Page 1

imagination at work

GE Energy

™

Arc Vault

Installation, Operation, Maintenance

Protection System

Page 2

Arc Vault™ Protection System DEH-41483 Rev. 3

© 2011 General Electric All Rights Reserved

Page 3

DEH-41483 Rev. 3 Arc Vault™ Protection System

HAZARD CATEGORIES

The following important highlighted information appears

throughout this document to warn of potential hazards or

to call attention to information that clarifies a procedure.

Carefully read all instructions and become familiar with

the devices before trying to install, operate, service or

maintain this equipment.

DANGER

Indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates that if the hazard is not avoided could result in

minor or moderate injury.

TRADEMARKS

Arc Vault™ Protection System

WARRANTY

This document is based on information available at the

time of its publication. While efforts have been made to

ensure accuracy, the information contained herein does

not cover all details or variations in hardware and

software, nor does it provide for every possible

contingency in connection with installation, operation,

and maintenance. Features may be described herein that

are not present in all hardware and software systems. GE

Industrial Solutions assumes no obligation of notice to

holders of this document with respect to changes

subsequently made. GE Industrial Solutions makes no

representation or warranty, expressed, implied, or

statutory, with respect to, and assumes no responsibility

for the accuracy, completeness, sufficiency, or usefulness

of the information contained herein. No warrantees of

merchantability or fitness for purpose shall apply.

Contact your local sales office if further information is

required concerning any aspect of Arc Vault™ operation

or maintenance.

Contact your local sales office if further information is

required concerning any aspect of Arc Vault™ operation

or maintenance.

NOTICE

Is used to notify of practices not related to personal

injury.

© 2011 General Electric All Rights Reserved iii

Page 4

Arc Vault™ Protection System DEH-41483 Rev. 3

Table of Contents

iv © 2011 General Electric All Rights Reserved

Page 5

DEH-41483 Rev. 3 Arc Vault™ Protection System

Table of Contents

TABLE OF CONTENTS

SECTION 1. Introduction.........................................................................................................................................................................................................1

General Information ....................................................................................................................................................................................................................1

Related publications....................................................................................................................................................................................................................1

SECTION 2. Receiving, Handling and Storage..............................................................................................................................................................2

Receiving...........................................................................................................................................................................................................................................2

Equipment packages.................................................................................................................................................2

Inspecting for Damage ..............................................................................................................................................2

Filing a Claim.............................................................................................................................................................2

Handling............................................................................................................................................................................................................................................2

Lifting.........................................................................................................................................................................2

Rollers .......................................................................................................................................................................3

Forklifts......................................................................................................................................................................3

Jacks .........................................................................................................................................................................5

Storage...............................................................................................................................................................................................................................................5

Switchgear.................................................................................................................................................................5

SECTION 3. Description...........................................................................................................................................................................................................7

General...............................................................................................................................................................................................................................................7

Summary Description.................................................................................................................................................................................................................7

Compartment Areas....................................................................................................................................................................................................................8

Arc Vault compartment .............................................................................................................................................................................................................8

Feeder Cable Compartment....................................................................................................................................13

Cable lugs - mechanical type..................................................................................................................................13

Ground Bus ...................................................................................................................................................................................................................................13

SECTION 4. Equipment Installation ................................................................................................................................................................................15

General............................................................................................................................................................................................................................................15

Site Location............................................................................................................................................................15

Foundation Requirements.......................................................................................................................................15

Foundation Preparation...........................................................................................................................................15

Assembly and Installation of Switchgear Equipment...............................................................................................................................................17

General Requirements............................................................................................................................................17

Detailed Assembly and Installation Instructions (indoor) ........................................................................................17

Anchoring Switchgear Equipment Indoors.................................................................................................................................................................... 20

Anchoring By Anchor Bolts......................................................................................................................................20

Anchoring By Weld..................................................................................................................................................20

Control Wire Connections .......................................................................................................................................21

Power Cable Connections.......................................................................................................................................21

Relays and Control Devices....................................................................................................................................22

SECTION 5. Installing and Removing The Arc Vault Device................................................................................................................................23

General............................................................................................................................................................................................................................................23

Inspection and Preparation of Arc Vault..................................................................................................................23

Arc Vault Installation................................................................................................................................................23

Rejection Feature....................................................................................................................................................23

© 2011 General Electric All Rights Reserved v

Page 6

Arc Vault™ Protection System DEH-41483 Rev. 3

Table of Contents

Installing Arc Vault Device .....................................................................................................................................................................................................23

Pre-Installation precautions .................................................................................................................................... 23

Installation Procedures ........................................................................................................................................... 23

SECTION 6. Testing and inspection................................................................................................................................................................................25

General............................................................................................................................................................................................................................................25

Key Interlocks ..............................................................................................................................................................................................................................25

Test......................................................................................................................................................................... 25

Arc Vault Relay............................................................................................................................................................................................................................26

Final Steps to Be Taken Before Energizing Equipment.............................................................................................................................................26

SECTION 7. Operation...........................................................................................................................................................................................................27

Arc Vault device Operation....................................................................................................................................................................................................27

Arc Vault Drawout Operation...............................................................................................................................................................................................27

Arc Vault Positions..................................................................................................................................................27

Drawout Operation..................................................................................................................................................27

Front Doors ...................................................................................................................................................................................................................................27

Operation ................................................................................................................................................................ 27

Door Removal......................................................................................................................................................... 27

Door Installation...................................................................................................................................................... 28

Arc Vault Equipment Accessories.......................................................................................................................................................................................28

Arc Vault Key Interlock............................................................................................................................................ 28

Key Interlock Operation Check............................................................................................................................... 28

Padlocking the Cassette Racking Door.................................................................................................................. 29

Padlocking the Arc Vault Cassette ......................................................................................................................... 29

Padlocking the Shutter............................................................................................................................................29

Removing Shutter Units (on a de-engergized cubicle)........................................................................................... 30

Installing a Shutter Unit (in a de-energized cubicle)............................................................................................... 30

SECTION 8. Initial Test and Activation...........................................................................................................................................................................31

Making Arc Vault Ready to Test..........................................................................................................................................................................................31

Device Test Procedure.............................................................................................................................................................................................................32

Arc Vault Relay Controller Setup.........................................................................................................................................................................................33

Verify Primary Circuit Current and Voltage...................................................................................................................................................................33

Arc Vault System Activation Procedure ..........................................................................................................................................................................33

SECTION 9. Energizing the Switchgear.........................................................................................................................................................................34

Before energizing.......................................................................................................................................................................................................................34

Uninterruptable Power Supply................................................................................................................................ 34

Potential Transformer Fuse Block FB1.............................................................................................................................................................................34

Energizing Procedures.............................................................................................................................................................................................................34

SECTION 10. Post Event Procedure...................................................................................................................................................................................35

SECTION 11. Maintaining the Switchgear......................................................................................................................................................................36

Maintenance Requirements..................................................................................................................................................................................................36

Device and Instrument Compartments...........................................................................................................................................................................36

Maintenance of Arc Vault Device .......................................................................................................................................................................................36

Arc Vault Device: Test for Proper Operation .......................................................................................................... 36

Checks After Switchgear Is De-energized.............................................................................................................. 36

vi © 2011 General Electric All Rights Reserved

Page 7

DEH-41483 Rev. 3 Arc Vault™ Protection System

Table of Contents

Lubrication...............................................................................................................................................................36

Instruments, Instrument Transformers, and Relays................................................................................................37

Arc Vault Compartment Interiors ............................................................................................................................37

Bus Area .........................................................................................................................................................................................................................................37

Cable Compartment.................................................................................................................................................................................................................37

Overall equipment.....................................................................................................................................................................................................................38

Paint Refinishing.........................................................................................................................................................................................................................38

Arc Vault Lifting Mechanism pt # GAVLD1..................................................................................................................................................................... 38

SECTION 12. Troubleshooting .............................................................................................................................................................................................39

APPENDIX A. Torque Values..................................................................................................................................................................................................40

© 2011 General Electric All Rights Reserved vii

Page 8

Arc Vault™ Protection System DEH-41483 Rev. 3

Table of Contents

viii © 2011 General Electric All Rights Reserved

Page 9

DEH-41483 Rev. 3 Arc Vault™ Protection System

Introduction

SECTION 1. INTRODUCTION

GENERAL INFORMATION

This manual contains procedures for receiving, handling,

storage, equipment installation, operation, and

maintenance and service of Low Voltage Switchgear with

Arc Vault™ Protection System.

• Summary of switchgear equipment which is a list of

all the components furnished with the switchgear,

including the breakers, identified by catalog

number.

These are all the documents necessary to install, operate,

and maintain the equipment. One complete set of

drawings and instruction books is shipped with the

equipment.

NOTICE

The personnel responsible for installing, operating,

and servicing this equipment should be thoroughly

familiar with the contents of this manual.

