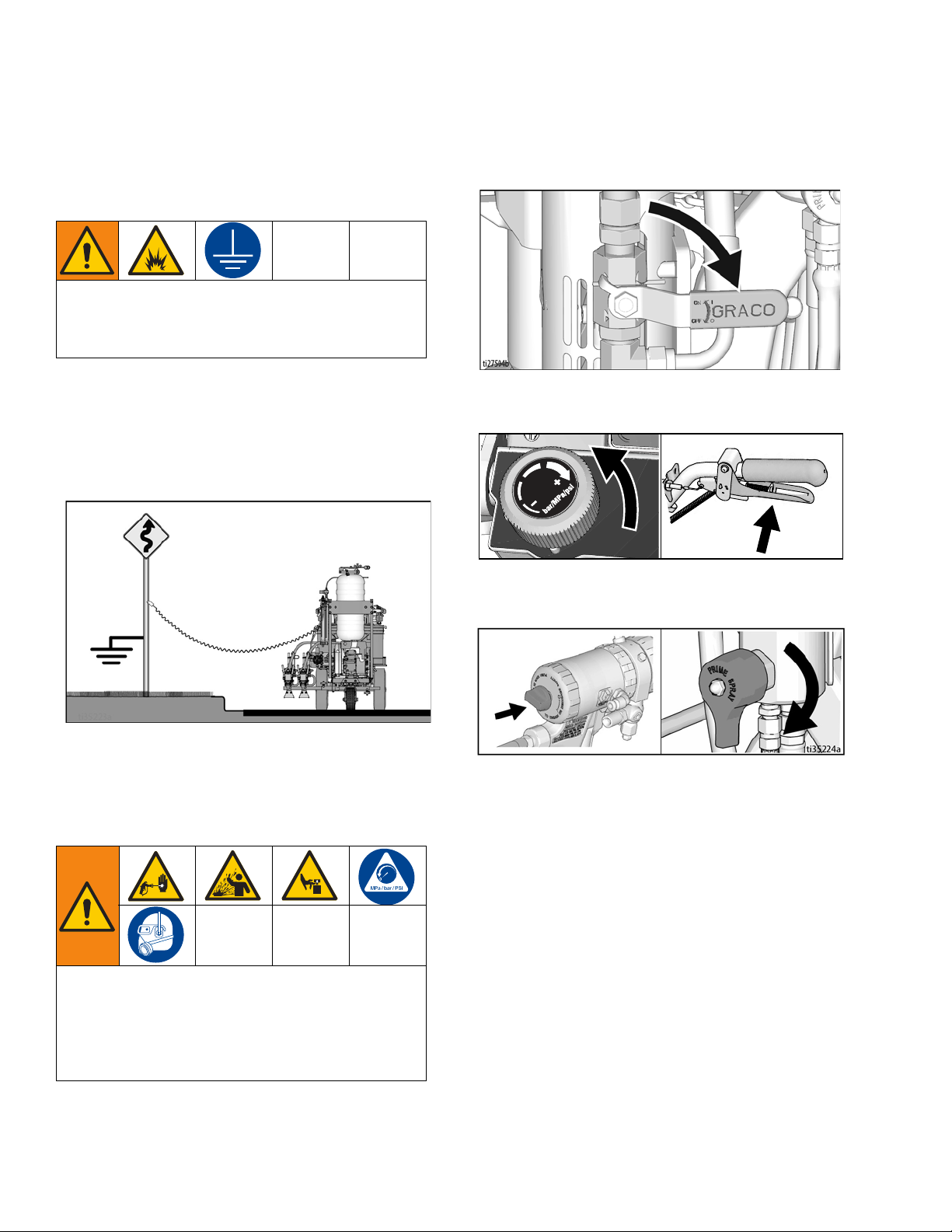

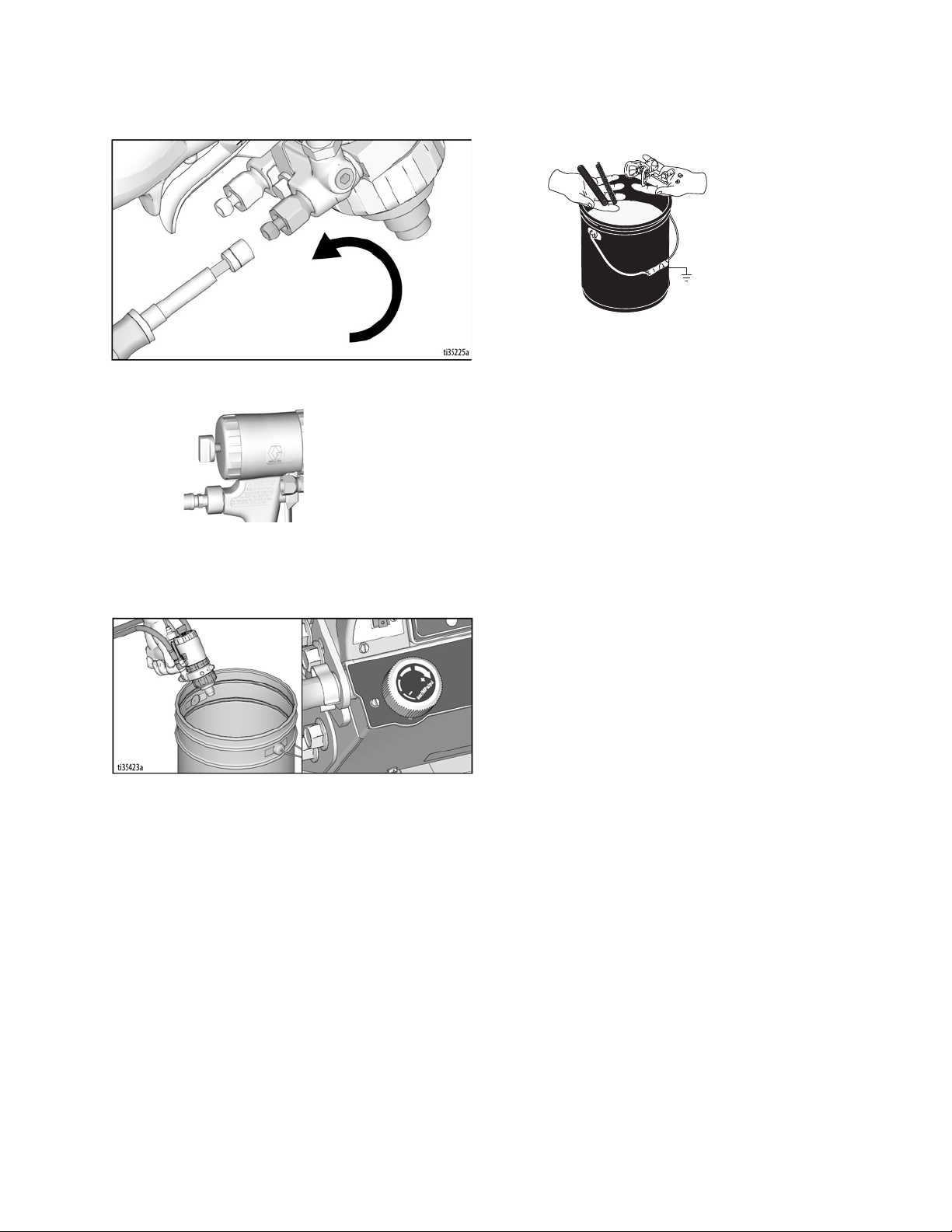

Grounding Procedure (For Flammable Flushing Fluids Only)

ti28013a

Grounding Procedure

(For Flammable Flushing Fluids

Only)

This equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

1. Position striper so that the tires are not on pavement.

2. Striper is shipped with a grounding clamp. Grounding clamp must attach to grounded object (e.g.

metal sign post).

1. Perform Grounding Procedure (For Flammable

Flushing Fluids Only), page 12.

2. Set both pump ON/OFF valves to OFF.

3. Turn pressure control to lowest setting. Trigger all

guns into waste basket to relieve pressure.

3. Disconnect grounding clamp after flushing is complete.

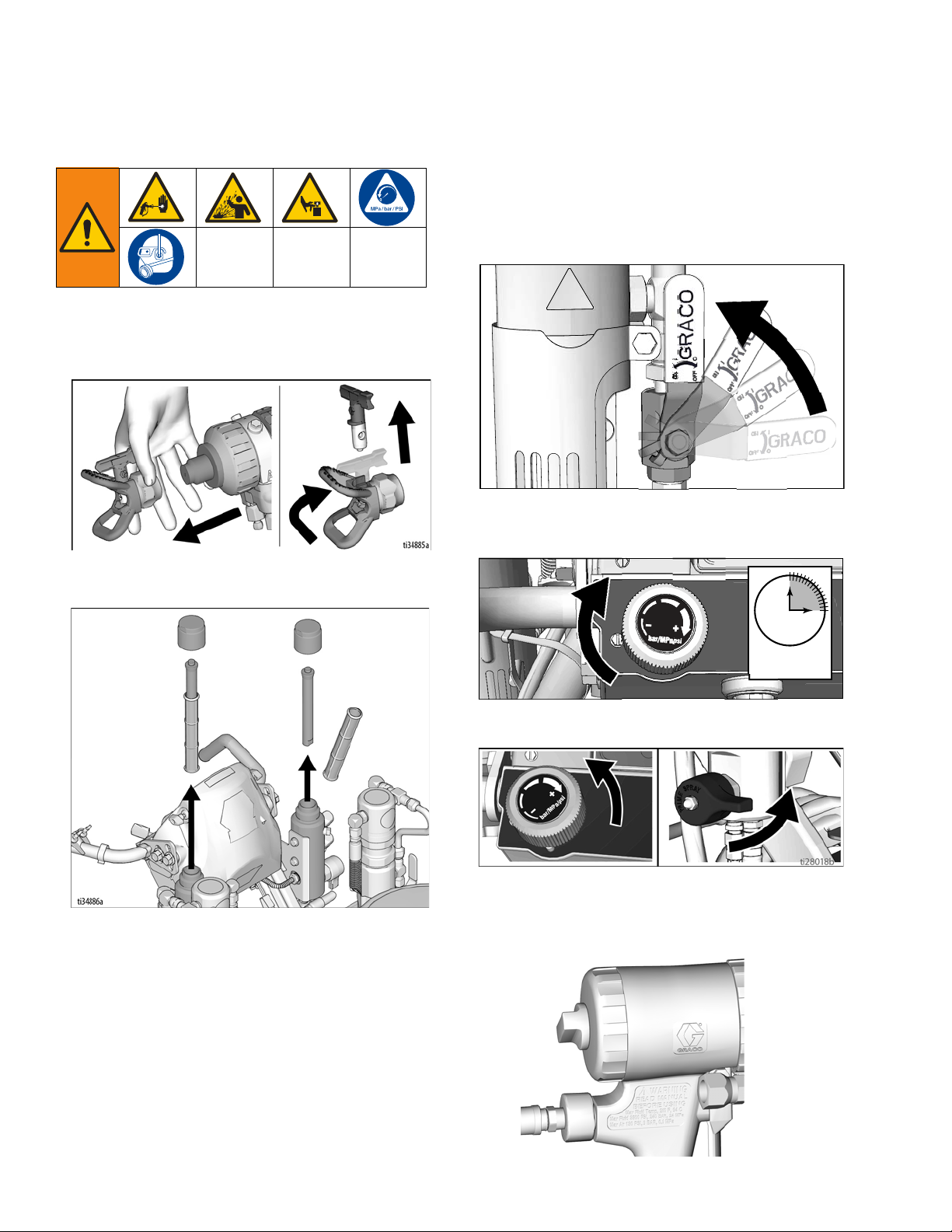

Pressure Relief Procedure

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

4. Engage all gun piston safety locks. Turn prime

valves to prime positions.

5. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved:

a. Remove the Spray Tip Adapter (3) and VERY

SLOWLY remove the Front Retaining Ring (17).

b. Loosen the nut or coupling completely.

c. Clear the obstruction in the hose or tip.

