Page 1

USER MANUAL

ZX400/ZX400i

: Rev.A

: 2016.11

: 920-016411-00

Version

Issue Date

P/N

Page 2

CONTENTS

1. Barcode Printer ............................................................................................................................................................................... 1

1-1 Box Content ................................................................................................................................................................................... 1

1-2 Getting To Know Your Printer ....................................................................................................................................................... 2

2. Printer Setup ......................................................................................................................................................................................... 5

2-1 Loading the label roll ..................................................................................................................................................................... 5

2-2 Loading & Removing the Ribbon .................................................................................................................................................. 9

2-3 Connecting The Printer To The Host Computer ........................................................................................................................ 11

2-4 Wizard CD Standard Installation ................................................................................................................................................. 12

2-5 Wizard CD Other Choice Installation .......................................................................................................................................... 15

3. Operation Panel ................................................................................................ .................................................................................. 17

3-1 LED Operation Panel ................................................................................................................................................................... 17

3-2 LCD Interface Introduction .......................................................................................................................................................... 19

3-3 LAN Setting .................................................................................................................................................................................. 24

3-4 LCD Password ............................................................................................................................................................................. 26

3-5 LCD Interface Function ............................................................................................................................................................... 28

3-6 Label size calibration and Self Test Page .................................................................................................................................. 32

3-7 Error Alerts................................................................................................................................................................................... 34

3-8 USB Host ...................................................................................................................................................................................... 38

4 NetSetting for Ethernet ........................................................................................................................................................................ 40

4-1 Installing the NetSetting software .............................................................................................................................................. 40

4-2 The Interface of NetSetting ......................................................................................................................................................... 42

5 Accessories ......................................................................................................................................................................................... 49

5-1 Preparation Steps ........................................................................................................................................................................ 49

5-2 Installing the Cutter ..................................................................................................................................................................... 50

5-2-1 Installing the Guillotine Cutter ................................................................................................................................................. 50

5-2-2 Installing the Rotary Cutter ................................................................................................................................ ...................... 53

5-3 Installing The Label Dispenser ................................................................................................................................................... 56

6 Maintenance and Adjustment ............................................................................................................................................................. 59

6-1 Installing / removing the print head module .............................................................................................................................. 59

6-2 Adjusting the print line ................................................................................................................................................................ 60

6-3 Adjusting ribbon tension ............................................................................................................................................................ 61

6-4 Cleaning the thermal print head ................................................................................................................................................. 62

6-5 Adjusting the balance and print head tension ........................................................................................................................... 63

6-6 Ribbon shield settings ................................................................................................................................................................ 64

6-7 Cutter settings ............................................................................................................................................................................. 65

6-8 Troubleshooting .......................................................................................................................................................................... 66

APPENDIX

Page 3

ZX400/ZX400i

FCC COMPLIANCE STATEMENT

FOR AMERICAN USERS

Federal Communication Commission Interference Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference

by one of the following measures:

● Reorient or relocate the receiving antenna.

● Increase the separation between the equipment and receiver.

● Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

● Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

FCC Caution: Any changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to operate this equipment.

TO WHICH THIS DECLARATION RELATES

IS IN CONFORMITY WITH THE FOLLOWING STANDARDS

FCC CFR Title 47 Part 15 Subpart B:2015 Class B,CISPR 22:2008 ANSI C63.4: 2014 ICES-003 Issue 6:2016, Class B

IEC 60950-1:2005(Second Edition)+Am1:2009+Am2:2013

EN60950-1:2006+A11:2009+A1:2010+A12:2011+A2:2013

EN55022:2010+AC:2011 Class B

EN55032:2012+AC:2013

EN61000-3-2:2014

EN61000-3-3:2013

AS/NZS CISPR 22:2009+A1:2010

EN55024:2010+A1:2015

IEC61000-4-2 Ed. 2.0:2008

IEC61000-4-3 Ed. 3.2:2010

IEC61000-4-4 Ed. 3.0:2012

IEC61000-4-5 Ed. 3.0:2014

IEC61000-4-6 Ed. 4.0:2013

IEC61000-4-8 Ed. 2.0:2009

IEC61000-4-11 Ed. 2.0:2004

Page 4

SAFETY INSTRUCTIONS

Please read the following instructions carefully.

Keep the equipment away from humidity.

Before you connect the equipment to the power outlet, please check the

voltage of the power source.

Make sure the printer is off before plugging the power connector into

the power jack.

It is recommended that you connect the printer to a surge protector to

prevent possible transient overvoltage damage.

Be careful not to get liquid on the equipment to avoid electrical

shock.

For safety and warranty reasons, ONLY qualified service personnel

should open the equipment.

Do not repair or adjust energized equipment under any circumstances.

CAUTION

Danger of explosion if battery is incorrectly replaced. Replace only with the equivalent

type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

Only use with designated power supply adapter model.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

Specifications are subject to change without notice

Page 5

1

1. Barcode Printer

1-1 Box Content

Please check that all of the following items are included with your printer.

(Package content and Logo style may vary per region。)

Barcode Printer

ZX420i ZX420

Label Stock USB Cable Quick Guide

Ribbon Power Adapter CD

Power Cord

Empty Ribbon Core

(Including GoLabel software

and user’s manual.)

Page 6

2

1-2 Getting To Know Your Printer

(ZX420i)

Front View

Rear View

EXTERNAL LABEL INSERT

AUTO-CALIBRATION BUTTON

POWER JACK

TOP COVER

VIEWING WINDOW

FRONT COVER

LCD PANEL

POWER BUTTON

FEED BUTTON

OPERATOR PANEL

BT/Wi-Fi PORT (OPTIONAL)

RS232 PORT

USB PORT

USB HOST (OPTIONAL)

PARALLEL PORT (OPTIONAL)

Page 7

3

(ZX420)

Front View

Rear View

EXTERNAL LABEL INSERT

AUTO-CALIBRATION BUTTON

POWER JACK

TOP COVER

VIEWING WINDOW

FRONT COVER

POWER BUTTON

FEED BUTTON

BT/Wi-Fi PORT (OPTIONAL)

USB PORT

PARALLEL PORT (OPTIONAL)

Page 8

4

Open The Printer Cover

ADJUSTABLE SENSOR

PAPER GUIDE

PLATEN ROLLER

RELEASE LEVER FOR PRINT HEAD

RELEASE LEVER FOR PRINT HEAD

LABEL ROLL GUIDE

PAPER GUIDE

RIBBON REWIND HUB

RIBBON SUPPLY HUB

PRINT MECHANISM

HANDLE OF PAPER GUIDE

Page 9

5

2. Printer Setup

2-1 Loading the label roll

This printer supports the following printing methods:

Thermal transfer printing (TTP):Requires a ribbon for transferring a printed image to a medium.

Direct thermal printing (DTP):Does not require a ribbon, only thermal paper.

Please check which printing method you are using and alter the settings accordingly in the printer driver, printer menu, and/or

software.