Before any installation work is performed, thoroughly

read and understand the material in this instruction

manual and the drawings furnished with the equipment.

The documentation shipped with the equipment includes

the Summary, Front View, Elementary Diagram,

Connection Diagram and Instruction Book. This material

is located in a forward compartment tagged

"INSTRUCTIONS IN THIS COMPARTMENT." The

documentation provides all of the information necessary

for installation of the switchgear. When requesting

information from the General Electric Company, include

the complete data appearing on the equipment

nameplate, requisition number, summary number, and

elementary diagram number. The nameplate is located in

the lower left, front corner of the lineup.

When requesting information concerning any specific

item furnished with the switchgear, refer to that item by

description, part number, its location within this manual,

and any applicable drawing number. Any material

external to the equipment, which may be required to

meet local codes (such as mats, screens, railings, etc.), is

not furnished by the General Electric Company.

If there are any questions or requirements not covered in

this manual or in the accompanying drawings, please

contact the local sales office of the General Electric

Company.

RELATED PUBLICATIONS

In addition to instruction books, the following drawings

will be supplied as required for each order of Arc Vault

equipment:

• General arrangement drawings, including front view

and floor plan.

• Elementary and connection drawings (or wiring

routing tables) which indicate and identify test and

connection points including terminal blocks, device

studs, switch contact developments, and remote

connections.

© 2011 General Electric All Rights Reserved 1

Page 10

Arc Vault™ Protection System DEH-41483 Rev. 3

Receiving, Handling and Storage

SECTION 2. RECEIVING, HANDLING AND

STORAGE

RECEIVING

Equipment packages

Every package leaving the factory is plainly marked with

the case number, requisition number, and customer's

order number. If the equipment has been split for

shipment, the section numbers of the equipment

enclosed in each shipping package are identified.

NOTICE

To avoid the loss of any parts when unpacking, the

contents of each container should be carefully

checked against the packing list before discarding the

packing material.

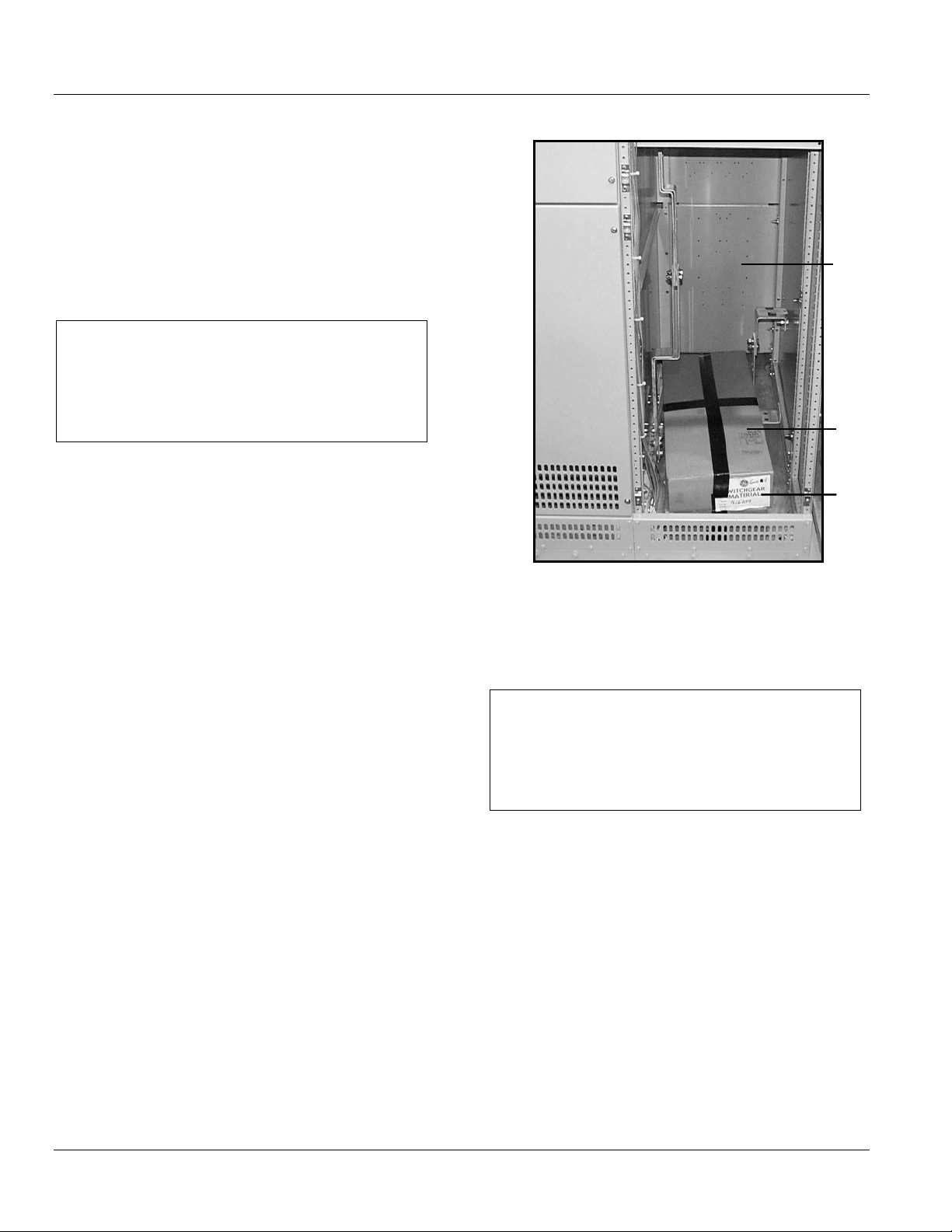

The contents of each shipping package are listed on the

Master Packing List. In addition, this list includes the

number of the shipping crate in which miscellaneous

parts needed to install and operate the equipment (such

as hardware, contact lubricant, touch-up paint, breaker

closing devices, etc.) are located. Normally, such devices

are packed in a cardboard carton and the carton secured

in an empty switchgear compartment. See Figure 2-1. If

such items are packed in a switchgear section instead of

a separate crate, the list will indicate the appropriate

section number in which they are stored.

Figure 2-1 Packaging of loose material for shipment

1

2

3

1-Spare compartment

2-Carton containing loose material

3-Shipping label listing contents of carton

Inspecting for Damage

All equipment leaving the factory is carefully inspected

and packed by personnel experienced in the proper

handling and packing of electrical equipment. Upon

receipt of any equipment, immediately perform a visual

inspection to ascertain if any damage has been

sustained in shipping or if there are any loose parts.

Circuit breakers and Arc Vaults may be shipped

separately in individual containers with the breaker in the

open position. Circuit breakers and Arc Vaults should be

unpacked and visually inspected for damage or loose

parts as soon as possible after they have been received.

Be sure to inspect all devices mounted or packed inside

compartments of each section to see if any have been

dislodged or damaged.

Filing a Claim

If any damage is evident, or indication of rough handling

is visible, file a claim for damage at once with the

transportation company and notify the nearest General

Electric Company Sales Office immediately. Information

on damaged parts, part number, case number,

requisition number, etc., should accompany the claim.

HANDLING

NOTICE

It is preferable to leave the shipping skids in place

under the switchgear until it reaches its final location.

The equipment should be installed in its final location

prior to installing the circuit breakers.

