Page 1

Instructions - Parts

Circulation and

Return Tube Kits

309852E

ENG

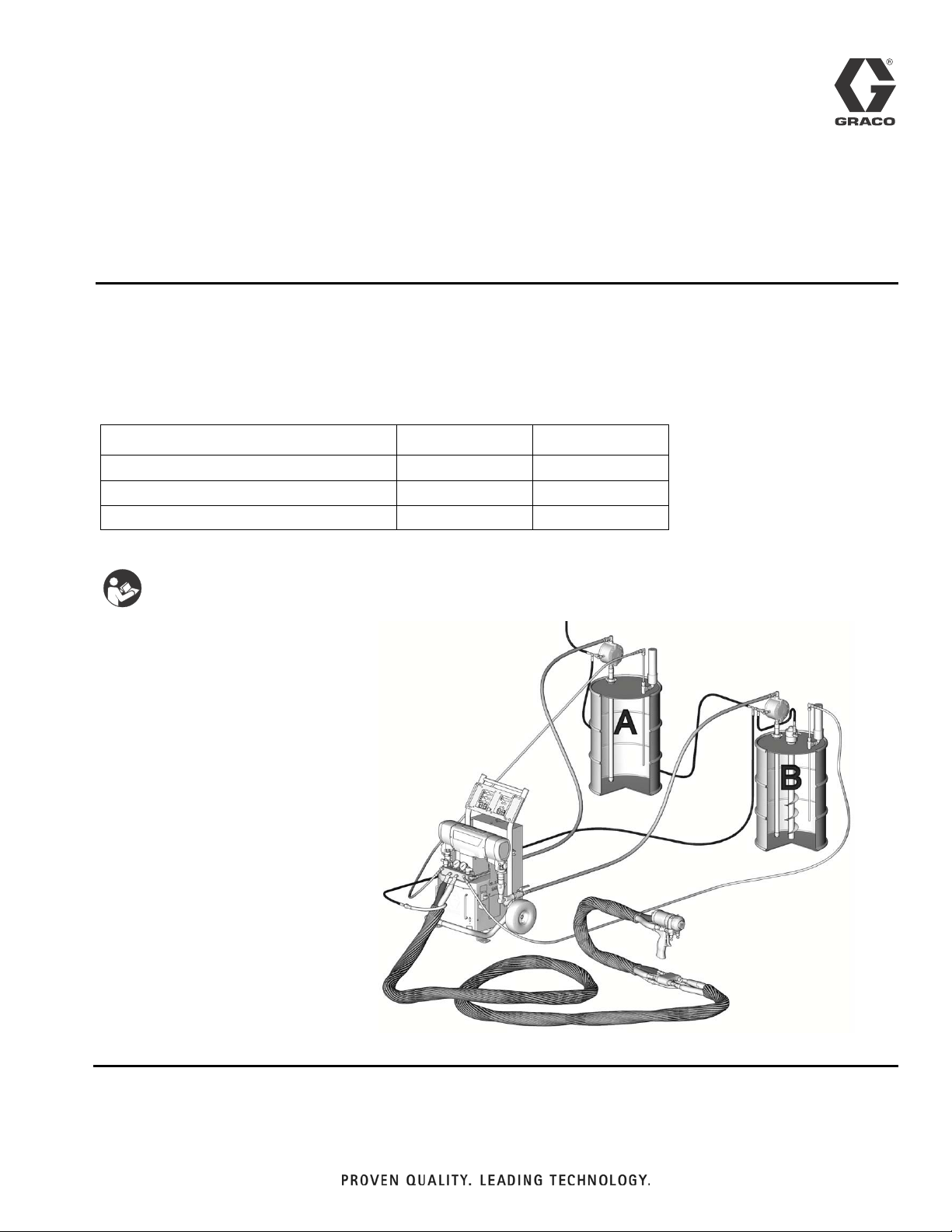

For recirculation of polyurethane materials from proportioner to 55 gal. (200

liter) fluid supply drums.

