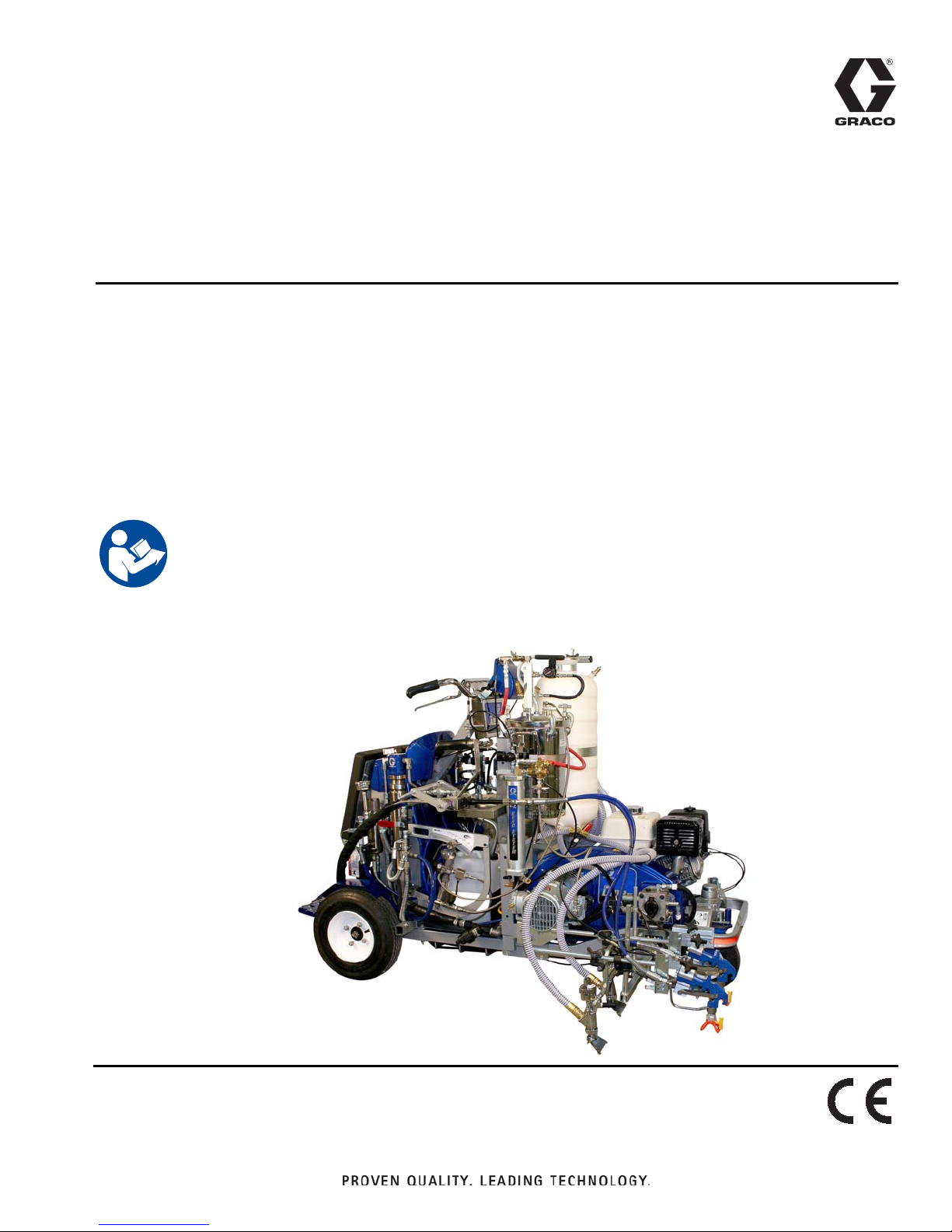

Graco LineLazer IV 250MMA, 17G589 Operation, Parts

Operation, Parts

LineLazer IV 250MMA

Self-Propelled Line Striper

For the application of line striping materials.

For use with only Benox® L40LV liquid initiator BPO (B)

For professional use only.

For outdoor use only.

Not for use in hazardous locations or explosive atmospheres.

3A3111 A

EN

Maximum Operating Speed: 10 mph (16 kph)

Maximum Operating Pressure: 3000 psi (20.7 MPa, 207 bar)

Model 17G589

Important Safety Instructions

Read all warnings and instructions in this manual,

related manuals and the engine manual.

Be familiar with the controls and the proper usage of

the equipment. Save these instructions.

