Page 1

Refrigerant

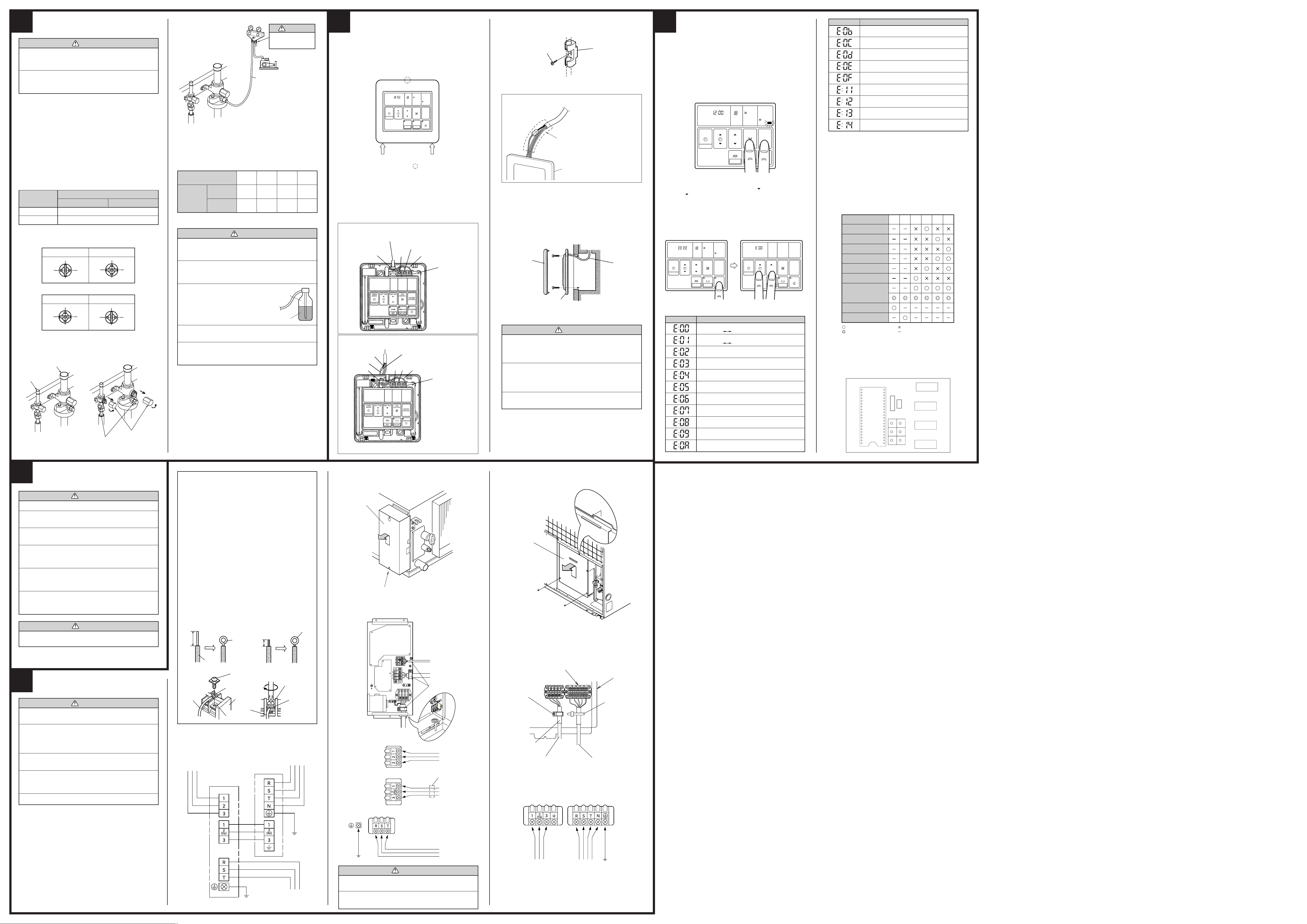

R407C

SPLIT TYPE AIR CONDITIONER

Duct Type

INSTALLATION INSTRUCTION

SHEET

(PART NO. 9365748039)

This air conditioner uses new refrigerant HFC (R407C).

