Page 1

Instructions - Parts

PR70 and PR70v

Integrated Heat

For controlling material temperature in heated tanks and hoses.

Models LC0250, LC0251,

LC0252, LC0253

Important Safety Instructions

Read all warnings and instructions in all supplied manuals. Save these instructions.

312761B

Assembly LC0252 Shown

ti12577a

Page 2

Supplied Manuals

Contents

Supplied Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . 4

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connect Electrical Cord . . . . . . . . . . . . . . . . . . . 5

Install Low Power Temperature Control Modules 6

Connect 3-wire Module Power . . . . . . . . . . . . . . 6

Adjust Rotary Switch . . . . . . . . . . . . . . . . . . . . . . 7

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cable Connections . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Install Upgrade Token . . . . . . . . . . . . . . . . . . . . 10

Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . 11

Diagnostic Information . . . . . . . . . . . . . . . . . . . 11

Simplified Wiring Schematic . . . . . . . . . . . . . . . 11

Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . 12

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . 17

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Graco Ohio Standard Warranty . . . . . . . . . . . . . . 20

Graco Ohio Information . . . . . . . . . . . . . . . . . . . . 20

Supplied Manuals

Assemblies with a Standard Display Module

include manual 312393. Assemblies with an

Advanced Display Module include manuals 312759

and 312760.

