Page 1

INSTRUCTIONS-PARTS LIST

308645

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

Rev. D

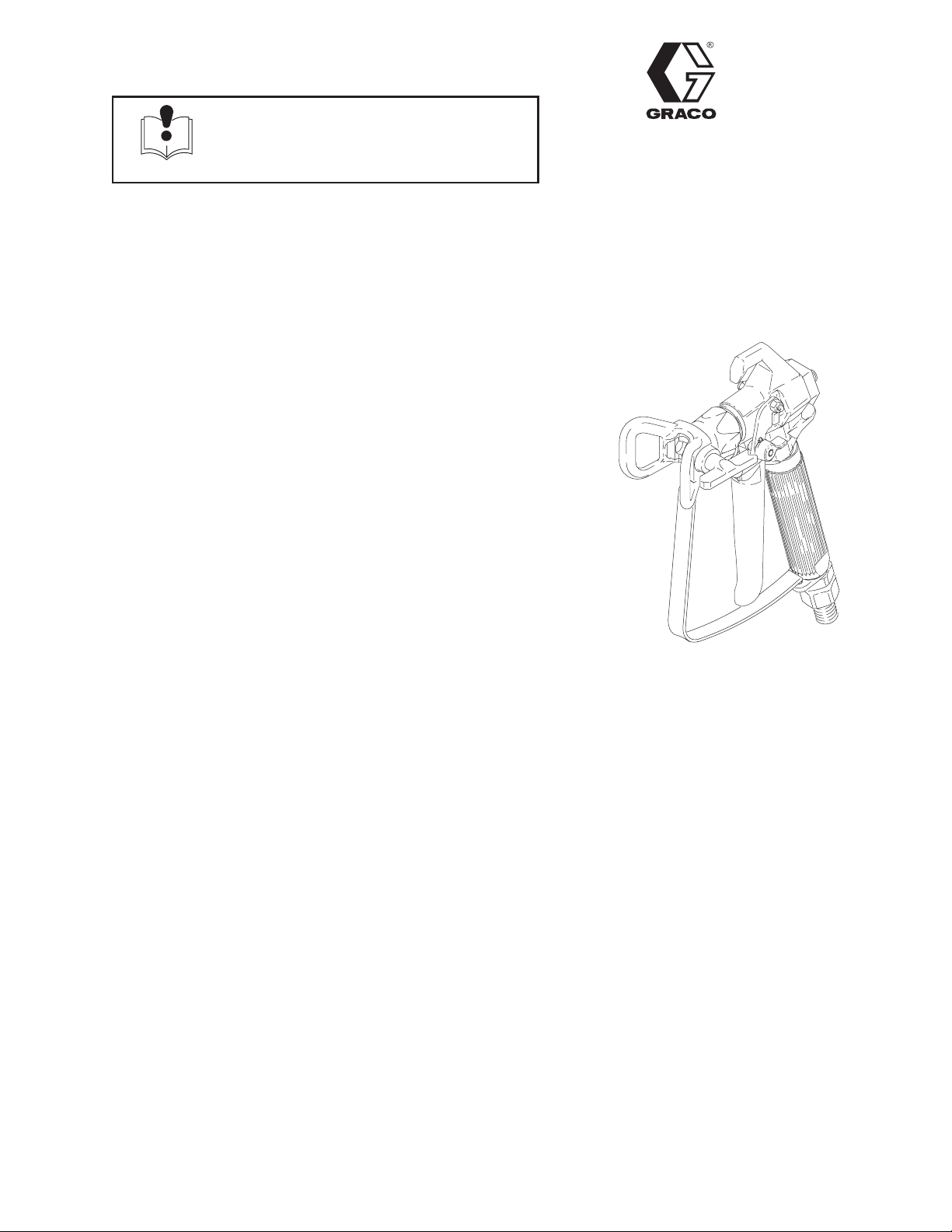

Contractor FTx Airless Spray Gun

3600 psi (252 bar) MAXIMUM WORKING PRESSURE

Model 238350, Series A

Includes RACr DripLesst Guard, 515 size

SwitchTipt, and 4-finger trigger.

