GORMAN-RUPP PUMPS T SERIES, T10A61-B Installation, Operation And Maintenance Manual

CDSW

OM---01936---OB03

August 15, 1984

Rev. K 11/22/02

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

TSERIESPUMP

MODEL

T10A61---B

INCLUDING: /FM, /WW

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

www.gormanrupp.com

ECopyright by the Gorman-Rupp Company

TABLE OF CONTENTS

INTRODUCTION PAGE I --- 1.................................................

SA FE TY --- SECTION A PA GE A --- 1...........................................

IN STALLAT ION --- SECTION B PA GE B --- 1....................................

Pump Dimensions PAGE B --- 1.....................................................

PREINSTALLATION INSPECTION PAGE B --- 1............................................

Battery Specifications And Installation PAGE B --- 2....................................

POSITIONING PUMP PA GE B --- 2.......................................................

Lifting PA GE B --- 2.................................................................

Mounting PA GE B --- 2.............................................................

SUCTION AND DISCHARGE PIPING PAGE B --- 2.........................................

Materials PA GE B --- 2..............................................................

Line Configuration PAGE B --- 2......................................................

Connections to Pump PAGE B --- 2..................................................

Gauges PA GE B --- 3...............................................................

SUCTION LINES PAGE B --- 3...........................................................

Fittings PA GE B --- 3...............................................................

Strainers PA GE B --- 3..............................................................

Sealing PAGE B --- 3...............................................................

Suction Lines In Sumps PAGE B --- 3.................................................

Suction Line Positioning PAGE B --- 3................................................

DISCHARGE LINE S PA GE B --- 4........................................................

Siphoning PA GE B --- 4.............................................................

Valves PA GE B --- 4................................................................

Bypass Lines PA GE B --- 4..........................................................

AUTOMATIC AIR RELEASE VALVE PAGE B --- 5...........................................

Theory of Operation PAGE B --- 6....................................................

Air Release V alve Installation P AGE B --- 6............................................

ALIGNMENT PAGE B --- 7..............................................................

Coupled Drives PA GE B --- 8........................................................

V-Belt Drives PA GE B --- 8...........................................................

OP E R ATION --- SE CTION C PAGE C --- 1......................................

PRIMING PA GE C --- 1.................................................................

STARTING PA GE C --- 1................................................................

OPERATION PA GE C --- 1..............................................................

Lines With a Bypass PAGE C --- 1....................................................

Lines Without a Bypass PAGE C --- 1.................................................

Leakage PAGE C --- 2..............................................................

Liquid Temperature And Overheating PAGE C --- 2.....................................

Strainer Check PAGE C --- 2.........................................................

Pump Vacuum Check PAGE C --- 2..................................................

STOPPING PA GE C --- 3................................................................

Cold Weather Preservation PAGE C --- 3..............................................

BEARING TEMPERATURE CHECK PAGE C --- 3..........................................

TROUBLESHOO T I N G --- S E C T I O N D PA G E D --- 1..............................

PREVENTIVE MAINTENANCE PAGE D --- 3...............................................

i

TABLE OF CONTENTS

(continued)

PUMP MAINTENANCE AND REPAIR --- SECTION E PAGE E --- 1................

PERFORMANCE CURVE PA GE E --- 1...................................................

PARTS LISTS:

Pump Model PAGE E --- 3..........................................................

Repair Rotating Assembly PAGE E --- 5...............................................

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E --- 6.........................

Cleanout Access And Suction Check Valve Removal PAGE E --- 6.......................

Suction Head And Wear Plate Removal PAGE E --- 6...................................

Rotating Assembly Removal PAGE E --- 7.............................................

Impeller Removal P AGE E --- 8......................................................

Seal Removal And Disassembly PAGE E --- 8.........................................

Shaft and Bearing Removal and Disassembly PAGE E --- 8.............................

Shaft and Bearing Reassembly and Installation P AGE E - -- 9............................

Seal Reassembly and Installation P AGE E --- 10........................................

Impeller Installation PAGE E --- 12.....................................................

Rotating Assembly Installation PAGE E --- 13...........................................

