Page 1

GE Monogram

Installation

Instructions

®

36" Downdraft

Gas Cooktops

Models

ZGU365

Page 2

CAUTION

WARNING

ATTENTION

CAUTION

Before you begin—Read these instructions completely and carefully.

IMPORTANT: Save these instructions for local inspector’s use.

IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these instructions with the Consumer.

NOTE TO CONSUMER: Keep these instructions with your Owners Manual

for future reference.

This appliance must be properly grounded. See “Power Supply”, page 8.

Cet appareil doit être correctement mis à la terre. Voir << Alimentation électrique >> à la page 8.

If you have a question concerning the installation of this product, call the GE Answer

Center® Consumer Information Service at

800.626.2000, 24 hours a day, 7 days a week. If

you received a damaged cooktop, you should

immediately contact your dealer or builder.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

Do not store or use combustible materials,

gasoline or other flammable vapors and

liquids in the vicinity of this or any other

appliance.

•Installation of this cooktop must conform

with local codes, or in the absence of local

codes, with the National Fuel Gas Code,

ANSI Z223.1, latest edition. In Canada,

installation must conform with the current

Proper installation is the responsibility of the

installer. Product failure due to improper

installation is not covered under the GE

Appliance Warranty. See the Owners Manual

for warranty information.

For Monogram local service in your area,

1-800-444-1845.

For Monogram service in Canada,

1-888-880-3030.

For Monogram Parts and Accessories, call

1-800-626-2002.

Natural Gas Installation Code, CAN/CGAB149.1 or the current Propane Installation

Code, CAN/CGA-B149.2, and with local

codes where applicable.

•This cooktop has been design-certified by

the American Gas Association according to

ANSI Z21.1, latest edition and Canadian Gas

Association according to CAN/CGA-1.1

latest edition.

•Your cooktop must be electrically grounded

in accordance with local codes or, in the

absence of local codes, in accordance with

the National Electrical Code (ANSI/NFPA

70, latest edition). In Canada, electrical

grounding must be in accordance with the

current CSA C22.1 Canadian Electrical Code

Part 1 and/or local codes.

Contents

2

Design Information

Models Available ........................................................... 3

Accessories ..................................................................... 3

Dimensions and Clearances ......................................... 3

Advance Planning ......................................................... 4

Ductwork Advance Planning........................................ 4

Tools and Materials Required...................................... 4

Cabinetry/Ductwork

Cut the Opening ........................................................... 5

Venting Options ............................................................ 6

Ductwork Fittings .......................................................... 7

Power Supply Locations ............................................... 8

Installation

Step 1: Install Downdraft Vent ..................................... 9

Step 2: Install Ductwork ............................................. 10

Step 3: Install Pressure Regulator.............................. 10

Step 4: Install the Cooktop ........................................ 11

Step 5: Electrical Connections ................................... 12

Step 6: Connect Power ............................................... 12

Step 7: Assemble Burners, Check Ignition ............... 12

Step 8: Install Filters,

Check Operation of Downdraft ................................. 13

JXRB57 Kit, Indoor Remote Blower Location ........ 14

JXBC57 Kit, Outdoor Remote Blower Location ...... 17

Page 3

Design Information

Gas Downdraft Cooktop

Models

Available

Accessories

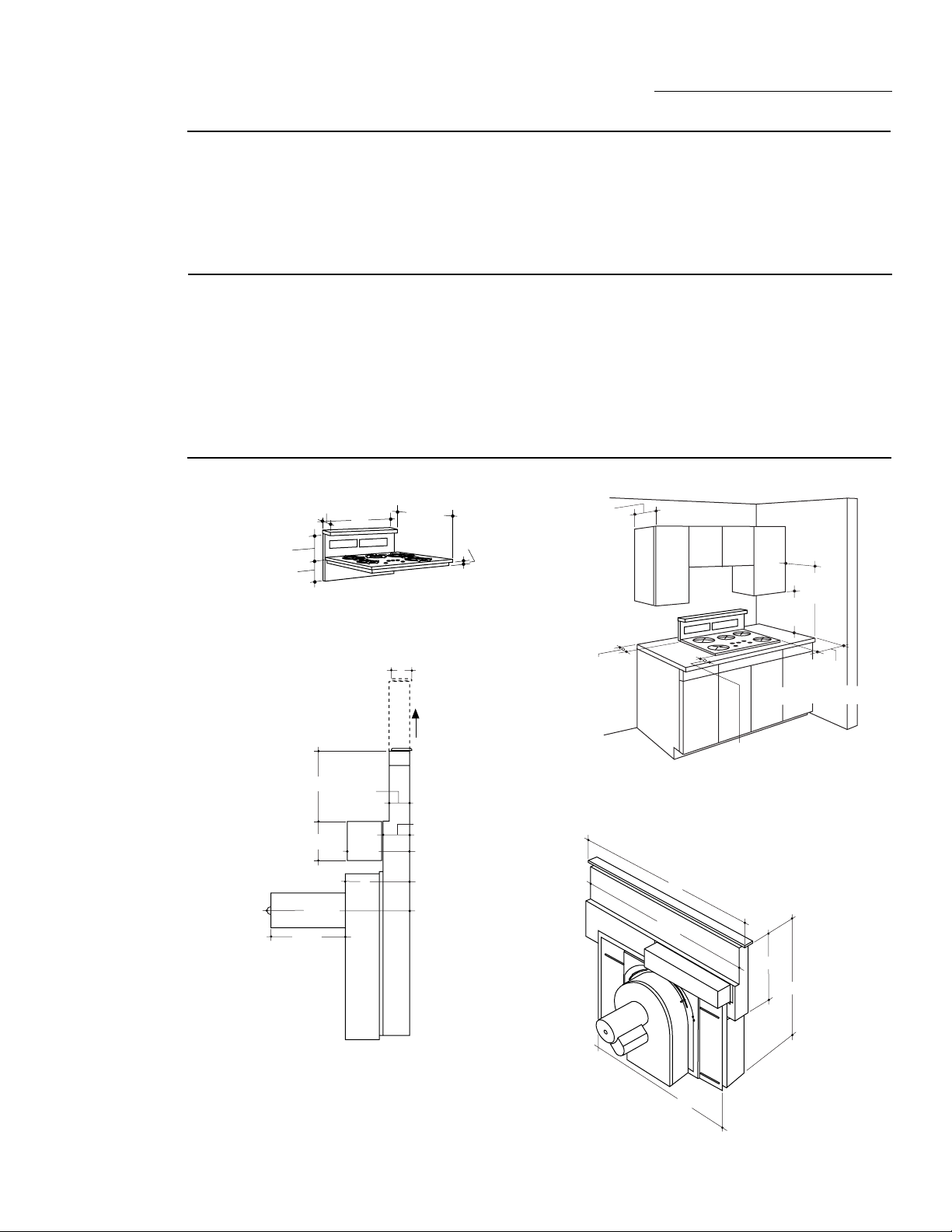

Dimensions

and Clearances

ZGU365

36" gas downdraft cooktops

These models are shipped for natural gas

operation. They can be converted to liquid

propane. (Order JXLP56 conversion kit.)

