Page 1

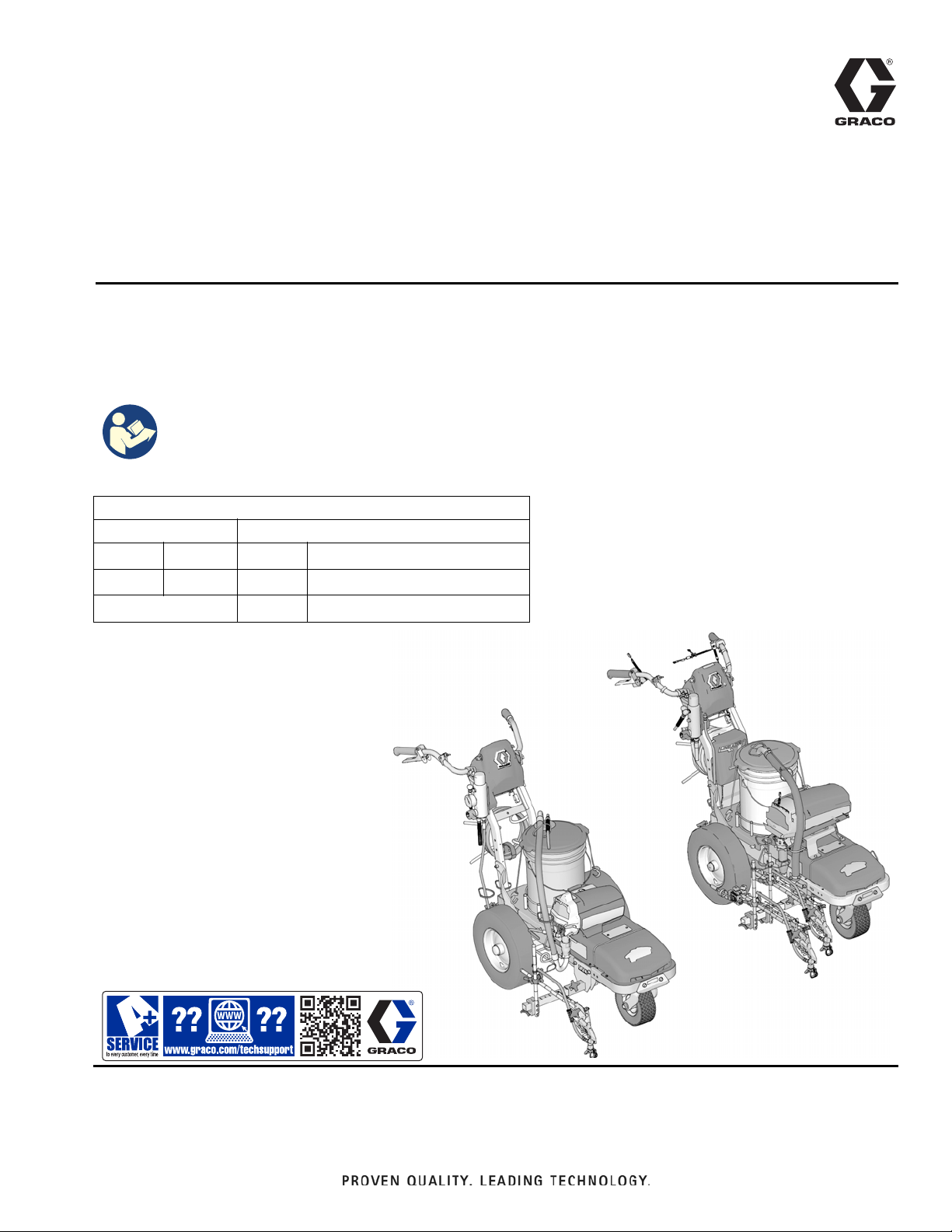

Operation, Repair, Parts

LineLazer ES 2000

LineLazer ES 1000

LineLazer™ ES 1000 / ES 2000

Airless Line Striper

For the application of line striping materials.

For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

Maximum Operating Pressure: 3300 psi (22.8 MPa, 228 bar)

Important Safety Instructions

Read all warnings and instructions in this manual and in related manuals

before using the equipment. Be familiar with the controls and the proper

usage of the equipment. Save these instructions.

Related Manuals:

ES 1000 ES 2000

311254 Gun 311254 Gun

334599 Pump 310643 Pump

3A3428 Auto-Layout Application Methods

3A4603F

EN

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

Page 2

Contents

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Component Identification (ES 1000) . . . . . . . . . . . 9

Component Identification (ES 2000) . . . . . . . . . . 10

Tip Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery and Charger . . . . . . . . . . . . . . . . . . . . . . . 12

Battery Type and Charging Profiles . . . . . . . . . 12

Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . 12

Charging the Battery . . . . . . . . . . . . . . . . . . . . . 13

Grounding Procedure

(AC Wall Power) . . . . . . . . . . . . . . . . . . . . . . . 14

Power Requirements . . . . . . . . . . . . . . . . . . . . 14

Extension Cords . . . . . . . . . . . . . . . . . . . . . . . . 14

Pails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Grounding Procedure

(Battery Power) (For Flammable Flushing Fluids

Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 16

Setup/Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SwitchTip and Guard Assembly . . . . . . . . . . . . 19

Gun Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Install Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Position Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Select Manual Guns . . . . . . . . . . . . . . . . . . . . . 20

Select Auto Guns (ES 2000) . . . . . . . . . . . . . . . 21

Gun Positions Chart . . . . . . . . . . . . . . . . . . . . . 22

Gun Arm Mounts . . . . . . . . . . . . . . . . . . . . . . . . 23

Change Gun Position

(Front and Back) . . . . . . . . . . . . . . . . . . . . . 23

Change Gun Position

(Left and Right) . . . . . . . . . . . . . . . . . . . . . . 23

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Trigger Sensor Adjustment (ES 2000) . . . . . . . 24

Gun Cable Adjustment . . . . . . . . . . . . . . . . . . . 25

Straight Line Adjustment . . . . . . . . . . . . . . . . . . 26

Handle Bar Adjustment . . . . . . . . . . . . . . . . . . . 26

Paint Stripe Width . . . . . . . . . . . . . . . . . . . . . . . . . 27

Spray Test Stripe . . . . . . . . . . . . . . . . . . . . . . . 27

Clearing Tip Clogs . . . . . . . . . . . . . . . . . . . . . . 27

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Flush Drain Tube . . . . . . . . . . . . . . . . . . . . . . . 28

Flush Hose and Gun . . . . . . . . . . . . . . . . . . . . . 29

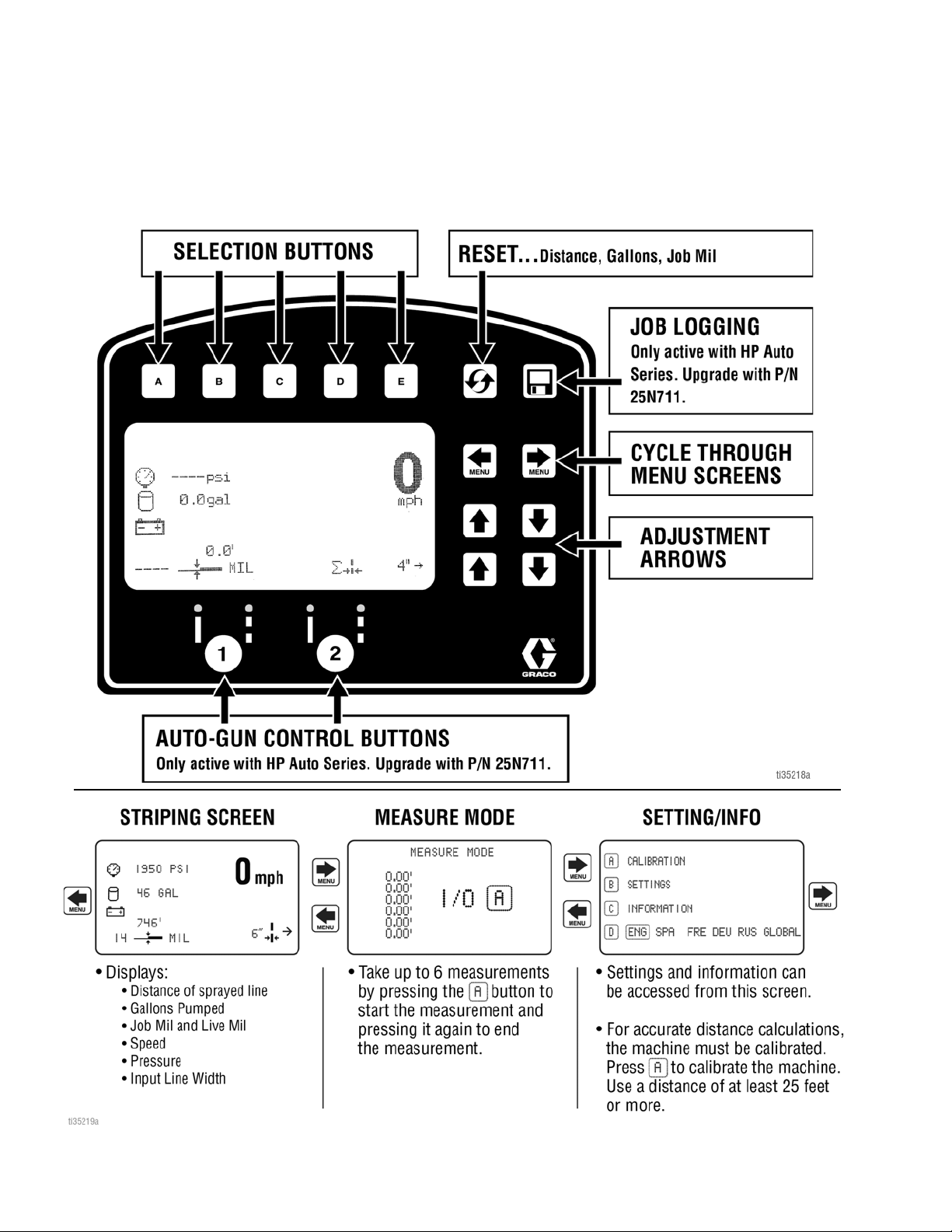

LineLazer V LiveLook Display . . . . . . . . . . . . . . . 30

ES 2000 (Standard Series) . . . . . . . . . . . . . . . . 30

Initial Setup (ES 2000 Standard Series) . . . . . . 31

Striping Mode (ES2000 Standard Series) . . . . . 33

Measure Mode (ES2000 Standard Series) . . . . 34

Setup/Information . . . . . . . . . . . . . . . . . . . . . . . 35

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

ES2000 (HP Auto Series) . . . . . . . . . . . . . . . . . . . . 38

LineLazer V LiveLook Display . . . . . . . . . . . . . . . 39

ES2000 (HP Auto Series) . . . . . . . . . . . . . . . . . 39

Initial Setup (ES2000 HP Auto Series) . . . . . . . 40

Striping Mode (ES2000 HP Auto Series) . . . . . . 42

Measure Mode (ES2000 HP Auto Series) . . . . . 43

Layout Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Stall Calculator . . . . . . . . . . . . . . . . . . . . . . . . . 45

Angle Calculator . . . . . . . . . . . . . . . . . . . . . . . . 46

Setup/Information . . . . . . . . . . . . . . . . . . . . . . . 48

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Marker Layout Mode . . . . . . . . . . . . . . . . . . . . . 51

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Troubleshooting (ES 1000 & ES 2000) . . . . . . . . . 54

Mechanical/Fluid Flow . . . . . . . . . . . . . . . . . . . . 54

Electrical (ES 1000) . . . . . . . . . . . . . . . . . . . . . . 56

ES 2000 Troubleshooting . . . . . . . . . . . . . . . . . 60

Electrical (ES 2000) . . . . . . . . . . . . . . . . . . . . . . 62

Sprayer Will Not Run (ES 1000 & ES 2000) . . . 68

Sprayer Will Not Shut Off (ES 1000 & ES 2000) 70

Inverter (ES 1000 & ES 2000) . . . . . . . . . . . . . . 71

Sprayer does not have - 100 VAC for 120V units - 220

VAC for 230V units (ES 1000& ES 2000) . . . . . . 72

Battery Will Not Charge (ES 1000 & ES 2000) . 73

Parts Drawing - ES 1000 . . . . . . . . . . . . . . . . . . . . 74

Parts List - ES 1000 . . . . . . . . . . . . . . . . . . . . . . . . 75

Parts Drawing - ES 1000 . . . . . . . . . . . . . . . . . . . . 76

Parts List - ES 1000 . . . . . . . . . . . . . . . . . . . . . . . . 77

Parts Drawing - ES 1000 . . . . . . . . . . . . . . . . . . . . 78

Parts List - ES 1000 . . . . . . . . . . . . . . . . . . . . . . . . 79

Parts Drawing - ES 1000 . . . . . . . . . . . . . . . . . . . . 80

Parts List - ES 1000 . . . . . . . . . . . . . . . . . . . . . . . . 81

Swivel Wheel Assembly . . . . . . . . . . . . . . . . . . 81

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Parts Drawing - ES 1000 . . . . . . . . . . . . . . . . . . . . 82

2 3A4603F Operation, Repair, Parts

Page 3

Contents

Parts List - ES 1000 . . . . . . . . . . . . . . . . . . . . . . . . 83

Gun Holder and Arm . . . . . . . . . . . . . . . . . . . . . 83

Gun Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Parts Drawing - ES 1000 . . . . . . . . . . . . . . . . . . . . 84

Parts List - ES 1000 . . . . . . . . . . . . . . . . . . . . . . . . 85

Voltage Meter Box, 120V (ES1000 & ES2000) . . .86

Voltage Meter Box, 230V (ES1000 & ES2000) . . .86

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Voltage Meter Box, 120V . . . . . . . . . . . . . . . . . . 87

Voltage Meter Box, 230V . . . . . . . . . . . . . . . . . . 87

Control Box, 120V (ES 1000) . . . . . . . . . . . . . . . . . 88

Control Box, 230V (ES 1000) . . . . . . . . . . . . . . . . . 88

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Control Box, 120V (ES 1000) . . . . . . . . . . . . . . . 89

Control Box, 230V (ES 1000) . . . . . . . . . . . . . . . 89

Wiring Diagram - 120V (ES 1000) . . . . . . . . . . . . .90

Wiring Diagram - 230V (ES 1000) . . . . . . . . . . . . .91

Control Board Wiring Diagram . . . . . . . . . . . . . . . 92

110/120V (ES 1000) . . . . . . . . . . . . . . . . . . . . . . 92

230V (ES 1000) . . . . . . . . . . . . . . . . . . . . . . . . . 93

Parts Drawing - ES 2000 . . . . . . . . . . . . . . . . . . . . 94

Parts List - ES 2000 . . . . . . . . . . . . . . . . . . . . . . . . 95

Parts Drawing - ES 2000 . . . . . . . . . . . . . . . . . . . . 96

Parts List - ES 2000 . . . . . . . . . . . . . . . . . . . . . . . . 97

Parts Drawing - ES 2000 . . . . . . . . . . . . . . . . . . . . 98

Parts List - ES 2000 . . . . . . . . . . . . . . . . . . . . . . . . 99

Parts Drawing - ES 2000 . . . . . . . . . . . . . . . . . . . 100

Parts List - ES 2000 . . . . . . . . . . . . . . . . . . . . . . . 101

Parts Drawing - ES 2000 . . . . . . . . . . . . . . . . . . . 102

Parts List - ES 2000 . . . . . . . . . . . . . . . . . . . . . . . 103

Swivel Wheel Assembly . . . . . . . . . . . . . . . . . 103

Parts Drawing - ES 2000 . . . . . . . . . . . . . . . . . . . 104

Parts List - ES 2000 . . . . . . . . . . . . . . . . . . . . . . . 105

Gun Holder and Arm . . . . . . . . . . . . . . . . . . . . 105

Gun Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Parts Drawing - ES 2000 . . . . . . . . . . . . . . . . . . . 106