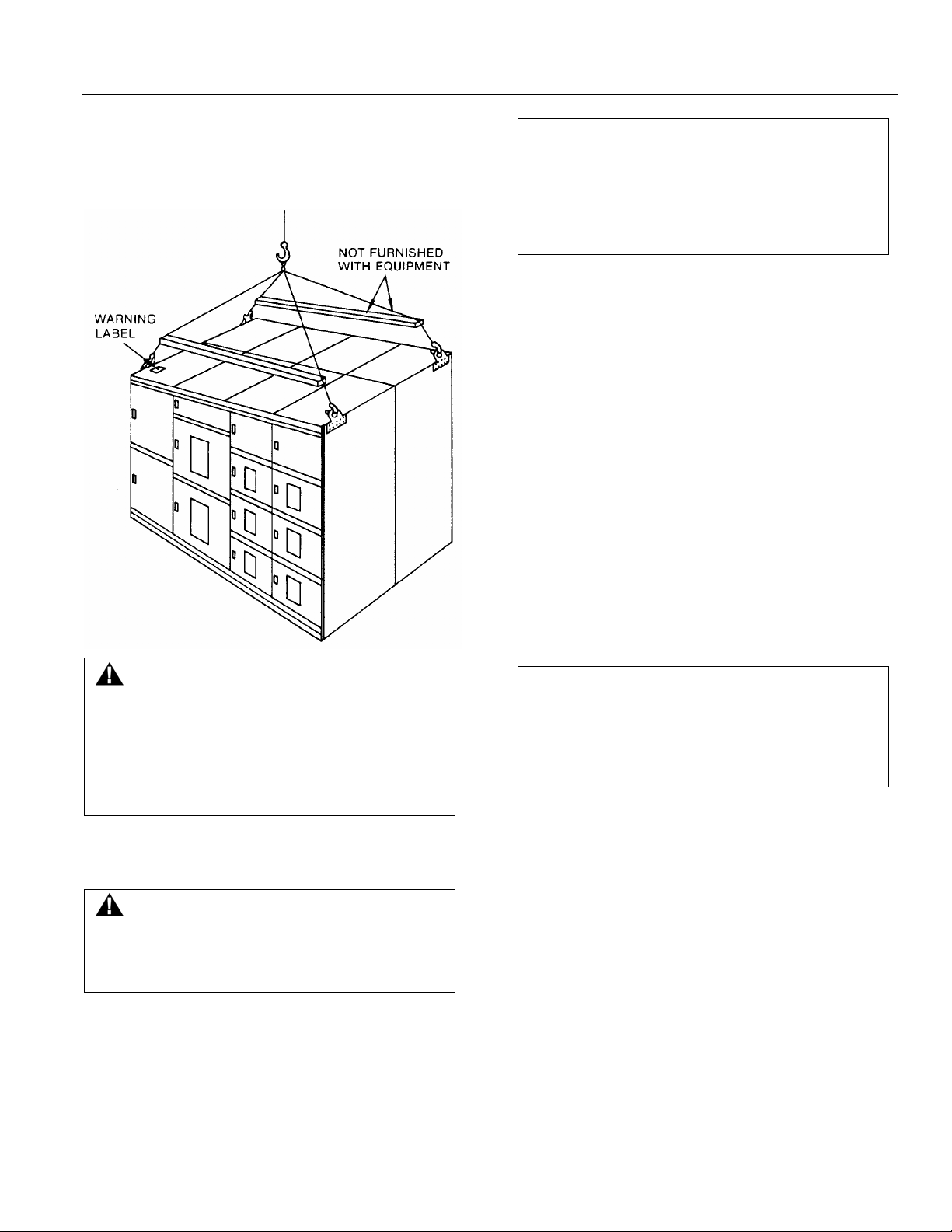

Lifting

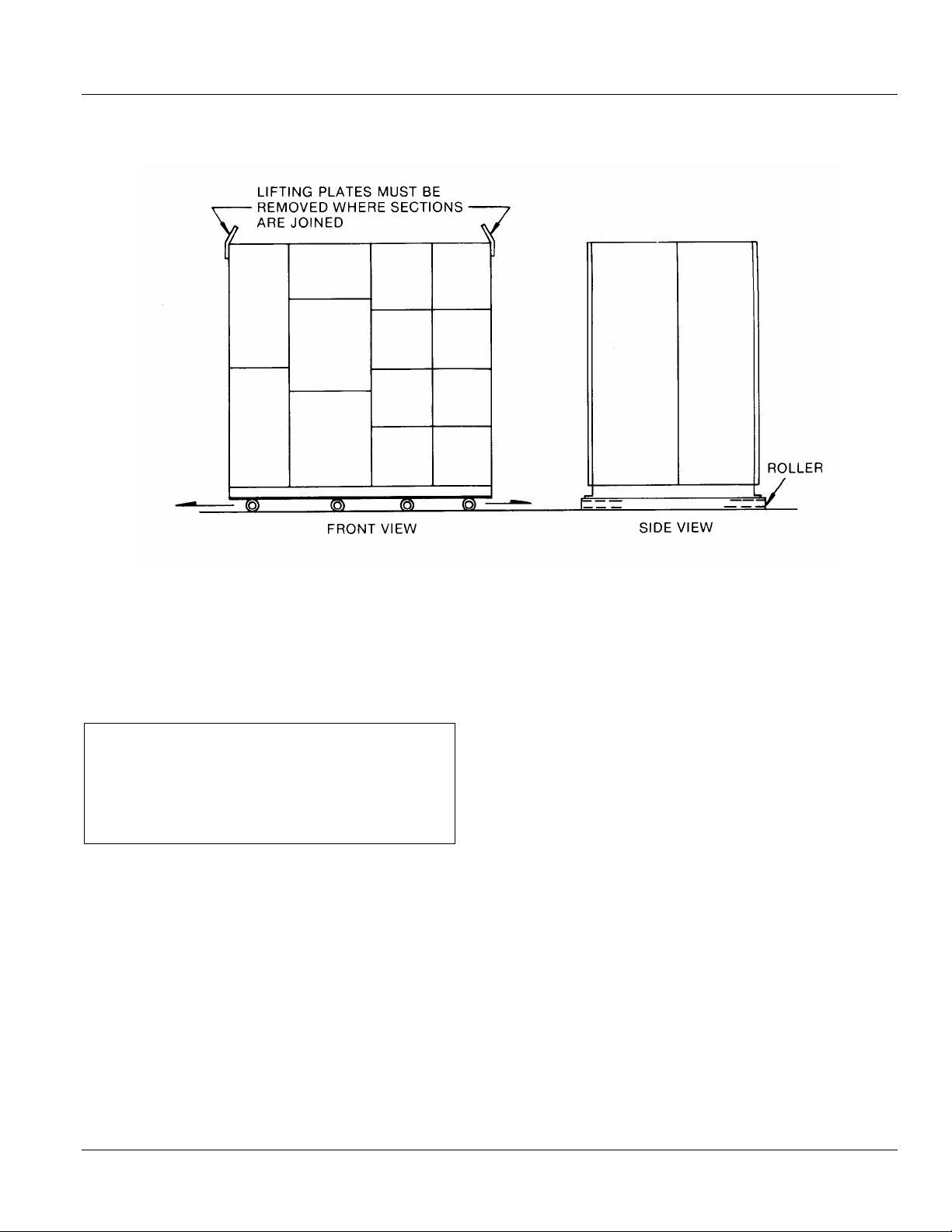

The indoor switchgear sections are best handled by lifting

with a crane as shown in Figure 2-2. Removable lifting

plates are provided, as standard equipment, on the top of

each switchgear section. To preserve the external

appearance of the equipment, it is suggested that the

lifting plates be left in place except where adjacent

equipments must be bolted together, i.e. shipping splits,

etc.

Utilize four equal length cables and an overhead crane,

each with a minimum load rating of twice the weight of

the Switchgear. Estimated weights for shipping splits

appear on the Front View drawings.

2 © 2011 General Electric All Rights Reserved

Page 11

DEH-41483 Rev. 3 Arc Vault™ Protection System

Receiving, Handling and Storage

Example: Switchgear Section Weight = 2,000 pounds. The

crane and the four lift cables must have a minimum load

lifting capacity of 4,000 pounds.

Figure 2-2 Recommended lifting method

CAUTION

Gently lower the switchgear section onto the level site

location. If the switchgear is roughly handled or

jarred, it is possible to damage or misalign internal

components.

Rollers

If crane facilities are not available, the equipment may be

moved into position by means of construction rollers

placed under the shipping skids. The switchgear may be

raised enough for the placement of rollers by means of a

fork lift or jack.

There should never be less than four rollers under the

equipment unless the line-up is less than five feet long.

Use one roller for each 18 inches of equipment length.

Forklifts

WARNING

The angle between the cables and the top of the

equipment must be at least 45 degrees. If this is not

possible because of lack of headspace, spreader bars

must be used. Also, lift cables with greater load

capability may be necessary, depending upon the

angle between the cables and the crane hook.

Connect a cable from the crane to the four lifting plates

located on the top-front and rear of the indoor

switchgear. See Figure 2-2.

WARNING

Do not stand under switchgear while it is being

moved. Serious injury may occur if the cables or

lifting device fail.

