Page 1

INSTRUCTIONS-PARTS LIST

308943

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

Kit, Swivel Wheel

Line Lazer 3500, 5000

Model 241105, Series A

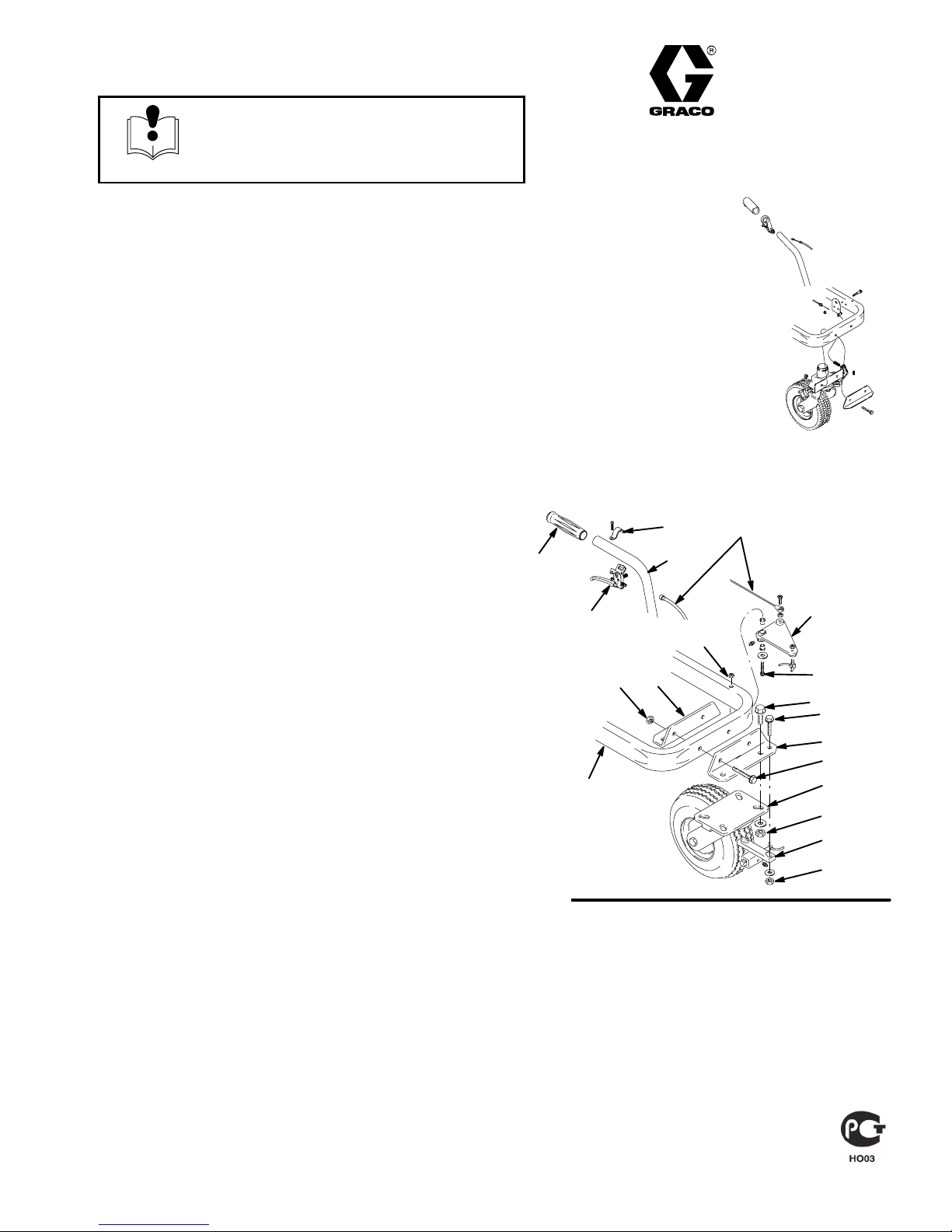

Old Caster Wheel Removal

Fig. 1. Remove old caster wheel and associated wheel

hardware as outlined in the steps following.

20

21

19

Rev. D

3

1 . Unfasten release lever bracket (21) and remove

release lever (22) from handle (19).

2 . Remove cable (3), actuator lever (94) and lever

hardware by unfastening capscrew (37) and locknut (26).

3 . Remove old swivel caster (114), caster latch (112)

and related hardware by unfastening capscrews

(87,117), and nuts (40,115).

4 . Unfasten two locknuts (40) from capscrews (39)

and remove rear caster bracket (31) and front

caster bracket (38) from cart (110).

5 . Remove handle grip (20) from handle (19).