Page 10

6

Now fold the label roll guide up

Place the label roll on the label supply hub,

pushing it right up to the printer housing.

(Do not apply too much pressure to avoid

damaging the label stock.)

Page 11

7

Load the label roll into the printer as shown in the illustration.

Pass it through the printer as indicated by the red arrows.

Pass the label stock through the

adjustable Sensor and up to the tear-off plate.

Page 12

8

2. Return the print head release lever to its original position.

1. The labels pass between the wall of the printer housing and the adjustable paper guide.

Then close the printer cover.

Page 13

9

2-2 Loading & Removing the Ribbon

Loading Ribbon

Place the printer on a flat surface

and open the printer cover

Place a new ribbon on the ribbon supply hub.

The illustration as below shows you how to install the ribbon.

Ink side out

Page 14

10

Pass the ribbon under the print head and back up on the other side.

Attach it to the empty ribbon core.

Page 15

11

2-3 Connecting The Printer To The Host Computer

Please make sure that the printer is switched off.

Connect the power cord to the AC adapter and connect the adapter to the printer.

Connect the USB / parallel cable to the printer and host computer.

(The type of cable may vary according to the products which you purchase.)

Switch on the printer. The LED indicator should now lights up.

BARCODE PRINTER

(Ports may vary per model。)

Page 16

12

2-4 Wizard CD Standard Installation

Step.01 Insert the Super Wizard CD in the CD/DVD drive of the host computer and the installation program should pop up

automatically.

You will see the Welcome screen first. On the Welcome screen, choose “STANDARD INSTALLATION”.

Step.02 The wizard will then ask you to make sure your USB and power cables are connected and that the power is

turned on. Then click “NEXT”.

Step.03 The next screen you will see is, “Install the GoLabel Software and Windows driver”. Click “NEXT” to continue.

NOTE

* If the Super Wizard program did not run automatically, you can either turn on the “Auto-run” setting for

your CD/DVD driver or double-click the icon of CD/DVD driver to run the program manually.

Page 17

13

Step.04 As the printer driver and GoLabel are installing, a screen will display a progress bar. While downloading

completed you will see Installation completed. Click “NEXT” to continue.

Step.05 You can also print a test label. If don’t print a test label, the screen display as step 6.

NOTE

* If you need more resources, tools or reference documents, you can also find them on Super Wizard CD.

Just click “Other Choices” on the Welcome Screen to access the files.

Page 18

14

Step.06 Once the installation is complete, you can start to make and print labels with GoLabel or through the printer driver.

Page 19

15

2-5 Wizard CD Other Choice Installation

Step.01 Click “OTHER CHOICES” to next screen and select “PRINTER DRIVERS”.

Step.02 Click “INSTALL SEAGULL SCIENTIFIC WINDOWS DRIVER” to next screen, and click “NEXT”.

Step.03 Select “I accept the terms in the license agreement”, and click ”Next”,then click ”Finish” to step 4.

Page 20

16

Step.04 The Driver Wizard will guide you through the installation procedure. Select "Install printer drivers" and click

“Next”.

Step.05 With a USB connection, search models such as the right diagram printer device. Specify your printer model

and click ”Next”.

Step.06 Enter the printer name (you can use default), then click "Next" to display as right diagram.

Click "Finish" button to start installation.

Step.07 Driver installation completed.

Page 21

17

3. Operation Panel

3-1 LED Operation Panel

(For ZX400i Series)

POWER Button

Press the POWER button to turn on the printer, and the START UP SCREEN appears. The printer is on “ready to print”

status, the LCD screen should display the message “READY“ on the screen.

When printer is turned on, hold and press down the POWER button for 3 second will turn the printer off.

FEED Button

Turn on the printer and press the FEED button.

When you press the FEED button, the printer will advance media until the FEED button is released.

If you are using continuous labels, pressing the FEED button will advance a length of media until the button is released.

If you are using media with gaps, pressing the FEED button once will advance only one label.

If the label does not stop at the correct position, you need to run the auto-detection function for your media,

please see Section 3.6 Label Calibration and Self-Test.

PAUSE PRINTING_FEED Button

Pressing the FEED button while the printer is in standby mode will set the printer to pause mode. In this mode,

the printer can receive commands, but it will only process them when it is reset to standby mode. Pressing the

FEED button again will reset the printer to standby mode.

Pressing the FEED button during printing will interrupt printing. When the FEED button is pressed again, the printer

resumes printing. Example: While a 10-label print job is running, you press the FEED button to pause the printer.

Two of the labels have been printed. To resume printing and print the remaining eight labels, you will need to press

the FEED button again.

CANCEL PRINTING_FEED Button

Press and hold the FEED button for 3 seconds during printing cancels a print job. The current print job is cancelled.

Example: While a 10-label print job is running, you press the FEED button. Two of the labels have been printed.

The print job is cancelled and the remaining eight labels will not be printed

LCD PANEL

FEED BUTTON

POWER BUTTON

OPERATOR PANEL

OPERATOR PANEL

Page 22

18

(For ZX400 Series)

POWER Button

Press the POWER button to turn on the printer, and the START UP SCREEN appears. The printer is on “ready to print”

status. When printer is turned on, hold and press down the POWER button for 3 second will turn the printer off.

FEED Button

Turn on the printer and press the FEED button.

When you press the FEED button, the printer will advance media until the FEED button is released.

If you are using continuous labels, pressing the FEED button will advance a length of media until the button is released.

If you are using media with gaps, pressing the FEED button once will advance only one label.

If the label does not stop at the correct position, you need to run the auto-detection function for your media,

please see Section 3.6 Label Calibration and Self-Test.

PAUSE PRINTING_FEED Button

Pressing the FEED button while the printer is in standby mode will set the printer to pause mode. In this mode,

the printer can receive commands, but it will only process them when it is reset to standby mode. Pressing the

FEED button again will reset the printer to standby mode.

Pressing the FEED button during printing will interrupt printing. When the FEED button is pressed again, the printer

resumes printing. Example: While a 10-label print job is running, you press the FEED button to pause the printer.

Two of the labels have been printed. To resume printing and print the remaining eight labels, you will need to press

the FEED button again.

CANCEL PRINTING_FEED Button

Press and hold the FEED button for 3 seconds during printing cancels a print job. The current print job is cancelled.

Example: While a 10-label print job is running, you press the FEED button. Two of the labels have been printed.

The print job is cancelled and the remaining eight labels will not be printed

FEED BUTTON

POWER BUTTON

Page 23

19

3-2 LCD Interface Introduction

Getting Started

Press the POWER button to turn on the printer, and the START UP SCREEN appears.

Power on

If the printer is on “ready to print” status, the LCD screen should display the message “Ready“ on the screen.

Please keep pressing button and wait for the timer to be filled, then the LCD interface will enter

into the MAIN PAGE for SETTING MODE. You can make various setting functions in SETTING

Enter Main

Page 24

20

Operations on Setting Page

On MAIN PAGE, press or button to move the cursor and select the functions.