12 3A6466A Operation, Repair, Parts

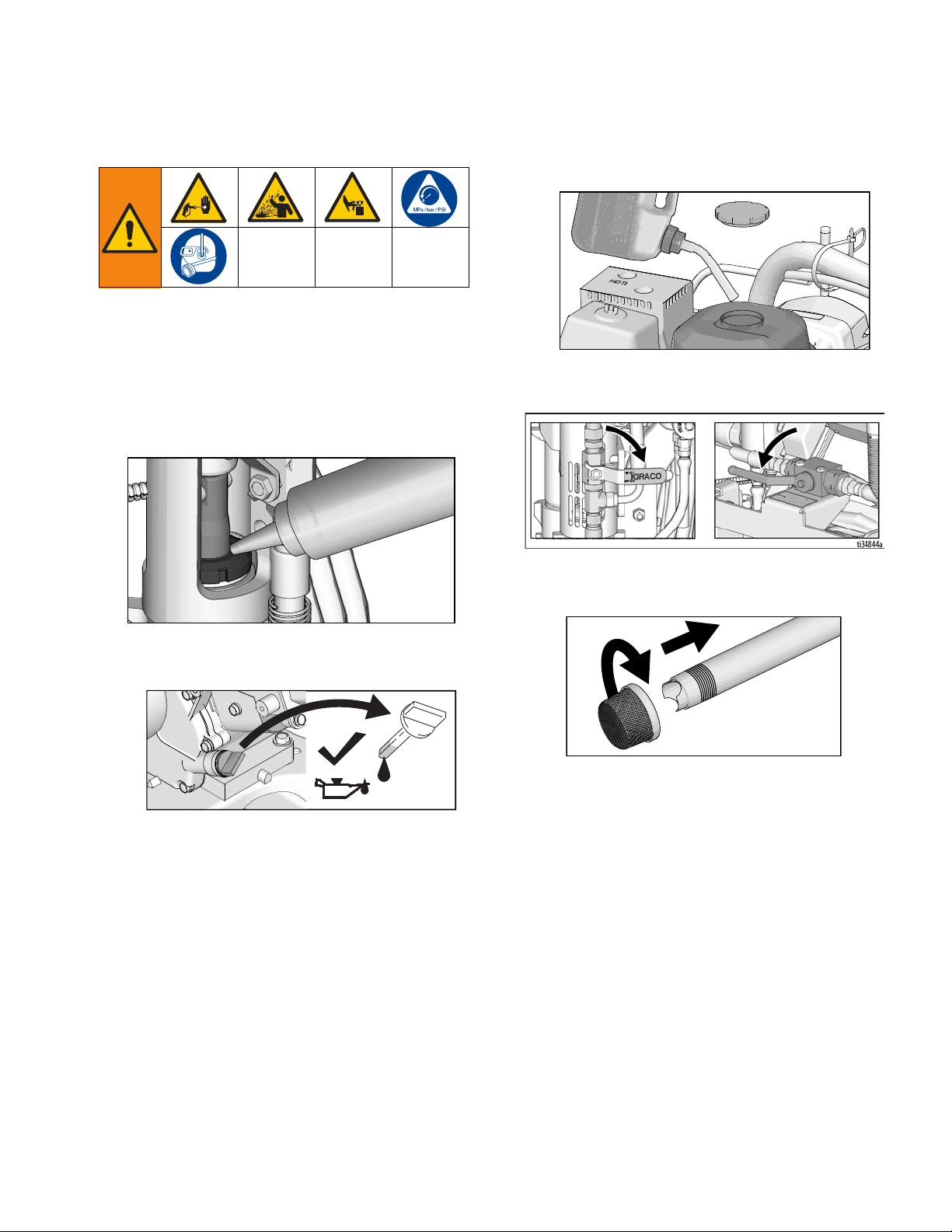

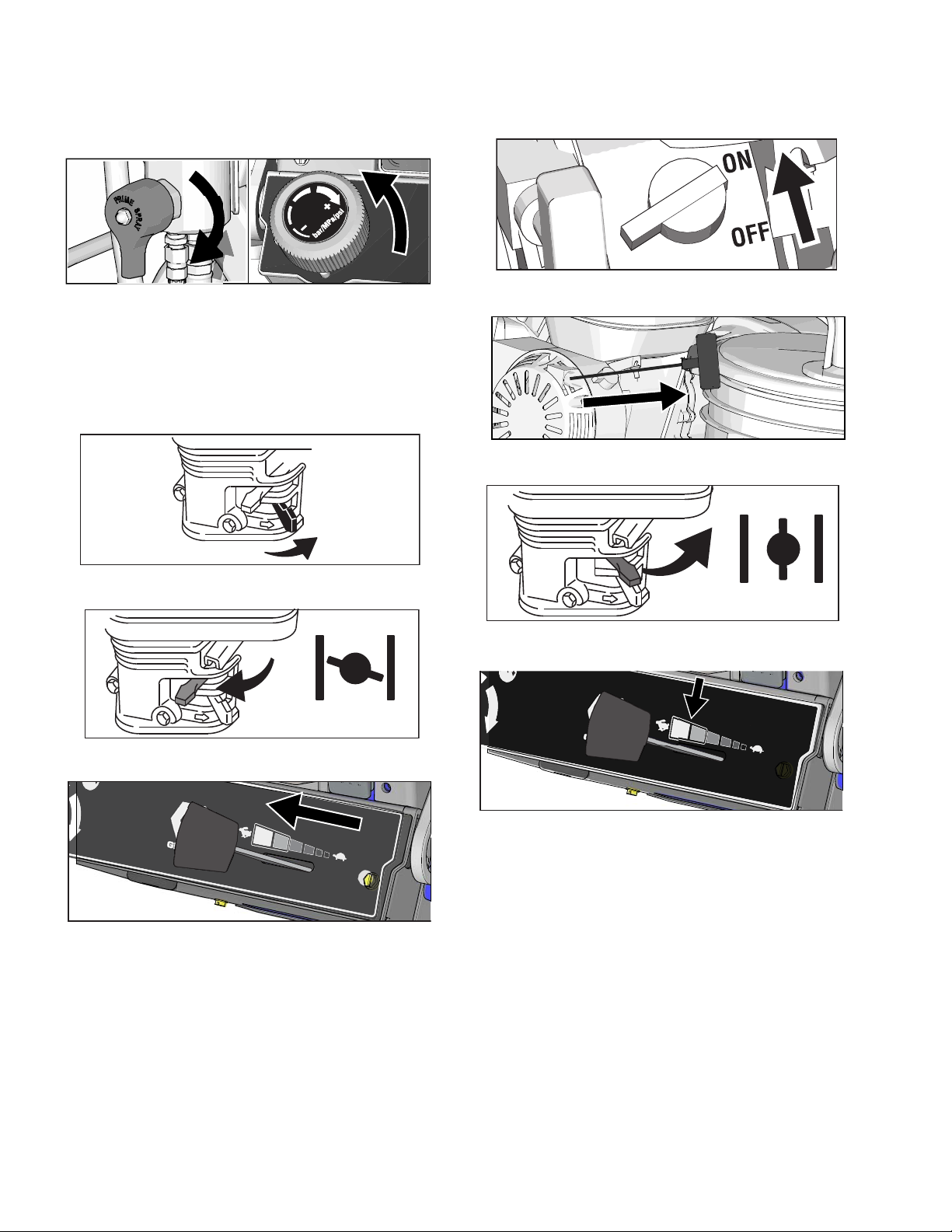

Setup/Startup

ti27611a

ti27612a

Setup/Startup

5. Fill fuel tank.

1. Perform

Pressure Relief Procedure

, page 12.

2. Perform Grounding Procedure (For Flammable

Flushing Fluids Only), page 12, if using flammable

materials.

3. Fill throat packing nut with Throat Seal Liquid (TSL)

to decrease packing wear.

ti28014a

4. Check engine oil level. Add SAE 10W-30 (summer)

or 5W-30 (winter). See engine manual.

6. Set A and B side pump ON/OFF valves to OFF. Set

proportioning valve to “non-proportioning.”

7. If removed, install strainers on both A and B suction

tubes.

ti27610a

3A6466A Operation, Repair, Parts 13

Setup/Startup

ti28015a

ti27617a

ti27618a

ti28151a

ti27620a

ti27766a

ti27618a

ti28152a

8. Turn both prime valves to prime. Turn pressure control counterclockwise to lowest pressure.

NOTE: Minimum hose size allowable for proper

sprayer operation is 3/8 in. x 11 feet & 1/4 in. x 7 feet

for LLV 200MMA.

9. Start engine:

a. Move fuel valve to open.

ti27616a

d. Set engine switch to ON.

ti27619a

e. Pull starter cord.

10. After engine starts, move choke to open.

b. Move choke to closed.

c. Set throttle to fast.

11. Set throttle to desired setting.

14 3A6466A Operation, Repair, Parts

Setup/Startup

ti28017a

ti28016a

15s

TI2410A

12. Digital display is functional after engine starts.

13. Mix BPO catalyst with component B per manufacturer’s recommendation.

14. Place siphon tube in component B pail and drain

tube in separate waste pail.

15. Set B side pump ON/OFF valve to ON (pump is now

active).

17. Turn pressure down, turn prime valve to spray.

18. Return drain line to component B pail.

19. Engage piston safety lock.

20. Open B side fluid valve (about three full turns).

16. Increase pressure control enough to start pump.

21. Disengage piston safety lock.

Pump is primed when fluid flows from drain tube.

3A6466A Operation, Repair, Parts 15

Setup/Startup

22. Hold gun against a grounded metal flushing pail.

Trigger gun and increase fluid pressure slowly until

pump runs smoothly.

High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. Do not stop

leaks with hand or rag.

23. Inspect fittings for leaks. If leaks occur, turn sprayer

OFF immediately. Perform Pressure Relief Proce-

dure, page 12. Tighten leaky fittings. Repeat

Startup, steps 1 - 22. If no leaks, continue to trigger

gun until system is thoroughly primed. Proceed to

step 24.

27. Insert SwitchTip in tip bore and firmly thread

assembly onto gun.

28. Test spray onto cardboard. Adjust pressure to

achieve desired results.

24. Close B side fluid valve on gun, and repeat step 14 23 for pump “A” with component A material.

25. Perform Pressure Relief Procedure, page 12.

26. Engage piston safety lock. Use end of SwitchTip to

press OneSeal into tip guard, with curve matching

tip bore.

To avoid serious injury from skin injection, do not put

your hand in front of the spray tip when installing or

removing the spray tip and tip guard.

29. Aim gun into waste bucket, open purge air valve to

purge mixed material from tip and spray tip adapter.

NOTICE

Purge air valve must be open to purge material from

gun. Purging material maintains the gun’s functionality

and prevents hardened material in gun components.

16 3A6466A Operation, Repair, Parts

Setup/Startup

Keep Components A and B

Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage equipment. To prevent cross-contamination:

• Never interchange component A and component

B wetted parts.

• Never use solvent on one side if it has been contaminated from the other side.

Changing Materials

NOTICE

Changing the material types used in your equipment

requires special attention to avoid equipment damage

and downtime.

• When changing materials, flush the equipment

multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers on suction

tubes after flushing.

• Check with your material manufacturer for chemical compatibility.