These gas downdraft cooktops are equipped

with an vent system which can be retracted

when not in use.

•JXBA56WW, white or JXBA56BB, black

motor and blower assembly is required for

both models. Be sure to order the color that

matches the cooktop.

8-3/4"

15"

2"

36"

19-3/4"

2"

•JXRB57 optional accessory for indoor

remote location of the blower/motor

assembly. Use this kit when the blower and

motor assembly will be located outside of or

below the cabinet floor.

•JXBC57 optional outdoor cover accessory

may be ordered for installation of blower

and motor assembly on the outside wall.

13"

Max.

30"

Min.

18"

Min.

7-1/2"

3-1/4"

12-3/8"

5-3/8"

2-1/4"

6-3/8"

7"

2"

3-1/4"

8-1/2" Lift

3-7/8" Min.

From Cooktop

to Rear Vertical

Combustible

When Installed

8" Min. to

Wall When

Installed Both Sides

1-1/2" Min.

When Installed

36"

33-3/4"

14-3/4"

27"

26"

3

Page 4

Design Information

Gas Downdraft Cooktop

Advance

Planning

The combined installation of a downdraft vent

and cooktop require careful consideration.

Countertop Requirements:

The countertop must have a deep flat surface

to accommodate the cooktop and the vent.

Countertops with a rolled front edge and

backsplash may not provide the flat surface

area required.

Clearances

•The downdraft system with blower, motor

and ductwork will occupy the cabinet below

the cooktop. Drawers cannot be installed

below this cooktop.

•Refer to “Dimensions & Clearances” for

information on appropriate placement and

necessary clearances when planning installation.

•Avoid placing cabinetry directly above the

cooktop when possible.

•If cabinetry is used above cooking surface:

–Use cabinets no more than 13" deep.

–Maintain 30" minimum clearance between

cooktop and unprotected cabinets directly

above cooktop.

–If clearance is less than 30", protect cabinet

bottoms with flame-retardant millboard at

Base Cabinet Requirements:

This installation requires a 24" min. deep

cabinet base. The cabinet must be at least 36"

wide.

least 1/4" thick or gypsum board at least

3/16" thick covered with 28 gauge sheet

steel or .02" thick copper.

–Clearance between cooktop and protected

cabinetry must not be less than 24".

EXCEPTION: Installation of a listed microwave oven or cooking appliance over the

cooktop shall conform to the installation

instructions packed with that appliance.

–Working areas adjacent to the cooktop

should have 18" minimum clearance between countertop and cabinet bottom.

•Installation must conform with local codes.

In the absence of local codes, the gas cooktop

must comply with the National Fuel Gas Code,

ANSI Z223.1, latest edition.

Ductwork Advance Planning

Prepare ductwork to vent to outdoors:

•Use the shortest and straightest duct run

possible:

–Duct run should not exceed equivalent

length of 150 feet.

–Refer to “Duct Fittings” chart to calculate

equivalent length for various duct

configurations.

Gas and Electrical Locations

Plan the placement of the electrical outlet and

gas carefully. Gas and electrical outlets cannot

be placed on the back wall of the cabinet

because it may interfere with the downdraft

plenum.

•The downdraft blower system is designed to

use 3-1/4"x10" ductwork. It can be

transitioned to 6" round.

•Ductwork MUST be vented to the outside–

never into a crawl space, attic or other

enclosed space.

•Determine the need for a wall cap or roof

cap. Order the cap in advance.

•Refer to “Power Supply Locations” page 8 for

details.

4

Page 5

Cabinetry/Ductwork

Gas Downdraft Cooktop

Tools and

Materials

Required

Cut the

Opening

•Self-adhesive gasket

(supplied)

•Two clamping

brackets and

screws (supplied)

•Gas pressure

regulator (supplied)