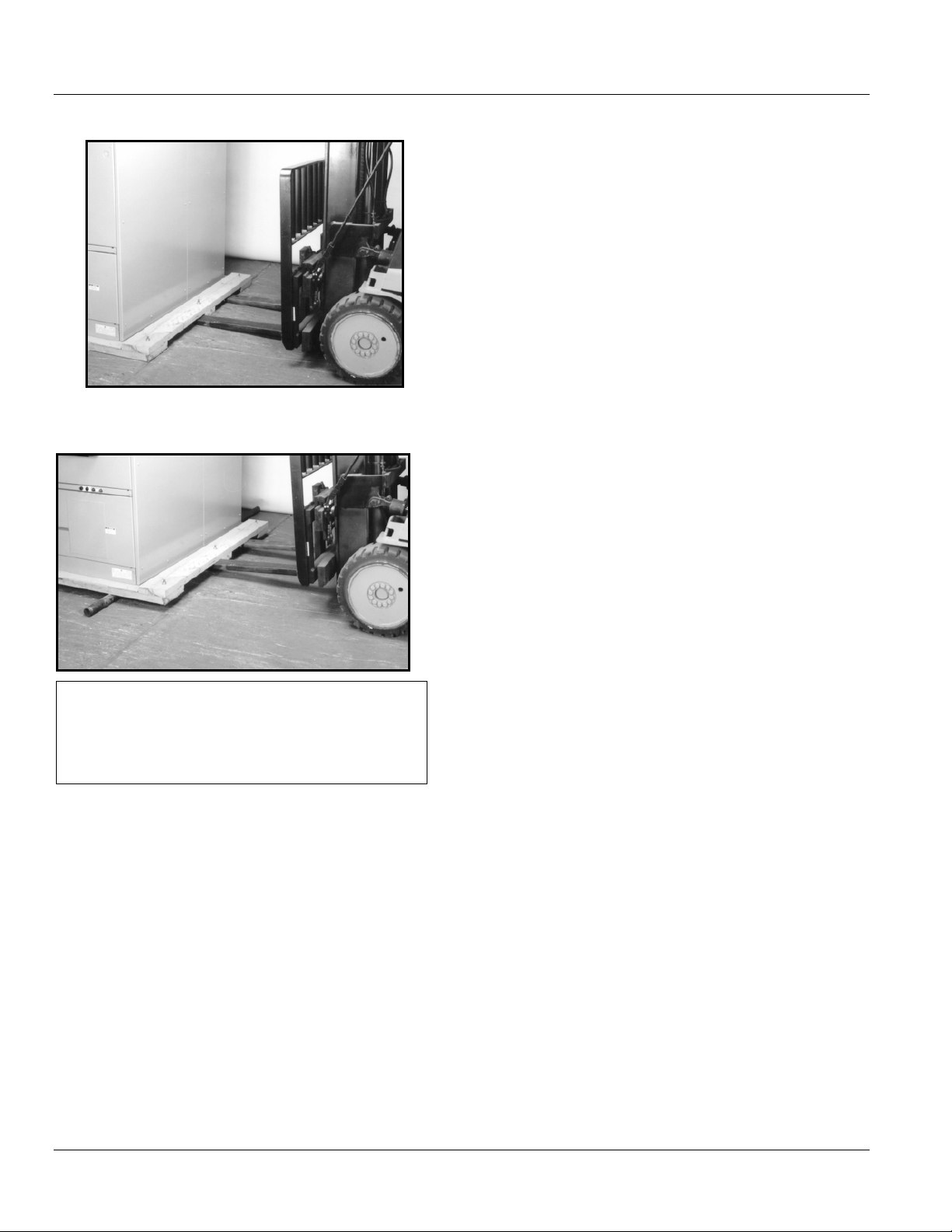

When using a forklift to raise the line-up to position rollers

underneath, proceed as follows:

1. Expand forklift tines to their maximum (widest)

extension.

2. Carefully insert tines of forklift below one side of the

switchgear line-up at the approximate center of the

panel as shown in Figure 2-3.

NOTICE

Do not attempt to lift or move the equipment with a

forklift positioned in the front or rear of the

equipment. Equipment may tip over and get

damaged.

1. Raise equipment and position one roller under the

skids close to the raised end of the line-up.

2. Carefully lower the gear until it rests on the roller as

shown in Figure 2-4.

3. Repeat the lifting process at the other end and place

the appropriate number of rollers under the skids

spacing them evenly across the width of the line-up.

© 2011 General Electric All Rights Reserved 3

Page 12

Arc Vault™ Protection System DEH-41483 Rev. 3

Receiving, Handling and Storage

Figure 2-3 Placing forklift tines under shipping skid

Figure 2-4 Placement of rollers under shipping skid

NOTICE

If shipping skids are removed prior to final placement

of equipment, rollers may only be used to move the

equipment in a direction parallel to the front.

4. While carefully pushing the switchgear to its final site

position, the rollers that are freed from the rear of the

switchgear are then repositioned at the forward end.

This procedure should be continued until the

switchgear is in its final location. See Fig. 2-8.

5. When the switchgear is in its final position, remove all

lug bolts holding the shipping skids to the switchgear

line-up.

6. Insert the tines of the forklift at one end of the line-

up, raise slightly, and remove the loose rollers.

7. Lower the end of the gear carefully to the floor.

8. Raise the other end of the line-up slightly and

remove the remaining roller at that end.

4 © 2011 General Electric All Rights Reserved

Page 13

DEH-41483 Rev. 3 Arc Vault™ Protection System

Receiving, Handling and Storage

Figure 2-5 Method of rolling equipment into place

Jacks

Jacks may be used in place of forklifts to raise and lower

switchgear. Jacks

1. Place a jack under the front and rear corners of one

end of the line-up.

CAUTION

Do not place jacks in any other location other than

the front and rear corners of the switchgear. Doing so

may result in serious damage to the switchgear

equipment.

2. Raise the switchgear evenly and just enough to

position a roller beneath the equipment. Gently lower

the switchgear onto the roller. Repeat the procedure

at the opposite end of the switchgear, raising the

gear far enough to place the appropriate number of

rollers under the skids, spacing then evenly across

the width of the line up. Gently lower the gear onto

the rollers.

4. When the switchgear is in its final position, remove all

lag bolts holding the shipping skids to the switchgear

line-up.

5. Place one jack at each corner, front and rear, of the

switchgear. Carefully raise the line-up evenly and

remove the rollers and the shipping skids. Evenly

lower the line-up to the floor and remove the jacks.

STORAGE

Switchgear

If it is necessary to store the switchgear equipment for

any length of time, the following precautions should be

taken to prevent corrosion or deterioration.

1. Remove protective covering. Check thoroughly for

damage.

2. Store in a clean, dry, rodent-free location with

moderate temperature and provide protective

coverings to prevent dirt, water, or other foreign

substances from entering the switchgear.

3. While carefully pushing the switchgear to its final site

position, the rollers that are freed from the rear of the

switchgear are then repositioned at the forward end.

This procedure should be continued until the

switchgear is in its final location.

© 2011 General Electric All Rights Reserved 5

Page 14

Arc Vault™ Protection System DEH-41483 Rev. 3

Receiving, Handling and Storage

CAUTION

Remove all cartons, containers and any other

miscellaneous packaging and packing material from

inside the switchgear sections before energizing any

internal heaters. To prevent fire, remove any plastic or

polyethylene shrouding from the switchgear sections

before energizing any internal heaters.

3. If dampness or condensation may be encountered in

the storage location, heaters must be placed inside

the switchgear sections to prevent moisture damage.

Approximately 250 watts of heat in each section is

required. On outdoor switchgear equipment, this

may be accomplished by making a temporary power

supply connection to the heaters already installed in

the equipment.

CAUTION

If the space heaters are to be temporarily energized

from external source, it is important to remove the

fuses on the secondary side of the control power

transformer. This precaution is to prevent a feed back

of higher voltage to other portions of the equipment

through the CPT primary.

6 © 2011 General Electric All Rights Reserved

Page 15

DEH-41483 Rev. 3 Arc Vault™ Protection System

Description

SECTION 3. DESCRIPTION

GENERAL

This section contains a description of the General Electric

Arc Vault™ Low Voltage gear. It also describes the

functions of the electrical and mechanical systems of Arc

Vault.

