Page 1

B

OM−01228−05

August 9, 2006

Rev. B 07-15-08

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

UNIT SERIES PUMP

MODEL

UNIT 608

tankleenor

r

THE GORMAN-RUPP COMPANY MANSFIELD, OHIO

www.grpumps.com

GORMAN-RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

2006 The Gorman-Rupp Company

Page 2

Register your new

Gorman-Rupp pump online at

www.grpumps.com/register.

Valid serial number and e-mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman-Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

Page 3

TABLE OF CONTENTS

INTRODUCTION PAGE I − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY - SECTION A PAGE A − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION − SECTION B PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Dimensions PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREINSTALLATION INSPECTION PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT INSTALLATION PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning Unit and Setup PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Configuration PAGE B − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hose Connections PAGE B − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SUCTION LINES PAGE B − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Suction Line Positioning PAGE B − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISCHARGE LINES PAGE B − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siphoning PAGE B − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valves PAGE B − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION − SECTION C PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRIMING PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leakage PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Liquid Temperature And Overheating PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOPPING PAGE C − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cold Weather Preservation PAGE C − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING − SECTION D PAGE D − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREVENTIVE MAINTENANCE PAGE D − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP MAINTENANCE AND REPAIR - SECTION E PAGE E − 1. . . . . . . . . . . . . . . . .

STANDARD PERFORMANCE PAGE E − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS LISTS:

UNIT 608 tankleenor PAGE E − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PPO (UNIT 608) PAGE E − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13559 Eductor Valve Assembly PAGE E − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41331−009 Reel Assembly PAGE E − 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46341−428 Hose Assembly PAGE E − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46312−009 Standpipe Assembly PAGE E − 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E − 13. . . . . . . . . . . . . . . . . . . . . . . . .

Pump Disassembly PAGE E − 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Removal PAGE E − 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Removal and Disassembly PAGE E − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Reassembly and Installation PAGE E − 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Installation PAGE E − 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

TABLE OF CONTENTS

(continued)

Pump Reassembly PAGE E − 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Final Pump Assembly PAGE E − 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION PAGE E − 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Assembly PAGE E − 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDUCTOR VALVE DISASSEMBLY AND REASSEMBLY PAGE E − 17. . . . . . . . . . . . . . . . . . . . . . . . .

Eductor Valve Disassembly PAGE E − 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Eductor Valve Reassembly PAGE E − 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOSE AND REEL DISASSEMBLY AND REASSEMBLY PAGE E − 17. . . . . . . . . . . . . . . . . . . . . . . . .

Hose Disassembly PAGE E − 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reel Disassembly PAGE E − 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reel Reassembly PAGE E − 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hose Reassembly PAGE E − 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STANDPIPE DISASSEMBLY AND REASSEMBLY PAGE E − 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standpipe Disassembly PAGE E − 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 5

UNIT SERIES

OM−01228

INTRODUCTION

Thank You for purchasing a Gorman-Rupp pump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

The Unit 608 tankleenor is designed to permit

quick, efficient cleaning of below-ground petroleum sotrage tanks without disturbing the product

or disrupting service. The cleaning system is capable of extracting gel precipitates, rust, water or other contaminants that present problems in fuel storage.

The tankleenor incorporates portable, lightweight components allowing one man operation.

The system utilizes an 0-Series self-priming centrifugal pump that is close-coupled to a single-phase

explosion-proof electric motor equipped with 50

feet of grounded power cable.

If there are any questions regarding the pump or

its application which are not covered in this manual or in other literature accompanying this unit,

please contact your Gorman-Rupp distributor, or:

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901−1217

Phone: (419) 755−1011

or:

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631−2870

For information or technical assistance on the electric motor, contact the motor manufacturer’s local

dealer or representative.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed instructions and precautions for every aspect of

each specific application. Therefore, it is the responsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operator safety nor pump integrity are compromised by the installation. Pumps and related

equipment must be installed and operated according to all national, local and industry standards.

The following are used to alert maintenance personnel to procedures which require special attention, to those which could damage equipment, and

to those which could be dangerous to personnel:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

Hazards or unsafe practices which COULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possible damage which could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation,and

maintenance, or which clarify a procedure.

PAGE I − 1INTRODUCTION

Page 6

UNIT SERIES

SAFETY - SECTION A

This information applies to operation

and maintenance of the UNIT 608 tankleenorr. Refer to the manual accompanying the electric motor before attempting to begin operation.

Because pump installations are seldom

identical, this manual cannot possibly

provide detailed instructions and precautions for each specific application.

Therefore, it is the owner/installer’s responsibility to ensure that applications

not addressed in this manual are performed only after establishing that neither operator safety nor pump integrity

are compromised by the installation.

OM−01228

Before operating or servicing the pump,

be certain proper safety practices are

followed. Provide adequate ventilation,

prohibit smoking, wear static-resistant

clothing and shoes. Clean up all fuel

spills immediately after occurrence.

Connect the ground wire to the tank fill

pipe or other ground connection before

operating the unit. Static electric buildup could develop during cleaning operation, causing hazardous sparks.

Before attempting to open or service the

pump:

1. Familiarize yourself with this manual.

2. Unplug the motor to ensure that

the pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Vent the pump slowly and cautiously.

6. Drain the pump.

This pump is designed to handle water,

gasoline or other petroleum products.

Do not attempt to pump corrosive or

highly volatile liquids which may damage the pump or endanger personnel as

a result of pump failure.

Do not operate the pump against a

closed eductor control valve for long

periods of time. This could bring the liquid to a boil, build pressure, and cause

the pump casing to rupture or explode.

Overheating may produce dangerous

fumes. Use extreme caution when venting the pump, or when removing covers,

plates, plugs or fittings.

Overheated pumps can cause severe

burns and injury. If overheating of the

pump occurs:

1. Stop the pump immediately.

2. Allow the pump to completely cool

if overheated.

3. Refer to instructions in this manual

before re-starting the pump.

PAGE A − 1SAFETY

Page 7

UNIT SERIESOM−01228

The electrical power used to operate

this unit is high enough to cause injury

or death to personnel. Connect the electrical plug to a grounded power supply;

never use gas piping as an electrical

ground. Be sure the power supply is of

the correct voltage and phase. Do not

run the motor if the power supply is not

within acceptable limits. If a circuit

breaker or fuse is tripped, examine and

correct the problem before re-starting

the unit.

Inspect the suction hose regularly for

cuts, punctures or severe abrasion before operation. Replace the entire hose

assembly if there is any possibility of

leakage or exposure of the integral

spring steel strap inside the hose.

Never attempt to change the electrical

plug or alter the length of the power cord

with a splice. Equipment failure or personal injury could result if all connections are not waterproof and compatible

with the current used.

PAGE A − 2 SAFETY

Page 8

UNIT SERIES OM−01228

INSTALLATION − SECTION B

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section offers only general recommendations and

practices required to inspect, position, and arrange the pump and piping.