•Large flat-blade

screwdriver

•Saw

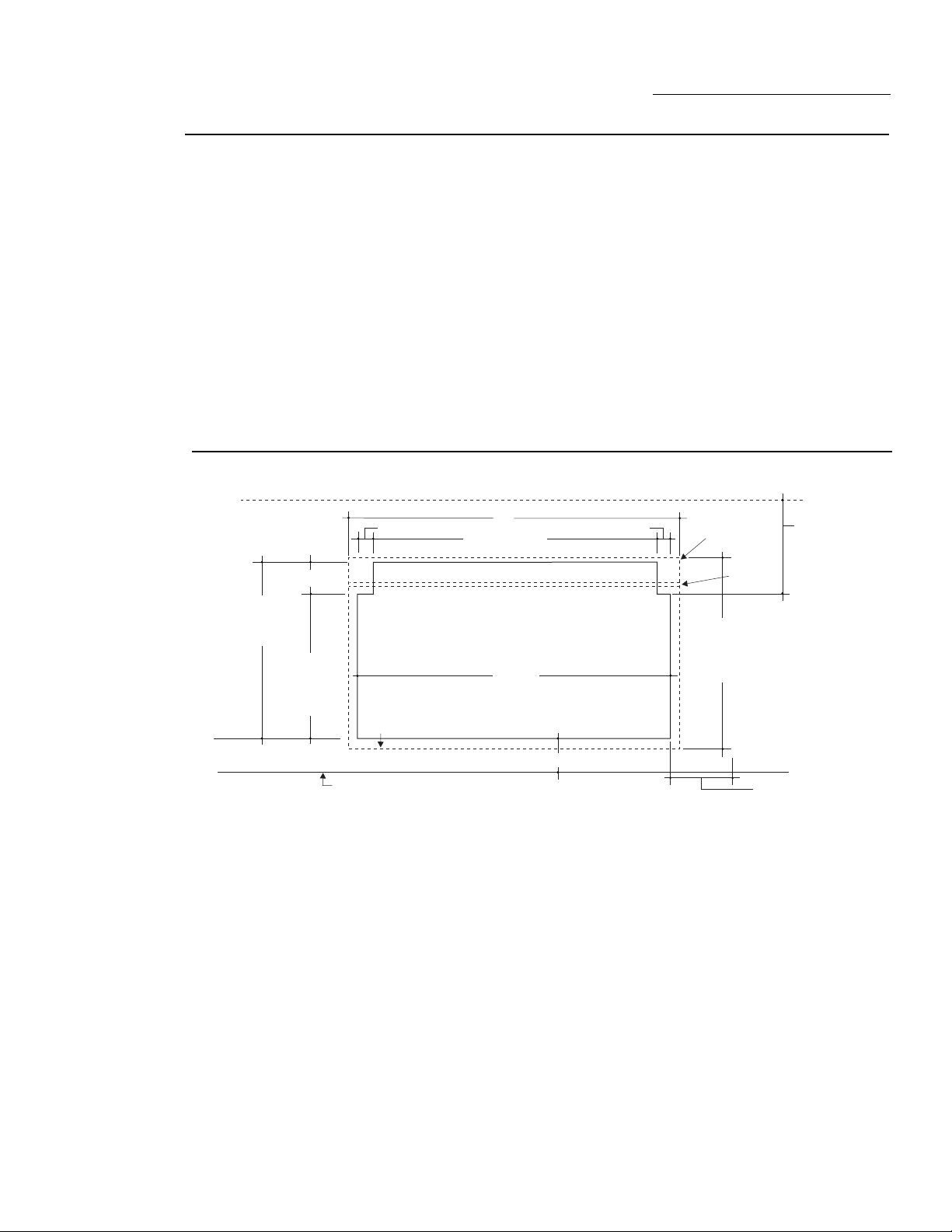

Top View–Countertop Surface

2-9/16"

20-11/16"

Cutout

Depth

18-1/8"

Cooktop

Cutout

Depth

3/4" Cooktop Overlap

•Carpenter’s square

•Pipe wrench

•Manual gas line

shut-off valve

•3/4" NPT x 3/4"

I.D. or 1/2" NPT x

1/2" I.D. flare

union adaptor for

connection to

supply line

1/4"

34" Vent Cutout

Cooktop Area Cutout

36"

34-1/2"

•Duct work to suit the

installation

•1/2" NPT x 3/4"

I.D. or 1/2" I.D.

flare union adaptor

for connection to

regulator

•Gas-resistant pipe

joint sealant

1/4"

1/4" Overlap

21-3/4"

Total Flat

Surface

Required

•5 foot AGA-certified

flexible metal

appliance connector, 3/4" or 1/2"

I.D. to match gas

supply line:

–If required by local

codes, use solid

pipe with fittings.

Note: Purchase new

flexible line, DO

NOT USE OLD,

PREVIOUSLY USED

FLEXIBLE LINE.

4-5/8" Cooktop

Cutout to

Rear Vertical

Combustible

1/8" Gap

Surface

2-1/4" Min. Clearance to Cutout

Front Edge of Countertop

Measure carefully when cutting countertop.

Make sure sides of opening are parallel and

rear and front cuts are exactly perpendicular

to sides.

•The Monogram gas downdraft cooktop is

designed to fit in a 36" or larger base

cabinet.

•The countertop cutout for the cooktop

must be:

–34-1/2" at the front of the counter and,

–34" at the back

–18-1/8" front to back notch

–20-11/16" front to back of cutout

The notches at the back of the cutout are:

–2-9/16" forward and 1/4" to the inside.

Follow the illustration shown.

8-13/16" Min. Cutout

to Wall Both Sides

•Allow at least 4-5/8" clearance between back

of cutout and combustible wall.

•Allow at least 8-13/16" clearance from right

and left sides of cutout to adjacent wall.

•Allow at least 2-1/4" clearance between front

of cutout and front edge of countertop.

Caution:

countertops and cabinets

should withstand 200°F heat

generated by the cooktop.

