Page 1

Operation

ti28037a

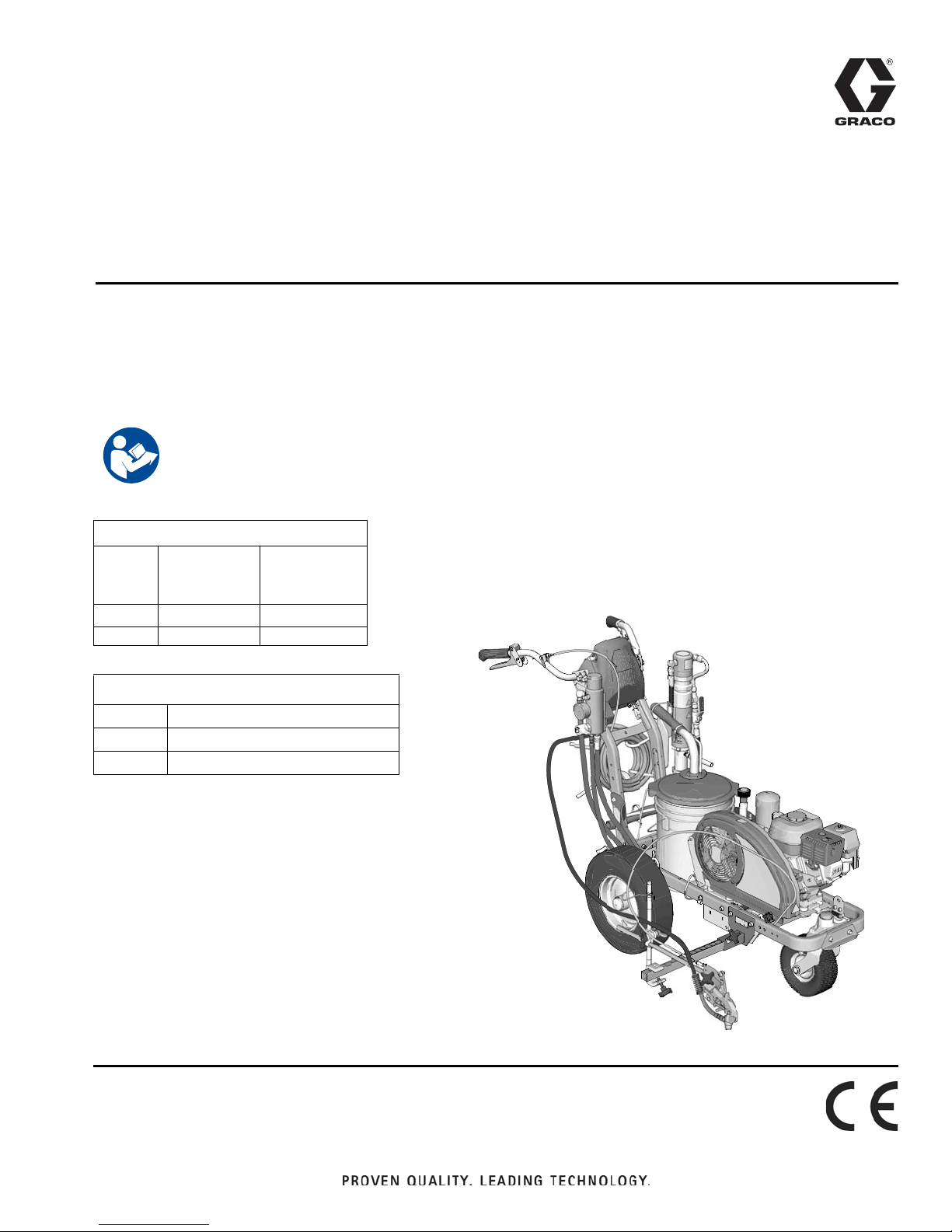

LineLazer™ 130HS Airless Line Stripers 3A3392B

EN

For the application of line striping materials.

For professional use only.

For outdoor use only.

Not for use in explosive atmospheres or hazardous locations.

Maximum Operating Pressure: 3300 psi (22.8 MPa, 228 bar)

Important Safety Instructions

Read all warnings and instructions in this manual and in related manuals.

Be familiar with the controls and the proper usage of the equipment.

Save these instructions.