Model 824004, Series A

Includes RACr DripLesst Guard, 515 size

SwitchTipt, and 4-finger trigger.

Model 239045, Series A

Includes Flat Tip Guard and 4-finger trigger.

Models 238350, 824004

05963

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 1996, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Table of Contents

Symbols

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation/Operation 5. . . . . . . . . . . . . . . . . . . . . . . . . . .

System Requirements 5. . . . . . . . . . . . . . . . . . . . . . . . . .

How to Use the Trigger Safety Latch 5. . . . . . . . . . . . .

How to Use the Gun 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Adjust the Spray Pattern 6. . . . . . . . . . . . . . . . . .

How to Clean the Spray Tip

and Clear a Spray Tip Obstruction 7. . . . . . . . . . . .

How to Clean the Filter 8. . . . . . . . . . . . . . . . . . . . . . . . . .

Service 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 15. . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Warranty 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

D This equipment is for professional use only.

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

Technical Data on page 15 for the maximum working pressure of this equipment.

D Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Do not use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

D Do not use hoses to pull equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 66_C (150_F) or below –40_C (–40_F).

D Wear hearing protection when operating this equipment.

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

2 308645

Page 3

WARNING

INJECTION HAZARD

Spray from the gun, leaks or ruptured components can inject fluid into your body and cause extremely

serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also

cause serious injury.

D Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi-

cal attention.

D Do not point the gun at anyone or at any part of the body.

D Do not put your hand or fingers over the spray tip.

D Do not stop or deflect leaks with your hand, body, glove or rag.

D Do not “blow back” fluid; this is not an air spray system.

D Always have the tip guard and the trigger guard on the gun when spraying.

D Check the gun diffuser operation weekly. See page 8.

D Be sure the gun trigger safety operates before spraying.

D Lock the gun trigger safety when you stop spraying.

D Follow the Pressure Relief Procedure on page 5 if the spray tip clogs and before cleaning,

checking or servicing the equipment.

D Tighten all fluid connections before operating the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

Do not repair high pressure couplings; you must replace the entire hose.

D Fluid hoses must have spring guards on both ends, to help protect them from rupture caused by

kinks or bends near the couplings.

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers.

D Keep clear of all moving parts when starting or operating the pump.

D Before servicing the equipment, follow the Pressure Relief Procedure on page 5 to prevent the

equipment from starting unexpectedly.

RECOIL HAZARD

Due to the high pressure fluid emitted, a strong recoil action may occur when you trigger this gun. If

you are unprepared, your hand could be forced back toward your body or you could lose your balance

and fall, resulting in serious injury.

308645 3

Page 4

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D If there is any static sparking or you feel an electric shock while using this equipment, stop spray-

ing immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

D Keep the spray area free of debris, including solvent, rags, and gasoline.

D Electrically disconnect all equipment in the spray area.

D Extinguish all open flames or pilot lights in the spray area.

D Do not smoke in the spray area.

D Do not turn on or off any light switch in the spray area while operating or if fumes are present.

D Do not operate a gasoline engine in the spray area.

D Ground the equipment and the object being sprayed. Refer to your pump instruction manual.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

4 308645

Page 5

Installation/Operation

System Requirements

WARNING

Keep the wallet-sized warning card provided with

this gun with the operator at all times. The card

contains important treatment information should an

injection injury occur. Additional cards are available

at no charge from Graco Inc.

WARNING

Be sure your system has a bleed-type master air

valve (pneumatic pumps only) and a pressure drain

valve. These accessories help reduce the risk of

serious bodily injury, including fluid injection,

splashing in the eyes or on the skin, or injury from

moving parts, if you are adjusting or repairing the

pump or gun.

1. The bleed-type master air valve (air-powered

pumps only) relieves air trapped between this

valve and the pump after the air regulator is shut

off. Trapped air can cause the pump to cycle

unexpectedly.

Pressure Relief Procedure

1. Engage the gun safety latch.

2. Turn the ON/OFF switch to OFF.

3. Unplug the power supply cord.

4. Disengage the gun safety latch. Hold a metal part

of the gun firmly to a grounded metal pail. Trigger

the gun to relieve pressure.

