Graco LineDriver ES Series, LineDriver ES 25N555, LineDriver ES 25N556 Operation - Repair - Parts

Operation, Repair, Parts

LineDriver™ ES

3A6623C

For the propulsion of line striping and removal equipment. Not approved for use in

explosive atmospheres or hazardous locations. For professional use only.

Models: 25N555, 25N556

10 mph (16 kph) Maximum Operating Speed

Important Safety Instructions

Read all warnings and instructions in this manual and in related LineLazer,

GrindLazer and ThermoLazer manuals before using the equipment. Save

these instructions.

Related Manuals:

710-0138 Delta-Q Battery Charger

3A6720 Hitch Receiver Kit

LineDriver ES

EN

Model Cord Adapter

--- 25N555 North America

North America

Australia

CEE 7/7

25N556

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

Denmark

Italy

Switzerland

United Kingdom

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Trailer Loading & Unloading . . . . . . . . . . . . . . . . 8

Charging the Batteries . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Manual Brake Adjustment or Replacement . . . 11

Throttle Linkage Adjustment . . . . . . . . . . . . . . . 12

Hitch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . 13

Accelerator Calibration (Using Kit 25N880) . . . 14

Transaxle Service . . . . . . . . . . . . . . . . . . . . . . . 15

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Battery Pack Replacement . . . . . . . . . . . . . . . . 16

Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . 16

Transaxle Replacement . . . . . . . . . . . . . . . . . . 17

Traction Motor Replacement . . . . . . . . . . . . . . . 17

Motor Controller Replacement . . . . . . . . . . . . . 17

Troubleshooting - LineDriver . . . . . . . . . . . . . . . . 18

Troubleshooting - Motor Controller . . . . . . . . . . . 19

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Parts Drawing - Detail Views . . . . . . . . . . . . . . . . . 25

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wiring Diagram - Harness 25N661 . . . . . . . . . . . . 29

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring Diagram - Harness 25E406 . . . . . . . . . . . . 31

