Page 1

Technical Service Guide

September 2018

2017/2018 18, 24, 26 Cu. Ft. BottomFreezer Refrigerators

GYE18JBL

GYE18JML

GYE18JSL

GYE18JEM

GFE24JGKF

GFE24JMKF

GFE24JSKF

GFE24JBL

GFE26JBM

GFE26JEM

GFE26JMM

GFE26JSM

XFE26JSM

31-9293

Page 2

Safety Information

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing

this product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

Warranty

For Warranty Information:

1. Go to http://products.geappliances.com

2. Search the model number.

3. Click on the Literature tab.

4. Click on Use and Care Manual.

5. Locate the Warranty page.

GE Appliances, a Haier Company

Copyright © 2018

All rights reserved. This service guide may not be

reproduced in whole or in part in any form without written

permission from GE Appliances, a Haier Company.

– 2 –

Page 3

Table of Contents

Safety Information ........................................................................................................................2

Warranty .......................................................................................................................................2

Table of Contents ..........................................................................................................................3

Safety Requirements ....................................................................................................................9

Nomenclature ...............................................................................................................................10

Specications ...............................................................................................................................11

Installation ...................................................................................................................................12

Refrigerator Location ............................................................................................................12

Additional Specications .......................................................................................................12

Clearances ...........................................................................................................................12

Leveling ................................................................................................................................12

Leveling Refrigerator Doors ..................................................................................................13

Operating Instructions .................................................................................................................14

Temperature Control .............................................................................................................14

Cooling System O ...............................................................................................................14

°F to °C .................................................................................................................................14

Tone Volume .........................................................................................................................14

Door Alarm ............................................................................................................................14

Lock ......................................................................................................................................15

Turbo Cool ............................................................................................................................15

Demo Mode ..........................................................................................................................15

Sabbath Mode ......................................................................................................................15

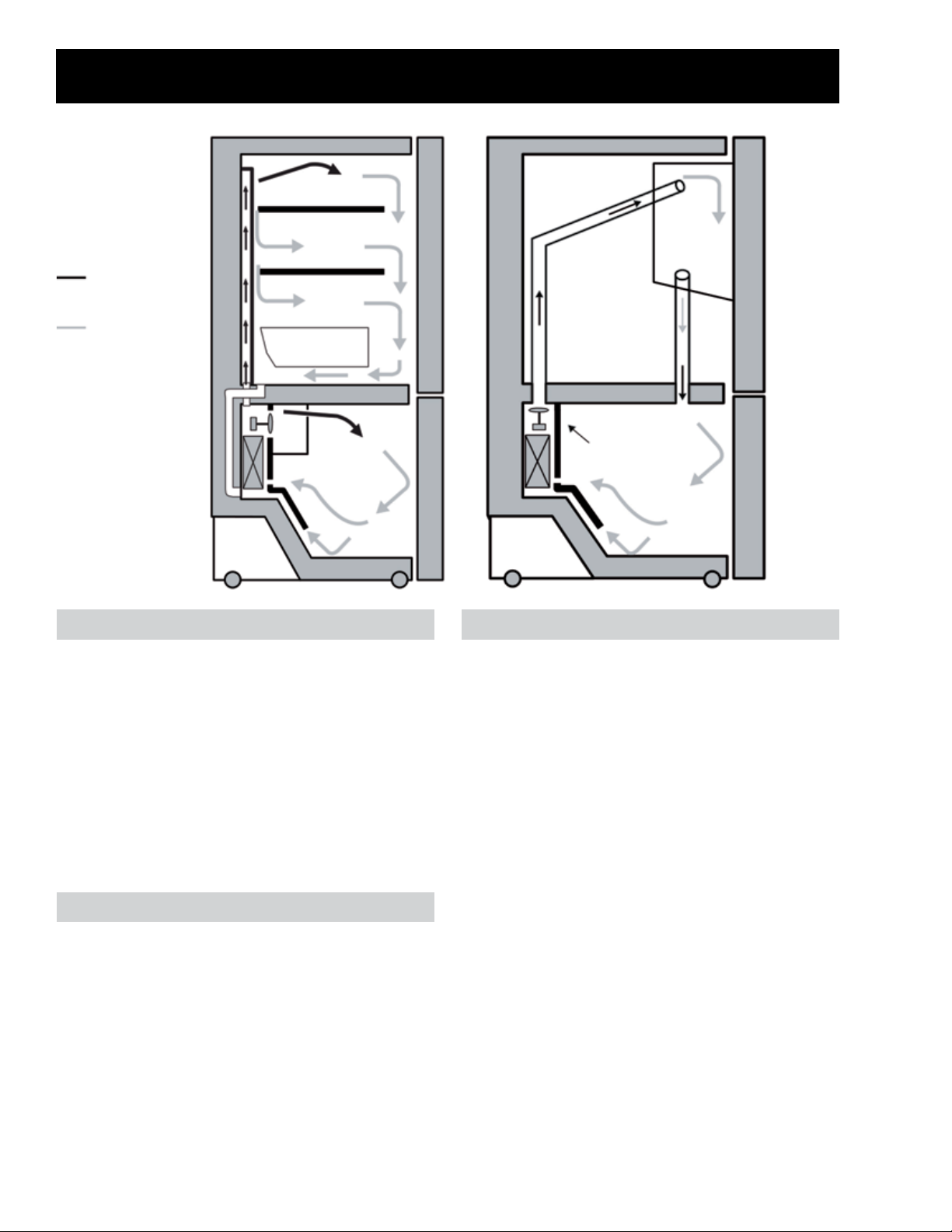

Air Flow .........................................................................................................................................16

Refrigerator Air Flow .............................................................................................................16

Freezer Air Flow ...................................................................................................................16

Ice Box Air Flow ....................................................................................................................16

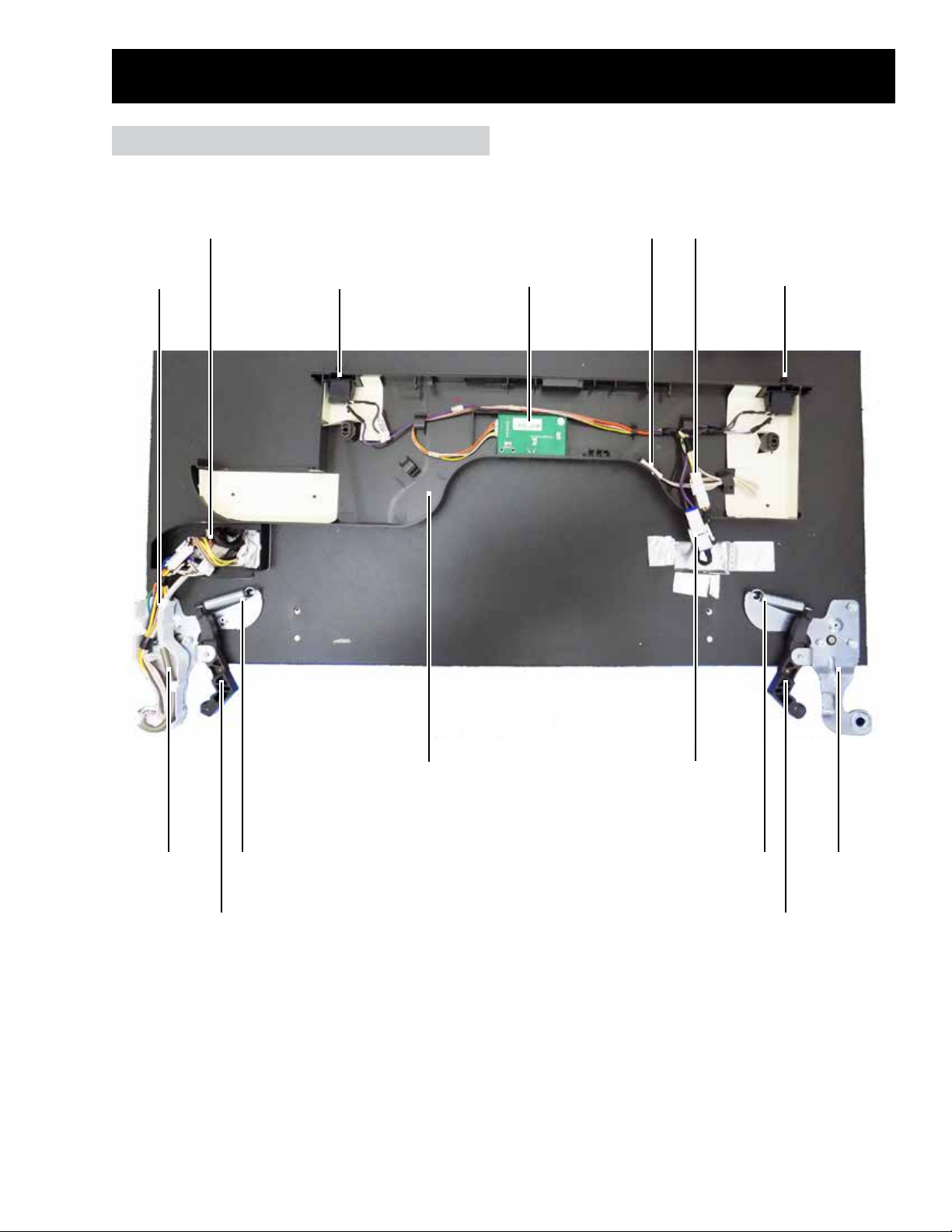

Cabinet Top ..................................................................................................................................17

Cabinet Top Components .....................................................................................................17

Hinge Covers ........................................................................................................................18

Top Interface .........................................................................................................................18

(Continued next page)

– 3 –

Page 4

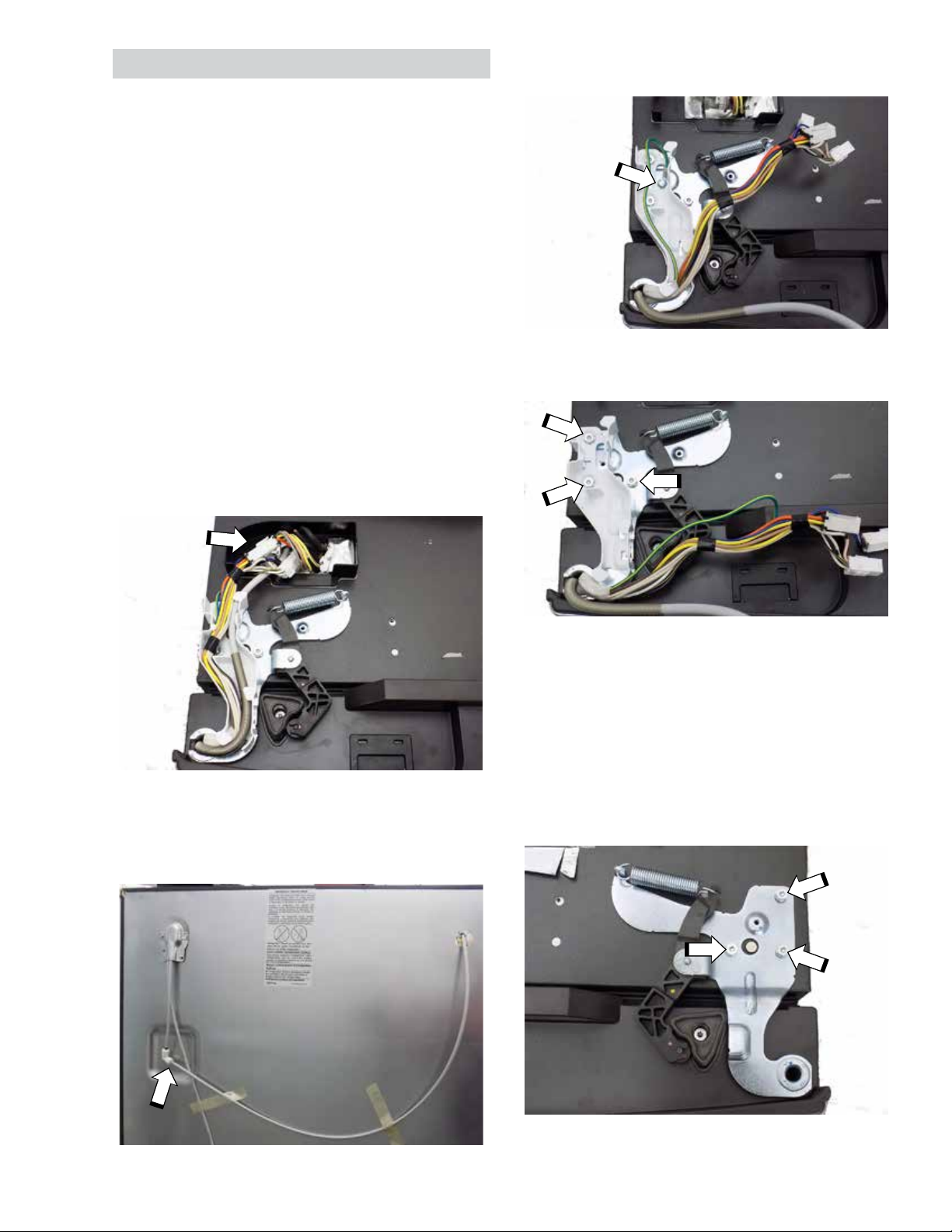

Top Door Hinges ...................................................................................................................19