Related Manuals

LL IV 250 DC Operation 333388

Global Symbols 334224

LL IV 250 DC Repair 334053

LL IV 250 DC Parts 334054

Pressurized Bead System 332230

Bead Gun Kit 332226

Bead Gun 308612

Displacement Pump 309277

Airless Spray Gun 308491

2-Gallon Pressure Tank 308370

LL IV 250 DC Repair (French 334136

LL IV 250 DC Repair (Spanish 334137

Contents

Important Benzoyl Peroxide (BPO) Information . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 8

Soft Key Message . . . . . . . . . . . . . . . . . . . . . . . . 8

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Flushing Procedure . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Flush the Equipment . . . . . . . . . . . . . . . . . . . . . 15

MMA Smart Control Operation . . . . . . . . . . . . . . . 16

Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MMA/Epoxy Mode . . . . . . . . . . . . . . . . . . . . . . . 17

Flush Timer Setup . . . . . . . . . . . . . . . . . . . . . . . 17

17H095 Mix Manifold Parts . . . . . . . . . . . . . . . . . . 19

16P125 Slave Pump Linkage Parts . . . . . . . . . . . . 20

17H093 BPO Slave Pump Parts List . . . . . . . . . 22

17H093 Slave Pump Fittings . . . . . . . . . . . . . . . . . 23

Subassembly Items . . . . . . . . . . . . . . . . . . . . . . . . 24

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 26

2 3A3111 A

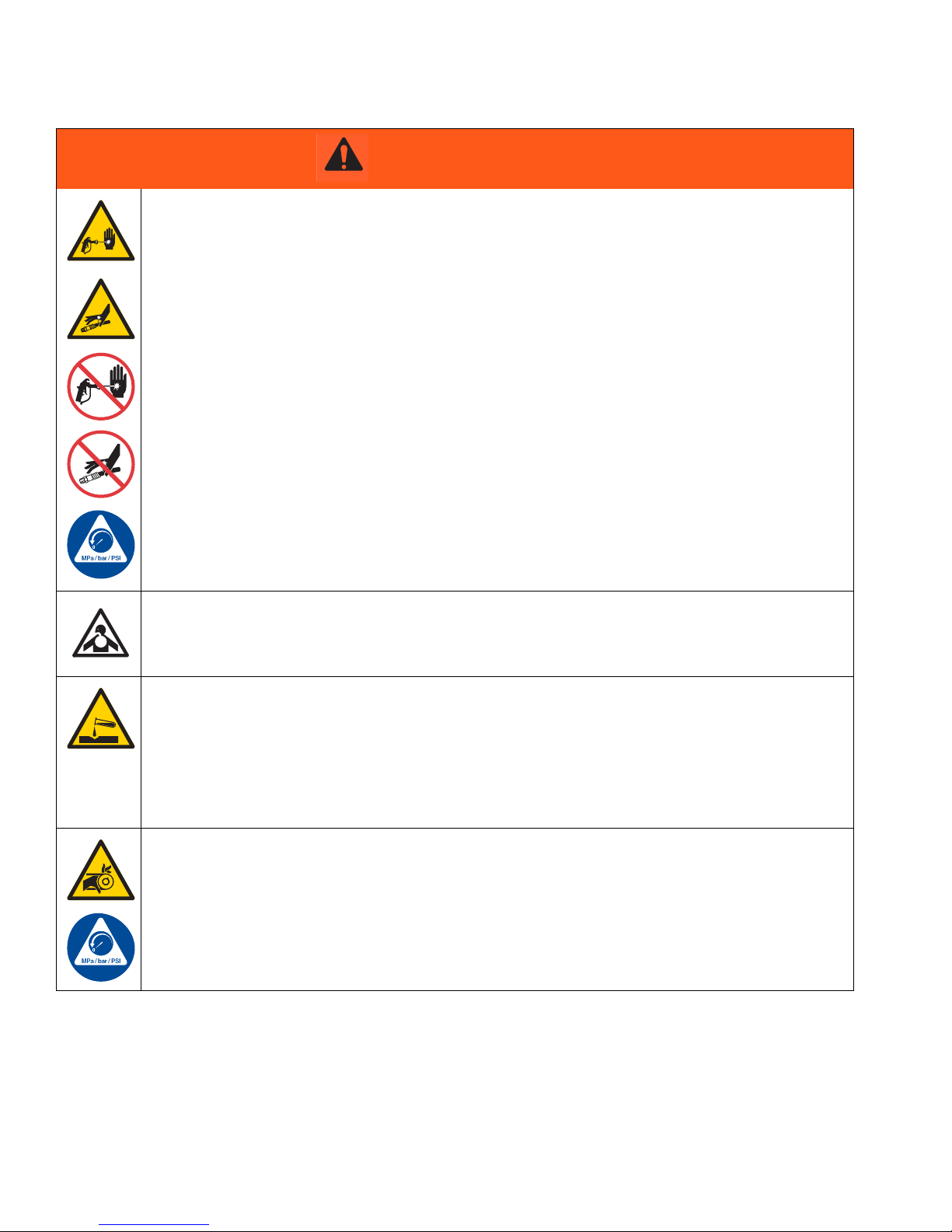

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

TRAFFIC HAZARD

Being struck by other vehicles may result in serious injury or death.

• Do not operate in traffic.

• Use appropriate traffic control in all traffic areas.

• Follow local highway and transportation regulations for traffic control (for example: Manual on Uniform

Traffic Control Devices, U.S. Department of Transportation).

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire

and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable

• and can ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

• cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

• are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

• are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

• until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

3A3111 A 3

Warnings

WARNING

INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a

cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or ser-

vicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon

monoxide can cause death.

• Do not operate in an enclosed area.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property

damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier

for compatibility.

ENTANGLEMENT HAZARD

Rotating parts can cause serious injury.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pres-

sure Relief Procedure and disconnect all power sources.

4 3A3111 A

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pres-

sure Relief Procedure and disconnect all power sources.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system compo-

nent. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufac-

turer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

• Do not carry passengers.