For authorized service personnel only.

WARNING!

CAUTION!

1 For the air conditioner to operate satisfactorily, install it as outlined in this installation instruction sheet.

2 Connect the indoor unit and outdoor unit with the air conditioner piping and cords available from our standard parts. This

installation instruction sheet describes the correct connections using the installation set available from our standard parts.

3 Installation work must be performed in accordance with national wiring standards by authorized personnel only.

4 If refrigerant leaks while work is being carried out, ventilate the area. If the refrigerant comes in contact with a flame, it

produces a toxic gas.

5 Do not turn on the power until all installation work is complete.

• Be careful not to scratch the air conditioner when handling it.

• After installation, explain correct operation to the customer, using the operating manual.

• Let the customer keep this installation instruction sheet because it is used when the air conditioner is serviced or moved.

STANDARD PARTS

The following installation parts are furnished. Use them as required.

INDOOR UNIT ACCESSORIES

This mark indicates procedures which, if improperly performed, might lead to the death or serious injury of the

user.

This mark indicates procedures which, if improperly performed, might possibly result in personal harm to the user,

or damage to property.

WARNING

SELECTING THE MOUNTING

POSITION

Decide the mounting position together with the customer as follows:

CONNECTION PIPE REQUIREMENT

Table 1

Diameter

Small

12.7 mm

• Use 0.8 mm to 1.6 mm thick pipe.

• Use pipe with water-resistant heat insulation.

• Use pipe that can withstand a pressure of 3,040 kPa.

Large

28.58 mm

Maximum

length

50 m

Maximum height

(between indoor

and outdoor)

30 m

ELECTRICAL REQUIREMENT

Table 2

INDOOR UNIT OUTDOOR UNIT

Power supply

cord (mm2)

Fuse capacity (A) 10 40

Connection

cord (mm2)

• Always use H07RN-F or equivalent to the connection cord. (for EURO)

• Install the disconnection device with a contact gap of at least 3 mm

nearby the units. (Both indoor unit and outdoor unit)

MAX 2.5 8.0

MIN 1.5 6.0

MAX 2.5

MIN 1.5

INSTALLATION PROCEDURE

Install the air conditioner as follows.

1

INDOOR UNIT INSTALLATION

1. CONVEYANCE METHOD

Fig. 3

Packing hardware (4 pieces)

2. INSTALLING HANGERS

Fig. 4 Hanging bolt installation diagram

1,550 mm

450 mm

65 mm

713 mm

660 mm

1,410 mm

AIR

Inlet port

Outlet port

AIR AIR

Fig. 5

Hanging bolt M10

(Procure locally)

Washer

Special nut A

Hanger

Special nut B

CAUTION

Fasten the unit securely with special nuts A and B.

Bolt Strength 9.81 to 14.71 N·m (100 to 150 kgf·cm)

3. LEVELING

Use the procedure in the following figure to adjust the levelness.

Fig. 6

4. MOUNTING THE DUCT

Follow the procedure in the following figure to install the ducts.

Fig. 7 Flange positions for connecting the duct.

1,250 mm

14 mm370 mm∗ 20 mm

Inlet port flange

75 mm

15 mm

∗ 25 mm

350 mm

∗ Spacing between flange and drain pan.

35 mm

2 × 160 pitch=320 mm

CAUTION

If an intake duct is installed, take care not to damage the

temperature sensor (the temperature sensor is attached

to the intake port flange).

Fig. 8 Static pressure characteristic curve (recommend range)

External static pressure

Air flow

CAUTION

Install the air inlet grille for air circulation.

The correct temperature can not be detected.

Outlet port flange

7 × 150 pitch=1,050 mm

1,200 mm

Standard

5. INSTALLING DRAIN PIPE

Fig. 9 Position of drain piping and coolant piping.

60 mm

50 mm

427 mm

200 mm

Safety drain pipe

ø25.4 mm (O.D.)

50 mm

CAUTION

1 This product has drain ports in two locations. Follow

the procedure in the figure to connect drain pipes to

each of them.

2 Be sure to properly insulate the drain pipes.

The position of the installed drain pipe should have a downward gradient

of 1/50 to 1/100. Make sure that drain pipe is installed whitout rises.

