Page 1

1.4 mm Working Tools

Operating Manual

GE

Inspection Technologies Remote Visual Inspection

www.geinspectiontechnologies.com

Page 2

Table of Contents

What You Have Received ......................................................................1

Distally Inserted Tools ..........................................................................1

Proximally Inserted Tools......................................................................3

1.4 mm Working Tools 1

Safety Cap ........................................................................................

Tools Requiring Disassembly ................................................................6

Hook / Comparitor (Gage) Assembly ..................................................10

User Care and Maintenance ..............................................................11

Service Contact Information ..............................................................12

What You Have Received

DISTAL REFERS TO WORKING END OF TOOL.

PROXIMAL

REFERS TO PLUNGER END OF TOOL.

Distally Inserted Tools

Part Number: Description:

WT-141432HC Hook Comparitor Cable 3.2M Working Length

WT-141426HC Hook Comparitor Cable 2.6M Working Length

WT-148032M 8.0mm Magnet Tool 3.2M Working Length

WT-148026M 8.0mm Magnet Tool 2.6M Working Length

WT-144032M 4.0mm Magnet Tool 3.2M Working Length

WT-144026M 4.0mm Magnet Tool 2.6M Working Length

WT-143532B 3.5mm Brush Tool 3.2M Working Length

WT-143526B 3.5mm Brush Tool 2.6M Working Length

5

Key:

WT=Working Tool, First Two Digits=Cable Diameter, Third and Forth Digits=Tool Diameter,

Fifth and Sixth Digits=Working Length.

www.geinspectiontechnologies.com

Page 3

2 1.4 mm Working Tools

Distally Inserted Tools (continued...)

1 Find the proximal end of the working tool and carefully insert the tool into the

working channel at the distal end of the VideoProbe

2 Carefully slide tool through the working channel to the desired location.

®

.

www.geinspectiontechnologies.com

Page 4

1.4 mm Working Tools 3

Proximally Inserted Tools

Part Number: Description:

WT-141432P 1.4mm Three Prong Gripper Tool 3.2M Working Length

WT-141426P 1.4mm Three Prong Gripper Tool 2.6M Working Length

WT-141432A 1.4mm Alligator Tool 3.2M Working Length

WT-141426A 1.4mm Alligator Tool 2.6M Working Length

WT-141432S 1.4mm Snare Tool 3.2M Working Length

WT-141426S 1.4mm Snare Tool 2.6M Working Length

Key:

WT=Working Tool, First Two Digits=Cable Diameter, Third and Forth Digits=Tool Diameter,

Fifth and Sixth Digits=Working Length.

1 Find the distal end of the working tool and carefully insert the tool into the

working channel at the proximal end of the VideoProbe.

www.geinspectiontechnologies.com

Page 5

4 1.4 mm Working Tools

Proximally Inserted Tools (continued...)