OUTLINE DRAWING

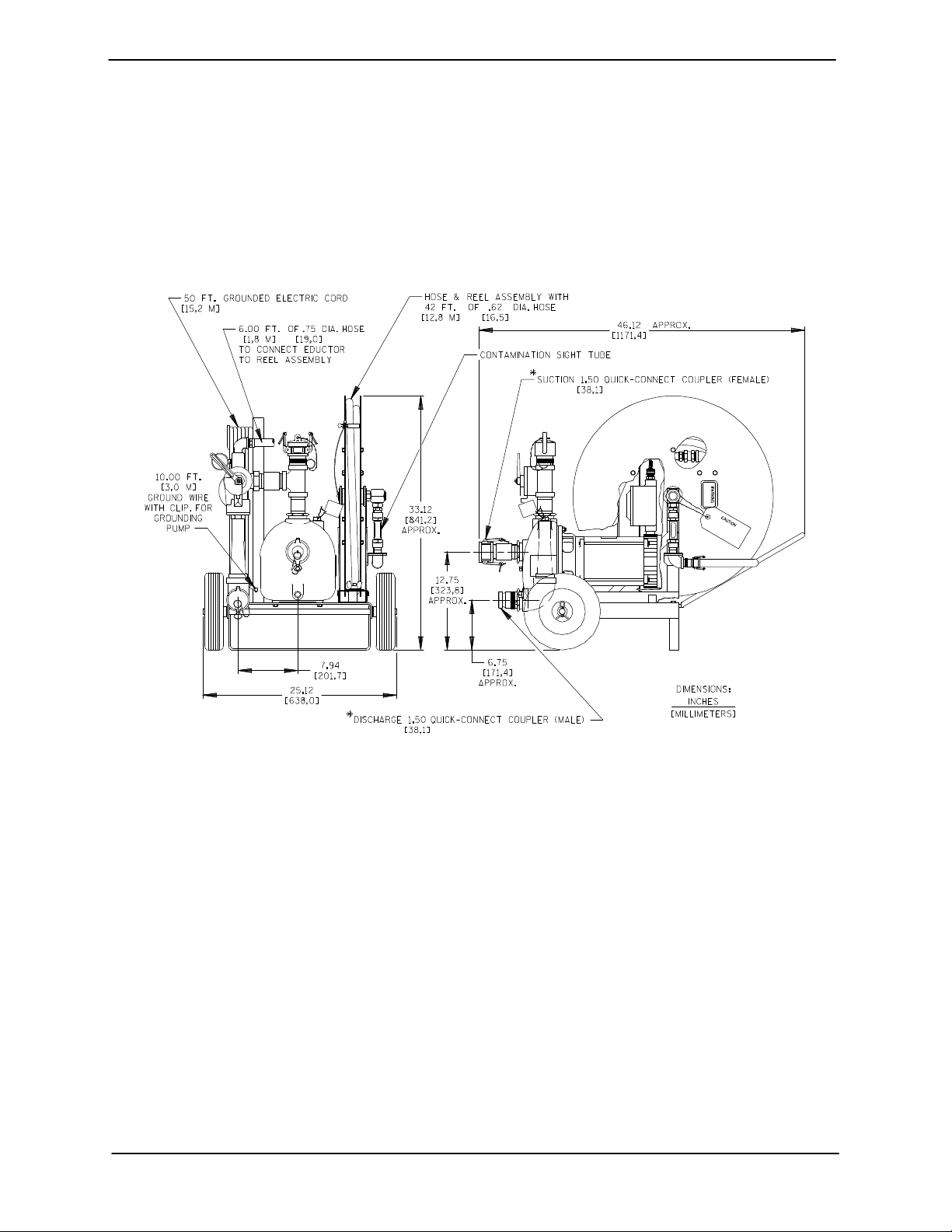

Pump Dimensions

See Figure 1 for the approximate physical dimensions of this pump.

Figure 1. Pump Model UNIT 608

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested before shipment from the factory. Before installation,

inspect the unit for damage which may have occurred during shipment. Check as follows:

a. Inspect the pump, reel assembly, hose and

motor for cracks, dents, damaged threads,

and other obvious damage.

b. Check for and tighten loose attaching hard-

ware. Since gaskets tend to shrink after drying, check for loose hardware at mating surfaces.

c. Carefully read all tags, decals, and markings

on the unit, and perform all duties indicated.

d. If the pump and motor have been stored for

more than 12 months, some of the compo-

nents or lubricants may have exceeded their

maximum shelf life. These must be inspected

or replaced to ensure maximum pump service.

e. Check to ensure the following standard

equipment items are included with the pump

assembly:

Detachable reel assembly.

42 foot long hydrocarbon-resistant hose.

8 foot long connector hose.

15 foot long suction and discharge hose.

12 foot long stainless steel standpipe.

10 foot long ground wire.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

PAGE B − 1INSTALLATION

Page 9

OM−01228 UNIT SERIES

Gorman-Rupp distributor or the factory to determine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

UNIT INSTALLATION

Lifting

This unit is mounted on a two-wheel moveable

base. It weighs approximately 260 pounds (118 kilograms) including suction and discharge hoses

and the standpipe. If it is necessary to lift the unit,

use lifting equipment with a capacity of 5 times the

weight of the unit to ensure safe lifting.

Use lifting and moving equipment in

Table 1. Pump Specifications

good repair and with adequate capacity

to prevent injuries to personnel or damage to equipment.

Mounting

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mounting is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibration.

Specifications

See Table 1 for typical pump specifications.

Pump

Model

02D3 115/230 1 1 3450 60 Hz 1−1/2" 1−1/2"

See Table 1 for typical pump specifications.

Power

Cable

50 Ft.

(15,2 M.)

Positioning Unit and Setup

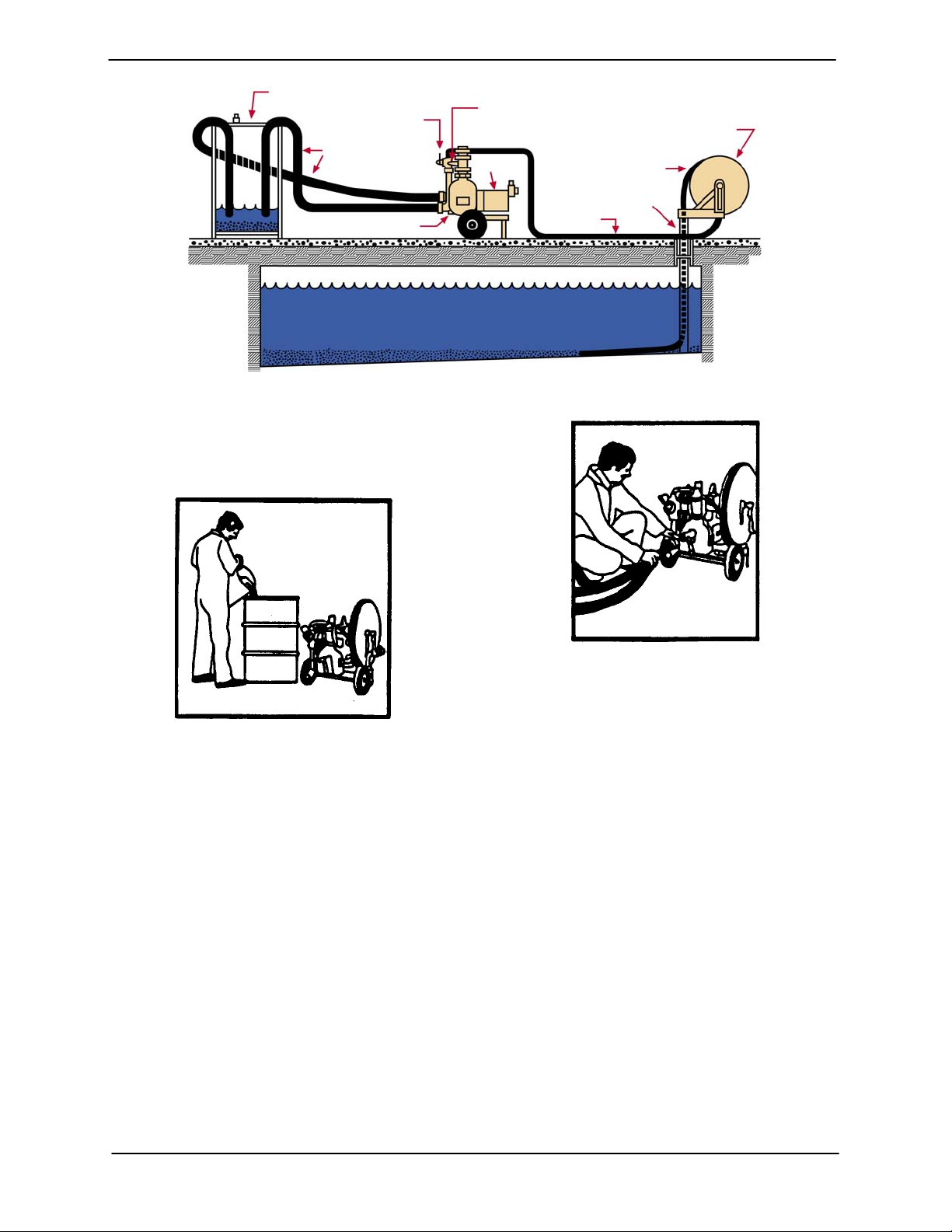

Figure 2 shows a typical installation of the tankleenor system.

Voltage Phase Horse-

power

Table 2. Unit Specifications

Reel

Assembly

42 Ft.

(12,8 M.)

Suction

Hose

1−1/2" x 15 Ft.

38,1 MM x 4,6 M

Motor

RPM

Discharge

Hose

1−1/2" x 15 Ft.