Select a designated function and press FEED button, you will enter the SETTING PAGES for the function.

or

or

Select

Enter

Select

Enter

On SETTING PAGES, press or button to select the setting items.

Select a designated function and press FEED button, you will enter the SETTING VALUE PAGES for the function.

Page 25

21

On SETTING VALUE PAGES, press or button to change the setting values.

NOTE

* The blue arrow indicates the value you are selected.

** The red tick indicates that the selected value is applied now.

Select

or

Apply

Press FEED button will apply the setting value you just selected, and the red tick will appear to mark the value.

Page 26

22

Exit from Current Page to Ready Status

The icon on top-left corner displays the capture of upper level screen and also guides you back to upper level with

left or up arrow.

NAVIGATION ICON

On SETTING VALUE PAGES, press

Back to the Setting

On SETTING PAGES, press button will go back to the MAIN PAGE

Back to the Main page

Page 27

23

On MAIN PAGE, select the “EXIT” icon and press the FEED button to exit from SETTING MODE and the printer goes back to

READY status.

EXIT from Setting Mode

Back to the Ready status

or

Page 28

24

3-3 LAN Setting

or

Select

or

Operations on Setting Page

On MAIN PAGE, press or button to move the cursor and select the functions.

Select a designated function and press FEED button, you will enter the SETTING PAGES for the function.

Enter LAN Setting

On LAN Setting PAGE, press or button to select the setting items.

Select a designated

function

Select DHCP and press FEED button, you will be able to setup DHCP function

Page 29

25

The default of DHCP is Disable. Press button to change the setting values.

Select to enable DHCP

Press FEED button twice to save the setting.

Press FEED once to exit

Press FEED again to

save and return to

previous

Page 30

26

3-4 LCD Password

Operations on Setting Page

On MAIN PAGE, press or button to move the cursor and select the functions.

Seclect a designated function and press FEED button, you will enter the SETTING PAGE for the

Select Device

Enter LCD Password

The default of LCD Setting is Disable. Press or button to change the setting values.

Select button to

Enable Password

Page 31

27

Select button again to setup

the password

Press FEED button once to exit

Press FEED button twice to save the setting

Press FEED button again to save and

return to previous SETTING PAGE

Page 32

28

3-5 LCD Interface Function

Main Page

Setting items for printer, ex. Printing speed, darkness.

Also includes a Printing Wizard for your ease of printing.

Setting items for printing label, ex. Rotation, Printing position offset.

Option modules and connection port settings.

Self-Diagnose functions for printer, ex. TPH testing, self-test page printing.

Self-Diagnose functions for printer, ex. TPH testing, self-test page printing.

Printer

Label

Device

Analysis

Exit

Page 33

29

Status of LCD Interface

When printer is on standby status (ready to print), the LCD interface will display “Ready” on screen.

You can only print on this “Ready“ status.

Icon Definition

If there is any printers error, the LCD screen will display the error screen to show the type of error.

You can fix the error according the notice.

To upper level

To upper level

Lock

Unlock

Scroll the value

ERROR

ERROR ICON

Appears on the NAVIGATION ICON of SettingPages.

It guides you back to upper level bypressing “LEFT“ key.

Appears on the NAVIGATION ICON of SettingValue Pages.

It guides you back to upper level by pressing “UP“ key.

On Setting Value pages, press “RIGTH“ key to

lock the value for preventing unexpected change.

For locked value, press “RIGHT” key again to unlock the value.

On Setting Value pages, press “UP“ or “DOWN“

key to scroll the values for your selection.

Page 34

30

Page 35

31

Page 36

32

3-6 Label size calibration and Self Test Page

The printer can automatically detect and store label height.

That means the host computer does not need to transmit the label height to the printer.

And the self-test function lets you check whether the printer is functioning normally.

Here is how you run the label size calibration and self test.

Step.01 Check that the label stock is loaded correctly.

Step.02 Switch off the printer.

Step.03 Switch the printer on again, keeping the FEED button pressed. When the READY LED starts to flash

red and the STATUS LED lights up orange, release the FEED button. The printer will now measure

the label stock and store the label height

Step.04 Once the printer has successfully measured the label stock, it will print a self-test label.

The contents of a self-test printout are listed below.

(The data below is for reference only, actual result may vary according to each situation.)

Model & Version

USB ID setting

Serial port setting

MAC address of Ethernet port

IP protocol setting

IP address of Ethernet

Gateway setting

Netmask setting

Card Status

Network Status

Number of DRAM installed

Image buffer size

Number of forms

Number of graphics

Number of fonts

Number of Asian fonts

Number of Databases

Number of Scalable fonts

Free memory size

Speed, Density, Ref. Point, Print direction

Label width, Form length, Stop position

Cutter, Label Dispenser, Mode

Sensor Setting

Code Page

Page 37

33

Label Calibration Button

A hardware button to make a Label Calibration while printer encountering ‘’Media Error’’ during the cases when first-time

printer start up or change label or ribbon to another type, such as change using gap label to continuous or black mark

labels.

NOTE

* Press C-button is equivalent to the auto-sensing command ‘’~S,SENSOR’’ that will cancel on-printing-job and make the

Label Calibration immediately.

Press the button 1or 2seconds.

Press the button 1or 2seconds.

CALIBRATION BUTTON

Page 38

34

3-7 Error Alerts

(For ZX400i Series)

In the event of a problem that prevents normal functioning of the printer, you will see an error message on LED indicators and

hear some beep signals. Please refer to below table for the error alerts.

LCD TOUCH PANEL

OPERATOR PANEL

FEED BUTTON

POWER BUTTON

OPERATION

TOUCH PANEL

Page 39

35

Page 40

36

(For ZX400 Series)

In the event of a problem that prevents normal functioning of the printer, you will see an error message on LED indicators and

hear some beep signals. Please refer to below table for the error alerts.

Green Light

Red Light

Red Light flashes

Types

LED above the display

Beeps

Description

Solution

Power Indictor

Status Indictor

Print head

is open

4x2

beeps

The print

mechanism is not

closed.

Please make sure that the print

mechanism is closed correctly.

Print head is

overheat

The print head is

too hot.

Once the print head has cooled

down, the printer switches to

standby mode.

check

ribbon

3x2

beeps

No ribbon is

loaded.

Please make sure that the

printer is set to thermal

direct mode.

The ribbon is

finished or the

ribbon roll is not

moving.

Replace the ribbon roll.

FEED BUTTON

(Status Indictor)

POWER BUTTON

(Power Indictor)

Page 41

37

check

media

1x2

beeps

Unable to detect

the paper.

Please make sure that the gap

sensor is positioned correctly. If

that does not fix the problem,

run the auto-detection function

again.

The labels are

finished.

Replace the label roll.

Paper jam.

Check the path of paper feeding.

Page 42

38

3-8 USB Host

Definition : USB Host port supports either device:USB memory stick, keyboard or scanner.

Purpose:

USB memory stick : It extends the user memory space up to 32GB for Graphic, Font, Label Format, DBF and Command

files downloading. The printer’s Firmware also can be updating if copy new version of Firmware into USB memory stick.