Suction Head And Wear Plate Installation PAGE E --- 13.................................

Suction Check Valve Installation P AGE E - -- 13.........................................

PRESSURE RELIEF VALVE MAINTENANCE PAGE E --- 14..................................

LUBRICATION PA GE E --- 14.............................................................

Seal Assembly PAGE E --- 14.........................................................

Bearings PAGE E --- 14..............................................................

ii

TSERIES

OM--01936

INTRODUCTION

Thank You for purchasing a Gorman-Rupppump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

This Installation, Operation, and Maintenance

manual is designed to help you achieve the best

performance and longest life from your GormanRupp pump.

This pump is a T Series, semi-open impeller, selfpriming centrifugal model with a suction check

valve. The pump is designed for handling mild industrial corrosives, residues and slurries containing large entrained solids. The basic material of

construction is gray iron, with stainless steel impeller , impeller shaft and wearing parts.

Ifthereare anyquestionsregarding thepump orits

applicationwhichare not coveredin thismanualor

in other literature accompanying this unit, please

contact your Gorman -Rupp distributor, or write:

promised by the installation. Pumps and related

equipment must be installed and operated ac-

cording to all national, local and industry standards.

The following are used to alert maintenance personnel to procedures which require special attention, tothosewhich coulddamage equipment,and

to those which could be dangerous to personnel:

Immediate hazardswhich WILL result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-- 1217

Phone: (419) 755--1011

or:

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631--2870

Forinformationor technicalassistance onthepower source, contact the power source manufacturer’s local dealer or representative.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed instructions and precautions for every aspect of

each specific application. Therefore, it is the responsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operatorsafetynorpumpintegrity are com-

Hazards or unsafe practices which

COULDresult in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

HazardsorunsafepracticeswhichCOULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possibledamagewhich couldresult fromfailure

to follow the procedure.

NOTE

Instructions to aid in installation, operation,and

maintenance, or which clarify a procedure.

PAGE I -- 1INTRODUCTION

TSERIES OM--01936

SAFETY --- SECTION A

This information applies to T Series basic pumps. Gorman-Rupp has no control over or particular knowledge of the

powersourcewhichwill be used. Refer

to the manual accompanying the power

source before attempting to begin operation.

Because pump installations are seldom

identical, this manual c annot possibly

provide detailed instructions and precautions for each specific application.

Therefore, it is the owner/installer’s responsibility to ensure that applications

not addressed in this manual are performed only

after establishing that neither operator safety nor pump integrity

are compromised by the installation.

This pump is designed to handle mild

industrial corrosives, mud and slurries

containing large entrained solids. Do

not attempt to pump volatile, flammable, or highly corrosive liquids

which may damage thepump or endanger personnel as a result of pump failure.

After the pump has been positioned,

make certain that the pump and all piping connections are tight, properlysupported and secure before operation.

Beforeattemptingto open orservice the

pump:

1. Familiarize yourself with this manual.

2. Disconnect or lock out the power

source, or take other action to ensure that the pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Vent the pump slowly and cautiously.

5. Close the suction and discharge

valves.

6. Check the temperature before

opening any covers, plates, or

plugs.

7. Drain the pump.

Do not operate the pump without

shields and /or guards in place over the

drive shafts, belts and/or couplings, or

other rotating parts. Exposed rotating

parts can catch clothing, fingers, or

tools. causing severe injury to personnel.

Do not operate the pump against a

closed discharge valve for long periods

oftime.Ifoperatedagainstacloseddischarge valve, pump components will

deteriorate, and the liquid could come

to a boil, build pressure, and cause the

pump casing to rupture or e xplode.

PAGE A -- 1SAFETY

TSERIESOM--01936

Use lifting and moving equipment in

good repair and with adequate capacity

toprevent injuries to personnelor damage to equipment.

Overheated pumps can cause severe

burns and injury. If overheating of the

pump occurs:

1. Stop the pump immediately.

2. Allowthepumpto completelycool.

3. Refer to instructions in thismanual

before restarting the pump.

Donotattempttodisengageanypartof

an overheated pump unit. Vapor pres sure within the pump casing can eject

these parts with great force when they

are disengaged. Allow the pump to

completely cool before servicing it.