5. Engage the gun safety latch.

6. Open the system pressure drain valve. Leave the

pressure drain valve open until you are ready to

spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, VERY SLOWLY loos-

en the tip guard retaining nut or hose end coupling to

relieve pressure gradually, then loosen completely.

Now clear the tip or hose obstruction.

How to Use the Gun Trigger Safety

2. The pressure drain valve assists in relieving fluid

pressure in the displacement pump, hose and gun:

triggering the gun to relieve pressure may not be

sufficient.

3. Strain the fluid you are spraying if it contains

particles which could clog the spray tip.

Grounding

To reduce the risk of static sparking, ground the sprayer and all other spray equipment used or located in the

spray area. Check your local electrical code for detailed grounding instructions for your area and type of

equipment.

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you:

D are instructed to relieve the pressure,

D stop spraying,

D check or service any of the system equipment,

D or install or clean the spray tip.

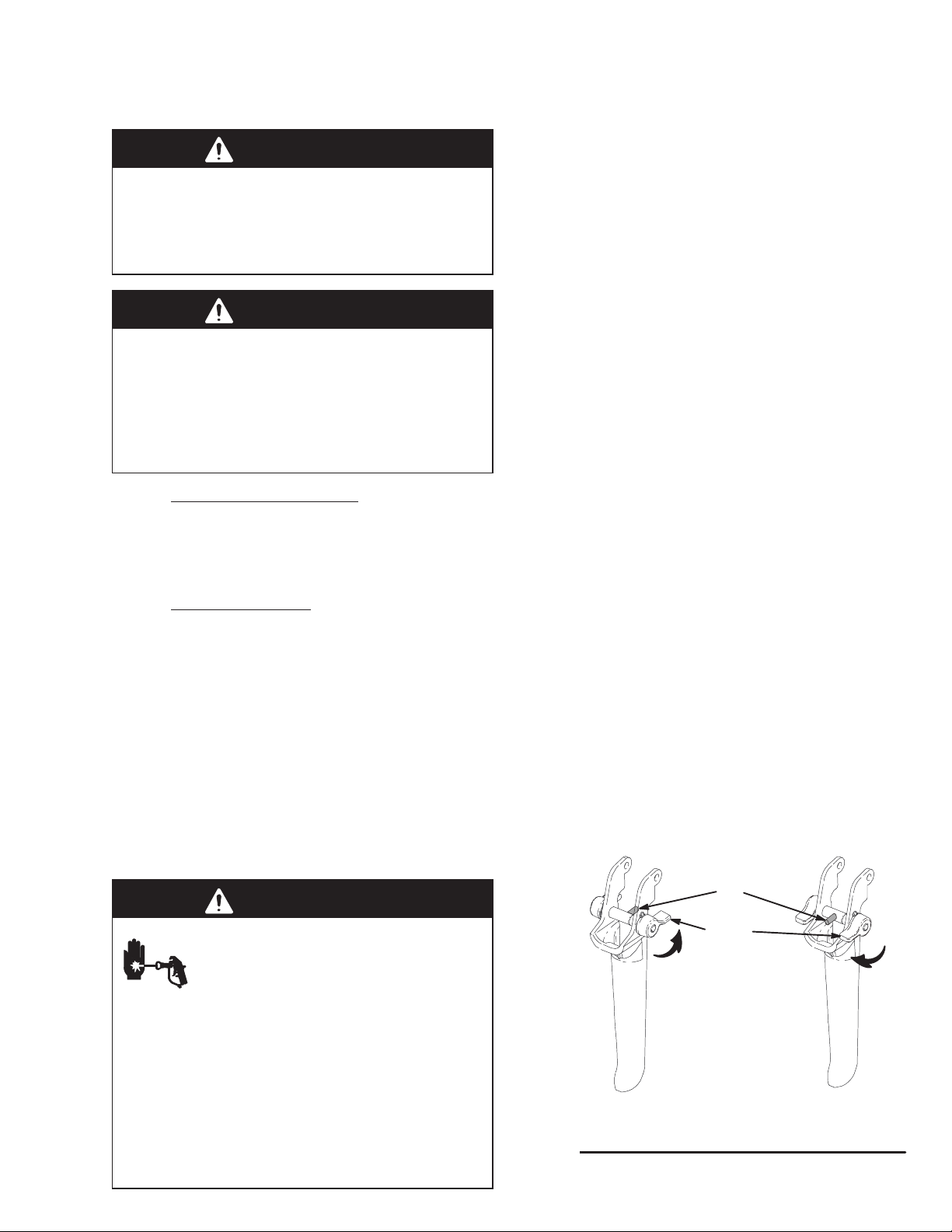

1. To engage the gun trigger safety, turn the latch

counterclockwise toward the handle until the

detent of the latch locks on and the pin is at a right

angle with the gun body. See Fig. 1.

2. To disengage the gun trigger safety, turn the latch

clockwise away from the handle to unlock the

detent of the latch and turn the pin 180_ from the

gun body.

PIN

LATCH

ENGAGED DISENGAGED

Fig. 1

308645 5

05964

Page 6

Installation/Operation

How to Use the Gun

1. Connect a grounded fluid hose to the gun inlet.

See Fig. 2

2. With no tip installed, start the pump. Flush the

pump according to the instructions supplied with it.

Prime the system with the fluid.

3. Follow the Pressure Relief Procedure on

page 5. Be sure the gun trigger safety is engaged. See Fig. 1.

4. Graco Flat Tip Style Driplesst Guard

Install the tip (A) and the gasket (B) in the nut of

the tip guard (C). Screw the assembly firmly onto

the gun. Tighten the assembly with a wrench. See

Fig. 2.

NOTE: If the gasket (B) is not installed, the gun

will leak.

5. Reverse-A-Clean (RAC) IV Models 238350 and

824004

Install the RAC IV SwitchTip (40) and the tip guard

(41). See manual 308644, supplied. See Fig. 2.