3A6466A Operation, Repair, Parts 17

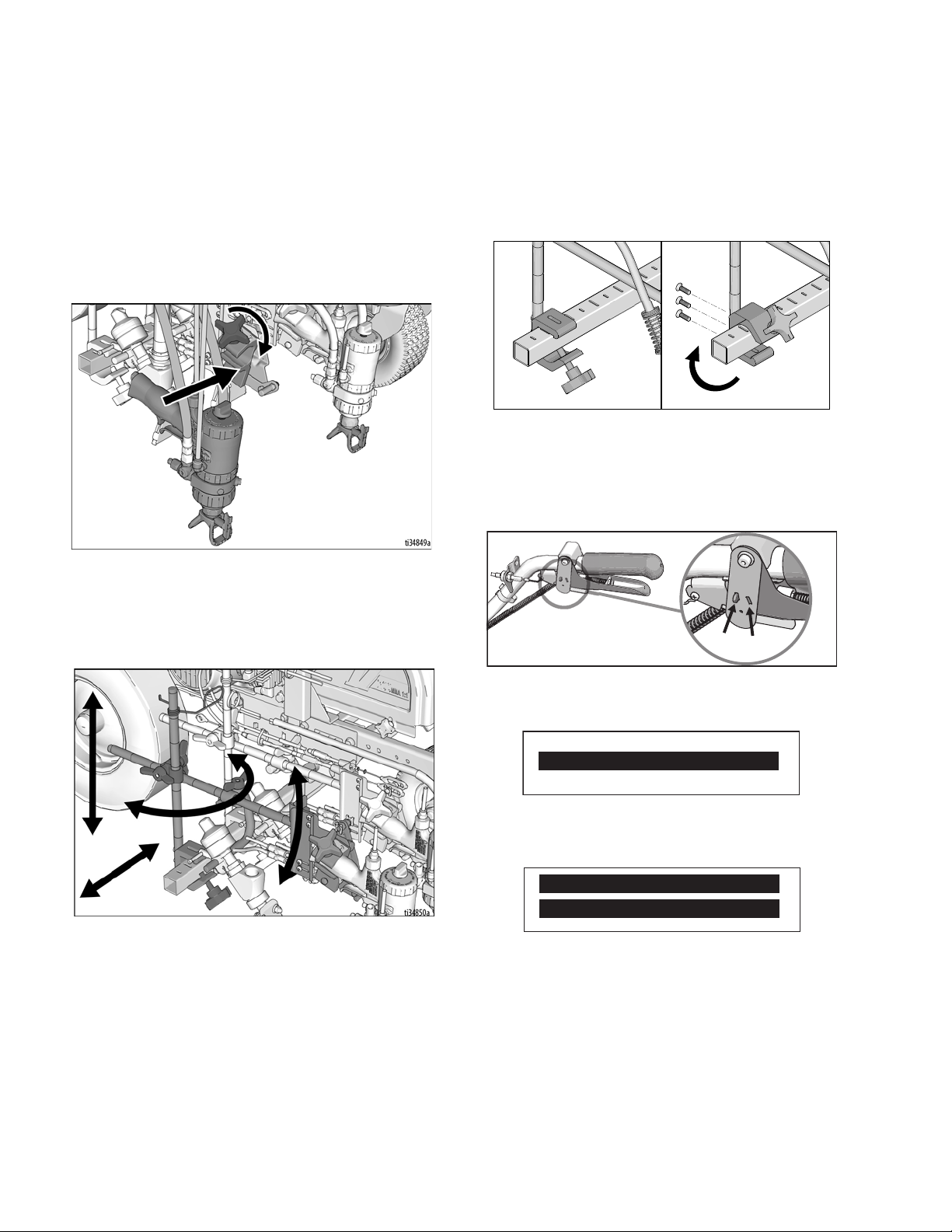

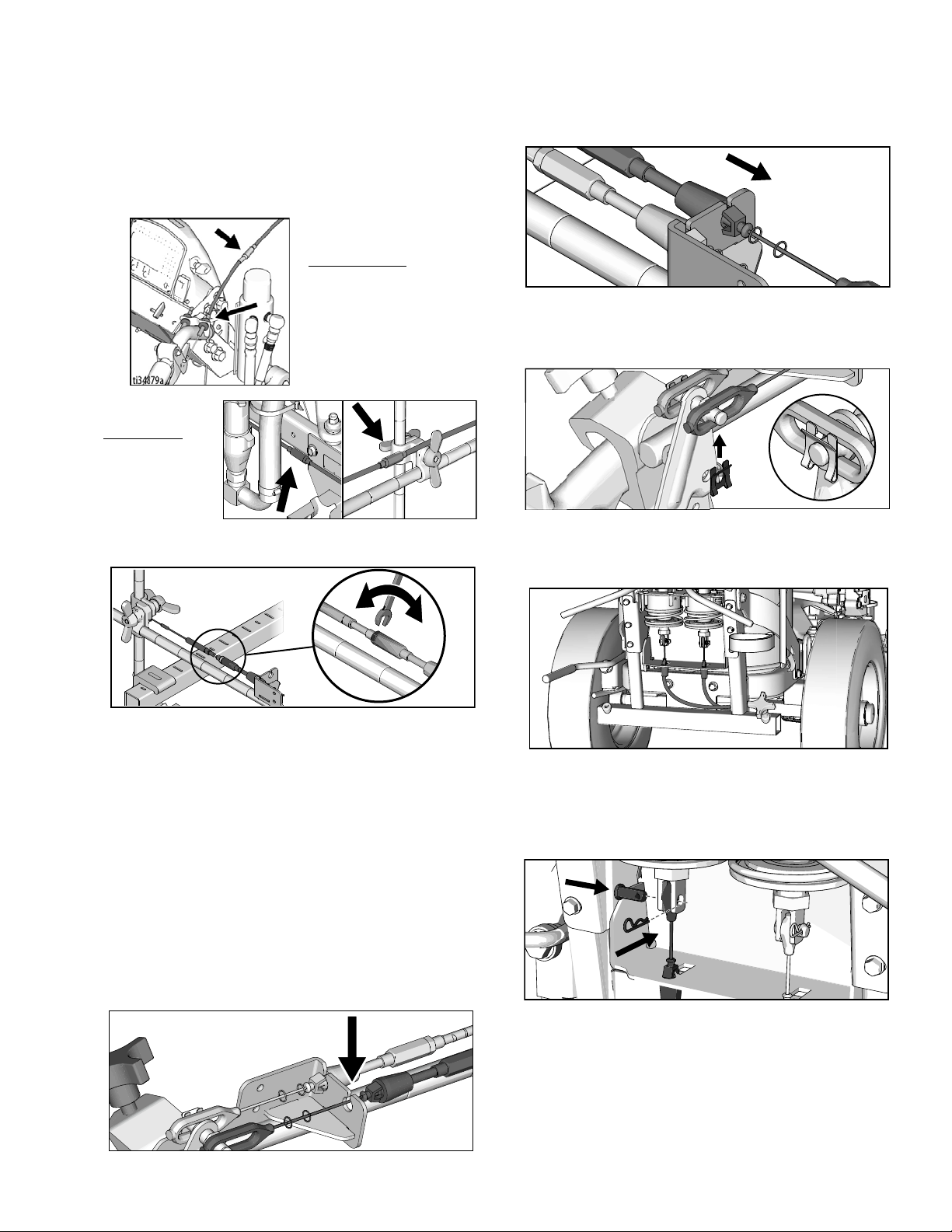

Gun Placement

ti28129a

1

2

ti27780a

ti27781a

ti27782a

Gun Placement

Install Guns

1. If pressurized, perform Pressure Relief Procedure,

page 12.

2. Insert guns into gun holder. Tighten clamps.

Position Gun

3. Position gun: up/down, forward/reverse, left/right.

See Gun Positions Chart, page 20, for examples.

NOTE: When striping above a curb, the mounting clamp

can be rotated for clearance.

Manual Guns Selection

4. Connect gun cables to left or right gun selector

plates.

a. One gun: Disconnect one gun selector plate

from trigger.

b. Both guns simultaneously: Adjust both gun

selector plates to the same position.

18 3A6466A Operation, Repair, Parts

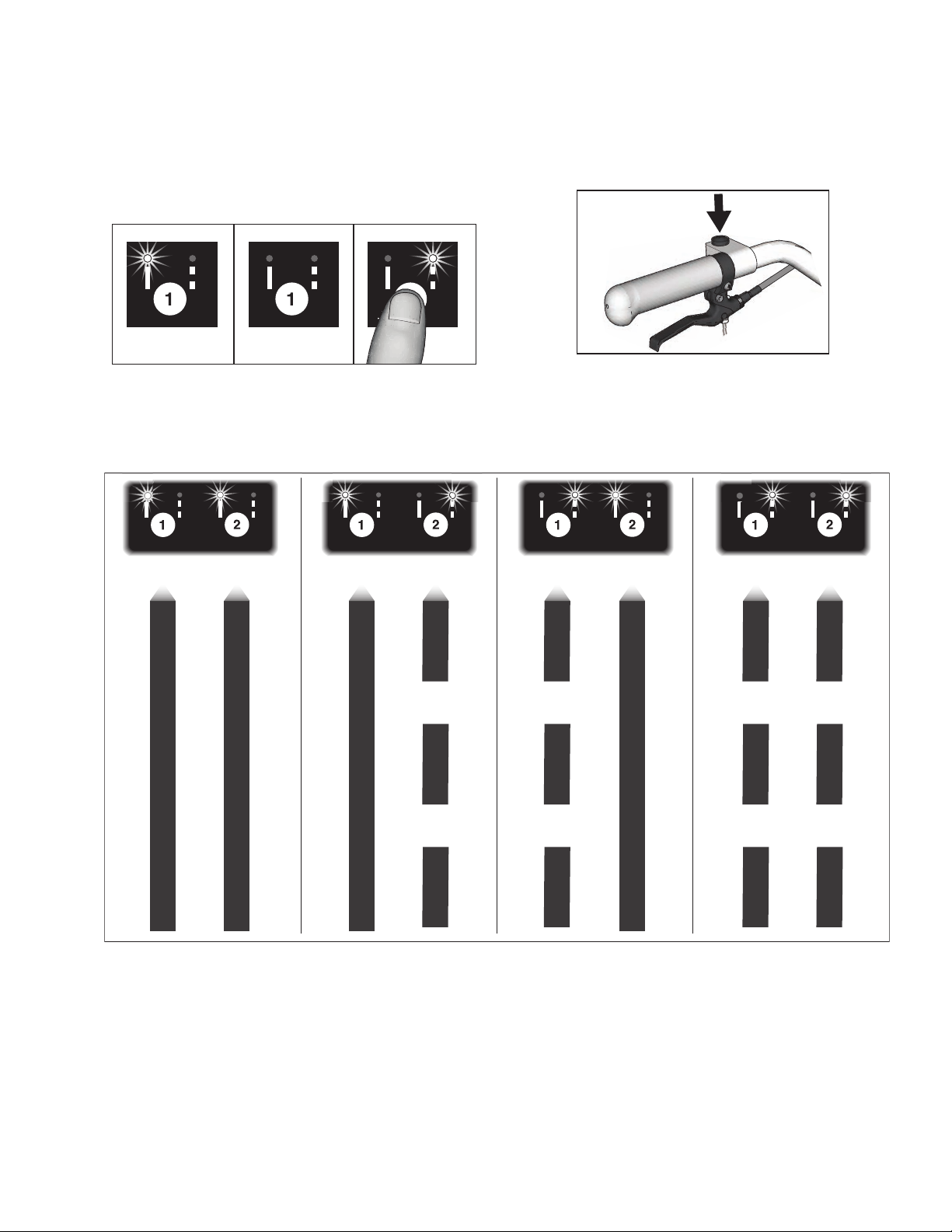

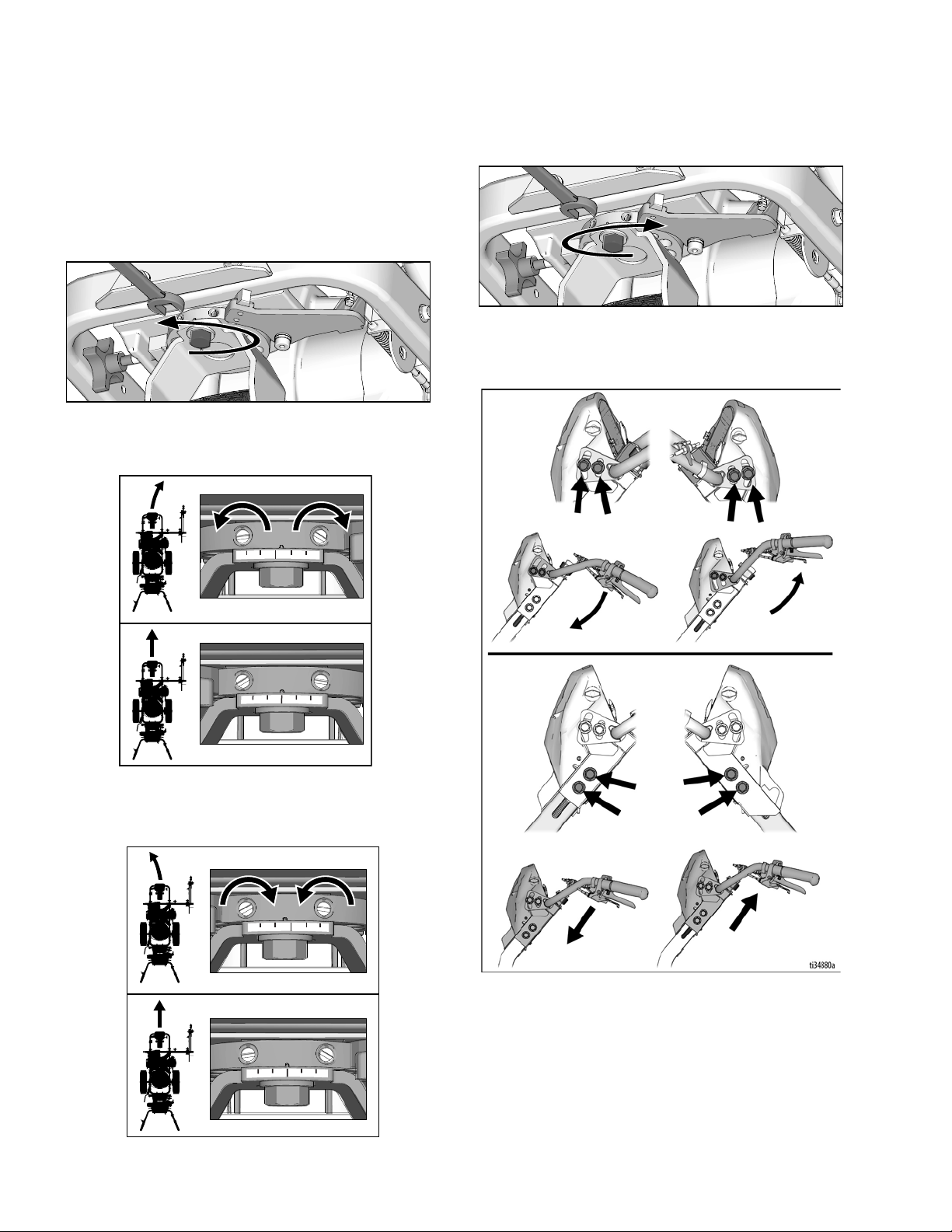

Auto Guns Selection

1s

ti27784a

ti27881a

ti27785a

Gun

1

Gun

2

Gun

1

Gun

2

Gun

1

Gun

2

Gun

1

Gun

2

Gun Placement

1. Use the gun selector buttons to determine which

guns are active. Each gun selector has 3 settings:

continuous line, OFF, and programmed line pattern.