Use lifting and moving equipment in

good repair and with adequate capacity

toprevent injuries to personnelor damage to equipment.

PAGE A -- 2 SAFETY

INSTALLATION --- SECTION B

OM--01936TSERIES

Review all SAFETY information in Section A.

Since pump installationsareseldomidentical,this

section offers only general recommendations and

practices required to inspect, position, and arrange the pump and piping.

Most of the information pertains to a standard

static lift application where the pump is posi-

tionedabovethefreelevelofliquidto bepumped.

If installed ina floodedsuction application where

the liquid is supplied to the pump under pressure,

some of the information such as mounting, line

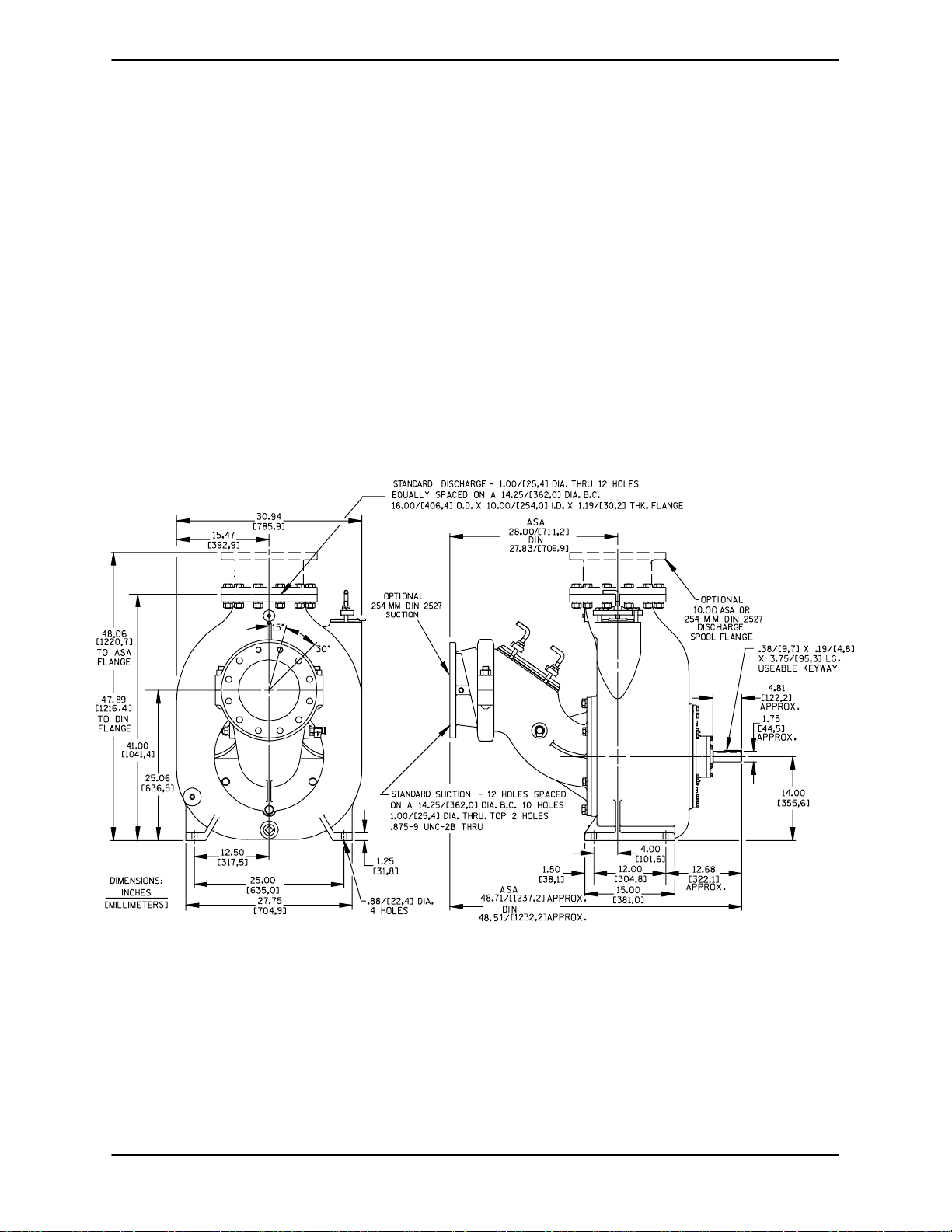

OUTLINE DRAWING

configuration, and priming must be tailored to the

specific application. Since the pressure supplied

to the pump is critical to performance and safety,

be sure to limit the incoming pressure to 50% of

the maximum permissible operating pressure as

shown on the pump performance curve.

