Page 1

GE

Measurement & Control

XL Go+™ VideoProbe

Inspection Technologies

®

XL Go+ delivers increased prob-

ability of detection with new

XpertSuite™

Feel more confident about your

assets and the decisions you

need to make

XL Go+ VideoProbe

Page 2

See more easily

XL Go+™ VideoProbe® is one of the most portable and ver-

satile video borescopes on the market today and with new

XpertSuiteTM features like enhanced steering responsiveness, improved probe light output, a sunlight readable LCD

and external monitor, XL Go+ provides you with the best

possible quality of defect information.

Make better decisions through better defect detection.

See the Dierence

See how the XpertSuite features improve probabilitiy of

detection. To watch, snap a photo of the icon or go to

http://bit.ly/xEvbF8

XL Go+ VideoProbe

Page 3

Redefine Portability

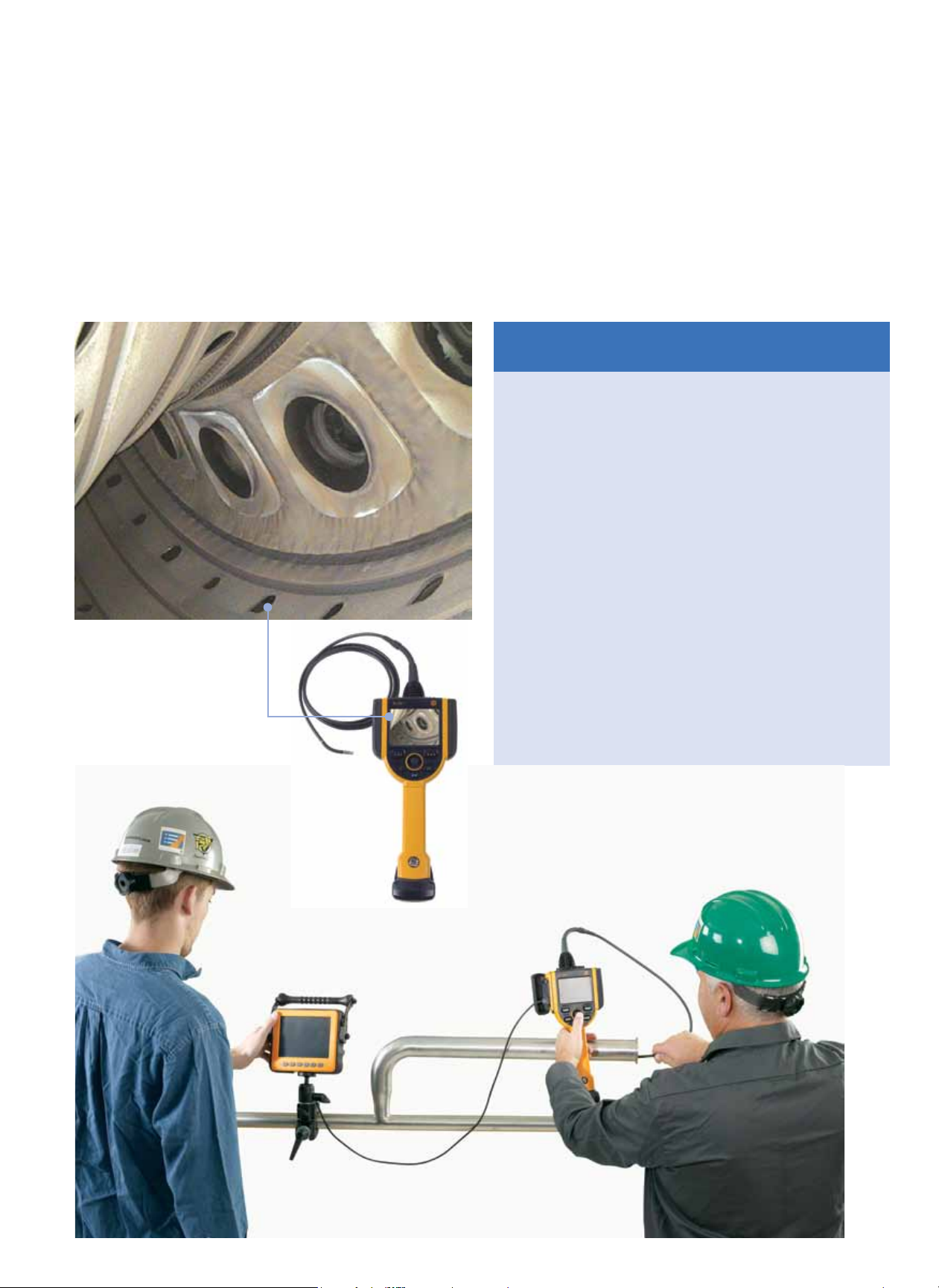

Whether you're climbing a 100 meter tower to inspect a wind

turbine gearbox, crawling atop a renery heat exchanger or

creeping under a turbofan jet engine on a test stand, a por-

table video borescope is essential.