2. Use the gun trigger control to actuate guns.

4 Examples:

\

3A6466A Operation, Repair, Parts 19

Gun Placement

Gun Positions Chart

1 One line

2 One line up to 24 in. (61cm) wide

3 Two lines

4 One line or two lines to spray around obstacles

5 One gun curb

6 Two gun curb

7 Two lines or one line up to 24 in. (61 cm) wide

20 3A6466A Operation, Repair, Parts

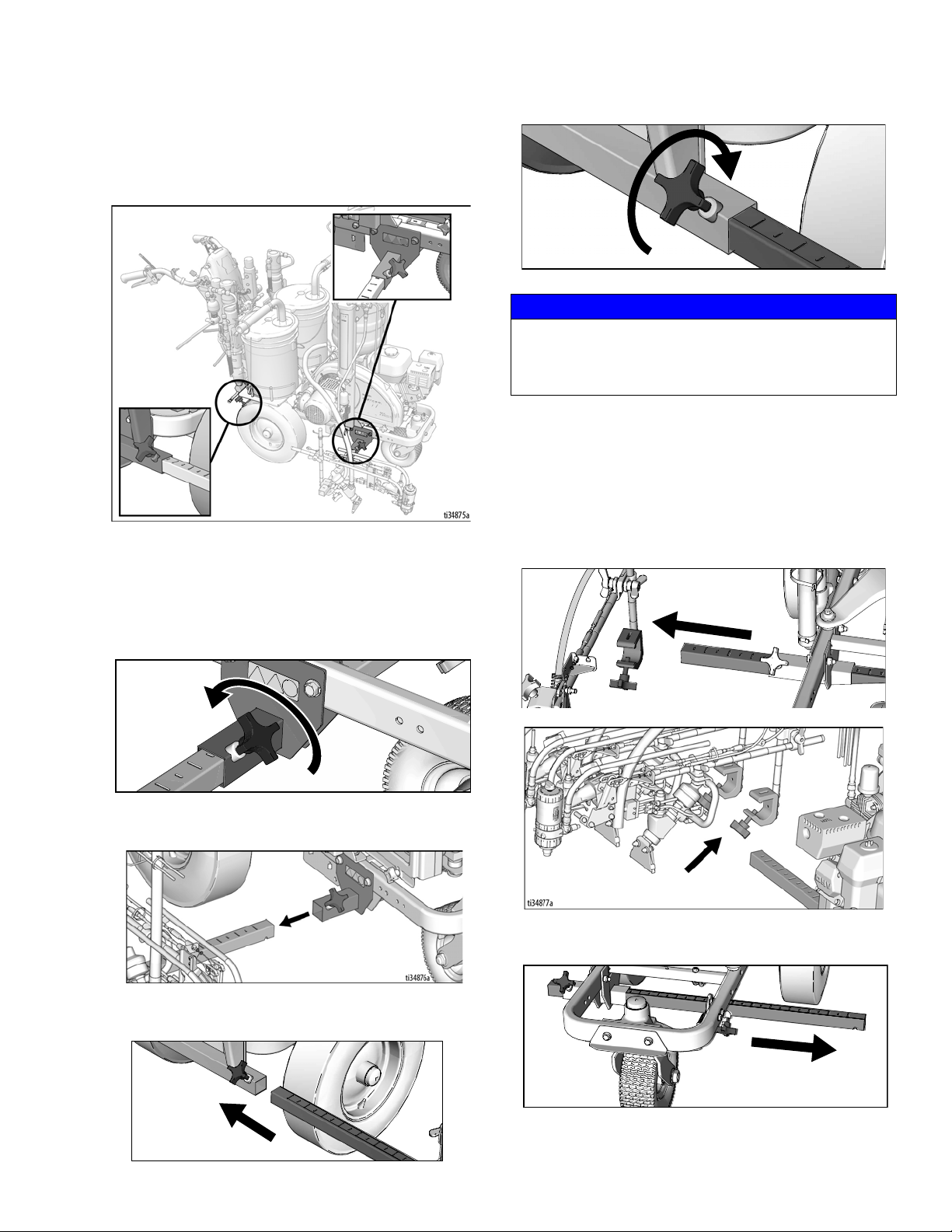

Gun Placement

ti27797a

ti27800a

Gun Arm Mounts

This unit is equipped with front and rear gun arm mounts

to allow the operator to place the guns in the optimal

location.

Change Gun Position

4. Tighten gun arm knob into gun arm mounting slot.

ti27798a

NOTICE

Make sure all hoses, cables, and wires are properly

routed through brackets and do NOT rub on tire.

Contact with tire will result in damaged hoses, cables,

and wires.

Change Gun Position

(Left and Right)

Removal

1. Loosen vertical gun arm knob on gun arm mounting

bar and remove.

(Front and Back)

1. Loosen gun arm knob and remove from gun arm

mounting slot.

ti27796a

2. Slide gun arm assembly (including gun and hoses)

out from gun arm mounting slot.

3. Slide gun arm assembly into desired gun arm

mounting slot.

ti27799a

2. Extend mounting bar on opposite side of the

machine.

3A6466A Operation, Repair, Parts 21

Gun Placement

HP Auto Series

Installation

1. Install vertical gun mount onto gun bar.

NOTE: Make sure all hoses, cables, and wires are

properly routed through brackets.

Trigger Sensor Adjustment

1. Start striper engine. Manually pull the trigger. Spray

icon should appear simultaneously with start of fluid

spray.

No fluid spray

2. Turn screw in handle clockwise if spray icon

appears before fluid spray starts.

ti27802a

No spray icon

3. Turn screw in handle counterclockwise if fluid spray

starts before spray icon appears.

ti27803a

4. Continue adjusting screw in handle until timing of

spray icon and fluid spray are synchronized.

22 3A6466A Operation, Repair, Parts

Gun Placement

Manual Guns

Auto Guns

(has 2 locations)

ti27805a

ti27806a

ti27807a

ti27809a

Gun Cable Adjustment

Adjusting the gun cable will increase or decrease the

gap between the trigger plate and the gun trigger. To

adjust trigger gap, perform the steps below.

ti27885a

1. Use wrench to loosen locking nut on cable adjuster.

3. Insert plastic cable retainer into cable bracket hole.

4. Install cable end onto trigger plate pin and install

clip.

5. Route cable around unit and up through cable holes

behind hose mount.

2. Loosen or tighten adjuster until desired result is

3. Use wrench to tighten locking nut on the adjuster.

Adding Gun Cable (Auto Gun)

The HP Auto Series can be equipped with two gun actuators. Each gun actuator is capable of operating one

cable.

1. Select cable end with adjuster.

2. Install exposed cable through cable bracket slot.

3A6466A Operation, Repair, Parts 23

ti27804a

achieved. NOTE: More thread exposed means less

gap between gun trigger and trigger plate.

ti27808a

6. Route cable end loop through rectangular hole in

bracket and insert plastic cable retainer into the

actuator bracket. Install cable end onto actuator rod

and install pin.

Gun Placement

ti27810a

ti27811a

ti27812a

ti27813a

Straight Line Adjustment

The front wheel is set to center the unit and allows the

operator to form straight lines. Over time, the wheel may

become misaligned and will need to be readjusted. To

re-center the front wheel, perform the following steps:

1. Loosen bolt on the front wheel bracket.

2. If striper arcs to the right, loosen left set screw and

tighten right set screw for fine tune adjustment.

4. Roll the striper. Repeat steps 2 and 3 until striper

rolls straight. Tighten bolt on wheel alignment plate

to lock the new wheel setting.

Handle Bar Adjustment

3. If striper arcs to the left, loosen right set screw and

tighten left set screw.

24 3A6466A Operation, Repair, Parts

Gun Placement

ti27886a

ti27888a

Dot Laser

LASER LIGHT HAZARD. Avoid direct eye contact.

1. Remove battery cover.

2. Attach ON/OFF switch to desired location on the

handle bar.

4. Route wires from the switch to the battery and connect to the (+) and (-) terminals.

ti27818a

5. Connect the switch leads to the wire harness.

6. Reattach battery cover.

ti27815a

3. Attach laser to desired location on the gun arm.

7. Turn on laser and position dot underneath gun

head.

ti27816a

3A6466A Operation, Repair, Parts 25

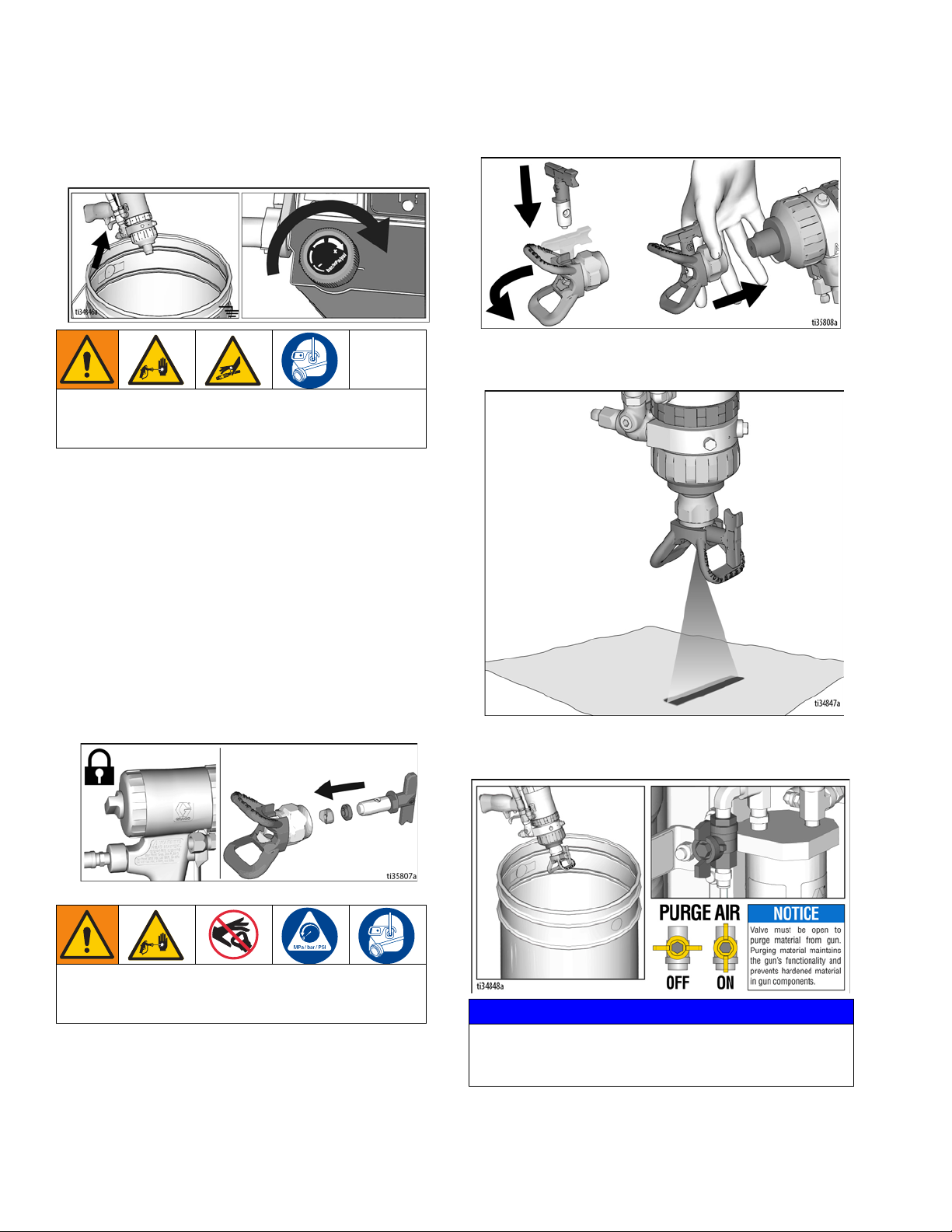

Cleanup

ti28017a

ti28016a

15s

Cleanup

1. Perform Pressure Relief Procedure, page 12.

2. Remove guard and tip from all guns and place in

acetone.