Parts List - ES 2000 . . . . . . . . . . . . . . . . . . . . . . . 107

Distance Sensor Replacement (ES 2000) . . . . . 108

Wiring Diagram - 120V (ES 2000) . . . . . . . . . . . . 109

Control Board Wiring Diagram . . . . . . . . . . . . . . 110

110/120V (ES2000) . . . . . . . . . . . . . . . . . . . . . 110

230V (ES2000) . . . . . . . . . . . . . . . . . . . . . . . . 111

Wiring Diagram - 230V (ES 2000) . . . . . . . . . . . . 112

World Key Symbol . . . . . . . . . . . . . . . . . . . . . . . . 113

Technical Specifications . . . . . . . . . . . . . . . . . . . 114

CALIFORNIA PROPOSITION 65 . . . . . . . . . . 114

Technical Specifications . . . . . . . . . . . . . . . . . . . 115

Technical Specifications . . . . . . . . . . . . . . . . . . . 116

End of Product Life . . . . . . . . . . . . . . . . . . . . . . . 117

Graco Standard Warranty . . . . . . . . . . . . . . . . . . 118

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 119

3A4603F Operation, Repair, Parts 3

Page 4

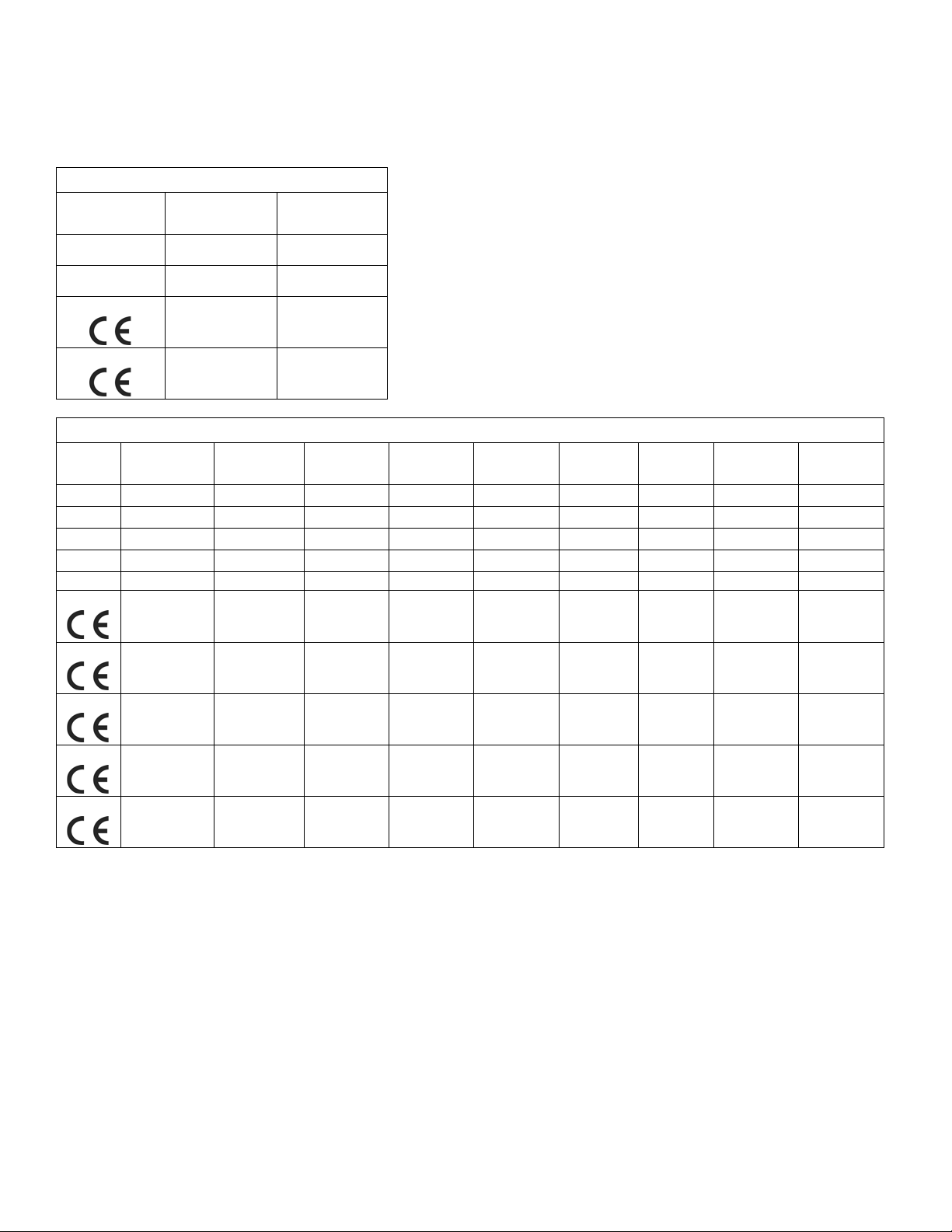

Models

Models

LineLazer ES 1000

Model 1 Battery

25M226

25N784

25M228

25N785

Model 2 Batteries

Included

25N550

25N551

25N552

25N559

25N560

25N553

Included

120V

230V

Standard

Series

2 Batteries

Included

120V

230V

HP Auto

Series

LineLazer ES 2000

Number of

Manual Guns

20

11

02

11

02

10

Number of

Auto Guns

120V 230V LazerGuide

1700

LazerGuide

2000

25N554

25N561

25N562

25N657

01

20

02

11

4 3A4603F Operation, Repair, Parts

Page 5

Warnings

120V US

230V

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these

symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard

symbols and warnings not covered in this section may appear throughout the body of this manual where applicable.

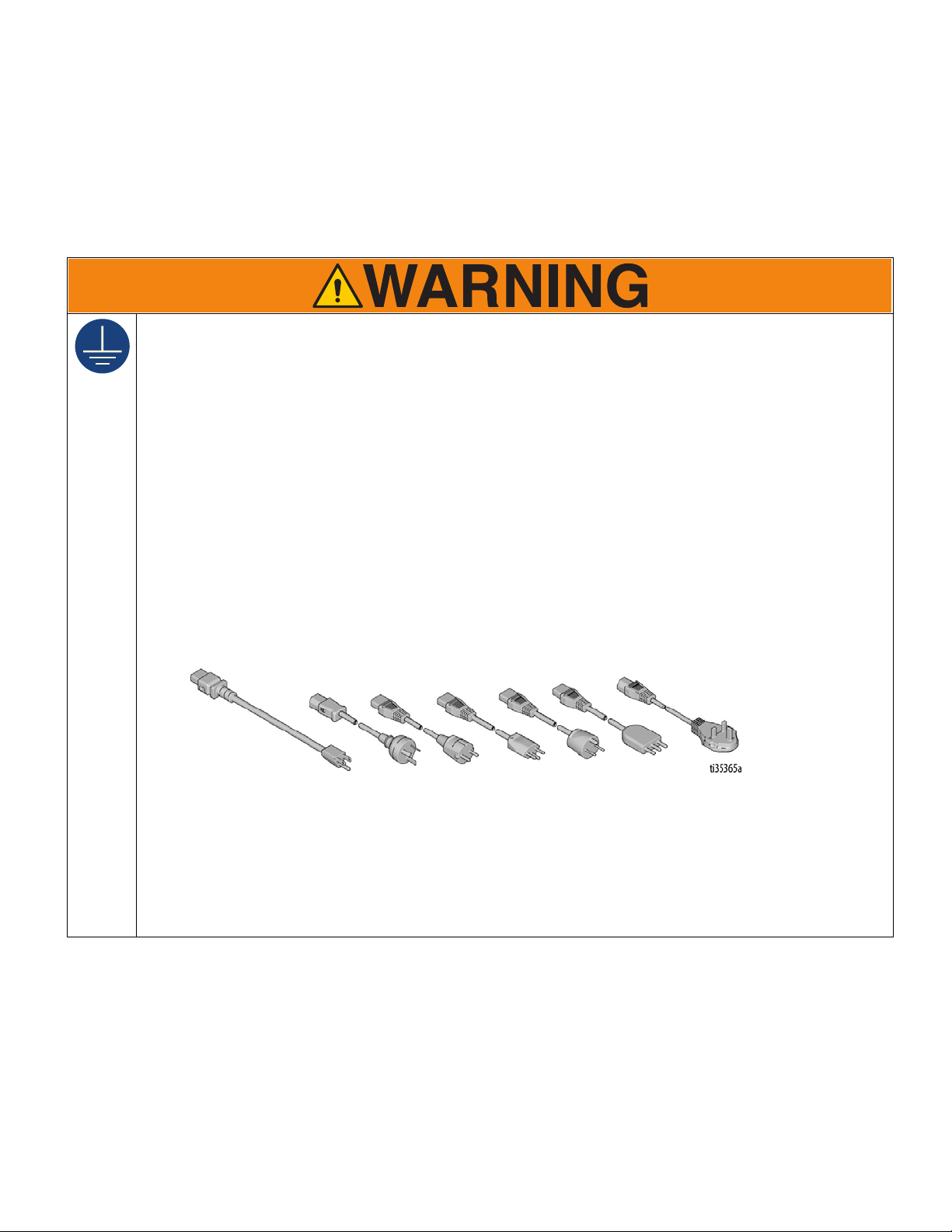

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This product is equipped with a cord having

a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding wire to either flat

blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes is the grounding

wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely

understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a qualified

electrician.

• This product is for use on a nominal 120V or 230V circuit and has a grounding plug similar to the plugs

illustrated in the figure below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

Extension Cords:

• Use only a 3-wire extension cord that has a grounding plug and a grounding receptacle that accepts the

plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary use 12 AWG (2.5mm

minimum to carry the current that the product draws.

• An undersized cord results in a drop in line voltage and loss of power and overheating.

3A4603F Operation, Repair, Parts 5

2

)

Page 6

Warnings

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire

and explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition such as

cigarettes, motors, and electrical equipment.

• Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity creates

a risk of fire or explosion in the presence of paint or solvent fumes. All parts of the spray system, including

the pump, hose assembly, spray gun, and objects in and around the spray area shall be properly grounded

to protect against static discharge and sparks. Use Graco conductive or grounded high-pressure airless

paint sprayer hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge. Do not use pail

liners unless they are antistatic or conductive.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

• Do not spray flammable or combustible liquids in a confined area.

• Sprayer generates sparks. Keep spray area well-ventilated. Keep a good supply of fresh air moving through

the area.

• Keep pump assembly in a well ventilated area when spraying, flushing, cleaning, or servicing. Do not spray

pump assembly.

• Do not smoke in the spray area or spray where sparks or flame is present.

• Do not operate light switches, engines, or similar spark producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

• Know the contents of the paints and solvents being sprayed. Read all Safety Data Sheets (SDSs) and

container labels provided with the paints and solvents. Follow the paint and solvents manufacturer’s safety

instructions.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that

injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any

part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while spraying,

follow the Pressure Relief Procedure for turning off the unit and relieving the pressure before removing

the nozzle tip to clean.

• Equipment maintains pressure after power is shut off. Do not leave the equipment energized or under

pressure while unattended. Follow the Pressure Relief Procedure when the equipment is unattended or

not in use, and before servicing, cleaning, or removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3300 psi (22.8 MPa, 228 bar). Use Graco replacement parts or

accessories that are rated a minimum of 3300 psi (22.8 MPa, 228 bar).

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

6 3A4603F Operation, Repair, Parts

Page 7

Warnings

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your

material, request Safety Data Sheet (SDS) from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety

hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off, disconnect power cord, and disconnect battery before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

• Wait five minutes after disconnecting power cord before servicing.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheet (SDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

3A4603F Operation, Repair, Parts 7

Page 8

Warnings

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited

to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

BATTERY HAZARD

Lead-acid batteries produce explosive gases and contain sulfuric acid that can cause severe burns. To avoid

sparks and injury when handling or working with a lead-acid battery:

• Only use the battery type specified for use with the equipment. See Technical Data.

• Read and follow the battery manufacturer’s warnings.

• Exercise caution when working with metallic tools or conductors to prevent short circuits and sparks.

• Keep all sparks, flames, and cigarettes away from batteries.

• Always wear protective eyewear and protective equipment for face, hands, and body.

• If you have direct contact with battery fluid, flush with water and consult a physician immediately.

• Installation and maintenance must be performed by knowledgeable personnel only.

8 3A4603F Operation, Repair, Parts

Page 9

Component Identification (ES 1000)

ti30321a

PRIME SPRAY

16

1

1

2

3

4

6

7

5

8

9

2

3

6

7

8

9

11

10

14

17

15

16

12

13

4

5

11

10

12

14

15

13

17

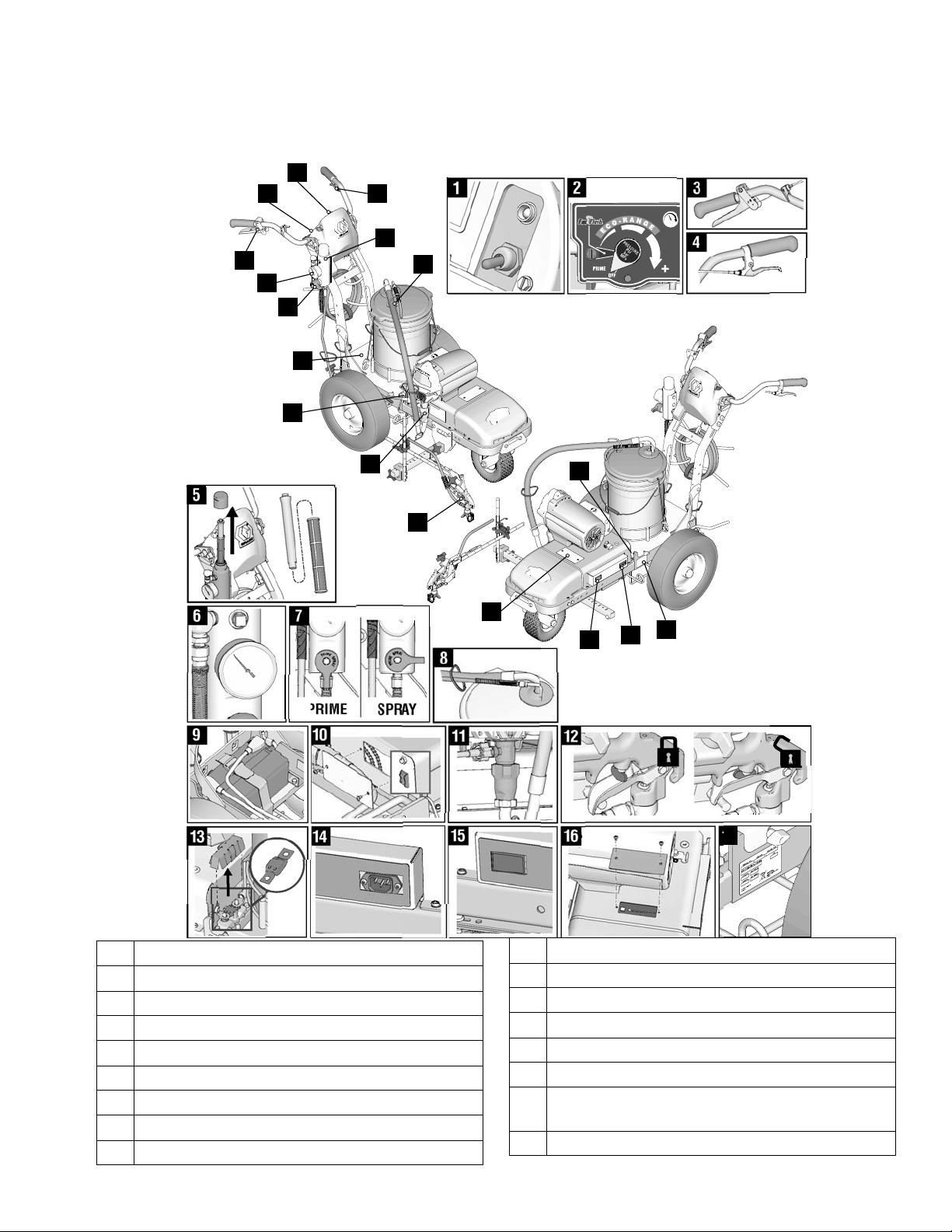

Component Identification (ES 1000)

1 ON/OFF Switch

2 Pressure Control & Display

3 Spray Gun Trigger

4 Turn Control

5 Filter

6 Pressure Gauge

7 Prime/Pressure Valves

8 Drain and Siphon Hoses

9 Battery Compartment

10 Inverter Circuit Breakers

11 Pump

12 Trigger Safety

13 Fuse

14 Charging Port

15 Voltage Meter

16 LED Status Center & Battery Type Selector

17 Serial ID

Access

3A4603F Operation, Repair, Parts 9

Page 10

Component Identification (ES 2000)

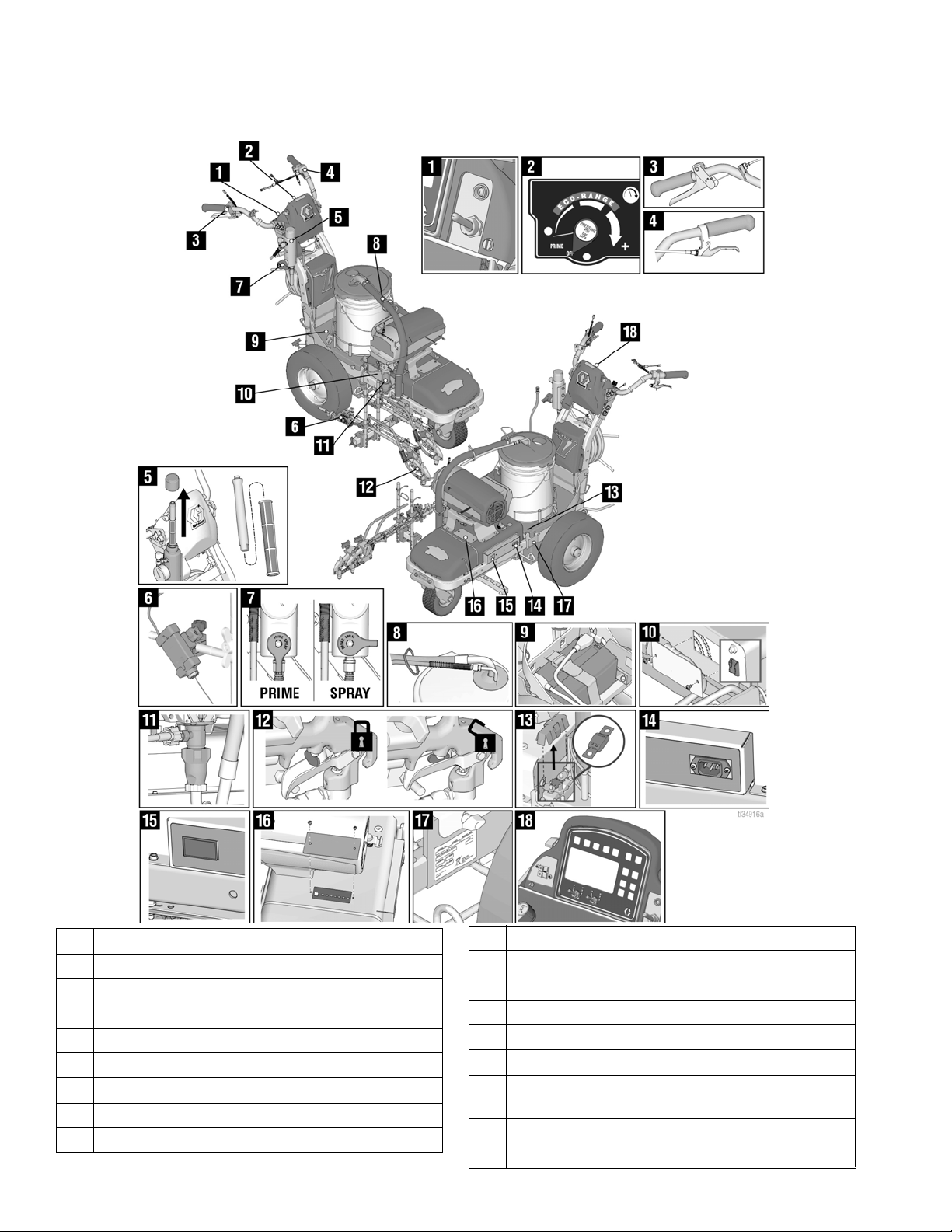

Component Identification (ES 2000)