PR70 and PR70v Operation and Parts Manuals

Part Description

312393 PR70 with Standard Display Module Opera-

tion and Maintenance Manual

312759 PR70 and PR70v with Advanced Display

Module Operation and Maintenance Manual

312760 PR70 and PR70v with Advanced Display

Module Repair and Parts Manual

MD2 Dispense Valve Manual

Part Description

312185 MD2 Dispense Valve Instructions and Parts

Manual

PR70 and PR70v Feed Systems Manual

Part Description

312394 PR70 and PR70v Feed Systems Manual

PR70 and PR70v Integrated Heat Manual

Part Description

312761 PR70v Integrated Heat Instructions - Parts

Manual

2 312761B

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

Equipment With Grounding Plug

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

Hard-Wired Equipment

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

312761B 3

Page 4

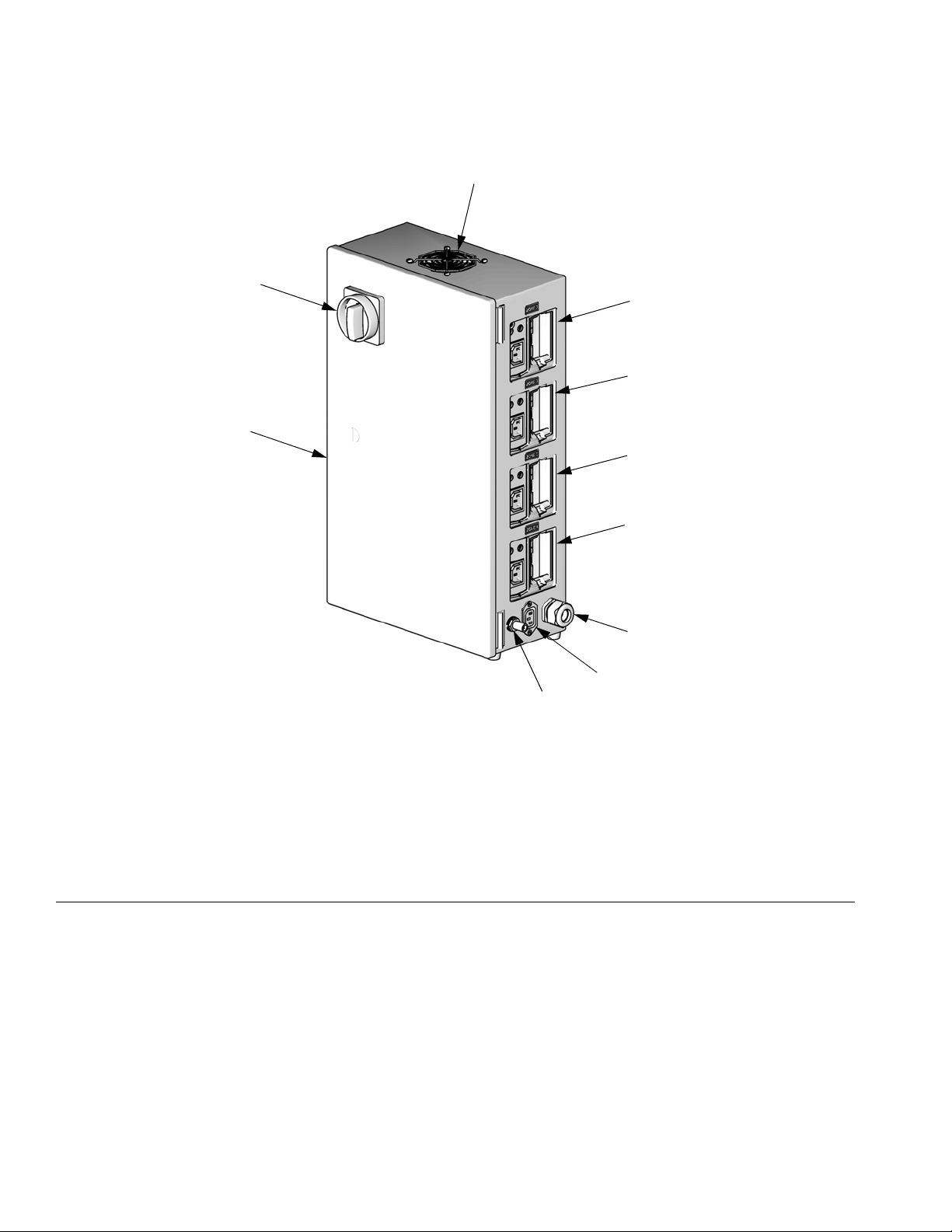

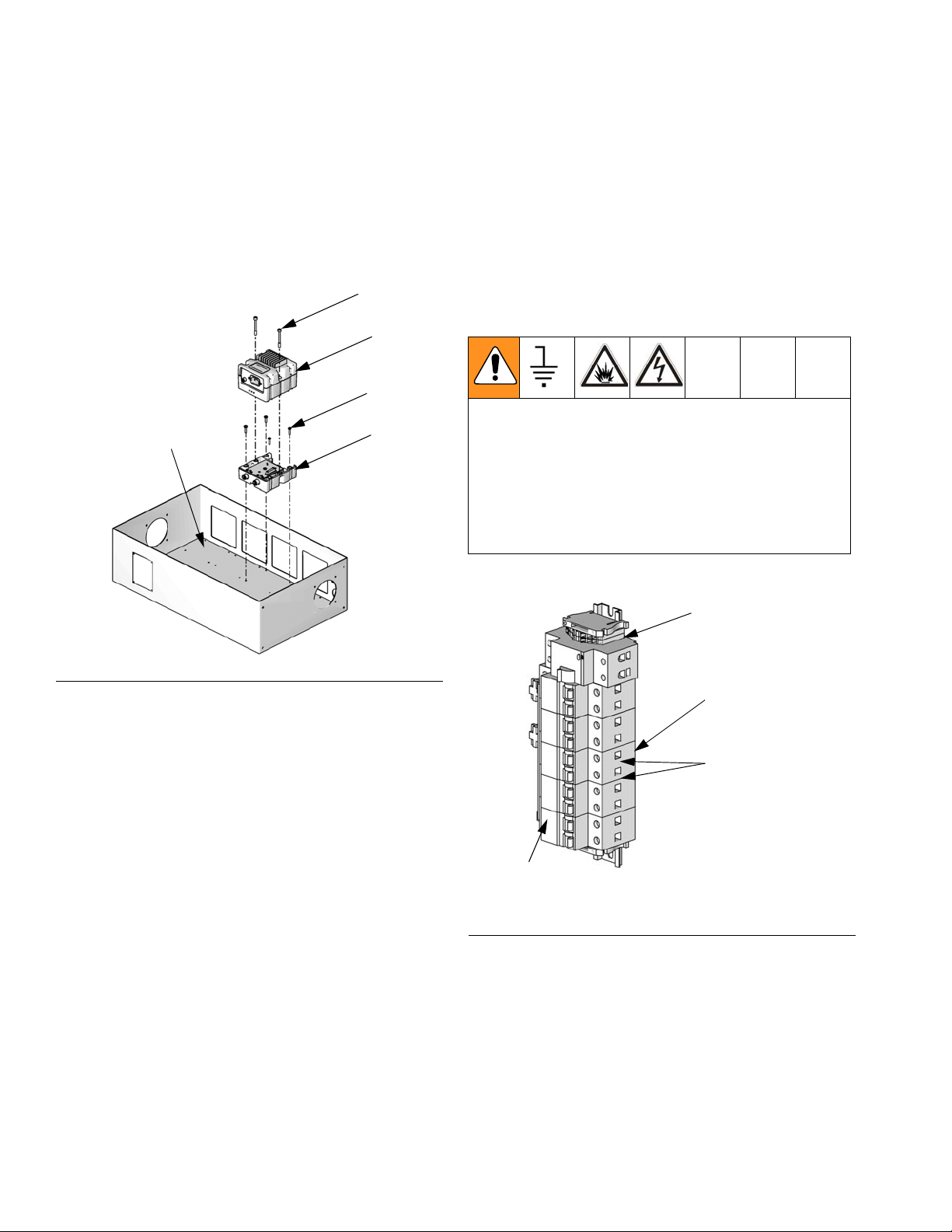

Component Identification

Component Identification

AE

AK

AF

AD

AC

AB

Assembly LC0253 Shown

FIG. 1: Heat Control Box

Key:

AA Zone 1

AB Zone 2

AC Zone 3

AD Zone 4

AE Electrical Disconnect Switch

AF Fan

AA

AG

ti12577a

AH

AJ

AG Integrated Heat Power Inlet

AH Integrated Heat Power Outlet

to Machine

AJ CAN Connection Output to

Machine

AK Heat Control Box

4 312761B

Page 5

Grounding

Grounding

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric

shock by providing an escape wire for the electric current. This product is equipped with a chord having a

grounding wire. A 3-blade grounding plug must be

installed or the machine may be hard wired. The plug