4. Place B side siphon tube set in grounded metal pail

partially filled with acetone. Attach ground wire to

true earth ground.

5. Set B side pump valve to ON (pump is now active).

3. For both filter manifolds, unscrew cap, remove filter,

and assemble without filter.

6. Increase pressure control enough to start pump.

Pump is primed when solvent flows from drain tube.

7. Turn pressure down, turn prime valve to spray.

8. Return drain line to component B pail.

9. Engage piston safety lock.

26 3A6466A Operation, Repair, Parts

Cleanup

TI2410A

FLUSH

TI3375A

10. Open B fluid valve (about three full turns).

11. Disengage piston safety lock.

12. Hold gun against a grounded metal flushing pail.

Trigger guns and increase fluid pressure slowly until

pump run smoothly.

14. Clean mixing chamber, tip, and tip guard in acetone

fluid.

15. Fill pump with Pump Armor and reassemble filter,

guard and tip.

16. Disassemble Front End of Fusion Gun, page 47.

17. Remove Mix Chamber & Side Seal Cartridges,

page 48, steps 7-8, place in acetone.

18. Lubricate o-rings, see Lubrication, page 46.

19. Dissassemble Check Valves, page 50, step 5,

place in acetone with tips and air cap.

20. Lubricate o-rings, see Lubrication, page 46.

13. Close B fluid valve, turn B pump valve OFF. Repeat

steps 4-12 for A side pump and gun.

21. Reassemble Front End of Fusion Gun, page 47.

22. Reassemble Mix Chamber & Side Seal Car-

tridges, page 49.

23. Reassemble Check Valves, page 50.

24. Each time you spray and store, fill throat packing

nut with TSL to decrease packing wear.

3A6466A Operation, Repair, Parts 27

Cleanup

For overnight shutdown

1. Perform Pressure Relief Procedure, page 12.

2. Leave purge air valve turned on and gun detriggered while machine is still running.

NOTE: Grease gun daily to prevent 2 component curing

and keep fluid passages clean. Purge air carries grease

mist through air chamber (AC), impingement ports (IP),

and out mix chamber nozzle (N), coating all surfaces.

Use Graco 117773 Grease, see page 87.

NOTE: Flow paths are not shown to scale, for clarity.

See Parts List, pages 70-72, for part numbers and reference locations.

3. Remove grease fitting cap (37). Using grease gun,

dispense grease into fitting (25) until grease mist

sprays from mix chamber nozzle (N). Do not

over-grease; use 2 shots maximum. Do not spray

grease mist on sprayed material.

4. Replace grease cap (37).

28 3A6466A Operation, Repair, Parts

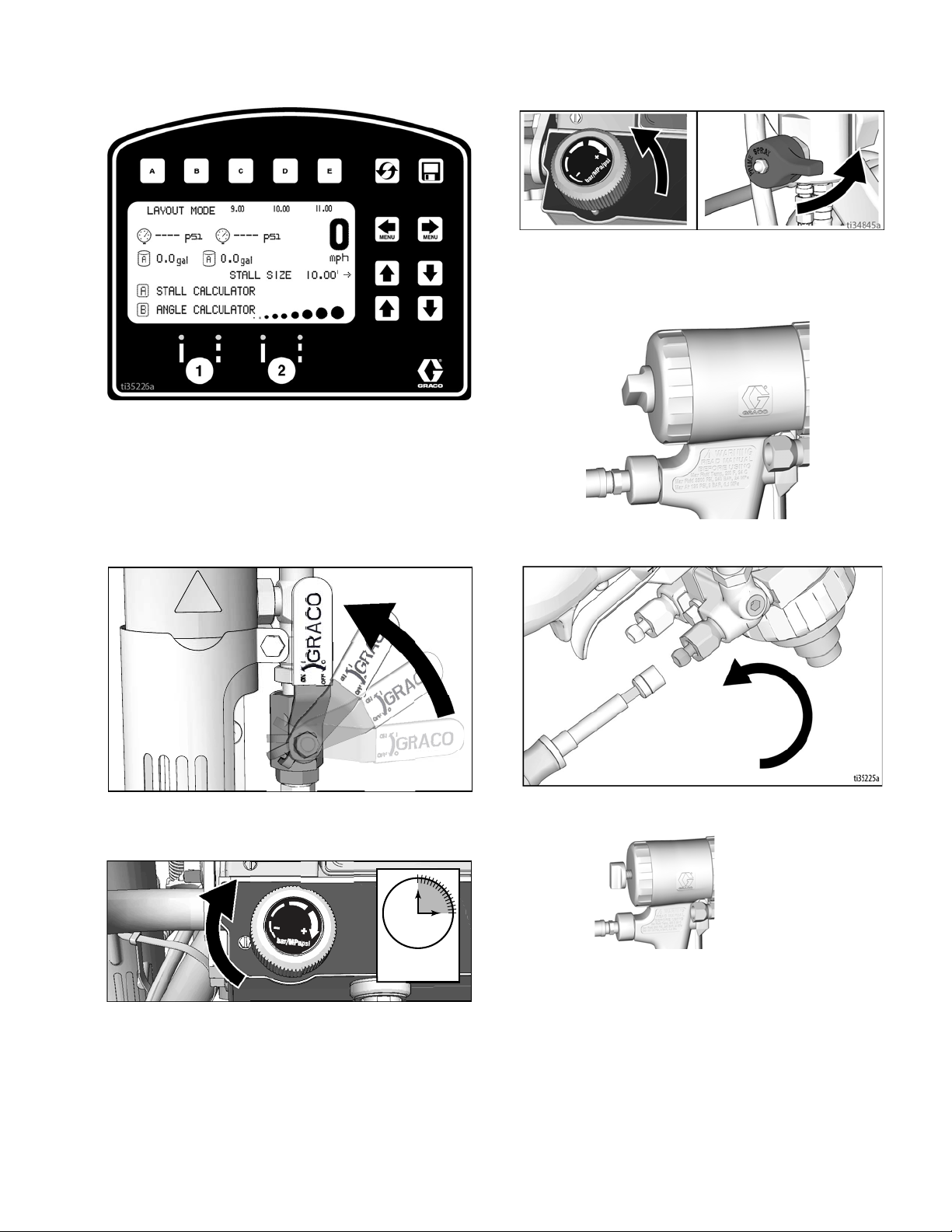

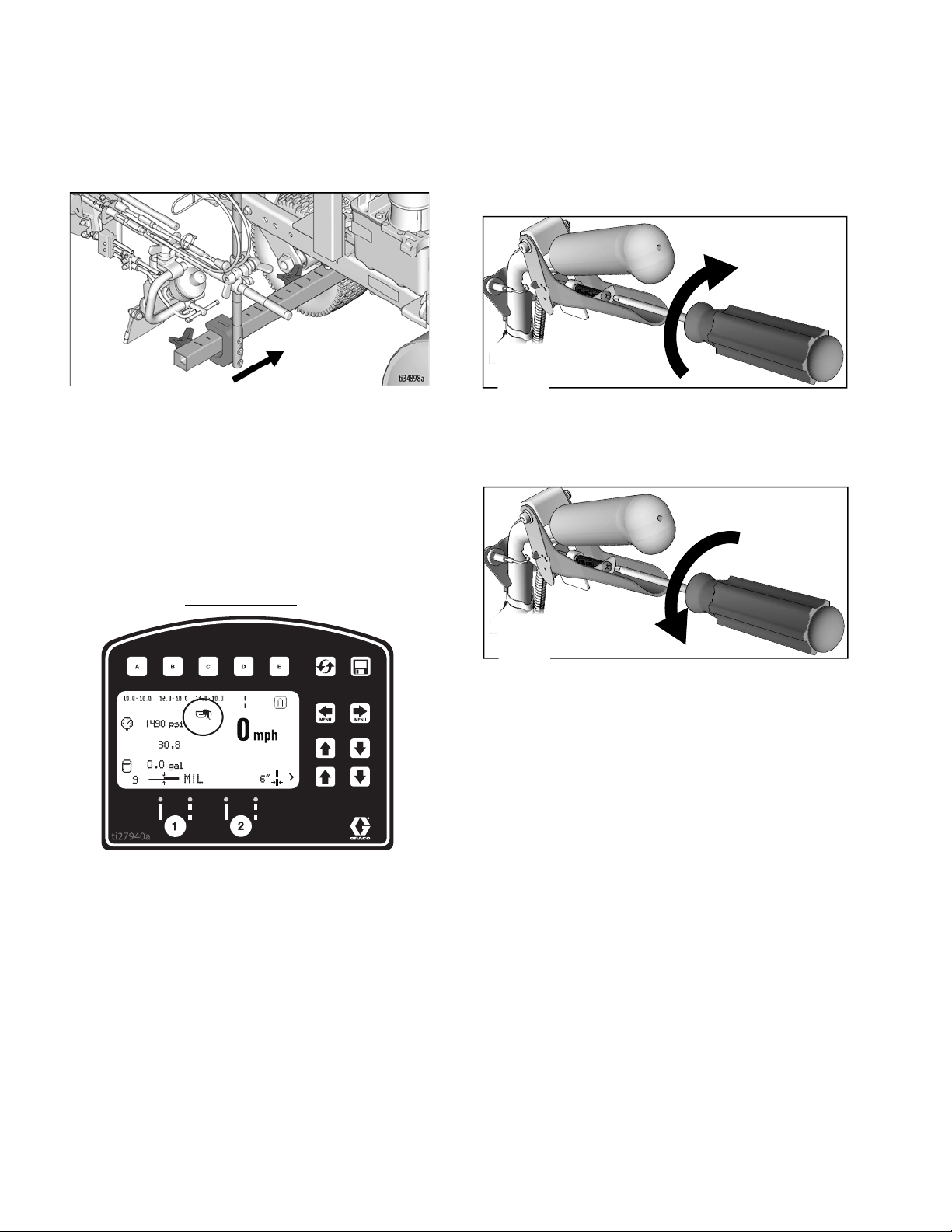

LineLazer V LiveLook Display

35

36

HP Auto Series

LineLazer V LiveLook Display

3A6466A Operation, Repair, Parts 29

LineLazer V LiveLook Display

ti35233a

CALIBRATION

A

SETTINGS

B

INFORMATION

C

ENG SPA FRE DEU RUS WORLD

D

LAYOUT MODE

E

ti27828a

26 Ft.

8M

ti27829a

Initial Setup (HP Auto Series)

The initial setup prepares the striper for operation based

on a number of user entered parameters. Language

selections and the units of measure selections can be

set before you start or changed later.

Language

From Setup/Information select appropriate language by

pressing until the language is outlined.

US Units

Pressure = psi

Volume = gallons

Distance = feet

Line Thickness = mil

SI Units

Pressure = bar (MPa available)

Volume = liters

Distance = meters

Line thickness = micron (g/m

2

available)

Paint Specific Gravity = Use UP and DOWN arrows

to set specific gravity. Required to determine paint

thickness.

NOTE: All units can be changed individually at any

time.

Calibration

1. Check rear tire pressure 55 ± 5 psi (379 ± 34 kpa)

and fill if necessary.

2. Extend steel tape to distance greater than 26 ft.

(8m).

ENG = English

SPA = Spanish

FRE = French

DEU = German

RUS = Russian

WORLD = Symbols see World Symbol Key, page

89.

NOTE: Language can be changed later.

Units

Press to enter settings and then again to

enter units. Select appropriate units of measure.

30 3A6466A Operation, Repair, Parts

LineLazer V LiveLook Display

ti35233a

CALIBRATION

A

SETTINGS

B

INFORMATION

C

ENG SPA FRE DEU RUS WORLD

D

LAYOUT MODE

E

ti27912a

3. Press to select Setup/Information.

4. Press for Calibration. Set TRAVEL DIST to 25 ft

(7.6m) or longer. Longer distances ensure better

accuracy, depending on conditions.

6. Press and release gun trigger control to start calibration.

7. Move striper forward. Keep laser dot on steel tape.

8. Stop when laser aligns with 26-ft (8m) or distance

entered on steel tape (25-ft / 7.6m distance).

5. Turn on laser and align laser dot with 1 foot

(30.5cm) on steel tape.

9. Press and release gun trigger control to complete

calibration.

ti27912a

• Calibration is not complete when the exclamation

symbol is displayed.

