Page 1

Instructions–Parts List

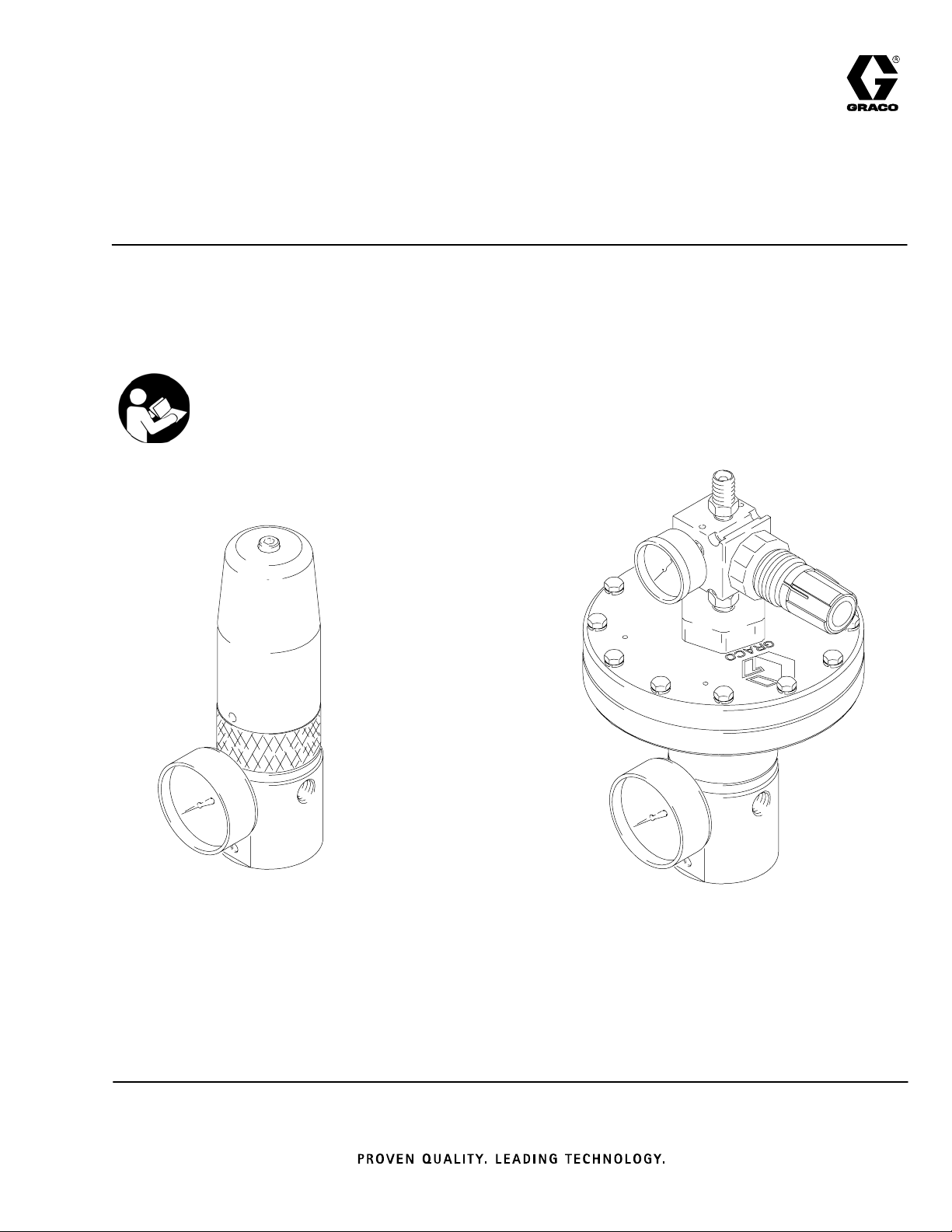

STAINLESS STEEL,

WATERBASE-COMPATIBLE, HIGH PRESSURE

Fluid Pressure Regulators

For precise downstream pressure and flow control.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 2 for List of Models and Table of Contents.

308647P

EN

Model 238890,

238892

(spring-operated)

U.S. Patent No. 4942899

06290

06288

Model 238894

(air-operated)

06540A

Page 2

Table of Contents

List of Models 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts

238889, 238890, 238891, and 238892 14. . . . . . . . . .

238893, 238894, 248090, and 255072 16. . . . . . . . . .