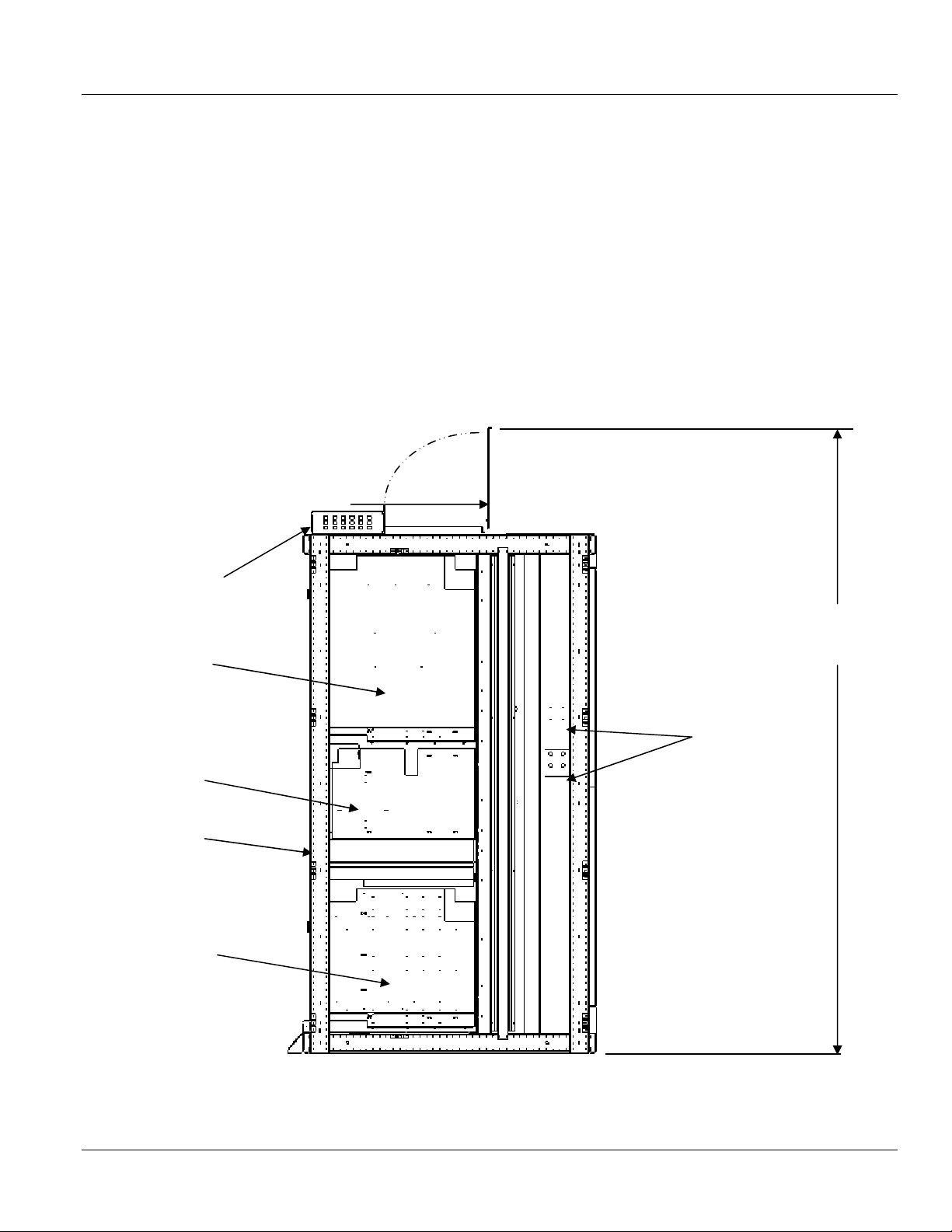

Figure 3-1 is a side view of a typical Arc Vault section

showing compartmentation.

Figure 3-1 Side view of Arc Vault Stack

Refer to Figure 4-3 on page 17 for cable entry space dimensions and location.

Ceiling height above exhaust door must be min. 12 feet. Exception to this requirement is above cable entry space. Sprinkler

heads cannot be located within a five foot radius of the perimeter of the Arc Vault stack.

SUMMARY DESCRIPTION

General Electric Arc Vault Protection System is a free

standing assembly of metal-enclosed sections containing

cable termination provisions, auxiliary power circuit

protective devices, controls, and instrumentation.

INTERSECTIONAL

CONTROL WIRING

TROUGH

ELECTRONICS

COMPARTMENT

ARC VAULT

DEVICE

COMPARTMENT

COMPARTMENT

DOORS

Exhaust Door requires

clearance from

conduit, Plumbing

and other mechanical

devices.

Open Exhaust Door

Height is 94.1 inch

CABLE CONNECT

BUS

BOTTOM

ELECTRONICS

COMPARTMENT

INCLUDING UPS

© 2011 General Electric All Rights Reserved 7

Page 16

Arc Vault™ Protection System DEH-41483 Rev. 3

Description

COMPARTMENT AREAS

The front enclosure of each section is divided into three

individual compartments. These compartments house

controls component, the Arc Vault™ device and the

optional Uninterruptable Power Supply compartment.

ARC VAULT COMPARTMENT

A standard Arc Vault compartment, Figure 3-2, is located

below the controls compartment.

Routine wiring inspections and fuse checks or fuse

replacements can be performed with the Arc Vault

compartment door in the closed position so that operators

are protected from the energized primary circuits.

Figure 3-2 Arc Vault compartment

Figure 3-3 Arc Vault controls compartment

1

2

1. Compartment door

2. Arc Vault device

An Arc Vault controls compartment, Figure 3-3, is available

as a standard feature. Internal hinged panels are used to

mount instruments and other devices associated with the

Arc Vault monitoring and control.

Relays and similar devices may be installed in the

compartment behind the swing-out device panel.

Potential transformer

fuse block FB1

The Arc Vault compartment is a closed-door drawout

compartment. Figure 3-4 and Figure 3-5 shows standard

construction. The Arc Vault compartment doors remain

closed and latched while the Arc Vault is racked out from

the CONNECTED position, through TEST, to the

DISCONNECTED position.

Arc Vault compartment doors do not have any ventilation

slots, thus protecting operators from hot ionized gases

which may be vented by the Arc Vault during circuit

interruption. Additionally, the Arc Vault compartment is

enclosed by grounded steel barriers on the top, sides,

bottom, and front. In the back, a flame-retardant, track

resistant, glass-filled polyester base minimizes the

possibility of fault communication between compartments

to the bus.

8 © 2011 General Electric All Rights Reserved

Page 17

DEH-41483 Rev. 3 Arc Vault™ Protection System

1

Description

Figure 3-4 Arc Vault compartment

4

3

1. Access port to racking mechanism

2. Racking access door screw

3. Arc Vault position indicator

4. Arc Vault device escutcheon

2

© 2011 General Electric All Rights Reserved 9

Page 18

Arc Vault™ Protection System DEH-41483 Rev. 3

Description

Figure 3-5 Arc Vault compartments showing drawout rails

3

4

5

2

6

1

1

1. Drawout rails

2. Cassette bottom and racking box

3. Secondary disconnects

4. Cassette side barrier

5. Primary disconnects (covered by shutter)

6. Racking arm

Primary disconnect shutters, Figure 3-6 ,are available as

options to provide protection against contact with the

energized stationary primary disconnects when the device

is removed from its compartment. The shutters are

constructed from glass-reinforced polyester insulating

material.

Referring to Figure 3-6, the shutters (movable barriers)

prevent frontal access to the primary disconnect line

stationary disconnects.

10 © 2011 General Electric All Rights Reserved

Page 19

DEH-41483 Rev. 3 Arc Vault™ Protection System

Description

Figure 3-6 Arc Vault primary disconnect shutters in closed position

1

2

3

4

1. Cassette Walls

2. Shutters (retractable barrier)

3. Shutter Operating lever

4. Racking mechanism insertion port

The shutters are closed when the Arc Vault is in the

DISCONNECT Position. As the Arc Vault is racked from the

DISCONNECT Position to the TEST Position the shutters

remain fully closed. As the device is racked from the TEST

Position to the CONNECTED Position, the shutters open

allowing the device to connect to the primary disconnects.

The cassette racking arm slots engage fixed racking

anchor pins on the sides of the Arc Vault. As the racking

arms are rotated by operation of the racking crank, the Arc

Vault is pulled into the compartment, and locked in its final

connected position.

Note that extra items shown in Figure 3-6, (such as

secondary disconnects and shutters) are optional and may

appear in any compartment or not be included at all,

depending on the equipment specified.

Figure 3-7 Arc Vault Device front view

© 2011 General Electric All Rights Reserved 11

Page 20

Arc Vault™ Protection System DEH-41483 Rev. 3

Description

Figure 3-8 Frame 2 Arc Vault (rear view)

Primary disconnects

The Arc Vault compartment has four positions as described in the following chart.

Device Position in

the cassette

Primary

Disconnects

Secondary

Disconnects

Arc Vault Functionality

Arc Vault can be operated electrically.

CONNECTED Engaged Engaged

Ready to transfer arc

Arc Vault device ready to test.

TEST Disengaged Engaged

Control circuits operations can be tested and

verified. Plasma gun can be discharged

DISCONNECTED Disengaged Disengaged

WITHDRAWN Disengaged Disengaged

Locked out during transition, Safe for

maintenance when fully disconnected.

Arc Vault can be removed from the

compartment. Safe for maintenance.

Arc Vault door

position

Closed

Closed

Closed

Open

12 © 2011 General Electric All Rights Reserved

Page 21

DEH-41483 Rev. 3 Arc Vault™ Protection System

Description

Figure 3-9 Racking handle for movement of Arc Vault

1

1. Arc Vault device position indicator

Movement of the Arc Vault between the CONNECTED, TEST,

and DISCONNECTED positions is performed by the use of a

racking handle, see Figure 3-9, which engages the racking

mechanism mounted on the cassette. An optional remote

racking device is also available. Movement to the

WITHDRAWN position is manually performed after opening

the compartment door. These positions are illustrated and

described more fully in SECTION 5 .

WARNING

The door should NOT be opened when the Arc Vault is

charged and in the CONNECTED position. Although

the device compartment door may be opened in any

position, it is recommended that the door only be

opened when the Arc Vault is in the DISCONNECTED

or WITHDRAWN position.

Cable lugs - mechanical type

When furnished, the terminal boards, for such connections

are located in an enclosed vertical wiring trough mounted

on the side of the cable compartment. The trough is of steel

construction with bolted covers to provide an isolation

barrier between the control wiring and the adjacent power

cables.