LineLazer 130HS

Model: Standard

1 Manual Gun

17H447

17H448

Related Manuals:

3A3391 Parts

311254 Gun

311845 Pump

Standard

2 Manual Guns

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

Page 2

Table of Contents

Table of Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tip Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component Identification (LL 130HS) . . . . . . . . . . 7

Grounding Procedure

(For Flammable Flushing Fluids Only) . . . . . . 8

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 8

Setup/Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SwitchTip and Guard Assembly . . . . . . . . . . . . 11

Gun Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Install Guns . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Position Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Select Guns . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Gun Positions Chart . . . . . . . . . . . . . . . . . . . . . 13

Gun Arm Mounts . . . . . . . . . . . . . . . . . . . . . . . . 14

Change Gun Position

(Front and Back) . . . . . . . . . . . . . . . . . . . . . 14

Change Gun Position

(Left and Right) . . . . . . . . . . . . . . . . . . . . . . 15

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Gun Cable Adjustment . . . . . . . . . . . . . . . . . . . 15

Straight Line Adjustment . . . . . . . . . . . . . . . . . . 16

Handle Bar Adjustment . . . . . . . . . . . . . . . . . . . 16

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

LineLazer 130HS . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Hydraulic Oil/Filter Change . . . . . . . . . . . . . . . . . . 21

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 24

2 3A3392B Operation

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard sym-

bols and warnings not covered in this section may appear throughout the body of this manual where applicable.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or solvent flowing through the equipment can cause static sparking. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool. Fuel is flammable and can

ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths

(potential static arc).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are present.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until you

identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event that

injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks with any

part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs while spraying,

follow the Pressure Relief Procedure for turning off the unit and relieving the pressure before removing

the nozzle tip to clean.

• Equipment maintains pressure after power is shut off. Do not leave the equipment energized or under pressure while unattended. Follow the Pressure Relief Procedure when the equipment is unattended or not

in use, and before servicing, cleaning, or removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3300 psi. Use Graco replacement parts or accessories that are rated

a minimum of 3300 psi.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

3A3392B Operation 3

Page 4

Warnings

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon monoxide

can cause death.

• Do not operate in an enclosed area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request Safety Data Sheet (SDS) from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety

hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for

compatibility.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow

the Pressure Relief Procedure and disconnect all power sources.

ENTANGLEMENT HAZARD

Rotating parts can cause serious injury

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the Pres-

sure Relief Procedure and disconnect all power sources.

4 3A3392B Operation

Page 5

Warnings

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read Safety Data Sheet (SDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is not limited

to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

CALIFORNIA PROPOSITION 65

The engine exhaust from this product contains a chemical known to the State of California to cause cancer,

birth defects or other reproductive harm.

This product contains a chemical known to the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

