Page 1

Instructions for Use

Installation and Servicing

T o be left with the user

Hideaway 80

G.C. No. 41 313 25

Open Flue Boiler

221756A.10.00

0991

BS 6332

BS 5258

This is a Cat I2H Appliance

Reference in these instructions to British Standards and Statutory

Regulations/Requirements apply only to the United Kingdom.

The instructions consist of three parts, User, Installation and Servicing Instructions, which includes the Guarantee Registration

For Ireland the rules in force must be used.

Card. The instructions are an integral part of the appliance and must, to comply with the current issue of the Gas Safety

(Installation and Use) Regulations, be handed to the user on completion of the installation.

Guarantee Registration

Thank you for installing a new Glow-worm appliance in your home.

Glow-worm appliances' are manufactured to the very highest standard so we are pleased

In the center pages are to be found your Guarantee Registration Card, which we recommend you complete and

If this card is missing you can obtain a copy or record your registration by telephoning the Heatcall Customer

Our Guarantee gives you peace of mind plus valuable protection against breakdown by covering the cost of:

✔

All replacement parts

❏

✔

All labour charges

❏

All call-out charges

✔

❏

to offer our customers' a Comprehensive First Year Guarantee.

return as soon as possible.

Service number 01773 828100.

REGISTER YOUR GLOW-WORM APPLIANCE

FOR 1ST YEAR GUARANTEE PROTECTION

CALL 0208 247 9857

One Contact Local Service

Customer Services:

Tel: (01773) 828100

Fax: (01773) 828070

Hepworth Heating Ltd.,

Nottingham Road, Belper, Derbyshire. DE56 1JT

General/Sales enquiries:

Tel: (01773) 824141 Fax: (01773) 820569

Page 2

Important Information

Notes and General Information

Please read these instructions and follow them carefully for the

safe and economical use of your boiler.

The boiler is automatic in operation, once the pilot is lit and the

controls have been set.

Glow-worm Hideaways’ are central heating boilers, to provide

heating and if required an indirect domestic hot water supply.

Gas Safety (Installation and Use) Regulations

In your own interests and that of safety, it is the Law that ALL gas

appliances are installed by a competent person in accordance

with the current issue of the above regulations.

CE Mark

This boiler meets the requirements of Statutory Instrument, No.

3083 The Boiler Efficiency Regulations, and therefore is deemed

to meet the requirements of Directive 92/42/EEC on the efficiency

requirements for new hot water boilers fired with liquid or

gaseous fuels.

Type test for purposes of Regulation 5 certified by:

Notified body 0086.

Product/production certified:

Notified body 0086.

The CE Mark on this appliance shows compliance with:

1. Directive 90/396/EEC on the approximation of the Laws of

the Member States relating to appliances burning gaseous

fuels.

2. Directive 73/23/EEC on the harmonization of the Laws of the

Member States relating to electrical equipment designed for

use within certain voltage limits.

3. Directive 89/336/EEC on the approximation of the Laws of

the Members States relating to electromagnetic

compatibility.Information for the Installer and Service Engineer.

Control of Substances Hazardous to Health

Under Section 6 of The Health and Safety at Work Act 1974, we

are required to provide information on substances hazardous to

health.

The adhesives and sealants used in this appliance are cured

and give no known hazard in this state.

Insulation Pads/Ceramic Fibre, Glassyarn

These can cause irritation to skin, eyes and the respiratory tract.

If you have a history of skin complaint you may be susceptible

to irritation. High dust levels are usual only if the material is

broken.

Normal handling should not cause discomfort, but follow normal

good hygiene and wash your hands before eating, drinking or

going to the lavatory.

If you do suffer irritation to the eyes or severe irritation to the skin

seek medical attention.

Boiler Thermostat

These contain very small amounts of xylene in the sealed phial

and capillary. If broken, under normal circumstances the fluid

does not cause a problem, but in cases of skin contact, wash

with cold water.

If swallowed drink plenty of water and seek medical attention.

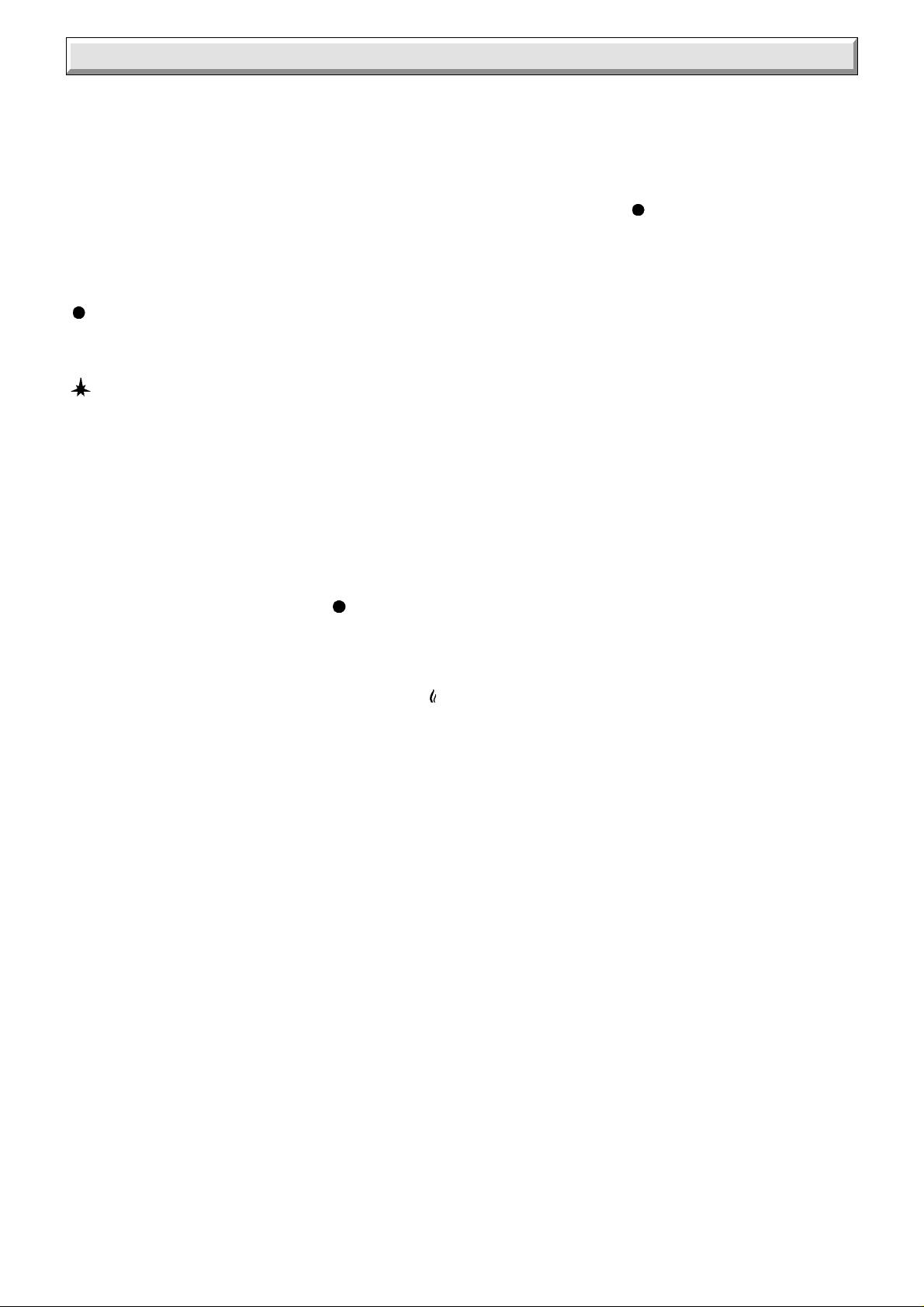

CONTENTS DESCRIPTION SECTION PAGE No.

INSTRUCTIONS

FOR USE

Introduction 3

Lighting the Boiler 4

INSTALLATION

INSTRUCTIONS

General Data 1 5

Water Systems 2 7

Flue and Ventilation 3 8

Installation 4 9

Casing Location 5 11

Electrical Wiring 6 12

Commissioning 7 13

SERVICING

INSTRUCTIONS

Servicing 8 15

Replacement Parts 9 17

Fault Finding 10 20

Spare Parts 11 24

221756A

2

Page 3

Instructions for Use

Warning

Make sure that nothing obstructs the rear side grilles or

clearances. See diagram 1.2 and 1.3 for minimum clearances.

Boilers Installed in a Compartment

If the boiler is fitted in a compartment, cupboard etc., do not

obstruct the purpose built compartment vents or grille on the

boiler.

Do not use the compartment for storage purposes.

Maintenance

To ensure the continued efficient and safe operation of the

boiler it is recommended that it is checked and serviced at

regular intervals. The frequency of servicing will depend upon

the particular installation conditions and usage, but in general

once a year should be enough.

If this appliance is installed in a rented property there is a duty

of care imposed on the owner of the property by the current

issue of the Gas Safety (Installation and Use) Regulations,

Section 35.

It is the law that servicing is carried out by a competent person.

To obtain service please call your installer or Heatcall (Glow-

worm’s own service organisation) using the telephone number

given on the inside of the front panel.

Please be advised that the ‘Benchmark’ logbook should be

completed by the installation engineer on completion of

commissioning and servicing.

All CORGI Registered Installers carry a CORGI ID card, and

have a registration number. Both should be recorded in your

boiler Logbook. You can check your installer is CORGI registered

by calling CORGI direct on :- 01256 372300.

FLUE

BLOCKAGE

SAFETY DEVICE

RESET BUTTON

SETTING

POINTS

E

PIEZO

IGNITION

BUTTON 'C'

GAS

CONTROL

KNOB 'A'

7991

THERMOSTAT

CONTROL

KNOB 'B'

SETTING

POINT

Boiler Electrical Supply

WARNING. This boiler must be earthed.

The boiler must only be connected to a 230V~50Hz supply,

protected by a 3A fuse, maximum.