Use general hard polyvinyl chloride pipe (VP25) and connect it with adhesive (polyvinyl chloride) so that there is no leakage. Do not perform air

bleeding.

1 Main drain

On the main drain, provide one trap near the indoor unit.

Fig. 10

Unit

Trap

2 Safety drain

There is no need to provide a trap for the safety drain. If the safety

drain is connected to the main drain, make the connection below the

main trap.

Fig. 11

95 mm

40 mm

235 mm

318 mm

404 mm

Main drain pipe

ø38.1 mm (O.D.)

H1=100 mm (Approx.)

H

2=50~100 mm

Drain pipe

1

H

2

H

3

CONNECTING THE PIPING

CAUTION

1 Do not use mineral oil on flared part.

Prevent mineral oil from getting into the system as this

would reduce the lifetime of the units.

2 Never use piping which has been used for previous

installations. Only use parts which are delivered with

the unit.

3 While welding the pipes, be sure to blow dry nitrogen

gas through them.

1. FLARE PROCESSING

(1) Cut the connection pipe with pipe cutters so that the pipe is not de-

formed.

(2) Holding the pipe downward so that cuttings cannot enter the pipe and

remove the burrs.

(3) Remove the flare nut from the indoor unit pipe and outdoor unit and

assemble as shown in (Table 3) and insert the flare nut onto the pipe,

and flare with a flaring tool.

(4) Check if the flared part “L” (Fig. 20) is spread uniformly and that there

are no cracks.

Table 3

Pipe

Small pipe

(12.7 mm dia.)

Flare nut

width across flats 24 mm

Fig. 20

Width across flats

L dimension

1.9 to 2.2 mm

2. BENDING PIPES

CAUTION

1 To prevent breaking of the pipe, avoid sharp bends.

Bend the pipe with a radius of curvature of 150 mm or

over.

2 If the pipe is bent repeatedly at the same place, it will

break.

3. CONNECTION PIPES

(1) As shown in the figure, connect the piping for the indoor and outdoor

units.

(2) On the large pipe side, braze the provided flange joint and connection

pipe.

(3) After the pipes, an air tightness test must be formed.

Toperform the test, close the valve and increase the pressure of the

nitrogen gas to 30 kg/cm2G (2.94 MPa).

Fig. 22 Indoor unit side

Nut

Gasket * (Accessory)

Flange joint

Flare nut

Connection pipe

(Small)

CAUTION

Make sure that the folded portion of the gasket (marked *)

is facing the indoor unit.

Indoor unit side

Folded portion

Fig. 23 Outdoor unit side

Valve A

Flare nut

Blazing the pipe

Washer

Bolt

Connection pipe

(Large)

Valve B

Gasket (Accessory)

Flange joint

Washer

Bolt (Accessory)

Blazing the pipe

Name and Shape

Remote

controller

Flange joint

Gasket

Special nut A

(large flange)

Special nut B

(small flange)

Washer

Coupler heat

insulation

Flange joint

insulation

Binder (Large)

Binder (Small)

Remote

controller

cord clamp

Screw

Q’ty

Use for air conditioner

operation

1

For connecting the piping

1

Installation between flange

joint and indoor unit

1

For suspending the indoor

4

unit from ceiling

4

8

For indoor side pipe joint

1

(small)

For indoor side pipe joint

(large)

1

For fixing the connection

pipe (Large and small)

1

For fixing the remote

controller cord

1

For installing the remote

10

controller cord

For installing the remote

10

controller cord clamp

For installing the remote

2

controller

OUTDOOR UNIT ACCESSORIES

Name and Shape

Flange joint

assembly

Q’ty

For connecting the piping

1

Application

Application

INDOOR UNIT

WARNING

Install at a place that can withstand the weight of the indoor and outdoor units and install positively so that the

units will not topple or fall.

(1) Install the indoor unit on a place having a sufficient strength so that it

withstands against the weight of the indoor unit.

(2) The inlet and outlet ports should not be obstructed; the air should be

able to blow all over the room.

(3) Leave the space required to service the air conditioner (Fig. 1).