38,1 MM x 4,6 M

Cycle Suction

Coupler

Ground

Wire

10 Ft.

(3,1 M.)

Standpipe Length

(Min) − (Max)

7.25 Ft. − 12 Ft.

2,2 M − 3,7 M

Discharge

Coupler

PAGE B − 2 INSTALLATION

Page 10

UNIT SERIES OM−01228

CONTAMINANT TANK

(USER SUPPLIED)

DIVERTER VALVE

SUCTION/DISCHARGE RECIRCULATION HOSES

PUMP

TANK

EDUCTOR

MOTOR

STANDPIPE

(GUIDE TUBE)

RETURN

HOSE

REEL ASSEMBLY

CLEANOUT

HOSE

Figure 2. Typical Installation

Perform the following steps, which are illustrated

by Figures 3 through 10, to set up the tankleenor

system for operation.

Figure 3.

See Figure 3 and fill a 55 gallon (208 L) drum (not

supplied) or other ventilated container with

approximately 20 gallons (76 L) of operating liquid

(water). Depending on the size and contamination

of the tank being cleaned, more than one drum

may be required.

Figure 4.

See Figure 4 and install the quick-connect fittings

on the suction and discharge hoses to the eductor

discharge and pump suction. Submerge the other

ends of the hoses in the drum containing the operating liquid (shown in Figure 2).

PAGE B − 3INSTALLATION

Page 11

OM−01228 UNIT SERIES

Figure 7.

Figure 5.

See Figure 7 and position the pump close to the

reel assembly and attach the 8-foot hose from the

See Figure 5 and lower the telescopic standpipe

through the tank fill pipe until it reaches the bottom

of the tank. Adjust the length of the standpipe as

necessary.

top of the eductor to the hose reel.

Figure 6.

See Figure 6 and remove the hose reel assembly

from the pump base and attach it to the standpipe.

Secure it in place with the spring clip on the reel assembly. Align the reel assembly with the direction

of the first cleaning path (see OPERATION, Sec-

tion C).

Figure 8.

See Figure 8 and attach the unit ground wire clip to

the tank fill pipe or other ground connection.

Connect the ground wire to the tank fill

pipe or other ground connection before

operating the unit. Static electric build-

up could develop during the cleaning

operation causing hazardous sparks.

PAGE B − 4 INSTALLATION

Page 12

UNIT SERIES OM−01228

run the motor if the power supply is not

within acceptable limits. If a circuit

breaker or fuse is tripped, examine and

correct the problem before re-starting

the unit.

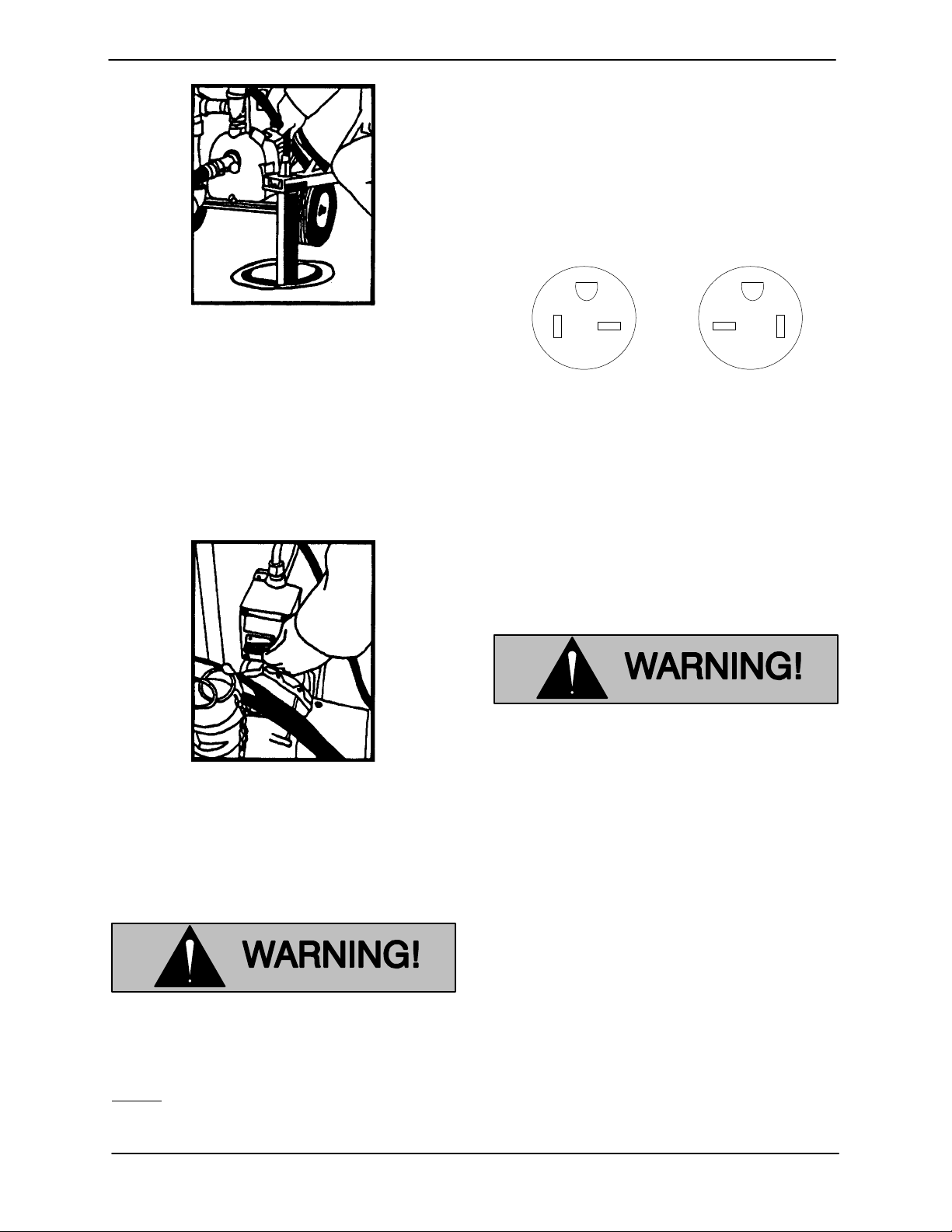

Figure 9.

See Figure 9 and remove the clip that holds the

hose assembly on the reel and insert the nozzle

into the standpiipe. Push the hose down the standpipe until a slight resistance it felt. This occurs

when the suction nozzle travels over the rollers at

the end of the standpipe.

Figure 10.

See Figure 10 and make sure the motor switch is

OFF. Plug the power cable into a 20 amp/120 volt

grounded outlet.

G

Figure 11.

This pump is furnished with a grounded, 20

amp/120 Volt electrical plug as required by the Na-

tional Electric Code (see Figure 11). No cord or

plug substitution is authorized by the Gorman-

Rupp Company.

G

PlugReceptacle

Never attempt to change the electrical

plug or alter the length of the power cord

with a splice. Equipment failure or per-

sonal injury could result if all connec-

tions are not waterproof and compatible

with the electrical current used.

Refer to OPERATION, Section C before starting

the pump.

The electrical power used to operate

this unit is high enough to cause injury

or death to personnel. Connect the electrical plug to a grounded power supply;

never use gas piping as an electrical

ground. Be sure the power supply is of

the correct voltage and phase. Do not

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses.

Hose Connections

Check all hose and pump connections to be sure

the quick-connect couplers and joints are com-

pletely sealed. Hose lines may have to be sup-

ported and secured when filled and operated un-

der pressure.

PAGE B − 5INSTALLATION

Page 13

OM−01228 UNIT SERIES

SUCTION LINES

Position the suction hose as far away as possible

from the discharge hose. The two hoses must be

on opposite sides of the drum.

Suction Line Positioning

The depth of submergence of the suction line is

critical to efficient pump operation. Figure 12

shows recommended minimum submergence vs.

velocity.

NOTE

The pipe submergence required may be reduced

by installing a standard pipe increaser fitting at the

end of the suction line. The larger opening size will

reduce the inlet velocity. Calculate the required

submergence using the following formula based

on the increased opening size (area or diameter).