3A3392B Operation 5

Page 6

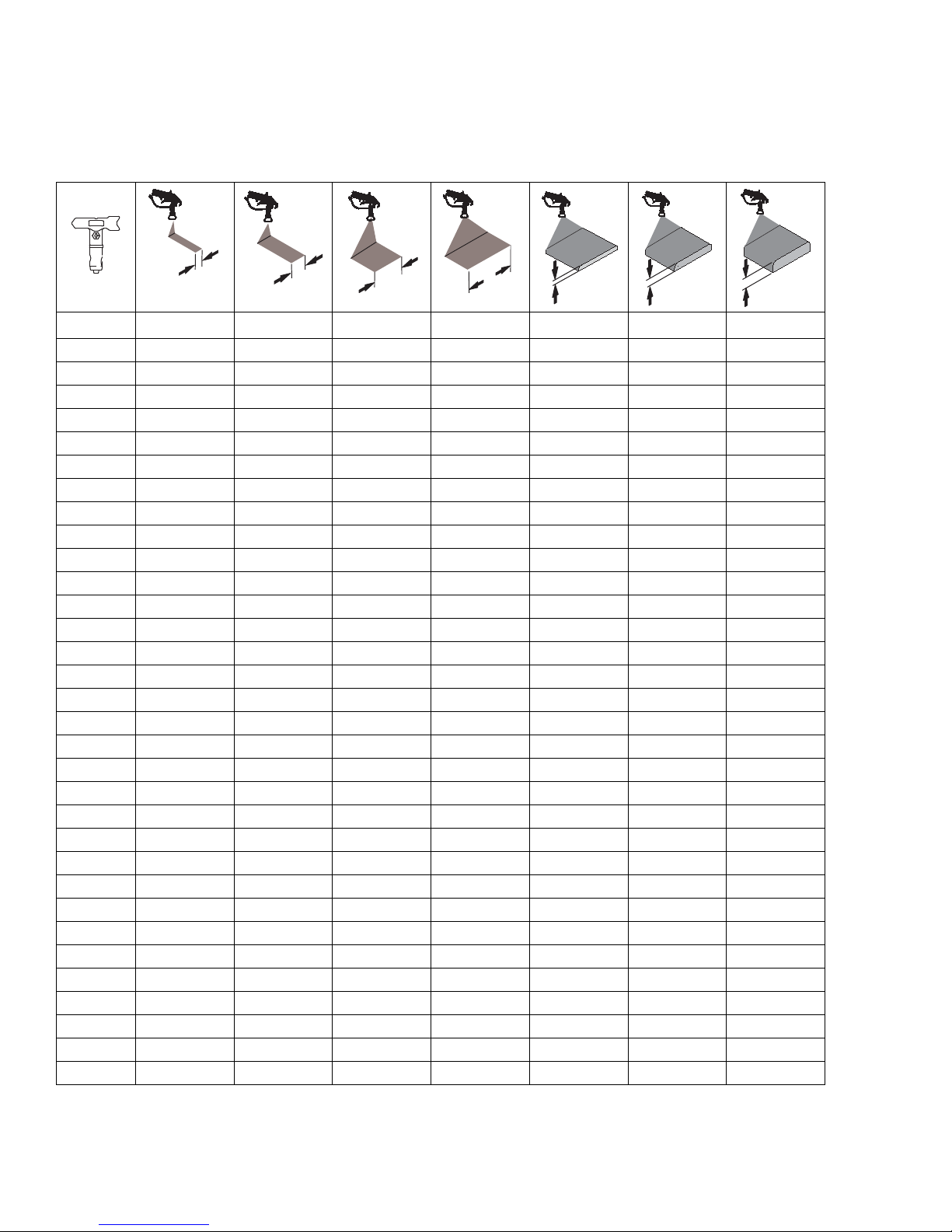

Tip Selection

ti27606a

in.

(cm)

ti27505a

in.

(cm)

ti27506a

in.

(cm)

ti27507a

in.

(cm)

ti27508a

ti27509a

ti27605a

Tip Selection

ti27510a

LL5213* 2 (5)

LL5215* 2 (5)

LL5217

LL5219

LL5315

LL5317

LL5319

LL5321

LL5323

LL5325

LL5327

LL5329

LL5331

LL5333

LL5335

LL5355

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

4 (10)

LL5417 6 (15)

LL5419 6 (15)

LL5421 6 (15)

LL5423 6 (15)

LL5425 6 (15)

LL5427 6 (15)

LL5429 6 (15)

LL5431 6 (15)

LL5435 6 (15)

LL5621 12 (30)

LL5623 12 (30)

LL5625 12 (30)

LL5627 12 (30)

LL5629 12 (30)

LL5631 12 (30)

LL5635 12 (30)

LL5639 12 (30)

*Use 100 mesh filter to reduce tip clogs.