Fig. 1

1 If a service hole is to be provided at the bottom of the product.

200 mm

890 mm

30 mm

1,920 mm

2 If the service hole referenced in 1 is not to be provided.

900 mm 900 mm

400 mm

Service Hole

OUTDOOR UNIT

WARNING

1 Install the unit where it will not be tilted by more than 5°.

2 When installing the outdoor unit it may be exposed to

strong wind, fasten it securely.

(1) If possible, do not install the unit where it will exposed to direct sunlight.

(If necessary, install a blind that does not interfere with the air flow.)

(2) Install the outdoor unit in a place where it will be free from being dirty

or getting wet by rain as much as possible.

(3) Install the unit where connection to the indoor unit is easy.

(4) During heating operation, drain water flows from the outdoor unit.

Therefore, install the outdoor unit in a place where drain water flow

will not be obstructed. (Reverse cycle model only)

(5) Do not place animals and plants in the path of the warm air.

(6) Take the air conditioner weight into account and select a place where

noise and vibration are small.

(7) Select place so that the warm air and noise from the air conditioner do

not disturb neighbors.

(8) Install inlet and outlet ducts in order to maintain stable operation in

cold or snowy regions.

(9) Provide the space shown in Fig. 2 so that the air flow is not blocked.

Product mass

85 kg

Leave the packing materials on until the unit is at the installation site.

Remove the packing hardware and dispose of it.

2

OUTDOOR UNIT INSTALLATION

1. CONVEYANCE METHOD

• If you are suspending the unit and conveying it to its installation location, place the ropes under the bottom, using the two places on the

front and rear provided for suspending it.

• Be sure to suspend the unit with ropes from 4 places and be careful not

to subject it to impacts.

• Place protective boards on the unit so the rope doesn’t make contact

with the bell mouth.

• Use 2 ropes which are 7 m in length or longer.

Fig. 12

Product mass

245 kg

Protective boards

Rope suspension area

Level meter

AB

The side of the unit that holds the drain port (A) should be slightly lower

than the opposite side of the unit (B). The slant should allow from 0 to

20 mm of difference between (A) and (B).

(2) Drain Processing (Reverse cycle model only)

• Remove the rear panel.

Fig. 14

Rear panel

Knockout hole

Drain pipe mounting holes

Drain pan

Drain pipe

• Since the drain water flows out of the outdoor unit during heating operation, install the drain pipe and connect it to an commercial 16 mm

hose. (When heating the outdoor temperature is 0 °C or less, construct

so that drain water from the outdoor unit will not freeze in the drain

pipe.)

• Always use a drain pipe at three places.

Rear panel

Hose

Unit

Air Outlet Grille Air Inlet Grille

(Room)

Fig. 16

Unit: mm

75

Knockout hole

• If the piping is connected from the left and rear, be sure that there is

enough space around the unit to make connections.

(2) Remove the front panel right.

210

30

36

Fig. 17

Front panel right

Valve

Unit

Main

Safety

• Once the installation is complete, check the flow of drain water.

(4) Open the piping and connection cord knockout holes of the desired

direction with nippers, etc.

After opening a hole in the center of bush, pierce with connection

cord. (Rear, Right and Left wiring)

Drain pipe

Fig. 19

Connection cord

(Power supply cord)

Bush

Connection cord

(Indoor unit and

outdoor unit

connection cord)

Pipe

Knockout hole

When bending the pipe, do not bend

it as is. The pipe will be collapsed.

In this case, cut the heat insulating

pipe with a sharp cutter as shown in

Fig. 21, and bend it after exposing

the pipe. After bending the pipe as

you want, be sure to put the heat insulating pipe back on the pipe, and

secure it with tape.

Fig. 21

Pipe

Heat insulating

pipe

Cutter

Cut line

Table 4 Tightening torque

Pipe Tightening torque

Flare nut (Small pipe) 49 to 53.9 N·m (500 to 550 kgf·cm)

Bolt (flange joint) 34.3 to 39.2 N·m (350 to 400 kgf·cm)

When the flare nut is tightened properly by your hand, hold the body side

coupling with a separate spanner, then tighten with a torque wrench

(Fig. 24).