Connecting an USB keyboard to printer for ‘’Keyboard Mode’’ mode operation.

Plug-in an USB scanner to operate the printer in ‘’Keyboard Mode’’ .

Usage of Extended Memory

USB memory stick : It supports hot-plugging function; printer will create a Folder ‘’\LABELDIR’’ and switch ‘’User Flash’’

to ‘’ Extended Memory‘’ automatically while user plugs an USB memory stick into a GoDEX printer.

Connect the USB Stick plugged -in printer to PC via USB Device or Ethernet port and run ‘’GoLabel’’ software to

download Graphic, Font, Label Format, DBF and Command files to the printer.

Detail download procedures, please refer to ‘’GoLabel On-line Help’’.

Usage of Firmware Update

Remove USB memory stick from printer and plug-in it to a PC’s USB port; delete Firmware ‘’*.bin’’ file from

‘’\LABELDIR\FW’’ of USB memory stick if it existing; or create a Folder ‘’\LABELDIR\FW’’ to USB memory stick if it doesn’t

existing.

Copy a new version of Firmware ‘’xxxx.bin’’ to the Folder ‘’\LABELDIR\FW’’; and then remove USB and plug-in

back to the printer that going to update Firmware.

The printer will update the Firmware automatically when plug-it-into the printer and printer find-out the Firmware

in ‘’\LABELDIR\FW’’ is newer version.

Don’t remove the USB memory stick out while it’s under updating with ‘’Flash Writing...’’message that displays on

LCD panel.

Page 43

39

USB Keyboard

When plug-in an USB keyboard to the printer, LCD touch panel will display “Enter Standalone”, press the

“Y” key on keyboard to entering to the dialog for “Keyboard Mode” operation.

Here have six sub-dialogs “Recall Label” “Country Code” “Code Page” “Clock Setting” “Database Setting”

“Label Edit” is able operating by keyboard as follow definition:

1. Press “ESC” key to exist from “Keyboard Mode” or back to previous dialog

2. Press “F1”, it will let the printer from “Home Page” mode entering into “Keyboard Mode”

3. Press “Enter”, “Arrow” and “Alphabetic” keys as the usual in PC that will perform the key-in function of

“Keyboard Mode”.

Scanner

When plug-in an USB scanner to the printer, LCD touch panel will display “Enter Standalone”, tap the

“Y” to entering the dialog of “Keyboard Mode” operation.

Scanner is using in “Keyboard Mode” to scanning the “Serial Number, Variable” and Print Quantity while

the printer prompts a message on LCD touch panel and wait for data input.

* The USB Host port on GoDEX printer is without ‘’HUB’’ function.

** The USB Memory Stick supports with ‘’FAT32’’Disk Format and up to 32GB only. The certified venders are Transcend,

Apacer, Patriot, Consair and Kingston.

*** The download function for Graphic, Font, Label Format, DBF and Command files is operated by GoLabel of PC and

must go through the a ‘’i’’ ‘’x’’ model printer itself.

**** On a PC, user may copy entire folder’’\LABELDIR’’ from USB memory stick to PC or vice-versa. Copy a sub-folder or

individual file in ‘’\LABELDIR’’ to PC or vice-versa is not supported.

Page 44

40

4 NetSetting for Ethernet

4-1 Installing the NetSetting software

The NetSetting software is used to manage the network configurations when connecting the printer via Ethernet port.

It is available on product CD or can be downloaded from official website. To install the NetSetting, please follow below

steps.

Step.01 Insert the product CD in the CD/DVD drive, and click “OTHER CHOICES” buttom.

Step.02 Select “ETHERNET”.

Step.03 Click "Install Ethernet NetSetting Software", installation screen as right diagram, click "Next".

Step.04 Specify the “Installation Folder", then click ”Next” to installing.

Page 45

41

Step.05 Once the installation is completed, you will see the NetSetting icon on your desktop as right diagram.

Page 46

42

4-2 The Interface of NetSetting

GoDEX printer can also be used through a network connection (as a remote network printer), make sure the printer

connected to the Internet and the power cord, you can use the Interface of NetSetting to search connected network

printers.

Step.01 Click the NetSetting icon to start the program, you will see the start page as left diagram. Click the magnifier icon

to search the Godex printers which are connected via Ethernet port in you network environment (as right diagram).

Step.02 There are six tabs on the top of interface which can configure different types of network settings. But for the data

security reason, you need correct password to enter the configuration pages.

NOTE

* The default password is “1111”, you can change the password later from the “IP Setting” tab.

Page 47

43

IP Setting

The IP Setting tab can change the printer name, Port number, Gateway setting and the password for configuring the printer. You

can also set the printer’s IP address ether by DHCP or by Static IP.

You can press “Set” button to apply the settings and “ReGet” button to refresh the setting values.

NOTE

* To fully benefit from the NetSetting software, you should be familiar with basic networking principles. Please

contact your network administrator for related network setting information.

* When enabling DHCP, if you find the IP Address as: IP = 169.254.229.88, Net mask = 255.255.0.0, Gateway = invariable (last

value), the IP Address is invalid.

Page 48

44

Alert Path Setting

NetSetting will send the alert messages to designated mail account when the error happened on printer.

The alert messages are sent by SMTP (Simple Mail Transfer Protocol) or SNMP (Simple Network Management Protocol).

You can set or change the configurations of SMTP and SNMP on this “Alert Path Setting” tab.

You can press “Set” button to apply the settings and “ReGet” button to refresh the setting values.

Page 49

45

Alert Message Setting

For the alert message notification function, you can decide which error cases need to be sent out to the operator.

Moreover, the alert messages can be set to be sent by SMTP, SNMP or both.

You can press “Set” button to apply the settings and “ReGet” button to refresh the setting values.

Page 50

46

Printer Configuration

Set or change the configurations of connected printer. Most of key settings for the printer operation can be done by this setting

page.

You can press “Set” button to apply the settings and “ReGet” button to refresh the setting values.

Page 51

47

User Command

The “User Command” tab provides a communication interface for operator to control the printer. Input printercommands in

"Input Command" window and press “Send Command” button, the commands will be sent to the printer.

For some commands that will return response message, the message will be displayed in "Output Message" window.

You can press “Set” button to apply the settings and “ReGet” button to refresh the setting values.

Page 52

48

Firmware Download

On “Firmware Download” tab, the current version of printer firmware will be showed on the screen. If you need to update the

printer firmware, just specify the file location of firmware file and press “Start Download Firmware”button. The printer firmware

then can be updated remotely.

In addition to the firmware update, you can press “Recover To Factory Settings” button to restore the printer configurations back

to factory default.

Page 53

49

5 Accessories

5-1 Preparation Steps

Before installing the optional modules, please make some preparations as follows.

1. Turn off the printer :

Remember to switch off the printer before installing any module.

2. Open the printer cover

NOTE

* Remember to switch off the printer before installing the cutter.

