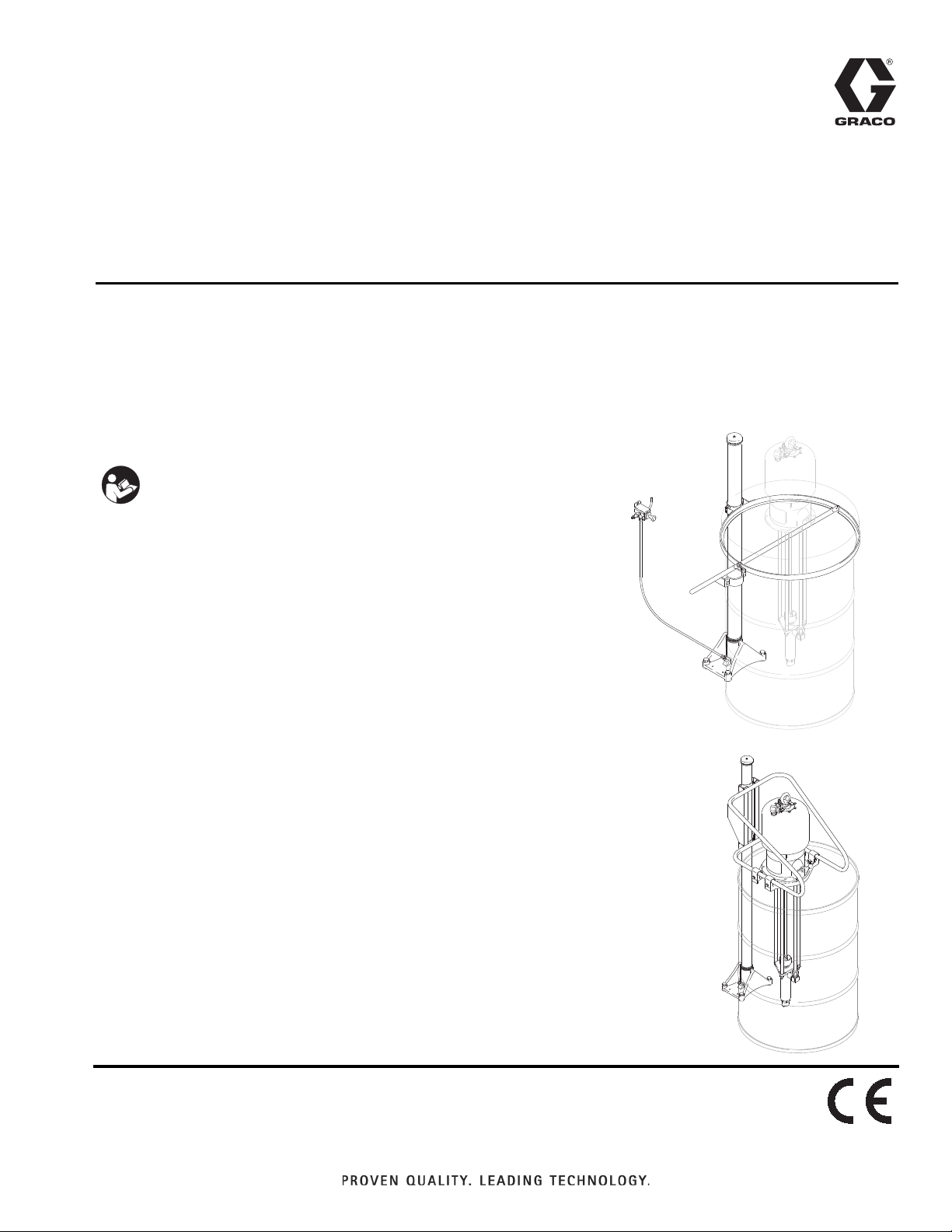

Page 1

Instructions-Parts List

06529b

06523b

Elevators and

306287W

Pump Supports

Used to raise and lower select Graco circulation and supply pumps. For professional use

only.

200 psi (1.4 MPa, 14 bar) Maximum Air Input Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

See page 2 for a list of models.