All wiring must be in accordance with the current issue of

BS7671.

2

Heat resistant cable having a conductor size of 0.75mm

0.22mm), to BS6500 Table 16 must be used.

, (24/

To Connect an Electrical Plug

The colours of three core flexible cable are, Brown - live, Blue

- neutral, Green and yellow - earth.

As the markings on your plug may not correspond with these

colours continue as follows:

The wire coloured brown must be connected to the terminal

marked “L” or Red.

The wire coloured blue must be connected to the terminal

marked “N” or Black.

The wire coloured green and yellow must be connected to the

terminal marked “E”, Green or the earth symbol

.

GAS CONTROL KNOB

= OFF

= PILOT/IGNITION

= MAIN BURNER

Diagram 1

Safety Device

This appliance is fitted with a flue blockage safety device which

will shut down the appliance in the event of abnormal flue

conditions. This device is NOT a substitute for an independently

mounted Carbon Monoxide detector.

The safety device is reset, after three minutes, by pushing in the

button shown in diagram 1.

Shut down can occur during certain climate conditions, but if it

recurs the chimney flue and air inlet into the room must be

checked and any problems found corrected by a competent

person, before the boiler is used again.

3 221756A

Page 4

Instructions for Use

To Light the Boiler

WARNING. If the pilot light goes out for any reason, do not

attempt to relight until three minutes have gone by.

Remove the door by pulling forwards with the fascia at the top.

Lift up to free from bottom side lugs.

Refer to diagram 1 to identify the controls.

Check that the mains electrical supply to the boiler is switched

OFF.

Check that the Flue Blockage Safety Device has not operated,

that is, the button is in. Refer to Safety Device instructions.

Push in slightly and turn gas control knob “A” clockwise until

'is against its setting point.

'

Turn thermostat control knob “B” anticlockwise until “O” is

against its setting point.

Push in slightly and turn gas control knob “A” anticlockwise until

' is against its setting point, then push fully and hold in.

'

Push and release piezo ignition button “C” until the pilot burner

lights.

Air may be present in the supply pipe so the lighting of the pilot

may need to be repeated until all the air has been expelled.

When the pilot is alight, view through window “E”, keep gas

control knob “A” fully pushed in for about 15 seconds, then

release.

If the burner fails to stay alight, wait three minutes, then repeat

the lighting procedure only now keep control knob “A” depressed

for a little longer before releasing. The Flue Blockage Safety

Device may also need resetting, refer to instructions above.

If the gas control knob “A” is turned to '

prevents it being turned on again for a short period. No attempt

should be made to relight the pilot for at least three minutes.

Make sure that the pilot is alight and stable, then switch on the

electrical supply.

Press in and turn gas control knob “A” anticlockwise until '

is against its setting point.

Set any remote controls to call for heat.

Turn the boiler thermostat knob “B” clockwise until “MAX” is

against its setting point and the main burner will light. Adjust

thermostat to required setting between “MIN” and “MAX”.

“MAX” is about 82

Refit the door by fitting the hooked runner at the bottom into the

slot in the side panels and pushing onto the studs.

o

C (180oF).

', a safety lock

To Turn the Boiler Off

For short periods. Turn the boiler thermostat control knob “B”

anticlockwise to “O”. The pilot will remain alight. To relight the

main burner turn the thermostat control knob “B” clockwise to

the desired setting between “MIN” and “MAX”.

For longer periods. Push in slightly and turn gas control knob

“A” fully clockwise until “

thermostat control knob “B” anticlockwise to “O”. Isolate the

boiler from the electrical supply. Follow the full lighting procedure

to relight.

Refer also to “Protection Against Freezing”.

” is against its setting point. Turn

Gas Leak or Fault

If a gas leak or fault exists or is suspected the boiler must be

turned off, including the electrical supply and must not be used

until the fault has been put right. Advice/help should be obtained

from the local gas undertaking or your installation/servicing

company.

Protection Against Freezing

If the boiler is to be out of use for any long period of time during

severe weather conditions we recommend that the whole of the

system including the boiler, be drained off to avoid the risk of

freezing up. If an immersion heater is fitted in the domestic hot

water cylinder make sure it is switched off.

Sheet Metal Parts

WARNING. This appliance contains metal parts (component)

and care should be taken when handling and cleaning, with

particular regard to edges.

Cleaning

Keep the casing clean by wiping it over occasionally with a

damp soapy cloth and dry with a polishing cloth.

'

Do not use abrasive cleaners.

Replacement Parts/Boiler Identification

If replacement parts are required apply to your local supplier or

gas undertaking. Please quote the name of the boiler and its

serial number which can be found on the data label positioned

on the boiler top, to the rear of the inclined flueway cleaning

door.

221756A

Clearance

Minimum clearances must be left around the boiler as shown in

diagram 1.2 and 1.3.

4

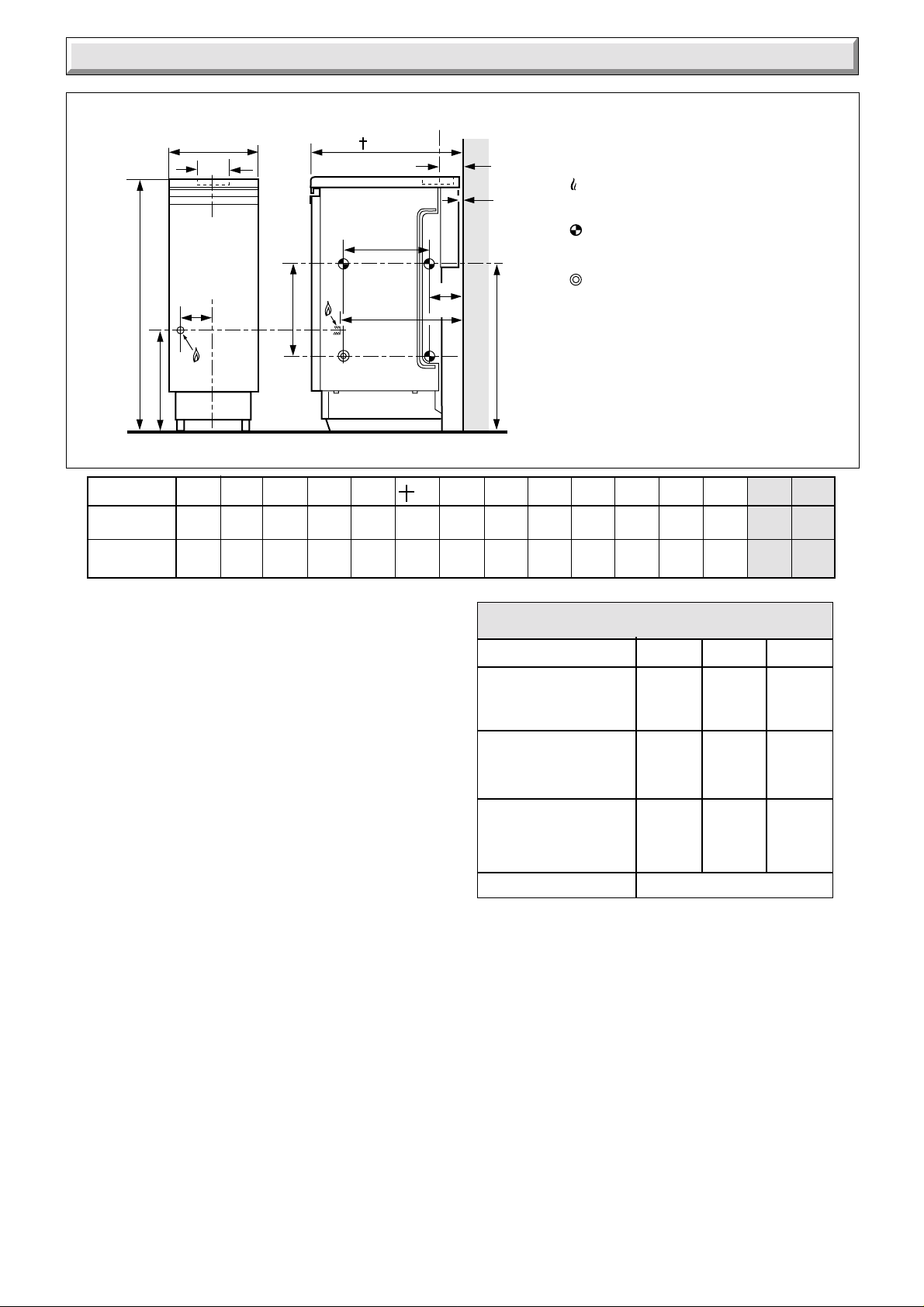

Page 5

A

N

*

C

L

FLUE

1 General

F (MIN)

L (MIN)

H

C

L

FLUE

G

(MIN)

✝ A SPECIAL TOP CASING

TO SUIT 600mm (23

5

/

in.)

8

WORKTOPS IS AVAILABLE

GAS CONNECTION

1

Rc

1

/

(

/

2

2

in. B.S.P.T.)

WATER CONNECTIONS

Rc1 (1in. B.S.P.T.)

1177

C

M

E

L

B

D

J (MIN)

K

(MIN)

C

WATER CONNECTIONS Rc1

reduced with DISTRIBUTOR

TUBE to Rc

(pumped return)

✽ INSIDE DIAMETER OF

SOCKET FOR 125mm (5in.)

NOMINAL DIAMETER FLUE

TO BS567

GENERAL DIMENSIONS - given in millimetres (Approx. inches)

ABCDE FGHJK LMN

mm 387 171 598 294 400 533 3 300 445 121 82 900 146

in. 151/463/4231/2111/2153/421

1

/8113/4171/243/431/2351/253/

Sheet Metal Parts

Warning. When installing or servicing this boiler care should be

taken when handling sheet metal parts, to avoid the possibility

of personal injury.

Important Notice

This boiler is for use only on G20 gas.

Wherever possible, all materials, appliances and components

to be used shall comply with the requirements of British

Standards.