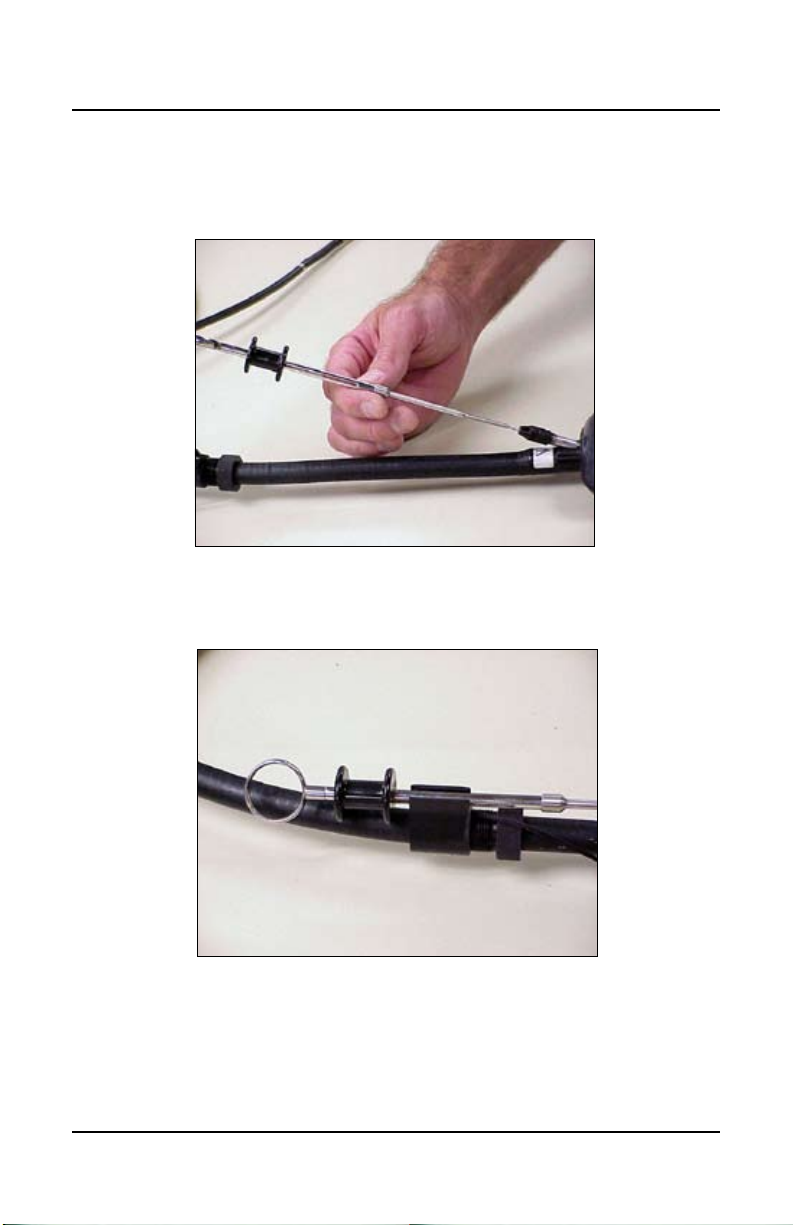

2 Carefully slide tool through the working channel to the desired location.

3 Use the clip on the Umbilical tube to keep Plunger Handle secure when not in

use.

www.geinspectiontechnologies.com

Page 6

1.4 mm Working Tools 5

Safety Cap

1 Use the supplied safety cap to secure the end of non-plunger activated tools.

www.geinspectiontechnologies.com

Page 7

6 1.4 mm Working Tools

Tools Requiring Disassembly

Part Number: Description:

WT-143032A 3.0mm Alligator Tool 3.2M Working Length

WT-143026A 3.0mm Alligator Tool 2.6M Working Length

Key:

WT=Working Tool, First Two Digits=Cable Diameter, Third and Forth Digits=Tool Diameter,

Fifth and Sixth Digits=Working Length.