Page 2

Table of Contents

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . 2

List of Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Information . . . . . . . . . . . . . . . . . . . . . . 4

Fixed Mount Elevator . . . . . . . . . . . . . . . . . . . . . 4

Pump Support Bracket . . . . . . . . . . . . . . . . . . . . 5

Cover Support . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Air Connection . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Starting and Adjusting the Elevator . . . . . . . . . . 6

Changing Drums . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Seals and Gaskets . . . . . . . . . . . . . . . . . . . . . . . 7

Push-Pull Valve . . . . . . . . . . . . . . . . . . . . . . . . . 7

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Elevator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Support and Control . . . . . . . . . . . . . . . . . . . . . 10

Support and Control

(Models 237746 Series A, 241663 Series A,

237579, 237578) . . . . . . . . . . . . . . . . . . . . . 12

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 16

List of Models

Elevators

Part Number Series Description

204385 D Standard Elevator with Fixed Mounting

207408 C Heavy Duty Elevator with Fixed Mounting - Designed with increased

strength and rigidity to allow frequent raising and lowering loads ranging

between 120-400 lbs. (54-81 kg).

205332 B Bare Elevator

237746 A Elevator Assembly, includes 204385 Elevator, 237578 Cover Support,

and 237579 Air Control Kit

241663 A Elevator Assembly, includes 204385 Elevator, 207562 Cover Support,

and 207561 Air Control Kit

Pump Supports

Part Number Series Description

206232 A Frame Support (open mounting)

207562 A Ring Support (cover mounting)

237578 A Ring Support (cover mounting)

Air Control Kits

Part Number Series Description

207561 A For use with Supports 206232 or 207562

237579 A For use with Support 237578

2 306287W

Page 3

Warnings

WARNING

WARNINGWARNING

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in your separate pump manual and disconnect all power

sources.

