Page 1

CDSW

OM---01936---OB03

August 15, 1984

Rev. K 11/22/02

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

TSERIESPUMP

MODEL

T10A61---B

INCLUDING: /FM, /WW

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

www.gormanrupp.com

ECopyright by the Gorman-Rupp Company

Page 2

TABLE OF CONTENTS

INTRODUCTION PAGE I --- 1.................................................

SA FE TY --- SECTION A PA GE A --- 1...........................................

IN STALLAT ION --- SECTION B PA GE B --- 1....................................

Pump Dimensions PAGE B --- 1.....................................................

PREINSTALLATION INSPECTION PAGE B --- 1............................................

Battery Specifications And Installation PAGE B --- 2....................................

POSITIONING PUMP PA GE B --- 2.......................................................

Lifting PA GE B --- 2.................................................................

Mounting PA GE B --- 2.............................................................

SUCTION AND DISCHARGE PIPING PAGE B --- 2.........................................

Materials PA GE B --- 2..............................................................

Line Configuration PAGE B --- 2......................................................

Connections to Pump PAGE B --- 2..................................................

Gauges PA GE B --- 3...............................................................

SUCTION LINES PAGE B --- 3...........................................................

Fittings PA GE B --- 3...............................................................

Strainers PA GE B --- 3..............................................................

Sealing PAGE B --- 3...............................................................

Suction Lines In Sumps PAGE B --- 3.................................................

Suction Line Positioning PAGE B --- 3................................................

DISCHARGE LINE S PA GE B --- 4........................................................

Siphoning PA GE B --- 4.............................................................

Valves PA GE B --- 4................................................................

Bypass Lines PA GE B --- 4..........................................................

AUTOMATIC AIR RELEASE VALVE PAGE B --- 5...........................................

Theory of Operation PAGE B --- 6....................................................

Air Release V alve Installation P AGE B --- 6............................................

ALIGNMENT PAGE B --- 7..............................................................

Coupled Drives PA GE B --- 8........................................................

V-Belt Drives PA GE B --- 8...........................................................

OP E R ATION --- SE CTION C PAGE C --- 1......................................

PRIMING PA GE C --- 1.................................................................

STARTING PA GE C --- 1................................................................

OPERATION PA GE C --- 1..............................................................

Lines With a Bypass PAGE C --- 1....................................................

Lines Without a Bypass PAGE C --- 1.................................................

Leakage PAGE C --- 2..............................................................

Liquid Temperature And Overheating PAGE C --- 2.....................................

Strainer Check PAGE C --- 2.........................................................

Pump Vacuum Check PAGE C --- 2..................................................

STOPPING PA GE C --- 3................................................................

Cold Weather Preservation PAGE C --- 3..............................................

BEARING TEMPERATURE CHECK PAGE C --- 3..........................................

TROUBLESHOO T I N G --- S E C T I O N D PA G E D --- 1..............................

PREVENTIVE MAINTENANCE PAGE D --- 3...............................................

i

Page 3

TABLE OF CONTENTS

(continued)

PUMP MAINTENANCE AND REPAIR --- SECTION E PAGE E --- 1................

PERFORMANCE CURVE PA GE E --- 1...................................................

PARTS LISTS:

Pump Model PAGE E --- 3..........................................................

Repair Rotating Assembly PAGE E --- 5...............................................

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E --- 6.........................

Cleanout Access And Suction Check Valve Removal PAGE E --- 6.......................

Suction Head And Wear Plate Removal PAGE E --- 6...................................

Rotating Assembly Removal PAGE E --- 7.............................................

Impeller Removal P AGE E --- 8......................................................

Seal Removal And Disassembly PAGE E --- 8.........................................

Shaft and Bearing Removal and Disassembly PAGE E --- 8.............................

Shaft and Bearing Reassembly and Installation P AGE E - -- 9............................

Seal Reassembly and Installation P AGE E --- 10........................................

Impeller Installation PAGE E --- 12.....................................................

Rotating Assembly Installation PAGE E --- 13...........................................

Suction Head And Wear Plate Installation PAGE E --- 13.................................

Suction Check Valve Installation P AGE E - -- 13.........................................

PRESSURE RELIEF VALVE MAINTENANCE PAGE E --- 14..................................

LUBRICATION PA GE E --- 14.............................................................

Seal Assembly PAGE E --- 14.........................................................

Bearings PAGE E --- 14..............................................................

ii

Page 4

TSERIES

OM--01936

INTRODUCTION

Thank You for purchasing a Gorman-Rupppump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

This Installation, Operation, and Maintenance

manual is designed to help you achieve the best

performance and longest life from your GormanRupp pump.

This pump is a T Series, semi-open impeller, selfpriming centrifugal model with a suction check

valve. The pump is designed for handling mild industrial corrosives, residues and slurries containing large entrained solids. The basic material of

construction is gray iron, with stainless steel impeller , impeller shaft and wearing parts.

Ifthereare anyquestionsregarding thepump orits

applicationwhichare not coveredin thismanualor

in other literature accompanying this unit, please

contact your Gorman -Rupp distributor, or write:

promised by the installation. Pumps and related

equipment must be installed and operated ac-

cording to all national, local and industry standards.

The following are used to alert maintenance personnel to procedures which require special attention, tothosewhich coulddamage equipment,and

to those which could be dangerous to personnel:

Immediate hazardswhich WILL result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901-- 1217

Phone: (419) 755--1011

or:

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631--2870

Forinformationor technicalassistance onthepower source, contact the power source manufacturer’s local dealer or representative.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed instructions and precautions for every aspect of

each specific application. Therefore, it is the responsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operatorsafetynorpumpintegrity are com-

Hazards or unsafe practices which

COULDresult in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

HazardsorunsafepracticeswhichCOULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possibledamagewhich couldresult fromfailure

to follow the procedure.

NOTE

Instructions to aid in installation, operation,and

maintenance, or which clarify a procedure.

PAGE I -- 1INTRODUCTION

Page 5

TSERIES OM--01936

SAFETY --- SECTION A

This information applies to T Series basic pumps. Gorman-Rupp has no control over or particular knowledge of the

powersourcewhichwill be used. Refer

to the manual accompanying the power

source before attempting to begin operation.

Because pump installations are seldom

identical, this manual c annot possibly

provide detailed instructions and precautions for each specific application.

Therefore, it is the owner/installer’s responsibility to ensure that applications

not addressed in this manual are performed only

after establishing that neither operator safety nor pump integrity

are compromised by the installation.

This pump is designed to handle mild

industrial corrosives, mud and slurries

containing large entrained solids. Do

not attempt to pump volatile, flammable, or highly corrosive liquids

which may damage thepump or endanger personnel as a result of pump failure.

After the pump has been positioned,

make certain that the pump and all piping connections are tight, properlysupported and secure before operation.

Beforeattemptingto open orservice the

pump:

1. Familiarize yourself with this manual.

2. Disconnect or lock out the power

source, or take other action to ensure that the pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Vent the pump slowly and cautiously.

5. Close the suction and discharge

valves.

6. Check the temperature before

opening any covers, plates, or

plugs.

7. Drain the pump.

Do not operate the pump without

shields and /or guards in place over the

drive shafts, belts and/or couplings, or

other rotating parts. Exposed rotating

parts can catch clothing, fingers, or

tools. causing severe injury to personnel.

Do not operate the pump against a

closed discharge valve for long periods

oftime.Ifoperatedagainstacloseddischarge valve, pump components will

deteriorate, and the liquid could come

to a boil, build pressure, and cause the

pump casing to rupture or e xplode.

PAGE A -- 1SAFETY

Page 6

TSERIESOM--01936

Use lifting and moving equipment in

good repair and with adequate capacity

toprevent injuries to personnelor damage to equipment.

Overheated pumps can cause severe

burns and injury. If overheating of the

pump occurs:

1. Stop the pump immediately.

2. Allowthepumpto completelycool.

3. Refer to instructions in thismanual

before restarting the pump.

Donotattempttodisengageanypartof

an overheated pump unit. Vapor pres sure within the pump casing can eject

these parts with great force when they

are disengaged. Allow the pump to

completely cool before servicing it.

Use lifting and moving equipment in

good repair and with adequate capacity

toprevent injuries to personnelor damage to equipment.

PAGE A -- 2 SAFETY

Page 7

INSTALLATION --- SECTION B

OM--01936TSERIES

Review all SAFETY information in Section A.

Since pump installationsareseldomidentical,this

section offers only general recommendations and

practices required to inspect, position, and arrange the pump and piping.

Most of the information pertains to a standard

static lift application where the pump is posi-

tionedabovethefreelevelofliquidto bepumped.