** Do not use to cut adhesive labels! Glue residue will be left on the cutter blade and impair its functioning.

Page 54

50

5-2 Installing the Cutter

5-2-1 Installing the Guillotine Cutter

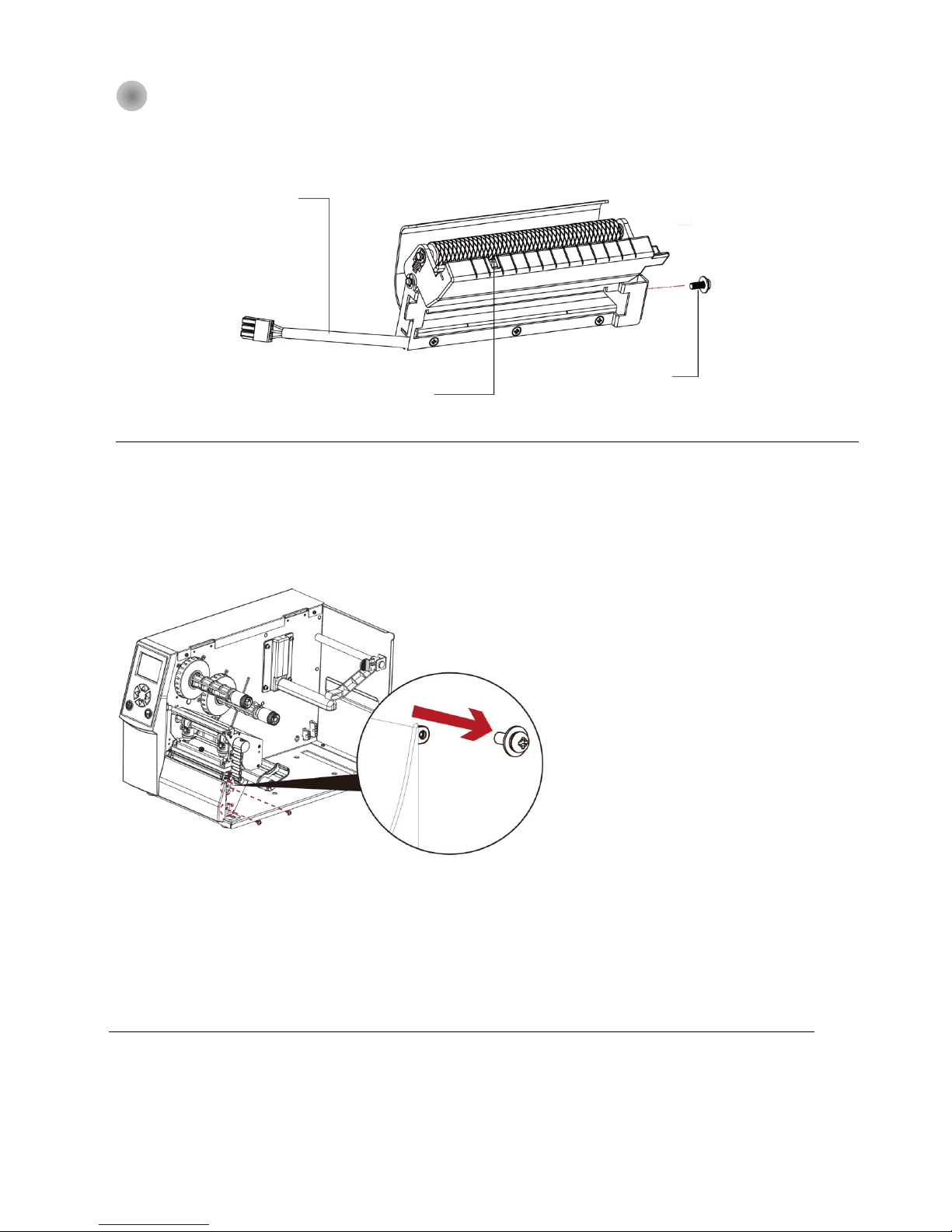

Overview Of Guillotine Cutter

Steps for installing the Guillotine Cutter:

(Power off the printer and remove the power cable before installing the guillotine cutter module)

NOTE

* Power off the printer and remove the cable from the connector before installing guillotine cutter module.

** Labels with adhesive glue are not applicable or otherwise could result to malfunction.

*** Applicable label size is at maximum width of 118mm and minimum length of 30mm. (Usage with labels outside this range

will be excluded from warranty terms)

