Page 1

Owner's Manual

". | =*=

Generator

Wheel kit

Storage Cover

Batter)" charge cables

Spare Spark Plug,Air Filter, and Oil Filter

Spark PlugWrench

Locking20 Amp plug

Locking30 Amp plug

Engineoil

Owner's manual

Enginemanual

If any parts are missing or damaged, call 1-800-270-1408.

Questions? Help is just a moment away!

Call:Generac Generator Helpline - 1-800-270-1408 M-F 8-5 CT

Web: www.generac-portables.com or www.briggsandstratton.com

SafetyRules.................................... 2-3

Assembly...................................... 4-5

Know Your Generator ............................. 6

Operation .................................... 7-I I

Product Specifications............................. 12

Maintenance.................................... 12

Storage........................................ 12

Troubleshooting ................................. 13

Schematic...................................... 14

Wiring Diagram ................................. 15

Replacement Parts............................. {6-19

Warranty ................................. Last Page

Page 2

EQUIPMENT

DESCRIPTION

Read this manual carefully and become familiar

with your generator. Know its applications, its

limitations and any hazards involved.

Thisgenerator is an engine-driven, revolving field, alternating

current (AC) generator.It was designed to supply electrical

power for operating compatible electrical lighting,appliances,

tools andmotor loads.Thegenerator's revolvingfield is

driven at about 3,600 rpm by a single-cylinderengine.

WARNING

The engine exhaust from this product contains I

chemicals known to the State of California to cause

cancer, b rth defects, or other reproduct ve harm.

DANGER

CAUTION! Do Not exceed the generator's

wattage/amperage capacity.See"Don't Overload the

Generator" on page I I.

Everyeffort hasbeenmade to ensurethat information inthis

manualisaccurateand current However,Generac reserves

the right to change,alter or otherwise improvethe product

and this document at anytime without prior notice.

The EmissionControl Systemfor this generator iswarranted

for standardsset by the Environmental Protection Agency.For

warranty informationrefer to the engineowner's manual.

SAFETY RULES

The safety alert symbol (_k) isusedwith a signalword

(DANGER, CAUTION,WARNING), a pictorial and/or a

safety messageto alert you to hazards.DANGER indicates

a hazardwhich, ifnot avoided,will result in death or serious

injury. WARNING indicatesa hazard which, if not avoided,

couldresult in death or serious injury.CAUTION

indicatesa hazardwhich, ifnot avoided,might result in

minor or moderate injury.CAUTION, when used

without the alert symbol, indicates a situation that could

result in equipment damage.Follow safety messagesto

avoid or reduce the risk of injury or death.

Operate generator ONLY outdoors.

Keep at least 2 feet of clearance on all sidesof generator for

adequateventilation.

Do not operate generator insideany building or enclosure,

includingthe generator compartment of a recreational vehicle

(RV).

DANGER

National ElectricCode requires generator to be properly

grounded to an approved earth ground. Call an electrician for

local grounding requirements.

DANGER

When usinggenerator for backup power, notify utility

company.Use approved transfer equipment to isolate

generator from electric utility.

Use aground fault circuit interrupter (GFCI) in any damp or

highly conductive area,such as metal decking or steel work.

Do not touch bare wires or receptacles.

Do not usegenerator with electrical cords which are worn,

frayed,bare or otherwise damaged.

Do not operate generator in the rain.

Do not handle generator or electrical cords while standing in

water, while barefoot, or while handsor feet are wet.

Do not allow unqualified persons or children to operate or

service generator.

Page 3

, WARNING

, WARNING

WHEN ADDING FUEL

Turn generator OFF and let it cool at least2 minutes before

removing gascap.Loosen cap slowly to relievepressure in tank_

Fill fuel tank outdoors.

Do not overfill tank.Allow spacefor fuel expansion.

Keepgasoline away from sparks,open flames, pilot lights, heat,

and other ignition sources.

Do not light a cigarette or smoke.

NHEN OPERATING EQUIPMENT

Do not tip engine or equipment at anglewhich causes

gasoline to spill.

tHEN TRANSPORTING OR REPAIRING EQUIPMENT

Transport/repair with fuel tank EMPTY or with fuel shutoff

valve OFE

Disconnect spark plug wire.

NHEN STORING GASOLINE OR EQUIPMENT WITH

FUEL IN TANK

Store awayfrom furnaces,stoves,water heaters, clothes

dryers or other appliancesthat have pilot light or other

ignition source becausethey can ignite gasoline vapors.

Do not touch hot surfaces.

Allow equipment to cool before touching.

CAUTION

Do not tamper with governed speed.Generator supplies

correct rated frequency and voltage when running at governed

speed.

Do not modify generator in any way.

CAUTION

See"Don't Overload Your Generator" on page I h

Start generator and let engine stabilize before connecting

electrical loads.

Connect electrical loads in OFF position, then turn ON for

operation.

Turn electrical loads OFF and disconnect from generator

before stopping generator.

DANGER

Do not allow any openflame, spark, heat, or lit cigarette

during andfor several minutes after charging a battery.

Wear protective goggles,rubber apron, and rubber gloves.

CAUTION

Use generator only for intended uses.

tf you have questions about intended use,askdealer or

contact Generac.

Operate generator only on level surfaces.

Do not expose generator to excessive moisture, dust, dirt, or

corrosive vapors.

Do not insert any objects through cooling slots.

tf connected devices overheat, turn them off and disconnect

them from generaton

Shut off generator if.'

-electrical output is lost;

-equipment sparks,smokes,or emits flames;

-unit vibrates excessively.

Page 4

Your generator requires some assemblyand is ready for

use after it has been properly serviced with the

recommended oil and fuel.

If you have any problems with the assembly of your

generator, please call the generator helpline at

1-800-270-1408.

IMPORTANT: Any attempt to run the unit before it has

been serviced with the recommended oil wilt result in an

engine failure.

REMOVE G EN ERATOR

FROM CARTON

• Set the carton on a rigid flat surface with "This SideUp"

arrows pointing upward.

• Carefully open the top flaps of the shipping carton.

Review"Cold Weather Operation" on page9.

• Cut down corners at one end of carton from top to

bottom and laythat side of carton down flat.

• Remove all packing material, carton fillers, etc.

• Remove the generator from the shipping carton.