Where no British Standards exist, materials and equipment

should be fit for their purpose and of suitable quality and

workmanship.

1.1 Data

Approx.weight of boiler: 98.5kg (217 lb)

RANGE RATING

NOMINAL

HEAT INPUT

(GROSS)

NOMINAL

HEAT

OUTPUT

BURNER

SETTING

PRESSURE

(HOT)

INJECTOR

HIDEAWAY 80

kW

26.02 27.9 29.68

Btu/h

Btu/h

mbar

88,780 95,200 101,270

kW

20.52 21.98 23.45

70,000 75,000 80,000

11.5 13.2 15.2

in.w.g

3

3

/

(

/

in. B.S.P.T.)

4

4

Diagram 1.1

4

min medium max

4.6 5.3 6.1

205753

Water content: 8.64litre (1.9 gal)

Gas connection: Rc1/2(1/2 BSP)

Water connection: Rc1 (1inch BSP)

Electrical supply: 230V - 50Hz fused at 3A

Burner: Aeromatic

The Seasonal Efficiency Domestic Boilers UK (SEDBUK) is

71.7%.

The value is used in the UK Government’s Standard Assessment

Procedure (SAP) for energy rating of dwellings. The test data

from which it has been calculated have been certified by B.S.I.

1.2 Range Rating

This boiler is range rated and may be adjusted to suit individual

systems. The table gives settings and outputs.

The boiler input is supplied preset to maximum and should be

adjusted to suit system requirements.

1.3 Statutory Requirements

The installation of this boiler must be carried out by a competent

person in accordance with the relevant requirements of the

current issue of:

Manufacturer’s instructions, supplied.

The Gas Safety (Installation and Use) Regulations, The Building

Regulations, Local Water Company Byelaws, The Building

Standards (Scotland) Regulations, applicable in Scotland, The

Health and Safety at Work Act, The Control of Substances

Hazardous to Health, The Electricity at Work Regulations and

any applicable local regulations.

Detailed recommendations are contained in the current issue of

the following British Standards and Codes of Practice:

BS6798, BS5440 Part 1 and 2, BS5449, BS6700, BS6891,

BS5546, BS7478, BS7593, BS7671.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

5 221756A

Page 6

1 General

1.4 B.S.I. Certification

This boiler is certificated by B.S.I. for safety and performance.

It is, therefore, important that no alteration is made to the boiler

unless approved, in writing, by Hepworth Heating Ltd.

Any alteration not approved by Hepworth Heating Ltd., could

invalidate the B.S.I. certification, boiler warranty and could also

infringe the statutory requirements.

1.5 Gas Supply

The gas installation shall be in accordance with the current

issue of BS6891.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

On completion test the gas installation using the pressure drop

method and suitable leak detection fluid, purge in accordance

with the current issue of BS6891.

1.6 Electrical

Warning. This boiler must be earthed.

The electrical installation must be carried out by a competent

person. All external components must be of the approved type

and must be connected in accordance with the current issue of

BS7671 and any local regulations which may apply.

Connection of the boiler and any system controls to the mains

supply should be through a 3A fused double pole isolating

switch, having a minimum double pole contact separation of

3mm, serving only the boiler and system controls.

2

Heat resistant flexible cable of at least 0.75mm

issue of BS6500 Table 16 must be used for all connections

within the boiler casing.

, to the current

1.7 Boiler Location

The boiler must not be installed in a room used or intended to

be used as sleeping accommodation or a room containing a

bath or shower.

This boiler is not suitable for installation out of doors.

The boiler must stand on a level floor, conforming with local

authority requirements and building regulations. The base

temperature is within the requirements of the current issue of

BS5258. The boiler may be stood on a wooden floor but a metal

plate is required to protect plastic tiles and similar floor coverings.

Suitable clearance needs to be available at the sides of the

boiler to ease connection of pipework. The actual clearances

will vary according to site conditions.

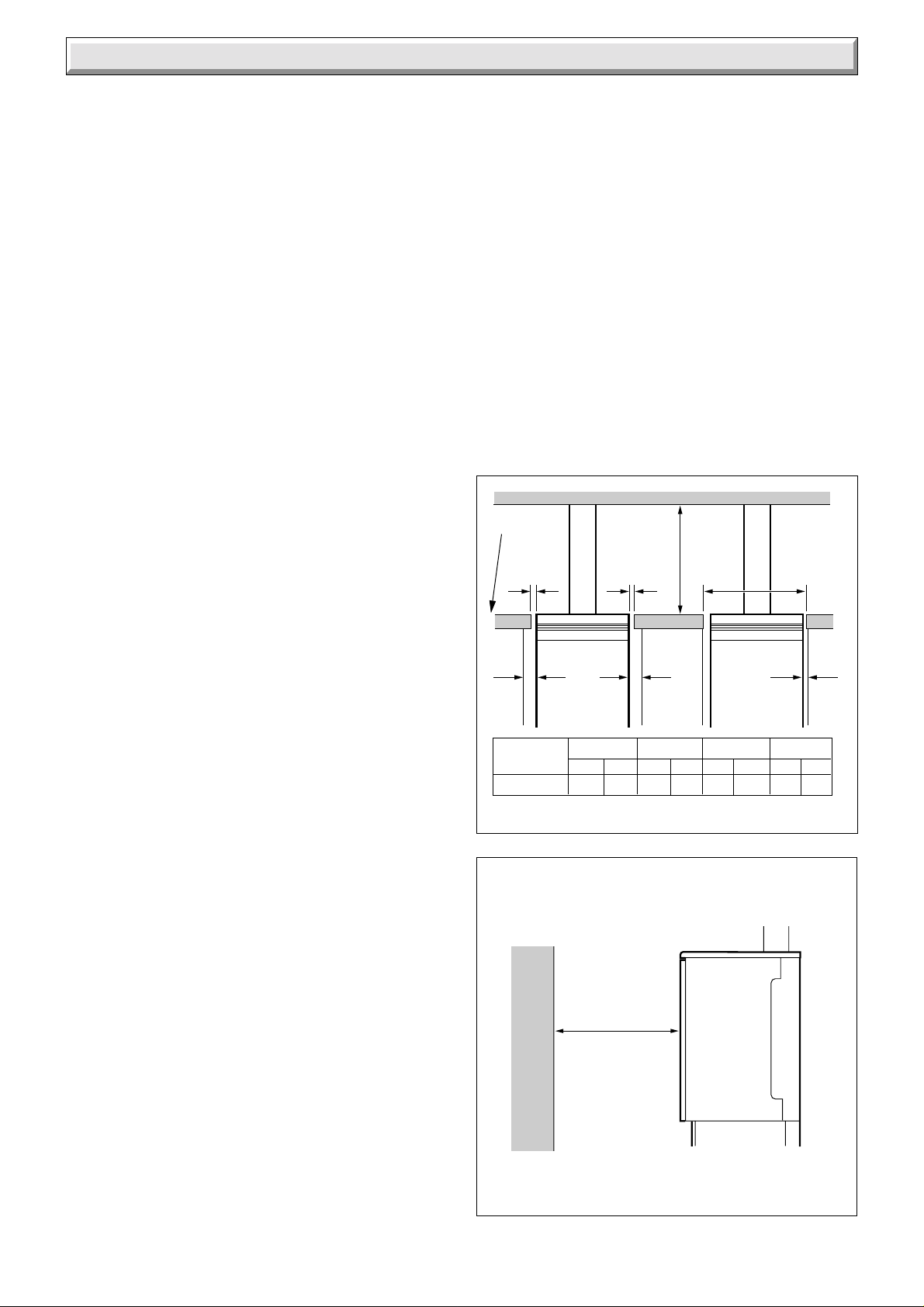

When the boiler is to be installed level with work surfaces,

minimum clearances to fixtures, walls and the like should be

provided, see diagram 1.2.

To ease minimum clearances it may be necessary to modify

units or fixtures.

A front access clearance should be provided as shown in

diagram 1.3.

The minimum gap behind the top casing is dimension “G” in

diagram1.1. The boiler can be sited further away from the wall

if required to align with kitchen units.

Combustible wall material must be 25mm (1in) away from flue

components.

A special top casing, part number 425562 can be bought, to

enable boiler casings to be arranged flush with 600mm (23

deep worktops.

Where the installation of the boiler will be in an unusual location,

special procedures may be necessary, the current issue of

BS6798 gives detailed guidance on this aspect.

5

/8in)

A compartment used to enclose the boiler must be designed

and constructed specifically for this purpose. An existing

cupboard or compartment modified for the purpose may be

used. Details of essential features of cupboard and compartment

design are given in the current issue of BS6798.

Make sure that nothing will obstruct the side clearances or side

grilles. If installing the boiler in a compartment make sure that

openings and vents are not obstructed.

1.8 Heating System Controls

The heating system should have installed: a programmer and

room thermostat controlling the boiler.

Thermostatic radiator valves may be installed in addition to the

room thermostat.

Note: For further information, see The Building Regulations

1991 - Conservation of fuel and power, 1995 edition - Appendix

G, table 4b.

WORKTOP

254

W

(10 in.)

BOILER

Y

BOILER

Diagram 1.2

Diagram 1.3

Z

8

0911

X

W

MODEL

80

70 - 80

BOILER

W(MIN) X(MIN) Y(MIN) Z(MIN)

mm in mm in mm in mm in

40 1

X

5

/8 6 1/4 437 171/4 10 3/

TOP & SIDE CLEARANCES

WALL OR

FIXTURE

530 (21in.)

FRONT CLEARANCE

1529

221756A

6

Page 7

2 Water Systems

2.1 Water Pressure Head

This boiler must not be connected to a sealed water system.

This boiler shall only be connected to an open vented cistern

water supply, with a minimum head of 1metre (39in) and a

maximum of 27metre (90ft).

2.2 Inhibitor

Attention is drawn to the current issue of BS5449 and BS7593

on the use of inhibitors in central heating systems.