Wall coverings,

5

Page 6

Ductwork

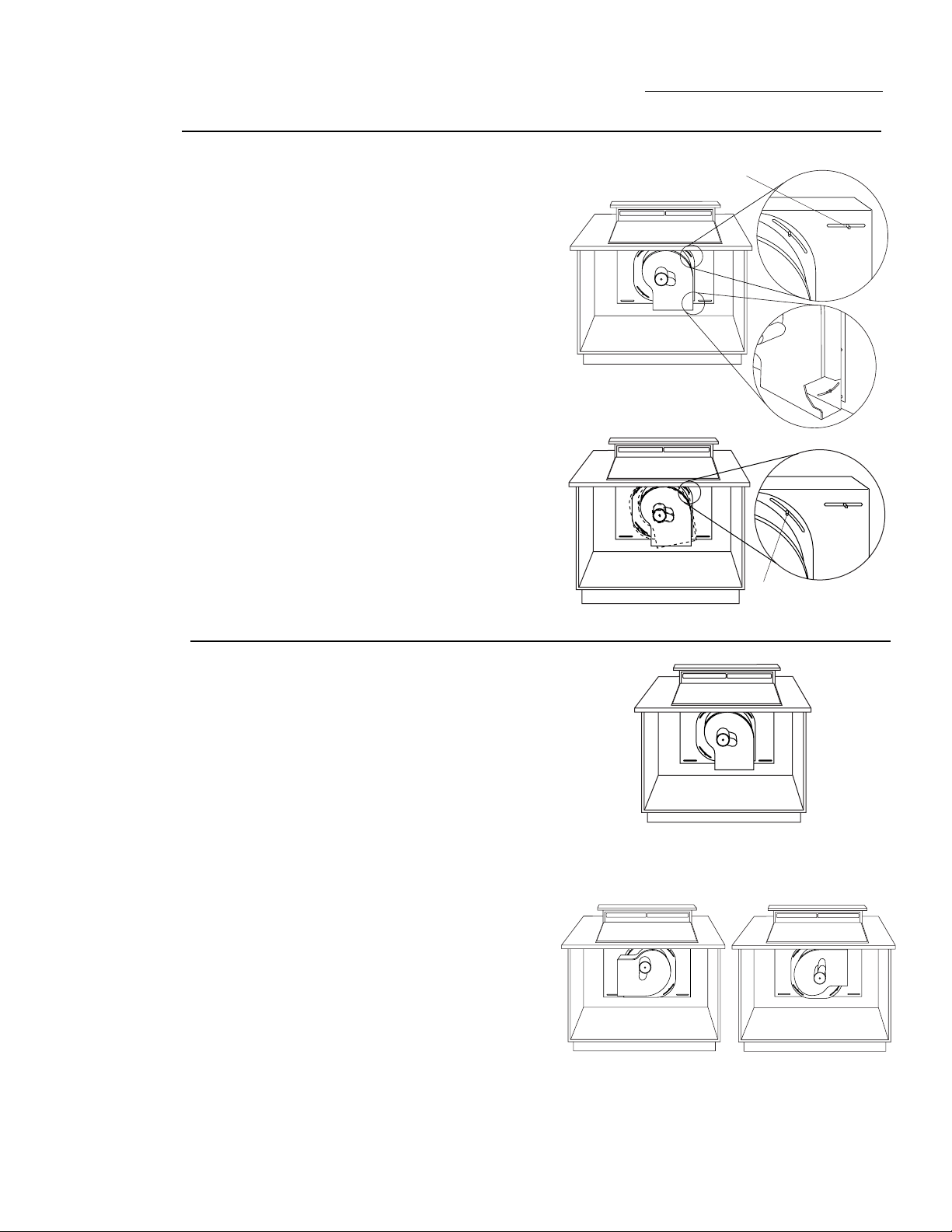

Loosen Screws to Rotate

30° to Left or 30° to Right

Discharge Right

Discharge Left

Gas Downdraft Cooktop

Venting

Options

• The downdraft vent is shipped with the

discharge outlet pointing straight down and

can be changed to the left or right side.

• The blower outlet is sized for 3-1/2" x 10"

and can be transitioned to 6" round.

Side to side adjustments:

The entire blower mounting plate can be

adjusted 3-1/2" to the left or right. This will

help to align vent discharge to house

ductwork.

30° Rotation

For even more flexibility, the entire blower

can be rotated up to 30° towards the left or

30° towards to right.

Discharge direction

The blower assembly may be removed and

turned 90° for a left or right side discharge.

Loosen Screws to

Adjust Blower

Left to Right

Nut Location

Inside the Blower

Discharge

6

• A left or right 90° direction adjustment

should be performed before dropping into

the countertop opening.

• Flatten the shipping box to use as a pad.

• Lay the vent on its back onto the pad.

To change to a left or right discharge:

• Remove 4 nuts holding the blower to the

mounting plate. See illustration. One nut is

just inside the blower discharge.

• Remove and turn the blower to the right or

left.

• Reinstall the 4 nuts.

To locate the ductwork holes in the cabinet

floor or side walls:

• Temporarily, place vent into the countertop

opening.

• Push the vent all the way to the back of the

opening.

• If you are transitioning to 6" round, place

transition piece over the discharge outlet.

– Mark the location and remove the

assembly.

– Cut holes and install ductwork

connections.

30" Rotation Left or Right

Discharge Down

(as Supplied)

Order JXRB57 for installation of the blower and motor

below the floor.

Order JXBC57 for installation of the blower and motor

outdoors.

Page 7

Ductwork

Gas Downdraft Cooktop

Duct

Fittings

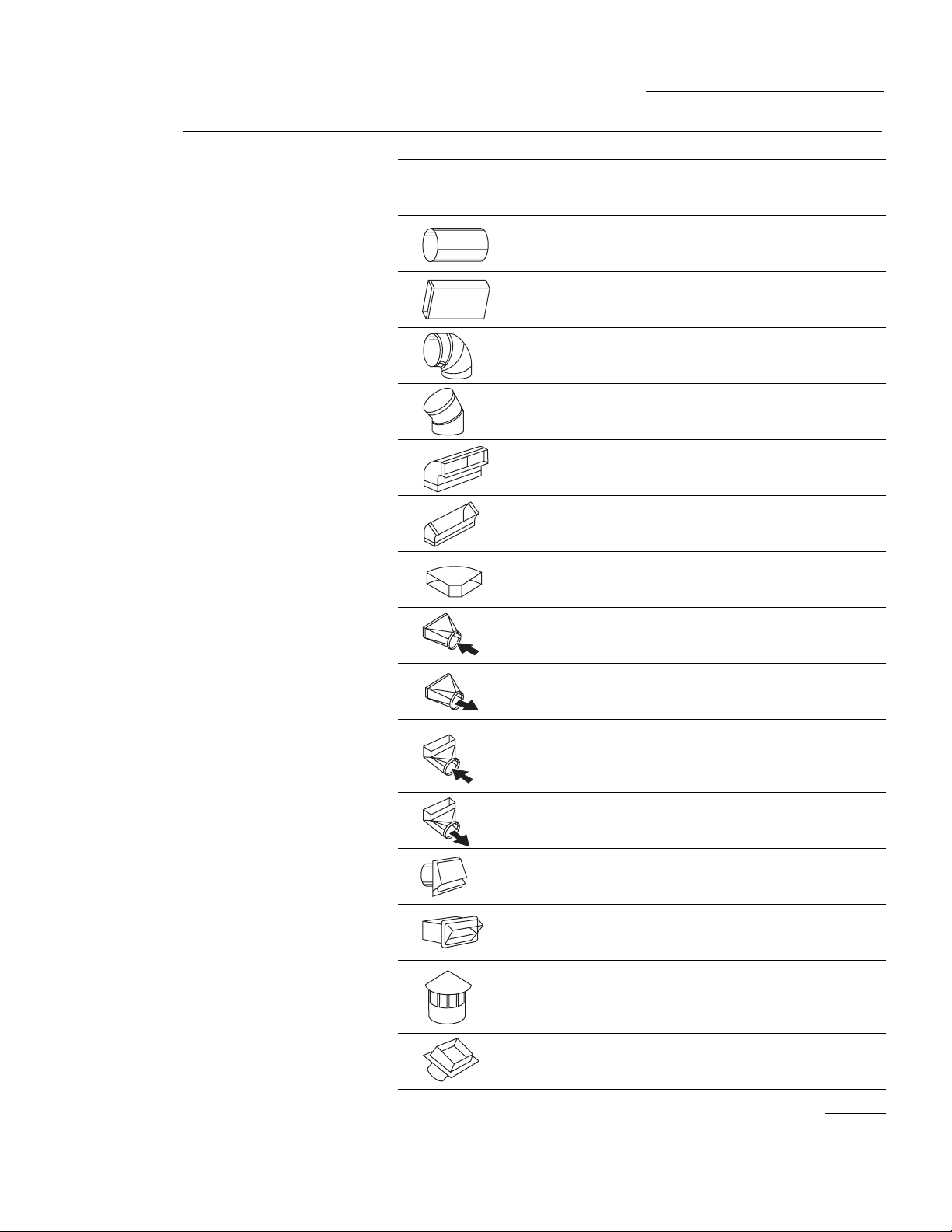

Use this form to

compute maximum

permissible lengths

for duct runs to

outdoors.

Note: Do not exceed

maximum permissible

equivalent lengths!