1 ON/OFF Switch

2 Pressure Control & Display

3 Spray Gun Trigger

4 Turn Control

5 Filter

6 Laser

7 Prime/Pressure Valves

8 Drain and Siphon Hoses

9 Battery Compartment

10 3A4603F Operation, Repair, Parts

10 Inverter Circuit Breakers

11 Pump

12 Trigger Safety

13 Fuse

14 Charging Port

15 Voltage Meter

16 LED Status Center & Battery Type Selector

Access

17 Serial ID

18 Display

Page 11

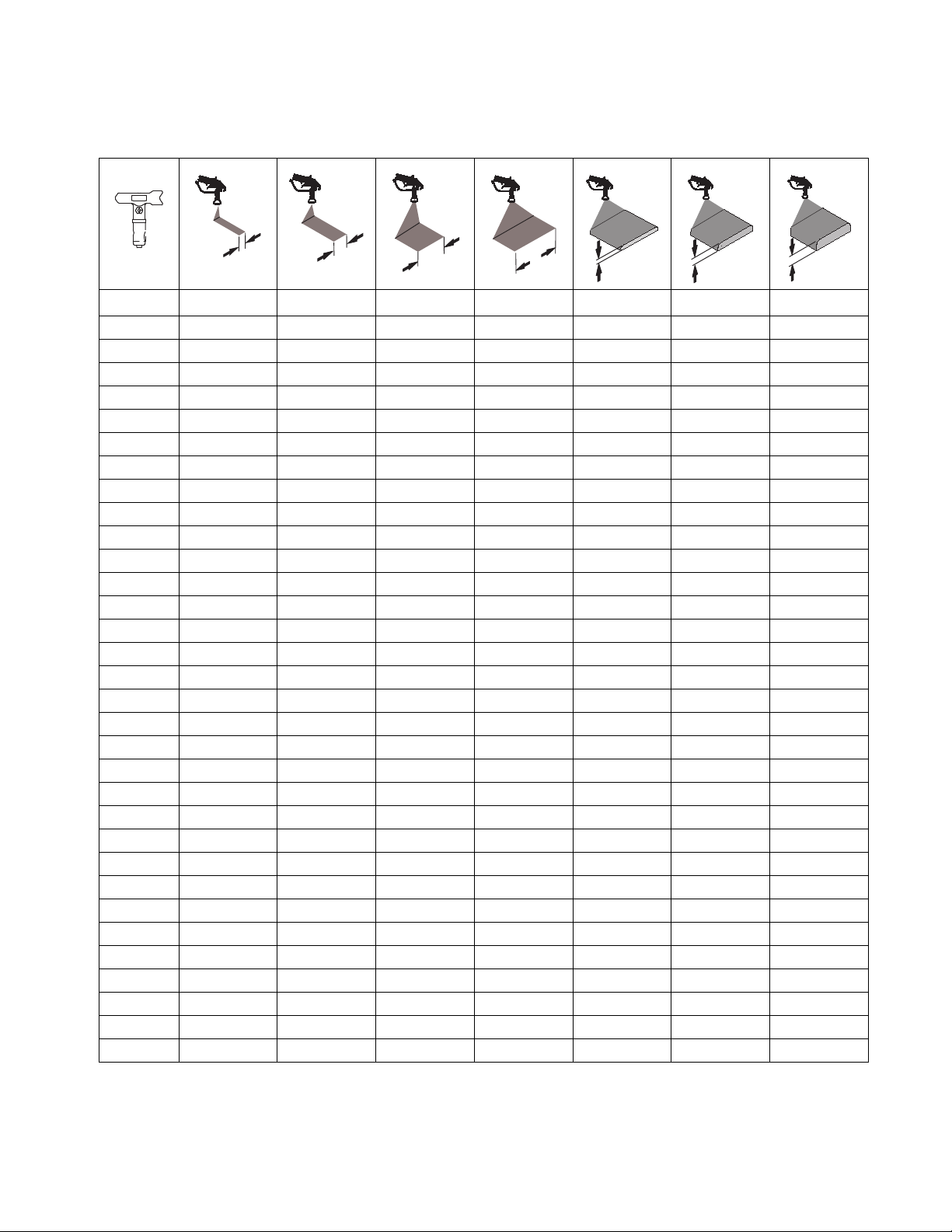

Tip Selection

ti27606a

in.

in.

in.

in.

(cm)

ti27508a

ti27509a

Tip Selection

(cm)

ti27506a

(cm)

ti27505a

(cm)

LL5213* 2 (5)

LL5215* 2 (5)

LL5217

LL5219

LL5315

LL5317

LL5319

LL5321

LL5323

LL5325

LL5327

LL5329

LL5331

LL5333

LL5335

LL5355

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

LL5417 6 (15)

LL5419 6 (15)

LL5421 6 (15)

LL5423 6 (15)

LL5425 6 (15)

LL5427 6 (15)

LL5429 6 (15)

LL5431 6 (15)

LL5435 6 (15)

LL5621

LL5623

LL5625

LL5627

LL5629

LL5631

LL5635

LL5639

ti27507a

12 (30)

12 (30)

12 (30)

12 (30)

12 (30)

12 (30)

12 (30)

12 (30)

ti27510a

ti27605a

*Use 100 mesh filter to reduce tip clogs.

3A4603F Operation, Repair, Parts 11

Page 12

Battery and Charger

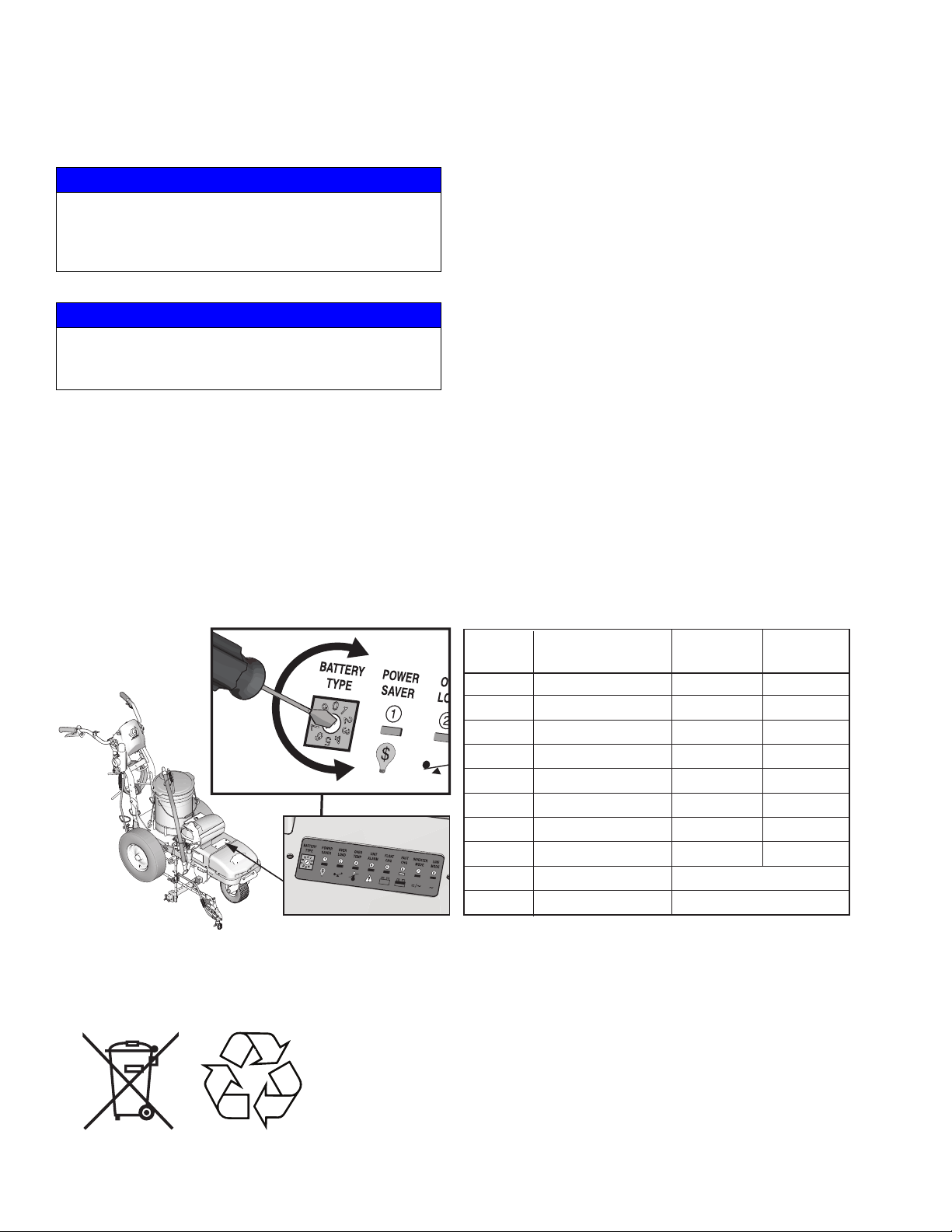

BATTERY TYPE SELECTOR SETTINGS

Switch

Position Description Boost/Vdc Float/Vdc

0 Charger Off

1 Gel USA 14.0 13.7

2 AGM 1 14.1 13.4

3 AGM 2

(Graco Supplied) 14.6 13.7

4 Sealed Lead Acid 14.4 13.6

5 Gel Euro 14.4 13.8

6 Open Lead Acid 14.8 13.3

7 LiFePO4 14.4 14.4

8 De-sulphation 15.5

(4 hours then Off)

9 Not used

ti30488a

Battery and Charger

NOTICE

If the battery level is below 9.7V, the on-board charger

will not be allowed to charge the battery. Charge battery

with an external charger to raise the level above 10.0V

to activate the on-board charger, or replace the battery.

NOTICE

Do not expose sprayer to rain or washdown. Exposure

could cause damage to electrical components. Store

and transport covered or indoors.

Battery Type and Charging Profiles

Graco recommends using a 12V 100 Ahr Absorbent

Glass Mat (AGM) DEEP CYCLE battery.The charger is

set for this charging profile from the factory. If a different

battery is used, the charging profile can be set at the

LED Status Center. The initial charge rate is 30 amps.

• Battery Protection Features: Unit is designed to

protect the battery by shutting down at 10.5V and

not allowing charging to occur above 15.5V.

• Self Discharge: Lead acid batteries can

self-discharge in as little as 3 months depending on

storage temperatures. The hotter the storage

temperature, the faster the self-discharge occurs.

To prevent damage to the battery, it is important to

keep the battery in a charged state.

• Battery Life: Battery recharge cycles depend on

the depth of discharge per cycle. A battery that is

discharged to 50% depth will get over twice as

many cycles in its life compared to it being

discharged to 100% depth each cycle.

Only use batteries that allow an initial charge rate of 30

amps or higher.

Use a small flat head screw driver to turn the arrow to

point at the number that correlates with the chosen

battery.

Battery Disposal

Do not place batteries in the trash. Recycle batteries according to local regulations.

12 3A4603F Operation, Repair, Parts

Page 13

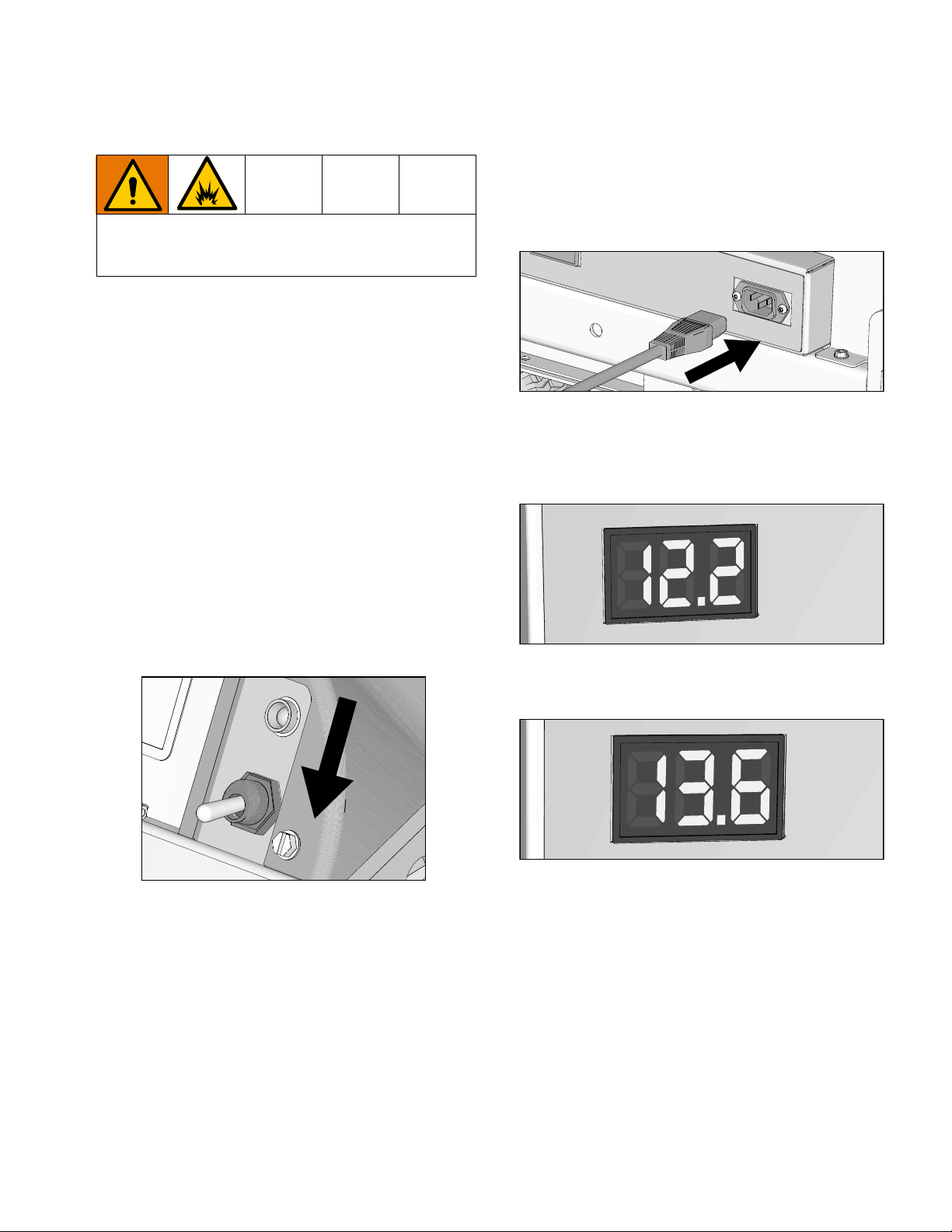

Charging the Battery

ti30322a

ti30358a

ti30359a

ti30360a

Replace and charge battery only in well-ventilated

area and away from flammable or combustible

materials, including paints and solvents.

If the battery level is below 9.7V, the on-board charger

will not be allowed to charge the battery. Charge battery

with an external charger to raise the level above 10.0V to

activate the on-board charger, or replace the battery.

Use an extension cord with an undamaged ground

contact. If an extension cord is necessary, use a 3-wire,

12 AWG (2.5 mm

Batteries are fully charged when leaving the factory.

Due to self-discharging of the battery, charge battery

before first use. It takes ~3 hours to charge a dead

battery to 80%. It takes ~5 hours to charge a fully

depleted battery (double these times for 2 battery unit).

2

) minimum.

Battery and Charger

3. Plug charging cord into charging port on the unit.

Connect an extension cord, minimum 12AWG

(2.5mm

2

), to the charging cord and plug it into wall

power.

4. When power is connected the voltmeter will turn on

and the charger will immediately begin charging.

User should be able to see voltmeter start to climb

to indicate charging is occurring.

1. Place unit in dry, well-ventilated area and away from

flammable or combustible materials, including

paints and solvents.

2. Ensure power switch is in OFF position.

5. Battery will charge to 14.6-14.8 volts and then it will

come back down to ~13.6 volts when fully charged.