Figure 12. Recommended Minimum Suction Line Submergence vs. Velocity

DISCHARGE LINES

Siphoning

Do not terminate the discharge line at a level lower

than that of the liquid being pumped. Otherwise, a

siphoning action causing damage to the pump

could result.

shutoff of the system. Make sure this valve is in the

shutoff position after turning the pump off.

If the eductor valve is not in the shutoff

position when turning the pump off, a si-

Valves

This unit is equipped with an eductor control valve

on the discharge side of the pump. The eductor

has a 3-position valve for vacuum, backflush or

PAGE B − 6 INSTALLATION

phoning action could be created, draining

the pump casing, the suction and dis-

charge lines, and the contaminated liquid

in the drum back into the tank.

Page 14

UNIT SERIES

OPERATION − SECTION C

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and

decals attached to the pump.

This pump is designed to handle water,

gasoline or other petroleum products.

Do not attempt to pump corrosive or

highly volatile liquids which may damage the pump or endanger personnel as

a result of pump failure.

OM−01228

Attempting to climb a side or end wall will

cause the hose and nozzle assembly to flip

over and create a severe tangling situation.

Therefore, it is essential to establish the rel-

ative size and position of the underground

tank to properly operate the hose assem-

bly.

The nozzle will precisely follow any horizontal irreg-

ularities of the tank bottom The hose assembly is

not, however, capable of climbing the side or end

walls of the tank.

The following information must be established

prior to beginning a cleaning job:

a. The size of the tank to be cleaned.

b. The direction of the tank’s longitudinal axis.

c. The diameter of the tank’s fill pipe through

which the standpiipe is inserted.

d. The location of the fill pipe with respect to the

length of the tank.

e. Availability of the proper electrical service and

receptacle required for safe operation of the

unit.

This information is necessary to properly install

and operate the pump and to direct the hose assembly within the tank. The hose assembly must

be directed along the bottom of a horizontal, cylindrical tank, and centered within an 18 to 24 inch

wide (457 to 610 mm) cleaning path.

After the pump has been installed, make

certain that the pump and all piping or

hose connections are secure before op-

eration.

PRIMING

Install the pump and piping as described in IN-

STALLATION. Make sure that the piping connec-

tions are tight, and that the pump is securely posi-

tioned.

Remove the dust cap on top of the discharge port

and fill the pump casing with liquid. Be sure to rein-

stall the dust cap after filling the pump casing.

Once filled, the pump will prime and reprime. Be-

tween operations, liquid in the pump may be lost

through evaporation or by spillage if the pump has

been moved. Check the priming chamber to see if

it is full before the pump is started.

The hose assembly is designed so that the hose

nozzle travels straight out from the standpipe and

along the bottom of the tank. The direction of

nozzle travel is adjusted to the tank by rotating the

reel and standpipe assembly to align the cleaning

path with the longitudinal axis of the tank.

OPERATION PAGE C − 1

Leakage

No leakage should be visible at pump mating sur-

faces, or at pump connections or fittings. Keep all

line connections and fittings tight to maintain maxi-

mum pump efficiency.

Page 15

OM−01228 UNIT SERIES

Liquid Temperature And Overheating

The maximum liquid temperature for this unit is

160 F (71C). Do not apply it at a higher operating

temperature.

Overheating can occur if operated with the eductor

valve in the shutoff position for an extended period

of time. Operating against a closed valve could

bring the liquid to a boil, build pressure, and cause

the pump to rupture or explode. If overheating occurs, stop the pump and allow it to completely cool

before servicing it. Refill the pump casing with cool

liquid.

Do not operate the pump against a

closed eductor control valve for long

periods of time. If operated against a

closed eductor control valve, pump

components will deteriorate, and the

liquid could come to a boil, build pres-

sure, and cause the pump casing to rup-

ture or explode.

OPERATION

Refer to INSTALLATION, Section B for proper set-

up of the cleaning system.

Turn the eductor valve to the shutoff position See

Figure 1 for the three positions of the eductor valve.

Do not operate the pump against a

closed eductor control valve for long

periods of time. If operated against a

closed eductor control valve, pump

components will deteriorate, and the

liquid could come to a boil, build pres-

sure, and cause the pump casing to rup-

ture or explode.

a) Shutoff b) Vacuum c) Backflush

Figure 1. Eductor Valve Positioning

Turn the power switch on and rotate the eductor

valve to the vacuum position (Figure 1-b). Observe

the sight glass on the reel assembly. As soon as liquid appears, the tankleenor is ready for operation. Slowly push the hose along the bottom of the

tank. Dirt and contaminates will appear in the sight

glass as they are removed. Stop feeding the hose

into the tank until the sight glass clears, then continue feeding the nozzle along the bottom of the

tank until resistance is felt, indicating that the

nozzle has contacted the end of the tank.

A very slight movement of the reel and

standpipe assembly results in much great-

er movement of the hose and nozzle. Use

extreme caution when repositioning the

reel and standpipe to prevent tangling the

hose.

OPERATIONPAGE C − 2

Page 16

UNIT SERIES

OM−01228

With experience, the operator will learn how to

move the hose to achieve thorough cleaning. The

nozzle should be run to the end of the tank, then

retracted to the standpipe while observing the

sight gauge for additional contaminates during the

return path.

The hose and nozzle cleaning path must

be centered within an 18 to 24 inch wide

(457 to 610 mm) strip, running longitudinally (lengthwise) in the bottom of a cylindrical tank. Prior knowledge of the tank

size and direction are essential to ensure

proper hose travel and direction. If the

hose does not traverse the bottom of the

tank within the 18 to 24 inch wide (457 to

610 mm) strip, the nozzle may run up the

tank side wall and cause the hose to flip

over, creating a severe tangling situation.

Tangling the hose will result in great difficulty in retrieving the hose through the

standpipe and probable destructive damage to the hose. Damage to the hose or

nozzle cause by improper use will not be

covered by the pump warranty. If the hose

becomes tangled, see TROUBLESHOOTING, Section D.

If the suction nozzle becomes clogged with debris,

as evident when product is present in the sight

glass but no movement is observed, the obstruction can normally be flushed from the hose by reversing the liquid flow for a few seconds (see Figure 1-c). After backflushing, return the valve to the

vacuum position (Figure 1-b) and resume the

cleaning process.

STOPPING

When the cleaning job is completed or the cleaning

drum becomes full, turn the switch to the pump off

and turn the eductor valve in the shutoff position

(Figure 1-a). This will prevent the liquid in the drum

and pump from siphoning back into the tank.

When the cleaning job is completed, clean the

system for storage as follows:

Wipe the hose assembly as it is reeled up

from the tank.

Place the suction nozzle of the hose as-

sembly in a container of clean water and

pump water until the liquid being discharged appears clear.

Use caution when winding the hose as-

sembly onto the reel to ensure that the

hose assembly doesn’t kink" or twist. This

could result in permanent damage to the

hose assembly. Damage resulting from im-

properly winding the hose onto the reel will

not be covered by the pump warranty.

Rewind the hose assembly onto the reel.

Use caution when winding the hose onto

the reel to ensure that the hose doesn’t

kink"or twist, which can result in permanent damage to the hose.

When the hose is fully wound onto the reel,

anchor it in place with the retaining clip.

Rotate the reel several times to drain excess liquid from the hose.

Disconnect the reel assembly from the

standpipe and secure it on the base. Disconnect the power cable and ground wire.

Coil and stow them on the cable retaining

rack.

Disconnect and drain the suction and dis-

When performing the cleaning operation,

keep the suction and discharge hoses

submerged and off the bottom of the container. Otherwise, spillage or flow shutoff

could occur.

OPERATION PAGE C − 3

charge hoses.

If the unit will be stored for an extended period, re-

move the drain plug from the pump casing and

drain any remaining liquid. Clean and reinstall the

drain plug.

Page 17

OM−01228 UNIT SERIES

Cold Weather Preservation

In below freezing conditions, drain the pump to

prevent damage from freezing. Also, clean out any

solids by flushing with a hose. Operate the pump

for approximately one minute; this will remove any

remaining liquid that could freeze the pump rotating parts.

OPERATIONPAGE C − 4

Page 18

UNIT SERIES

TROUBLESHOOTING − SECTION D

Review all SAFETY information in Section A.

Before attempting to open or service the

pump:

1. Familiarize yourself with this manual.

2. Unplug the motor to ensure that the

pump will remain inoperative.

3. Allow the pump to completely cool if

overheated.