Fig. 24

Holding spanner

Body side

Torque wrench

CAUTION

Hold the torque wrench at its grip, keeping it in the right

angle with the pipe as shown in Fig. 24, in order to tighten

the flare nut correctly.

• Connecting the flange joint.

Fig. 25 Indoor unit side

Flange joint

Connection pipe

(Small)

Connection pipe

(Large)

CAUTION

1 Be sure to apply the pipe against the port on the in-

door unit correctly. If the centering is improper, the flare

nut cannot be tightened smoothly. If the flare nut is

forced to turn, the threads will be damaged.

2 Use the new gaskets provided with each of the parts.

4. INSULATION ON THE PIPE JOINT

Indoor unit side

In order to prevent condensation, apply the insulation without leaving any

gaps.

Fig. 27

Flange joint insulation

Indoor unit side

Coupler heat insulation

CAUTION

There should be no gaps between the insulation and the

product.

Outdoor unit side

Seal with the accessory insulation so that water does not enter at the top

of the pipe insulation installed to the connection pipe.

Fig. 28

(Example)

Coupler heat

insulation

Gasket

Bolt

Drain pipe

For outdoor side pipe joint

1

Installation between flange

joint assembly and valve B

1

For fixing the flange joint

2

assembly

For outdoor unit drain piping

work (Reverse cycle model

3

only)

• Installing the unit individually

Fig. 2

Front side

• There is no limit to the height of the side wall.

• The height of the wall (H) on the front side and rear side should be

1,200 mm or less.

• If the wall height exceeds 1,200 mm, add dimension (h) to the respective service space dimensions L1 and L2.

10 mm or more

500 mm

or more

10 mm or more

L1

Top blower

h

Front

air intake

H (1,200 mm or less)

200 mm or

more

L2

outlet

h

Rear

air

intake

H (1,200 mm or less)

2. OUTDOOR UNIT PROCESSING

When the outdoor unit will be exposed to strong wind, fasten it with anchor bolts at the four places indicated by the arrows (Fig. 13).

(1) Anchor Bolt Positions

• The distance between the left and right anchor bolts should be at least

850 mm.

Fig. 13

1,300 mm

1,000 mm

850 mm

650 mm

678 mm

• Set the unit on a strong stand, such as concrete blocks to minimize

shock and vibration.

• Do not set the unit directly on the ground because it will cause problems.

3. OUTDOOR UNIT CONNECTION CORD AND

PIPE CONNECTION PREPARATIONS

(1) Piping and connection cord mounting direction (5-way mounting pos-

sible).

Fig. 15

Left piping

Rear piping

Front piping

Bottom piping

• Remove the rear panel in order to install the left piping.

• If a mounting bracket is installed at the knockout hole section in the

base, do not connect the piping from the bottom.

Right piping

(3) Before connecting flange joint assembly to ball valve.

Remove bolts, valve plate and gasket.

Fig. 18

Ball valve

Gasket

Valve plate

Washer

Bolt

Holding

spanner

Fig. 26

Torque wrench

Tighten the bolts evenly.

CAUTION

Torque wrench

Flange joint pipe

Coupler heat

insulation

5. SECURING THE PIPING (Indoor unit only)

• Secure the two pipes so that they are parallel, using a binder or other

means.

Fig. 29

Indoor unit side

300~400 mm

CAUTION

If the pipes are not secured, there is a risk of damage to

the unit’s internal piping.

Binder (Large)

- Continuted on back -

Page 2

4 5

VACUUM PROCESS

Fig. 31

CAUTION

1 Do not purge the air with refrigerants but use a vacuum

pump to vacuum the installation! There is no extra refrigerant in the outdoor unit for air purging!

2 Use a vacuum pump for R407C exclusively. Using the

Gauge manifold

L

O

H

I

Service hose

CAUTION

Use a clean gauge manifold and charging hose

for R407C exclusively.

Vacuum pump

• Insert the end of a flat blade screwdriver at the arrow parts of the groove

• Disconnect the remote controller cord from the remote controller termi-

Fig. 32

same vacuum pump for different refrigerant may damage the vacuum pump or the unit.

1. VACUUM

(1) Remove the cap, and connect the gauge manifold and the vacuum

pump to the charging valve by the service hoses.