3A4603F Operation, Repair, Parts 13

Page 14

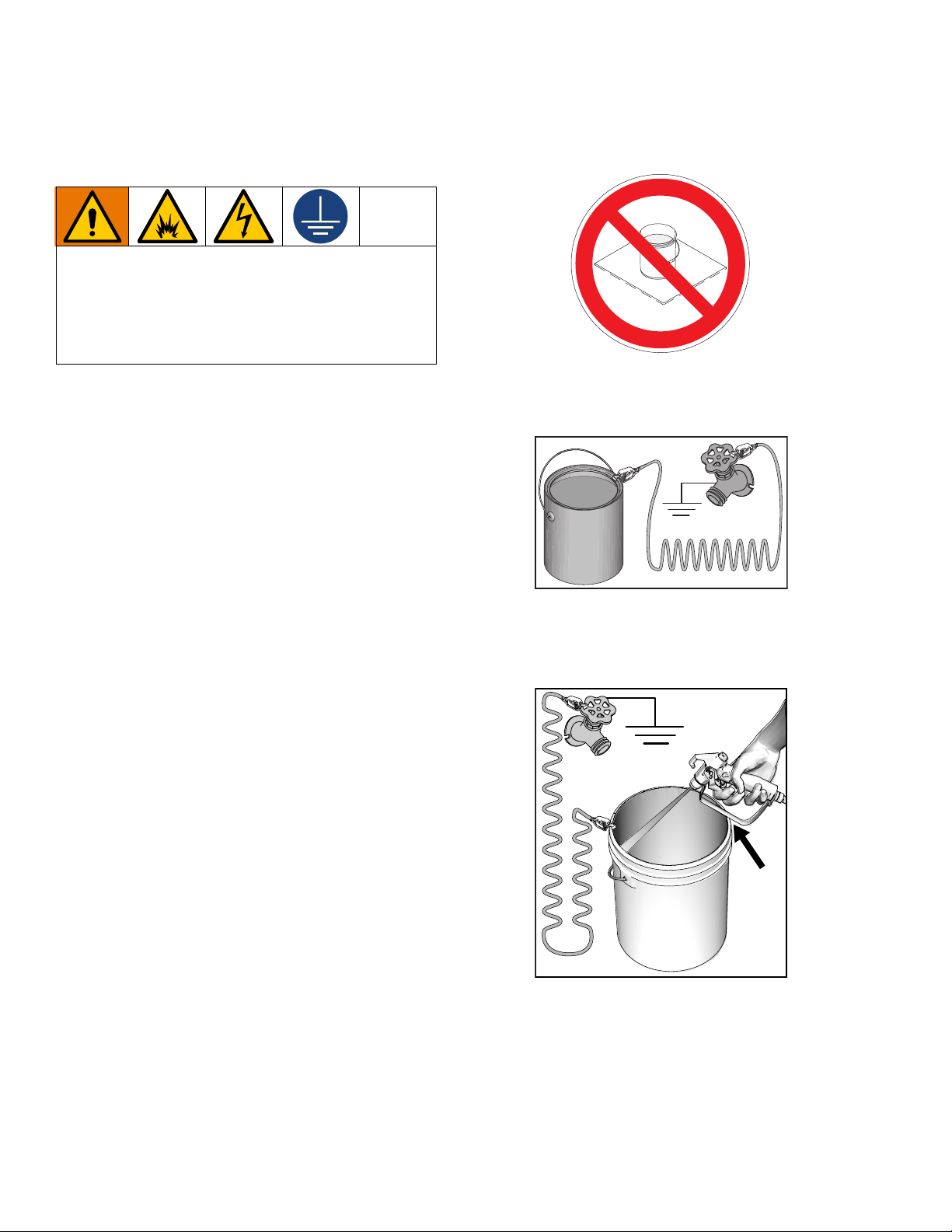

Grounding Procedure (AC Wall Power)

ti24584a

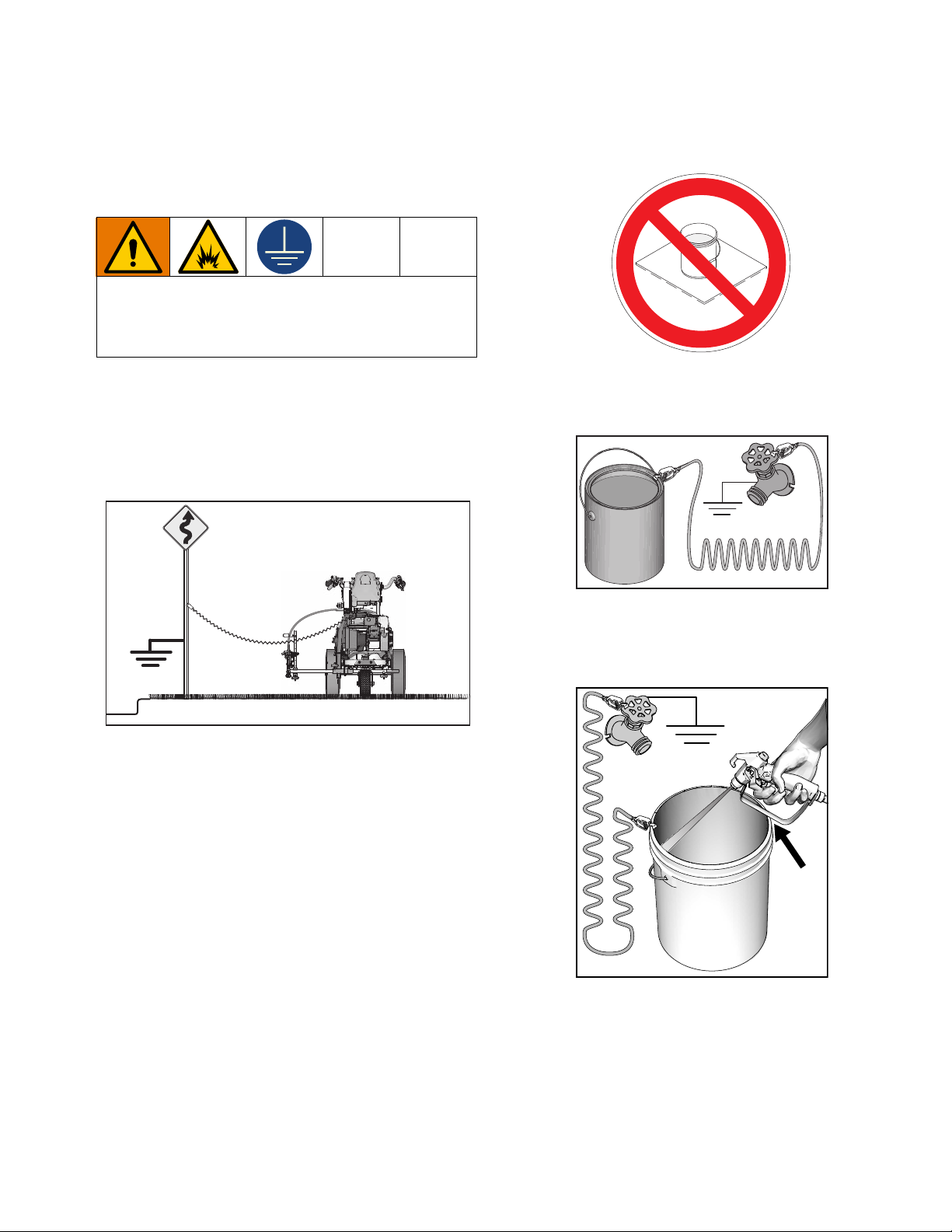

Grounding Procedure

(AC Wall Power)

This equipment must be grounded to reduce the risk

of static sparking and electric shock. An electric shock

or static spark can cause fumes to ignite or explode.

An improper ground can cause electric shock. A good

ground provides an escape wire for the electric

current.

Position the striper so the wheels are on a true

grounded surface. Not on pavement.

The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided; if it does not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Do not place pail on a non-conductive surface such as

paper or cardboard which interrupts grounding

continuity.

Always ground a metal pail: connect a ground wire to

the pail. Clamp one end to the pail and the other end to

a true earth ground such as a water pipe.

Power Requirements

• 100-120V units require 100-120 VAC, 50/60 Hz, 12

or 15A, 1 phase.

• 230V units require 230 VAC, 50/60 Hz, 7 or 9A, 1

phase.

Extension Cords

Use an extension cord with an undamaged ground

contact. If an extension cord is necessary, use a 3-wire,

12 AWG (2.5 mm

2

) minimum.

Pails

Solvent and oil-based fluids: follow local code. Use

only conductive metal pails, placed on a grounded

surface such as concrete.

To maintain ground continuity when sprayer is

flushed or pressure is relieved: hold metal part of

spray gun firmly to the side of a grounded metal pail

then trigger gun.

ti24585a

14 3A4603F Operation, Repair, Parts

Page 15

Grounding Procedure (Battery Power) (For Flammable Flushing Fluids Only)

ti27615a

ti24584a

Grounding Procedure

(Battery Power) (For Flammable

Flushing Fluids Only)

This equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

1. Position striper so that the tires are not on

pavement.

2. Striper is shipped with a grounding clamp.

Grounding clamp must attach to grounded object

(e.g., metal sign post).

Do not place pail on a non-conductive surface such as

paper or cardboard which interrupts grounding

continuity.

Always ground a metal pail: connect a ground wire to

the pail. Clamp one end to the pail and the other end to

a true earth ground such as a water pipe.

3. Disconnect grounding clamp after flushing is

complete.

Pails

Solvent and oil-based fluids: follow local code. Use

only conductive metal pails, placed on a grounded

surface such as concrete.

To maintain ground continuity when sprayer is

flushed or pressure is relieved: hold metal part of

spray gun firmly to the side of a grounded metal pail

then trigger gun.

ti24585a

3A4603F Operation, Repair, Parts 15

Page 16

Pressure Relief Procedure

ti30322a

ti27608a

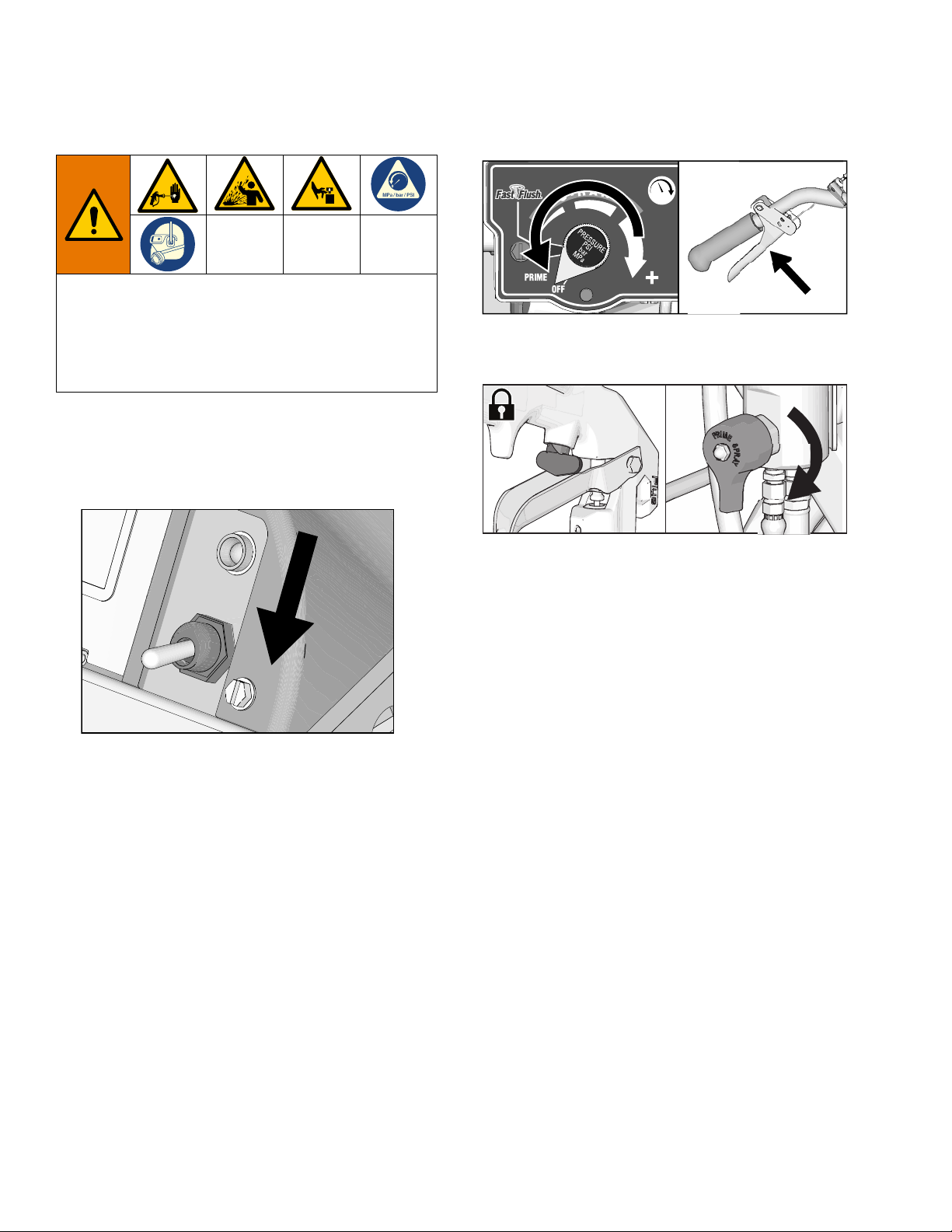

Pressure Relief Procedure

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing fluid

and moving parts, follow the

Procedure

when you stop dispensing and before

cleaning, checking, or servicing the equipment.

1. Perform Grounding Procedure if using flammable

materials.

2. Turn ON/OFF Switch to OFF.

Pressure Relief

3. Turn pressure control to lowest setting. Trigger all

guns to relieve pressure.

ti30323a

4. Engage all gun trigger locks. Turn prime valve

down.

v

5. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved:

a. VERY SLOWLY loosen the tip guard retaining

nut or the hose end coupling to relieve pressure

gradually.

b. Loosen the nut or coupling completely.

c. Clear the obstruction in the hose or tip.

16 3A4603F Operation, Repair, Parts

Page 17

Setup/Startup

ti30322a

ti27612a

ti27614a

ti30324a

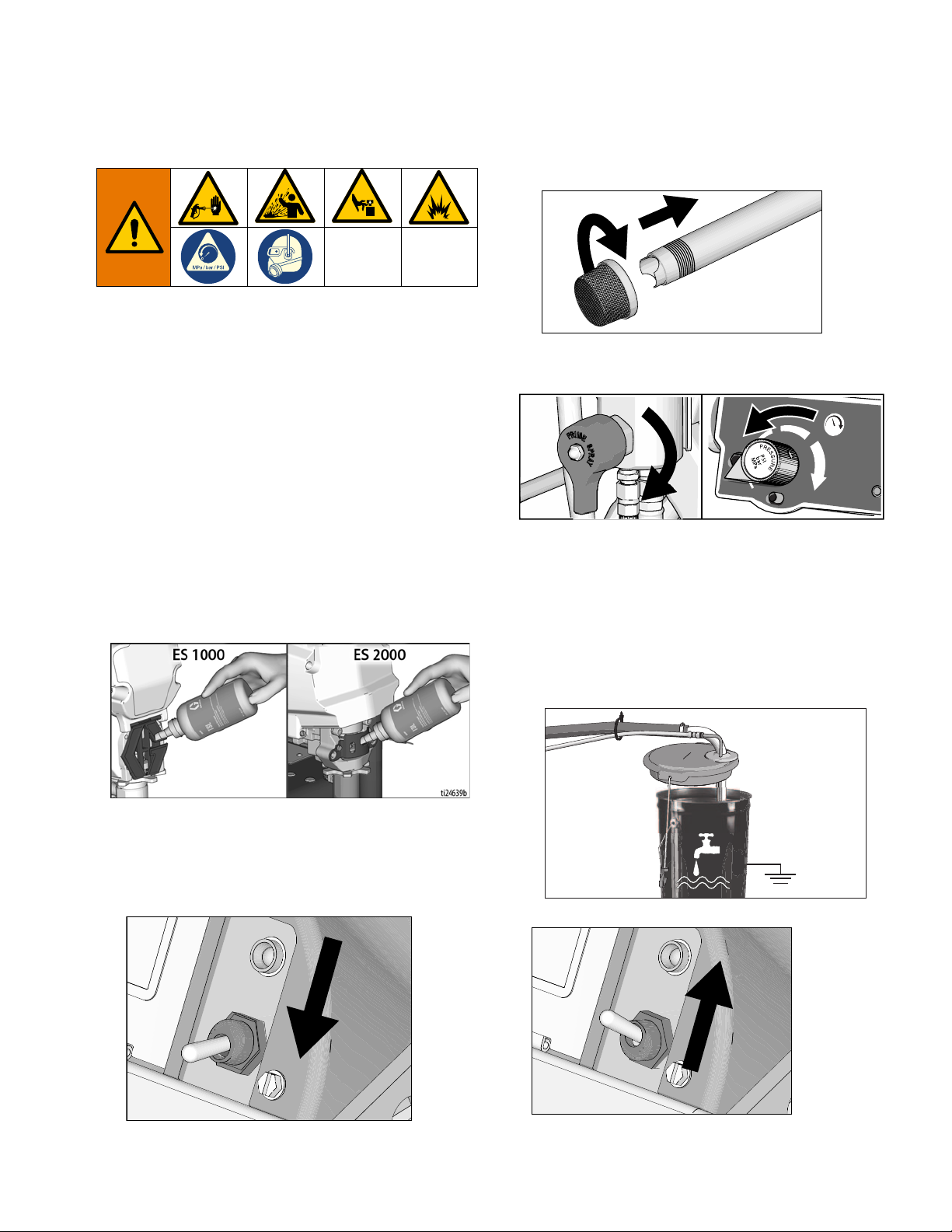

Setup/Startup

6. If removed, install strainer.

1. Perform

Pressure Relief Procedure

, page 16

.

2. Charging the Battery, page 13.

3. Perform Grounding Procedure (AC Wall Power),

page 14, or Grounding Procedure (Battery

Power) (For Flammable Flushing Fluids Only),

page 15, if using flammable materials.

4. Fill throat packing nut with TSL to prevent

premature packing wear. Do this daily or each time

you spray.

a. Place the TSL bottle nozzle into the top center

opening in the grill at the front of the sprayer.

b. Squeeze bottle to dispense enough TSL to fill

the space between the pump rod and packing

nut seal.