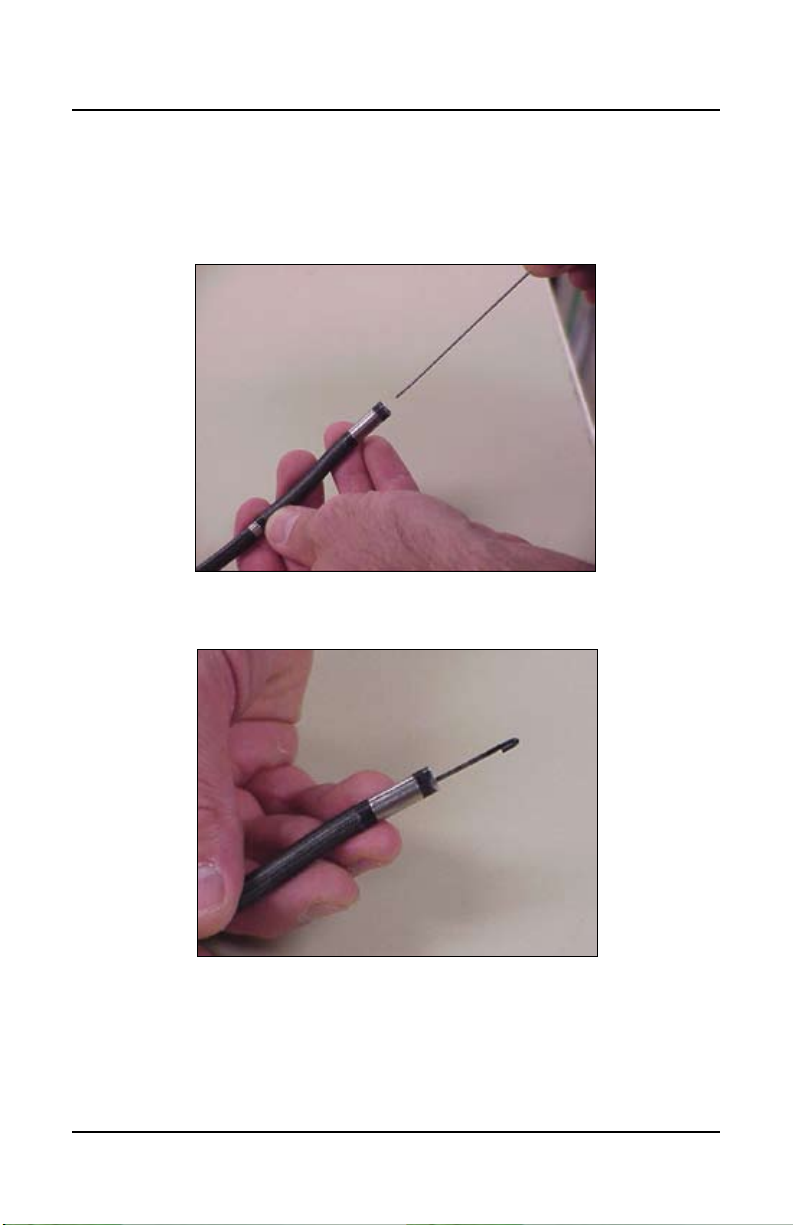

1 Plunger handle of working tool must be dissembled prior to insertion into the

working channel.

a Loosen thumbscrew.

www.geinspectiontechnologies.com

Page 8

1.4 mm Working Tools 7

Tools Requiring Disassembly (continued...)

b Slide back black Actuator.

c Unscrew metal cap.

www.geinspectiontechnologies.com

Page 9

8 1.4 mm Working Tools

Tools Requiring Disassembly (continued...)

d Remove cable pin from cable.

d Remove metal cap from cable.