4000 psi (27.6 MPa, 276 bar) Maximum Fluid Working Pressure

Description Carbon Steel Stainless Steel

Return Tube Kit 246477 24D106

Circulation Kit 246978

Circulation Kit With Moisture-Lok Hose 24E379 24D107

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

246978 Kit shown installed in Reactor™ proportioning

system. Some parts shown are not included in kit.

TI3465a

Page 2

Return Tube Kit

Return Tube Kit

The Return Tube Kit can be installed singly or as

a pair. Two are included in the Circulation Kit,

page 3.

1. Keep A and B compo-

nents separate

CAUTION

To prevent cross-contamination of fluid, mark A component (ISO) connections with red tape. Mark B component (RES) connections with blue tape. Do not

interchange or cross-connect A component and B

component parts.

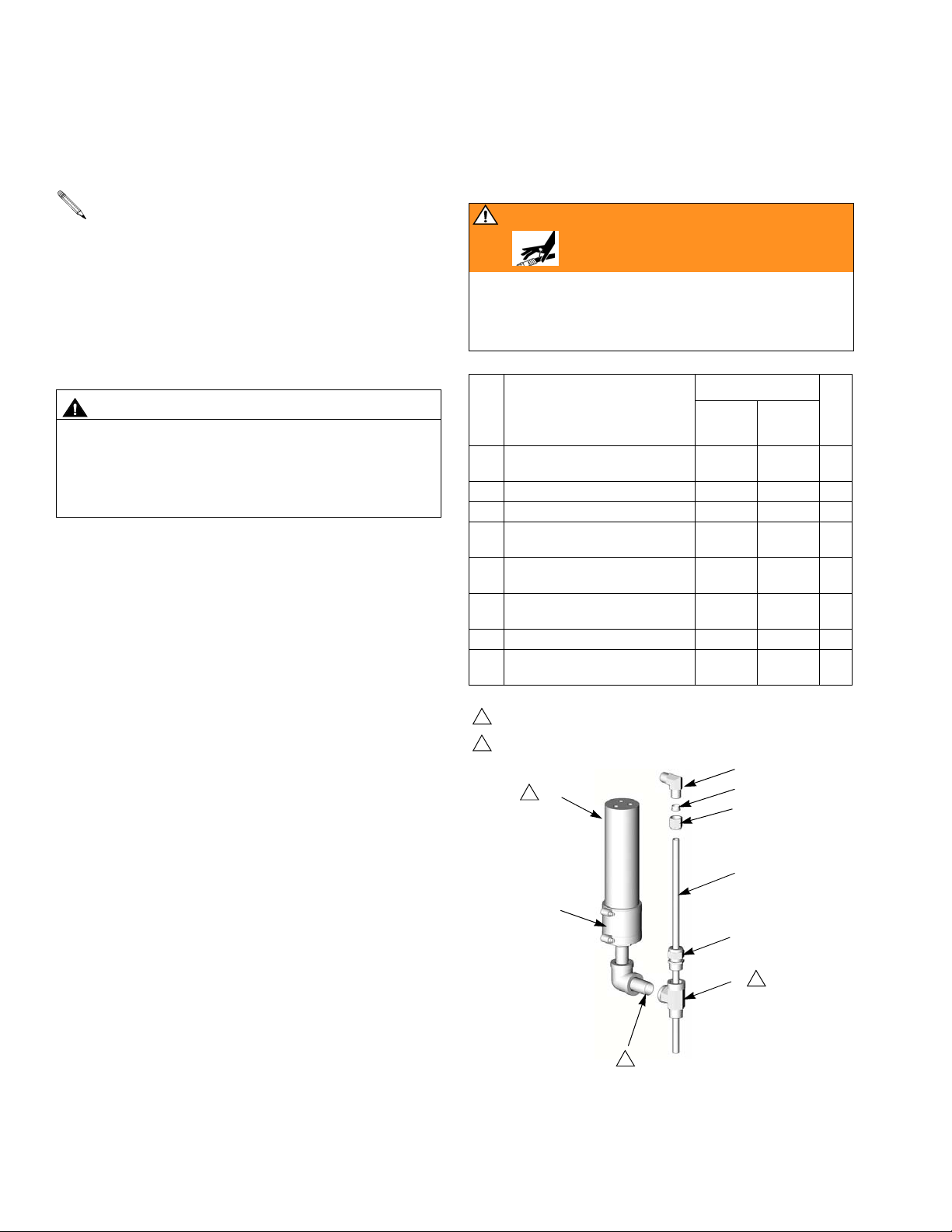

2. Assemble return tube kit

Remove dryer carriage (C). Using awl or similar

tool, punch a few small holes in each end of carriage. Reinstall carriage.