Forfurtherassistance, contact yourGorman-Rupp

distributor or the Gorman-Rupp Company.

Pump Dimensions

SeeFigure1fortheapproximatephysicaldimensionsofthispump.

Figure 1. Pump Model T10A61--B

PREINSTALLATION INSPECTION

Thepump assemblywasinspected and tested beforeshipment from the factory. Before installation,

inspect the pump fordamage which may have occurred during shipment. Check as follows:

a. Inspectthe pump forcracks, dents,damaged

threads, and other obvious damage.

b. Check for and t ighten loose attaching hard-

ware. Since gaskets tend to shrink after drying, check for loose hardware at mating s urfaces.

c. Carefully read all warnings and cautions con-

tained in this manual or affixed to the pump,

and perform all duties indicated. Note the direction of rotation indicated on the pump.

PAGE B -- 1INSTALLATION

OM--01936 TSERIES

Check that the pump shaft rotates counterclockwise when facing the impeller.

Thepumpassemblycanbeseriously

damagedifthecablesor chainsused tolift

andmovetheunitareimproperlywrapped

Only operate this pump in the direction indicated by the arrow on the pump body

and on the accompanying decal. Refer to

Rotation in OPERATION,SectionC.

d. Checklevels and lubricate as necessary. Re-

fer to LUBRICATION in the MAINTENANCE

AND REPAIRsection of this manual and perform duties as instructed.

e.Ifthepumpandpowersourcehavebeen

stored for more than 12 months, some of the

components or lubricants may have exceeded their maximum shelf life. These must

be inspected or replaced to ensure maximum pump service.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to determinethe repair or updating policy. Do notputthe

pump into service until appropriate action has

been taken.

POSITIONING PUMP

Lifting

around the pump.

Mounting

Locatethepump inanaccessibleplaceas closeas

practicalto the liquid being pumped. Levelmounting is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibration.

SUCTION AND DISCHARGE PIPING

Pump performance is adversely effected by increased suction lift, discharge elevation, and friction losses. See the performance curve and operating range shown on Page E-1 to be sure your

overall application allows the pump to operate

within the safe operation range.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatiblewiththe liquidbeingpumped. If hoseis

used in suctionlines, it mustbe the rigid-wall, reinforcedtype toprevent collapse under suction.Using piping couplings in suction lines is not recommended.

Use lifting equipment with a capacity of at least

6,700 pounds. This pump weighs approximately

1,340 pounds, not including the weight of acces-

soriesor customerinstalledequipment. Customer

installed equipment such as suction and dischargepipingmust beremoved beforeattempting

to lift.

Make sure that hoists and other lifting equipment

areof sufficientcapacitytos afely handle thepump

assembly.Ifchains andcablesare used,make certain that they are positioned so that they will not

damage thepump, andso that the load willbe balanced.

PAGE B -- 2 INSTALLATION

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make minimum use of elbows and fittings, which substantiallyincreasefriction loss.Ifelbowsarenecessary,

use the long-radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it exactlywith t he pump port. Never pulla pipeline into

place by tightening the flange bolts and/or cou plings.

OM--01936TSERIES

Lines near the pump must be independently supported to avoid strain on the pump which could

cause excessive vibration, decreased bearing life,

and increased shaft and seal wear. If hose-type

linesare used, theyshouldhave adequatesupport

to secure them when filled with liquid and under

pressure.

Gauges

Most pumps are drilled and tapped for installing

dischargepressureandvacuumsuctiongauges.If

these gauges are desired for pumps that are not

tapped, drill and tap the suction and discharge

lines not less than 18 inches (457 mm) from the

suction and discharge ports and install the lines.