(2) Vacuum the indoor unit and the connecting pipes until the pressure

gauge indicates -0.1 Mpa (-76 cmHg).

(3) When -0.1 MPa (-76 cmHg) is reached, operate the vacuum pump for

at least 1 hour.

(4) After vacuuming inside the indoor unit and the piping, remove the cap

of the two valves.

(5) Open the spindle (handle) of the two valves from the closed state.

(Table 6)

(6) Tighten the cap and charging valve of the two valves to the specified

torque (Table 5).

Table 5

Tightening torque

Large valve Small valve

Handle 1.47 N · m (15 kgf · cm) or less

Cap 14.7 to 19.6 N · m (150 to 200 kgf · cm)

Table 6

Valve A

Open valve state Closed valve state

Valve B

Open valve state Closed valve state

∗ If the spindle (handle) is not fully open, performance

will drop and an abnormal sound will be generated.

Fig. 30

Valve B

Valve A

(Small pipe)

(Large pipe)

Charging

valve

Cap

2. ADDITIONAL CHARGE

• Up to a pipe length of 30 m, charging with additional refrigerant is not

necessary.

• If the pipe length exceeds 30 m, charging with refrigerant is necessary.

• Charge with additional refrigerant in the amounts shown in the table

below.

Table 7

Actual pipe length

Additional

refrigerant

(R407C)

Reverse cycle

Cooling

model

model

30 m

(99 ft)

None

None

CAUTION

1 When moving and installing the air conditioner, do not

mix gas other than the specified refrigerant R407C inside the refrigerant circuit.

2 When charging the refrigerant R407C, always use an

electronic balance for refrigerant charging (to measure the refrigerant by weight).

3 When charging the refrigerant, take

into account the slight change in the

composition of the gas and liquid

phases, and always charge from the

liquid phase side whose composition is stable.

4 Add refrigerant from the charging valve after the com-

pletion of the work.

5 The maximum length of the piping is 50 m. If the units

are further apart than this, correct operation can not

be guaranteed.

40 m

(132 ft)

500 g

(18 oz)

1,000 g

(35 oz)

50 m

(164 ft)

1,000 g

(35 oz)

2,000 g

(70 oz)

Gas

Liquid

g/m

(oz/ft)

50 g/m

(1.8 oz/3.3 ft)

100 g/m

(3.5 oz/3.3 ft)

R407C

(1) When remote controller exposed

Fig. 33

REMOTE CONTROLLER

INSTALLATION

at the side of the remote controller case and remove the remote controller case top by turning the screwdriver.

nal board.

CLOCK

NON STOP

TIMER

MODE

CLOCK ADJUST

1) Make a notch in the thin part (

controller case top and bottom with nippers, file, etc.

2) Connect the remote controller cord to the remote controller terminal board specified in (Fig. 33).

3) Clamp the remote controller cord sheath with the binder (small) as

shown in Fig. 33.

4) Cut off the excess binder.

5) Clamp the remote controller cord to a wall, etc. with the remote

controller cord clamp furnished (Fig. 34).

• except for Australia model

Remote controller cord

Binder (small)

• only for Australia model

Remote controller cord

Shield wire

Wire (green)

Binder (small)

• Use a shielded wire (obtained locally) for the remote controller cord.

TEMP

AUTO

°C

HIGH

COOL

ZONE

SET

CONTROL

ENERGY SAVE

DAY OFF

DEFROST

MASTER

CONTROL

START/STOP

21

SET TIME TEMP./DAY FAN

part of Fig. 32) at the remote

White

Red

Join wire from remote controller to shield of

remote controller cord with connector

(obtained locally).

13

2

Black

Remote controller

terminal board

Remote controller

terminal board

Fig. 34

Remote controller cord

Tapping screw (flush heads)

Remote controller

cord clamp

• only for Australia model

Wrap the connection between the

connector and the shielded wire with vinyl

tape or some other type of insulation.

Remote controller

(2) When remote controller cord embedded

1) Embed the remote controller cord and box.

2) Pass the remote controller cord through the hole at the remote controller case bottom and install the cord to the box (Fig. 35).

3) Connect the remote controller cord to the remote controller terminal board specified in (Fig. 33).