Fig. 1

22

110

40

31

94

26

37

117

87

38

39

114

115

112

40

8885A

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 1999, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

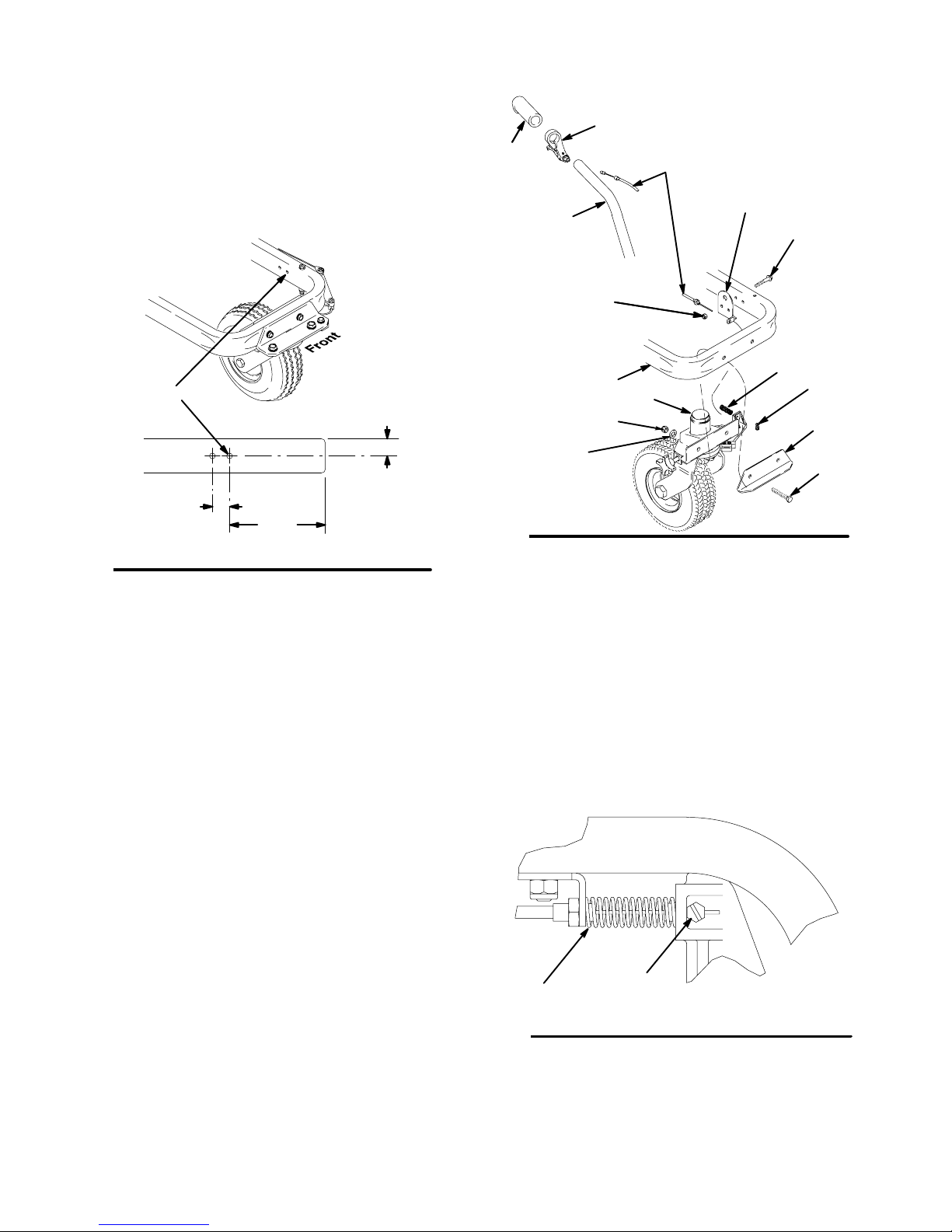

Installation

Assemble the swivel wheel kit according to the following steps.

1 . Put front of cart on cement block or other type of

support in place of removed caster wheel.

10 . Fig. 4. Install wire stop (7) on cable wire (10) and

finger tighten wire stop screw.

9

18

10

2 . Fig. 2. Drill two holes thru right side of chassis

frame as viewed from front.

1.0 in

4X Ĭ .330

Thru. Both Walls

1.0 in

5.55 in

Fig. 2

3 . Fig. 3. Mount cable bracket (11) on right side of

cart (110), as viewed from front, with two flange

screws (15) and two lock nuts (16).

4 . Slide actuator lever (9) on cart handle (H) and

tighten. Install handle grip (18). Replace other

handle grip if needed.

5 . Insert two cap screws (13) into front caster

bracket (12) and mount on front of cart (110).

6 . Assemble swivel caster (1) to cart (110) and cap

screws (13) extending thru cart. Fasten with two

lock nuts (14) and washers (19) and tighten.