Remove large fitting included with dryer (10). It

is not needed for this application.

Apply thread sealant (8) to threads. Assemble

return tube kit as shown at right.

3. Install kit in drum

WARNING

To reduce the risk of serious injury including fluid

injection, use high pressure return hoses rated to withstand the maximum working pressure of the proportioner. See proportioner operation manual.

Return Tube Kit

Ref.

No. Description

1 ELBOW, 90°; 1/2 in. (13

mm) OD tube x 1/2 npt(m)

2 FERRULE, tube; sst 117453 117453 1

3 NUT, tube, flareless 117454 16C636 1

4 TUBE; sst; 1/2 in. (13 mm)

OD; 4 ft (1.2 m)

5 BUSHING, strain relief; 3/4

npt(m)

6 TEE, street; 3/4 npt (mxf)

run; 3/4 npt(f) branch

8 SEALANT, pipe; 6 ml 110110 110110 1

10 KIT, accessory, desiccant

dryer

1

Apply thread sealant (8) to threads.

2

Punch holes in ends of carriage (C).

C

2

(CS)

246477

117532 16C635 1

15C514 15C514 1

117811 117811 1

111337 16C637 1

247616 247616 1

(SST)

24D106

1

2

3

Qty

4

Open drum port. Lower kit into drum. Screw tee

(6) into drum port to secure. Use bushing (5) to

adjust position of tube (4) in tank.

4. Install circulation kit,

10

5

6

1

page 3

1

2 309852E

TI3446a

Page 3

Circulation Kit

Circulation Kit

1. Install two return tube

kits, page 2

CAUTION

To prevent cross-contamination of fluid, mark A component (ISO) connections with red tape. Mark B component (RES) connections with blue tape. Do not

interchange or cross-connect A component and B

component parts.

E

102

106

TI15106a

2. Connect circulation kit

Remove fittings from elbows (A, B) at the proportioner fluid manifold. Only used with 24697

For 246978: Screw reducing nipples (104) into

elbows. Connect one end of hoses (102) to

each nipple.

For 24E379 and 24D107: Connect elbows (105)

to the proportioner fluid manifold. Connect fitting

(106) to return tube. Connect one end of hoses

(102) to each elbow.

Connect other end of A side hose (102) to

elbow (E) of A component return tube kit.

Repeat for B side hose.

Ref.

No. Part No. Description Qty

101 KIT, return tube; see page 2 2

102 † H45010 HOSE, fluid; nylon; 1/2 in. (13 mm)

ID; 1/2 npsm(fbe); 10 ft (3.05 m)

◆ 262176 HOSE, B; 1/4 in. (6.35 mm) ID; (10

ft (3.05 m)

★ 262239 HOSE, B; 1/4 in. (6.35 mm) ID; (10

ft (3.05 m)

104 † 162449 NIPPLE, reducing; 1/2 x 1/4 npt 2

105 ◆ 122311 FITTING, elbow; 9/16-18 JIC 06 x

1/4 npt

★ 122786 FITTING, elbow; 9/16-18 JIC 06 x

1/4 npt

106 ◆ 124151 FITTING, 9/16-18 JIC 06 x 1/2 npt 2

★ 124152 FITTING, 9/16-18 JIC 06 x 1/2 npt 2

† 246978 Circulation Kit only.

◆ 24E379 Circulation Kit only.

★ 24D107 Circulation Kit only.

2

2

2

2

2

24E379 and 24D107 Circulation Kit

105

102

105

102

TI15107a

309852E 3

246978 Circulation Kit

A

104

102

B

104

102

TI3510a

Page 4

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 309852

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MIINNEAPOLIS, MN 55440-1441

Copyright 2003, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 04/2010

Loading...

Loading...