**** Stop position (^Ex command) should set to 26~27 through GoLabel before using the guillotine cutter.

COVER

CONNECTION CABLE OF GUILLOTINE CUTTER

1. Remove the screw (as circle indicated).

Page 55

51

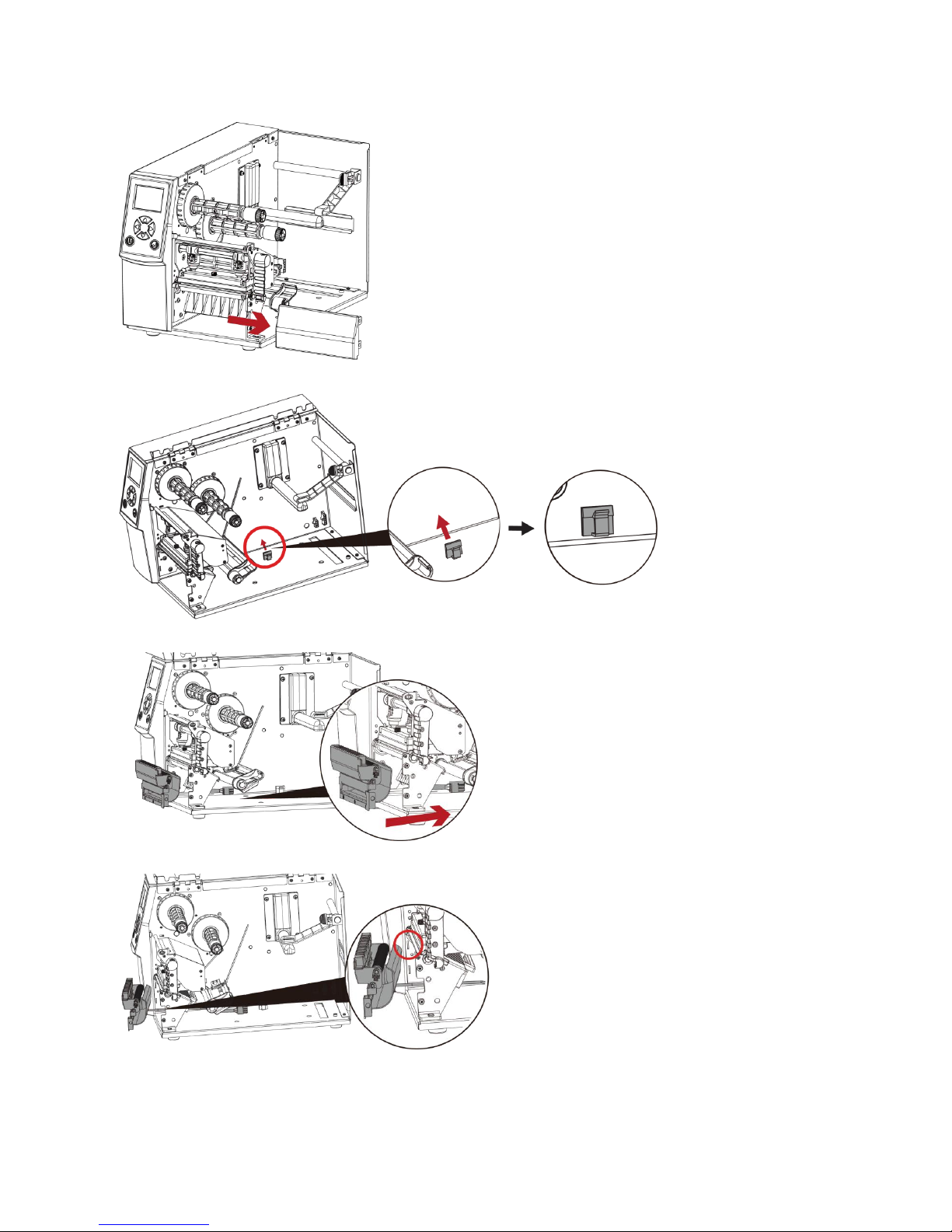

3. Stick the hub onto the circled area.

4. Direct the cutter’s cable through the platen

bracket of the printer.

5. Engage the catchs of the cutter module firmly

into the printer.

2. Remove the cover panel by pushing to

right-hand side.

Page 56

52

6. Tighten the screws and plug the cutter’s cable into the printer in the direction of the arrow.

NOTE

* Printer power should be off when plugging the connector to avoid malfunction

7. Put the cable into the hub.

8. Close printer cover.

Page 57

53

5-2-2 Installing the Rotary Cutter

Overview Of Rotary Cutter

Steps for installing the Rotary Cutter:

(Power off the printer and remove the power cable before installing the guillotine cutter module)

NOTE

* Power off the printer and remove the cable from the connector before installing rotary cutter module.

** Labels with adhesive glue are not applicable or otherwise could result to malfunction.

*** Applicable label size is at maximum width of 118mm and minimum length of 30mm. (Usage with labels outside this range will be

excluded from warranty terms)

**** Stop position (^Ex command) should set to 29~30 before using the rotary cutter.

CONNECTION CABLE OF ROTARY CUTTER

COVER

1.

Remove the screw (as circle indicated).

Page 58

54

3. Stick the hub onto the circled area.

4. Direct the cutter’s cable through the platen

bracket of the printer.

5. Engage the catchs of the cutter module firmly

into the printer.

2. Remove the cover panel by pushing to

right-hand side.

Page 59

55

NOTE

* Printer power should be off when plugging the connector to avoid malfunction

6. Plug the cutter’s cable into the printer in the direction of the arrow.

7. Put the cable into the hub.

8. Close printer cover.

Page 60

56

5-3 Installing The Label Dispenser

The Overview of the Label Dispenser

Steps for installing the Label Dispenser:

(Power off the printer and remove the power cable before installing the label dispenser module)

NOTE

* A label liner thickness of 0.006 mm ± 10% and a weight of 65 g/m2 ± 6% are recommended.

** The label dispenser will take labels up to a max. width of 110 mm, and labels should be at least 25 mm high.

*** When using the label dispenser, set the stop position to 9 mm.

CONNECT CABLE OF LABEL

DISPENSER

PAPER SENSOR

SCREWS

1. Remove the screw (as circle indicated).

Page 61

57

2. Remove the cover panel by pushing to

right-hand side.

3. Stick the hub onto the circled area.

4. Direct the label dispenser’s cable through the platen

bracket of the printer.

5. Engage the catchs of the label dispenser module

firmly into the printer.

Page 62

58

6. Plug the label dispenser’s cable into the printer in the direction of the arrow.

NOTE

* Printer power should be off when plugging the connector to avoid malfunction

7. Put the cable into the hub.

8. Close printer cover.

Page 63

59

6 Maintenance and Adjustment

6-1 Installing / removing the print head module

NOTE

* Remember to switch off the printer before removing the print head module.

1. Open the printer cover.

2. Using a screwdriver or a

coin, loosen the screw to

take out the TPH module.

3. Turn the print head

counterclockwise

to a top right position

4. Turn the print head

counterclockwise

to a top right position

Page 64

60

6-2 Adjusting the print line

1. Open the printer

cover.

2. Using a screwdriver or a

coin to loosen the screw

3. Turn the print head

counterclockwise

to a top right position

If no improvement is visible, turn the

screws(A) clockwise or counterclockwise

as far as possible and be sure to align with

the indicator board and indicator line.

Repeat the adjustment process until printing

quality has improved.

Page 65

61

6-3 Adjusting ribbon tension

You can adjust the ribbon tension by turning the ribbon shaft knob (see illustration) clockwise or counterclockwise.

There are 4 possible settings, which is marked on the ribbon supply hub.

# 1 : Tension is the highest

# 4 : Tension is the lowest

If the tension is so low that the ribbon does not move forward, you need to reduce the tension of the ribbon supply hub.

To set the tension, press in the knob and turn it clockwise or counterclockwise as required.

Increasing the tension of the ribbon rewind hub will remove any wrinkling of the ribbon during printing,

which results from the use of different ribbon materials. (For details about the wrinkling/creasing of ribbons,

see Section 6-6.)

If you are using a very narrow ribbon, the printer may not move the label stock forward (particularly with

a ribbon that is less than 2" wide). In that case, reduce the tension by turning the knob of the ribbon supply hub

counterclockwise.

Page 66

62

6-4 Cleaning the thermal print head

Dirt on the print head or ribbon may result in inadequate print quality

(there are only partial images on the label). The printer cover should therefore be kept

closed when possible.

Keeping dirt and dust away from the paper or labels ensures a good print quality

and a longer lifespan of the print head. Here is how you clean the print head:

1. Switch off the printer.

2. Open the printer cover.

3. Remove the ribbon.

4. Release the print head by turning the print head release lever.

5. To remove any label residue or other dirt from the print head

(see Red arrow), please use a soft lint-free cloth dipped in alcohol to wipe.

NOTE

* The print head should be cleaned once a week.

** Please make sure that there are no metal fragments or other hard particles on the soft cloth used to clean

the print head.

Page 67

63

6-5 Adjusting the balance and print head tension

1. Open the printer

2. Using a screwdriver or a

coin to loosen the screwcoin to loosen the screw

When using a variety of label stock

and ribbons, the ink may not be evenly distributed.

If there is no printed image on one side of the paper,

or the ribbon wrinkles, the print head pressure

must be readjusted using the TPH spring boxes.

Move the TPH spring boxes as shown in the illustration

to change the print head pressure.

The wider the label you are using, the further apart

the TPH spring boxes must be moved away from

each other. If there is no quality improvement,

you need to change the pressure on the TPH spring boxes.