If installed ina floodedsuction application where

the liquid is supplied to the pump under pressure,

some of the information such as mounting, line

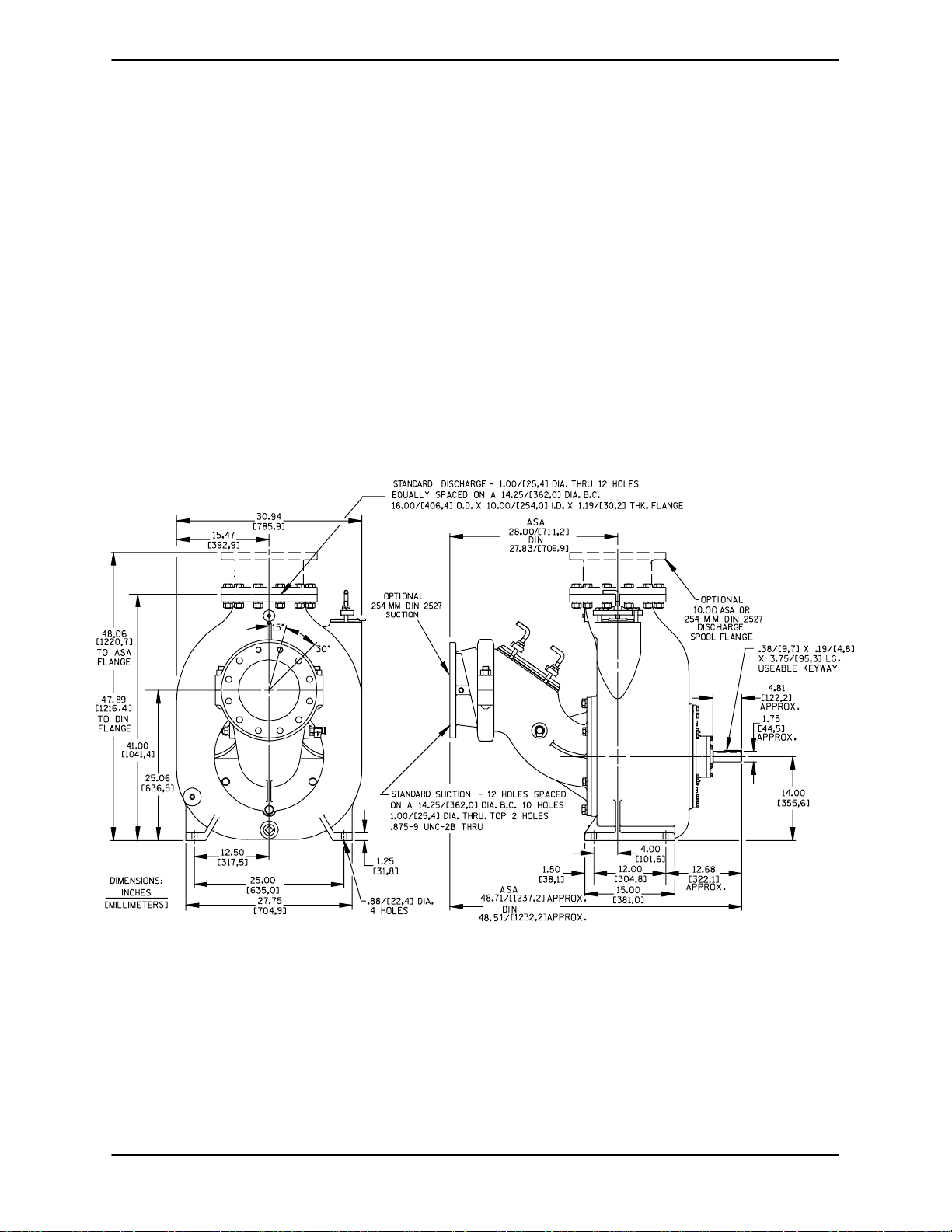

OUTLINE DRAWING

configuration, and priming must be tailored to the

specific application. Since the pressure supplied

to the pump is critical to performance and safety,

be sure to limit the incoming pressure to 50% of

the maximum permissible operating pressure as

shown on the pump performance curve.

Forfurtherassistance, contact yourGorman-Rupp

distributor or the Gorman-Rupp Company.

Pump Dimensions

SeeFigure1fortheapproximatephysicaldimensionsofthispump.

Figure 1. Pump Model T10A61--B

PREINSTALLATION INSPECTION

Thepump assemblywasinspected and tested beforeshipment from the factory. Before installation,

inspect the pump fordamage which may have occurred during shipment. Check as follows:

a. Inspectthe pump forcracks, dents,damaged

threads, and other obvious damage.

b. Check for and t ighten loose attaching hard-

ware. Since gaskets tend to shrink after drying, check for loose hardware at mating s urfaces.

c. Carefully read all warnings and cautions con-

tained in this manual or affixed to the pump,

and perform all duties indicated. Note the direction of rotation indicated on the pump.

PAGE B -- 1INSTALLATION

Page 8

OM--01936 TSERIES

Check that the pump shaft rotates counterclockwise when facing the impeller.

Thepumpassemblycanbeseriously

damagedifthecablesor chainsused tolift

andmovetheunitareimproperlywrapped

Only operate this pump in the direction indicated by the arrow on the pump body

and on the accompanying decal. Refer to

Rotation in OPERATION,SectionC.

d. Checklevels and lubricate as necessary. Re-

fer to LUBRICATION in the MAINTENANCE

AND REPAIRsection of this manual and perform duties as instructed.

e.Ifthepumpandpowersourcehavebeen

stored for more than 12 months, some of the

components or lubricants may have exceeded their maximum shelf life. These must

be inspected or replaced to ensure maximum pump service.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to determinethe repair or updating policy. Do notputthe

pump into service until appropriate action has

been taken.

POSITIONING PUMP

Lifting

around the pump.

Mounting

Locatethepump inanaccessibleplaceas closeas

practicalto the liquid being pumped. Levelmounting is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibration.

SUCTION AND DISCHARGE PIPING

Pump performance is adversely effected by increased suction lift, discharge elevation, and friction losses. See the performance curve and operating range shown on Page E-1 to be sure your

overall application allows the pump to operate

within the safe operation range.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatiblewiththe liquidbeingpumped. If hoseis

used in suctionlines, it mustbe the rigid-wall, reinforcedtype toprevent collapse under suction.Using piping couplings in suction lines is not recommended.

Use lifting equipment with a capacity of at least

6,700 pounds. This pump weighs approximately

1,340 pounds, not including the weight of acces-

soriesor customerinstalledequipment. Customer

installed equipment such as suction and dischargepipingmust beremoved beforeattempting

to lift.

Make sure that hoists and other lifting equipment

areof sufficientcapacitytos afely handle thepump

assembly.Ifchains andcablesare used,make certain that they are positioned so that they will not

damage thepump, andso that the load willbe balanced.

PAGE B -- 2 INSTALLATION

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make minimum use of elbows and fittings, which substantiallyincreasefriction loss.Ifelbowsarenecessary,

use the long-radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it exactlywith t he pump port. Never pulla pipeline into

place by tightening the flange bolts and/or cou plings.

Page 9

OM--01936TSERIES

Lines near the pump must be independently supported to avoid strain on the pump which could

cause excessive vibration, decreased bearing life,

and increased shaft and seal wear. If hose-type

linesare used, theyshouldhave adequatesupport

to secure them when filled with liquid and under

pressure.

Gauges

Most pumps are drilled and tapped for installing

dischargepressureandvacuumsuctiongauges.If

these gauges are desired for pumps that are not

tapped, drill and tap the suction and discharge

lines not less than 18 inches (457 mm) from the

suction and discharge ports and install the lines.

Installationcloserto the pump may result inerratic

readings.

SUCTION LINES

Toavoidair pockets whichcouldaffect pumppriming, the suction line must be as short and direct as

possible.Whenoperationinvolvesasuctionlift,the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

Fittings

three or four times the cross section of the suction

line,and that the openings willnot permit passage

of solids larger than the solids handling capability

of the pump.

Thispump is designedto handleup to 3-inch (76,2

mm) diameter spherical solids.

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an airtight seal. Follow the sealant manufacturer’s recommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

Suction Lines In Sumps

If a single suction line is installed in a sump, it

should be positioned away from the wall of the

sumpat a distanceequalto 1-1/2timesthediameter of the suction line.

If there is a liquid flow from an open pipe into the

sump, the flow should be kept away from the suctioninlet because the inflow willcarry air down into

the sump, and air entering the suction line will reduce pump efficiency .

Suction lines shouldbethe same sizeas the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be installedwith the flat part of the reducers uppermost

to avoid creating air pockets. Valves are not normally used in suction lines, but if a valve is used,

install it w ith the stem horizontal to avoid air pockets.

Strainers

If a s trainer is furnished with the pump, be certain

touse it;any sphericalsolidswhichpass througha

strainer furnished with the pump will also pass

through the pump itself.

If a strainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

Ifitis necessary to positioninflowcloseto the suctioninlet, installa bafflebetween theinflow and the

suctioninlet at a distance 1-1/2 times the diameter

of the suction pipe. The baffle will allow entrained

air to escape from the liquid before it is drawn into

the suction inlet.

If two suction lines are installed in a single sump,

theflow pathsmayinteract, reducingtheefficiency

of one or both pumps. To avoid this, position the

suction inlets so that they are separated by a distance equal to at least 3 times the diameter of the

suction pipe.