must be plugged into an outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

Improper installation of the grounding plug is able to

result in a risk of electric shock. The wire with insulation

having an outer surface that is green with or without yellow stripes is the grounding wire. Do not modify the plug

provided; if it does not fit the outlet, have the proper outlet installed by a qualified electrician. Only connect the

product to an outlet having the same configuration as

the plug. Do not use an adapter with this product.

Installation

Connect Electrical Cord

appropriate gauge wire for the machine amperage.

See the following table.

Number of Zones

installed in Heat

Control Box

1 30 10 (2.59) / 3

2 30 10 (2.59) / 3

3 40 8 (3.26) / 3

4 40 8 (3.26) / 3

Install Plug

The equipment must be grounded. Grounding

reduces the risk of static and electric shock by providing an escape wire for the electrical current due to

static build up or in the event of a short circuit.

Improper installation of the grounding plug is able to

result in a risk of electric shock. The wire with insulation having an outer surface that is green with or without yellow stripes is the grounding wire.

2.

For machines that will not be hard-wired,

3-blade 240V, 1-phase grounding plug onto

cord (129). The machine must use a receptacle that

accepts the plug on the product.

For machines that will be hard-wired,

the machine. The grounding wire must be used.

Rating

(Amps)

Gauge (mm

Number of Wires

2

) /

install a

hard-wire

Machine may be hard-wired or installed using a

plug.

