Genie GCL-GH Owner's Manual

112118.501539 07-12

™

GCL-GH

Heavy Duty Operator

NEMA 4 & 4X APPLICATION

INSTALLATION SUPPLEMENT

FOR ALL HP RATINGS

GCL-GH

This supplement instruction is to be used in combination with the standard accompanying

GCL-GH™ Installation Manual. This supplement contains installation instruction and illustrated

parts breakdowns which specify parts included in the GCL-GH

™

COMMERCIAL-INDUSTRIAL DOOR OPERATOR.

NOT F OR RESIDENTIAL U S E

™

NEMA 4 & 4X assemblies.

IMPORTANT: Prior to installing or operating an GCL-GH™ Commercial-Industrial Door Operator, carefully read the GCL-GH

Installation Manual and any other instructions and warnings accompanying the unit.

™

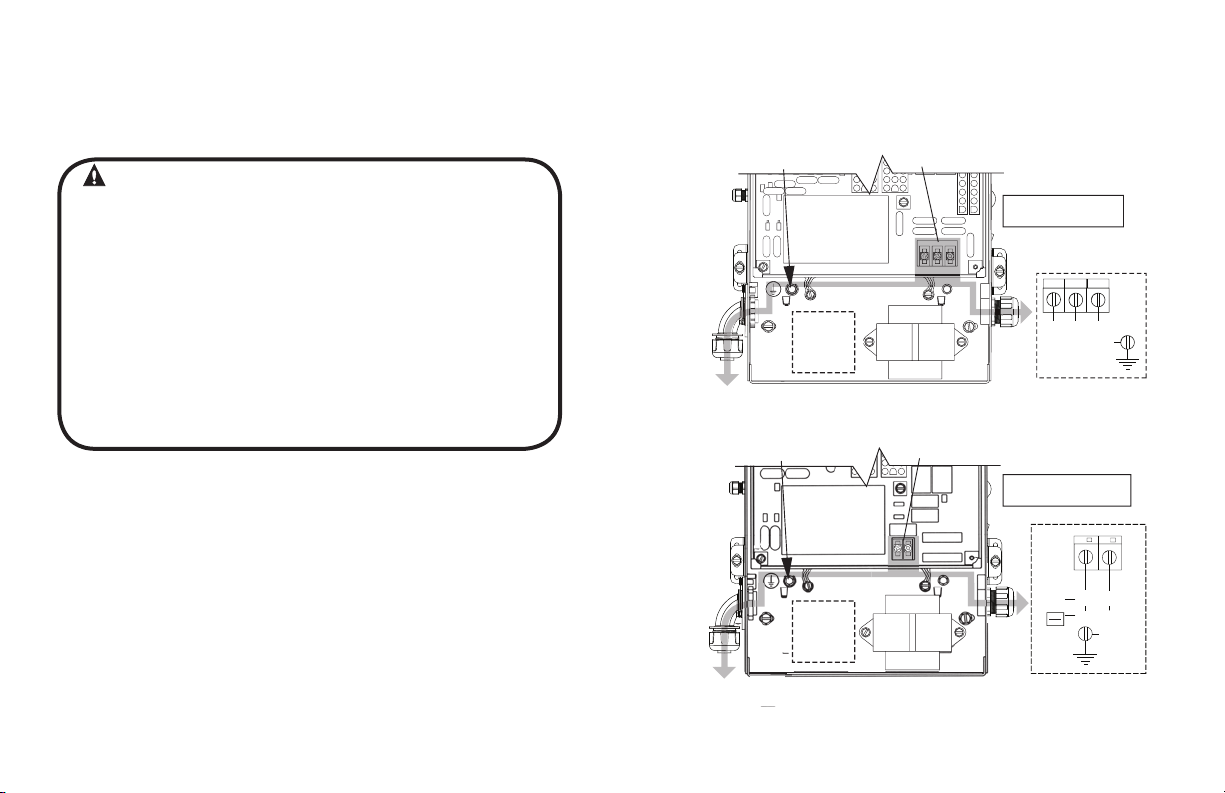

High Voltage Wiring

(SUPPLEMENT TO SECTION 5 OF THE ACCOMPANYING GCL-GH™ INSTALLATION MANUAL)

Line Voltage Wiring Fig. 1

WARNING

• DO NOT apply power to operator until instructed to do so.

• The Genie

®

Company recommends that line voltage wiring

be performed by a qualified electrician.

• Be sure that electrical power has been disconnected from the

input power wires being connected to the operator prior to

handling these wires. An appropriate lock-out /tag-out procedure

is recommended.

• Line voltage wiring must meet all local building codes.

• Make sure operator voltage, phase and frequency nameplate

ratings are identical to the job site line voltage ratings.

• Input power wiring must be properly sized for the operators

amperage rating located on the nameplate.

• To reduce the risk of electric shock, make sure the chassis of this

unit is properly grounded.

1) Remove LINE VOLTAGE INPUT PLUG and install proper

fittings and 1/2”conduit.

2) Route proper LINE VOLTAGE wires into operator.

3) Locate LINE INPUT terminals on circuit board. Using

correct connectors, attach wires to LINE INPUTS, and GROUND

terminal.

• Keep low

voltage and line voltage wires separate.

• Route all line voltage wires as shown. Use liquid tight fittings

and conduit.

• Plug all unused conduit holes with liquid tight plugs.

NOTE: LIQUID-TIGHT FITTINGS AND CONDUIT ARE NOT PROVIDED.