Fig. 35 [Example]

Remote controller

case top

Remote controller case bottom

Remote

controller

cord

• After wiring work is complete, return the remote controller case top to

its original state.

CAUTION

1 Do not bundle the remote controller cord, or wire the

remote controller cord in parallel, with the indoor unit

connection wire (to the outdoor unit) and the power

supply cord. It may cause erroneous operation.

2 When installing the remote controller and cord near a

source of electromagnetic waves, separate the remote

controller from the source of the electromagnetic waves

and use shielded cord.

3 Do not touch the remote controller PC board and PC

board parts directly with your hands.

8

TEST RUNNING

1. REMOTE CONTROLLER

• Supply power to the crankcase heater 12 hours before the start of operation in the winter.

• For test running, when the remote controller FAN CONTROL button

and MASTER CONTROL button are pressed simultaneously for more

than three seconds when the air conditioner is not running, the air conditioner starts and TEST is displayed on the remote controller display.

However, the SET TEMP./DAY setting button does not function, but all

other buttons, displays, and protection functions operate (Fig. 44).

Fig. 44

CLOCK

NON STOP

21

TIMER

SET TIME TEMP./DAY FAN

MODE

CLOCK ADJUST

• When EE : EE blinks at the current time display, there is an error inside

the air conditioner. If the SET TIME button (

button ( ) are pressed simultaneously for more than three seconds,

the self diagnosis check will start and the error contents will be displayed at the current time display (Fig. 45). When the operation lamp

lights, press the START/STOP button and after operation lamp goes

off, perform the same operation (Fig. 45). Process the error contents by

referring to (Table 8).

Fig. 45

CLOCK

NON STOP

21

TIMER

MODE

CLOCK ADJUST

Stop operation.

Error cord Error contents

TEMP

°C

SET TIME TEMP./DAY FAN

CONTROL

SET

DAY OFF

Communication error

(indoor unit

Communication error

(indoor unit

Room temperature sensor open

Room temperature sensor shortcircuited

Indoor heat exchanger temperature sensor open

Indoor heat exchanger temperature sensor

shortcircuited

Outdoor heat exchanger temperature sensor open

Outdoor heat exchanger temperature sensor

shortcircuited

Power source connection error

Float switch operated

Outdoor temperature sensor open

AUTO

HIGH

DEFROST

MASTER

CONTROL

START/STOP

COOL

TEMP

°C

SET

Table 8

remote controller)

outdoor unit)

AUTO

HIGH

COOL

DEFROST TEST

CONTROL

MASTER

CONTROL

START/STOP

DAY OFF

) and SET TEMP./DAY

21

TIMER

SET TIME TEMP./DAY FAN

MODE

CLOCK ADJUST

AUTO

CONTROL

MASTER

CONTROL

SET

START/STOP

DAY OFF

Error cord Error contents

Outdoor temperature sensor shortcircuited

Discharge pipe temperature sensor open

Discharge pipe temperature sensor shortcircuited

Outdoor low pressure abnormal

Discharge pipe temperature abnormal

Model abnormal

Indoor fan abnormal

Outdoor signal abnormal

Outdoor EEPROM abnormal

• To stop test running, press the START/STOP button.

• For the operation method, refer to the operating manual and perform

operation check.

• Check that there are no abnormal sounds or vibration sounds during

test running.

2. OUTDOOR UNIT

When the outdoor temperature drops, the outdoor unit’s fans may switch

to low speed, or one of the fans may stop intermittently.

ERROR

The LED lamps operate as follows (Table 9) according to the error contents.

Table 9

Error contents LED1 LED2 LED3 LED4 LED5 LED6

Signal abnormal

Indoor unit abnormal

Discharge pipe

temperature abnormal

Outdoor heat exchanger

temperature abnormal

Outdoor temperature

abnormal

Power sorce connection

error

EEPROM abnormal

Outdoor high pressure

abnormal

Discharge pipe

temperature abnormal

: 0.5s ON/0.5s OFF (flash) : OFF

: 0.1s ON/0.1s OFF (flash) : Indefinite

When the fault is cleared, the LED lamp goes off.

However, for discharge pipe temperature abnormal and high pressure

abnormal, the LED lamp lights continuously for 24 hours, as long as the

power is not turned off.