The XL Go+ VideoProbe system combines portability with

performance—delivering sharp, clear digital images on a

system designed to meet inspection needs across a wide

range of industry applications.

XL Go+ combines cordless operation with a host of features

found in systems three times as large. Unlike other video borescopes, the XL Go+ has no bulky base unit, no backpacks, no

tethered scopes or power cords to get in the way—ensuring

unlimited inspection access and unprecedented ease of use.

XL Go+ in wind turbine nacelle

XL Go in wind turbine nacelle

XL Go+ VideoProbe

1

Page 4

XL Go+ in gas trubine

2

XL Go+ VideoProbe

Page 5

Redefine Image Quality

The ultra-compact XL Go+ VideoProbe system doesn’t sacrice image quality for the sake of portability. Its white LED and crystal–clear active matrix VGA LCD give inspectors the sharp, detailed images needed to ensure accurate detection and analysis,

even in applications with poor lighting conditions. The XpertBrightTM LCD has enhanced image quality for better readability in

sunny or snowy outdoor environments and harsh indoor lighting. An intuitive user interface makes it easy to save still images or

record motion video to the internal ash memory or removable USB® ThumbDrive®.

XL Go+'s Versatile Features

•

XpertSuite—enhances the probability of detecting

and identifying aws using precise steering, superior

visibility and easier viewing.

•

LED technology—produces more light output than

most other LED video borescope, uses less power

and runs cooler than traditional illumination systems.

•

VGA LCD—matches display to CCD imager

performance for outstanding image quality.

•

Still images and motion video—captures non-com-

pressed BMPs, compressed JPGs or MPEG video.

•

Optical tip adapters—oers numerous Field-of-View,

Depth-of-Field and Direction-of-View options for

enhanced versatility in multiple applications, and are

more reliable than LED lenses.

XL Go+ with XpertVision

TM

External Monitor

XL Go+ VideoProbe

3

Page 6

XL Go+ in engine inspection

XL Go+ VideoProbe

Page 7

Redefine Ruggedness

The XL Go+ VideoProbe system is constructed to withstand the

rigors of the industrial workplace. Shock absorbing materials

and seals are strategically incorporated to resist impact

damage and to prevent dust and water intrusion.

To ensure top performance in a wide range of environmental

conditions, XL Go+ has been subjected to a battery of

performance tests.

Performance Tests

•

MIL-STD-810G

•

Test Method 506.4 Rain and Blowing Rain

•

Test Method 507.4 Humidity

•

Test Method 509.4 Salt Fog

•

Test Method 510.4 Sand and Dust

•

Test Method 511.4 Explosive Atmosphere

•

Test Method 514.5 Vibration

•

Test Method 516.5 Shock

•

Test Method 521.2 Icing/Freezing Rain

•

MIL-STD-461F2 (Above Deck)

•

Test Method RE102 Radiated Emissions

•

Test Method RS103 Radiated Susceptibility

Note: All tests were performed on a fully functioning

system, including monitors.