If an inhibitor is to be used in the system contact should be made

with a manufacturer so that they can recommend their most

suitable product.

If using in an existing system take special care to drain the entire

system, including the radiators, then thoroughly cleaning out

before fitting the boiler, whether or not adding an inhibitor.

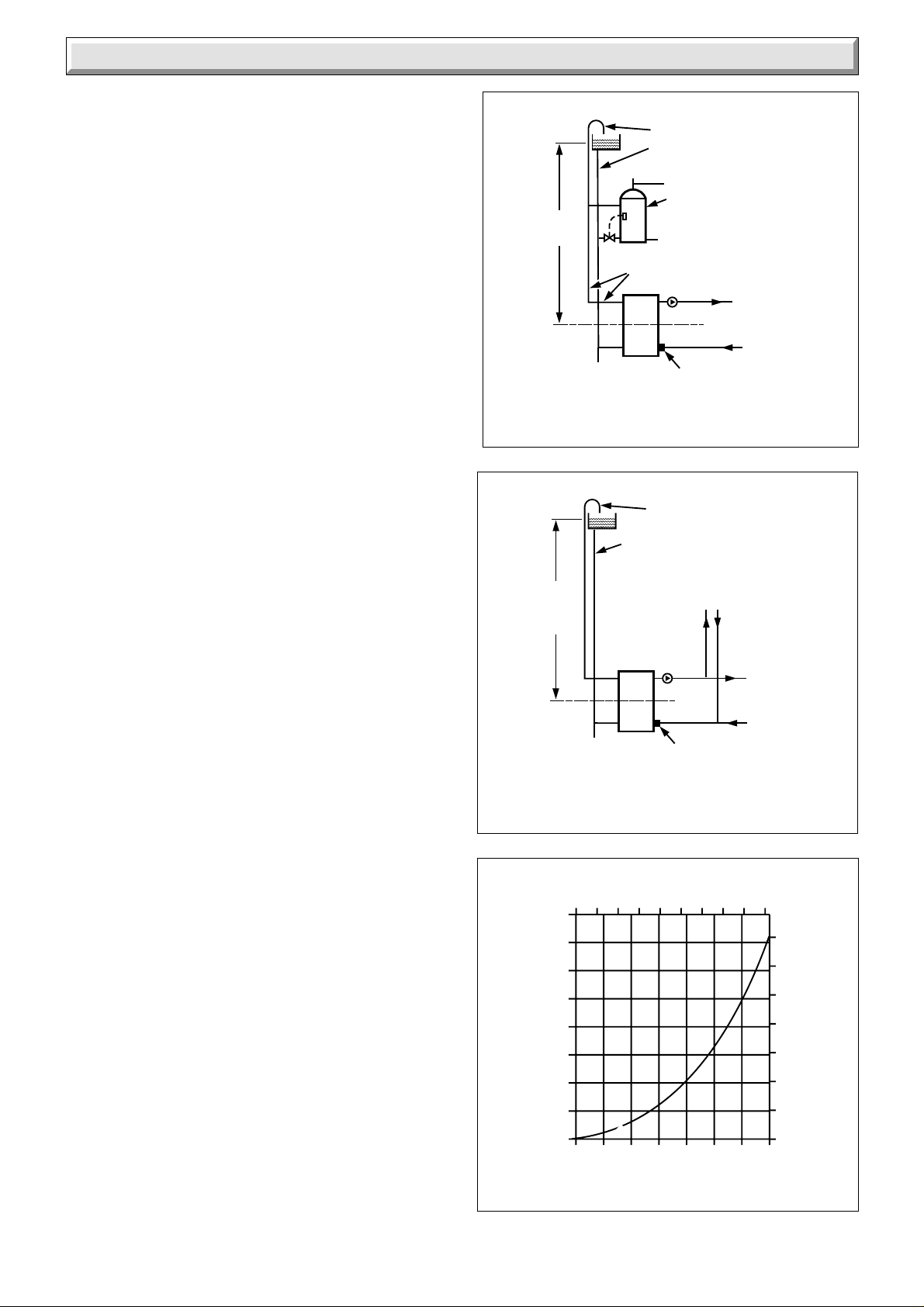

2.3 Gravity Domestic Hot Water and Pumped

Central Heating

It is recommended that a cylinder thermostat is used to prevent

the stored water temperature becoming too high when the

heating pump is off.

The domestic hot water primary flow and return must be 28mm

od. The installation must comply with the current issue of

BS5546 and BS6700, see diagram 2.1.

If the above conditions cannot be met, it is suggested that a fully

pumped system is used.

2.4 Pumped Central Heating and Domestic Hot

Water

Where a single flow and return is taken from the boiler, a

minimum static head of 1metre (39in) must be provided between

the water level in the cold water cistern and the centre of the

waterway, see diagram 2.2.

2.5 Circulation Pump

Normally the pump should be set to give a temperature difference

oC

(20oF), across the boiler. At the appropriate flow rate the

of 11

resistance through the boiler can be found by reference to the

pressure loss graph, diagram 2.3.

Use a pump with integral valves or fit valves as close to the

pump as possible.

REFER TO BS 5546

22mm VENT

15mm COLD FEED

INDIRECT

CYLINDER

(Shown with

27metres

Max.

DRAIN OFF

COCK

recommended

thermostat and valve).

28mm

PUMP

BOILER

C

Distributor tube in

pumped return

connection

L

PUMPED HEATING AND GRAVITY

DOMESTIC (DIAGRAMMATIC)

22mm VENT

15mm

COLD FEED

1 metre

MIN.

27metres

MAX.

DRAIN OFF

COCK

TO INDIRECT

CYLINDER

PUMP

BOILER

C

L

Distributor tube in

pumped return

connection

FULLY PUMPED SYSTEM

(DIAGRAMMATIC)

0869

To Heating

Circuit

Diagram 2.1

0870

To Heating

Circuit

Diagram 2.2

2.6 Domestic Hot Water Cylinder

For all systems supplying domestic hot water the cylinder must

be indirect.

2.7 Safety Valve

A safety valve need not be fitted to an open vented system.

2.8 Draining Tap

A drain tap must be fitted at the lowest points of the system

which will allow the draining of the entire system, including the

boiler and domestic hot water cylinder.

FLOW RATE (GALLON/MINUTE)

0123456789

2.00

1.75

1.50

1.25

1.00

0.75

0.50

WATER PRESSURE LOSS

(metre HEAD OF WATER)

0.25

0

6

0

FLOW RATE (LITRES/MINUTE)

12 18

24 30 36 42

PRESSURE LOSS OF BOILER

70

60

50

40

30

20

WATER PRESSURE LOSS

10

0

(INCHES HEAD OF WATER)

Diagram 2.3

7 221756A

1074

Page 8

3 Flue and Ventilation

Important Note

The boiler is fitted with a Flue Blockage Safety Device, which

will shut down the boiler if there is an unacceptable spillage of

products at the draught diverter.

This safety device MUST NOT under any circumstances be

interferred with or put out of action. The safety device must only

be replaced with the Glow-worm parts.

3.1 Flue

The integral draught diverter on the Hideaway range of boilers

makes the combustion performance independent of conditions

in the secondary flue, but in common with other fuels an efficient

flue is necessary to make sure of a trouble free installation.

The flue must be at least equivalent to 1m vertical.

The boiler flue socket is designed to take flue pipes to the

current issue of BS567. If a flue pipe to BS715 is to be used, an

adapter must be fitted to the boiler flue socket, as diagram 1.1.

The flue must be in accordance with the current issue of

BS5440 Part 1.

3.2 Flue Guidelines

The flue should be kept as short as possible. Horizontal or very

shallow runs of the flue should be avoided as they encourage

local cooling.

Always choose a flue route which will cause the least cooling of

the flue.

There should be a vertical rise of at least 600mm (2ft) before

using a bend. 90

End with a certificated flue terminal, preferably above ridge

height, but at least above the eaves of a pitched roof.

An existing chimney must be thoroughly swept and all debris

cleared away before lining.

o

elbows should not be used.

3.3 Timber Frame Buildings

If the boiler is to be installed in a timber frame building it should

be fitted in accordance with the Institute of Gas Engineers

document IGE/UP/7/1998. If in doubt seek advice from the local

gas undertaking or Hepworth Heating Ltd.

3.5 Ventilation for Boilers Installed in a

Cupboard or Compartment

When the boiler is fitted in a cupboard or compartment, high and

low level purpose designed, permanent openings must be

provided to supply air for combustion and compartment

ventilation.

The air vents must have minimum areas in accordance with

“Compartment Air Vent B”. The figures quoted refer to the

minimum acceptable effective area.

Both the high and low level openings must communicate with

the same room, or must both be on the same wall to outside air.

If air vent grilles are fitted to a cavity wall, the opening through

the wall must be ducted.

Where ventilation air to a compartment is taken from a room or

space, then the room or space must be fitted with a ventilation

opening as specified in “Air Vent Table A”.

For information regarding compartment requirements refer to

the appropriate section of the current issue of BS6798.