• Check work area for reduced overhead clearance (e.g. doorways, tree branches, parking ramp ceilings)

and avoid contacting them.

BATTERY HAZARD

The battery may leak, explode, cause burns, or cause an explosion if mishandled. Contents of an open

battery can cause severe irritation and/or chemical burns. If on skin, wash with soap and water. If in eyes,

flush with water for at least 15 minutes and get immediate medical attention.

• Only use the battery type specified for use with the equipment. See Technical Data.

• Battery maintenance must only be performed or supervised by personnel knowledgeable of batteries

and the required precautions. Keep unauthorized personnel away from battery.

• Do not dispose of battery in fire. The battery is capable of exploding.

• Follow local ordinances and/or regulations for disposal.

• Do not open or mutilate the battery. Released electrolyte has been known to be harmful to the skin and

eyes and to be toxic.

• Remove watches, rings, or other metal objects.

• Only use tools with insulated handles. Do not lay tools or metal parts on top of battery.

3A3111 A 5

Important Benzoyl Peroxide (BPO) Information

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects or

other reproductive harm. Wash hands after handling.

WARNING

Important Benzoyl Peroxide (BPO) Information

BPO contains highly reactive (unstable) chemicals that produce the curing reaction of methacrylic resins. The highly

reactive property of BPO also produces hazards that require great care and caution in the handling, processing, storage, transportation and disposal of BPO.

BPO is flammable and potentially explosive when reacting to contamination by other materials or when

exposed to heat or heat build-up from contamination reactions. A contamination reaction can cause BPO to

reach its Self-Accelerating Decomposition Temperature (SADT). Reaction may start slowly, taking from seconds to days, gradually building up heat. This can produce an explosion. To help prevent fire and explosion:

• Read and understand the BPO manufacturer’s warnings and Safety Data Sheet (SDS) to know specific

hazards and precautions related to BPO.

• Prevent contamination of BPO with other materials (even small amounts), including but not limited to

diluents, polyester overspray, sanding dust, polymerization accelerators and promoters

metals. Keep work area clean and free of waste.

• Never return BPO to the original container.

• Remove spills promptly so no residues remain.

• Keep BPO away from heat, sparks and open flames.

• Never dilute BPO with acetone or any solvent. This can produce an extremely shock-sensitive compound

that can explode.

• Use only genuine manufacturer’s parts in the catalyst system (hoses, fittings, etc.). A reaction may result

between substituted parts and BPO.

• Store BPO in the original containers in a cool, dry and well-ventilated area away from direct sunlight and

away from other chemicals in accordance with BPO manufacturer’s recommendations.

• Do not store BPO for an extended period of time.

• To prevent contact with BPO, wear appropriate personal protective equipment, including chemically impermeable gloves, boots, aprons and goggles.