GROUND BUS

Figure 3-10 Cable termination provisions

On a 480V nominal system the Arc Vault Protection System

can be applied on systems with available current up to

65KA.

Feeder Cable Compartment

The rear cable and terminal compartment, Figure 3-10,

provides for cable installation and terminations. The cable

bending space meets the requirements of the National

Electric Code. Various arrangements of single or double

cable terminals are provided, depending upon the

purchaser's requirements.

When specified, racks for the support of feeder cables are

located in the cable compartment. The actual support of

the cables is provided by lashing them to these racks.

Also located in the cable compartments are provisions for

terminating control wires between external devices and

control circuits within the switchgear equipment.

© 2011 General Electric All Rights Reserved 13

All General Electric AKD-20 switchgear sections are

grounded to the internal equipment ground bus (4), Figure

3-11, located at the bottom of the cable compartment.

Page 22

Arc Vault™ Protection System DEH-41483 Rev. 3

Description

Figure 3-11 AKD-20 Cable termination compartment

1

2

3

4

1. Feeder runbacks

2. Vertical riser bus covers

3. Horizontal main bus

4. Ground bus (behind steel cover)

14 © 2011 General Electric All Rights Reserved

Page 23

DEH-41483 Rev. 3 Arc Vault™ Protection System

Equipment Installation

SECTION 4. EQUIPMENT INSTALLATION

GENERAL

This chapter contains complete instructions for installing

General Electric Arc Vault Low-voltage equipment.

CAUTION

Personnel installing this equipment must be familiar

with this instruction manual and all articles of the

National Electrical Code applicable to the installation

of this switchgear. In addition, all drawings, both

mechanical installation and electrical, must be

understood and strictly followed to prevent damage

to the switchgear or equipment being protected by

the switchgear.

Foundation Requirements

For optimum performance of your General Electric

switchgear equipment, the foundation requirements

expressed in this chapter should be strictly adhered to.

NOTICE

The foundation for the outdoor switchgear must

provide proper drainage of ground and surface water

accumulations away from the equipment.

The foundation must be strong enough to prevent

sagging due to the weight of the switchgear structure

and to withstand the shock stress caused by the

opening of the breakers under fault conditions. The

shock loading is approximately 1.5 times the static

load.

NOTICE

Before installation work is started, it is important to

review all of the drawings provided, including the

General Electric equipment arrangement drawings,

site installation drawings, elementary and remote

connection drawings, mechanical connection

drawings, and the summary of equipment list.

All expendable hardware for shipping purposes only,

is painted yellow or tagged with yellow adhesive tape

and may be discarded at completion of the

installation phase.

Site Location

In general, the location of the switchgear equipment will

have been predetermined during the specification and/or

procurement of equipment phases. Indoor locations within

buildings impose certain requirements which must be met

so that the switchgear may operate efficiently with a

minimum of maintenance.

In locating the Arc Vault equipment, adequate aisle space

must be provided at the front and rear of the equipment to

ensure proper ventilation of and to allow service and

maintenance with the front and rear doors open. The

recommended aisle space is shown on the floor plan

supplied with the equipment drawings.

The switchgear equipment should be placed in an area

where clean, dry air is free to circulate around and above it.

Since air is taken into the equipment at the bottom of each

section and exhausted at the top, a location with good

airflow must be provided for efficient operation. A minimum

of 30 inches of clear space above the equipment is

recommended.

© 2011 General Electric All Rights Reserved 15

The foundation must be flat and level in all planes. Refer to

Figure 4-1 for definition of flat and level.

Figure 4-1 Definition of flat and level

Plumb line

Perpendicular

Plane#1

Plane#2

Foundation Preparation

Refer to Figure 4-2 along with the owner's foundation

construction drawings, and the General Electric

supplemental installation drawings. Although the indoor

switchgear equipment can be mounted directly on a

smooth, level floor, it is recommended that recessed steel

channels be installed for supporting the equipment. Anchor

bolts and channels are to be provided by the purchaser.

Surface of pad

on both axes

to within 0.25"

over 10' span

.062"

NOTICE

When the equipment is installed on a surface subject

to impact (shock) loads due to operating conditions or

environmental seismic (earthquake) conditions, the

anchor bolts should be fabricated of medium carbon

steel (grade 5 load rating).

The floor channels under the front and rear switchgear

anchor points (see Figure 4-2) should be embedded in a

level concrete slab with their top surfaces flush with the

finished floor. It is essential that these steel channels be

level and aligned with each other prior to final anchoring, to

Page 24

Arc Vault™ Protection System DEH-41483 Rev. 3

Equipment Installation

prevent distortion of the switchgear structure, to assure

proper mechanical and electrical connections between

shipping splits, and to assure proper interfacing to other

close-coupled equipment.

Arc Vault section, Switchgear and Load Center Substations

are frequently mounted on steel floors and/or structural

steel in industrial installations (such as a mezzanine) to

minimize usage of production floor space. Regardless of the

If studs or anchor bolts are to be used, they should be

installed in the foundation as it is poured. It is important

that the studs or bolts are spaced to agree with dimensions

given on the General Electric job drawings. The dimensions

between anchor bolts for a particular installation are

dependent upon the configuration of equipment ordered.

The dimensions shown on Figure 4-2 cover all of the

standard enclosures available for Arc Vault equipment.

type of mounting surface, the requirements for a smooth

level surface remain.

Figure 4-2 Location of equipment anchor points

16 (22 section)

16 (22 section)

46.5

All units are in inches

If studs or anchor bolts are to be used, they should be

installed in the foundation as it is poured. Space the studs

or bolts to agree with dimensions given on the General

Electric job drawings. The dimensions between anchor bolts

for a particular installation are dependent upon the

configuration of equipment ordered. The dimensions shown

on Figure 4-2 cover the standard enclosure available for Arc

Vault equipment.

Figure 4-3 illustrates the space available for conduit and/or

cable entrance through the bottom or top of each

equipment section. The space required for control wiring

entry to the optional wiring trough is also shown.

16 © 2011 General Electric All Rights Reserved

Page 25

DEH-41483 Rev. 3 Arc Vault™ Protection System

Equipment Installation

Figure 4-3 Floor plan and cable entry space

ASSEMBLY AND INSTALLATION OF SWITCHGEAR

EQUIPMENT

General Requirements

Before assembling or installing the switchgear equipment,

all components should be available at the site location. This

will facilitate switchgear component identification as well

as installation. The foundation should be prepared in

accordance with the instructions in SECTION 4 Equipment

Installation, and all embedded conduits installed and

capped.

NOTICE

If rollers are to be used for movement of the

equipment to its permanent installation, it is

recommended that the shipping skid not be removed

until the equipment is placed in position over the

anchor bolts.

If a transformer is not part of the installation, and/or the

equipment has been split for shipment, place the center

section on the foundation first. Assemble the remaining

sections outward from the center section, in each direction.

first in accordance with the instructions furnished with the

transformer. All remaining sections of the switchgear

should then be installed.

NOTICE

Before assembling and installing the switchgear

equipment, the foundation must be absolutely level

and clear of debris to prevent damage and possible

mis-operation of the switchgear equipment.

Detailed Assembly and Installation Instructions (indoor)

The recommended procedure for installation of an indoor

switchgear or Load Center Unit Substation is as follows:

1. POSITION THE EQUIPMENT-Position the equipment or

sections of the complete equipment in their final location.

If the switchgear equipment is part of a Load Center Unit

Substation, the transformer section should be set on its pad

© 2011 General Electric All Rights Reserved 17

Page 26

Arc Vault™ Protection System DEH-41483 Rev. 3

Equipment Installation

Figure 4-4 Lifting plate location

Lifting Plate

NOTICE

If the lifting plates must be reassembled on the

equipment for lifting, they must be moved to

locations where unused screw holes are available,

generally by shifting the plate horizontally on the

mounting surface one bolt-hole from its previous

location. When remounting the lifting plates, torque

the mounting bolts to 7-9 ft-lbs.

NOTICE

NOTICE

If the equipment line-up was split into shipping

sections, the lifting plates on corners of adjacent

sections shown in Figure 4-4 must be removed.

Failure to remove these plates will interfere with

mating adjacent sections and prevent installation of

bus splice plates, structure tie plates, etc.

Arc Vault sections are equipped with lifting plates. These

plates can be left in place when the Arc Vault section is

positioned separate from the line up. Lifting plates must be

removed if section will be positioned directly next to the

switchgear line up.

Once the lifting plates have been removed, they may be

discarded.

All mating sections of the equipment line-up

(including transformer, if applicable) must be securely

fastened together prior to tightening anchor bolts

fastening the equipment to the mounting surface.

2. REMOVE THE SHIPPING SKIDS-The equipment is fastened

to the shipping skids with 3/8-3 lag screws through the

equipment anchoring holes. See Figure 4-6.