Humidity Sensor Board .........................................................................................................20

RJ45 Connector ....................................................................................................................20

Ambient Thermistor...............................................................................................................20

FF Door Switches .................................................................................................................21

Door and Drawer Handles ............................................................................................................22

Door Handles ........................................................................................................................22

Freezer Drawer Handle ........................................................................................................22

Door and Drawer Gaskets ............................................................................................................23

Door Bins ......................................................................................................................................24

Dispenser (Left) Door Bins ...................................................................................................24

Right Door Bins ....................................................................................................................24

Dispenser Door ............................................................................................................................25

Dispenser Door Removal .....................................................................................................25

Left Center Hinge Removal ..................................................................................................25

Dispenser Board ...................................................................................................................25

Dispenser Board Connector Locations .................................................................................26

Dispenser LEDs ....................................................................................................................26

Dispenser Recess Components ...........................................................................................27

Ice Funnel .............................................................................................................................28

Paddle Switch .......................................................................................................................28

Duct Door Motor ...................................................................................................................29

Duct Door .............................................................................................................................29

Recess Heater ......................................................................................................................29

Articulating Mullion ................................................................................................................30

Water Tank Cover .................................................................................................................31

Water Tank ............................................................................................................................31

Dual Valve.............................................................................................................................31

Diodes ..................................................................................................................................32

Ice Box Compartment ...................................................................................................................33

Ice Box Components ............................................................................................................33

Ice Box Door .........................................................................................................................34

Ice Bucket .............................................................................................................................34

(Continued next page)

– 4 –

Page 5

Ice Box Port Gaskets ............................................................................................................34

Collar Port .............................................................................................................................35

Icemaker Access Cover ........................................................................................................35

Ice Box Thermistor................................................................................................................35

Auger Motor ..........................................................................................................................36

Icemaker ...............................................................................................................................36

Fill Tube ................................................................................................................................37

Fill Tube Heater ....................................................................................................................37

Right Door ....................................................................................................................................38

Right Door Removal .............................................................................................................38

Right Center Hinge Removal ................................................................................................38

Door - Top .....................................................................................................................................39

Door - Top Component Locator ............................................................................................39

Top Door Bumper..................................................................................................................39

Closure Cam .........................................................................................................................39

Top Hinge Bushing ...............................................................................................................39

Door - Bottom ...............................................................................................................................40

Door - Bottom Component Locator .......................................................................................40

Bottom Door Bumper ............................................................................................................40

Bottom Hinge Bushing ..........................................................................................................40

Door Stop .............................................................................................................................40

Water Filter Cartridges .................................................................................................................42

Water Filter (MFWP) .............................................................................................................43

Water Filter (XWP) ................................................................................................................43

Refrigerator Compartment ............................................................................................................44

Refrigerator Component Locator ..........................................................................................44

Adjustable Shelves ...............................................................................................................45

Climate Zone Pans ...............................................................................................................45

Pan Covers ...........................................................................................................................45

Mullion Striker .......................................................................................................................46

Upper LED Housing ..............................................................................................................46

Refrigerator (FF) Thermistor .................................................................................................47

Lower LEDs ..........................................................................................................................47

(Continued next page)

– 5 –

Page 6

Air Tower ............................................................................................................................... 48

Damper .................................................................................................................................49

MWFP Manifold ....................................................................................................................49

XWF Manifold .......................................................................................................................51

Freezer Drawer ............................................................................................................................52

Upper Basket ........................................................................................................................52

Bottom Basket ......................................................................................................................52

Drawer Gasket ......................................................................................................................53

Drawer Front Removal .........................................................................................................53

Freezer ........................................................................................................................................55

Freezer Component Locator .................................................................................................55

Upper Basket Slides .............................................................................................................56

Pinion Cross Bar ...................................................................................................................56

Pinion Gears .........................................................................................................................56

Lower Basket Slides .............................................................................................................57

Slide Holders ........................................................................................................................57

Freezer Thermistor ...............................................................................................................57

Freezer Drawer Switch .........................................................................................................58

Freezer LEDs .......................................................................................................................58

Evaporator Cover .................................................................................................................59

Evaporator Fan .....................................................................................................................61

Evaporator Components ..............................................................................................................62

Evaporator Component Locator ...........................................................................................62

Icemaker Blower Fan ............................................................................................................63

Evaporator Thermistor ..........................................................................................................63

Defrost Thermostat ...............................................................................................................64

Defrost Heater ......................................................................................................................65

Evaporator ............................................................................................................................65

Thermistors ...................................................................................................................................66

Thermistor Check Points ......................................................................................................66

Thermistor Replacement ......................................................................................................66

Defrost Operation .........................................................................................................................67

Adaptive Defrost ...................................................................................................................67

(Continued next page)

– 6 –

Page 7

Pre-Chill ................................................................................................................................67

Defrost Heater Operation .....................................................................................................67

Dwell .....................................................................................................................................67

Post Dwell .............................................................................................................................67

Abnormal Defrost ..................................................................................................................67

Cabinet - Rear ..............................................................................................................................68

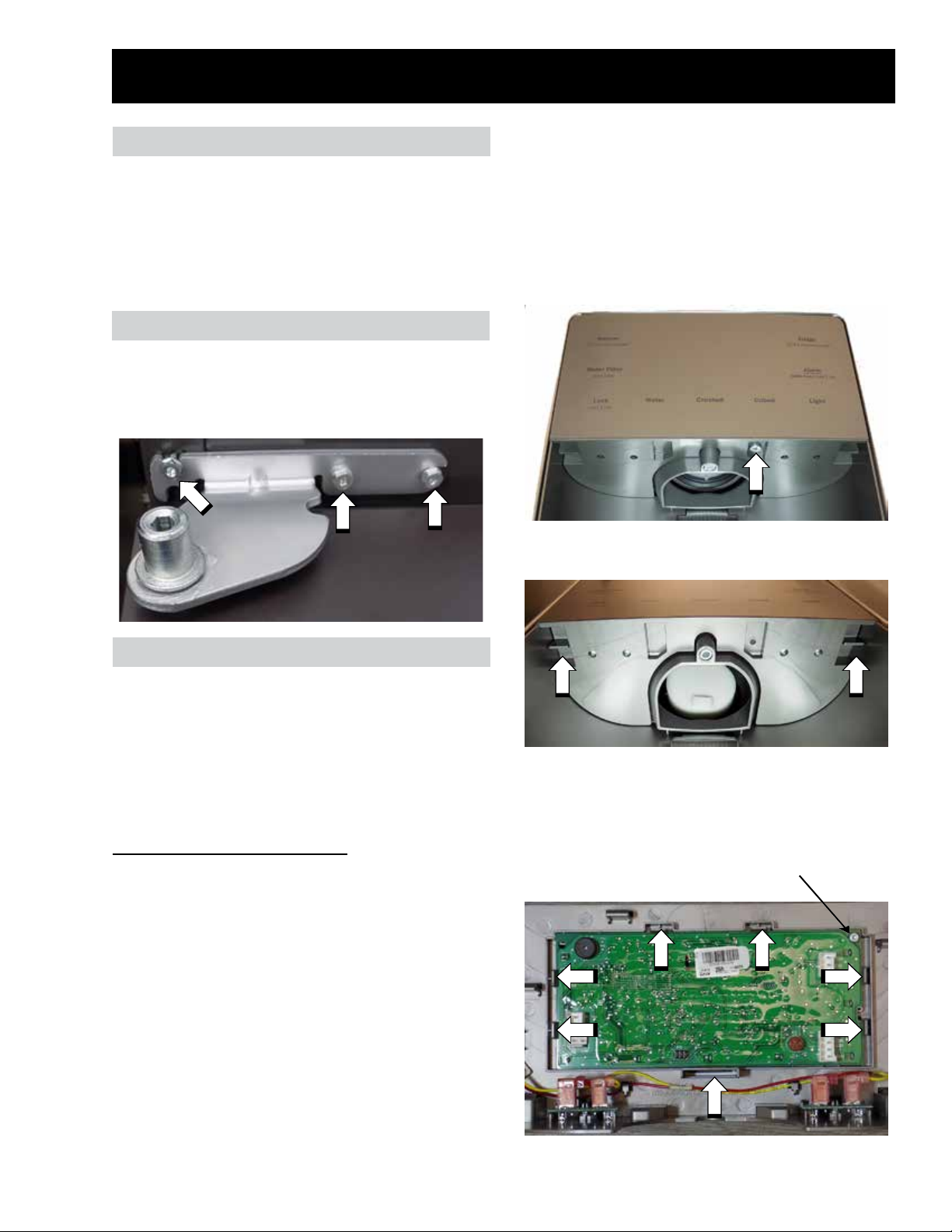

Cabinet - Rear Component Locator ......................................................................................68

Main Board ...........................................................................................................................69

Main Board Connector Locations .........................................................................................70

Connector Locations (continued) ..........................................................................................71

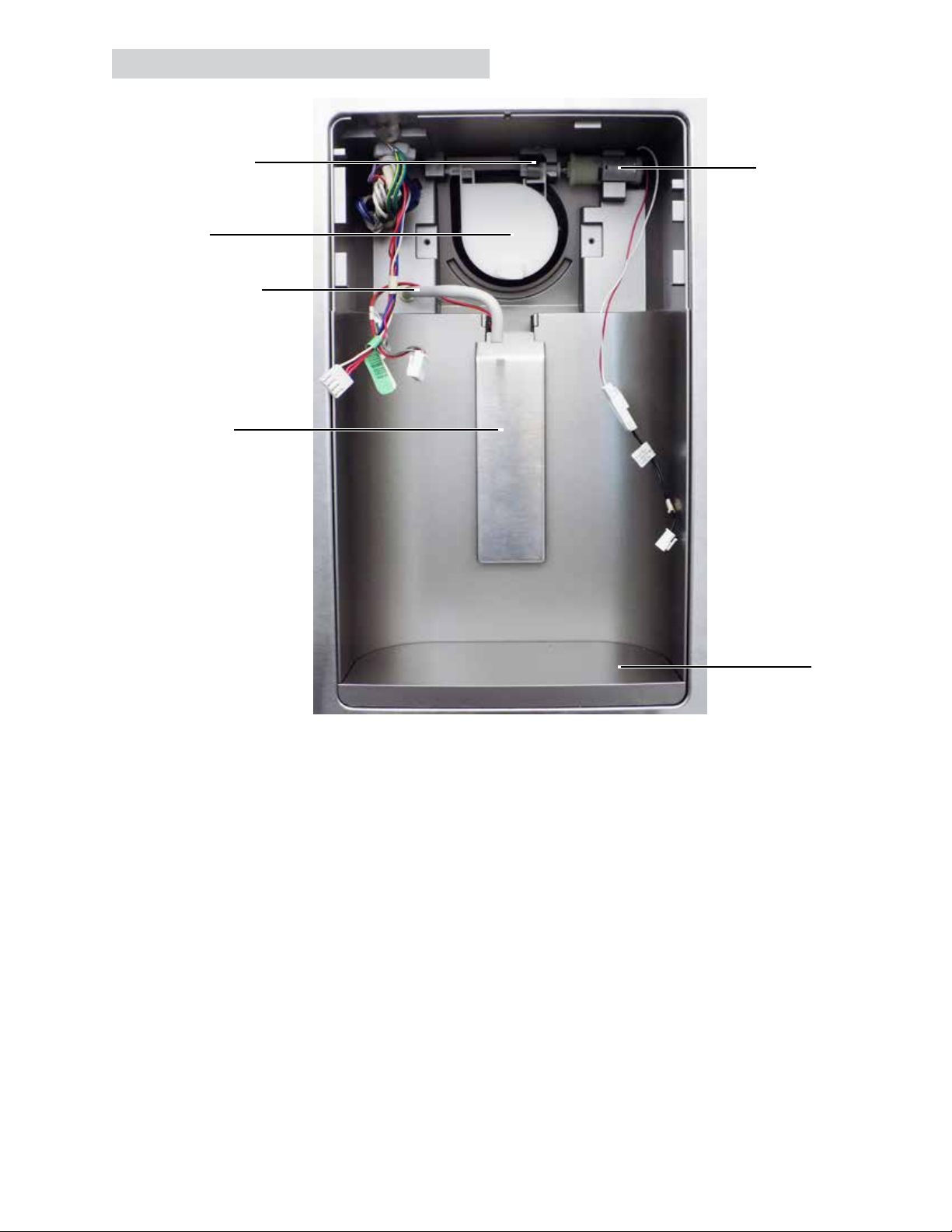

Machine Compartment .................................................................................................................72

Machine Compartment Cover ...............................................................................................72

Machine Compartment Component Locator ........................................................................72

Isolation Valve.......................................................................................................................73

Drain Tube ............................................................................................................................74

Condenser Fan .....................................................................................................................74

PTCR Relay/Overload ..........................................................................................................76

Capacitor ..............................................................................................................................77

Compressor ..........................................................................................................................77

Drier ......................................................................................................................................78