Fig. 46 ERROR LED DISPLAY LAYOUT

CN14

TEST

IC 1

LED3

LED6

LED2

LED5

LED1

LED4

6

POWER

WARNING

1 The rated voltage of this product is 380-415 V 3ø 50 Hz.

2 Before turning on verify that the voltage is within the

342 to 457 V range.

3 Always use a special branch circuit and install a spe-

cial receptacle to supply power to the air conditioner.

4 Use a special branch circuit breaker and receptacle

matched to the capacity of the air conditioner.

(Install in accordance with standard.)

5 Perform wiring work in accordance with standards so

that the air conditioner can be operated safely and positively.

6 Install a leakage special branch circuit breaker in ac-

cordance with the related laws and regulations and electric company standards.

CAUTION

When the voltage is low and the air conditioner is difficult

to start, contact the power company the voltage raised.

7

ELECTRICAL WIRING

WARNING

1 Before starting work, check that power is not being sup-

plied to the indoor and outdoor unit.

HOW TO CONNECT WIRING

TO THE TERMINALS

A. For solid core wiring (or F-cable)

(1) Cut the wire end with a wire cutter or wire-cutting pliers, then strip

the insulation to about 25 mm (15/16”) to expose the solid wire.

(2) Using a screwdriver, remove the terminal screw(s) on the terminal

board.

(3) Using pliers, bend the solid wire to form a loop suitable for the

terminal screw.

(4) Shape the loop wire properly, place it on the terminal board and

tighten securely with the terminal screw using a screwdriver.

B. For strand wiring

(1) Cut the wire end with a wire cutter or wire-cutting pliers, then strip

the insulation to about 10 mm (3/8”) to expose the strand wiring.

(2) Using a screwdriver, remove the terminal screw(s) on the terminal

board.

(3) Using a round terminal fastener or pliers, securely clamp a round

terminal to each stripped wire end.

(4) Position the round terminal wire, and replace and tighten the ter-

minal screw using a screwdriver.

Fig. 36

A. Solid wire

Insulation

Strip 25 mm (15/16”)

Wire

Loop

Screw with

special washer

Round

terminal

Terminal

board

Wire

Terminal block

B. Strand wire

Strip 10 mm (3/8”)

Screw with

special washer

Round

terminal

Round

terminal

2. INDOOR UNIT SIDE

(1) Remove the control box cover and install each connection cord.

Fig. 38

Control box cover

Loosen the screws. (2 locations)

(2) After wiring is complete, clamp the remote controller cord, connection

cord and power supply cord with cord clamp.

(3) Attach the control box cover

Fig. 39

Remote controller cord

Connection cord

(To outdoor unit)

Cord clamp

3. OUTDOOR UNIT SIDE

(1) Remove the control box metal cover and install each connection cord.

Fig. 41

Control box metal cover

(2) After wiring is complete, clamp connection cord and power supply

cord with cord clamp.

(3) Attach the control box cover.

Fig. 42

Terminal board

Control box

metal

Cord clamp

Cable clip

2 Match the terminal board numbers and connection cord

colors with those of the outdoor unit.

Erroneous wiring may cause burning of the electric

parts.

3 Connect the connection cord firmly to the terminal

board. Imperfect installation may cause a fire.

4 Always fasten the outside covering of the connection

cord with the cord clamp. (If the insulator is chafed,

electric leakage may occur.)

5 Always connect the ground wire.

1. CONNECTIONS DIAGRAM

Fig. 37

Remote controller

Indoor unit

Red

White

Black

Ground

Outdoor unit

Power supply

3ø4W 380-415V

Ground

Power supply

3ø3W 380-415V

Power supply cord

Fig. 40

Red

Ground

White

Black

Remote controller

Connection cord

Outdoor unit

Power supply

CAUTION

1 Use care not to mistake the power supply and

connection wires when installing.

2 Install so that the wire for the remote controller will

not come in contact with other connection wires.

Insulation tube

Fig. 43

Connection cord

(indoor unit and outdoor

unit connection cord)

indoor unit

Power supply cord

Power supply

Ground

PART NO. 9365748039

Loading...

Loading...