7. If adjusting the pressure does not give a good

spray pattern, follow the Pressure Relief Proce-

dure on page 5 and then try another tip size.

8. Use a full-open, full-close triggering action. Hold

the gun about 12 in. (350 mm) from and at right

angles to the work surface. Don’t swing the gun in

an arc. Practice to find the best length and speed

of stroke.

How to Adjust the Spray Pattern

1. To adjust the spray pattern direction, follow the

Pressure Relief Procedure on page 5. Loosen

the tip guard retaining nut (B). Turn the tip guard/

tip groove horizontally (C) for a horizontal pattern

and vertically (A) for a vertical pattern. Tighten the

nut. See Fig. 3.

2. The spray tip orifice and spray angle determines

the coverage and size of pattern. When more

coverage is needed, use a larger spray tip rather

than increasing fluid pressure.

41

40

05965

B

A

C

Fig. 2

6. Start the pump. Adjust the fluid pressure until the

spray is completely atomized. Use the lowest

pressure necessary to get the desired results.

Higher pressure may not improve the spray pattern

and will cause premature tip wear and pump wear.

CAUTION

The openings in the tip guard reduce paint buildup on

the tip guard while spraying. Any damage to the

sharp edges of the openings causes paint to collect

at that area. Never hang the gun by the tip guard.

KEY

A Tip guard shown in position for

vertical spray pattern

B Retaining nut

C Tip guard shown in position for

horizontal spray pattern

B

A

A

Fig. 3

C

05971

6 308645

Page 7

Installation/Operation

How to Clean the Spray Tip

and Clear a Spray Tip Obstruction

WARNING

To reduce the risk of fluid injection or splashing in

the eyes or on the skin, do not hold a hand, body

or rag in front of the spray tip when cleaning or

checking a clogged tip. Point the gun toward the

ground or into a waste container when checking to

see if the spray tip is cleared.

DO NOT try to “blow back” paint; this is NOT an air

spray gun.

DO NOT wipe fluid buildup off the gun or spray tip

until pressure is relieved.

Cleaning during the day.

1. Follow Pressure Relief Procedure on page 5.

2. Clean the front of the tip frequently during the day

to help reduce buildup. Also clean the tip and tip

guard at the end of each work day. Use a solventsoaked brush to clean the spray tip.