4. Close the eductor control valve.

5. Check the temperature before opening any covers, plates, or plugs.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

OM−01228

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

UNIT FAILS TO

PRIME

PUMP STOPS OR

FAILS TO DELIVER

RATED FLOW OR

PRESSURE

Pump fails to start. Check electrical connections.

Air leak in suction line. Correct leak.

Lining of suction hose collapsed. Replace suction hose.

Leaking or worn seal or pump gasket. Check pump vacuum. Replace

leaking or worn seal or gasket.

Air leak in suction line. Correct leak.

Suction intake not submerged at proper Check installation and correct

level or sump too small. submergence as needed.

Lining of suction hose collapsed. Replace suction hose.

Impeller or other wearing parts worn Replace worn or damaged parts.

or damaged. Check that impeller is properly

centered in the pump casing and

that it rotates freely.

Impeller clogged. Free impeller of debris.

Leak in hose assembly above product Replace hose.

level.

Clogged nozzle and/or hose assembly. Backflush system.

Open circuit in motor windings or Check motor continuity.

power cable.

TROUBLESHOOTING PAGE D − 1

Page 19

OM−01228

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

UNIT SERIES

PUMP REQUIRES

TOO MUCH

POWER

UNIT CLOGS

FREQUENTLY

EXCESSIVE NOISE

HOSE ASSEMBLY

WILL NOT REEL

BACK UP THE

STANDPIPE. HOSE

SEEMS STUCK IN

STANDPIPE.

Liquid solution too thick. Dilute if possible.

Low or incorrect voltage. Measure voltage, both when pump

is running and when shut off.

Liquid solution too thick. Dilute if possible.

Discharge line clogged or restricted; Check discharge lines; straighten

hose kinked. hose.

Feeding hose assembly into tank too Feed hose assembly slowly and

fast. watch flow through sight glass.

Cavitation in pump. Reduce suction lift and/or friction

losses in suction line. Record

vacuum and pressure gauge

readings and consult local

representative or factory.

Pumping entrained air. Locate and eliminate source of air

bubble.

Pump or drive not securely mounted. Secure mounting hardware.

Impeller clogged or damaged. Clean out debris; replace damaged

parts.

Hose assembly has become tangled Shutoff unit and drain hose

and the flat spring strap inside the hose assembly back into the tank. Rewill not allow the assembly to easily move reel from the standpipe.

slide back through the bottom opening Do not force the hose assembly

of the standpipe. Tangling has occurred through the standpipe. Carefully

due to improperly directing the hose raise the standpipe (with the hose

inside the tank or by continuing to feed assembly still inside) out of the tank

the hose assembly after the nozzle has fill pipe, then carefully feed the

contacted the end of the tank. hose assembly back through the

standpipe. Roll the hose assembly

back into the reel, making sure the

steel strip inside the hose is not

twisted. The steel strip must roll

parallel to the axis of the reel

(similar to the tape in a measuring

tape ruler). Set up the equipment

again, this time being careful to

properly feed the hose assembly

into the tank.

TROUBLESHOOTINGPAGE D − 2

Page 20

UNIT SERIES

OM−01228

PREVENTIVE MAINTENANCE

Since pump applications are seldom identical, and

pump wear is directly affected by such things as

the abrasive qualities, pressure and temperature

of the liquid being pumped, this section is intended

only to provide general recommendations and

practices for preventive maintenance. Regardless

of the application however, following a routine preventive maintenance schedule will help assure

trouble-free performance and long life from your

Gorman-Rupp pump. For specific questions concerning your application, contact your GormanRupp distributor or the Gorman-Rupp Company.

Record keeping is an essential component of a

good preventive maintenance program. Changes

in suction and discharge gauge readings (if so

equipped) between regularly scheduled inspections can indicate problems that can be corrected

before system damage or catastrophic failure occurs. The appearance of wearing parts should also

be documented at each inspection for comparison

as well. Also, if records indicate that a certain part

(such as the seal) fails at approximately the same

duty cycle, the part can be checked and replaced

before failure occurs, reducing unscheduled down

time.

For new applications, a first inspection of wearing

parts at 250 hours will give insight into the wear rate

for your particular application. Subsequent inspections should be performed at the intervals shown

on the chart below. Critical applications should be

inspected more frequently.

Preventive Maintenance Schedule

Service Interval*

Item

General Condition (Temperature, Unusual

Noises or Vibrations, Cracks, Leaks,

Loose Hardware, Etc.) I

Pump Performance (Gauges, Speed, Flow) I

Impeller Clearance I

Piping I

Daily Weekly Monthly Semi-

Annually

Annually

Legend:

I = Inspect, Clean, Adjust, Repair or Replace as Necessary

C = Clean

R = Replace

* Service interval based on an intermittent duty cycle. Adjust schedule as required for lower or

higher duty cycles or extreme operating conditions.

TROUBLESHOOTING PAGE D − 3

Page 21

UNIT SERIES OM−01228

PUMP MAINTENANCE AND REPAIR - SECTION E

MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK

OPERATING PERFORMANCE.

LIFT

(FT./M)

5 1,5

/

10 3,0

/

15 4,6

/

20 6,1

/

BACKFLUSH = 7.5 GPM (28,4 LPM) @25 PSI (1,7 BAR).

TRANSFER FLOW = 81 GPM (307 LPM) THROUGH PUMP WITH 1−1/2 INCH HOSE.

STANDARD PERFORMANCE FOR UNIT 608 tankleenor

Based on 70 F (21 C) clear water at sea level

with minimum suction lift. Since pump installations

are seldom identical, your performance may be difference due to such factors as viscosity, specific

gravity, elevation, temperature, and impeller trim.

EDUCTOR CAPACITY

(GPM/LPH)

3.25 738

/

2.70 613

/

1.84 418

/

0.60 137

/

If your pump serial number is followed by an N",

your pump is NOT a standard production model.

Contact the Gorman-Rupp Company to verify performance or part numbers.

VACUUM

(IN. OF HG./BAR)

15 1,03

16 1,10

16 1,10

18 1,24

/

/

/

/

r

MAINTENANCE & REPAIR PAGE E − 1

Page 22

PARTS PAGE

UNIT SERIESOM−01228

SECTION DRAWING

Figure 1. UNIT 608 tankleenor

r

MAINTENANCE & REPAIRPAGE E − 2

Page 23

UNIT SERIES OM−01228

PARTS LIST

UNIT 608 tankleenor

r

(From S/N 1347755 Up)

If your pump serial number is followed by an N", your pump is NOT a standard production model. Contact

the Gorman-Rupp Company to verify part numbers.

ITEM

NO.

10 DUST CAP S1296 −−− 1

11 PIPE TEE U24 11999 1

12 PIPE NIPPLE T2414 16079 1

13 RED PIPE BUSHING AP3224 11999 1

14 HOSE AND REEL ASSY 41331−011 −−− 1

15 −HOSE REEL ASSY 41331−009 −−− 1

16 −HOSE ASSY 46341−428 −−− 1

17 DUST PLUG S1295 −−− 1

18 COUPLER S1293 −−− 1

19 PIPE COUPLING AE24 15079 1

20 PIPE NIPPLE T24 15079 1

21 RED PIPE BUSHING AP3224 11999 1

22 1HP 1P X-PROOF MOTOR M13 −−− 1

23 WARNING DECAL 2613FE −−− 1

24 X-PROOF SWITCH S2219 −−− 1

25 PIPE NIPPLE T08 15079 1

26 RED PIPE BUSHING AP1208 15079 2

27 PIPE NIPPLE T12 15079 1

28 PIPE COUPLING AE1612 15079 1

29 CABLE GRIP ASSY 27111−622 −−− 1

30 FORK TERMINAL 27215−061 −−− 1

31 CONNECTOR 27284−003 −−− 4

PART NAME PART

NUMBER

1 PUMP PARTS ONLY PPO (UNIT 608) −−− 1

2 EDUCTOR VALVE ASSY 13559 −−− 1

3 STREET ELBOW RS12 11999 1

4 CORD ASSY 7987F −−− 1

5 HOSE ASSEMBLY 46341−012 −−− 1

6 PIPE COUPLING AE24 15079 1

7 PIPE NIPPLE T24 15079 1

8 ADAPTOR S1294 −−− 1

9 CABLE TIE 27111−222 −−− 2

MAT’L

CODE

QTY ITEM

NO.