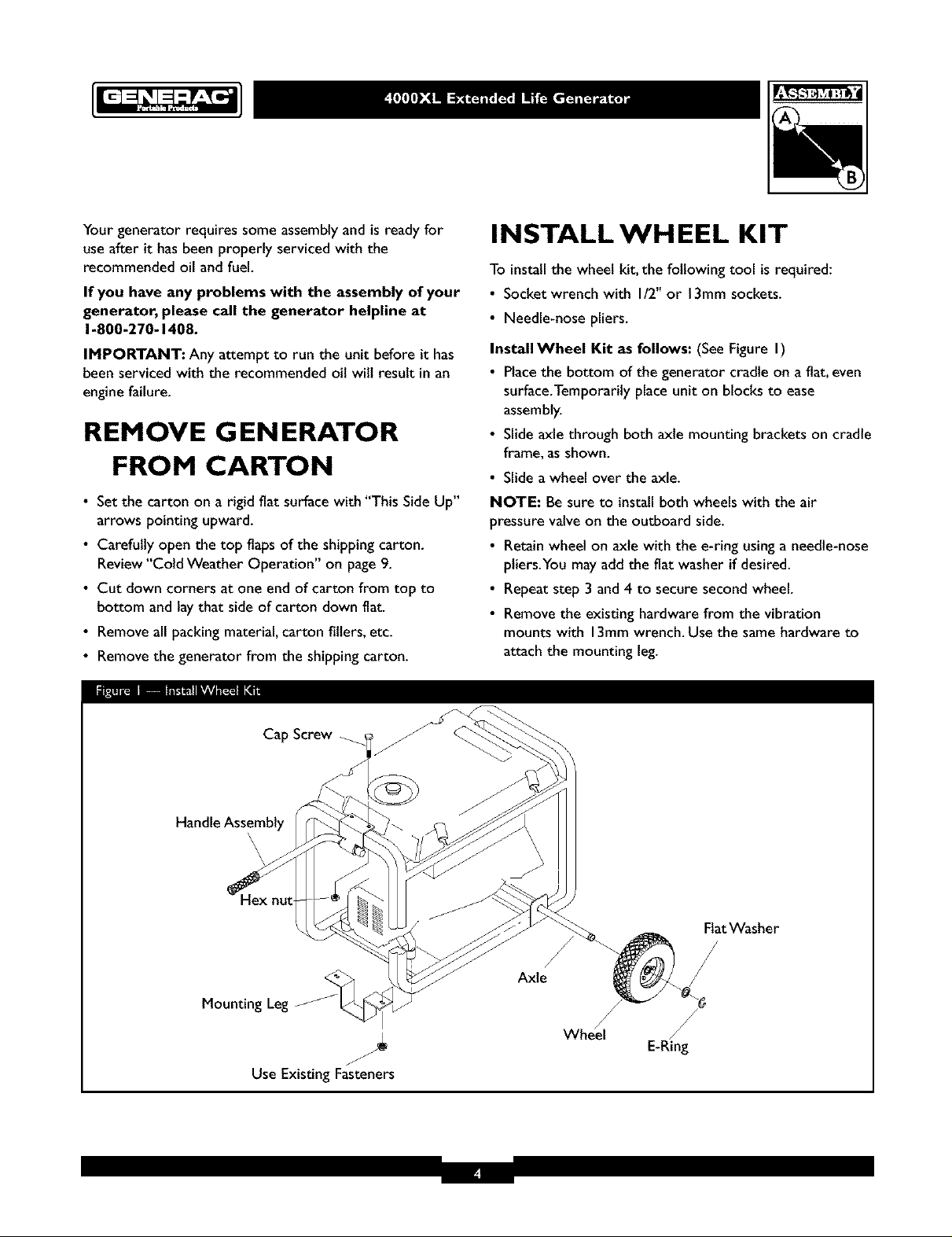

INSTALL WHEEL KIT

To installthe wheel kit, the following tool is required:

• Socket wrench with I/2" or 13mmsockets.

• Needle-nose pliers.

Install Wheel Kit as follows: (SeeFigure I)

• Placethe bottom of the generator cradle on a flat, even

surface.Temporarily place unit on blocks to ease

assembly.

• Slide axle through both axle mounting brackets on cradle

frame, as shown.

• Slide a wheel over the axle.

NOTE: Besure to installboth wheels with the air

pressure valve on the outboard side.

• Retain wheel on axle with the e-ring usinga needle-nose

pliers.You may add the fiat washer if desired.

• Repeat step 3 and 4 to secure second wheel.

• Remove the existing hardware from the vibration

mounts with 13mmwrench. Use the same hardware to

attach the mounting leg.

Cap Screw

Handle Assembly

\

\

\

Mounting Leg

Use Existing Fasteners

Axle

FlatWasher

/

/

E-Ring

Page 5

• Removethe temporary blocks.

• Center the handle bracket on generator frame at control

panel end of cradle.

• Attach handle bracket with two capscrews and two hex

nuts. Use two 13mm wrenches to tighten hardware.

• Check that all fasteners are tight andthe tires are

inflated between 15-40 PSI.

BEFORE STARTING THE

ENGINE

Add Oil

CAUTION! Any attempt to crank or start the engine

before it has been properly filled with the recommended

oil may result in an engine failure.

To fill your engine with oil:

• Place generator on a level surface.

• Follow the oil grade recommendations and oil fill

instructions given inthe engine owner's manual.

NOTE: The generator's revolving field rides on a

prelubricated and sealed ball bearing that requires no

additional lubrication for the life of the bearing.

Add Gasoline

_ ARNING! Never fill fuel tank indoors. Never

fill fuel tank when engine is running or hot.Allow

unit to cool for two minutes before refueling. Do

Not light a cigarette or smoke when filling the fuel

tank.