Installationcloserto the pump may result inerratic

readings.

SUCTION LINES

Toavoidair pockets whichcouldaffect pumppriming, the suction line must be as short and direct as

possible.Whenoperationinvolvesasuctionlift,the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

Fittings

three or four times the cross section of the suction

line,and that the openings willnot permit passage

of solids larger than the solids handling capability

of the pump.

Thispump is designedto handleup to 3-inch (76,2

mm) diameter spherical solids.

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an airtight seal. Follow the sealant manufacturer’s recommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

Suction Lines In Sumps

If a single suction line is installed in a sump, it

should be positioned away from the wall of the

sumpat a distanceequalto 1-1/2timesthediameter of the suction line.

If there is a liquid flow from an open pipe into the

sump, the flow should be kept away from the suctioninlet because the inflow willcarry air down into

the sump, and air entering the suction line will reduce pump efficiency .

Suction lines shouldbethe same sizeas the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be installedwith the flat part of the reducers uppermost

to avoid creating air pockets. Valves are not normally used in suction lines, but if a valve is used,

install it w ith the stem horizontal to avoid air pockets.

Strainers

If a s trainer is furnished with the pump, be certain

touse it;any sphericalsolidswhichpass througha

strainer furnished with the pump will also pass

through the pump itself.

If a strainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

Ifitis necessary to positioninflowcloseto the suctioninlet, installa bafflebetween theinflow and the

suctioninlet at a distance 1-1/2 times the diameter

of the suction pipe. The baffle will allow entrained

air to escape from the liquid before it is drawn into

the suction inlet.

If two suction lines are installed in a single sump,

theflow pathsmayinteract, reducingtheefficiency

of one or both pumps. To avoid this, position the

suction inlets so that they are separated by a distance equal to at least 3 times the diameter of the

suction pipe.