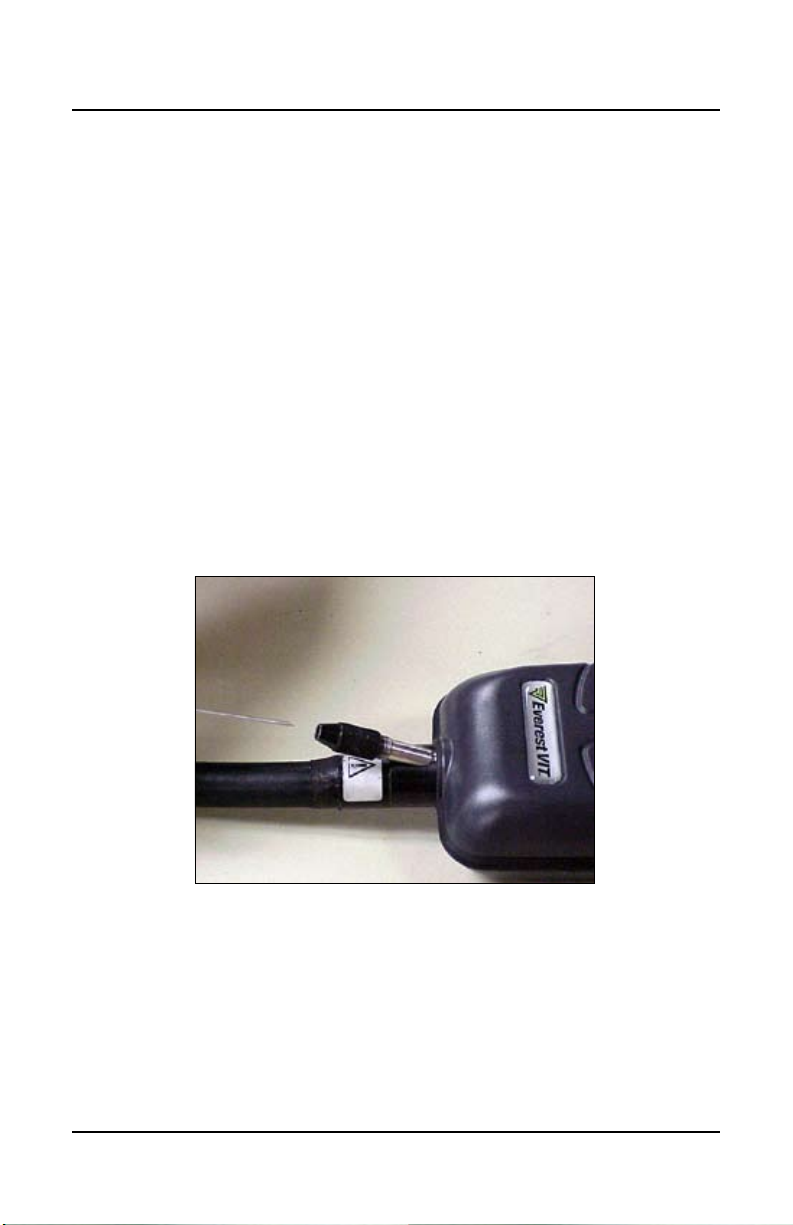

2 Insert proximal end of cable through the distal end of the VideoProbe®.

3 Re-assemble plunger handle in reverse order of Step 1 (e-a).

NOTE: On re-assembly make sure enough of the cable is showing so thumbscrew

makes a good connection.

www.geinspectiontechnologies.com

Page 10

1.4 mm Working Tools 9

Hook / Comparitor (Gage) Assembly

Part Number: Description:

WT-H Hook Piece (Qty 5)

WT-C Comparitor Piece (Qty 5)

Key:

WT=Working Tool, First Two Digits=Cable Diameter, Third and Forth Digits=Tool Diameter,

Fifth and Sixth Digits=Working Length.

NOTES:

• Always check the hook and comparitor (gage) assemblies prior to inspection of an

engine for any looseness, bends, deformity, or other irregularities.

• Check the threaded portion of the spring shaft. Do not use if it is deformed.

1 Grip cable portion with pliers and push the hook or comparitor (gage) over

the spring shaft’s distal end.

www.geinspectiontechnologies.com

Page 11

10 1.4 mm Working Tools

Hook / Comparitor (Gage) Assembly (continued...)

2 Screw the hook over the spring shaft’s distal end slowly turning the hook

clockwise.

www.geinspectiontechnologies.com

Page 12

1.4 mm Working Tools 11

Environmental Compliance

The equipment that you bought has required the extraction and use of natural resources

for its production. It may contain hazardous substances that could impact health and the

environment.

In order to avoid the dissemination of those substances in our environment and to diminish

the pressure on the natural resources, we encourage you to use the appropriate take-back

systems. Those systems will reuse or recycle most of the materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact

your local or regional waste administration.

Visit www.ge.com/inspectiontechnologies for take-back instructions and more information

about this initiative.

www.geinspectiontechnologies.com

Page 13

12 1.4 mm Working Tools

Service Contact Information

USA

GE Inspection Technologies Tel: 315-554-2000 ext. 1

Product Service Dept. Fax: 866-899-4184

721 Visions Drive Email: rvi-service@ge.com

Skaneateles, NY 13152

Germany

GE Inspection Technologies Tel: +49-7471-9882 20

Lotzenäcker 4 Fax: +49 7471-9882 30

72379 Hechigen Email: rvi-infoeuropa@ge.com

Hong Kong

GE Inspection Technologies Tel: +852-2877-0801

Unit 1602, 16/F Sing Pao Building Fax: +852-2877-0868

101 King's Road Email: rvi-infohongkong@ge.com

North Point, Hong Kong

www.geinspectiontechnologies.com

Page 14

©2008 General Electric Company.

VideoProbe is a registered trademark of General Electric Company.

XL PRO is a trademark of GEneral Electric Company.

Customer Support Centers

North/South America

721 Visions Drive

Skaneateles, NY 13152

Tel: 888-332-3848

315-554-2000 ext . 1

Email: geit-info@ge.com

Europe

Lotzenäcker 4

72379 Hechingen

Germany

Tel: +49 (0) 7471 9882 0

Email: rvi-infoeuropa@ge.com

Asia/Pacific

Unit 1602, 16/F Sing Pao Building

101 King’s Road

North Point

Hong Kong

Tel: +852 2877 0801

Email: rvi-infohongkong@ge.com

XA161 Rev. F Printed in USA

www.geinspectiontechnologies.com

Manufactured in USA by GE Inspection Technologies

Loading...

Loading...