• Calibration is finished when the check mark symbol

is displayed.

10. Calibration is now complete.

Go to Measure Mode (HP Auto Series), page 33, and

verify accuracy by measuring the tape.

3A6466A Operation, Repair, Parts 31

LineLazer V LiveLook Display

ti27881a

Striping Mode (HP Auto Series)

Ref. Description

Select a “Favorite”, press for less than one sec-

ond.

1

Save a “Favorite”, press and hold for more than

three seconds.

2 Cycles between viewing line width or paint and

space value.

Cycles between Manual Mode, Semi-Automatic

Mode, Automatic Mode.

Manual Mode : Press and hold gun trigger

control to stripe.

Semi-Automatic Mode : Press and release

3

gun trigger control to stripe the programmed

length one time when in Skip Mode.

Automatic Mode : Press and release gun

trigger control to start striping. Press and release

button again to stop.

4 Resets trip distance.

5 Job Data Logger, page 42.

6 Scrolls between menu screens.

7 Paint and Space length OR line width adjustment

buttons.

8 Auto guns activation buttons.

9 MIL thickness. While spraying “Instant MIL avg” is

displayed. When stopped total “Job MIL avg” is

displayed.

10 Total gallons (liters) sprayed, Pump A and B

11 Total line length sprayed.

12 Pressure, Pump A and B

Operating in Striping Mode

Striper must be running before activating gun trigger

control.

1. Make sure engine is running.

2. Use gun activation buttons to select guns and line

type.

ti27893a

3. Press gun trigger control to begin spraying.

In Automatic Mode or Semi-Automatic Mode the or

will flash when gun trigger control is pressed to sig-

nal mode is active.

32 3A6466A Operation, Repair, Parts

LineLazer V LiveLook Display

ti27842a

Measure Mode (HP Auto Series)

Measure Mode replaces a tape measure to measure

distances when laying out an area to be striped.

1. Use to select Measure Mode.

2. Press and release gun trigger control. Move striper

forwards or backwards. (Moving backwards is a

negative distance.)

3. Press and release gun trigger control to end measured length. Up to six lengths are viewable.

The most recent measured length is also saved as the

measured distance in the Stall Calculator display. See

Stall Calculator, page 35.

If an auto gun is activated, press and hold gun trigger

control at any time to apply a dot. If trigger is held while

striper is moving, a dot is marked every 12-inches

(30.5cm).

Ref. Description

1 Press to start measurement, Press to stop

measurement.

2 Hold to reset values to zero.

3 Job Data Logger, page 42.

4 Scroll between main menu screens

5 Last measurement taken

6 Press to start measurement, press to stop

measurement

3A6466A Operation, Repair, Parts 33

LineLazer V LiveLook Display

ti27918a

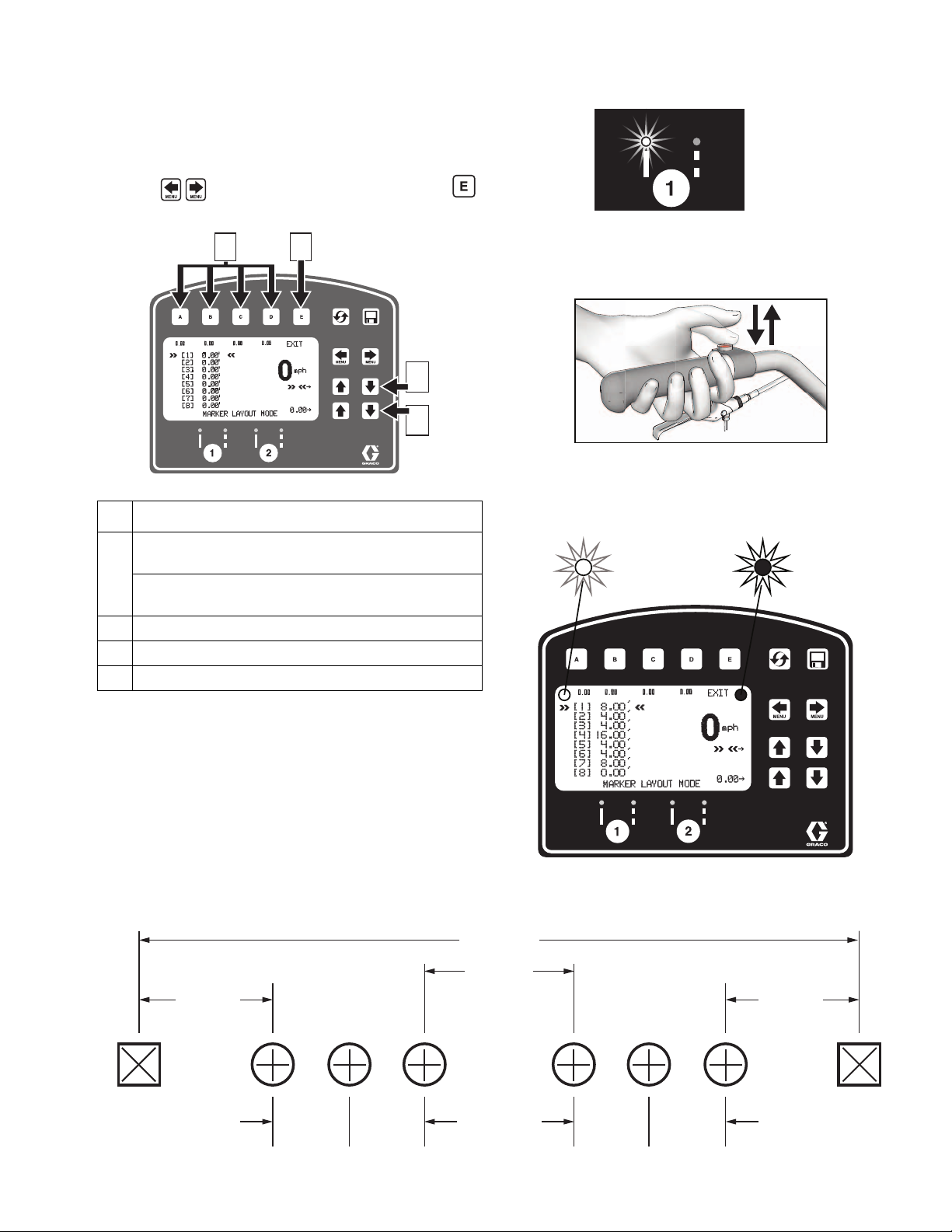

Layout Mode

Layout Mode is used to calculate and mark parking lot

stalls.

1. Use to select Layout Mode.

2. Use gun activation buttons to select guns.

3. Press and release gun trigger control and move

striper forward.

ti27912a

4. Striper default is to place a dot every 9.0 ft (2.7m) to

mark the stall size. Stall size is adjustable.

5. Dots are laid down until gun trigger control is

pressed and released again.

Ref. Description

1 Opens Stall Calculator Menu.

See Stall Calculator, page 35.

2 Opens Angle Calculator Menu.

See Angle Calculator, page 36.

Select a “Favorite”, press for less than one sec-

3

ond.

Save a “Favorite”, press and hold for more than

three seconds.

4 Job Data Logging, page 42.

5 Scroll between menu screens.

6 Adjust stall size/dot spacing.

7 Adjust dot size.

8 Auto Gun activation buttons.

9 Pressure, Pump A and B

10 Total gallons (liters) sprayed, Pump A and B

An indicator on the screen alternately flash when gun

trigger control is pressed to signal mode is active.

34 3A6466A Operation, Repair, Parts

LineLazer V LiveLook Display

Stall Calculator

Stall Calculator is used to set the stall size. The striper

divides the measured length by the stall size to

determine the number of stalls that will fit in the length

measured. User can adjust number of stalls to a round

number and stall width is calculated.

1. Use to select Layout Mode. Press to

open Stall Calculator Menu.

2. The most recent length measured in Measure Mode

is automatically displayed. Press gun trigger control

to start a new measurement. Press again to stop

measuring.

When measuring between curbs, the distance from

the back tire/curb to the gun/laser dot, can be

accounted for by setting the Offset (x) value.

a. Back the striper up to the curb, then use a tape

measure to measure from where the tire touches

the curb to the laser dot on the ground.

b. Use to enter the offset (x) value.

c. This value can be stored by holding for 2

seconds.

d. The value stored under can be added to the

measured distance before or after the

measurement is taken between the curbs.

e. The offset (x) value can also be adjusted before or

after the measurement is taken by using .

Stall size and calculated number of stalls are both

adjustable.

3. Press to return to Layout Mode. The Stall size

is saved and displayed on the Layout Mode screen.

Ref. Description

1 Opens Angle Calculator Menu.

See Angle Calculator, page 36.

2 Exits and returns stall size to Layout Mode.

3 Measured distance.

4 Calculated # of stalls. Changing the number of

stalls will change the stall size.

5 Adjusts number of stalls.

6 Stall size. Changing stall size changes the

calculated # of stalls.

7 Adjusts stall size.

8 Press to start measurement, Press to stop

measurement.

9 Adjust Offset (x)

10 Stores Offset (x). Hold for 2 seconds to store

value.

3A6466A Operation, Repair, Parts 35

4. Press and release gun trigger control to start marking dots. Press and release gun trigger control again

to stop.

LineLazer V LiveLook Display

7

8

5

6

STALL

SIZE

LINE

LENGTH

B

C

STALL

DEPTH

OFF SET

ANGLE

DOT SPACING

ti27857a

Angle Calculator

Angle Calculator is used to determine the offset value

and dot spacing value for a layout.

1. Use to select Layout Mode. Press to

open Angle Calculator Menu.

1

2 3 4

2. Dot spacing (B) and offset (C) are calculated based

on the parameters entered:

Stall angle

Stall depth

Stall size (width)

Line Length

3. Press to transfer calculated offset distance to

Layout Mode. Save this value in favorites if desired.

ti27850a

Ref. Description

1 Transfers calculated dot spacing, B, to Layout

Mode.

2 Transfers calculated offset, C, to Layout Mode.

3 Exits and returns to Layout Mode without transfer-

ring any values.

4 Data Logging.

5 Select input variables.

6 Adjust the variable selected.

7 Calculated dot spacing, B.

8 Calculated offset, C.

36 3A6466A Operation, Repair, Parts

LineLazer V LiveLook Display

ti27842a

4. Press to transfer calculated dot spacing dis-

tance to Layout Mode. Save this value in favorites if

desired.

5. Press and release gun trigger control to start marking stall size dots. Press and release gun trigger

control to stop marking.

3A6466A Operation, Repair, Parts 37

LineLazer V LiveLook Display

Setup/Information

Use to select Setup/Information.

Press to select Language.

See Language, page 30.

See Calibration, page 30.

See Settings, page 39.

See Information, page 40.

See Marker Layout Mode, page 41.

38 3A6466A Operation, Repair, Parts

Settings

Use to select Setup/Information. Press to

open Settings Menu.

Chooses the machine type. Necessary for accurate gallon

counting.

Use to set time and date. Needed for accurate Data Logging.

LineLazer V LiveLook Display

Set units with

Use to adjust screen contrast to the desired value.

For programmed skip lines, press to choose:

Paint first

or

Space first

ti28158a

In Auto-mode, guns won’t fire or will shut off if speed is below set

value.

Enable or Disable Low Speed Shutoff

Adjust low speed setting.

3A6466A Operation, Repair, Parts 39

LineLazer V LiveLook Display

Stroke Counter

Pressure Transducer

Distance Sensor

Touch Pad Buttons

Engine Voltage

Battery Voltage

Clutch

Solenoid 1

Solenoid 2

Battery charge state

Information

Use to select Setup/Information. Press to

open Information Menu.

Displays and logs life, data, and striper information.

View and test functionality of component

Logs last four error codes that occurred.

Code Description

02 = Over pressure

03 = No transducer detected

Reset error codes

40 3A6466A Operation, Repair, Parts

LineLazer V LiveLook Display

1

2

3

4

ti27860a

1

ti27862a

[1] 8.00´

[2] 4.00´

[3] 4.00´

[4] 16.00´

[5] 4.00´

[6] 4.00´

[7] 8.00´

[8] 0.00´

8.00 ft. 8.00 ft.

4.00 ft.

4.00 ft.

16.00 ft.

48.00 ft.

4.00 ft.4.00 ft.

ti23812a

Marker Layout Mode

The Marker Layout Mode feature sprays a dot or a

series of dots to mark an area.

1. Use to select Setup/Information. Press

to open Marker Layout Mode.

Ref. Description

4. Set gun switch to skip line or solid line.

ti27918a

5. Press and release gun trigger control to start marking dots. Press and release gun trigger control again

to stop.

ti27912a

An indicator before and after Marker Mode on the

screen alternately flash when gun trigger control is

pressed to signal mode is active.