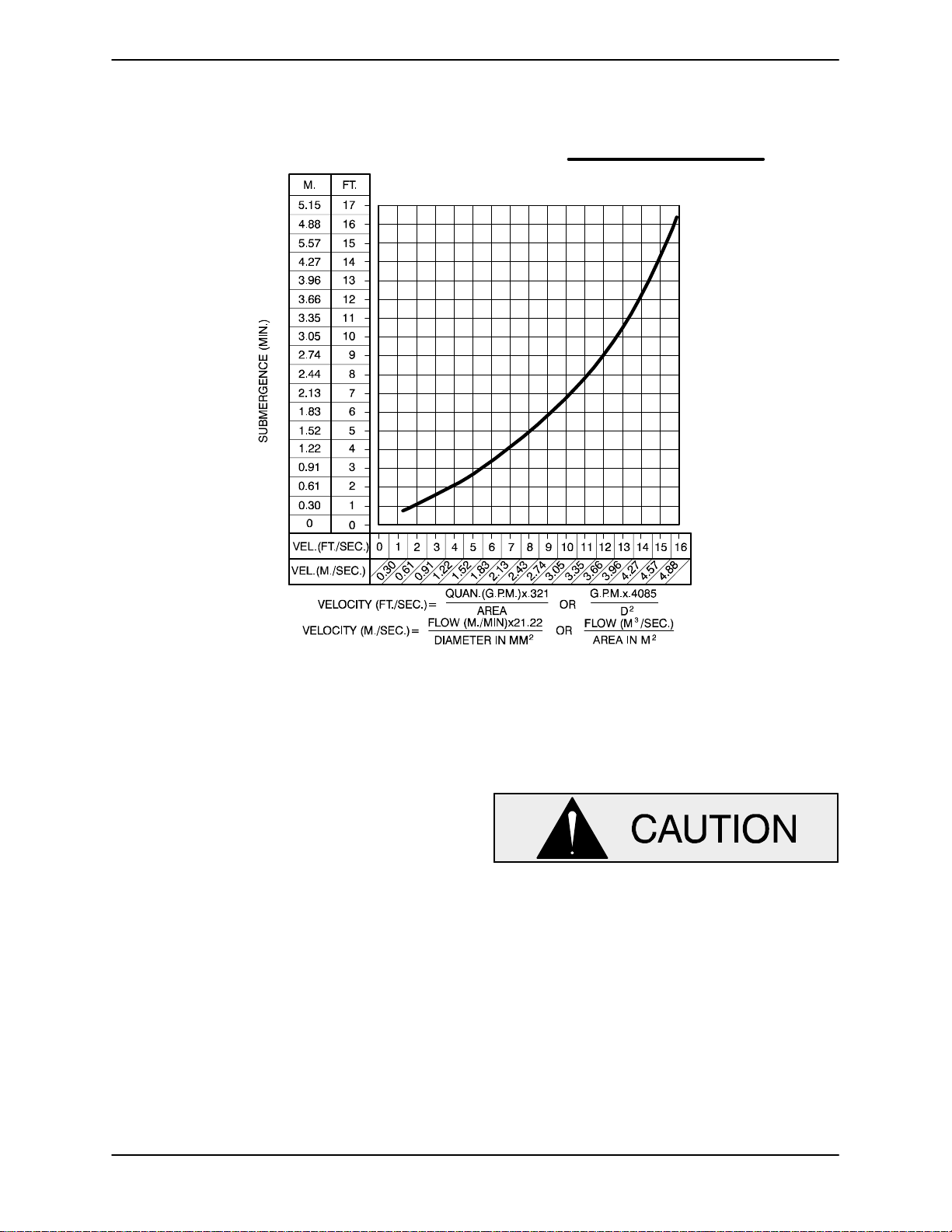

Suction Line Positioning

The depth of submergence of the suction line is

critical to efficient pump operation. Figure 2 shows

recommended minimum submergence vs. veloc-

ity.

PAGE B -- 3INSTALLATION

OM--01936 TSERIES

NOTE

The pipe submergence required may be reduced

byinstalling a standard pipe increaser fittingatthe

endof the suctionline.The larger opening size will

reduce the inlet velocity . Calculate the required

submergence using the following formula based

on the increased opening size (area or diameter).

Figure 2. Recommended Minimum Suction Line Submergence vs. Velocity

DISCHARGE LINES

Siphoning

Donot terminate the dischargeline at a levellower

than that of the liquid being pumped unless a siphon breaker is used in the line. Otherwise, a siphoning action causing damage to the pump

could result.

Valves

A check valve in the discharge lineis normallyrecommended, but it is not necessary in low discharge head applications.

If a throttling valve is desired in the discharge line,

useavalveaslargeasthelargestpipetominimize

friction losses. Never install a throttling valve in a

suction line.

Withhighdischarge heads,it isrecommendedthat

a throttling valve and a system check valve be installed in the discharge line to protect the pump

from excessive shock pressure and reverse rotation when it is stopped.

Iftheapplicationinvolvesa highdischarge

head, gradually close the discharge

throttling valve before stopping the pump.

Bypass Lines

If it is mecessary to permit the escape of air to atmosphere during initial priming or in the repriming

cycle, install a bypass line between th epump and

thedischarge check valve. Thebypasslineshould

be sized so that it does not affect pump discharge

capacity.

ItisrecommendedthataGorman---RuppAutomatic Air Release Valve be installed in the bypass line.

PAGE B -- 4 INSTALLATION

OM--01936TSERIES

Do Not install a manual shut---off valvein a bypass

line. If a manual shut---offvalve is installedto facilitateservice ofthe AirReleaseValve,the valvemust

not be left closed during operation. See the supplement at the end of this section for additionalinformationon bypass linesand the Gorman---Rupp

Automatic Air Release Valve.

NOTE

Thebypass line may clog occasionally, particularly

when pumping liquids containing large solids. If

clogging occurs, locate and remove theclog. Ifthe

clog is located between the discharge check valve

andtheAir ReleaseValve, thevalvewillnotclose. If

theclog is locatedin theReliefValveitself, or in the

line between the Relief Valve and the sump, the

valve will not open.

Donot terminate the dischargeline at a levellower

than that of the liquid being pumped unless a siphon breaker is used in the line; otherwise, a siphoning action could result, causing damage to

the pump.