Flexible ducting:

If flexible metal

ducting is used, all the

equivalent feet values

in the table should be

doubled. The flexible

metal duct should be

straight and smooth

and extended as much

as possible.

Do NOT use flexible

plastic ducting.

Gas Downdraft

Cooktop

Model ZGU365

150' maximum

equivalent length

Note: Any home

ventilation system,

such as a cooktop with

a downdraft exhaust

mechanism, may

interrupt the proper

flow of combustion air

and exhaust required

by fireplaces, gas

furnaces, gas water

heaters and other

naturally vented

systems. To minimize

the chance of interruption of such

naturally vented

systems, follow the

heating equipment

manufacturer’s

guidelines and safety

standards such as those

published by NFPA

and ASHRAE.

Equivalent Quantity Equivalent

Duct Piece Dimensions Length* Used Length

1 ft.

6" round, (per foot

straight length)

1 ft.

3-1⁄4" x 10" (per foot

straight length)

6"

90° elbow 15 ft.

6"

45° elbow 9 ft.

3-1⁄4" x 10"

90° elbow 16 ft.

3-1⁄4" x 10"

45° elbow 5 ft.

3-1⁄4" x 10"

90° flat elbow 18 ft.

6" round

to 3-1⁄4" x 10"

transition 7 ft.

3-1⁄4" x 10"

round to 6"

transition 5 ft.

6" round to

1

⁄4" x 10"

3

transition

90° elbow 20 ft.

3-1⁄4" x 10" to 6"

round transition

90° elbow 12 ft.

6" round

wall cap

with damper 21 ft.

3-1⁄4" x 10"

wall cap

with damper 27 ft.

6" round

roof cap 20 ft.

6" round

roof vent 24 ft.

* Actual length of straight duct plus duct fitting

equivalent. Equivalent length of duct pieces are based

on actual tests conducted by GE Evaluation Engineering and reflect requirements for good venting

performance with any downdraft cooktop.

Total Duct Run

Total

7

Page 8

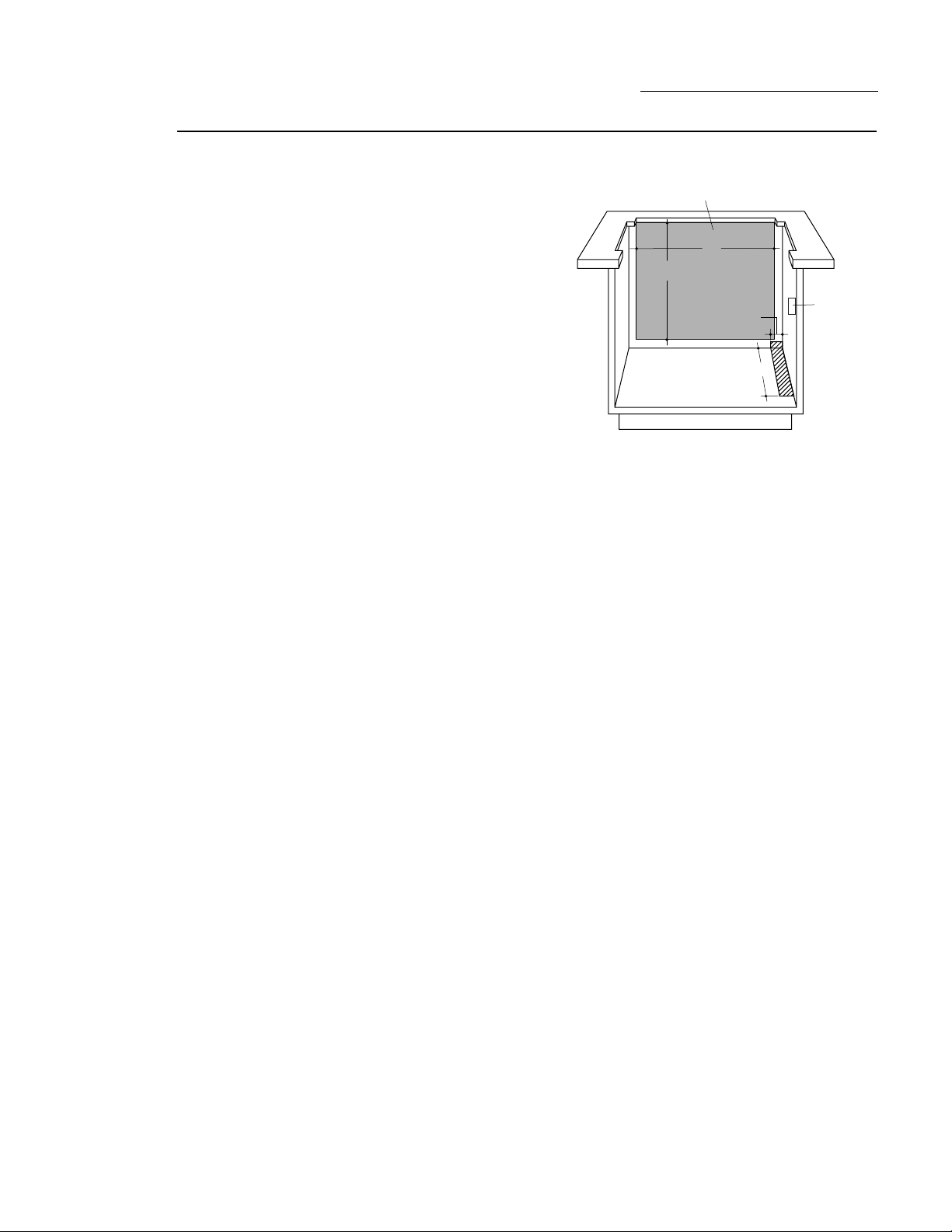

Gas and Electrical Supply

Gas Location

29-1/2"

Electrical

Outlet

12" Above

Cabinet Floor

Do Not Locate Gas or Electrical

Connections Within Shaded Area

34"

14"

4"

Gas Downdraft Cooktop

Power Supply

Locations

Gas supply:

These cooktops are designed to operate on

natural gas at 4" of water column pressure or

on LP gas at 10" of water column pressure.

–These cooktops are shipped from the

factory set for natural gas. If you decide

to use this cooktop with LP gas, conversion

adjustments must be made by a service

technician or other qualified person.

JXLP56 conversion kit is required for

LP operation.

•The pressure regulator must be connected in

series with the manifold of the cooktop and

must remain in series with the supply line

regardless of type of gas being used.

For proper operation, the maximum inlet

pressure to the regulator must be no more

than 10" water column pressure for natural

gas and 14" water column pressure for LP gas.

•When checking the regulator, the inlet

pressure must be at least 1" greater than the

regulator output setting.