GCL-GH

Heavy Duty Operator

www.geniecompany.com 06-12

Figure 1

HIGH

VOLTAGE

INPUT

PLUGS

(Right

& Left)

HIGH

VOLTAGE

INPUT

PLUGS

(Right

& Left)

LINE

GROUND

Optional

Accessory

Modules

Optional

Additional

Transformer

ROUTE HIGH VOLTAGE WIRING

IN THE SHADED AREA AS SHOWN

LINE

GROUND

Optional

Additional

Transformer

ROUTE HIGH VOLTAGE WIRING

IN THE SHADED AREA AS SHOWN

208/240V 480/575V

LINE INPUT

TERMINALS

LINE INPUT

TERMINALS

Three Phase

LINE IN

POWER CONNECTIONS

L1

L3

L2

LINE 1

LINE 2 LINE 3

GND

Single Phase

POWER CONNECTIONS

L1/L1

N/L2

LINE

NEUTRAL

115V

(HOT)

LINE 1

LINE 2

208V

230V

GND

1

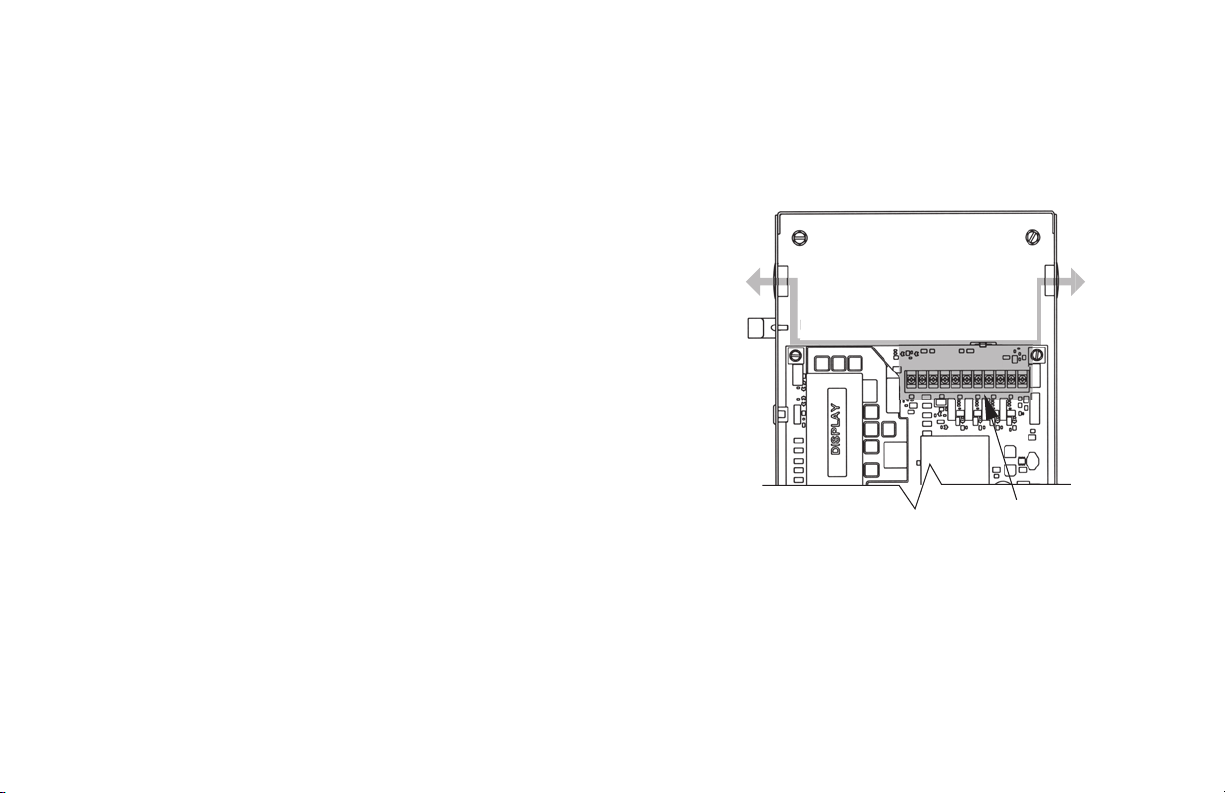

Low Voltage Wiring

(SUPPLEMENT TO SECTION 5 OF THE ACCOMPANYING GCL-GH™ INSTALLATION MANUAL)

Low Voltage Control Wiring (general) Fig. 2

1) Connect all LOW VOLTAGE control circuit wires to this side

of unit using 1/2” conduit or flexible convoluted tubing.

• Keep low voltage and line voltage wires separate.

• Route all low voltage control wiring as shown. Use liquid tight

fittings and conduit. This includes all control circuit wires such as

wall controls, timers and single button input devices as well as

radio control and safety circuit wiring. See Figs 2 through 10 in

this section.

• Plug all unused conduit holes with liquid tight plugs.

LOW

VOLTAGE

INPUT

PLUGS

(Left &

Right)

ROUTE LOW VOLTAGE WIRING

IN THE SHADED AREA AS SHOWN

NOTE: For a detailed description of control wire terminals see Appendix B in

the Standard GCL-GH

NOTE: LIQUID-TIGHT CONDUIT AND FITTINGS ARE NOT PROVIDED

GCL-GH

™

Installation Manual.

Heavy Duty Operator

www.geniecompany.com 06-12

Figure 2

LOW VOLTAGE

CONTROL WIRE

TERMINALS

2

Loading...

Loading...