244734 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

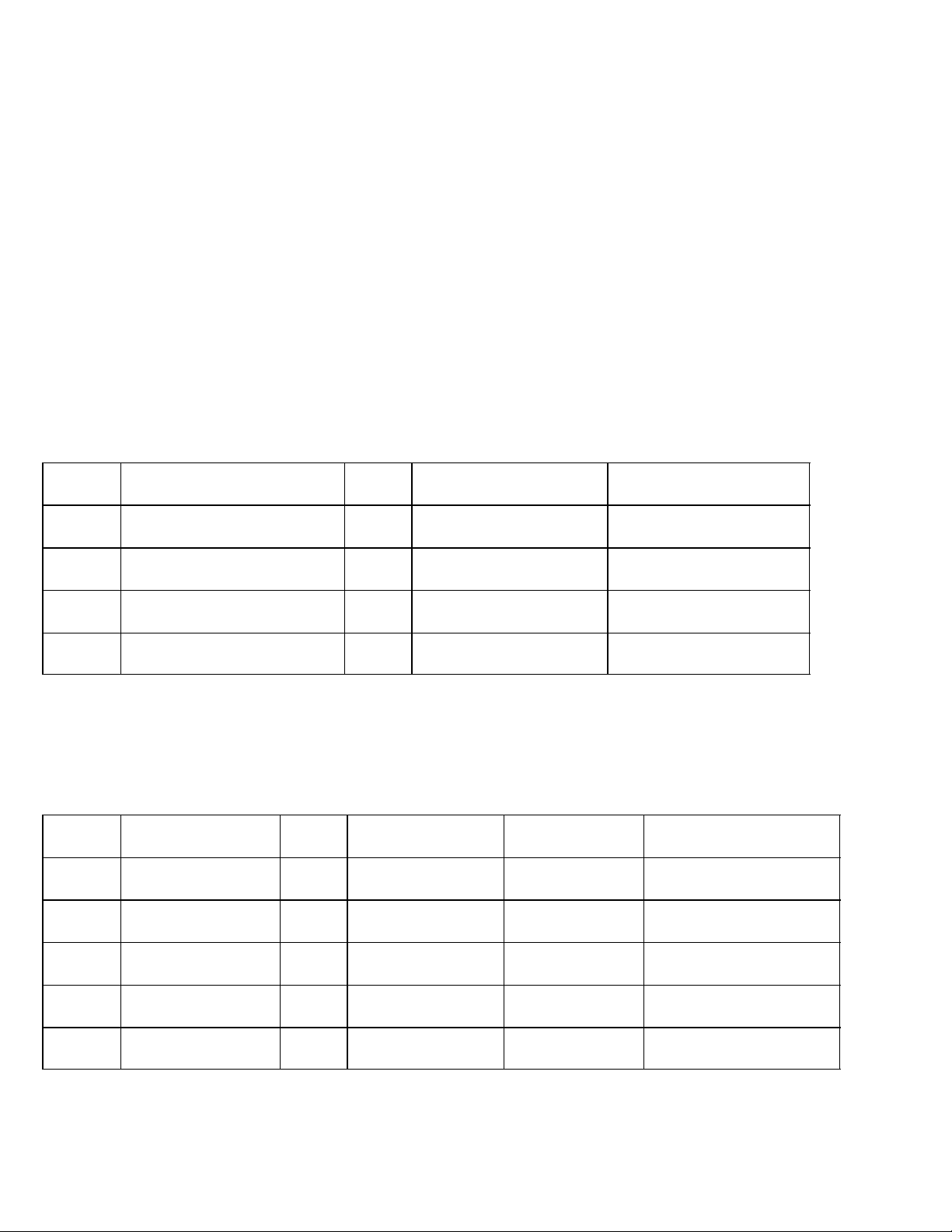

List of Models

Spring-Operated Models

Part No. Description Range

238889 with EZ Flush gauge port plug Medium

238890 with fluid pressure gauge Medium

238891 with EZ Flush gauge port plug High

238892 with fluid pressure gauge High

Technical Data 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Chart 21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensional Drawings 23. . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 24. . . . . . . . . . . . . . . . . . . . . .

Graco Information 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Fluid

Inlet Pressure

6000 psi

(41 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

Regulated Fluid

Outlet Pressure

500–3000 psi

(3.4–21 MPa, 34–207 bar)

500–3000 psi

(3.4–21 MPa, 34–207 bar)

3000–5000 psi

(21–34 MPa, 207–345 bar)

3000–5000 psi

(21–34 MPa, 207–345 bar)

Air-Operated Models

Part No. Description Range

238893

238894

244734

248090

255072

2 308647

with EZ Flush gauge

port plug

with fluid pressure

gauge

with EZ Flush gauge

port plug

with fluid pressure

gauge (LASD)

high resolution with

fluid pressure gauge

Full

Full

Full

Full

Full

Maximum Inbound

Air Pressure

100 psi

(0.7 MPa, 7 bar)

100 psi

(0.7 MPa, 7 bar)

100 psi

(0.7 MPa, 7 bar)

100 psi

(0.7 MPa, 7 bar)

100 psi

(0.7 MPa, 7 bar)

Maximum Fluid

Inlet Pressure

6000 psi

(41 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

6000 psi

(41 MPa, 414 bar)

Regulated Fluid

Outlet Pressure

500–4000 psi

(3.4–28 MPa, 34–276 bar)

500–4000 psi

(3.4–28 MPa, 34–276 bar)

500–4000 psi

(3.4–28 MPa, 34–276 bar)

500–4000 psi

(3.4–28 MPa, 34–276 bar)

500–2700 psi

(3.4–19 MPa, 34–190 bar)

Page 3

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Do not kink or over bend the hose or use the hose to pull equipment.

D Do not exceed the maximum working pressure of the lowest rated component in your system. Do

not exceed 6000 psi (41 MPa, 414 bar) maximum fluid inlet pressure of the regulator or the

maximum working pressure of the lowest-rated component in your system.

D Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

D Always wear protective eyewear, gloves, clothing, and respirator as recommended by the fluid and

solvent manufacturer.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

3308647

Page 4

WARNING

SKIN INJECTION HAZARD

Spray from the gun, leaks, or ruptured components can inject fluid into your body and cause extremely

serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also

cause serious injury.

D Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate

surgical treatment.

D Do not point the gun at anyone or at any part of the body.

D Do not put your hand or fingers over the spray gun tip or extruder gun tip.

D Do not stop or deflect leaks with your hand, body, glove or rag.

D Always have the tip guard and the trigger guard on the gun when spraying.

D Check the gun diffuser operation weekly. Refer to the gun manual.

D Be sure the gun trigger safety operates before spraying.

D Lock the gun trigger safety when you stop dispensing.

D Follow the Pressure Relief Procedure on page 7 if the spray tip clogs and before cleaning,

checking, or servicing the equipment.

D Tighten all fluid connections before operating the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. Do not

repair high pressure couplings; you must replace the entire hose.

D Fluid hoses must have spring guards on both ends to help protect them from rupture caused by

kinks or bends near the couplings.

HALOGENATED HYDROCARBON HAZARD

Never use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents, or

fluids containing such solvents in these regulators. In the unlikely event that there is a diaphragm

failure and the vent hole in the aluminum spring cap is plugged, a serious chemical reaction could

occur, with the possibility of explosion, which could cause death, serious injury, and/or substantial

property damage.

Consult your fluid suppliers to ensure that the fluids used are compatible with aluminum parts.