Improper wiring may cause electric shock or other

serious injury if work is not performed properly. Have

a qualified electrician perform any electrical work. Be

sure your installation complies with all National, State

and Local safety and fire codes.

1. Each machine comes with a permanent 10 ft power

cable without a plug. If a permanent extension cable

must be installed onto the existing cable or if an

extension cord is necessary, be sure to use the

312761B 5

Page 6

Installation

Install Low Power Temperature Control Modules

The low power temperature control modules are

installed in the Heat Control box at the factory. If a low

power temperature control module must be replaced,

perform the following procedure.

124a

124

119

120

125

8. Use two hex head cap screws (124a) to install low

power module (124) onto base module (125).

9. Change rotary switch position on new low power

temperature control module. See Adjust Rotary

Switch on page 7.

10. Reconnect CAN cables (113, 130) and power

cables.

Connect 3-wire Module Power

Connecting the power must be performed by a qualified electrician. The equipment must be grounded.

Grounding reduces the risk of static and electric shock

by providing an escape wire for the electrical current

due to static build up or in the event of a short circuit.

The wire with insulation having an outer surface that is

green with or without yellow stripes is the grounding

wire.

ti12703a

FIG. 2

Remove Old Low Power Temperate Control Module

1. On units with a grounding plug, unplug unit from

wall.

On hard-wired units, use facility power switch to

turn off incoming power.

2. Unplug data connection and power cables from low

power temperature control modules. Do not disconnect other end of cables.

3. Remove hex head cap screws (124a) from low

power temperature control module.

4. Remove low power module (124).

5. Remove four socket head cap screws (119).

6. Remove base module (125).

4

3

2

1

Main Power

Breaker

F

IG. 3: Breaker Numbering

116

141

141a

ti12627b

Install New Low Power Temperate Control Module

7. Use four socket head cap screws (119) to install

base module (125) onto enclosure back

panel (120).

6 312761B

Page 7

Installation

There is one breaker for each heated hose or heated

tank. The lower number breakers are used for the

heated tanks if installed. See F

IG. 3. For example, if

there are two heated tanks installed and two heated

hoses, breakers #1 and #2 are used for the heated

tanks and breakers #3 and #4 are used for the heated

hoses. If there is one heated tank and one heated hose,

then breaker #1 is used for the heated tank and breaker

#2 is used for the heated hose. Each breaker has a different rating so it is important that the correct breaker is

used.

The 3-wire module power is connected in the Heat Control box at the factory. The power cord (118) for each low

power temperature control module has a connector on

one end and three power leads on the other. The three

power leads must be connected to the appropriate

breaker (114) and ground terminal (116).

1. Connect the power cord connector to the low power

temperature control module.

2. Connect the green wire to any unused ground terminal block (116).

Set the rotary switch (S) to the specific selection according to the settings listed in the following table.

Low Power Temperature Control Module

Rotary Switch Location

S

ti12361a

F

IG. 4

Low Power Temperature Control Module

Rotary Switch Settings

3. Find the breaker with the same number as the module as shown in F

IG. 3 on page 6 and FIG. 6 on

page 9.

4. Connect the black and white wires to the

breaker (141) labeled with the same number as the

module. The black and white wires can connect to

either terminal (141a) in the same breaker (141).

Adjust Rotary Switch

The rotary switch setting must only be adjusted on

new low power temperature control modules after

installation.

The rotary switch setting indicates which zone number

the low power temperature control module will control in

the system. The low power temperature control module

uses a 16-position rotary switch.

The modules must always be set to the zone number shown on the label above the module.

Switch

Setting Zone

11

22

33

44

312761B 7

Page 8

Setup

Setup

Cable Connections

3

ti12356a

1

2

5

6

4

ti12357a

F

IG. 5: Low Power Temperature Control Module Cable Connections

1 Overtemperature Switch Connection

2 RTD Temperature Sensor Connection

3 Output Power Connection

4 DC Output Connection

5 Input Power Connection

6 CAN Connections

7Base

The overtemperature switch connection (1), RTD temperature sensor connection (2), and output power

connection (3) connect to the respective components of

a temperature control option. The display module must

be updated to specify which zone number is used with

which temperature control option. See the PR70 and

PR70v Operation manual referenced at the beginning of

this manual for more information.