Turning the screw left increases the pressure,

while turning it right reduces the pressure.

Be sure not to turn the screw so that it goes below Mark(B).

Reset Mark (A)

Mark (B)

Page 68

64

6-6 Ribbon shield settings

The use of different ribbon materials may cause wrinkling of the ribbon, which in turn affects the print result

as illustrated by the examples in (a) and (b). To change the print quality, you can adjust the ribbon shield screws.

If your print result looks like the example in (a), you need to turn ribbon shield screw clockwise.

If your print result looks like the example in (b), you need to turn ribbon shield screw counterclockwise.

NOTE

* If you adjust the screw by more than two full turns, the paper feed may no longer function correctly. In that case,

unscrew the ribbon shield screws to align the reset mark and restart the adjustment process.

To keep track of the change in print quality, you should adjust the screws by half a turn at a time.

Print a test page. If there is no improvement in the print result, turn the screw by another half turn.

Do not turn the adjustment screw more than two full turns(360〫).

Reset Mark

Page 69

65

6-7 Cutter settings

NOTE

* Remember to switch off the printer before removing the CUTTER.

** The label medium should be at least 30 mm long to ensure correct functioning of the cutter.

Switch off the printer before removingthe CUTTER.

(Remove or install cutter refer to ‘’accessories’’ in Section 5)

Unscrew the screw at the

bottom of cutter .

Remove the cutter cover.

Clean and remove jammed paper.

Reinstall CUTTER back onto printer.

Page 70

66

6-8 Troubleshooting

NOTE

* If any problems occur that are not described here, please contact your dealer.

Page 71

67

APPENDIX-PRODUCT SPECIFICATIONS

Model Name

ZX420

ZX420i

ZX430

ZX430i

Print Method

Thermal Transfer / Direct Thermal

Resolution

203 dpi (8 dots/mm)

300 dpi (12 dot/mm)

Print Speed

6 ips (152 mm/s)

4 ips (102 mm/s)

Print Width

4.25” (108mm)

4.16” (105.7mm)

Print Length

Min. 0.16” (4 mm)** ; Max . 157.44” ( 3999mm)

Min. 0.16” (4 mm)** ; Max. 73.19“(1859 mm)

Processor

32-bit RISC CPU

Memory

Flash

128 MB Flash (60 MB for user storage)

SDRAM

32 MB

Sensor Type

Adjustable reflective sensor and transmissive sensor, left aligned

Media

Type

Continuous form, gap labels, black mark sensing, and punched hole; label length set by auto sensing or programming

Width

Tear : Min. 1” (25.4 mm) – Max. 4.64” (118 mm)

Cutter : Max. 4.61” (117 mm)

Dispenser / Rewind : Max. 4.64” (118 mm)

Thickness

Min. 0.003” (0.076 mm) – Max. 0.01” (0.25 mm)

Label roll diameter

Max. 8” (203.2 mm) with 3" (76.2 mm) core

Max. 6” (152.4 mm) with 1.5" (38.1 mm) core

Max. 5" (127 mm) with 1" (25.4 mm) core

Core diameter

Min. 1 " (25.4 mm) – Max. 3" (76.2 mm)

Ribbon

Types

Wax, wax/resin, resin

Length

Max. 1476’ (450 m)

Width

Min. 1.18” (30 mm) – Max. 4.33” (110 mm)

Ribbon roll diameter

3” (76.2 mm)

Core diameter

1” (25.4 mm)

Printer

Language

EZPL, GEPL, GZPL auto switch

Software

Label design

software

GoLabel (for EZPL only)

Driver

Windows 2000, XP, Vista, Windows 7, 8.1 and 10 , Windows Server 2003 & 2008、 MAC、 Linux

DLL

Win CE, .NET, Andriod, Windows Mobile, Windows 2000 / XP / VISTA / 7 / 8.1 / 10

Resident

Fonts

Bitmap Fonts

6, 8, 10, 12, 14, 18, 24, 30, 16X26 and OCR A & B

Bitmap fonts 90°, 180°, 270° rotatable, single characters 90°, 180°, 270° rotatable

Bitmap fonts 8 times expandable in horizontal and vertical directions

TTF Fonts

TTF Fonts (Bold / Italic / Underline ). 0°,90°, 180°, 270° rotatable

Download

Fonts

Bitmap Fonts

90°, 180°, 270° rotatable, single characters 90°, 180°, 270° rotatable

Asian Fonts

16x16, 24x24. Traditional Chinese (BIG-5), Simplified Chinese(GB2312), Japanese (S-JIS), Korean (KS-X1001)

90°, 180°, 270° rotatable and 8 times expandable in horizontal and vertical directions

TTF Fonts

TTF Fonts (Bold / Italic / Underline ). 0°,90°, 180°, 270° rotatable

Barcodes

1-D Bar Codes

China Postal Code, Codabar, Code 11, Code 32,Code 39, Code 93, Code 128 (subset A, B, C), EAN-8, EAN-13, EAN 8/13 (with 2 & 5 digits

extension), EAN 128, FIM, German Post Code, GS1 DataBar, HIBC, Industrial 2 of 5 , Interleaved 2-of-5 (I 2 of 5), Interleaved 2- o-f 5 with

Shipping Bearer Bars, ISBT – 128, ITF 14, Japanese Postnet, Logmars, MSI, Postnet, Plessey, Planet 11 & 13 digit, RPS 128, Random Weight,

Standard 2 of 5, Telepen, UPC-A, UPC-E, UPC-A and UPC-E with EAN 2 or 5 digit extension, UCC 128, UCC/EAN-128 K-Mart

2-D Bar Codes

Aztec code, Code 49,Codablock F , Datamatrix code, MaxiCode, Micro PDF417, Micro QR code, PDF417,QR code, TLC 39

Code Pages

Codepage 437, 737,850, 851, 852, 855, 857, 860, 861, 862, 863, 865, 866, 869,

Windows 1250, 1251, 1252, 1253, 1254, 1255, 1257

Unicode UTF8、UTF16BE、UTF16LE

Graphics

Resident graphic file types are BMP and PCX, other graphic formats are downloadable from the software

Interfaces

• USB 2.0 (B-Type)

• USB 2.0 (B-Type)

• Serial port: RS-232 (DB-9)

• IEEE 802.3 10/100 Base-Tx Ethernet

port

(RJ-45)

• USB Host (A-Type)

• USB 2.0 (B-Type)

• USB 2.0 (B-Type)

• Serial port: RS-232 (DB-9)

• IEEE 802.3 10/100 Base-Tx

Ethernet port (RJ-45)

• USB Host (A-Type)

Control Panel

•1 Power on/standby button

with green color LED backlight

• 1 Calibration button at rear

panel

• 1 Control key : FEED /

PAUSE / CANCEL with dual

color LED backlight: Ready

(Green); Error (Red)

• Color TFT LCD with navigation

button

•1 Power on/standby button with green

color LED backlight

• 1 Calibration button at rear panel

• 1 Control key : FEED / PAUSE /

CANCEL with dual color LED backlight:

Ready (Green); Error (Red)

•1 Power on/standby

button with green color

LED backlight

• 1 Calibration button at

rear panel

• 1 Control key : FEED

/ PAUSE / CANCEL with

dual color LED backlight:

Ready (Green); Error

(Red)

• Color TFT LCD with navigation

button

•1 Power on/standby button with

green color LED backlight

• 1 Calibration button at rear panel

• 1 Control key : FEED / PAUSE /

CANCEL with dual color LED

backlight: Ready (Green); Error

(Red)

RTC

Standard

Power

Auto Switching 100-240V AC, 50-60Hz

Environment

Operation

temperature

41°F to 104°F (5°C to 40°C)

Storage temperature

-4°F to 140°F (-20°C to 60°C)

Humidity

Operation

20-85%, non-condensing

Storage

10-90%, non-condensing

Agency Approvals

CE (EMC)、FCC Class B、CB、UL、cUL、CCC

Dimension

Length

15.86” (403 mm)

Height

10.79” (274 mm)

Width

10.24” (260 mm)

Weight

23.81lbs (10.8 Kg), excluding consumables

Options

Cutter (Dealer Install)

Parallel port adaptor module (Centronic female 36-pin)(Dealer Install)

Bluetooth (Dealer Installer)

Wireless LAN (IEEE 802.11 b/g/n) (Dealer Install)

External label rewinder

Label Dispenser (Dealer Install)

* Specifications are subject to change without notice. All company and/or product names are trademarks and/or registered trademarks of their respective owners.

** Minimum print height and maximum print speed specification compliance can be dependent on non-standard material variables such as label type, thickness, spacing, liner

construction, etc. GoDEX is pleased to test non-standard materials for minimum print height, and maximum print speed capability.

Page 72

68

APPENDIX- INTERFACE

Page 73

Step 7.

Step 6.

Step 8.

Step 2. Step 3.

1

2

ZX400(i)/BPZ400(i) Series 無線網路安裝說明

ZX400(i)/BPZ400(i) Series Wi-Fi Module Installation

Step 1.

1

Step 4.

Step 5.

2

1

2

1

2

2

Wi-Fi

BT

Wi-Fi

1

Page 74

Step 7.

Step 6.

Step 8.

Step 2.

Step 3.

1

2

ZX400(i)/BPZ400(i) Series 藍牙模組安裝說明

ZX400(i)/BPZ400(i) Series BlueTooth Module Installation

Step 1.

1

2

Step 4.

Step 5.

1

2

1

1

2

2

BT

BT

Wi-Fi

Page 75

Step 7.

Step 6.

Step 8.

Step 2.

Step 3.

ZX400(i)/BPZ400(i) Series 並列傳輸模組安裝說明

ZX400(i)/BPZ400(i) Series Parallel module Installation

Step 1.

Step 4.

Step 5.

2

1

1

2

2

1

1

2

2

1

Page 76

GoDEX Printer Compliance Insert

Note: This equipment may be used on an IT power system.

For Users in English Speaking Regions (en)

Caution: This marking indicates that the user should read all included documentation before use.

The users of this product are cautioned to use accessories and peripherals approved by GoDEX International Co.,Ltd. The use of

accessories other than those recommended, or changes to this product that are not approved by GoDEX International Co.,Ltd. ,

may void the compliance of this product and may result in the loss of the user’s authority to operate the equipment.

Caution: For power supply, use GoDEX provided. No user-serviceable parts.

FCC Digital Emissions Compliance

This equipment has been tested and found to comply with the limits for a CLASS A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instructions, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at own expense.

Canadian Digital Apparatus Compliance

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations

CE Marking: Refer to the Declaration of Conformity for a list of the EU Directives and Standards that this product complies with.

Für Anwender in Deutschland (de)

Vorsicht: Diese Kennzeichnung weist darauf hin, dass der Benutzer vor dem Gebrauch alle mitgelieferten Unterlagen lesen soll.

Die Benutzer dieses Produkts werden darauf hingewiesen, nur Zubehörteile und Peripheriegerä te zu verwenden,

die von GoDEX International Co.,Ltd. genehmigt sind. Falls nicht empfohlene Zubehö rteile verwendet oder an diesem Produkt Ä nderungen

vorgenommen werden, die nicht von GoDEX International Co.,Ltd. genehmigt sind, kann dadurch die behördliche Konformitä t des Produkts

verletzt werden und der Benutzer die Berechtigung zur Verwendung des Gerä ts verlieren.

Vorsicht:

Nur das

beigefügte original

GoDEX

Netzteil verwenden. Enthä lt

keine Teile, die vom

Benutzer gewartet werden

können.

CE-Kennzeichnung: Die Konformitä tserklä rung enthä lt eine Liste der EU-Richtlinien und Normen, denen das Produkt entspricht.

Warnhinweis

Dies ist ein Produkt der Klasse A. In Wohnumgebungen kann dieses Produkt Funkstörungen verursachen.

In diesem Fall obliegt es dem Anwender, angemessene Maßnahmen zu ergreifen.

Pour les utilisateurs canadiens et franç ais (fr)

Attention: Ce marquage indique que l’usager doit, avant l’utilisation, lire toute la documentation incluse.

Attention: Pour la source d'alimentation, utilisez GoDEX International Co.,Ltd. Il ne contient aucune pièce réparable par l’utilisateur.

Utilisateurs de ce produit sont avisés d’utiliser des accessoires et des périphé riques approuvés par GoDEX International Co.,Ltd.

L’utilisation d’accessoires autres que ceux recommandé s ou des changements à ce produit qui ne sont pas approuvés

par GoDEX International Co.,Ltd. peuvent annuler la conformité de ce produit et mettre fin au droit qu’a l’usager d’utiliser l’équipement.

Conformité aux normes canadiennes sur les appareils numériques

Cet appareil numé rique de la classe A respecte toutes les exigences du Réglement sur le maté riel brouilleur du Canada.

AVERTISEMENT: Il s’agit d’un produit de classe A. Dans un environnement domestique, ce produit pourra provoquer des interférences

radio auquel cas l’utilisateur pourrait avoir à prendre de mesures adé quates.

適用於臺灣使用者(zh-tw)

注意:此標誌表示使用者應在使用前先閱讀所有隨附的文件。

本產品的使用者必須小心使用科誠股份有限公司許可的配件與週邊設備。 使用非上述建議的配件,或是在未經科誠股份有限公司許

可的情況下變更本產品可能會使得本產品的相容性失效,並且使得使用者 喪失操作設備的權力。

請使用科誠股份有限公司電源。無使用者可自行維修之零件。

www.godexintl.com

GoDEX International

Co.,Ltd.

313-043200-101

사용자안내문

이 기기는 업무용 환경에서 사용할 목적으로 적합성평가를 받은 기기로서

가정용 환경에서 사용하는 경우 전파간섭의 우려가 있습니다

Loading...

Loading...