6 3A3392B Operation

Page 7

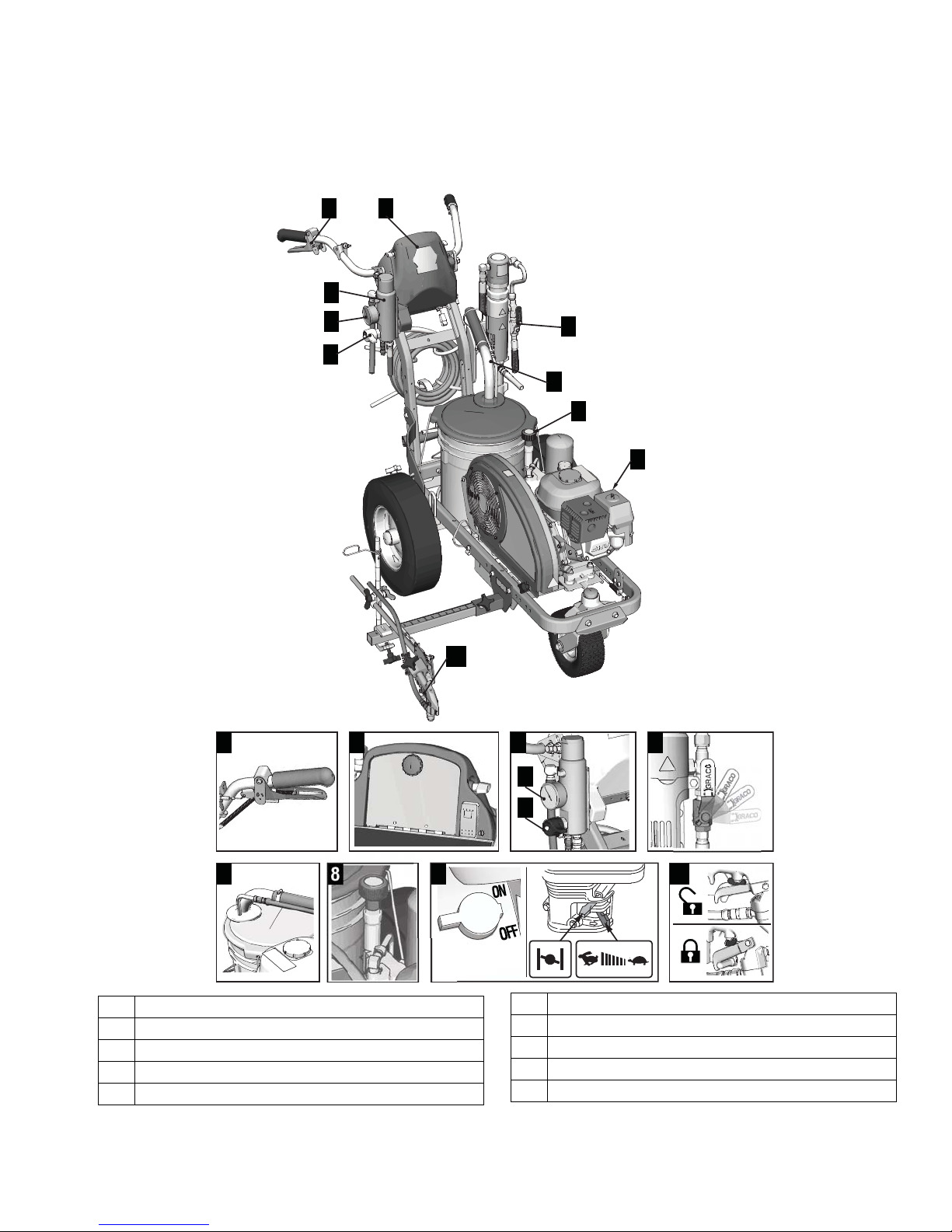

Component Identification (LL 130HS)

8

1 3 62

7 9 10

1

3

2

5

4

6

7

8

10

9

4

5

ti28038a

Component Identification (LL 130HS)