Condenser ............................................................................................................................78

Refrigeration System ....................................................................................................................79

Replacing Sealed System Components .......................................................................................80

Evacuation and Charging Procedures ..................................................................................80

Lokring ..........................................................................................................................................81

Lokring Rules ........................................................................................................................81

Process Tube Joint ...............................................................................................................81

Drier Joints ...........................................................................................................................82

Evaporator Joints ..................................................................................................................82

Compressor Joints ................................................................................................................83

Condenser Joints ..................................................................................................................83

Service Mode ...............................................................................................................................84

Service Mode Tests ..............................................................................................................85

(Continued next page)

– 7 –

Page 8

Schematic Diagram ......................................................................................................................86

Index .............................................................................................................................................87

– 8 –

Page 9

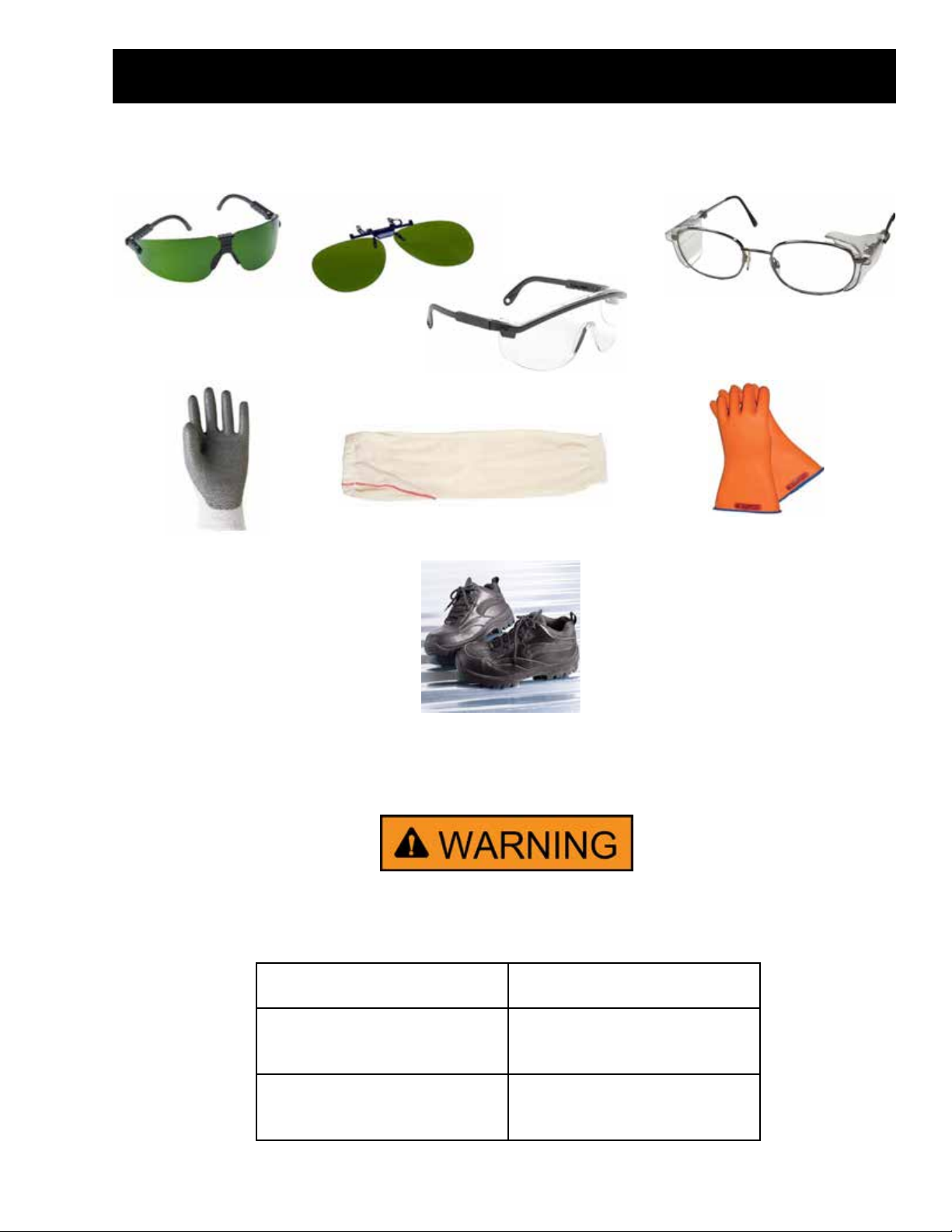

Safety Requirements

GE Factory Service Employees are required to use safety glasses with side shields, safety gloves and

steel toe shoes for all repairs.

Brazing Glasses

Dyneema®Cut Resistant

Glove

Prescription Safety Glasses

Safety Glasses must be

ANSI Z87.1-2003 compliant

Plano Type Safety Glasses

Cut Resistant Sleeve(s)

Electrically Rated Glove and

Dyneema® Cut Resistant Glove

Keeper

Steel Toed Work Boot

Prior to disassembly of the refrigerator to access components, GE

Factory Service technicians are REQUIRED to follow the Lockout /

Tagout (LOTO) 6 Step Process:

Step 1

Plan and Prepare

Step 2

Shut down the appliance

Step 3

Isolate the appliance

Step 4

Apply LOTO device and lock

Step 5

Control (discharge) stored

energy

Step 6

“Try It” verify that the appliance

is locked out

– 9 –

Page 10

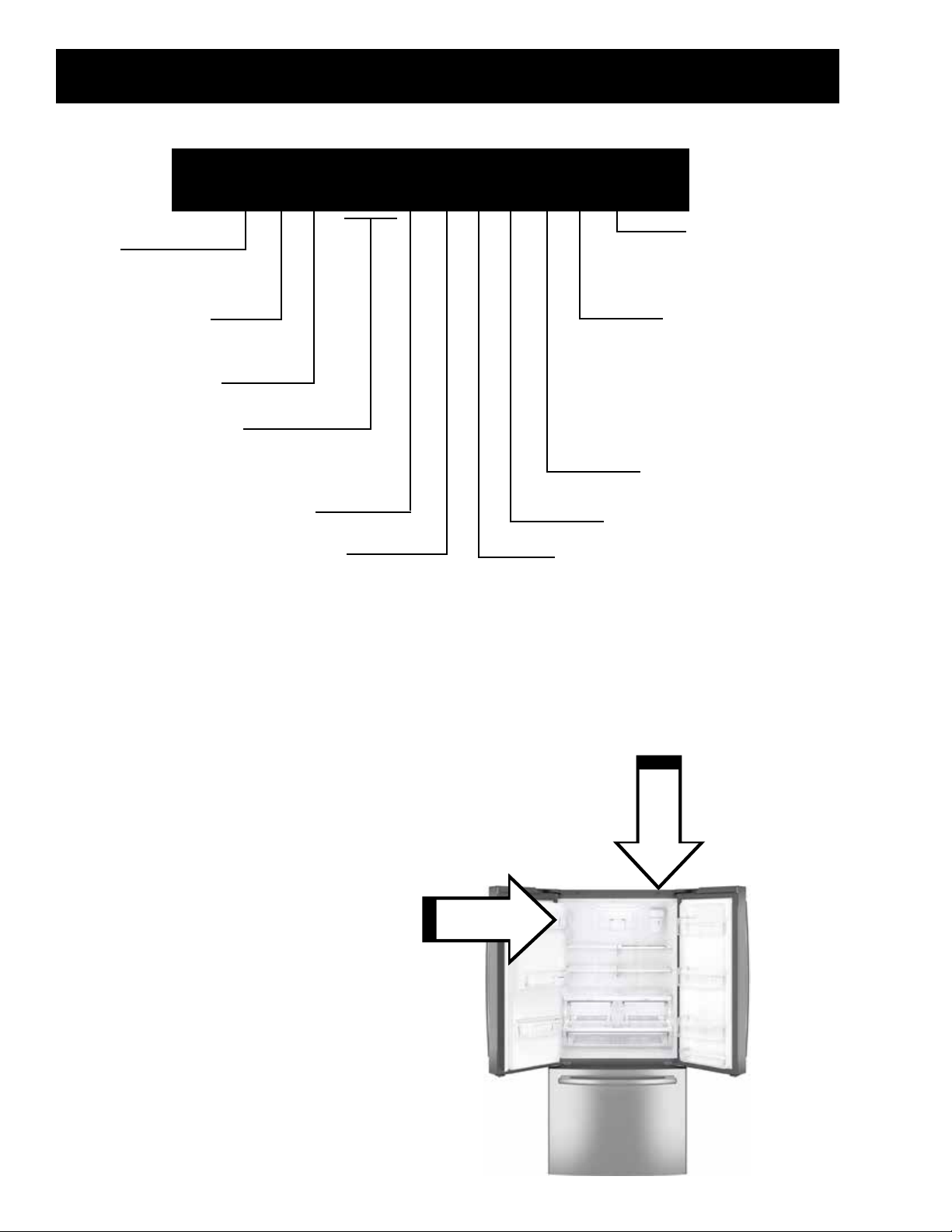

Model Number

Brand

G: GE Appliances

X: Crosley

Conguration

F: Full Depth

Y: Counter Depth

Energy

E: E-Star

Capacity

18: 17.5 Cubic Feet

24: 23.8 Cubic Feet

26: 25.5 Cubic Feet

Nomenclature

G Y E 1 8 J B L A F T S

Feature Pack

J: Deluxe

Finish

B: Black Stainless

G: High Gloss

M: Slate

S: Stainless Steel

Handle Color

B: Black

S: Stainless Steel

W: White

Color

B: Black

D: Black Slate

E: Slate

S: Stainless Steel

T: Black Stainless

W: White

Door Swing

F: French

Engineering Digit

Model Year:

K: 2016

L: 2017

M: 2018

The nomenclature breaks down and explains what the letters and numbers mean in the model number.

Serial Number

The rst two characters of the serial number identify the month and year of manufacture. The letter

designating the year repeats every 12 years.

Example: FL123456S = March, 2018

A – JAN

D – FEB

F – MAR

G – APR

H – MAY

L – JUN

M – JUL

R – AUG

S – SEP

T – OCT

V – NOV

2024 – Z

2023 – V

2022 – T

2021 – S

2020 – R

2019 – M

2018 – L

2017 – H

2016 – G

2015 – F

2014 – D

The Model Serial

ID Tag is located

on the left side

of the refrigerator

compartment.

The Mini Manual is

located under the

right hinge cover.

Z – DEC

2013 – A

– 10 –

Page 11

Specications

WARNING

Electrical Shock Hazard

Death or serious injury can result from failure

to follow these instructions.

• Service by a qualied service technician

only.

• Disconnect power before servicing this

product.

• Reconnect all grounding devices after

service.

• Replace all parts and panels before

operating.

ELECTRICAL SPECIFICATIONS

Max Defrost Control

w/No Door Openings 96 hrs @ 40 min

Evap Defrost Thermostat

Defrost Heater

Fill Tube Heater

Mullion Heater

Recess Heater

95 - 65°F

120 VAC / 33

13 VDC / 136Ω

13 VDC / 24Ω

13 VDC / 100Ω

NO LOAD PERFORMANCE

CONTROL POSITION 0 / 37°F and

AMBIENT TEMPERATURE OF

Fresh Food, °F

Frozen Food, °F

Percent Running Time

65°F 90°F

38 - 40 36 - 38

0 - 1 0 - 2

25 - 50 50 - 80

REFRIGERATION SYSTEM

Minimum Equalized Pressure

@ 70°F 40/45 PSIG

@ 90°F 48/60 PSIG

R134a Refrig. Chg.

18 cu. ft. models:

24 cu. ft. models:

Ω

26 cu. ft. models:

4.00 ounces

4.25 ounces

4.48 ounces

REFRIGERATION DIAGNOSIS

To access the low pressure side of the system,

install a WJ56X61 valve only on the process

tube extending from the compressor case.

Duct Door Heater

Duct Door Motor

Damper Motor

Isolation Valve

Icemaker Valve

Dispenser Valve

Compressor Windings

Ice Blower Fan

Evaporator Fan

Condenser Fan

Auger Motor

Icemaker

120 VAC / 1100Ω

13 VDC / 15Ω

415Ω

120 VAC / 320Ω

120 VAC / 320Ω

120 VAC / 120Ω

120 VAC / 4Ω & 6Ω

6-13 VDC

8-11 VDC

9-10 VDC

120 VAC

120 VAC

– 11 –

Page 12

Installation

WARNING

Refrigerator Location

The product should not be installed in the

following locations:

• Where the temperature will go below 60°F

(16°C) because it will not run often enough to

maintain proper temperatures.

• Where the temperature will go above 100°F

(37°C) because it will not perform properly.

• In a location exposed to water (rain, etc.) or

direct sunlight.

• The refrigerator should be installed on a oor

strong enough to support it fully loaded.

NOTE: Not recommended for installation on

carpeted ooring.

Additional Specications

• 115 volt 60Hz, 15 or 20-amp power supply is

required.

Clearances

These refrigerators should have the following

clearances for ease of installation, proper air

circulation, and enough room for plumbing and

electrical connections.