306287W 3

Page 4

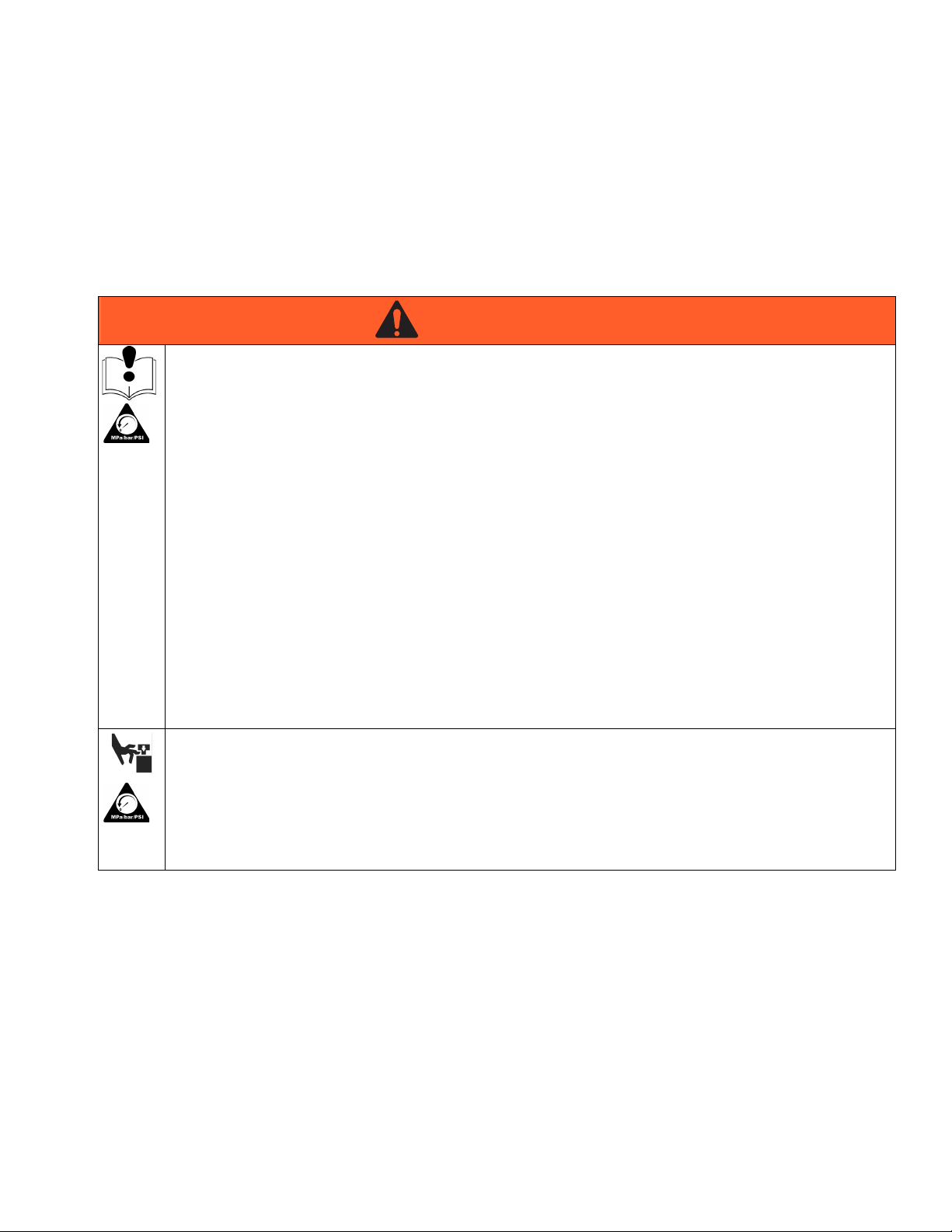

Installation

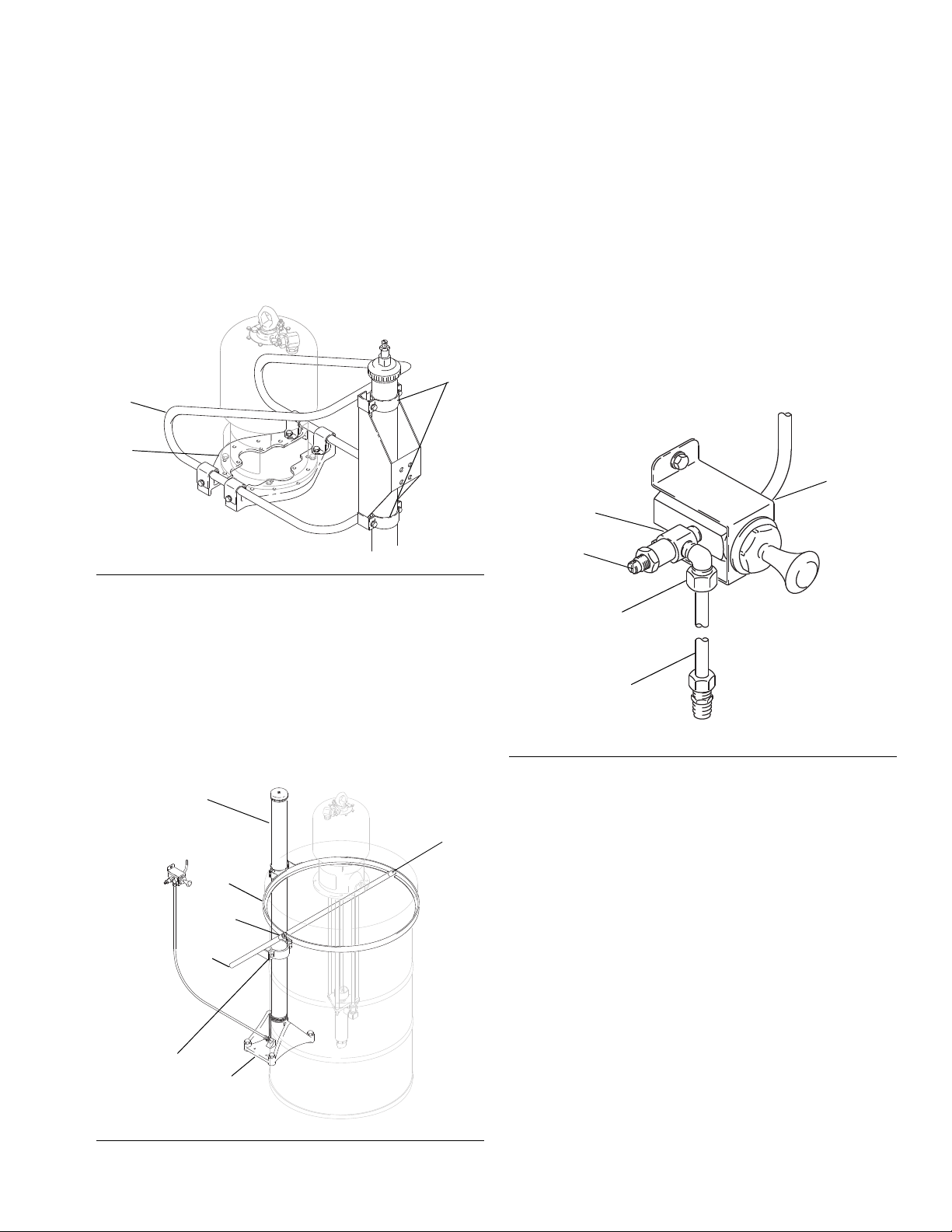

06523b

40

14 or 28

17

06530

Raised: 94 in

(2390 mm)

Lowered: 55 in

(1400 mm)

0.25 in

(6.4 mm)

0.5 in (13mm) bolt

Shim

Level

Installation

General Information

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures and the

parts drawing.