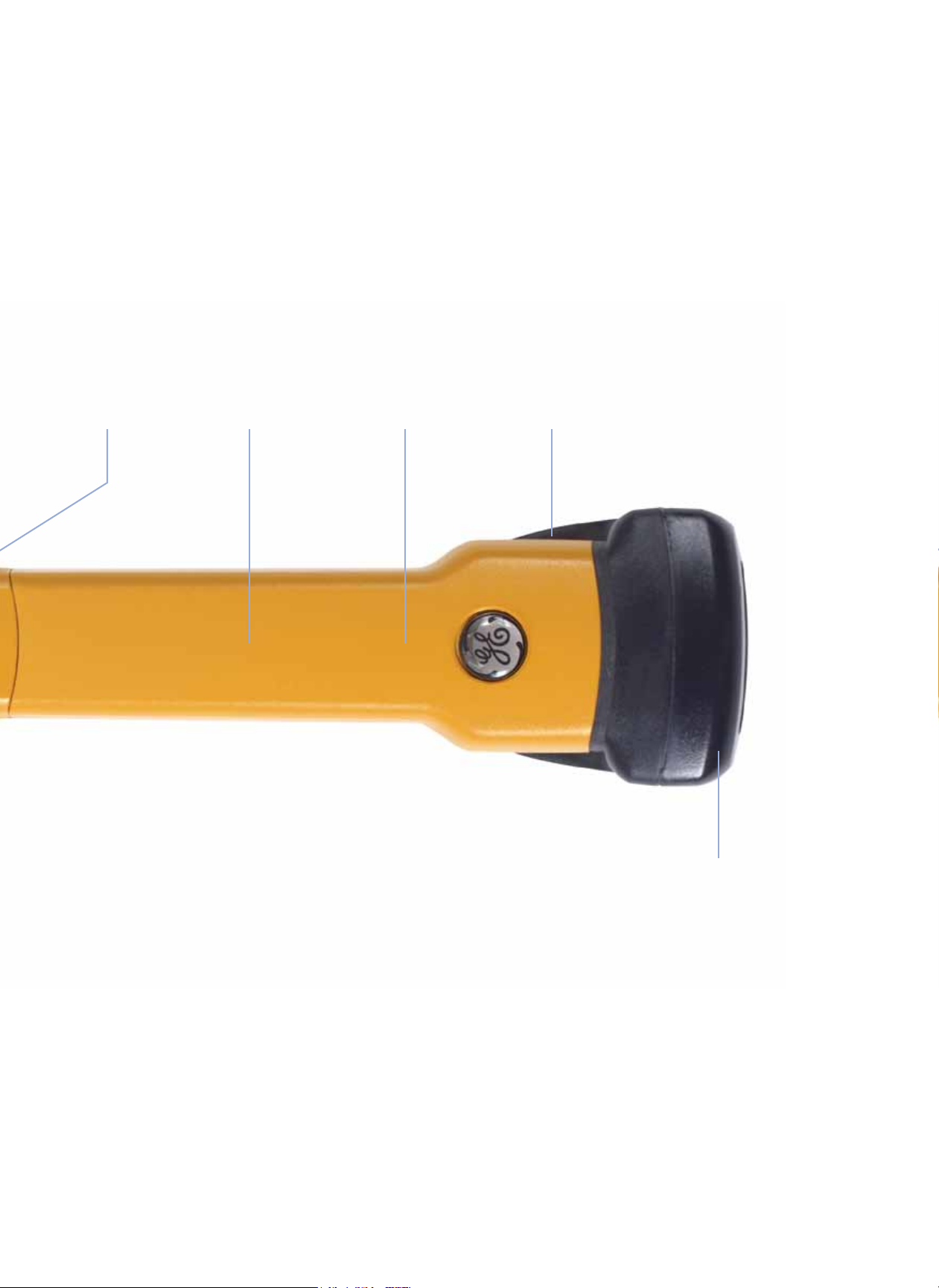

Titanium camera head is eight times

generation video borescopes

1

stronger than previous

Laser-welded bending neck seam

http://bit.ly/wkSIFK

See Testing

See how XL Go+ performs during testing.

To watch, snap a photo of the icon or go to

http://bit.ly/wkSIFK

Double-threaded tips

1

United States Depar tment of Defense - Test Method Standard for Environmental

Engineering considerations and laboratory tests

2

United States Department of Defense Interface Standard – Requirements for the Control of