, and non-stainless

6 3A3111 A

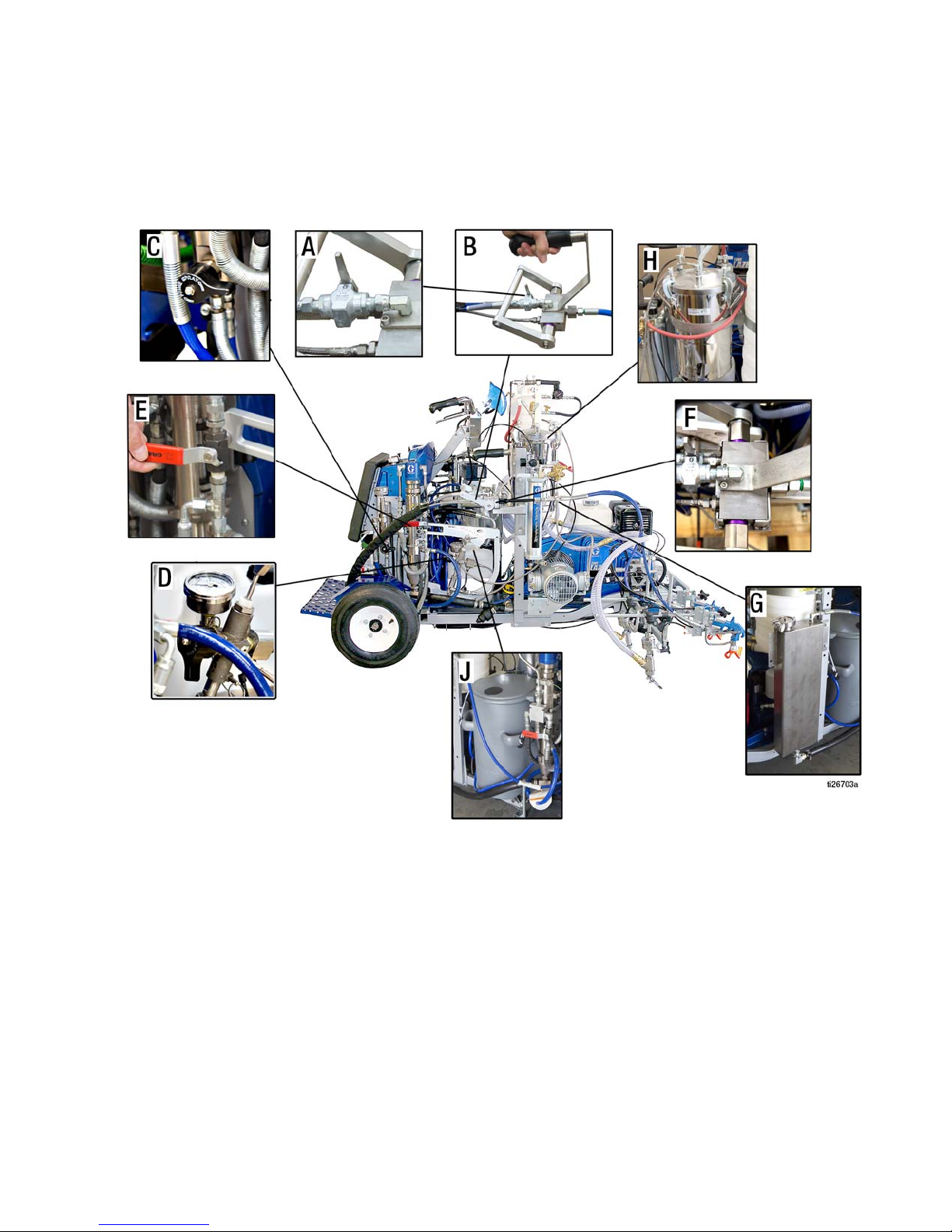

Component Identification

Component Identification

A Solvent Valve

B Material Supply Valve

C Resin Dump Valve

D Benzoylperoxide (BPO) Dump Valve

E Hydraulic Valve

For complete operation and parts information refer to the related manuals listed on the cover of this document. This

document provides the operation information required when spraying two part coatings.