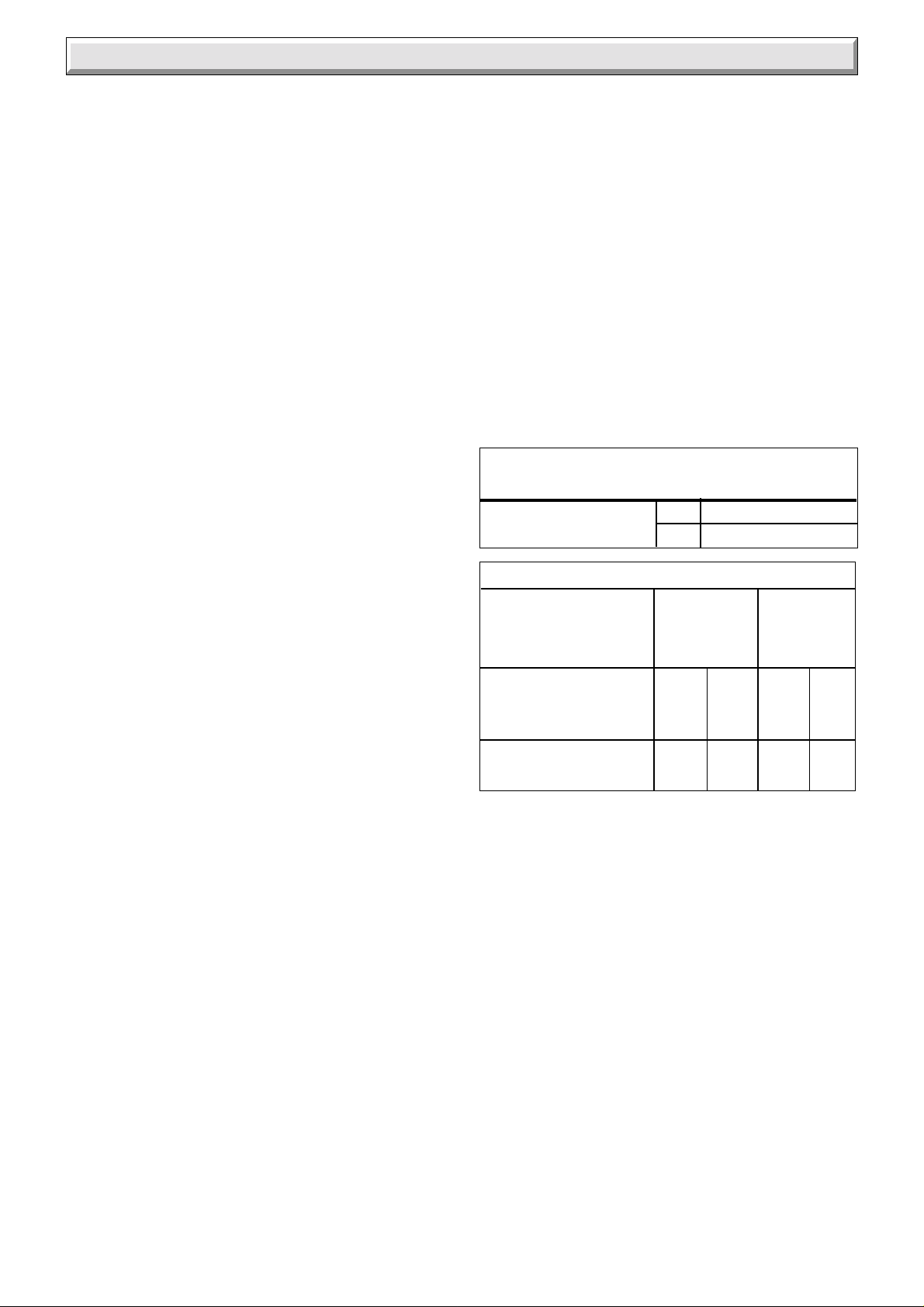

AIR VENT TABLE 'A' FOR

ROOM/SPACE INSTALLATIONS

2

EFFECTIVE

AREA OF VENT

COMPARTMENT AIR VENT TABLE 'B'

COMPARTMENT

VENTILATION

REQUIREMENTS

VENTILATION

FROM ROOM

OR SPACE

FROM

OUTSIDE

cm

in

104

2

16

HIGH LEVEL LOW LEVEL

VENT AREA VENT AREA

272cm242in2544cm284in

136cm221in2272cm242in

2

2

3.4 Ventilation for Boiler Installed in a Room

or Space

If the boiler is to be installed in a room or space a purpose

designed permanent ventilation opening, to supply air for

combustion, must be provided on an outside wall to external air,

refer to the current issue of BS5440 Part 2 for details.

The opening may be directly into the room or the space

containing the boiler, or an outside wall of an adjacent room or

space which has an internal permanent air vent, of the same

size, into the room or space containing the boiler.

Do not ventilate through a bedroom, bedsitting room, private

garage or a room containing a bath or shower.

When the boiler is installed in a room or internal space already

containing other fuel burning appliances then the air supply of

such appliances must be taken into account.

The ventilation opening areas are given in “Air Vent Table A”.

The figures quoted refer to the minimum acceptable effective

area.

221756A

3.6 Extract Fans

If an extract fan is fitted in the premises, there is a possibility that

if adequate inlet openings are not provided, spillage of the

products from the boiler could occur.

When openings are fitted in accordance with the current issue

of BS5440 Part 2 and this section, extract fans should not cause

down draught, but where such fan installations are found, a

spillage test must be carried out in accordance with the current

issue of BS5440 Part 1 and any corrective work done.

8

Page 9

4 Installation

Before fitting the boiler make sure the location selected is in

accordance with the requirements of Section 1.7.

4.1 Unpacking

The boiler casing panels are packed separately within the main

case. They are designed to enable the gas and water connections

to be made before fitting the casing panels.

The main casing brackets, distributor tube and loose items, in a

plastic bag, are packed in the top fitment.

4.2 Casing Brackets

Fit the four casing brackets as shown in diagram 4.1, using eight

No.8 screws.

Push the captive nuts, supplied loose, on to the casing brackets

as shown in diagram 4.1.

4.3 Water Connections - Gravity Domestic Hot

Water and Pumped Heating

It is important that all connections are made as shown in

diagram 4.2.

Heating flow, any one of the four upper connections may be

used.

Domestic hot water gravity flow, any one of the three remaining

upper connections may be used.

Heating return, the distributor tube, packed in the top fitment,

MUST be fitted into either one of the front lower connections on

ALL installations, see diagram 4.3.

Domestic hot water gravity return, any one of the three remaining

lower connections may be used for the gravity domestic hot

water return.

Fit plugs into all unused connections.

Note, if only limited clearance is available, it is recommended

that the front connections are used.

4.4 Water Connections - Fully Pumped

Systems

It is important that all connections are made as shown in

diagram 4.4.

The water distributor, packed in the top fitment, MUST be fitted

into the return connection on ALL installations, see diagram 4.3.

Fit plugs into all unused connections.

Note, if only limited clearance is available it is recommended

that the front connections are used.

4.5 Positioning/Connecting Boiler

Having selected the position of the boiler, make sure that

sufficient clearances will be left around the boiler as described

in Section1.7.

Fit the distributor tube, see diagram 4.2 or 4.4 for location, see

diagram 4.3 for alignment. Fit appropriate fittings and plugs into

the boiler connections.

Important. Do not route any pipe across the front of the boiler

thermostat pocket, the controls, burner supply pipe, combustion

chamber cover or the flueway cleaning door. The gas supply

pipe should be run along the left hand side of the boiler.

Pipework must not be routed directly below the draught diverter

hood across the boiler, but it may be routed under the edges of

the draught diverter.

CAPTIVE

NUT

CASING

BRACKET

No.8 SCREW (8)

CAPTIVE

NUT

CASING

BRACKET

CASING BRACKETS FITTING

ALTERNATIVE

HEATING OR

DOMESTIC

HOT WATER

FLOW

ALTERNATIVE

HEATING

RETURN

With distributor

GRAVITY

tube (not shown)

DOMESTIC

RETURN TO

ANY OF THE

3 REMAINING

LOWER CONNECTIONS

WATER CONNECTIONS - GRAVITY

DOMESTIC, PUMPED HEATING

UPPER MARKER

must lie between the

two outer NOTCHES

DISTRIBUTOR

TUBE

must be in

pumped return

connection

UPPER

MARKER

1000

Diagram 4.1

0873

Diagram 4.2

1277

DISTRIBUTOR TUBE

9 221756A

Diagram 4.3

Page 10

4 Installation

When suitable installation clearances are available, position

the boiler in readiness to connect pipework.

If suitable clearances are not available it will be necessary to

preplumb the gas and water connections before positioning the

boiler.

When the front connections are used it is essential that any

pipework or fittings be assembled as shown in diagram 4.5, that

is, do not stick out more than shown.

Make the water connections to the system pipework.

Make the gas connection to gas supply at the union gas service

cock. Test the complete gas installation for soundness and

purge in accordance with the current issue of BS6891.

4.6 Pump within Boiler Casing

If the pump is to be fitted inside the boiler casing connect it as

shown to either of the upper front flow connections, see diagram

4.6.

There must be sufficient clearance “X” between the pump body

and the flueway cleaning door to allow removal of the door.

Dependent upon the type of pump used, the flow pipe

arrangements and pump may require titling backwards to clear

the casing door.

4.7 Flue Connection

The flue should be 125mm (5in) nominal diameter, refer to

Section 3 and diagram 1.1.

Fix and seal the flue to the hood in accordance with normal

practice.

ALTERNATIVE FLOW

POSITIONS

ALTERNATIVE

RETURN

POSITIONS

With distributor

tube (not shown)

WATER CONNECTIONS FULLY

PUMPED SYSTEMS

VIEW ON ARROW 'A'

57 MAX.

(21/4in.)

BOILER

0874

Diagram 4.4

'A'

1524

57 MAX.

(21/4in.)

PIPEWORK

CASING CLEARANCES

Diagram 4.5

Clearance 'X' must be left to enable cleaning

door removal and boiler servicing

175

'X'

(7)

FLUEWAY

CLEANING

DOOR

35 (13/8)

ALTERNATIVE

R.H. FLOW

CONNECTION

L.H. FLOW

CONNECTION

PUMP CLEARANCES

ISOLATING

VALVES

Diagram 4.6

0875

221756A

10

Page 11

5 Casing Location / Fitting

5.1 Side Vent Grille

One vent grille is supplied with the boiler which can be fitted at

the rear of the left or right hand side casing. The grille is fitted

on the opposite side to any pipework connections.

Fit the grille, if required, to the side panel as shown in diagram

5.1 prior to fixing the side panel. The plastic pegs are a tight fit

and are best pushed home with a flat faced tool.

Do not use the grille if water connections are on both sides of the

boiler or if the boiler is screened by fixtures.