7. Turn prime valve down. Turn pressure control

counterclockwise to lowest pressure.

NOTE: Minimum hose size for proper sprayer

operation is 1/4 in. x 50 ft for LL ES 1000 and 3/8 x 20’

for ES 2000.

8. Place siphon tube set in grounded metal pail

partially filled with flushing fluid. Attach ground wire

to true earth ground. Use water to flush water-based

paint and mineral spirits to flush oil-based paint and

storage oil.

NOTE: If running off wall power, plug cord into charging

port. If using an extension cord, use a 3-wire, 12 AWG

(2.5mm

5. Turn ON/OFF Switch to OFF.

2

) minimum with an undamaged ground contact.

ti27613a

9. Turn ON/OFF Switch to ON:

3A4603F Operation, Repair, Parts 17

Page 18

Setup/Startup

ti27771a

ti30349a

10. ES 1000: Turn pressure control to prime. Allow fluid

to circulate for 15 seconds.

ES 2000: Increase pressure 1/2 turn to start motor

and allow fluid to circulate for 15 seconds.

11. Turn pressure down, turn prime valve horizontal.

Disengage gun trigger lock.

12. Hold all guns against a grounded metal flushing pail.

Trigger guns and increase fluid pressure slowly until

pump runs smoothly to spray.

13. Inspect fittings for leaks. If leaks occur, turn sprayer

OFF immediately. Perform

Procedure

Setup/Startup

, page 16. Tighten leaky fittings. Repeat

, steps 1 - 13. If no leaks, continue to

Pressure Relief

trigger gun until system is thoroughly flushed.

Proceed to step 14.

14. Place siphon tube in paint pails.

ti27613a

15. Trigger all guns again into a flushing fluid pail until

paint appears. Assemble tips and guards.

High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. Do not stop

leaks with hand or rag.

ti27774a

16. ES 2000: Digital display is functional when unit is

turned on.

18 3A4603F Operation, Repair, Parts

Page 19

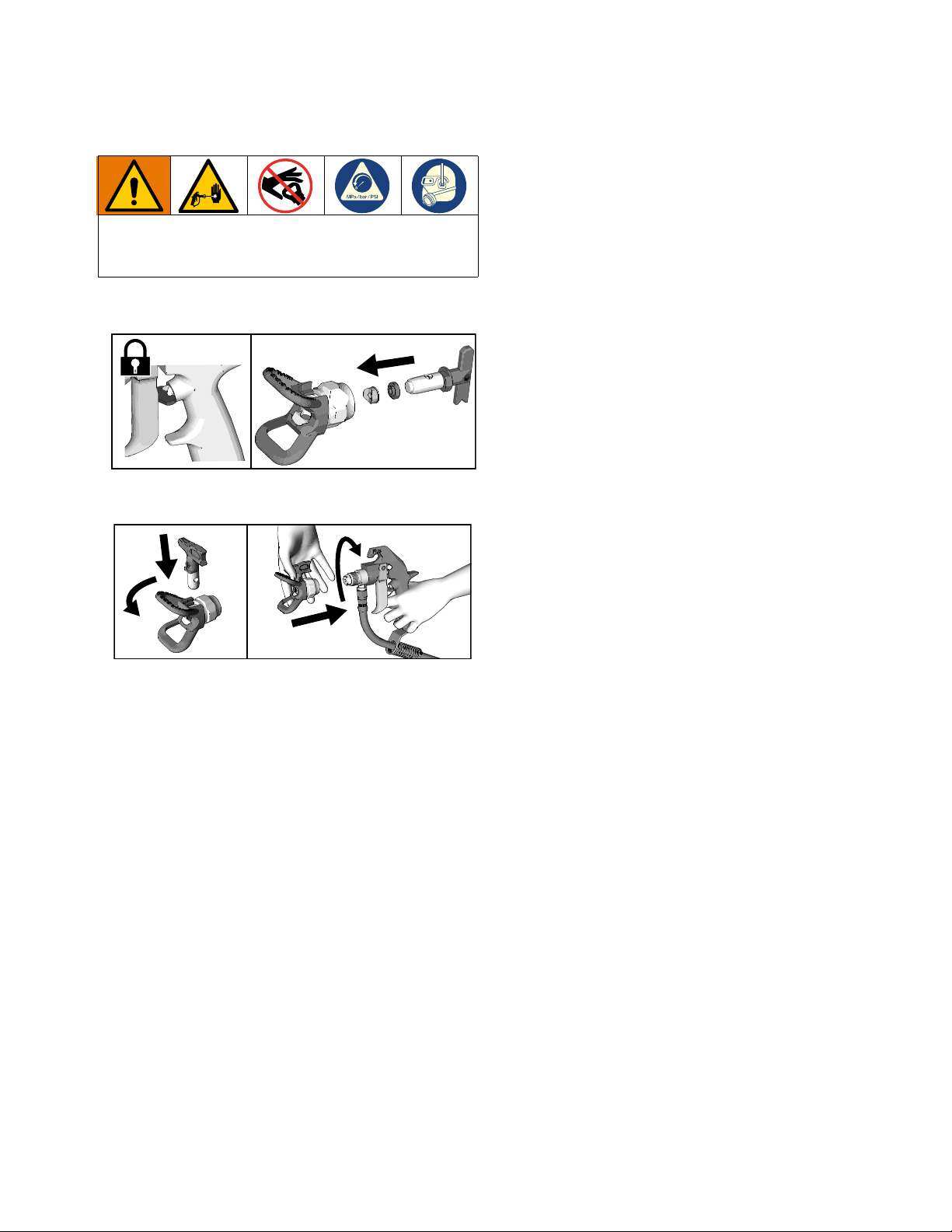

SwitchTip and Guard Assembly

ti27775a

ti27776a

To avoid serious injury from skin injection do not put

your hand in front of the spray tip when installing or

removing the spray tip and tip guard.

1. Engage trigger lock. Use end of SwitchTip to press

OneSeal into tip guard, with curve matching tip bore.

2. Insert SwitchTip in tip bore and firmly thread

assembly onto gun.

Setup/Startup

3A4603F Operation, Repair, Parts 19

Page 20

Gun Placement

ti27777a

ti27778a

ti28129a

ti28130a

1

2

ti27781a

ti27782a

ti27782a

Gun Placement

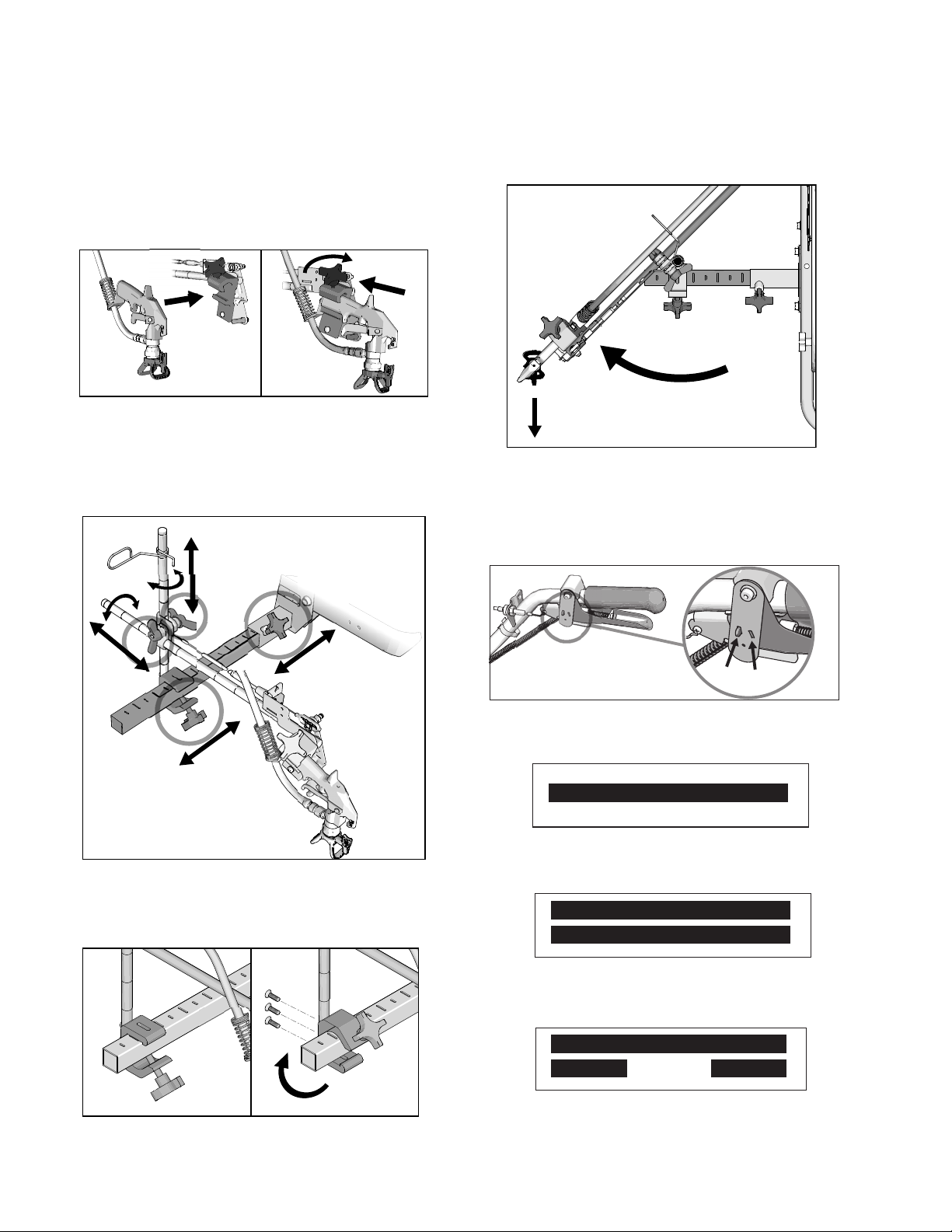

Install Gun

1. Insert guns into gun holder. Tighten clamps.

Position Gun

2. Position gun: up/down, forward/reverse, left/right.

See Gun Positions Chart, page 22 for examples.

Another option can be to swing the gun out at an angle

and rotate the tip guard. This results in better visibility

for the user.

Select Manual Guns

3. Connect gun cables to left or right gun selector

plates.

NOTE: When striping above a curb, the mounting clamp

can be rotated for clearance.

ti27780a

a. One gun: Disconnect one gun selector plate

from trigger.

b. Both guns simultaneously: Adjust both gun

selector plates to the same position.

c. Solid-skip and skip-solid: Adjust solid-line gun

to position 1 and skip-line to position 2.

20 3A4603F Operation, Repair, Parts

Page 21

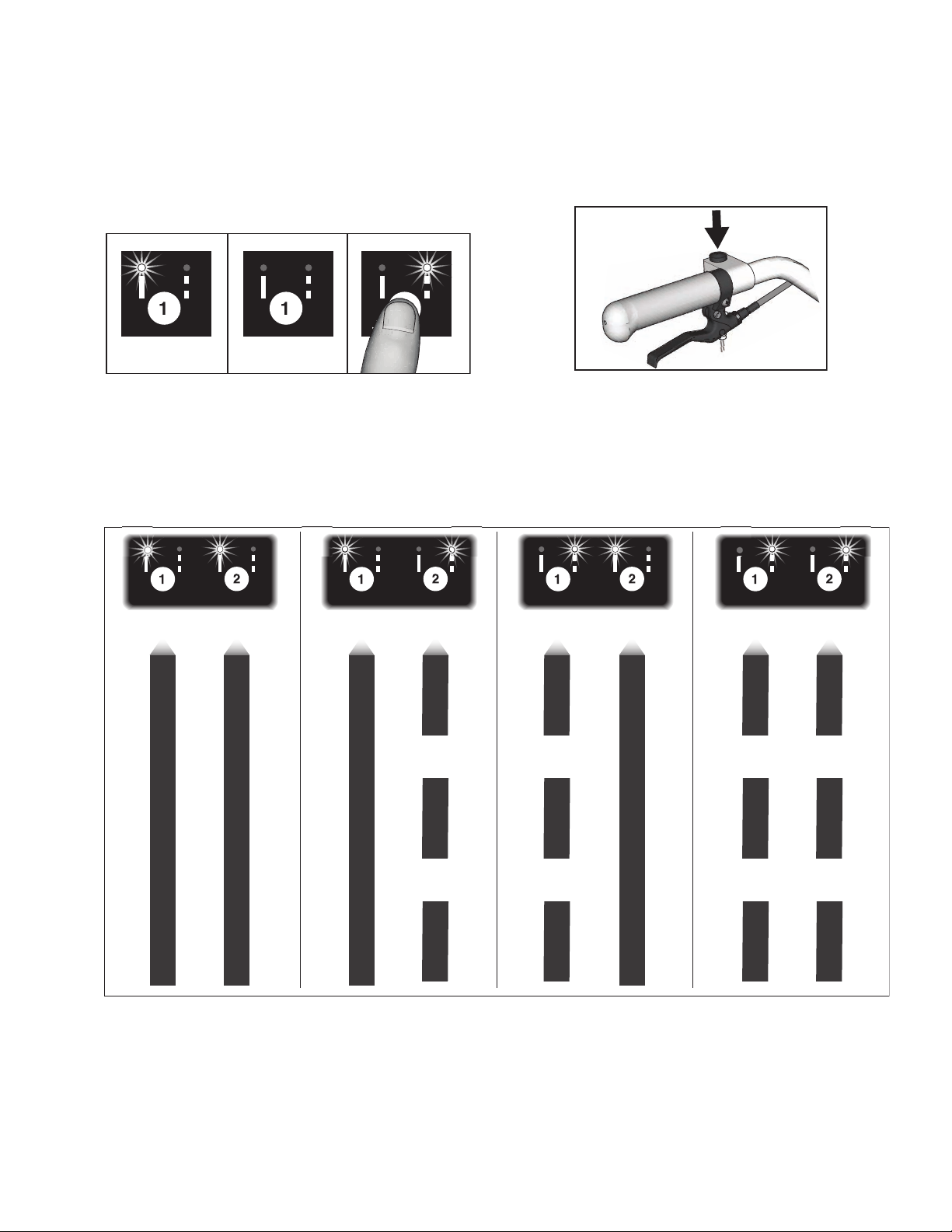

Select Auto Guns (ES 2000)

1s

ti27784a

ti27881a

ti27785a

Gun

1

Gun

2

Gun

1

Gun

2

Gun

1

Gun

2

Gun

1

Gun

2

Gun Placement

1. Use the gun selector buttons to determine which

guns are active. Each gun selector has 3 settings:

continuous line, OFF and programmed line pattern.