TOXIC FLUID HAZARD

Graco does not manufacture or supply the reactive chemical components that may be used in this

equipment and is not responsible for injury or property loss, damage, expense or claims (direct or

consequential) that arise from the use of such chemical components.

4 308647

Page 5

Notes

5308647

Page 6

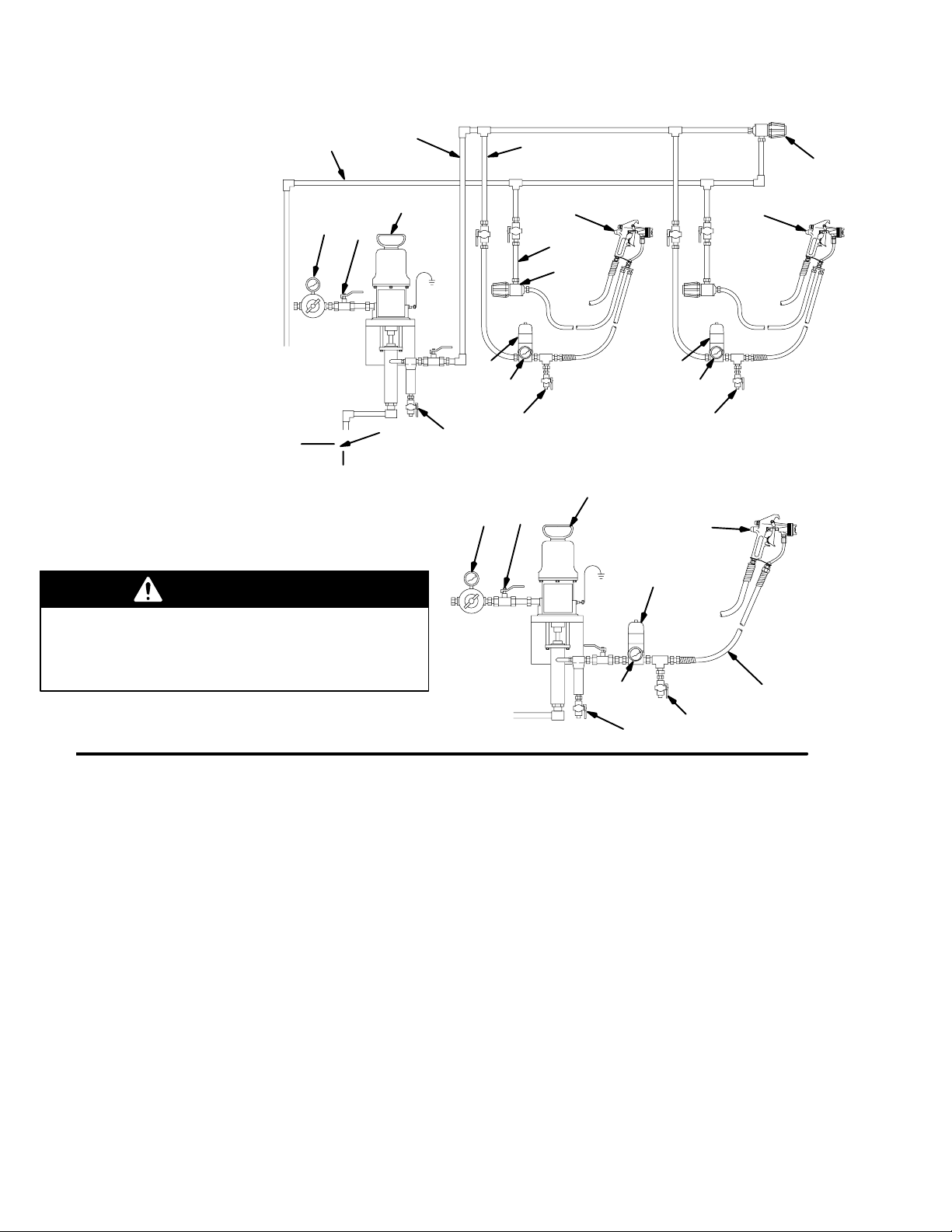

Installation

Multiple Circulating Spray Station

Key

A Air regulator

B Bleed-type master air valve

C Pump

D Fluid filter and drain valve

E Main fluid supply line

F Gun fluid supply line

G Fluid regulator

with fluid pressure gauge (H)

H Fluid pressure gauge

J Air-assisted airless spray gun

K Back pressure valve

L Fluid return line

M Main circulating line

N Fluid supply container

P Drain valve

WARNING

M

A

E

C

B

G

N

D

F

K

J

L

K

G

H

P

H

P

J

06461

Single Direct Spray Station

C

B

A

G

J

Do not use PTFE tape on pipe threads. Such use

could cause a hazardous condition due to loss of

grounding continuity. Also, if pieces of the tape break

off, the function of the regulator could be affected.

Fig. 1

The installations shown in Fig. 1 are only a guide for

selecting and installing a circulating or direct system;

they are not actual system designs. Contact your

Graco distributor for assistance in designing a system

to suit your needs.

NOTE: Before you install the regulator, thoroughly

flush the system to remove metal chips and other

contaminants. A fluid filter (D) of 60-mesh or finer

should always be installed upstream of the regulator.

Connections

Install the fluid regulator (G) in the spray gun fluid

supply line (F), as shown in the typical installation

drawings on this page. Connect only one spray gun

or dispensing valve to each fluid regulator.

H

D

Apply pipe sealant to the male pipe threads, and

connect the fluid supply line (F) to the fluid regulator’s

3/8 npt(f) inlet. Connect the line from the gun (J) to the

fluid regulator’s 3/8 npt(f) outlet. Install the gauge or

plug into the 1/4 npt(f) gauge port.

Make sure the direction of fluid flow agrees with the IN

and OUT markings on the regulator body.

P

F

06462

Flush the System

The regulator was tested in lightweight oil. Flush the

entire system with a solvent compatible with the fluid

being dispensed. Then test the system.

Mounting Bracket

A Mounting Bracket is available for mounting the

regulator. Order Part 222515 for the bracket and

mounting hardware.