No. 8

SCREW (2)

1018

5.2 Side Casings

Fit side casing by locating their lugs into the lower slots in the

base tray, see diagram 5.2.

Secure the casing sides to the casing bracket at the front top.

5.3 Top Casing

The top casing can be fitted in two alternative positions. that is,

with either the front edge flush with the door or overhanging it,

see diagram 5.3.

For a flush fitting top casing, fit four plastic pegs in holes “A” as

shown in diagram 5.3. For overhanging top casing, fit four

plastic pegs in holes “B”. The plastic pegs are a tight fit so they

are best pushed home with a flat faced tool.

Fit the top casing by engaging the pegs into the holes in the side

casings and then makes sure they are fully engaged by pushing

the pegs down.

PLASTIC PEG

SIDE VENT GRILLE

(If required, will fit to

left or right side casing)

0885

CASING

BRACKET

No. 8

SCREW (2)

SIDE CASINGS FITTING

PLASTIC PEG (4)

CASING

BRACKET

BOILER

PLINTH

LOCATING

LUG AND

SLOT

Diagram 5.2

TOP CASING

1180

SIDE VENT GRILLE

SIDE CASING

(R.H. SHOWN)

Diagram 5.1

A

SIDE

CASING

B

A

(L.H.)

PEG POSITIONS IN TOP CASING

A = FRONT EDGE FLUSH

B = 10mm (3/8 in) FRONT OVERHANG

AB

AB

SIDE

CASING

DOOR

DOOR

TOP CASING FITTING

AB

SIDE

CASING

Diagram 5.3

B

AB

11 221756A

Page 12

AP

AP

P

P

CB

CB

CB

CB

230

(9)

25

(1)

230

(9)

230

(9)

6 Electrical Wiring

6.1 Control Box Cable Connection

Remove the screw and cover from the mains inlet connector,

see diagram 6.1.

Using heat resistant flexible cable of suitable length and rating,

as Section 1.6, connect the cable to the terminals in the

connector. Secure the outer sheathing with the clamp.

Engage slots and lugs, replace connector cover and secure

with screw.

Connect mains inlet connector to the control box and use three

of the cable clips, supplied loose, pushed on to the edge of the

left hand panel in positions “CB” as shown in diagram 6.2 to

make sure that the cable does not touch any hot surfaces.

6.2 Circulation Pump Cable Connection

Heat resistant cable with a rating as stated in Section 1.6 must

be used for all wiring near the boiler, including the pump, if within

the boiler casing.

Support the pump cable away from hot surfaces if within the

boiler casing by pushing two cable clips, supplied loose, on to

the top edge of one side casing, as shown as “P” or “AP” in

diagram 6.2.

6.3 Flue Blockage Safety Device - Capillary

and Interrupter Electrical Leads

For transit the capillary is taped to the side of the boiler.

Remove tape and place capillary into cable clips provided, see

diagram 6.2.

Note: Capillary must not touch the heat exchanger side.

Secure the interrupter electrical leads so as not to strain them,

see diagram 6.2.

N

CABLE

CLAMP

MAINS INLET CONNECTOR

SAFETY DEVICE CAPILLARY

CLIP POSITION

COVER

L

E

0878

SLOTS

LUGS

Diagram 6.1

8064

6.4 System Controls

The electrical installation must be in accordance with the

current issue of BS7671.

The electrical isolator must isolate both the boiler and system

controls.

6.5 Testing

Checks to ensure electrical safety should be carried out by a

competent person.

In the event of an electrical fault after installation of the boiler,

preliminary system checks must be carried out, that is, earth

continuity, polarity and resistance to earth as described in a

multimeter instruction book.

CAPILLARY AND

INTERRUPTER

ELECTRICAL LEADS CLIP

Fit 2 pump cable

clips at positions P

Alternative pump

cable clips (if feed is

on the left hand side)

at positions AP

Fit 4 control

box feed cable

clips at positions

CB

221756A

CABLE CLIP POSITIONS

12

Diagram 6.2

Page 13

7 Commissioning

P

M

K

(Shown

closed)

E

B

SETTING

POINT

L

A

J

SETTING

POINT

= OFF

= PILOT/IGNITION

= MAIN BURNER

F

N

C

H

K

(Shown

open)

G

A. GAS CONTROL KNOB J. PHIAL POCKET

B. THERMOSTAT CONTROL K. GAS SERVICE COCK

C. PIEZO IGNITION BUTTON L. DATA BADGE

E. VIEWING WINDOW M. GAS CONTROL VALVE

F. BURNER GAS RATE ADJUSTMENT N. PILOT ADJUSTMENT SCREW

G. BURNER PRESSURE TEST POINT P. FLUE BLOCKAGE SAFETY

H. CONTROL BOX DEVICE RESET BUTTON

8061

BOILER COMPONENTS

Please ensure the “Benchmark” logbook is completed and left

with the user.

7.1 Preliminaries

The whole of the system, with the pump removed, should be

thoroughly flushed out with cold water.

Refit the pump and fill the system.

Examine for water soundness and vent all air from the system,

including the pump. Make sure that all valves are open.

7.2 Initial Lighting, Testing and Adjustment

Caution. The following should be carried out by a competent

person.

Identify the controls by reference to diagram 7.1.

Check that the gas service cock “K” is closed, indicator slot

vertical.

Make sure that the thermostat phial is fully inserted in the phial

pocket “J” and is securely located by the retaining split pin.

Check that the mains electrical supply is switched off.

Set thermostat control knob “B” to “O”.

Remove the burner pressure test point screw “G” and fit a

suitable pressure gauge.

Open gas service cock “K”, slot horizontal.

Note: Make sure the Flue Blockage Safety Device reset button

'P' is fully pushed in.

Turn gas control knob “A” to '

in. At the same time push and release button “C” until the pilot

' pilot ignition position and push

Diagram 7.1

burner lights, view through window “E”. At this stage air may be

present in the supply pipes so this operation may need to be

repeated.

When the pilot burner lights, keep knob “A” fully pushed in for

about 15 seconds. If the pilot burner fails to stay alight repeat

the operation only this time keep knob “A” pushed in for a little

longer.

Note: Should the boiler fail to operate correctly refer to the Fault

Finding - Section 10.

If gas control knob “A” is turned to ' ', a safety lock prevents

it being turned on again. No attempt should be made to push

in and turn knob “A” until three minutes have gone by.

Make sure that the pilot burner is alight and stable, see diagram

7.2, for flame dimensions, switch on the electrical supply. Set

any remote controls so that they are calling for heat. Turn

control knob “”A” to '

control knob “B” between “MIN” and “MAX”, the main burner will

light. “MAX” is about 82oC (180oF).

Test for gas soundness around the boiler gas components with

a suitable leak detection fluid.

Ten minutes after lighting, check the burner setting pressure

and adjust if necessary, as follows, remove cover “F”, see

diagram 7.1 and turn adjustment screw to obtain the required

heat input, turn anticlockwise to decrease, see diagram 7.1 data

label “L” for settings. Replace cover.

If any doubt exists the gas rate should be checked at the gas

meter, this should be in the range:

' main burner position. Set thermostat

13 221756A

Page 14

7 Commissioning

Hideaway 80 - 3.1 to 3.5m3/h 87 to 100ft3/h

These figures are for guidance only.

Stick the self adhesive arrow indicator, from the loose items

pack, to the data label against the rating the boiler is set to.

Allow the water system to warm up and set the pump to give the

correct temperature difference of 11

return.

There should be no undue noise in the pipework or heat

emitters, no pumping over of water or entry of air at the open

vent above the cold water cistern.

Allow the water system to reach maximum working temperature

and examine for water soundness. Whilst hot the system should

be drained rapidly to complete the flushing process.

Refill the system, vent and check for water soundness.

o

C (20oF) between flow and

7.3 Operational Checks

Check operation of the flame failure device as follows, with the

main burner alight, turn the gas valve control knob “A” fully

clockwise to its stop ' ', this will put out the main and pilot

flames. The safety device should close within 60 seconds, a

click from the valve will indicate this.

Remove the pressure gauge and refit the pressure test point

screw “G”. Make sure that a gas tight seal is made.

Turn thermostat knob “B” to “O” and relight the pilot burner as

Section 7.2.

Do not attempt to adjust the thermostat calibration screw.

Relight the main burner.

FLAME

DIMENSION

3-4 (1/8)

SPARK

GAP

PILOT

BURNER

ASSEMBLY

PILOT FLAME AND

SPARK GAP DIMENSIONS

UPPER

HOOK

VIEW 1

13 (1/2 in.)

APPROX.

VIEWING

WINDOW

Diagram 7.2

STUD

DOOR

FASCIA

0890

1356

7.4 Spillage Test

Test the appliance spillage of the flue products at the draught

diverter as detailed in the current issue of BS5440 Part 1.

7.5 Completion and User Information

Instruct and demonstrate the efficient and safe operation of the

boiler and heating/domestic hot water system.

Hand the Instructions for Use to the user, for keeping and make

sure that they are understood.

Advise the user that to ensure the continued efficient and safe

operation of the boiler it is recommended that it is checked and

serviced as necessary at regular intervals. The frequency of

servicing will depend upon the particular installation conditions

and usage, but in general once a year should be enough.

Draw attention, if applicable, to the current issue of the Gas

Safety (Installation and Use) Regulations, Section 35, which

imposes a duty of care on all persons who let out any property

containing a gas appliance.

Advise that the boiler is fitted with a Flue Blockage Safety

Device and refer to the Instructions for Use.

Reminder - Leave these instructions and the “Benchmark”

logbook with the user.

Fit the plinth front by locating the sides over the boiler plinth then

lowering to engage the upper and lower hooks, see diagram

7.3.

Fit the door by locating the hooked runner at the bottom into the

slots in the side casings and pushing onto the studs on the side

casings.

LOWER

HOOK

VIEW 2

VIEW 1

VIEW 2

PLINTH / DOOR FITTING

PLINTH

FRONT

Diagram 7.3

221756A

14

Page 15

8 Servicing

Servicing must be carried out by a competent person.