• Sides: 1/8 inch

• Top (Cabinet/Hinge Cover): 1 inch

• Back: 2 inches

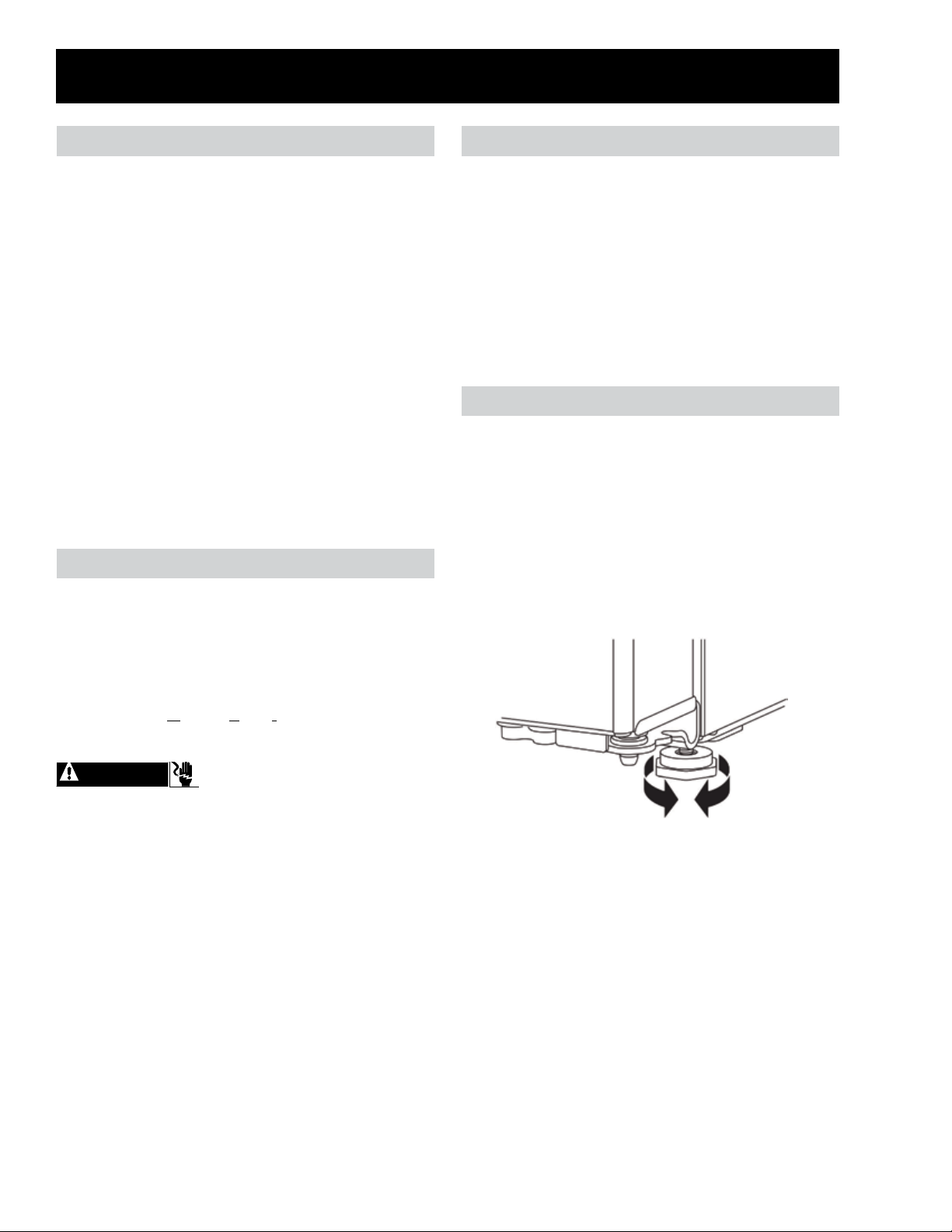

Leveling

The refrigerators have adjustable legs at the front

corners. The leveling legs should be set so the

refrigerator is rmly positioned on the oor and

the front is raised enough that the doors close

easily when opened about halfway.

To Adjust the Leveling Legs:

• Turn the legs clockwise to raise or

counterclockwise to lower the refrigerator.

• An individual properly grounded branch circuit

or circuit breaker is recommended.

NOTE: A GFI (Ground Fault Interrupter) is not

recommended.

Electrical Shock Hazard

• It is required that the refrigerator be plugged

into a grounded 3-prong outlet.

• Ground prong should not be removed.

• Use of a 2-prong adapter or an extension

cord is prohibited.

• Frayed or damaged power cord should

immediately be replaced.

– 12 –

Page 13

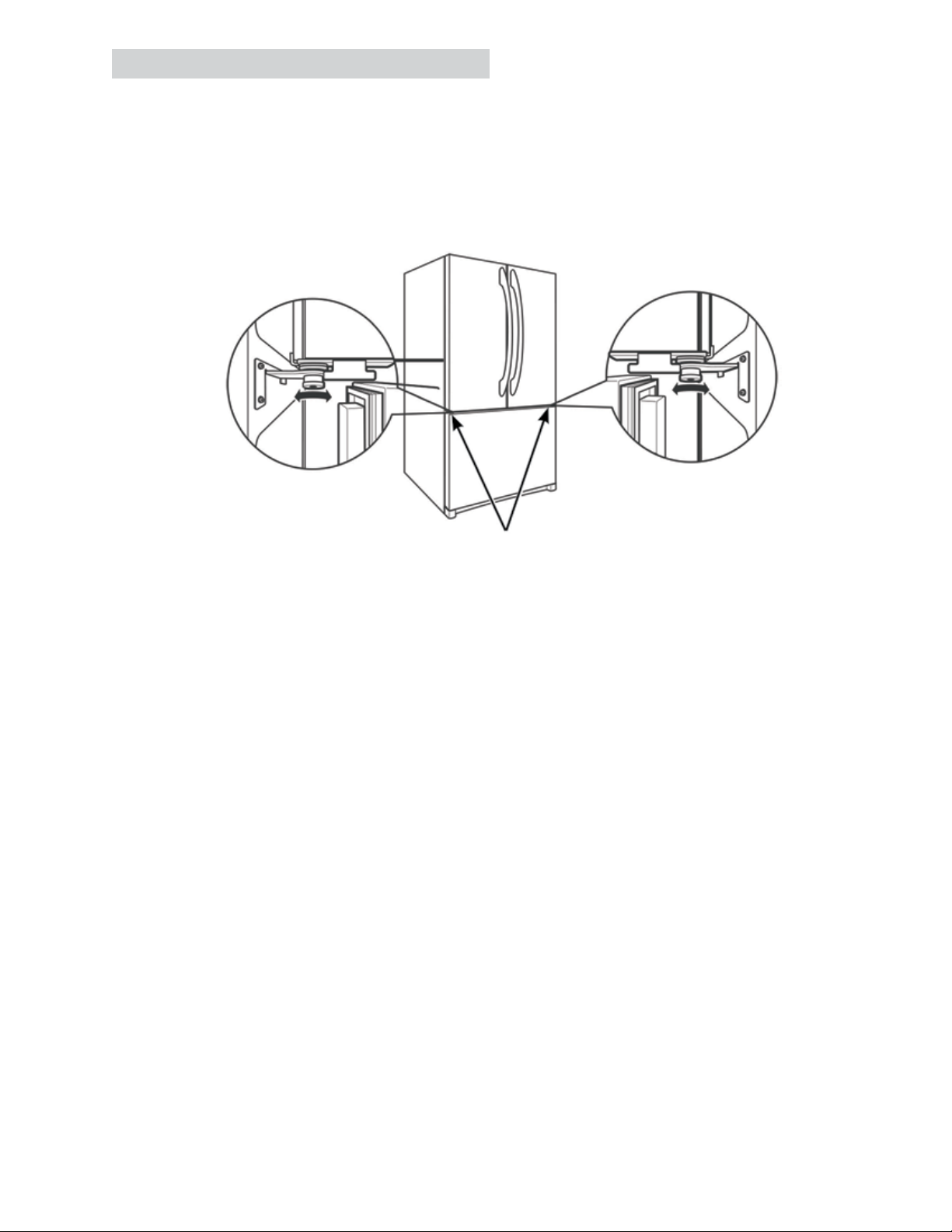

Leveling Refrigerator Doors

The refrigerators door height can be adjusted on both doors. Prior to adjusting the door height, the

refrigerator should be leveled for best results. After the cabinet has been properly leveled, a 1/4-in.

Allen wrench can be used to turn the pin in the bottom hinges of the refrigerator doors.

To Adjust the Door Height:

• Turn the left or right adjustment pin clockwise to raise, or the the adjustment pin counterclockwise to

lower the corresponding door.

Adjustment Pin

Locations

– 13 –

Page 14

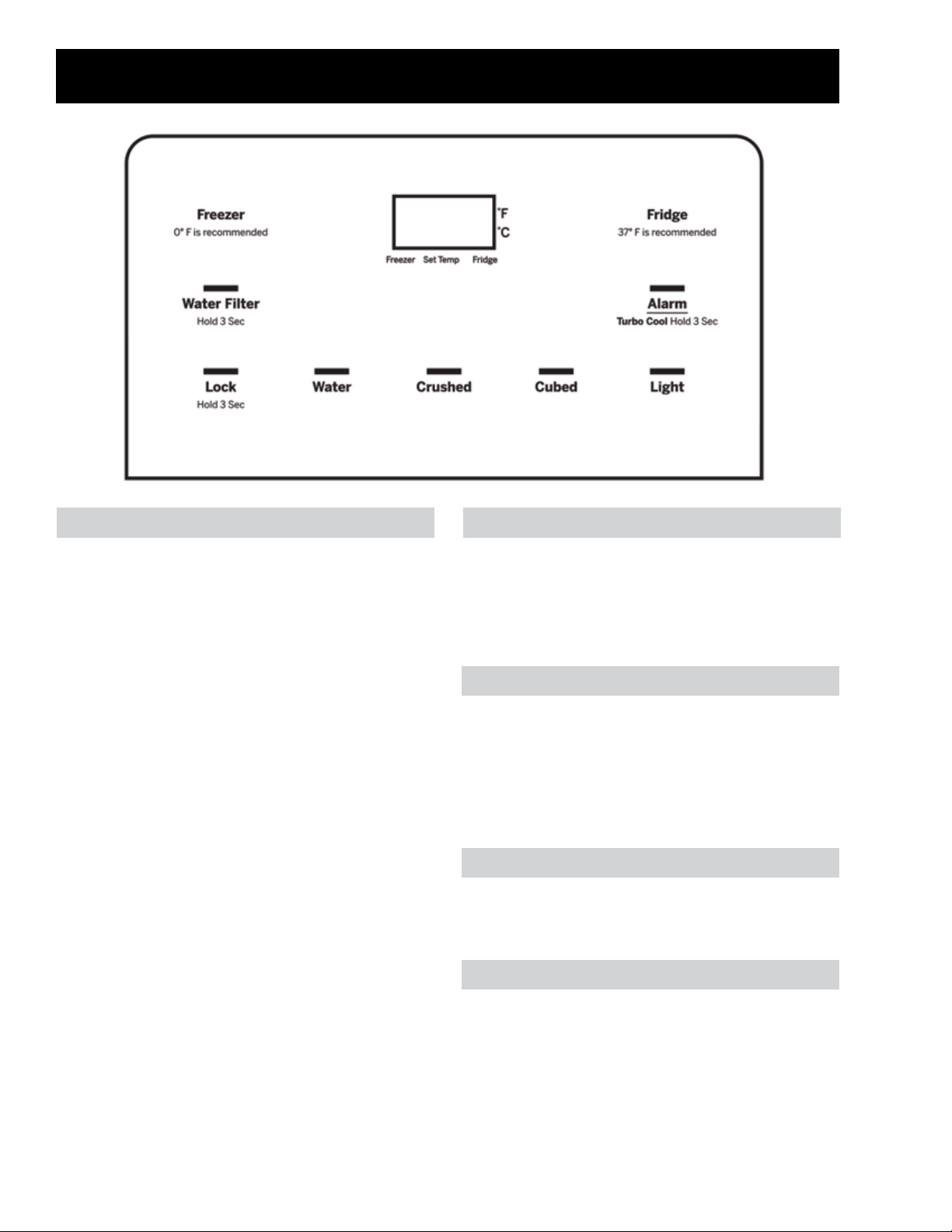

Operating Instructions

Temperature Control Cooling System O

The temperature display will only show the set

temperatures of the refrigerator.

Default freezer temperature is 0°F. Freezer

temperature can be set to -6°F to 6°F. To change

the temperature setting press the Freezer pad to

display the current set temperature and "wake up"

the display. Then press the Freezer pad again

to increase the set temperature. Once the set

temperature reaches 6°F the next press of the

Freezer pad will cycle the set temperature back

to -6°F.

The default refrigerator temperature is 37°F.

Refrigerator temperature can be set to 34°F

to 44°F. To change the temperature setting,

press the Fridge pad to display the current set

temperature and "wake up" the display. Then

press the Fridge pad again to increase the set

temperature. Once the set temperature reaches

44°F the next press of the Fridge pad will cycle

the set temperature back to 34°F.