Technical Specifications . . . . . . . . . . . . . . . . . . . . 32

CALIFORNIA PROPOSITION 65 . . . . . . . . . . . 32

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 33

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 34

2 3A6623C

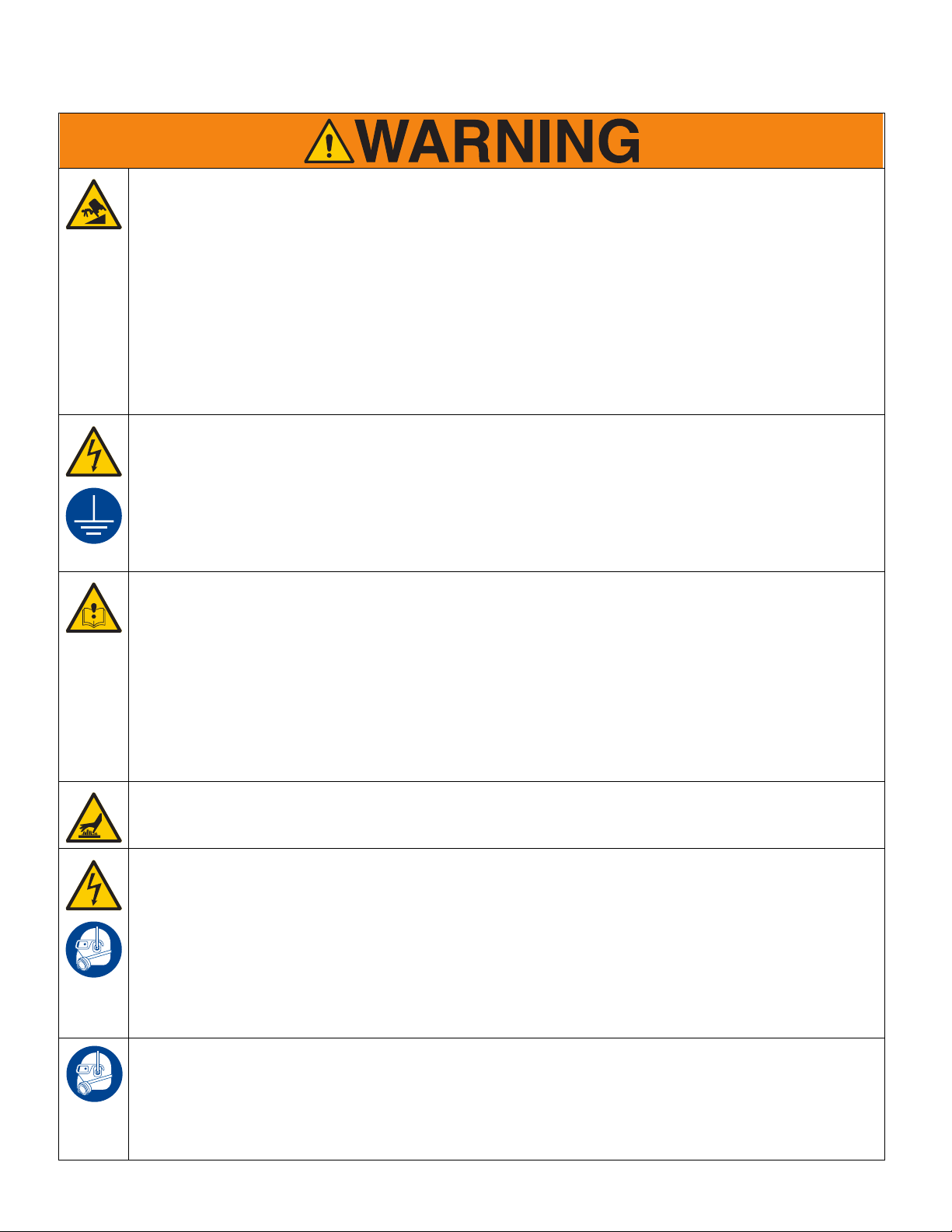

Warnings

120V US

230V

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard sym-

bols and warnings not covered in this section may appear throughout the body of this manual where applicable.

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. This product is equipped with a cord having a

grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding wire to either flat

blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes is the grounding

wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a qualified

electrician.

• This product is for use on a nominal 120V or 230V circuit and has a grounding plug similar to the plugs illustrated below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

TRAFFIC HAZARD

Vehicle strikes may result in serious injury or death.

• Do not operate in traffic.

• Use traffic control.

3A6623C 3

Warnings

MOVING VEHICLE HAZARD

Careless and reckless behavior causes accidents. Falling from vehicle, running into people or object, or being

struck by other vehicles may result in serious injury or death.

•

Do not operate unless attached to line striping or line removal equipment.

•

Do not step on forward/reverse pedals.

•

Make turns slowly. Do not make turns greater than 45°.

•

Loss of traction may occur going downhill.

•

Do not operate on slopes greater than 7.5°.

•

Do not carry passengers.

•

Do not tow.

•

Use with line striping or line removal equipment only.

•

Use appropriate traffic control in all traffic areas. Refer to manual on Uniform Traffic Control Devices (MUTCD), U.S.

Department of Transportation, Federal Highway Administration or local highway and transportation regulations.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric

shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create safety

hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe burns:

• Do not touch hot fluid or equipment.

BATTERY HAZARD

Lead-acid batteries produce explosive gases and contain sulfuric acid that can cause severe burns. To avoid

sparks and injury when handling or working with a lead-acid battery:

• Only use the battery type specified for use with the equipment. See Technical Data.

• Read and follow the battery manufacturer’s warnings.

• Exercise caution when working with metallic tools or conductors to prevent short circuits and sparks.

• Keep all sparks, flames, and cigarettes away from batteries.

• Always wear protective eyewear and protective equipment for face, hands, and body.

• If you have direct contact with battery fluid, flush with water and consult a physician immediately.

• Installation and maintenance must be performed by knowledgeable personnel only.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including eye

injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

4 3A6623C

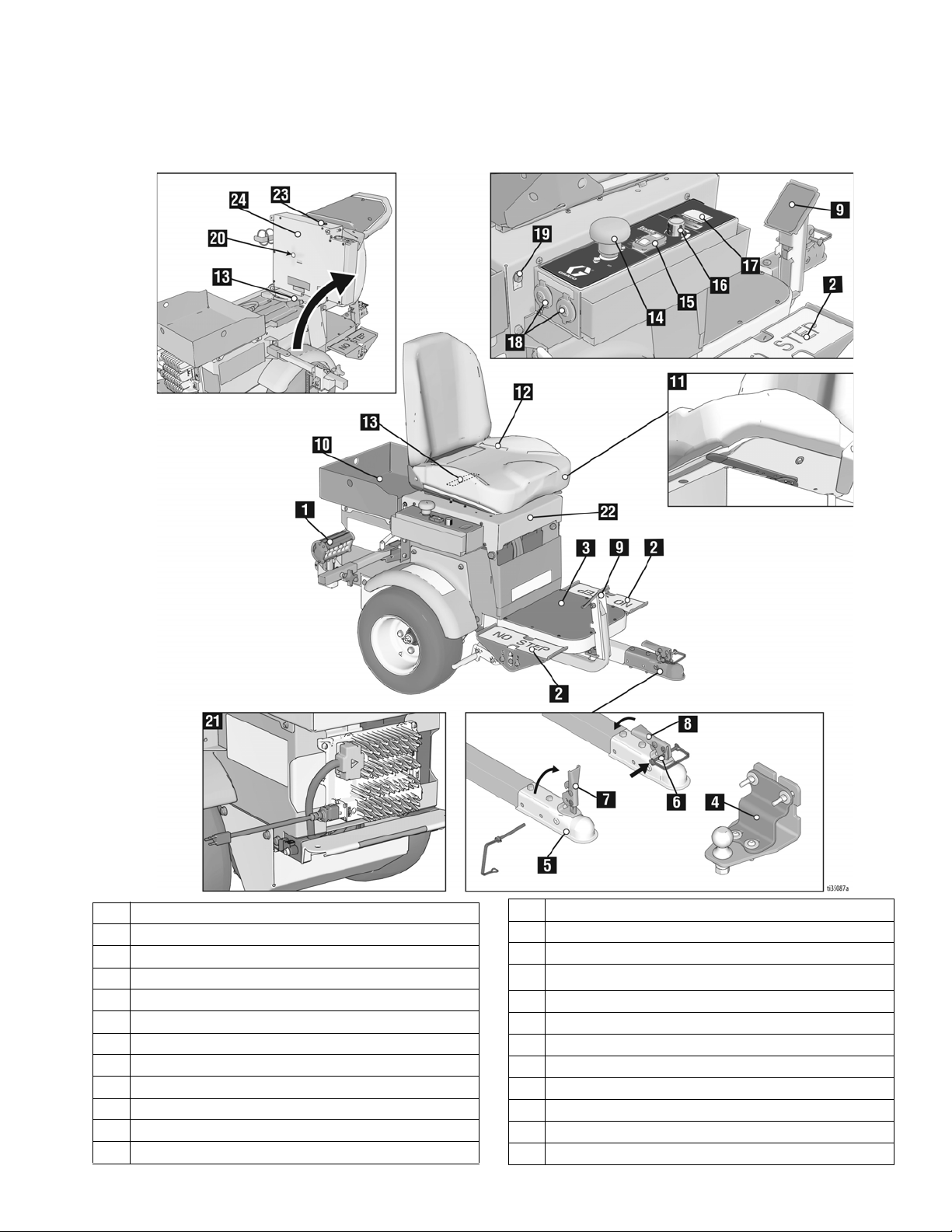

Component Identification

Component Identification

1 Headlight

2 Direction/Speed Pedals

3 Step Plate

4 Hitch

5 Coupler

6 Safety Pin Location

7 Handle Open

8 Handle Locked

9 Manual Brake

10 Tool Tray

11 Seat Adjustment

12 Operator Seat

3A6623C 5

13 Serial ID

14 Power Switch

15 Speed Switch

16

ExactMil

17 Voltage Meter

18 12V Aux. Power

19 Light Socket

20 Motor Controller Diagnostic Light