1 Manual spray gun trigger

2 Storage box

3 Filter

4 Pressure gauge

5 Prime/Pressure relief valve

3A3392B Operation 7

6 Pump ON/OFF lever

7 Drain and siphon tubes

8 Pressure control

9 Engine ON/OFF switch

10 Trigger safety

Page 8

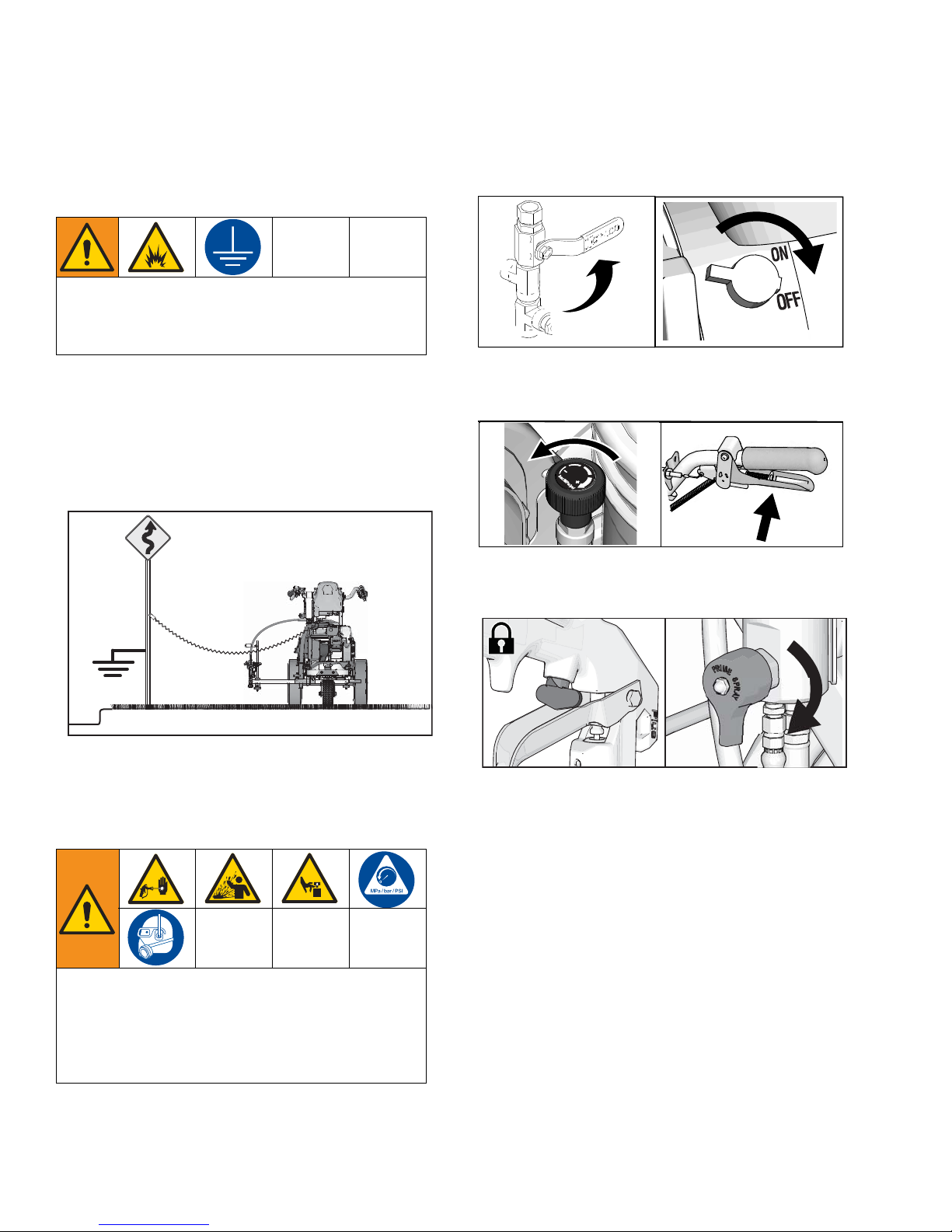

Grounding Procedure (For Flammable Flushing Fluids Only)

ti23144a

ti28013a

ti27608a

Grounding Procedure

(For Flammable Flushing Fluids

Only)

This equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

1. Position striper so that the tires are not on pavement.

2. Striper is shipped with a grounding clamp. Grounding clamp must attach to grounded object (e.g.

metal sign post).

1. Perform Grounding Procedure if using flammable

materials.

2. Set pump switch to OFF. Turn engine OFF.

ti27504a

3. Turn pressure control to lowest setting. Trigger all

guns to relieve pressure.

ti27615a

3. Disconnect grounding clamp after flushing is complete.

Pressure Relief Procedure

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

4. Engage all gun trigger locks. Turn prime valve

down.

5. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved:

a. VERY SLOWLY loosen the tip guard retaining

nut or the hose end coupling to relieve pressure

gradually.

b. Loosen the nut or coupling completely.

c. Clear the obstruction in the hose or tip.

8 3A3392B Operation

Page 9

Setup/Startup

ti27610a

ti27611a

ti23144a

ti27612a

ti28015a

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before cleaning, checking, or servicing the equipment.

Setup/Startup

6. Set pump switch to OFF.

ti27504a

7. If removed, install strainer.

1. Perform

Pressure Relief Procedure

, page 8.

2. Perform Grounding Procedure (For Flammable

Flushing Fluids Only), page 8 if using flammable

materials.

3. Fill throat packing nut with Throat Seal Liquid (TSL)

to decrease packing wear.

ti28014a

4. Check engine oil level. Add SAE 10W-30 (summer)

or 5W-30 (winter). See engine manual.

8. Turn prime valve down. Turn pressure control counterclockwise to lowest pressure.

NOTE: Minimum hose size allowable for proper

sprayer operation is 3/8 in. x 22 ft for LL130

HS.

9. Place siphon tube set in grounded metal pail partially filled with flushing fluid. Attach ground wire to

true earth ground. Use water to flush water-base

paint and mineral spirits to flush oil-base paint and

storage oil.

5. Fill fuel tank.

3A3392B Operation 9

ti27613a

Page 10

Setup/Startup

ti27617a

ti5250a

ti27619a

ti27620a

ti27766a

ti5250a

10. Start engine:

a. Move fuel valve to open.

b. Move choke to closed.

c. Set throttle to fast.

ti27616a

11. After engine starts, move choke to open.

12. Set throttle to desired setting.

d. Set engine switch to ON.

e. Pull starter cord.

10 3A3392B Operation

Page 11

Setup/Startup

15s

ti28039a

ti28040a

ti28041a

ti27775a

ti27776a

13. Set pump switch to ON (pump is now active).

ti23793a

14. Increase pressure control enough to start pump.

Allow fluid to circulate for 15 seconds.

17. Inspect fittings for leaks. If leaks occur, turn sprayer

OFF immediately. Perform Pressure Relief Proce-

dure. Tighten leaky fittings. Repeat Setup/Startup,

steps 1 - 17. If no leaks, continue to trigger gun until

system is thoroughly flushed. Proceed to step 18.

18. Place siphon tube in paint pails.

ti27613a

19. Trigger all guns again into a flushing fluid pail until

paint appears. Assemble tips and guards.

15. Turn pressure down, turn prime valve horizontal.

Disengage gun trigger lock.

16. Hold all guns against a grounded metal flushing pail.

Trigger guns and increase fluid pressure slowly until

pumps run smoothly.

ti27774a

SwitchTip and Guard Assembly

1. Engage trigger lock. Use end of SwitchTip to press

OneSeal into tip guard, with curve matching tip

bore.