Equipment shipping sections up to 10 feet long will be

fastened to the skids with four lag screws, one in each

corner. The shipping skid and lag screws are expendable

material and may be disposed of at the purchaser's

discretion.

3. FASTEN SECTIONS TOGETHER-After placement of the

equipment and installing the anchor bolts loosely, the

various shipping sections must be rigidly fastened together.

Through-bolts fasten each section of the switchgear

equipment to the adjacent section. Figure 4-5 shows the

location of the through-bolts.

18 © 2011 General Electric All Rights Reserved

Page 27

DEH-41483 Rev. 3 Arc Vault™ Protection System

Equipment Installation

Figure 4-5 Location of through-bolts

Figure 4-6 Equipment attachment to shipping skids

After completing the installation of the main bus splice bars,

the joint covers may be mounted and secured by a 3/8-16

nylon bolt and polyester flat washer if the bus insulation

option has been supplied with the equipment.

4. INTERCONNECT CONTROL WIRING - Interconnection of

control wiring across shipping splits is accomplished by

connecting to terminal blocks located in the cross-section

wiring trough on top of the equipment.

© 2011 General Electric All Rights Reserved 19

Page 28

Arc Vault™ Protection System DEH-41483 Rev. 3

Equipment Installation

If terminal blocks are provided, each wire must be attached

to the correct point on the terminal block, following the

circuit identification number attached to each wire.

ANCHORING SWITCHGEAR EQUIPMENT INDOORS

Correct anchoring of the switchgear equipment to the

foundation is very important. After completion of reassembly of the equipment at the shipping splits, the

equipment anchoring procedure should be completed.

Anchoring By Anchor Bolts

1. The front of the equipment is attached to the embedded

channel sills (1), Figure 4-7, by two 3/16-inch fillet welds (2).

It is recommended that two welds, each 2-1/2 inches long

(min.), be used for each section to firmly tie the bottom

width post (3) to the channel sill.

2. The rear of the equipment may be anchored by one of

three procedures:

• The first method is by plug welds (4), Figure 4-7, using

the anchor bolt holes in the rear sill angle (5). The plug

weld should receive a minimum 1/2-inch bead around

the entire circumference of the anchor bolt hole.

Indoor equipment is normally secured to its final mounting

surface by anchor bolts threaded into the embedded

channel sills. The bolts were loosely threaded into place

before reassembling the equipment shipping splits and

connecting to the close-coupled transformer, if appropriate.

The anchor bolts should now be tightened with a torque of

35-40 ft-lbs.

Anchoring By Weld

An alternate method of anchoring the equipment to its

foundation is to weld the equipment to floor sills (or the

floor itself if constructed of steel). Several methods, shown

on Figure 4-7, are available to the purchaser for welding the

equipment to the channel sills.

• A second method of securing the front and rear sill

angles (5) to the channel sill (1) is the use of two linear

fillet welds (2) for each section. It is recommended that

each weld be 2-1/2 inches long (min.) with a 3/16-inch

fillet (min.).

• A third method for anchoring the rear of the equipment

is to remove the rear sill angle (5) from the switchgear

and weld the rear bottom width post (6) to the channel

sill (1). These welds (2) should, like the front welds,

have a 3/16-inch (min.) fillet and each have a

minimum length of 2-1/2 inches.

20 © 2011 General Electric All Rights Reserved

Page 29

DEH-41483 Rev. 3 Arc Vault™ Protection System

Equipment Installation

Figure 4-7 Indoor equipment weld anchoring

1. Channel sill

2. 3/16-inch fillet weld

3. Front sill angle

4. Plug weld in anchor bolt hole

5. Rear sill angle

6. Rear width post

The four anchor bolts should be tightened with a torque of

45-55 ft-lbs.

CAUTION

If the equipment is to be subjected to operational or

environmental (seismic) shock loading, the factory

must be consulted for anchoring recommendations.

Control Wire Connections

For external control wiring, refer to Figure 4-3 for

switchgear cable area dimensions, and connect the control

wires to the switchgear section as follows.

1. When control conduits enter the switchgear from

below, they should not extend more than one inch

above the floor. The control wires may be pulled

through the conduits before or after the switchgear is

installed.

2. Route the control wires from the conduits through the

wiring trough at the side of the cable compartment,

shown in Figure 4-3. Connect the cables to the terminal

blocks in accordance with the connection diagrams for

the equipment.

3. If the control conduits enter from above, drill the top

cover within the available space indicated. See Figure

4-3. Control wires should be routed to the wiring trough

and connected to the terminal blocks as described

previously.

Power Cable Connections

Connect the main cables to the main lugs. Before any main

cable connections are made, the cables should be identified

to indicate their phase relationship with the equipment.

Adequate electrical and mechanical clearances must be

provided between conduit, cables, and bus.

© 2011 General Electric All Rights Reserved 21

Page 30

Arc Vault™ Protection System DEH-41483 Rev. 3

Equipment Installation

Where the cables enter the section, they can be lashed to

Figure 4-8 Typical cable lashing

optional cable supports at the rear of the cable

compartment as required.

Mechanical cable terminals are normally included with the

switchgear (compression terminals are supplied when

ordered) and are mounted at the ends of the breaker

runbacks in the cable compartment. Carefully follow the

cable manufacturer's recommendations for installation of

cable.

Nylon rope – 3/8

inch (9.5 mm)

diameter.

Minimum of 5

wraps

Install the cables in the proper path to the terminals, using

temporary lashing if required. Cut the cables to the proper

length. Strip the insulation to the desired dimension, being

careful not to damage any strands.

6 inches

(152 mm)

For copper cables, coat the wires with GE lubricating grease

D6A15A2, insert the cables into the terminals, and tighten

per torque values in Table A-2 in Appendix A.

For aluminum cables, wire brush the wire strands

thoroughly. Immediately after wire brushing, coat the cable

strands with a quality oxide inhibiting compound such as

Penetrox A. Insert exposed wires into the terminals and

tighten the set screws in accordance with values shown in

the torque Table A-2 in Appendix A.

CAUTION

The torque values shown in the table are for dry

threads only. Do not grease or otherwise lubricate the

threads on the cable terminals as this will permit

over-tightening of the screw and possible damage to

the terminal or cable.

The cable supports in Figure 4-8 can be optionally ordered

from the factory. The following instructions for cable

lashing should be used as a guide. Run and bend the main

cable in a most convenient orientation, making sure the

main cable has been located directly up against any cable

braces (if present) before it connects to the main cable

terminals.

Using a 3/8 inch diameter continuous nylon rope or

equivalent (minimum 2000 pounds tensile strength) at 6

inches from the main cable terminals, make five revolutions

around the "A" and "B" phase main cables, making sure the

rope does not overlap. Make five revolutions around the "B"

This should result in the oozing of compound material from

between individual strands. Wipe off any excess compound.

Bolt the cable terminal connectors to the ends of the bars in

the cable compartment. A non-oxidizing grease, such as GE

lubricating grease D6A15A2 furnished with each

equipment, should be used at these connection surfaces.

The bolts should be tightened in accordance with values

shown in the torque Table A-2 in Appendix A.

and "C" phase main cables. With the remaining rope, wrap

around the main cable lashing between the "B" and "C"

phase and the cable brace (if present) with a minimum of 5

revolutions getting as much revolutions as possible

between the phases. Continue wrapping between the "A"

and "B" phase around the main cable lashing and the cable

brace (if present) with a minimum of 5 revolutions getting as

much revolutions as possible between the phases. Securely

tie off the remaining rope. Repeat this lashing at every 6-

Lash the cables securely to the cable support, if present, to

inch interval.

take their weight off the runbacks and to brace them

against short circuit forces in the event of a fault.

Relays and Control Devices

Remove all blocking on relays and devices as shown in the

instructions accompanying the devices.

WARNING

Risk of shock. The equipment must be completely deenergized before installing or removing the arc fault

device. Failure to do so may result in death or serious

injury.

22 © 2011 General Electric All Rights Reserved

Page 31

DEH-41483 Rev. 3 Arc Vault™ Protection System

Installing and Removing The Arc Vault Device

SECTION 5. INSTALLING AND REMOVING THE

ARC VAULT DEVICE

GENERAL

Inspection and Preparation of Arc Vault

Before installing, operating, or removing an Arc Vault, check

thoroughly for damaged or loose parts and for any dirt or

foreign matter which may be on the Arc Vault. Be sure that

a thin film of GE lubricating grease D6A15A2 is present on

primary disconnects of the switchgear before installing the

Arc Vault.

Arc Vault Installation

To install an Arc Vault, proceed as follows:

1. Before installing check the contact areas on each

primary disconnect bar or cluster of fingers for foreign

matter that may have accumulated. Clean these areas

if necessary. Be sure that a thin film of GE lubricating

grease D6A15A2 covers the contact areas before

putting the Arc Vault in the compartment.