To turn o the cooling system, press and hold

both Fridge and Freezer pads until the display

shows OFF. To turn the cooling system on, press

either Fridge or Freezer pads and the display will

show the set temperature.

°F to °C

To change the temperature display between

Fahrenheit and Celsius, press and hold Alarm

and Freezer for 5 seconds. Temperature display

can also be changed using Service Mode Test t14

(see Service Mode Tests in the in the Service

Mode section of this service guide).

Tone Volume

Door alarm volume or the sound in response to

pressing a pad cannot be changed.

Door Alarm

The actual temperature will vary from the set

temperature based on factors such as door

opening, amount of food, defrost cycling and

room temperature.

NOTE: Frequent door openings or a door left

open for periods of time may increase the internal

temperature of the refrigerator compartment

temporarily.

Press the Alarm pad to toggle the door alarm

between ON and OFF states. The alarm will

sound if any door or drawer is left open for more

than two minutes. Once the door or drawer is

closed, the alarm will stop.

– 14 –

Page 15

Lock

Sabbath Mode

The dispenser pads can be locked to prevent

inadvertent presses or to keep children from

making selections/changing settings. Press and

hold the Lock pad for 3 seconds to lock out ice

and water dispenser and all other controls. Press

and hold Lock to unlock the controls.

Turbo Cool

TurboCool™ rapidly cools the refrigerator

compartment in order to more quickly cool foods.

Use TurboCool™ when adding a large amount

of food to the refrigerator compartment, putting

away foods after they have been sitting out at

room temperature, or when putting away warm

leftovers. It can also be used if the refrigerator

has been without power for an extended period.

To set the TurboCool™, press the Alarm pad for

3 seconds. The display will show "tC".

NOTE: The refrigerator temperature cannot

be changed during TurboCool™. The freezer

temperature is not aected during TurboCool™.

When opening the refrigerator door during

TurboCool™, the fans will continue to run if they

have cycled on.

Demo Mode

Demo Mode deactivates compressor, fans, and

defrost heater. All keys on the control panel are

functional. The display will show and blink 888

then switch to displaying the set temperature. To

enter Demo Mode press Lock, Cubed, and Light

pads simultaneously for 5 seconds. To exit Demo

Mode, cycle power to the refrigerator. Demo

Mode can also be entered from Service Mode

Test t1.

Sabbath Mode is designed to eliminate changes

in operations of the refrigerator due to human

interactions. This mode is entered by the

consumer during observance of the Sabbath or

during specic religious holidays.

While in the Sabbath Mode, the appliance will still

operate normally. However, the appliance will not

respond to any consumer actions.

While in the Sabbath Mode, it may be noticed

that the fan is running when the door is opened;

however, this is not a result of any interactions

with the refrigerator. The fan will operate at

random times. The defrost heater will continue to

defrost the appliance and defrost will be activated

on a timer. The defrost heater will not defrost

as a result of door openings or any consumer

actions.

DISPLAYS, ALARMS and LIGHTS: The main

temperature control displays will be deactivated;

therefore, they will not be lit, sound a tone or

operate when touched. Door alarms will be

disabled. Lights will always be on but at a dim

light setting.

To turn on Sabbath Mode, press and hold the

Lock and Light pads until the display shows SA

briey before going blank. Repeat the process to

turn o Sabbath Mode. Temperature set point will

be displayed. Sabbath mode will automatically

exit four days after being entered.

– 15 –

Page 16

Cold Air

Mixed Air

Air Return To

Evaporator

Air Flow

Refrigerator

Ice Blower Fan

Freezer

Freezer

Refrigerator Air Flow

Cold air is circulated into the compartment by

the evaporator fan. When cooling is required,

the main board opens the damper and turns on

the fan to push cold air from the evaporator up

and out the air tower. The air circulates through

the refrigerator compartment and is pulled back

to the freezer below the evaporator by the way

of the air return passage behind the evaporator.

That warm moist air then gets pull back across

the evaporator coil to extract the heat and

moisture.

Freezer Air Flow

Cold air is circulated in the freezer by the

evaporator fan. When cooling is required, the

main board turns on the fan to circulate cold air

from the evaporator through the evaporator cover.

The air is pulled back to the evaporator through

two ducts built into the bottom of the evaporator

cover. That air then gets pulled back across the

evaporator coil to extract the heat and moisture.

Ice Box Air Flow

Freezer air is circulated into the ice box by the

ice blower fan located in the freezer. The blower

pushes freezer air up and through the top ice

box air duct. Air in the ice box is then forced

out through the return air passage (bottom air

duct) to mix and be circulated with the rest of the

freezer air.

– 16 –

Page 17

Cabinet Top Components

Cabinet Top

AC and DC Door

Connections

Door Water

Line

Left FF

Door Switch

Thermistor

RJ45 and Humidity

Sensor Board

Ambient

Harness

Connector (DC)

Right FF

Door Switch

Left Door

Hinge

Left Door

Closure

Left Closure

Spring

Top Interface*

– 17 –

Switch Harness

Connector (AC)

Right Closure

Spring

Right Door

*Top interface shown in service position.

Right Door

Hinge

Closure

Page 18

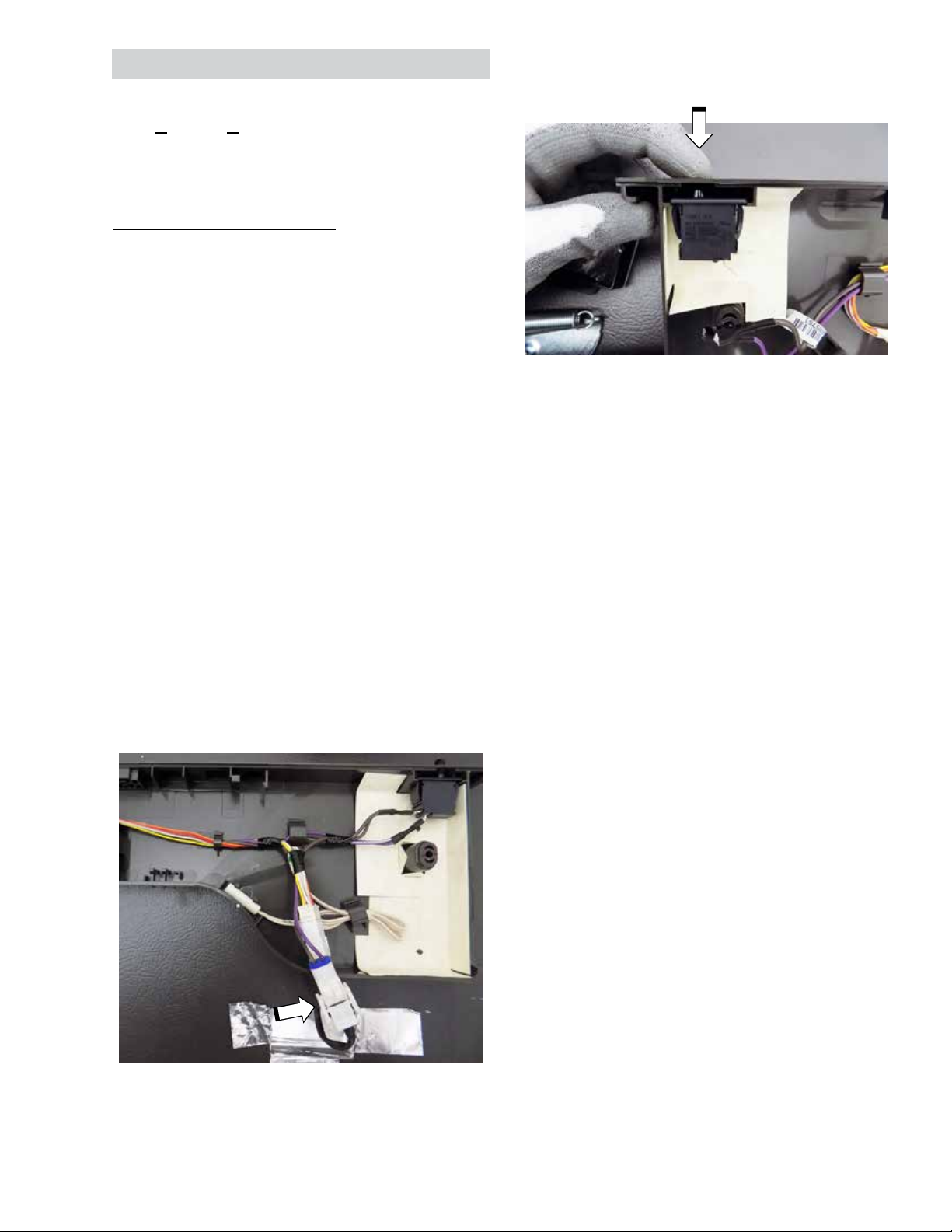

Hinge Covers Top Interface

Left and right hinge covers need to be removed

in order to access the components under the top

interface and to remove the doors.

Hinge Cover Removal

1. Remove one Phillips-head screw for the

desired hinge cover.

2. For the left hinge cover, use a at-blade

screwdriver inserted into the slot on the left

side of the hinge cover and pry to the right

while lifting up on the cover. For the right

hinge cover, proceed to next step.

The top interface houses the refrigerator door

switches, ambient thermistor, switch harness,

DC harness, and RJ45 connector and humidity

sensor board. If the interface needs to be

replaced, all of the components under the

interface will come as part of the assembly. If

a component under the interface needs to

be replaced, that component can be ordered

separately. To service any of the components

under the top interface, the top interface

must be put into the service position (see

the Top Interface callout under Cabinet Top

Components in this section of this service guide).

Top Interface Removal

1. Remove the left and right hinge covers.

2. Remove two Phillips-head screws.

3. Lift the hinge cover up to remove the cover

from the hinge.

3. Flip the top interface back (put into service

position).

4. Disconnect the AC and DC harness

connectors.

5. Remove the interface from the top of the

cabinet.

– 18 –

Page 19

Top Door Hinges

Door hinges incorporate a spring loaded closure.

The closure arms roll over cams mounted to the

top of the refrigerator doors to close the doors

once the doors are a couple inches from closing.

The closure arm and hinge come as an assembly

but the spring can be ordered separately.

Top Left Door Hinge Removal

NOTE: Leave the doors shut during this process

to prevent damage to doors or damage to the

consumer's property.

5. Remove the 1/4-in. hex-head screw mounting

the ground wire to the hinge.

1. Remove the left and right hinge covers.

2. Put the top interface into the service position

(see Top Interface Removal under Top

Interface in this section of this service guide).

3. Disconnect three door wiring connectors

tucked into the top of the cabinet.

4. Disconnect the door water line from the 90°

union located behind the refrigerator and pull

the water line from the cabinet through the

front.

6. Remove three 5/16-in. hex-head screws and

lift the hinge from the cabinet.

Top Right Door Hinge Removal

NOTE: Leave the doors shut during this process

to prevent damage to doors or damage to the

consumer's property.

1. Remove the right hinge cover.

2. Remove three 5/16-in. hex-head screws and

lift the hinge from the cabinet.

– 19 –

Page 20

Humidity Sensor Board

The Humidity board is located under the center

of the top interface. The humidity sensor on

the board provides the main board with relative

humidity percentages based on the feedback

voltage (see table below). The feedback voltage

will range between 1 to 4 VDC. The relative

humidity percentage is used to determine the

articulating mullion heater on time (the greater the

humidity, the greater the heater run time).

Relative Humidity Voltage (DC)

20% 1.5 V

50% 2.3 V

80% 3.1 V

Humidity Sensor Board Diagnosing

Before changing the board, ensure the proper

voltages are going to the humidity board.

Humidity sensor voltages can be checked at the

humidity board or main board.

Connector on Humidity Board

• Orange to tan/black: 13 VDC

• Orange to white: 13 VDC

Humidity Sensor Board Removal

1. Place the top interface in the service position

(see Top Interface Removal, under Top

Interface in this section of the service guide).

2. Remove one 1/4 in. hex-head screw and

disconnect the wiring harness.

RJ45 Connector

The RJ45 connector is mounted to the humidity

sensor board inside the top interface and is only

available with the humidity sensor board. The

RJ45 connector is the access point to update

software using a software update module (SUM)

or connect a service diagnostic tool.

Ambient Thermistor

The ambient thermistor is located under the top

interface. The thermistor clips into the backside

of the top interface and is used to determine the

oset temperature of the refrigerator.

• White or tan/black to red/white: 5 VDC

• Yellow to red/white: 1 - 4 VDC

NOTE: 0 or 5 VDC from yellow to red/white

may indicate a bad humidity sensor. Replace the

humidity board if there are no open or shorted

wires to the board.

Connectors on Main Board

• J4 pin 4 (orange) to J4 pin 5 (tan/black): 13

VDC

• J4 pin 4 (orange) to J2 pin 3 (white/silver):

13 VDC

• J5 pin 5 (red/white) to J4 pin 5 (tan/black) or

J2 pin 3 (white/silver): 5 VDC

• J5 pin 5 (red/white) to J5 pin 6 (yellow/

white): 1 - 4 VDC

NOTE: 0 or 5 VDC from J5 pin 5 to J5 pin 6 may

indicate a bad humidity sensor. Replace the

humidity board if there are no open or shorted

wires to the board.