Select a “Favorite”, press for less than one second.

1

Save a “Favorite”, press and hold for more than

three seconds.

2 Exits and returns to Information Menu.

3 Select value to change.

4 Adjust spacing value.

2. Use arrow keys to set up a marker pattern.

3. Marker layout example shows a typical lane layout

for reflective markers. Set space sizes up to eight

consecutive measurements. By leaving zeros in any

space, Marker Layout Mode will skip to the next

measurement in a continuous loop.

Some other uses of Marker Layout Mode are:

• Multiple spaced handicap stall layout

• Double line stalls

3A6466A Operation, Repair, Parts 41

LineLazer V LiveLook Display

ti28063a

START RECORDING NEW JOB

VIEW JOBS

EXIT

A

E

Data Logging

The LLV control is equipped with Data Logging, which

allows the user to recall job data and export the data

from the machine to a USB drive.

1. Press the to open the Data Logging pop up

window.

2. Choose to start recording a new job or view jobs

previously done.

Start recording a new job.

Erase all jobs

Export all jobs to USB

Erase jobs

Export job to USB

Job data is compiled while spraying. A summary of volume sprayed, distance sprayed and average mil thickness is displayed for the entire job. The job is also

broken down by colors, line widths and stencil volume

sprayed.

42 3A6466A Operation, Repair, Parts

Maintenance

TI3864a

Reversible

Reversible

Maintenance

MMA Fusion Gun

Supplied Tool Kit

• Hex Nut Driver; 5/16

• Screwdriver; 1/8 blade

• Nozzle Drill Bit; See T

• Impingement Port Drill Bit; various sizes depending

on port size. See T

• 117661 Pin Vise; dual reversible chucks

• 551189 Grease Gun; with 3 oz grease

ABLE 1, page 45.

ABLE 3, page 45.

As Needed

1. Clean Outside of Gun, page 44.

2. Clean Mix Chamber Nozzle, page 45, a minimum

of once a day.

3. Spray Tip Adapter, page 44.

4. Clean Muffler, page 44.

5. Clean Fluid Manifold, page 44.

6. Clean Passages, page 45.

7. Clean Impingement Ports, page 46.

Daily

Follow Cleanup, page 26.

Weekly to Monthly

1. Clean Mix Chamber and Side Seal Cartridges, page

49. Check o-rings.

Keep Gun Clean

Keep gun clean with accessory gun cover, page 87.

Applying a light coat of lubricant will make cleaning easier.

2. Clean/Dissassemble Check Valves, page 50.

Check o-rings and filters.

3A6466A Operation, Repair, Parts 43

Maintenance

Flush Gun

If it is necessary to flush gun, use following procedure.

1. Follow Grounding Procedure (For Flammable

Flushing Fluids Only), page 12.

2. Flush with acetone into a grounded metal pail, holding a metal part of fluid manifold firmly to side of

pail. Use the lowest possible fluid pressure when

flushing.

3. Perform Pressure Relief Procedure, page 12.

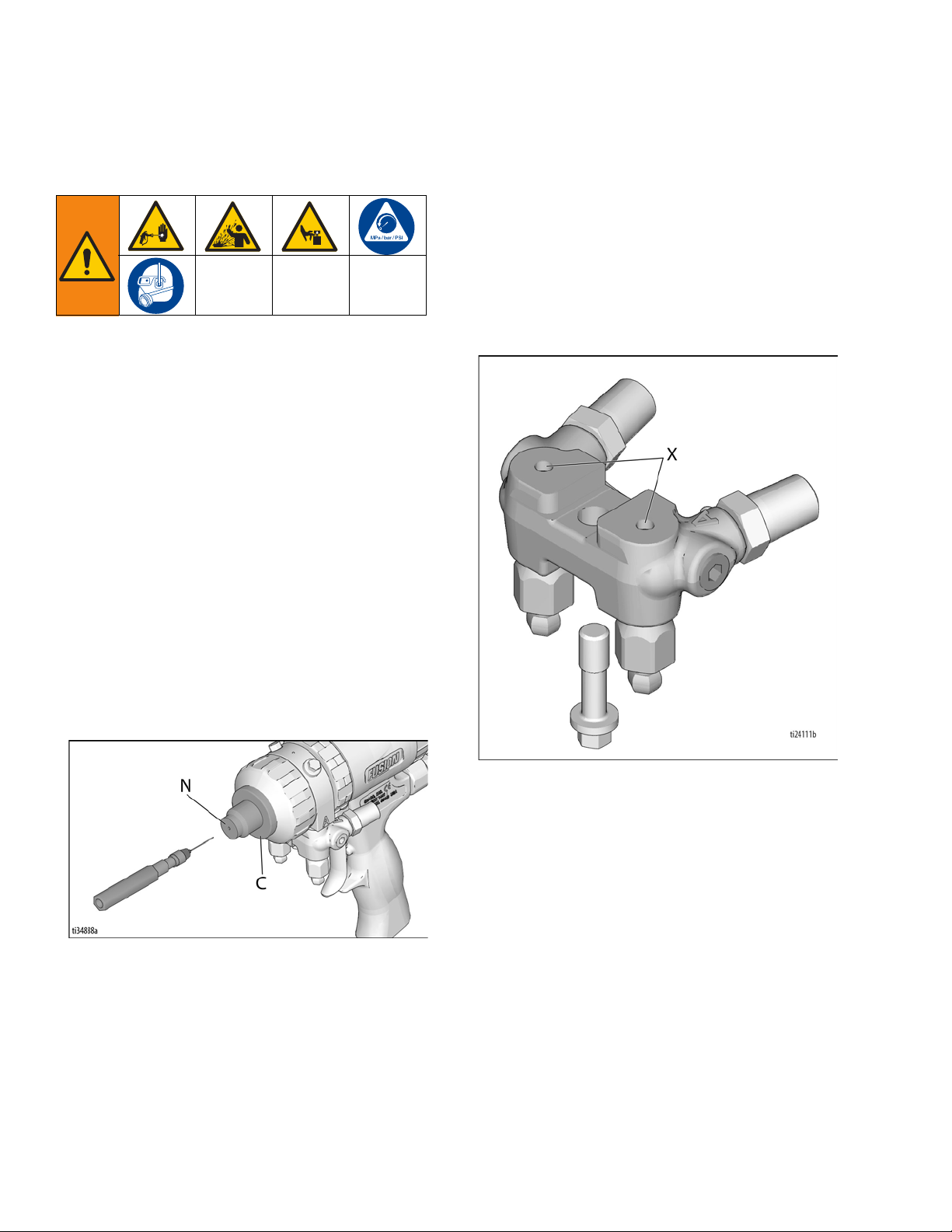

Clean Outside of Gun

Clean Muffler

Remove and clean muffler with acetone.

Clean Fluid Manifold

Clean fluid manifold sealing faces with acetone and a

brush whenever removed from gun. Be sure to clean the

two fluid ports (X) in the top mating surface. Do not damage the flat sealing surfaces. Coat with grease if left

exposed, to seal out moisture.

Wipe off outside of gun with acetone.

Spray Tip Adapter

Soak spray tip adapter in acetone. If necessary, clean

holes with 3/32” drill bit.

44 3A6466A Operation, Repair, Parts

Maintenance

Clean Mix Chamber Nozzle

1. Engage piston safety lock, page 10.

2. Refer to Table 1: Nozzle Drill Bit Sizes. Also see

identification chart under Drill Bit Kits, page 63.

Use the appropriate size drill bit to clean mix chamber nozzle (N). If necessary, clean spray tip adapter

(C) gently with stiff brush. If necessary, remove tip

adapter and clean mix chamber with drill bit.

Clean Passages

If necessary, clean out passages in fluid housing and

handle with drill bits. Refer to Table 2: Passage Diame-

ters and to Cutaway View - Gun, page 70 for diameter

and location of passages. All drill bits are available in an

accessory kit. Order kit 248969 for Air Purge Handle

Cleanout Drill Kit, page 63.

Table 2: Passage Diameters

Passage Description

Optional Air Inlet C 7/16, 1/8

Purge Air Not Shown 1/8 (3.1)

Piston Air E, F 1/8 (3.1)

Air Exhaust G 11/32, 1/8

Air Valve Bore H 9/32 (7.1)

Cleanoff Air Not Shown 3/32 (2.35)

Check Valve Holes Not Shown 3/32 (2.35)

Grease Not Shown 3/32 (2.35)

Ref. Letter

(page 70)

Diameter,

in. (mm)

(11.0, 3.1)

(8.7, 3.1)

Table 1: Nozzle Drill Bit Sizes

Flat Spray

Mix Chamber

Part No.

AF2020

Drill Size in. (mm)

Remove Spray Tip Adapter

1. Perform Pressure Relief Procedure, page 12.

2. Close fluid valves A and B before turning spray tip

adapter (C).

3/32, .094

(2.35)

3A6466A Operation, Repair, Parts 45

Maintenance

Mix Chamber

AF2020

Clean Impingement Ports

1. Follow Pressure Relief Procedure, page 12.

2. Disconnect both air lines and remove fluid manifold

(M).

3.

Flush Gun

, page 44. If gun will not flush, see page 48.

4. Disassemble Front End of Fusion Gun, page 47.

5. Push mix chamber forward until impingement ports

(IP) are visible. See Table 3: Impingement Port

Drill Bit Sizes for appropriate size drill to clean

ports. Also see identification chart under Drill Bit

Kits, page 63. Some mix chambers have counterbored holes (CB) and require two drill sizes to clean

impingement ports completely.

Table 3: Impingement Port Drill Bit Sizes

Mix Chamber

Part No.

AF2020 #76, .020 (0.50) #53, .060 (1.50)

Impingement Port (IP)

Drill Bit Size

in. (mm)

6. Push mix chamber back in position.

7. Reassemble Front End of Fusion Gun, page 47.

8. Attach fluid manifold. Connect air. Gun is ready for

use.

Counterbore (CB)

Drill Bit Size

in. (mm)

Lubrication

Liberally lubricate all o-rings, seals, and threads. Lubricate threads and inside of retaining ring (9). See page

87 to order lubricant.

46 3A6466A Operation, Repair, Parts

Maintenance

Engaged

Disassemble Front End of

Fusion Gun

1. Perform Pressure Relief Procedure, page 12.

2. Flush Gun, page 44.

NOTICE

If lock ring (R) is stuck due to material buildup, do not

force it by turning entire front end. Locating tabs (Z)

may break off. Soak front of gun in solvent to soften

cured material and free lock ring.

3. Unscrew lock ring (R) until front end of gun is loose.

Turn fluid housing (F) 1/8 turn counterclockwise.

Unscrew lock ring completely and remove front end

of gun.

2. Thread on spray tip adapter (10) to mixing chamber,

and press in assembly until spray tip adapter bottoms out on the retaining ring (9). This ensures that

mix chamber is all the way back.

3. Check that o-ring (21) is in position. Liberally lubricate o-ring, threads of lock ring (R) and handle (H),

and outside of lock ring. Orient front end (F) as

required for desired fluid manifold mounting (bottom

mounting is shown). Insert keyed end (W) of mix

chamber in socket (X). Screw lock ring onto handle

as far as possible by hand.

4. Turn fluid housing 1/8 turn clockwise to engage

Reassemble Front End of

Fusion Gun

1. Engage Piston Safety Lock, page 10.

3A6466A Operation, Repair, Parts 47

slots (Y) and tabs (Z). Push on front end to ensure it

is properly seated. Continue screwing lock ring (R)

onto handle (H) very securely. When properly

assembled, lock ring is snug against handle.

Maintenance

Remove Mix Chamber & Side

Seal Cartridges

1. Perform Pressure Relief Procedure, page 12.

2. Remove fluid manifold (M). Leave air connected.

6. Remove spray tip adapter (10) and retaining ring

(9). Inspect o-ring (3) inside retaining ring.

NOTICE

To prevent cross-contamination of side seal cartridges,

do not interchange A component and B component

parts. The A component cartridge is marked with an A.

7. Pull out side seal cartridges (18).

3. Flush gun to remove residual A and B components.

Perform Pressure Relief Procedure, page 12.

4. Shut off air.

8. Pull mix chamber (19) out rear of fluid housing.

Inspect for damage and clean ports, page 46.

Inspect o-ring (23) in front of fluid housing.

NOTICE

To prevent cross-contamination of the gun’s wetted

parts, mix chamber is marked with an A and a notch

(N) on back edge. Be sure the A side of mix chamber is

on the A side of gun.