Inlow discharge headapplications(less than30

feet or 9,1 meters), it is recommended that the bypass line be run back to thewet well, and located 6

inches (152,4 mm) below the water level or cut-off

point of the low level pump. In some installations,

this bypass line may be terminated with a six-toeight foot length of 1-1/4 inch (31,8 mm) I.D.

smooth-bore hose; air and liquid vented during

the priming process will then agitate the hose and

break up any solids, grease, or other substances

likely to cause clogging.

A bypass line that is returned to a wetwell

must be secured againstbeing d rawn into

the pump suction inlet.

this will reduce overall pumping efficiency. There-

fore, it is recommended that a Gorman-Rupp

Automatic Air Release Valve be installed in the

bypass line.

Gorman-Rupp Automatic Air Release Valves are

reliable, and require minimum maintenance. See

AUTOMATICAIR RELEASE VALVEin this section

for installation and theory of operation of the Automatic Air Release Valve. Consult your GormanRupp distributor, or contact the Gorman-Rupp

CompanyforselectionofanAutomaticAirRelease

Valve to fit your application.

A manual shut-off valve should not be

installed in any bypass line. A manual

shut-off valve may inadvertently be left

closed during operation. A pump which

has lost prime may continue to operate

without reaching prime, causing dangerousoverheatingand possible explosive rupture of the pump casing. Personnel could be severely injured.

Allow an over-heated pump to cool before servicing. Do not remove plates,

covers,gauges,orfittings fromanoverheated pump. Liquid within the pump

canreachboilingtemperatures,andvaporpressure within the pumpcan cause

parts being disengaged to be ejected

with great force. After the pump cools

drain the liquid from the p ump by removing the casing drain plug. Use caution when removing the plug to prevent

injury to personnel from hot liquid.

,

It is also recommended that pipe unions be installed at each 90_ elbow in a bypass line to ease

disassembly and maintenance.

In high discharge head applications (more than

30 feet or 9,1 meters), an excessive amount of liquid may be bypassed and forced back to the wet

well under the full working pressure of the pump;

AUTOMATIC AIR RELEASE VALVE

When properly installed and correctly adjusted to

the specific hydraulic operating conditions of the

application, the Gorman-Rupp Automatic Air ReleaseValvewillpermitairtoescapethroughthebypass line, and then close automatically when the

pump is fully primed and pumping at full capacity.