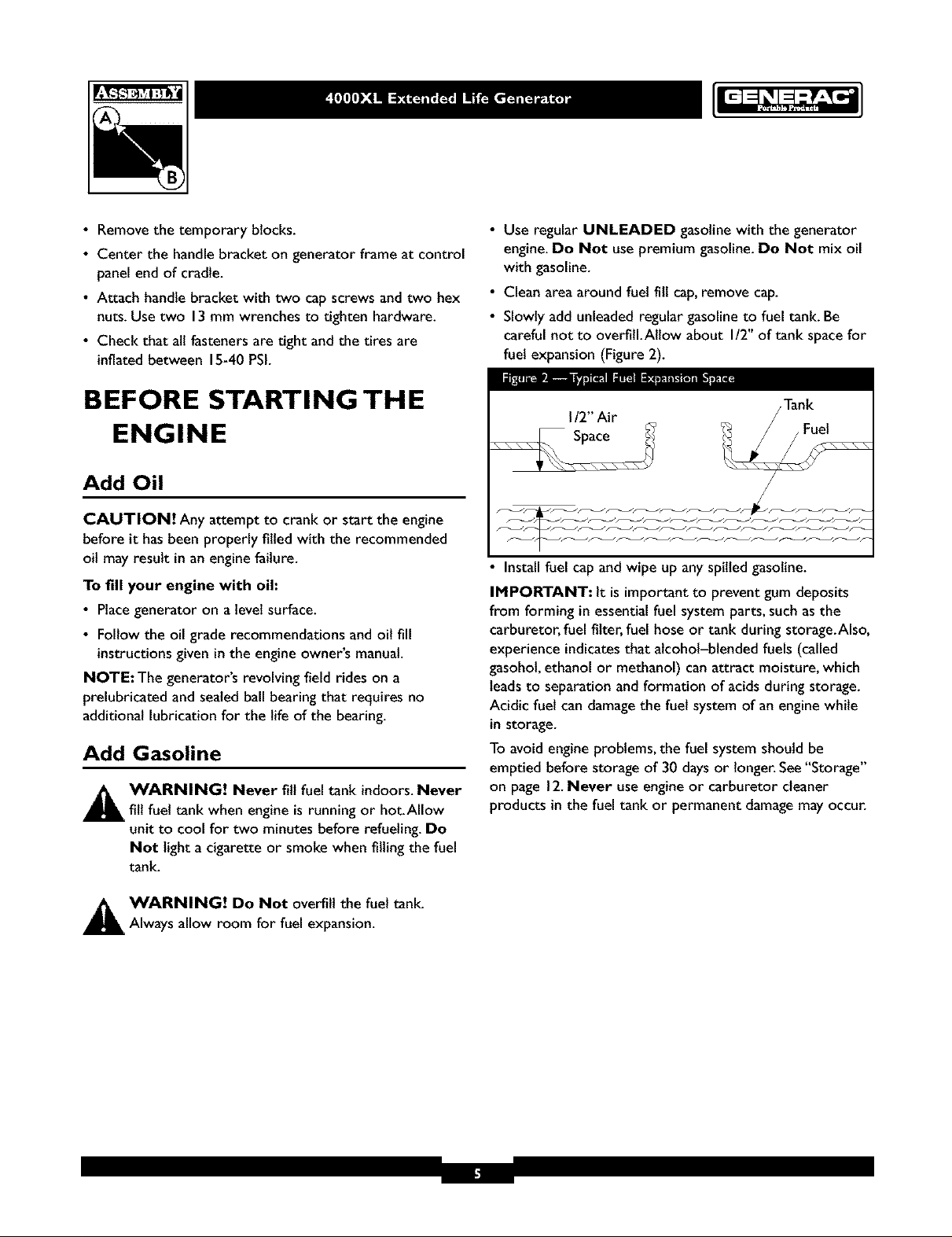

• Use regular UNLEADED gasolinewith the generator

engine.Do Not use premium gasoline. Do Not mix oil

with gasoline.

• Clean areaaround fuel fill cap,remove cap.

• Slowly add unleaded regular gasoline to fuel tank. Be

careful not to overfill.Allow about I/2" of tank spacefor

fuel expansion (Figure 2).

112" Air

Install fuel capand wipe up any spilled gasoline.

IMPORTANT: It is importantto prevent gum deposits

from forming in essentialfuel system parts,such asthe

carburetor,fuel filter,fuel hose or tank during storage.Also,

experience indicatesthat alcohol-blended fuels (called

gasohol,ethanol or methanol) canattract moisture, which

leadsto separation and formation of acids during storage.

Acidic fuel can damagethe fuel system of an enginewhile

in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 daysor longer.See"Storage"

on page 12.Never useengine or carburetor cleaner

products in the fuel tank or permanent damagemay occur.

,_ WARNING! Do Not overfill the fuel tank.

Always allow room for fuel expansion.