NOTE: Always use Genuine Graco Parts and Accessories, available from your Graco distributor. If you supply

your own accessories, be sure they are adequately

sized and pressure rated for your system.

To reduce the risk of serious injury, including fluid

injection, splashing in the eyes or on the skin, or

injury from moving parts:

1. Always relieve air and fluid pressure in the pump

2. Keep your fingers and hands away from moving

3. When the pump is in the raised elevator position,

4. Before working on the elevator, remove the pump

Fixed Mount Elevator

Locate the elevator where there is at least 9 ft (2.75 m)

overhead clearance. Mark and drill holes for 0.5 in. (13

mm) mounting bolts. See FIG. 2 and the dimensional

drawing on page 15. Level the base (17), using shims if

necessary. Secure the base to the floor using four 1/2

in. (13 mm) mounting bolts which are long enough to

prevent the elevator from tipping.

before raising the elevator.

parts when raising or lowering the elevator to prevent pinching or amputating them including

between the drum and pump mounting assembly.

do not leave it unattended. Keep air supplied to the

elevator. Block the pump, drum cover or pump

support bracket before working on the pump.

and relieve air pressure to the elevator.

FIG. 1

4 306287W

FIG. 2

Page 5

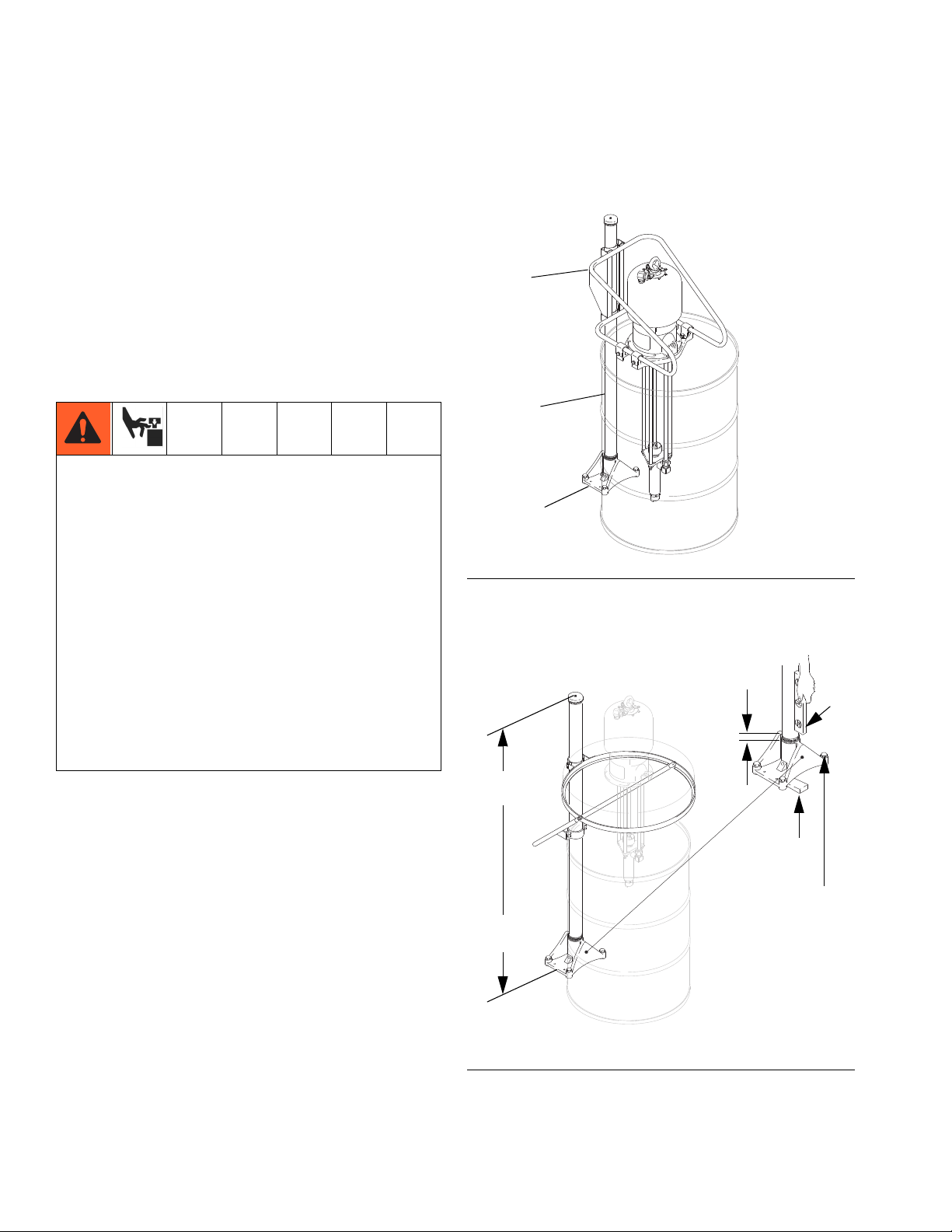

Installation

Pump Support

Ref. No. 31

06528

40

38

34

06529b

49, 45

45

49

48

17

44, 42

14 or 28

Push-Pull Valve

Ref. No. 60

06531

54

60

55

52

51

Pump Support Bracket

Set an open drum against the elevator base (17). Position the bracket (40) on top of the drum so that the

clamp (34) recesses are tight against the elevator riser

tube (14 or 28). See FIG. 1 and FIG. 3. Raise the riser

tube up about 0.25 in. (6.4 mm), install the clamps (34)

and tighten securely. Attach the pump mounting brackets (38)

FIG. 3

Air Connection

Screw the restrictor valve (55) into the push-pull valve

(60) as shown in FIG. 5. Mount the valve on the wall at a

convenient height, using the mounting bracket (54).

Connect the master air supply to the valve. Screw the

elbow fitting (52) into the 1/8 npt(f) inlet of the restrictor

valve. Push one end of the copper tube (51) into the

elbow and tighten the fitting. Screw the straight fitting