6 308647

Page 7

Installation

Grounding the System

WARNING

FIRE AND EXPLOSION HAZARD

Before operating the fluid pressure

regulator, ground the system as

explained below.

Pump: Use a ground wire and clamp. Loosen the

grounding lug locknut (W) and washer (X). Insert one

end of a 1.5 mm@ (12 ga) minimum ground wire (Y)

into the slot in lug (Z) and tighten the locknut securely.

Connect the other end of the wire to a true earth

ground. Order Part 237569 Ground Wire and Clamp.

W

X

Y

Z

0864

Fig. 2

Air and fluid hoses: Use only electrically conductive

hoses.

Heaters, if used: See the heater instruction manual.

Air compressor: Follow manufacturer’s

recommendations.

Spray gun: Ground through connection to a properly

grounded fluid hose and pump.

Fluid supply container: Follow your local code.

Object being sprayed: Follow your local code.

Solvent pails used when flushing: Follow your local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the pail on

a nonconductive surface, such as paper or cardboard,

which interrupts the grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of the spray gun

firmly to the side of a grounded metal pail, then trigger

the gun.

Pressure Relief Procedure

WARNING

SKIN INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you

D Are instructed to relieve the pressure

D Stop spraying

D Check or service any of the system equipment

D Install or clean the spray tips

7308647

Page 8

Operation

Adjusting the System Pressure

CAUTION

D The new system must be cleaned and tested

thoroughly before admitting fluid to the regulator

to avoid contaminants clogging or damaging the

regulator.

D Always use the lowest possible air and fluid

pressures for your application. High pressures

can cause premature spray tip, regulator, and

pump wear.

NOTES:

D The fluid pressure regulator controls pressure

downstream from its outlet.

D If you are using an accessory fluid pressure gauge

(H in Fig. 1), relieve the spray gun line pressure

after you reduce the regulator pressure to ensure a

correct gauge reading.

2. Adjust the pump air pressure and fluid regulator for

the desired spray pattern. Use the lowest possible

air and fluid pressures for your application. For

optimum performance, the inbound fluid pressure

should be at least 500 psi (3.4 MPa, 34 bar) above

the regulated fluid pressure.

NOTE: Do not exceed a 2000 psi (14 MPa,

138 bar) pressure drop between the regulator inlet

and outlet. Excessive pressure drop will cause

premature regulator component wear.

For example: With 3500 psi (24.5 MPa, 245 bar)

to the regulator, the minimum regulated outlet

pressure would be 1500 psi (10.5 MPa, 105 bar).

3. In a circulating system, also adjust the back

pressure valve (K).

4. Record all the settings for future reference.

Cleaning the Regulator

1. Make a note of the proper way to adjust pressure,

from the following descriptions:

D On a spring-operated regulator, turn the

adjusting screw (10) counterclockwise to

decrease pressure and clockwise to increase

pressure to the spray gun or extruder gun.

D On an air-operated regulator, increase supply

air pressure to increase fluid pressure.

Decrease supply air pressure to decrease fluid

pressure. Supply air up to 100 psi (0.7 MPa,

7 bar). See the chart on page 20 for air versus

fluid pressure.

NOTE: Air-operated regulator Models 238893 and

238894 are provided with an air supply regulator

(31) to control the fluid set pressure. For

increased sensitivity in pressure set point

performance, an alternative air regulator, such as

Part 206197, may be used. This alternative air

regulator uses a sensitive diaphragm design to

maintain a higher, more accurate air pressure

setting.

Do not allow fluid to settle in the system.

Flush the regulator whenever the rest of the system is

flushed (see page 9). Before you flush the system,

follow the Pressure Relief Procedure on page 7,

then completely decrease the regulated fluid pressure.

See step 1 in Adjusting the System Pressure, at left.

Before you remove the regulator for thorough cleaning

and inspection, follow the Pressure Relief Procedure

on page 7. Then remove the regulator, clean it, and

inspect all parts.

8 308647

Page 9

Operation

Flushing

D Flush before changing colors, before fluid can dry in

the equipment, at the end of the day, before storing,

and before repairing equipment.

D Flush at the lowest pressure possible. Check

connectors for leaks and tighten as necessary.

D Flush with a fluid that is compatible with the fluid

being dispensed and the equipment wetted parts.

1. Record the pressure adjustment setting of the fluid

regulator before flushing.

2. Shut off the pump and relieve fluid pressure in the

system by triggering the gun and opening the back

pressure regulator or other bypass valve.

3. Never exceed the maximum working pressure of

the lowest rated system component. Remove the

gauge if the flushing pressure will exceed the

gauge range.

4. Open the fluid regulator fully.

a. Spring Operated Regulators Only: Open the

fluid regulator by turning the adjusting screw

(10) fully clockwise.

b. Air Operated Regulator Only: Increase the air

regulator setting to fully open the fluid

regulator. You will have to reset the fluid

regulator’s pressure setting after flushing.

5. Supply solvent to the system. Set pump to the

lowest possible pressure, and start pump.

6. Flush until thoroughly clean.

7. Adjust the fluid regulator to the desired setting.

a. Spring Operated Regulators Only: Turn the

adjustment screw (10) counterclockwise to

return to the desired pressure setting.

b. Air Operated Regulator Only: Adjust the air

regulator to return to the desired fluid pressure

setting.

9308647

Page 10

Troubleshooting

WARNING

To reduce the risk of serious bodily injury, including

skin injection, splashing in the eyes or on the skin,

or injury from moving parts, always follow the Pres-

sure Relief Procedure on page 5 whenever the

pump is shut off, before installing, cleaning, adjusting, removing, or servicing the valve or any part of

the system, and whenever you stop dispensing.

NOTE: Check all possible solutions in the chart below

before you disassemble the regulator.

Problem

No pressure regulation Damaged diaphragm Replace diaphragm.

No fluid flow Damaged valve actuator Replace valve actuator.