Suction Line Positioning

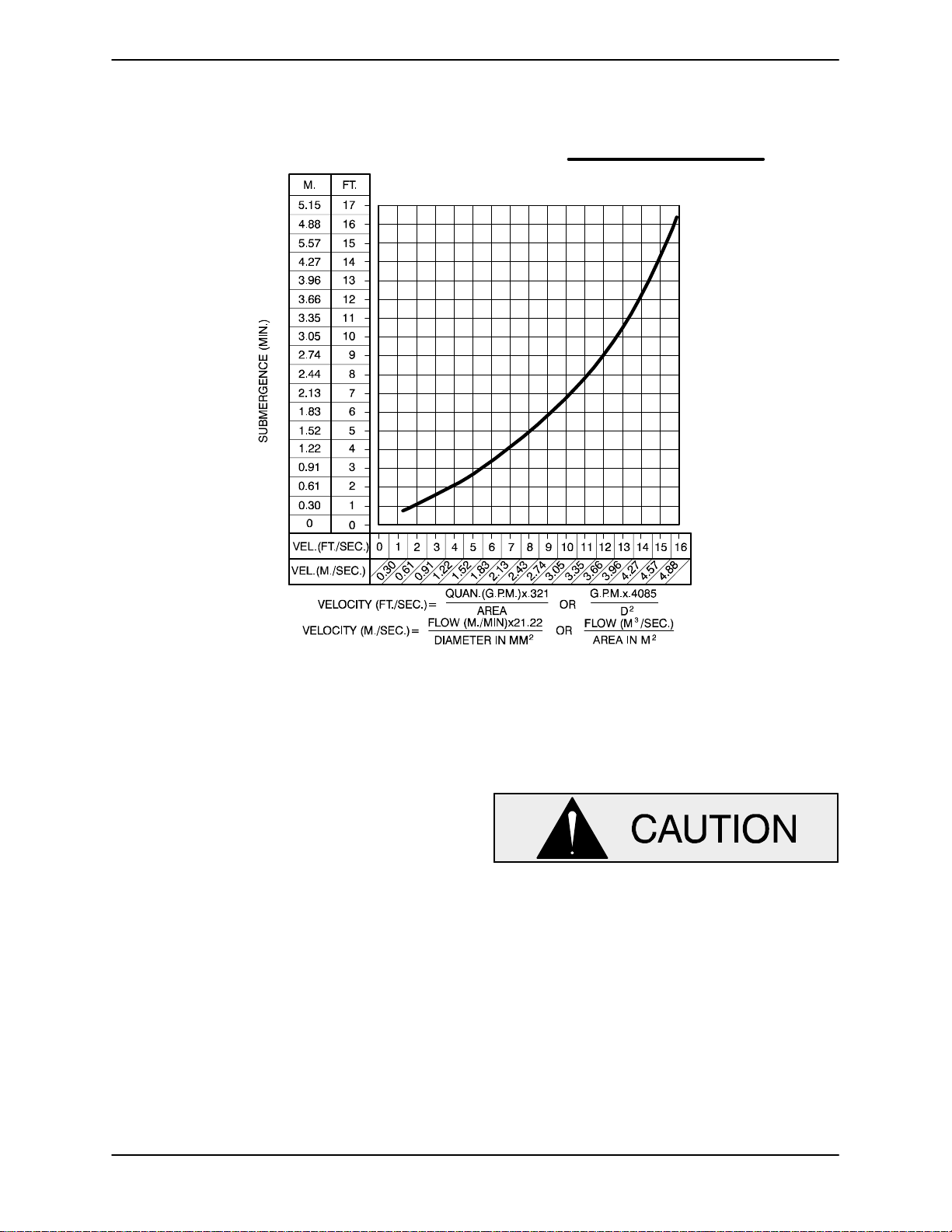

The depth of submergence of the suction line is

critical to efficient pump operation. Figure 2 shows

recommended minimum submergence vs. veloc-

ity.

PAGE B -- 3INSTALLATION

Page 10

OM--01936 TSERIES

NOTE

The pipe submergence required may be reduced

byinstalling a standard pipe increaser fittingatthe

endof the suctionline.The larger opening size will

reduce the inlet velocity . Calculate the required

submergence using the following formula based

on the increased opening size (area or diameter).

Figure 2. Recommended Minimum Suction Line Submergence vs. Velocity

DISCHARGE LINES

Siphoning

Donot terminate the dischargeline at a levellower

than that of the liquid being pumped unless a siphon breaker is used in the line. Otherwise, a siphoning action causing damage to the pump

could result.

Valves

A check valve in the discharge lineis normallyrecommended, but it is not necessary in low discharge head applications.

If a throttling valve is desired in the discharge line,

useavalveaslargeasthelargestpipetominimize

friction losses. Never install a throttling valve in a

suction line.

Withhighdischarge heads,it isrecommendedthat

a throttling valve and a system check valve be installed in the discharge line to protect the pump

from excessive shock pressure and reverse rotation when it is stopped.

Iftheapplicationinvolvesa highdischarge

head, gradually close the discharge

throttling valve before stopping the pump.

Bypass Lines

If it is mecessary to permit the escape of air to atmosphere during initial priming or in the repriming

cycle, install a bypass line between th epump and

thedischarge check valve. Thebypasslineshould

be sized so that it does not affect pump discharge

capacity.

ItisrecommendedthataGorman---RuppAutomatic Air Release Valve be installed in the bypass line.

PAGE B -- 4 INSTALLATION

Page 11

OM--01936TSERIES

Do Not install a manual shut---off valvein a bypass

line. If a manual shut---offvalve is installedto facilitateservice ofthe AirReleaseValve,the valvemust

not be left closed during operation. See the supplement at the end of this section for additionalinformationon bypass linesand the Gorman---Rupp

Automatic Air Release Valve.

NOTE

Thebypass line may clog occasionally, particularly

when pumping liquids containing large solids. If

clogging occurs, locate and remove theclog. Ifthe

clog is located between the discharge check valve

andtheAir ReleaseValve, thevalvewillnotclose. If

theclog is locatedin theReliefValveitself, or in the

line between the Relief Valve and the sump, the

valve will not open.

Donot terminate the dischargeline at a levellower

than that of the liquid being pumped unless a siphon breaker is used in the line; otherwise, a siphoning action could result, causing damage to

the pump.

Inlow discharge headapplications(less than30

feet or 9,1 meters), it is recommended that the bypass line be run back to thewet well, and located 6

inches (152,4 mm) below the water level or cut-off

point of the low level pump. In some installations,

this bypass line may be terminated with a six-toeight foot length of 1-1/4 inch (31,8 mm) I.D.

smooth-bore hose; air and liquid vented during

the priming process will then agitate the hose and

break up any solids, grease, or other substances

likely to cause clogging.

A bypass line that is returned to a wetwell

must be secured againstbeing d rawn into

the pump suction inlet.

this will reduce overall pumping efficiency. There-

fore, it is recommended that a Gorman-Rupp

Automatic Air Release Valve be installed in the

bypass line.

Gorman-Rupp Automatic Air Release Valves are

reliable, and require minimum maintenance. See

AUTOMATICAIR RELEASE VALVEin this section

for installation and theory of operation of the Automatic Air Release Valve. Consult your GormanRupp distributor, or contact the Gorman-Rupp

CompanyforselectionofanAutomaticAirRelease

Valve to fit your application.

A manual shut-off valve should not be

installed in any bypass line. A manual

shut-off valve may inadvertently be left

closed during operation. A pump which

has lost prime may continue to operate

without reaching prime, causing dangerousoverheatingand possible explosive rupture of the pump casing. Personnel could be severely injured.

Allow an over-heated pump to cool before servicing. Do not remove plates,

covers,gauges,orfittings fromanoverheated pump. Liquid within the pump

canreachboilingtemperatures,andvaporpressure within the pumpcan cause

parts being disengaged to be ejected

with great force. After the pump cools

drain the liquid from the p ump by removing the casing drain plug. Use caution when removing the plug to prevent

injury to personnel from hot liquid.

,

It is also recommended that pipe unions be installed at each 90_ elbow in a bypass line to ease

disassembly and maintenance.

In high discharge head applications (more than

30 feet or 9,1 meters), an excessive amount of liquid may be bypassed and forced back to the wet

well under the full working pressure of the pump;

AUTOMATIC AIR RELEASE VALVE

When properly installed and correctly adjusted to

the specific hydraulic operating conditions of the

application, the Gorman-Rupp Automatic Air ReleaseValvewillpermitairtoescapethroughthebypass line, and then close automatically when the

pump is fully primed and pumping at full capacity.