Electromagnetic Interference Characteristics of Subsystems and Equipment

Double tungsten braid

insertion tube

Note: 6.1 mm Ø probe shown at 2:1 scale

XL Go+ VideoProbe

5

Page 8

D

adapts to menu state

Soft Keys

Torsional Strain Relief

provides insertion tube rotation independent

of hand-set

XL Go+ VideoProbe

XpertBright Readable LCD

A

B

C

Soft Keys

B

adapts to menu state

provides maximum readability in harsh

lighting environments for enhanced image quality

Page 9

Shock Absorbing Materials

XpertSteer Probe Articulation

offers quick steering responsiveness for tight

probe control - bump steering enables slight

adjustments to probe position

High Strength Housing

uses impact-resistant materials

for system durability

Colored Housing

provides high visibility

protects system from impact damage

Shown Actual Size

®

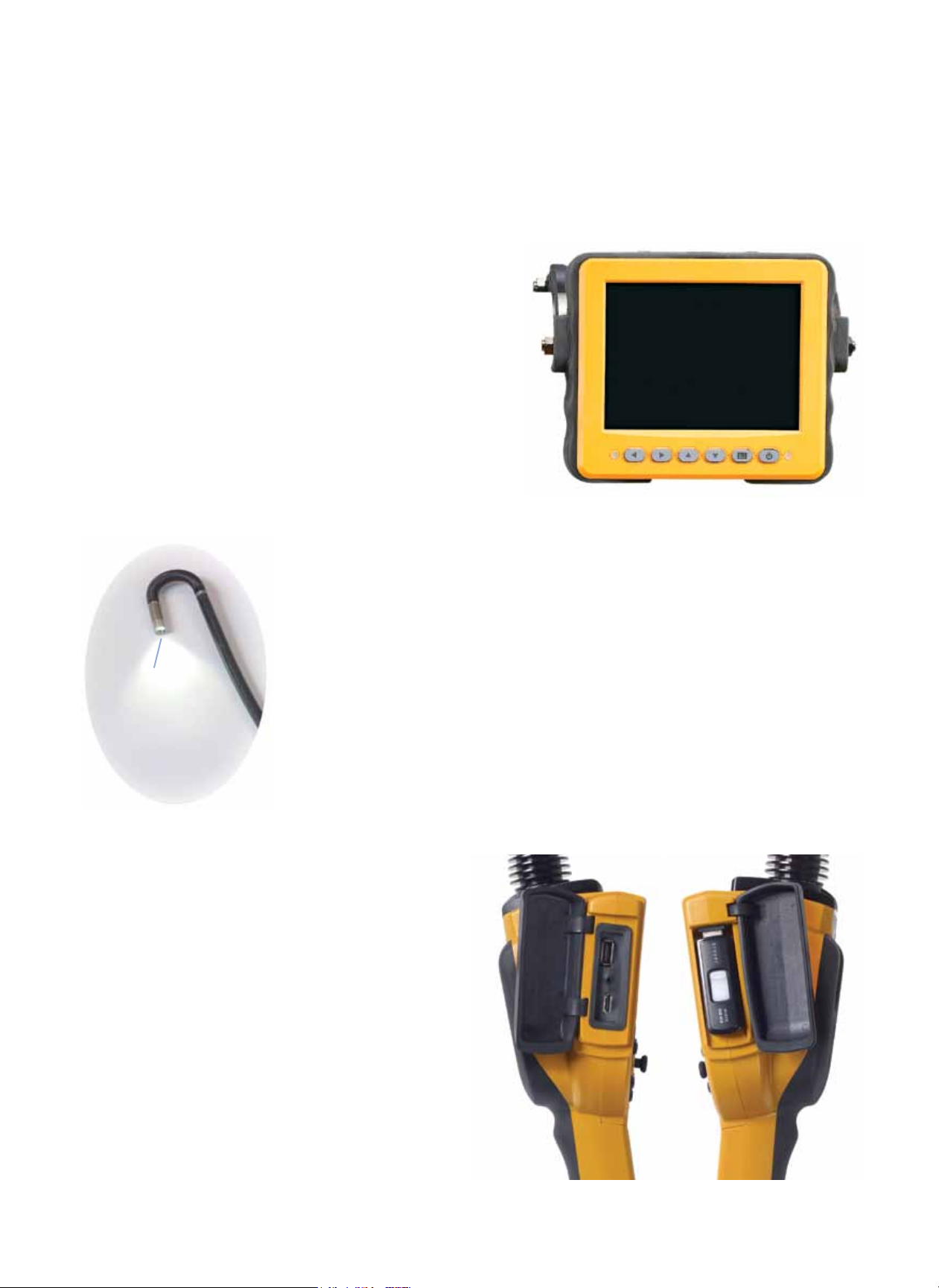

Port

A: Second USB

Li-Ion Battery

(four-hour battery optional)

provides two hours of operation

monitor or other external devices

allows use of additional

memory devices

B: Headphone Jack

allows recording and listening

to audio annotation

C: VGA Video Out Port

displays XL Go+ video on XpertVision

D: Covered USB Port

protects memory device

XL Go+ VideoProbe

Page 10

XpertSuiteTM Improves Probability of Detection

XL Go+ has a host of new features designed to help increase the probability of detection. XpertSuite complements the Go's

superior image quality to provide enhanced performance to assist in locating and measuring defects.

XpertVision™ External Monitor

An optional battery-operated monitor supplements the XL Go+

system. The monitor easily connects to the Go and provides additional

viewing by a second inspector or remote observation.

XpertBright™ Readable LCDs

Both the XL Go+ and the XpertVision LCDs are designed for maximum

readability in strong outdoor lighting, harsh factory lighting or snowy

environments. XpertBright enables optimum viewing while enhancing

image quality.

XpertVision External Monitor

XpertSteer™ Probe Articulation

Coupled with Servomotor All-Way® articulation, XpertSteer oers quick, responsive

steering. When you stop steering the probe stops moving - no more overshooting.