2. Use the gun trigger control to actuate auto guns.

4 Examples:

3A4603F Operation, Repair, Parts 21

Page 22

Gun Placement

1

2

3

4

5

6

7

ti27786a

Gun Positions Chart

1 One line

2 One line up to 24 in. (61cm) wide

3 Two lines

4 One line or two lines to spray around obstacles

22 3A4603F Operation, Repair, Parts

5 One gun curb

6 Two gun curb

7 Two lines or one line up to 24 in. (61 cm) wide

Page 23

Gun Placement

ti30326a

ti27796c

ti30327a

ti27797a

ti30328a

ti30329a

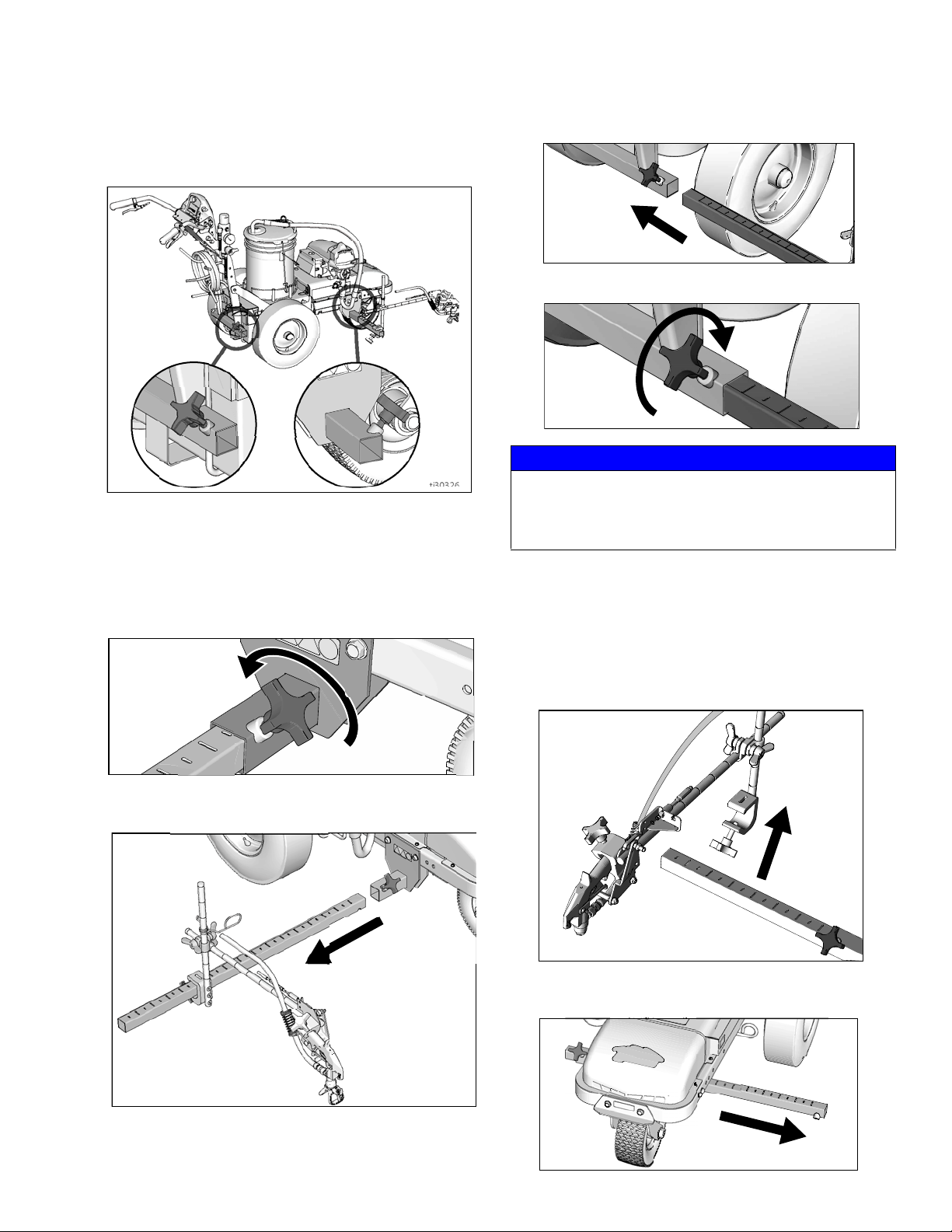

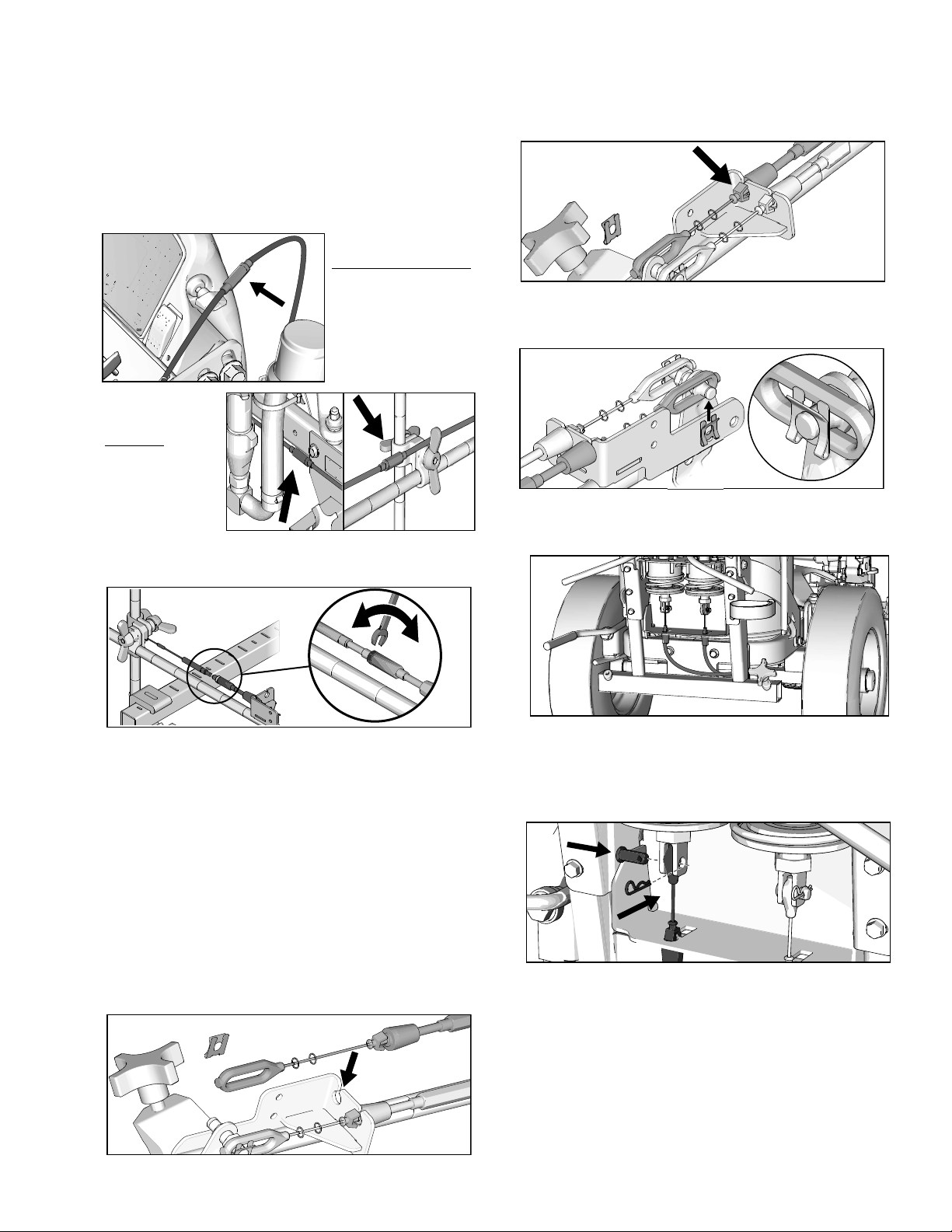

Gun Arm Mounts

This unit is equipped with front and rear gun arm

mounts.

Change Gun Position

(Front and Back)

3. Slide gun arm assembly into desired gun arm

mounting slot.

4. Tighten gun arm knob into gun arm mounting slot.

ti27798a

NOTICE

Make sure all hoses, cables, and wires are properly

routed through brackets and do NOT rub on tire.

Contact with tire will result in damaged hoses, cables,

and wires.

Change Gun Position

1. Loosen gun arm knob and remove from gun arm

mounting slot.

2. Slide gun arm assembly (including gun and hoses)

out from gun arm mounting slot.

(Left and Right)

Removal

1. Loosen vertical gun arm knob on gun arm mounting

bar and remove.

2. Extend mounting bar on opposite side of the

machine.

3A4603F Operation, Repair, Parts 23

Page 24

Gun Placement

ti27801a

ES 2000

Installation

1. Install vertical gun mount onto gun bar.

NOTE: Make sure all hoses, cables, and wires are

properly routed through brackets.

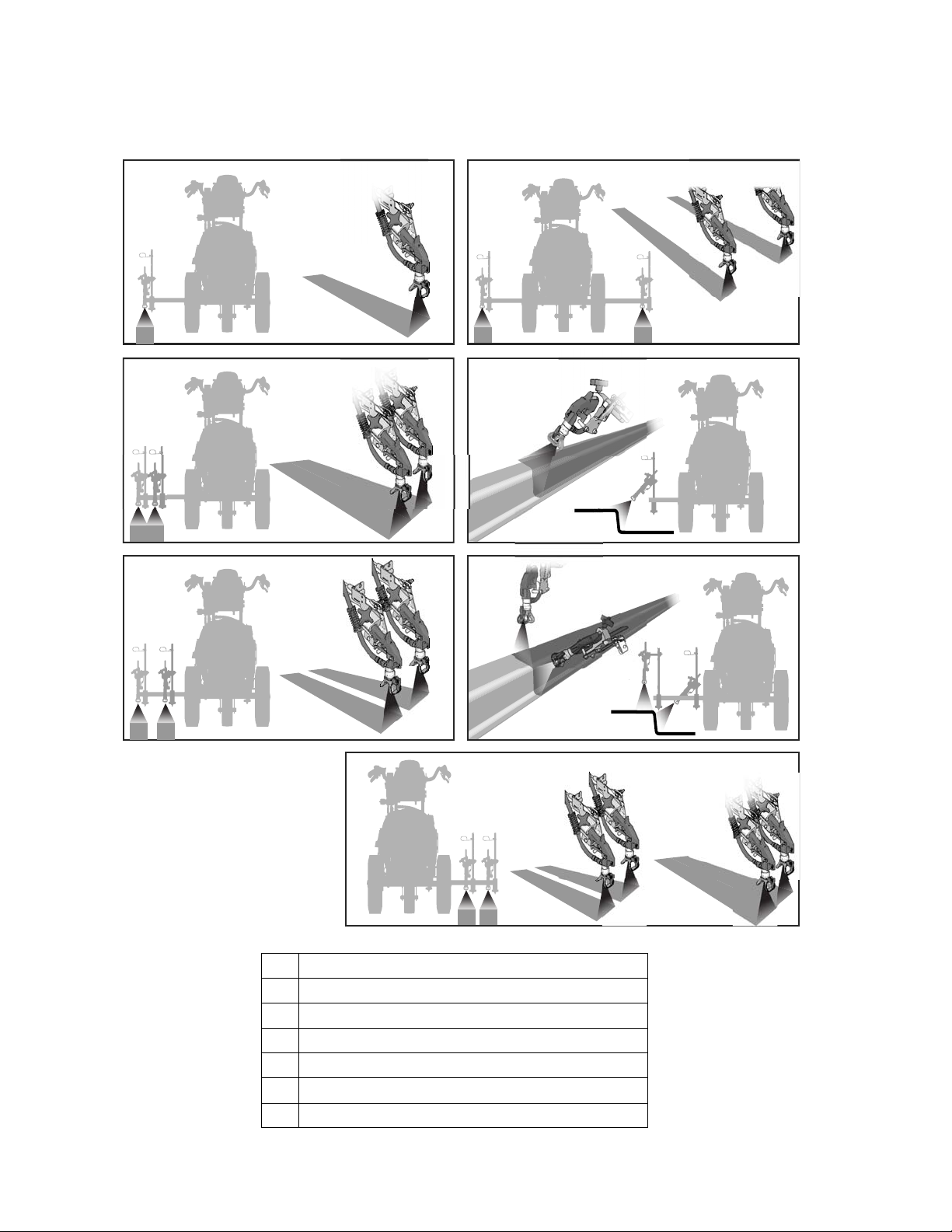

Trigger Sensor Adjustment (ES

2000)

1. Turn striper on. Engage trigger. Spray icon should

appear simultaneously with start of fluid spray.

No fluid spray

2. Turn screw in handle clockwise if spray icon

appears before fluid spray starts.

ti27802a

No spray icon

3. Turn screw in handle counterclockwise if fluid spray

starts before spray icon appears.

ti27803a

4. Continue adjusting screw in handle until timing of

spray icon and fluid spray are synchronized.

Adjustment of the gun cables might be necessary.

ti27883a

24 3A4603F Operation, Repair, Parts

Page 25

Gun Placement

ES 1000 & ES 2000

ES 2000

ti27805b

ti27806b

ti27807b

ti27809a

Gun Cable Adjustment

Adjusting the gun cable will increase or decrease the

gap between the trigger plate and the gun trigger. To

adjust trigger gap, perform the steps below.

ti27884a

ti27885a

1. Use wrench to loosen locking nut on cable adjuster.

3. Insert plastic cable retainer into cable bracket hole.

4. Install cable end onto trigger plate pin and install

clip.

5. Route cable around unit and up through cable holes

behind hose mount.

ti27804a

2. Loosen or tighten adjuster until desired result is

achieved. NOTE: More thread exposed means less

gap between gun trigger and trigger plate.

3. Use wrench to tighten locking nut on the adjuster.

Adding Gun Cable (ES 2000)

The ES 2000 can be equipped with two gun actuators.

Each gun actuator is capable of operating one cable.

1. Select cable end with adjuster.

2. Install exposed cable through cable bracket slot.

ti27808a

6. Route cable end loop through rectangular hole in

bracket and insert plastic cable retainer into the

actuator bracket. Install cable end onto actuator rod

and install pin.

3A4603F Operation, Repair, Parts 25

Page 26

Gun Placement

ti27810a

ti27811a

ti27812a

ti27813a

ti27814a

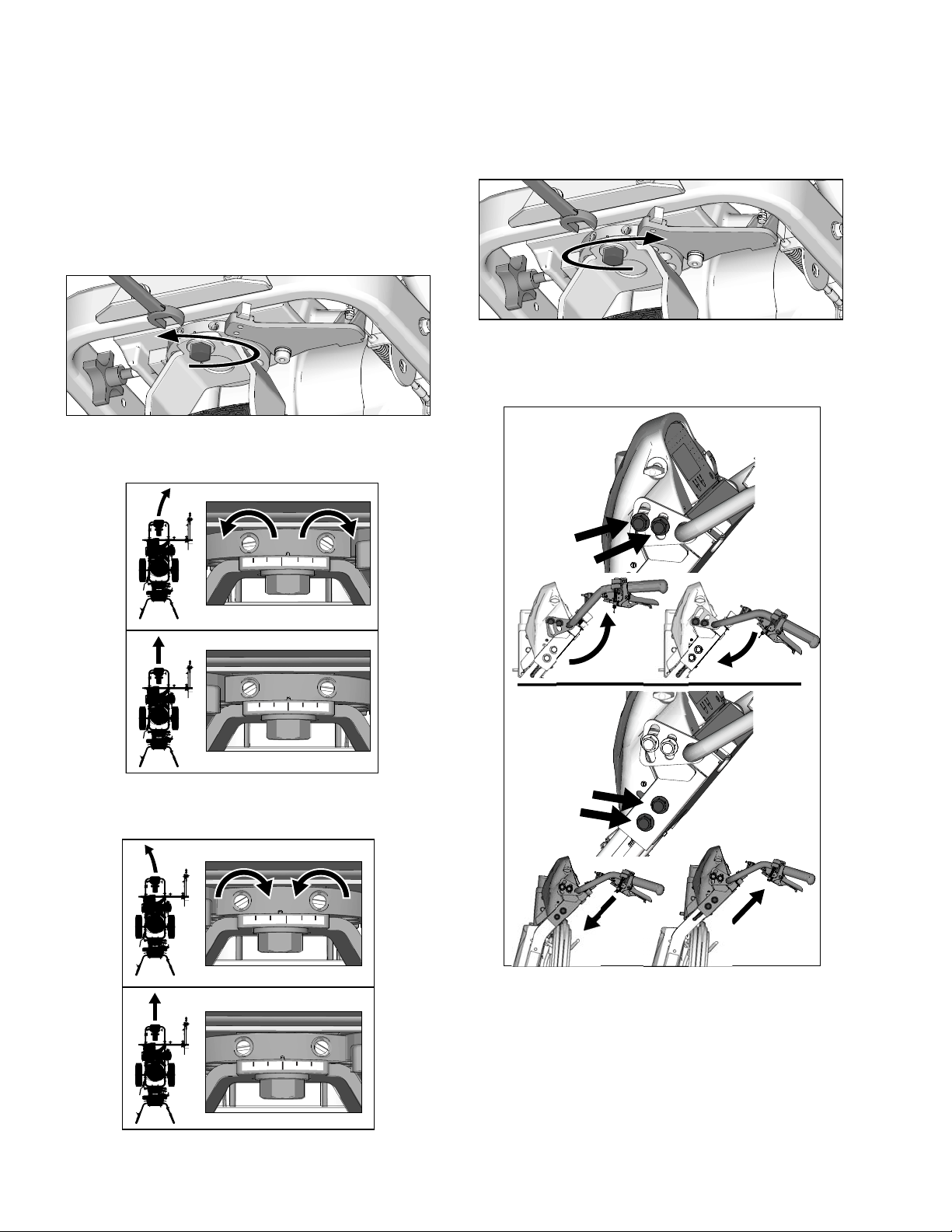

Straight Line Adjustment

The front wheel is set to center the unit and allow the

operator to form straight lines. Over time, the wheel may

become misaligned and will need to be readjusted. To

re-center the front wheel, perform the following steps:

1. Loosen bolt on the front wheel bracket.

2. If striper arcs to the right, loosen left set screw and

tighten right set screw for fine tune adjustment.

4. Roll the striper. Repeat steps 2 and 3 until striper

rolls straight. Tighten bolt on wheel alignment plate

to lock the new wheel setting.

Handle Bar Adjustment

3. If striper arcs to the left, loosen right set screw and

tighten left set screw.

26 3A4603F Operation, Repair, Parts

Page 27

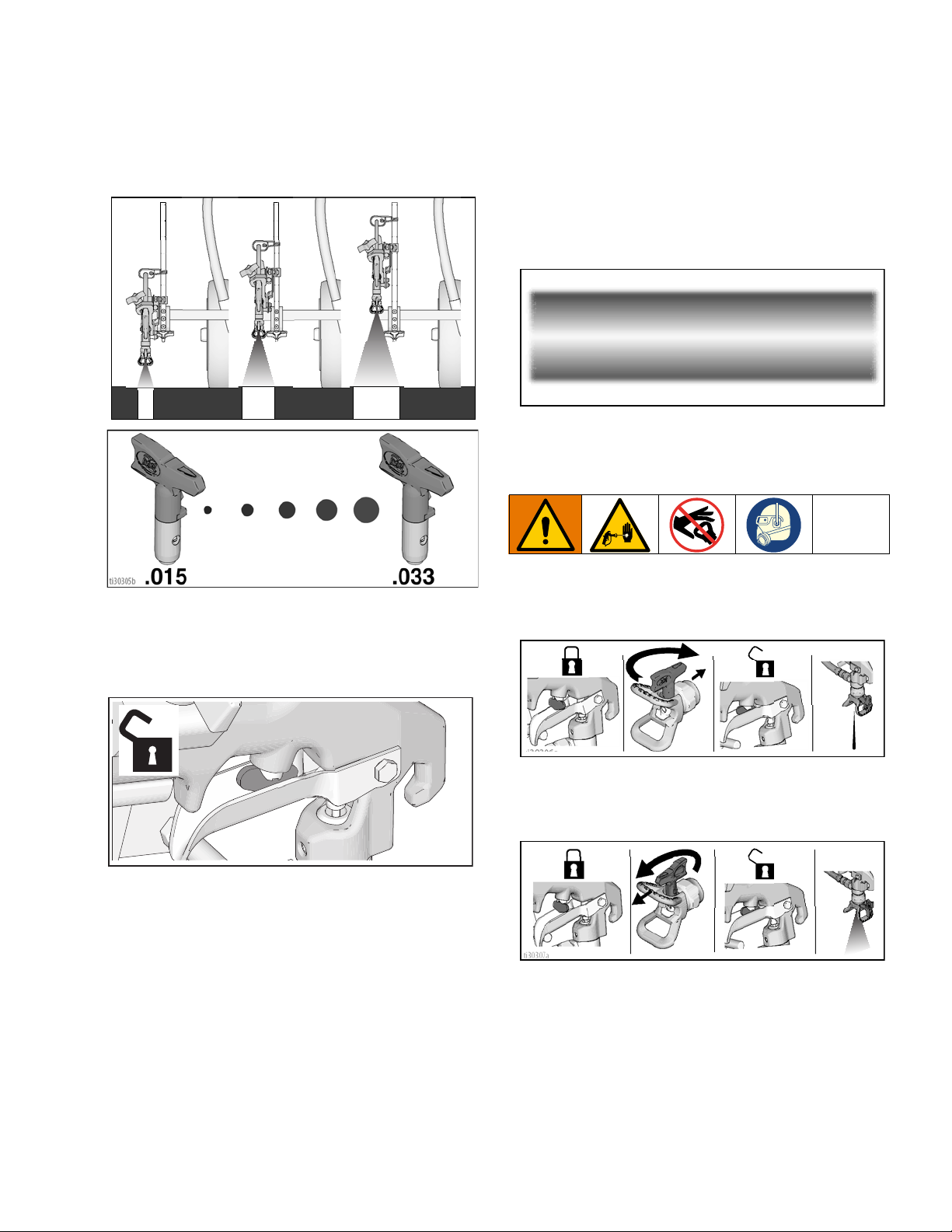

Paint Stripe Width

ti30078a

ti30103a

Paint Stripe Width

1. Adjust gun up or down to change paint stripe width.

ti30304a

Spray Test Stripe

2. Trigger gun and spray test pattern. Slowly adjust

pressure to eliminate heavy edges. Use smaller tip

size if pressure adjustment can not eliminate heavy

edges.