Page 6

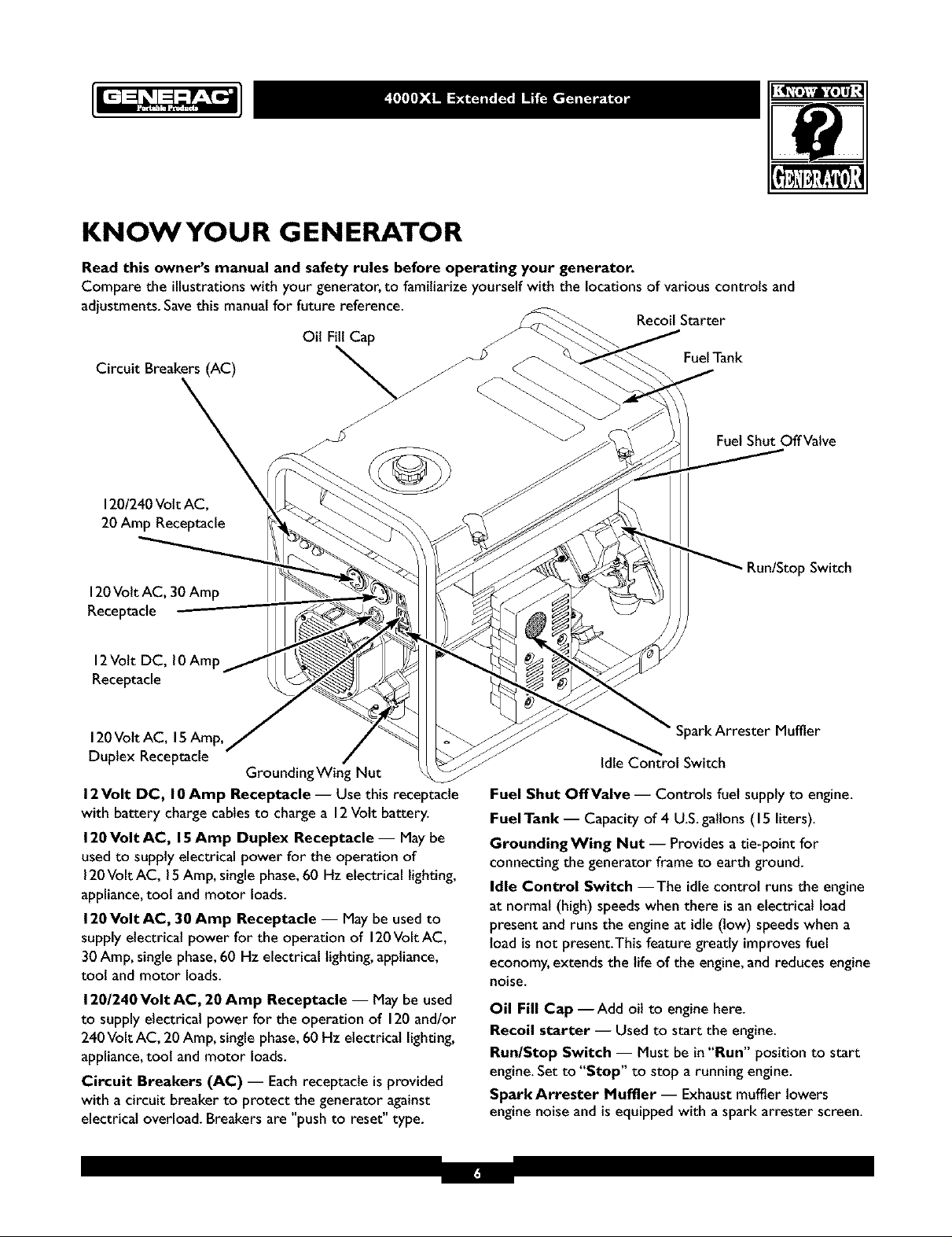

KNOWYOUR GENERATOR

Read this owner's manual and safety rules before operating your generator.

Compare the illustrations with your generator, to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

Oil Fill Cap

Circuit Breakers (AC) _ _-

1201240Volt AC,

20 Amp Receptacle

120Volt AC, 30 Amp

Receptacle

12Volt DC, 10Amp

Receptacle

Recoil Starter

FuelTank

Fuel Shut Off Valve

Run/Stop Switch

120Volt AC, 15Amp,

Duplex Receptacle

GroundingWing Nut

12Volt OC, 10Amp Receptacle- Use this receptacle

with battery charge cables to charge a 12Volt battery.

120Volt AC, 15Amp Duplex Receptacle -- May be

usedto supply electrical power for the operation of

120Volt AC, 15Amp, single phase,60 Hz electrical lighting,

appliance,tool and motor loads.

120Volt AC, 30 Amp Receptacle -- Maybe used to

supply electrical power for the operation of 120Volt AC,

30 Amp, singlephase,60 Hz electrical lighting,appliance,

tool and motor loads.

12012.40Volt AC, 20 Amp Receptacle -- May be used

to supply electrical power for the operation of 120and/or

240 Volt AC, 20 Amp, single phase,60 Hz electrical lighting,

appliance,toot and motor loads.

Circuit Breakers (AC) -- Eachreceptacle isprovided

with a circuit breaker to protect the generator against

electrical overload. Breakers are "push to reset" type.

SparkArrester Muffler

Idle Control Switch

Fuel Shut OffValve -- Controls fuel supply to engine.

Fuel Tank -- Capacity of 4 U.S.gallons (15 liters).

GroundingWing Nut -- Provides a tie-point for

connecting the generator frame to earth ground.

Idle Control Switch --The idlecontrol runs the engine

at normal (high) speeds when there is an electrical load

present and runs the engine at idle (low) speedswhen a

load is not present.This feature greatly improves fuel

economy,extends the life of the engine,and reduces engine

noise.

Oil Fill Cap --Add oil to engine here.

Recoil starter -- Used to start the engine.

Run/Stop Switch -- Must be in "Run" position to start

engine. Set to "Stop" to stop a running engine.

Spare Arrester Muffler -- Exhaust muffler lowers

engine noise and is equipped with a spark arrester screen.

Page 7

GROUNDING THE

GENERATOR

The National Electrical Code requires that the frame and

external electrically conductive parts of this generator be

properly connected to an approved earth ground. Local

electrical codes mayalso require proper grounding of the

unit. For that purpose, a GROUNDING WING NUT is

provided on the generator end (Figure 3).

Wing Nut

I. Turn the fuel valve to the "On" position (Figure 4).

FuelValve is shown in

the "On" position

2.

Make sure the Idle Control switch is in"Off" position

(Figure 5).

I_I_'_L:I_ [eL_l _"_a

IDLE

Generally, connecting a No. 12AWG (American Wire

Gauge) stranded copper wire to the grounding wing nut

and to an earth-driven copper or brass grounding rod

(electrode) provides adequate protection against electrical

shock. Becareful to keepthe grounding wire attached after

connecting the stranded copper wire. However, local codes

may vary widely. Consult with a local electrician for

grounding requirements in your area.

Properly grounding the generator helps prevent electrical

shock if aground fault condition exists in the generator or

in connected electrical devices,especiallywhen the unit is

equipped with a wheel kit. Proper grounding also helps

dissipate static electricity, which often builds up in

ungrounded devices.

OPERATING THE

GENERATOR

_ CAUTION! Never start or stop unit withelectrical loads connected AND with the connected

devicesturned ON.

Starting the Engine

Disconnect all electrical loads from the generator. Follow

these start instruction steps in numerical order:

.

Setthe Run/Stop switch to "Run" position (Figure 6).

4.

Placethe choke lever in the "Full" choke position

(Figure7).

"Full" choke

Position

Page 8

S.

Grasp the recoil handle and pull slowly until slight

resistance is felt.Then pull rapidly one time only to

start engine.

• If engine starts, proceed to step 7.

• If engine fails to start, proceed to step 6.

6.

Move the choke lever to "Half" choke position, and

pull recoil handle twice.

• If engine fails to start, repeat steps 4 thru 6.

7. Move choke leverto "Run" position. If engine falters,

move choke leverto "Half" choke position until the

engine runs smoothly and then to "Run" position.

NOTE: If engine still fails to start after 3 pulls,check for

proper oll level in crankcase.This unit is equipped with a

Low Oit Shutdown System.Seeenginemanual.

Refer to the engine owner's manual for complete

starting instructions.

Connecting Electrical Loads

• Let engine stabilize and warm up for a few minutes after

starting.

• Plugin and turn on the desired 120and/or 240 VottAC,

single phase,60 Hz electrical loads.

• Do Not connect 240Volt loads to the 120Volt

receptacles.

• Do Not connect 3_hase loadsto the generator.

• Do Not connect 50 Hz loads to the generator.

• DO NOT OVERLOADTHE GENERATOR. See

"Don't Overload the Generator" on page I I.

Stopping the Engine

• Unplug all electrical loads from generator panel

receptacles.Never start or stop engine with electrical

devices plugged in and turned on.

• Put the idle control switch in the "Off" position.

• Let engine run at no-load for 30 secondsto stabilize the

internal temperatures of engine and alternator.

• Move run/stop switch to "Stop".

• Close the fuel shut-off valve.

switch off, the engine will run at the normal high engine

speed. Always have the switch off when starting and

stopping the engine.