A bump steering feature enables tight probe control. A small "bump" of the joystick

moves the probe at a small increment for better defect visibility.

Camera in tip

XpertLight™ Probe Illumination

Increased probe light output improves the image quality and the likelihood of a

thorough inspection. The increase in light output also improves performance in

larger area applications.

Temperature Warning System

A sensor integrated into the camera head monitors

temperature and provides three levels of on-screen indication

to prevent damage from high-temperature environments.

Probe Operating Temperature up to 100°C (212°F)

The probe can gain faster access in higher-temperature

applications where cooling time is needed (e.g., aircraft

engines).

Data Storage Options

Save still images and MPEG motion video to internal ash

memory or choose between two external USB® ThumbDrive®

bays.

8

XL Go+ VideoProbe

Page 11

XL Go+ in large gas turbine

XL Go+ VideoProbe

9

Page 12

Powerful Software Technology

Advanced User Interface

Intuitive drop-down menus combined with on-screen cues make XL Go+

simple to operate and powerful enough to offer text, audio and graphic

annotation.

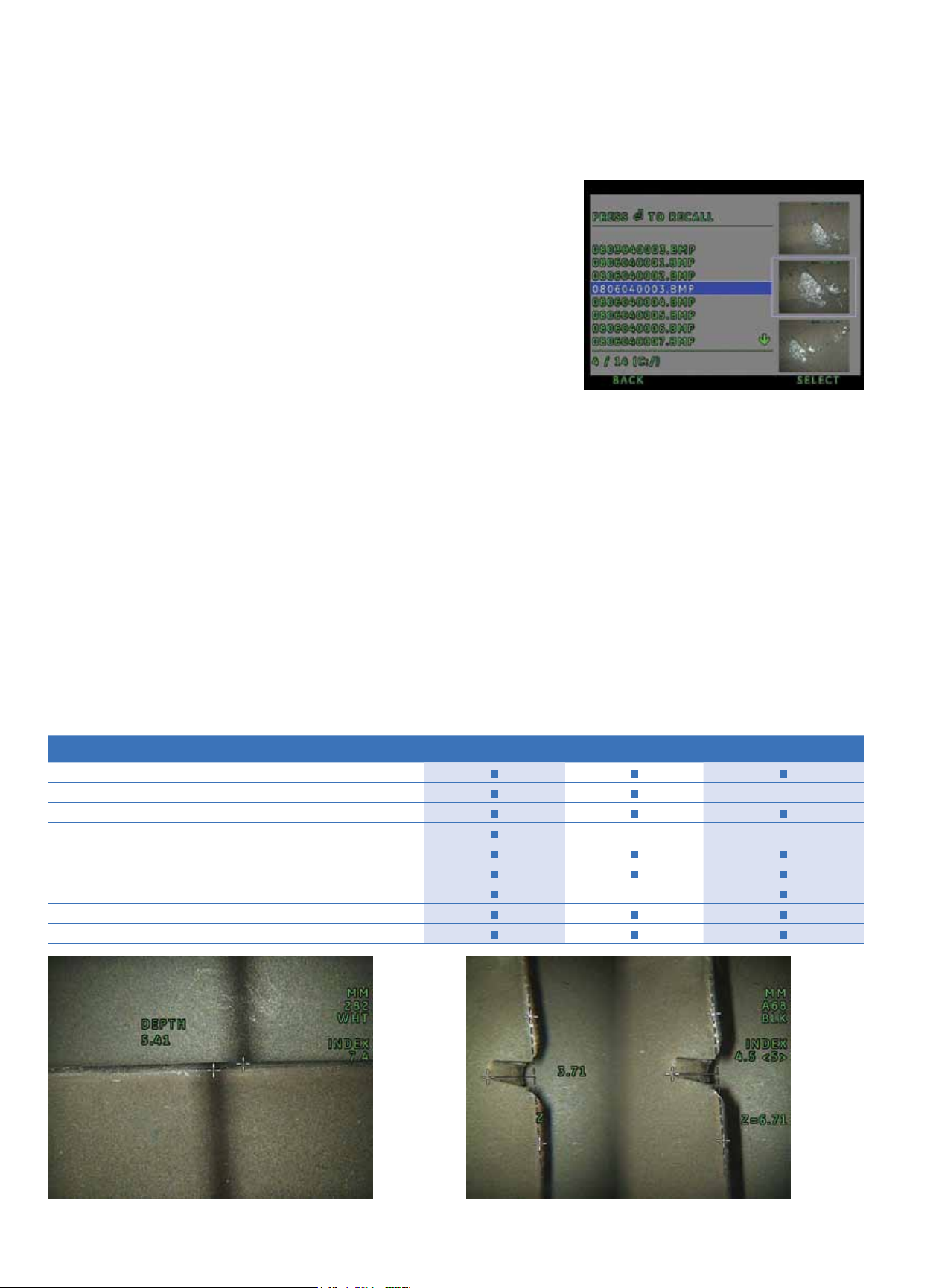

File Manager

XL Go+ uses a convenient method for recalling files, creating folders, copying

and viewing thumbnail images. Save images directly to USB® ThumbDrive®

and transfer files from the system to USB drives.

File management system with a thumbnail-based image and

video recall system

Patented Menu Directed Inspection (MDI)

MDI is the first software tool to standardize the inspection process in the NDT industry. This optional patented software helps

guide inspectors through the inspection process and intelligently names saved images and videos, and auto-generates

reports—saving time, improving quality and increasing productivity.

Tip Map

XL Go+ has a Tip Map that aids inspectors in guiding the tip. A grid shows the tip direction and helps inspectors maintain orien-

tation or better navigation.

Measurement

The XL Go+ is the only video borescope to offer ShadowProbe®, StereoProbe® and Comparison measurement capabilities.

Inverse + and Zoom features allow precise cursor placement.

Supported Measurement Features

Feature ShadowProbe

Length/Distance

Depth

Point to Line

Skew

Area

Multi-Segment Length

Circle Gauge

3x Zoom Windows