2. Insert SwitchTip in tip bore and firmly thread assembly onto gun.

High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. Do not stop

leaks with hand or rag.

3A3392B Operation 11

Page 12

Gun Placement

ti27777a

ti27778a

ti28129a

ti28130a

1

2

ti27780a

ti27781a

ti27782a

ti27782a

Gun Placement

Install Guns

1. Insert guns into gun holder. Tighten clamps.

Position Gun

2. Position gun: up/down, forward/reverse, left/right.

See Change Gun Position (Front and Back),

page 14 and Change Gun Position (Left and

Right), page 15 for examples.

Another option can be to swing the gun out at an angle

and rotate the tip guard. This results in better visibility

for the user.

Select Guns

3. Connect gun cables to left or right gun selector

plates.

NOTE: When striping above a curb, the mounting clamp

can be rotated for clearance.

12 3A3392B Operation

a. One gun: Disconnect one gun selector plate

from trigger.

b. Both guns simultaneously: Adjust both gun

selector plates to the same position.

c. Solid-skip and skip-solid: Adjust solid-line gun

to position 1 and skip-line to position 2.

Page 13

Gun Positions Chart

1

2

3

4

5

6

7

ti27786a

Gun Placement

1 One line

2 One line up to 24 in. (61cm) wide

3 Two lines

4 One line or two lines to spray around obstacles

5 One gun curb

6 Two gun curb

3A3392B Operation 13

7 Two lines or one line up to 24 in. (61 cm) wide

Page 14

Gun Placement

ti28042a

ti27797a

ti27798a

Gun Arm Mounts

This unit is equipped with front and rear gun arm

mounts.

2. Slide gun arm assembly (including gun and hoses)

out from gun arm mounting slot.

ti27795a

3. Slide gun arm assembly into desired gun arm

mounting slot.

4. Tighten gun arm knob into gun arm mounting slot.

Change Gun Position

(Front and Back)

1. Loosen gun arm knob and remove from gun arm

mounting slot.

ti27796a

NOTICE

Make sure all hoses, cables, and wires are properly

routed through brackets and do NOT rub on tire.

Contact with tire will result in damaged hoses, cables,

and wires.

14 3A3392B Operation

Page 15

Gun Placement

ti27799a

ti27919a

ti27800a

ti28044a

Change Gun Position

(Left and Right)

Removal

1. Loosen vertical gun arm knob on gun arm mounting

bar and remove.

Installation

1. Install vertical gun mount onto gun bar.

NOTE: Make sure all hoses, cables, and wires are

properly routed through brackets.

Gun Cable Adjustment

Adjusting the gun cable will increase or decrease the

gap between the trigger plate and the gun trigger. To

adjust trigger gap, perform the steps below.

1. Use wrench to loosen locking nut on cable adjuster.

2. Extend mounting bar on opposite side of the

machine.

ti27884a

2. Loosen or tighten adjuster until desired result is

achieved. NOTE: More thread exposed means less

gap between gun trigger and trigger plate.

3. Use wrench to tighten locking nut on the adjuster.

3A3392B Operation 15

Page 16

Gun Placement

ti27810a

ti27811a

ti27812a

ti27813a

ti27814a

Straight Line Adjustment

The front wheel is set to center the unit and allow the

operator to form straight lines. Over time, the wheel may

become misaligned and will need to be readjusted. To

re-center the front wheel, perform the following steps:

1. Loosen bolt on the front wheel bracket.

2. If striper arcs to the right, loosen left set screw and

tighten right set screw for fine tune adjustment.

4. Roll the striper. Repeat steps 2 and 3 until striper

rolls straight. Tighten bolt on wheel alignment plate

to lock the new wheel setting.

Handle Bar Adjustment

3. If striper arcs to the left, loosen right set screw and

tighten left set screw.

16 3A3392B Operation

Page 17

Cleanup

TI3371A

ti6269a

TI3375A

ti3322b

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

1. Perform Pressure Relief Procedure, page 8.

2. Remove guard and SwitchTip from all guns.

Cleanup

4. Clean filter, guard and SwitchTip in flushing fluid.

FLUSH

5. Place siphon tube set in grounded metal pail partially filled with flushing fluid. Attach ground wire to

true earth ground. Perform Startup steps 10 - 16

(see page 10) to flush out paint in sprayer. Use

water to flush water-base paint and mineral spirits

solvent (also called white spirit) to flush oil-base

paint.

3. Unscrew cap, remove filter. Assemble without filter.

6. Hold gun against paint bucket and pull trigger until

water or solvent appears.

7. Move gun to solvent or water bucket. Hold gun

against bucket and pull trigger until the system is

thoroughly flushed.

8. Fill pump with Pump Armor and reassemble filter,

guard and SwitchTip.