–If the regulator is set for 4" of water column

pressure, the inlet pressure must be at

least 5".

–If the regulator is set for 10" of water

column pressure, the inlet pressure must

be at least 11".

For ease of installation, and if local codes

permit, the gas supply line into the cooktop

should be 1/2" or 3/4" ID flexible metal

appliance connector, three to five feet long.

Note: Purchase new flexible line. DO NOT

USE OLD, PREVIOUSLY USED FLEXIBLE

LINE.

•Make gas connection through rear wall, or

on cabinet floor at rear, as illustrated.

Electrical supply:

•A properly-grounded 3-prong receptacle

should be located within reach of cooktop’s

four foot power cord.

– Locate the receptacle inside the cabinet on

the right side wall. See illustration.

IMPORTANT: (Please read carefully).

FOR PERSONAL SAFETY, THIS APPLIANCE

MUST BE PROPERLY GROUNDED.

The power cord of this appliance is equipped

with a three-prong (grounding) plug which

mates with a standard three-prong grounding

wall receptacle to minimize the possibility of

electric shock hazard from this appliance. The

customer should have the wall receptacle and

circuit checked by a qualified electrician to

make sure the receptacle is properly

grounded and has correct polarity.

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility

and obligation of the customer to have it

replaced with a properly grounded threeprong wall receptacle.

Do Not, Under Any Circumstances, Cut Or

Remove The Third (ground) Prong From The

Power Cord.

Do not use an extension cord.

8

Page 9

Installation

Plastic Ties

Gas Downdraft Cooktop

Remove

Packaging

Step

1

Install

Downdraft

Vent

• Remove the shipping materials and the

carton, set carton aside. The carton can be

used as a pad when changing or adjusting

vent direction.

• Remove the plastic ties on both ends at the

top of the vent.

Optional Method

Secure to Cabinet

Side With Top

Screw on Case

Or Use Second Screw

Preferred Method

Secure the Upper

Brackets With Screws

Located on the side of

Case and Attach to

Back Wall of Cabinet

Secure the Lower Brackets

to Blower Housing

Place the downdraft vent into the countertop

cutout, against the back side.

• Secure the downdraft to the countertop

supplied brackets. See illustration.

– Fasten brackets to top screws on the front

side of the vent, secure to cabinet side wall

just below the countertop. Or,

– Fasten one bracket to vent side and secure

to cabinet back wall.

– Install two brackets on the bottom of the

vent. Attach brackets to slide screws on the

vent and to the floor using wood screws

(not supplied).

• When installing in a tile countertop surface,

it may be necessary to apply a locally

approved caulking to cover any gaps.

9

Page 10

Installation

Gas Downdraft Cooktop

Step

2

Install the

Ductwork

Step

3

Install

Pressure

Regulator

• The downdraft blower system is designed for

use with 3-1/4" x 10" ductwork. It can be

transitioned to 6" round.

•Ductwork MUST be vented to the outside –

never into a crawl space, attic or other

enclosed space.

•6" PVC duct should be used when installing

under a concrete slab.

Note: Local building code must be followed

for installation and in specifying approved

type and schedule of PVC duct used.

• DO NOT USE flexible plastic ducting.

• Always use appropriate roof or wall cap with

damper. Laundry type wall caps should

never be used.

• Use the straightest duct run possible.

• For satisfactory performance the duct run

should not exceed 150 ft. or its equivalent

•Install the supplied pressure regulator and

nipple in the gas line as close to the cooktop

inlet as possible. Allowances for ventilation

ducting may be necessary.

–Make sure the regulator is installed in the

right direction.

•Install a manual shut-off valve in the gas line

in an easily accessible location.

Note: Instead of using solid piping to connect

to pressure regulator, an approved flexible

metal appliance connector may be used

between the pipe stub and the shut-off valve

and the pressure regulator, if local codes

permit.

– Appropriate flare nuts and adapters are

required at each end of the flexible

connector.

•Turn on the gas. Check for leaks using a

liquid leak detector at all joints in the system

(the pressure test nipple is adjacent to the

gas inlet pipe on the rear right hand side of

the cooktop bottom.

CAUTION

gas leaks.

PRUDENCE

CAUTION

DE FLAMME POUR VÉRIFIER S’IL Y A

DES FUITES.

Do not use a flame to check for

IL NE FAUT PAS UTILISER

length when bends or various fittings are

used. Refer to the table of equivalent lengths

to calculate your installation.

• Install ductwork so the piece of duct nearest

the downdraft unit slots INTO the next

piece of the duct. Secure the joints with selftapping screws and apply duct tape around

the joints to ensure an airtight seal.

Duct Tape

Over Seam and Screw

Air

Screw

Regulator

Solid Piping

or Flexible

Connector

Shut-Off

Valve

Pipe Stub

IMPORTANT: Disconnect the cooktop and

the individual shut-off valve from the gas

supply piping system during any pressure

testing of that system at test pressures greater

than 1/2 psig. Isolate the cooktop from the

gas supply piping system by closing the

individual manual shut-off valve to the

cooktop during any pressure testing of the gas

supply piping system at test pressures equal to

or less than 1/2 psig.

10

Page 11

Installation

Gas Downdraft Cooktop

Step

4

Install the

Cooktop

Note: If the cooktop is installed into a 36"

base cabinet, the pressure regulator MUST BE

installed to the bottom of the cooktop before

the cooktop is placed into the cabinet.

•Remove packaging from the cooktop.

•To insure a good fit, position the cooktop

over the cutout opening and carefully lower

into place. Check edges all the way around

to be sure all cutout edges are concealed

and there are no gaps.

•Carefully, lift and remove the cooktop.

•Cut a 3/16" gasket strip in half. Peel off the

backing and apply to the underside of the

glass cooktop edge.

–on each side at least 3/8" from the back

and as close to the edge as possible without

protruding.

•Apply the other gasket strip to the underside

of the glass at the front of the cooktop.

•Remove remaining adhesive backing.

•Position the cooktop over the opening,

making sure that the power cord is dropped

into the cabinet.

•Lower the cooktop into the cutout, pressing

gently and evenly to seat.

1/16"

3/8"

Note: If the cooktop is installed in a 36" base

cabinet, the mounting brackets cannot be

used because of interference with the cabinet

sides. In this case, the cooktop can be secured

to the cabinet with angle brackets (not

supplied).

–Remove one screw at the bottom of the

cooktop body on both sides and secure the

bracket with those screws. Then, secure the

brackets to the cabinet sides.

•Insert hold-down bracket into highest slots

on the right and left sides of the cooktop:

– Cooktop has three slots, the highest

available will depend on the thickness of

the countertop.