21 Battery Charger

22 Seat Lid

23 Buzzer

24 Seat Cover

™

Speed Control

Operation

ti11087a

ti10936a

M

ti11086a

ti11085a

Operation

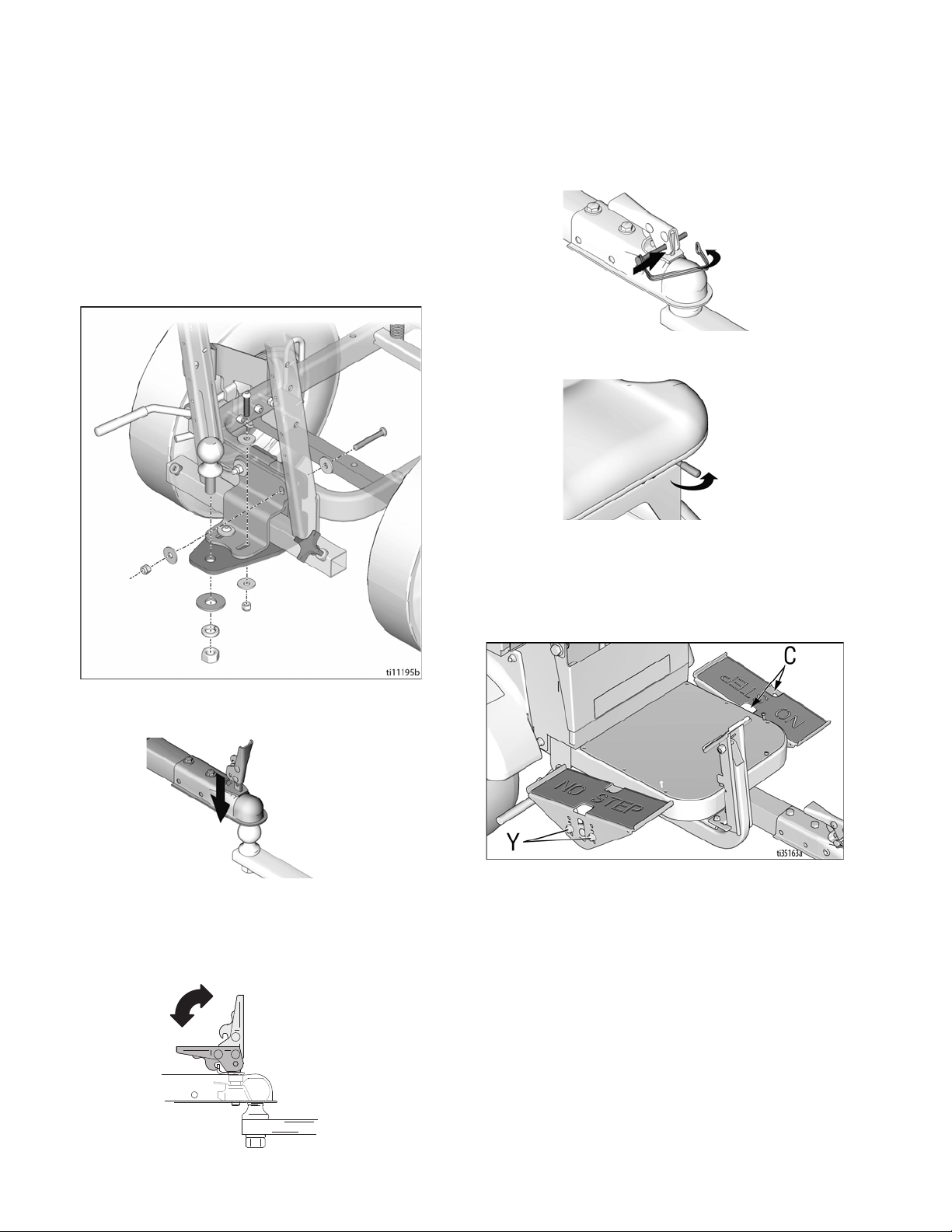

Setup

1. Install supplied ramp onto pallet.

2. Connect Hitch Receiver to line striping or line

removal equipment - Hitch Receiver Kit 25N787

Manual 3A6720.

5. Insert safety pin in latch

6. Adjust seat forward/backward with lever below seat.

7. Adjust height of pedals to desired position by

removing/replacing bolts (Y).