32 HANDLE 5438A 15990 1

33 BASE 13832 24000 1

34 HEX HD CAPSCREW B0605 15991 2

35 HEX NUT D06 15991 2

36 LOCK WASHER J06 15991 2

37 NAME PLATE 38818−016 −−− 1

38 SPACER WASHER 5382 15991 4

39 AXLE 6158D 15990 1

40 HAIR PIN CLIP 21183−010 −−− 2

41 TIRE S752 −−− 2

42 PIPE ELBOW R32 11999 1

43 RED PIPE BUSHING AP3224 11999 1

44 ADAPTOR S1294 −−− 1

45 CABLE TIE 27111−222 −−− 2

46 DUST CAP S1296 −−− 1

47 SPACER WASHER 5382 15991 4

48 WING NUT BB06 15991 1

49 LOCK WASHER J06 15991 1

50 WASHER 31131−011 17040 1

51 HEX HD CAPSCREW B0606 15991 4

52 T-TYPE LOCK WASHER BL06 15991 8

53 HEX NUT D06 15991 4

54 STANDPIPE ASSY 46312−009 −−− 1

55 GROUND WIRE ASSY 13830 −−− 1

56 HEX HD CAPSCREW B0403 15991 1

57 T-TYPELOCK WASHER BL04 15991 2

58 HEX NUT D04 15991 1

NOT SHOWN:

PART NAME PART

NUMBER

SUCTION HOSE ASSY 46341−013 −−− 1

DISCHARGE HOSE ASSY 46341−014 −−− 1

MAT’L

CODE

QTY

MAINTENANCE & REPAIR PAGE E − 3

Page 24

SECTION DRAWING

UNIT SERIESOM−01228

Figure 2. PPO (UNIT 608)

MAINTENANCE & REPAIRPAGE E − 4

Page 25

UNIT SERIES OM−01228

PARTS LIST

PPO (UNIT 608)

ITEM

NO.

1 PUMP CASING 6366 10010 1

2 IMPELLER 6594 14000 1

3 MECHANICAL SEAL 25271−821 −−− 1

4 FILL PLUG ASSEMBLY 48271−060 −−− 1

5 PUMP CASING GASKET 2958GB 20000 1

6 INTERMEDIATE BRACKET 6367 10010 1

7 STUD C0606 15991 8

8 HEX NUT D06 15991 8

9 RD HD MACHINE SCREW X0402 14990 3

10 ROTATION DECAL 2613M −−− 1

11 STUD C0606 15991 4

12 LOCK WASHER J06 15991 4

13 HEX NUT D06 15991 4

14 IMPELLER ADJUSTING SHIM SET 5889 170001 1

15 VANE PLATE 6378 10010 1

16 PIPE PLUG P08 15079 1

17 PIPE PLUG P04 15079 1

18 IMPELLER NUT AT07S 15991 1

19 VANE PLATE O-RING S1487 −−− 1

NOT SHOWN:

PART NAME

NAME PLATE 38818−020 13990 1

DRIVE SCREW BM#04−03 17000 4

REDUCWER COUPLING AE1208 15079 1

PART

NUMBER

MAT’L

CODE

QTY

INDICATES PARTS RECOMMENDED FOR STOCK

MAINTENANCE & REPAIR PAGE E − 5

Page 26

SECTION DRAWING

UNIT SERIESOM−01228

Figure 3. 13559 Eductor Valve Assembly

MAINTENANCE & REPAIRPAGE E − 6

Page 27

UNIT SERIES OM−01228

PARTS LIST

13559 Eductor Valve Assembly

ITEM

NO.

1 VENTURI 13562 13040 1

2 VALVE EDUCTOR BODY 13560 13047 1

3 VALVE PLUG 13563 14004 1

4 WAVE WASHER S1592 −−− 1

5 GASKET 13564G 20000 1

6 HANDLE 13777 11000 1

7 O-RING S2120 −−− 1

8 RD HD MACHINE SCREW X0402 15991 1

9 LOCK WASHER J04 15991 1

10 FLAT WASHER K04 15991 1

11 INDEX PLATE 13565 17990 1

12 VALVE CAP 13564 13040 1

13 NOZZLE 13561 13040 1

14 GASKET 13562G 20000 1

15 COMPOUND GAUGE S155 −−− 1

INDICATES PARTS RECOMMENDED FOR STOCK

PART NAME

PART

NUMBER

MAT’L

CODE

QTY

MAINTENANCE & REPAIR PAGE E − 7

Page 28

SECTION DRAWING

UNIT SERIESOM−01228

Figure 4. 41331−009 Reel Assembly

MAINTENANCE & REPAIRPAGE E − 8

Page 29

UNIT SERIES OM−01228

PARTS LIST

41331−009 Reel Assembly

ITEM

NO.

1 REEL SPINDLE 31781−009 14100 REF

2 RD HD NYLOCK MACHINE SCREW XA#10−01−1/2 15991 1

3 SNAP RING 24124−134 −−− 1

4 RETAINING WIRE ASSEMBLY 41158−804 −−− 1

5 THUMB SCREW BH0401−1/2 15991 1

6 CLAMP ASSEMBLY 41125−803 −−− 1

7 REEL DISC 31281−031 13090 2

8 SPACER 31481−001 13150 7

9 HEX HD CAPSCREW B0503 15991 14

10 LOCK WASHER J05 15991 14

11 WASHER 31131−061 19210 2

12 SWIVEL 46381−102 −−− 1

13 SIGHT TUBE ASSEMBLY 46311−015 −−− 1

14 GROMMET 27135−081 −−− 1

15 SPRING 31977−002 15091 1

16 COTTER PIN M0303 15991 1

17 HOSE BASE ASSEMBLY 41583−551 24151 1

18 WARNING DECAL 38816−126 −−− 2

19 PIPE ASSEMBLY 46335−046 −−− 1

20 CAUTION TAG 38816−124 −−− 1

21 ADAPTOR S2237 −−− 1

22 PIPE ELBOW R12 11999 1

PART NAME

−SIGHT TUBE 26867−105 −−− 1

−MALE ADAPTOR 26525−302 −−− 1

−CLOSE NIPPLE T12 15079 1

PART

NUMBER

MAT’L

CODE

QTY

MAINTENANCE & REPAIR PAGE E − 9

Page 30

SECTION DRAWING

UNIT SERIESOM−01228

Figure 5. 46341−428 Hose Assembly

MAINTENANCE & REPAIRPAGE E − 10

Page 31

UNIT SERIES OM−01228

PARTS LIST

46341−428 Hose Assembly

ITEM

NO.

1 HOSE GUARD NOT AVAILABLE −−− 1

2 FERRULE 26526−307 −−− 1

3 HOSE COUPLING 31874−018 14990 1

4 ROLL PIN S2196 −−− 1

5 ROLL PIN 21154−673 −−− 1

6 TAPE NOT AVAILABLE −−− 1

7 HOSE NOT AVAILABLE −−− 1

8 HOSE NOZZLE 38634−015 14100 1

9 HOSE NOZZLE GUARD 34875−003 17000 1

10 FLAT HEAD MACHINE SCREW 21516−002 −−− 4

11 ROLLER PIN 31312−015 14100 1

12 ROLLER 31411−086 23050 1

13 INSTALLATION TAG 38817−086 −−− 1

PART NAME

PART

NUMBER

MAT’L

CODE

QTY

MAINTENANCE & REPAIR PAGE E − 11

Page 32

SECTION DRAWING

UNIT SERIESOM−01228

Figure 6. 46312−009 Standpipe Assembly

PARTS LIST

ITEM

NO.

1 ROLL PIN S1611 −−− 2

2 ROLLER 31411−099 23050 3

3 ROLLER PIN 31312−014 14100 3

4 INNER/OUTER STAND ASSEMBLY 46312−011 24170 1

5 ROLLER 31141−022 23050 1

PART NAME

PART

NUMBER

MAT’L

CODE

MAINTENANCE & REPAIRPAGE E − 12

QTY

Page 33

OM−01228UNIT SERIES

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY

Review all SAFETY information in Section A.

Follow the instructions on all tags, label and decals attached to the pump.

This pump requires little service due to its rugged,

minimum-maintenance design. However, if it becomes necessary to inspect or replace the wearing

parts, follow these instructions which are keyed to

the sectional views (see Figures 1, 2 and 3) and the

accompanying parts lists.