2. Remove the spray tip and blow out the obstruction

by applying air to the front of the spray tip. Or, let

the spray tip and gun nozzle soak to dissolve the

obstruction. If it won’t dissolve, jar it out by tapping

the back of the spray tip against a flat surface.

Gun with RAC IV Tip and Guard; Models 238350 and

824004

1. Lock the gun trigger safety. Rotate the RAC IV tip

handle 180_. See Fig. 4.

2. Unlock the gun trigger safety. Trigger the gun into

a pail or onto the ground to remove the clog.

3. Lock the gun trigger safety. Rotate the tip handle

to the spraying position.

4. If the tip is still clogged, lock the gun trigger safety,

shut off the sprayer and disconnect the power

source, and open the pressure drain valve to

relieve pressure. Clean the spray tip as shown in

manual 308644, supplied with the RAC IV.

Clearing an obstruction.

If the spray tip clogs while spraying, immediately stop

spraying, then:

Gun with Standard Flat Tip and Guard

1. Lock the gun trigger safety, open the pressure

drain valve.

CAUTION

Never soak the entire gun in solvent. Prolonged

exposure to solvent can ruin the packings.

A

KEY

A Handle shown in spraying

position. Turn handle

180_ and

trigger gun to clear clog.

Fig. 4

05966

308645 7

Page 8

Installation/Operation

How to Check the Gun Diffuser Operation

Check the diffuser operation weekly. The gun diffuser/

seat (A) breaks up spray and reduces the risk of fluid

injection when the tip is not installed. Perform the test

below. If it fails, replace the entire Needle Kit, Part No.

218070, as instructed on page 7. Diffuser/seats are not

sold separately since the gun will leak if an old needle

is used with a new diffuser/seat.

1. Follow Pressure Relief Procedure on page 5.

2. Remove the tip guard and spray tip.

3. Start the sprayer and adjust it to the lowest

pressure.

4. Aim the gun into a grounded metal pail while

holding it firmly to the pail. Trigger the gun. If the

fluid emitted is not diffused into an irregular

stream, replace the entire needle kit immediately.

See Fig. 5.

How to Clean the Filter (See Fig. 6.)

Clean the filter assembly (17) daily, as follows:

4. Apply lithium-base grease to the threads of the

gun handle (14) and reassemble the gun.

A

05967

Fig. 5

26

5

1. Follow Pressure Relief Procedure on page 5.

2. Push up on the trigger guard (12) and swing it

away from the trigger (5).

3. Unscrew the gun handle (6) from the housing (26).

Remove the filter and clean it in compatible

solvent.

Fig. 6

12

6

05968

8 308645

Page 9

How to Flush the Gun

Installation/Operation

WARNING

To reduce the risk of serious bodily

injury, including splashing fluid in the

eyes or on the skin, or static electric

discharge when flushing:

D Be sure the entire system, including flushing

pails, are properly grounded.

D Remove the tip guard and spray tip.

D Maintain metal to metal contact between the

gun and the flushing pail.

D Use the lowest possible pressure.

Always flush the pump and the gun before the fluid

being sprayed can dry in it.

NOTE: If it is available, the flushing procedure

provided in your pump or sprayer manual should be

used instead of this procedure.

1. Follow Pressure Relief Procedure on page 5.

2. Remove the tip guard and spray tip. Soak and

clean the parts.

WARNING

Do not spray paint from the gun with the gun safety

latch set to the cleaning position.

7. Trigger the gun. Rotate the latch clockwise all the

way up to the cleaning position as shown in Fig. 7.

Release the trigger. The gun is now in continuous

cleaning mode without the need to manually trigger

the gun.

8. Aim the gun into the solvent pail. Start the pump at

its lowest pressure. Circulate the fluid until the

system is thoroughly flushed.

9. Trigger the gun and turn the latch counterclockwise to rotate the pin parallel with the gun.

Release the trigger to stop flushing.

10. Follow the Pressure Relief Procedure, page 5.

LATCH

PIN

3. Put the pump intake in a grounded pail of water or

solvent.

4. Start the pump at its lowest pressure.

5. Trigger the gun into the original pail. When water

or solvent appears, release the trigger.