(53) into the base (17) of the elevator. Push the other

end of the copper tube (51) into this fitting and tighten

the fitting.

Cover Support

Place the cover in its proper position in the support ring

(49) and tighten the capscrews (45). Set an open drum

against the elevator base (17) and put the cover on the

drum so the support clamp (44) recesses are tight

against the elevator riser tube (14 or 28). Raise the tube

0.25 in. (6.4 mm), then tighten the clamp screws (42).

See FIG. 4.

FIG. 5

FIG. 4

306287W 5

Page 6

Operation

Operation

Starting and Adjusting the

Elevator

Moving parts can pinch or amputate your fingers.

When the pump is operating and when raising or

lowering the elevator, keep your fingers and hands

away from the elevator, pump support, drum cover,

and lip of the drum.

You must adjust the elevator to ensure that the cover is

supported by the drum.

1. Close all air regulators and air valves.

2. Open the main air bleed valve. Pull up on the air

control valve and let the elevator rise to its full

height. Normal operation requires only a few seconds for air pressure to build up or exhaust, and to

start raising or lowering the elevator.

3. Set a full 200 liter (55 gal.) drum against the elevator

base.

4. With your hands away from the drum and the cover,

push down on the air control valve and lower the

elevator until the cover rests on the lip of the drum.

The support clamp recesses must be tight against

the elevator riser tube.

Changing Drums

Moving parts can pinch or amputate your fingers.

When the pump is operating and when raising or

lowering the elevator, keep your fingers and hands

away from the elevator, pump support, drum cover,

and lip of the drum.

NOTICE

Shortened or recycled drums may cause the pump or

agitator to bottom out in the drum, causing damage.

Contact your fluid supplier to order a standard size

drum.

1. Stop the pump. Close the pump air bleed valve.

2. Pull up on the air control valve to raise the elevator.

3. Remove the empty drum and place the full drum

against the elevator base.

4. Lower the elevator. See Starting and Adjusting

the Elevator.

5. Raise the elevator 1/4 in. (6.4 mm), then tighten the

support clamp screws. This ensures that the cover

rests on the drum lip when the elevator is in the lowered position.