Pressure creeps above

setting

Pressure drops below

setting

Cause Solution

Leaking or dirty seat Replace cartridge, or clean seat.

Metal chip or contamination

between ball and seat

Damaged diaphragm Replace diaphragm.

Damaged o-ring or improper seal Replace the o-ring under the seat.

Damaged or clogged air regulator or

line (air-operated regulator only)

Leaking or dirty seat Replace cartridge, or clean seat.

Large change in inlet pressure Stabilize regulator inlet pressure.

Empty/clogged supply line Fill/flush supply line.

Damaged or clogged air regulator or

line (air-operated regulator only)

Replace cartridge, or clean seat area.

Clear obstruction in line. Service regulator if necessary.

Clear obstruction in line. Service regulator if necessary.

Using valve beyond its rated flow

capacity

Large change in inlet pressure Stabilize regulator inlet pressure.

Fluid leaks from spring

housing

Chatter Excessive pressure differential

10 308647

Loose fluid housing Tighten the four cap screws.

Damaged diaphragm Replace diaphragm.

between pump and gun

Excessive flow rate Reduce fluid flow through regulator.

Install valve for each spray gun or

dispensing valve.

Reduce pump pressure to not more than

2000 psi (14 MPa, 138 bar) greater than

required gun pressure.

Connect only one spray gun or dispensing valve to each fluid regulator.

Page 11

Service

Service Kits

For the Fluid Diaphragm Repair Kit, order Part 238747.

Parts included in this kit are marked with an asterisk,

for example (7*), in the Parts Drawings and Lists on

pages 14 and 16.

For the Cartridge Repair Kit, order Part 238748 for all

models except 248090. Parts included in this kit are

marked with a dagger, for example (3{), in the Parts

Drawings and Lists on pages 14 and 16.

For the Cartridge Repair Kit for 248090, order Part

248098. Parts included in this kit are marked with a

checkmark, for example (3n), in the Parts Drawings

and Lists on pages 14 and 16.

To convert from a spring-operated to an air-operated

regulator, order the Air-Operated Conversion Kit, Part

238749. Parts included in this kit are marked with a

double dagger, for example (37}), in the Parts

Drawings and Lists on pages 14 and 16.

NOTE: To convert from a medium-pressure-range,

spring-operated model to a high-pressure-range,

spring-operated model (or vice versa), order the

appropriate spring (11) from the Parts List on

page 15.

Installing the Air-Operated Conversion Kit

(See Parts Drawings on pages 14–16)

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

2. On the spring-operated regulator, turn the

adjusting screw (10) counterclockwise until it is

loose enough to fully relieve the spring tension.

3. Use a strap wrench or an equivalent wrench to

loosen and remove the spring cover (2), spring

retainers (6 and 27), and spring (11).

4. Place the stabilizing spring (22) of the air-operated

regulator on the piston rod (6). Install the

conversion kit assembly onto the backing plate (8).

Torque to 15 to 20 ft-lb (20 to 27 NSm).

5. Plumb an air line up to the 1/4 npt(m) threads of

the nipple (35) on the air regulator.

6. Flush the system (see page 9), and set the

regulator pressure by following the procedure in

Adjusting the System Pressure on page 8.

11308647

Page 12

Service

Replacing the Fluid Diaphragms

See Fig. 3, and follow the steps below. For parts that

are not called out in Fig. 3, see the Parts Drawing on

page 14.

1. Relieve the pressure, and remove the regulator

from the fluid line.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

2. Turn the adjusting screw (10) counterclockwise

until it is loose to fully relieve the spring tension.

3. Remove the four base housing screws (9) from the

base housing (4), and pull the base housing free of

the backing plate (8).

4. Remove the diaphragm and valve actuator

subassembly (1, 7, 12, 13, and 19).

5. Clean and inspect the bore in the backing plate (8)

for wear, and replace it if necessary.

6. Remove the o-ring (17) from the groove in the

base housing (4), clean and inspect the base

housing, and replace if necessary.

7. Install a new o-ring (17) in the groove in the base

housing (4).

8. Lightly lubricate the backing plate (8) bore and

plunger (7) with a lithium-based grease.

9. Install the new, pre-assembled diaphragm

subassembly into the backing plate (8).

NOTE: The diaphragms will have a bow in them

before you install them.

10. Align the holes in the diaphragms with the backing

plate (8).

11. Install the backing plate/diaphragms assembly

over the base housing (4). Hold the backing plate

(8) tightly against the base housing, and install the

four base housing screws (9).

12. Torque the base housing screws (9) first to 20 to

25 ft-lb (27 to 34 NSm), then to 30 to 35 ft-lb (41 to

48 NSm) in the sequence shown in Fig. 3.

2

backing

plate (8)

diaphragm

and valve

actuator

subassembly

Fig. 3

10

cartridge

assembly

Torque Sequence for Regulator

17

3

5

Base Housing Screws (9)

4

4

2

9

1

3

06656

12 308647

Page 13

Service

Replacing the Cartridge

See Fig. 3, and follow the steps below. For parts that

are not called out in Fig. 3, see the Parts Drawing on

page 14.

CAUTION

Handle the hard carbide parts, which are the ball

(16), valve actuator (1), and valve seat (14), carefully

to avoid damaging them.

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

2. Remove the cartridge assembly by loosening the

valve housing (5) with a 6 mm hex wrench and

pulling the cartridge assembly out of the base

housing (4).

NOTE: The retaining nut (3) often loosens when

removing the cartridge assembly from the base

housing. Be sure to re–torque as described in

step 4.

3. Inspect and clean the internal walls of the base

housing (4).

NOTE: Be careful that you do not scrape or

gouge the internal walls of the base housing,

because they are sealing surfaces.

4. Re-torque the retaining nut (3) to 140 to 160 in-lb

(16 to 18 NSm).

NOTE: You must re-torque the retaining nut

before you install it in the base housing in step 5.

5. Install the new cartridge assembly in the base

housing (4), and torque the valve housing (5) to 30

to 35 ft-lb (41 to 48 NSm).