This manual will alert personnel to known procedures which require special attention, to those

which could damage equipment, and to those

which could be dangerous to personnel. However,

this manual cannot possibly anticipate and provide

detailed precautions for every situation that might

occur during maintenance of the unit. Therefore, it

is the responsibility of the owner/maintenance personnel to ensure that only safe, established main-

tenance procedures are used, and that any procedures not addressed in this manual are performed

only after establishing that neither personal safety

nor pump integrity are compromised by such practices.

Before attempting to service the pump, disconnect

the power source to ensure that the pump will remain inoperative. Close all valves in the suction

and discharge lines.

For motor service and repair, consult the literature

supplied with the motor, or contact your local motor

representative.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Vent the pump slowly and cautiously.

6. Drain the pump.

Before operating or servicing the pump,

be certain proper safety practices are

followed. Provide adequate ventilation,

prohibit smoking, wear static-resistant

clothing and shoes. Clean up all fuel

spills immediately after occurrence.

Pump Disassembly

(Figure 2)

Before attempting to service the pump, remove the

pump housing drain plug (16) and drain the pump.

Clean and reinstall the drain plug.

If installed, disconnect the suction and discharge

hoses from the pump. See Figure 1 and and install

the dust cap (10) and dust plug (17) to protect the

suction and discharge ports from damage or contamination. Unscrew the hose assembly (5) from

the elbow (3).

To service the impeller (2), seal assembly (3), or vane plate (15), the pump casing (1) must be separated from the intermediate (6). See Figure 1 and

remove the hardware (51, 52 and 53) securing the

pump casing to the base (33).

Remove the nuts (8) and separate the pump casing and gasket (5) from the intermediate bracket

(6).

It is not necessary to remove the piping for the

eductor (2, Figure 1) from the pump casing unless

Before attempting to open or service the

pump:

the eductor requires service. If the eductor requires service, disengage only enough piping to

allow removal of the eductor.

1. Familiarize yourself with this manual.

2. Unplug the motor to ensure that

Impeller Removal

(Figure 2)

the pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

MAINTENANCE & REPAIR PAGE E − 13

For access to the impeller (2), disengage the machine screws (9) and remove the vane plate (15).

Page 34

Clean the adhesive sealant from the faces of the

vane plate and the intermediate. Remove the vane

plate O-ring (19).

UNIT SERIESOM−01228

Insert a large flat head screwdriver in the slot in the

end of the shaft of the motor (22, Figure 1) to prevent shaft rotation and remove the impeller nut

(18).

Insert a soft metal bar between the vanes of the impeller and use the bar to unscrew the impeller from

the motor shaft in a counterclockwise direction.

Use caution not to damage the impeller vanes.

Use caution when removing the impeller; tension

on the seal spring will be released as the impeller is

removed.

Remove the impeller adjusting shims (14). Tie and

tag the shims or measure and record their thickness for ease of reassembly.

Seal Removal and Disassembly

(Figure 2)

Remove the seal spring. Apply oil to the shaft and

work it up under the rubber bellows. Slide the rotating portion of the seal off the shaft.

Remove the hardware (12 and 13) securing the intermediate bracket (6) to the motor, and slide the

intermediate bracket and stationary seal components off the shaft as a unit. Use a suitably sized

dowel to press the seal stationary element and seat

out of the intermediate from the back side.

Most cleaning solvents are toxic and

flammable. Use them only in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent containers.

The seal is not normally reused because wear patterns on the finished faces cannot be realigned

during reassembly. This could result in premature

failure. If necessary to reuse an old seal in an emergency, carefully wash all metallic parts in fresh

cleaning solvent and allow to dry thoroughly.

Handle the seal parts with extreme care to prevent

damage. Be careful not to contaminate precision

finished faces; even fingerprints on the faces can

shorten seal life. If necessary, clean the faces with a

non-oil based solvent and a clean, lint-free tissue.

Wipe lightly in a concentric pattern to avoid

scratching the faces.

Inspect the seal components for wear, scoring,

grooves, and other damage that might cause leakage. If any components are worn, replace the complete seal; never mix old and new seal parts.

If a replacement seal is being used, remove it from

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter.

Seal Reassembly and Installation

(Figure 2)

Clean the seal cavity and shaft with a cloth soaked

in fresh cleaning solvent.

To ease installation of the seal, lubricate the bellows with water or a very small amount of light lubricating oil, and apply a drop of light lubricating oil

on the finished faces. Assemble the seal as follows,

(see Figure 7).

MAINTENANCE & REPAIRPAGE E − 14

Page 35

OM−01228UNIT SERIES

SPRING

IMPELLER

SHIMS

IMPELLER

IMPELLER

SHAFT

SPRING

RETAINER

BELLOWS

RETAINER

DRIVE BAND

INTERMEDIATE

ROTATING

ELEMENT

STATIONARY

ELEMENT

STATIONARY

SEAT

Figure 7. 25271−821 Seal Assembly

This seal is not designed for operation at

temperatures above 160F (71C). Do not

use at higher operating temperatures.

Position the intermediate bracket (6) on a flat surface with the impeller side facing up. Subassemble

the stationary element and seat, and use even

pressure to press this subassembly into the intermediate bracket until squarely seated in the intermediate bore.

Carefully slide the assembled intermediate and

stationary seal components over the motor shaft

and secure the intermediate to the motor with the

hardware (12 and 13).

Subassemble the rotating element into the retainer

and bellows. Lubricate the I.D. of the bellows with

water, and slide this subassembly onto the shaft

until the polished faces contact. Install the seal

spring and spring retainer.

Impeller Installation

(Figure 2)

Inspect the impeller and replace it if cracked or

badly worn.

For maximum pump efficiency, the impeller should

be centered within the vane plate scroll.

To verify the impeller positioning, measure the

vane plate and impeller as shown in Figure 8. Use

these measurements to calculate the required impeller location (dimension E). Add or remove impeller adjusting shims (14) until dimension E is obtained.

MAINTENANCE & REPAIR PAGE E − 15

Page 36

B

2

AB

UNIT SERIESOM−01228

CD

D

2

E

Step 2Step 1 Step 3

B

+

A

2

Figure 8. Centering Impeller Within Vane Plate Scroll

Install the correct thickness of impeller shims and

screw the impeller onto the shaft until fully seated.

NOTE

At the slightest sign of binding, immediately back

the impeller off, and check the threads for dirt. Do

not try to force the impeller onto the shaft.

When the impeller is properly positioned, apply

‘Loctite Threadlocker No. 242’ or equivalent compound to the shaft threads and screw the impeller

nut (18) onto the shaft until tight.

NOTE

After the impeller has been properly positioned,

check for free rotation. Correct any scraping binding before further reassembly.

−

D

+

C

2

Ease the pump housing over the vane plate. Be

careful not to damage the vane plate O-ring. Se-

cure the housing to the intermediate bracket with

the nuts (8).

Final Pump Assembly

(Figure 1)

Secure the pump casing to the base (33) with the

previously removed hardware (51, 52 and 53). If removed, reinstall the eductor (2) and piping. Install

the hose (5) in the elbow (3). Make certain that all

piping connections are tight, properly supported

and secure.

(Figure 2)

=

E

Clean any remaining adhesive sealant from the

faces of the vane plate (15) and intermediate. Apply a thin coating of ‘3-M Scotch Grip Adhesive No.

847’ or equivalent compound to the face of the intermediate. Secure the vane plate to the intermediate bracket using the machine screws (9).

Pump Reassembly

(Figure 2)

Install the vane plate O-ring (29) into the groove in

the vane plate. Install the pump casing gasket (5).

Fill the pump casing with clean liquid. Reinstall the

fill plug (4) and tighten it.

Refer to OPERATION, Section C, before putting

the pump back into service.

LUBRICATION

Seal Assembly

The seal assembly is lubricated by the medium being pumped and no additional lubrication is required.

MAINTENANCE & REPAIRPAGE E − 16

Page 37

OM−01228UNIT SERIES

EDUCTOR VALVE DISASSEMBLY AND

REASSEMBLY

All instructions in this section are keyed to Figure 3

and the accompanying parts list.

Eductor Valve Disassembly

Unscrew the hose assembly (5, Figure 1) and disconnect the valve assembly from the pump. Remove the pressure gauge (15) and disengage the

piping from the eductor valve.