6. Before operation, ensure that all fasteners and tube

connections are tightened securely.

NOTE: To increase or decrease the operating speed of

the elevator, loosen the hex nut of the restrictor valve

and turn the valve needle either in or out.

6 306287W

Page 7

Service

Torque to 20-40 ft-lb (27-54 N•m)

Torque to 15-20 ft-lb (20-27 N•m)

Torque to 90-130 ft-lb (122-175 N•m)

Torque to 30-60 ft-lb (40-80 N•m)

Apply lubricant to inside surface

Apply tape

Apply Loctite® 542 Sealant to threads

1

2

3

4

5

6

7

06532

8

10

20

21

17

19

12 or 24

25

4 7

13 or 29

3 6

2 7

1

5

4

9 or 18

14 or 28

5

Service

Lubrication

Every two to six weeks, take the cap (20) off the riser

tube (14 or 28) and put a few drops of light, high grade

motor oil on the inside surface of the tube to lubricate

the leather packing (10). See FIG. 6. When replacing the

cap, torque to 20-40 ft-lb (37-54 N•m).

Be careful not to dent or damage the riser tube (14 or

28). Dents may cause the elevator to bind, making

operation impossible.

Seals and Gaskets

To replace the leather cup packings (10), screw the

bearing housing (25) out of the riser tube (14 or 28) and

slide the tube up off the piston (11). See FIG. 6. Screw

the piston retainer capscrew (21) out of the piston body

and remove the parts. Inspect parts for wear and damage and replace as necessary.

NOTICE

NOTE: When replacing packings, install a new spreader

(5). This will increase the life of the packings.

Soak new leather packing (10) in light oil, and put lithium

grease on the inside surface of the tube. Re-assemble

in the reverse order. Apply Loctite® 542 thread sealant

to the internal threads of the piston body (11) and the

threads of the capscrew (21). Torque the capscrew to

15-20 ft-lb (20-27 N•m).

To replace the guide tube gasket (19), screw the guide

tube (13 or 29) out of the elevator base (17). Take the

gasket out. See FIG. 6. Be careful not to damage the

outside bearing surface of the guide tube. Put a new

gasket into the base. Put PTFE tape on the threads of

the guide tube and screw it into the base. Torque to

90-130 ft-lb (122-175 N•m).

Push-Pull Valve

Remove the valve guide (71), washer (64), o-ring (66*)

and seal (67*). Pull the assembled valve parts out of the

valve body (70). See the Parts Drawing on page 10. Disassemble parts, clean and inspect. Re-assemble the

valve, using new parts as necessary.

FIG. 6

306287W 7

Page 8

Parts

Torque to 90-130 ft-lb (122-175 N•m)

Apply Loctite® TL-222 to threads

Torque to 30-60 ft-lb (40-80 N•m)

Apply Loctite® 542 Sealant to threads

Torque to 20-40 ft-lb (37-54 N•m) Apply tape

Torque to 15-20 ft-lb (20-27 N•m) Apply lubricant to inside surface

1

5

2

6

3

7

4

8

6524b

3

3

6

17

4

31

8 6

24

7 1

19*

10*

5*

8

4

21

14 or 28

7

20

29 or 13

5 2

25

26

16 or 27

1

11

*30

15

9 or 18

12

Parts

Elevator

8 306287W

Page 9

Elevator - Parts List

9427b

2

3

10

12

16

15

1

17

8

7

4

6

5

11

9

Parts

Model 204385, Series D (see page 8)

Standard Elevator with Fixed Mounting

Includes items 3-17, 19-21, 25-26, 30, 31 below

Model 207408, Series C (see page 8)

Heavy Duty Elevator with Fixed Mounting

Includes items 3-8, 10-11, 15, 17-21, 24-31 below

Ref.

No. Part No. Description Qty.