PAGE B -- 5INSTALLATION

Page 12

OM--01936 TSERIES

Theory of Operation

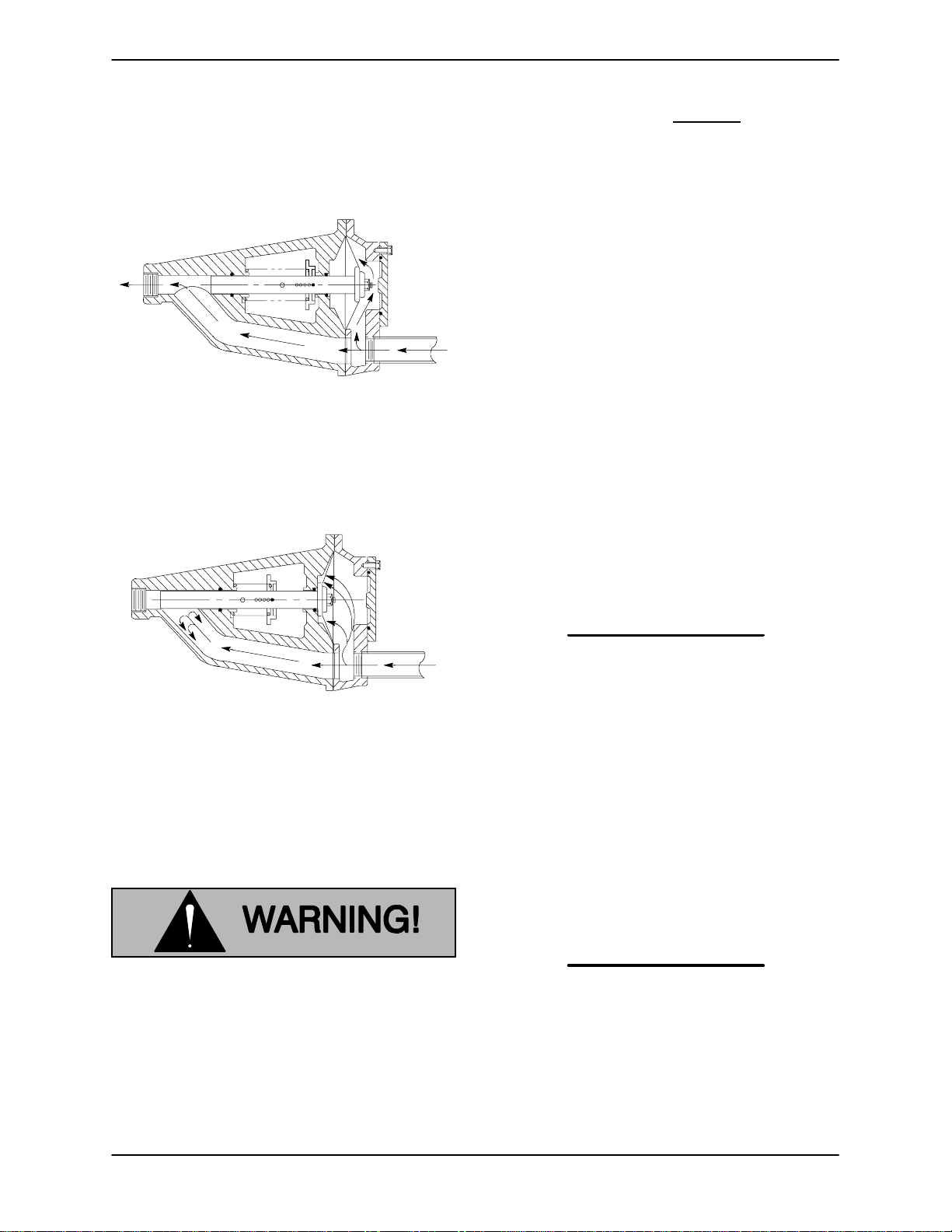

Figures 3 and 4 show a cross-sectional view of the

AutomaticAir Release Valve, and a corresponding

description of operation.

Figure 3 Valve in Open Position

Duringthe primingcycle, airfromthe pump casing

flowsthroughthebypassline,andpassesthrough

theAirReleaseValvetothewetwell(Figure3).

liters] per minute) will occur when the

valve is fully closed.Be sure

the bypass

line is directed back to the wet well or

tank to prevent hazardous spills.

Whenthe pump shutsdown, thespring returnsthe

diaphragm to its original position. Any solids that

mayhave accumulatedin the diaphragm chamber

settle to the bottom and are flushedout during the

next priming cycle.

NOTE

The valve will remain open if the pump does not

reach its designed capacity or head. V alveclosing

pressureis dependentupon thedischargeheadof

the pump at full capacity. The range of the valve

closing pressure is established by the tensionrate

ofthespringasorderedfrom thefactory.Valveclosing pressure can be further adjusted to the exact

system requirements by moving the spring retaining pin up or down the plunger rod to increase or

decrease tension on the spring. Contact your Gorman-Rupp distributor or the Gorman-Rupp Company for information about an Automatic Air Release Valve for your specific application.

Figure 4 Valve in Closed Position

When the pump is fully primed, pressure resulting

from flow against the valve diaphragm compresses the spring and closesthe valve(Figure 4).

The valve will remain closed, reducing the bypass

ofliquidto 1to5 gallonsper minute,untilthepump

loses its prime or stops.

Some le akage (1 to 5 gallons [3.8 to 19

Air Release Valve Installation

The A utomatic Air Release Valve must be inde pendently mounted in a horizontal position and

connected to the discharge line of the self-priming

centrifugal pump (see Figure 5).

NOTE

IftheAirReleaseValveistobeinstalledonastaged

pump application, contact the factory for specific

installationinstructions.

PAGE B -- 6 INSTALLATION

Page 13

OM--01936TSERIES

INSTALL AIR RELEASE VALVE

IN HORIZONTAL POSITION

90_ LONG

RADIUS

ELBOW

BLEED LINE 1”

(25,4 MM) DIA. MIN.

(CUSTOMER FUR NISHED)EXTEND 6”

(152 MM) BELOW

PUMP OFF LIQUID

LEVEL

SUPPORT

BRACKET

CLEAN-OUT

COVER

SUCTION

LINE

WET WELL

OR SUMP

DISCHARGE PIPE

DISCHARGE

CHECK VALVE

PUMP DISCHARGE

SELF-PRIMING

CENTRIFUGAL

PUMP

Figure 5. Typical Automatic Air Release Valve Installation

The valve inlet line must be installed between the

pumpdischargeportandthenon-pressurizedside

of the discharge check valve. The valve inlet is at

thelargeendofthevalvebody,andisprovided

with standard 1 inch NPT pipe threads.

The valve outlet is located a t the opposite end of

the valve, and is also equipped with standard 1

inch NPT pipe threads. The outlet should be connectedto a bleedline whichslopes back to thewet

well or sump. The bleed line must be the samesize

asthe inletpiping,orlarger.Ifpipingisusedfor the

bleed line, avoid the use of elbows whenever possible.

NOTE

It is recommended that each Air Release Valve be

fitted with an independent bleeder line directed

back to the wet well. If multiple Air Release Valves

areinstalledinasystem,theymust be fitted withindependent bleeder lines; never use a common

manifold pipe. Contact your Gorman-Rupp distributor or the Gorman-RuppCompany for information about installation of an Automatic Air Release

Valvefor your specific application.

ALIGNMENT

Thealignment of the pumpand itspower source is

critical for trouble-free mechanical operation. In

either a flexible coupling or V-belt driven system,

thedriver and pumpmustbe mounted soth attheir

shaftsare aligned with andparallel toeach other.It

is imperative that alignment be checked after the

pump and piping are installed, and before operation.

NOTE

Check Rotation, Section C, before final alignment

of the pump.

Whenmountedatthe Gorman-Ruppfactory,driver

andpumparealignedbeforeshipment.Misalignment will occur in transit and handling. Pumps

must be checked and realigned before operation.

Beforechecking alignment, tighten the foundation

bolts. The pump casing feet and/or pedestal feet,

andthedrivermountingboltsshouldalsobetightly

secured.

PAGE B -- 7INSTALLATION

Page 14

OM--01936 TSERIES

ARA

A

V

When checking alignment, disconnect

the power source to ensure that the

pump will remain inoperative.

Figure6B. AligningNon-SpiderTypeCouplings

Adjusting the alignment in one direction

may alter the alignment in another direction. check each procedure after altering

alignment.

Coupled Drives

When using couplings, the axis of the power

source must be aligned to the axis of the pump

shaft in both the horizontal and vertical planes.

Mostcouplings requirea specificgap or clearance

between the drivingand the driven shafts. Refer to

the coupling manufacturer’s service literature.

Alignspiderinserttypecouplingsby usingcalipers

to measure the dimensions on the circumference

of the outer ends of the coupling hub every 90 degrees. The coupling is in alignment when the hub

ends are the same distance apart at all points (see

Figure 6A).

Align non-spider type couplings by using a feeler

gaugeortaper gaugebetweenthecouplinghalves

every 90 degrees. The coupling is in alignment

whenthehubsarethesamedistanceapartatall

points (see Figure 6B).

Checkparalleladjustmentby layingastraightedge

across both coupling rims at the top, bottom, and

side. When the straightedge rests evenly on both

halves of the coupling, the coupling is inhorizontal

parallel alignment. If the coupling is misaligned,

use a feeler gauge between the coupling and the

straightedge to measure the amount of misalignment.

V-Belt Drives

When using V-belt drives, the power source and

the pump must be parallel. Use a straightedge

alongthesidesofthe pulleystoensurethat thepulleys are properly aligned (see Figure 6C). In drive

systemsusing twoormorebelts,make certainthat

the belts are a matched set; unmatched sets will

cause accelerated belt wear.

Figure 6A. Aligning Spider-Type Couplings

MISALIGNED:

SHAFTS

NOT P

LLEL

Figure 6C. Alignment of V-Belt Driven Pumps

MISALIGNED:

SHAFTS

NOT IN LINE

ALIGNED:SHAFTS

PARALLEL AND

SHE

ES IN LINE

PAGE B -- 8 INSTALLATION

Page 15

Tightenthe beltsinaccordancewiththe beltmanufacturer’s instructions. If the belts are too loose,

they will slip; if the belts are too tight, t here willbe

excessivepower loss and possible bearing failure.

Select pulleys that will match the proper speed ratio; overspeeding the pump may damage both

pump and power source.

OM--01936TSERIES

Do not operate the pump without the

guard in place over the rotating parts.

exposed rotating parts can catch clothing, fingers,or tools,causing severe injury to personnel.

PAGE B -- 9INSTALLATION

Page 16

TSERIES

OM--01936

OPERATION --- SECTION C

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and decals attached to the pump.

This pump is designed to handle mild

industrialcorrosives,residues and slurries containing large entrained solids.

Do not attempt to pump volatile, corrosive, or flammable materials which may

damage the pump or endanger personnel as a result of pump failure.

Pump speed and operating condition

points must be within the continuous performance range shown on the curve.

(See Section E, Page 1.)

1. The pump is being put into service for the

first time.

2. Thepump has notbeen usedfor aconsiderable length of time.

3. The liquid in the pump casing has evaporated.

Once the pump casing has been filled, the pump

will prime and reprime a s necessary.

After filling the pump casing, reinstall

and tighten the fill plug. Do not attempt

to operate the pump unless all connecting piping is securely installed. Otherwise, liquid in the pump forced out

under pressure could cause injury to

personnel.

Tofill the pump, remove the pump casing fill cover

or fill plug in the top of the casing, and add clean

liquid until the casing is filled. Replace the fill cover

or fill plug before operating the pump.

PRIMING

Install the pump and piping as described in INSTALLATION. Make sure that the piping connec-

tions are tight, and that the pump is securely

mounted. Check that the pump is properly lubricated (see LUBRICATION in MAINTENANCE

AND REPAIR).

This pump is self-priming, but the pump should

never be operated unless there is liquid in the

pump casing.