Secure the valve in a vice and unscrew the venturi

(1) from the valve body (2). Remove the gasket (14)

and clean the mating surfaces.

Use a socket wrench to unscrew the eductor

nozzle (13) from the valve body.

To service the valve plug (3), remove the valve handle (6) and index plate (11) by removing the hardware (8, 9 and 10). Unscrew the valve cap (12) from

the valve body. Remove the gasket (5) and clean

the mating surfaces.

Slide the valve plug into the valve body and install

the wave washer (4).

NOTE

Apply Never-Seez" or equivalent compound on all

eductor threads before reassembly.

Replace the cap gasket (5) and screw the cap into

the valve body until fully seated.

Position the index plate (11) on the plug shaft with

the words SHUT-OFF" at the indicator on the valve

body. Reassemble the handle (6) at the 9 o’clock

position and secure it with the attaching hardware

(8, 9 and 10).

Screw the valve nozzle (13) into the valve body until

fully seated.

Install the venturi gasket (14) and screw the venturi

into the valve body until fully seated.

Install the pressure gauge (15).

Check the operation of the valve handle for free

movement in all positions.

Remove the wave washer (4) and pull the valve

plug from the valve body. Remove the O-ring (7)

from the groove in the valve plug shaft.

Eductor Valve Reassembly

Clean the valve plug (3), valve cap (12) nozzle (13)

and valve body (2) with a cloth soaked in fresh

cleaning solvent.

Most cleaning solvents are toxic and

flammable. Use them only in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent containers.

Inspect all eductor valve components and replace

them as required.

Reinstall the valve piping and secure it to the pump

assembly. See Figure 1 and reconnect the hose (5)

to the elbow (3).

HOSE AND REEL DISASSEMBLY AND

REASSEMBLY

Hose Disassembly

(Figure 5)

Remove the hose and reel assembly from the unit

base. See Figure 4, loosen the thumbscrew (5), remove the clamp (6) and unwind the hose assembly

from the reel. Reach through the hole in the side of

the reel disc (7) and use a wrench to unscrew the

hose assembly from the pipe assembly (19).

Inspect the nozzle end of the hose assembly. Disassembly in the field is not recommended; however, if the nozzle or other parts require replacement,

individual parts are available.

Apply a small amount of light oil to the O-ring (7)

and install it in the groove on the valve plug shaft.

MAINTENANCE & REPAIR PAGE E − 17

To remove the nozzle (8), remove the screws (10)

and separate the guard (9) from the hose end.

Page 38

UNIT SERIESOM−01228

If the roller (12) requires replacement, grind the

head off the roller pin (11), tap the pin out of the

guard and remove the roller.

To remove the nozzle (8) from the hose, tap the roll

pin (5) out of the nozzle and separate the nozzle

from the hose and strap (6).

Inspect the hose assembly for cuts,

punctures or severe abrasion. Replace

the complete hose assembly if there is

any possibility of leakage or exposure

of the integral steel tape.

Do not try to separate the tape or hose guard from

the hose. If the hose, tape or guard are damaged,

the compete hose assembly must be replaced; individual parts are not available.

If replacement of the pipe assembly (19) or reel

spindle is required, remove the hardware (9 and

10) and separate the discs and spacers (8). Remove the internal pipe fittings as required.

If the spring (15) requires replacement, remove the

cotter pin (16) from the base assembly (17) and

pull the clip from the base.

Reel Reassembly

(Figure 4)

If removed, position the spring (15) in the base and

secure it by sliding the cotter pin (16) over the clip,

then through the hole in the bottom of the base.

Spread the end of the cotter pin.

Clean the sight tube assembly parts, pipe assembly parts, spindle and swivel fitting with fresh cleaning solvent.

Reel Disassembly

(Figure 4)

With the hose assembly (5, Figure 1) removed, use

an open ended wrench on the hex fitting on the

bottom of the swivel (12) while using another open

ended wrench to unscrew the sight tube assembly

from the swivel. Slide the sight tube assembly

down through the grommet (14).

It is not necessary to disassemble the sight tube

assembly unless the glass gauge is broken. If the

glass gauge is to be replaced, unscrew the elbow

(22) from the close nipple in the bottom of the

gauge. Unscrew the close nipple from the bottom

of the gauge and the adaptor from the top of the

gauge.

Disengage the machine screw (2) from the reel

spindle (1) and remove the thumbscrew (5) clamp

(6) and wire (4).

To remove the swivel (12), immobilize the reel

spindle and unscrew the swivel from the spindle.

To remove the reel discs (7) from the base (17), remove the snap ring (3), spread the top of the base

assembly slightly, and lift the assembled spindle

and discs from the base. Remove the washers (11)

from the spindle.

Most cleaning solvents are toxic and

flammable. Use them only in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent containers.

NOTE

Apply Loctite Pipe Sealant with Teflon" or equivalent compound to all pipe thread connections before reassembly.

If removed, reassemble the pipe assembly (19) to

the spindle (1). Position the two discs (7) on the

spindle and secure them with the spacers (8) and

hardware (9 and 10).

Position the washers (11) on the spindle. Slightly

spread the top of the base assembly and position

the reel in the holes in the sides of the base. Screw

the swivel (12) into the spindle.

Secure the reel to the base with the snap ring (3).

Secure the clamp (6, thumbscrew (5) and wire assembly (4) to the spindle with the machine screw

(2).

If the glass sight gauge is being replaced, hand

tighten the brass fittings on the ends of the tube to

MAINTENANCE & REPAIRPAGE E − 18

Page 39

OM−01228UNIT SERIES

make certain the gaskets inside the brass end nuts

seal the glass tube. Use caution not to break the

glass tube. After tightening the fittings, apply 3−4

drops of ‘Loctite Threadlocker No. 242’ or equivalent compound to each threaded joint. The threadlocker will leach" into the threads to prevent loosening of the sight glass tube. Install the male adaptor and close nipple in the ends of the sight gauge.

NOTE

When tightening the sight tube adaptor and close

nipple, hold the hex fittings on either end of the

sight tube assembly with an open ended wrench to

prevent the end fittings of the sight tube assembly

from tightening and breaking the sight gauge.

Slide the sight tube assembly up through the

grommet (14) with the male adaptor fitting toward

the swivel (12). Screw the sight tube assembly into

the swivel, then reinstall the elbow (22).

See Hose Reassembly when connecting the

hose to the reel.

Assemble the roller (12) in the nozzle guard and

install with the roller pin (11). Peen the end of the

pin to retain the roller.

Connect the other end of the hose assembly to the

reel assembly. Reach through the access hole in

the reel discs with two open end wrenches and

tighten the fittings.

NOTE

The reel end of the hose assembly must be positioned so the word TOP" on the hose fitting is visible when looking down at the fitting between the

reel discs.

Coil the hose into the reel assembly and and check

the position of the hose nozzle. The nozzle must be

positioned as shown in Figure 4 with the roller

away from the center of the reel.

STANDPIPE DISASSEMBLY AND

REASSEMBLY

Hose Reassembly

(Figure 5)

Clean the nozzle parts in fresh cleaning solvent.

Most cleaning solvents are toxic and

flammable. Use them only in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent containers.

Insert the hose nozzle (8) into the end of the hose

assembly so the hole in the metal tape inside the

hose aligns with the hole in the nozzle and secure it

with the roll pin (5).

Install the nozzle guard (9) over the nozzle and secure with the machine screws (10).

Standpipe Disassembly

(Figure 6)

If the rollers (2) require replacement, grind off the

ends of the roller pins (3) and tap the pins from the

standpipe.

The roller (5) can be removed by removing the roll

pin from the roller and standpipe wall.

Standpipe Reassembly

(Figure 6)

If removed, position the roller (5) between the walls

of the standpipe and secure it with the previously

remove roll pin.

Align the rollers (2) with the holes in the tubing wall

and tap the roller pins (3) through the walls and roller. Peen the end of the roller pins to secure.

MAINTENANCE & REPAIR PAGE E − 19

Page 40

For U.S. and International Warranty Information,

Please Visit www.grpumps.com/warranty

or call:

U.S.: 419−755−1280

International: +1−419−755−1352

For Canadian Warranty Information,

Please Visit www.grcanada.com/warranty

or call:

519−631−2870

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA

Loading...

Loading...