9. Each time you spray and store, fill throat packing

nut with TSL to decrease packing wear.

3A3392B Operation 17

Page 18

Maintenance

Maintenance

LineLazer 130HS

Periodic Maintenance

DAILY: Check engine oil level and fill as necessary.

DAILY: Check hydraulic oil level and fill as necessary.

DAILY: Check hose for wear and damage.

DAILY: Check gun safety for proper operation.

DAILY: Check prime/spray drain valve for proper opera-

tion.

DAILY: Check and fill gas tank

DAILY: Check that displacement pump is tight.

DAILY: Top off TSL level in displacement pump packing

nut to help prevent material buildup on piston rod and

early wear of packing.

AFTER THE FIRST 20 HOURS OF OPERATION: Drain

engine oil and refill with clean oil. Reference Honda

Engines Owner’s Manual for correct oil viscosity.

Caster Wheel

1. Once each year, tighten nut under dust cap until

spring washer bottoms out, then back off the nut 1/2

to 3/4 turn.

2. Once each month, grease the wheel bearing.

3. Check pin for wear. If pin is worn out, there will be

play in the caster wheel. Reverse or replace the pin

as needed.

4. Check caster wheel alignment as necessary. To

align; page 16.

WEEKLY: Remove engine air filter cover and clean element replace, if necessary. If operating in an unusually

dusty environment, check filter daily.

WEEKLY/DAILY: Remove any debris from hydraulic

rod.

AFTER EACH 100 HOURS OF OPERATION: Change

engine oil. Reference Honda Engines Owner’s Manual

for correct oil viscosity.

SEMI-ANNUALLY: Check belt wear, replace if necessary.

YEARLY OR 2000 HOURS: Replace hydraulic oil and

filter element with Graco hydraulic oil 169236 (5 gallon/18.9 liter) or 207428 (1 gallon/3.8 liter) and filter element 246173; page 21.

SPARK PLUG: Use only BPR6ES (NGK) or

W20EPR--U (NIPPONDENSO) plug. Gap plug to 0.028

to 0.031 in (0.7 to 0.8 mm). Use spark plug wrench

when installing and removing plug.

18 3A3392B Operation

Page 19

Troubleshooting

Problem Cause Solution

Gas engine pulls hard

(won't start).

Engine won't start. Engine switch is OFF. Turn engine switch ON.

Engine operates, but displacement pump does

not operate.

Displacement pump

operates, but output is

low on upstroke

Displacement pump

operates but output is low

on downstroke and/or on

both strokes.

Hydraulic pressure is too high. Turn hydraulic pressure knob counterclockwise to

lowest setting.

Engine is out of gas. Refill gas tank. Honda Engines Owner's Manual.

Engine oil level is low. Try to start engine. Replenish oil, if necessary.

Honda Engines Owner's Manual.

Spark plug cable is disconnected or damaged. Connect spark plug cable or replace spark plug.

Cold engine. Use choke.

Fuel shutoff lever is OFF. Move lever to ON position.

Oil is seeping into combustion chamber. Remove spark plug. Pull starter 3 to 4 times.

Clean or replace spark plug. Start engine. Keep

sprayer upright to avoid oil seepage.

Pump valve is OFF. Turn pump valve ON.

Pressure setting is too low. Turn pressure adjusting knob clockwise to

increase pressure.

Fluid filter is dirty. Clean filter.

Tip or tip filter is clogged. Clean tip or tip filter. Manual 311254.

Displacement pump piston rod is stuck due to

dried paint.

Belt worn, broken or off pulley. Replace.

Hydraulic fluid too low. Shut of sprayer. Add fluid*.

Hydraulic motor not shifting. Set pump valve OFF. Turn pressure down. Turn

Piston ball is not seating. Service piston ball. Manual 311845.

Piston packings are worn or damaged. Replace packings. Manual 311845.

Strainer is clogged. Clean strainer.

O-ring in pump is worn or damaged. Replace o-ring. Manual 311845.

Intake valve ball is packed with material or is not

seating properly.

Engine speed is too low. Increase throttle setting.

Suction tube air leak. Tighten suction tube.

Pressure setting is too low. Increase pressure.

Fluid filter, tip filter or tip is clogged or dirty. Clean filter.

Large pressure drop in hose with heavy materials.

Repair pump. Manual 311845.

engine OFF. Pry rod up or down until hydraulic

motor shifts.

Clean intake valve. Manual 311845.

Use larger diameter hose and/or reduce overall

length of hose. Use of more than 100 ft of 1/4 in.

hose significantly reduces performance of

sprayer. Use 3/8 in. hose for optimum performance (22 ft minimum).