Charging a Battery

A ARNING! Storagebatteries giveoff explosive

hydrogengas while recharging.An explosive mixture

will remain around the battery for a long time after

it has been charged.The slightest spark can ignite

the hydrogen and causean explosion, resulting in

blindnessor other serious injury.

A WARNING! Do Not permit smoking, open

flame,sparksor anyothersourceofheatarounda

battery.Wear protective goggles,rubber apron and

rubber gloves when working around a battery.

Battery electrolyte fluidis an extremely caustic

sulfuric acid solution that can causesevere burns. If

spill occurs flush areawith clear water immediately.

Your generator has the capability of recharging a discharged

12Volt automotive or utility style storage battery. Do Not

usethe unit to charge any6Volt batteries. Do Not use the

unit to crank an enginehaving a discharged battery.

To recharge 12Volt batteries, proceed as follows:

• Check fluidlevel in all battery cells. If necessary,add

ONLY distilled water to cover separators in battery cells.

Do Not use tap water.

• If the battery isequipped with vent caps,make sure they

are installed and are tight.

• If necessary,clean battery terminals.

• Connect battery charge cable connector plug to panel

receptacle identified by the words "12-VOLTS D.C".

• Connect battery charge cable clamp with red handle to

the positive (+) battery terminal (Figure8).

12VOLT D.C.

RECEPTACLE

Operating Automatic Idle Control

This switch isdesignedto greatly improve fuel economy.

When this switch is turned ON, the engine will only

run at its normal high governed engine speed when an

electrical load is connected.When an electrical load is

removed,the enginewill run at a reduced speed.With the

+

POS NEG

12VOLTBAl-I'ERY

I:|

Page 9

• Connect battery chargecableclamp with black handle

to the negative (-) battery terminal (Figure8).

• Start engine. Let the engine run while battery recharges.

• When battery hascharged,shut down engine

NOTE: Use an automotive hydrometer to test battery

state of charge and condition. Follow the hydrometer

manufacturer's instructions carefully.Generally,a battery is

considered to be at 100%state of chargewhen specific

gravity of its fluid (asmeasuredby hydrometer) is 1.260 or

higher.

COLD WEATH ER

OPERATION

Under certain weather conditions (temperaturesbelow

40°F [4°C] and a high dew point),your generator may

experience icingof the carburetor and/or the crankcase

breather system.

In an emergency,use the original shipping box asa

temporary shelter:

• Cut off all flaps.

• Cut out one of the longsidesof the box to expose

exhaust side of unit.Ensurea minimum of two feet

clearance between open side of box and nearest object.

• Cut appropriate slots to accessreceptacles of unit.

• Start unit, then place box over it.

IMPORTANT: Remove shelter when temperature is

above 40°F [4°C].

For a more permanent shelter,build a structure that will

enclose three sides and the top of the generator:

• Make sure entire muffler-side of generator is exposed.

Note that your generator may appear different from that

shown in Figure 9.

• Ensure a minimum of two feet clearance between open

side of box and nearest object.

• Face exposed end away from wind and elements.

• Enclosure should hold enough heat created by the

generator to prevent problems.

A CAUTION! Never run unit indoors.Do Not

enclose generator any more than shown.

RECEPTACLES

120 Volt AC, 15 Amp Receptacles

Eachof these outlets is protected againstoverload by

15Amp push-to-reset type circuit breakers (Figure 10).

Use each outlet to operate 120Volt, 60 Hz,single phase

loads requiring 1,800(I.8 kW) watts at 15Amps of current.

Page 10

120/240 Volt AC, 20 Amp Locking

Receptacle

Use a NEMA LI4-20 plug with this receptacle. Connect a

4-wire cord set rated for 250Volts at 20 Amps (or greater)

(Figure I I).You canuse the same4-wire cord if you plan to

run a 120Volt load.

4-Wire Cord Set

I

120 Volt AC, 30 Amp Locking

Receptacle

Use a NEMA L5-30 plug with this receptacle.Connect a

3-wire cord set rated for 125Volts AC at 30 Amps to the

plug (Figure 12).

pa_ Ip,(*]kv_aJr.,T *" . * :" ._ m

3-Wire Cord Set

i NEMA L5-30

Neutral

120V

' (Neutral)

Y (Hot) X (Hot)

NEMA L14-20

This receptacle powers 120/240Volt AC, 60 Hz,single

phaseloadsrequiring up to 2,400 watts of power at

20 Amps for 120Volts;4,000 watts of power (4.0 kW) at

16.7Amps for 240Volts.The outlet is protected by a

20 Amp push-to-reset circuit breaker.

_L CAUTION! Although this outlet israted for

240Volt 20Amp (up to 4,800 watts), the generator

is only rated for 4,000 watts. Powering loadsthat

exceed the wattage/amperage capacity of the

generator can damageit or causeserious injuries.

240 Volt loads powered through this outlet should

not exceed 16.7Amps of current draw.

Ground (Green)

Hot

Ground (Green)

Use this receptacle to operate 120Volt AC, 60 Hz, single

phaseloadsrequiring up to 3,600 watts (3.6 kW) of power

at 30Amps.The outlet is protected by a 30Amp

push-to-reset circuit breaker.

12 Volt DC, I 0 Amp Receptacle

This connector (identified by the legend"I2-VOLT D.C")

supplies 12Volts DC at I0Amps through battery charging

cablesfor recharging 12Volt batteries (Figure 13).See

"Charging a Battery" on page 8.

IIII Ip,iV_II[IIDI*ql[9]_ll; _tq

Page 11

DON'T OVERLOAD YOU R

GENERATOR

Capacity

You must make sure your generator can supply enough

rated (running) and surge (starting) watts for the items you

wilt power at the same time. Follow these simple steps:

I. Select the items you will power at the same time.

2. Total the rated (running) watts of these items.Thisis

the amount of power your generator must produce to

keep your items running.SeeFigure 14.

3. Estimate how many surge (starting) watts you will

need.Surge wattage isthe short burst of power

needed to start electric motor-driven tools or

appliancessuch asa circular saw or refrigerator.

Becausenot all motors start at the same time, total

surge watts can be estimated by adding only the

item(s) with the highest additional surge watts to the

total rated watts from step 2.

Example:

Tool or Appliance

Window Air

Conditioner

Refrigerator

Deep Freezer

Television

Light (75 Watts)

Total Rated (Running)Watts = 3075

Highest Additional SurgeWatts = 1800

Total Generator Output Required = 4875

Rated (Running)

Watts

1200

800

50O

500

75

3075 Total

Running Watts

Power Management

To prolong the life of your generator and attached devices,

it is important to take care when addingelectrical loads to

your generator.There should be nothing connected to the

generator outlets before starting it's engine.The correct

and safeway to managegenerator power is to sequentially

add loads as follows:

I. With nothingconnected to the generator, start the

engine asdescribed in this manual.