Before starting any servicing, turn off the gas and electrical

supply to the boiler.

Always test for gas soundness after completing any servicing

or replacement of gas carrying components.

8.1 Gain Access to Boiler

Pull door forwards at the top to disengage studs and lift to

release from the slots, see diagram 7.3.

Lift the plinth front up and forwards to withdraw, see diagram

7.3.

If the top casing is removed, care must be taken not to damage

or lose any plastic pegs when refitting, see Section 5.3.

8.2 Boiler Flueways

Unscrew the union nut securing the gas service cock to the gas

valve, see diagram 8.1.

Remove the mains inlet connector by pulling downwards, see

diagram 8.1.

Remove electrical connections from the interupter, see diagram

8.1.

Remove the retaining split pin from the phial pocket then

withdraw the phial and capillary, see diagram 8.2.

Remove the four screws retaining the combustion chamber

cover and burner assembly, see diagram 8.3.

Ease the gas service cock away from the gas valve and unhook

the pipe support bracket from the tie bar to enable the assembly

of cover, control box, gas valve and burner to be withdrawn

forward.

Remove graphite coated nuts to release baffle tray, remove

from combustion chamber taking care not to damage the

insulation material.

Remove self-tapping screws which retain the flueway cleaning

door and lift door clear, see diagram 8.4.

Remove flueway baffles, see diagram 8.7.

Place a sheet of paper in the combustion chamber to catch any

flue debris.

Access for flueway cleaning is made through the flueway

cleaning and combustion chamber openings.

Thoroughly clean boiler flueways and fins from the top and

bottom with a suitable stiff brush. Remove any debris from the

base of the combustion chamber.

Check that the flueways are clear, view with the aid of a mirror

or reflector.

GAS

SERVICE

COCK

(turn off)

(shown

closed)

MAINS INLET

CONNECTOR

(pull downwards)

7992

THERMOSTAT

CAPILLARY

PHIAL

POCKET

SECURING THE

THERMOSTAT PHIAL

TIE

BAR

BAFFLE

TRAY

GRAPHITE

COATED NUT

ACCESS FOR SERVICING

FLUEWAY

CLEANING

DOOR

SELFTAPPING

SCREW (4)

1870

LOCATION

WASHER

RETAINING

SPLIT PIN

Diagram 8.2

7993

COMBUSTION

CHAMBER

COVER

PIPE

SUPPORT

BRACKET

SECURING

SCREW (4)

Diagram 8.3

0908

ELECTRICAL

CONNECTIONS

ISOLATION OF

GAS AND ELECTRICITY

Diagram 8.1

ACCESS TO FLUEWAY

15 221756A

Diagram 8.4

Page 16

8 Servicing

8.3 Burners and Injectors

Follow instructions to remove the cover, burner and controls

assembly as described in Section 8.2.

Remove the screw securing the lint arrester gauze to combustion

chamber cover. Remove arrester by lifting slightly and

withdrawing forwards to clear burner supply pipe and

thermocouple etc., see diagram 8.5.

Remove the four burner securing nuts from the flange of the

burner supply pipe.

Remove the burner from the cover/supply pipe flange.

Remove the securing nut, washer and burner end cap from

burner, see diagram 8.6.

Clean the burner parts and lint arrester with a vacuum cleaner.

Check that the main burner injector is not damaged or blocked.

Clean or renew as necessary, do not clean with a wire or sharp

instrument. Refer to Section 9.2 and diagram 8.5.

When replacing the lint arrester locate the two lugs into the slots

on the combustion chamber cover and locate around the feed

pipe etc., then secure with the screw.

8.4 Service Checks

Inspect the thermocouple and pilot burner, clean or renew as

necessary.

Check the condition of the insulation panels in the combustion

chamber. Renew if necessary.

Check the condition of the seals on the flueway cleaning door

and the combustion chamber, renewing if necessary.

8.5 Reassembly

Make sure that the baffle tray is replaced and secured with the

graphite coated nut, previously removed.

Make sure that the thermostat phial is fully inserted into the phial

pocket. Position the location washer behind the retaining split

pin, see diagram 8.2.

COMBUSTION

MAIN

BURNER

CHAMBER

COVER

INJECTOR

SECURING

NUT(4)

LINT

ARRESTER

REMOVAL OF BURNER

BURNER

BODY

1147

BURNER

SUPPLY PIPE

SECURING

SCREW

Diagram 8.5

1153

WASHER

8.6 Operational Check

Light the boiler and carry out the operational checks as described

in Sections 7.2 and 7.3.

BURNER

END CAP

BURNER SERVICING

BAFFLES

SECURING

NUT

Diagram 8.6

6116

HEAT

EXCHANGERS

Diagram 8.7

221756A

16

Page 17

9 Replacement of Parts

Before removing or replacing any parts turn off the gas and

electrical supplies to the boiler.

Always test for gas soundness after replacing any gas carrying

components.

Replacement of parts is in the reverse order to removal unless

stated otherwise.

9.1 Gas Valve

Gain access to the boiler as Section 8.1.

Refer to the relevant parts of Section 8.2.

Disconnect the thermocouple nut, interrupter electrical

connections and pilot tube connections at the gas valve, see

diagram 9.1.

Support the valve and remove the four right hand flange screws

to disconnect the gas valve from the burner supply pipe.

Ease the gas service cock union out and remove the valve

taking care not to damage the “O” ring seal at the flange.

Inspect the condition of the “O” ring seal and renew if necessary.

Remove the union half and refit into replacement valve on the

inlet, left hand side. Use a little jointing compound, on external

thread only, to ensure gas soundness.

It will be necessary to purge air from the gas supply, relighting

should be carried out as Section 7.2.

9.2 Injectors

Gain access to the boiler as Section 8.1.

Refer to the relevant parts of Section 8.2 and 8.3.

Unscrew the injector from the manifold and renew as necessary.

When replacing the injector use a little jointing compound, on the

external thread only, to ensure gas soundness.

Replace thermostat phial.

GAS

VALVE

PLUG

GAS

VALVE

INTERRUPTER

CONNECTIONS

REMOVAL OF GAS VALVE

SECURING SCREW (2)

AND NUT (2)

PILOT

BURNER

PILOT

SHIELD

8058

PILOT

TUBE

NUT

GAS

OUTLET

FLANGE

SCREW

(4)

THERMOCOUPLE

NUT

Diagram 9.1

2038

THERMOCOUPLE

NUT

IGNITION

LEAD

(CLEAR

END)

9.3 Thermocouple

Gain access to boiler as Section 8.1.

Remove the lint arrester as Section 8.3.

Disconnect the thermocouple by unscrewing nuts at the gas

valve and pilot burner, see diagram 9.1 and 9.2. Withdraw the

thermocouple.

Replace the lint arrester as Section 8.3.

9.4 Pilot Burner

Gain access to boiler as Section 8.1.

Remove cover and burner controls assembly, as relevant parts

of Section 8.2.

Remove lint arrester as Section 8.3.

Disconnect the ignition lead at the electrode, see diagram 9.2.

Disconnect the thermocouple nut at the pilot burner.

Disconnect the pilot tube nut, ease out the tube and injector

which is hooked on to the pilot tube.

Remove the nut retaining the spark electrode and remove.

Remove the two screws and nuts securing the pilot burner and

shield to the combustion chamber cover.

Reassemble in the reverse order, hooking pilot injector over

pilot tube olive when refitting.

Replace thermostat phial, Section 8.5.

Replace lint arrester, Section 8.3.

Check that the pilot flame length is as shown in diagram 7.2.

SPARK

ELECTRODE

PILOT ASSEMBLY

REAR

INSULATION

PANEL

CLIP

BAFFLE

TRAY

INSULATION PANELS

PILOT

INJECTOR

SIDE

INSULATION

PANEL

SCREW

GRAPHITE

COATED

NUT

PILOT

TUBE

NUT

Diagram 9.2

6305

Diagram 9.3

17 221756A

Page 18

9 Replacement of Parts

7995

IGNITION LEAD

(BLACK END)

THERMOSTAT

SECURING

SCREW (2)

PIEZO UNIT

CONTROL BOX

CUT-OUT FOR

CAPILLARY

THERMOSTAT

AND CAPILLARY

THERMOSTAT

CONTROL KNOB

HOOK

SECURING SCREW

ELECTRICAL

CONTROL BOX

COVER

COVER

SECURING

SCREW (4)

ELECTRICAL

CONTROL BOX

ELECTRICAL

CONNECTORS

Diagram 9.4

9.5 Spark Electrode

Gain access to the boiler as Section 8.1.

Disconnect the thermocouple nut and withdraw thermocouple

from pilot burner, see diagram 9.2.

Disconnect the nut retaining the spark electrode and remove.

Check that the spark gap is as shown in diagram 7.2.

9.6 Insulation Panels

Gain access to the boiler as Section 8.1.

Remove the burner assembly as the relevant parts of Section

8.2.

Remove the two screws retaining each side insulation panel

within the combustion chamber and remove panel, see diagram

9.3.

Release the rear insulation panel upper clips and lift out panel.

Reassemble in reverse order.

Refit the thermostat phial as the relevant part of Section 8.5.

9.7 Boiler Thermostat

Follow the relevant instructions in Section 8.1.

Remove the mains inlet connector by pulling downwards, see

diagram 8.1.

Remove the retaining split pin from the phial pocket then

withdraw the phial and capillary, see diagram 8.2

Pull off the thermostat control knob.

Gain access to inside of the control box by removing the

securing screw located at the top of control box and unhooking

at the bottom, see diagram 9.4.

Remove the two screws which secure the boiler thermostat to

the control box, see diagram 9.4.

Tilt the thermostat so that the electrical connections can be

removed.

Withdraw boiler thermostat from control box complete with

capillary tube and phial.

Refer to diagram 9.5 to connect electrical connectors.

Replace the thermostat phial as the relevant part of Section 8.5.