NOTE: The valve seat (14) is double sided and

may be reversed for extended life. The o-rings

(15, 18 and 20) and ball (16) must be replaced.

13308647

Page 14

Parts Drawing

Models 238889, 238890, 238891, and 238892

238889 with EZ Flush gauge port plug

238890 with fluid pressure gauge

Spring-Operated Regulator

500 to 3000 psi (3.4 to 21 MPa, 34 to 207 bar)

Regulated Fluid Outlet Pressure

10

6

2

3

6

27

238891 with EZ Flush gauge port plug

238892 with fluid pressure gauge

Spring-Operated Regulator

3000 to 5000 psi (21 to 34 MPa, 207 to 345 bar)

Regulated Fluid Outlet Pressure

7*

6

12*

13*

19*

1*

1

17*

29

30

4

6

11

6

8

DETAIL

Torque Sequence for Regulator

Base Housing Screws (9)

4

2

1

3

3{

2

14{

15{

28

9

5

20{

18{

7

7

16{

21{

5{

4

06289

Torque to 25 to 30 in-lb (2.8 to 3.4 NSm).

1

Torque to 140 to 160 in-lb (16 to 18 NSm).

2

Torque to 10 to 20 ft-lb (14 to 27 NSm).

3

Torque to 30 to 35 ft-lb (41 to 48 NSm).

4

Torque first to 20 to 25 ft-lb (27 to 34 NSm), then to 30 to 35

5

ft-lb (41 to 48 NSm) in the sequence shown in DETAIL at left.

Apply lithium-based grease when reassembling.

6

Apply a fluid-compatible grease to aid in reassembly.

7

14 308647

Page 15

Parts List

Models 238889, 238890, 238891, and 238892

Ref. Part No. Description Qty.

1 * ACTUATOR 1

2 238858 COVER, spring 1

3{ 191577 NUT, spring retainer 1

4 191578 BASE HOUSING; sst 1

5{ 191579 VALVE HOUSING; sst 1

6 191580 RETAINER, spring, guide 1

7 * PLUNGER, spring 1

8 191583 PLATE, backing 1

9 113623 BASE HOUSING SCREW,

cap, socket-head; M10 x 1.5 x 70 4

10 113624 ADJUSTING SCREW, cap,

socket-head; M8 x 1.25 x 45 1

11} 113625 SPRING, compression; red

for Models 238889 & 238890 1

113626 SPRING, compression; yellow

for Models 238891 & 238892 1

12 * DIAPHRAGM, regulator; TPE

cream colored 1

13 * DIAPHRAGM, regulator; PTFE

white 1

14{ 191914 SEAT, valve 1

15{ 113651 O-RING, packing; PTFE 1

16{ 112365 BALL 1

17* 109213 O-RING, packing; PTFE 025 1

Ref. Part No. Description Qty.

18{ 107079 O-RING, packing; PTFE 019 1

19 * O-RING, packing; PTFE 013 1

20{ 109450 O-RING, packing; PTFE 016 1

21{ 111858 SPRING, compression 1

23 113634 WRENCH, hex; 6 mm

(not shown) 1

27 191919 RETAINER, spring, sleeve 1

28 113641 GAUGE, pressure

for Model 238890 1

113654 GAUGE, pressure

for Model 238892 1

29 238896 PLUG, EZ Flush (includes Ref. 30)

for Models 238889 & 238891 1

30 107509 O-RING, packing; PTFE 007 1

* Included in Fluid Diaphragm Repair Kit 238747

{ Included in Cartridge Repair Kit 238748

} To convert to a higher or lower pressure range,

order one of the following compression springs:

113625 500 to 3000 psi

(3.4 to 21 MPa, 34 to 207 bar

113626 3000 to 5000 psi

(21 to 34 MPa, 207 to 345 bar)

15308647

Page 16

Parts Drawing

Models 238893, 238894, 248090, and 255072

}33

}28

8

}36

}37

}30

40

}35

}31

}34

32}

11}

238893 with EZ Flush gauge port plug

238894 with fluid pressure gauge

}2

3

248090 with fluid pressure gauge for

LASD material

255072 High Resolution

6

7

}6

Air-Operated Regulator

100 psi (0.7 MPa, 7 bar)

Maximum Inbound Air Pressure

500 to 4000 psi (3.4 to 28 MPa, 34 to 276 bar)

}22

Regulated Fluid Outlet Pressure

8

7*

7

12*

13*

19*

DETAIL OF MODEL 248090

41

42

4

39

1*

17*

1

38

4

42

41

}29

3

DETAIL

Torque Sequence for Regulator

Base Housing Screws (9)

4

2

1

3

25

3{n

2

14{n

15{n

20{n

5

9

18{n

7

7

25

16{n

21{n

5{n

4

06287

Torque to 25 to 30 in-lb (2.8 to 3.4 NSm).

1

Torque to 140 to 160 in-lb (16 to 18 NSm).

2

Torque to 15 to 20 ft-lb (20 to 27 NSm).

3

4

Torque to 30 to 35 ft-lb (41 to 48 NSm).

Torque first to 20 to 25 ft-lb (27 to 34 NSm), then to 30 to 35

5

ft-lb (41 to 48 NSm) in the sequence shown in DETAIL at left.

First torque to 30–33 in-lb (3.4–3.7 NSm) in alternating pattern

6

then torque to 68–72 in-lb (7.7–8.1 NSm) in alternating pattern.

Apply lithium-based grease when reassembling.

7

Torque to 75 to 80 in-lb (8.4 to 9.0 NSm).

8

16 308647

Page 17

Parts List

Models 238893, 238894, 248090, and 255072

Ref.

No. Part No. Description Qty.