Five Measurements per Image

®

StereoProbe

®

Comparison

ShadowProbe measurement

10

XL Go+ VideoProbe

StereoProbe measurement

Page 13

System and Accessories

Standard Accessories

A: Operating Manual

B: Optical Tip Case

C: 8GB ThumbDrive

D: AC Battery Charger

E: XL Go+ System with two-hour battery

F: Standard Shipping/Storage Case

Optional Accessories

G: XpertVision External Monitor

H: Tube Gripper & Rigidizer

I: Mini Magic Mount Kit

J: Four-Hour Battery

®

G

A

I

H

E

F

J

D

B

C

Mini Magic Mount Kit Empty and Mounted Menu Directed Inspection Software

Tube Gripper Two- and Four-Hour Battery Rigidizers and Grippers

XL Go+ VideoProbe

11

Page 14

Technical Specications

System

Case Dimensions: 48.8 x 38.6 x 18.5 cm (19.2 x 15.2 x 7.3 in)

System Weight:

In Case: 6.5 kg (14.3 lb)

Without Case: 1.73 kg (3.8 lb)

Power: 7.2V, 5100 mAh or 10,200 mAh Battery Pack

Construction: Polycarbonate housings with integrated Versalon

Dimensions: 9.53 x 13.34 x 34.29 cm (3.75 x 5.25 x 13.50 in)

LCD Monitor: Integrated transective 9.40 cm (3.70 in) active matrix

Joystick Control: 360° All-Way

Button Set: Access user functions, measurement and digital

Audio: Integrated 2.5 mm headset/microphone jack

Internal Memory: 4 GB ash memory

Data I/O Ports: Two USB

Brightness Control: Auto and Variable

Illumination Type: White LED

Long Exposure: Up to 12 seconds via auto and manual mode

White Balance: Fac tory default or user dened

XpertVision

(optional external monitor):

Weight: 1.12 kg (2.46 lb) with battery

LCD: 16.25 cm (6.4 in) diagonal active matrix VGA color LCD

Resolution: 640 x 480 pixels

Sunlight Readable: 1100 Cd/Msquared

Mounting: 75 x 75 mm (1/4-20) and vesa mount

Battery Run Time: 2 hours

AC: 90-264 VAC, 47-63 Hz, <1.2Arms @ 90 VAC

DC: 10.2V +5%/-3%,4.9 A

™

bumpers

VGA color LCD with Xper tBright, 640 x 480 resolution

gesture, menu access and navigation

functions

VGA Video Out

with XpertBright

®

tip articulation with Xper tSteer, bump

®

2.0 ports

(JP)

Standards Compliance and Classications

MIL-STD -810G: United States Department of Defense Environment Test s

MIL-STD -461F: United States Depar tment of Defense Electromagnetic

Standards Compliance: Group 1, Class A: EN61326-1

UL, IEC, EN CSA-C22.2:61010-1

UN/DOT T1-T8

Sections 506.4, 507.4, 509.4, 510.4, 511.4, 514.5, 516.5, 521.2

Interference RS103 and RE102 (Navy above deck)