•Secure the brackets to the underside of the

countertop with screws provided.

Gasket

Countertop

11

Page 12

Step

Front

Medium Head

And Cap

Medium Head

And Cap

Large Head

And Cap

Medium Head

And Cap

Small Head

And Cap

5

Electrical

Connections

Installation

Gas Downdraft Cooktop

•Connect the 3-pin plastic plug from the

blower/motor assembly to the 3-pin plastic

socket on the underside of the vent, next to

the conduit.

•Slide the metal cover over the connection

and secure with screws.

Step

6

Connect

Power

Step

7

Assemble

•Connect the 6-pin plastic plug from the

downdraft assembly to the 6-pin plastic

socket on the underside of the cooktop, next

to the power cord.

•Slide the metal cover over the connection

and secure with screws.

•Plug power cords into properly grounded

receptacle.

•Assemble burner as shown. Check to be sure

that burner heads are securely seated and

caps are positioned as shown.

Burner Grate

Service

Plate

Electrical

Supply Cord

Metal Cover

6-Pin

Plug

Electrical

6-Pin Socket

Pressure

Test Point

Pressure

Regulator

Burners,

Check

Ignition

12

Make sure slot in burner head

is positioned over electrode

Burner Cap

Burner Head

Burner Bowl

Electrode

•Check for proper ignition:

–Push in one control knob and turn 90° to

HIGH position.

–The igniter will spark and the burner will

light; the igniter will cease sparking when

the burner is lit.

–First test may require some time, while air is

flushed out of the gas line.

–Turn knob to OFF.

–Repeat the procedure for each burner.

Page 13

Step

8

Install

Installation

Gas Downdraft Cooktop

To raise the vent, turn the VENT knob to

RAISE/LOWER.

•Hold the knob until the vent begins to raise.

– The vent will automatically stop when it is

fully extended.

Filters

Check

Operation of

Downdraft

•Tip filter into the opening and pull straight

down so that the filter rests on slides.

•Slide the filter to the right side.

•Tip the other filter into the opening and

pull straight down.

•To turn the fan on, turn the FAN knob to

HIGH.

–Continue turning the FAN knob to select

a fan speed between HIGH and LOW.

Note: It is not necessary to turn the fan OFF

before lowering the vent. The fan will automatically turn off when the vent is lowered.

When the fan is not turned off before lowering the vent, it will automatically come on at

the previously selected speed when the vent is

fully raised.

To lower the vent, turn the VENT knob to

RAISE/LOWER. Hold the knob until the vent

begins to lower.

13

Page 14

This kit provides for the installation of the

blower and motor outside of the cabinet, such

as below the floor. Use this kit for indoor

remote installations only.

JXRB57 Kit

For Indoor Remote Blower Locations

Tools and Materials required:

• Pencil

• Measuring tape

• Drill with appropriate bits

• Nut driver

• Junction box

• Wire nuts

• Safety glasses

• 3-1/4" x 10" to 6" round transition.

• 3-1/4 x 10" duct, (or 6" round) sufficient length to reach

the outdoor wall cap or roof cap.

• Electrical cable and connectors, sufficient length to

connect the downdraft vent to the remote blower

location. 14-guage min. is recommended, must conform

to local codes.

Parts Supplied

Step

1

Prepare

the Vent

Note: A 3-1/4" x 10 transtion to 6" round is

required.

3"

Blower Wire Box

Loosen

Screw

Blower Conduit

Hanger Brackets

Package of screws

Cover Plate

• Flatten the shipping box to use as a pad.

• Place the unit on its back onto the protective pad.

• Remove the wire box on the plenum.

• Cut the blower leads approximately 3" from

the plug on the end of the vent.

• Remove the blower conduit by loosening the

screw on the fitting.

• Set aside the 3" wire leads with plug, wire

box and screws.

Outlet Plate

14

Page 15

JXRB57 Kit

14-1/2"

For Indoor Remote Blower Locations

Step

1

(continued)

• Remove the 4 nuts holding the blower to the

mounting plate. One nut is hidden inside

the outlet. Remove blower.

• Remove the blower mounting plate.

• Remove 2 screws along the bottom of the

blower box which are visible once blower

plate is removed.

• Carefully, turn the unit over to access the

back side.

• Remove 4 screws along the top of the blower

box.

• Turn unit over and remove the 4 screws

along the top.

• Remove the blower box.

• Retain all screws.

Important:

unused parts. If the

appliance is relocated at

a later time, parts may be

needed.

Save any

Hidden

Screws

Step

2

Determine

Blower

Location

• Determine location of the blower and

motor.

– The blower will fit between floor joists, 16”

on center. Or, provide a surface to attach

the entire assembly to the underside of the

floor.

• Secure mounting brackets to the top of the

blower with screws and nuts. One bracket in

each corner, as illustrated.

– Set the bracket at the ends of the curved

slots to reach a 14-1/2” span between floor

joists, or adjust for your installation

situation.

• Mark the installation location and cut hole

for 6” round duct.

• Secure the blower to the joists.

Blower

Blower Box

Blower

Mounting

Plate

15

Page 16

Step

Wiring to Blower Junction Box

Provided

Mounting

Screws

Blower

Wire

Box

Wire Nuts

3-Wire

Connectors

Plenum

JXRB57 Kit

For Indoor Remote Blower Locations

3

Connect

Ductwork

Downdraft

Duct Adapter

Outlet Cover

• The downdraft plenum can discharge from

either the right or left side. Select the side

that provides the best alignment to ductwork

extending to the blower assembly below.

– For a left side discharge, install the outlet

plate to the bottom of the plenum on the

left side. Install the cover plate to the

bottom of the right side. Reverse plates for

a right side discharge.

.

• Connect the plenum to the ductwork.

A transition is required to connect the

3-1/4" x 10" duct to the 6" round inlet on

the blower.

• Tape to seal all joints.

Step

4

Connect

Electrical

16

• Use electrical cable and connectors that

conform to local codes (14 gauge min. is

recommended). Use a length to reach

between the vent and the blower/motor

location.

• Attach the wire box removed from the

blower conduit to the end of new wiring.

• Use wire nuts to secure the wire to the 3"

remaining wires with plug.

• Insert the plug into the mating plug on the

vent.

• Reinstall wire box with original screws.

• Install a junction box withing reach of the

blower conduit.

• Use a conduit fitting to secure conduit to

junction box. The red plastic anti-short

bushing should be secured to the end of the

conduit.

• Use wire nuts to connect wires.