1 * ACTUATOR 1

2} 191584 HOUSING ADAPTER 1

3{n 191577 NUT, spring retainer 1

4 191578 HOUSING, base, for Models

238893 and 238894 1

197952 HOUSING, base,

for Model 248090 1

15J923 HOUSING, base,

for Model 255072 1

5{n 191579 VALVE HOUSING, sst 1

15J924 VALVE HOUSING,

for Model 255072 1

6} 191585 ROD, piston, for Models 238893,

238894, and 248090 1

15J920 ROD, piston, for Model 255072 1

7 * PLUNGER, spring 1

8 191583 PLATE, backing 1

9 113623 BASE HOUSING SCREW,

cap, socket-head; M10 x 1.5 x 70 4

11}z 114104 SCREW, machine 12

12 * DIAPHRAGM, regulator; TPE

cream colored 1

13 * DIAPHRAGM, regulator; PTFE 1

white 1

14{n 191914 SEAT, valve 1

15{n 113651 O-RING, packing; PTFE 1

16{ 112365 BALL, for Models 238893 and

238894 1

16n 15D092 BALL, for Models 248090 and

255072 1

17* 109213 O-RING, packing; PTFE 025 1

18{n 107079 O-RING, packing; PTFE 019 1

19 * O-RING, packing; PTFE 013 1

20{n 109450 O-RING, packing; PTFE 016 1

Ref.

No. Part No. Description Qty.

21{n 111858 SPRING, compression 1

22} 160062 SPRING, stabilizing 1

25 113654 GAUGE, pressure

for Models 238894 and 248090 1

28}z ––– COVER, diaphragm 1

29}z ––– HOUSING, diaphragm 1

30} 100326 SCREW, machine 1

31} 110341 REGULATOR, air 1

32} 100403 PLUG, pipe 1

33} 108190 GAUGE, pressure, air 1

34} 103656 NIPPLE, pipe, hex 1

35} 151519 NIPPLE, reducing; 1/4 x 1/8 npt 1

36} 192194 WASHER, support 1

15J921 WASHER, for Model 255072 1

37}z 180979 DIAPHRAGM; nylon, for Models

238893, 238894, and 248090 1

38 238896 PLUG, EZ Flush (includes Ref. 39)

for Model 238893 1

39 107509 O-RING, packing; PTFE 007

for Model 238893 1

40 15J922 RING, diaphragm,

for Model 255072 1

41 198241 PLUG, pressure for Models

248090 and 255072 2

42 111457 PACKING, o-ring; PTFE 012 for

Models 248090 and 255072 2

* Included in Fluid Diaphragm Repair Kit 238747

{ Included in Cartridge Repair Kit 238748

} Included in Air-Operated Conversion Kit 238749

n Included in Cartridge Repair Kit 248098

z Included in Diaphragm Housing Repair Kit

16P596.

17308647

Page 18

Parts Drawing

Model 244734

40

11}

}28

244734 with EZ Flush gauge port plug

5

Air-Operated Regulator, Full Range

100 psi (0.7 MPa, 7 bar)

Maximum Inbound Air Pressure

500 to 4000 psi (3.4 to 28 MPa, 34 to 276 bar)

Regulated Fluid Outlet Pressure

}37

}30

8

8

}36

7*

6

}29

3

12*

13*

}2

3

6

}6

}22

Torque to 25 to 30 in-lb (2.8 to 3.4 NSm).

1

Torque to 140 to 160 in-lb (16 to 18 NSm).

2

Torque to 15 to 20 ft-lb (20 to 27 NSm).

3

4

Torque to 30 to 35 ft-lb (41 to 48 NSm).

First torque to 30–33 in-lb (3.4–3.7 NSm) in alternating pattern

5

then torque to 68–72 in-lb (7.7–8.1 NSm) in alternating pattern.

Apply lithium-based grease when reassembling.

6

Torque first to 20 to 25 ft-lb (27 to 34 NSm), then to 30 to 35

7

ft-lb (41 to 48 NSm) in the sequence shown in DETAIL at right.

Torque to 75 to 80 in-lb (8.4 to 9.0 NSm).

8

38

41

1*

42

39

3{

7

9

20{

18{

16{

5{

Torque Sequence for Regulator

Base Housing Screws (9)

DETAIL

2

19*

17*

14{

15{

21{

1

4

42

41

2

6

6

4

TI1373

3

18 308647

4

1

Page 19

Parts List

Model 244734

Ref.

No. Part No. Description Qty.

1 * ACTUATOR 1

2} 191584 HOUSING ADAPTER 1

3{ 191577 NUT, spring retainer 1

4 197952 REGULATOR HOUSING 1

5{ 191579 VALVE HOUSING; sst 1

6} 191585 ROD, piston 1

7 * PLUNGER, spring 1

8 191583 PLATE, backing 1

9 113623 BASE HOUSING SCREW,

cap, socket-head; M10 x 1.5 x 70 4

11}z 114104 SCREW, machine; 1/4–20 x 1.0 12

12 * DIAPHRAGM, regulator; PTE

cream colored 1

13 * DIAPHRAGM, regulator; PTFE

white 1

14{ 191914 SEAT, valve 1

15{ 113651 O-RING, packing; PTFE 1

16{ 15D092 BALL 1

17* 109213 O-RING, packing; PTFE 025 1

Ref.

No. Part No. Description Qty.

18{ 107079 O-RING, packing; PTFE 019 1

19 * O-RING, packing; PTFE 013 1

20{ 109450 O-RING, packing; PTFE 016 1

21{ 111858 SPRING, compression 1

22} 160062 SPRING, stabilizing 1

28}z ––– COVER, diaphragm 1

29}z ––– HOUSING, diaphragm 1

30} 100326 SCREW, machine; 1/4–20 x 1/2 1

36} 192194 WASHER, support 1

37}z 180979 DIAPHRAGM; nylon 1

38 238896 PLUG, EZ Flush (includes Ref. 39) 1

39 107509 O-RING, packing; PTFE 007 1

40 198171 FITTING, elbow 1

41 198241 PLUG, pressure 2

42 111457 PACKING, o-ring; PTFE 012 2

* Included in Fluid Diaphragm Repair Kit 238747

{ Included in Cartridge Repair Kit 248098

} Included in Air-Operated Conversion Kit 238749

z Included in Diaphragm Housing Repair Kit

16P596.