The oset temperature is the temperature the

main control targets. Air temperature inside a

compartment is typically lower than the thermistor

reading due to cabinet thermistors proximity to

cabinet walls. The main control increases the

oset temperature when the ambient temperature

increases.

To access the thermistor, place the top interface

in the service position (see Top Interface

Removal, under Top Interface in this section of

the service guide).

To test or replace the thermistor, follow the steps

in the Thermistors section of this service guide.

– 20 –

Page 21

FF Door Switches

The FF door switches are AC volt switches that

have Normally Closed contacts (N.C.). The

switches are actuated by the top of the doors to

tell the main board to turn the refrigerator LEDs

on or o.

FF Door Switch Diagnosing

When one of the doors are opened, the switch

contacts are closed allowing 120 VAC to travel to

the main board. When closed, the doors engage

the switch to open the switch contacts, breaking

the 120 VAC circuit to the main board.

3. Disconnect the wires from the desired switch.

4. Push in on the plunger of the switch.

Switch Not Pressed (Door or Doors Open)

J7 on Main Board

• Pin 6 (purple/white) to pin 9 (orange): 120

VAC

Switch Pressed (Doors Closed)

J7 on Main Board

• Pin 6 (purple/white) to pin 9 (orange): 0 VAC

FF Door Switch Removal

1. Place the top interface in the service position

(see Top Interface Removal, under Top

Interface in this section of the service guide).

2. Disconnect the two pin switch harness to

remove power from the switches.

5. With the plunger pressed in, slide the switch

out of the top interface.

– 21 –

Page 22

Door and Drawer Handles

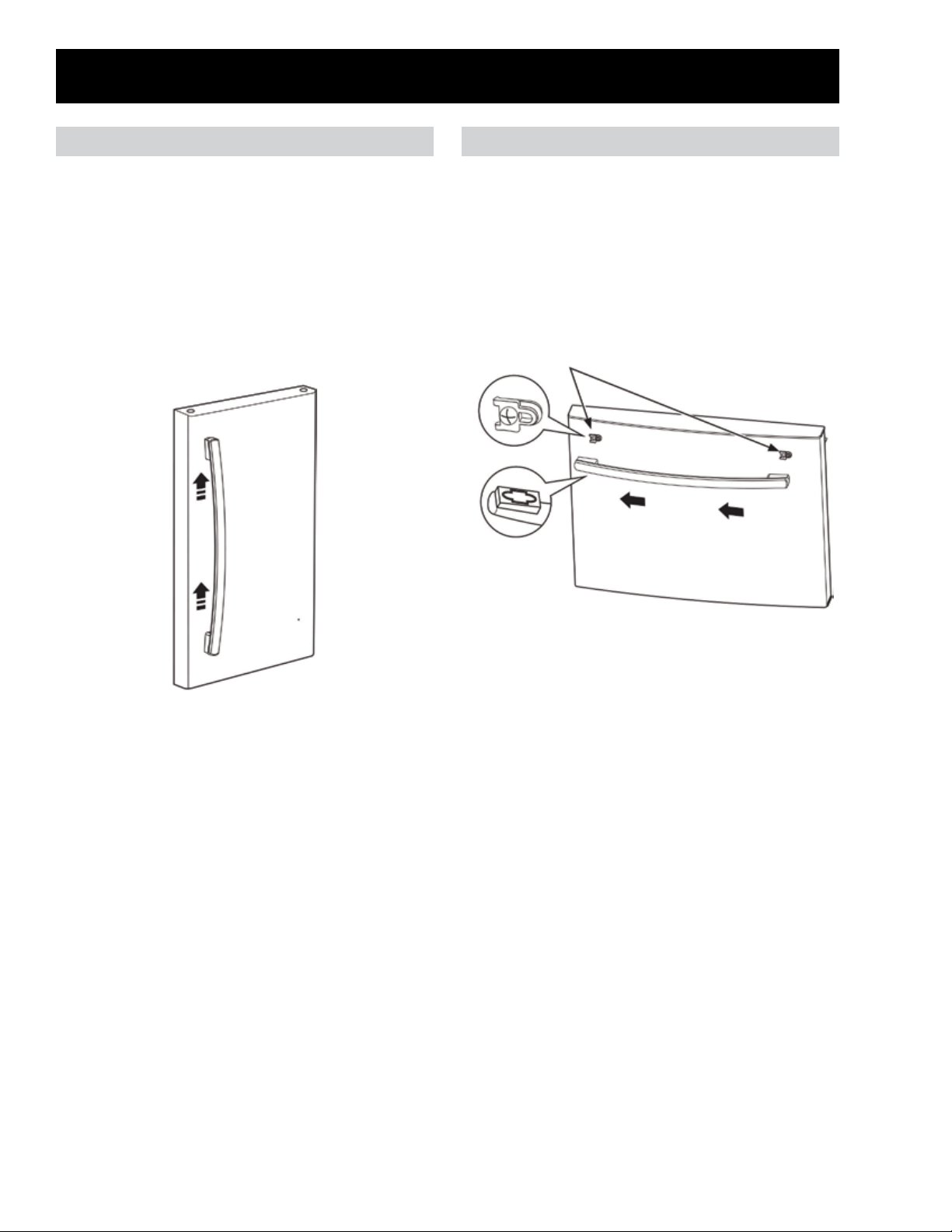

Door Handles Freezer Drawer Handle

Door handles slide and lock into fasteners

mounted to the doors.

Door Handle Removal

1. Slide the handle up to release it from the

mounting fasteners (be aware it takes some

force to release the handle from the mounting

fasteners mounted to the door).

2. Pull the handle away from the door.

The drawer handle slides and locks into fasteners

mounted to the drawer.

Drawer Handle Removal

1. Slide the handle to the left to release it from

the mounting fasteners.

2. Pull the handle away from the door.

Mounting Fasteners

– 22 –

Page 23

Door and Drawer Gaskets

Each door and drawer have a magnetic gasket that creates a positive seal to the front of the steel

cabinet. The magnetic gaskets are secured to the door or drawer by a barbed edge that locks into a

retainer channel.

Gasket Removal and Replacement

1. Starting at any corner, pull the old gasket out of the retaining channel.

2. Soak the new gasket in warm water to make it pliable.

3. Push the barbed edge of the gasket into the retainer channel.

NOTE: A thin coat of petroleum jelly or paran

wax can be applied to the hinge side (sealing

side) of the gaskets to improve closure across the

cabinet.

The door gaskets have a left and right side.

When installing a new gasket, ensure the wider

ends at the top and bottom of the gasket (shown

in the image to the right) are on the mullion side

of the door.

– 23 –

Page 24

Door Bins

Dispenser (Left) Door Bins Right Door Bins

The left refrigerator door has three removable

door bins. The top and bottom bins can be

interchanged but the middle bin must be used in

the middle location.

Bin Removal

To remove door bins, slide bin up and then pull away from the door.

The right refrigerator door has four removable

door bins. The top three bins can be

interchanged but the bottom bin must be used in

the bottom location.

– 24 –

Page 25

Dispenser Door

Dispenser Door Removal

1. Remove the door bins and ice bucket.

2. Follow Top Left Door Hinge Removal steps,

under Top Door Hinges in the Cabinet Top

section of this service guide.

3. Lift the door o the center hinge.

Left Center Hinge Removal

1. Remove the dispenser door.

2. Remove three screws for the center hinge

using a 5/16-in. socket or T20 Torx-head bit.

J1 on Dispenser Board

• Red to black: 13 VDC

• Red to blue: 13 VDC

Dispenser Board Removal

1. Remove one Phillips-head screw from under

the dispenser board.

2. Pull forward on the backside of the tabs under

the dispenser board.

Dispenser Board

The refrigerator uses a capacitive touch dispenser

board. Through the dispenser board, the user

can change the set temperature, temperature

units (°C or °F) and enter special modes such

as Sabbath, Demo, and Service Mode. The

dispenser board controls the duct door motor and

dispenser LEDs.

Dispenser Board Diagnosing

If the dispenser board is not illuminated, verify

proper voltage is going to the dispenser board. If

voltage is present, replace the dispenser board.

If voltage is not present, check connections at the

door hinge and main board before replacing the

main board. The display LEDs and numerical

segments can be tested by using Service Mode

Test t3.

J2 to J4 on Main Board

• J2 pin 8 (red/silver) to J4 pin 1 (black): 13

VDC

3. Disconnect four wiring connectors.

4. Remove one T15 Torx-head screw and

release seven tabs to remove the board from

the overlay.

Screw

• J2 pin 8 (red/silver) to J4 pin 3 (blue): 13

VDC

– 25 –

Page 26

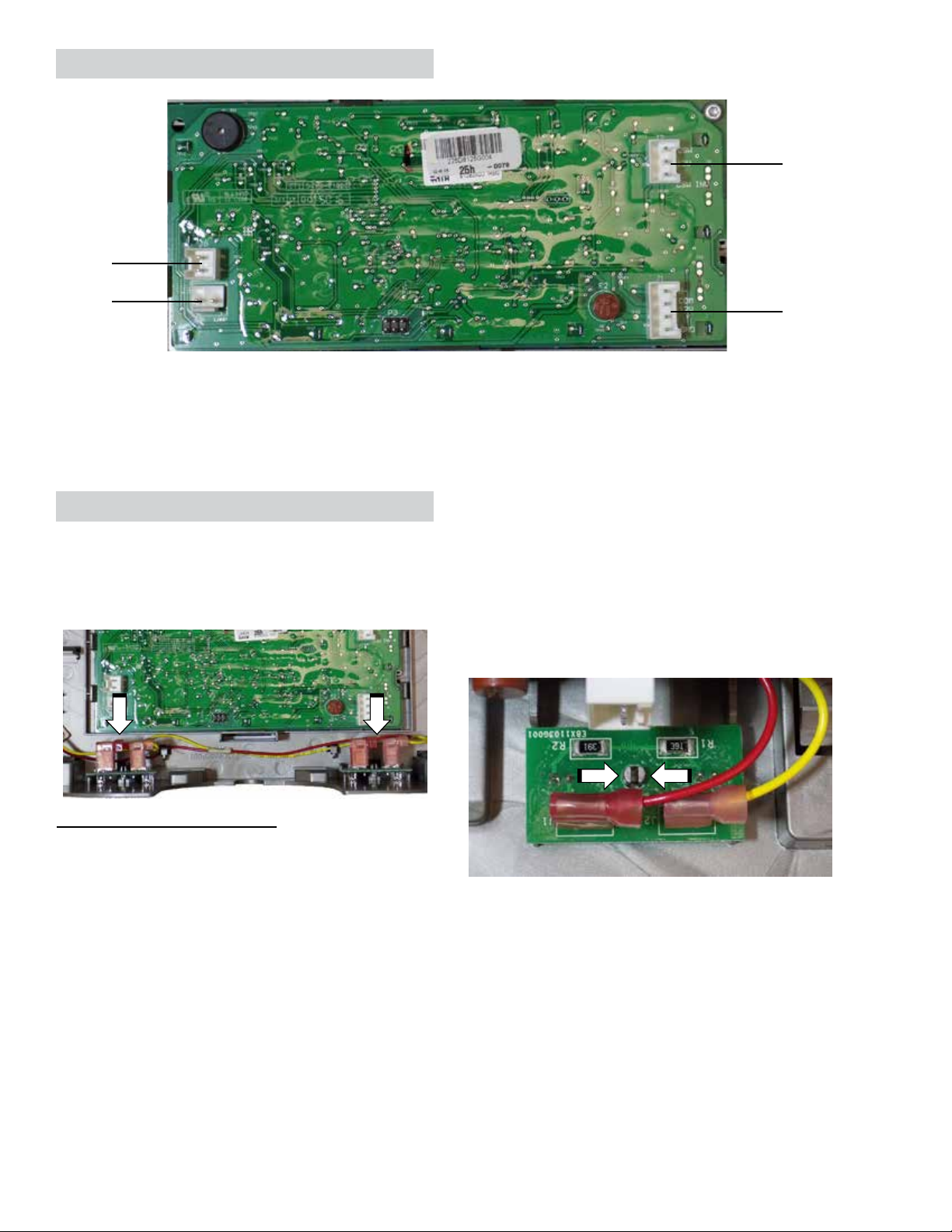

Dispenser Board Connector Locations

J5

J2

J3

J1: Communication and power from main board

J2: Paddle switch

J3: Duct door motor

J5: Dispenser LEDs

Dispenser LEDs

Two dispenser LEDs boards are located on the

back side of the dispenser control assembly. The

dispenser board turns on the LEDs when the light

button is pressed on the dispenser board.

J1

Dispenser LED Removal

1. Remove the dispenser board panel from the

door.

2. Squeeze the round clip in the middle of the

board and lift up on the LED board.