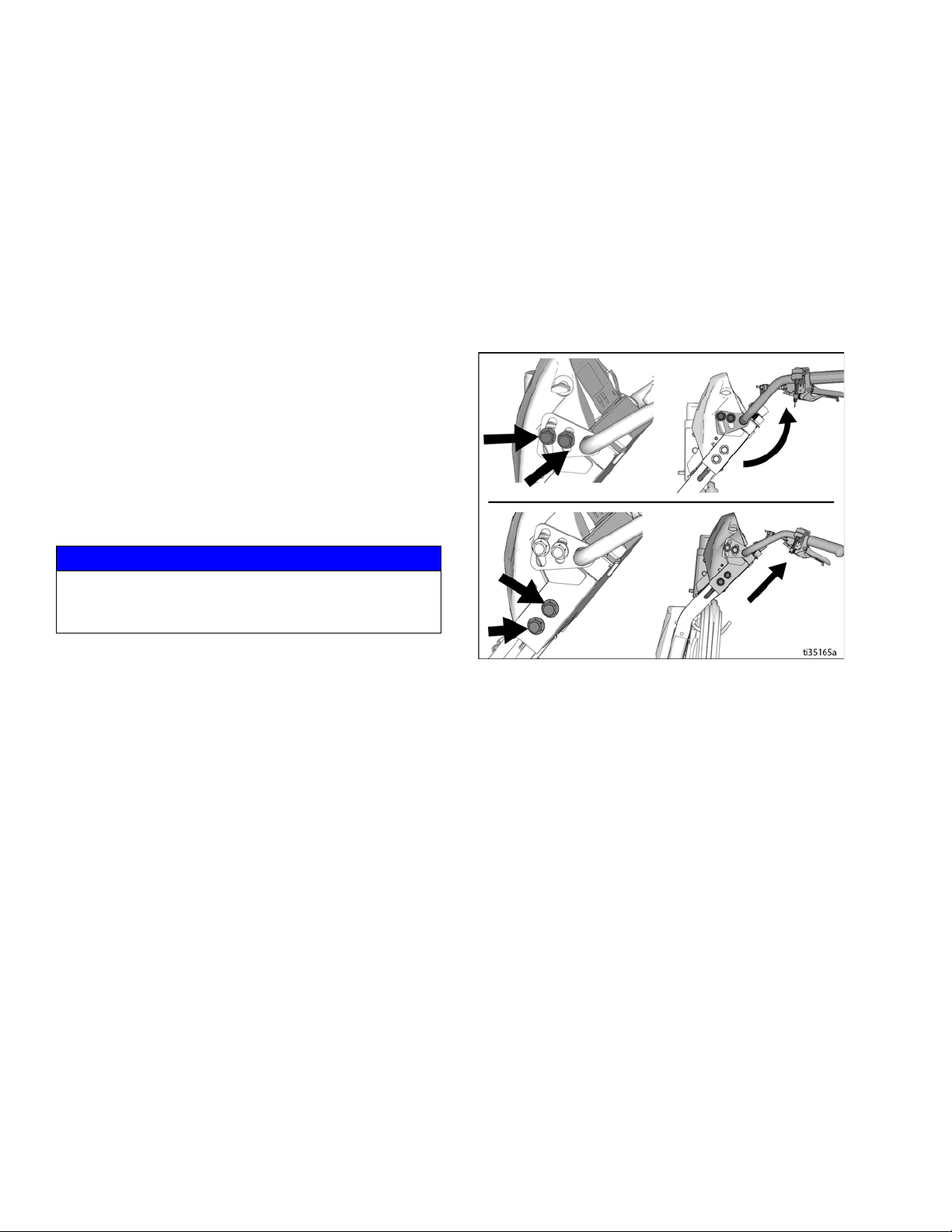

8. Loosen two bolts (C) on topside of pedals. Rotate

pedal to desired position. Tighten bolts.

3. Install LineDriver coupler to striper or grinder hitch

ball.

4. Latch coupler to locked position (M).

NOTE: If coupler is too tight to latch or is loose after

latching, coupler needs adjustment. Refer to Hitch

Adjustment, page 13.

9. Continue onto Startup, page 7.

6 3A6623C

Operation

ti10937a

ti10935a

ti11009a

Startup

1. Check battery charge level. Charge if not fully

charged.

2. Sit on seat to actuate safety switch. Ensure pedals

are not depressed.

3. Disengage Manual Brake on LineDriver and

attached equipment.

4. Turn power switch ON. Buzzer will sound in a few

seconds.

5. Operate control to release attached equipment.

NOTE: Interlocks in the LineDriver control system

remove drive power if the Power Switch is OFF, the

Direction/Speed Pedals are engaged when switching

power ON, or the driver lifts themself off the seat.

FREEWHEEL HAZARD

Loss of drive power causes LineDriver to freewheel,

which allows it to roll freely.

• Stay fully seated in the driver’s seat while operating the LineDriver.

• If loss of drive power occurs while LineDriver is in

motion, use the Manual Brake to bring LineDriver

to a stop.

• Always engage Manual Brake before turning

Power Switch OFF or standing up from seat.