Never operate this pump unless there is

liquid in the pump casing. The pump will

notprime when dry.Extended operationof

a dry pump will destroythe seal assembly.

Add liquid to the pump casing when:

STARTING

Consult the operations manual furnished with the

power source.

OPERATION

Lines With a Bypass

Ifa Gorman-RuppAutomatic AirRelease Valvehas

been installed, the valve will automatically open to

allow the pump to prime, and automatically close

after priming is complete (see INSTALLATION for

Air Release Valve operation).

If the bypass line is open, air from the suction line

willbe discharged through the bypass line back to

thewetwellduringtheprimingcycle.Liquidwill

then continue to circulate through the bypass line

while the pump is in operation.

Lines Without a Bypass

Open all valves in the discharge line and start the

power source. Priming is indicated by a positive

OPERATION PAGE C -- 1

Page 17

OM--01936

reading on the discharge pressure gauge or by a

quieteroperation.The pump may not primeimmediately because the suction line must first fill with

liquid. If the pumpfails to prime withinfiveminutes,

stop it and check the suction line for leaks.

Afterthepump has beenprimed, partiallyclosethe

discharge line throttling valve in order to fill the line

slowly and guard against excessive shock pressure which could damage pipe ends, gaskets,

sprinkler heads, and any other fixtures connected

to the line. When the discharge line is completely

filled,adjustthethrottlingvalve tothe requiredflow

rate.

Do not operate the pump against a

closed discharge throttling valve for

longperiodsof time.Ifoperatedagainst

a closed discharge throttling valve,

pump components will deteriorate, and

the liquid could come to a boil, build

pressure,and cause the pumpcasing to

rupture or explode.

Leakage

No leakage should be visible at pump mating surfaces, or at pump connections or fittings. Keep all

lineconnectionsand fittingstight to maintainmaxi mum pump efficiency.

Liquid Temperature And Overheating

TSERIES

Do not remove plates, covers, gauges,

pipe plugs, or fittings from an over heated pump. Vapor pressure within

the pump can cause parts being disengagedto be ejected withgreat force. Allow the pump to cool before servicing.

Asa safeguard against rupture orexplosiondueto

heat, this pump is equipped with a pressure relief

valve which will open if vapor pressure within the

pumpcasing reaches a critical point. Ifoverheating

does occur, stop the pump immediately and allow

it to cool before servicing it. Approach any over-

heated pump cautiously. It is recommended that

the pressure relief valve assembly be replaced at

each overhaul, or any time the pump casing overheats and activates the valve. Never replace this

valve with a substitute which has not been specified or provided by the Gorman-Rupp Company.

Strainer Check

If a suction strainer has been shipped with the

pump or installed by the user, check the strainer

regularly, and clean it as necessary. The strainer

shouldalsobe checked ifpump flowratebegins to

drop. If a vacuum suction gauge has been installed, monitor and record the readings regularly

to detect strainer blockage.

Never introduce air or steam pressure into the

pump casingorpipingto removea blockage. This

could result in personal injury or damage to the

equipment. If backflushing is absolutely necessary, liquid pressure must be limited to 50% of the

maximum permissible operating pressure shown

on the pump performance curve.

The maximum liquid temperature for this pump is

160_F(71_C). Do not apply it at a higher operating

temperature.

Overheating can occur if operated with the valves

in the suction or discharge lines closed. Operating

against closed valves could bring the liquid to a

boil, build pressure, and cause the pump to rupture or explode. If overheating occurs, stop the

pump and allow it to cool before servicing it. Refill

the pump casing with cool liquid.

Pump Vacuum Check

Withthe pump inoperative,installa vacuumgauge

in the system, using pipe dope on the threads.

Block the suction line and start the pump. At operating speed the pump should pull a vacuum of 20

inches (508 mm) or more of mercury. If it does not,

check forairleaks in the seal,gasket, ordischarge

valve.

Openthe suctionline, and readthe vacuum gauge

with the pump primed and at operation speed.

OPERATIONPAGE C -- 2

Page 18

TSERIES

OM--01936

Shut offthe pump. The vacuum gauge readingwill

immediately drop proportionate to static suction

lift,andshouldthenstabilize.Ifthe vacuumreading

falls off rapidly after stabilization, an air leak exists.

Before checking for the source of the leak, check

the point of installation of the vacuum gauge.

STOPPING

Never halt the flow of liquid suddenly. If the liquid

being pumped is stopped abruptly, damaging

shock waves can be transmitted to the pump and

piping system. Close all connecting valves slowly.

On engine driven pumps, reduce the throttle

speed slowly and allow the engine toidlebrieflybefore stopping.

If the application involves a highdischarge

head, gradually close the discharge

throttling valve before stopping the pump.

After stopping the pump, disconnect or lock out

the power source or take other action to ensure

that the pump will remain inoperative.

Cold Weather Preservation

In below freezing conditions, drain the pump to

preventdamage fromfreezing.Also, clean outany

solids by flushing with a hose. Operate the pump

for approximately one minute; this willremove any

remaining liquid that could freeze the pump rotat-

ing parts. If the pump will be idle for more than a

few hours, or if it has been pumping liquids containing a large amount of solids, drain the pump,

and flush it thoroughly with clean water. Toprevent

large solids from clogging the drain port and preventing the pump from completely draining, insert

a rod or stiff w ire in the drain port, and agitate the

liquid during the draining process. Clean out any

remaining solids by flushing with a hose.

BEARING TEMPERATURE CHECK

Bearingsnormallyrun at higher than ambient temperatures because of heat generated by friction.

Temperatures up to 160_F(71_C) are considered

normalforbearings,and theycan operatesafelyto

at least 180_F(82_C).

Checkingbearingtemperatures byhand isinaccurate. Bearing temperatures can be measured accurately by placing a contact-type thermometer

against the housing. Record this temperature for

future reference.

A sudden increase in bearing temperature is a

warning that t he bearings are at the point offailing

to operate properly. Make certain that the bearing

lubricant is of the proper viscosity and at the correct level (see LUBRICATION in MAINTENANCE

AND REPAIR). Bearing overheating can also be

caused byshaft misalignmentand/or excessivevibration.

When pumps are first started, the bearings may

seem to run at temperatures a bove normal. Con tinued operation should bring the temperatures

down to normal levels.

OPERATION PAGE C -- 3

Page 19

TROUBLESHOOTING --- SECTION D

Review all SAFETY information in Section A.

Beforeattempting to open or service the

pump:

1. Familiarizeyourselfwiththis manual.

2. Disconnect or lock out the power

source,ortake other actiontoensure

that the pump will remain inoperative.

3. Allow the pump to completely cool if

overheated.

4. Ventthe pump slowly and cautiously.

5. Close the suction and discharge

valves.

6. Check the temperature before opening any covers, plates, or plugs.

7. Drain the pump.

OM--01936TSERIES

Table 1. Trouble Shooting Chart

TROUBLE

PUMP FAILS TO PRIME Not enough liquid in casing.

PUMP STOPS OR FAILS

TO DELIVER RATED

FLOW OR PRESSURE

POSSIBLE CAUSE PROBABLE REMEDY

Suctioncheck valve contaminated or

damaged.

Air leak in suction line.

Lining of suction hose collapsed.

Leakingorwornsealorpumpgas-

ket.

Suction lift or discharge head too

high.

Strainer clogged.

Air leak in suction line.

Lining of suction hose collapsed.

Addliquidtocasing.SeePRIMING.

Clean or replace check valve.

Correct leak.

Replace suction hose.

Check pump vacuum. R eplace leak-

ingorwornsealorgasket.

Check piping installation and install

bypass line if needed. See INSTAL-

LATION.

Check strainer and clean if necessary.

Correct leak.

Replace suction hose.

TROUBLESHOOTING PAGE D -- 1

Page 20

OM--01936 TSERIES

Table 1. Trouble Shooting Chart (cont.)

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PUMP STOPS OR FAILS

TO DELIVER RATED

FLOW OR PRESSURE

(cont.)

PUMP REQUIRES TOO

MUCH POWER

Leakingorwornsealorpumpgasket.

Strainer clogged.

Suction intake not submerged at

proper level or sump too small.

Impellerorotherwearingparts

worn or damaged.

Impeller clogged.

Discharge head too high.

Suction lift too high.

Pump speed too slow.

Pump speed too high.

Discharge head too low.

Check pump vacuum. Replace

leakingorwornsealorgasket.

Check strainer and clean if necessary.

Check installation and correct submergence as needed.

Replace worn or damaged parts.

Check that impeller is properly centered and rotates freely.

Free impeller of debris.

Install bypass line.

Measure lift w/vacuum gauge. Re-

duce lift and/or friction losses in

suction line.

Check engine output; consult engine operation manual.

Check engine output.

Adjust discharge valve.

Liquid solution too thick.

Bearing(s) frozen.

PUMP CLOGS

FREQUENTLY

EXCESSIVE NOISE Cavitation in pump.

Discharge flow too slow.

Suction check valve or foot valve

clogged or binding.

Liquid solution too thick.

Pumping entrained air.

Pump or drive not securely

mounted.

Impeller clogged or damaged.

Dilute if possible.

Disassemble pump and check

bearing(s).

Open discharge valve fully to in-

crease flow rate, and run engine at

maximum governed speed.

Clean valve.

Dilute if possible.

Reduce suction lift and/or friction

losses in suction line. Record vacu-

um and pressure gauge readings

and consult local representative or

factory.

Locate and eliminate source of air

bubble.

Secure mounting hardware.

Clean out debris; replace damaged

parts.

TROUBLESHOOTINGPAGE D -- 2

Page 21

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

BEARINGS RUN TOO

HOT

Table 1. Trouble Shooting Chart (cont.)