PAGE B -- 5INSTALLATION

OM--01936 TSERIES

Theory of Operation

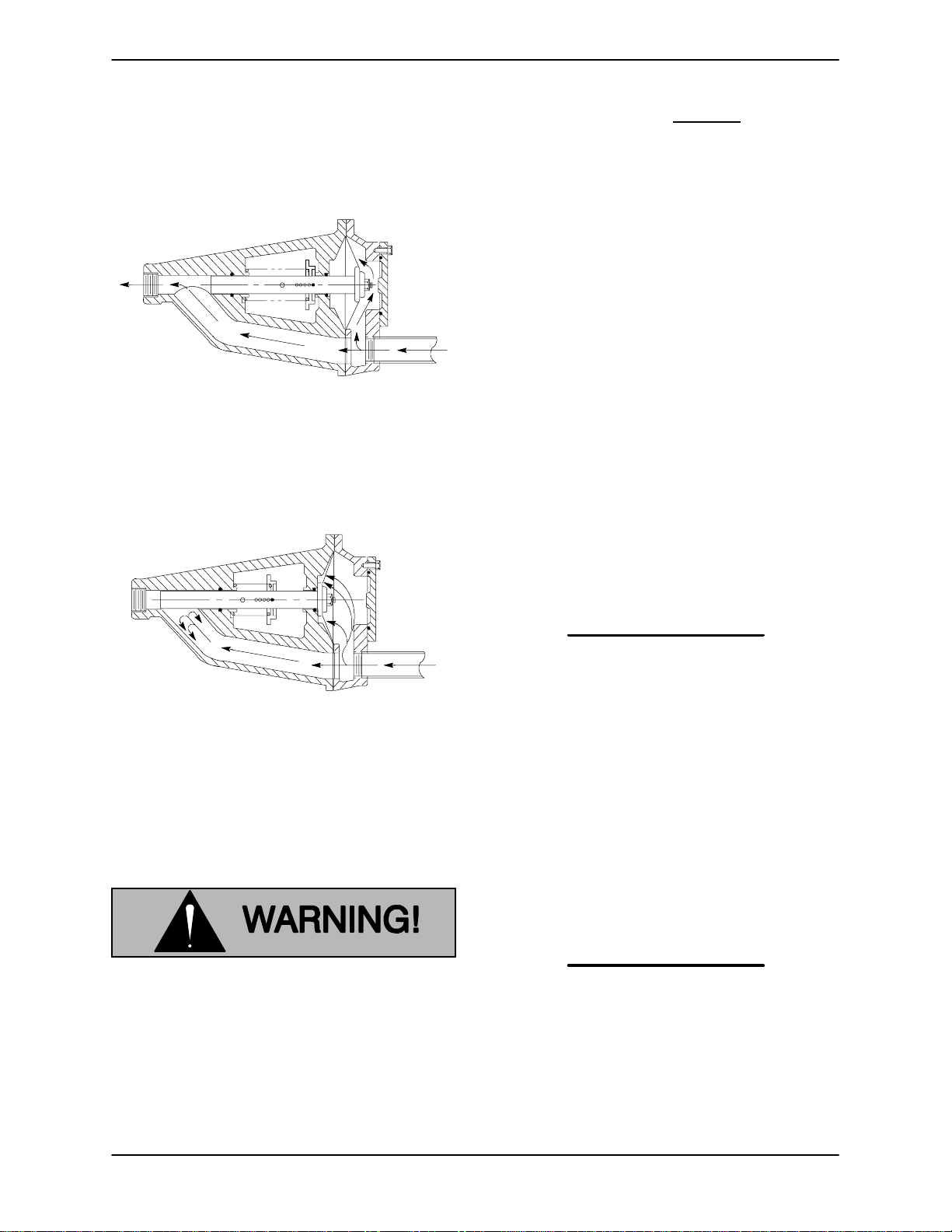

Figures 3 and 4 show a cross-sectional view of the

AutomaticAir Release Valve, and a corresponding

description of operation.

Figure 3 Valve in Open Position

Duringthe primingcycle, airfromthe pump casing

flowsthroughthebypassline,andpassesthrough

theAirReleaseValvetothewetwell(Figure3).

liters] per minute) will occur when the

valve is fully closed.Be sure

the bypass

line is directed back to the wet well or

tank to prevent hazardous spills.

Whenthe pump shutsdown, thespring returnsthe

diaphragm to its original position. Any solids that

mayhave accumulatedin the diaphragm chamber

settle to the bottom and are flushedout during the

next priming cycle.

NOTE

The valve will remain open if the pump does not

reach its designed capacity or head. V alveclosing

pressureis dependentupon thedischargeheadof

the pump at full capacity. The range of the valve

closing pressure is established by the tensionrate

ofthespringasorderedfrom thefactory.Valveclosing pressure can be further adjusted to the exact

system requirements by moving the spring retaining pin up or down the plunger rod to increase or

decrease tension on the spring. Contact your Gorman-Rupp distributor or the Gorman-Rupp Company for information about an Automatic Air Release Valve for your specific application.

Figure 4 Valve in Closed Position

When the pump is fully primed, pressure resulting

from flow against the valve diaphragm compresses the spring and closesthe valve(Figure 4).

The valve will remain closed, reducing the bypass

ofliquidto 1to5 gallonsper minute,untilthepump

loses its prime or stops.

Some le akage (1 to 5 gallons [3.8 to 19

Air Release Valve Installation

The A utomatic Air Release Valve must be inde pendently mounted in a horizontal position and

connected to the discharge line of the self-priming

centrifugal pump (see Figure 5).

NOTE

IftheAirReleaseValveistobeinstalledonastaged

pump application, contact the factory for specific

installationinstructions.

PAGE B -- 6 INSTALLATION

Loading...

Loading...