5. Disassemble Front End of Fusion Gun, page 47.

48 3A6466A Operation, Repair, Parts

Maintenance

B

A

TI2428A

19

N

TI2427A

18e

18c

18d

18b

Reassemble Mix Chamber &

Side Seal Cartridges

1. Apply thin coat of lubricant to mix chamber (19).

Install mix chamber. Etched A and notch (N) must

be on same side as A on fluid housing. Mix chamber

is keyed to fit in fluid housing.

NOTICE

To prevent cross-contamination of side seal cartridges,

do not interchange A component and B component

parts. The A component cartridge is marked with an A.

2. Carefully inspect side seal cartridge o-rings and surfaces. Replace worn or damaged parts. Liberally

lubricate o-rings (18d, 18e) and reassemble. Press

on side seal (18c) to check proper spring (18b)

operation.

3. Liberally lubricate and reinstall side seal cartridges

(18).

4. Lubricate all threads and reinstall retaining ring (9).

Install spray tip adapter (10).

5. Reassemble Front End of Fusion Gun, page 47.

6. Connect air, and trigger the gun a few times to

check for leaks. If either check valve pops out of its

seated position, there is a poor fluid seal on that

side of the mix chamber or side seal/cartridge components. Correct the problem before attaching the

fluid manifold.

7. Attach fluid manifold. Connect air. Return gun to

service.

3A6466A Operation, Repair, Parts 49

Maintenance

Dissassemble Check Valves

NOTE: Before disassembling, press on ball (26c) to test

check valve for proper movement and spring action.

1. Perform Pressure Relief Procedure, page 12.

2. Remove fluid manifold (M). Leave air connected.

Clean Fluid Manifold, page 44.

NOTICE

To prevent cross-contamination of the check valves, do

not interchange A component and B component parts.

The A component check valve is marked with an A.

5. Pry out check valves (26) at notch.

NOTICE

Damaged check valve o-rings (26f, 26g) may result in

external leakage. Replace o-rings if any damage is

seen.

6. Slide filter (26d) off. Clean and inspect parts. Thoroughly inspect o-rings (26f, 26g). If necessary,

remove screw (26b) and disassemble entire check

valve.

3. Flush gun to remove residual A and B components, page

44. Follow

4. Shut off air.

Pressure Relief Procedure

, page 12.

Reassemble Check Valves

1. Reassemble check valves. Screw (26b) should be

flush (within 1/16 in. or 1.5 mm) of housing (26a)

surface. Liberally lubricate o-rings (26f, 26g) and

carefully reinstall in fluid housing.

2. Attach fluid manifold. Connect air. Return gun to

service.

50 3A6466A Operation, Repair, Parts

Maintenance

5

14

TI2430A

16

17

15

TI2431A

TI2432A

TI2430A

5

Piston

1. Perform Pressure Relief Procedure, page 12.

2. Disconnect air (D) and remove fluid manifold (M).

5. Push piston shaft to remove piston (15). Inspect piston o-ring (16) and shaft o-ring (17).

6. Liberally lubricate piston o-rings. Reinstall piston.

Shaft is keyed for proper assembly. Push firmly to

seat piston.

3. Disassemble Front End of Fusion Gun, page 47.

4. Unscrew cylinder cap (5) and inspect o-ring (14).

7. Install cylinder cap (5).

8. Reassemble Front End of Fusion Gun, page 47.

9. Attach fluid manifold. Connect air. Return gun to

service.

3A6466A Operation, Repair, Parts 51

Maintenance

5

1428

24 30 4

TI2433A

Piston Safety Lock

1. Perform Pressure Relief Procedure, page 12.

2. Disconnect air (D) and remove fluid manifold (M).

Air Valve

1. Perform Pressure Relief Procedure, page 12.

2. Disconnect air (D) and remove fluid manifold (M).

3. Unscrew cylinder cap (5). Hold piston stop (28) with

wrench and unscrew from safety lock (4). Inspect

spring (30) and o-rings (14, 24).

4. Liberally lubricate o-rings and reassemble. Clean

threads with solvent or alcohol. Apply

medium-strength sealant to threads on stop (28)

and reassemble.

5. Attach fluid manifold. Connect air. Return gun to

service.

52 3A6466A Operation, Repair, Parts

3. Unscrew air valve plug (2) and remove spring (31).

Using a small diameter tool, push spool (32) out

from front. Inspect o-rings (24).

4. Liberally lubricate o-rings and reassemble. Torque

plug (2) to 125-135 in-lb (14-15 N•m).

Maintenance

Maintenance

LineLazer V 200MMA 1:1

Periodic Maintenance

DAILY: After every use, thouroughly clean gun and

components with acetone.

DAILY: Check air lines for clear passage ways. Ensure

paint is not backed into air hose/fittings.

DAILY: Check engine oil level and fill as necessary.

DAILY: Check hydraulic oil level and fill as necessary.

DAILY: Check hose for wear and damage.

DAILY: Check gun safety for proper operation.

DAILY: Check prime/spray drain valve for proper opera-

tion.

DAILY: Check and fill gas tank

DAILY: Check that displacement pump is tight.

DAILY: Top off TSL level in displacement pump packing

nut to help prevent material buildup on piston rod and

early wear of packing.

WEEKLY/DAILY: Remove any debris from hydraulic

rod.

AFTER EACH 100 HOURS OF OPERATION: Change

engine oil. Reference Honda Engines Owner’s Manual

for correct oil viscosity.

SEMI-ANNUALLY: Check belt wear, replace if necessary.

YEARLY OR 2000 HOURS: Replace belt.

AFTER EACH 500 HOURS OR 3 MONTHS OF OPERATION: Replace hydraulic oil and filter. Use Graco

hydraulic oil 169236 (5 gallon/20 liter) or 207428 (1 gallon/3.8 liter) and filter 246173. Oil change interval

dependent on environmental conditions.

SPARK PLUG: Use only BPR6ES (NGK) or

W20EPR--U (NIPPONDENSO) plug. Gap plug to 0.028

to 0.031 in (0.7 to 0.8 mm). Use spark plug wrench

when installing and removing plug.

Caster Wheel

1. Once each year, tighten nut under dust cap until

spring washer bottoms out, then back off the nut 1/2

to 3/4 turn.

AFTER THE FIRST 20 HOURS OF OPERATION: Drain

engine oil and refill with clean oil. Reference Honda

Engines Owner’s Manual for correct oil viscosity.

WEEKLY: Remove engine air filter cover and clean element. Replace if necessary. If operating in an unusually

dusty environment, check filter daily.

2. Once each month, grease the wheel bearing.

3. Check pin for wear. If pin is worn out, there will be

play in the caster wheel. Reverse or replace the pin

as needed.

4. Check caster wheel alignment as necessary. To

align; see page 24.

3A6466A Operation, Repair, Parts 53

Hydraulic Oil/Filter Change

ti2271a

199

ti2271a

Hydraulic Oil/Filter Change

Removal

1. Perform Pressure Relief Procedure, page 12.

2. Place drip pan or rags under sprayer to catch

hydraulic oil that drains out.

3. Remove drain plug. Allow hydraulic oil to drain.

4. Unscrew filter slowly - oil runs into groove and

drains out rear.

Installation

1. Apply a light film of oil on oil filter gasket. Install

drain plug and oil filter. Tighten oil filter 3/4 turn after

gasket contacts base.

2. Fill tank with Graco synthetic hydraulic oil, ISO 46.

3. Check oil level.

54 3A6466A Operation, Repair, Parts

Troubleshooting

Problem Cause Solution

Gas engine pulls hard (won’t

start).

Engine won’t start. Engine switch is OFF. Turn engine switch ON.

Engine operates, but displacement pump does not

operate.

Displacement pump operates, but output is low on

upstroke.

Hydraulic pressure is too high. Turn hydraulic pressure knob counterclockwise

to lowest setting.

Engine is out of gas. Refill gas tank. See Honda Engines Owner’s

Manual.

Engine oil level is low. Try to start engine. Replenish oil, if necessary.

See Honda Engine Owner’s Manual.

Spark plug cable is disconnected or damaged. Connect spark plug cable or replace spark

plug.

Cold engine. Use choke.

Fuel shutoff lever is OFF. Move lever to ON position.

Oil is seeping into combustion chamber. Remove spark plug. Pull starter 3 to 4 times.

Clean or replace spark plug. Start engine. Keep

sprayer upright to avoid oil seepage.

Pump valve is OFF. Turn pump valve ON.

Pressure setting is too low. Turn pressure adjusting knob clockwise to

increase pressure.

Fluid filter is dirty. Clean filter.

Tip or tip filter is clogged. Clean tip or tip filter. See spray gun manual.

Displacement pump piston rod is stuck due to

dried paint.

Belt worn, broken or off pulley. Replace.

Hydraulic fluid too low. Shut off sprayer. Add Hydraulic fluid.

Hydraulic motor not shifting. Set pump valve OFF. Turn pressure down.

Piston ball is not seating. Service piston ball. See Manual 309277.

Piston packings are worn or damaged. Replace packings. See Manual 309277.

Repair pump. See pump manual.

Turn engine OFF. Pry rod up or down until

hydraulic motor shifts.

Troubleshooting

3A6466A Operation, Repair, Parts 55

Troubleshooting

Problem Cause Solution

Displacement pump operates

but output is low on downstroke and/or on both strokes.

Pump is difficult to prime. Air in pump or hose. Check and tighten all fluid connections.

High engine speed at no load. Mis-adjusted throttle setting. Reset throttle to 3700 - 3800 engine rpm at no

Low stall or run pressure

shown on display.

Excessive paint leakage into

throat packing nut.

Fluid is spitting from gun. Air in pump or hose. Check and tighten all fluid connections. Rep-

Excessive leakage around

hydraulic motor piston rod

wiper.

Strainer is clogged. Clean strainer.

O-ring in pump is worn or damaged. Replace o-ring. See Pump manual 309277.

Intake valve ball is packed with material or is

not seating properly.

Engine speed is too low. Increase throttle setting.

Suction tube air leak. Tighten suction tube.

Pressure setting is too low. Increase pressure.

Fluid filter, tip filter or tip is clogged or dirty. Clean filter.

Large pressure drop in hose with heavy materials.

Intake valve is leaking. Clean intake valve. Be sure ball seat is not

Pump packings are worn. Replace pump packings. See Pump manual.

Paint is too thick. Thin the paint according to the supplier’s rec-

Engine speed is too high. Decrease throttle setting before priming pump.

Worn engine governor. Replace or service engine governor.

New pump or new packings. Pump break-in period takes up to 100 gallons

Faulty transducer. Replace transducer.

Throat packing nut is loose. Remove throat packing nut spacer. Tighten

Throat packings are worn or damaged. Replace packings. See Pump manual 309277.

Displacement rod is worn or damaged. Replace rod. See Pump manual 309277.

Tip is partially clogged. Clear tip.

Fluid supply is low or empty. Refill fluid supply. Prime pump. Check fluid

Insufficient air pressure Increase motor speed, check air caps, check

Piston rod seal worn or damaged. Replace these parts.

Clean intake valve. See Pump manual 309277.

Use larger diameter hose and/or reduce overall

length of hose. Use of more than 100 ft of 1/4

in. hose significantly reduces performance of

sprayer. Use 3/8 in. hose for optimum performance (22 ft minimum).

Reduce engine speed and cycle pump as

slowly as possible during priming.

nicked or worn and that ball seats well. Reassemble valve.

ommendations.

load.

of material.

throat packing nut just enough to stop leakage.

rime pump.

supply often to prevent running pump dry.

air connections.

56 3A6466A Operation, Repair, Parts

Problem Cause Solution

Fluid delivery is low. Pressure setting too low. Increase pressure.

Displacement pump outlet filter (if used) is dirty

or clogged.

Intake line to pump inlet is not tight. Tighten.

Hydraulic motor is worn or damaged. Bring sprayer to Graco distributor for repair.

Large pressure drop in fluid hose. Use larger diameter for shorter hose.

The sprayer overheats. Paint buildup on hydraulic components. Clean.

Oil level is low. Fill with oil.

Excessive hydraulic pump

noise.

Gallon (liter) counter not adding fluid volume.

Sprayer operates, but display

does not.

Distance not adding properly

(Measure mode will be inaccurate and speed will be

wrong).

Mils not calculating or calculates wrong.

Fluid spray starts after spray

icon is shown on display.

Spray icon does not show on

display when fluid is sprayed.

Spray icon is always shown

on display.

Pumps are running at largely

different speeds

Low hydraulic fluid level. Shut off sprayer. Add fluid.

Fluid pressure not high enough. Must be over 800 psi (55 bar) for counter to

Broken or disconnected pump counter wire,

both pumps.

Missing or damaged magnet. Reposition or replace magnet on pump, see

Bad sensor, both pumps. Replace sensor.