Graco Inc. 248570, 248571 Repair - Parts

Repair - Parts

UltraMix

Read warnings and instructions.

See page 3 for model information, including maximum working pressure and approvals.

™

Pumps

310671A

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2004, Graco Inc. is registered to I.S. EN ISO 9001

TI4598a

Contents

Manual Conventions

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Flush Before Using Equipment . . . . . . . . . . . . . . 6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 8

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Priming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Manual Conventions

WARNING

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Air Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Solenoid Replacement . . . . . . . . . . . . . . . . . . . 12

Sensor Replacement . . . . . . . . . . . . . . . . . . . . . 14

Sensor Repair . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Displacement Pump . . . . . . . . . . . . . . . . . . . . . 16

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 22

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 22

CAUTION

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in property damage or

destruction of equipment.

Note

Warnings included in instructions generally have a

symbol indicating the hazard. Follow the instructions

and read the hazard section on warning pages 4 to 5

for additional information.

A note indicates additional helpful information.

2 310671A

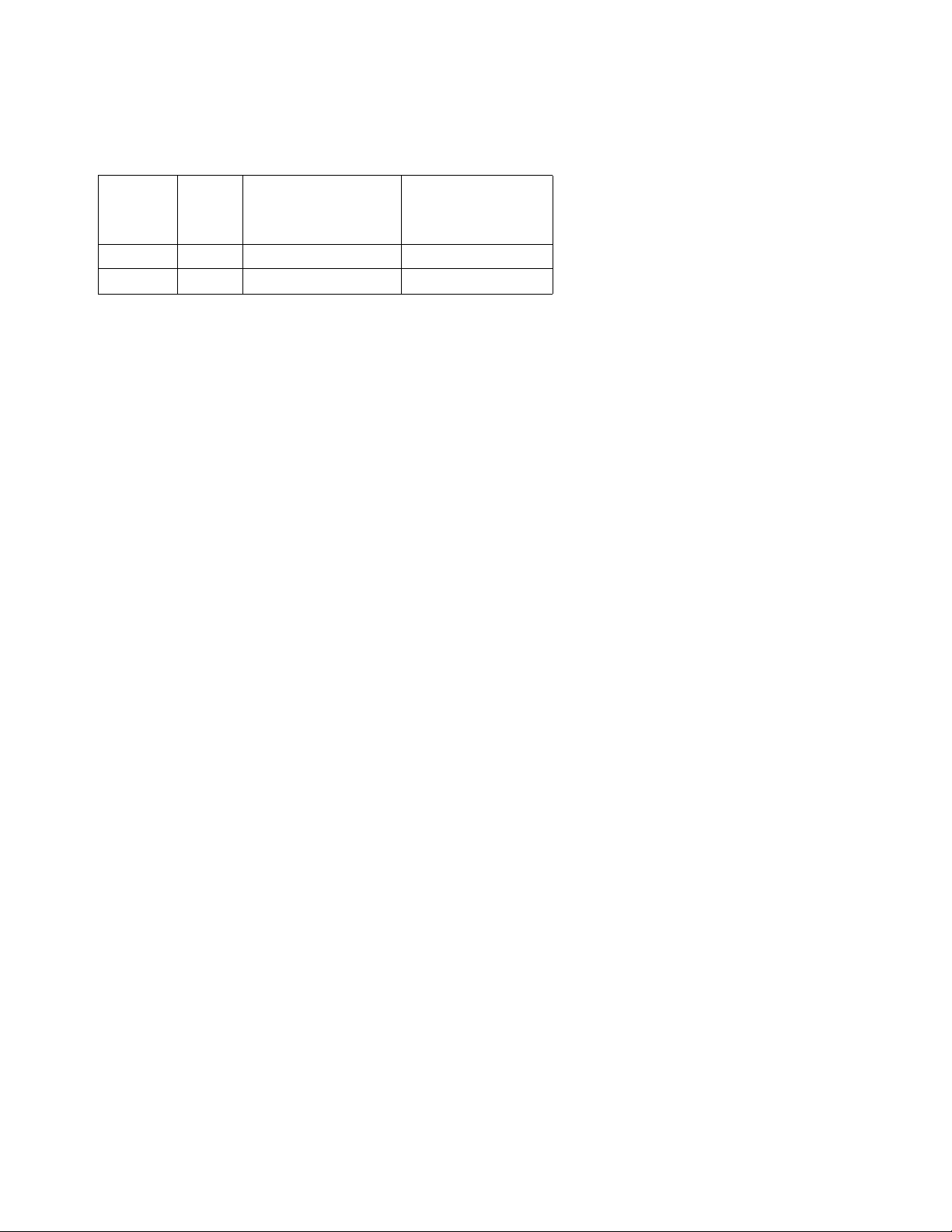

Models

Maximum

Working Pressure

Part No. Series Description

248570 A UltraMix cst Pump 250 (1.7, 17)

248571 A UltraMix sst Pump 250 (1.7, 17)

psi (MPa, bar)

Models

310671A 3

Warnings

Warnings

The following warnings include general safety information for this equipment. More specific warnings are included in

the text where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground equipment and conductive objects in work area. See Setup instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

4 310671A

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Tech nical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not use hoses to pull equipment.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

310671A 5

Setup

Setup

Grounding

WAR NING

Your system must be grounded. Read warnings, page

4.

Pump: connect ground wire and clamp to a true earth

ground.

Air and fluid hoses: use only electrically conductive

hoses.