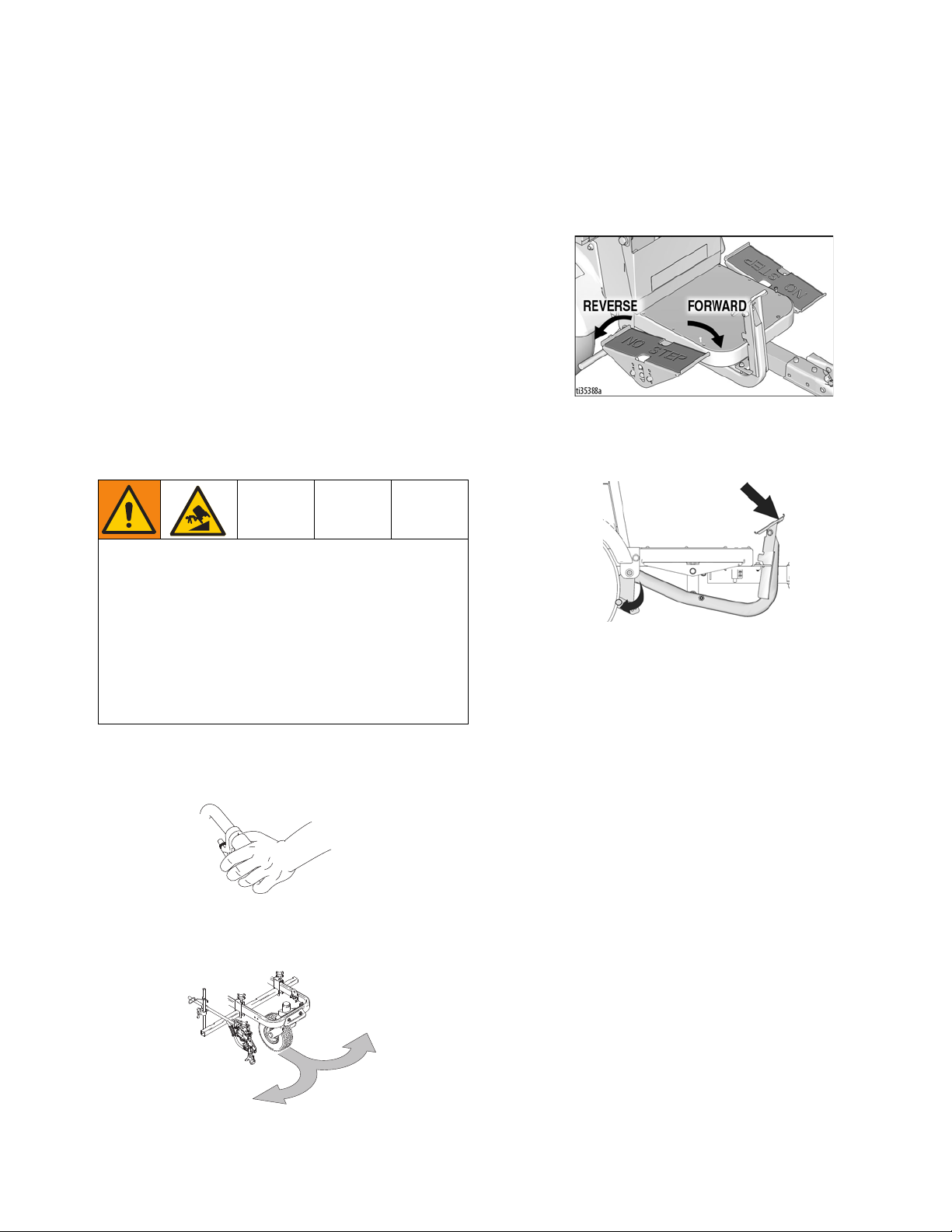

7. Move pedals to drive LineDriver, as shown below.

Switching from forward to reverse creates a braking

action.

NOTE: LineDriver stops when both feet are removed

from pedals.

8. Set Manual Brake when not operating LineDriver.

This prevents rolling when on an incline.

Operating on an Incline

• Engage the Manual Brake before turning the Power

Switch to OFF when parking on an incline.

NOTE: LineDriver motion is forward and reverse. Turns

are made with the striper or grinder.

• Turn the Power Switch to ON and allow the machine

to initialize before releasing the Manual Brake when

starting on an incline.

Enable ExactMil

™

Speed Control

ExactMil ensures a consistent paint thickness by holding

the speed steady.

6. Push striper or grinder handle bars to begin desired

turn.

1. Stop moving. Turn speed control knob all the way

counterclockwise.

2. Set Speed Switch to ExactMil position.

3. Depress foot pedal to go forward. Adjust speed control knob to desired speed setting.

NOTE: ExactMil speed control is only active when moving forward. Reverse speed is not impacted. ExactMil

speed control limits the maximum speed that can be

obtained with the pedal.

3A6623C 7

Operation

Disable ExactMil Speed Control

• Return Speed Switch to center position.

Enable ECO Mode

ECO Mode can be compared to half-throttle on a gas

powered unit. It is helpful when greater control is

needed, such as loading and unloading, driving in congested areas, and operating on slopes. It also extends

battery life.

• Set Speed Switch to ECO position.

NOTE: ECO Mode limits forward speed to 4 mph and

reverse speed to 2.6 mph.

Disable ECO Mode

• Return Speed Switch to center position.

12V Auxiliary Ports

• 12V auxiliary power ports are provided to power

accessories.

NOTICE

12V auxiliary ports must be used to power accessories.

Battery damage can result if other means are used to

power accessories.

Trailer Loading & Unloading

1. Always keep LineDriver connected to striper or

grinder.

2. Use a level surface to load and unload. Leave sufficient space behind ramps.

3. Use loading ramps sufficiently long and capable of

handling weight of unit and operator.

4. Adjust striper or grinder handlebar to highest position. Slide seat back as far as possible.

5. Use right foot to engage Manual Brake. Use left foot

to control speed. Use ECO Mode to limit speed.

6. Slowly drive straight up/down ramps (do not drive at

an angle).

7. Keep a firm grip on handlebars as the ramp is negotiated.

NOTE: Striper or grinder handlebars swing up/down as

the ramp is engaged/disengaged. Keep legs clear.

NOTE: Check Manual Brake clearance to tire and tire

pressure to ensure they are adjusted properly. Refer to

Manual Brake Adjustment or Replacement, page 11.