Dispenser LED Diagnosing

J5 on Dispenser Board

• Red to yellow: 13 VDC

3. Disconnect the wires from the board.

– 26 –

Page 27

Dispenser Recess Components

Duct Door Spring

Duct Door

Door Water Spout

Paddle and

Paddle Switch

Duct Door Motor

*Shown with ice funnel removed.

Drip Tray

– 27 –

Page 28

Ice Funnel

The ice funnel directs cubed and crushed ice from

the door chute to the consumer's glass.

Paddle Switch Diagnosing

• Silver to silver/black: N.C. contacts

• Silver to red: N.O. contacts

Ice Funnel Removal

1. Remove the dispenser board.

2. Remove two 1/4-in. hex-head screws.

3. Pull the funnel forward and turn the backside

of the funnel clockwise.

Switch not pressed (home position)

• Silver to silver/black: 0 VDC

• Silver to red: 13 VDC

Switch pressed

• Silver to silver/black: 13 VDC

• Silver to red: 0 VDC

Paddle Switch Removal

1. Remove the dispenser board.

2. Remove the ice funnel.

3. Using a at-blade screwdriver, gently pry the

tabs of the paddle out of the recess.

4. Lift the door water spout from the funnel.

Paddle Switch

Mounted to the backside of the paddle is a threeway micro switch. The switch tells the dispenser

board when the paddle is being pressed or when

it is in the home position.

4. Pull the top of the paddle away from the

recess then lift up on the paddle.

5. Remove the switch and wiring from the

backside of the paddle, making note of the

wiring routing for reinstallation.

– 28 –

Page 29

Duct Door Motor Duct Door

The duct door motor is a DC motor used to open

the duct door. The motor receives 13 VDC from

the dispenser board when the paddle switch is

activated and 2.5 VDC to hold the door open for 5

seconds once the paddle is released.

Duct Door Motor Diagnosing

The motor has a resistance of 15 ohms. To verify

duct door motor operation, activate the paddle

switch or use Service Mode Test t5 and verify

voltage at the J5 connector on the dispenser

board. Test t5 will operate the motor for 10

seconds.

Paddle Switch Pressed

• J5 black to J5 black/silver: 13 VDC

Duct Door Motor Removal

1. Remove the dispenser board.

2. Remove the ice funnel.

The duct door is used to keep ambient air from

entering the ice box. When ice is called for, the

duct door motor turns to open the duct door. The

duct door spring then return the duct door to the

closed position within 5 seconds of releasing the

paddle. If the door is not fully closing, check the

duct door spring to make sure it is not broken or

installed incorrectly.

Spring

3. Use a at-blade screwdriver to pry the duct

door motor and duct door away from the

recess.

4. Pull the duct door o the shaft of the duct

door motor.

Duct Door Removal

• Follow duct door motor removal steps.

Recess Heater

Foamed into the dispenser door is a 100-ohm

DC heater designed to keep the recess from

condensating. The heater is in parallel with the

ll tube heater, both are controlled by the main

board.

Recess Heater Diagnosing

The recess heater can be operated using Service

Mode Test t6. Test t6 will operate the heater for

60 seconds.

J2 to J5 on Main Board

• J2 pin 8 (red/silver) to J5 pin 3 (violet/white):

13 VDC

– 29 –

Page 30

Articulating Mullion

The articulating mullion contains a DC heater to

keep the mullion from forming condensation. The

heater ON time is based on the relative humidity

percentage calculated by the main board. The

calculation is based on the feedback provided by

the humidity sensor. The top of the articulating

mullion engages with the mullion striker to open

and close the mullion. When the mullion is in the

closed position, the mullion provides the mating

surface for the right door. If the articulating

mullion does not make contact with the mullion

striker, the dispenser door will need to be raised.

2. Remove two Phillips-head screws securing

the center mounting plate to the door (heater

connections are behind this plate).

Articulating Mullion (shown

in closed position)

Articulating Mullion Diagnosing

The heater in the mullion has a resistance of 24

ohms.

3. Slide the mullion up o the door.

J2 on Main Board

• Pin 8 (red/silver) to pin 6 (black/yellow): 13

VDC

Articulating Mullion Removal

1. Open the dispenser door and ip the

articulating mullion to the closed position.

4. Disconnect the two pin connector.

– 30 –

Page 31

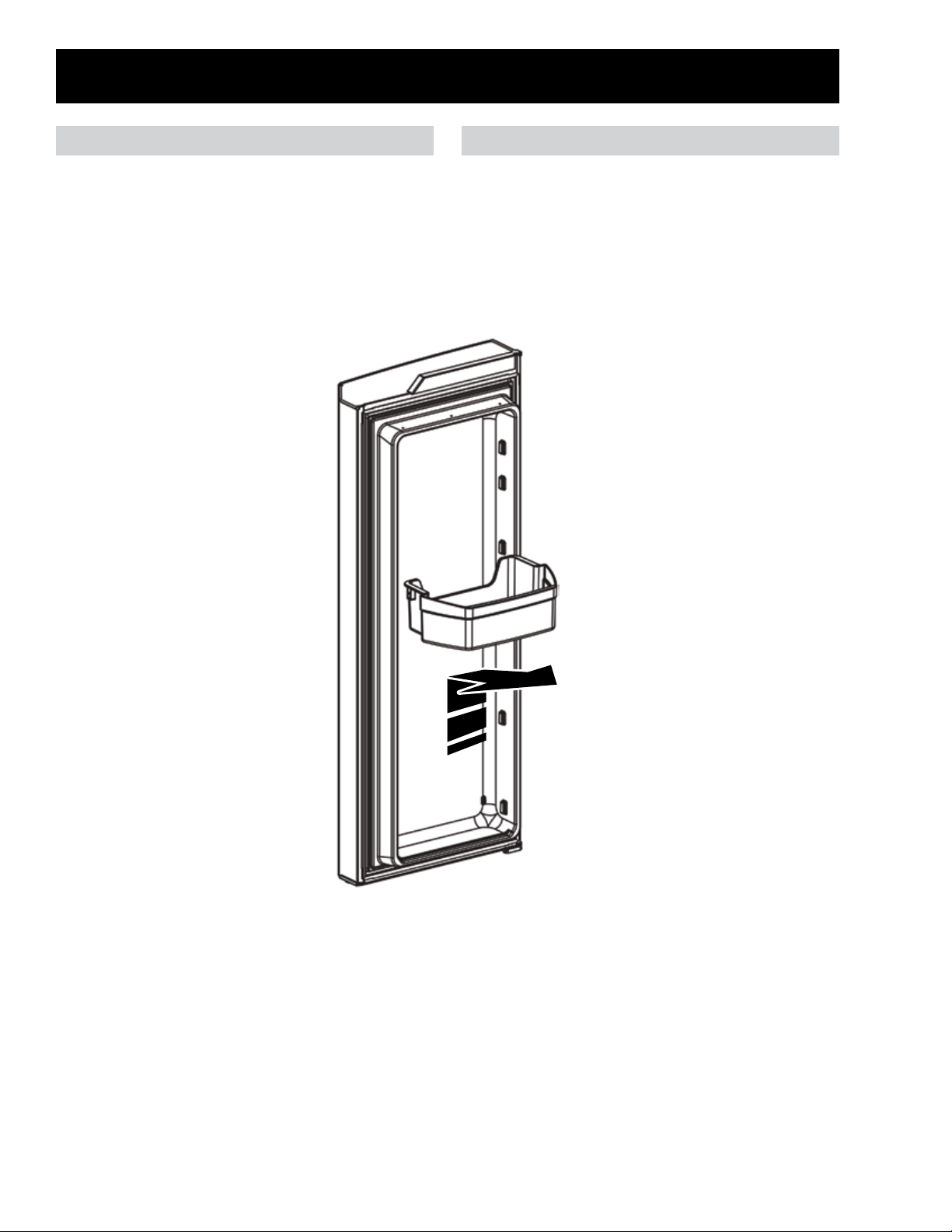

Water Tank Cover

The water tank cover is located behind the

lower door bin of the dispenser door. The cover

conceals the water tank and dual valve.

Water Tank Cover Removal

1. Remove the lower door bin.

2. Remove three Phillips-head screws.

3. Pull the clip from the collar of the dispenser

valve.

Water Tank

The coil-style water tank is located inside the

bottom of the dispenser door.

Water Tank Removal

1. Remove the water tank cover.

2. Remove two Phillips-head screws.

Collar

4. Push in on the collar of the dispenser valve

while pulling on the tank tubing to remove the

tubing from the valve.

5. Push in on the collar of the door water line

union while pulling on the tank tubing to

remove the tank tubing from the union.

Clip

Dual Valve

The dual valve is located behind the water tank

cover of the dispenser door. One solenoid opens

the dispenser side of the valve and the other

solenoid opens the icemaker side of the valve.

Dual Valve Diagnosing

The main board supplies voltage to the dual valve

and isolation valve. To test the dispenser side

of the dual valve, engage the dispenser paddle

switch while both door switches are engaged.

Voltage checks can be performed at the dual

valve connector or main board. If the dual valve

is getting voltage but no water, ensure isolation

valve is working.

Dispenser Valve:

• Yellow - orange: 120 VAC

(Continued next page)

– 31 –

Page 32

Main Board

• J7 pin 3 (yellow) - J7 pin 9 (orange): 120

VAC

The icemaker supplies the voltage to the

icemaker valve and isolation valve. To test the

icemaker valve, cycle the icemaker. Voltage

checks can be performed at the dual valve

connector. If the dual valve is getting voltage but

no water, ensure isolation valve is working.

Icemaker Valve

• White - orange: 120 VAC

Dual Valve Removal

1. Remove the water tank cover.

2. Pull the clips from the collars of the water

valve.

Diodes

The isolation valve is shared between the

dispenser and icemaker valves circuits; diodes

are used to prevent voltage from the main board

going to the valve not intended to be energized.

The diodes are part of the dual valve harness

attached to the dual valve solenoids. Should one

of the diodes fail, replace the dual valve.

Collar

Clip

Collar

3. Push in on the collars on the water valve

while pulling the water lines out to remove the

lines from the dual valve.

4. Remove two Phillips-head screws.

Diodes

Diode Diagnosing

When a diode fails, it can either open or short.

If one of the diodes should open, the isolation

valve will not receive power for one of the water

operations. If one of the diodes should short,

one of the water operations will cause both the

icemaker and dispenser valve to activate.

5. Disconnect the 4-pin water valve connector.

– 32 –

Page 33

Ice Box Components

Ice Box Compartment

Icemaker

On/O Switch

Icemaker

Icemaker

Fill Cup

Upper Port Gasket

Collar Port

Feeler Arm

Icemaker

Status LED

Ice Box Thermistor

Icemaker Access

Cover

Lower Port Gasket

Auger Motor

– 33 –

Page 34

Ice Box Door Ice Box Port Gaskets

The ice box door comes as an assembly to

include the ice box door gasket, door latch, door

latch cover, and ice box door. The door must be

replaced as an assembly.

Ice Box Door Removal

1. Remove two T15 Torx-head screws securing

the top ice box door hinge to the door.

2. Release the door latch and lift the door o the

lower ice box door hinge.

The dispenser door has two ice box port gaskets.

The gaskets are used to seal the ice box inlet and

outlet air ports to the inlet and return air ports of

the cabinet when the dispenser door is closed.

Ice Box Port Gasket Removal

1. Using a at-blade screwdriver, pry the gasket

port away from the door.

Ice Bucket

The ice bucket comes as an assembly to include

the crusher, fork, auger, and bucket. The bucket

must be replaced as an assembly. Turning the

auger in the bucket clockwise produces crushed

ice, turning the auger counterclockwise releases

cubed ice.

Ice Bucket Removal

1. Open the ice box door.

2. Lift up on the handle of the bucket and pull

the bucket out of the ice box.

Handle

2. Pull the gasket out of the gasket port.

– 34 –

Page 35

Collar Port Icemaker Access Cover

The collar port redirects the air going into the ice

box for optimum ice production.

Collar Port Removal

1. Remove the top ice port gasket from the door.

2. Push up and in on the tab located inside the

port of the door (viewed from outside the

door).

The access cover conceals the electrical

connections for the icemaker and auger motor

as well as provide the ice box thermistor with a

mounting location.

Icemaker Access Cover Removal

1. Remove the ice bucket.

2. Remove three Phillips-head screws.

3. Unclip the thermistor from the backside of the

cover.

3. Remove the ice bucket.

4. Pull collar port out from inside the door.

Ice Box Thermistor

The main board uses the thermistor to monitor

ice box temperatures and regulate the icemaker

blower fan. To access the thermistor, remove the

icemaker access cover.

To test or replace the thermistor, follow the

steps under Thermistor Replacement in the

Thermistors section of this service guide.

– 35 –

Page 36

Auger Motor Icemaker

The auger motor is a reversible AC motor. When

the auger motor turns the auger in the bucket

clockwise crushed ice is produced. When

the auger motor turns the auger in the bucket

counterclockwise cubed ice is released. During

cubed operation, the main board sends 120 VAC

on J7 pin 2 to the motor to activate a reversing

relay inside the motor.

Auger Motor Diagnosing

Operating voltage for the auger motor can be

checked at the auger motor connector or at J7 on

the main board.