19308647

Page 20

Technical Data

fluid

Model 238890

spring operated, with

fluid pressure gauge

Model 238889

spring operated, with

EZ Flush plug

Maximum fluid

inlet pressure

Regulated fluid

outlet pressure

range

Maximum inbound

air pressure

Fluid inlet/outlet

size

Gauge port size 1/4 npt(f) 1/4 npt(f) 1/4 npt(f) 1/4 npt(f)

Fluid pressure

gauge (Models

238890, 238892,

and 238894)

Maximum flow

(in 65 cp material)

Maximum fluid

viscosity

Maximum operating temperature

Weight (with gauge) 7.0 lb (3.2 kg) 7.0 lb (3.2 kg) 11.7 lb (5.3 kg) 11.7 lb (5.3 kg)

Fluid diaphragms PTFE with TPE

Wetted parts (all

models)

Adjustment tool

(spring-operated

models)

6000 psi

(41 MPa, 414 bar)

500–3000 psi

(3.4–21 MPa,

34–207 bar)

–– –– 100 psi

3/8 npt(f) 3/8 npt(f) 3/8 npt(f)

0–3000 psi

(0–21 MPa,

0–207 bar)

2 gpm (7.6 lpm) 2 gpm (7.6 lpm) 2 gpm (7.6 lpm) 2 gpm (7.6 lpm)

up to 15,000 cp up to 15,000 cp up to 15,000 cp up to 15,000 cp

120_ F (50_ C) 120_ F (50_ C) 120_ F (50_ C) 120_ F (50_ C)

backing

304, 316, 17–4 passivated SST, nickel– and cobalt–bound tungsten carbide, PTFE for all

models; ceramic for model 248090, 244734, and 255072 only.

6 mm hex wrench 6 mm hex wrench –– ––

Model 238892

spring operated, with

fluid pressure gauge

Model 238891

spring operated, with

EZ Flush plug

6000 psi

(41 MPa, 414 bar)

3000–5000 psi

(21–34 MPa,

207–345 bar)

0–5000 psi

(0–34 MPa,

0–345 bar)

PTFE with TPE

backing

Models 238894,

248090, and 255072

air operated, with

pressure gauge

Model 238893

air operated, with EZ

Flush plug

6000 psi

(41 MPa, 414 bar)

500–4000 psi

(3.4–28 MPa,

34–276 bar)

(0.7 MPa, 7 bar)

1/2 npt(f) for 248090

0–5000 psi

(0–34 MPa,

0–345 bar)

PTFE with TPE

backing

Model 244734

air operated, with

pressure sensor

ports

6000 psi

(41 MPa, 414 bar)

500–4000 psi

(3.4–28 MPa,

34–276 bar)

100 psi

(0.7 MPa, 7 bar)

1/2 npt(f)

––

PTFE with TPE

backing

Air Requirements for Air-Operated Regulators

(Models 238893, 238894, 248090, and 255072)

The following table shows the approximate air pressure needed to regulate the air-operated regulator to a given

fluid outlet pressure.

Regulated Fluid Outlet Pressure

Models 238894, 248090,

and 255072 Model 255072

20 308647

Air Pressure

psi MPa bar psi MPa bar psi MPa bar

28 0.19 1.9 1000 7 69 550 4 40

49 0.34 3.4 2000 14 138 1150 8 80

70 0.48 4.8 3000 21 207 1800 12 120

90 0.62 6.2 4000 28 276 2450 17 170

100 0.68 6.8 4000 28 276 2700 19 190

Page 21

psi

(MPa, bar)

6000

(41, 414)

5000

(34, 345)

4000

(28, 276)

3000

(21, 207)

Performance Chart

Fluid Pressure Regulators,

Models 238889 through 238894 and 248090

2000

(14, 138)

REGULATED (outbound) FLUID PRESSURE

1000

(7, 69)

0

0.0 0.5 1.0 1.5 2.0

gpm

(lpm)

(1.9)

Test Conditions

Regulators tested in oil at 70_ F (21_ C) and at

6000 psi (41 MPa, 414 bar) inbound fluid pressure.

(3.8) (5.7) (7.6)

FLUID FLOW

Key

65 cp oil

3000 cp oil

21308647

Page 22

Notes

22 308647

Page 23

Dimensional Drawings

Models 238889 and 238891 with port plug

Models 238890 and 238892 with gauge

(spring operated)

3/8 npt

inlet

port

3/8 npt

outlet

port

1/4 npt

gauge

A

port

B

06290

1/4–20 UNC mounting holes,

1/2 in. (12 mm) deep (both sides)

Model 238893 with port plug

Model 238894 with gauge

Models 248090 and 255072 with gauge and

1/2 npt inlet and outlet ports

(air operated)

A Height: 10.0 in. (254 mm)

B Diameter of diaphragm cover: 7.0 in. (179 mm)

A Height: 8.9 in. (225 mm)

B Diameter of base housing: 2.65 in. (70 mm)

Model 244734

(air operated)

A Height: 8.1 in. (206 mm)

B Diameter of diaphragm cover: 7.0 in. (179 mm)

3/8 npt

(1/2 npt for

248090)

inlet port

A

B

06288

1/4 npt

gauge port

1/4–20 UNC mounting holes,

1/2 in. (12 mm) deep (both sides)

3/8 npt

(1/2 npt for 248090)

outlet port

A

1/2 npt

outlet

port

B

TI1372

1/4–20 UNC mounting holes,

1/2 in. (12 mm) deep (both sides)

1/2 npt

inlet port

23308647

Page 24

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from

defects in material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended,

or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the

equipment determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained

in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD

BUT NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches,

hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in

making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures

judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 308647

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES S P.O. BOX 1441 S MINNEAPOLIS MN 55440–1441 S USA

Copyright 1997, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

www.graco.com

Revised April 2012

24 308647

Loading...

Loading...