Front

8851A

11

Fig. 3

H

16

110 Ref

19

1

14

15

8

7

12

13

Cable Adjustment

Adjust the cable as follows:

1 . Fig. 4. Make sure cable is routed between the top

of sprayer frame and underneath the motor mount

plate.

2 . Check that cable is snug and cable nut (A) under

spring is tight. Extend cable wire and draw tight in

wire stop (7). Tighten wire stop screw.

3 . Check that release lever frees wheel to turn.

Readjust cable if necessary.

7 . Install one end of cable (10) in actuator lever (9).

8 . Route cable (10) from actuator lever (9) down

handle and between cart base (110) and motor

mount plate (108) to swivel caster (1). Fasten

cable to cable bracket using nut provided with

cable.

9 . Install compression spring (8) over cable wire and

in front of caster wheel (1).

2 308943

Fig. 4

A

7

8835A

Page 3

Caster Wheel Alignment

Operation

(See letter call–outs in Parts drawing on page 5.)

1 . Loosen bolt (D).

2 . Push line striper forward following a straight refer–

ence line.

3 . Stop.

4 . Tighten bolt (D).

Continuous Radius Striping

1 . Push line striper around radius.

2 . Stop.

3 . Tighten knob (E).

4 . Verify accuracy, then paint.

Swivel Hub Bearing (G) Adjustment

1 . To swivel less freely, tighten nut (A). 2 . To swivel more freely, loosen nut (A).

Operation

Caster Wheel

(See letter call–outs in Parts drawing on page 5.)

1 . Once each year, tighten nut (A) until spring washer

bottoms out. Then back off the nut 1/2 to 3/4 turn.

2 . Once each year, tighten nut (B) until it begins to

compress spring washer. Then tighten the nut an

additional 1/4 turn.

3 . Once each month, grease the wheel bearing (F).

4 . Check pin (C) for wear. If pin is worn out, therewill

be play in the caster wheel. Reverse or re–place

the pin as needed.

308943 3

Page 4

Parts Drawing/List

t

18

9

10

Ref

No. Part No. Description Qty

241105 KIT ASSY, swivel wheel Ref

1 287881 . CASTER, swivel 1

1a 240719 . CASTER ASSY, swivel 1

1aa 240940 . . BRACKET, hub 1

1ab 240942 . . SHAFT, fork 1

1ac 193528 . . ARM, detent 1

1ad 193662 . . PIN, locking, tapered 1

1ae 110754 . . SCREW, cap, soc hd 2

1af 181818 . . KNOB, pronged 1

1ag 114548 . . BEARING, bronze 2

1ah 113484 . . SEAL, grease 1

1aj 113485 . . BEARING, cup/cone 2

1ak 112825 . . SPRING, belleville 1

1am 112405 . . NUT, lock 1

1an 114648 . . CAP, dust 1

1ap 15J603 . . WASHER, plain 1

1ar 113962 . . WASHER, hardened 1

1as 114681 . . SCREW, cap, hex hd 1

1at 193660 . . DISK, adjuster 1

1au 193661 . . JAW 1

1av 108483 . . SCREW, shoulder, soc hd 1

1aw 120476 . . BOLT 1

2 113471 . SCREW, cap, hex hd 1

3 112405 . NUT, lock 1

4 112825 . SPRING, belleville 1

5 193658 . SPACER, seal 2

6 114549 . WHEEL, pneumatic 1

7 114802 . STOP, wire 1

8 114682 . SPRING, compression 1

9 194310 . LEVER, actuator 1

10 241445 . CABLE 1

11 15F910 . BRACKET, cable 1

12 240991 . BRACKET, caster, front 1

13 114982 . SCREW, cap, flang hd 2

14 101566 . NUT, lock 2

15 110837 . SCREW, flange, hex 2

16 111040 . NUT, lock, nylock 2

18 108063 . GRIP, handle 2

19 100731 . WASHER 2

11

15

16

1aa (Shee

8

1

7

14

12

19

2

13

5

4

6

ti8386a

Sheet 1 of 2

4 308943

Page 5

Parts Drawing/List

1ac 1aa 1af1ad 1ae

A

C

A

1ab

FB

Detail A

1ag

1ab (Ref)1an1am

1ak

1aj1ah

1aw1ap 1ar 1as 1at 1au 1av

A–A

Sheet 2 of 2

A

G

D3 (Ref)

1aa(Ref)

1af (Ref)

E

8838B

308943 5

Page 6

Graco Phone Number

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1–800–690–2894 Toll Free.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

International Offices: Belgium, Korea, China, Japan

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

6 308943

Graco Headquarters: Minneapolis

http://www.graco.com

2/1999, Rev 9/2006

Loading...

Loading...