7

8 312761B

Page 9

Data Cable Connections

130

130

130

Setup

4

3

2

1

ti12625a

113

F

IG. 6: Data Cable Connections

The low power temperate control modules must be connected together using the female-female CAN

cables (130) as shown in F

IG. 6. Then they must be con-

nected to the display module using the female-male

CAN cable (113).

312761B 9

Page 10

Operation

Operation

See the PR70 and PR70v Operation manual referenced

at the beginning of this manual for operating instructions.

Maintenance

Install Upgrade Token

1. Ensure system is inactive and control power is on.

2. Remove access cover (C).

C

4. Press and hold the left red token upload button (M)

for three seconds. The red indicator light (L) will

flash up to three seconds after the software is

uploaded.

5. Remove token (T).

6. Replace access cover (C).

7. Repeat procedure for all low power temperature

control modules.

8. Turn machine power off then on after all modules

are upgraded.

Clean

Keep heat sink fins clean at all times. Wipe the fins

clean with a dry cloth or clean them using compressed

air.

Do not use conductive cleaning solvents on the low

power temperature control modules.

ti12358a

F

IG. 7: Remove Access Cover

3. Insert and press token (T) firmly into slot.

There is no preferred orientation of token.

L

S

ti12359a

T

M

F

IG. 9: Clean Heat Sink Fins

Heat Sink Fins

ti12357a

F

IG. 8: Install Token

10 312761B

Page 11

Troubleshooting

Circuit Breaker

If the circuit breaker is tripped, manually flip the breaker

back to the “on” position. Find and correct the problem

before continuing operation.

Diagnostic Information

Module Status LEDs

7

Table 1: LED Status Signal

Signal Description

Troubleshooting

Green on Low power temperature control mod-

ule is powered up.

Yellow Internal communication in progress.

Red solid Low power temperature control mod-

ule failure.

Red flashing Software is updating.

Simplified Wiring Schematic

208-240V

50/60 Hz

1 phase

GFEP

Breaker #1

Circuit

FIG. 10: LED Signals

Circuit

Breaker #2

Circuit

Breaker #3

Circuit

Breaker #4

LED

Signals

ti12357a

Circuit

Breaker #5

Low Power

Fan

312761B 11

Temp Cont

Module #1

Low Power

Temp Cont

Module #2

Low Power

Temp Cont

Module #3

Low Power

Temp Cont

Module #4

Machine

Power

Page 12

Troubleshooting

Wiring Schematic

2

GFPE 112

1

NN

FIG. 11: Wiring Schematic, Page 1 of 2

12 312761B

Page 13

Troubleshooting

FIG. 12: Wiring Schematic, Page 2 of 2

312761B 13

Page 14

Parts

Parts

118

108, 107

121

124

105

117

102

101

130

144

104

103

127

128

119

125

126

120

113

132

114

129

115

135

134

116

133

135

102

106

146

145

1

1

1

141

116

115

123

131

117

110

122

136

198

121

ti12471b

111

1

14 312761B

112

Heated hose and heated tank circuit breakers shown for reference only. See

Circuit Breakers on page 17 for part numbers.