6. Follow the Pressure Relief Procedure, page 5.

Fig. 7

05969

308645 9

Page 10

Service

D

23

C

B

A

1

Torque to 26–32 ft-lb

1

(35–43 N.m)

Fig. 8

NOTE: The needle (C), diffuser/seat (A), gasket (B)

and locknut (D) must be replaced together. They are

included in Repair Kit 218070.

4

05970

Disassembly (See Fig. 8)

1. Follow the Pressure Relief Procedure on page

5.

2. Remove the tip guard assembly. See Fig. 2.

3. Squeeze the trigger while unscrewing the diffuser/

seat (A) and gasket (B).

4. If the gun handle (6) was removed, hand tighten it

into the fluid housing (26); it should fit easily.

5. Adjust the needle before using the gun. Procedure

below.

6. Be sure the trigger guard and tip guard are

installed before using the gun.

Adjusting the needle (See Fig. 9)

1. Engage the gun safety latch.

2. Hold the gun with the nozzle straight up.

3. Hold your finger against the trigger with light

pressure. Turn the locknut (D) clockwise until you

feel the trigger depress slightly.

4. Turn the adjusting nut 3/4 turn counterclockwise.

5. Connect the fluid hose. Install the tip guard and

prime the system. Trigger the gun and release it.

The fluid flow should stop immediately. Engage the

safety latch and try to trigger the gun. No fluid

should flow. If the gun fails either test, relieve

pressure, disconnect the hose and readjust the

needle.

4. Remove the locknut (D) and end cap (23).

5. Tap the rear of the gun with a plastic mallet to

push the needle assembly out the front.

Reassembly (See Fig. 8)

1. Guide the threaded end of the needle assembly

into the front of the gun.

2. Install the end cap, aligning its guides with the

holes in the rear of the gun. Install the locknut (D)

loosely.

3. Squeeze the trigger while installing the gasket (B)

and diffuser/seat (A). Torque the diffuser seat to

26–32 ft-lb (35–43 N.m).

1

2

Fig. 9

Engage trigger

safety latch

Arrows indicate

clockwise turn

1

D

2

05972

10 308645

Page 11

Service

Replace Swivel

(See Fig. 10)

Disassembly

1. Follow Pressure Relief Procedure on page 5.

2. Push up on trigger guard (12) and swing trigger

guard away from trigger (5).

3. Unscrew gun handle (6) from housing (26).

Remove filter and clean in compatible solvent.

4. Remove swivel (15), guard retainer (42) and

cushion o-ring (43).

5. Save guard retainer and cushion o-ring.

Reassembly

1. Clean internal thread of handle (6).

2. Install guard retainer (42), cushion o-ring (43) and

swivel (15).

3. Apply PST pipe seal (included in Swivel Kit

238817) to external thread of swivel (15) that

connects to handle (6).

4. Install swivel (15) into handle (6). Torque swivel to

250 in-lb.

5. Engage trigger guard (12) to retainer guard (42).

12

Fig. 10

6

42

43

15

05968

308645 11

Page 12

Model 238350, Series A

Model 824004, Series A

Model 239045, Series A

Parts Drawing

n41

n40

232632

Included with 1

21

33

31

1

18

22n

17

20

16

5

37

2

45

1

2

45

12

6

05962

42

43

12 308645

1

Purchase separately

2

Included with 239045

15

Page 13

Parts List

Model 238350, Series A; Model 824004, Series A

Ref.

No. Part No. Description Qty.

1 218070 NEEDLE–DIFFUSER/SEAT KIT 1

5 238199 4-FINGER TRIGGER

6 195788 HANDLE, round 1

10Y 222385 KIT, warning card 1

11Y 187348 COVER, warning 1

12 195495 TRIGGER GUARD 1

15 238817 SWIVEL, kit 1

16 179750 SPRING RETAINER 1

17n 218131 FLUID FILTER ASSEMBLY 1

(standard 50 mesh) includes

replaceable items 16, 18, 20, 21 1

18 179731 STRAINER ELEMENT 1

(standard 50 mesh)

20 179763 SPRING 1

21 179722 SPRING RETAINER (color coded blue)

(for standard 50 mesh filter) 1

22n 179733 GASKET 1

23 191244 END CAP 1

26 190973 FLUID HOUSING 1

(standard) 1

Ref.