8 3A6623C

Operation

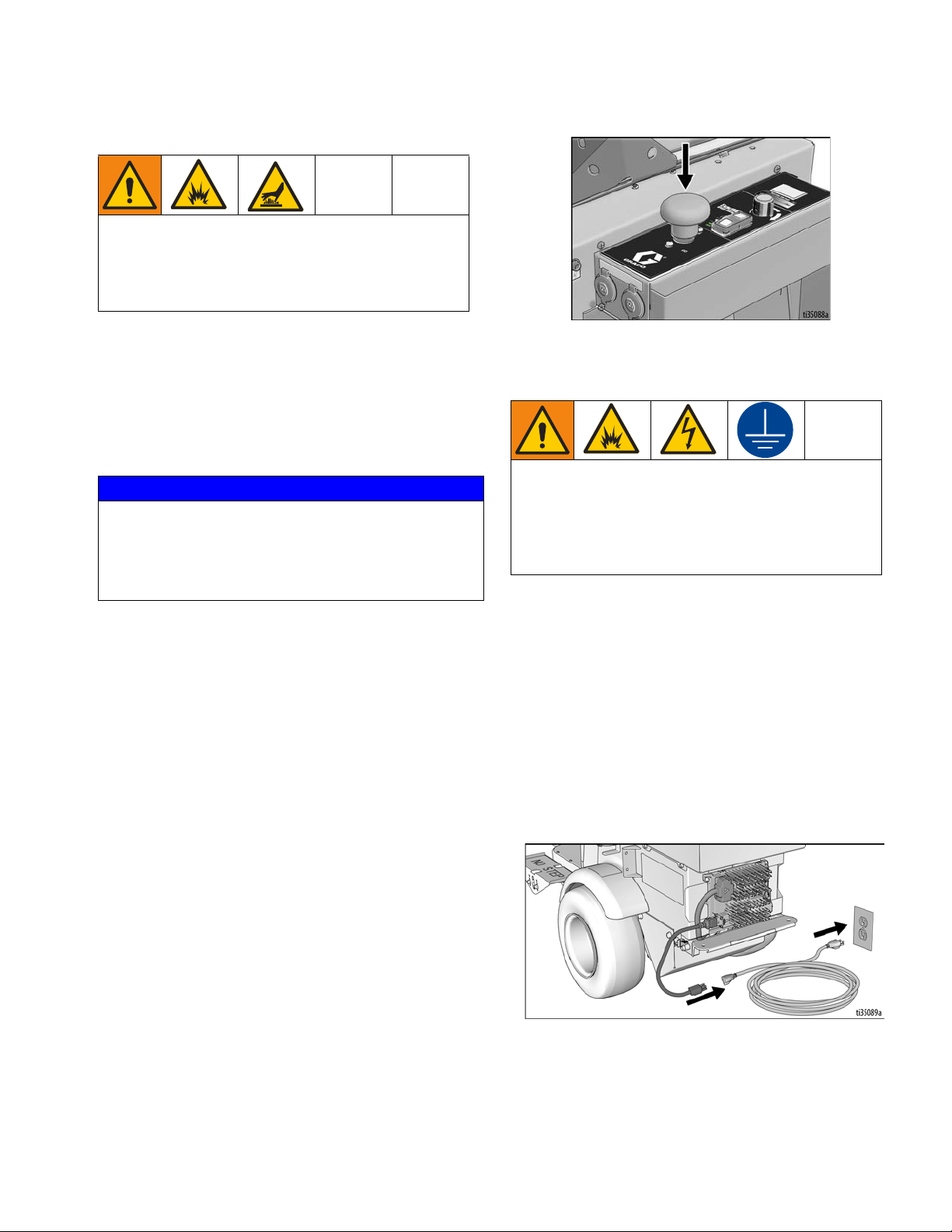

Charging the Batteries

Replace and charge battery only in well-ventilated

area and away from flammable or combustible materials, including paints and solvents. The charger may

become hot while charging. Do not touch. Refer to

Charger Manual for additional information.

The charger may be used any time the LineDriver is not

being used. When the batteries are fully charged, the

charger automatically stops. If the LineDriver is stored

for an extended period, the batteries may self-discharge

enough for the charger to automatically recharge the

batteries. For optimum battery life, always leave the

charger plugged in.

NOTICE

Lead acid batteries can self-discharge in as little as 3

months depending on storage temperatures. The hotter

the storage temperature, the faster the self-discharge

occurs. To prevent damage to the battery, it is important to keep the battery in a charged state.

Batteries are fully charged when leaving the factory.

Due to self-discharging of the battery, charge battery

before first use. It takes ~18 hours to charge a fully

depleted battery, and ~8 hours to charge the battery 3/4

full.

3. Ensure power switch is in OFF position.

4. Plug charging cord into charging port on the unit.

Connect an extension cord, per charger manual, to

the charging cord and plug it into wall power.

This equipment must be grounded to reduce the risk

of static sparking and electric shock. An electric

shock or static spark can cause fumes to ignite or

explode. An improper ground can cause electric

shock. A good ground provides an escape wire for

the electric current.

Always use an outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided; if it does not fit the

outlet, have the proper outlet installed by a qualified

electrician.

NOTE: Battery life depends on the depth of discharge

per cycle. A battery that is discharged to 50% depth will

get over twice as many cycles in its life compared to it

being discharged to 100% depth each cycle.

1. Place unit in dry, well-ventilated area and away from

flammable or combustible materials, including

paints and solvents.

2. Position the driver so the wheels are on a true

grounded surface, not on pavement.

3A6623C 9

Power Requirements

• All models use the same battery charger. Refer to

Technical Specifications, page 32, for power

requirements.

Operation

DISPLAY

CHARGING

OUTPUT

INICATOR

USB PORT

STATE OF

CHARGE

INDICATOR

FAULT

INDICATOR

ti35137a

5. The Charging Output Indicator means that the charger output is active.

6. When power is connected, charger will immediately

begin charging.