109

102

Assembly LC0252 Shown

Page 15

LC0253

LC0250

Control Box, Heat,

Ref Description

101 GUARD, fan,

80 mm x 80 mm

102 SCREW, panhead

machined

103 NUT, lock, hex 105334 105334 105334 105334 4

104 FAN, brushless,

80 x 80 x 25, 24 VDC

105 CONNECTOR, straight,

M8, 3-PIN, solder

106 SWITCH, disconnect,

3-pole, 40A

107 SHAFT, disconnect, elec-

tric

108 HANDLE, disconnect,

electric

109 FILTER, screen, fan, 80

mm x 80 mm

110 SCREW 120916 120916 120916 120916 2

111 FOOT, BUMPER 123698 123698 123698 123698 4

112 SCREW 120885 120885 120885 120885 4

113 CABLE, CAN, male /

female, 0.4 m

114 CONNECTOR, thru,

M12, male / female

115 BLOCK, end stop, termi-

nal, tan, 35 mm RA

116 BLOCK, terminal, spg,

4P, ground, 600V/20A

117 CORD, power, v-lock,

C14/C13, 10A

118 CORD, power, v-lock,

15P/C13, 10A

119 SCREW, socket head

cap, 10-32 x 0.62, stain-

less steel

120 PANEL, back, enclosure,

12 in.

PANEL, back, enclosure,

20 in.

121 ENCLOSURE,

12 x 12 x 6, 2 load

ENCLOSURE,

20 x 12 x 6, 4 load

122 GRIP, cord,

0.51 - 0.71, 3/4

GRIP, cord,

0.35 - 0.63, 3/4

123 SCREW, pan head

machined,

M5 - 0.8 x 12 mm

124 MODULE, low power,

Graco Control Architec-

ture

125 MODULE, Graco Control

Architecture, base

1 Load, 240V

121560 121560 121560 121560 1

105676 105676 105676 105676 10

121556 121556 121556 121556 1

121590 121590 121590 121590 1

121568 121568 121568 121568 1

121149 121149 121149 121149 1

121148 121148 121148 121148 1

121559 121559 121559 121559 1

121226 121226 121226 121226 1

121612 121612 121612 121612 1

123384 123384 123384 123384 2

123686

(Qty 3)

121599

(Qty 2)

121598

(Qty 1)

113003

(Qty 4)

121584 121584

121563 121563

121603 121603

121725 121725 121725 121725 2

256270

(Qty 1)

289697

(Qty 1)

LC0251

Control Box, Heat,

2 Load, 240V

123686

(Qty 3)

121599

(Qty 3)

121598

(Qty 2)

113003

(Qty 8)

256270

(Qty 2)

289697

(Qty 2)

LC0252

Control Box, Heat,

3 Load, 240V

123686

(Qty 4)

121599

(Qty 4)

121598

(Qty 3)

113003

(Qty 12)

121585 121585 1

121565 121565 1

121171 121171 1

256270

(Qty 3)

289697

(Qty 3)

Control Box,

Heat, 4 Load,

240V Qty

123686

(Qty 4)

121599

(Qty 5)

121598

(Qty 4)

113003

(Qty 16)

256270

(Qty 4)

289697

(Qty 4)

Parts

1

1

1

312761B 15

Page 16

Parts

LC0253

LC0250

Control Box, Heat,

Ref Description

126 † COVER, heat box 15U672 15U672 1

127 NUT, hex 110911

128 WASHER, plain #10 120907 120907 2

129 CORD, 10/3, 40A,

SOOW, CU, 600V

CORD, 8/3, 30A, SOOW,

CU, 600V

130 CABLE, CAN, 90 female /

90 female

131 RAIL, DIN 514014

132 GASKET, enclosure,

heat, Graco Control

Architecture

133 CONNECTOR, bus bar, 2

phase, 4 poles

CONNECTOR, bus bar, 2

phase, 6 poles

CONNECTOR, bus bar, 2

phase, 8 poles

CONNECTOR, bus bar, 2

phase, 10 poles

134 TERMINAL 121648 121648 121648 121648 2

135 CAP 121649 121649 121649 121649 2

136 CONNECTOR, power,

panel mount

137 LABEL, zone1 15V283 15V283 15V283 15V283 1

138 LABEL, zone2 15V284 15V284 15V284 1

139 LABEL, zone3

140 LABEL, zone4 15V286 1

141 CIRCUIT, breaker, 2-pole,

10A, C type

142† ENCLOSURE, Graco

Control Architecture, door

143 CABLE, CAN, M12 x

M12, 5P, female / female,

straight x right angle

144 TERMINAL, ring, #8

AWG, 1/4 in. stud

145 CIRCUIT, breaker, 63A,

GFI

146 BRACKET, disconnect,

40A

197†

198 PLATE, legend, serial

199†

LABEL, electric shock

number

PLUG, retainer

1 Load, 240V

065054 065054

(Qty 0.6)