2. Plugin and turn on the first load,preferably the largest

load you have.

3. Permit the generator output to stabilize (engine runs

smoothly and attached device operates properly.

Additional Surge

(Starting)Watts

1800

1600

5O0

1800 Highest

SurgeWatts

4. Plug in and turn on the next load.

5. Again, permit the generator to stabilize.

6. Repeat steps 4 and 5for each additional load.

Never add more loadsthan the generator capacity.Take

specialcare to consider surgeloads in generator capacity,

asdescribed above.

Rated*

Tool or Appliance

Essentials

LightBulb - 75 watt

Deep Freezer

SumpPump

Refrigerator/Freezer - 18Cu. Ft.

Water Well Pump- I/3 HP

Heating/Cooling

Window AC - 10,000BTU

Window Fan

FurnaceFanBlower - I/2 HP

Kitchen

Microwave Oven - 1000Watt

Coffee Maker

Electric Stove - SingleElement

Hot Plate

Family Room

DVD/CD Player

VCR

Stereo Receiver

Color Television - 27"

Personal Computer w/I 7" monitor

Other

Security System

AM/FM Clock Radio

GarageDoor Opener - I/2 HP

Electric Water Heater - 40 Gallon

DIY/Job Site

Quartz Halogen Work Light

Airless Sprayer - I/3 HP

Reciprocatin_ Saw

Electric Drill - I/2 HP

Circular Saw - 7 I/4"

Miter Saw - I0"

Planer/Jointer - 6"

Table Saw/RadialArm Saw - I0"

Air Compressor - I-I/2 HP

*Wattages listed are approximate only. Check toot or

appliance for actual wattage.

(Running)

Watts

75

500

8O0

8O0

1000

12O0

3OO

8O0

1000

1500

1500

25O0

100

100

450

5o0

8o0

18o

3O0

480 520

40O0

1000

600 1200

960 960

1000 1000

1500 1500

1800 1800

1800 1800

2000 2000

2500 2500

Additional

Surge

(Starting)

Watts

500

1200

1600

20O0

1800

6O0

1300

Page 12

SPECIFICATIONS

Maximum SurgeWatts ................. 6,600 watts

Continuous Wattage Capacity ........... 4,000 watts

Power Factor .............................. 1.0

Rated Maximum Continuous AC Load Current:

At 120Volts ....................... 33.3Amps

At 240 Volts ....................... 16.7Amps

Phase................................. I-phase

Rated Frequency ....................... 60 Hertz

FuelTank Capacity................... 4 U.S.gallons

ShippingWeight ......................... 134 Ibs.

GENERAL MAINTENANCE

RECOMMENDATIONS

The Owner/Operator is responsible for making sure that

all periodic maintenance tasks are completed on a timely

basis;that all discrepanciesare corrected; and that the unit

is kept clean and properly stored. Never operate a

damaged or defective generator.

Engine Maintenance

Seeengine owner's manualfor instructions.

contact with used motor oil. Used motor oil has

_ AUTION! Avoid prolonged or repeated skin

been shown to cause skin cancer in certain

laboratory animals.Thoroughly wash exposed areas

with soap and water.

KEEPOUT OF REACH OF CHILDREN. DON'T

POLLUTE.CONSERVE RESOURCES.RETURN

USED OILTO COLLECTION CENTERS.

Generator Maintenance

Generator maintenanceconsists of keeping the unit clean

and dry. Operate and store the unit in a clean dry

environment where it will not be exposed to excessive

dust, dirt, moisture or any corrosive vapors.Cooling air

slots in the generator must not become clogged with

snow, leavesor anyother foreign material.

NOTE: Do Not use a garden hoseto clean generator.

Water can enter engine fuel system and causeproblems. In

addition, if water enters generator through cooling air slots,

some of the water will be retained in voids andcracks of

the rotor and stator winding insulation.Water and dirt

buildup on the generator internal windings will eventually

decreasethe insulation resistanceof these windings.

To Clean the Generator

• Use a damp cloth to wipe exterior surfaces clean.

• A soft bristle brush may be used to loosen caked on dirt

or oil.

• A vacuum cleaner may be used to pick up loose dirt and

debris.

• Low pressure air (not to exceed 25 psi) maybe used to

blow awaydirt. Inspect cooling air slots and opening on

generator.These openings must be kept clean and

unobstructed.

STO RAG E

The generator should be started at least once every seven

claysandallowed to run at least 30 minutes. If this cannot

be done and you must store the unit for more than

30 days,use the following guidelines to prepare it for

storage.

Generator Storage

• Clean the generator asoutlined in"ToClean the

Generator"

• Check that cooling air slots and openings on generator

are open and unobstructed.

_ CAUTION! Storage covers can be flammable.

Do Not place a storage cover over a hot

generator. Let the unit coot for a sufficient time

before placing the cover on the unit.

Engine Storage

See engine owner's manualfor instructions.

Other Storage Tips

• To prevent gum from forming in fuel system or on

essential carburetor parts, add fuel stabilizer into fuel

tank and fill with fresh gasoline. Run the unit for several

minutes to circulate the additive through the carburetor.

The unit and fuel can then be stored for up to

24 months. Fuel stabilizer can be purchased locally.

• Do Not store gasoline from one season to another

unless it has been treated as described above.

• Replace fuel container if it starts to rust. Rust and/or dirt

in fuel can cause problems if it's used with this unit.

• Store in clean and dry area.

Page 13

TROUBLESHOOTING

Problem

Cause

I. Circuit breaker isopen.

Engine is running, but

no AC output is

available.

Engine runs good but

bogs clown when loads

are connected.

2. Poor connection or defective cord set.

3. Connected device isbad.

4. Fault in generator.

I. Short circuit in a connected load.

2. Generator is overloaded.

3. Enginespeed istoo slow.

4. Shorted generator circuit.

4. Contact Generac service facility.

4. Contact Generac service facility.

I. Run/Stopswitch set to "Stop".

2. Dirty air cleaner.

3. Out of gasoline.

4. Stalegasoline.

4. Drain gastank and fill with fresh fuel.

5. Spark plug wire not connected to spark

plug.

6. Badspark plug.

Engine will not start; or

starts and runs rough.

7. Water in gasoline.

8. Overchoking.

8.

9. Low oil level.

10. Excessivelyrich fuel mixture.

I I. Intake valve stuck open or closed.