J7 on Main Board (Cubed)

• Pin 1 (tan) to pin 9 (orange): 120 VAC

• Pin 2 (grey) to pin 9 (orange): 120 VAC

J7 on Main Board (Crushed)

• Pin 1 (tan) to pin 9 (orange): 120 VAC

The refrigerator uses an electronic icemaker. The

toggle switch on the front of the icemaker turns

the icemaker ON/OFF. The green LED on the

front of the icemaker indicates that there is power

to the icemaker and the icemaker is turned on.

The icemaker will produce seven cubes per

cycle approximately 100 to 130 cubes in a 24hour period, depending on freezer compartment

temperature, room temperature, number of door

openings and other use conditions. The icemaker

will ll with water when the mold body thermistor

of the icemaker cools to 15°F (-10°C). A newly

installed refrigerator may take 12 to 24 hours

to begin making ice cubes. When the bin lls

to the level of the feeler arm (keeping the feeler

arm in the back position), the icemaker will stop

producing ice.

On/O Switch

Feeler Arm

• Pin 2 (grey) to pin 9 (orange): 0 VAC

Auger Motor Removal

1. Remove the ice bucket.

2. Remove the icemaker access cover.

3. Remove two Phillips-head screws.

4. Disconnect the 3-pin connector.

Green Power LED

Normal Operation

• To hear a buzzing sound each time the

icemaker lls with water.

• For several cubes to be joined together.

• If ice is not used frequently, old ice cubes will

become cloudy, taste stale and shrink.

– 36 –

(Continued next page)

Page 37

Icemaker Diagnosing

To manually cycle the icemaker, turn the icemaker

o for 30 seconds then turn it back on and press

in and release the feeler arm of the icemaker

three times within 5 seconds. When the icemaker

calls for water it will deliver 120 VAC to the water

valves and to J18 on the main board. The door

switches do not need to be engaged in order to

cycle the icemaker.

Fill Tube

The icemaker ll tube is not removable. The

tube is foamed into the dispenser door (left

door). Should the tube be damaged or need to

be replaced, the dispenser door will need to be

replaced.

Fill Tube Heater

J18 and J7 on Main Board (During Fill)

• J18 (white) - J7 pin 9 (orange): 120 VAC

Icemaker Valve (During Fill)

• White - orange: 120 VAC

Isolation Valve Connector (During Fill)

• Yellow/black - orange: 60 VAC*

*As a result of the diodes in the isolation valve

circuit, only 60 VAC will be read from a voltmeter

when checking for voltage going to the isolation

valve.

Icemaker Removal

1. Remove the ice bucket.

2. Remove the icemaker access cover.

3. Remove two 1/4-in. hex-head screws.

Foamed into the dispenser door is a 136-ohm

heater designed to keep the ll tube from freezing.

The heater is in parallel with the recess heater,

both are controlled by the main board.

Fill Tube Heater Diagnosing

The ll tube heater can be operated using Service

Mode Test t6. Test t6 will operate the heater for

60 seconds.

J2 to J5 on Main Board

• J2 pin 8 (red/silver) to J5 pin 3 (violet/white):

13 VDC

4. Disconnect the icemaker harness connector.

– 37 –

Page 38

Right Door

Right Door Removal

1. Remove the door bins.

2. Follow Top Left Door Hinge Removal steps,

under Top Door Hinges in the Cabinet Top

section of this service guide.

3. Lift the door o the center hinge.

Right Center Hinge Removal

1. Remove the right door.

2. Remove three screws for the center hinge

using a 5/16-in. socket or T20 Torx-head bit.

– 38 –

Page 39

Door - Top

Door - Top Component Locator

Closure

Top Door

Bumper

*The door harness and water line will pass through the top hinge bushing on dispenser doors.

Top Door Bumper

Top Door Bumper Removal

1. Remove the door gasket.

2. Push down on the door bumper to remove it

from the door.

Top Hinge Bushing

The top hinge inserts into the top bushing. If

worn, the bushing can be replaced.

Top Hinge Bushing Removal

1. For the side needing to be removed, follow

Top Left Door Hinge Removal steps, under

Top Door Hinges in the Cabinet Top section

of this service guide.

Cam

Top Hinge

Bushing*

Closure Cam

The spring-loaded closure from the hinge rolls

across the closure cam to close the door when

the door is a couple inches from closing.

Closure Cam Removal

1. For the side needing to be removed, follow

Top Left Door Hinge Removal steps, under

Top Door Hinges in the Cabinet Top section

of this service guide.

2. Remove one T20 Torx head screw.

2. Using a putty-knife of at-blade screwdriver

pry the bushing from the top of the door.

– 39 –

Page 40

Door - Bottom

Door - Bottom Component Locator

Bottom Hinge

Bushing

Door Stop

Bottom Door Bumper

Bottom Door Bumper Removal

1. Remove the door gasket.

2. Rotate the bumper up.

Bottom Door

Bumper

Bottom Hinge Bushing

The center hinge pin inserts into the bottom

bushing. If worn, the bushing can be replaced.

Bottom Hinge Bushing Removal

• Follow the Door Stop Removal steps, under

Door Stop in the next section.

3. Using a small at-blade screwdriver, pry the

bumper from the bottom of the door.

Door Stop

The door stop prevents the door from opening

too far. When the door is fully opened the stop

makes contact with the outside of the center

hinge, preventing the door handle from coming

in contact with the cabinetry. Should the door be

travelling past the stop position, check for a bent

or broken door stop, or a center hinge pin that

has been raised too high.

Door Stop Removal

1. For the side needing to be removed, follow

Top Left Door Hinge Removal steps, under

Top Door Hinges in the Cabinet Top section

of this service guide.

2. Lift the door o the center hinge.

(Continued next page)

– 40 –

Page 41

3. Remove two T20 Torx-head screws.

4. Pull the door stop and bushing out of the door.

5. The bushing is keyed, turn the bushing to

align the tabs of the bushing with the slots in

the door stop.

Slots

Tab

Tab

6. Pull the bushing out of the door stop.

NOTE: Like the door stop, the door is also keyed.

Once a bushing is reinstalled into a door stop the

tabs of the bushing will need to be aligned with

the slots in the door to reinstall the door stop.

– 41 –

Page 42

Water Filter Cartridges

The water lter cartridge is located in the right rear upper corner of the refrigerator. There will be two

dierent style of cartridges depending on the model size and when the models were manufactured.

The 26 cu. ft. models use the XWF style lter. The 18 and 24 cu. ft. model use MWFP style lters until

they transition to XWF lters mid-2018.

MWFPXWF

When to Replace the Filter

There is a replacement indicator light for the water lter cartridge on the dispenser. A red light will start

blinking when the lter needs to be replaced soon. The lter cartridge should be replaced when the

replacement indicator light turns red or if the ow of water to the dispenser or icemaker decreases or if

the ice cubes are getting hollow or small. The indicator should turn red after 6 months or 170 gallons

have been dispensed.

– 42 –

Page 43

Water Filter (MFWP) Water Filter (XWP)

MWFP Filter Cartridge Removal

• Slowly turn the lter to the left. Do not pull

down on the cartridge.

MWFP Filter Cartridge Installation

1. Fill the replacement cartridge with water

from the tap to allow for better ow from the

dispenser immediately after installation.

2. Line up the arrow on the cartridge and the

manifold. Place the top of the new cartridge

up inside the holder. Do not push it up into

the manifold.

3. Slowly turn it to the

right until the lter

cartridge stops. DO NOT

OVERTIGHTEN. The

cartridge will move about a

1/2 turn.

4. Run water from the dispenser for 1-1/2

gallons (about three minutes) to clear the

system and prevent sputtering.

5. Press and hold the Water Filter pad on the

dispenser board for three seconds.

NOTE: Remove the water lter to immediately

stop any water leak from the Icemaker/Dispenser

system. The water lter manifold acts as a cut-o

valve when the lter is removed and will prevent

further leaking.

XWF Filter Cartridge Removal

1. Open the lter cartridge housing by squeezing

two front tabs and gently pull the cover down.

2. Rotate the lter down.

3. Grasp the lter and slowly turn it

counterclockwise about a 1/4 turn. The lter

should automatically release itself when it has

been rotated far enough to the left.

Filter Cartridge Installation

1. Follow XWF Filter

Cartridge Removal

steps.

2. Line the ports on the

lter with the ports of

the manifold, and gently

insert the lter.

3. Slowly turn the lter

to the right until it

stops. DO NOT

OVERTIGHTEN. The

lter will move about a

1/4 turn (90 degrees),

until the arrow on the

lter aligns with the

arrow on the manifold.

4. Slowly push the lter up

into the clips. Close the

lter cover by pushing

upwards on the cover

until the tabs lock into

place.

5. Run water from the dispenser for 2 gallons

(about ve minutes) to clear the system and

prevent sputtering. If water is not owing,

check to make sure the lter has been fully

rotated to the right.

6. Press and hold the Water Filter pad on the

dispenser board for three seconds.

NOTE: Remove the water lter to immediately

stop any water leak from the Icemaker/Dispenser

system. The water lter manifold acts as a cut-o

valve when the lter is removed and will prevent

further leaking.

– 43 –

Page 44

Refrigerator Compartment

Refrigerator Component Locator

Mullion Striker

Upper LED

FF Thermistor

Ice Box Air Inlet Duct

Water Filter*

Adjustable

Shelves (x4)

Ice Box

Return Air Duct

Center Track

Air Tower

Climate Zone

Slides (x3)

Lower LED (x2)

Climate Zone

Vegetable Pans (x2)

Climate Zone

Meat Pan

*MWFP style lter is shown. The 26 cu. ft. models will use XWF style lter. The 18 and 24 cu. ft. model

will transition to XWF lters mid-2018.

– 44 –

Page 45

Adjustable Shelves Pan Covers

The refrigerator has four adjustable shelves.

Each shelf can be raised or lowered but cannot

be moved right to left or vise-versa because the

center is the only location of a shelving track.

Instead of outer tracks, the shelves use the liner

to support the liner side of each shelf.

Adjustable Shelf Removal

1. Tilt the front of the shelf up.

2. Lift the rear of the shelf up to disengage the

top hook of the shelf from the center track.

3. Pull the shelf out from the refrigerator.

The refrigerator has two pan covers. The two

vegetable climate zone pans slide in and out of

the upper pan cover. The lower meat climate

zone pan slides in and out of the lower pan cover.

Each pan cover has a climate zone slide to adjust

the air ow into the pans. Moving the upper

climate zone slides to the left and the lower slide

to the right increases the air ow.

Open

Close

Upper Climate Control Slides

CloseOpen

Lower Climate Control Slide

Climate Zone Pans

The refrigerator has three pans; each pan has a

climate zone slide associated with it to increase

or decrease airow into the pans. The top two

are vegetable pans and the lower full width pan is

the meat pan.

Climate Zone Pan Removal

1. Slide the pans out to the stop position.

2. Lift the front of the desired pan up and out of

the pan cover.

Each side of the pan covers are supported by

two studs which are screwed into the liner (18 cu.

ft. models) or one stud and the rear indent in the

liner (24 and 26 cu. ft. models).

Pan Cover Removal

1. For the upper pan cover, remove both

vegetable pans. For the lower pan cover,

remove all pans.

2. Lift up on the front of the upper pan cover and

pull the cover out. Repeat the process for the

lower cover.

– 45 –

Page 46

Mullion Striker

The top of the articulating mullion engages with

the mullion striker to open and close the mullion.

When the articulating mullion does not make

contact with the mullion striker, the dispenser

door may need to be raised.

Mullion Striker Removal

• Remove two Phillips-head screws.

Upper LED Housing

Upper LED Diagnosing

• When the LED housing fails completely, the

lower LED boards will still work.

Main Board with Door Open

• J4 pin 2 (red/yellow) - J5 pin 1 (pink/black):

4 - 13 VDC *(see NOTE)

Two Pin Connector at Cabinet

• Red - black: 4 - 13 VDC *(see NOTE)

NOTE: When one or both of the refrigerator

doors are opened, the main board delivers 4 VDC

to the LED housing and gradually increases the

voltage to 13 VDC for full brightness.

Upper LED Removal

1. Using two ngers, push forward on the

indicated areas to release the rear tabs of the

shield to lower the rear of the shield.

The main source of light comes from the upper

LED housing. Strip LEDs are connected to

the outside of the housing while the inside of

the housing holds the foam block which the

refrigerator (FF) thermistor slides into. If any

of the LEDs fail, the housing would need to be

replaced. Counter-depth models use a smaller

LED housing.

18 cu. ft.

24 & 26 cu. ft.

2. Pull forward and down to release the front lip

of the LED shield.

3. Remove two 1/4-in. hex-head screws.

– 46 –

(Continued next page)

Page 47

4. Tip the front of the LED housing down and

pull the housing away from the refrigerator.

Lower LEDs

18 cu. ft.

24 & 26 cu. ft.

NOTE: When lowering the LED housing, pay

attention to the foam block and where the block

is located. It is important that the thermistor be

reinstalled in the block behind the LED housing to

maintain proper temperatures.

5. Disconnect 2-pin connector.

Foam Block &

Thermistor

The refrigerator has two lower LED boards to