3 100139 PLUG, pipe; 1/8 npt 1

4 100422 LOCKWASHER, int shkprf; 3/4” 1

5* 150230 SPREADER, packing 1

7* 155899 GASKET, rubber 1

8 156306 WASHER, back-up 1

9 157633 SPRING, helical compression

(Model 204385)

10* 158260 PACKING, cup; leather 1

11 192198 BODY, piston 1

12 158262 BEARING, piston (Model 204385) 1

13 158263 TUBE, guide (Model 204385) 1

14 158264 TUBE, riser (Model 204385) 1

15 158265 WASHER, special plain 1

16 158267 TUBE, stop (Model 204385) 1

17 158270 BASE, stationary (Model 204385

and 207408)

18 158388 SPRING, helical compression

19* 158429 GASKET, copper 1

20 161320 CAP, tube 1

21 192199 SCREW, special cap 1

(Model 207408)

24 167870 GUIDE, riser tube (Model 207408) 1

25 167871 HOUSING, elevator bearing 1

26 167872 BEARING, PTFE tape 1

27 167873 TUBE, stop (Model 207408) 1

28 167874 TUBE, riser (Model 207408) 1

29 167875 TUBE, guide (Model 207408) 1

30* 722834 PACKING, o-ring 1

31 16T421 ADAPTER, pipe hex; 1/8 npt (mxf) 1

*Recommended spare parts. Keep on hand to

reduce down time.

Model 205332, Series B (see below)

Bare Elevator

Includes items 1-17 below

Ref.

No. Part No. Description Qty.

1 203743 VALVE, restrictor; includes items

56- 59 on page 11

2 205333 CAP, elevator mounting 1

3 205334 TUBE, elevator riser 1

4 100155 NUT 1

5 150179 PACKING, cup; leather 1

6 156306 WASHER, flat 1

7 158109 GASKET; rubber 1

8 164246 CAP, tube air 1

9 164247 TUBE, guide, elevator 1

10 164248 SPACER 1

1

11 164249 PISTON 1

12 169969 FITTING, quick disconnect; 1/8

npt(m)

15 159840 ADAPTER; 1/4 npt(f) x 1/8 npt(m) 1

16 100030 BUSHING; 1/4 npt(m) x 1/8 npt(f) 1

17 16T421 ADAPTER, pipe hex; 1/8 npt (mxf) 1

1

1

1

1

306287W 9

Page 10

Parts

Screw firmly against seat, back off 1/4 turn

Apply adhesive

1

2

Ref. No. 31: 206232 Pump Support Assembly

06526

48

47

45

49

42

43

44

46

Ref. No. 41: 207562

Cover Support Assembly

62

Ref. No. 50: 207561 Air Control Kit

54

*61

65

*69

68

73

72

70

67*

66

53

64

51

71

52

63

56

59

*57

58

1/8 npt

1

2

06527

06525

40

32

39

37

33

38

33

32

34

36

35

Support and Control

10 306287W

Page 11

Support and Control - Parts List

Parts

Ref.

No. Part No. Description Qty.

31 206232 PUMP SUPPORT ASSEMBLY

Includes items 32- 40

32 100057 SCREW, hex hd cap; 5/16-18 x 3/4” 8

33 100214 LOCKWASHER, spring; 5/16” 12

34 158271 CLAMP, tube; support ring and

bracket

35 100133 LOCKWASHER, spring; 3/8” 4

36 100469 SCREW, hex hd cap; 3/8-16 x 3/4” 4

37 100538 SCREW, hex hd cap; 5/16-18 x 1/2” 4

38 166573 BRACKET, pump mounting 2

39 166574 STRAP, support bracket 4

40 206762 FRAME, support, pump 1

41 207562 COVER SUPPORT ASSEMBLY

Includes items 42-49

42 100057 SCREW, hex hd cap; 5/16-18 x 3/4” 4

43 100214 LOCKWASHER, spring; 5/16” 4

44 158271 CLAMP, tube; support ring and

bracket

45 100022 SCREW, hex hd cap; 1/4-20 x 3/4” 2

46 100181 NUT, square; 5/16-18 4

47 100268 SCREW, rd hd mach; 10-24 x 3/8” 2

48 202776 BRACE, support 1

49 202777 RING, support 1

50 207561 KIT, control, air

Includes items 51-73

51 057024 TUBE, copper; 0.25” (6.4 mm)

tube, 5 ft (1.52 m)

Ref.

No. Part No. Description Qty.