12. Enginehaslostcompression. 12.

I. Out of gasoline. I.

Engine shuts down 2. Low oil level. 2.

during operation. 3. Fault in engine. 3.

I. Loadistoo high. I.

Engine lacks power. 2. Dirty air filter. 2.

3. Engineneeds to be serviced. 3.

I. Choke isopened too soon. I.

Engine "hunts" or

falters. 2.

2. Carburetor isrunning too rich or too

lean.

Solution

I. Resetcircuit breaker.

2. Check and repair.

3. Connect another device that is ingood

condition.

I. Disconnect shorted electrical load.

2. See"Don't Overload the Generator"

on page I I.

3. Contact Generac Power Systems

servicefacility.

I. Setswitch to "Run".

2. Clean or replace air cleaner.

3. Fill fuel tank.

5. Connect wire to spark plug.

6.

Replacespark plug.

7.

Drain gastank; fill with fresh fuel.

Put choke lever to "Run" position.

9.

Fill crankcaseto proper level.

10.

Contact Generac Power Systems

servicefacility.

II.

Contact Generac Power Systems

servicefacility.

Contact Generac Power Systems

servicefacility.

Fillfuel tank.

Fill crankcaseto proper level.

Contact Generac Power Systems

servicefacility.

See"Don't Overload the Generator"

on page I I.

Replaceair filter.

Contact Generac Power Systems

servicefacility.

Move choke to halfway position till

engine runs smoothly.

Contact Generac Power Systems

servicefacility.

Page 14

SCHEMATIC

PO/_ER POWER

mH O'('d

>X

O/('d LO_

R

m H

D •

S D

G

A

E

S

O

N

A

SPARK

PLUG

ENG

IGNITION

BATTERY CHARGE

BRN BLK BRN

66 55 77

RED BLK

AUTO 13 55

3

o/

RED

Page 15

WIRING DIAGRAM

BLO

11

]FEEDBACK \

BATTERY

CHARGE

RECTIFIER

\

GATE

SIGNAL

pq

GRN

3 PIN

NUT ON ENGINE BLOCK

LOW OIL

PRE££URE

SWITCH

ENGINE CATHODE

RUN

SWITCH

LOW OIL

PRESSURE

LED

Page 16

EXPLODEDVIEW- MAIN UNIT

57

45 \

58

8

\

47 _

5

\

1 --t _t!

¢'

J_

J

SEE

DETAIL " Y

10

\

\

\

6

3O

23

14

/

16

DETAIL " Y "

@

24

\

59

61

\

65

62

.?

\

65

89

67

66

7o

Page 17

_r3

PARTS LIST- MAIN UNIT

Item Part # Qty

I A93199GS

2 A84021GS

3 NSP

4 66365GS

5 84141JGS

6 83540JGS

7 65791GS

8 96796GS

9 73054GS

10 86307GS 4

II 47480GS I

12 84508GS 2

13 B2153GS 4

14 83208GS I

15 B4986GS I

16 66476GS 2

17 89476GS I

18 70644GS I

19 84346GS 3

20 40976GS 2

21 83083GS I

22 83071GS I

23 81917GS I

24 77816GS I

25 SRV66825DGS I

26 85652GS 2

27 67989GS l0

28 20566GS I

29 84409GS I

30 74908GS 4

31 87116GS I

32 86308GS 4

33 65795GS I

34 66849AGS I

35 67022GS 2

36 84132GS I

Description

CRADLE

SUPPORT,Engine

ENGINE

HOUSING, EngineAdapter

ASSY,Rotor (Inctds Item 7)

ASSY,Stator

BEARING

WASHER

DECAL, Fuel Shut Off

SCREW

SCREW

MOUNT, Vibe

SCREW

BRACKET,Muffler

DECAL, Ground

SCREW

GASKET,Exhaust

SCREW

SCREW

SCREW

SCREEN,SparkArrest

MUFFLER

PIN,Roll

DECAL, Caution Hot Muffler

CARRIER,Rear Bearing

MOUNT, Vibe

NUT

DECAL, 1-800

SLEEVING,Flexo

SCREW

ASSY,Control Panel(see page 18)

BOLT

RECTIFIER,Battery Charge

SCREW

GROMMET,Rubber

ASSY,Drive Module Pwr Reg.

Item Part # Qty Description

37 66386GS I ASSY,Brush Holder

38 66849GS 2 SCREW

39 B4871GS I COVER, Bearing Carrier

40 189404GS 2 DECAL, Heat Shield

41 86494GS I SCREW,Wing

42 86292GS I SCREW

43 77395GS 4 NUT, Lock

44 83465GS 4 GROMMET,Tank

45 93826GS I DECAL, Operating Instructions

46 78831BGS 4 SCREW

47 80270GS VALVE,Tank

48 78299GS BUSHING, PtasticTank

49 85134GS GUAGE, Fuel

50 88325GS ASSY,Tank,Fuel

(IncludesItems 47 & 48)

51 J84042GS SHIELD,Heat

52 84687GS INSULATION

53 85000GS CLIP,Insulation

54 14353621GS WIRE, Ground

55 23762GS WASHER

56 26850GS 2 WASHER

57 92982GS DECAL, Danger

58 189405GS DECAL, Control Panel

59 BB3061GS BOTTLE,Oil

60 43483GS PLUG,250V 20 A 4-Prong

61 37806GS PLUG, 125V 30A 3-Prong

62 70185GS FILTER,Oil

63 78601GS CLEANER,Air

64 65787GS CABLE,Battery Charge

65 189383GS MANUAL, Owners

66 A8926GS MANUAL, Engine

67 84882GS WRENCH, Spark Plug

69 72347GS PLUG,Spark

70 84895GS COVER, Storage

Optional Accessories Not Included:

84883GS Cord Wrap

Page 18

_r3

EXPLODED VIEW AND PARTS LIST - CONTROL PANEL

14

2

f

1

'\ 7

\

\

\

\

8

18

17 F 24

19 \

12_

25.