Bearing temperature is high, but

within limits.

Check bearing temperature regular-

ly to monitor any increase.

OM--01936TSERIES

Low or incorrect lubricant.

Suction and discharge lines not

properly supported.

Drive misaligned.

PREVENTIVE MAINTENANCE

Sincepump applicationsareseldom identical,and

pump wear is directly affected by such things as

the abrasive qualities, pressure and temperature

oftheliquidbeingpumped, thissectionisintended

only to provide general recommendations and

practices for preventive maintenance. Regardless

of the application however, following a routine preventive maintenance schedule will help assure

trouble-free performance and long life from your

Gorman-Rupp pump. For specific questions concerning your application, contact your GormanRupp distributor or the Gorman -Rupp Company.

Record keeping is an essential component of a

good preventive maintenance program. Changes

in suction and discharge gauge readings (if so

Check for proper type and level of

lubricant.

Check piping installation for proper

support.

Align drive properly.

equipped) between regularly scheduled inspections can indicate problems that can be corrected

before system damage or catastrophic failure occurs.The appearanceof wearingparts shouldalso

bedocumented at eachinspection forcomparison

as well. Also, if records indicate that a certain part

(such as the seal) fails at approximately the same

duty cycle, the part can be checked and replaced

beforefailureoccurs,reducing unscheduleddown

time.

For new applications, a first inspection of wearing

partsat250 hourswillgiveinsightintothe wearrate

foryourparticularapplication.Subsequentinspections should be performed at the intervals shown

on the chart below. Critical applications should be

inspected more frequently.

TROUBLESHOOTING PAGE D -- 3

Page 22

OM--01936 TSERIES

Preventive Maintenance Schedule

Service Interval*

Item

General Condition (Temperature, Unusual

Noises or Vibrations, Cracks, Leaks,

Loose Hardware, Etc.) I

Pump Performance (Gauges, Speed, Flow) I

Bearing Lubrication I R

Seal Lubrication (And Packing Adjustment,

If So Equipped) I R

V-Belts (If So Equipped) I

Air Release Valve Plunger Rod (If So Equipped) I C

Front Impeller Clearance (Wear Plate) I

Rear Impeller Clearance (Seal Plate) I

Check Valve I

Pressure Relief Valve (If So Equipped) C

Pump and Driver Alignment I

Shaft Deflection I

Bearings I

Bearing Housing I

Piping I

Driver Lubrication --- See Mfgr’s Literature

Daily Weekly Monthly Semi-

Annually

Annually

Legend:

I = Inspect, Clean, Adjust, Repair or Replace as Necessary

C= Clean

R= Replace

* Service interval based on an intermittent duty cycle equal to approximately 4000 hours annually.

Adjust schedule as required for lower or higher duty cycles or extreme operating conditions.

TROUBLESHOOTINGPAGE D -- 4

Page 23

TSERIES

OM--01936

PUMP MAINTENANCE AND REPAIR --- SECTION E

MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK

OPERATING PERFORMANCE.

STANDARD PERFORMANCE FOR PUMP MODEL T10A61--B

Based on 70_F(21_C) clear water at sea level

with minimumsuction lift. Since pump installations

areseldomidentical,yourperformancemaybedifferent due to such factors as viscosity, specific

gravity, elevation, temperature, and impeller trim.

Contact the Gorman-RuppCompany to verify performance or part numbers.

Pump speed and operating condition

If your pump serial number is followed by an “N”,

your pump is NOT astandardproductionmodel.

MAINTENANCE & REPAIR PAGE E -- 1

points must be within the continuous performance range shown on the curve.

Page 24

OM--01936 TSERIES

SECTION DRAWING

Figure E---1. Pump Model T10A61---B, /FM, /WW

MAINTENANCE & REPAIRPAGE E -- 2

Page 25

TSERIES

OM--01936

PARTS LIST

(From S/N 806819 up)

Pump Model T10A61---B, /FM, /WW

Ifyourpump serial number is followedby an “N”,your pump is NOT a standard production model. Contact

the Gorman-Rupp Company to verify part numbers.

ITEM

PART NAME PART

NO.

NUMBER

MAT’L

CODE

QTY ITEM

NO.

PART NAME PART

NUMBER

MAT’L

CODE

QTY

1 PUMP CASING 38222---701 10010 1

2 REPAIR ROTATING ASSY 44163---064 --- --- --- 1

/WW REPAIR ROT ASSY 44163---247 ------ --- 1

3 CHECK VALVE ASSY 46421---037 --- --- --- 1

4 ---CHECK VALVE BODY 38341---805 10010 1

5 ---PIPE PLUG P08 15079 1

6

---CHECK VALVE 46411---082 24010 1

7

---PIVOT CAP 38141- --003 11060 2

8 ---HEX HD CAPSCREW B0606 17000 2

9 ---LOCKWASHER AK06 17000 2

10 ---FLAT WASHER KB08 17090 2

11 SHOULDER TYPE CPLG 25552---213 --- ------ 1

12

CLEANOUT CVR GSKT 38688---008 20000 1

13 CLAMP BAR 38111---004 11010 2

14 MACHINE BOLT A1014 15991 4

15 CLAMP BAR SCREW 31912---009 15000 2

16 CLEANOUT CVR ASSY 48271---018 --- --- --- 1

17 PIPE PLUG P04 15079 1

18 DISCH STICKER 6588BJ --- --- --- 1

19 NAMEPLATE 38818---040 13990 1

20 DRIVE SCREW BM#04---03 17000 4

21

SHIM SET 48261---056 --- --- --- 6

22 CASING RING 31281---016 15990 1

23 HEX HD CAPSCREW B0806 15991 6

24 LOCKWASHER J08 15991 6

25 HEX HD CAPSCREW B0805 15991 6

26 LOCKWASHER J08 15991 6

27 FILL CVR PLATE ASSY 42111---344 --- ------ 1

28 ---FILL CVR PLATE NOT AVAILABLE 1

29 ---WARNING PLATE 38816---097 13990 1

30 ---DRIVE SCREW BM#04---03 17000 2

31 ---FILL COVER GASKET 50G 19210 1

32 CLAMP BAR SCREW 31912---009 15000 1

33 MACHINE BOLT A1014 15991 2

34 CLAMP BAR 38111---004 11010 1

35 ROTATION DECAL 2613M --- --- --- 1

36

BRG HSG O-RING S1914 --- ------ 1

37

SEAL END PLT O-RING S1914 --- ------ 1

38

FRONT WEAR PLATE 38691---826 17070 1

39 PIPE PLUG P08 15079 1

40

SUCTION HD GASKET 38682---811 20000 1

41 PIPE PLUG P24 10009 1

42 HEX HD CAPSCREW B1408 15991 2

43 LOCKWASHER J14 15991 2

44 HEX HD CAPSCREW B1207 15991 4

45 LOCKWASHER J12 15991 4

46 PRESS RELIEF VLV 46431---803 ------ --- 1

INDICATES PARTSRECOMMENDED FOR STOCK

[ OPTIONAL MECHANICAL SEAL(S) MUST BE USED WITH MECHANICAL SEAL SHAFT SLEEVE OR SOLID SST SHAFT.

47 RED PIPE BUSHING AP2008 11999 1

48 PIPE PLUG P20 10009 1

49 SUCTION HEAD 38246---609 10010 1

50 SUCTION STICKER 6588AG ------ --- 1

NOT SHOWN:

FILL HR PRIME STK 6588AH ---- -- --- 1

LUB DECAL 11421 --- --- --- 1

INSTRUC LABEL 2613DK ---- -- --- 1

WARNING DECAL 2613FE --- --- --- 1

WARNING DECAL 38816---302 --- ------ 1

OPTIONAL:

DISASSEMBLYTOOL 12858 24000 1

ADI WEARPLATE 38691---826 1102H 1

ASTL WEARPLATE 46451---750 24160 1

ADI REPAIR ROT ASSY 44163---233 ---- -- --- 1

10” SPOOL FLANGE 38642---607 10000 1

/FM FLANGE KIT 48213- --080 --- ------ 1

/FM FLANGE KIT 48213- --084 --- ------ 1

/WW SUCT FLANGE 38341---805 10010 1

PRESSURE RELIEF VALVES:

---SEWAGE TYPE 46431---628 --- --- --- 1

---STAINLESS STEEL 26662---101 --- --- --- 1

CASING HEATERS:

---120V 47811---014 --- --- --- 1

---240V 47811---015 --- --- --- 1

CHECK VALVE ASSYS:

---NEO MOLDED TYPE 46411---082 --- --- --- 1

n ---VITON MOLDED 46411---081 ------ --- 1

HI TEMP SHUT-DOWN KITS:

---145ºF 48313---186 --- --- --- 1

---130ºF 48313---256 --- --- --- 1

---120ºF 48313---257 --- --- --- 1

HI TEMP SHUT-DOWN 48313---172 --- --- --- 1

THERMOSTAT KIT 145ºF

AIR RELEASE VALVES:

--- 10 # CO MP SP R ING GRP33 --- 0 7 A --- --- --- 1

--- 25 # CO MP SP R ING GRP33 --- 0 7 --- --- --- 1

--- 80 # CO MP SP R ING GRP33 --- 0 7 B --- --- --- 1

BRG HOUSING O -RING

n ---VITON 25154---458 --- --- --- 1

n KALREZr AND VITONt ARE PRODUCTS OF THE DUPONT CORP

L AFLASr IS A PRODUCTOF THE 3M CORP

MAINTENANCE & REPAIR PAGE E -- 3

Page 26

OM--01936 TSERIES

SECTION DRAWING

Figure E-2. 44163---064 And 44163---247 WW Repair Rotating Assembly

MAINTENANCE & REPAIRPAGE E -- 4

Page 27

TSERIES

OM--01936

PARTS LIST

44163---064 And 44163---247 Repair Rotating Assembly

Note: Order complete Repair Rotating Assemby for /WW model from the Pump Model Assembly Parts List

on page E---3. Repair Rotating Assembly for /WW model includes all of the standard parts listed below.