2. Check to see that the Arc Vault matches its respective

compartment. The Arc Vault is assigned a part or mark

number. This number is shown on the sheets of the

summary, the front view drawings, and on the

identification card on the Arc Vault shipping carton. The

Arc Vault may also be identified using the 6 digit

catalog number.

3. To locate the Arc Vault in the proper compartment,

refer to the breaker location list on the front view

drawing. Find the proper Arc Vault device by the

identification card on the carton.

Rejection Feature

Drawout breakers of the same type and rating are

interchangeable in their equipment compartments.

Arc Vault devices will be rejected in a standard AKD-20

switchgear compartment. Drawout breakers will be

rejected from a Arc Vault compartment.

INSTALLING ARC VAULT DEVICE

Pre-Installation precautions

Prior to lifting the Arc Vault to its intended compartment

location, observe the following precautions.

1. Check the compartment to ensure that it is free of

foreign objects.

2. Verify that the Arc Vault is the correct type for that

compartment.

3. Ensure that the Arc Vault is discharged.

4. Apply a thin fresh coat of GE lubricating grease

D6A15A2 to the breaker’s primary disconnects.

5. Ensure that the position indicator on the cassette is in

the disconnected position and is correctly positioned

for initial engagement. To do this, open the racking

handle door and insert the racking handle and rotate it

fully counterclockwise.

Installation Procedures

To install the Arc Vault, proceed as follows.

1. Carefully place the Arc Vault device in front of the

section in which it is to be installed.

2. Open the compartment door by rotating the door latch

assembly ¼ turn clockwise.

3. Using the Arc Vault lifting mechanism shown in Figure

11-1 page 38 (or a suitable lifting mechanism and the

appropriate lifting fixture), raise the device above the

elevation of the rails.

WARNING

Do not stand under the Arc Vault during the lifting

operation. This may result in injury if the device is not

positioned properly on rails.

4. Fully withdraw rails to stops.

5. Slowly lower and guide the device to allow the 4 Arc

Vault wheels to align with the rails. Remove the lifting

device. The device is now positioned on the draw-out

rails.

6. Roll the device into the compartment until the racking

forks meet the racking pin, this is the DISCONNECT

position. If an incorrect Arc Vault has been installed, the

interference pins on the Arc Vault will interfere with the

rejection pins in the compartment prior to reaching the

disconnect position. At this point, the racking forks on

the cassette are contacting the fixed racking pins on

the device.

7. Slide rails back into compartment. Close the

compartment door and rotate latch ¼ turn counterclockwise.

8. Engage the racking handle by using a slot screwdriver

to open the racking shaft door by rotating it clockwise,

then insert hex manual racking handle.

9. Rotate the handle clockwise as far as it will go. As you

rotate the handle clockwise, the device will travel from

the DISCONNECT, through the TEST.

10. See SECTION 1 for detailed procedure during racking to

start test procedure.

© 2011 General Electric All Rights Reserved 23

Page 32

Arc Vault™ Protection System DEH-41483 Rev. 3

Installing and Removing The Arc Vault Device

To remove the Arc Vault

1. Discharge the Arc Vault by pressing the Discharge

button.

2. Use a slot screwdriver the open the racking shaft door

by turning clockwise. Insert the racking handle and

rotate it counterclockwise until the Arc Vault travels

from CONNECT through TEST to the DISCONNECT

position, as shown by the position indicator. This

operation should be performed with the door closed.

3. Open the compartment door and fully extend the

drawout rails. Roll Arc Vault out to rail stops. This is the

WITHDRAWN position.

4. Attach the lifting device and raise Arc Vault off

drawout rails.

5. Push the drawout rails back into the compartment.

6. Pull the Arc Vault forward until the primary disconnects

clear the compartment.

7. Lower the Arc Vault onto a flat surface free of

protrusions that could damage internal parts.

Figure 5-1 Engage the racking screw with the racking

handle

1

3

1. Arc Vault drawout position indicator

2. Racking shaft access

3. Racking handle

2

24 © 2011 General Electric All Rights Reserved

Page 33

DEH-41483 Rev. 3 Arc Vault™ Protection System

Testing and inspection

SECTION 6. TESTING AND INSPECTION

Table 6-1 Switchgear test voltage

GENERAL

After the equipment has been installed and all connections

made, it must be tested and inspected before it is put in

service. Although the equipment and devices have been

tested at the factory, a final field test must be made to be

sure that the equipment has been properly installed and

that all connections are correct.

WARNING

Risk of shock. The equipment must be completely deenergized while the tests are in progress. Failure to do

so may result in death or serious injury.

Directions for testing relays, instruments, and meters are

given in the instruction book furnished for each device. The

proper settings of the protective relays and Arc Vault trip

units are normally determined from a complete power

system coordination study performed by the purchaser or

their consultant; therefore, the settings of these devices

must be made by the purchaser. When the equipment is

shipped from the factory, the time dial of all inverse-time

induction disc relays (i.e., IFC types) is set to zero to prevent

contact bounce during transportation.

Switchgear

Voltage Rating

600V

480V

KEY INTERLOCKS

After initial installation of the switchgear equipment, all

necessary interlock keys should be inserted into the

appropriate locks and all spare keys should be stored in a

location in accordance with the owner's established

procedures.

ANSI

Test Voltage,

AC RMS

2200V

1960V

Field

Test Voltage,

AC RMS

1650V

1470V

CAUTION

Refer to the key interlock schematic included in the

summary furnished with the equipment to determine

the sequence of operation and the correct number of

operating keys required. This precaution is necessary

since the improper use of spare keys will defeat the

interlocking scheme.

NOTICE

The trip setting adjustments of the relay for each Arc

Vault may be at any setting when shipped from the

factory and must be correctly set prior to energizing

the equipment.

General instructions for setting the relays are given in Arc

Vault Relay Controller page 33.

The extent of the tests on the equipment as a whole will

depend on the type and function of the equipment. Tests

which should be performed, however, include Arc Vault

operation, and switchgear meggering, phasing, and

grounding checks.

If local codes demand a high potential test, or the

purchaser wishes to make these tests, the voltage should

not exceed 75 percent of the IEEE factory test voltage.

For the power circuit, the IEEE factory test voltage is two

times switchgear rating plus 1,000 volts.

CAUTION

Potential and control power transformers must be

disconnected during high-voltage testing.

© 2011 General Electric All Rights Reserved 25

Test

The compartment housing the Arc Vault has a TEST position

in which the primary contacts are disconnected while the

secondary contacts are still engaged. This TEST position

permits complete testing of the electrical control circuit

without energizing the primary power circuit. When the Arc

device is first put into service, its control circuit must

Vault

be thoroughly tested while in this position to make sure

that all closing and tripping circuits are complete and

functioning properly.

The TEST position is not suitable for inspection and

maintenance of the Arc Vault

be used only for testing Arc Vault

Once in the TEST position the device can be tested by

pressing the “Press to Charge” button. The indicators

directly above the button will show the state of the device.

Red light - indicated not charged

Yellow light – indicates charging or discharging this may

take a few seconds

Green light – indicated fully charged

Once the green light is lit, a test fire of the unit can be

performed by turning the momentary “Test Switch” to the

test position. You may hear the plasma gun internal to the

device discharge. You will see the indicator lights change

state and the “Event Alarm” yellow “pop out” indication

extract.

device and should therefore

device operation.

Page 34

Arc Vault™ Protection System DEH-41483 Rev. 3

Testing and inspection

Reset the pop out indicator by depressing the yellow

indicator. This procedure may be repeated if desired.

ARC VAULT RELAY

The calibration of the Arc Vault relay trip system is

comprised of the following components.

Discharged

Charged

1. Manually exercise all circuit breakers that the, Arc Vault

relay will be controlling, and other operating

mechanisms to make certain they are properly aligned

and operate freely.

2. Conduct an electrical insulation resistance test to make

sure the switchgear is free from short circuits and

grounds. This should be done both phase-to-ground

and phase-to-phase with the switches or circuit

breakers both opened and closed. The Arc Vault Device

shall be in the discharged state. This test should be

performed with a 1000 volt meggar. Disconnect all

control circuits before checking resistance.

3. Upstream breaker must be tested to verify it is

functional and can clear the fault in less than 5 cycles.

WARNING

Upstream breaker is responsible for interrupting arcing

event. Make sure breaker is functional upon trip signal.

Failure to do so may result in death or serious injury.

3A. Verify CTs are properly connected.

• Relay

• Current transformers Class C50 or better 5000:5A

• Shunt trip on the tripable device

WARNING

Correct current transformer class and rating is critical

to proper system function.

All control components, except the CT’s and the Shunt trip

are integrally mounted in the Arc Vault Protection System

stack in drawout construction. The Relay is automatically

connected to the device via a drawout secondary

disconnect block.

WARNING

Never disengage the relay without shorting the