Item Part # Qty

I 83976GS I

2 83975GS I

3 66818GS 2

4 66821GS

5 68867CGS

6 68868CGS

7 75207AGS

8 75207GGS 2

9 82538GS I

10 84134GS I

II 83514GS I

12 83970GS I

17

26

24 4

10

\ _ 9

\ 16 3

13

Description Item Part # Qty Description

PANEL,Control 13 84028GS I TRANSFORMER,Idle Control

BOX, Control 14 67022GS I GROMMET, Rubber

OUTLET, 120VAC, 15A Duplex 15 85584GS I BAR, Bus

OUTLET, 12V DC 16 84543AGS 2 SCREW

OUTLET, 120/240VAC, 20A 17 84543CGS 9 SCREW

Locking 18 84198GS 3 SHIELD,Circuit Breaker

OUTLET, 120VAC, 30A 19 84197GS I BAR, Circuit Breaker Retaining

Locking 21 75476GS 2 SCREW

BREAKER,Circuit 22 22264GS 4 WASHER,Lock

BREAKER,Circuit 23 51715GS 4 NUT

SWITCH, On/Off Rocker 24 84543BGS l0 SCREW

GROMMET,Rubber 25 84335GS I HARNESS,Wire

BREAKER,Circuit 26 82542GS I BAR, DC Outlet Retaining

CONTROL BOARD,System

Page 19

_rs

EXPLODED VIEWAND PARTS LIST-WHEEL KIT

'\

\

\

\

\

8

/

J

USE EXISTING FASTENERS

TB SECURE ITEM #2

Item Part # Qty Description

I 189715GS I ASSY,Handle

2 BI764GS I LEG,Mounting

3 52858GS 2 NUT, Locking

4 39287GS 2 SCREW

5 191267FGS I AXLE

6 B4966GS 2 WHEEL

7 191265GS 2 E-RING

8 22247GS 2 WASHER

/

_c

6

Page 20

LIMITED WARRANTY

GENERAC PORTABLE PRODUCTS OWNERWARRANTY POLICY Effective October I, 2001

LIMITED WARRANTY

"Generac Portable Products,LLC will repair or replace,free of charge,any part, or parts of the equipment that are defectivein material or

workmanship or both.Transportation charges on parts submitted for repair or replacement under this Warranty must be borne by purchaser.

This warranty is effective for the time periods and subject to the conditions provided for in this policy. For warranty service, find the nearest

Authorized Service Dealer in our dealer Iocator map at www.generac-portables.com or call 1-877-544-0982.THERE ISNO OTHER EXPRESS

WARRANT'_I IMPLIEDWARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESSFORA PARTICULAR PURPOSE,ARE

LIMITED TO THE TIME PERIOD SPECIFIED,OR TO THE EXTENT PERMITTED BY LAW ANY AND ALL IMPLIEDWARRANTIES ARE

EXCLUDED. LIABILITY FOR CONSEQUENTIAL DAMAGES UNDER ANY AND ALL WARRANTIES ARE EXCLUDED TO THE EXTENT

EXCLUSION IS PERMITTED BY LAW. Some states do not allow limitationson how long an impliedwarranty lasts,and some states do not

allow the exclusion or limitationof incidental or consequential damages,so the above limitation and exclusion may not apply to you.This

warranty gives you specific legal rights and you mayalso have other rights which vary from state to state and country to country."

WARRANTY PERIOD*

PRODUCTS**

Portable Generator

SideValve EnginePowered)

Portable Generator

(Overhead Valve EnginePowered)

Electric Powered PressureWasher

Gasoline Powered PressureWasher

*The warranty period beginson the date of purchaseby the first retail consumer or commercial end user,and continues for the period of time

stated in the table above. "Consumer use" meanspersonal residential household use by a retail consumer. "Commercialuse" means all other uses,

includingusefor commercial, income producing or rental purposes. Once equipment hasbeen used commercially, it shall thereafter be considered

to be in commercial usefor purposes of this warranty. Used equipment, demonstration equipment and equipment used for prime power in place

of a utility are not warranted.Accessory parts such as guns,hoses, wands and nozzles are excluded from the product warranty.

** The gasoline engine and starting batteries are warranted solely by the manufacturers of those products.

WARRANTY REGISTRATION IS NOT NECESSARYTO OBTAINWARRANTY ON GENERAC PORTABLE PRODUCTS

EQUIPMENT. SAVEYOUR PROOF OF PURCHASE RECEIPT. IFYOU DO NOT PROVIDE PROOF OFTHE INITIAL

PURCHASE DATE ATTHETIME WARRANTY SERVICE IS REQUESTED, THE MANUFACTURING DATE OFTHE

EQUIPMENTWILL BE USEDTO DETERMINE THE WARRANTY PERIOD.

CONSUMER USE

I year

2 years

(2rid year parts only)

I year

I year

COMMERCIAL USE

90 days

I year

None

90 days

About your equipment warranty:

Generac PortableProductswelcomeswarranty repair and apologizesto you for being inconvenienced.AnyAuthorized ServiceDealer mayperform

warranty repairs.Most warranty repairs are handled routinely,but sometimes requestsfor warranty service may not be appropriate. For example,

warranty would not apply if equipment damageoccurred becauseof misuse,lackof routine maintenance,shipping,handling,warehousing or improper

installation.Similarly,warranty isvoid if the serial number of the equipment hasbeen removed or the equipment hasbeen altered or modified.

if a customer differs with the decision of the Service Dealer, an investigationwill be made to determine whether the warranty applies.Ask the

Service Dealer to submit all supporting facts to its Distributor for review. If the Distributor decides that the claim isjustified, the customer will be

fully reimbursed for those items that are defective.To avoid misunderstandings that might occur between the customer and the Dealer, listed

below are some of the causes of equipment failure that the warranty does not cover:

Normal wear:

Outdoor Power Equipment,likeall mechanical devices,needs periodic parts,service and replacement to perform well.This warranty

does not cover repair when normal use has exhausted the life of a part or the equipment.

Installation and Maintenance:

This warranty does not apply to equipment or parts that havebeen subiected to improperor unauthorizedinstallationor alteration,

misuse,negligence,accident, overloading,overspeeding, improper maintenance, repair or storage so as, in Generac Portable Products'

judgment, to adversely affect its performance and reliability.This warranty alsodoes not cover normal maintenance such as adiustments,

fuel system cleaningand obstruction (due to chemical,dirt, carbon or lime, etc.).

Other Exclusions:

Also excluded from this warranty are wear items such asquick couplers, oil gauges,belts,o-rings, filters,pump packing,etc., pumps

which havebeen run without water supplied or damageor malfunctions resulting from accidents,abuse,modifications, alterations, or

improper servicing or freezing or chemical deterioration.

Warranty is available only through service dealers authorized by Generac Portable Products.This warranty does not apply to

service by any other entity.

You may locate your nearest Authorized Generac Portable Product Service Dealer in our dealer Iocator map at

www.generac-portables.com or call 1-877-544-0982.

Generac Portable ProductsAre Made Under One Or More Of The FollowingPatents: (Other PatentsPending)

5902094 5823752 5718255 5890413

Generac Portable Products, LLC

Jefferson,Wisconsin U.S.A.

Loading...

Loading...