Clearing Tip Clogs

1. Release trigger. Engage gun trigger lock. Rotate

SwitchTip. Disengage gun trigger lock and trigger

gun to clear the clog.

1. Disengage trigger lock.

ti30306a

2. Engage gun trigger lock, return SwitchTip to original

position, disengage gun trigger lock and continue

spraying.

3A4603F Operation, Repair, Parts 27

Page 28

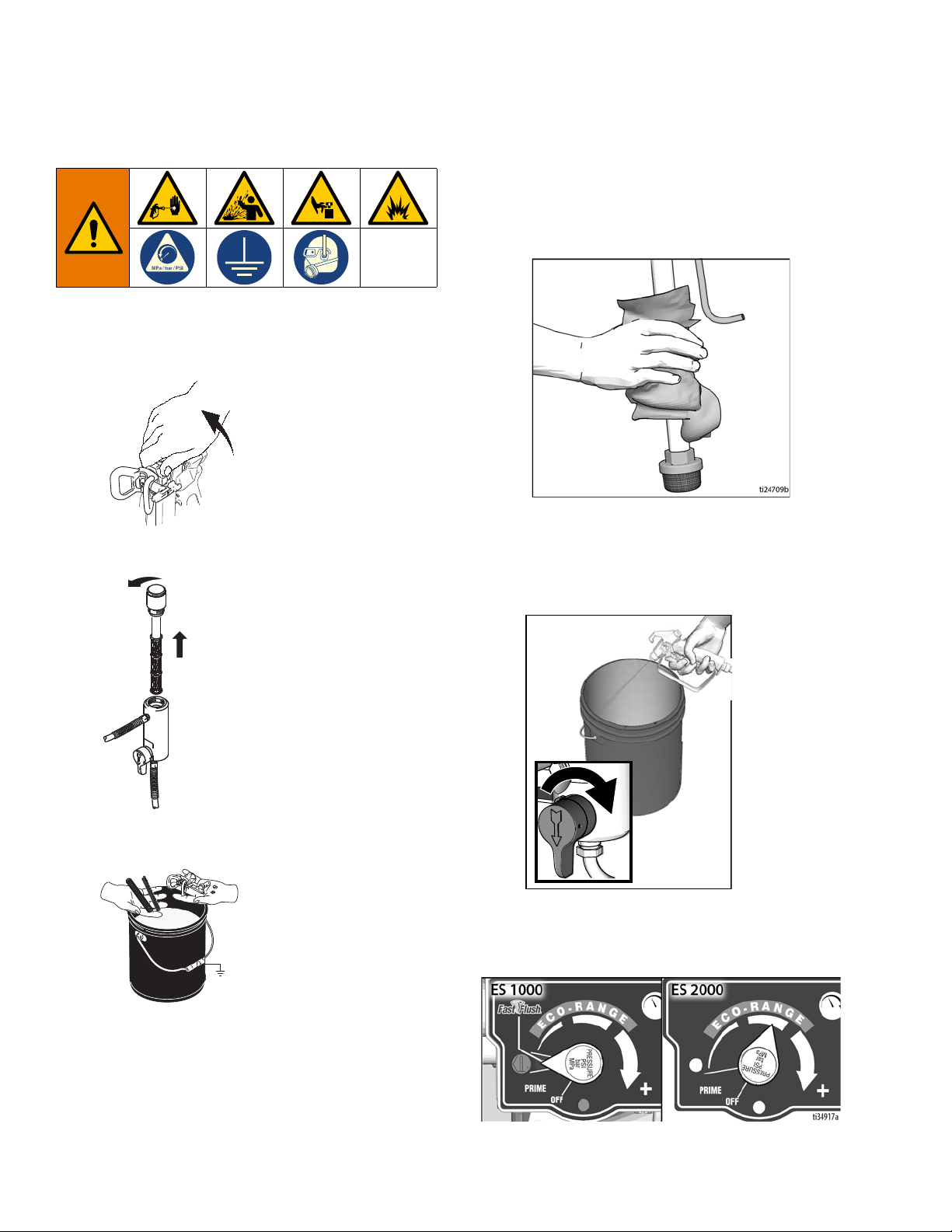

Cleanup

TI3371A

ti6269a

FLUSH

TI3375A

Cleanup

1. Perform Pressure Relief Procedure, page 16.

2. Remove guard and SwitchTip from all guns.

Flush Drain Tube

6. Remove fluid intake and drain tube from paint, wipe

excess paint off outside.

3. Unscrew cap, remove filter. Assemble without filter.

4. Clean filter, guard and SwitchTip in flushing fluid.

7. Place siphon tube set in grounded metal pail

partially filled with flushing fluid. Use water for water

base paint and mineral spirits for oil-based paint.

8. To flush drain tube and pump turn prime valve down.

ti24713a

9. Turn pressure control to Fast Flush (ES1000), or 1/2

position (ES2000), and operate until the pump runs

steady and flushing fluid appears in the waste pail.

5. Attach ground wire to true earth ground or plug unit

into grounded outlet.

28 3A4603F Operation, Repair, Parts

Page 29

Flush Hose and Gun

Cleanup

10. To flush airless hose and spray gun, turn prime

valve horizontal.

11. Hold gun against waste pail. Disengage trigger lock.

Trigger gun and turn pressure control to Fast Flush

(ES1000), or 1/2 position (ES2000), and operate

until the pump runs steady and flushing fluid

appears.

12. Stop triggering gun.

13. Fill pump with Pump Armor and reassemble filter,

guard and SwitchTip.

14. Each time you spray and store, fill throat packing

nut with TSL to decrease packing wear.

3A4603F Operation, Repair, Parts 29

Page 30

LineLazer V LiveLook Display

LineLazer V LiveLook Display

ES 2000 (Standard Series)

30 3A4603F Operation, Repair, Parts

Page 31

Initial Setup (ES 2000 Standard Series)

ti27828a

26 Ft.

8M

ti27829a

LineLazer V LiveLook Display

The initial setup prepares the striper for operation based

on a number of user entered parameters. Language

selections and the units of measure selections can be

set before you start or changed later.

Language

From Setup/Information select appropriate language by

pressing until the language is outlined.

US Units

Pressure = psi

Volume = gallons

Distance = feet

Line Thickness = mil

SI Units

Pressure = bar (MPa available)

Volume = liters

Distance = meters

Line thickness = micron (g/m

Paint Specific Gravity = Use UP and DOWN arrows

to set specific gravity. Required to determine paint

thickness.

NOTE: All units can be changed individually at any

time.

2

available)

Calibration

1. Check rear tire pressure 55 ± 5 psi (379 ± 34 kpa)

and fill if necessary.

2. Extend steel tape to distance greater than 26 ft.

(8m).

ENG = English

SPA = Spanish

FRE = French

DEU = German

RUS = Russian

WORLD = Symbols see World Key Symbol, page

113.

NOTE: Language can be changed later.

Units

Press to enter settings and then again to enter

units. Select appropriate units of measure.

3A4603F Operation, Repair, Parts 31

Page 32

LineLazer V LiveLook Display

ti27827a

ti27830a

1 FT 2 FT 3 FT 4 FT 5 FT 6 F

ti27831a

26 FT 27 FT 28 FT 29 FT 30 FT 31 F25 FT

ti27832a

3. Press to select Setup/Information.

4. Press for Calibration. Set TRAVEL DIST to 25 ft

(7.6m) or longer. Longer distances ensure better

accuracy, depending on conditions.

\

6. Push to start calibration.

ti27826a

7. Move striper forward. Keep unit aligned with steel

tape.

8. Stop when chosen part of unit aligns with 26-ft (8m),

or distance entered, on steel tape (25-ft./ 7.6m distance).

5. Align part of the unit with 1 foot (30.5cm) on steel

tape.

9. Push to complete calibration.

ti27941a

• Calibration is not complete when the exclamation

symbol is displayed.

• Calibration is finished when the check mark symbol

is displayed.

10. Calibration is now complete.

Go to Measure Mode (ES2000 Standard Series), page

34, and verify accuracy by measuring the tape.

32 3A4603F Operation, Repair, Parts

Page 33

Striping Mode (ES2000 Standard Series)

ti27890a

LineLazer V LiveLook Display

Ref. Description

1 Resets Distance, Gallons, Mils

*2 Job logging

3 Scroll between menu screens

4 Line width adjustment buttons

*5 Auto gun buttons

6 MIL thickness. While spraying “Instant MIL avg” is

displayed. When stopped total “Job MIL avg” is

displayed.

7 Total gallons sprayed

8 Total line length sprayed.

9 Pressure

* Not active in Standard Series. Upgrade to HP Auto

Series with P/N 25N711.

Operating in Striping Mode

1. Make sure ON/OFF switch is ON position.

2. Set pump switch to ON.

3. Pull trigger to spray.

3A4603F Operation, Repair, Parts 33

Page 34

LineLazer V LiveLook Display

ti27834a

1 2

3

4

Measure Mode (ES2000 Standard Series)

Measure Mode replaces a tape measure to measure

distances when laying out an area to be striped.

1. Use to select Measure Mode.

Ref. Description

2. Press and release . Move striper forwards or

backwards. (Moving backwards is a negative distance.)

3. Press and release to end measured length. Up

to six lengths are viewable.

1 Press to start measurement, Press to stop

measurement

2 Hold to reset values to zero

3 Scroll between main menu screens

4 Last measurement taken

34 3A4603F Operation, Repair, Parts

Page 35

Setup/Information

ti27835b

Use to select Setup/Information.

LineLazer V LiveLook Display

Press to select Language.

See Language, page 31.

See Calibration, page 31.

See Settings, page 36.

See Information, page 37.

3A4603F Operation, Repair, Parts 35

Page 36

LineLazer V LiveLook Display

Settings

Use to select Setup/Information. Press to

open Settings Menu.

Chooses the machine type. Necessary for accurate

gallon counting.

Use to set time and date.

Use

Set units with

Use to adjust screen contrast to the desired

value.

36 3A4603F Operation, Repair, Parts

Page 37

Information

Stroke Counter

Pressure Transducer

Distance Sensor

Touch Pad Buttons

Battery Voltage

Use to select Setup/Information. Press to

open Information Menu.

LineLazer V LiveLook Display

Displays and logs life data and striper information.

View and test functionality of components.

Logs last four error codes that occurred.

Code Description

02 = Over pressure

03 = No transducer detected

Reset error codes

3A4603F Operation, Repair, Parts 37

Page 38

ES2000 (HP Auto Series)

ES2000 (HP Auto Series)

38 3A4603F Operation, Repair, Parts

Page 39

LineLazer V LiveLook Display

ES2000 (HP Auto Series)

LineLazer V LiveLook Display

3A4603F Operation, Repair, Parts 39

Page 40

LineLazer V LiveLook Display

ti27827a

ti27828a

26 Ft.

8M

ti27829a

Initial Setup (ES2000 HP Auto Series)

The initial setup prepares the striper for operation based

on a number of user entered parameters. Language

selections and the units of measure selections can be

set before you start or changed later.

Language

From Setup/Information select appropriate language by

pressing until the language is outlined.

US Units

Pressure = psi

Volume = gallons

Distance = feet

Line Thickness = mil

SI Units

Pressure = bar (MPa available)

Volume = liters

Distance = meters

Line thickness = micron (g/m

2

available)

Paint Specific Gravity = Use UP and DOWN arrows

to set specific gravity. Required to determine paint

thickness.

NOTE: All units can be changed individually at any

time.

Calibration

1. Check rear tire pressure 55 ± 5 psi (379 ± 34 kpa)

and fill if necessary.

2. Extend steel tape to distance greater than 26 ft.

(8m).

ENG = English

SPA = Spanish

FRE = French

DEU = German

RUS = Russian

WORLD = Symbols see World Key Symbol, page

113.

NOTE: Language can be changed later.

Units

Press to enter settings and then again to enter

units. Select appropriate units of measure.

40 3A4603F Operation, Repair, Parts

Page 41

LineLazer V LiveLook Display

ti27827a

ti27830a

ti27841a

ti27912a

ti27843a

ti27912a

3. Press to select Setup/Information.

4. Press for Calibration. Set TRAVEL DIST to 25 ft

(7.6m) or longer. Longer distances ensure better

accuracy, depending on conditions.

6. Press and release gun trigger control to start calibration.

7. Move striper forward. Keep laser dot on steel tape.

8. Stop when laser aligns with 26-ft (8m) or distance

entered on steel tape (25-ft./7.6m distance).

5. Turn on laser and align laser dot with 1 foot

(30.5cm) on steel tape.

9. Press and release gun trigger control to complete

calibration.

• Calibration is not complete when the exclamation

symbol is displayed.

• Calibration is finished when the check mark symbol

is displayed.

10. Calibration is now complete.

3A4603F Operation, Repair, Parts 41

Page 42

LineLazer V LiveLook Display

ti27881a

Striping Mode (ES2000 HP Auto Series)

Ref. Description

Select a “Favorite”, press for less than one sec-

ond.

1

Save a “Favorite”, press and hold for more than

three seconds.

2 Cycles between viewing line width or paint and

space value.

Cycles between Manual Mode, Semi-Automatic

Mode, Automatic Mode.

Manual Mode : Press and hold gun trigger

control to stripe.

Semi-Automatic Mode : Press and release

3

gun trigger control to stripe the programmed

length one time when in Skip Mode.

Automatic Mode : Press and release gun

trigger control to start striping. Press and release

button again to stop.

4 Resets trip distance.

5 Job Data Logger, page 52.

6 Scrolls between menu screens.

7 Paint and Space length OR line width adjustment

buttons.

8 Auto guns activation buttons.

9 MIL thickness. While spraying “Instant MIL avg” is

displayed. When stopped total “Job MIL avg” is

displayed.

10 Total gallons (liters) sprayed.

11 Total line length sprayed.

12 Pressure

Operating in Striping Mode

Striper must be running before activating gun trigger

control.

1. Make sure ON/OFF switch is ON position.

2. Use gun activation buttons to select guns and line

type.

ti27913a

3. Press gun trigger control to begin spraying.

In Automatic Mode or Semi-Automatic Mode the or

will flash when gun trigger control is pressed to sig-

nal mode is active.

42 3A4603F Operation, Repair, Parts

Page 43

Measure Mode (ES2000 HP Auto Series)

ti27914a

2 3

5

4

1

ti27842a

ti27915a

ti27842a

LineLazer V LiveLook Display

Measure Mode replaces a tape measure to measure

distances when laying out an area to be striped.

1. Use to select Measure Mode.

2. Press and release gun trigger control. Move striper

forwards or backwards. (Moving backwards is a

negative distance.)

3. Press and release gun trigger control to end measured length. Up to six lengths are viewable.

The most recent measured length is also saved as the

measured distance in the Stall Calculator display. See

Stall Calculator, page 45.

If an auto gun is activated, press and hold gun trigger

control at any time to apply a dot. If trigger is held while

striper is moving, a dot is marked every 12-inches

(30.5cm).

Ref. Description

1 Press to start measurement, Press to stop

measurement.

2 Hold to reset values to zero.

3 Job Data Logger, page 52.

4 Scroll between main menu screens

5 Last measurement taken

3A4603F Operation, Repair, Parts 43

Page 44

LineLazer V LiveLook Display

5

6

7

ti27912a

ti27849a

Layout Mode

Layout Mode is used to calculate and mark parking lot

stalls.

1. Use to select Layout Mode.

192 34

8

Ref. Description

ti27916a

2. Use gun activation buttons to select guns.

ti27918a

3. Press and release gun trigger control and move

striper forward.

4. Striper default is to place a dot every 9.0 ft (2.7m) to

mark the stall size. Stall size is adjustable.

5. Dots are laid down until gun trigger control is

pressed and released again.

1 Opens Stall Calculator Menu.

See Stall Calculator, page 45.

2 Opens Angle Calculator Menu.

See Angle Calculator, page 46.

Select a “Favorite”, press for less than one

3

second.