Operating Environment

Tip Operating Temp: -25°C to 100°C (-13°F to 212°F)

Reduced articulation below 0°C (32°F)

System Operating Temp: -20°C to 46°C (-4°F to 115°F)

Storage Temperature: -25°C to 60°C (-13°F to 140°F)

Relative Humidity: 95% maximum, non-condensing

Waterproof: Insertion tube and tip to 14.7 psi (1 bar, 10.2 m of H2O,

Ingress Protec tion: IP55

33.5 ft of H2O)

Software

Operating System: Real-time, multi-tasking operating system

User Interface: Simple drop-down, menu-driven operation

Menu navigation using articulation joystick

File Manager: Embedded file manager software supporting:

File and Folder creation, naming, deleting

Store to internal flash (C:\) or USB ThumbDrive

Copy between USB and C:\

Audio Data: PC compatible (.A AC) file format

Image Control: Invert, Zoom (5X digital)

Image Capture and Recall

Digital Zoom: Continuous (5.0X)

Image Formats: Bitmap (.BMP), JPEG (.JPG)

Video Format: MPEG 4

Text Annotation: Built-in full screen text overlay generator

Graphic Annotation: User placement of arrows

Articulation Control: "Steer & Stay" articulation lock/fine ar ticulation

Tip “Home” return to neutral forward-tip orientation

User-selectable fine or coarse control

XpertSteer probe articulation offers quick steering

responsiveness for tight probe control - bump steering

enables slight adjustments to probe position

Software Updates: Field updateable via USB ThumbDrive

Languages: English, Spanish, French, German, Italian, Russian,

Japanese, Korean, Portuguese, Chinese, Polish

®

Tip Articulation

Insertion Tube Length Straight Tube

2.0 m, 3.0 m, 3.2 m, 4.5 m Up/Down – 160° min, Left/Right – 160° min

6.0 m, 8.0 m, 9.6 m Up/Down – 150° min, Left/Right – 150° min

Note: Typical articulation exceeds minimum specications

Camera

5.0 mm ( 0.197), 6.1 mm (0.242 in) and 8.4 mm (0.331 in) Diameter Probes

Image Sensor: 1/6 inch Color SUPER HAD

Pixel Count: 440,000 pixels

Housing: Titanium

3.9 mm (0.154 in) and 6.2 mm (0.244 in) Diameter Probes

Image Sensor: 1/10 inch Color SUPER HAD

Pixel Count: 290,000 pixels

Housing: Titanium

CAMER A DIAME TER INSERTION TUBE WORKING LENGTH

3.9 mm (0.154 in) 2.0 m (6.6 ft) 3.0 m (9.8 ft)

5.0 mm (0.197 in) 2.0 m (6.6 ft) 3.0 m (9.8 ft)

6.1 mm (0.242 in) 2.0 m (6.6 ft) 3.0 m (9.8 ft) 4.5 m (14.8 ft) 6.0 m (19.7 ft) 8.0 m (26.2 ft)

6.2 mm (0.244 in) 3.2 m (10.5 ft)

8.4 mm (0.331 in.) 2.0 m (6.6 ft) 3.0 m (9.8 f t) 4.5 m (14.8 ft) 6.0 m (19.7 ft) 8.0 m (26.2 ft) 9.6 m (31.5 ft)

™

CCD camera

™

CCD camera

12

XL Go+ VideoProbe

Page 15

Technical Specications

Tip Optics

Tip View (DOV) Tip Color Field of

View

(FOV)*

Standard Tips

FORWARD

FORWARD

FORWARD

FORWARD

FORWARD

FORWARD

FORWARD

FORWARD

FORWARD

OBLIQUE

FORWARD

FORWARD

FORWARD

FORWARD BLACK 120˚ 5–200 mm (0.20–7.87 in.) XLG3T84120FN

FORWARD

FORWARD

FORWARD

SIDE

SIDE

SIDE

SIDE

SIDE

SIDE

SIDE

SIDE

SIDE

SIDE

SIDE

SIDE

NONE

ORANGE

NONE

WHITE

ORANGE

YELLOW

BLACK

BLACK

PURPLE

NONE

YELLOW

BLACK

NONE

WHITE

YELLOW

BROWN

RED

BROWN

GREEN

BLUE

BLUE

RED

GREEN

BLUE

BROWN

GREEN

BLUE

120˚ 5–120 mm (0.20–4.72 in) XLG3T61120FG

100˚ 5–120 mm (0.20–4.72 in) PXT5100FG

120˚ 25 mm (0.98 in.)–innity PXT62120FF

120˚ 4–190 mm (0.16–7.48 in.) PXT62120FN

120˚ 4–100 mm (0.16–3.94 in) XLG3T61120SG

100˚ 4–100 mm (0.16–3.94 in) PXT5100SG

120˚

ShadowProbe® Measurement Tips

FORWARD

SIDE

WHITE

BLUE

StereoProbe® Measurement Tips

FORWARD

FORWARD

FORWARD

SIDE

SIDE

SIDE

SIDE

SIDE

*FOV is specified diagonally.