ITEM

PART NAME PART

NO.

NUMBER

MAT’L

CODE

QTY ITEM

NO.

PART NAME PART

NUMBER

MAT’L

CODE

QTY

1 IMPELLER 38615---014 17070 1

SEAL ASSEMBLY 46512---192 --- --- --- 1

2

3 SEAL END PLATE 38272---228 17070 1

SEAL PLATE GSKT 38684---302 19140 1

4

BEARING O-RING S1874 --------- 1

5

6 BEARING HOUSING 38251---506 10010 1

7 VENTED SEAL PLUG 38649---009 15079 1

8 VENTED BRG PLUG 38649---009 15079 1

9

BR G HO U SING O -RI N G S333 --- --- --- 1

10 HEX HD CAPSCREW B0605 1/2 15991 6

11 LOCKWASHER J06 15991 6

12

BALL BEARING 23422---412 --- --- --- 1

13 RE TAIN ING RING S2 15 --- --- --- 1

IMPELLER SHAFT KEY N0612 15990 1

14

OIL SEAL S1917 --- ------ 1

15

16 OIL LEVEL SIGHT GAUGE S1471 --- --- --- 1

17 BEARING CAP 38322---415 10010 1

18 BRG DRAIN PLUG P12 15079 1

19 SEAL DRAIN PLUG P12 15079 1

20

IMPELLER SHAFT 38515---548 1706H 1

BALL BEARING 23421---461 --- --- --- 1

21

22 HEX HD CAPSCREW B0808 17000 4

23 LOCKWASHER J08 17000 4

24

OIL SEAL S1917 --- ------ 1

IMPELLER WASHER 10278 17090 1

25

26

IMPELLER CAPSCREW DM1004S 17090 1

27 PIPE PLUG P12 15079 1

IMPELLER SHIM SET 5091 17090 REF

28

SEAL END PLATE O-RING S1914 --- --- --- 1

29

30

BRG HOUSING O-RING S1914 ------ --- 1

ROT ASSY SHIM SET 48261---056 --- --- --- 6

31

32 SHIPPING PLUG 11495D 15079 1

33 SHIPPING PLUG 11495D 15079 1

NOT SHOWN:

ROTATION DECAL 2613M --- --- --- 1

INSTRUCTION TAG 6588U --- --- --- 1

OPTIONAL:

ADI IMPELLER 38615---014 1102H 1

ADI SEAL END PLATE 38272---413 1102H 1

ROTATINGASSY O-RING:

n ---VITON 25154---458 --- --- --- 1

PERMALON SEAL 46512---189 --- ------ 1

[ METAL BELLOWS MECH SEAL ASSY

[LAFLAS SEAL 46512---193 --- --- --- 1

[ METAL BELLOWS MECH SEAL ASSY

n (KALREZ) 46512---183 ------ --- 1

INDICATES PARTSRECOMMENDED FOR STOCK

[ OPTIONAL MECHANICAL SEAL MUST BE USED WITH MECHANICAL SEAL SHAFT SLEEVE OR /WWS SOLID SST SHAFT.

n KALREZr AND VITONt ARE PRODUCTS OF THE DUPONT CORP

L AFLASr IS A PRODUCTOF THE 3M CORP

MAINTENANCE & REPAIR PAGE E -- 5

Page 28

OM--01936 TSERIES

PUMP AND SEAL DISASSEMBLY

AND REASSEMBLY

Review all SAFETY information in Section A.

Followtheinstructionsonall tags,label anddecals attached to the pump.

This pump requires little service due to its rugged,

minimum-maintenance design. However, if it becomesnecessarytoinspect orreplace thewearing

parts, follow these instructions which are keyed to

the sectional views (see Figures E-1 and E-2) and

the accompanying parts lists.

As described on the following pages, this manual

willalert personnel to known procedures which require special attention, to those which could damage equipment, and to those which could be dangeroustopersonnel. However, this manualcannot

possibly anticipate and provide detailed precautions for every situation that might occur during

maintenanceof theunit. Therefore, itistheresponsibilityof the owner/maintenance personnel to ensure that only safe, established maintenance proceduresare used, andthat anyproceduresnotaddressedinthis manualareperformedonlyafterestablishingthat neitherpersonalsafetynor pumpintegrity are compromised by such practices.

Many service functions may be performed by

drainingthe pumpa nd removingthe suctionhead.

Ifmajor repairisrequired, thepiping and/orengine

must be disconnected. The following instructions

assume complete disassembly is required.

sure that the pump will remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

Use lifting and moving equipment in

good repair and with adequate capacity

toprevent injuries to personnelor damage to equipment. Suction and discharge hoses and piping must be removed from the pump before lifting.

Cleanout Access And Suction Check Valve

Removal

(Figure E-1)

Beforeattemptingtoservicethe pump,removethe

casing drain plug (21) and drain the pump. Clean

and reinstall the drain plug.

Forcleanout access, loosen the clamp screws (41)

and clamp bars (40) securing the cleanout cover

(39) to the suction head (26).

Beforeattemptingtoservicethe pump,disconnect

orlock out the power source or take other action to

ensure that the pump will remain inoperative.

Close all valves in the suction and discharge lines.

Beforeattemptingto open orservice the

pump:

1. Familiarize yourself with this manual.

2. Disconnect or lock out the power

source, or take other action to en-

To remove the check valve assembly, reach

through the cleanout opening and remove the

hardware (35, 36 and 37) securing the check valve

(31) to the valve body (33) and suction head.

Replace the cleanout cover gasket (38) before reinstalling the cover.

Suction Head And Wear Plate Removal

(Figure E-1)

To remove the suction head, support it with a s uitablehoist and slingand remove the hardware (22,

23, 24 and 25) securing it t o the pump casing. Remove the suction head gasket (20).

MAINTENANCE & REPAIRPAGE E -- 6

Page 29

TSERIES

OM--01936

If the wear plate (19) does not slide easily fromthe

casing bore, install capscrews (1/2-13 UNC X 1

inch long, not supplied) in the tapped holes provided. Using a suitable puller, remove it from the

casing.

Rotating Assembly Removal

(Figure E-2)

Therotatingassemblymayberemovedfromeither

side of the casing; however , it is recommended

that it be removedt hrough the suction head opening.

Theimpeller (1)should beloosenedwhiletherotating assembly is still secured to the pump casing.

Before loosening the impeller,removethesealcavitydrain plug (19) and draintheseal lubricant. This

willprevent the oil in the seal cavity from escaping

as the impellerisloosened.Cleanand reinstallthe

seal cavity drain plug.

Immobilize the impeller by wedging a block of

wood between the vanes and remove the impeller

capscrew and washer (25 and 26). Install a lathe

dog on the drive end of the shaft (16) with the “V”

notch positioned over the shaft keyway. Strike the

lathe dog sharply in a counterclockwise direction

(when facing the drive end of the shaft). When the

impeller breaks loose,remove thewood block and

lathe dog. Do not fully unscrew the impeller from

the shaft at this time.

(Figure E-1)

An optional disassembly tool for removing and installing the rotating assembly is available from the

factory. If improvised tools are used, be sure they

areheavy enoughfor safeuseand willnotdamage

the pump.

Remove the inner hardware (11 and 12) from the

casing ring (15). If the removal tool is used, follow

theinstructionspackagedwith it,andpull therotating assembly from the pump casing (see Figure

E-3 for removal tool use). If the removal tool is not

used, install three of the inner capscrews in the

jacking holes in the casing ring, and use them to

press the rotating assembly into the pumpcasing

until the bearing housing is free.

Remove the jacking screws from the casing ring.

Remove the outer hardware (13 and 14) and shim

sets (16). Separate the casing ring from the pump

casing. Tie and tag the shim s ets for ease of reassembly.

After the rotating assembly is loosened, screw a

5/8-11 U NC X 16 inch long threaded rod into the

hole in the impeller shaft. Support the drive end of

the shaft with a 1-13/16” (46 mm) minimum I.D.

pieceofpipeorasetofhandlesasshowninFigure

E-3, and slide the complete rotating assembly

through the suction head opening. Once free, use

a suitable hoist and sling and attach it to the lifting

eye provided at the top of the bearing housing to

movethe rotatingassemblyto asuitable workarea

for further disassembly.

ADD PIPE

AS REQUIRED

Figure E-3. Rotating Assembly Removal With Tool

MAINTENANCE & REPAIR PAGE E -- 7

Page 30

OM--01936 TSERIES

Impeller Removal

(Figure E-2)

Unscrew the impeller from the shaft in a counterclockwise direction(when facing the impeller). Use

caution when unscrewing the impeller; tension on

theshaft sealspring willbereleasedas the impeller

is removed.

Remove the impeller adjusting shims (28). Tieand

tag the shims or measure and record their thickness for ease of reassembly.

Seal Removal And Disassembly

(Figure E-2)

Remove the seal spring. Apply oil to the shaft and

workit up underthe bellows. Slidetherotatingportion of the seal off the shaft as a unit.

Usetwo stiff wires with hookedends to remove the

stationary portion of the seal.

is not recommended. These operations

should be performed only in a properly

equipped shop by qualified personnel.

Remove the bearing housing drain plug (18) and

drain the lubricant. Clean and reinstall the drain

plug.

Disengage the hardware (10 and 11) and remove

the bearing cap (17), O-ring (9) and oil seal (15)

from the shaft. Press the oil s eal from the bearing

cap.