Save a “Favorite”, press and hold for more than

three seconds.

4 Job Data Logging, page 52.

5 Scroll between menu screens.

6 Adjust stall size/dot spacing.

7 Adjust dot size.

8 Auto Gun activation buttons.

9 Pressure.

An indicator on the screen alternately flash when gun

trigger control is pressed to signal mode is active.

44 3A4603F Operation, Repair, Parts

Page 45

LineLazer V LiveLook Display

Stall Calculator

Stall Calculator is used to set the stall size. The striper

divides the measured length by the stall size to

determine the number of stalls that will fit in the length

measured. User can adjust number of stalls to a round

number and stall width is calculated.

1. Use to select Layout Mode. Press to

open Stall Calculator Menu.

2. The most recent length measured in Measure Mode

is automatically displayed. Press gun trigger control

to start a new measurement. Press again to stop

measuring.

When measuring between curbs, the distance from

the back tire/curb to the gun/laser dot, can be

accounted for by setting the Offset (x) value.

a. Back the striper up to the curb, then use a tape

measure to measure from where the tire touches

the curb to the laser dot on the ground.

b. Use to enter the offset (x) value.

c. This value can be stored by holding for 2

seconds.

d. The value stored under can be added to the

measured distance before or after the

measurement is taken between the curbs.

e. The offset (x) value can also be adjusted before or

after the measurement is taken by using .

Stall size and calculated number of stalls are both

adjustable.

Ref. Description

1 Opens Angle Calculator Menu.

See Angle Calculator, page 46.

2 Exits and returns stall size to Layout Mode.

3 Measured distance.

4 Calculated # of stalls. Changing the number of

stalls will change the stall size.

5 Adjusts number of stalls.

6 Stall size. Changing stall size changes the

calculated # of stalls.

7 Adjusts stall size.

8 Press to start measurement, Press to stop

measurement.

9 Adjust Offset (x).

10 Stores Offset (x). Hold for 2 seconds to store

value.

3. Press to return to Layout Mode. The Stall size

is saved and displayed on the Layout Mode screen.

4. Press and release gun trigger control to start

marking dots. Press and release gun trigger control

again to stop.

3A4603F Operation, Repair, Parts 45

Page 46

LineLazer V LiveLook Display

1

7

8

2 3 4

5

6

ti27850a

STALL

SIZE

LINE

LENGTH

B

C

STALL

DEPTH

OFF SET

ANGLE

DOT SPACING

ti27857a

Angle Calculator

Angle Calculator is used to determine the offset value

and dot spacing value for a layout.

1. Use to select Layout Mode. Press to

open Angle Calculator Menu.

2. Dot spacing (B) and offset (C) are calculated based

on the parameters entered:

Stall angle

Stall depth

Stall size (width)

Line Length

3. Press to transfer calculated off set distance to

Layout Mode. Save this value in favorites if desired.

Ref. Description

1 Transfers calculated dot spacing, B, to Layout

Mode.

2 Transfers calculated off set, C, to Layout Mode.

3 Exits and returns to Layout Mode without

transferring any values.

4 Data Logging.

5 Select input variables.

6 Adjust the variable selected.

7 Calculated dot spacing, B.

8 Calculated off set, C.

46 3A4603F Operation, Repair, Parts

Page 47

LineLazer V LiveLook Display

ti27842a

4. Press to transfer calculated dot spacing

distance to Layout Mode. Save this value in

favorites if desired.

5. Press and release gun trigger control to start

marking stall size dots. Press and release gun

trigger control to stop marking.

3A4603F Operation, Repair, Parts 47

Page 48

LineLazer V LiveLook Display

Setup/Information

Use to select Setup/Information.

Press to select Language.

See Language, page 31.

See Calibration, page 31.

See Settings, page 49.

See Information, page 50.

See Marker Layout Mode, page 51.

48 3A4603F Operation, Repair, Parts

Page 49

Settings

ti28158a

Use to select Setup/Information. Press to

open Settings Menu.

Chooses the machine type. Necessary for accurate gallon

counting.

Use to set time and date. Needed for accurate Data

LineLazer V LiveLook Display

Logging.

Set units with

Use to adjust screen contrast to the desired value.

For programmed skip lines, press to choose:

In Auto-mode, guns won’t fire or will shut off if speed is below set

value.

Enable or Disable Low Speed Shutoff

Adjust low speed setting.

3A4603F Operation, Repair, Parts 49

Page 50

LineLazer V LiveLook Display

Stroke Counter

Pressure Transducer

Distance Sensor

Touch Pad Buttons

Battery Voltage

Information

Use to select Setup/Information. Press to

open Information Menu.

Displays and logs life data and striper information.

View and test functionality of component

Logs last four error codes that occurred.

Code Description

02 = Over pressure

03 = No transducer detected

Reset error codes

50 3A4603F Operation, Repair, Parts

Page 51

LineLazer V LiveLook Display

1

2

3

4

ti27860a

1

ti27918a

ti27912a

ti27862a

[1] 8.00´

[2] 4.00´

[3] 4.00´

[4] 16.00´

[5] 4.00´

[6] 4.00´

[7] 8.00´

[8] 0.00´

8.00 ft. 8.00 ft.

4.00 ft.

4.00 ft.

16.00 ft.

48.00 ft.

4.00 ft.4.00 ft.

ti23812a

Marker Layout Mode

The Marker Layout Mode feature sprays a dot or a

series of dots to mark an area.

1. Use to select Setup/Information. Press

to open Marker Layout Mode.

Ref. Description

Select a “Favorite”, press for less than one

second.

1

Save a “Favorite”, press and hold for more than

three seconds.

4. Set gun switch to skip line or solid line.

5. Press and release gun trigger control to start

marking dots. Press and release gun trigger control

again to stop.

An indicator before and after Marker Mode on the

screen alternately flash when gun trigger control is

pressed to signal mode is active.

2 Exits and returns to Information Menu.

3 Select value to change.

4 Adjust spacing value.

2. Use arrow keys to set up a marker pattern.

3. Marker layout example shows a typical lane layout

for reflective markers. Set space sizes up to eight

consecutive measurements. By leaving zeros in any

space, Marker Layout Mode will skip to the next

measurement in a continuous loop.

Some other uses of Marker Layout Mode are:

- Multiple spaced handicap stall layout

- Double line stalls

3A4603F Operation, Repair, Parts 51

Page 52

LineLazer V LiveLook Display

Data Logging

The LLV control is equipped with Data Logging, which

allows the user to recall job data and export the data

from the machine to a USB drive.

1. Press the to open the Data Logging pop up

window.

2. Choose to start recording a new job or view jobs

previously done.

Start recording a new job.

Erase all jobs

Export all jobs to USB

Erase jobs

Export job to USB

Job data is compiled while spraying. A summary of

volume sprayed, distance sprayed and average mil

thickness is displayed for the entire job. The job is

also broken down by colors, line widths and stencil

volume sprayed.

52 3A4603F Operation, Repair, Parts

Page 53

Maintenance

Maintenance

Routine maintenance is important to ensure proper operation of your sprayer. Maintenance includes performing

routine actions which keep your sprayer in operation and prevents trouble in the future.

Activity Interval

Inspect/clean sprayer filter, fluid inlet strainer, and gun filter.

Inspect motor shield vents for blockage.

Fill TSL by adding through TSL fill point.

Check hose for wear and damage.

Check gun safety for proper operation.

Check drain valve for proper operation.

Verify calibration.

Tighten nut under dust cover on front caster until spring washer bottoms out,

then back off the nut 1/2 to 3/4 turn.

Grease wheel bearings.

Check caster wheel alignment.

Check sprayer stall.

With sprayer gun NOT triggered, sprayer motor should stall and not restart

until gun is triggered again.

If sprayer starts again with gun NOT triggered, inspect pump for

internal/external leaks and check prime valve for leaks.

Throat packing adjustment

When pump packing begins to leak after extended use, tighten packing nut

down until leakage stops or lessens. This allows approximately 100 gallons

of additional operation before a repacking is required. Packing nut can be

tightened without 0-ring removal.

Daily or each time you spray

Daily or each time you spray

Daily or each time you spray

Daily or each time you spray

Daily or each time you spray

Daily or each time you spray

Daily or each time you spray

Once per year or as needed

Once per month

Daily or each time you spray

Every 1000 gallons (3785 liters)

As necessary based on usage

3A4603F Operation, Repair, Parts 53

Page 54

Troubleshooting (ES 1000 & ES 2000)

Troubleshooting (ES 1000 & ES 2000)

Mechanical/Fluid Flow

1. Follow Pressure Relief Procedure, page 16, before

checking or repairing.

2. Check all possible problems and causes before

disassembling the unit.

What to Do

What to Check

Problem

Control board status light is blinking or the

light is off and there is power to the sprayer.

Pump output is low Spray tip worn. Follow Pressure Relief Procedure,

If check is OK, go to next check

Fault condition exists. Determine fault correction from page 56.

Spray tip clogged. Follow Pressure Relief Procedure,

Paint supply. Refill and reprime pump.

Intake strainer clogged. Remove and clean, then reinstall.

Intake valve ball and piston ball are

not seating properly.

Fluid filter or tip filter is clogged or

dirty.

Prime valve leaking. Follow Pressure Relief Procedure,

Verify pump does not continue to

stroke when gun trigger is released.

(Prime valve not leaking.)

Leaking around throat packing nut

which may indicate worn or damaged

packings.

Pump rod damage. Repair pump. See pump manual.

Low stall pressure. Turn pressure knob fully clockwise. Make

Piston packings are worn or damaged. Replace packings. See pump manual.

O-ring in pump is worn or damaged. Replace o-ring. See pump manual.

Intake valve ball is packed with

material.

Large pressure drop in hose with

heavy materials.

Check extension cord for correct size. See Extension Cords, page 14.

When check is not OK, refer to this

column

Follow Pressure Relief Procedure,

page 16.

page 16, then replace tip. See separate

gun or tip manual.

page 16. Check and clean spray tip.

Remove intake valve and clean. Check

balls and seats for nicks; replace if

necessary. See pump manual. Strain

paint before using to remove particles

that could clog pump.

Clean filter.

page 16, then repair prime valve.

Service pump. See pump manual.

Replace packings. See pump manual.

Also check piston valve seat for

hardened paint or nicks and replace if

necessary. Tighten packing nut/wet-cup.

sure pressure control knob is properly

installed to allow full clockwise position. If

problem persists, replace pressure

transducer.

Clean intake valve. See pump manual.

Reduce overall length of hose.

54 3A4603F Operation, Repair, Parts

Page 55

Problem

What to Check

If check is OK, go to next check

Troubleshooting (ES 1000 & ES 2000)

What to Do

When check is not OK, refer to this

column

Motor runs but pump does not stroke Connecting rod assembly damaged. Replace connecting rod assembly. See

Gears or drive housing damaged. Inspect drive housing assembly and

Excessive paint leakage into throat packing

nut

Fluid is spitting from gun Air in pump or hose. Check and tighten all fluid connections.

Pump is difficult to prime Air in pump or hose. Check and tighten all fluid connections.

Sprayer operates for 5 to 10 minutes then

stops

Throat packing nut is loose. Remove throat packing nut spacer.

Throat packings are worn or

damaged.

Displacement rod is worn or

damaged.

Spray tip is partially clogged. Clear tip.

Fluid supply is low or empty. Refill fluid supply. Prime pump. See

Intake valve is leaking. Clean intake valve. Be sure ball seat is

Pump packings are worn. Replace pump packings. See pump

Paint is too thick. Thin the paint according to supplier

Pump packing nut too tight. When

pump packing nut is too tight the

packings on the pump rod restrict

pump action and overloads the motor.

pump manual.

gears for damage and replace if

necessary.

Tighten throat packing nut just enough to

stop leakage.

Replace packings. See pump manual.

Replace rod. See pump manual.

Cycle pump as slowly as possible during

priming.

pump manual. Check fluid supply often

to prevent running pump dry.

Cycle pump as slowly as possible during

priming.

not nicked or worn and that ball seats

well. Reassemble valve.

manual.

recommendations.

Loosen pump packing nut. Check for

leaks around throat. If necessary,

replace pump packings. See Pump

manual.

3A4603F Operation, Repair, Parts 55

Page 56

Troubleshooting (ES 1000 & ES 2000)

Electrical (ES 1000)

Symptom: Sprayer does not run, stops running, or will

not shut off.

Keep clear of electrical and moving parts during

troubleshooting procedures. To avoid electrical shock

hazards when covers are removed for

troubleshooting, wait five minutes after disconnecting

power cord for stored electricity to dissipate.

1. Perform Pressure Relief Procedure, page 16.

4. Remove control box cover to view control board

status light. To determine which code (or any other

2. Turn the ON/OFF switch OFF wait 30 seconds and

then turn power back ON again (this ensures

sprayer is in normal run mode).

3. Turn pressure control knob clockwise 1/2 turn.

code besides voltage supply) refer to the control

board status light. Turn the ON/OFF switch OFF,

remove the control cover then turn power back ON.

Observe the status light. Blinking LED total count

equals the error code (for example: two blinks

equals CODE 02).

Error Code Messages

CODE MESSAGE ACTION

02 HIGH PRESSURE DETECTED -

RELIEVE PRESSURE

03 PRESSURE TRANSDUCER NOT

DETECTED

05 MOTOR NOT SPINNING Check for mechanical failure and check motor

06 MOTOR OVERHEATED Turn sprayer OFF. Check motor connections. Check

Check for clogs. Use only Graco spray hoses, use a

minimum of 50ft/15m.

Check transducer connection.

connections. Material may be too thick, thin material.

shroud vents for blockage. Sprayer may take up to an hour

to cool.

Problem What to Check How to check

Sprayer does not run at all

AND

Control board status light never

lights

Sprayer does not shut off

AND

Control board status light blinks 2

times repeatedly

56 3A4603F Operation, Repair, Parts

See flow chart, page 68.

Control board.

Replace control board.

Page 57

Troubleshooting (ES 1000 & ES 2000)

Problem What to Check How to check

Sprayer does not run at all

AND

Control board status light blinks 2

times repeatedly

Sprayer does not run at all

AND

Control board status light blinks 3

times repeatedly

Check transducer or

transducer connections

Check transducer or

transducer connections

(control board is not detecting

a pressure signal).

Make sure there is no pressure in the system (see

Pressure Relief Procedure, page 16). Check fluid path

for clogs, such as clogged filter.

Use airless paint spray hose with no metal braid. A small

hose or metal braid hose may result in high-pressure

spikes.

Turn ON/OFF switch OFF and disconnect power to

sprayer by unplugging power cord and disconnecting

battery.

Check transducer and connections to control board.

Disconnect transducer from control board socket. Check

that transducer and control board contacts are clean and

secure.

Reconnect transducer to control board socket. Connect

power, turn ON/OFF switch ON and control knob

1/2 turn clockwise. If sprayer does not run properly, turn

ON/OFF switch OFF and go to next step.

Install new transducer. Connect power, turn ON/OFF

switch ON and control knob 1/2 turn clockwise. Replace

control board if sprayer does not run properly.

Turn ON/OFF switch OFF and disconnect power to

sprayer by unplugging power cord and disconnecting

battery.

Check transducer and connections to control board.

Disconnect transducer from control board socket. Check

to see if transducer and control board contacts are clean

and secure.

Reconnect transducer to control board socket. Connect

power, turn ON/OFF switch ON and control knob to 1/2

turn clockwise. If sprayer does not run, turn ON/OFF

switch OFF and go to next step.

Connect a confirmed working transducer to control

board socket.

Turn ON/OFF switch ON and control knob to 1/2 turn

clockwise. If sprayer runs, install new transducer.

Replace control board if sprayer does not run.

Check transducer resistance with an ohmmeter (less

than 9k ohm between red and black wires and 3-6k ohm

between green and yellow wires).

3A4603F Operation, Repair, Parts 57

Page 58

Troubleshooting (ES 1000 & ES 2000)

GRN BLU R BLK

GRN BLU R BLK

STEP 2:

STEP 3:

STEP 1:

GRN BLU R BLK

Problem What to Check How to check

Sprayer does not run at all

AND

Control board status light blinks 5

times repeatedly

Control is commanding motor to

run but motor shaft does not

rotate. Possibly locked rotor

condition, an open connection

exists between motor and

control, there is a problem with

motor or control board, or motor

amp draw is excessive.

1. Remove pump and try to run sprayer. If motor runs,

check for locked or frozen pump or drive train.

If sprayer does not run, continue to step 2.

2. Turn ON/OFF switch OFF and disconnect power to

sprayer by unplugging power cord and

disconnecting battery.

3. Disconnect motor connector(s) from control board

socket(s). Check that motor connector and control

board contacts are clean and secure. If contacts

are clean and secure, continue to step 4.

4. Set sprayer to OFF and spin motor fan 1/2 turn.

Restart sprayer. If sprayer runs replace control

board. If sprayer does not run, continue to step 5.

5. Perform Spin Test: Test at large 4-pin motor field

connector. Disconnect fluid pump from sprayer.

Test motor by placing a jumper across pins 1 & 2.

Rotate motor fan at about 2 revolutions per second. A

cogging resistance to motion should be felt at the

fan. The motor should be replaced if no resistance

is felt. Repeat for pin combinations 1 & 3 and 2 & 3.

Pin 4 (the green wire) is not used in this test. If all

spin test is positive, continue to step 6.

58 3A4603F Operation, Repair, Parts

Page 59

Problem What to Check How to check

1-3 ohms

Sprayer does not run at all

AND

Motor is hot or there is a fault in

the motor thermal device.

Control board status light blinks 6

times repeatedly

Basic electrical problems Motor leads are securely

fastened and properly mated

Troubleshooting (ES 1000 & ES 2000)

6. Perform Field Short Test: Test at large 4-pin motor