NOTE: Battery will charge to ~30 volts while charging

and then it will come back down to ~27 volts after fully

charging.

NOTE: The Charge Display may show codes to indicate

different conditions. Refer to charger manual for addi-

tional information.

• ‘F’ codes meaning that an internal fault condition

has caused charging to stop.

• ‘E’ codes meaning that an external error condition

has caused charging to stop.

7. When battery charge indicator is solid green, the

charge is complete.

10 3A6623C

Maintenance

Maintenance

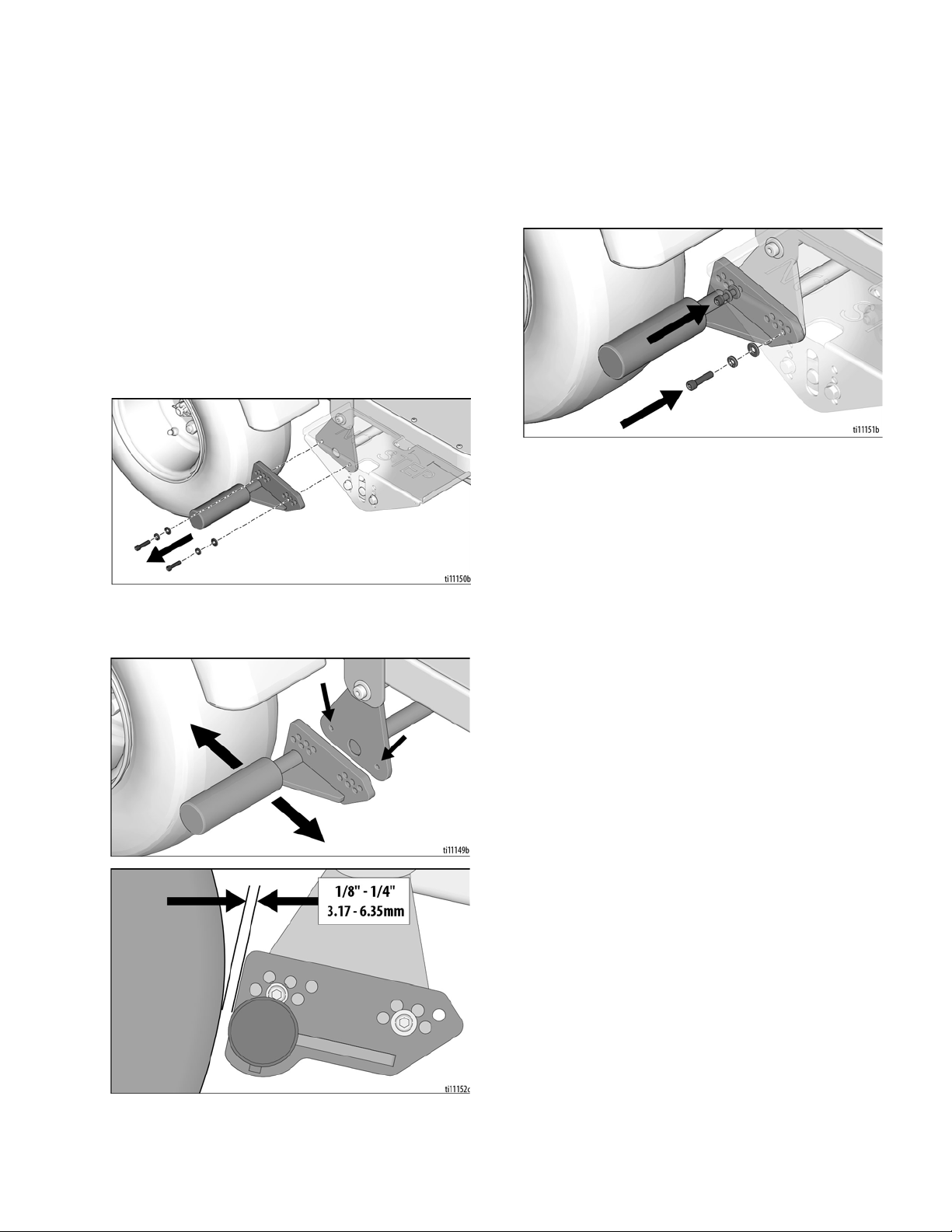

Manual Brake Adjustment or

Replacement

1. Block tires so LineDriver will not move. Release

Manual Brake.

2. Ensure power switch is in OFF position.

3. Inflate tires to operating pressure per tire sidewall.

Remove two bolts securing brake rod.

4. Select a hole pattern that positions the brake rod 1/8

to 1/4 in. from the tire.

5. Install two bolts and secure brake rod. Repeat for

second tire.

NOTE: Brake rods are not interchangeable from side to

side. Model shown in the graphic above is the right side

version.

3A6623C 11

Loading...

Loading...