No. Part No. Description Qty.

31 105334 LOCKNUT;

32 177538 TRIGGER STUD 1

33 179737 ACTUATOR PIN 2

37 195419 NEEDLE HOUSING 1

39Y 222385 WARNING CARD (not shown) 1

40n 221515 SWITCHTIP SPRAY TIP,

41n 237859 RAC 1

DripLess Guard

See manual 308644 for other tip sizes 1

42 113409 RETAINER, guard 1

43 104938 O-RING, cushion 1

45 220251 KIT, tip guard 1

M4 x 0.7 thread 1

SZ 515 1

Y Replacement Danger and Warning labels, tags and

cards are available at no cost.

n Keep these spare parts on hand to reduce down

time.

308645 13

Page 14

Accessories

FILTERS

3000 psi (210 bar) Maximum Working Pressure.

Adequate filtering is important for a good surface finish

and to minimize tip clogging. Elements are available in

various mesh sizes.

Filter elements and assemblies

224455 Two, 50 mesh elements, (179731)

224456 Two, 100 mesh elements, (179732)

218131 50 mesh filter assembly; includes spring,

50 mesh element and two spring retainers

218133 100 mesh filter assembly; includes spring,

100 mesh element and two spring

retainers

TOOLS

Nylon Brushes

Use to thoroughly clean the gun’s fluid passages.

101891 0.375” (9 mm) dia.

101892 0.625” (16 mm) dia.

220222 Standard DripLesst Tip Guard. Order

flat tip separately. See your distributor

for available sizes.

222674 Heavy Duty RACR DripLesst Tip Guard.

Order SwitchTip separately. See your

distributor for available sizes.

FINE FINISH RAC TIPS

These tips provide and extremely fine finish with more

consistent material thickness. See your distributor for

available sizes.

TIP EXTENSIONS

These tip extensions extend tip from the spray gun to

spray hard to reach areas.

Wrench 171147

Fits all hexes on the gun.

TIP GUARDS

These tip guards fit all Graco airless spray guns.

Choose the one that’s right for your application. One of

these tip guards is included with every Graco airless

gun.

237859 RACR DripLesst

Guard.

Order SwitchTip separately. See your

distributor for available sizes.

223390 12 inch extension

223391 18 inch extension

223392 24 inch extension

HEAVY DUTY EXTENSIONS

Provides extended spraying for hard to reach

applications.

224413 12 inch extension

224414 18 inch extension

224415 36 inch extension

224416 72 inch extension

236406 Includes 18 in. and 36 in. heavy duty

extension; RAC IV dripless tip guard;

180_ directional nozzle; and 45_swivel.

14 308645

Page 15

Technical Data

PTFE

PTFE

Graco Phone

Maximum Working Pressure 3600 psi (252 bar). . . . . .

Fluid Orifice Size 0.125 in. (3.18 mm). . . . . . . . . . . . . . .

Wetted Parts Stainless steel, Polyethylene,. . . . . . . . .

Aluminum, Polyurethane, Nylon, R

Brass, Tungsten carbide, UHMW

Weight 17 oz. (482 g). . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inlet 1/4 npsm(m)swivel. . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Material Temperature 120_F(50_C). . . . . . .

Sound Data

Sound Pressure Level 78 dB(A)*. . . . . . . . . . . . . . . .

Sound Power Level 87 dB(A)*. . . . . . . . . . . . . . . . . . .

* Measured while spraying waterbase paint – gravity

1.36 through a 517 tip at 3,000 psi (207 bar).

Per ISO 3744

R is a registered trademark

Number

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor

closest to you: 1–800–690–2894 Toll Free.

308645 15

Page 16

Graco Warranty

Graco warrants all equipment listed in this manual which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of

any special extended or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or

replace any part of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed,

operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance or structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT

NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, gas engines,

switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance

in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures

judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procédures concernées.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty

Program”.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Foreign Offices: Belgium, Korea, Hong Kong, Japan

Sales Offices: Minneapolis, Detroit

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

PRINTED IN U.S.A. 308645 February 1996, Revised October 1999

16 308645

Loading...

Loading...