Troubleshooting

*Check hydraulic fluid level often. Do not allow it to become too low. Use only Graco approved hydraulic fluid.

3A3392B Operation 19

Page 20

Troubleshooting

Problem Cause Solution

Pump is difficult to prime. Air in pump or hose. Check and tighten all fluid connections.

Reduce engine speed and cycle pump as slowly

as possible during priming.

Intake valve is leaking. Clean intake valve. Be sure ball seat is not nicked

or worn and that ball seats well. Reassemble

valve.

Pump packings are worn. Replace pump packings. Manual 311845.

Paint is too thick. Thin the paint according to the supplier's recom-

mendations.

Engine speed is too high. Decrease throttle setting before priming pump.

High engine speed at no

load.

Low stall or run pressure

shown on display.

Excessive paint leakage

into throat packing nut.

Fluid is spitting from gun. Air in pump or hose. Check and tighten all fluid connections. Reprime

Excessive leakage

around hydraulic motor

piston rod wiper.

Fluid delivery is low. Pressure setting too low. Increase pressure.

The sprayer overheats.

Excessive hydraulic

pump noise.

Mis-adjusted throttle setting. Reset throttle to 3700-3800 engine rpm at no

load.

Worn engine governor. Replace or service engine governor.

New pump or new packings. Pump break-in period takes up to 100 gallons of

material.

Throat packing nut is loose. Remove throat packing nut spacer. Tighten throat

packing nut just enough to stop leakage.

Throat packings are worn or damaged. Replace packings. Manual 311845.

Displacement rod is worn or damaged. Replace rod. Manual 311845.

pump.

Tip is partially clogged. Clear tip. Manual 311254.

Fluid supply is low or empty. Refill fluid supply. Prime pump.Check fluid supply

often to prevent running pump dry.

Piston rod seal worn or damaged. Replace these parts.

Displacement pump outlet filter (if used) is dirty or

Clean filter.

clogged.

Intake line to pump inlet is not tight. Tighten.

Hydraulic motor is worn or damaged. Bring sprayer to Graco distributor for repair.

Large pressure drop in fluid hose. Use larger diameter or shorter hose.

Paint buildup on hydraulic components. Clean.

Oil level is low. Fill with oil.

Low hydraulic fluid level. Shut off sprayer. Add fluid*

20 3A3392B Operation

Page 21

Hydraulic Oil/Filter Change

ti2271a

Hydraulic Oil/Filter Change

Removal

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

1. Perform Pressure Relief Procedure, page 8.

2. Place drip pan or rags under sprayer to catch

hydraulic oil that drains out.

3. Remove drain plug. Allow hydraulic oil to drain.

4. Unscrew filter slowly - oil runs into groove and

drains out rear.

Installation

1. Apply a light film of oil on filter gasket. Install drain

plug and oil filter. Tighten oil filter 3/4 turn after gasket contacts base.

2. Fill with five quarts of Graco hydraulic oil 169236 (5

gallon/20 liter) or 207428 (1 gallon/3.8 liter).

3. Check oil level.

3A3392B Operation 21

Page 22

Technical Data

Technical Data

LineLazer 130

Engine Honda GX120cc

Maximum fluid working pressure 3300 psi (227 bar, 22.7 MPa)

Maximum free-flow delivery 1.3 gpm 4.9 lpm

Cycles per gallon/liter 85 cpg 22.5 cpl

Hydraulic reservoir capacity 1.25 gallons (4.73 liters)

Hydraulic pressure 1825 psi (124 bar)

Maximum Tip Size

1 gun 0.037 in.

2 guns 0.029 in.

Noise level (dBa)

Sound power

Sound pressure

Vibration level*

Left Hand

Right Hand

* Vibration measured per ISO 5349 bsed on 8 hr daily exposure

Inlet/Outlet Sizes

Inlet paint strainer

Outlet paint filter

Pump inlet size 1 in. npsm(m)

Fluid outlet size 3/8 npt(f)

Dimensions/Weight

Height 44.5 in. 113.03 cm

Length 68.25 in. 173.36 cm

Width 34.25 in. 87.0 cm

Weight (dry, without packaging) 263 lb 119 kg

HS

US Metric

110 dBa per ISO 3744

96 dBa measured at 3.1 feet (1m)

2.90 m/sec

2.83 m/sec

16 mesh (1190 micron) stainless steel screen, reusable

50 mesh (250 micron) stainless steel screen, reusable

2

2

Wetted parts...PTFE, Nylon, polyurethane, V-Max™

leather, tungsten carbide, stainless steel, chrome plating, nickel-plated carbon steel, ceramic

22 3A3392B Operation

Page 23

Notes

Notes

3A3392B Operation 23

Page 24

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2016, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A3392

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision

B, April 2018

Loading...

Loading...