3A3111 A 7

F Mix Manifold

G Solvent Tank

H BPO Pressure Pot

JResin Tank

Operation

ti23144a

ti3441a

PAINT

ti3305a

ti3324a

ti6473a

ti26702a

Operation

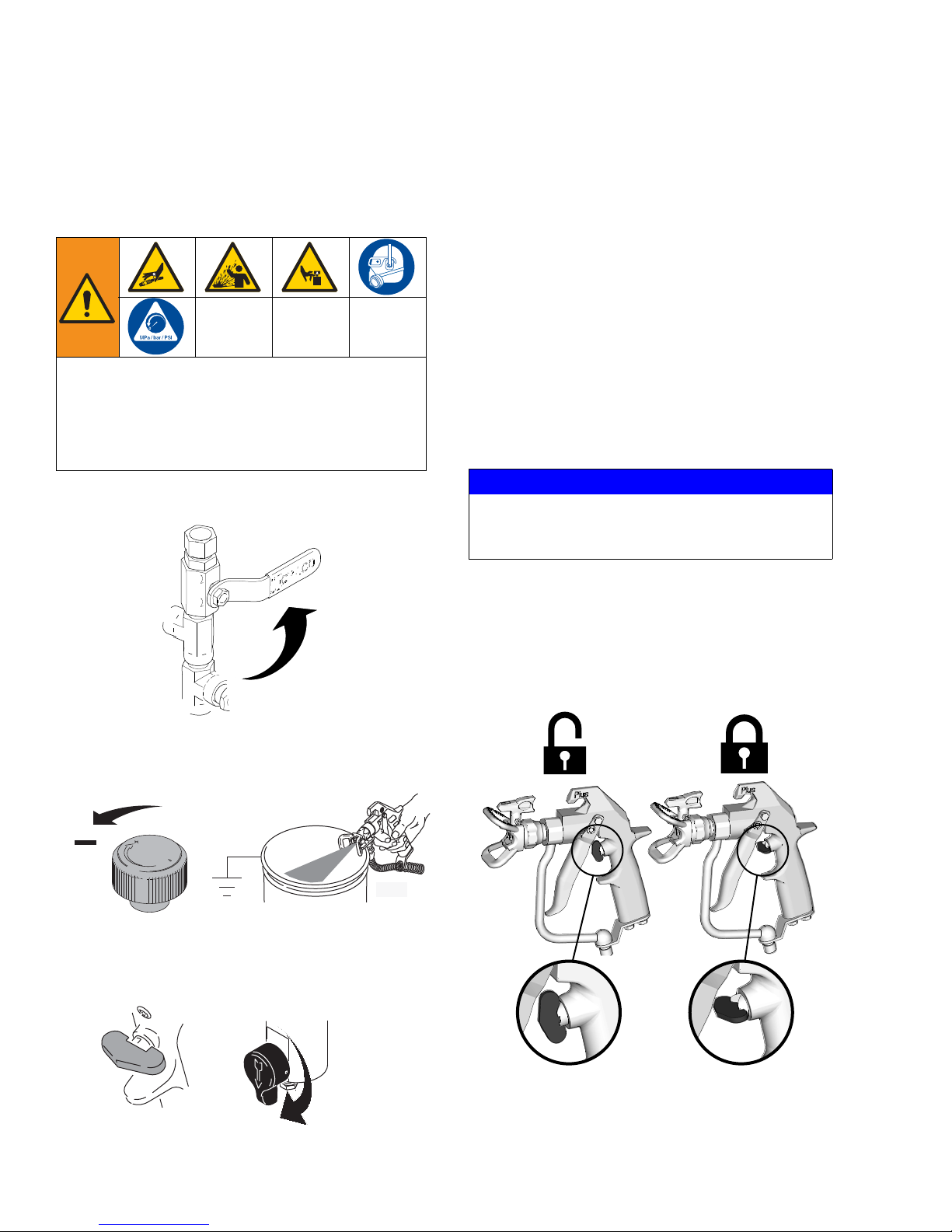

Pressure Relief Procedure

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before cleaning, checking, or servicing the equipment.

1. Set both (2) pump valves to OFF. Turn engine OFF.

4. Leave drain valve(s) open until you are ready to

spray again.

5. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved:

a. VERY SLOWLY loosen the tip guard retaining

nut or the hose end coupling to relieve pressure

gradually.

b. Loosen the nut or the coupling completely.

c. Clear the obstruction in the hose or tip.

Soft Key Message

NOTICE

To prevent damage to soft key buttons, do not

press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

Trigger Lock

Always engage the trigger lock when you stop spraying

to prevent the gun from being triggered accidentally by

hand or if dropped or bumped.

2. Turn pressure control to lowest setting. Trigger all

guns to relieve pressure.

3.

Engage all gun trigger locks. Turn both (2) prime

valves down.

8 3A3111 A

Loading...

Loading...