Page 17

The blower and motor assembly can be

Base

Assembly

Outlet Pan

mounted on an outside wall. This kit provides

a means to mount the blower outside with a

protective cover.

JXBC57 Kit

For Outdoor Remote Blower Locations

Materials Required

(not supplied)

• Approved liquid tight service connections for use

between the wire compartment on the base and inside

the structure.

• 7 wire nuts or other approved connectors.

• Six 5/16" dia. fasteners compatible with the type of

material the base is being fastened to.

• 3-1/4" x 10" to 6" round transition.

• 3-1/4 x 10" duct, (or 6" round) sufficient length to reach

the outdoor installation location.

• Electrical cable and connectors, sufficient length to

connect the downdraft vent to the remote blower

location. 14-guage min. is recommended, must

conform to local codes.

Tools required:

• Pencil or chalk

• Measuring tape

• Drill with appropriate bits

• Phillips head screwdriver

• 1/4" Nut driver

• Wire nuts

• Safely glasses

Step

1

Check

Parts

Supplied

• Separate the cover from the base assembly

by removing 5 screws. Retain screws.

• Check to be sure all parts are present.

Package of screws

4 Hanger Brackets

Cover

Cover Plate

Outlet Plate

Junction Box

Damper

17

Page 18

Step

10" Min

Above Ground

6-11/16"

16"

4-3/4"

6"

12"

Align

With Duct

Opening

On Outside

Wall

1-13/16"

12-15/16"

6 Holes

For 5/16

Fastners

3"

Blower Wire Box

Blower Conduit

Loosen

Screw

2

Mark

Mounting

Location

JXBC57 Kit

For Outdoor Remote Blower Locations

• The base is designed to be mounted to studs

on 16" centers. Use the dimensions shown to

determine the location of the ducting and

wiring through the wall.

– Or Place the base against the exterior wall

and mark the 6 mounting locations, the 6"

duct location and the hole for the wiring.

Use pencil or chalk.

• The bottom of the base assembly must be

10" min. above the ground. There should be

no obstructions to the discharge from the

damper.

• Cut a 6-1/8" dia. hole in the vertical structure to accommodate a 6" round duct

another hole for the wiring.

• Drill 6 pilot holes through the wall for the

6/16" fasteners.

Step

3

Prepare

the Vent

CAUTION:

do not damage electrical wiring or hidden utilities.

Check for interference with floor joists and stud walls. If

necessary, locate the base to provide a secure

installation.

• Place a 6" round duct through the hole

extending approximately 3" from the wall to

provide a proper seal with the blower.

Secure the duct to the building structure to

prevent it from being pushed back when the

blower is installed.

• Flatten the shipping box to use as a pad.

• Place the unit on its back onto the protective

pad.

• Remove the wire box on the plenum.

• Cut the blower leads approximately 3" from

the plug on the end of the vent.

• Remove the blower conduit by loosening the

screw on the fitting.

• Set aside the 3" wire leads with plug, wire

box and screws.

When cutting or drilling into a wall or ceiling,

18

Page 19

Step

3

(continued)

• Remove the 4 nuts holding the blower to the

mounting plate. One nut is hidden inside

the outlet. Remove blower.

• Remove the blower mounting plate.

• Remove 2 screws along the bottom of the

blower box which are visible once blower

plate is removed.

• Carefully, turn the unit over to access the

back side.

• Remove 4 screws along the top of the blower

box.

• Turn the unit over and remove the 4 screws

along the top.

• Remove the blower box.

• Retain all screws.

Important: Save any unused parts. If the

appliance is relocated at a later time, parts

may be needed.

JXBC57 Kit

For Outdoor Remote Blower Locations

Hidden

Screws

Blower

Blower

Mounting

Plate

Blower Box

Step

4

Connect

Blower

Wires

• The downdraft plenum can discharge from

either the right or left side. Select the side

that provides the best alignment to ductwork

extending to the blower assembly.

– For a left side discharge, install the outlet

plate to the bottom of the plenum on the

left side. Install the cover plate to the

bottom of the right side. Reverse plates for

a right side discharge.

.

• A transition is required to connect the

3-1/4" x 10" duct to the 6" round inlet on

the blower.

• Tape to seal all joints.

• Check that the red plastic anti-short bushing

is secured in the end of the conduit. Install

the blower conduit into the conduit connector

on the junction box and tighten the screw.

• Install a liquid tight fitting in the hole of the

wire compartment on the base, sized to fit wire

being used.

• Run the electrical wiring from the downdraft

vent to the wire compartment.

• Attach the green ground leads from the wire

compartment, connecting one to the green

ground lead on the blower and the other to

the ground lead of the wiring from the

downdraft vent.

• Connect the neutral (white) and power lead

(black) from the blower to the leads from the

downdraft vent.

• Use wire nuts to connect wires.

Duct Adapter

Base

Assembly

Wires

to Vent

Strain

Relief

Downdraft

Outlet Cover

Blower

Conduit

Red AntiShort Bushing

Conduit

Connector

Wire

Compartment

Green Ground

Leads

19

Page 20

JXBC57 Kit

For Outdoor Remote Blower Locations

Step

5

Connect

Electrical

Step

6

Mount

Blower

• Use electrical cable and connectors that

conform to local codes (14 gauge min. is

recommended). Use a length to reach

between the vent and the blower/motor

location.

• Attach the wire box removed from the

blower conduit to the end of new wiaring.

• Use wire nuts to secure the wire to the 3"

remaining wires with plug.

• Insert the plug into the mating plug on the

vent.

• Reinstall wire box with original screws.

• Mount the blower onto the mounting plate.

Secure with original nuts.

• Install damper to bottom of outlet with 4

screws.

Blower

Wire

Box

Plenum

Provided

Mounting

Screws

Wire Nuts

Wiring to Blower Junction Box

3-Wire

Connectors

Step

7

Finalize

Installation

20

• Place the cover over the the assembled kit

and secure with 16 screws.

Page 21

Notes

21

Page 22

Notes

22

Page 23

Notes

23

Page 24

Monogram.

General Electric Company

Louisville, KY 40225

NOTE: While performing installations described in this book,

safety glasses or goggles should be worn.

To obtain specific information concerning any

Monogram product or service, call GE Answer Center

®

consumer information service at 800.626.2000—any

time, day or night.

For Monogram local service in your area, call

1-800-444-1845.

NOTE: Product improvement is a continuing endeavor at General

®

Electric. Therefore, materials, appearance and specifications are

subject to change without notice.

Pub. No. 49-8999-1

Part No. 183D5580P082

2000 GE Appliances

(N.D. 505) 5/00

Printed in Mexico

Loading...

Loading...