52 100112 FITTING, 90° male elbow; 0.25”

1

53 100113 FITTING, straight; 0.25” (6.4 mm)

54 154634 BRACKET, mounting 1

2

55 203743 VALVE, restrictor

56 101448 NUT, hex jam; 3/8-24 1

57* 157628 PACKING, o-ring 1

58 160162 BODY, valve 1

59 160163 NEEDLE, valve 1

60 202295 VALVE, push-pull

1

61* 100272 LOCKWASHER, int shkprf, no. 6 1

62* 104560 SCREW, pan hd mach; 6-32 x 3/8” 1

63 154519 KNOB 1

64 154526 WASHER, special plain 1

2

65* 154570 WASHER, special plain 1

66* 154594 PACKING, o-ring 1

67* 155500 SEAL, o-ring 1

68* 155811 SEAL, flat cup; air intake 1

69* 155921 SEAL, flat cup; air exhaust 1

70 157160 BODY, valve 1

71 157161 GUIDE, valve 1

1

72 161129 STEM, large round; air intake 1

73 161132 STEM, small square 1

1

*Recommended spare parts. Keep on hand to

reduce down time.

(6.4 mm) tube, 1/8 npt

tube, 1/8 npt

Includes items 56-59

Includes items 61-73

1

1

1

1

306287W 11

Page 12

Parts

106

1

06217b

101

103

208

202

209

203

215

211

204

214

215

216

208

206

207

105

102

110

111

108

102

109

201

(REF)

2

104

106

Drum cover is not included.

See page 8 for parts.

1

2

103

205, 210,

212, 213

Support and Control

(Models 237746 Series A, 241663 Series A, 237579, 237578)

Model 237746, Series A

Standard Elevator with Fixed Mounting

Includes 204385 Elevator (see page 8), 237579 Air Control Kit, and 237578 Cover Support Assembly

Model 241663, Series A

Standard Elevator with Fixed Mounting

Includes 204385 Elevator (see page 8), 207561 Air Control Kit (see page 10), and 207562 Cover Support Assembly

(see page 10)

237579 Air Control Kit

Includes items 101-111

237578 Cover Support Assembly

Includes items 201-216

12 306287W

Page 13

Parts

Support and Control- Parts List

(Models 237746 Series A, 241663 Series A, 237579, 237578)

Model 237746, Series A

Standard Elevator with Fixed Mounting

Includes 204385 Elevator (see page 8), 237579 Air Control Kit, and 237578 Cover Support Assembly

Model 241663, Series A

Standard Elevator with Fixed Mounting

Includes 204385 Elevator (see page 8), 207561 Air Control Kit (see page 10), and 207562 Cover Support Assembly

(see page 10)

237579 Air Control Kit

Ref.

No. Part No. Description Qty.

101 203743 VALVE, restrictor

Includes items 56-59 (see page 10)

102 202295 VALVE, push-pull

Includes items 61-72 (see page 10)

103 TUBE; nylon; 7 ft; purchase locally 1

104 103473 STRAP, tie wire 2

105 190231 BRACKET, valve 1

106 113208 FITTING, tube 2

108 169969 FITTING, air, quick disconnect 1

109 112896 SCREW, cap, hex hd; 1/4-20; 1/2”

(13 mm) long

110 104123 WASHER, lock, spring; 1/4” size 2

111 104121 NUT, hex; 1/4-20 2

237578 Cover Support Assembly

Ref.

No. Part No. Description Qty.

201 190272 STUD, brace, left side 1

1

202 190273 STUD, brace, left side 1

203 190187 BRACKET, support, rear 1

1

204 190181 BRACKET, riser tube 1

205 158271 CLAMP, support 1

206 202776 BRACE, support 1

207 100268 SCREW, rd hd machine; 10-24 x

3/8” (10 mm) long

208 112895 SCREW, cap, hex hd; 1/4-20; 3/4”

2

209 112944 SCREW, cap, button hd; 5/16-18;

210 100057 SCREW, cap, hex hd; 5/16-18; 3/4”

211 108946 NUT, hex; 5/16-18 2

212 100181 NUT, square; 5/16-18 2

213 100214 WASHER, lock, spring; 5/16” size 2

214 112894 SCREW, cap, hex hd; 5/16-18;

215 112904 WASHER, lock, spring; 5/16; SST 4

216 112900 NUT, square; 5/16-18; SST 2

(19 mm) long

3/4” (19 mm)

(19 mm)

SST

2

2

2

2

2

306287W 13

Page 14

Notes

Notes

14 306287W

Page 15

Dimensions

.056" (14.2 mm)

8.88"

(225.9 mm)

5.5"

(140 mm)

NOTE: For elevator height dimensions,

refer to FIG. 2 and Installation on page 4.

06533

Dimensions

306287W 15

Page 16

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 1964, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions.

This manual contains English. MM 306287

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision W, February, 2014

Loading...

Loading...