Air compressor: follow manufacturer’s recommendations.

Spray gun: ground through connection to a properly

grounded fluid hose and pump.

Fluid supply container: follow local code.

Object being sprayed: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the spray gun

firmly to the side of a grounded metal pail, then trigger

the gun.

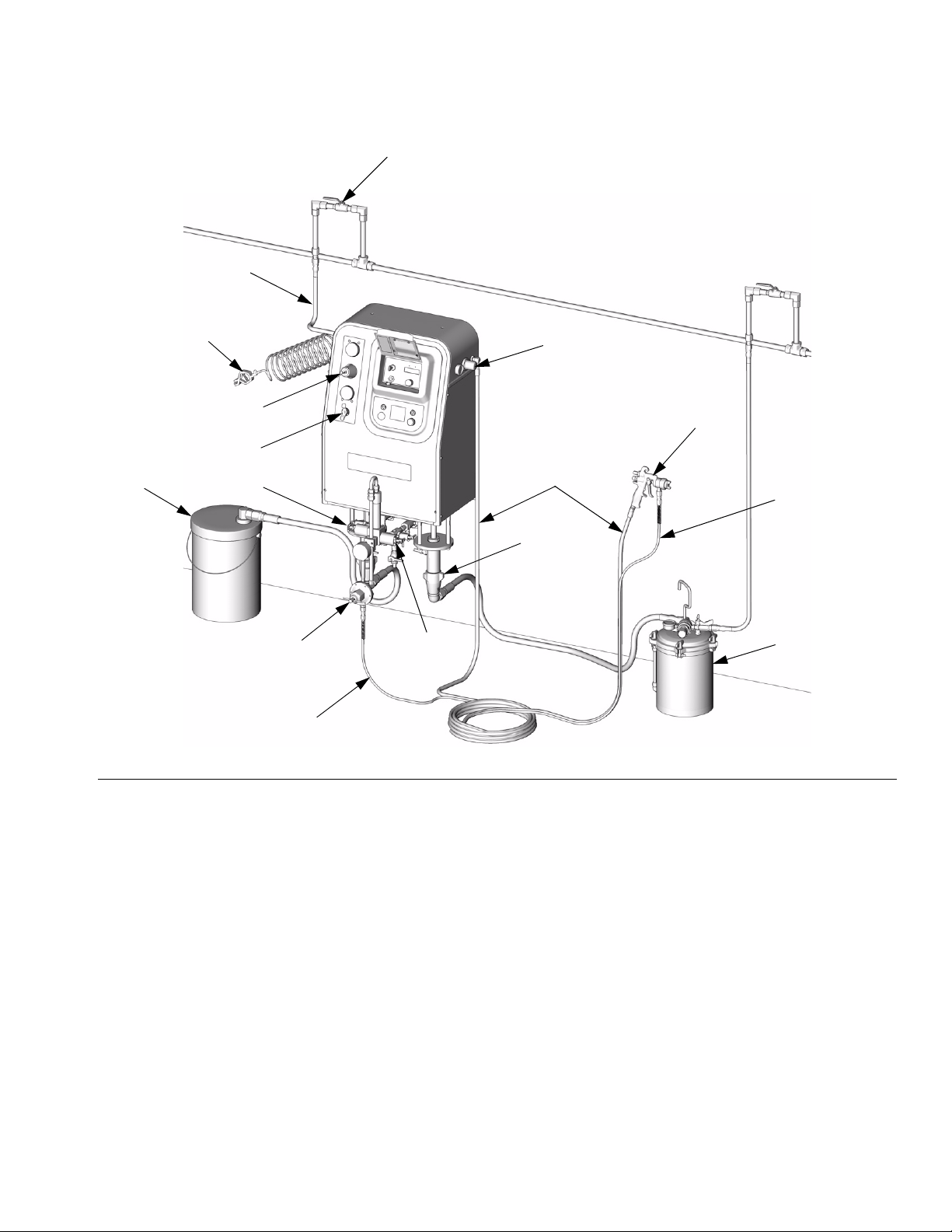

Accessories

Install the following accessories in the order shown in

F

IG. 1, using adapters as necessary.

Air Line

• Bleed-type master air valve (D): required in your

system to relieve air trapped between it and the air

motor when the valve is closed.

WAR NING

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury from splashing or moving parts.

Be sure the valve is easily accessible from the pump

and located downstream from the air regulator.

• Pump air regulator (E): to control pump speed and

outlet pressure. Locate it close to the pump.

Fluid Line

• Fluid drain valve (G): required in your system, to

relieve fluid pressure in the hose and gun.

WAR NING

Read warnings, page 4.

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the equipment with a

compatible solvent before using the equipment. See

Flushing, page 8.

6 310671A

Setup

B

A

R

E

L

P

D

J

F

M

F

H

G

N

FIG. 1: Typical Installation, shown on a ProMix Easy Plural Component Proportioner

N

K

TI4955a

Key:

A Main Air Supply Line

B Air Shutoff Valve

C Pump Air Filter (inside cabinet)

D Bleed-type Master Air Valve (required)

E Pump Air Regulator

F UltraMix Pumps

G Fluid Mix Manifold and Valves

H Fluid Pressure Regulator

J Component A Fluid Supply

K Component B Fluid Supply

L Gun Air Pressure Regulator

M Gun Air Supply Line

N Gun Fluid Supply Line

P Airspray Gun

R Ground Wire

310671A 7

Loading...

Loading...