Remove the bearing cap O-ring (9).

Place a block of wood against the impeller end of

theshaftandtaptheshaft(20)andassembled

bearings (12 and 21) from the bearing housing.

After removing the shaft and bearings, clean and

inspect the bearings in place as follows.

An alternate method of removing the stationary

portion of the seal is to remove the hardware (22

and 23) and separate the seal end plate (3) from

thebearinghousing(6). Removethesealend plate

and bearing housing O-rings (29 and 30). Position

theseal endplateon aflat surfacewiththe impeller

side down. Use a wooden dowel or other suitable

tooltopress on the backsideof the stationaryseat

untilthe seat, O-rings, and stationary element can

be removed.

If no further disassembly is required, refer to Seal

Installation.

Shaft and Bearing Removal and Disassembly

(Figure E-2)

When the pump is properly operated and maintained,the bearing housingshouldnot require disassembly. Disassemble the shaft and bearings

only when there is evidence of wear or damage.

To prevent damage during removal from

the shaft, it is recommended that bearings

be cleaned and inspected in place.Itis

strongly recommended that the bearings

be replaced any time the shaft and bearings are removed.

Clean the bearing housing, shaft and all component parts (except the bearings) with a soft cloth

soaked in cleaning solvent. Inspect the parts for

wear or damage and replace as necessary.

Most cleaning solvents are toxic and

flammable. Use themonly in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solventcontainers.

Shaft and bearing disassembly in the field

Clean the bearings thoroughly in fresh cleaning

solvent.Dry the bearings with filtered compressed

air and coat with light oil.

MAINTENANCE & REPAIRPAGE E -- 8

Page 31

TSERIES

Bearings must be kept free of all dirt and

foreign material. Failureto do so willgreatly shorten bearing life. Do not spin dry

bearings. This may scratch the balls or

races and cause premature bearing failure.

Rotate the bearings by hand to check for roughnessor bindingand inspectthe bearing balls. Ifrotation is rough or the bearing balls are discolored,

replace the bearings.

The bearing tolerances provide a tight press fit

onto the shaft and a snug slip fit into the bearing

housing. Replace the bearings, shaft, or bearing

housing if the proper bearing fit is not achieved.

Ifbearing replacementisrequired,remove the outboard bearing retaining ring (13), and use a bearingpulleroranarbor(orhydraulic)presstoremove

the bearings (12 and 21) from the shaft.

OM--01936

small nicks andburrs with a fine file or emery cloth.

Replace the shaft if defective.

Position the inboard oil seal (24) in the bearing

housing bore with the lip positioned as shown in

Figure E-2. Press the oil seal into the housing until

thefaceisjust flush with the machinedsurfaceon

the housing.

To prevent damage during removal from

the shaft, it is recommended that bearings

be cleaned and inspected in place.Itis

strongly recommended that the bearings

be replaced any time the shaft and bearings are removed.

The bearings may be heated to ease installation.

An induction heater, hot oil bath, electric oven, or

hotplatemaybeusedtoheatthebearings.Bearings should never be heated w ith a direct flame or

directly on a hot plate.

Press the inboard oil seal (24) from the bearing

housing bore.

Shaftand BearingReassembly andInstallation

(Figure E-2)

Clean the bearing housing, shaft and all component parts (except the bearings) with a soft cloth

soaked in cleaning solvent. Inspect the parts for

wear or damage as necessary.

Most cleaning solvents are toxic and

flammable. Use themonly in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solventcontainers.

Inspect the shaft for distortion, nicks or scratches,

or for thread damage on the impeller end. D ress

NOTE

Ifahot oil bathisused to heatthebearings, boththe

oil and the container must be absolutely clean. If

the oil has been previously used, it must be thor-

oughly filtered.

Heat the bearings to a uniform temperature no

higher than 250_F(120_C), and slidethebearings

onto the shaft, one at a time, until they are fully

seated. This should be done quickly, in one continuous motion, to prevent the bearings from cooling and sticking on the shaft.

Use caution when handling hot bearings to prevent burns.

NOTE

Position the inboard bearing (7) on the shaft with

theloading groovetoward theimpellerasindicated

by the following illustration.

MAINTENANCE & REPAIR PAGE E -- 9

Page 32

OM--01936 TSERIES

BALL LOADING

GROOVE POSITIONED

AWAY FROM

LOADING

GROOVE

DIRECTIONOF

THRUST

INSTALLATION OF NEW DEPARTURE OR

BCA/FEDERAL MOGAL 5300W SERIES BEARINGS

(OPEN OR ENCLOSED IMPELLERS)

IMPELLER

Figure E-4. Inboard Bearing Positioning

NOTE

Positionthebearing (12)on theshaftwiththeretainingring intheouterracetowardthe driveend ofthe

shaft.

Afterthe bearings have been installedand allowed

to cool, check to ensure that they have not moved

away from the shaft shoulders in shrinking. If

movement has occurred, use a suitable sized

sleeve and a press to reposition the bearings

against the shaft shoulders.

BALL LOADING

DIRECTIONOF

THRUST

INSTALLATIONOF MRC/SKF 5300M OR

(OPEN OR ENCLOSED IMPELLERS)

GROOVE POSITIONED

TOWARD

LOADING

GROOVE

FAFNIR 5300W SERIES BEARINGS

IMPELLER

the bearing bore, push against the outer

race. Never hit the balls or ball cage.

Press the outboard oil seal (15) into the bearing

cap (17) with the lippositionedas shown in Figure

E-4. Replace the bearing cap O-ring (9), and secure the bearing cap with the hardware (10 and

11).Be carefulnot to damage the oilseal lip onthe

shaft keyway.

Lubricate the bearing housing as indicated in LU-

BRICATION at the end of this section.

If heating the bearings is not practical, use a suitablesizedsleeve,and anarbor(or hydraulic)press

to install the bearings on the shaft.

When installing the bearings onto the

shaft, never press or hit against the outer

race, balls, or ball cage. Press only on the

inner race.

Securethe outboardbearing (12) on the shaft with

the bearing retaining ring (13).

Slide the shaft and assembled bearings into the

bearing housing until the retaining ring on the outboard bearing seats against the bearing housing.

Seal Reassembly and Installation

(Figures E-2 and E-4)

Cleanthe sealcavity and shaft witha cloth soaked

in fresh cleaning solvent.

Most cleaning solvents are toxic and

flammable. Use themonly in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solventcontainers.

The sealisnotnormallyreused because wear patterns on the finished faces cannot be realigned

during reassembly. This could result in premature

failure.Ifnecessary toreuse anoldsealin anemer gency, carefully wash all metallic parts in fresh

cleaning solvent and allow to dry thoroughly.

When installing the shaft and bearings into

Handlethe seal parts with extreme care t o prevent

damage. Be careful not to contaminate precision

MAINTENANCE & REPAIRPAGE E -- 10

Page 33

TSERIES

OM--01936

finished faces; even fingerprints on the faces can

shortenseallife.Ifnecessary,cleanthefaceswitha

non-oilbased solvent and a clean, lint-free tissue.

Wipe lightly in a concentric pattern to avoid

scratching the faces.

Inspect the seal components for wear, scoring,

grooves,and otherdamage t hat might cause leakage.Inspect the sealareaoftheimpellershaft, and

replace it if badly damaged. Dress any small

scratcheswith a fine fileor emery cloth.If any com-

RETAINER

SPRING

IMPELLER

ponents are worn, replace the complete seal;

never mix old and new seal parts.

If a replacement seal is being used, remove it from

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter.

To ease installation of the seal, lubricate the bellows and stationary seat O-rings with water or a

very small amount of oil, and apply a drop of light

lubricating oil on the finished faces. Assemble the

seal as follows, (see Figure E-5).

WEAR PLATE ASSEMBLY

SEAL END PLATE

O-RINGS

IMPELLER SHIMS

BELLOWS

ROTATING

ELEMENT ELEMENT

Figure E-5. 46512--192 Seal Assembly

STATIONARY

front of the sealend plate (3) until it seats squarely

against the bore shoulder. Be careful not to damage the seal face.

IMPELLER

SHAFT

STATIONARY

SEAT

This seal is not designed for operation at

temperatures above 160

_F(71_C). Donot

use at higher operating temperatures.

Lubricate the stationary seat O-rings with water or

light oil, and install them in the stationary seat. Install the stationary seal element in the stationary

seat. Press this stationary subassembly into the

MAINTENANCE & REPAIR PAGE E -- 11

Install the seal end plate gasket (4) and seal end

plate O-ring (29). Position the seal end plate and

stationaryseat over the shaft. Position the seal end

plate so that the cast word “TOP” is upper most

and secure it to the bearing housing (6) w ith the

hardware(22and 23).Torquethehardwareto90ft.

lbs.(1,080in. lbs. or 12,4 m. kg.). Be carefulnotto

Page 34

OM--01936 TSERIES

damage the stationary element on the shaft

threads.

NOTE

It is recommended that a tapered sleeve be installedoverthethreadsof theimpellershaft toease

installation of the rotating seal components.

Lubricate the shaft with a small amount of light oil

and slide the rotating subassembly (consisting of

rotating element, bellows and retainer), onto the

shaft. Apply firm, steady pressure on the seal retainer as it slides onto the shaft until the seal faces

contact.

Install the seal spring. Lubricate the seal as indicated in LUBRICATION aftertheimpellerisinstalled.

If necessary to reuse an old seal in an emergency, carefully separate the rotating and stationary seal faces from the bellows retainer and stationary seat.

Installthe stationary seal element in the stationary

seat. Press this stationary subassembly into the

seal end plate bore until it seats squarely against