Make sure that the capillary is positioned so that it passes

through the cut out in the control box, see diagram 9.4.

221756A

18

Page 19

9 Replacement of Parts

N

L

VIEW OF PLUG

WHEN REMOVED

E

THERMOSTAT

GAS VALVE

C

N/C

CONTROL BOX AND GAS VALVE WIRING

9.8 Piezo Unit

Pull door forward at the top to disengage the studs and lift to

release from slots, see diagram 7.3.

Remove mains inlet connector by pulling downwards, see

diagram 8.1.

Open the control box by removing securing screw and support

on the hook on the bottom of the control box cover, see diagram

9.4.

Disconnect the ignition lead at the piezo unit.

Note: To ease the removal of the piezo unit it is advisable to

temporarily remove the boiler thermostat from the control box.

Depress the retaining tabs and remove the Piezo unit.

9.9 Ignition Lead

Gain access to the boiler as Section 8.1.

Disconnect the ignition lead at the piezo unit, see diagram 9.4,

and section 9.8.

Remove the lint arrester gauze as the relevant parts of Section

8.3.

Disconnect the ignition lead at the spark electrode, see diagram

9.2.

When reconnecting the lead make sure that the clear end is

fitted to the spark electrode and that the black protective

sleeving is in place before fitting the lint arrester gauze.

GREEN/

YELLOW

230V~ 50Hz

MAINS SUPPLY

FUSED AT 3A

NL

CHASSIS

BLACK

EARTH

GREEN / YELLOW

BLUE

BROWN

Diagram 9.5

9.11 Flue Blockage Safety Device

Gain access to the boiler as Section 8.1.

Remove the electrical connections from the safety device body.

Remove the capillary from cable clips, see diagram 9.7.

To remove the phial assembly, first gain access through flue

cleaning door as Section 8.1.

Unscrew securing nut and withdraw the phial assembly from the

flue, see diagram 9.8.

Remove the locknut securing the Flue Blockage Safety Device

to the bracket and withdraw the Flue Blockage Safety Device

and phial assembly, see diagram 9.6.

CAPILLARY

ELECTRICAL

CONNECTIONS

FLUE

BLOCKAGE

SAFETY DEVICE

SECURING

LOCKNUT

8079

8056

9.10 Electrical Control Box

Gain access to the boiler as Section 8.1.

Disconnect the mains inlet connector, see diagram 8.1.

Remove the retaining split pin from the phial pocket then

withdraw phial and capillary, see diagram 8.2.

Disconnect the gas valve plug from the valve, see diagram 9.1.

Release the control box by removing the securing screw located

at the top of control box and unhooking at the bottom, see

diagram 9.4.

Pull the ignition lead off piezo unit, see diagram 9.4.

When refitting control box make sure the thermostat capillary is

positioned so that it passes through the cut out in the control

box, see diagram 9.4.

Refit thermostat phial, refer to Section 8.5.

ELECTRICAL CONNECTIONS

19 221756A

Diagram 9.6

Page 20

CABLE CLIPS

FLUE

BLOCKAGE

SAFETY

DEVICE

9 Replacement of Parts

CAPILLARY

8066

5042

LOCATION STUD

SECURING NUT

PHIAL

PHIAL ASSEMBLY

CAPILLARY REMOVAL

Diagram 9.7

10 Fault Finding - Electrical

10.1 Electrical

Refer to functional flow diagram 10.1, electrical fault finding

chart, diagram 10.2 and wiring diagram 9.5.

IMPORTANT. The preliminary electrical system checks

contained in a multimeter instruction book are the first checks

to be carried out during and fault finding procedure. On

completion of the service fault finding task which has required

the breaking and remaking of electrical connections then checks.

earth continuity, polarity and resistance to earth must be

repeated.

10.2 Thermocouple

To test the thermocouple a meter with a range 0 to 30mV is

required together with a thermocouple interrupter test unit

similar to the British Gas Multimeter and interrupter.

Refer to thermocouple fault finding chart, diagram 10.3 and

diagnosis graph, diagram 10.4.

PHIAL ASSEMBLY REMOVAL

L

GAS VALVE

CONTROL SOLENOID

THERMOSTAT

C N/C

BLACK

BROWN

VIEW OF

PLUG WHEN

BLUE

REMOVED

Diagram 9.8

L

N

1073

N

10.3 Pilot and Ignition

Refer to pilot and ignition fault finding chart, see diagram 10.6

and 10.3.

10.4 Flue Blockage Safety Device

If the device operates it indicates there is a problem with the

chimney. Make sure that the air vents are free from obstruction.

Carry out spillage checks as BS5440 Part 1 and put right as

necessary.

221756A

FUNCTIONAL FLOW WIRING

20

Diagram 10.1

Page 21

10 Fault Finding - Electrical

Carry out preliminary electrical checks to

make sure the electrical supply is available

at the boiler. Check that external controls

are calling for heat. Make sure that the

system is filled, the

device is reset, the gas supply is available

and the pilot is lit.

Isolate electrical supply to the

control box.

Remove the control box cover and

check all cables.

flue blockage safety

0899/A

Turn boiler thermostat to Max.

Is there continuity between

'C' and 'NC'.

YES

Turn boiler thermostat to 'O'.

Is there open circuit between 'C'

and 'NC'.

YES

Restore electrical supply with pilot

burner lit and boiler thermostat set

between 'MIN' and 'MAX', does the

main burner light.

YES

NO

Faulty thermostat.

Replace.

NO

NO

Turn boiler thermostat to "O'.

Does main burner extinguish.

Boiler controls in order.

ELECTRICAL FAULT FINDING

YES

Faulty gas valve.

NO

Replace.

Diagram 10.2

21 221756A

Page 22

10 Fault Finding - Thermocouple

With the boiler cold, check connections of the thermocouple, boiler flue blockage safety device

and gas valve. Reset flue blockage safety device.

Disconnect flue blockage safety device connectors at points A and B at the gas valve,

see diagram Interrupter Electrical Connections.

Test continuity of the flue blockage safety device. Is there continuity?

YES

Re-connect boiler flue blockage

safety device to points A and B.

Disconnect thermocouple at

connection point D of the gas valve.

Test continuity between point C and the

body of the gas valve.

Is there continuity?

NO

YES

2327/B

NO

Faulty boiler flue blockage

safety device, renew.

Faulty flue blockage safety device

connectors into gas valve,

either at A or C.

Renew where faulty.

Test continuity of thermocouple between inner

connection point D and point E.

Is there continuity?

NO

Faulty thermocouple, renew.

YES

Thermocouple and boiler flue blockage

safety device circuit satisfactory.

THERMOCOUPLE AND FLUE BLOCKAGE SAFETY DEVICE FAULT FINDING

GAS VALVE

29

27

25

23

21

ABC

19

17

1546

CONNECTION "A"

Diagram 10.3

5032

FLUE

BLOCKAGE

SAFETY

DEVICE

CONNECTION "E"

CONNECTION "B"

15

13

11

Open Circuit Voltage (millivolts)

9

0246810121416182022

Closed Circuit Voltage (millivolts)

DIAGNOSIS GRAPH FOR

THERMOCOUPLE CIRCUIT

221756A

Diagram 10.4

CONNECTION

"D"

INTERRUPTER ELECTRICAL

CONNECTIONS

22

POINT "C"

Diagram 10.5

Page 23

10 Fault Finding - Pilot

START HERE

Check gas line - open all cocks,

rectify any blockages, purge out

any air. Check

safety device is reset,

check all thermocouple circuit

connections are clean and in good

condition.

flue blockage

Does pilot light?

NO YES NO YES

Apply match to pilot burner instead

of pressing piezo unit button.

Does pilot light?

NO YES

Undo tubing nut at pilot burner.

Press gas valve knob.

Does gas flow freely?

NO YES

Rectify blockage in pilot injector,

or renew pilot injector.

0905A

Does pilot stay alight when

gas valve knob is released?

PILOT SATISFACTORY

Does pilot flame

envelope thermocouple?

NO YES

Check aeration. If necessary Clean pilot, rectify blockage in

pilot injector, or replace.

Undo tubing nut at pilot outlet of

gas valve. Press gas valve knob.

Does gas flow freely?

NO YES

Change blocked pilot tube.

Change gas valve.

Check thermocouple circuit using

Thermocouple Fault - Finding

diagram.

On pressing piezo unit button

is there a spark across

electrode gap?

NO YES

Pull ignition lead off electrode.

Hold end of lead close to pilot

burner and operate piezo unit.

Is there a spark across gap?

NO YES

Pull ignition lead off piezo unit.

Using blade of a screwdriver,

touch unit chassis and leave

approx. 4mm gap from connection

tag on piezo unit. Operate piezo.

Is there a spark across gap?

NO YES

Change

piezo unit.

Change

ignition unit.

PILOT / IGNITION FAULT FINDING

Check electrode gap. Reposition,

or replace electrode as necessary.

Diagram 10.6

23 221756A

Page 24

11 Spare Parts

11.1 Ordering

When ordering spare parts quote the part number and description, stating the model and serial number off the data label “L”, see

diagram 7.1.

If ordering from British Gas also quote the GC appliance number off the data label and the required spare part GC number.

1

3

2

13

8067

12

5

11

7

4

10

8

9

6

Diagram 11.1

Key No Part No Description GC Part No

1 800001 Gas control valve

2 205753 Injector - 80

3 203414 Pilot burner 312 246

4 203508 Injector - pilot 395 674

5 900001 Thermocouple c/w nut

6 202571 Thermostat c/w screws

7 204687 Control knob assy - thermostat

8 202713 Piezo unit

9 WW4609 Ignition lead assembly 136 464

10 202605 Spark Electrode 395 720

11 425794 Flue Blockage Safety device E02686

12 208302 Sight glass 312 419

13 212031 "O" Ring - gas valve 312 602

Because of our constant endeavour for improvement, details may vary slightly from those shown in these instructions.

221756A

24

Loading...

Loading...