121566

(Qty 1)

15U740 1

121558 121558 121558 121558 1

121634 121634 121634 121634 1

277674

(Qty 1)

121685 121685 121685 121685 1

123421 123421 123421 123421

123687 123687 123687 123687

16C235 16C235 16C235 16C235

XXXXX XXXXX XXXXX XXXXX

293564 293564 293564 293564

123699 123699 123699 123699

LC0251

Control Box, Heat,

2 Load, 240V

121597

(Qty 1)

514014

(Qty 0.83)

121566

(Qty 2)

15U741 1

277674

(Qty 2)

LC0252

Control Box, Heat,

3 Load, 240V

110911 2

121158 121158 12

121597

(Qty 2)

514014

(Qty 0.83)

121566

(Qty 3)

15U742 1

15V285 15V285 1

277674

(Qty 3)

Control Box,

Heat, 4 Load,

240V Qty

121597

(Qty 3)

514014

(Qty 0.83)

121566

(Qty 4)

15U743 1

277674

(Qty 4)

12

1

1

1

1

1

1

† Part not shown.

Replacement Danger and Warning labels, tags, and cards are available at no cost.

16 312761B

Page 17

Parts

Circuit Breakers

See the PR70 and PR70v Repair - Parts manual referenced at the beginning of this manual to find the heated

hose and heated tank assembly numbers for your system.

Heated Hose Circuit Breakers

Installed Heated

Hose Package Circuit Breaker

LC0881 121630

LC0882 121631

LC0883 121632

LC0884 121630

LC0885 121631

LC0886 121632

LC0887 121630

LC0888 121631

LC0889 121632

LC0890 121632

LC0891 121633

LC0190 121630

LC0191 121631

LC0192 121632

LC0193 121630

LC0194 121631

LC0195 121632

LC0196 121630

LC0197 121631

LC0198 121632

LC0199 121632

LC0200 121633

LC0201 121630

LC0202 121631

LC0203 121632

LC0204 121630

LC0205 121631

LC0206 121632

LC0207 121630

LC0208 121631

LC0209 121632

LC0210 121632

LC0211 121633

Heated Tank Assembly Circuit Breakers

Installed Heated

Tank Assembly Circuit Breaker

LC0237

LC0238

LC0254

LC0255

LC0259

LC0260

121633

121635

312761B 17

Page 18

Parts

18 312761B

Page 19

Technical Data

Technical Data

Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208-240V 50/60 Hz, 1 phase for heat - 10 kW max.

(Qty 4) 2500W outputs

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 lb (13.6 kg) - 1 and 2 Zone Models

50 lb (22.7 kg) - 3 and 4 Zone Models

Dimensions

C

A

Assembly LC0253 Shown

F

IG. 13: Dimensions

1 and 2 Zone

Assemblies

Ref

A (height) 12 (305) 20 (508)

B (width) 12 (305) 12 (305)

C (depth) 6 (152) 6 (152)

in. (mm)

3 and 4 Zone

Assemblies

in. (mm)

ti12626a

B

ti12628a

312761B 19

Page 20

Graco Ohio Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Ohio Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER,

Toll Free: 1-800-746-1334 or Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

contact your Graco distributor or call to identify the nearest distributor.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 312761

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO OHIO INC. 8400 PORT JACKSON AVE NW, NORTH CANTON, OH 44720

Copyright 2008, Graco Ohio Inc. is registered to I.S. EN ISO 9001

www.graco.com

Rev 9/2009

Loading...

Loading...