**Indicates tips with maximum brightness.

BLACK

BLACK

BLACK

BLUE

BLUE

BLUE

BLUE

BLUE

50˚/50˚

60˚/60˚

60˚/60˚

50˚/50˚

45˚/45˚

50˚/50˚

60˚/60˚

60˚/60˚

Depth of Field

(DOF)

80˚ 6–80 mm (0.24–3.15 in) PXT480FG

90˚ 3-40 mm (0.12-1.57 in) PXT490FN

50˚ 50 mm (1.97 in)–innity PXT550FF XLG3T6150FF

50˚ 12–200 mm (0.47–7.87 in) PXT550FG XLG3T6150FG

80˚ 3-20 mm (0.12-0.79 in) PXT580FN XLG3T6180FN

90˚ 20 mm (0.79 in)-innity XLG3T6190FF

50˚ 12–80 mm (0.47–3.15 in) XLG3T6150FB

40˚ 100 mm (3.94 in.)–innity PXT6240FF

40˚ 250 mm (9.84 in)–innity XLG3T8440FF**

40˚ 80 - 500 mm (3.15 - 19.68

in)

80˚

25–500 mm (0.98–19.68

in)

80˚ 4–80 mm (0.16–3.15 in) PXT480SG

90˚ 2-16 mm (0.08-0.63 in) PXT490SN

50˚ 45 mm (1.77 in.)–innity XLG3T6150SF

50˚ 9–160 mm (0.35–6.30 in) PXT550SG XLG3T6150SG

80˚ 1–20 mm (0.04–0.79 in) PXT580SN XLG3T6180SN

80˚ 18 mm (0.71 in) – innity PXT6280SF

80˚ 5 mm (0.20 in) – innity PXT62120SN

40˚ 250 mm (9.84 in)–innity XLG3T8440SF**

80˚

25–500 mm (0.98–19.68 in)

4–200 mm (0.16–7.87 in)

50˚ 12–30 mm (0.47–1.18 in) XLG3TM6150FG

50˚ 7–24 mm (0.28–0.94 in) XLG3TM6150SG

5–45 mm (0.20–1.77 in) PXTM45050FG

4–80 mm (0.16–3.15 in) PXTM56060FG

4–50 mm (0.16–1.97 in)

4–45 mm (0.16–1.77 in) PXTM45050SG

2–50 mm (0.08–1.97 in.) PXTM54545SG

2–50 mm (0.08–1.97 in)

4–80 mm (0.16–3.15 in) PXTM626060SG

4–50 mm (0.16–1.97 in)

3.9 mm Optical

Tip Part #

5.0 mm Optical

Tip Part #

6.1 mm Optical

Tip Part #

XLG3TM616060FG

XLG3TM615050SG

6.2 mm Optical

Tip Part #

PXTM626060FG

8.4 mm Optical

Tip Part #

XLG3T8440FG

XLG3T8480FG

XLG3T8480SG

XLG3T84120SN

XLG3TM846060FG

XLG3TM846060SG

XL Go+ VideoProbe

13

Page 16

US

www.geinspectiontechnologies.com

Standar ds Complianc e

Every Measurement System is su pplied with a Certif icate

of Comp liance that indicates t hat the prob e was

manufa ctured and tested to me asurement s tandards

tracea ble to NIST (N ational Ins titute of Sta ndards and

Technolo gy). Furth er, ever y Measureme nt System is

suppli ed with a me asurement ve rification bloc k that

contain s test targ ets which ar e NIST tracea ble.

C

GEIT-65045EN (01/12)

© 2012 General Electric Company. All Rights Reserved. Specications subject to change without prior notice. Video Probe, StereoProbe, Sha dowProbe, All-Way and X pertSuite are registered t rademarks of GE Inspe ction Techn ologies, LP. XL Go+ i s a trademark of GE I nspection Technologies, LP. Other company or product names mentioned in this document may be trademarks or registered trademarks of their respective

companies, which are not aliated with GE.

XL Go+ VideoProbe

Loading...

Loading...